Page 1

de Originalbetriebsanleitung 4

en Original instructions 9

fr Notice originale 13

nl Oorspronkelijke gebruiksaanwijzing 18

it Istruzioni originali 23

es Manual original 28

pt Manual original 33

sv Bruksanvisning i original 38

fi Alkuperäiset ohjeet 42

no Original bruksanvisning 46

da Original brugsanvisning 50

pl Instrukcja oryginalna 54

el Πρωτότυπες οδηγίες χρήσης 59

hu Eredeti használati utasítás 64

ru Оригинальное руководство по

эксплуатации 69

RBE 15-180

Page 2

2

1

2

3

4

5

8

7

6

Page 3

3

RBE 15-180

B

B

mm (in)

40 (1

9

/16)

B

L

mm (in)

760 (29

15

/16)

D

max

mm (in)

180 (7

3

/32)

U ° 270

v

0

m/s 8,4 - 28

P

1

W 1550

P

2

W 940

m kg (lbs) 3,4 (7.5)

a

h/Kh

m/s

2

< 2,5/ 1,5

L

pA/KpA

dB(A) 94 / 3

L

WA/KWA

dB(A) 105 / 3

13.

*1) Serial-Number: 02243...

*2) 2014/30/EU, 2006/42/EC, 2011/65/EU

*3) EN 60745-1:2009+A11:2010, EN 60745-2-4:2009+A11:2011

2016-02-10, Volker Siegle

Direktor Produktentstehung & Qualität (Vice President Product Engineering & Quality)

*4) Metabowerke GmbH - Metabo-Allee 1 - 72622 Nuertingen, Germany

Page 4

ENGLISH en

9

Original instructions

We declare under our sole responsibility: These

tube belt sanders, identified by type and serial

number *1), comply with all relevant requirements of

the directives *2) and standards *3). Technical file

at *4) - see page 3.

The wraparound tube sander is for glazing,

tarnishing, texturing, polishing and smoothing pipes

without the use of water.

The user bears sole responsibility for any damage

caused by improper use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

For your own protection and for the

protection of your electrical tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Reading the operating instructions will reduce the risk of injury.

Pass on your electrical tool only together with these

documents.

General Power Tool Safety Warnings

WARNING – Read all safety warnings and

all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference! The term "power tool" in the warnings

refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

3.1 Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

3.2 Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication.

A moment of inattention while

opera

ting power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

3.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the rate

for which it was designed.

1. Declaration of Conformity

2. Specified Use

3. General Safety Instructions

Page 5

ENGLISHen

10

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool's operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

3.5 Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

Hold the power tool by the insulated gripping

surfaces because the abrasive belt may

contact its own cord. Damage to a "live" wire may

energise metal parts of the power tool and cause an

electric shock.

Flying sparks are created when sanding metal.

Ensure that no persons are in danger. Due to the

risk of fire, all combustible materials must be

removed from the work area (area affected by flying

sparks).

During machining, of metals in

particular, conductive dust can form

deposits inside the machine. This can lead to the

transfer of electrical energy onto the machine

housing. This can mean a temporary danger of

electric shocks. This is why it is necessary when the

machine is running to blow compressed air through

the rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine must

be held firmly.

We recommend using a stationary extractor system

and connecting a residual current circuit-breaker

(FI) upstream. When the machine is shut down via

the FI circuit-breaker, it must be checked and

cleaned. See chapter 8. Cleaning for more

information on cleaning the motor.

Wear ear protectors. Exposure to noise can cause

hearing loss.

Wear protective gloves.

WARNING – Always wear protective

goggles.

Secure the workpiece against slipping, e.g. with the

help of clamping devices.

Always guide the

machine with both hands on the

handles provided. Loss of control can cause

personal injury.

Never place your hand near rotating parts of the

device or near the rotating sanding belt.

Remove sanding dust and similar material only

when the machine is not in operation.

Pull the plug out of the plug socket before any

adjustments, conversions or servicing are

performed.

The rated speed of the sanding belt must be at least

equal to the belt speed in idling marked on the

power tool. A sanding belt running faster than its

rated speed can break and fly apart.

Check prior to each use that the sanding belt is

correctly attached and is completely on the rollers.

Carry out a trial run: Allow the machine to run at

idling speed for 30 seconds in a safe location. Stop

immediately if significant vibrations occur or if other

defects are noted. If such a situation occurs, check

the machine to determine the cause.

Reduce dust exposure:

Particles generated when working with this

machine may contain substances that can

cause cancer, allergic reactions, respiratory

diseases, birth defects or other propagation

defects. Some of these substances include: Lead

(in paint containing lead), mineral dust (from bricks,

concrete etc.), additives used for wood treatment

(chromate, wood preservatives), some wood types

(such as oak or beech dust), metals, asbestos.

The risk depends on for how long the user or nearby

persons are exposed to the substance.

This dust must not be allowed to enter your body.

Do the following to reduce exposure to these

substances: Ensure good ventilation of the

workplace and wear appropriate protective

equipment, such as respirators able to filter

microscopically small particles.

Observe the relevant guidelines for your material,

staff, application and place of application (e.g.

occupational health and safety regulations,

disposal).

Collect the generated particles at the source, avoid

deposits in the surrounding area.

Use suitable accessories for special work (see

chapter 10.), thus less particles enter the

environment in an uncontrolled manner.

Use a suitable extraction unit.

4. Special Safety Instructions

Page 6

ENGLISH en

11

Reduce dust exposure with the following measures:

- Do not direct the escaping particles and the

exhaust air stream at yourself or nearby persons

or on dust deposits.

- Use an extraction unit and/or air purifiers

- Ensure good ventilation of the workplace and

keep clean using a vacuum cleaner Sweeping or

blowing stirs up dust

- Vacuum or wash the protective clothing Do not

blow, beat or brush

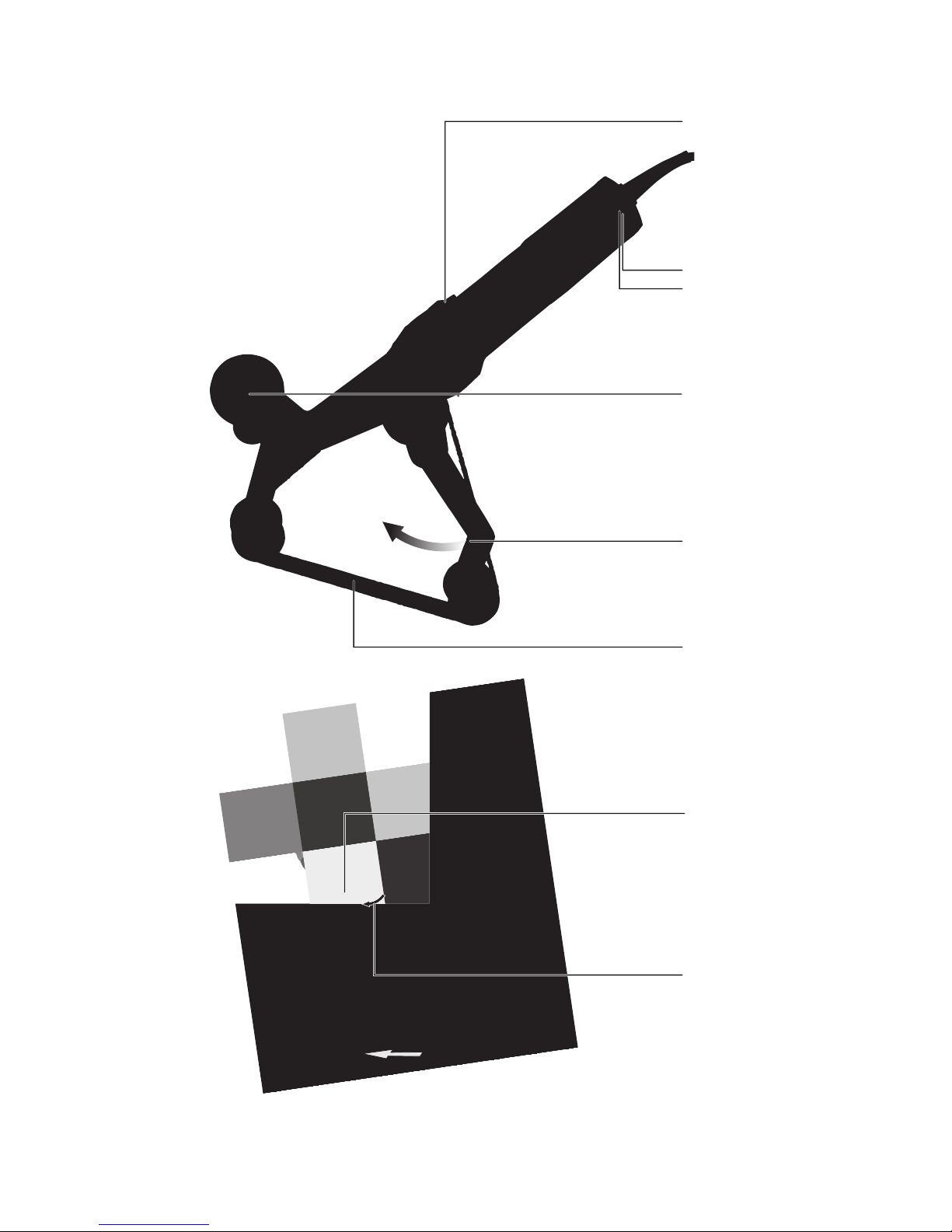

See page 2

1 Sliding switch

2

Adjusting wheel for

setting belt speed

3 Electronic signal indicator

4 Additional handle

5 Tensioner arm for replacing the sanding belt

6Sanding belt

7 Press in the spindle locking button only when

the spindle is stationary

8 Arrow (direction of rotation of

drive shaft

)

Before plugging in, check that the rated mains

voltage and mains frequency, as stated on the

rating label, match with your power supply.

Always install an RCD with a max. trip current

of 30 mA upstream.

Attaching the additional handle

Always work with the additional handle

attached (4)! Secure the additional handle by

screwing it tightly to the left or right.

7.1 On/Off switch, continuous activation

Always guide the machine with both hands.

The machine must not be allowed to draw in

additional dust and shavings. When switching

the machine on and off, keep it away from dust

deposits.

After switching off the machine, only place it

down when the motor has come to a standstill.

In continuous operation, the machine

continues running if it is forced out of your

hands. Therefore, always hold the machine using

the handles provided, stand in a safe position and

concentrate.

Switching on/

Continuous activation

: Push sliding

switch (1) forward. For continuous

activation, now tilt downwards until it

engages.

Switching off: Press the rear end of the slide

switch (1) and release.

7.2 Setting belt speed

The belt speed can be preset via the setting wheel

(2)and is infinitely variable.

Positions 1-6 correspond approximately to the

following belt speeds:

1 ........ 8,4 m/s 4 ....... 20,6 m/s

2 ........ 12,5 m/s 5 ....... 24,6 m/s

3 ........ 16,5 m/s 6 ....... 28,8 m/s

7.3 Sanding belt replacement

See illustration on page 3.

- Release the tensioner arm (5) and remove the

sanding belt (6).

- Place the new sanding belt on the rollers such that

its direction of circulation (arrows on the inside of

the sanding belt) matches the arrow (8) on the

gearbox.

- Release the tensioner arm (5).

- Ensure that the sanding belt is completely on the

rollers.

7.4 Sanding procedure

Place the machine on the material such that the

sanding belt is parallel to the surface of the

workpiece.

When working, please ensure that the machine is

operated at right angles to the pipe so that the belt

does not fall off the rollers.

Using the additional handle, the belt can be pressed

against the pipe and at same time placed around it.

The angle of contact and the cutting output may be

changed by the contact pressure.

Keep the machine in constant motion because

otherwise recesses could be produced in the

material.

Motor cleaning: blow compressed air through the

rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine must

be held firmly.

The electronic signal display (3) lights up

and the load speed decreases. There is too

much load on the machine! Run the machine

in idling until the electronics signal indicator

switches off.

The machine does not start. The

electronic signal display (3) flashes. The

restart protection is active. If the mains plug is

inserted with the machine switched on, or if the

power supply is restored following an interruption,

the machine does not start up. Switch the machine

off and on again.

5. Overview

6. Initial Operation

7. Use

0

I

1

8. Cleaning, Maintenance

9. Troubleshooting

Page 7

ENGLISHen

12

Use only genuine Metabo accessories.

If you need any accessories, check with your

dealer.

The dealer needs to know the exact model of your

power tool in order to select the correct accessory.

For a complete range of accessories, see

www.metabo.com or the main catalogue.

Repairs to electrical tools must be carried out

by qualified electricians ONLY!

If you have Metabo electrical tools that require

repairs, please contact your Metabo service centre.

For addresses see www.metabo.com.

You can download spare parts lists from

www.metabo.com.

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

Only for EU countries: Never dispose of

power tools in your household waste! In

accordance with European Directive 2002/

96/EC on used electronic and electric equipment

and its implementation in national legal systems,

used power tools must be collected separately and

handed in for environmentally compatible recycling.

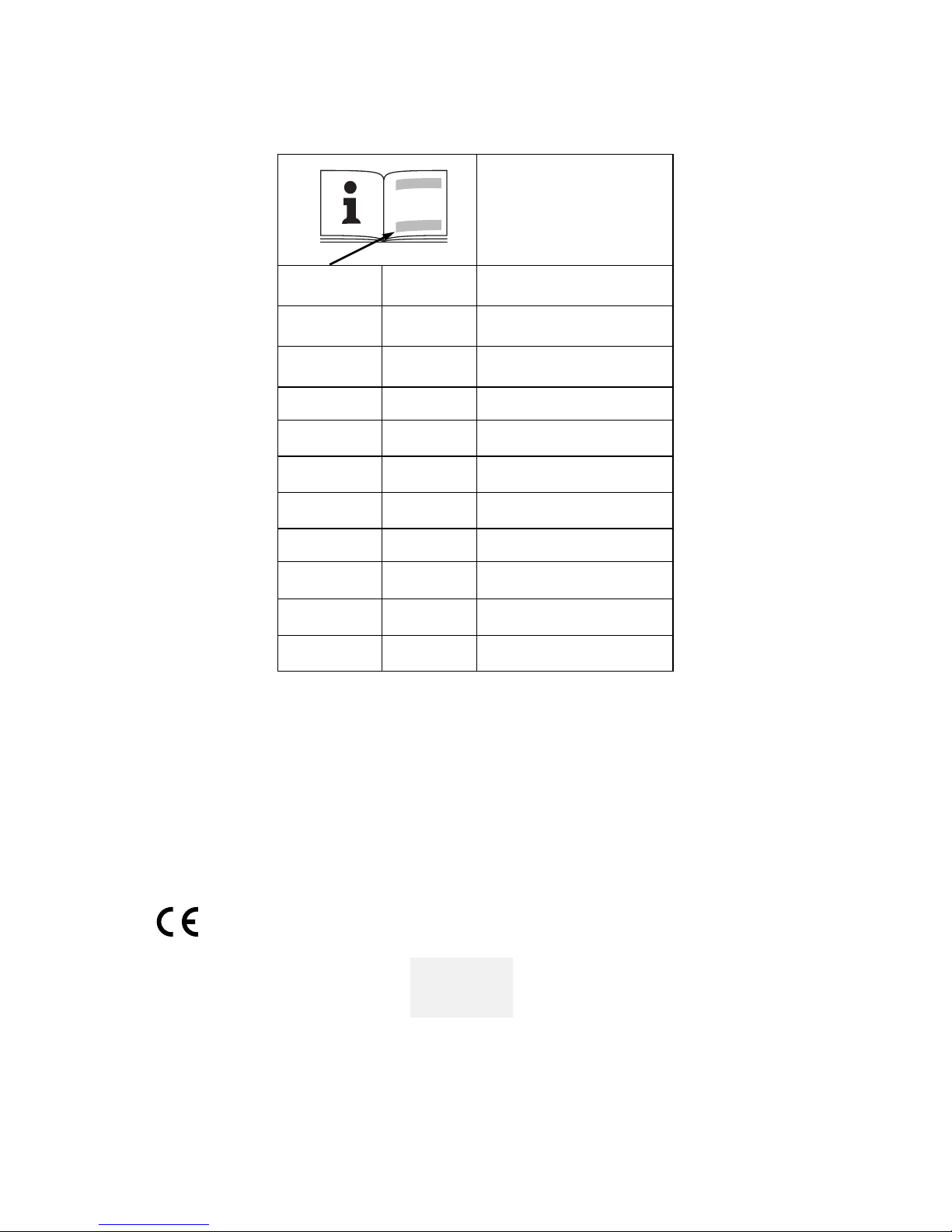

Explanatory notes on the specifications on page 3.

Changes due to technological progress reserved.

B

B

=Sanding belt width

B

L

=Sanding belt length

D

max.

=max. pipe diameter

U =max. angle of contact

v

0

* =Belt speed in idling

P

1

=Nominal power input

P

2

=Power output

m =Weight without mains cable

Measured values determined in conformity with

EN 60745.

Machine in protection class II

~ Alternating current

* Energy-rich, high-frequency interference can

cause fluctuations in speed. The fluctuations

disappear, however, as soon as the interference

fades away.

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

Emission values

These values make it possible to assess the

emissions from the power tool and to compare

different power tools. Depending on the operating

conditions, the condition of the power tool or the

accessories, the actual load may be higher or lower.

For assessment purposes, please allow for breaks

and periods when the load is lower. Based on the

adjusted estimates, arrange protective measures

for the user e.g. organisational measures.

Vibration total value

(vector sum of three directions)

determined in accordance with EN 60745:

a

h

=Vibration emission value

(sanding surfaces)

K

h

= Uncertainty (vibration)

Typical A-effective perceived sound levels

:

L

pA

=Sound pressure level

L

WA

=Acoustic power level

KpA, KWA= Uncertainty

During operation the noise level can exceed

80 dB(A).

Wear ear protectors!

10. Accessories

11. Repairs

12. Environmental Protection

13. Technical Specifications

Page 8

Loading...

Loading...