Page 1

ES20

Compact Sampling System

User’s Manual

97447 Issue 2

December 2017

Page 2

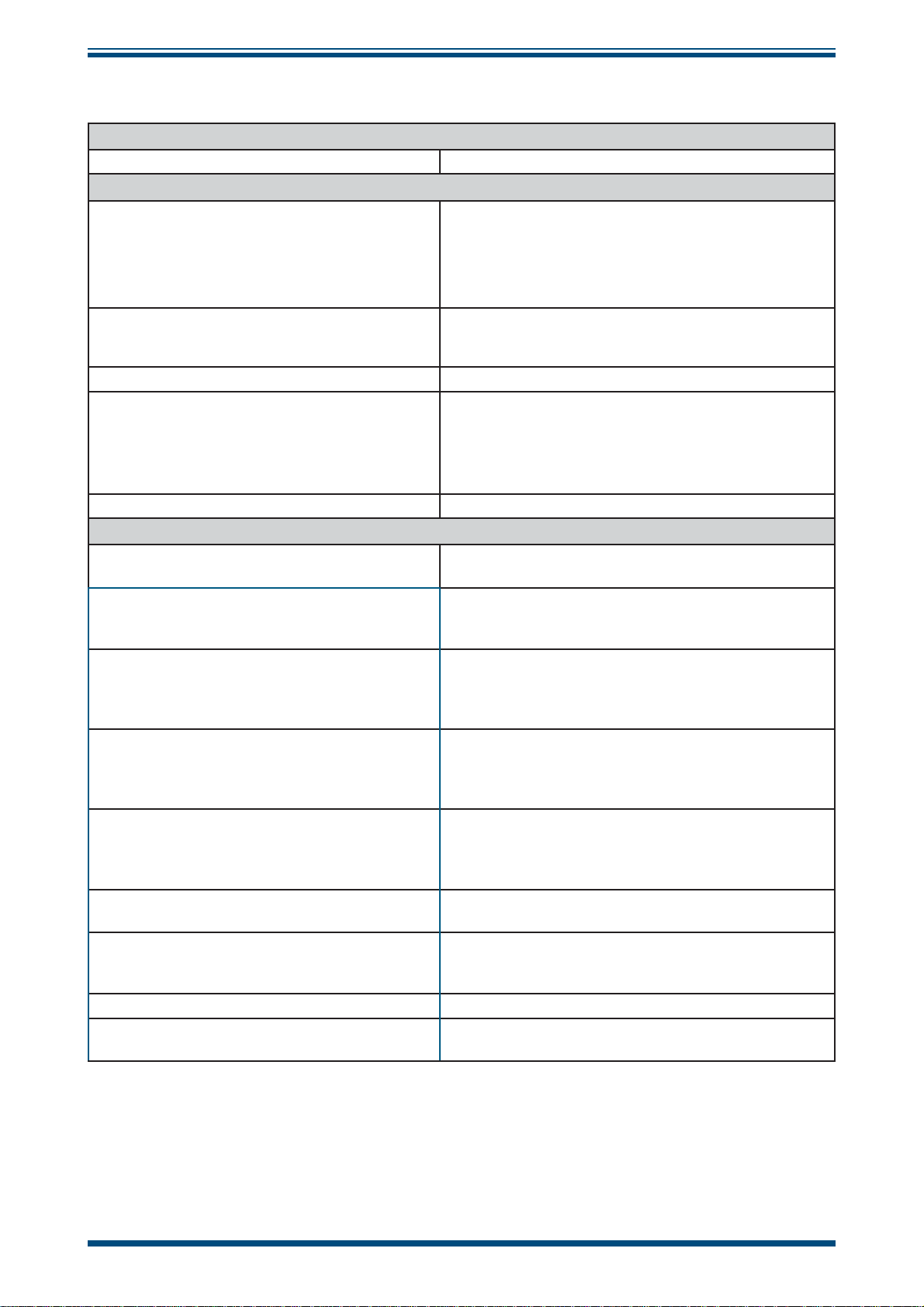

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

ES20

Compact Sampling System

For Michell Instruments' contact information please go to

www.michell.com

© 2017 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

ES20 User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Pressure Safety ............................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ............................................................................................VIII

1.1 Materials ......................................................................................................... viii

1.2 Filtration .......................................................................................................... viii

1.3 Pressure Control and Measurement ..................................................................... 1

1.4 Flow Control ..................................................................................................... 1

1.5 Mounting Variants ............................................................................................. 1

1.6 System Designs ................................................................................................. 1

1.7 System Confi gurations ........................................................................................ 2

1.8 Enclosure Confi gurations ..................................................................................... 3

2 INSTALLATION ..................................................................................................4

2.1 Sampling System Installation ............................................................................... 4

2.1.1 Relevant Manual Section for Installation.......................................................... 4

2.2 Process or Atmospheric Pressure With Particulate Filter ........................................ 5

2.2.1 Mounting Details ........................................................................................... 5

2.2.2 Gas Connections ........................................................................................... 5

2.2.3 Electrical Connections .................................................................................... 5

2.2.4 Power Supply ................................................................................................ 5

2.3 Process or Atmospheric Pressure With Coalescing Filter ........................................ 6

2.3.1 Mounting Details ........................................................................................... 6

2.3.2 Gas Connections ........................................................................................... 6

2.3.3 Drainage Connections .................................................................................... 6

2.3.4 Electrical Connections .................................................................................... 6

2.3.5 Power Supply ................................................................................................ 6

2.4 Vacuum Pressure With Particulate Filter .............................................................. 7

2.4.1 Mounting Details ........................................................................................... 7

2.4.2 Gas Connections ........................................................................................... 7

2.4.3 Electrical Connections .................................................................................... 7

2.4.4 Power Supply ................................................................................................ 7

2.5 Dew-Point Measurement System .......................................................................... 8

2.6 Monitor Installation ............................................................................................. 8

2.7 Process Connection ............................................................................................ 9

2.7.1 Transmitter Connection .................................................................................. 9

2.7.2 Monitor Connection ....................................................................................... 9

2.7.3 Terminal Rail Connection ............................................................................... 9

3 OPERATION ....................................................................................................10

3.1 Sampling Start-Up Procedure ............................................................................. 10

3.1.1 Relevant Manual Section for Operation ......................................................... 10

3.2 Process Pressure With Particulate Filter .............................................................. 11

3.2.1 Sample Flow 'Start-Up' Procedure ................................................................. 11

3.3 Process Pressure with Coalescing Filter .............................................................. 11

3.3.1 Sample Flow 'Start-Up' Procedure ................................................................. 11

3.4 Atmospheric Pressure with Particulate Filter........................................................ 12

3.4.1 Sample Flow 'Start-Up' Procedure ................................................................. 12

iv 97447 Issue 2, December 2017

Page 5

ES20 User’s Manual

3.5 Atmospheric Pressure with Coalescing Filter ....................................................... 12

3.5.1 Sample Flow 'Start-Up' Procedure ................................................................. 12

3.6 Vacuum Pressure With Particulate Filter ............................................................ 13

3.6.1 Sample Flow 'Start-Up' Procedure ................................................................. 13

4 MAINTENANCE ................................................................................................14

4.1 General Maintenance Guidelines ........................................................................ 14

4.2 Filter Element Maintenance ............................................................................... 14

4.2.1 Particulate Filter Maintenance ..................................................................... 14

4.2.2 Coalescing Filter Maintenance ...................................................................... 16

4.3 Transmitter Maintenance ................................................................................... 18

Figures

Figure 1 Replacement of HDPE Guard .....................................................................19

Appendices

Appendix A Technical Specifi cations .............................................................................. 21

Appendix B Quality, Recycling & Warranty Information ...................................................23

Appendix C Return Document & Decontamination Declaration ........................................ 25

Michell Instruments v

Page 6

ES20 User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

Refer to Appendix A, Technical Specifi cations.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied standards may be found in Appendix A, Technical Specifi cations.

vi 97447 Issue 2, December 2017

Page 7

ES20 User’s Manual

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

barg pressure unit (=100 kP or 0.987 atm)

ºC degrees Celsius

ºF degrees Fahrenheit

DC direct current

dp dew point

Hz Hertz

kg kilogram(s)

lb pound

Nl/min normal liters per minute

mA milliampere

max maximum

min minute(s)

% percentage

psig pounds per square inch

scfh standard cubic feet per hour

temp temperature

V Volts

W Watts

Ω Ohms

Warnings

The following general warning listed below is applicable to this instrument. It is repeated

in the text in the appropriate locations.

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially hazardous

operations need to be carried out.

Michell Instruments vii

Page 8

1 INTRODUCTION

Michell Instruments designs and manufactures a broad range of sampling systems for a

wide spectrum of industries and processes from the economical compressed air market

to the oil and gas process market.

The ES20 Compact Sampling System (CSS) is a standard modular product designed to

appeal to customers who require an economic system delivered for fast integration into

their own work package.

Fast delivery is achieved through a simple modular build system on a single base plate

design completed with supply chain stocking of all required ES20 CSS parts.

The ES20 CSS is a standard fast delivery product, covering a small portion of the

Michell Instruments’ overall sampling system and process analyzer sampling system

capabilities.

1.1 Materials

To ensure continuous and reliable dew-point or moisture measurement it is important

that the dew-point transmitter is exposed to stable conditions of the gas to be monitored.

The ES20 CSS utilizes high quality materials which ensure that the sample gas travels

smoothly through the system.

Gas wetted parts:

• Stainless steel tube, fi lter housing and fi ttings (316 stainless steel)

• Filter element (borosilicate glass microfi bers)

• Transmitter sample block (316 stainless steel)

• Flowmeter (borosilicate glass) with Viton

• Pump (Tefl on

1.2 Filtration

If the gas contains impurities it is crucial to remove the contaminants before they reach

the sensing device. The ES20 CSS is supplied with a fi lter housing into which recyclable

particulate or coalescing fi lter cartridges can be inserted.

Filtration methods:

®

seals

®

)

• Particulate fi lter (solid contaminants)

• Coalescing fi lter with adjustable drain (solid and liquid aerosol

contaminants)

• HDPE guard (fi lter) for sensing element (standard)

• Air fi lter (with vacuum pump (standard)

Page 9

ES20 User’s Manual

1.3 Pressure Control and Measurement

Pressure has a direct effect on dew point. The ES20 CSS utilizes a set of confi gurable

options for atmospheric or system line pressure dew-point measurement.

Pressure control features:

• Pressure gauge (dual scale: bar and psi)

• Isolation valves (needle valve type)

• Self-regulating vacuum pump

1.4 Flow Control

Flow rate of a gas can affect the transmitter’s accuracy and infl uence the systems’

response time. Every sampling system contains a set of components which help to

maintain optimum fl ows of 1 to 5 Nl/min (2.1 to 10.6 scfh).

INTRODUCTION

Flow control:

• Flowmeter (with particulate or coalescing fi lter)

• Isolation valves (needle valve type)

• Flowmeter with needle valve (with vacuum pump only)

1.5 Mounting Variants

Depending on the application the sampling system can be supplied in 3 variations:

• Mounted on base plate

• Mounted on base plate inside a windowed GRP enclosure

• Mounted on base plate inside a windowed SS enclosure (316 stainless

steel)

1.6 System Designs

The ES20 CSS can be supplied in various confi gurations and can be used with many

Michell products and accessories such as:

• Easidew Transmitter

• Easidew I.S. Transmitter

• Easidew PRO I.S. Transmitter

• Easidew Online Hygrometer

• Cermet II Hygrometer

• Cooling or venting coil

Michell Instruments 1

Page 10

INTRODUCTION

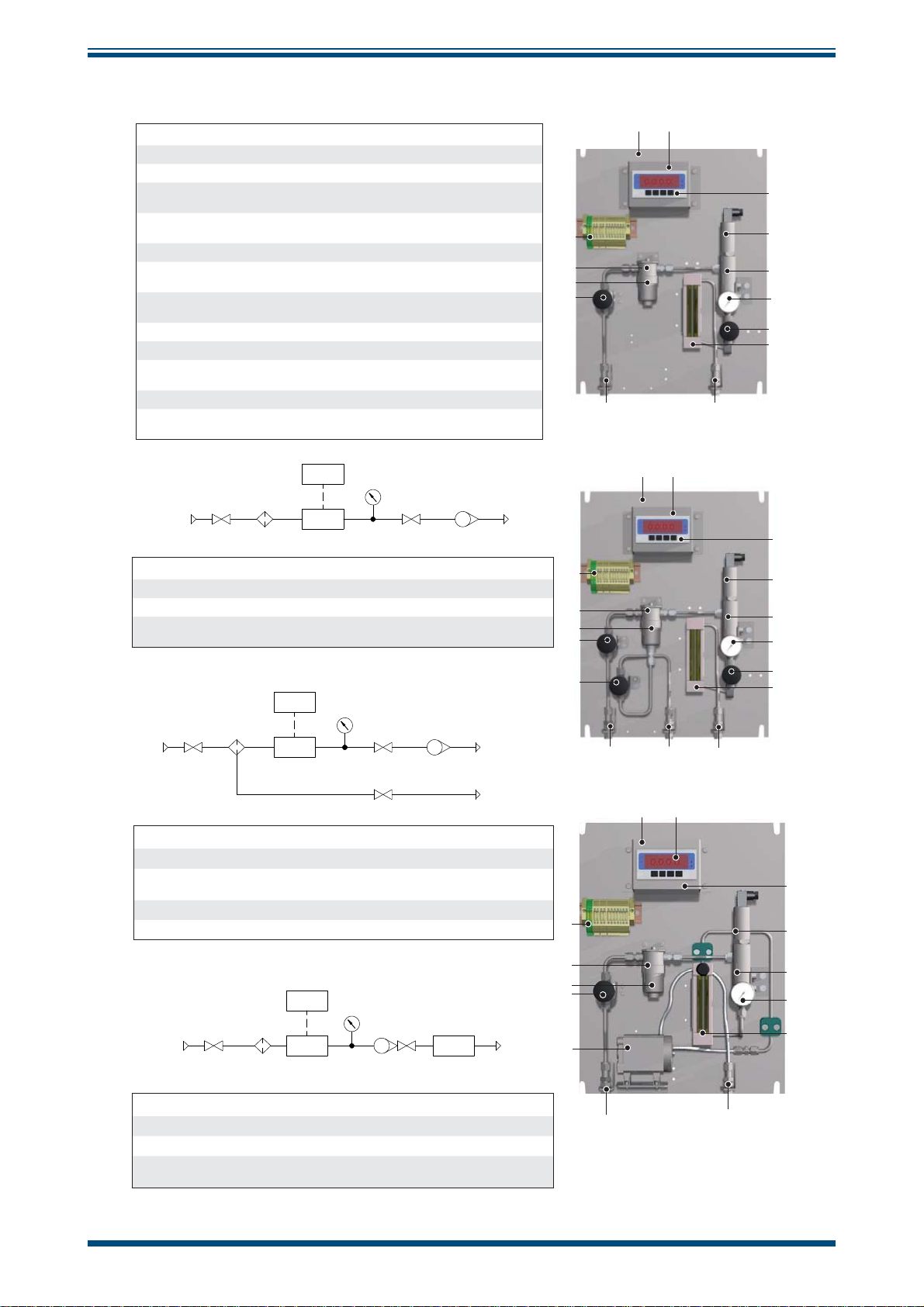

1.7 System Confi gurations

ES20 User’s Manual

ES20 CSS fi tted with Particulate Filter

Components used Specifi cations

1 Base plate 316 stainless steel

Inlet process connection and

2

material

Outlet process connection and

3

material

6mm or ¼” fi tting (316 stainless steel)

6mm or ¼” fi tting (316 stainless steel)

4 Isolation valve Needle valve type

5 Filter housing

Particulate fi lter (inside fi lter

6

housing)

316 stainless steel (340 barg maximum),

gasket (Viton

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles)

®

)

7 Pressure gauge 0 to 20 barg (dual scale: bar and psi)

8 Sensor sample block 5/8” SS sample block (316 stainless steel)

9 Flowmeter

Borosilicate glass (2 to 12 Nl/min), seals

®

)

(Viton

10 Terminal rail 13 terminals

Process indicator mounting bracket

11

*$6,1/(7

(optional)

1(('/(

9$/9(

3$57,&8/$7(

),/7(5

($6,'(:

021,725

($6,'(:

6(1625

1/8 DIN cutout

35(6685(

*$8*(

1(('/(

9$/9(

)/2:0(7(5

ES20 CSS fi tted with Coalescing Filter*

Components used Specifi cations

12 Drainage connection 6mm or ¼” fi tting (316 stainless steel)

13 Coalescing fi lter (inside fi lter housing)

*In addition to particulate fi lter fi tted components

($6,'(:

021,725

&2$/(6&,1*

*$6,1/(7

1(('/(

9$/9(

),/7(5

($6,'(:

6(1625

Borosilicate glass microfi bres (99.5+% removal

of 0.1 micron particles and aerosols)

1(('/(

)/2:0(7(5

9$/9(

1(('/(

9$/9(

*$6

287/(7

%<3$66

287/(7

*$6

287/(7

10

5

6

4

2

10

5

13

4

4

212

111

17**

18**

8

7

4

9

3

111

17**

18**

8

7

4

9

3

111

ES20 CSS fi tted with Vacuum Pump*

Components used Specifi cations

14 Flowmeter with needle valve

15 Vacuum pump Anti-overpressure mechanism (Tefl on

16 Pressure gauge -1 to 1 barg

*In addition to particulate fi lter fi tted components

($6,'(:

021,725

3$57,&8/$7(

*$6,1/(7

1(('/(

9$/9(

),/7(5

($6,'(:

6(1625

Optional Dew-Point Measurement Device

Components used Specifi cations

17 Monitor

18

(to be ordered separately)**

Dew-Point Transmitter

ordered separately)**

(to be

Borosilicate glass (2 to 12 Nl/min), seals

®

(Viton

)

35(6685(

*$8*(

)/2:0(7(5

$1'9$/9(

9$&880

3803

Refer to Monitor datasheet

Refer to Transmitter datasheet

®

)

*$6

287/(7

17**

10

5

6

4

18**

8

16

14

15

2

3

2 97447 Issue 2, December 2017

Page 11

ES20 User’s Manual

1.8 Enclosure Confi gurations

INTRODUCTION

Base Plate

457mm

350mm

2mm (D)

GRP Enclosure

530mm

430mm

200mm (D)

Stainless Steel Enclosure

500mm

400mm

200mm (D)

Michell Instruments 3

Page 12

INSTALLATION

2 INSTALLATION

2.1 Sampling System Installation

It is essential that the connection of electrical and gas supplies

to this instrument be undertaken by competent personnel.

Relevant sections of this manual must be read in full before

commencing measurement (see below).

ES20 User’s Manual

2.1.1 Relevant Manual Section for Installation

Please check below for the relevant product code structure and select the manual

section associated with the sampling system ordered.

NOTE: Compare the 2nd (Feature B - fi lter) and 4th (Feature D - pressure)

option from the ordered ES20 CSS product code with the table below:

Section 2.2 Section 2.3 Section 2.4

B1 - D1

Process or Atmospheric

Pressure

Process or Atmospheric

B2 - D1

Pressure

B1 - D2

Vacuum

Pressure

4 97447 Issue 2, December 2017

Page 13

ES20 User’s Manual

2.2 Process or Atmospheric Pressure With Particulate Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

2.2.1 Mounting Details

The ES20 CSS base plate or enclosure is designed to be wall-mounted. It should be

rigidly mounted vertically in a position free from high vibration levels and shaded from

direct sunlight.

Dimensional drawings are shown in Section 1.8.

2.2.2 Gas Connections

Gas connections to the ES20 CSS are via 6mm or ¼” Swagelok® tube fi ttings located at

the base of the mounting plate or enclosure.

INSTALLATION

Connections are marked as follows:

GAS IN

GAS OUT

2.2.3 Electrical Connections

All electrical connections should be made to the terminal rail supplied in the sampling

system.

For GRP and SS housing versions - all cables to or from the sampling system should go

through the M20 plastic cable glands provided at the base of the enclosure.

Sample gas entry point with a maximum supply pressure of 20 barg

(145 psig)

Sample gas exit point

Care must be taken to ensure that the outlet isolation valve is

not fully closed.

2.2.4 Power Supply

NOTE: Refer to the label on the terminal rail for the supply voltage required

by the sampling system.

Go to Section 2.5 - Dew-Point Measurement System.

Michell Instruments 5

Page 14

INSTALLATION

ES20 User’s Manual

2.3 Process or Atmospheric Pressure With Coalescing Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

2.3.1 Mounting Details

The ES20 CSS base plate or enclosure is designed to be wall-mounted. It should be

rigidly mounted vertically in a position free from high vibration levels and shaded from

direct sunlight.

Dimensional drawings are shown in Section 1.8.

2.3.2 Gas Connections

Gas connections to the ES20 CSS are via 6mm or ¼” Swagelok® tube fi ttings located at

the base of the mounting plate or enclosure.

Connections are marked as follows:

GAS IN

GAS OUT

2.3.3 Drainage Connections

Drainage connections to the ES20 CSS are via 6mm or ¼” Swagelok® tube fi ttings

located at the base of the mounting plate or enclosure.

2.3.4 Electrical Connections

Sample gas entry point with a maximum supply pressure of 20 barg

(145 psig)

Sample gas exit point

Care must be taken to ensure that the outlet isolation valve is

not fully closed.

All electrical connections should be made to the terminal rail supplied in the sampling

system.

For GRP and SS housing versions - all cables to or from the sampling system should go

through the M20 plastic cable glands provided at the base of the enclosure.

2.3.5 Power Supply

NOTE: Refer to the label on the terminal rail for the supply voltage required

by the sampling system.

Go to Section 2.5 - Dew-Point Measurement System.

6 97447 Issue 2, December 2017

Page 15

ES20 User’s Manual

2.4 Vacuum Pressure With Particulate Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

2.4.1 Mounting Details

The ES20 CSS base plate or enclosure is designed to be wall-mounted. It should be

rigidly mounted vertically in a position free from high vibration levels and shaded from

direct sunlight.

Dimensional drawings are shown in Section 1.8.

2.4.2 Gas Connections

Gas connections to the ES20 CSS enclosure are via 6mm or ¼” Swagelok® tube fi ttings

located at the base of the mounting plate or enclosure.

INSTALLATION

Connections are marked as follows:

GAS IN

GAS OUT

2.4.3 Electrical Connections

All electrical connections should be made to the terminal rail supplied in the sampling

system.

For GRP and SS housing versions - all cables to or from the sampling system should go

through the M20 plastic cable glands provided at the base of the enclosure.

Sample gas entry point with a maximum supply pressure of 1 bara (14.5

psia)

Sample gas exit point

Care must be taken to ensure that the outlet isolation valve is

fully open.

2.4.4 Power Supply

NOTE: Refer to the label on the terminal rail for the supply voltage required

by the sampling system.

Go to Section 2.5 - Dew-Point Measurement System.

Michell Instruments 7

Page 16

INSTALLATION

The following procedures must be carried out by a qualifi ed

2.5 Dew-Point Measurement System

The dew-point measurement system is NOT supplied as standard.

A dew-point measurement system can be obtained by contacting your local distributor

or Michell Instruments (see www.michell.com for details).

NOTE: Refer to the relevant installation sections from the manual supplied

with Michell’s dew-point measurement system.

ES20 User’s Manual

installation engineer.

2.6 Monitor Installation

The monitor is NOT supplied as standard.

A monitor can be obtained by contacting your local distributor or Michell Instruments

(see www.michell.com for details).

NOTE: Refer to the relevant sections from the manual supplied with Michell’s

monitor.

8 97447 Issue 2, December 2017

Page 17

ES20 User’s Manual

2.7 Process Connection

The following procedures must be carried out by a qualifi ed

2.7.1 Transmitter Connection

The transmitter cable is NOT supplied as standard.

A cable can be obtained by contacting your local distributor or Michell Instruments (see

www.michell.com for details).

NOTE: Please refer to the relevant sections from the manual supplied with

Michell’s product, e.g. Easidew Online.

INSTALLATION

installation engineer.

2.7.2 Monitor Connection

Note: Please refer to the relevant sections from the manual supplied with

Michell’s product, e.g. Easidew Online or Easidew monitor.

2.7.3 Terminal Rail Connection

The transmitter cable can be directly connected to the terminal rail. In order to do that,

refer to terminal markings.

Make sure that the correct power supply is provided, otherwise

The transmitter requires a 12 to 28 V supply.

the transmitter can be damaged.

Michell Instruments 9

Page 18

OPERATION

3 OPERATION

3.1 Sampling Start-Up Procedure

The ES20 CSS is designed for continuous operation.

Immediately after the power is applied, all the electronic components, including the

dew-point transmitter, will begin operation and all measured output signals can be

viewed on a fi tted monitor or wired to other receivers from the terminal rail.

It is essential that the connection of electrical and gas supplies

to this instrument be undertaken by competent personnel.

Relevant sections of this manual must be read in full before

commencing measurement (see below).

ES20 User’s Manual

3.1.1 Relevant Manual Section for Operation

Please check below for the relevant product code structure and select the manual

section associated with the sampling system ordered.

NOTE: Compare the 2nd (Feature B - fi lter) and 4th (Feature D - pressure)

option from the ordered ES20 CSS product code with the table below:

Section 3.2 Section 3.3 Section 3.4 Section 3.5 Section 3.6

B1 - D1

Process Pressure

with Particulate

Filter

B2 - D1

Process Pressure

with Coalescing

Filter

B1 - D1

Atmospheric

Pressure with

Particulate Filter

B2 - D1

Atmospheric

Pressure with

Coalescing Filter

B1 - D2

Vacuum Pressure

with Particulate

Filter

10 97447 Issue 2, December 2017

Page 19

ES20 User’s Manual

3.2 Process Pressure With Particulate Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

3.2.1 Sample Flow 'Start-Up' Procedure

Proceed as follows:

OPERATION

1. Ensure the outlet isolation valve is fully

2. Open the inlet isolation valve slowly, making sure that the pressure

indicated on the pressure gauge does not exceed the maximum

operational pressure of 20 barg (290 psig). If achievable, ensure that the

inlet isolation valve is fully

3. Adjust the outlet isolation valve, setting the sample gas fl ow rate to

approximately 5 Nl/min (10.6 scfh) (indicated on the fl owmeter).

4. Allow the sample gas to purge the system for the period of time indicated

in the Good Measurement Practice Section (Stabilization Times).

OPEN.

3.3 Process Pressure with Coalescing Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

3.3.1 Sample Flow 'Start-Up' Procedure

CLOSED.

Proceed as follows:

1. Ensure the outlet and drain isolation valves are fully

2. Open the inlet isolation valve slowly, making sure that the pressure

indicated on the pressure gauge does not exceed the maximum

operational pressure of 20 barg (290 psig). If achievable, ensure that the

inlet isolation valve is fully

3. Adjust the outlet isolation valve, setting the sample gas fl ow rate to

approximately 5 Nl/min (10.6 scfh) (indicated on the fl owmeter).

4. If necessary adjust the drain isolation valve to release excessive amount

of liquids from the fi lter housing.

NOTE: If required the drain isolation valve can be slightly

may be necessary to adjust the inlet and outlet isolation valves to

achieve normal operating conditions.

5. Allow the sample gas to purge the system for the period of time indicated

in the Good Measurement Practice Section (Stabilization Times).

OPEN.

CLOSED.

OPEN. It

Michell Instruments 11

Page 20

OPERATION

3.4 Atmospheric Pressure with Particulate Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

3.4.1 Sample Flow 'Start-Up' Procedure

Proceed as follows:

ES20 User’s Manual

1. Ensure the outlet isolation valve is fully

2. Open the inlet isolation valve making sure that the sample gas fl ow rate

is set to approximately 5 Nl/min (10.6 scfh) (indicated on the fl owmeter).

3. Allow the sample gas to purge the system for the period of time indicated

in the Good Measurement Practice Section (Stabilization Times).

OPEN.

3.5 Atmospheric Pressure with Coalescing Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

3.5.1 Sample Flow 'Start-Up' Procedure

Proceed as follows:

1. Ensure the outlet is fully

2. Open the inlet isolation valve making sure that the sample gas fl ow rate

is set to approximately 5 Nl/min (10.6 scfh) (indicated on the fl owmeter).

OPEN and drain isolation valves are fully CLOSED.

3. If necessary adjust the drain isolation valve to release excessive amount

of liquids from the fi lter housing.

NOTE: After adjusting the drain isolation valve it may be necessary

to adjust the inlet valve to achieve normal operating conditions

4. Allow the sample gas to purge the system for the period of time indicated

in the Good Measurement Practice Section (Stabilization Times).

12 97447 Issue 2, December 2017

Page 21

ES20 User’s Manual

3.6 Vacuum Pressure With Particulate Filter

NOTE: All other options from the product confi guration have no effect on the

operation described in this Section.

3.6.1 Sample Flow 'Start-Up' Procedure

Proceed as follows:

1. Ensure that the control valve located on the top of the fl owmeter is

fully OPEN by turning fully counter-clockwise (valve is designed for fl ow

adjustment only, not intended to be used as a shut-off valve).

2. Slowly open the inlet isolation valve making sure that pressure indicated

on the pressure gauge is within -0.33 barg (-4.7 psig) and 0 barg (0 psig).

If achievable, ensure that the inlet isolation valve is fully

Note: Ensure that the pressure indicated on the pressure gauge is

showing a vacuum and that the fl owmeter is not operating. If this

is not the case DO NOT switch on the pump.

OPERATION

OPEN.

3. Set the valve on the fl owmeter to half way (clockwise to

on the pump by turning on the power to it. This will allow the sample gas

to fl ow through the system.

4. By adjusting the control valve located on the fl owmeter, set the sample

gas fl ow rate to approximately 5 Nl/min (10.6 scfh).

5. Allow the sample gas to purge the system for the period of time indicated

in the Good Measurement Practice Section (Stabilization Times).

CLOSE). Switch

Michell Instruments 13

Page 22

MAINTENANCE

4 MAINTENANCE

4.1 General Maintenance Guidelines

Routine maintenance of the sampling system is confi ned to fi lter element replacement

and regular recalibration of the dew-point transmitter.

4.2 Filter Element Maintenance

The composition of the gas determines the frequency of the fi lter element replacement,

i.e. liquid and particulate contaminates, corrosive elements etc.

A disposable fi lter element continues to fi lter at its original effi ciency as long as it is

kept in service. The life of the element is determined by the increase in fl ow resistance

caused by trapped solids in the element. The element should be changed when the fl ow

falls below an acceptable level, or the pressure drop becomes too high. In any case the

element should be replaced before the pressure drop across it reaches 0.7 barg (10.2

psig). The disposable fi lter elements cannot be cleaned as the solids are trapped within

the depth of the element not on the surface.

ES20 User’s Manual

4.2.1 Particulate Filter Maintenance

To replace the particulate fi lter element (Michell part SSF-PF-10PK (pack of 10)), proceed

as follows:

1. Switch off the pump (if fi tted) and isolate any gas supplies to the sampling

system.

NOTE: Wear protective gloves when handling the fi lter housing.

2.

Remove the bowl (1,2), element retainer (3) and fi lter element (4).

NOTE: In order to untighten the bowl a spanner/wrench may be

needed.

Disposable and sintered PTFE fi lter elements are sealed by compression

against a fl at surface (5). Gaskets are not required between the fi lter element

and components of the housing. The element is located by guides which fi t

the inside diameter of the tube at each end.

14 97447 Issue 2, December 2017

Page 23

ES20 User’s Manual

The fi lter tube is securely sealed by tightening the element retainer a 1/4 to

1 turn after it fi rst contacts the fi lter element, the amount will depend on the

housing type and element size. A mark on the end of the retainer is used as

a guide.

3. Before replacing the housing bowl ensure that the mating threads and

sealing faces are clean and damage free. It is recommended that the

threads and sealing faces are lubricated with a small amount of silicone

grease before assembly.

MAINTENANCE

4. Re-connect the tube with its fi tting to its original confi guration.

5. Resume normal system operation by opening up the gas supplies to the

sampling system as described in the relevant section of the Start-up

Procedures (Section 3).

Michell Instruments 15

Page 24

MAINTENANCE

4.2.2 Coalescing Filter Maintenance

To replace the coalescing fi lter element (Michell part SSF-CF-10PK (pack of 10)), proceed

as follows:

1. Isolate any gas supplies to the sampling system.

NOTE: Wear protective gloves when handling the fi lter housing.

2. Unscrew the couplings (1 and 2) on the picture below.

1

2

3

ES20 User’s Manual

3. Disconnect the tube with its fi tting (3).

4.

Remove the bowl (1,2), element retainer (3) and fi lter element (4).

NOTE: In order to untighten the bowl a spanner/wrench may be

needed.

Disposable and sintered PTFE fi lter elements are sealed by compression

against a fl at surface (5). Gaskets are not required between the fi lter element

and components of the housing. The element is located by guides which fi t

the inside diameter of the tube at each end.

16 97447 Issue 2, December 2017

Page 25

ES20 User’s Manual

The fi lter tube is securely sealed by tightening the element retainer a 1/4 to

1 turn after it fi rst contacts the fi lter element, the amount will depend on the

housing type and element size. A mark on the end of the retainer is used as

a guide.

5. Before replacing the housing bowl ensure that the mating threads and

sealing faces are clean and damage free. It is recommended that the

threads and sealing faces are lubricated with a small amount of silicone

grease before assembly.

6.

MAINTENANCE

Re-connect the tube with its fi tting to its original confi guration.

7. Resume normal system operation by opening up the gas supplies to the

sampling system as described in the relevant section of the Start-up

Procedures (Section 3).

Michell Instruments 17

Page 26

MAINTENANCE

4.3 Transmitter Maintenance

Calibration

Routine maintenance of the Easidew transmitter is confi ned to regular re-calibration

by exposure of the Easidew to sample gases of known moisture content to ensure that

the stated accuracy of the Easidew is maintained. Calibration services traceable to the

UK National Physical Laboratory (NPL) and the US National Institute of Standards and

Technology (NIST) are provided by Michell Instruments.

Michell Instruments offers a variety of re-calibration and exchange sensor schemes to

suit specifi c needs. A Michell representative can provide detailed, custom advice (for

Michell Instruments’ contact information go to www.michell.com).

Transmitter replacement

The composition of the gas determines the frequency of the transmitter replacement,

i.e. liquid and particulate contaminates, corrosive elements, etc.

ES20 User’s Manual

It is recommended that the transmitter is changed on an annual basis to maintain the

accuracy of the system.

Michell Instruments can provide an exchange transmitter. Prior to recalibration being

necessary, an exchange transmitter can be ordered from Michell Instruments or any

authorized dealer. Once the transmitter and calibration certifi cate have been received it

can be fi tted and the original transmitter returned to Michell Instruments.

To replace the transmitter, proceed as follows:

1. Isolate the sampling system from the sample gas supply and switch off

all electrical supplies.

2. Unplug the sensor cable, unscrew and withdraw the sensor from the

sample block.

3. Fit a new/recalibrated transmitter ensuring the bonded seal is positioned

between the sensor and sample block.

4. Plug in the sensor cable and resume normal system operation by opening

up the gas supplies to the sampling system in accordance with the relevant

section of the Start-up Procedures (Section 3).

18 97447 Issue 2, December 2017

Page 27

ES20 User’s Manual

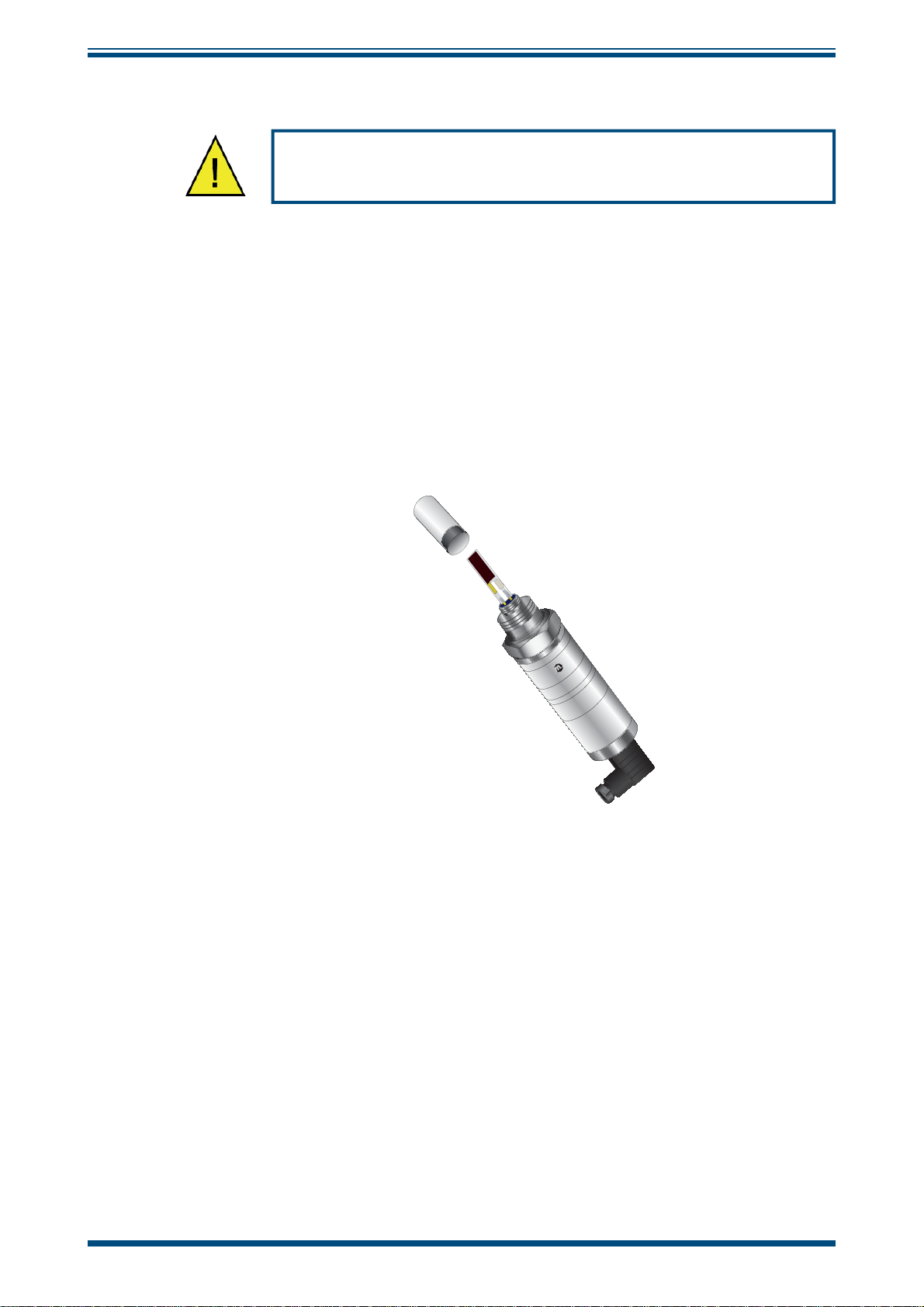

Sensor Guard Replacement

The sensor is supplied with a white HDPE guard (standard) or a stainless steel guard

(if specifi ed at time or order). The method of replacement is the same for both types.

HDPE Guard

The HDPE guard provides <10μm protection to the dew-point sensor. It is designed

to show any contamination and the guard should be changed if the surface becomes

discolored. When replacing the guard, care should be taken to handle the guard by the

bottom part only. Replacement guards (EA2-HDPE) - pack of 10 - can be obtained by

contacting Michell Instruments (www.michell.com) or your local distributor.

MAINTENANCE

Wear protective gloves when handling the sensor guard.

HANDLE,

USING

GLOVES, BY

x

BLACK PART

ONLY

E

n

e

H

m

C

u

I

r

6

t

s

0

M

n

9

I

0

Figure 1

Replacement of HDPE Guard

r

e

t

t

i

m

s

0

n

2

a

+

r

/

T

B

4

0

y

3

0

a

s

1

w

e

W

-

e

g

d

r

:

i

s

a

E

R

N

d

e

e

i

t

3

r

g

s

b

n

a

6

a

c

g

m

B

n

a

n

a

i

C

C

L

K

,

8

y

l

4

d

E

e

t

i

n

U

Stainless Steel Guard

The stainless steel guard provides <80μm protection to the dew-point sensor. It is

designed to show any contamination and the guard should be changed if the surface

becomes discolored.

When replacing the guard, care should be taken to handle the guard by the bottom part

only. A replacement guard (SSG) can be obtained by contacting Michell Instruments

(www.michell.com) or your local distributor.

Bonded Seal

If the installed bonded seal gets damaged or lost, a pack of 5 replacement bonded seals

can be obtained by contacting Michell Instruments, or your local distributor, and quoting

part number BS-58-PK5.

Michell Instruments 19

Page 28

APPENDIX A

ES20 User’s Manual

Appendix A

Technical Specifi cations

20 97447 Issue 2, December 2017

Page 29

ES20 User’s Manual

Appendix A Technical Specifi cations

Electrical Specifi cations

Supply Voltage (Vacuum Pump Only) 230 V AC

Operating Specifi cations

Operating Temperature

ES20 fi tted with:

Particulate or coalescing fi lter w/out monitor

Particulate or coalescing fi lter with monitor

Vacuum pump with or w/out monitor

Compensated Temperature Range:

Storage Temperature: -40 to +60°C (-40 to +140°F)

Operating Inlet Pressure

ES20 fi tted with:

Particulate Filter

Coalescing Filter

Vacuum Pump

Flow Rate 1 to 5 Nl/min (2.1 to 10.6 scfh)

-40 to +60°C (-40 to +140°F)

0 to +50°C (+32 to +122°F)

0 to +40°C (+32 to +104°F)

-20 to +50°C (-4 to +122°F)

NOTE: The transmitter accuracy statement is only valid for

the temperature range: -20/+50°C (-4 to +122°F)

0 to 20 barg (0 to 290 psig)

0 to 20 barg (0 to 290 psig)

-0.3 to 1 barg (-4.7 to 14.5 psig)

APPENDIX A

Mechanical Specifi cations

Process Connection and Material

Ingress Protection

No enclosure

GRP & SS enclosures

Housing Material

Base plate

GRP enclosure

SS enclosures

Dimensions

Base plate

GRP enclosure

SS enclosures

Pressure and Flow Control

Atmospheric or system pressure

Vacuum pressure

Gas Filtration

Electrical Connections

Base plate

GRP & SS enclosures

Interchangeability Fully interchangeable components

Sample Block Process Connection

Inlet/outlet connections via 6mm or ¼” stainless steel

fi ttings, 316 stainless steel

No protection (base plate only)

IP66, NEMA 4X

316 stainless steel

Glass fi ber reinforced polyester and 4mm safety glass

316 stainless steel and 4mm safety glass

457 x 350 x 2mm (18 x 13.8 x .08") (hxwxd)

530 x 430 x 200mm (20.9 x 16.9 x 7.9") (hxwxd)

500 x 400 x 200mm (19.7 x 15.7 x 7.9") (hxwxd)

Via isolation valves, pressure gauge and fl owmeter

Isolation valve, pressure gauge, fl owmeter with valve &

self-regulating vacuum pump

Particulate fi lter

Coalescing fi lter

Via terminal rail

Via M20 plastic cable glands

Compatible with various dew-point transmitters with

5/8" process connection

Compatible Dew-Point Transmitters (5/8" UNF process connection versions only):

• Easidew Transmitter

• Easidew I.S. Transmitter

• Easidew PRO I.S. Transmitter

Michell Instruments 21

Page 30

APPENDIX B

ES20 User’s Manual

Appendix B

Quality, Recycling

& Warranty

Information

22 97447 Issue 2, December 2017

Page 31

ES20 User’s Manual

Appendix B Quality, Recycling & Warranty Information

Michell Instruments is dedicated to complying to all relevant legislation and directives.

Full information can be found on our website at:

www.michell.com/compliance

This page contains information on the following directives:

• ATEX Directive

• Calibration Facilities

• Confl ict Minerals

• FCC Statement

• Manufacturing Quality

• Modern Slavery Statement

APPENDIX B

• Pressure Equipment Directive

• REACH

• RoHS2

• WEEE2

• Recycling Policy

• Warranty and Returns

This information is also available in PDF format.

Michell Instruments 23

Page 32

APPENDIX C

ES20 User’s Manual

Appendix C

Return Document

&

Decontamination Declaration

24 97447 Issue 2, December 2017

Page 33

ES20 User’s Manual

Appendix C Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

APPENDIX C

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLF EDVLFÀDPPDEOHRUWR[LFJDVHVDVLPSOHSXUJHZLWK GU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

Michell Instruments 25

Page 34

NOTES:

Page 35

Page 36

http://www.michell.com

Loading...

Loading...