Metabo W 7-115, W 7-125, W 7-115 Quick, W 7-125 Quick, W 10-125 Instructions For Use Manual

...Page 1

Made in Germany

Instruções de serviço . . . . . . .página 37

Instrucciones de manejo . . . .página 26

Mode d’emploi . . . . . . . . . . . . . .page 15

Instructions for use . . . . . . . . . .page 5

170 26 7970 - 0207

W 7-115

W 7-125

W 7-115 Quick

W 7-125 Quick

W 10-125

W 10-125 Quick

W 10-150 Quick

WE 9-125 Quick

WE 14-125 Plus

WE 14-125 VS

WE 14-150 Plus

WE 14-150 Quick

WEP 14-125 Quick

WEP 14-150 Quick

WP 7-115 Quick

WP 7-125 Quick

WPS 7-115 Quick

WPS 7-125 Quick

01_Ums_Nafta_7970_0207 18.12.2007 14:47 Uhr Seite 1

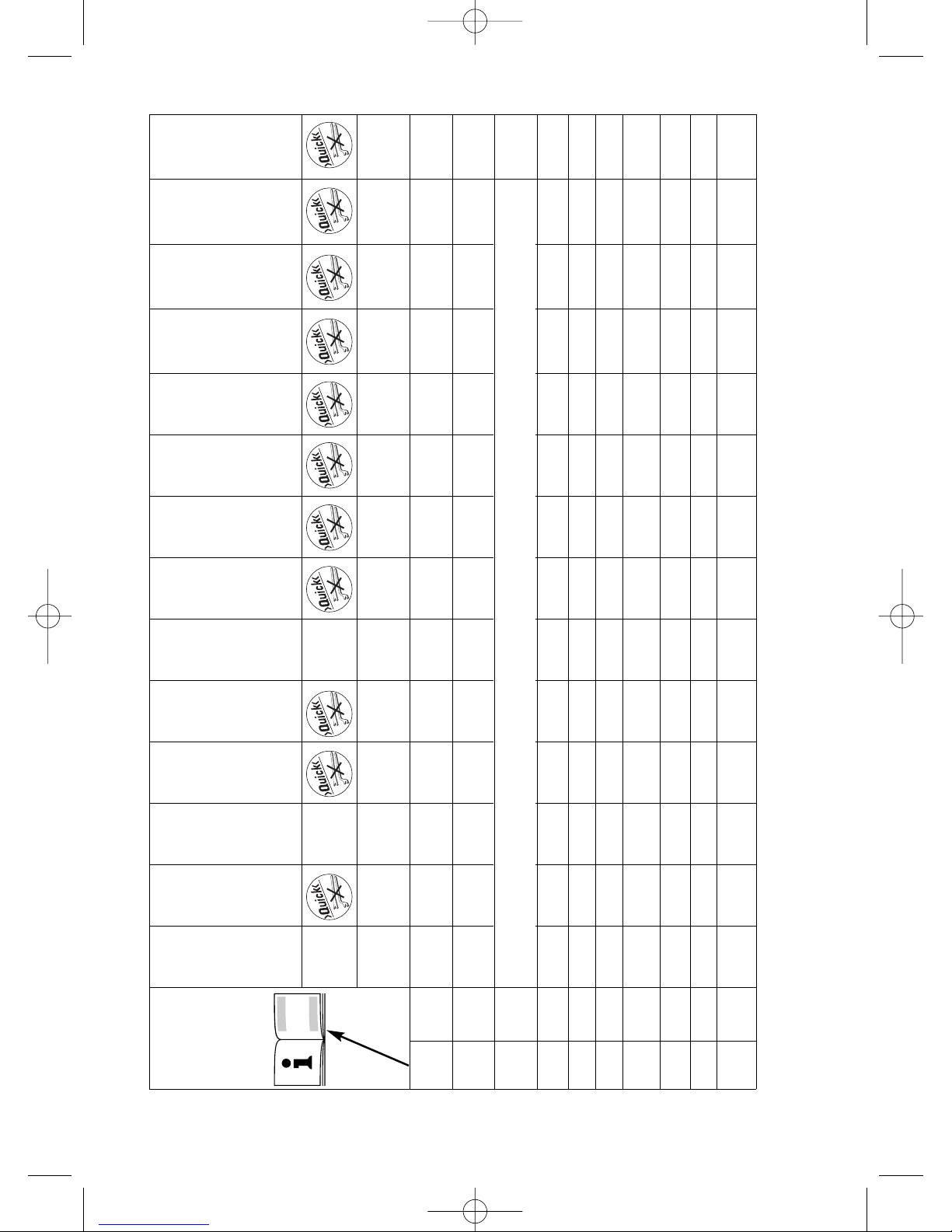

Page 2

2

–– –

––––––––

D

max

mm 115 115 125 125 125 125 125 150 125 125 125 150 150 125

(in) (4 1/2) (4 1/2) (5) (5) (5) (5) (5) (6) (5) (5) (5) (6) (6) (5)

n /min 10.000 10.000 9.000 10.000 9.000 10.000 10.000 9.000 3.000- 7.000- 3.000- 6.000- 9.000

10.500

10.000 10.500 10.500 9.000

M M 14

5/8"-11 UNC

P

1

W 900 900 900 900 900 1.010 1.010 1.010 900 1.400 1.400 1.400 1.400 1.400

P

2

W

460 460 460 460 460 600 600 600 510 800 800 800 800 800

I

120V

A 8 8 8 8 8 8.5 8.5 8.5 7.5 12 12 12 12 12

a

hw

m/s

2

55555555555555

(ft/s

2

) (15) (15) (15) (15) (15) (15 (15) (15) (15) (15) (15) (15) (15) (15)

L

pA

dB(A) 84 84 84 84 84 86 86 86 84 85 85 85 85 86

L

WA

dB(A) – – – – – 99 99 99 – – – – – 99

m kg 1,8 1,8 1,8 1,8 1,8 1,8 1,8 1,8 1,9 1,9 1,9 1,9 1,9 1,9

(lbs) (4.0) (4.0) (4.0) (4.0) (4.0) (4.0) (4.0) (4.0) (4.2) (4.2) (4.2) (4.2) (4.2) (4.2)

© 2007 Metabowerke GmbH, Postfach 1229, D-72602 Nürtingen

W 7-115

W 7-115 Quick

WP 7-115 Quick

WPS 7-115 Quick

W 7-125

WP 7-125 Quick

WPS 7-125 Quick

W 10-125 Quick

W 10-125

WE 9-125 Quick

WE 14-125 Plus

WE 14-150 Plus

WE 14-150 Quick

WEP 14-150 Quick

WEP 14-125 Quick

W 10-150 Quick

W 7-125 Quick

15

WE 14-125 VS

TC

electronic

VTC

electronic

VTC

electronic

VTC

electronic

VC

electronic

TC

electronic

01_Ums_Nafta_7970_0207 18.12.2007 14:47 Uhr Seite 2

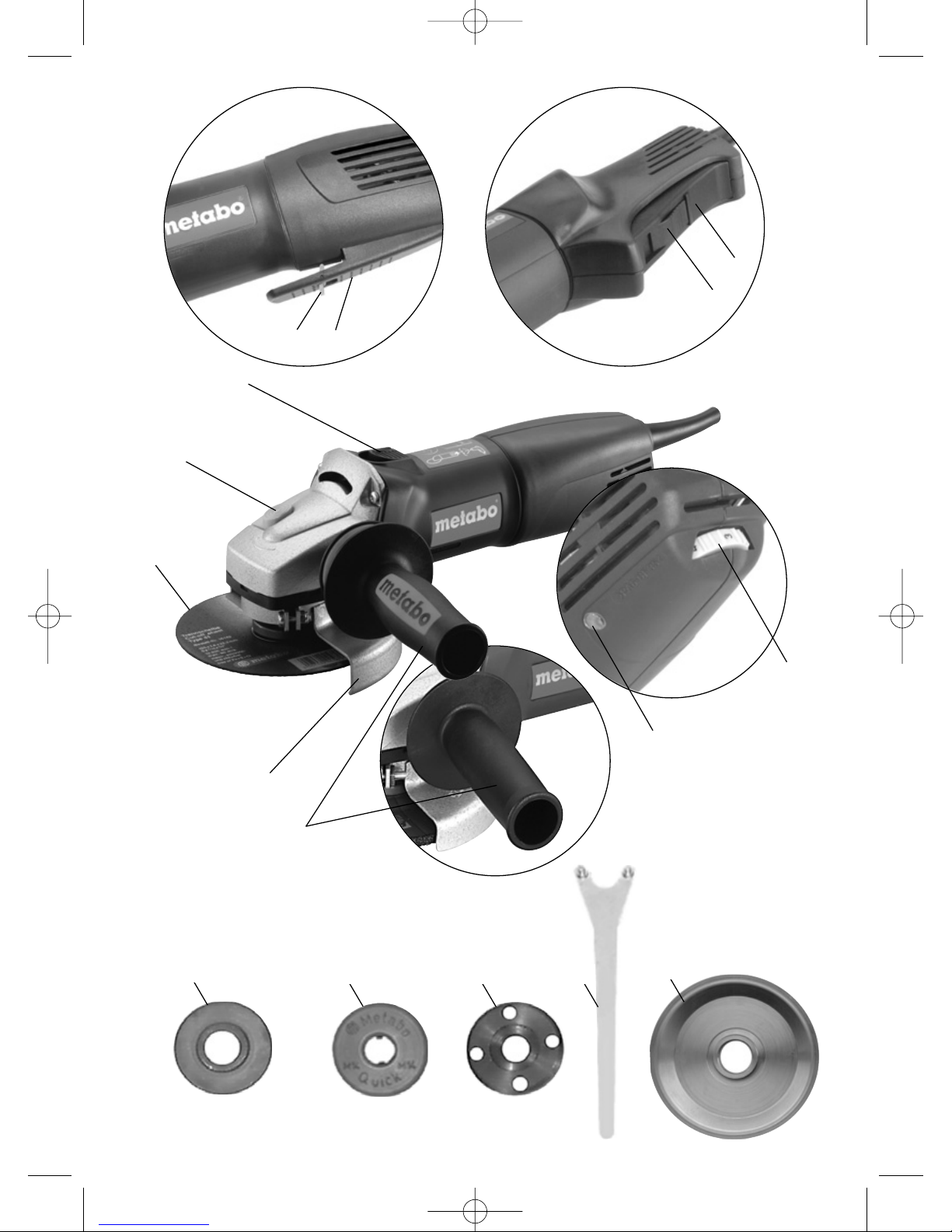

Page 3

3

11

14

10

12 13

5

1

2

3

4

8

9

WP...

WPS...

89

WEP...

6

7

01_Ums_Nafta_7970_0207 18.12.2007 14:47 Uhr Seite 3

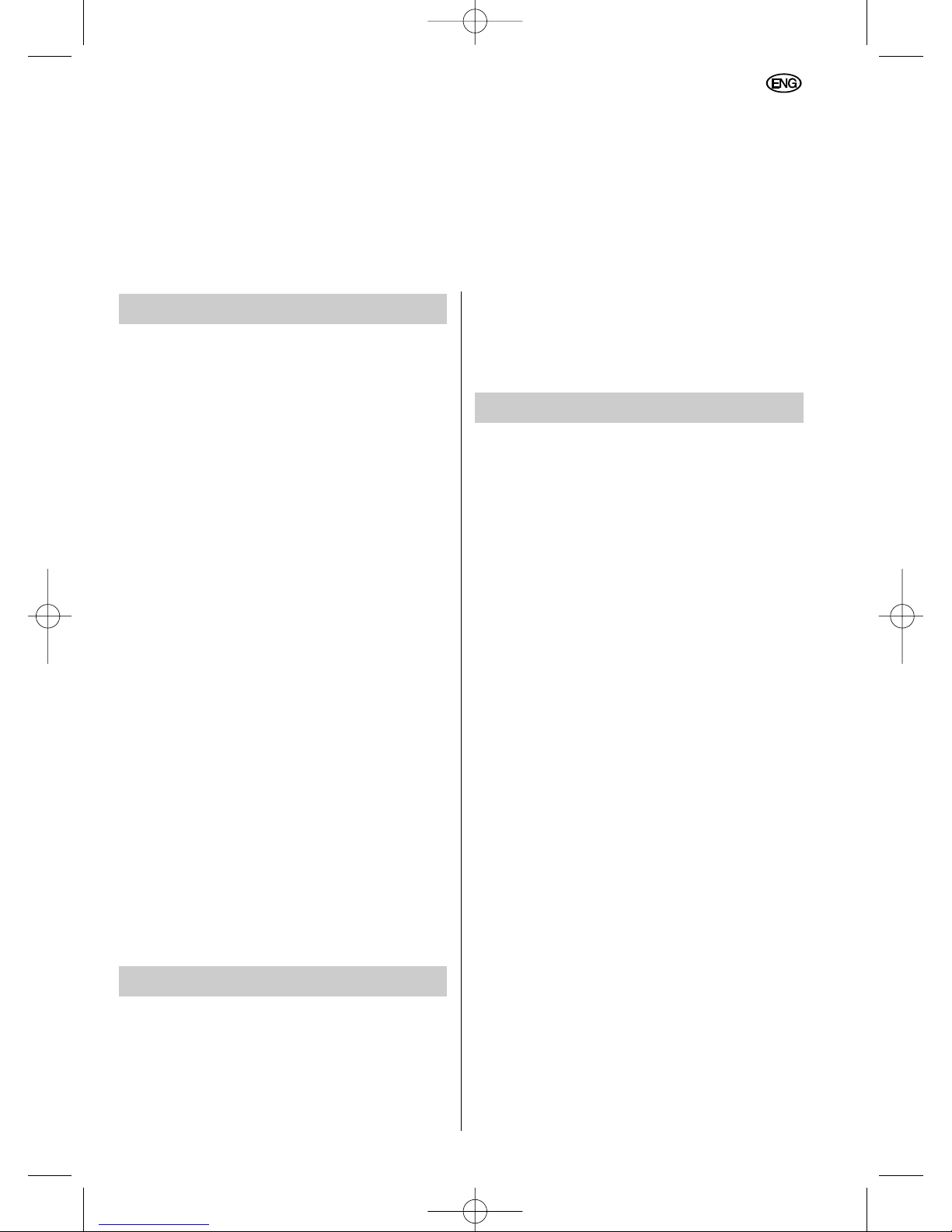

Page 4

4

b

a

c

d

e f

f f

h i j

k l

m

g

n

o

5": 55139

6": 55140

See section 9 and 12.5 for proper installation.

Voir les sections 9 et 12.5 pour effectuer l’installation.

Ver puntos 9 y 12.5 para la correcta instalación.

Consultar as secções 9 e 12.5 para uma instalação apropriada.

01_Ums_Nafta_7970_0207 18.12.2007 14:47 Uhr Seite 4

Page 5

Contents

1 Proper Use

2 General Safety Rules

3 Specific Safety Rules

4 Functional Description

5 Special Product Features

6 Assembly, Initial Use

7 Operation, Switching On/Off

8 Operation, Setting Speed

(depending on equipment)

9 Operation, Fitting Tools

9.1 Fitting cutting and grinding discs

9.2 Securing/releasing the Quick

clamping nut (11): For Type 27

grinding wheel use only

9.3 Securing/releasing the

clamping nut (12):

For Type 1 cut-off wheels OR

Type 27 grinding wheels

10 Maintenance

11 Troubleshooting

12 Accessories

12.1 Removing the wheel guard

12.2 Fitting the hand guard

12.3 Fitting the backing pad and sanding

discs

12.4 Fitting the wire brush

12.5 Fitting the cup-grinding wheel with

wheel guard

12.6 Fitting the cutt-off wheel guard

13 Repairs

14 Environmental Protection

15 Technical Specifications

1 Proper Use

Equipped with the appropriate accessories,

Metabo angle grinders are suitable for cutting,

grinding, sanding with a backing pad and

brushing metal, concrete, stone and similar

materials in dry operating conditions.

Saw discs, saw chains or similar parts must not

be used under any circumstances.

The operator bears sole responsibility for any

damage caused by inappropriate use.

The generally recognised accident prevention

regulations and the accompanying Safety

Instructions must be observed.

2 General Safety Rules

1 WARNING! Read and understand all

instructions.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS.

2 Work Area

2.1 Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

2.2 Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

2.3 Keep bystanders, children, and visitors

away while operating a power tool. Distractions

can cause you to lose control.

3 Electrical Safety

3.1 Grounded tools must be plugged into an

outlet properly installed and grounded in

accordance with all codes and ordinances.

Never remove the grounding prong or modify

the plug in any way. Do not use any adapter

plugs. Check with a qualified electrician if you

are in doubt as to whether the outlet is

properly grounded. If the tools should

electrically malfunction or break down, grounding

provides a low-resistance path to carry electricity

away from the user.

Applicable only to Class I (grounded) tools.

3.2 Double insulated tools are equipped with

a polarized plug (one blade is wider than the

other).This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a

Instruction for use

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new Metabo power tool.

Every Metabo power tool is carefully tested and is subjected to the strict quality controls of the Metabo

Quality Assurance section. However, the service life of any power tool is to a great degree dependent on

yourself as the user. Please read and understand the information contained in these Operating

Instructions and the accompanying documents. The more care you exercise in handling your Metabo

power tool, the longer will be the reliable service it provides for you.

5

ENGLISH

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 5

Page 6

polarized outlet. Do not change the plug in

any way. Double insulation eliminates the

need for the three-wire grounded power cord and

grounded power supply system.

Applicable only to Class II (double insulated) tools.

3.3 Avoid body contact with grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

3.4 Don’t expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

3.5 Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the

risk of electric shock.

3.6 When operating a power tool outside, use

an outdoor extension cord marked

"W-A" or "W". These cords are rated for outdoor

use and reduce the risk of electric shock.

4 Personal Safety

4.1 Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool while tired or under the

influence of drugs, alcohol or medication. A

moment of inattention when operating power tools

may result in serious personal injury.

4.2 Dress properly. Do not wear loose

clothing or jewelry. Contain long hair. Keep

your hair, clothing and gloves away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

4.3 Avoid accidental starting. Be sure switch

is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that

have the switch on invites accidents.

4.4 Remove adjusting keys or wrenches

before turning the tool on. A wrench or a key

that is left attached to a rotating part of the tool

may result in personal injury.

4.5 Do not overreach. Keep proper footing

and balance at all times. Proper footing and

balance enable better control of the tool in

unexpected situations.

4.6 Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat or hearing protection must be used for

appropriate conditions.

5. Tool Use and Care

5.1 Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

5.2 Do not force tool. Use the correct tool for

your application. The correct tool will do the job

better and safer at the rate for which it is

designed.

5.3 Do not use tool if switch does not turn it

on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

5.4 Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the risk

of starting the tool accidentally.

5.5 Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

5.6 Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained tools

with sharp cutting edges are less likely to bind

and are easier to control.

5.7 Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tool's

operation. If damaged, have the tool serviced

before using. Many accidents are caused by

poorly maintained tools.

5.8 Use only accessories that are

recommended by the manufacturer for your

model. Accessories that may be suitable for one

tool may become hazardous when used on

another tool.

6 SERVICE

6.1 Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel

could result in a risk of injury.

6.2

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow

Maintenance instructions may create a risk of

electric shock or injury.

3 Specific Safety Rules

Always use proper guard with grinding wheel.

A guard protects operator from broken wheel

fragments.

Accessories must be rated for at least the

speed recommended on the tool warning

label.

Wheels and other accessories running over rated

speed can fly apart and cause injury. Use at least

"max. 80 m/s".

Hold tool by insulated gripping surfaces when

performing an operation where the cutting

tool may contact hidden wiring or its own

cord.

ENGLISH

6

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 6

Page 7

Contact with a"live" wire will make exposed metal

parts of the tool "live" and shock the operator.

Pay particular attention to the

parts of the text marked with this

symbol for your own safety and

the protection of your power tool.

Always wear eye goggles and hearing protection.

Use other available protective equipment such as

protective gloves, suitable protective work

clothing and helmet.

Before using the angle grinder, install the side

handle (5) and always keep both hands on the

tool at all times during use.

During machining, of metals

in particular, conductive dust

can form deposits inside the

machine. This can lead to the

transfer of electrical energy onto the machine

housing. This can mean a temporary danger of

electric shocks. This is why it is necessary when

the machine is running to blow compressed air

through the rear ventilation slots of the machine

regularly, frequently and thoroughly. Here, the

machine must be held firmly.

It is recommended to use a stationary extraction

system and to place a ground fault circuit

interrupter (GFCI) downstream.

If the angle grinder is deactivated by the GFCI

circuit interrupter, the angle grinder must be

checked and cleaned. Cleaning the motor, see

Maintenance.

The dust generated during operation is often

injurious to health (e.g. when processing oak and

beech woods, stone or paintwork which may

contain lead or other harmful materials). This dust

must not be allowed to penetrate the body. Use

dust-extraction equipment as well as wearing a

suitable dust mask.

Remove any accumulations of dust thoroughly,

using a suitable vacuum cleaner.

Dust can be explosive!

Materials which generate hazardous dusts or

vapours during processing (e.g. asbestos) should

not be used.

Ensure that sparks produced during work do not

constitute a risk to the user or other personnel

and are not able to ignite inflammable

substances. Endangered areas must be protected

with flame-resistant covers. Make sure that firerisk areas are always provided with suitable fire

extinguishers.

Ensure that the accessories used always fulfil

the following minimum requirements.

Respect the maximum

grinding-disc diameter (please

see Technical Specifications).

The diameter of the central

hole in the grinding disc (3)

must fit the inner flange (10)

without any play. Do not use

any adapters or reducers.

The permitted speed n

max

must

correspond at least to the

no-load speed for the power

tool (please see Technical

Specifications).

Use at least "max. 45 m/s".

Carry out a test run after every tool change,

ensuring that you are holding the angle grinder

firmly with both hands.

Hold the angle grinder away from your body.

Ensure that there is no-one present in the area at

risk. Run the angle grinder for approximately

30 seconds.

The angle grinder runs on for approx. 5 seconds

after switch-off.

Observe the information and instructions provided

by the tool or accessory manufacturer.

Do not contaminate discs with grease or subject

them to impact.

Damaged, eccentric or vibrating tools should not

be used.

Never use cutting discs for grinding purposes.

Cutting discs must not be subjected to any lateral

pressure. During cutting or grinding operation,

always work with the wheel guard (4) fitted.

Use tools in dry operating conditions only.

Do not attempt to touch the moving tool - risk of

injury.

Ensure that no damage is caused to gas or water

pipes, electrical cables and weight-bearing walls

(statics).

max. 80 mm

3

10

7

ENGLISH

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 7

Page 8

When using the power tool outdoors, an FI safety

switch with a maximum tripping current of 30 mA

must be connected on the incoming line side.

Angle grinder in continuous operation: To avoid

the possibility of unintentional start-up: always

turn off the switch when the plug is removed from

the socket or if an interruption to the power supply

has occurred.

Use elastic cushioning layers, if they are provided

with the coated abrasive and if they are called for.

If using threaded hole discs, ensure that the

thread in the disc is long enough for the

spindle.

Hold the work piece securely in place.

Ensure that ventilation openings are kept clear

when working in dusty conditions. If it should

become necessary to clear dust, first disconnect

the tool from the mains supply (use non metallic

objects) and avoid damaging internal parts.

Abrasive wheels shall be stored and handled with

care in accordance with manufacturer`s

instructions.

If operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

When using grinding wheel attachments, the

guard must always be attached to the tool and

positioned for maximum safety, so the least

amount of wheel is exposed from the side the tool

is being operated.

Grinding wheels or any other accessory must

have a maximum safe operation speed greater

than the “no load RPM” marked on the tool´s

nameplate.

Always use auxiliary handle for maximum

control over torque reaction or kick-back.

Operation of the grinder without the side handle

could cause loss of control of the grinder,

resulting in possible serious personal injury.

Before using a grinder or installing a new

wheel, inspect the grinding wheel for chips

and cracks. Remove bad wheels immediately.

Run the tool at no load for one minute, holding

the tool in the direction away from people.

Wheels with flaws will normaly break apart during

this time.

Carefully handle both the tool and individual

grinding wheels to avoid chipping or cracking.

Install a new wheel if tool is dropped while

grinding. Do not use a wheel that may be

damaged. Fragments from a wheel that bursts

during operation will fly away at great velocity

possibly striking you or bystanders.

Warning! Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

– Lead from lead-based paints,

– Crystalline silica from bricks and cement and

other masonry products, and

– Arsenic and cromium from chemically treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as dust masks that are specially

designed to filter out microscopic particles.

Read operation instructions

Wear safety goggles

If the safety clutch is tripped, switch the angle

grinder off immediately and remedy the fault.

Do not use this tool with “woodcarving” blades.

Use of “woodcarving” blades can cause kickback

resulting in loss of control and possible serious

injury.

A damaged or cracked side handle must be

replaced. Never operate a machine with a

defective side handle.

Symbols on the tool:

Class II Construction

V volts

A amperes

Hz hertz

.../min revolutions per minute

~ alternating current

n0 no load speed

The „C“ and „US“ indicators adjacent to

the CSA Mark signify that the product

has been evaluated to the applicable

CSA and ANSI/UL Standards, for use

in Canada and the U.S., respectively.

ENGLISH

8

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 8

Page 9

4 Functional Description

Refer to illustrations on page 3

(Please fold out).

1* Slide-switch (locking)

2 Spindle-lock button

3* Grinding disc

4 Wheel guard

5* Side handle / Side handle with vibration

damping

6* Electronic system indicator (VTC, TC only)

7* Knurled wheel for setting speed (VC, VTC)

8 Switch loc

9 Switch trigger

10* Inner flange

11* Quick clamping nut

or alternative

12* Clamping nut with

13* Pin spanner

14* Inner flange (for type 27 wheels 6" diameter)

*depending on equipment

5 Special Product Features

Metabo S-automatic safety clutch

If the tooling jams, the torque

of the machine will be

restricted. As the torque is still

very high always hold the

machine with both hands on

the handles and stand safely,

and concentrate on your work.

Marathon-Motor

The dust-protected Metabo

Marathon-Motor with its

Metabo winding-protection grid

and powder-coated coil

winding ensures up to 50%

longer service life.

Wheel guard

The wheel guard requires no tools for adjustment.

This allows it to be adjusted for a variety of

applications in a matter of seconds.

Auto-stop carbon brushes

When the auto-stop carbon brushes wear down to

a predetermined level the power tool is

automatically switched off, thus ruling out the

possibility of damage to the armature.

Additional side handle with vibration damping

(depending on scope of supply):

For comfortable work in continuous operation.

VC/VTC/TC electronic speed-control system

(depending on equipment)

This electronic control system ensures the correct

grinding speed for the relevant material (VC/VTC)

and maintains close to a constant speed, even

under load (VC/VTC/TC).

The Vario-Tacho-Constamatic (VTC)/ TachoConstamatic (TC) electronic system also features

starting-current limitation, electronicallycontrolled, smooth start-up, coil-temperature

monitoring and an electronic restart safety device.

Refer to the Technical Specifications for the

equipment level for your specific angle grinder.

6 Assembly, Initial Use

Before initial use, check that the mains

voltage and mains frequency stated on

the rating plate match the figures for

your own mains supply.

Fit side-handle

For reasons of safety, always fit the side

handle (5) to the right or left-hand side

of the angle grinder before commencing

work.

Fit wheel guard

(before working with the grinding disc)

Use correct guard for type of wheel

being used. See sections 12.4 and 12.5

for cup wheel guard and cut-off wheel

guard.

Remove the clamping nut (12) or the Quick

clamping nut (11) and the inner flange (10) from

the spindle. When fitting the wheel guard (4) to

the angle grinder, ensure that the notch on the

wheel guard coincides with the corresponding

marking on the tool itself.

Turn the wheel guard so that the closed

area is towards the operator.

Connect to mains supply.

With VTC, TC electronic system (depending on

equipment):

The red electronic system indicator (6) lights up

briefly when the mains connection is made, thus

indicating standby mode.

9

ENGLISH

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 9

Page 10

7 Operation, Switching On/Off

Always guide the machine with both

hands!

First switch on, then apply the tool to

the work piece!

It must be avoided that the machine

draws in additional dust and shavings.

When switching the machine on and off,

keep it away from dust deposits.

After switching off the machine, only

place it down when the motor has come

to a standstill.

In the case of VTC, TC electronic control:

the red electronic signal indicator (6) comes on

briefly when the machine is switched on.

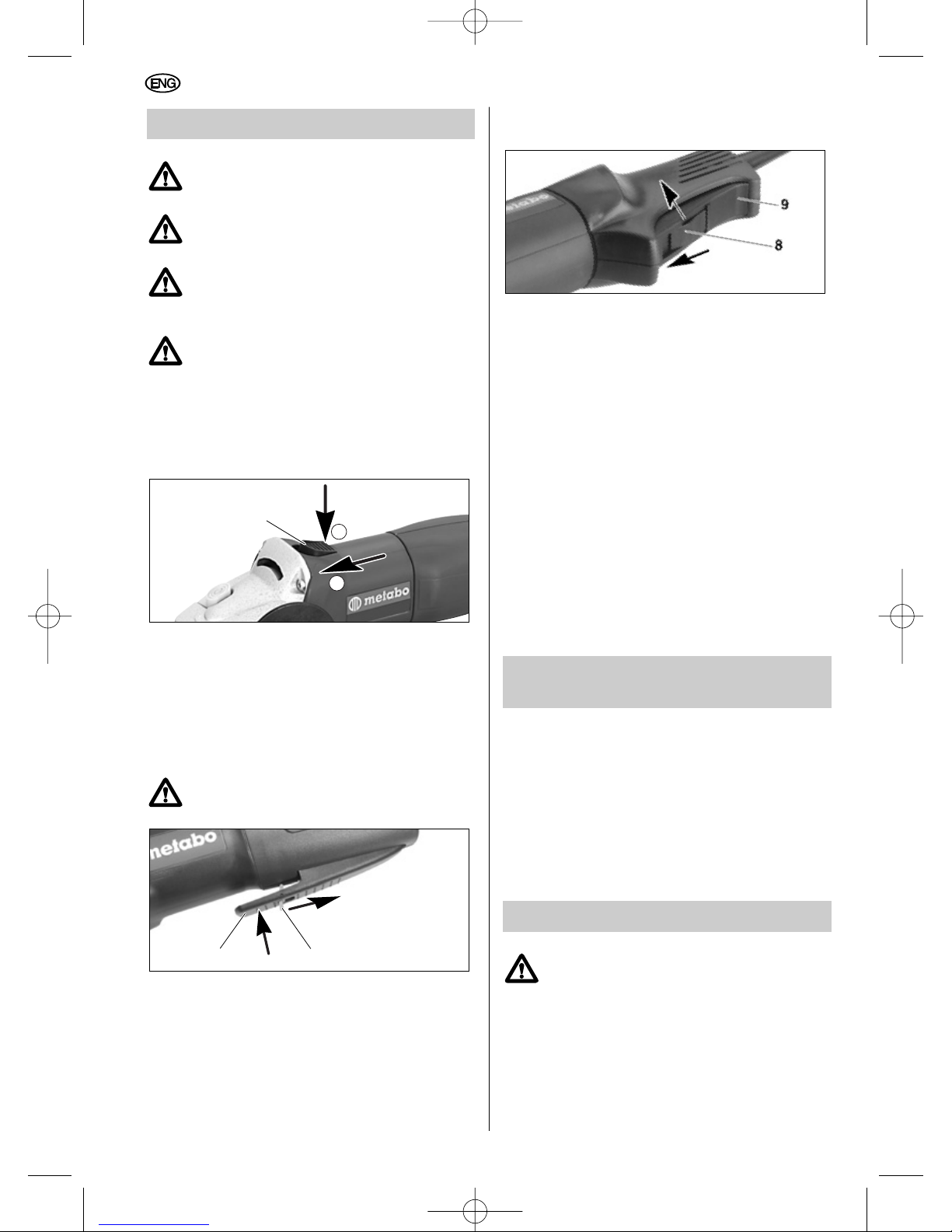

Machines with slide-switch (1):

(Machines with the designation W... or WE...)

Switching on: slide the slide-switch (1) forward

until it engages.

Switching off: press the rear end of the slideswitch.

Machines with switch lock

(Safety switch because it cannot be locked):

(Machines with the designation WEP...)

Do not carry or suspend the machine

by the trigger switch (9).

Switching on: slide the switch lock (8) in the

direction of the arrow and press the switch

trigger (9).

Switching off: Release the switch trigger (9).

Tools with switch trigger (9):

(Machines with the designation WP... or WPS...)

Switching on: slide the switch lock (8) in the

direction of the arrow and press the switch trigger

(9).

Switching off: Release the switch trigger (9).

Continuous operation:

(Machines with the designation WP...)

Switch on the angle grinder and slide the switch

lock (8) forward until it engages.

Switching off continuous operation:

Briefly press the switch trigger (9) and release.

Restart safety device

(only with VTC/TC electronic system):

If the mains connection is made with the angle

grinder still switched on or if the power supply is

restored after an interruption, the angle grinder

will refuse to start. The red electronic system

indicator (6) flashes. Switch angle grinder off and

then on again.

8 Operation, Setting Speed

(depending on equipment)

Set the recommended speed with the knurled

wheel (7).

Grinding disc, cutting disc, cup grinding

wheel: high speed setting

Brush: middle speed setting

Surface dressing discs: low to middle speed

setting

Apply only light pressure to the tool when working

at low speeds.

9 Operation, Fitting Tools

Before any tool changing operation,

always remove the plug from the mains

supply socket and check that the angle

grinder is switched off and that the

spindle has come to a halt.

Locking the spindle

Press in the spindle-lock button (2) and turn the

spindle by hand until the spindle-lock button can

be felt to engage in position.

9 8

1

0

I

ENGLISH

10

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 10

Page 11

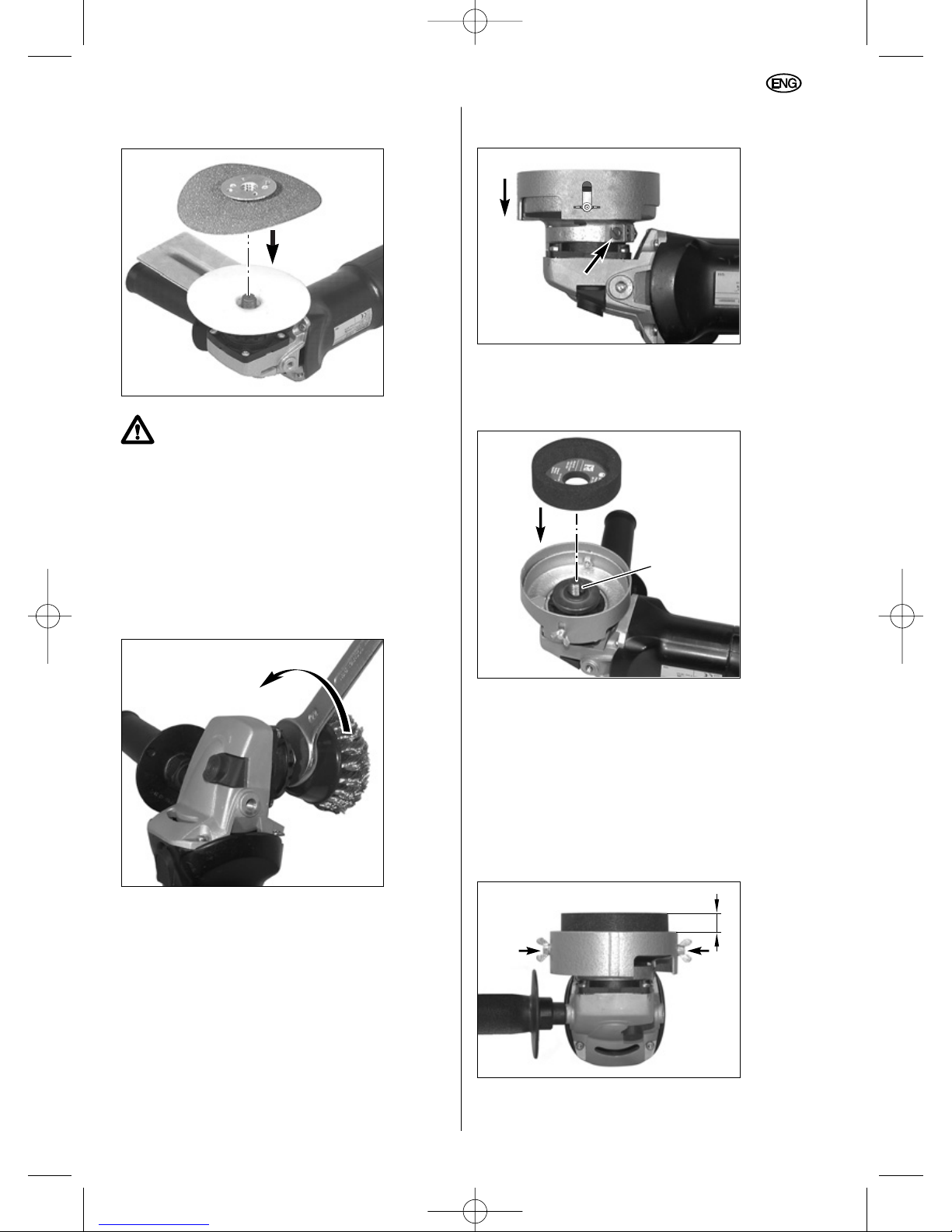

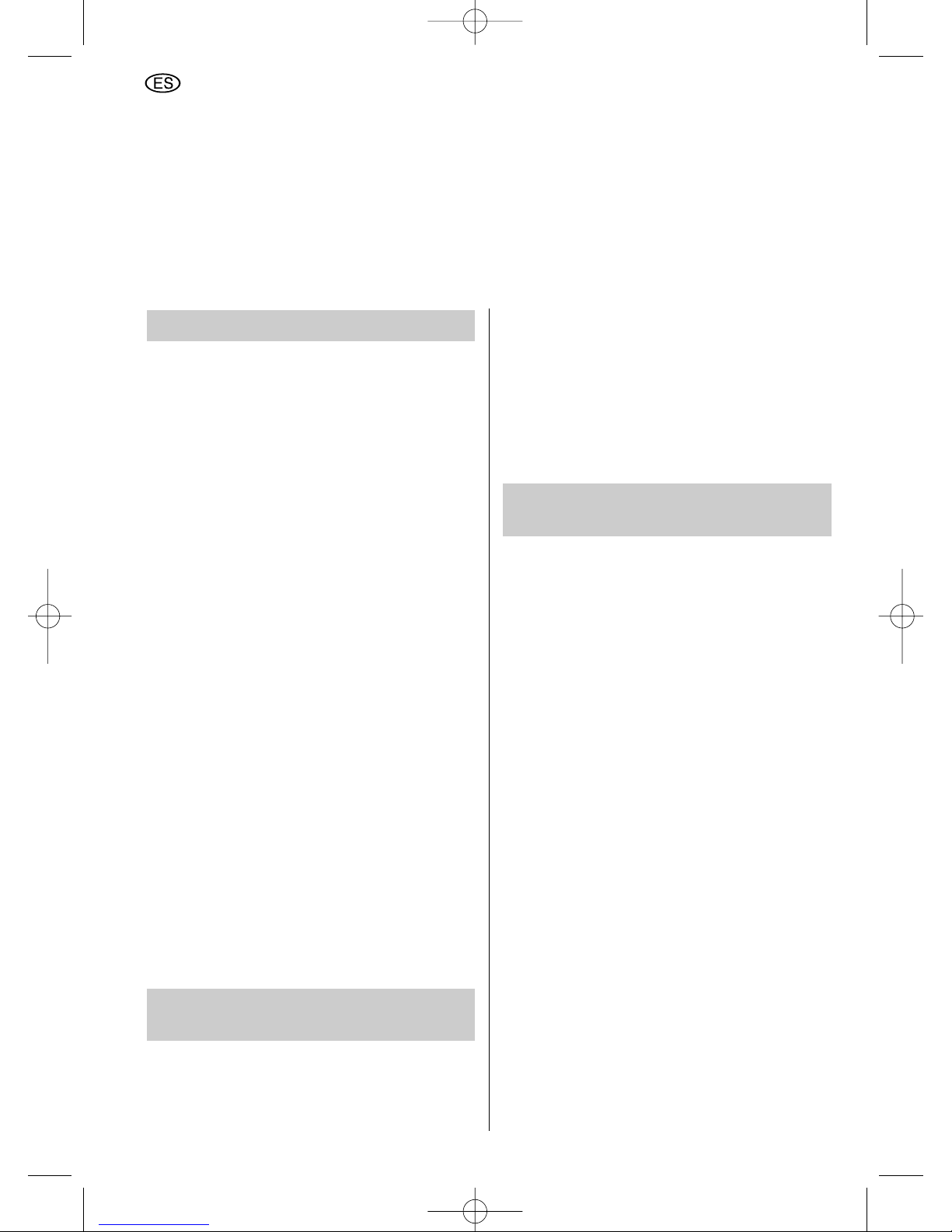

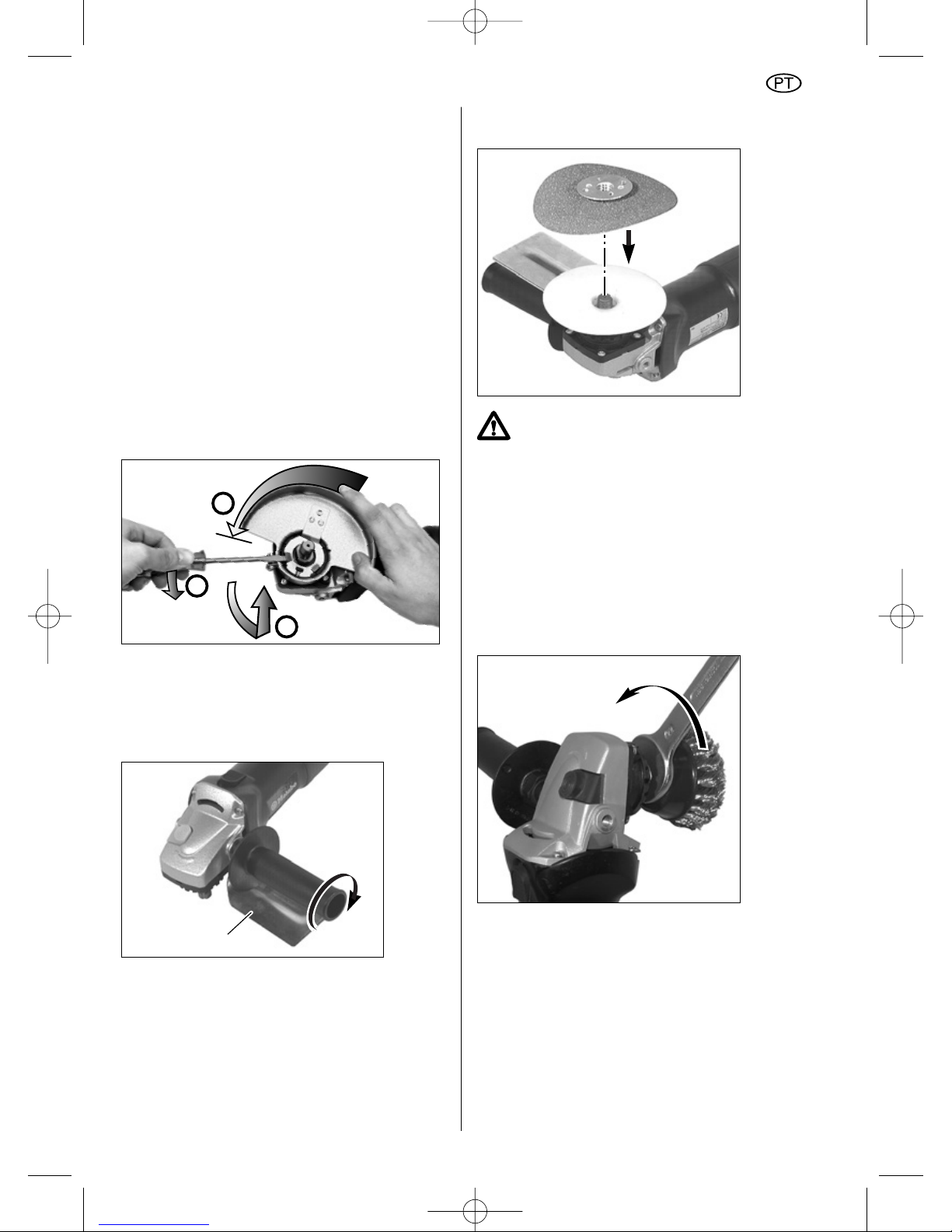

9.1 Fitting cutting and grinding discs

Locate the inner flange (10) for type 1 cutting

discs, (10) for type 27 wheels 5” diameter or

smaller, or (14) for type 27 wheels 6” diameter, as

illustrated, ensuring that the inner flange cannot

turn on the spindle.

Position the cutting disc or the grinding disc on the

inner flange, as illustrated, ensuring that the cutting

disc is supported evenly by the inner flange. When

cutting, the sheet metal flange on the cutter disc

should be resting on the inner flange.

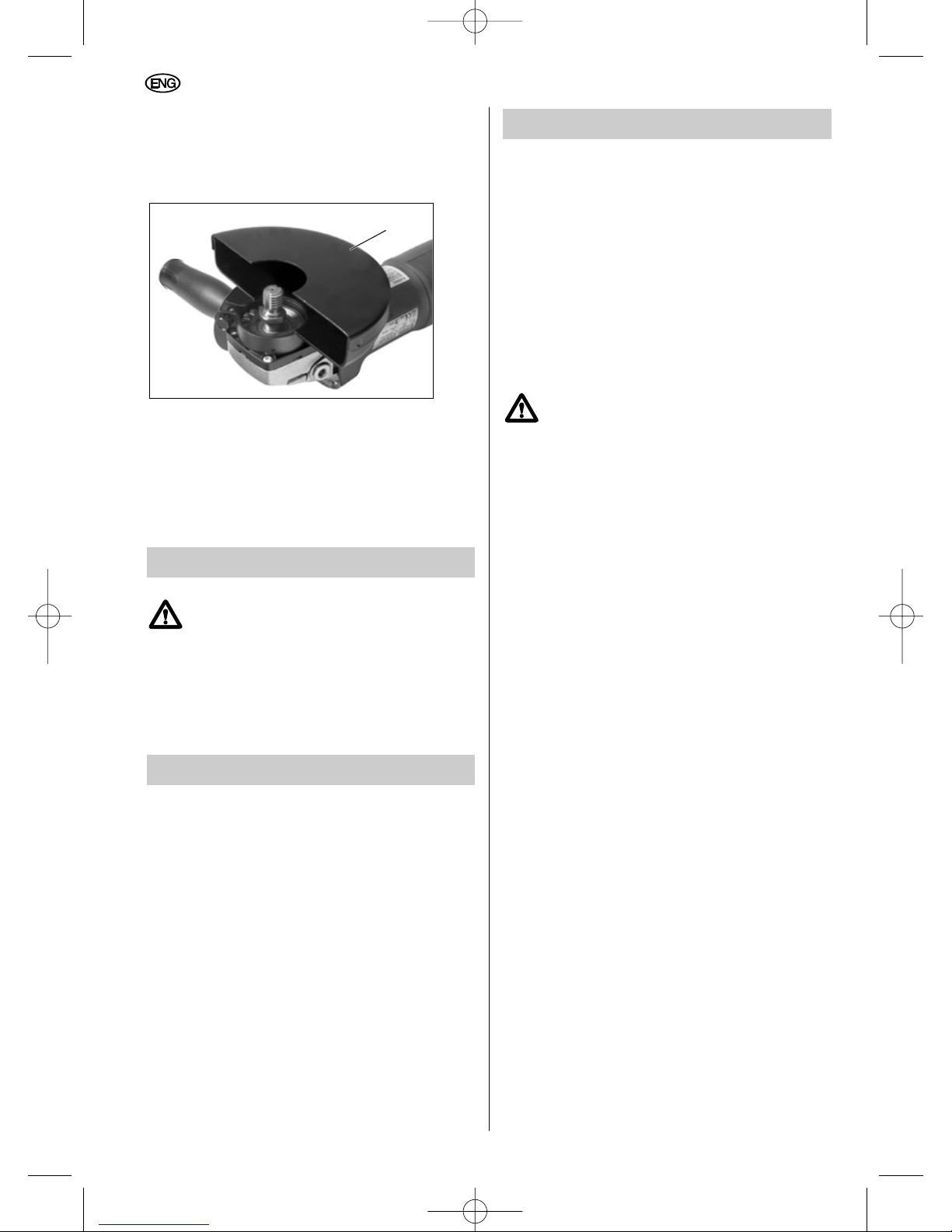

9.2 Securing/releasing the Quick

clamping nut (11): For Type 27

grinding wheel use only

Securing

For tools which are thicker than 8 mm

(5/16”) in the clamping area, use the

clamping nut (12) with the pin spanner

(13) instead of the Quick clamping

nut (11).

Fit the Quick clamping nut (11) in the grooves on

the spindle as illustrated. Lock the spindle in

position. Turn the Quick clamping nut (11)

clockwise by hand until tight. Tighten the Quick

clamping nut by turning the grinding wheel firmly

in a clockwise direction.

Releasing

After switch-off, the angle grinder runs on for

approx. 5 seconds. Press the spindle-lock button

(2) shortly before the grinding tool comes to a

final halt and the Quick clamping nut releases

itself.

Using the spindle-lock button (2) to stop

the spindle is only permitted if the

Quick clamping nut is in use!

Screw the Quick clamping nut off.

9.3 Securing/releasing the

clamping nut (12):

For Type 1 cut-off wheels OR

Type 27 grinding wheels

Securing

For wheels thinner than 3/16" turn clamping nut

(12) onto the spindle with the raised collar away

from the wheel so that the wheel can be clamped

securely. Tighten securely using spanner wrench

(13).

For wheels 3/16" and thicker, turn clamping nut

(12) onto spindle with the raised collar facing the

wheel so that the collar engages the ID of the

wheel. Tighten securely using spanner wrench

(13).

12

12

12

14

11

10

10

14

11

ENGLISH

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 11

Page 12

Lock the spindle in position. Fit the pin spanner

(13) onto the clamping nut (12) and turn

clockwise to tighten.

Releasing

Lock the spindle in position, slacken off the

clamping nut with the pin spanner (13) and

screw off.

10 Maintenance

Remove the plug from the mains supply socket

before undertaking any maintenance work.

Motor cleaning: blow compressed air through the

rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine

must be held firmly.

The auto-stop carbon brushes must only be

replaced in an accredited workshop. Have checks

and maintenance carried out by Metabo

Authorized Services.

11 Troubleshooting

With VTC, TC electronic system:

electronic system indicator (6) lights up.

The coil temperature is too high. Allow the angle

grinder to run under no-load conditions until the

indicator display is extinguished.

12 Accessories

Use original Metabo accessories only.

Your Metabo dealer will supply you with any

accessories you may require.

To assist in selecting the correct accessories,

make sure that you take a note of the exact

model of your tool for your dealer.

Refer to illustrations on page 4:

a Wheel guard with cutting and chasing guide

for processing stone

b Hand guard

c Safety goggles

d Cup-grinding wheel guard

e Cup-grinding wheel for surface smoothing

f Wire brushes

g Lamellar surface dressing discs

h Cutting and grinding discs

i Backing pads

j Cling-fit backing pads

k Sanding discs

l Diamond cutting blade

m Extension for working with backing pads

n Pin spanner (offset)

o cutt-off wheel guard

12.1 Removing the wheel guard

12.2 Fitting the hand guard

(working with backing pad and sanding

disc or brush)

Remove the tool, wheel guard and side-handle,

as necessary.

Fit the hand guard (b) over the threaded part of

the handle (5). Adjust the hand guard and fit to

the angle grinder along with the side-handle.

b

1

2

3

12

13

ENGLISH

12

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 12

Page 13

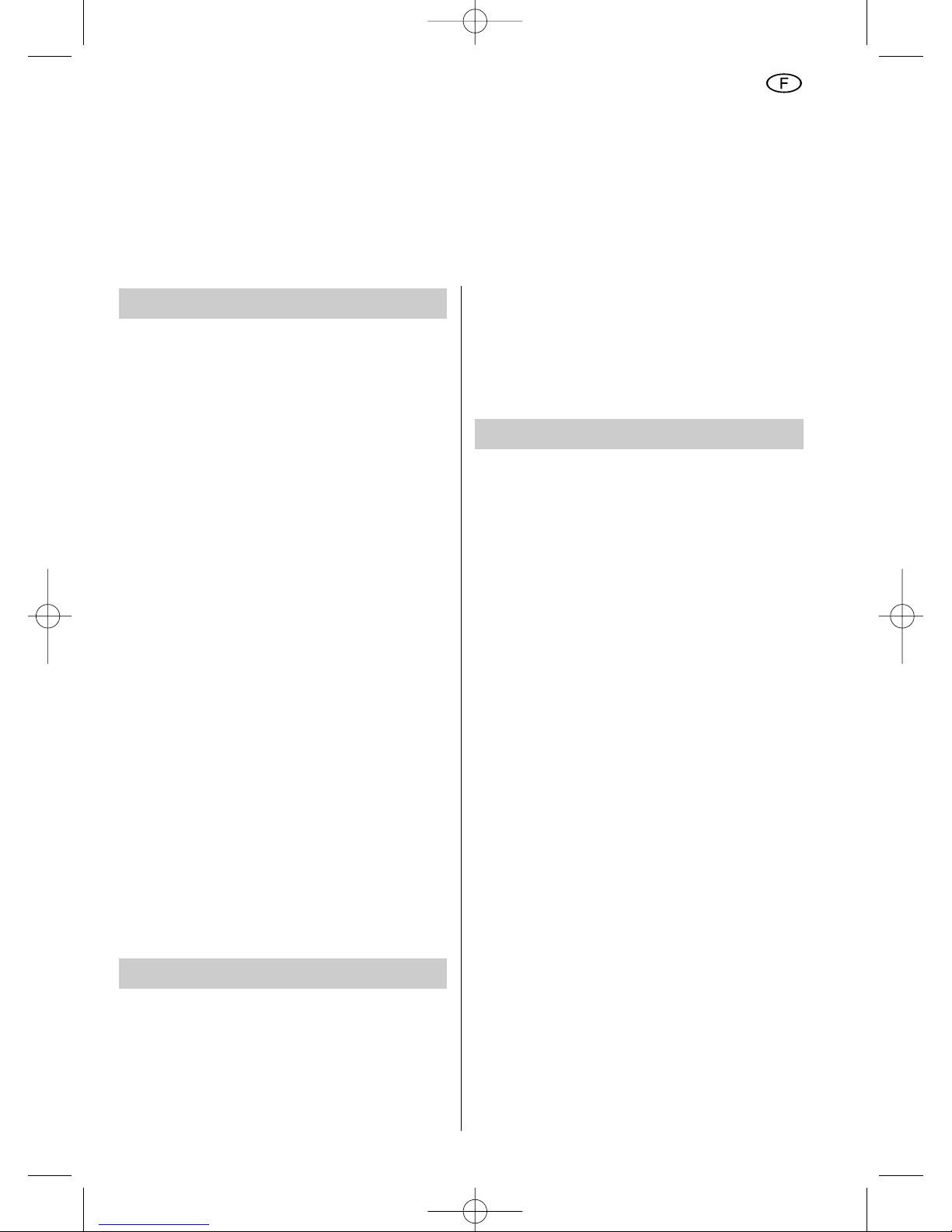

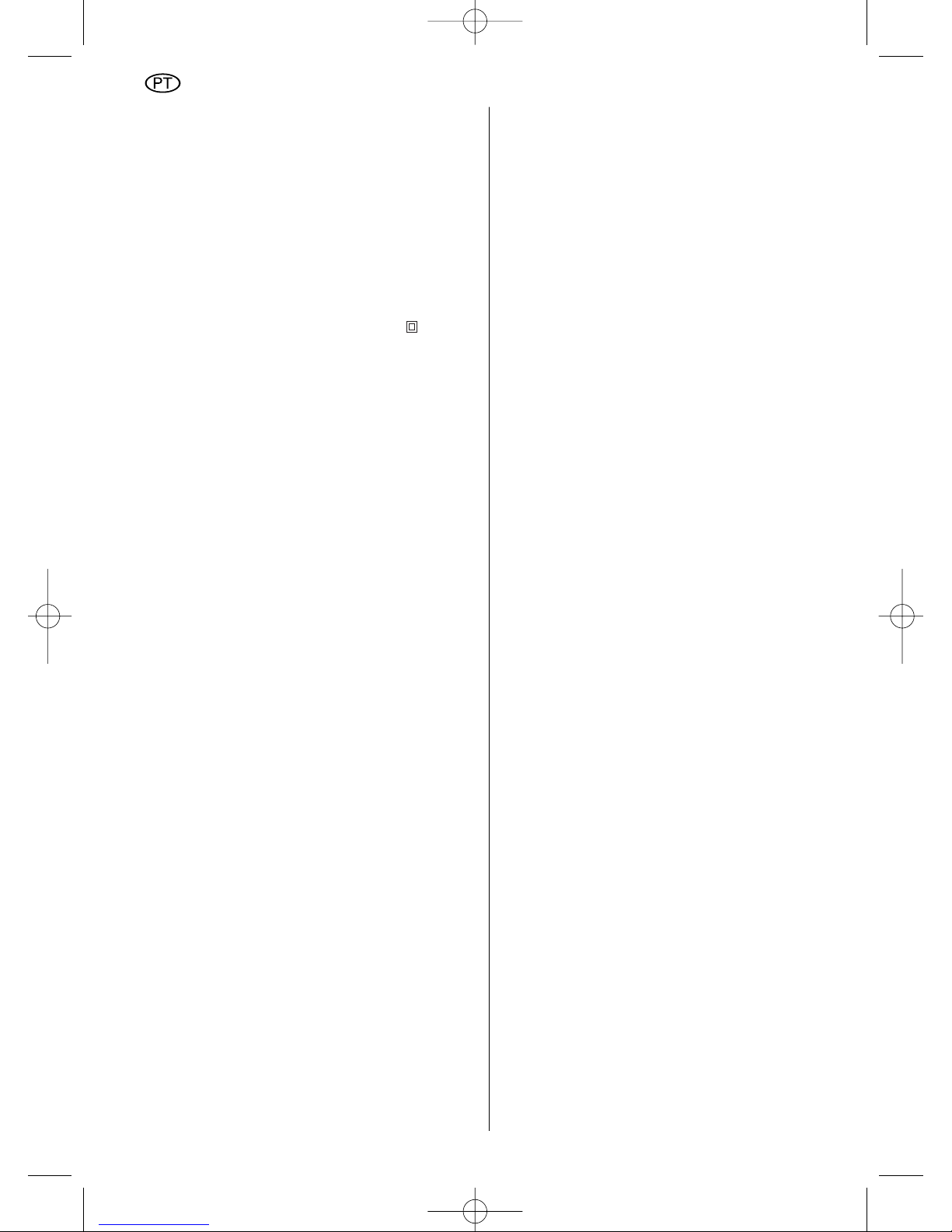

12.3 Fitting the backing pad and sanding

disc

Use only the clamping nut supplied

along with the backing pad.

Locate the backing pad (i) on the spindle, as

illustrated. Mount the sanding disc (k) with the

backing pad clamping nut supplied. Lock the

spindle in position. Tighten the sanding disc and

backing pad by turning clockwise by hand.

Slacken off manually or with the pin spanner (13),

as necessary.

12.4 Fitting the wire brush

Fit the hand guard.

Remove the wheel guard (4). Lock the spindle in

position. Mount the wire brush (f) and tighten with

the 22 mm AF open-ended spanner (7/8").

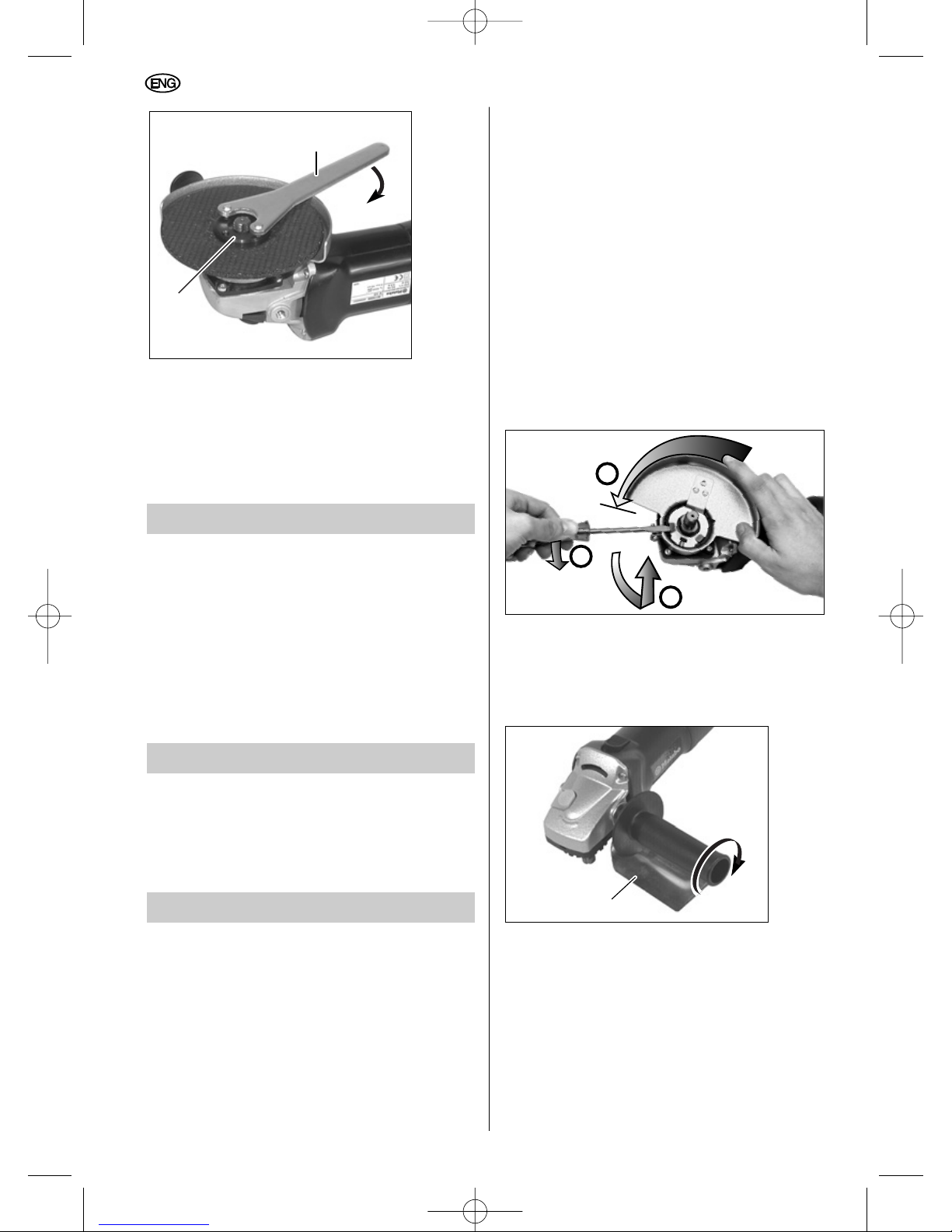

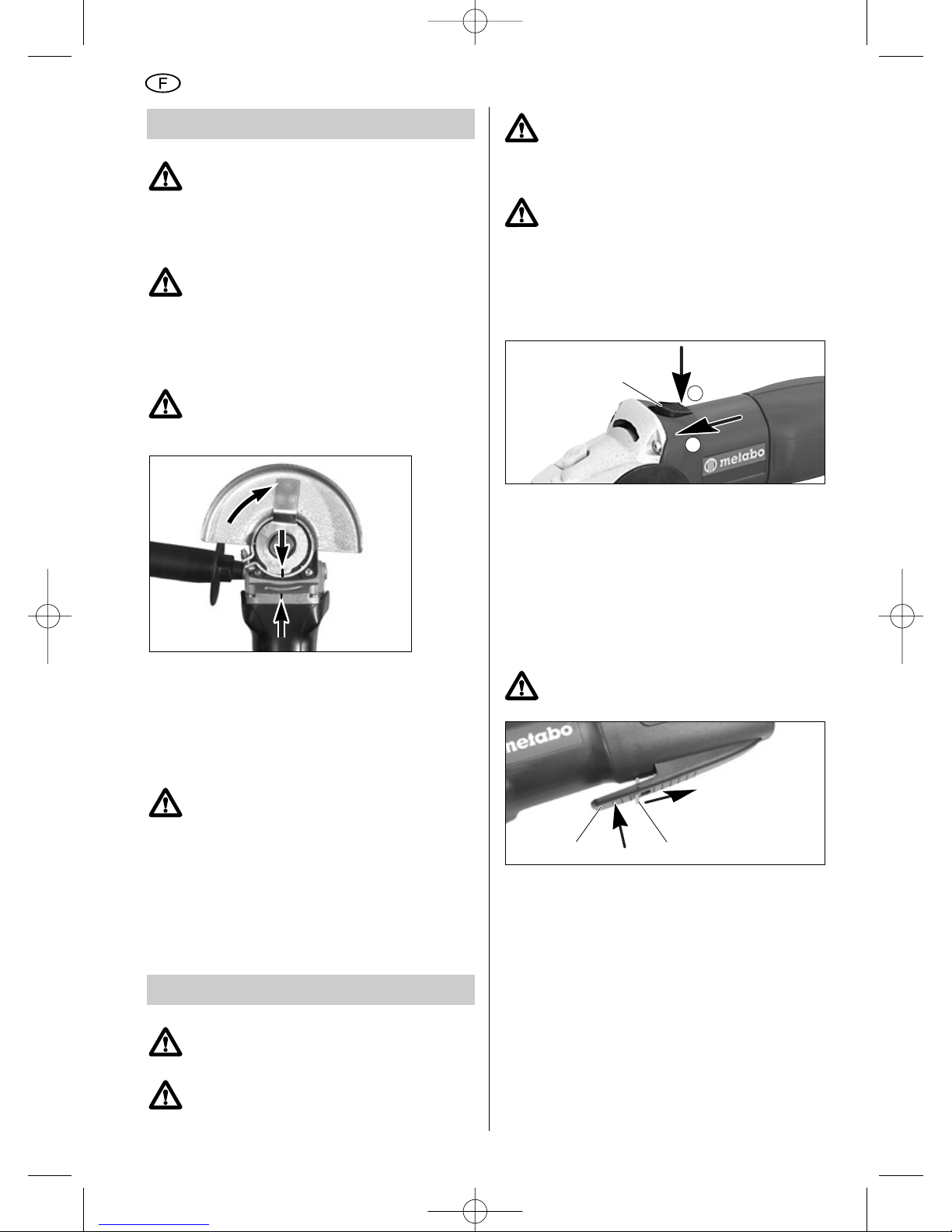

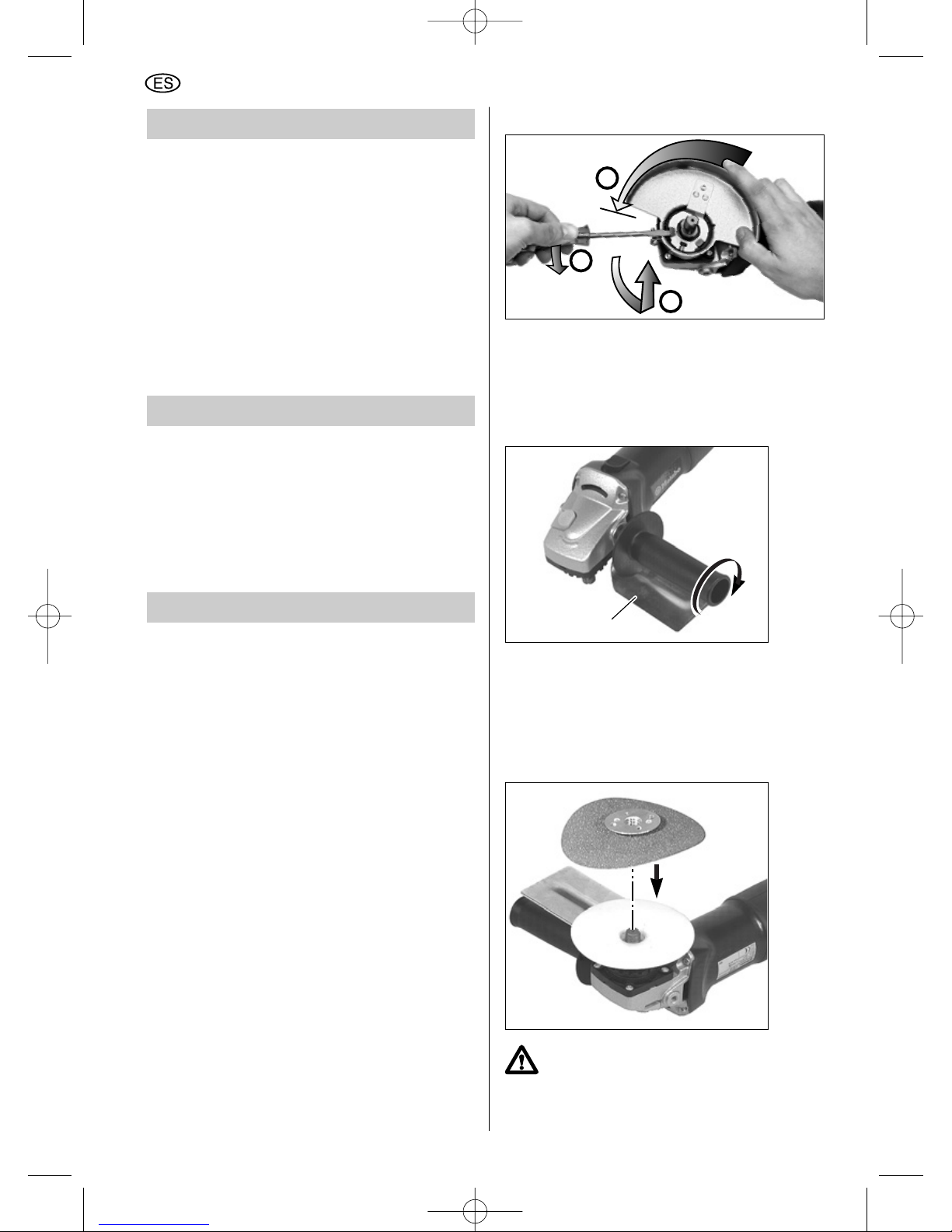

12.5 Fitting the cup-grinding wheel with

wheel guard

Remove the wheel guard (4). Fit the cup-grinding

wheel guard to the angle grinder, turning it on in

the direction indicated by the arrow until fully in

position. Use a screwdriver to tighten the screw.

Locate the inner flange (10) on the spindle,

ensuring that the flange cannot turn on the

spindle. Position the cup-grinding wheel so that it

rests evenly on the inner flange.

Screw the clamping nut (12) or the Quick

clamping nut (11) onto the spindle. Lock the

spindle in position. Secure the cup-grinding wheel

with the clamping nut (12) or the Quick clamping

nut (11).

Use the offset pin spanner (n) if the clamping nut

(12) is being used.

Set the cup-grinding wheel/wheel guard

projection as required (approx. 0.5 - 1 cm/

10

13

ENGLISH

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 13

Page 14

0.2" - 0.4"). Slacken off the two wing screws and

adjust the wheel guard evenly upwards or down.

Retighten wing screws.

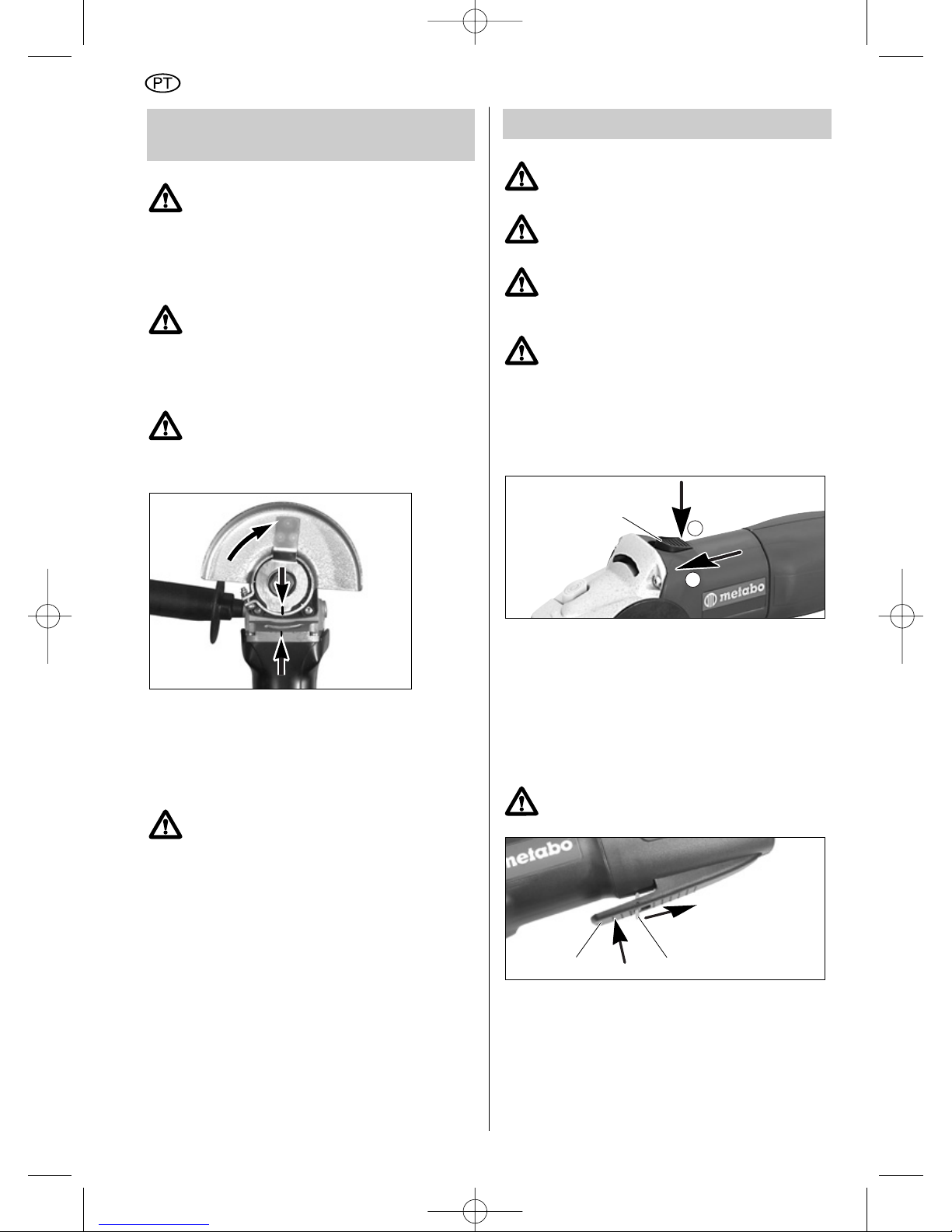

12.6 Fitting the cut-off wheel guard

Remove the wheel guard (4). Fit the cut-off wheel

guard (o) by aligning the 3 raised retention nibs

on the guard with the slots on the flange. Push

the guard on fully, then rotate the guard and

position the guard between the operator and

the wheel. Tighten the clamping screw to secure

the guard in position.

13 Repairs

Repairs to power tools must be carried

out by a qualified electrician only.

Any Metabo power tools in need of repair can be

sent to one of the addresses listed on the secondlast page.

Please send the tool for repair with a brief

description of the fault identified.

14 Environmental Protection

Metabo packaging is 100% suitable for recycling.

Power tools and accessories at the end of their

service life still contain large amounts of valuable

raw materials and plastics which can likewise be

fed back into a recycling process.

As the dust generated during grinding/cutting may

contain harmful materials, do not dispose of it

along with domestic waste but ensure it is taken

to a collection point for special waste for proper

disposal.

These Operating Instructions are printed on paper

produced in a chlorine-free bleaching process.

15 Technical Specifications

Notes on the details on page 2.

We reserve the right to undertake modifications to

reflect technical advances.

D

max

= maximum grinding disc diameter

n = no-load speed

M = spindle thread

P

1

= rated input

P

2

= output power

I

120V

= current at 120 V

a

hw

= typically rated acceleration in the

hand-arm area

Typical A-rated acoustic level:

L

pA

= acoustic pressure level

L

WA

= acoustic power level

Wear ear protectors!

m = weight

Measured values established according to

EN 50144.

The stated technical specifications are subject to

tolerances (as specified in the respective current

standards).

o

ENGLISH

14

02_ENG_Nafta_7970_0207 18.12.2007 14:49 Uhr Seite 14

Page 15

Table des matières

1 Utilisation en conformité

2 Règles de sécurité générales

3 Consignes de sécurité spéciales

4 Vue d'ensemble

5 Caractéristiques spécifiques du produit

6 Mise en service

7 Mise en marche et arrêt

8 Réglage de la vitesse (selon l'équipement)

9 Montage des outils

9.1 Mise en place des meules de

tronçonnage et d'ébarbage

9.2 Fixation/Desserrage de l’écrou de

serrage Quick (11) : à utiliser avec la

meule boisseau de type 27 uniqument

9.3 Fixation/Desserrage de l’écrou de

serrage Quick (12) : à utiliser avec la

meule de tronçonnage de type 1 OU la

meule boisseau de type 27 uniquement

10 Maintenance

11 Dépannage

12 Accessoires

12.1 Déposer le protecteur de sécurité

12.2 Mise en place du protège-main

12.3 Mise en place du plateau à poncer

et du disque abrasif

12.4 Mise en place de la brosse

métallique à fils d'acier

12.5 Mise en place de la meule boisseau

droite et du protecteur de sécurité

12.6 Fixation du protecteur à découpe

13 Réparations

14 Protection de l'environnement

15 Caractéristiques techniques

1 Utilisation en conformité

Equipées des accessoires d'origine Metabo

correspondants, les meuleuses d'angle

conviennent au tronçonnage, au meulage, au

ponçage avec plateau à poncer et au brossage

des métaux, du béton, de la pierre et matériaux

similaires, sans utilisation d'eau.

Ne jamais utiliser de lame de coupe, de chaîne

de coupe ou outil semblabe.

En cas de dommages résultant d'une utilisation

non conforme, seule la responsabilité du

propriétaire est engagée.

Il convient de respecter les prescriptions

généralement reconnues en matière de

prévention des accidents ainsi que les consignes

de sécurité jointes.

2 Règles de sécurité générales

1 AVERTISSEMENT! Vous devez lire et

comprendre toutes les instructions.

Le non-respect, même partiel, des instructions ciaprès entraîne un risque de choc électrique,

d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS.

2 Aire de travail

2.1 Veillez à ce que l’aire de travail soit propre

et bien éclairée. Le désordre et le manque de

lumière favorisent les accidents.

2.2 N'utilisez pas d’outils électriques dans

une atmosphère explosive, par exemple en

présence de liquides, de gaz ou de poussières

inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les

poussières ou les vapeurs.

2.3 Tenez à distance les curieux, les enfants

et les visiteurs pendant que vous travaillez

avec un outil électrique. Ils pourraient vous

distraire et vous faire faire une fausse manœuvre.

3 Sécurité électrique

3.1 Les outils mis à la terre doivent être

branchés dans une prise de courant

correctement installée et mise à la terre

conformément à tous les codes et règlements

pertinents. Ne modifiez jamais la fiche de

quelque façon que ce soit, par exemple en

enlevant la broche de mise à terre. N'utilisez

pas d'adaptateur de fiche. Si vous n’êtes pas

certain que la prise de courant est

correctement mise à la terre, adressez-vous à

un électricien qualifié. En cas de défaillance ou

de défectuosité électrique de l'outil, une mise à la

terre offre un trajet de faible résistance à

l'électricité qui autrement risquerait de traverser

l'utilisateur.

Mode d'emploi

Cher client,

Nous vous remercions de la confiance que vous nous avez témoignée par l'achat de votre nouvel

appareillage électrique Metabo. Chaque outillage électrique Metabo est soigneusement testé et subit les

contrôles de qualité particulièrement sévères du programme d'assurance-qualité Metabo. Toutefois, la

longévité d'un outillage électrique dépend grandement de vous. Veuillez donc tenir compte des

informations du présent mode d'emploi ainsi que des documents joints. La longévité et la fiabilité de

votre outillage électrique Metabo seront d'autant plus élevées que vous le traiterez avec soin.

15

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 15

Page 16

S'applique aux outils de classe I (mis à la terre)

seulement.

3.2 Les outils à double isolation sont équipés

d’une fiche polarisée (une des lames est plus

large que l’autre), qui ne peut se brancher que

d’une seule façon dans une prise polarisée. Si

la fiche n’entre pas parfaitement dans la prise,

inversez sa position ; si elle n’entre toujours

pas bien, demandez à un électricien qualifié

d’installer une prise de courant polarisée.

Ne modifiez pas la fiche de l’outil. La double

isolation élimine le besoin d’un cordon

d’alimentation à trois fils avec mise à la terre ainsi

que d’une prise de courant mise à la terre.

S’applique aux outils de classe II seulement.

3.3 Evitez tout contact corporel avec des

surfaces mises à la terre (tuyauterie,

radiateurs, cuisinières, réfrigérateurs, etc.).

Le risque de choc électrique est plus grand si

votre corps est en contact avec la terre.

3.4 N’exposez pas les outils électriques à la

pluie ou à l’eau. La présence d’eau dans un outil

électrique augmente le risque de choc électrique.

Cette consigne est facultative pour les outils

étanches à l’eau ou à l’épreuve de

l'éclaboussement.

3.5 Ne maltraitez pas le cordon. Ne

transportez pas l’outil par son cordon et ne

débranchez pas la fiche en tirant sur le

cordon. N’exposez pas le cordon à la chaleur,

à des huiles, à des arêtes vives ou à des

pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un

cordon endommagé augmente le risque de choc

électrique.

3.6 Lorsque vous utilisez un outil électrique à

l’extérieur, employez un prolongateur pour

l'extérieur marqué « W-A » ou « W ». Ces

cordons sont faits pour être utilisés à l’extérieur et

réduisent le risque de choc électrique.

4 Sécurité des personnes

4.1 Restez alerte, concentrez-vous sur votre

travail et faites preuve de jugement. N’utilisez

pas un outil électrique si vous êtes fatigué ou

sous l’influence de drogues, d’alcool ou de

médicaments. Un instant d'inattention suffit pour

entraîner des blessures graves.

4.2 Habillez-vous convenablement. Ne portez

ni vêtements flottants ni bijoux. Confinez les

cheveux longs. N’approchez jamais les

cheveux, les vêtements ou les gants des

pièces en mouvement. Des vêtements flottants,

des bijoux ou des cheveux longs risquent d’être

happés par des pièces en mouvement.

4.3 Méfiez-vous d’un démarrage accidentel.

Avant de brancher l’outil, assurez-vous que

son interrupteur est sur ARRÊT. Le fait de

transporter un outil avec le doigt sur la détente ou

de brancher un outil dont l’interrupteur est en

position MARCHE peut mener tout droit à un

accident.

4.4 Enlevez les clés de réglage ou de serrage

avant de démarrer l’outil. Une clé laissée dans

une pièce tournante de l’outil peut provoquer des

blessures.

4.5 Ne vous penchez pas trop en avant.

Maintenez un bon appui et restez en équilibre

en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

4.6 Utilisez des accessoires de sécurité.

Portez toujours des lunettes ou une visière.

Selon les conditions, portez aussi un masque

antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur et/ou un

appareil antibruit.

5. Utilisation et entretien des outils

5.1 Immobilisez le matériau sur une surface

stable au moyen de brides ou de toute autre

façon adéquate. Le fait de tenir la pièce avec la

main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de l’outil.

5.2 Ne forcez pas l'outil. Utilisez l’outil

approprié à la tâche. L’outil correct fonctionne

mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

5.3 N’utilisez pas un outil si son interrupteur

est bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et

doit être réparé.

5.4 Débranchez la fiche de l’outil avant

d’effectuer un réglage, de changer

d’accessoire ou de ranger l’outil. De telles

mesures préventives de sécurité réduisent le

risque de démarrage accidentel de l’outil.

5.5 Rangez les outils hors de la portée des

enfants et d’autres personnes

inexpérimentées. Les outils sont dangereux

dans les mains d’utilisateurs novices.

5.6 Prenez soin de bien entretenir les outils.

Les outils de coupe doivent être toujours bien

affûtés et propres. Des outils bien entretenus,

dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

5.7 Soyez attentif à tout désalignement ou

coincement des pièces en mouvement, à tout

bris ou à toute autre condition préjudiciable

au bon fonctionnement de l’outil. Si vous

constatez qu’un outil est endommagé, faitesle réparer avant de vous en servir. De

nombreux accidents sont causés par des outils

en mauvais état.

5.8 N’utilisez que des accessoires que le

fabricant recommande pour votre modèle

d’outil. Certains accessoires peuvent convenir à

un outil, mais être dangereux avec un autre.

16

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 16

Page 17

6 RÉPARATION

6.1 La réparation des outils électriques doit

être confiée à un réparateur qualifié. L’entretien

ou la réparation d’un outil électrique par un

amateur peut avoir des conséquences graves.

6.2 Pour la réparation d’un outil, n’employez

que des pièces de rechange d’origine.

Suivez les directives données à la section

« Réparation » de ce manuel. L’emploi de

pièces non autorisées ou le non-respect des

instructions d’entretien peut créer un risque de

choc électrique ou de blessures.

3 Consignes de

sécurité spéciales

Avant d'utiliser l'outillage électrique, lisez

attentivement et intégralement les consignes de

sécurité (cahier rouge) et le présent mode

d'emploi. Conservez tous les documents fournis

avec l'outillage électrique. Si vous prêtez votre

outillage électrique, veillez à toujours joindre

également cette documentation.

Pour votre propre protection et

pour celle de votre outillage

électrique, tenez compte des

passages repérés par ce

symbole !

Munissez-vous toujours de lunettes de protection

et d’une protection auditive. Utilisez également

tout autre équipement de sécurité des personnes,

comme des gants, des vêtements de protection

adéquats et un casque.

Avant l'utilisation de la meuleuse d'angle, adaptez

la poignée (5) et guidez toujours la meuleuse

d'angle avec les deux mains.

En cours de travail, et surtout

s’il s’agit de métaux, il est

possible que des poussières

conductrices s’accumulent

dans la machine. Il se peut alors qu’il y ait un

transfert d’énergie électrique sur le corps de

machine. Ainsi, par moment il pourra y avoir un

risque d’électrocution. Pour cette raison, il est

impératif de nettoyer la machine régulièrement,

fréquemment et soigneusement, en soufflant de

l’air comprimé à travers les fentes d’aération à

l’arrière pendant que la machine tourne. Veiller à

bien maintenir la machine pendant ce temps.

Il est recommandé d’installer un système

d’aspiration fixe et de prévoir un disjoncteur à

courant de défaut (FI).

Lorsque la meuleuse d’angle est arrêtée par son

interrupteur de protection FI, la meuleuse d’angle

doit être vérifiée et nettoyée. Voir nettoyage du

moteur sous maintenance.

La poussière qui se dégage pendant les travaux

est souvent nocive pour la santé (par ex. dans le

cas du chêne et du hêtre ou de couches de

peinture susceptibles de contenir du plomb ou

autres substances toxiques). Cette poussière ne

doit pas être inhalée. Utilisez un dispositif

d'aspiration et portez en supplément un masque

antipoussières approprié !

Eliminez soigneusement la poussière qui se

dépose, par ex. en l'aspirant à l'aide d'un

aspirateur approprié ! La poussière peut

provoquer des risques d'explosion.

Le meulage de matériaux produisant des

poussières ou des vapeurs nocives pour la santé

(p. ex. l'amiante) est formellement interdit.

Veillez à ce que les étincelles produites lors de

l’utilisation ne provoquent aucun risque, par ex.

celui d’atteindre l’utilisateur ou d’autres

personnes, ou d’incendie de substances

inflammables. Toute zone à risque doit être

protégée par des bâches difficilement

inflammables. Tenez un moyen d’extinction

adéquat à votre disposition pour travailler dans

une zone à risque d’incendie.

Utiliser toujours des pièces de rechange

répondant aux exigences minimales

suivantes.

Respecter le diamètre maximal

de meule (voir caractéristiques

techniques). Utiliser des

meules de type "max 80 m/s".

Le diamètre intérieur du disque

abrasif (3) doit s'ajuster sans

jeu sur le flasque d’appui (10).

Ne pas utiliser d'adaptateurs

ou de réducteurs.

La vitesse admissible n

max

doit correspondre au minimum

à la vitesse à vide de

l'outillage électrique (voir

caractéristiques techniques).

Utiliser au minimum des outils

de type "max 45 m/s".

Après chaque changement d'outil, procéder à un

essai de fonctionnement en tenant fermement la

meuleuse d'angle des deux mains.

max. 80 mm

3

10

17

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 17

Page 18

Tenir la meuleuse d'angle éloignée du corps.

Veiller à ce que personne ne se trouve dans la

zone de danger. Faire marcher la meuleuse

d'angle pendant environ 30 secondes.

Après sa mise hors circuit, la meuleuse d'angle

continue à fonctionner pendant encore environ

5 secondes.

Tenir compte des indications du fabricant de l'outil

ou de l'accessoire !

Protéger les meules contre la graisse et les

chocs !

Ne pas utiliser d'outils endommagés, présentant

un défaut de circularité ou générant des

vibrations.

Ne jamais utiliser des meules de tronçonnage

pour des travaux de meulage ! Les meules de

tronçonnage ne doivent en aucun cas être

soumises à une pression latérale. Utiliser

systématiquement le protecteur de sécurité (4)

lors des travaux de tronçonnage ou de

meulage !

Les outils doivent toujours être secs lors de leur

utilisation !

Ne pas toucher l'outil en mouvement, risque de

blessures !

Eviter de provoquer des dommages au niveau de

conduites de gaz ou d'eau, de câbles électriques

et de murs porteurs (pour des questions de

stabilité).

En cas d'utilisation de l'outillage électrique en

plein air, monter en amont un disjoncteur

différentiel avec un courant de déclenchement de

30 mA max !

Mise en service discontinue de la meuleuse

d´angle: Pour éviter tout redémarrage

intempestif : Déverrouiller systématiquement la

gâchette lorsque la fiche est débranchée du

secteur ou en cas de coupure de courant.

Utiliser des intercalaires élastiques s'ils sont mis à

disposition avec le matériau de ponçage et s'ils

sont nécessaires.

En cas d'utilisation de disques taraudés veillez à

ce que le filet dans le disque soit assez long pour

loger la longueur de la broche.

Bien fixer l'outil.

Veuillez faire en sorte que les orifices d'aération

soient dégagés en cas de travaux créant de la

poussière. Si l'enlèvement de la poussière devait

être nécessaire, débranchez en premier l'outil

électrique du réseau d'alimentation électrique

(utiliser des objets non métalliques) et évitez

d'endommager les pièces internes.

Les disques de meuleuse doivent être conservés

et manipulés soigneusement selon les indications

du fabricant.

S’il est inévitable de faire fonctionner l’outil

électrique dans des endroits humides, utilisez un

disjoncteur de fuite à la terre. Pour plus de

sécurité, portez des chaussures et des gants en

caoutchouc d’électricien.

Lors de l’utilisation d’accessoires, le capot doit

toujours être installé et positionné de sorte à

assurer une sécurité maximum, la surface de

meule exposée devant être la plus réduite

possible du côté de l’utilisateur.

Les meules (ou tout autre accessoire) doivent

avoir une vitesse de fonctionnement maximum

(garantissant une sécurité optimale) supérieure

au nombre de tours/minute hors charge indiqué

sur la plaque signalétique.

Utilisez toujours la poignée auxiliaire pour

contrer au maximum le couple de réaction ou

l’effet de recul. Manier la meuleuse sans

poignée peut entraîner une perte de contrôle et

des blessures graves.

Avant d’utiliser la meuleuse ou d’installer une

nouvelle meule, vérifiez l’absence de brèches

et de fissures sur la meule. Changez

immédiatement toute meule défectueuse.

Faites fonctionner l’outil hors charge pendant

une minute, en prenant garde à ce que l’outil

ne soit pas orienté vers les personnes se

trouvant à proximité. Les meules défectueuses

doivent normalement se partager au cours de

cette opération.

Manipulez l’outil et les meules avec

précaution pour éviter les brèches et les

fissures. Si vous faites chuter l’outil en cours

de fonctionnement, installez une nouvelle

meule. N’utilisez jamais de meule

endommagée. Les fragments produits par une

meule se désintégrant en cours de

fonctionnement sont projetés à très grande

vitesse et risquent de vous atteindre ou

d’atteindre les personnes se trouvant à proximité.

Attention ! Les poussières générées par les

travaux de meulage, sciage, affûtage, perçage et

autres travaux de construction contiennent des

substances chimiques pouvant provoquer des

cancers, des malformations à la naissance voire

une infertilité. Voici quelques exemples de ces

substances chimiques :

– le plomb (dans les peintures à base de plomb),

– la silice cristallisée (dans les briques, le ciment

et autres matériaux de maçonnerie),

– l’arsenic et le chrome (dans le bois de

charpente traité chimiquement).

Les risques encourus dépendent de la fréquence

à laquelle vous effectuez tel ou tel type de travail.

Pour réduire votre exposition à ces substances

chimiques, travaillez dans un endroit ventilé et

portez un équipement de sécurité homologué,

comme des masques anti-poussière

spécialement conçus pour filtrer les particules

microscopiques.

18

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 18

Page 19

Lire le mode d'emploi

Porter des lunettes de protection

En cas de déclenchement du débrayage de

sécurité, mettre immédiatement la meuleuse

d'angle hors circuit et remédier au dysfonctionnement.

Ne pas utiliser de lames "à sculpter" avec cet

outil. L'utilisation de lames "à sculpter" peut

générer un effet de recul se traduisant par une

perte de contrôle et pouvant ainsi être à l'origine

de blessures graves.

Une poignée avant endommagée ou craquelée

doit être remplacée. N'utilisez pas la machine si la

poignée avant est défectueuse.

Symboles sur l'outil:

Construction de classe II

V volts

A ampères

Hz hertz

.../min révolutions par minute

~ courant alternatif

n0 vitesse à vide

Les mentions "C" et "US" ajoutées au

label CSA signifient qu'il s'agit d'un

produit conforme aux normes CSA et

ANSI/UL, applicables pour un emploi

du produit respectivement au Canada

et aux Etats-Unis.

4 Vue d'ensemble

Voir page 3 (déplier le document).

1* Curseur de commutation (verrouillable)

2 Bouton de blocage de l'arbre portemeule

3* Meule

4 Protecteur de sécurité

5* Poignée avant / poignée avant avec

amortisseur de vibrations

6* Signaux électroniques lumineux

(uniquement VTC, TC)

7* Molette de réglage de la vitesse (VC, VTC)

8 Dispositif de blocage de la gâchette

9 Gâchette

10* Flasque d'appui

11* Ecrou de serrage Quick

ou

12* Ecrou de serrage avec

13* Clé à ergots

14* Flasque d’appui

(pour les meules de type 27, diamètre 6")

*selon l'équipement

5 Caractéristiques

spécifiques du produit

Débrayage de sécurité Metabo S-automatic

Si l'outil interchangeable reste

coincé ou accroché, la

transmission de la force vers le

moteur est limitée. Comme

dans ce cas, on rencontre des

forces élevées, il faut

systématiquement saisir la

machine des deux mains aux

poignées prévues à cet effet, veiller à bien se

camper sur ses jambes et à se concentrer sur

son travail.

Moteur Marathon

Le moteur Marathon, protégé

contre la poussière, garantit

une longévité jusqu'à 50 %

plus élevée grâce à la grille

Metabo de protection du

bobinage et aux bobines

inductrices époxydées.

Protecteur de sécurité

Le réglage sans outils du protecteur de sécurité

permet une adaptation ultrarapide aux différentes

applications.

Balais autorupteurs

Lorsque les balais autorupteurs sont usés,

l'outillage s'arrête automatiquement, ce qui évite

les risques d'endommagement du collecteur.

Poignée avant supplémentaire avec

amortisseur de vibrations (suivant version) :

Assure le confort pour travaux en continu.

Système électronique VC/VTC/TC

(selon l'équipement)

Le système électronique permet un meulage

adapté au type de matériau (VC/VTC) et une

vitesse pratiquement constante, même en charge

(VC/VTC/TC).

Le système électronique Vario-TachoConstamatic VTC / Tacho-Constamatic TC

dispose en outre d'une limitation du courant de

démarrage, d'un démarrage électronique

progressif, d'une surveillance de la température

du bobinage ainsi que d'une protection

électronique de redémarrage.

Pour connaître l'équipement de votre outillage

électrique, reportez-vous aux caractéristiques

techniques.

19

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 19

Page 20

6 Mise en service

Avant la mise en service, s'assurer que

la tension secteur et la fréquence

indiquées sur la plaquette signalétique

correspondent à celles du courant que

vous utilisez.

Montage de la poignée

Pour des raisons de sécurité, il est

impératif de toujours monter la poignée

(5) du côté droit ou du côté gauche de

la meuleuse d'angle avant de

commencer à travailler.

Montage du protecteur de sécurité

(pour les travaux avec des meules)

Utiliser le protecteur correspondant au

type de meule utilisé. Voir les sections

12.4 et 12.5 pour les protecteurs

circulaires et les protecteurs à découpe.

Retirer l'écrou de serrage (12) ou l'écrou de

serrage Quick (11) et le flasque d'appui (10) de

l'arbre porte-meule.

Lors de la mise en place du protecteur de

sécurité (4) sur la meuleuse d'angle, veiller à ce

que l'encoche sur le protecteur coïncide avec le

repère sur la meuleuse d'angle.

Tourner le protecteur de sécurité de

sorte que la partie fermée soit tournée

vers l'utilisateur !

Brancher la fiche secteur.

Dans le cas du système électronique VTC, TC

(selon l'équipement) :

Le signal électronique lumineux rouge (6)

s'allume brièvement lorsque l'on branche la fiche

secteur dans la prise de courant, indiquant ainsi

que la machine est prête à fonctionner.

7 Mise en marche et arrêt

Toujours tenir la machine par les deux

mains en travaillant !

Toujours mettre sous tension avant de

positionner la machine sur la pièce !

Veiller à éviter que la machine aspire

des poussières et copeaux

supplémentaires. Lors de la mise en

route et de l’arrêt de la machine, la tenir

loin des dépôts de poussière.

Après l’avoir arrêtée, ne poser la

machine qu’une fois que le moteur a

cessé de tourner.

Dans le cas du système électronique VTC,TC :

le signal électronique lumineux rouge (6) s'allume

brièvement lors de la mise en marche.

Machines avec curseur de commutation (1) :

(Machines portant la désignation W... ou WE...)

Mise en marche : pousser le curseur de

commutation (1) vers l'avant jusqu'à ce qu'il

s'enclenche.

Arrêt : appuyer sur l'extrémité arrière du curseur

de commutation.

Outils munis d'une sécurité de transport

(Dispositif de sécurité, la machine ne pouvant

pas être bloquée) :

(Machines portant la désignation WEP…)

Ne pas utiliser pas la gâchette (9) pour

porter ou suspendre l'outil.

Mise en marche : Faire coulisser le dispositif de

blocage de la gâchette (8) dans le sens de la

flèche et enfoncer la gâchette (9).

Arrêt : Relâcher la gâchette (9).

Machines avec gâchette (9) :

(Machines portant la désignation WP... ou WPS...)

9 8

1

0

I

20

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 20

Page 21

Mise en marche : Faire coulisser le dispositif de

blocage de la gâchette (8) dans le sens de la

flèche et enfoncer la gâchette (9).

Arrêt : Relâcher la gâchette (9).

Blocage en position de marche:

(Machines portant la désignation WP...)

Mettre en marche la meuleuse d'angle et faire

coulisser le dispositif de blocage de la gâchette

(8) vers l'avant jusqu'à ce qu'il s'enclenche.

Désactivation du blocage en position de

marche : Enfoncer brièvement la gâchette (9) et

la relâcher.

Protection de remise en marche (uniquement

en cas de système électronique VTC/TC) :

La meuleuse d’angle ne démarre pas lorsque l’on

branche la fiche dans la prise de courant et que la

machine est sur la position "Marche" ou lors du

rétablissement de la tension après une coupure

de courant. Le signal électronique lumineux rouge

(6) clignote. Arrêter et redémarrer la meuleuse

d'angle.

8 Réglage de la vitesse

(selon l'équipement)

Régler la vitesse recommandée à l'aide de la

molette de réglage (7).

Meules de tronçonnage, meules d'ébarbage,

meules boisseau, disques à jante diamantée :

vitesse élevée

Brosses : vitesse moyenne

Plateaux de ponçage : vitesse faible à moyenne

Lors des travaux à faible vitesse, n'exercer qu'une

légère pression sur l'outillage électrique.

9 Montage des outils

Avant chaque opération de

transformation, débrancher la fiche de

la prise et s’assurer que la meuleuse

d’angle est hors circuit.

Blocage de l'arbre porte-meule

Enfoncer le bouton de blocage de l'arbre portemeule (2) jusqu'à ce que le bouton s'enclenche

de manière perceptible.

9.1 Mise en place des meules de

tronçonnage et d'ébarbage

Localisez le flasque d’appui (10) pour les meules

de tronçonnage de type 1, (10) les meules de

type 27 de diamètre 5" ou moins, ou (14) pour les

meules de type 27 de diamètre 6", comme

illustré, en vous assurant que le flasque d’appui

ne peut pas tourner sur la broche.

Poser, comme indiqué sur la figure, la meule de

tronçonnage ou la meule d’ébarbage sur le

flasque d’appui. Veiller à ce que la meule repose

de manière uniforme sur le flasque d’appui. Lors

du tronçonnage, le flasque de tôle de la meule de

tronçonnage doit être appliqué sur le flasque

d’appui.

9.2 Fixation/Desserrage de l’écrou de

serrage Quick (11) : à utiliser avec la

meule boisseau de type 27 uniquement

Serrage

11

10

10

14

21

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 21

Page 22

Pour les outils dont l'épaisseur est

supérieure à 8 mm dans la zone de

serrage, il convient d'utiliser l'écrou de

serrage (12) avec la clé à ergots (13) à la

place de l'écrou de serrage rapide

Quick (11).

Mettre en place l'écrou de serrage Quick (11)

dans les rainures de l'arbre, comme indiqué sur la

figure. Bloquer l'arbre. Serrer à la main l'écrou de

serrage Quick (11) en le tournant dans le sens

inverse des aiguilles d'une montre. Bloquer

l'écrou de serrage Quick en tournant fortement la

meule dans le sens des aiguilles d'une montre.

Desserrage

Après l'arrêt de la meuleuse, la meule continue à

tourner pendant environ 5 secondes. Juste avant

l'arrêt de l'outil de meulage, enfoncer le bouton de

blocage de l'arbre porte-meule (2) - l'écrou de

serrage Quick se débloque.

L'arrêt de la broche au moyen du

bouton de blocage de l'arbre portemeule (2) n'est autorisé qu'en cas

d'utilisation de l'écrou de serrage

Quick !

Dévisser l'écrou de serrage Quick.

9.3 Fixation/Desserrage de l’écrou de

serrage Quick (12) : à utiliser avec la

meule de tronçonnage de type 1

OU la meule boisseau de type 27

uniquement

Fixation

Pour les meules de moins de 3/16", tournez

l’écrou de serrage (12) sur la broche avec le bord

relevé opposé à la meule de manière à pouvoir

serrer la meule en toute sécurité. Serrez à fond à

l’aide d’une clé à fourche (13).

Pour les meules de 3/16" et plus, tournez l’écrou

de serrage (12) sur la broche avec le bord relevé

orienté vers la meule de sorte que le bord pénètre

dans l’ID de la meule. Serrez à fond à l’aide d’une

clé à fourche (13).

Bloquer l'arbre porte-meule. Mettre en place la clé

à ergots (13) sur l'écrou de serrage (12) et le

serrer à fond dans le sens des aiguilles d'une

montre.

Desserrage

Bloquer l'arbre porte-meule. Débloquer l'écrou de

serrage à l'aide de la clé à ergots (13) et le

dévisser.

10 Maintenance

Avant tout travail de maintenance : débrancher la

fiche de la prise de courant !

Nettoyage du moteur : nettoyer la machine

régulièrement, fréquemment et soigneusement,

en soufflant de l’air comprimé à travers les fentes

d’aération à l’arrière. Veiller à bien maintenir la

machine pendant ce temps.

Le remplacement des balais ne peut être effectué

que par l’usine de production ou par un atelier

spécialisé. Faire effectuer les inspections et les

opérations de maintenance par le service aprèsvente Metabo.

11 Dépannage

Avec système électronique VTC,TC :

Le signal électronique lumineux (6) s'allume et

la vitesse en charge diminue.

Température trop élevée du bobinage. Faire

tourner à vide la meuleuse jusqu'à ce que le

signal électronique lumineux s'éteigne.

12 Accessoires

Utilisez exclusivement des accessoires Metabo

d'origine.

12

13

12

12

12

14

22

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 22

Page 23

Pour vous procurer les accessoires voulus,

veuillez vous adresser à votre revendeur.

Afin de pouvoir choisir les accessoires

parfaitement adaptés, veuillez indiquer le type

exact de votre appareillage électrique à votre

revendeur.

Voir page 4 :

a Protecteur de sécurité avec semelle

d'appui pour le tronçonnage de la pierre

b Protège-main

c Lunette protectrice

d Protecteur de sécurité pour meules

boisseau

e Meule boisseau pour le lissage de surfaces

f Brosses métalliques à fils d'acier

g Plateau abrasif à lamelles

h Meules de tronçonnage et d'ébarbage

i Plateau souple à poncer

j Plateau à poncer à agrippage velcro

k Disques abrasifs

l Disque à jante diamantée

m Rallonge pour le travail avec des plateaux à

poncer

n Clé à ergots (coudée)

o protecteur à découpe

12.1 Déposer le protecteur de sécurité

12.2 Mise en place du protège-main

(pour les travaux avec des plateaux à

poncer et des disques abrasifs ou brosses)

Le cas échéant, déposer l'outil, le protecteur de

sécurité et la poignée.

Engager le protège-main (b) sur la partie filetée

au niveau de la poignée (5). Orienter le protègemain et le monter sur la meuleuse d'angle avec la

poignée.

12.3 Mise en place du plateau à poncer et

du disque abrasif

Utiliser exclusivement l'écrou de serrage

fourni avec le plateau à poncer !

Poser le plateau à poncer (i) sur l'arbre portemeule, comme indiqué sur la figure. Visser le

disque abrasif (k) à l'aide de l'écrou de serrage

fourni. Bloquer l'arbre porte-meule. Bloquer à la

main le disque abrasif avec le plateau à poncer

en le tournant dans le sens des aiguilles d'une

montre.

Desserrage à la main ou, le cas échéant, à l'aide

de la clé à ergots (13).

12.4 Mise en place de la brosse métallique

à fils d'acier

Monter le protège-main.

Déposer le protecteur de sécurité (4). Bloquer

l'arbre porte-meule. Visser la brosse métallique à

fils d'acier (f) et la serrer à fond à l'aide d'une clé

plate de 22 mm (7/8").

b

1

2

3

23

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 23

Page 24

12.5 Mise en place de la meule boisseau

droite et du protecteur de sécurité

Déposer le protecteur de sécurité (4). Dans le

sens de la flèche, emmancher le protecteur pour

meule boisseau (d) jusqu'en butée sur la

meuleuse d'angle. Bloquer la vis à l'aide d'un

tournevis.

Poser le flasque d'appui (10) sur la broche. Veiller

à ce que le flasque d'appui ne puisse pas se

tordre sur la broche. Poser la meule boisseau sur

le flasque d'appui.

Visser l'écrou de serrage (12) ou l'écrou de serrage

Quick (11) sur l'arbre porte-meule. Bloquer l'arbre.

Serrer la meule boisseau à l'aide de l'écrou de

serrage (12) ou de l'écrou de serrage Quick (11).

Dans le cas de l'écrou de serrage (12), utiliser la

clé coudée à ergots (n).

Selon les besoins, régler la longueur de la partie

de la meule boisseau dépassant du protecteur de

sécurité (environ 0,5-1 cm). A cet effet, dévisser

les deux vis à ailettes et faire coulisser de

manière régulière le protecteur de sécurité vers le

haut ou vers le bas. Revisser les vis à ailettes.

12.6 Fixation du protecteur à découpe

Retirez le protecteur (4). Posez le protecteur à

découpe (o) en alignant les 3 tenons de retenue

relevés sur le protecteur avec les encoches du

flasque. Enfoncez complètement le protecteur,

puis tournez le protecteur et positionnez-le entre

l’opérateur et la meule. Serrez l’écrou de

serrage pour fixer le protecteur en position.

13 Réparations

Les réparations des outillages

électriques doivent uniquement être

réalisées par des électriciens qualifiés !

Les outillages électriques Metabo à réparer

peuvent être envoyés à l'une des adresses

indiquées à l'avant-dernière page.

Lors de l'envoi à la réparation, veuillez indiquer le

défaut constaté.

14 Protection de

l'environnement

Les emballages Metabo sont recyclables à 100 %.

Les outillages électriques et les accessoires

usagés contiennent d'importantes quantités de

matières premières et de plastiques qui peuvent

également être recyclées.

Etant donné que la poussière de meulage

produite peut contenir des substances polluantes,

il convient donc de ne pas la jeter dans une

poubelle normale, mais de la mettre en décharge

dans un site de collecte de déchets spéciaux.

Le présent mode d'emploi est imprimé sur du

papier blanchi sans chlore.

o

10

24

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 24

Page 25

15 Caractéristiques techniques

Explications des indications de la page 2.

Sous réserve de modifications techniques.

D

max

= Diamètre maximal de meule

n = Vitesse à vide

M = Filetage de la broche

P

1

= Puissance nominale absorbée

P

2

= Puissance utile

I

120V

= Courant sous 120 V

a

hw

= Accélération typique pondérée au

niveau de la main et du bras

Niveau acoustique A standardisé :

L

pA

= Niveau de pression acoustique

L

WA

= Niveau de puissance acoustique

Porter une protection acoustique !

m = Poids

Valeurs de mesure calculées selon EN 50144.

Les caractéristiques indiquées sont soumises à

tolérance (selon les normes en vigueur

correspondantes).

25

FRANÇAIS

03_FR_Nafta_7970_0207 18.12.2007 14:50 Uhr Seite 25

Page 26

Indice

1 Aplicación de acuerdo a la finalidad

2 Normas generales de seguridad

3 Instrucciones especiales de seguridad

4 Vista de conjunto

5 Características especiales del producto

6 Puesta en marcha

7 Conexión y desconexión

8 Ajustar el número de revoluciones

(dependiendo del equipamiento)

9 Colocación de las herramientas

9.1 Colocar los discos de tronzar y

de desbaste

9.2 Apretar / aflojar la tuerca de sujeción

rápida (11): sólo para muelas abrasivas

del tipo 27

9.3 Apretar / aflojar la tuerca de sujeción

(12): para muelas de corte del tipo 1

O muelas abrasivas del tipo 27

10 Mantenimiento

11 Eliminación de anomalías

12 Accesorios

12.1 Desmontar la caperuza protectora

12.2 Colocar la protección para las manos

12.3 Colocar el plato de apoyo y la hoja

de lijar

12.4 Colocar el cepillo de alambre

12.5 Colocar la muela de cazoleta con

caperuza de protección

12.6 Colocar la caperuza de protección de la

muela de corte

13 Reparación

14 Protección ecológica

15 Especificaciones técnicas

1 Aplicación de acuerdo

a la finalidad

Las amoladoras angulares combinadas con los

accesorios originales son aptas para tronzar, lijar

con plato de apoyo y cepillar metal, hormigón,

piedra y otros materiales similares sin aplicar

agua.

No deben utilizarse en ningún caso ni hojas ni

cadenas de sierra o herramientas similares.

El usuario será responsable exclusivo de daños

causados por una utilización en

desacuerdo con la finalidad descrita del presente

aparato. Se debe prestar estricta atención a las

prescripciones generalmente reconocidas para la

prevención de accidentes laborales y a las

instrucciones de seguridad adjuntas.

2 Normas generales de

seguridad

1 ADVERTENCIA! Asegúrese de leer y

comprender todas las instrucciones.

De no seguir todas las instrucciones indicadas a

continuación se corre el riesgo de sufrir una

descarga eléctrica, fuego y/o lesión personal

grave.

GUARDE ESTAS INSTRUCCIONES.

2 Zona de trabajo

2.1 Mantenga su zona de trabajo limpia y bien

iluminada.Los bancos desordenados y los sitios

oscuros pueden ocasionar accidentes.

2.2 No ponga en marcha herramientas

eléctricas en ambientes propensos a

explosiones, como ante la presencia de

líquidos inflamables,de gases o de polvo.

Las herramientas eléctricas generan chispas que

pueden inflamar el polvo o los gases.

2.3 Mantenga alejados a personas

circundantes, niños y visitantes cuando

ponga una herramienta eléctrica en marcha.

Las distracciones le pueden hacer perder el

control.

3 Seguridad eléctrica

3.1 Las herramientas con puesta a tierra

deben ser conectadas a un tomacorriente

instalado correctamente y puesto a tierra

conforme a la legislación vigente. Nunca retire

el terminal de puesta a tierra ni modifique la

clavija bajo ninguna circunstancia. No use

ningún tipo de adaptador de enchufe.

Consulte a un electricista profesional si no

Instrucciones de manejo

Muy estimado Señor Cliente:

Le agradecemos la confianza puesta en nosotros al adquirir su herramienta eléctrica Metabo. Toda

herramienta eléctrica Metabo es comprobada minuciosamente siendo sometida a un estricto control de

calidad por la sección de aseguramiento de calidad de Metabo. No obstante, la vida útil de una