Page 1

Dew-Point Sampling

Dew-Point Sampling

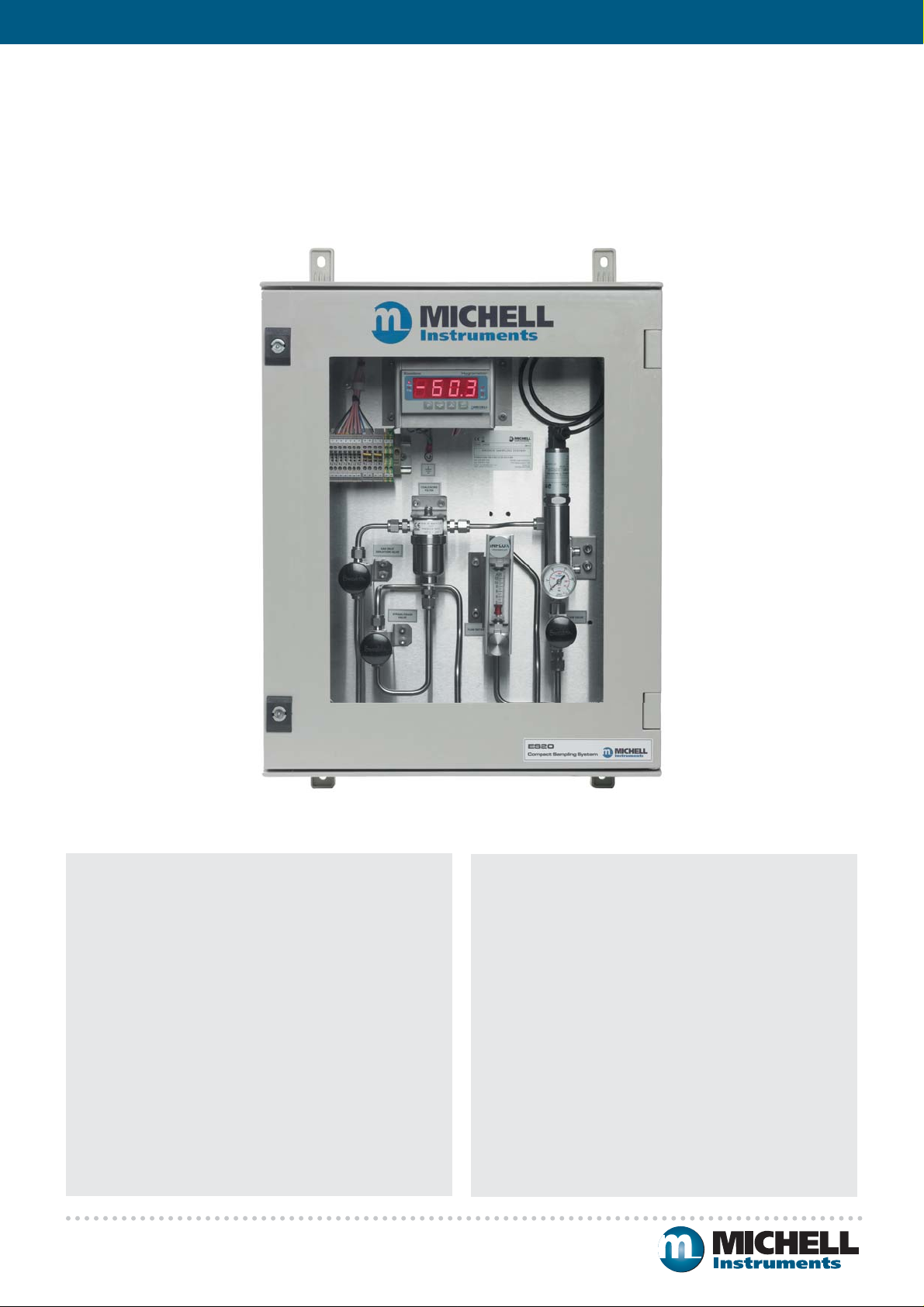

ES20 Compact Sampling System

Stainless Steel Sampling System

The ES20 Compact Sampling System is designed to reliably and accurately measure dew point

or moisture content in a wide variety of industrial gas applications up to 20 barg. This sampling

system is an economical and high quality solution with a short lead time.

Highlights

• Process connection via 6mm or 1/4” tube fi ttings

• Dew point, moisture content, fl ow, contamination

and pressure control

• Sample inlet pressure up to 20 barg

• Modular design

• Stainless steel tubing and fi ttings

• Flexible fi ltration options

• High quality components

• Designed for challenging process environments

• Optional displays

www.michell.com

Applications

• Compressed air dryers

• Pneumatics

• Plastic moulding

• Instrument air

• Hydrogen coolants

• Breathing air

• Pure feed gases

• Heat treatment gases

• Inert gases

Page 2

Dew-Point Sampling

ES20 Compact Sampling System

A Reliable Sampler for Moisture

Michell Instruments designs and manufactures a broad

range of sampling systems for a wide spectrum of industries

and processes from the economical compressed air market,

to the demanding oil and gas process market.

The ES20 sampling system is a standard modular, highquality product designed to address the needs for fi ltration,

pressure, and fl ow control.

High Quality Materials

To ensure continuous and reliable dew-point or moisture

measurement, it is important that the dew-point transmitter

is exposed to stable conditions of the gas being monitored.

The ES20 sampling system utilizes high quality materials

(gas wetted parts) which provide the optimum response to

moisture changes in the process.

Filtration Flexibility

If the gas contains impurities it is crucial to remove the

contaminants before they reach the sensing device. The

ES20 is supplied with a fi lter housing, into which recyclable

particulate or coalescing fi lter cartridges can be inserted.

Filtration methods:

• Particulate fi lter (solid contaminants)

• Coalescing fi lter with adjustable drain

(solid and liquid aerosol contaminants)

• HDPE guard (fi lter) for sensing element (standard)

• Air fi lter with optional vacuum pump (standard)

Pressure Control and Measurement

Pressure has a direct effect on dew point. The ES20 utilizes

a set of confi gurable components for atmospheric or process

system line pressure dew-point measurement.

Pressure control features:

• Pressure gauge (dual scale: bar and psi)

• Metering valves (needle valve type)

• Self-regulating vacuum pump

Mounting Variants

Depending on the application, the sampling system can be

supplied in 3 variations:

• Mounted on base plate

• Mounted on base plate inside a windowed GRP enclosure

• Mounted on base plate inside a windowed SS enclosure

(316 stainless steel)

System Designs

Michell Instruments has over 40 years of experience

providing dew-point and moisture measurement solutions.

Our sampling system designs ensure that dew-point and

moisture measurements can be performed in the most

suitable conditions.

The ES20 compact sampling system can be supplied in

various confi gurations and can be used in conjunction with

other Michell products, as follows:

• Easidew Transmitter

• Easidew I.S. Transmitter

• Easidew PRO I.S. Transmitter

• Easidew PRO XP Transmitter

• Easidew Online Hygrometer

• Cermet II Hygrometer

Documentation Package

Every ES20 is supplied with a CD-ROM containing the

following supplementary fi les for your sampling system:

• Manual

• Datasheet

• Flow diagrams

• Material certifi cation (optional)

• EC declaration of conformity

For add-on products such as transmitters or hygrometers (as

mentioned above), a printed manual of the specifi c product

is included with documentation.

Flow Control

The fl ow rate of a gas can affect the transmitter’s response

time. Every sampling system contains a set of components

which help maintain optimum fl ow (1 to 5 liters per minute).

Flow control:

• Flowmeter

• Metering valves (needle valve type)

• Flowmeter with needle valve (with vacuum pump only)

System Customization

If your application requires a customized solution, we have

a specialized design and manufacturing facility to cover your

requirements. Please contact us for more information.

www.michell.com

Page 3

Dew-Point Sampling

ES20 System Confi gurations

ES20 Fitted with Particulate Filter

Components used Specifi cations

1 Base plate 316 stainless steel

2 Inlet process connection and material 6mm or 1/4” fi tting (316 stainless steel)

3 Outlet process connection and material 6mm or 1/4” fi tting (316 stainless steel)

4 Metering valve Needle valve type

5 Filter housing

6 Particulate fi lter (inside fi lter housing)

7 Pressure gauge Center back mount (dual scale: Bar and PSI)

8 Sensor sample block 5/8” SS sample block (316 stainless steel)

9 Flowmeter

10 Terminal rail

11 Process indicator mounting bracket (optional) 1/8 DIN cut-out

($6,'(:

021,725

1(('/(

3$57,&8/$7(

*$6,1/(7

9$/9(

),/7(5

($6,'(:

6(1625

316 stainless steel (340 barg maximum), gasket

®

(Viton

)

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles)

Borosilicate glass (2 to 12 Nl/min),

seals (Viton®)

13 terminals (monitor or vacuum pump fi tted

only)

*$6)/2:',$*5$0

35(6685(

*$8*(

1(('/(

)/2:0(7(5

9$/9(

*$6

287/(7

11

1

17**

10

5

6

4

18**

8

7

4

9

2

11

1

3

17**

ES20 Fitted with Coalescing Filter*

Components used Specifi cations

12 Drainage connection and material 6mm or 1/4” fi tting (316 stainless steel)

13 Coalescing fi lter (inside fi lter housing)

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles and aerosols)

*In addition to particulate fi lter fi tted components

*$6)/2:',$*5$0

1(('/(

9$/9(

1(('/(

9$/9(

)/2:0(7(5

*$6

287/(7

%<3$66

287/(7

*$6,1/(7

1(('/(

9$/9(

&2$/(6&,1*

),/7(5

($6,'(:

021,725

($6,'(:

6(1625

ES20 Fitted with Vacuum Pump*

Components used Specifi cations

14 Flowmeter with needle valve

15 Vacuum pump Anti-overpressure mechanism (Tefl on

16 Pressure gauge Center back mount (dual scale: Bar and PSI)

*In addition to particulate fi lter fi tted components

($6,'(:

021,725

3$57,&8/$7(

*$6,1/(7

1(('/(

9$/9(

),/7(5

($6,'(:

6(1625

Borosilicate glass (2 to 12 Nl/min),

seals (Viton

35(6685(

*$8*(

®

)

*$6)/2:',$*5$0

)/2:0(7(5

$1'9$/9(

9$&880

3803

®

*$6

287/(7

)

10

5

18**

8

13

4

4

2

12

11

1

3

7

4

9

17**

10

18**

5

6

4

8

16

14

15

Optional Dew-Point Measurement Device

Components used Specifi cations

17 Monitor

18 Dew-Point Transmitter

(to be ordered separately)**

(to be ordered separately)**

Refer to Monitor datasheet

Refer to Transmitter datasheet

2

3

www.michell.com

Page 4

ES20 PRO XP System Confi gurations

Dew-Point Sampling

ES20 Fitted with Particulate Filter

Components used Specifi cations

1 Base plate 316 stainless steel

2 Inlet process connection and material 6mm or 1/4” fi tting (316 stainless steel)

3 Outlet process connection and material 6mm or 1/4” fi tting (316 stainless steel)

4 Metering valve Needle valve type

5 Filter housing

6 Particulate fi lter (inside fi lter housing)

316 stainless steel (340 barg maximum), gasket

®

)

(Viton

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles)

7 Pressure gauge Center back mount (dual scale: Bar and PSI)

8 Sensor sample block 3/4” SS sample block (316 stainless steel)

9 Flowmeter

Borosilicate glass (2 to 12 Nl/min),

seals (Viton®)

10 Conduit entry Access to internal connection

*$6)/2:',$*5$0

1(('/(

)/2:0(7(5

9$/9(

*$6

287/(7

*$6,1/(7

1(('/(

9$/9(

3$57,&8/$7(

),/7(5

($6,'(:

021,725

($6,'(:

6(1625

35(6685(

*$8*(

ES20 Fitted with Coalescing Filter*

Components used Specifi cations

12 Drainage connection and material 6mm or 1/4” fi tting (316 stainless steel)

13 Coalescing fi lter (inside fi lter housing)

*In addition to particulate fi lter fi tted components

($6,'(:

021,725

&2$/(6&,1*

*$6,1/(7

1(('/(

9$/9(

),/7(5

($6,'(:

6(1625

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles and aerosols)

*$6)/2:',$*5$0

1(('/(

)/2:0(7(5

9$/9(

1(('/(

9$/9(

*$6

287/(7

%<3$66

287/(7

14**

14**

1

8

10

5

7

6

4

4

9

2

3

1

8

10

5

7

13

4

4

9

4

Optional Dew-Point Measurement Device

Components used Specifi cations

Explosion Proof Dew-Point Transmitter/display

14

(to be ordered separately)**

Refer to Transmitter datasheet

ES20 Enclosure Confi gurations

GRP EnclosureBase Plate Stainless Steel Enclosure

457mm

350mm

Depth: 2mm

www.michell.com

530mm

430mm

Depth: 200mm

500mm

2

400mm

Depth: 200mm

12 3

Page 5

Dew-Point Sampling

Technical Specifi cations

Electrical Specifi cations

Supply voltage (vacuum pump only) 230 V AC**

Operating Specifi cations

Operating temperature

Particulate or coalescing fi lter without monitor

Particulate or coalescing fi lter with monitor

Vacuum pump with or without monitor

Operating inlet pressure

Flow rate 1 to 5 Nl/min

Mechanical Specifi cations

Process connection and material Inlet/outlet process connections via 6mm or 1/4” tube fi ttings, 316 stainless steel

Gas wetted parts Stainless steel tube, fi lter housing and fi ttings (316 stainless steel), Filter element (borosilicate glass

Ingress protection

Housing material

Dimensions

Pressure and fl ow control

Atmospheric or process pressure

Gas fi ltration Particulate fi lter - Borosilicate glass microfi bres (99.5+% removal of 0.1 micron particles)

Electrical connections

Interchangeability Fully interchangeable components

Sample block process connection Compatible with various dew-point transmitters with 5/8” and 3/4” UNF process connection

Dew-Point Measurement Specifi cations (Optional)*

Measurement range (dp) -100 to +20°C dew point, -110 to +20°C dew point

Accuracy (dp) Up to ±1°C dew point

*For all other specifi cations refer to the Easidew Transmitter and Easidew Online datasheets, available from your local Michell Instruments

representative or visit www.michell.com/uk

**Not available for the ES20 Easidew PRO XP version

ES20 fi tted with:

ES20 fi tted with:

Particulate fi lter

Coalescing fi lter

Vacuum pump

No enclosure

GRP & SS enclosures

Base plate

GRP enclosure

SS enclosure

Base plate

GRP enclosure

SS enclosure

Vacuum pressure

Base plate

GPR and SS enclosure

-15 to +60°C

0 to +50°C

0 to +40°C**

0 to 20 barg

0 to 20 barg

-0.3 bar to 1 barg**

microfi bres), Transmitter sample block (316 stainless steel), Flowmeter (borosilicate glass) with Viton

Pump (Tefl on®)

No protection (base plate only)

IP66, NEMA 4X

316 stainless steel

Glass fi bre reinforced polyester and 4mm safety glass

316 stainless steel and 4mm safety glass

457mm x 350mm x 2mm (h x w x d)

530mm x 430mm x 200mm (h x w x d)

500mm x 400mm x 200mm (h x w x d)

Via metering valves, pressure gauge and fl owmeter

Metering valve, pressure gauge, fl owmeter with valve and self-regulating vacuum pump**

Coalescing fi lter - Borosilicate glass microfi bres (99.5+% removal of 0.1 micron particles and aerosols)

Via terminal rail

Via M20 plastic cable glands

Up to ±2°C dew point

®

seals,

Related Products

MDM300 Hygrometer

With Panel Mount

Sampling System

Michell Instruments 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0) 1353 658000, Fax: +44 (0) 1353 658199, Email: info@michell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specifi cation changes without notice.

Issue no: ES20_97448_V2_UK_0915

QMA601

Process Moisture

Analyzer

© 2015 Michell Instruments

Loading...

Loading...