Page 1

Dew-Point Sampling

Dew-Point Sampling

ES70 Sampling System

Sample extraction, handling and conditioning techniques are of critical importance to assure optimal

performance and reliability of all analysers which accurately quantify specifi c components within a

process gas or liquid composition. With a wide variety of options required for pressure and fl ow

control, fi ltration, isolation and sample temperature control, it can be diffi cult to see what is really

required to get maximum performance from your analysers in any given application.

Highlights

• Indoor panel or outdoor enclosure mounting

options

• Process connection via 6mm or 1/4” tube fi ttings

• High quality components, stainless steel tubing

and fi ttings

• Sample inlet pressure up to 138 barg

• Flexible fi ltration options

• Choice of transmitter, fl ow and pressure control

• Comprehensive documentation options with BS

EN 10204 3.1 certifi cation and NACE MR0175

available

www.michell.com

Applications

• Natural gas production, processing & transmission

• Biomethane gas production

• Fiscal metering of gas

• LNG production processing and receiving terminals

• Hydrocarbon refi nery processing

• Catalyst protection

• Polymer production

• CNG production

• Heat treating furnaces

• Petrochemical process liquids

Page 2

Dew-Point Sampling

ES70 Sampling System

Our ES70 series sample systems provide a choice of indoor

or outdoor compatibility, sensor mount selection, along

with a wide range of features to facilitate regulation of

pressure and fl ow and the removal of contaminants. This

enables the system to deliver a properly conditioned sample

to the analyser for reliable measurements and troublefree operation. The optional integrated bypass system

increases transport speed of the sample while reducing

wastage. Each high quality sample system is constructed

from 316 stainless steel components, with BS EN 10204 3.1

material certifi cates and compliance to MR 0175/ISO 15156

available on request.

The ES70 series is designed to simplify sample system

confi guration by providing a set of choices for all requirements,

such as panel or enclosure mount, fi ltering, upstream and

downstream pressure and fl ow control etc. This provides

a quick and simple method to choose all the required

components suitable for the application requirements.

System Designs

Michell Instruments has over 40 years of experience

providing dew-point and moisture measurement solutions.

We also design and manufacture a broad range of sampling

systems for a wide spectrum of industries.

Our sampling system designs ensure that dew-point and

moisture measurements can be performed in the most

suitable conditions. The ES70 sampling systems can be

supplied in various confi gurations and are designed to be

used in conjunction with other Michell products, as follows:

• Easidew PRO XP Transmitter

• Easidew PRO I.S. Transmitter (with or without optional

fi eld display)

• Promet I.S. (with or without pressure transmitter)

• Liquidew I.S.

Process connections are available with either 6mm or 1/4”

tube fi ttings.

High Quality Materials

To ensure continuous and reliable dew-point or moisture

measurement, it is important that the transmitter

is exposed to stable conditions of the sample being

monitored.

The ES70 sampling system utilises high quality 316 stainless

steel components which provide the optimum response to

moisture changes in the process.

Mounting Variants

Depending on the application, the sampling system can be

supplied in 5 variations:

• Mounted on an open panel for indoor systems

• Mounted in an Outdoor Enclosure, IP66/NEMA4X rated,

with or without window, 304 grade stainless steel

• Mounted in an Outdoor Enclosure, IP66/NEMA4X rated,

with or without window, 316 stainless steel

Filtration and Fast Loop Flexibility

If the sample contains impurities it is crucial to remove

the contaminants before they reach the sensing device.

A fast-loop bypass fl ow arrangement can also be included

to reduce sample fl ow response time lag and to enable

the fi lter to be drained automatically of any potential

hydrocarbon liquids and hydrates formed. The ES70 system

can be supplied with various fi ltration and fast loop options;

• Particulate Filter: 5 micron stainless steel mesh

• Coalescing Filter with manual drain

• Combined coalescing/oleophobic membrane with

continuous drain fl ow (fast loop) - with single stage

regulation & glass tube (20 barg rated) or armoured fl ow

meter (130 barg rated) with integral fl ow metering valve.

• Combined coalescing/oleophobic membrane with

continuous drain fl ow (fast loop) - with Two Stage

Regulation & Armoured fl ow meter (130 barg rated)

with integral fl ow metering valve.

www.michell.com

Page 3

Dew-Point Sampling

Pressure and Flow Control Options

Various options are available for management of pressure

and fl ow within the sampling system;

• Upstream and Downstream, single stage or two stage

pressure regulation, with a choice of gauges.

• Downstream fl ow metering with a choice of glass tube

or armoured fl ow meters

Enclosure Environmental Control

Sampling systems fi tted within enclosures may need heating

to maintain a constant temperature environment of at least

10oC above the highest envisaged dew point temperature

independent of surrounding temperature variations. Similarly,

the enclosure temperature may need to be controlled when

ambient temperatures rise in summer months.

• Electrical heating with a choice of fi xed and variable

thermostats

• Vortex Cooling (instrument air required)

Documentation Packages

Michell provides soft copy ‘as built’ drawings and hazardous

area certifi cates, hard copies of calibration certifi cates,

pressure leak test certifi cates (as applicable), a packing

checklist and the relevant manuals. Customers can also

choose to select other standard documentation lists,

as well as duplicate documentation packs and material

certifi cation (EN10204-3.1 certifi cation and NACE MR0175

conformity). If you require additional documentation with

your system, please contact us for more information.

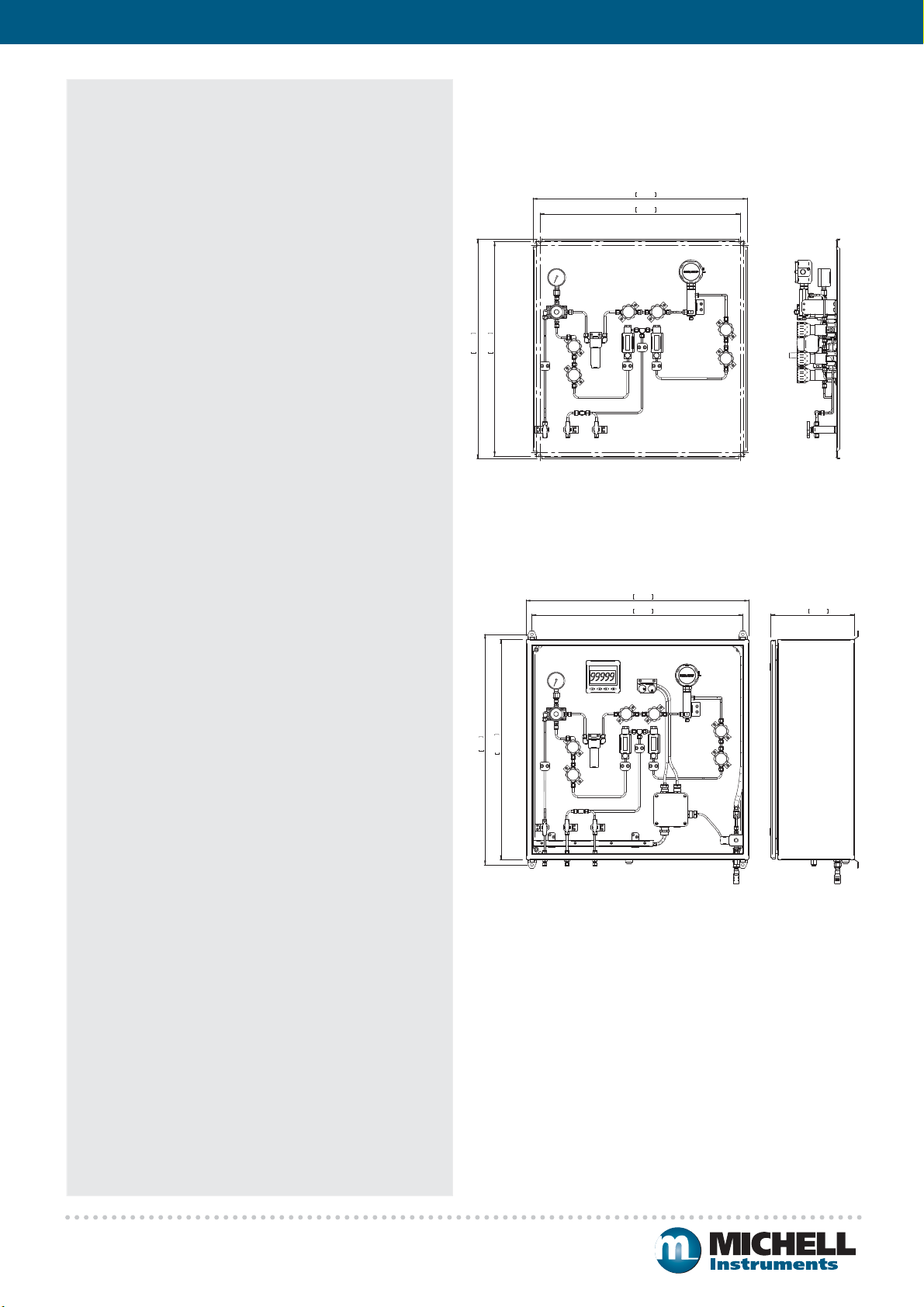

Dimensions

Indoor

750 29.5"

770 30.3"

Outdoor

750 29.5"

700 27.6"

800 31.5"

758 29.8"

300 11.8"

System Customisation

If the ES70 sampling system does not meet your particular

application requirements, we have a specialised design and

manufacturing facility to cover your requirements. Your Michell

offi ce or authorised distributor will be pleased to discuss your

specifi c application and installation requirements.

838 33"

800 31.5"

www.michell.com

Page 4

Dew-Point Sampling

Technical Specifi cations

Electrical Specifi cations

Supply voltage (sensor) 14 to 28 V DC

Supply voltage (sampling system) 240VAC or 110VAC

Operating temperature

ES70 fi tted with monitor 0 to +50°C

ES70 without monitor -20 to +60°C

Gas Operating Inlet Pressure 138 barg maximum

Gas Flow rate 1 – 5 nl/min

Liquid Operating Inlet Pressure 50 barg maximum

Liquid Flow rate Min 0.01 l/min, max 10 l/min

0.1 to 0.3 l/min recommended

Mechanical Specifi cations

Process connections and materials Inlet/outlet process connections via 6mm or 1/4” tube fi ttings, 316 SS

Gas wetted parts Transmitter sample block, fi lter housing and fi ttings, 316 SS

Dimensions Indoor panel: 750 x 750 x 2mm

Outdoor: 800 x 800 x 300mm

Dew Point Measurement Specifi cations * See chosen sensor datasheets

*For all other specifi cations refer to the Easidew/Liquidew/Promet datasheets, available from your local

Michell Instruments representative or visit

www.michell.com/uk

Related Products

MDM300 Hygrometer

With Panel Mount

Sampling System

QMA601

Process Moisture

Analyzer

Michell Instruments 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0) 1353 658000, Fax: +44 (0) 1353 658199, Email: info@michell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specifi cation changes without notice.

Issue no: ES70_97550_V1_UK_0418

© 2018 Michell Instruments

Loading...

Loading...