METER ATMOS 41 User Manual

ATMOS 41 INTEGRATOR GUIDE

SENSOR DESCRIPTION

The ATMOS41 All-in-One Weather Station is designed for continuous monitoring of environmental variables,

including all standard weather measurements (see Measurement Specifications). All sensors are integrated

into a single unit, requiring minimal installation effort. Ultra-low power consumption and a robust, no

moving parts design that prevents errors because of wear or fouling make the ATMOS41 ideal for long-term,

remote installations.

APPLICATIONS

• Weather monitoring

• Microenvironment monitoring

• Spatially distributed environmental monitoring

• Crop weather monitoring

• Fire danger monitoring/mapping

• Weather networks

18171-08

7.31.2020

ADVANTAGES

• Robust, no moving parts design

• Small form factor

• Integrated design for easy installation

• Low-input voltage requirements

• Low-power design supports battery-operated

dataloggers

• Supports the SDI-12 three-wire interface

• Tilt sensor informs user of out-of-level conditions

• No configuration necessary

• Measures all standard weather variables (plus

several others)

PURPOSE OF THIS GUIDE

METER Group provides the information in this

integrator's guide to help ATMOS41 All-in-One

Weather Station customers establish communication

between these sensors and their data acquisition

equipment or field data loggers. Customers using data

loggers that support SDI-12 sensor communications

should consult the data logger user manual. METER

sensors are fully integrated into the METER system of

plug-and-play sensors, cellular-enabled data loggers,

and data analysis software.

COMPATIBLE FIRMWARE VERSIONS

This guide is compatible with firmware versions

5.30 or newer.

METER Group, Inc. USA

2365 NE Hopkins Court, Pullman, WA 99163

T +1.509.332.2756 F +1.509.332.5158

E info@metergroup.com W metergroup.com

Figure 1 ATMOS 41 All-in-One Weather Station

SPECIFICATIONS

MEASUREMENT SPECIFICATIONS

Solar Radiation

Range 0–1750 W/m

Resolution 1 W/m

Accuracy

±5% of measurement typical

2

2

Humidity Sensor Temperature

Range –40 to 50 °C

Resolution 0.1 °C

Accuracy ±1.0 °C

Precipitation

Range 0–400 mm/h

Resolution 0.017 mm

Accuracy ±5% of measurement

from 0 to 50 mm/h

Vapor Pressure

Range 0–47 kPa

Resolution 0.01 kPa

Accuracy Varies with temperature

and humidity, ±0.2 kPa

typical below 40 °C

Barometric Pressure

Range 50–110 kPa

Resolution 0.01 kPa

Accuracy ±0.1 kPa from –10 to 50 ºC

±0.5 kPa from –40 to 60 ºC

Horizontal Wind Speed

Range 0–30 m/s

Resolution 0.01 m/s

Accuracy The greater of 0.3 m/s or

3% of measurement

Wind Gust

Range 0–30 m/s

Resolution 0.01 m/s

Accuracy The greater of 0.3 m/s or

3% of measurement

Wind Direction

Range 0°–359°

Resolution 1°

Accuracy ±5°

Relative Humidity

Range 0–100% RH (0.00–1.00)

Resolution 0.1% RH

Accuracy Varies with temperature

and humidity, ±3% RH typical

Air Temperature

Range –50 to 60 °C

Resolution 0.1 °C

Accuracy ±0.6 °C

Tilt

Range –90° to 90°

Resolution 0.1°

Accuracy ±1°

Lightning Strike Count

Range 0–65,535 strikes

Resolution 1 strike

Accuracy Variable with distance,

>25% detection at <10 km typical

Lightning Average Distance

Range 0–40 km

Resolution 3 km

Accuracy Variable

2

COMMUNICATION SPECIFICATIONS

Output

SDI-12 communication

PHYSICAL SPECIFICATIONS

Dimensions

Diameter 10 cm (3.94 in)

Height 34 cm (13.38 in), includes rain

gauge filter

Operating Temperature Range

Minimum –50 °C

Typical NA

Maximum 60 °C

NOTE: Barometric pressure and relative humidity sensors

operate accurately at a minimum of –40 °C.

ELECTRICAL AND TIMING CHARACTERISTICS

Supply Voltage (VCC to GND)

Minimum 3.6 VDC continuous

Typical NA

Maximum 15.0 VDC continuous

NOTE: ATMOS 41 must be continuously powered to workproperly.

NOTE: For the ATMOS 41 to meet digital logic levels specified

by SDI-12, it must be excited to 3.9 VDC or greater.

Digital Input Voltage (logic high)

Minimum 2.8 V

Typical 3.6 V

Maximum 5.0 V

Digital Input Voltage (logic low)

Minimum –0.3 V

Typical 0.0 V

Maximum 0.8 V

Digital Output Voltage (logic high)

Minimum NA

Typical 3.6 V

Maximum NA

NOTE: For the ATMOS 41 to meet digital logicl levels specified

by SDI-12, it must be excited to 3.9 VDC or greater.

Power Line Slew Rate

Minimum 1.0 V/ms

Typical NA

Maximum NA

Data Logger Compatibility

METER ZL6 and EM60 data loggers or any data

aquisition systems capable of switched 3.6- to

15.0-VDC excitation and SDI-12 communication

Cable Length

5 m (standard)

75 m (maximum custom cable length)

NOTE: Contact Customer Support if nonstandard cable length

is needed.

Connector Types

3.5-mm stereo plug connector or stripped and

tinned wires

Current Drain (during measurement)

Minimum 0.2 mA

Typical 8.0 mA

Maximum 33.0 mA

Current Drain (while asleep)

Minimum 0.2 mA

Typical 0.3 mA

Maximum 0.4 mA

Power Up Time (SDI ready)—aRx! Commands

Minimum NA

Typical 10 s

Maximum NA

Power Up Time (SDI ready)—Other Commands

Minimum NA

Typical 310 ms

Maximum NA

Power Up Time (SDI-12, DDI disabled)

Minimum NA

Typical 240 ms

Maximum NA

Measurement Duration

Minimum NA

Typical 110 ms

Maximum 3,000 ms

3

Power (brown)

Ground

GND

GND

220PF

COMPLIANCE

Manufactured under ISO 9001:2015

EM ISO/IEC 17050:2010 (CE Mark)

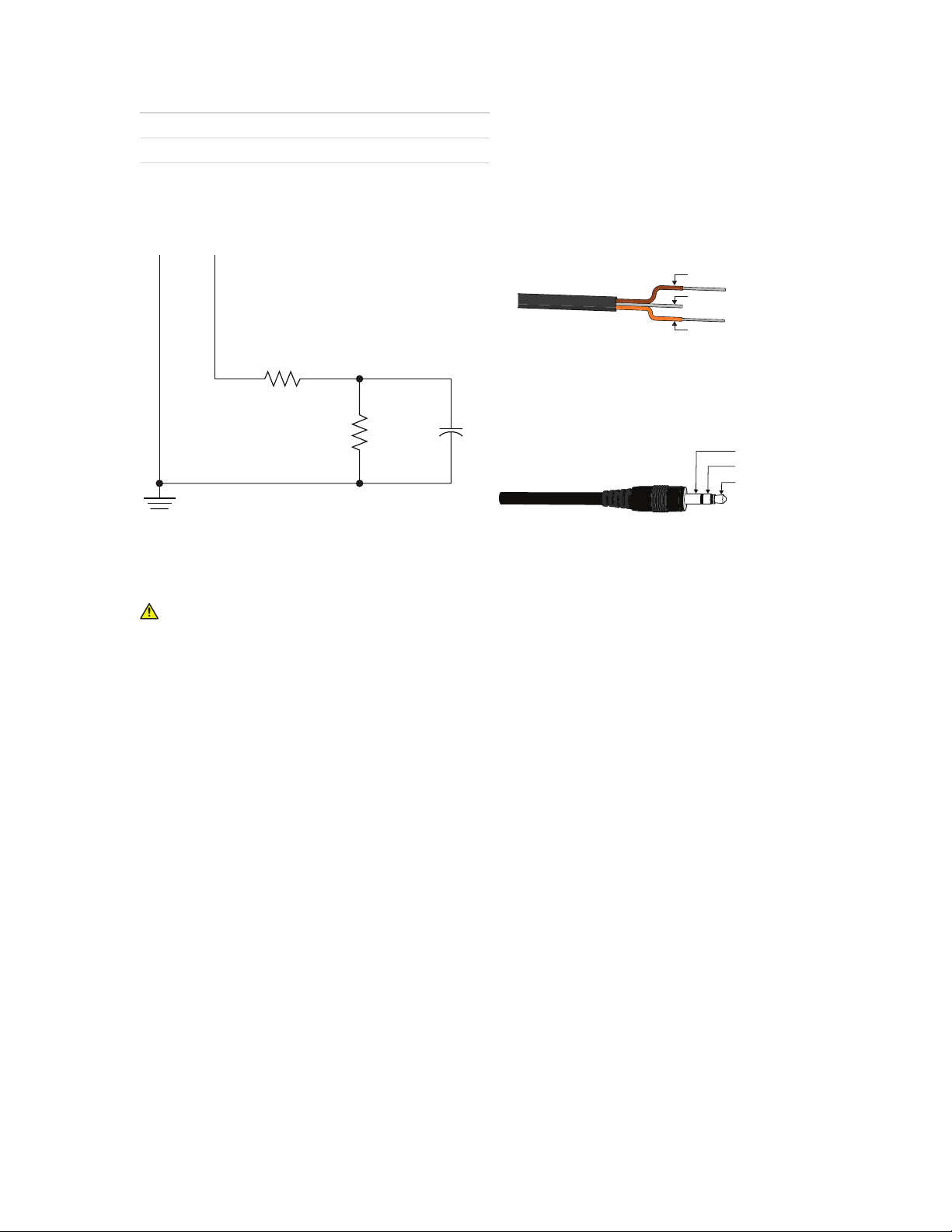

EQUIVALENT CIRCUIT AND CONNECTION TYPES

Refer to Figure 2 and Figure 3 to connect the ATMOS 41 to a logger. Figure 2 provides a low-impedance variant

of the recommended SDI-12 specification.

PIGTAIL CABLE

DATA

Ground (bare)

Digital

communication (orange)

R1

510

R2

100K

Figure 2 Equivalent circuit diagram

C1

NOTE: Some early ATMOS41 units may have the older Decagon

wiring scheme where the power supply is white, the digital out is

red, and the bare wire is ground.

STEREO CABLE

Digital communication

Power

Figure 3 Connection types

PRECAUTIONS

METER sensors are built to the highest standards, but misuse, improper protection, or improper

installation may damage the sensor and possibly void the warranty. Before integrating sensors into a sensor

network, followthe recommended installation instructions and implement safeguards to protect the sensor

from damaging interference.

SURGE CONDITIONS

Sensors have built-in circuitry that protects them against common surge conditions. Installations in

lightning-prone areas, however, require special precautions, especially when sensors are connected to a

well-grounded third-party logger.

Visit metergroup.com for articles containing more information.

CABLES

Improperly protected cables can lead to severed cables or disconnected sensors. Cabling issues can be

caused by many factors, including rodent damage, driving over sensor cables, tripping over the cable, not

leaving enough cable slack during installation, or poor sensor wiring connections. To relieve strain on the

connections and prevent loose cabling from being inadvertently snagged, gather and secure the cable

travelling between the ATMOS 41 and the data acquisition device to the mounting mast in one or more places.

Install cables in conduit or plastic cladding when near the ground to avoid rodent damage. Tie excess cable to

the data logger mast to ensure cable weight does not cause sensor to unplug.

SENSOR COMMUNICATIONS

METER digital sensors feature a 3-wire interface following SDI-12 protocol for communicating

sensor measurements.

SDI12 INTRODUCTION

SDI-12 is a standards-based protocol for interfacing sensors to data loggers and data acquisition equipment.

Multiple sensors with unique addresses can share a common 3-wire bus (power, ground, and data). Two-way

communication between the sensor and logger is possible by sharing the data line for transmit and receive

4

as defined by the standard. Sensor measurements are triggered by protocol command. The SDI-12 protocol

requires a unique alphanumeric sensor address for each sensor on the bus so that a data logger can send

commands to and receive readings from specific sensors.

Download the SDI-12 Specification v1.3 and learn more about the SDI-12 protocol.

DDI SERIAL INTRODUCTION

The DDI serial protocol is the method used by the METER family of data loggers for collecting data from

the sensor. This protocol uses the data line configured to transmit data from the sensor to the receiver only

(simplex). Typically, the receive side is a microprocessor UART or a general-purpose IO pin using a bitbang

method to receive data. Sensor measurements are triggered by applying power to the sensor. When the

ATMOS41 is set to address 0, a DDI serial string is sent on power up, identifying the sensor.

INTERFACING THE SENSOR TO A PC

The serial signals and protocols supported by the sensor require some type of interface hardware to be

compatible with the serial port found on most personal computers (or USB-to-serial adapters). There are

several SDI-12 interface adapters available in the marketplace; however, METER has not tested any of these

interfaces and cannot make a recommendation as to which adapters work with METER sensors. METER data

loggers and the ZSC and PROCHECK handheld devices can operate as a computer-to-sensor interface for

making on-demand sensor measurements. For more information, please contact Customer Support.

METER SDI12 IMPLEMENTATION

METER sensors use a low-impedance variant of the SDI-12 standard sensor circuit (Figure 2). During the

power-up time, sensors output some sensor diagnostic information and should not be communicated with

until the power-up time has passed. After the power up time, the sensors are compatible with all commands

listed in the SDI-12 Specification v1.3 except for the continuous measurement commands (aR0–aR9 and

aRC0–aRC9) and the concurrent measurement commands (aC–aC9 and aCC0–aCC9). M, R, and C command

implementations are found on pages 8–9.

Out of the factory, all METER sensors start with SDI-12 address 0 and print out the DDI serial startup string

during the power up time. This can be interpreted by non-METER SDI-12 sensors as a pseudo-break condition

followed by a random series of bits.

The ATMOS 41 will omit the DDI serial startup string (sensor identification) when the SDI-12 address is

nonzero.

ATMOS41 INTERNAL MEASUREMENT SEQUENCE

Upon power up, the ATMOS41 initializes an internal timer to 55. This internal timer is incremented by 1 every

second and resets to 0 after incrementing to 59. In addition, issuing an averaging command (aM!, aR0!, aR3!,

aR7!, and aC!) resets this timer to 55.

While powered up, the ATMOS41 continuously counts drops from the precipitation sensor and takes solar

radiation, wind, and air temperature measurements every 10 s at internal timer intervals of 0, 10, 20, 30, 40,

50 and logs these values internally. Orientation, vapor pressure, atmospheric pressure, and relative humidity

are measured every 60 s at the internal timer interval of 4 and logged internally. The aR4! command will output

instantaneous measurements of these parameters.

The aM!, aR0!, aR3!, aR7!, and aC! commands (and subsequent D commands when necessary) will compute

and output the averages, accumulations, or maximums of these measurements (and derived measurements)

and reset internal averaging counters and accumulators. Therefore, it is not necessary to oversample

the ATMOS41 and compute averages, accumulations, and maximums in external data systems. Less

frequent sampling has the additional benefit of decreasing data acquisition systems and ATMOS41 power

consumption. If the aM!, aR0!, aR3!, aR7!, and aC! commands are issued more frequently than 2 times their

measurement interval, the ATMOS41 will not average the measurements and will output instantaneous

values. The ATMOS 41 has four error codes available: general error code −9999, calibrations lost or corrupt

−9992, sensor undervoltage condition −9991, and invalid wind measurement error code −9990.

SDI12 CONFIGURATION

Table1 lists the SDI-12 communication configuration.

5

Loading...

Loading...