Page 1

Hygrosmart HS3

Advanced RH & Temperature Probe

User’s Manual

97516 Issue 5

July 2017

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

HygroSmart HS3 Probe

For Michell Instruments' contact information please go to

www.michell.com

© 2017 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

HygroSmart HS3 User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Calibration ...................................................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings .......................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Operating Flexibility ............................................................................................ 1

2 INSTALLATION ..................................................................................................2

2.1 Unpacking .......................................................................................................... 2

2.2 Probe Layout ...................................................................................................... 2

2.3 Maintenance Kits ................................................................................................ 3

2.4 Installation Instructions ...................................................................................... 4

2.4.1 Recommended Installation Environment ......................................................... 4

2.4.2 Element Filter Assembly Environment ............................................................. 4

2.4.3 Probe Wall Mounting ..................................................................................... 5

2.4.4 Duct Mounting .............................................................................................. 5

2.4.5 Pressurized Environment Installation .............................................................. 6

2.4.6 Electrical Requirements ................................................................................. 7

2.4.7 Electrical Connections .................................................................................... 7

2.4.8 Digital Serial Output ...................................................................................... 7

2.4.9 Analog Voltage Outputs ................................................................................. 7

2.4.10 Probe Ordered Confi guration .......................................................................... 8

2.4.11 Probe Reconfi guration ................................................................................... 8

2.4.12 Probe & Sensor Serialization Tracking ............................................................. 8

3 PROBE MAINTENANCE KIT OPERATION ..............................................................9

3.1 Application Software Overview ............................................................................ 9

3.2 Installation ......................................................................................................... 9

3.3 Establishing Communications .............................................................................. 9

3.4 Measurement Data Acquisition .......................................................................... 10

3.5 Probe Confi guration .......................................................................................... 11

3.6 Probe Adjustment ............................................................................................. 12

3.7 Loop Checking Simulation ................................................................................. 18

4 SENSOR REPLACEMENT ...................................................................................19

5 LOOP CHECKING SIMULATION .........................................................................21

5.1 Simulator Connection ........................................................................................ 21

5.2 Checking /Programming the Simulators ............................................................ 21

6 MAINTENANCE ................................................................................................22

6.1 Cleaning the Filter Element ............................................................................... 22

6.2 Probe Adjustment Procedure ............................................................................. 23

97516 Issue 5, July 2017

iv

Page 5

HygroSmart HS3 User’s Manual

Figures

Figure 1 HygroSmart HS3 Probe and Interchangeable Sensor .....................................1

Figure 2 HygroSmart HS3 Probe Packaging ...............................................................2

Figure 3 HygroSmart HS3 Probe Layout ....................................................................2

Figure 4 Acceptable Operating Conditions .................................................................4

Figure 5 Mounting Clamp (HS3-PMC) ........................................................................5

Figure 6 Probe Wall Mounting ...................................................................................5

Figure 7 Duct Mounting ...........................................................................................5

Figure 8 Probe Metal Gland ......................................................................................6

Figure 9 Securing Tether ..........................................................................................6

Figure 10 Electrical Connections .................................................................................7

Figure 11 Connection Console Screen Shot ..................................................................9

Figure 12 Probe and Sensor Information Screen Shot ................................................10

Figure 13 Measurement Data Acquisition Screen Shot ................................................10

Figure 14 Output Channel Example Screen Shot ........................................................11

Figure 15 Probe Confi guration Screen Shot ...............................................................11

Figure 16 Probe Adjustment Screen Shot ..................................................................12

Figure 17 Probe readings prior to adjustment ............................................................13

Figure 18 Editing the Adjustment Table .....................................................................14

Figure 19 Probe readings post-adjustment ................................................................14

Figure 20 Probe readings prior to adjustment ............................................................15

Figure 21 Editing the Adjustment Table .....................................................................15

Figure 22 Probe readings post-adjustment ................................................................16

Figure 23 Probe readings prior to adjustment ............................................................16

Figure 24 Editing the Adjustment Table .....................................................................17

Figure 25 Probe readings post-adjustment ................................................................17

Figure 26 Simulator Window Screen Shot ..................................................................18

Figure 27 Sensor Simulator ......................................................................................21

Figure 28 Filter Cap Removal ...................................................................................22

Figure 29 Filter Element Cleaning .............................................................................22

Figure 30 Dimensional Drawings...............................................................................26

Figure 32 Serial Port Parameters ..............................................................................28

Figure 31 Pinout ......................................................................................................28

Appendices

Appendix A Technical Specifi cations .............................................................................. 25

A.1 Dimensions ................................................................................. 26

Appendix B HS3 Modbus Communications and Register Map .......................................... 28

B.1 Communications .......................................................................... 28

B.2 Code examples ............................................................................ 29

B.3 Register Map ............................................................................... 30

Appendix C Quality, Recycling & Warranty Information ...................................................37

Appendix D Return Document & Decontamination Declaration ........................................ 39

Michell Instruments

v

Page 6

HygroSmart HS3 User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. For

Michell Instruments’ contact information please go to www.michell.com.

Calibration

HS3 Probes are adjusted in the factory prior to delivery. Recalibration is recommended after one

year of operation, depending on application. New, freshly calibrated sensors can be supplied quickly

by Michell Instruments, or recalibration can be carried out on site using one of the Michell humidity

calibration systems. Refer to Section 6.2 regarding calibration checking and adjustment of probes.

Safety Conformity

This product meets the essential protection requirements of the relevant EU standards and directives.

97516 Issue 5, July 2017

vi

Page 7

HygroSmart HS3 User’s Manual

Abbreviations

The following abbreviations may be used in this manual:

barg pressure unit (=100 kP or 0.987 atm) gauge

°C degrees Celsius

°F degrees Fahrenheit

EU European Union

g grams

3

grams per cubic metre

g/m

kg kilograms

Kj/kg kilojoules per kilogram

lb pound

mm millimetre

oz ounce

RH relative humidity

RS485 serial data transmission standard

RTU Remote Terminal Unit

T temperature

V Volts

V DC Volts of direct current

% percentage

" inch

ø diameter

Michell Instruments

vii

Page 8

HygroSmart HS3 User’s Manual

!

Warnings

The following general warning listed below is applicable to this instrument. It is repeated in the text

in the appropriate locations.

Where this hazard warning symbol appears in the following sections, it

is used to indicate areas where potentially hazardous operations need to

be carried out.

97516 Issue 5, July 2017

viii

Page 9

HygroSmart HS3 User’s Manual

1 INTRODUCTION

The HygroSmart HS3 is an accurate, stable and user confi gurable probe designed to

provide reliable relative humidity measurement for process control in a wide range

of applications. The HS3 Probe features interchangeable sensor technology ensuring

minimal process downtime and a low cost of ownership.

INTRODUCTION

Figure 1

1.1 Operating Flexibility

The HS3 Probe has been developed to be 100% customer confi gurable. One stock unit

can be set up by a customer into an application specifi c confi guration to cover any RH

demands on site. This fl exibility saves time and budget.

• Adjustable zero/span ranging of the RH, Temperature and Calculated

Hygrometric Outputs

• Selectable 0 to 1, 2.5, 5, 10 V output signals

• 2 selectable output voltage measured (RH & T) parameters or a choice of

5 calculated parameters (eg dew point)

• Addressable Modbus RTU over RS485 communications for up to 32 probes

• Probe digital Zero/Span calibration trimming

HygroSmart HS3 Probe and Interchangeable Sensor

Alternatively, the HS3 Probe can be confi gured at the factory at time of ordering for

customers who want a simple fi xed confi guration solution.

Michell Instruments

1

Page 10

INSTALLATION

2 INSTALLATION

2.1 Unpacking

Open the cardboard box and remove the plastic tray inside.

HygroSmart HS3 User’s Manual

Please check that the following components are present:

• HygroSmart HS3 Probe (with the interchangeable HygroSmart HS3 sensor)

• Certifi cate of Calibration

• Quick Start Guide

• User Manual

2.2 Probe Layout

The HS3 Probe with its constituent parts and physical features is detailed in the layout

below:

1 23456

Figure 2

HS3-PE PAA-000002 HS3-PE PAA-000001

HygroSmart HS3 Probe Packaging

98.5mm

HygroSmart HS3 Probe Electronics HygroSmart HS3 Interchangeable Sensor

3.87”

1 M12 5-pin probe electrical connector

2 Probe serial number

3 Probe to sensor connector alignment marks

4 Rotating probe cuff

5 Sensor serial number

6 Filter assembly

Figure 3

97516 Issue 5, July 2017

2

HygroSmart HS3 Probe Layout

Page 11

HygroSmart HS3 User’s Manual

2.3 Maintenance Kits

INSTALLATION

HS3-SCK

HS3 Probe Simulator Kit

Includes:

- Desk-mounted confi guration kit with 1.8m cable

- 3 sensor simulators (25%, 50%, 75%RH at 23°C (73°F))

- Spare probe electronics

- Carry case

HS3-CK

HS3 Probe Confi guration Kit

Includes:

- Desk-mounted confi guration kit with 1.8m cable

- Spare probe electronics

- Carry case

HS3-CKL

HS3 Logger/Confi guration Converter Cable 1.8 meters

Includes:

- 1.8 meter USB to RS485 converter cable with M12

connector

Michell Instruments

3

Page 12

INSTALLATION

2.4 Installation Instructions

2.4.1 Recommended Installation Environment

When choosing an installation site for the probe, consider the environment around it.

Ensure that the site:

• is clear of nearby obstructions which could limit air circulation to the

probe

• is away from any hot or cold spots - i.e. air conditioning or heater vents

• is not adjacent to any high power sources

• is representative of the surrounding environment at the point of interest

HygroSmart HS3 User’s Manual

The acceptable operating conditions for the sensor are detailed in

RH%

100

75

50

25

Figure 4

Maximum mixing ratio

250g water/kg dry air

Temp °C

-40 0 5025 70 85

Acceptable Operating Conditions

Figure 4

.

2.4.2 Element Filter Assembly Environment

The PVDF fi lter element protects the sensor against particulate contamination and the

effects of high velocity air-fl ow.

To ensure good air-fl ow to the sensor it is recommended to regularly clean the fi lter

element. See Section 6.1 for more details.

The HS3 Probe can be equipped with the following fi lter model

• F1 - PVDF (12mm diameter) black cap assembly

• F2 - 13mm (0.51”) HDPE protection cap

97516 Issue 5, July 2017

4

Page 13

HygroSmart HS3 User’s Manual

2.4.3 Probe Wall Mounting

A mounting clamp for the HS3 Probe (HS3-PMC) can be ordered as an accessory.

INSTALLATION

Figure 5

Mounting Clamp (HS3-PMC)

The clamp can be used to securely hold the probe body, and provides a 1/4" 20 UNC

thread to mount it to a fi xed surface.

It is recommended that the HygroSmart HS3 Probe is installed with the sensor and fi lter

assembly facing downwards.

55.5mm

2.19”

HS3-PE PAA-000002 HS3-PE PAA-000002

Figure 6

Probe Wall Mounting

2.4.4 Duct Mounting

When installing the HS3 Probe into a duct, ensure that the probe is inserted as far as

possible into the environment to be measured.

If the measurement environment is pressurized, then follow the guidelines in 2.4.5.

Michell Instruments

5

HS3-PE PAA-000002 HS3-PE PAA-000002

55.5mm

2.19”

Figure 7

Duct Mounting

HS3-PE PAA-000002 HS3-PE PAA-000002

55.5mm

2.19”

Page 14

INSTALLATION

HS3

000002

!

2.4.5 Pressurized Environment Installation

The HS3 Probe is a solid assembly with no internal air cavities; this ensures that an

external pressure of up to 10 barg will cause no damage to the probe.

The probe can be installed into pressurized environments by two different methods:

1. Through a vessel or duct wall using the Probe Metal Gland sealing

accessory.

2. Mounted entirely within the pressurized vessel.

HygroSmart HS3 User’s Manual

The Probe Metal Gland (HS3-PMG) is shown in

Figure 6.

It is designed to be installed in

the wall of the pressure vessel by the M25 x 1.5 thread on the rear (1). The O-ring (2)

provides the pressure seal. The probe can then be installed, and the gland tightened

until the shaft of the probe rotates with the turn of the nut.

2

1

Figure 8

Probe Metal Gland

For safety, always ensure that the probe is tethered to the vessel wall or the gland itself.

A tether can be attached to the probe around the base of the M12 mating connector,

see

Figure 7 f

or details.

HS3-PE PAA-000002

-PE PAA-

Figure 9

Securing Tether

When installing probe using the sealing gland, always ensure

that the securing tether is fi tted before applying pressure!

97516 Issue 5, July 2017

6

Page 15

HygroSmart HS3 User’s Manual

2.4.6 Electrical Requirements

The HygroSmart HS3 Probe requires a supply voltage from 5 to 28 V DC.

2.4.7 Electrical Connections

The electrical connections, as seen when looking at the base of the probe, are shown

in the following schematic:

OPERATION

Modbus Analog Cable Color

1 Comms A Output 1 Brown

2 Comms B Output 2 White

3 0 V N/C Blue

4 +5 V to +28 V +5 V to +28 V Black

5 0 V 0 V Gray

Note: M12 mating connector/cables are not supplied with the Probe, but can

be ordered as an accessory. They are available in 2, 5 & 10 meter lengths.

2.4.8 Digital Serial Output

The connections for Modbus RTU over RS485 communications are detailed in

In order to enable digital comms, both pins 3 & 5 should be grounded. See Appendix B for

mire details.

Figure 10

Electrical Connections

21

5

34

Figure

10.

NOTE: The probe will not output digital and voltage signals simultaneously.

2.4.9 Analog Voltage Outputs

The HS3 Probe will be set up, when ordered, to one of the following selection of voltage

outputs:

These voltage outputs can be reconfi gured at any time using one of the available

Maintenance Kits, in conjunction with the HS3 Probe Application Software.

0 - 1 V

0 - 2.5 V

0 - 5 V

0 - 10 V

Michell Instruments

7

Page 16

OPERATION

2.4.10 Probe Ordered Confi guration

The confi guration code of the HS3 Probe, when ordered, defi nes its precise set up. This

is detailed on the order acknowledgement & invoice documents.

2.4.11 Probe Reconfi guration

If at any point in time the HS3 Probe needs reconfi guration, this can be achieved quickly

and easily by using any of the available Maintenance Kits, in conjunction with the HS3

Probe Application Software.

2.4.12 Probe & Sensor Serialization Tracking

The HS3 Probe and associated interchangeable sensor have a unique serial number and

bar code identifi cation on the body of the devices. These serial numbers are also stored

within the sensor and probe electronics and can be accessed using the HS3 Application

Software.

HygroSmart HS3 User’s Manual

97516 Issue 5, July 2017

8

Page 17

HygroSmart HS3 User’s Manual

3 PROBE MAINTENANCE KIT OPERATION

The available Probe Maintenance Kits are detailed in Section 2.3. The operation of the

Maintenance Kits is as follows:

OPERATION

HS3-SCK

HS3-CK

HS3-CKL

Connect the probe to the connector on the desk-mounted confi guration

kit, connect the USB cable to the PC, then follow the setup procedure

detailed in Section 3.3.

Connect the M12 connector to the probe, and the USB cable to the PC

before following the setup procedure.

3.1 Application Software Overview

The HS3 Application Software is downloadable from the Michell website (www.michell.

com).

3.2 Installation

1. Extract the contents of the supplied zip fi le to a suitable location.

2. Close all currently running Windows programs.

3. Launch the installer and follow the on-screen instructions.

3.3 Establishing Communications

On launching the software the connection console will appear.

The connection console

between the software and HS3 Probe. Choose the Modbus slave address and

communications port from the drop-down lists and then click the

After a few seconds the software will report a successful connection, or not. If the

connection is successful, the word

(Figure 9)

allows you to establish a communications connection

Connect... button.

Connected and a green tick will appear above the

Quit button and the Continue button will enable.

If the software is unable to connect, check the physical connection between the probe

and PC, check which com port the adaptor is connected to and try again.

Michell Instruments

Figure 11

9

Connection Console Screen Shot

Page 18

OPERATION

From this window the probe and sensor information can be viewed by clicking the

Probe info. button. Alternatively click the Continue button on the console window to

open the

HygroSmart HS3 User’s Manual

Options window.

Figure 12

Click OK to close the probe information window.

Click the

Continue button on the console window to continue on to the Options window.

Probe and Sensor Information Screen Shot

3.4 Measurement Data Acquisition

This window can be opened from the Options window. As soon as it is opened, the

software automatically begins collecting, displaying and charting live data from the HS3

Probe.

Data collection occurs approximately twice a second. The chart update rate is two

seconds but this may be changed through the chart options window.

Figure 13

97516 Issue 5, July 2017

10

Measurement Data Acquisition Screen Shot

Page 19

HygroSmart HS3 User’s Manual

The two output (Output 1 and Output 2) channel units are highlighted in blue and

green.

OPERATION

In the example in

set to Temperature.

The expected output volts and volts percentage (of full scale) is also displayed here.

Errors and Warnings

When probe errors or warnings are encountered they will be highlighted in the

section and a link will appear.

Click the

View link to launch a new window which details the errors and warnings.

Figure 14

Figure 14

, Output 1 (in blue) is set to RH and Output 2 (in green) is

Output Channel Example Screen Shot

Status

3.5 Probe Confi guration

This screen can be opened from the Options window. Upon opening, the 'current

settings' column is updated with the parameters within the probe.

Michell Instruments

Figure 15

11

Probe Confi guration Screen Shot

Page 20

OPERATION

To change a setting, either choose defi ned values from the drop-down lists or enter

values into the text boxes under the

button to apply the settings.

After applying new settings, the software automatically reads back the probe confi guration

and displays it on screen in the left (current settings) column.

Advanced button takes you to the Probe Adjustment window via a password entry

The

box. Enter the password

3.6 Probe Adjustment

This window provides access to both the RH and temperature calibration tables, and the

probe Modbus address.

Picture below showing the default (factory) settings.

HygroSmart HS3 User’s Manual

Change settings column and then click the Apply

7316 to continue.

Figure 16

To change a value, type within the text boxes provided and click the Apply... button to

apply the new value(s) to the HS3 Probe.

Important : the values in point 1 to 5 must be in ascending order!

Values are checked before they are applied to the HS3 Probe according to a set of rules.

The rules are displayed on the right hand side of the window. The software will display

a warning if any values do not comply with the rules.

Clicking the Read... button reads and display the tables from the HS3 Probe.

Clicking the

Clicking the

RECOMMENDATION: It is a good idea to save the tables before editing them.

You can then Load (retrieve) the saved table in case any mistakes are made.

NOTE: If the Modbus address is changed, the software will continue

communicating with the probe under the new address.

97516 Issue 5, July 2017

12

Save... button saves the tables to a fi le.

Load... button loads the previously saved fi le.xxxxxxx

Probe Adjustment Screen Shot

Page 21

HygroSmart HS3 User’s Manual

The next example will demonstrate a 3 point humidity adjustment.

In this example 30, 50 and 70%RH , but any other point is also possible.

(%RH and Temperature adjustment are done in the same way)

st

Adjustment Point.

1

1. Place the HS3-Probe together with a reference in a controlled and stable

environment of 30%RH.

2. Check the readings of the HS3-probe and the reference.

• The Humidity reference is reading 30.8%RH.

• The HS3-probe reads 28.0%RH.

OPERATION

Figure 17

Probe readings prior to adjustment

3. Find the nearest point in the RH Adjustment table (in this example 30)

and change it into the measured reference value. (in this example 30.8).

4. Subtract the Humidity value of the HS3-probe from the reference value

(30.8 - 28.0 = 2.8).

5. Add the outcome to the reference value (30.8 + 2.8 = 33.6).

6. Enter this value in the corresponding fi eld of Corrected RH.

Michell Instruments

13

Page 22

SENSOR REPLACEMENT

HygroSmart HS3 User’s Manual

After Correction:

Figure 18

Figure 19

Editing the Adjustment Table

Probe readings post-adjustment

2nd Adjustment Point

1. Place the HS3-Probe together with a reference in a controlled and stable

environment of ± 50%RH.

2. Check the readings of the HS3-Probe and the reference.

• The Humidity reference is reading 50.2%RH.

• The HS3-Probe reads 51.3%RH.

97516 Issue 5, July 2017

14

Page 23

HygroSmart HS3 User’s Manual

SENSOR REPLACEMENT

Figure 20

3. Find the nearest point in the RH Adjustment table (in this example 50)

and change it into the measured reference value. (in this example 50.2).

4. Subtract the Humidity value of the HS3-Probe from the reference value

(50.2 – 51.3 = -1.1).

5. Add the outcome to the reference value (50.2 – 1.1 = 49.1).

6. Enter this value in the corresponding fi eld of Corrected RH.

Probe readings prior to adjustment

Michell Instruments

Figure 21

15

Editing the Adjustment Table

Page 24

LOOP CHECKING SIMULATION

After Correction:

HygroSmart HS3 User’s Manual

Figure 22

3rd Adjustment Point.

1. Place the HS3-Probe together with a reference in a controlled and stable

environment of ± 70%RH.

2. Check the readings of the HS3-Probe and the reference.

• The Humidity reference is reading 69.6%RH.

• The HS3-Probe reads 71.3%RH.

Probe readings post-adjustment

Figure 23

3. Find the nearest point in the RH Adjustment table (in this example 70) and

change it to the measured reference value (in this example 69.6%RH).

97516 Issue 5, July 2017

16

Probe readings prior to adjustment

Page 25

HygroSmart HS3 User’s Manual

4. Subtract the Humidity value of the HS3-Probe from the reference value

(69.6 – 71.3 = -1.7).

• Add the outcome to the reference value (69.6 -1.7 = 67.9).

• Enter this value in the corresponding fi eld of Corrected RH.

MAINTENANCE

After Correction:

Figure 24

Figure 25

Editing the Adjustment Table

Probe readings post-adjustment

Michell Instruments

17

Page 26

MAINTENANCE

3.7 Loop Checking Simulation

The simulator window provides a way to change the defi ned outputs on both the RH

and temperature channel.

HygroSmart HS3 User’s Manual

Figure 26

Enter the desired, simulated value(s) into the RH and/or temperature input text boxes

and click the relevant

change accordingly.

The values shown on the left under

To read (refresh the screen) probe values, click the

Apply button to apply the value. The analog output(s) should

Simulator Window Screen Shot

Probe values are read from the probe.

Read button.

97516 Issue 5, July 2017

18

Page 27

HygroSmart HS3 User’s Manual

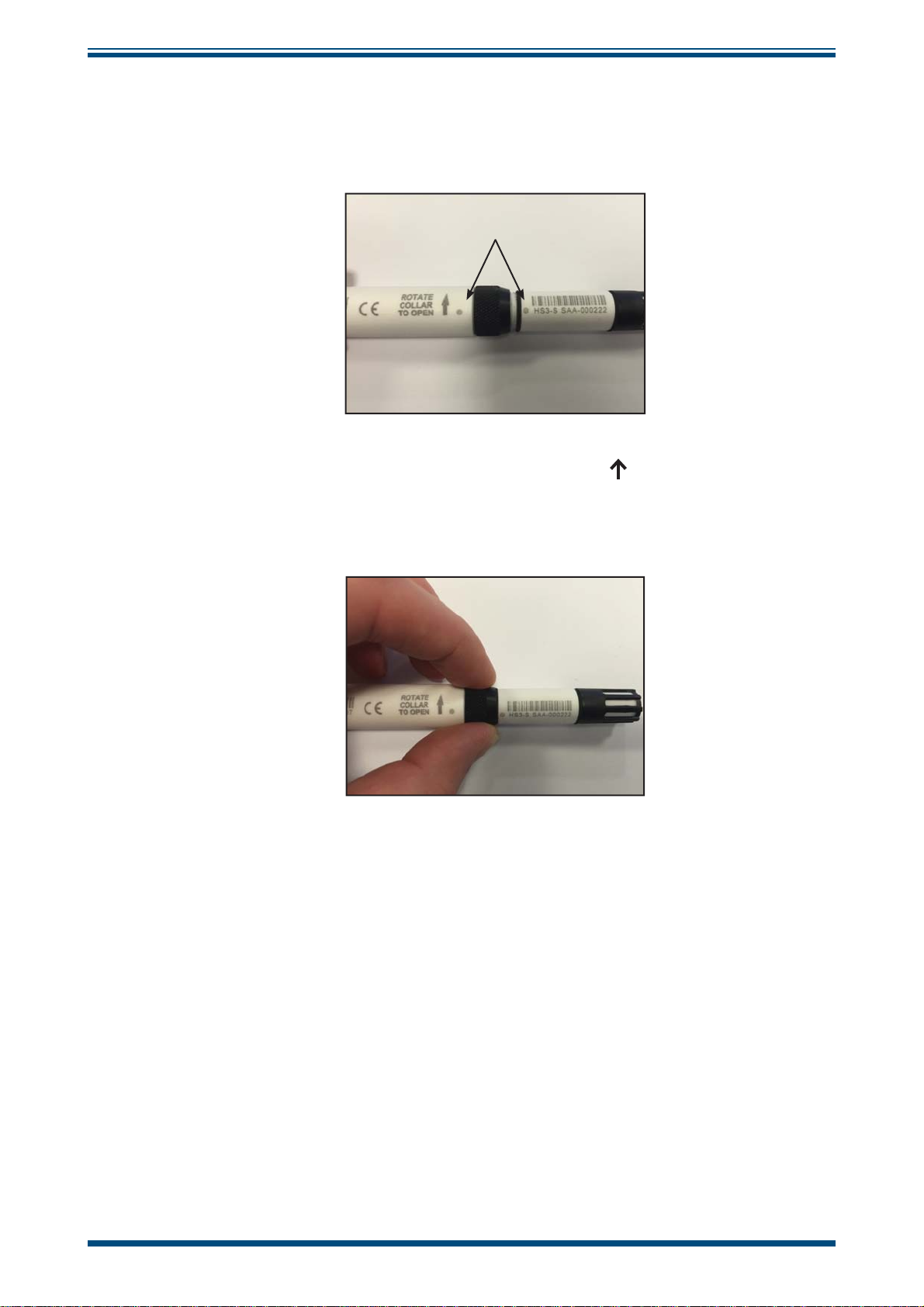

4 SENSOR REPLACEMENT

1. Remove the probe from its mounting position.

2. Remove the M12 connector from the probe.

APPENDIX A

3. Rotate the knurled collar in the direction indicated by the arrow, until

the sensor separates from the probe.

4. Remove the old sensor, and prepare the replacement.

Michell Instruments

19

Page 28

APPENDIX A

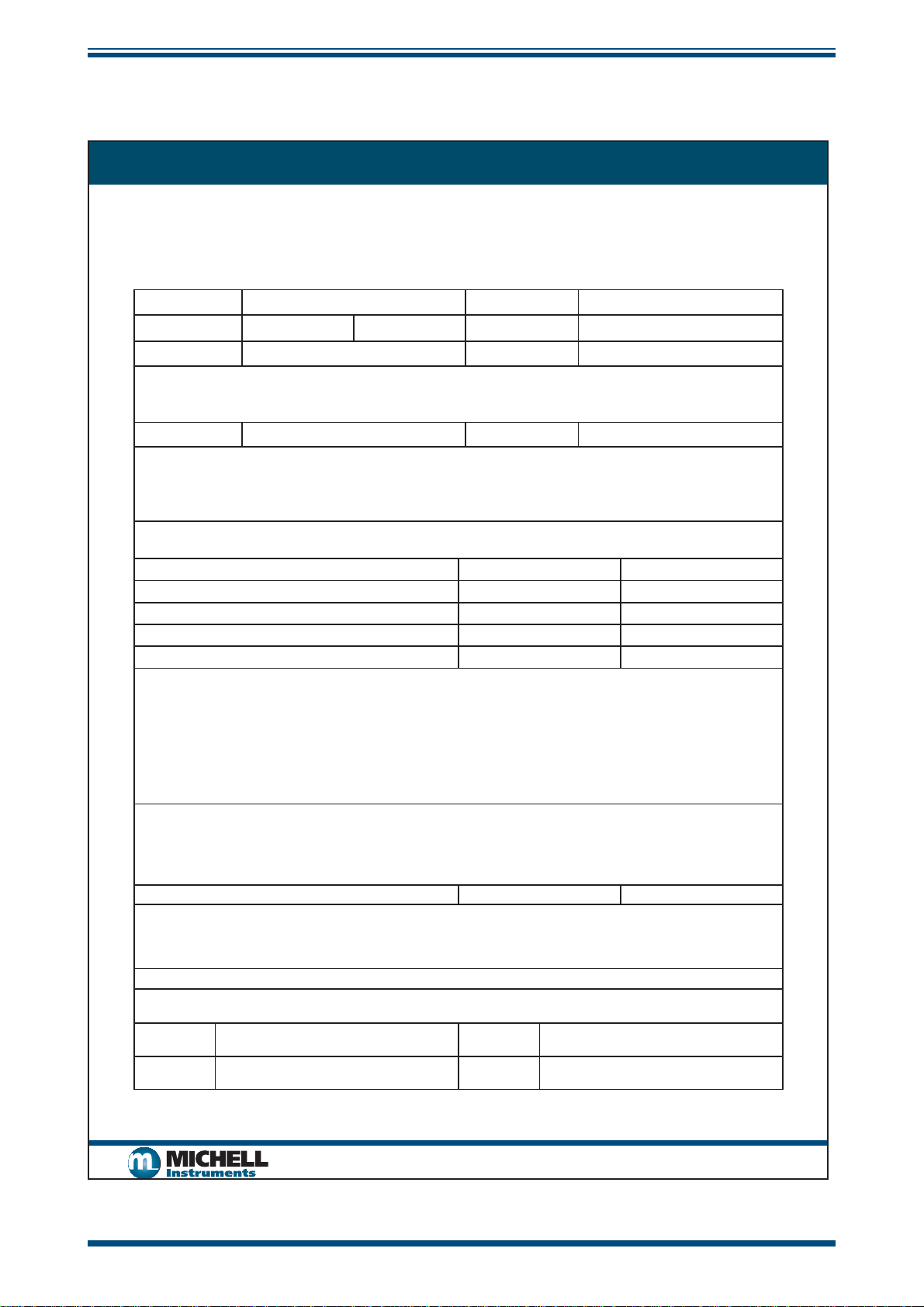

5. Align the dot on the probe with the dot on the sensor and gently place

the two together.

NOTE: Do not use force!

6. Rotate the knurled collar in opposite direction to the arrow until fi nger

tight.

HygroSmart HS3 User’s Manual

NOTE: No force should be needed to fi t the probe.

97516 Issue 5, July 2017

20

Page 29

HygroSmart HS3 User’s Manual

5 LOOP CHECKING SIMULATION

When the HS3-SCK is ordered, 3 fi xed output sensors will be provided. These sensors

can be identifi ed by the blue cap.

APPENDIX A

Each sensor is factory set with a RH and T output. The 3 supplied will be:

25% @ 23°C (73°F)

50% @ 23°C (73°F)

75% @ 23°C (73°F)

These simulators can be connected to a signal loop and used to check its functionality

and accuracy.

5.1 Simulator Connection

A probe electronics assembly is provided with the Simulator Kit.

A sensor simulator module can be connected to the probe in the same manner as a

sensor. See Section 4 for detailed instructions.

The simulator and probe assembly can then be connected to the loop which requires

testing.

Figure 27

Sensor Simulator

5.2 Checking /Programming the Simulators

The application software can be used to change the output range of any of the sensor

simulators. Ensure that the simulator to be re-ranged is attached to a probe, then

establish communications with the software as per the instructions in Section 3.3.

Section 3.7 details the functionality within the Application Software for re-ranging the

simulators.

Michell Instruments

21

Page 30

APPENDIX A

6 MAINTENANCE

6.1 Cleaning the Filter Element

It is necessary to keep the fi lter clean to ensure good airfl ow around the sensor element,

and to prevent a buildup of contamination which could cause harm to the sensor.

The cleaning procedure is as follows:

1. Carefully remove the fi lter cap from the HS3 sensor.

HygroSmart HS3 User’s Manual

Figure 28

2. Flow distilled water through the fi lter element from the inside out.

Figure 29

Filter Cap Removal

Filter Element Cleaning

3. Flow alcohol through the fi lter element from the inside out.

4. Using compressed air, dry the fi lter element from the inside out.

If there is any doubt about the cleanliness of the fi lter after cleaning, a replacement can

be ordered - order code A000018.

97516 Issue 5, July 2017

22

Page 31

HygroSmart HS3 User’s Manual

6.2 Probe Adjustment Procedure

The probe electronics provide a functionality which allows the user to apply a 5 point

correction table to the reading received from the sensor module, and adjust the probe

accordingly.

The usage of the adjustment tool in the application software is covered in Section

3.6. This section specifi cally relates to the method of generating the known conditions

required to make accurate adjustments.

In order to make a valid adjustment, the probe should be exposed to a environment of

stable humidity and temperature, which is also measured by an authoritative traceable

reference instrument. Michell Instruments offers a number of devices suitable for the

purpose, either with or without temperature control.

HygroCal100

The HygroCal100 enables quick and convenient generation of a known humidity condition

at ambient temperatures.

APPENDIX A

Its chamber allows seven relative humidity probes of various diameters to be installed

into the chamber simultaneously. The probes can be powered directly from the

HygroCal100, and monitored via the intuitive touch screen user interface.

This interface also allows the programming of a calibration profi le, so that a series of

humidity values can be generated and held automatically for a set time period. The

readings from all probes under test and the built-in reference can also be logged for

completely autonomous operation. The system is entirely self-contained, and weighs

just 3.2kg (7lbs) (including the battery pack), so is easily portable for making multiple

on-site checks.

OptiCal

For calibration at a variety of temperatures, the OptiCal humidity calibrator provides a

stable and accurate calibration environment over the 10 to 90% RH and +10 to +50°C

(+50 to +122°F) range. The stand-alone, transportable calibrator requires no external

services other than mains power, and features an integrated chilled mirror reference

instrument to enable the operator to perform calibrations that are traceable to national

standards.

Michell Instruments

23

Page 32

APPENDIX A

HygroSmart HS3 User’s Manual

Appendix A

Technical Specifi cations

97516 Issue 5, July 2017

24

Page 33

HygroSmart HS3 User’s Manual

APPENDIX A

Appendix A Technical Specifi cations

Performance Specifi cations

RH Measurement Range 0 to 100% RH

RH Accuracy @ 23°C (73°F) ± 0.8% RH (5 to 95%RH)

RH Thermal Coeffi cient <0.03% RH/°C typical

RH Measurement Response Time < 1 sec to RH event

RH Element Michell H8000

RH Long Term Stability ±1% RH per year

Temperature Measurement Range -40 to +85°C (-40 to +185°F)

Temperature Accuracy ±0.2°C (0.36°F)

Temperature Resolution ±0.01°C (±0.018°F)

Temperature Technology PT1000 1/3 DIN Class B

Recommended Storage Range +10 to +40°C (+50 to +104°F)

Calibration Traceable 5-point calibration certifi cate

Application Software Downloadable from www.michell.com

Electrical Specifi cations

Voltage Output Signals 0-1 V, 0-2.5 V, 0-5 V, 0-10 V

Digital Output Signal Modbus RTU over RS485 2-wire

Electrical Thermal Coeffi cient 0.0004%/°C

Load Resistance

0-1, 0-2.5 V :

0-5, 0-10 V :

Supply Voltage Range 5 to 28 V DC

Supply Current Consumption

5 V :

28 V :

Supply Protection Protected against reverse voltage and overvoltage

Dew point -40 to +100°C (-40 to +212°F)

Confi gurable Calculated Scales/

Ranges

Water activity 0 to 1

Absolute humidity 0 to 200 g/m

Specifi c enthalpy 0 to 800 KJ/kg

Frost point -50 to +10°C (-58 to +50°F)

Confi gurable Temperature Scales/

Range

°C, °F : -20 to 80°C, 0 to 50°C, -40 to +60°C,

-30 to +70°C, 0 to 100°C

CE Conformity 2004/108/EC heavy industrial immunity

Operating Specifi cations

Probe:

Probe Operating Temperature

Interchangeable sensor:

Recommended storage:

10K Ω

50K Ω

4 mA

7 mA

3

-40 to +85°C (-40 to +185°F)

-40 to +120°C (-40 to +248°F)

+10 to +40°C (+14 to +104°F)

Michell Instruments

25

Page 34

APPENDIX A

HygroSmart HS3 User’s Manual

Mechanical Specifi cations

Ingress Protection IP67 (NEMA 6)

Material

Dimensions

Probe & sensor body:

Interconnect ring:

Filter assembly:

Probe:

Interchangeable sensor:

Solid glass fi lled PBT

Anodized aluminum

HDPE or Molded polymer & PVDF

L=145mm, ø15mm (5.7", ø 0.6")

L= 56mm, ø12mm (2.2", ø 0.47")

Weight 31g (1.09oz) approx (packed weight 45g (1.59oz)

Electrical Connector M12 5 pin (A coded)

Mating connector/cable (optional) M12 Connector/cable 2, 5, 10 meter assembly

Product Marking Indelible laser etched alphanumeric/bar coded identifi cation

Maintenance Kits (Optional)

Desk-mounted confi guration kit, 3 x sensor simulators (25%,

HS3 Probe Simulator Kit

HS3 Probe Confi guration Kit

HS3 logger/confi guration converter

Cable

50%, 75%RH at 23°C (73°F)), spare probe electronics, carry

case

Desk-mounted confi guration kit, spare probe electronics, carry

case

1.8 meter USB to RS485 converter cable with M12 connector

A.1 Dimensions

0.59”

ø15mm

HygroSmart HS3 Probe Replacement Sensor - HS3-S-R

HygroSmart HS3 Probe - HS3-P

144mm

5.66”

55.5mm

2.19”

0.59”

ø15mm

98.5mm

98.5mm

3.87”

3.87”

45.5mm

1.79”

0.47”

ø12mm

0.47”

ø12mm

Figure 30

97516 Issue 5, July 2017

26

Dimensional Drawings

Page 35

HygroSmart HS3 User’s Manual

APPENDIX B

Appendix B

HS3 Modbus Communications

& Register Map

Michell Instruments

27

Page 36

APPENDIX B

HygroSmart HS3 User’s Manual

Appendix B HS3 Modbus Communications and Register Map

B.1 Communications

Modbus Cable Color

1 Comms A Brown

2 Comms B White

3 0 V Blue

4 +5 V to +28 V Black

50 V Gray

21

34

5

Figure 31

Parameter Value

Baud Rate 9600 bps

Stop Bits 1

Data Bits 8

Parity Check None

Flow Control None

Figure 32

The HS3 uses the Modbus RTU protocol to communicate.

All data is accessed by using Function Code 3 - Read Holding Registers, the byte order of the data

in the responses is Big Endian (AB).

Serial Port Parameters

Pinout

97516 Issue 5, July 2017

28

Page 37

HygroSmart HS3 User’s Manual

B.2 Code examples

This example shows the raw bytes to send to the probe to request relative humidity and temperature.

In this example there is one probe in the loop on address 1.

Request Relative Humidity:

Address Function

code

X01 X03 X00 X01 X00 X01 X25 XCA

Reply HS3 Probe:

Address Function code Byte count Data0 Hi Data0 Lo CRC Lo CRC Hi

X01 X03 X02 X01 xC5 X79 X87

Request temperature:

Address Function

code

X01 X03 X00 X01 X00 X01 xD5 X15

Start

address Hi

Start

addrss Hi

Start

address Lo

Start

address Lo

Length HiLength LoCRC 16 LoCRC 16

Length HiLength LoCRC 16 LoCRC 16

APPENDIX B

Hi

Hi

Reply HS3 Probe:

Address Function code Byte count Data0 Hi Data0 Lo CRC Lo CRC Hi

X01 X03 X02 X00 xEA x39 xCB

Useful resources:

www.simplymodbus.ca/FAQ.htm - excellent and easy to understand resource explaining the Modbus

protocol

www.scadacore.com/fi eld-applications/programming-calculators/online-hex-converter/ - convert

raw data into various data-types, useful for troubleshooting Modbus connections

www.baseblock.com/PRODUCTS/comtestpro.htm - free Modbus master-client for PC

Michell Instruments

29

Page 38

APPENDIX B

HygroSmart HS3 User’s Manual

B.3 Register Map

Addr: Gives the (base 10) address of each 16 bit register stored in the instrument.

R/W: Refer to R/W key following this table

Type: Indicates the data type of the register. For complex types, a letter is indicated which corresponds

to a description of the type found following this table.

Div: Some register values with a fi xed number of decimal places are stored internally as integers,

which must then be divided by the number in this column to give the real value.

Addr Description R/W Type Div Internal Name Comment

Instrument

0

Modbus address

1 Temperature R Int16 10 REG_TEMPERATURE

2 %RH R UInt16 10 REG_RH 0.0 to 100.0

3 Dew Point R Int16 10 REG_DEWPOINT

4 Frost Point R Int16 10 REG_FROSTPOINT

5 Water-Activity R UInt16 100 REG_WATER_ACTIVITY

Absolute

6

Humidity (g/m

7 Wet Bulb R Int16 10 REG_WET_BULB

8 Enthalpy R Int16 10 REG_ENTHALPY

water vapour

9

pressure over

water

water vapour

10

pressure over ice

water vapour

11

pressure over

water HI

water vapour

12

pressure over

water LO

water vapour

13

pressure over ice

HI

water vapour

14

pressure over ice

LO

15-31 Reserved

32 Status R TYPE_A REG_STATUS

R/W UInt16 REG_OWN_ADDR 1-32

Measured & Calculated Parameters

3

R UInt16 10 REG_ABS_HUMIDITY 0.0 to 6553.5

)

R UInt16 REG_WVP_WATER_INT 0 to 65535

R UInt16 REG_WVP_ICE_INT 0 to 65535

REG_WVP_WATER_F_HI

IEEE754

R

single

REG_WVP_WATER_F_LO

REG_WVP_ICE_HI

IEEE754

R

single

REG_WVP_ICE_LO

Miscellaneous

-250.0C TO

250.0C

-364.0C to

364.0C

-364.0C to

364.0C

0.000 to

1.000

-364.0C to

364.0C

-3000.0 to

3000.0

97516 Issue 5, July 2017

30

Page 39

HygroSmart HS3 User’s Manual

Temperature

33

Units

34 Reserved

Customer

35

Password

36-63 Reserved

Full Scale

64

Voltage

65 Output 1 Type R/W UInt16 REG_OUT1_TYPE

66 Output 2 Type R/W UInt16 REG_OUT2_TYPE

67 Output 1 Min R/W * * REG_VOUT1_MIN

68 Output 1 Max R/W * * REG_VOUT1_MAX

69 Output 2 Min R/W * * REG_VOUT2_MIN

70 Output 2 Max R/W * * REG_VOUT2_MAX

71 Output 1 %FS R Int16 10 REG_VOUT1_FS_THOU

72 Output 2 %FS R Int16 10 REG_VOUT2_FS_THOU

73-79 Reserved

Temperature & Relative Humidity Calibration Correction Tables

Temperature

80

table in1

Temperature

81

table out1

Temperature

82

table in2

Temperature

83

table out2

Temperature

84

table in3

Temperature

85

table out3

Temperature

86

table in4

Temperature

87

table out4

Temperature

88

table in5

Temperature

89

table out5

90 RH table in1

91 RH table out1

92 RH table in2

93 RH table out2

R/W UInt16 REG_TEMPERATURE_UNITS See Note 1

R/W UInt16 REG_CUSTOMER_PASSWORD See Note 2

Voltage Outputs

R/W UInt16 1000 REG_VOUT1_RANGE

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

Int16 10 REG_TEMP_CORR_IN1

Int16 10 REG_TEMP_CORR_OUT1

Int16 10 REG_TEMP_CORR_IN2

Int16 10 REG_TEMP_CORR_OUT2

Int16 10 REG_TEMP_CORR_IN3

Int16 10 REG_TEMP_CORR_OUT3

Int16 10 REG_TEMP_CORR_IN4

Int16 10 REG_TEMP_CORR_OUT5

Int16 10 REG_TEMP_CORR_IN5

Int16 10 REG_TEMP_CORR_OUT5

UInt16 10 REG_RH_CORR_IN1

UInt16 10 REG_RH_CORR_OUT1

UInt16 10 REG_RH_CORR_IN2

UInt16 10 REG_RH_CORR_OUT2

APPENDIX B

1000 / 2500 /

5000 / 10000

See Note 3

See Note 4

Michell Instruments

31

Page 40

APPENDIX B

HygroSmart HS3 User’s Manual

94 RH table in3

95 RH table out3

96 RH table in4

97 RH table out4

98 RH table in5

99 RH table out5

100-

109

110

111

112

113 Reserved

114

115

116-

119

120

121

122

123

124-

127

Reserved

Probe Firmware

version

Probe Serial

number HI

Probe serial

number LO

Probe fi rst cal

(MMYY)

Probe last cal

(MMYY)

Reserved

Sensor Firmware

version HI

Sensor Firmware

version LO

Sensor serial

number HI

Sensor serial

number LO

Reserved

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

RC/

WC

R UIny16 100 REG_FIRMWARE_VERSION

R TYPE_B

R TYPE_C

R TYPE_D

R TYPE_B

UInt16 10 REG_RH_CORR_IN3

UInt16 10 REG_RH_CORR_OUT3

UInt16 10 REG_RH_CORR_IN4

UInt16 10 REG_RH_CORR_OUT4

UInt16 10 REG_RH_CORR_IN5

UInt16 10 REG_RG_CORR_OUT5

Probe & Sensor Data

REG_PROBE_SERIAL_HI

REG_PROBE_SERIAL_LO

REG_PROBE_FIRST_CAL

REG_PROBE_LAST_CAL

REG_SENSOR_FIRMWARE_HI

REG_SENSOR_FIRMWARE_LO

REG_SENSOR_SERIAL_HI

REG_SENSOR_SERIAL_LO

97516 Issue 5, July 2017

32

Page 41

HygroSmart HS3 User’s Manual

APPENDIX B

R/W Key

Value Description

R Always readable

W Always writeable

RC Can only be read when REG_CUSTOMER_PASSWORD (register 35) contains 4660,

otherwise returns 0

WC Can only be written when REG_CUSTOMER_PASSWORD (register 35) contains 4660,

otherwise write operation is ignored

Note 1 - Temperature Register

Value Description

1 Temperature units = °C

2 Temperature units = °F

All parameters that sue temperature unit (temperature/dew-point/frost-point/wet bulb/output

settings/temperature correction table) will be automatically converted into the newly selected

temperature unit.

Note 2 - Customer Password

Writing

4460 to this register unlocks all registers marked as RC or WC.

Note 3 - Output 1 & 2 Type

Value Quantity to output

1 Temperature

2 %RH

3 Dew Point

4 Frost Point

5 Water Activity

6 Absolute Humidity (g/m

3

)

7 Wet Bulb

8 Enthalpy

9 water vapour pressure over water (Int16)

10 water vapour pressure over ice (Int16)

See also notes 1 & 4.

Michell Instruments

33

Page 42

APPENDIX B

Note 4 - Output 1 & 2 Min/Max

The register type and divider for Output 1 Min and Output 1 Max are inherited from the parameters

selected in Output 1 Type. For example, if Water Activity is selected, then the type is UInt16, and the

divider is 100 as per the register map entry.

The register type and divider for Output 2 Min and Output 2 Max are inherited from the parameters

selected in Output 2 Type.

Register TYPE_A (Status Register)

Bit Flag

0 Output 1 under range

1 Output 1 over range

2 Output 2 under range

3 Output 2 over range

4 Thermistor open-circuit

5 Thermistor short-circuit

6 RH element open-circuit

7 RH element short-circuit

8 Sensor communications error

9 Input volts too low

10 Logic volts too low

11 Temperature out-of-range

12 RH out-of-range

13 Not Used

14 Customer extended access

15 Diagnostic mode enabled

HygroSmart HS3 User’s Manual

One or more bits are set to '1' to indicate an error or alternative mode of operation.

Register TYPE_B (Serial Number Registers)

Two consecutive 16-bit registers form a 32-bit unsigned integer, X, that stores the serial number. The

displayed serial number has the format HH-DDDDDD, where H is a hex digit & D is a decimal digit.

HH = (X & 0x0FF00000) >> 20 (displayed as 2 hexadecimal digits)

DDDDDD = X & 0x000FFFFF (displayed as a decimal number)

Example: If REG_PROBE_SERIAL_HI = 0x0AA5 and REG_PROBE_SERIAL_LO = 0x464E, then the

probe serial number is displayed as "AA-345678"

97516 Issue 5, July 2017

34

Page 43

HygroSmart HS3 User’s Manual

Register TYPE_C (Date Registers)

The calibration dates are stored as 4 BCD digits in a word, 0xMMYY, where MM is a 2-digit BCD

month number & YY is a 2-digit Year.

Example: 0x112 = November 2025

Register TYPE_D (Sensor Firmware)

The fi rmware is displayed as "A.B.C", where A, B & C are integers in the range 0-255.

A = REG_SENSOR_FIRMWARE_HI & 0x00FF

B = (REG_SENSOR_FIRMWARE_LO & 0xFF00) >> 8

C = REG_SENSOR_FIRMWARE_LO & 0x00FF

Example: If REG_SENSOR_FIRMWARE_HI = 0x0001 and REG_SENSOR_FIRMWARE_LO = 0x0203,

the the sensor fi rmware version is displayed as "1.2.3"

APPENDIX B

Michell Instruments

35

Page 44

APPENDIX C

HygroSmart HS3 User’s Manual

Appendix C

Quality, Recycling

& Warranty

Information

97516 Issue 5, July 2017

36

Page 45

HygroSmart HS3 User’s Manual

APPENDIX C

Appendix C Quality, Recycling & Warranty Information

Michell Instruments is dedicated to complying to all relevant legislation and directives. Full information

can be found on our website at:

www.michell.com/compliance

This page contains information on the following directives:

• ATEX Directive

• Calibration Facilities

• Confl ict Minerals

• FCC Statement

• Manufacturing Quality

• Modern Slavery Statement

• Pressure Equipment Directive

• REACH

• RoHS2

• WEEE2

• Recycling Policy

• Warranty and Returns

This information is also available in PDF format.

Michell Instruments

37

Page 46

APPENDIX D

HygroSmart HS3 User’s Manual

Appendix D

Return Document

&

Decontamination Declaration

97516 Issue 5, July 2017

38

Page 47

HygroSmart HS3 User’s Manual

Appendix D Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

APPENDIX D

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLFEDVLFÀDPPDEOHRUWR[LFJDVHV DVLPSOHSXUJHZLWKGU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

Michell Instruments

39

Page 48

NOTES:

HygroSmart HS3 User’s Manual

97516 Issue 5, July 2017

40

Page 49

Page 50

http://www.michell.com

Loading...

Loading...