Page 1

G

F

N

J

S

Operating Instruction

Welding machine

Instructions d'utilisation

L’appareil de soudage sous

gaz protecteur

Bruksanvisning

Dekkgass-sveiseapparatet

Käyttökäsikirja

Parhaat onnittelumme tämän

korkealaatuisen

Bruksanvisning

skyddsgassvets

MIG/MAG 140

MIG/MAG 160

115 164 4534 GB/F/N/SF/S 2508 2.1

Page 2

G

F

N

J

S

Great Britain 1.

France 2.

Norge 3.

Suomi/ Finland 4.

Sverige 5.

Retain proof of purchase! You are only entitled to claim warranty against

proof of purchase.

Conservez le reçu d'achat! La garantie ne peut être accordée que sur

présentation de ce reçu.

Oppbevar kvitteringen!

Garantiytelser skjer kun på grunnlag av forelagt kvittering.

Säilytä ostokuitti!

Takuu on voimassa vain kuittia vastaan.

Förvara kvittot!

Garantianspråk erkännes endast mot uppvisande av kvitto.

Page 3

XS00028E.fm

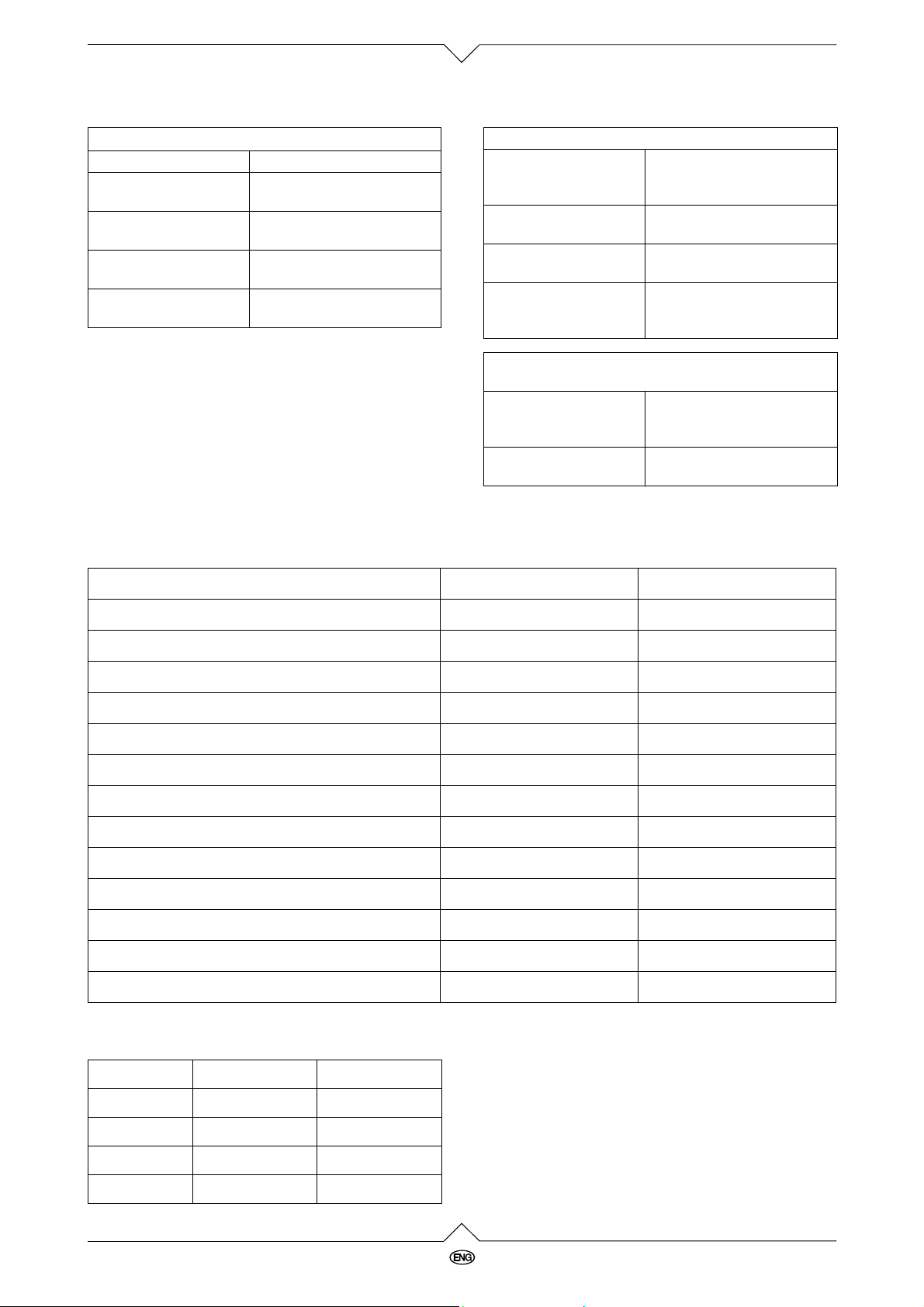

1Great Britain

Operation elements

1

2

3

4

5

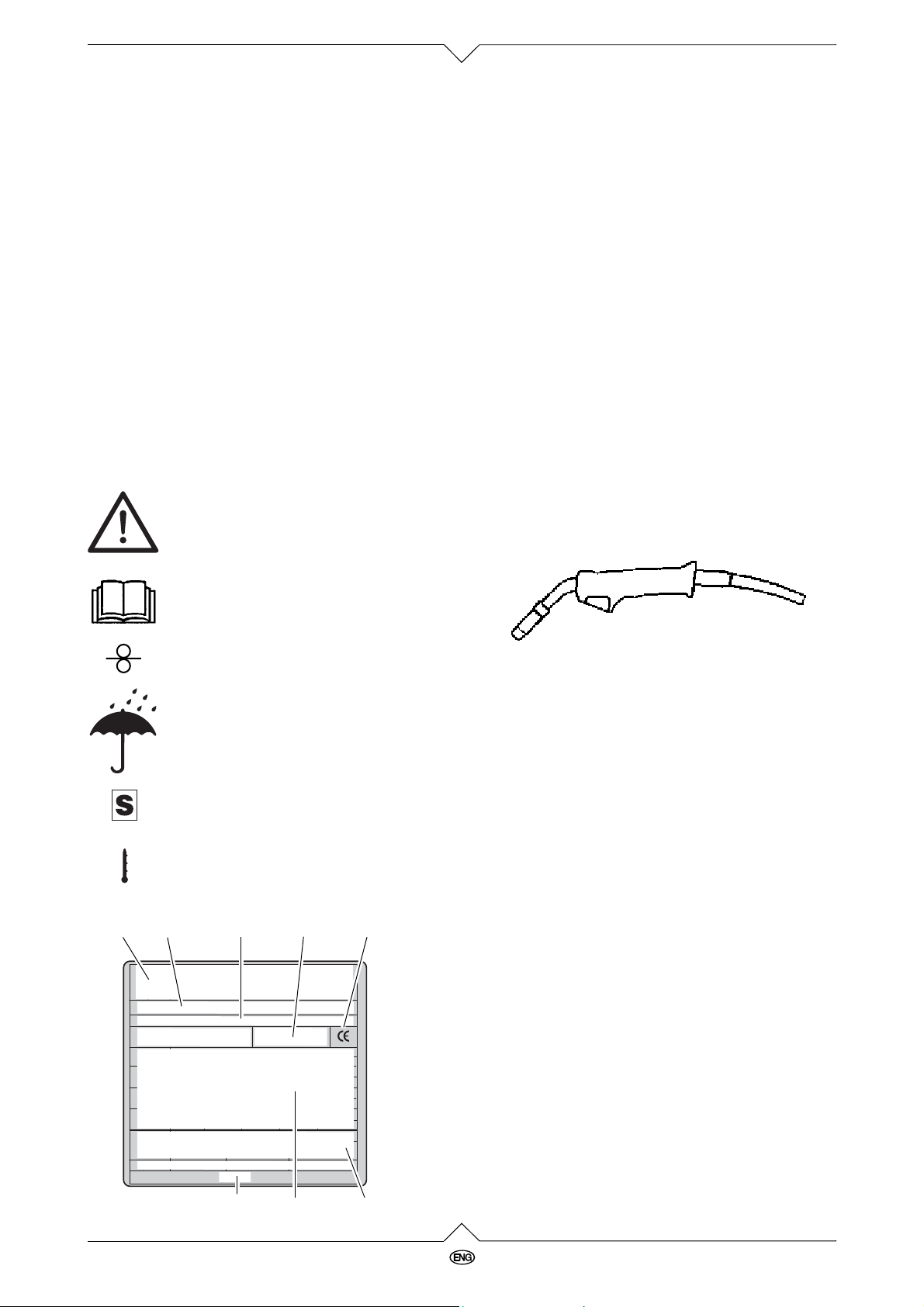

1 Connection for torch (+) pole

2 Switch on/off and welding currant

3 Wire feed regulator

4 Overload control light

5 Connection for earth clamp (–) pole

Dear customer,

Congratulations to your purchase of this high-quality

MIG/MAG welding machine.

To ensure your personal safety and for reasons of

appliance safety we ask you to read the instructions

completely before operating this machine and to

observe all points.

Basic Information for the Operator

The MIG/MAG welding machine is a DC welding

power source with integrated wire feed, designed

and manufactured exclusively for MIG and MAG

electric arc welding.

Any other use of this machine involves dangers and

is not permitted.

The welding machine must only be operated on the

mains voltage stated on the machine's rating plate.

Connection to the supply circuit must be made via

an earthed outlet, installed by a qualified electrician.

The supply circuit must be protected by a fuse or

miniature circuit breaker.

Depending on the mains connection conditions at

the point of connection, welding power sources can

cause disturbances to other consumers in the distribution system. Check with your power utility before

connecting to power. (Class A in accordance with

CISPR 11)

Keep the welding machine out of the reach of children.

Please note the hazards associated with the welding process and observe any work and fire prevention regulations.

The welding machine is not suitable for outdoor use

in rain. Store in a dry place.

The unit is not suitable for unfreezing pipes.

Danger!

A

person with a heart condition wearing a pace

maker must contact their doctor before operating this welding machine.

Safety Information and Accident

Prevention Measures

x Keep the welding machine out of the reach of

children.

x Observe all applicable work and fire prevention

regulations when operating this welding

machine. Observe all applicable accident prevention regulations.

x With welding a number of different hazards are

associated, which can pose a danger to health

under certain circumstances.

x When welding always wear a close fitting, dry

overall (preferably fire retardant welders

apparel) unsoiled by combustible substances,

sturdy, insulating boots, headgear and leather

welders gloves.

x Clothing made of synthetic fabrics and shoes

are not suitable.

Dry, insulating gloves worn on both hands protect against electric shock (open-circuit voltage

of the welding current circuit), hazardous rays

(heat and ultra-violet rays) as well as against

glowing metals and slag spatters. The ultra-vio

let radiation causes sunburn-like effects on

unprotected parts of the body.

Fumes – Vapours – Smoke

x During welding hazardous smoke and metal

dust develops. We strongly recommend the

wearing of welding fume respirators, and to weld

only in sufficiently vented rooms, to ensure the

necessary operator protection.

x For enclosed spaces forced ventilation, installed

below the welding area, must be used.

x The material to be welded must be free from hal-

ogen solvents or degreasing agents, to prevent

the generation of toxic vapours.

-

MIG/MAG 140/160

1.1

Page 4

x Metals coated with lead, graphite, cadmium,

zinc, mercury or beryllium, or containing any of

these materials, can generate much smoke dur

ing welding.

x Welding releases ozone, which is a type of oxy-

gen that can lead to irritation or disorder of the

respiratory organs.

x Degreasing agents such as trichlorethylene, tet-

rachloroethylene etc. vaporise during welding

and are chemically converted into phosgene.

Phosgene is poisonous!

UV-Rays

x The arc radiation can cause eye damage and

skin burns.

x For protection against sparks, heat, visible and

invisible rays suitable eye protection gear (welding visor or helmet with standardised filter

lenses to class 10 – 15 of DIN 4647, depending

on welding current) must be worn.

x Do not look into the arc with unprotected eyes

(risk of blinding and burns). The invisible ultraviolet radiation causes, with insufficient eye pro

tection, a very painful conjunctivitis, which

appears only hours later.

x Weld only within the range of visibility of other

persons, who can assist you in an emergency.

x Other persons or helpers near the arc must be

made aware of the hazards, and equipped with

the necessary protective gear.

x Neighbouring workplaces are to be screened off

to provide protection against radiation.

x When welding inside rooms and buildings suffi-

cient ventilation must be ensured.

Fire

Danger!

A

The arc temperature is approx. 2400 °C.

Before starting to weld observe the following information:

x Remove all combustible materials and objects

within a radius of 5 m from the welding point.

x Materials that can not be removed within a 5 m

radius must be protected by covering with sheet

metal, wet cloths etc.

x Any wall openings, cracks and the like must be

covered or sealed respectively, to prevent

uncontrolled flying of sparks.

x Keep fire extinguishing equipment such as fire

extinguisher, water pale etc. at hand.

x Keep in mind that by heat dissipation from the

welding point a fire may be started on covered

parts or in other rooms respectively.

x After completion of the welding work check the

vicinity of the welding point several times within

a period of 6 – 8 hours for heat conduction,

glowing combustion spots, hidden seats of fire

-

etc.

Handling of Shielding Gas Cylinders

x Observe all applicable regulations pertaining to

the handling of gas cylinders. Because of the

dangerously high internal pressure (up to 200

bar) shielding gas cylinders are to be specially

protected against mechanical damage, falling

over or falling down, heating up (max. 50°C),

prolonged radiation by sunlight and heavy frost.

x When the welding machine is equipped with a

gas cylinder too large in size this can cause, on

uneven ground, the welding machine to fall

over. To prevent subsequent damage to the

welding machine or the gas cylinder, use only

proper size gas cylinders (10l / 20l cylinders).

x Have cylinders refilled only by authorised filling

stations.

Electrical Hazards

-

x The connection to power mains and servicing of

the welding machine is to be done in accordance with VDE regulations or other standards

applicable in your area.

x Ensure proper protective bonding of the supply

circuit.

x Ensure proper protective bonding of the work-

bench.

x Any service or maintenance work must only be

carried out by qualified personnel.

x Replace defective or damaged parts of torch or

torch leads without delay.

x The unit must only be connected to an earthed

outlet as a matter of principle. Only connections,

including outlets and extension cables with an

earthed plug, having an earth conductor and

installed by a qualified electrician, are permitted.

x The fuse protection of the supply circuit must be

in accordance with local regulations. According

to these regulations fuses or miniature circuit

breakers respectively, suitable for the conductor

cross section, must be installed. Installation of a

fuse with to high an ampere rating may cause

line fire and subsequent fire damage to the

building.

x Replace damaged torch insulation and welding

cables without delay.

x Replacement of a damaged power cable, plug

etc. and repairs to the electrical components of

the welding machine must be left to a qualified

electrician.

x Welding torches must not be held in an armlock,

or in such way that electricity can run through

the body.

1.2

MIG/MAG 140/160

Page 5

x Switch the unit off for longer work breaks.

Unplug when work is completed and before relocating the unit. In case of accidents separate the

welding power source at once from the power

supply.

General Machine Description

The MIG/MAG welding machine consists of a transformer (static characteristic curve), a series-connected silicon rectifier, a welding circuit choke, and

a wire feed unit.

The welding machine is suitable for the welding of

different electrode wires (e.g. steel, see "Technical

Specifications") under a shielding gas cover (CO2,

mixed gas and argon).

The machine is fan cooled and has an overload protection.

Symbols Used

Danger!

Disregard of the following warnings

could cause serious personal injury

or material damage.

6 Manufacturer

7 Machine designation

8 Serial number

9 Standard information – This machine meets

the requirements of the standards mentioned

10 CE mark – This machine conforms to EC

directives as per declaration of conformity

11 Waste disposal symbol – the machine can be

disposed of through the manufacturer

12 Electrical performance data

13 Date of manufacture

Commissioning

Taking out of enclosed parts

All enclosed parts are inside the wire feed compartment and can be taken out after the wire feed compartment cover is removed..

Read operating instructions before

initial operation

Wire feed speed

Do not use in rain.

Welding machine suitable for welding in

environments with an increased electrical hazard.

Excess temperaturer

Information on the name plate:

6

78910

1213

11

Installation Conditions

x The protective gas welding unit must be

installed in a dry environment with sufficient

room for cooling.

x If the unit is placed on an inclined surface it must

be secured against falling: place the unit on a

suitable level support surface.

x The unit is designed for use in covered areas.

Welding outside in the rain is not permitted.

Mains connection

x Check to see that mains voltage matches the

voltage shown on the machine's rating plate.

x Set welding step switch to "0" before plugging

in.

Shielding gas cylinder connection

x Place gas cylinder onto the welding machine's

cylinder rack and secure with the chain to the

cylinder holder at the rear of the unit. Take off

the cylinder cap and open cylinder valve briefly,

facing away from your body.

x Screw pressure reducer to the gas cylinder

valve. Run gas hose from pressure reducer to

gas inlet port of the unit.

x Recommended gas flow rate in draft-free

rooms: 5-10 l/min.

MIG/MAG 140/160

1.3

Page 6

x When using adjustable pressure reducers set

flow rate according to litre scale in the clock with

the T-screw. Turning the T-screw in increases

the gas flow rate, turning it out reduces the gas

flow rate.

x While setting the gas flow rate, the unit must be

switched on and the torch's trigger switch held

down, so the solenoid gas valve is open. To prevent wasting electrode wire swing the wire feed

unit's leaf spring to the side.

Modifications and repairs to pressure reducers are

strictly prohibited due to the hazards involved. Send

faulty pressure reducers to a service centre.

Earth lead connection

Connect earth clamp of the unit's earth cable as

close as possible to the welding point. Ensure good

metal to metal contact.

Hints for Setting and Welding

Techniques

Switching the unit on

The unit is switched on with the combination ON/

OFF – welding step switch. With the switch in the

"0"- position the unit is electrically separated from

the power supply.

The unit is fitted with an embedded temperature

detector, which shuts the unit down in case of an

thermal overload.

The tripping of the thermal overload protector is indicated by the front panel control light. Welding power

source and wire feed are temporarily disabled.

After cooling down the welding power source is

automatically activated again, the control light extinguishes.

Preparation of the welds

The joint section of the workpieces to be welded

must be free of colour, metall covering, dirt, rust,

grease and humidity.

The preparation of the welds is to be done under

observation of all welding techniques regulations.

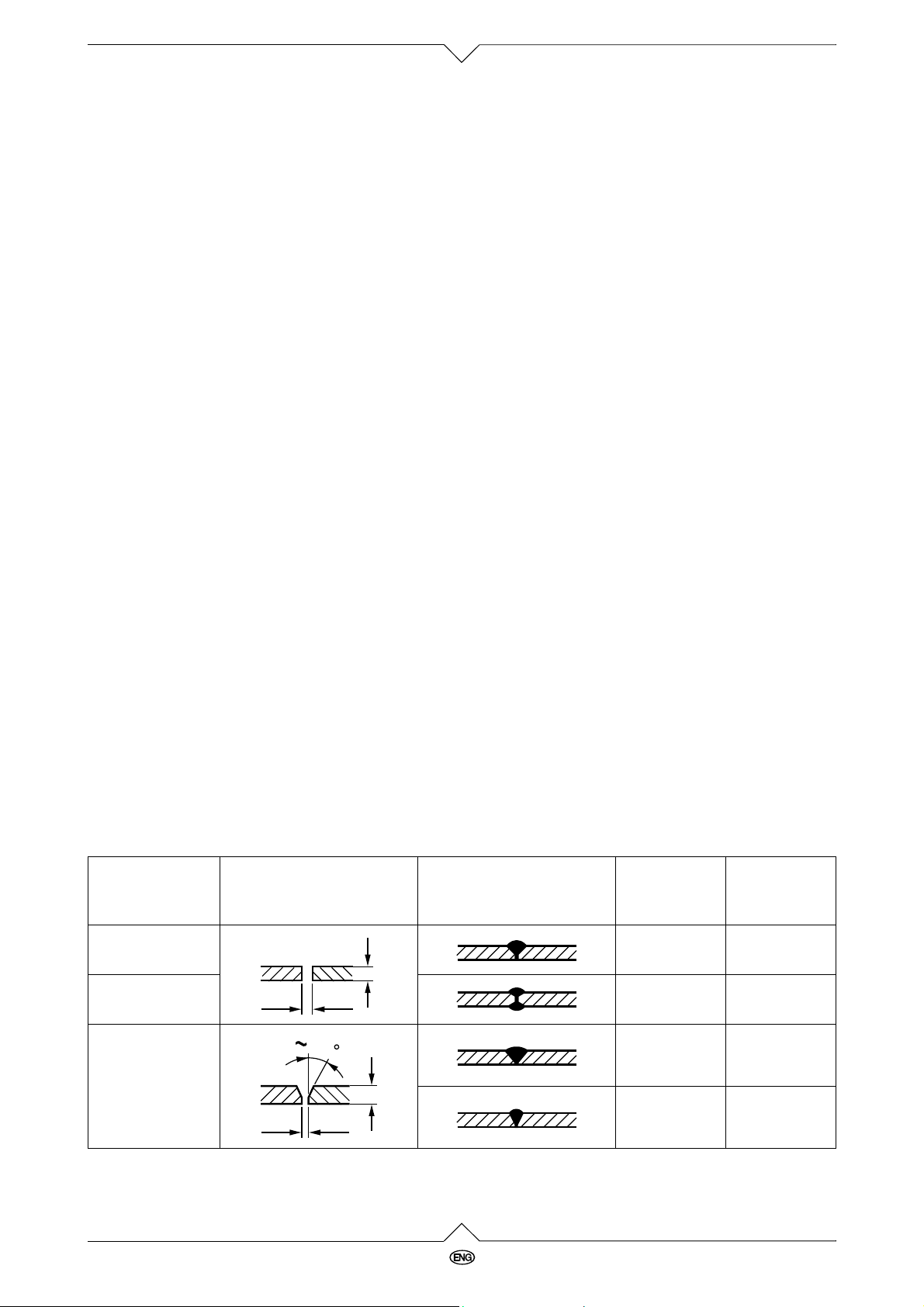

The right joint

The list gives hints for the shaping of the joints.

Form of joint Execution

Setting the welding parameters

After preparation of the welding machine the welding can begin.

To do so, welding voltage and wire feed have to be

matched to suit the welding task. If the wire feed

speed is increased the welding current increases

accordingly.

For every electrode wire diameter and every welding task optimal parameters can be found. They are

recognisable at the typical humming sound of the

arc, amongst other.

If there is too much deviation from the optimal

parameters, a satisfactory welding is not possible.

Platethick-

ness

s (mm)

Gapwidth

b (mm)

I-joint onesided < 1,5

I-joint on both

sides

V-joint

25

s

b

s

b

> 1,5

2 – 4 < 2

3 – 6 < 1

3 – 6 < 1

1.4

0

< 2

MIG/MAG 140/160

Page 7

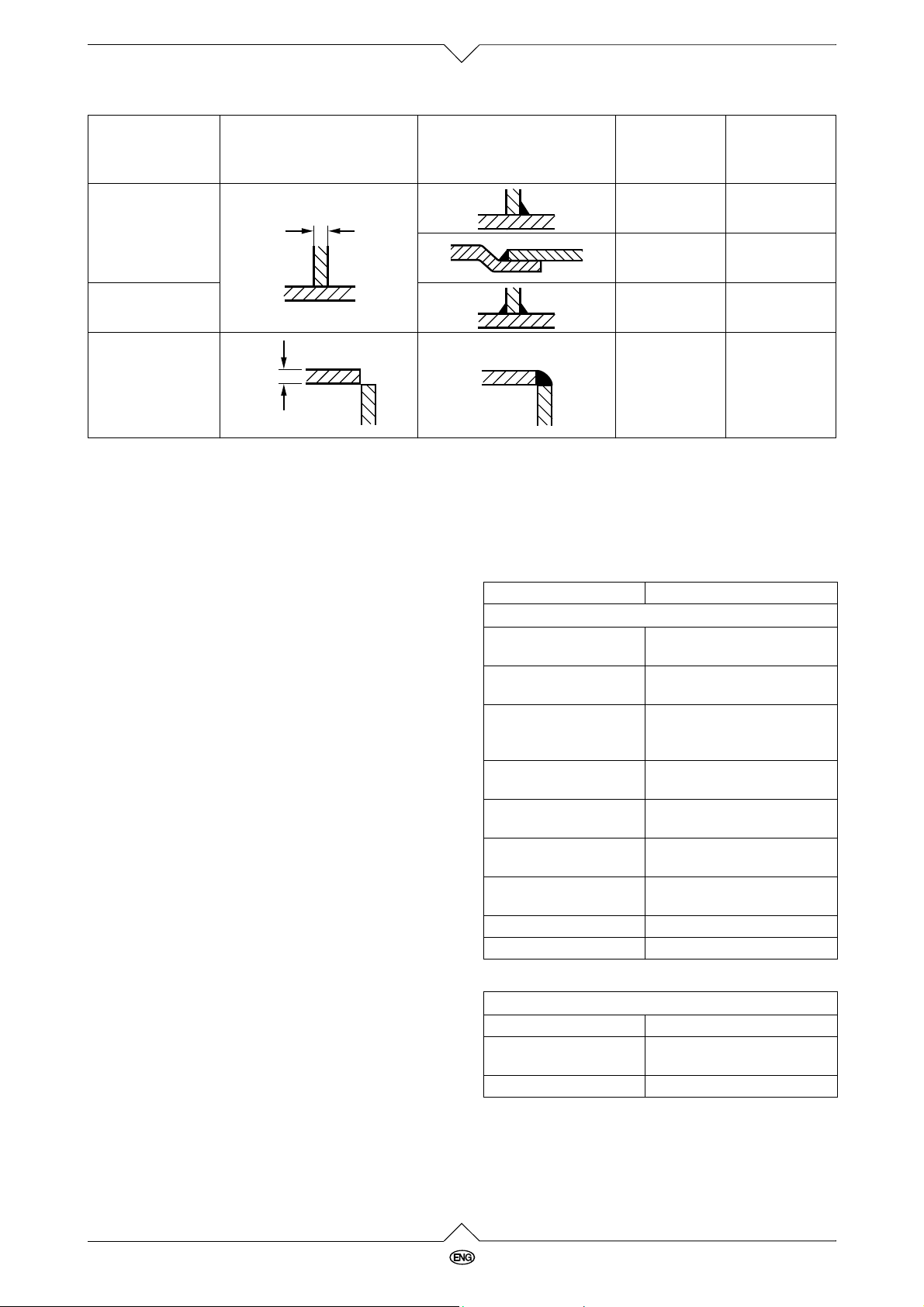

Form of joint Execution

Platethick-

ness

s (mm)

Gapwidth

b (mm)

K-joint

s

Double-K-joint

Cornerjoint

s

Care and Maintenance

The unit is nearly maintenance-free.

Danger – Voltage!

B

Disconnect from power before servicing!

x Check feed roller, pressure roller and wire lead-

in nozzle at regular intervals for dirt build-up,

clean if necessary.

x At appropriate intervals the complete torch

including torch leads should be cleaned, as

rubbed-off parts and dust build-up inside.

x The torch's contact tip is a wearing part. If its ori-

fice has enlarged the contact tip must be

replaced.

x On the inside of the plug-on gas shroud spatters

build up. These have to be removed when nec

essary. An anti-spatter spray eases this job and

keeps spatters from sticking to the shroud.

x Replace damaged cables without delay.

Trouble Shooting

Mechanical faults are mostly indicated by an irregular or completely blocked wire feed. Electrical faults

cause a malfunction of the unit, in part or complete.

> 0,6 –

0,6 – 1,5 –

> 0,6 –

> 1 –

2. Check of fuse for continuity and contact.

3. Visual check for possible shorts or overloads of

windings (discoloring).

Fault, Likely causes Remedy

• Noisy or unstable arc?

Incorrect welding voltage

Too much/too little wire

feed

Earth clamp loose or

high contact resistance

(rust, paint)

Contact tip worn or

-

incorrect diameter

Incorrect gas flow rate

setting

Workpiece not clean in

seam area

Power unit faulty Have machine checked by

Spiral liner dirty Clean or replace

Wire feed faulty See below

Correct with welding step

switch

Correct with wire feed pot

Ensure good contact

between earth clamp and

workpiece

Replace

Correct

Remove paint, rust, grease

etc.

service centre

Danger - Voltage!

B

Electrical fault finding must be left to a qualified electrician.

Further fault finding can proceed according to the

wiring diagram supplied.

Fault find should first start with the unit de-energized, and in the following order:

1. Check of the power supply cable connection

and all other connections on switches, transformer and choke, as well as all plug-and-socket

connections and soldered connections for tightness.

MIG/MAG 140/160

• Excessive spattering

Wire feed rate too high Correct with wire feed pot

Welding voltage too

high

Workpiece not clean Clean

Correct with welding step

switch

1.5

Page 8

• Wire feed motor does not run

No power Check power supply

Welding step switch in

"0" position

Torch trigger switch not

activated

Fuse blown Have replaced by a qualified

Motor faulty Have repaired by service

Set to a welding step

Activate torch trigger switch

electrician

centre

Technical Specification

• No wire feed

Pressure roller loose Increase pressure of leaf

spring with knurled thumb

screw

Wire kinked at wire

feed

Groove in feed roller

worn

Electrode wire stuck to

contact tip

• Machine shuts down, overload control light

comes on

Duty cycle exceeded Let machine cool down,

Power unit faulty Have repaired by service

Adjust wire lead-in nozzle

Replace

Replace contact tip, if wire is

deformed, reduce pressure

of pressure roller

observe duty cycle stated on

nameplate

centre.

MIG/MAG 140 MIG/MAG 160

Power supply 1 x 230 V, 50/60 Hz 1 x 230 V, 50/60 Hz

Power input max. 5,1 kVA 5,3 kVA

Current draw max. 22 A 23 A

Mains fuse, time-lag 16 A 16 A

Open-circuit voltage 17,5 – 28 V 19 – 30 V

Welding current range 30 – 140 A 30 – 160 A

max. Duty cycle (40°C) 4 % 8 %

Welding steps 4 4

Wire feed rate 1,0 – 12 m/min 1,0 – 12 m/min

Electrode wire diameter 0,6 – 0,8 mm 0,6 – 0,8 mm

Protection class IP 21 IP 21

Length x Width x Height 590 x 260 x 420 mm 590 x 260 x 420 mm

Weight 21 kg 26,5 kg

Current setting range

Position MIG / MAG 140 MIG / MAG 160

130A30A

250A60A

380A100A

4140A160A

1.6

MIG/MAG 140/160

Page 9

XS0028F.fm

2France

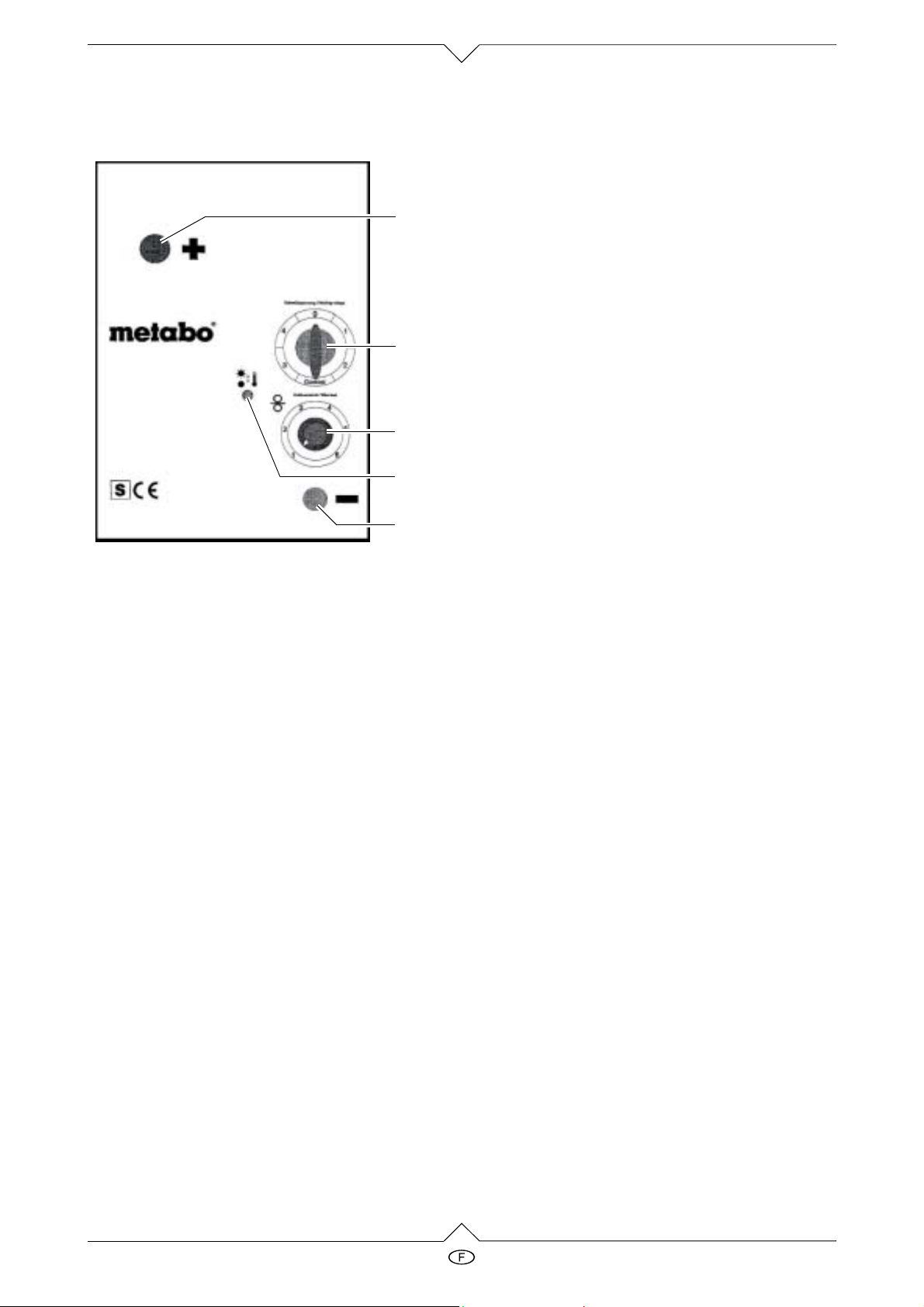

Eléments de commande

1 Branchement chalumeau Pôle (+)

trique des prises de courant doit être protégé par

fusibles ou par interrupteur automatique.

Selon les conditions de branchement sur secteur au

point de jonction, les sources de courant de soudage peuvent entraîner des perturbations dans le sec-

1

2

3

4

5

teur pour d’autres consommateurs. Pour résoudre

ce problème et pour éviter de telles perturbations, il

est nécessaire de se renseigner avant le branche

ment auprès de l’entreprise chargée de l’alimentation en courant. (Classe A selon CISPR 11)

Il faut tenir l’appareil hors de la portée des enfants.

Tenez compte des risques que représentent les travaux de soudage et respectez le règlement du travail ainsi que les consignes de prévention

d’incendie.

L’appareil doit être rangé à l’abri de l’humidité et

n’est pas conçu pour être utilisé dehors, lorsqu’il

pleut.

L'appareil ne convient pas au décongelage de

tubes.

Danger!

A

Les personnes qui portent un stimulateur cardiaque doivent obligatoirement consulter leur

médecin avant de travailler avec l’appareil à

soudage!

-

2 Interrupteur marche/arrêt et courant de

soudage

3 Régulateur d’avancement du fil

4 Indicateur de surcharge

5 Branchement pince à électrodes à la

masse Pôle (–)

Cher client, chère cliente,

nous vous félicitons d’avoir acheté cet appareil de

soudage sous gaz protecteur de haute qualité.

Afin de garantir votre sécurité et la sécurité de

l’appareil, nous vous prions de bien vouloir lire com

plètement et consciencieusement ces instructions

avant la mise en service, et de respecter ces instructions en tous points.

-

Conseils de principe pour l’utilisateur

L’appareil de soudage sous gaz protecteur MIG/

MAG est une source de courant continu avec avancement du fil intégré, conçue et construite uniquement pour le soudage à l’arc MIG, voire MAG.

Toute autre utilisation de l’appareil est soumise à

des risques et donc interdite.

L’appareil ne peut être mis en service que sous la

tension secteur indiquée sur la plaque signalétique.

Le branchement ne peut se faire qu’avec des prises

de courant de sécurité, qui auront été installées par

un spécialiste autorisé en électricité. Le circuit élec-

Conseils de sécurité et mesures

préventives contre les accidents

x L’appareil à soudage sous gaz protecteur doit

être tenu hors de la portée des enfants.

x Lorsque l’on travaille avec l’appareil à soudage

sous gaz protecteur, il faut respecter le règlement du travail ainsi que les consignes de prévention d’incendie en vigueur. Il faut également

respecter les instructions préventives en

vigueur contre les accidents !

x Lors du soudage, différentes sortes de risques

pourraient éventuellement causer des domma

ges à la santé.

x Lors du soudage, il faut porter une combinaison

fermant hermétiquement, ne portant pas de tra

ces de substances qui s’enflamment facilement,

et sèche (mieux encore une combinaison pour

soudeur très résistante aux flammes), des

chaussures robustes, isolantes (bottes), une

protection sur la tête et des gants à fourreau en

cuir.

x Les vêtements en matières synthétiques ainsi

que les chaussures basses ne sont pas adéquats. Des gants isolants aux deux mains protègent des secousses électriques (tension à vide

du circuit électrique de soudage), des radiations

nocives (rayons thermiques et ultraviolets) de

même que des éclaboussures de métal ardent

et de laitier. La radiation ultraviolette a un effet

semblable aux coups de soleil sur les parties du

corps qui ne sont pas protégées.

-

-

MIG/MAG 140/160

2.1

Page 10

Gaz – vapeurs – fumée

x Pendant le soudage, il y a formation de fumée

nocive et de poussière de métal. Nous vous

conseillons d’utiliser des masques de protection

contre la fumée et de veiller à une alimentation

suffisante d’air frais dans les locaux où s’effectue le soudage, afin de garantir la protection

nécessaire du personnel.

x Dans des locaux fermés, il est absolument indis-

pensable d’utiliser des exhausteurs qui devront

être installés en-dessous de la zone de soudage.

x Le matériel que l’on veut souder ne doit pas por-

ter de traces de dégraissants à solution

halogène, pour empêcher la formation de gaz

toxiques.

x Les métaux qui sont recouverts de plomb, de

graphite, de cadmium, de zinc, de mercure ou

de béryllium ou qui contiennent ces matériaux,

sont susceptibles de dégager beaucoup de

fumée au cours du soudage.

x Lors du soudage, il y a dégagement d’ozone. Il

s’agit d’une sorte d’oxygène qui peut entraîner

des irritations ainsi que des maladies des orga

nes respiratoires.

x Les produits solvants de graisse comme le tri-

chloréthylène, le perchloréthylène, etc. s’évaporent pendant le soudage et se transforment, dû

à une modification chimique, en gaz phosgène.

Le gaz phogène est toxique!

Rayons ultraviolets

x Les rayons de l’arc électrique peuvent provo-

quer des blessures aux yeux et des brûlures de

la peau.

x Pour se protéger des étincelles, de la chaleur,

des rayons visibles et invisibles, il faut porter

des protections optiques adéquates (écran pro

tecteur ou coiffe protectrice pourvus de verres

de protection contre les rayons d’échelons 10 à

15 normés DIN 4647, selon la puissance électri

que).

x On ne doit pas regarder l’arc électrique si les

yeux ne sont pas protégés (risque d’éblouissement et de brûlure). Si la protection est insuffisante, la radiation ultraviolette invisible provoquera une conjonctivite douloureuse que l’on ne

remarquera que quelques heures plus tard.

x Pour effectuer le soudage, il est nécessaire

d’avoir à proximité des personnes qui pourront

venir à l’aide immédiatement, en cas d’accident.

x Les personnes ou les assistants qui sont à

proximité de l’arc électrique doivent être informés des dangers existants et être équipés de la

protection adéquate.

x Il est nécessaire de protéger les places de tra-

vail environnantes de la radiation: installer les

écrans de protection en conséquence.

x Lors de travaux de soudage dans des pièces et

des bâtiments, il faut veiller à une bonne circulation de l’air.

Feu

Danger!

A

La température de l’arc électrique s’élève

environ à 2400 °C.

Avant de commencer les travaux de soudage,

veuillez suivre les conseils suivants:

x Dans un rayon de 5 m de l’endroit de soudure, il

faut éloigner toutes les substances et les objets.

x Les substances se trouvant dans un rayon de 5

m et qui ne peuvent pas être éloignées doivent

être protégées correctement: on les recouvre de

tôles d’acier, de linges mouillés, etc.

x Les ouvertures, fentes, orifices dans les murs,

etc., doivent être recouverts ou calfeutrés afin

de les protéger des flammèches incontrôlées.

-

x Les moyens d’extinction tels que les extincteurs

de feu, les seaux à eau, etc., sont à tenir à disposition.

x N’oubliez pas que, dû à la conduction de cha-

leur au point de soudure, un incendie peut se

déclarer sur des objets recouverts ou dans

d’autres pièces.

x Après avoir terminé les travaux de soudage,

assurez-vous à plusieurs reprises dans les 6 – 8

heures qui suivent, qu’il ne reste pas d’endroits

incandescents, de foyers ardents ou de conduc

tion thermique aux environs de l’endroit où le

soudage a eu lieu.

-

Maniement des bouteilles de gaz protec-

-

-

teur

x Pour le maniement des bouteilles de gaz protec-

teur, il faut respecter les consignes de sécurité

en vigueur. Il faut tout particulièrement protéger

les bouteilles de gaz protecteur, à cause de leur

haute pression interne (jusqu’à 200 bar), des

détériorations mécaniques, empêcher qu’elles

ne basculent ou dégringolent. Il faut également

empêcher qu’elles ne se réchauffent (max.

50

°C), ne soient exposées trop longtemps aux

rayons du soleil ou à un gel extrême.

x Lorsque l’on équipe l’appareil MIG/MAG de la

bouteille de gaz protecteur, il faut être conscient

du fait que de trop grandes bouteilles, posées

un sol inégal, peuvent faire basculer l’appareil.

Pour éviter les dommages qui en résulteraient

pour l’appareil, voire pour la bouteille de gaz, on

ne doit utiliser que des bouteilles de taille conve

nable (bouteilles de 10 ou 20 litres).

-

2.2

MIG/MAG 140/160

Page 11

x Pour faire remplir ou transvaser les bouteilles, il

faut s’adresser exclusivement aux firmes autorisées

Dangers venant du courant électrique

x Le branchement sur secteur ainsi que l’entretien

du dispositif de gaz protecteur doivent être faits

selon les consignes VDE.

x S’assurer que l’alimentation de courant est cor-

rectement mise à la terre.

x S’assurer que l’établi est correctement mis à la

terre.

x Seul un personnel qualifié peut effectuer l’entre-

tien.

x Les pièces du chalumeau ou du paquet de

tuyaux qui sont défectueuses ou détériorées

doivent être remplacées immédiatement.

x Le branchement de l’appareil ne pourra se faire

qu’à des prises de courant avec contact de mise

à la terre. On doit utiliser uniquement des bran

chements, y compris prises de courant et rallonges équipés de prises de courant de sécurité,

qui auront été installés par un spécialiste autorisé en électricité.

x La protection par fusibles du conducteur d’ame-

née aux prises de courant secteur doit correspondre aux consignes. Selon ces consignes, on

ne peut utiliser que des fusibles ou interrupteurs

automatiques qui correspondent à la section du

conducteur. Si la protection fusibles est trop

forte, il y a risque d’incendie au conducteur ou

risque de dommages suite à un incendie dans le

bâtiment.

x Si l’isolation du chalumeau ou les conducteurs

de soudage sont endommagés, il faut les remplacer immédiatement.

x Seul un spécialiste autorisé en électricité pourra

remplacer une ligne d’alimentation défectueuse,

une prise de courant de sécurité, etc., et effectuer les travaux de réparation de l’appareil à

soudage sous gaz protecteur.

x Il ne faut pas coincer le chalumeau soudeurs

sous le bras. En le tenant, il faut faire attention à

ce que le courant ne puisse passer dans le

corps humain.

x En cas d’une longue interruption du travail, met-

tez l’appareil hors-service. Après avoir fini le travail et avant de changer l’emplacement de

l’appareil, il faut retirer la prise de courant secteur. En cas d’accident, couper aussitôt la

source de courant de soudage du secteur.

courant en silicium intercalé à la suite, et d’un étranglement de la circulation de soudage, de même que

d’un dispositif d’avance d’électrode.

L’appareil est conçu pour le soudage de différentes

électrodes (par exemple l’acier, voir «Détails Techniques»), sous une atmosphère de gaz protecteur

(CO2, gaz mixte et argon.

L’appareil est refroidi par un ventilateur et muni

d’une protection de surcharge.

Symboles figurant sur l'appareil

Danger !

Le non-respect des mises en garde

suivantes peut entraîner des blessures ou des dommages matériels graves.

Avant de mettre en marche l'appareil,

lire les instructions d'utilisation.

-

Indications figurant sur la plaque signalétique :

6

6 Constructeur

7 Nom de l'appareil

Vitesse d'avance du fil

Ne pas utiliser sous la pluie

L'appareil peut être utilisé pour souder

dans un endroit à risque électrique

accru.

Surchauffe

78910

1213

11

Description générale de l’appareil

L’appareil de soudage sous gaz protecteur MIG/

MAG se compose d’un transformateur (Courbe

caractéristique statique) pourvu d’un redresseur de

MIG/MAG 140/160

8 Numéro de série

9 Norme de référence – cet appareil est con-

forme aux exigences de la norme indiquée.

2.3

Page 12

10 Sigle CE – cet appareil est conforme aux

directives européennes comme indiqué

dans la déclaration de conformité.

11 Symbole de mise au rebut – l'appareil peut

être remis au fabricant.

12 Caractéristiques électriques

13 Année de construction

Mise en service

Déballage des pièces jointes

Toutes les pièces jointes se trouvent dans le compartiment d’avance d’électrode et peuvent être retirées, après avoir enlevé la plaque de recouvrement.

Conditions de pose

x L'appareil de soudage sous protection doit être

implanté dans un environnement sec disposant

de suffisamment de place pour la ventilation.

x Quand l'appareil est placé sur une surface en

pente, il doit être empêché de basculer par des

moyens adéquats : placer l'appareil sur un sup

port plan approprié.

x L'appareil est conçu pour être utilisé dans des

locaux abrités. Il ne doit pas être soudé à l'extérieur par temps de pluie.

x Quantité de gaz qui circule – dans les pièces

sans courants d’air - à recommander: 5 – 10

litres par minute.

x Si l’on utilise des détendeurs réglables, il faut

régler la quantité de gaz qui circule selon la graduation en litres, à l’aide de la vis à garrot. Si l’on

visse vers l’intérieur, on augmente la quantité

qui circule. Si l’on vis vers l’extérieur, on diminue

la quantité qui circule.

x Lors du réglage, il faut mettre l’appareil en ser-

vice et l’interrupteur du chalumeau doit être

poussé pour pouvoir ouvrir la vanne magnétique. Pour éviter de consommer trop d’électrode,

on fait pivoter latéralement le ressort à lames de

l’avancement d’électrode.

Les opérations et réparations sur les détendeurs

sont interdits, á cause des dangers que représentent ces opérations. Les détendeurs qui sont défectueux doivent être expédiés à l’atelier prévu dans le

contrat de service après-vente.

Branchement de la pièce de travail

Connecter la borne de la pièce de travail à la ligne

de raccordement de la masse de l’appareil MIG/

MAG directement à côté du point de soudage. Véri

fier que le passage métallique au point de contact

est brillant.

-

Préparation du cordon de soudure

Les pièces de travail à souder ne doivent pas porter

de traces de peinture, couche métallique, pous-

-

sière, rouille, graisse ou humidité à l’endroit du cordon.

La préparation du cordon de soudure doit s’effectuer en respectant les consignes techniques de soudage.

Branchement secteur

x Vérifiez la concordance entre la tension indi-

quée sur la plaque signalétique et la tension de

votre secteur.

x Avant de brancher sur secteur, il faut mettre le

commutateur sélectif de tension secteur sur

zéro.

Branchement de la bouteille de gaz protecteur

x Poser la bouteille de gaz sur le support de bou-

teille de l’appareil et, à l’aide de la chaîne, fixer

la bouteille sur le support de bouteille de la paroi

arrière. Enlever le capuchon de sécurité et

ouvrir brièvement la soupape de la bouteille en

tenant celle-ci éloignée du corps.

x Visser le détendeur sur les tubulures filetées de

la bouteille de gaz. Installer le raccord de tuyau

entre le détendeur et le branchement d’alimentation de gaz de l’appareil MIG/MAG.

2.4

Conseils en matière de réglage et

de technique de soudage

Mise en service de l’appareil

Le réglage de l’appareil se fait à l’aide du commutateur de tension de soudage, combiné à l’interrupteur

Max-Min. Il faut couper l’appareil du secteur lorsque

l’interrupteur Max-Min. est sur zéro.

L’appareil est muni d’un contrôleur de température

qui met l’appareil hors service lors d’une surcharge.

Le déclenchement du contrôleur de température est

signalisé par un voyant lumineux. La source de cou

rant de soudage et l’avance d’électrode sont mis

provisoirement hors service.

Après refroidissement, la source de courant se rallume toute seule; le voyant lumineux s’éteint.

MIG/MAG 140/160

-

Page 13

Réglage des paramètres de soudage

Après préparation de l’appareil, on peut commencer

le soudage.

Pour cela, il faut ajuster les tensions de soudage et

la vitesse d’avance de l’électrode entre elles, en

fonction du travail de soudage à effectuer. Si on

augmente la vitesse d’avance de l’électrode, l’inten

sité du courant augmente également.

-

Pour chaque diamètre d’électrode de soudage et

chaque travail de soudage, on peut trouver les paramètres optimums. On les reconnaît entre autre au

bourdonnement typique émis par l’arc électrique.

Si l’on s’écarte trop des valeurs optimums, il ne sera

pas possible de souder sans défauts.

Le bon cordon de soudure

Dans le tableau, vous pouvez lire les instructions concernant réalisation de la forme de la fente.

Cordon-I d’un

côté

Cordon-I des

deux côtés

Cordon-V

Cordon-K

Cordon double-K

Cordon de coin

Forme de la fente Modèle Epaisseur

de la tôle

s (mm)

s

b

25

s

b

< 1,5

> 1,5

2 – 4 < 2

3 – 6 < 1

3 – 6 < 1

> 0,6 –

s

0,6 – 1,5 –

> 0,6 –

> 1 –

s

Largeur de

fente

b (mm)

0

< 2

MIG/MAG 140/160

2.5

Page 14

Entretien

L’appareil ne nécessite pratiquement pas d’entretien.

Danger – Tension électrique!

B

Avant de procéder à l’entretien de l’appareil

ou à un dépannage, il faut enlever la prise

secteur!

x Vérifier régulièrement la roue d’avancement, le

rouleau de pression et la tuyère d’entrée. S’ils

sont encrassés, il faut les nettoyer.

x A intervalles réguliers, il faut nettoyer le paquet

entier de tuyaux du chalumeau, vu que les

déchets de meulage et la poussière se dépo

sent à l’intérieur.

x La tuyère de contact du chalumeau est une

pièce d’usure perdue. Lorsque son forage est

trop gros, on doit la remplacer.

x Dans les parois intérieures du capuchon à gaz

enfichable du chalumeau, il y a des éclaboussures de métal qui s’incrustent. Si besoin est, il

faut les éliminer. Un agent séparateur facilite ce

travail et empêche que les éclaboussures ne

soient recollées de nouveau.

x Il faut remplacer immédiatement les lignes élec-

triques défectueuses.

Dépannage

On reconnaît dans la plupart des cas une panne

mécanique lorsque l’avance du fil est irrégulière ou

quand il y a un blocage de l’avancement du fil.

Les pannes électriques entraînent l’arrêt partiel ou

complet de l’appareil.

Danger – Tension électrique!

B

Le dépistage des erreurs dans la partie électrique de l’appareil ainsi que tous les travaux

sur les pièces électriques ne pourront être

effectués que par un spécialiste autorisé en

électricité.

En se rapportant au schéma de câblage, il est possible de dépister les autres erreurs.

Le dépistage des erreurs doit se faire d’abord sans

tension et dans l’ordre suivant:

1. Vérification de la stabilité du branchement secteur et des autres branchements aux commutateurs, du transformateur, de l’étranglement ainsi

que des prises de courant embrochables et des

jonctions par brasage.

2. Vérification du passage et du contact des fusibles.

3. Contrôle optique pour détecter éventuellement

les courts-circuits ou la surcharge de bobinages

(décoloration).

Panne, cause Dépannage

• Arc électrique qui vacille, voire instable?

Mauvaise position de

la tension de soudage

Trop / pas assez

d’électrode

Borne de connexion de

la pièce de travail est

lâche ou grande résistance au passage

(rouille, peinture)

Tuyère de contact

-

usée ou diamètre non

adéquat

Réglage de la quantité

de gaz n’est pas correct

La pièce de travail

n’est pas propre au

point du cordon de

soudure

Unité de puissance

défectueuse

Spirale enfichable

encrassée

Problème à l’avancement

• Beaucoup d’éclaboussures lors du soudage?

Trop d’électrode rembobiner le régulateur

Trop de tension de

soudage

Pièce de travail sale Nettoyer

• Le moteur d’avancement ne fonctionne pas?

Pas de tension secteur Contrôler le branchement

Commutateur de tension secteur est sur

zéro

Commutateur de chalumeau n’est pas

actionné

Fusible Faire remplacer par un spé-

Moteur défectueux Déposer à l’atelier de répa-

Corriger sur le commutateur

de tension à échelons

Régler sur le régulateur

d’avance de l’électrode

Etablir un bon contact entre

la pièce de travail et la borne

de connexion de la pièce de

travail

Remplacer

Régler la quantité de gaz

Enlever la peinture, la

rouille, la graisse, etc.

Déposer l’appareil à l’atelier

de réparation

Nettoyer et remplacer

Voir ci-dessous

d’avancement d’électrode

Faire descendre la tension

en diminuant au commutateur

secteur

Régler le degré de tension

Activer le commutateur de

chalumeau

cialiste en électricité autorisé

ration

2.6

MIG/MAG 140/160

Page 15

• Pas de transport de l’électrode?

Rouleau de pression

trop lâche

Electrode est pliée à

l’avancement

Rainure de la roue

d’avancement détériorée

Electrode incinérée à

la tuyère de contact

Augmenter la pression de

serrage sur le ressort à

lames à l’aide d’une vis

moletée

Aligner la tuyère d’entrée

Remplacer la roue d’avancement

Remplacer la tuyère de contact, au cas où l’électrode

est déformée. Diminuer la

pression de serrage

• L’appareil s’arrête, le voyant de surcharge

s’allume?

Durée de mise en service est dépassée (ED)

Unité de puissance

défectueuse

Laisser l’appareil refroidir,

respecter ED selon la plaque signalétique

Déposer l’appareil à l’atelier

de réparation.

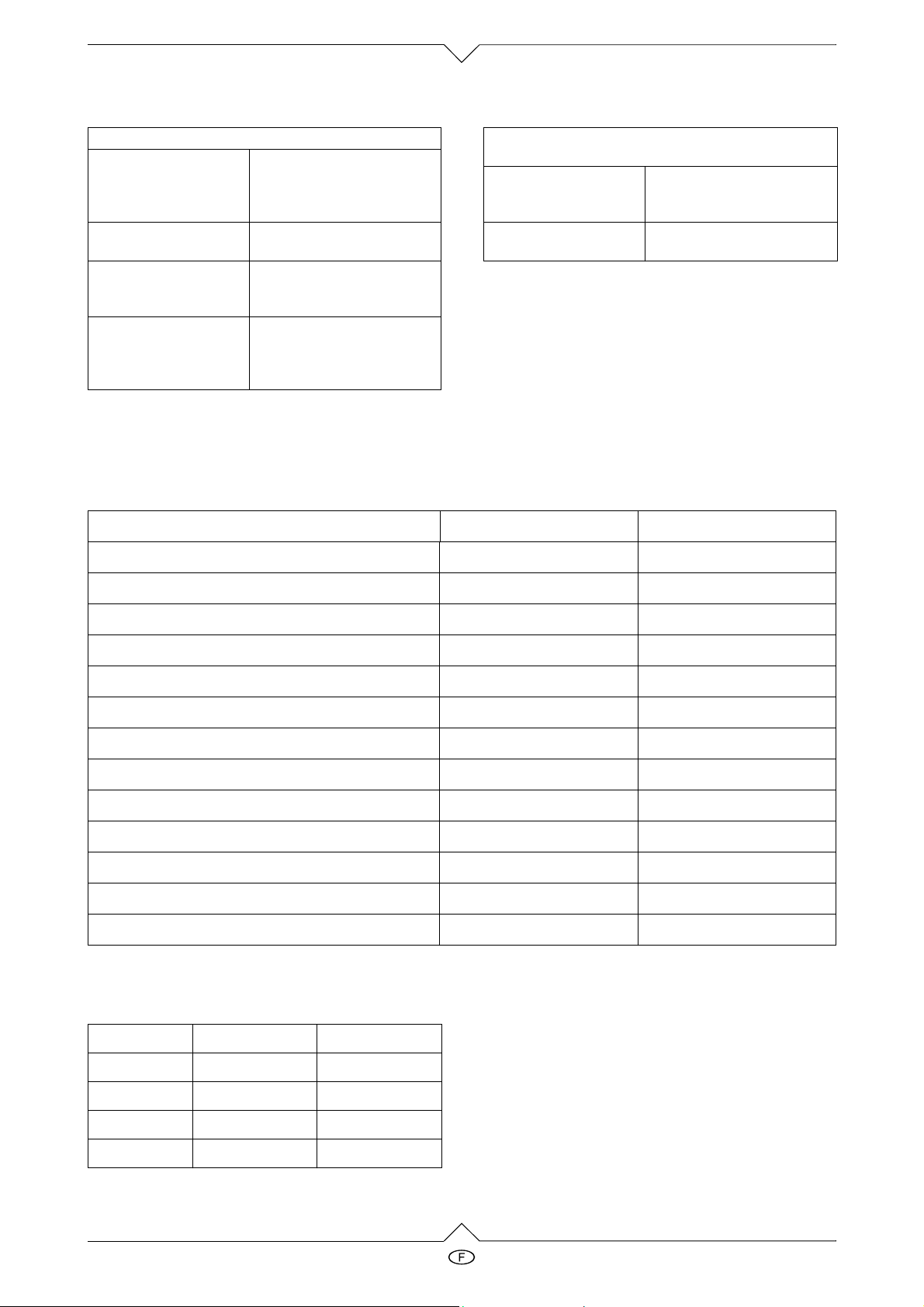

Détails techniques

MIG/MAG 140 MIG/MAG 160

Tension du secteur 1 x 230 V, 50/60 Hz 1 x 230 V, 50/60 Hz

Courant de ligne de raccordement max. 5,1 kVA 5,3 kVA

Courant de branchement max. 22 A 23 A

Protection par fusibles (à action retardée) 16 A 16 A

Tension en marche à vide 17,5 – 28 V 19 – 30 V

Etendue de réglage 30 – 140 A 30 – 160 A

Durée maximale d’allumage (40°C) 4 % 8 %

Echelons 4 4

Avancement du fil 1,0 – 12 m/min 1,0 – 12 m/min

Diamètre d’électrode 0,6 – 0,8 mm 0,6 – 0,8 mm

Mode de protection IP 21 IP 21

Longueur x largeur x hauteur 590 x 260 x 420 mm 590 x 260 x 420 mm

Poids 21 kg 26,5 kg

Plage de réglage du courant

Position MIG / MAG 140 MIG / MAG 160

130A30A

250A60A

380A100A

4140A160A

MIG/MAG 140/160

2.7

Page 16

XS0028N.fm

3Norge

Betjeningselementer

1

2

3

4

5

1 Tilkopling brenner (+)-pol

2 Av/på- og sveisestrømbryter

3 Innstilling sveisetrådfremtrekk

4 Overbelastningsindikator

5 Tilkopling jordledningskopling (–)-pol

Kjære kunde!

Takk for at du har kjøpt dette dekkgass-sveiseappa-

ratet med høy kvalitet.

For din egen sikkerhet og for apparatsikkerhetens

skyld ber vi deg lese hele denne bruksanvisningen

nøye før du tar apparatet i bruk, og følge alle punk

tene samvittighetsfullt.

styrrelser på nettet for andre apparater. For å

avklare dette spørsmålet og for å unngå forstyrrelser må man før tilkopling innhente opplysninger fra

strømleverandøren. (klasse A ifølge CISPR 11)

Barn må ikke ha tilgang til apparatet.

Det er viktig å være oppmerksom på farene som er

forbundet med sveiseprosessen og å overholde

arbeidsmiljø- og brannforskriftene.

Apparatet må beskyttes mot fuktighet ved oppbevaring og egner seg ikke til bruk utendørs i regnvær.

Apparatet er ikke egnet for opptining av rør.

Fare!

A

Personer med pacemaker bør alltid konsultere lege før sveising!

Sikkerhetsregler og ulykkesforebyggende tiltak

x Dekkgass-sveiseapparatet skal sikres mot barn.

x Ved arbeid med dekkgass-sveiseapparat skal

de aktuelle arbeidsmiljø- og brannvernforskriftene følges. De aktuelle forskriftene for å hindre

ulykker skal følges!

x Ved sveising kan det oppstå forskjellige farer

som under visse omstendigheter kan føre til helseskader.

x Ved sveising bør man ha på seg en tettsittende,

tørr arbeidsdress som ikke er forurenset av lettantennelige stoffer (helst en vanskelig antennelig sveisedress), solid, isolerende skotøy (støvler), hodebekledning og lærhansker med

mansjett.

x Klær av syntetiske materialer og vanlige små-

sko er uegnet. Isolerende hansker på begge

hender beskytter mot elektrisk støt (tomgangs

spenning i sveisestrømkretsen), mot skadelig

stråling (varme og UV-stråler) samt mot glø

dende metall- og slaggsprut. UV-stråling på

-

ubeskyttede kroppsdeler har samme virkning

som solbrenthet.

-

-

Viktige merknader for brukeren

Dekkgass-sveiseapparatet MIG/MAG er en likestrømskilde med integrert trådfremtrekk som er konstruert og bygd utelukkende for hhv. MIG- og MAGlysbuesveising.

All annen bruk av apparatet er forbundet med fare

og skal derfor unngås.

Apparatet skal bare drives med den nettspenningen

som er angitt på typeskiltet. Det må bare tilkoples

jordet stikkontakt som er installert av autorisert elek

troinstallatør. Strømkretsen til stikkontakten må

være sikret med smeltesikring eller vernebryter.

Avhengig av nettilkoplingsbetingelsene på tilkoplingspunktet kan sveisestrømkilden forårsake for-

3.1

-

Gass – damp – røyk

x Under sveisingen utvikles det skadelig røyk og

metallstøv. Vi anbefaler bruk av røykmaske og

at man bare sveiser i tilstrekkelig ventilerte rom

for å sikre den nødvendige beskyttelsen av personalet.

x Ved sveising i lukkede rom er det absolutt

påkrevd å bruke avtrekk som er plassert under

sveisesonen.

x Materialet som skal sveises, må være fritt for

halogenholdige avfettingsmidler for å hindre

dannelsen av giftige gasser.

x Metaller som er belagt med bly, grafitt, kad-

mium, sink, kvikksølv eller beryllium, eller som

MIG/MAG 140/160

Page 17

inneholder disse stoffene, kan utvikle kraftig

røyk under sveisingen.

x Ved sveising frigjøres ozon. Det er en form for

oksygen som kan føre til irritasjon og sykdommer i luftveiene.

x Klorholdige fettløsende midler som trikloretylen,

perkloretylen osv. fordamper ved sveising og

gjennomgår en kjemisk forvandling til fosgen.

Fosgen er giftig!

UV-stråler

x Strålene fra lysbuen kan føre til øyeskader og

hudforbrenninger.

x Som vern mot gnister, varme, synlige og usyn-

lige stråler må man bruke egnet øyevern

(beskyttelsesskjold eller beskyttelseshette med

standardiserte strålevernglass trinn 10 til 15

ifølge DIN 4647, avhengig av strømstyrke).

x Man må aldri se inn i lysbuen med ubeskyttede

øyne (fare for å bli blendet og brent). Hvis man

ikke beskytter øynene tilstrekkelig, forårsaker

de usynlige UV-strålene en svært smertefull bin

dehinnebetennelse som først merkes etter noen

timer.

x Sveising må bare skje innenfor synsvidden til

andre personer som kan komme raskt til hjelp i

nødsfall.

x Personer eller hjelpere som befinner seg i nær-

heten av lysbuen, må opplyses om farene og

utstyres med nødvendig beskyttelse.

x Arbeidsplasser i nærheten skal avskjermes på

en egnet måte for å beskyttes mot strålepåvirkning.

x Ved sveisearbeider i rom og bygninger skal det

sørges for tilstrekkelig ventilasjon.

Brann

Fare!

A

Lysbuens temperatur ligger på ca. 2400 °C.

Før sveisearbeidene begynner, må du være oppmerksom på følgende:

x Brennbare stoffer og gjenstander innenfor en

omkrets på 5 m fra sveisestedet må fjernes.

x Stoffer innenfor en omkrets på 5 m, som ikke

kan fjernes, skal dekkes til på en adekvat måte

med stålplater, våte kleder osv.

x Åpninger, sprekker, hull i murer osv. skal dek-

kes til eller tettes igjen for å unngå ukontrollert

gnistregn.

x Slokkemidler som brannslokkere, vannbøtter

osv. skal være i beredskap.

x Vær oppmerksom på at det på grunn av varme-

leding fra sveisestedet også kan oppstå brann

på tildekkede steder eller i andre rom.

x Etter at sveisearbeidene er slutt, må du i løpet

av de neste 6 til 8 timene flere ganger kontrollere sveisestedets omgivelser med hensyn til

gløding, brannsteder, varmeleding osv.

Behandling av dekkgassflasker

x I omgangen med dekkgassflasker skal de aktu-

elle sikkerhetsforskriftene følges. Særlig må

dekkgassflaskene sikres mot mekaniske skader, velting og fall og beskyttes mot oppvarming

(maks. 50 °C), langvarig solbestråling og sterk

kulde på grunn av det farlig høye indre trykket

(opptil 200 bar).

x Når MIG/MAG-apparatet monteres til dekkgass-

flasken, må man være klar over at for store flasker kan føre til at apparatet velter hvis underlaget er ujevnt. For å unngå at det oppstår skader

på apparatet eller gassflasken på denne måten,

bør det bare brukes flaskestørrelser som passer

til apparatet. (10 l- eller 20 l-flasker).

x Etterfylling eller omfylling skal bare foretas av

-

godkjente firmaer.

Farer på grunn av elektrisk strøm

x Tilkopling til nettet og vedlikehold av dekkgass-

anlegget skal utføres forskriftsmessig.

x Sørg for at strømforsyningen er jordet.

x Sørg for at arbeidsbenken er jordet.

x Vedlikehold skal bare utføres av kvalifisert per-

sonale.

x Defekte eller skadede deler på brenner eller

slangepakke skal straks byttes ut.

x Apparatet skal alltid bare koples til stikkontakter

som er jordet. Det er bare tillatt å bruke tilkoplinger inkludert stikkontakter og skjøteledninger

med jordede kontakter som er installert av en

autorisert elektroinstallatør.

x Sikringen av tilførselsledningen til nettkontak-

tene må være i samsvar med forskriftene. Ifølge

disse forskriftene er det bare tillatt å bruke sikringer eller automater som samsvarer med ledningstverrsnittet. Bruk av sikring med for høy

kapasitet kan føre til ledningsbrann eller brannskader på bygning.

x Skadet isolasjon på sveisebrenner og skadede

sveiseledninger skal skiftes ut umiddelbart.

x Bytte av skadet nettledning, stikkontakt osv. og

reparasjoner på dekkgass-sveiseapparatet skal

bare utføres av autorisert elektroinstallatør.

x Sveisebrenneren må ikke klemmes fast under

armen eller holdes slik at det kan gå strøm gjennom kroppen.

x Ved lengre pauser i arbeidet skal apparatet set-

tes ut av drift. Etter at arbeidet er slutt og før

apparatet sskal flyttes, må støpselet trekkes ut

MIG/MAG 140/160

3.2

Page 18

av kontakten. Ved uhell eller ulykker skal sveisestrømkilden umiddelbart skilles fra nettet.

Generell beskrivelse av apparatet

MIG/MAG-dekkgass-sveiseapparatet består av en

transformator (statisk karakteristikk) med silisiumlikeretter og en sveisekretsspole samt en trådfremtrekksenhet.

Apparatet er beregnet på sveising av forskjellige

sveisetråder (f.eks. stål, s. Tekniske data) under en

beskyttende gassatmosfære (CO

og argon).

Apparatet er ventilatorkjølt og utstyrt med overbelastningsvern.

Symboler på apparatet

Fare!

Følgende advarsler må tas til følge

for å unngå store personskader eller

skader på gjenstander

Les bruksanvisningen før apparatet

tas i bruk

Trådmatingshastighet

Skal ikke brukes når det regner

Sveiseapparatet egner seg for sveising i

omgivelser med økt elektrisk fare.

Overtemperatur

Opplysninger på typeskiltet:

6

6 Produsent

7 Apparatbetegnelse

78910

, blandingsgass

2

1213

11

8 Serienummer

9 Normhenvisning – Apparatet oppfyller kra-

vene i h.t. angitt standard

10 CE-merke – Apparatet oppfyller EU-direkti-

vet i h.t. samsvarserklæringen

11 Avhendingssymbol – Apparatet kan avhen-

des via produsenten

12 Elektriske ytelsesdata

13 Produksjonsår

Å ta apparatet i bruk

Uttak av vedlagte deler

Alle vedlagte deler befinner seg i rommet for fremtrekk av sveisetråd, og kan tas ut etter at lokket er

fjernet.

Oppstilling

x Lysbuesveiseapparatet skal plasseres i en tørr

omgivelse med tilstrekkelig frihet for kjøling.

x Når apparatet plasseres på en skrå flate, må

den beskyttes mot å falle over. Plasser apparatet på et egnet, flatt underlag.

x Apparatet er konsipert for bruk i rom med tak.

Når det regner må det ikke sveises utendørs.

Nettilkopling

x Kontroller at spenningen som er angitt på type-

skiltet, stemmer overens med nettspenningen i

strømnettet på stedet.

x Før støpselet settes i kontakten, skal nettspen-

ningsbryteren settes på null.

Tilkopling av dekkgassflasken

x Sett gassflasken på apparatets flaskeoppstil-

lingsplass og fest den til flaskeholderen på bakveggen med kjettingen. Etter at beskyttelseshetten er tatt av, skal flaskeventilen vendes bort

fra kroppen og åpnes et lite øyeblikk.

x Skru trykkreduksjonsventilen på gjengestussen

på gassflasken. Opprett slangeforbindelse mel

lom trykkreduksjonsventilen og gasstilførselstilkoplingen på MIG/MAG-apparatet.

x Anbefalt gassgjennomstrømning i trekkfrie rom:

5 – 10 liter/minutt.

x Hvis det brukes regulerbar trykkreduksjonsven-

til, skal gassgjennomstrømningen stilles inn

etter literskalaen ved hjelp av vingeskrue. Skru

innover for å øke gjennomstrømningen og skru

utover for å redusere den.

-

3.3

MIG/MAG 140/160

Page 19

x Mens innstillingen foregår, må apparatet være

slått på og brennerbryteren må være trykt inn,

slik at magnetventilen åpnes. For å unngå unø

dig sveisetrådforbruk, skal bladfjæren i sveisetrådfremtrekket svinges ut til siden.

Det er ikke tillatt å foreta inngrep og reparasjoner på

trykkreduksjonsventiler på grunn av de farene som

er forbundet med dette. Defekte trykkreduksjonsventiler skal sendes inn til serviceverkstedet.

Tilkopling av arbeidsstykket

Klem fast arbeidsstykkeklemmen fra MIG/MAGapparatets jordledning i umiddelbar nærhet av sveisestedet. Pass på at det er metallisk blank overgang

på kontaktstedet.

Forberedelse av sveisefugen

Arbeidsstykkene som skal sveises, skal være frie for

lakk, metallbelegg, smuss, rust, fett og fuktighet.

Forberedelsene av sveisefugen skal gjennomføres i

henhold til de sveisetekniske forskriftene.

Anvisninger om innstilling og om

sveiseteknikk

bryteren. Apparatet er skilt fra nettet når Max-Minbryteren står på null.

-

Apparatet er utstyrt med en temperaturføler som

kopler ut apparatet elektrisk ved overbelastning.

Kontrollampen gir signal når temperaturføleren reagerer. Sveisestrømkilden og sveisetrådfremtrekket

blir forbigående koplet ut.

Etter avkjøling koples strømkilden automatisk inn

igjen; signallampen slukkes.

Innstilling av sveiseparametere

Etter at forberedelsene er gjennomført, kan sveisingen begynne.

Sveisespenning og trådfremtrekkshastighet skal da

tilpasses til hverandre i henhold til sveiseoppgaven.

Hvis trådfremtrekkshastigheten økes, øker strøm

styrken.

Det er mulig å finne optimale parametere for enhver

sveisetråddiameter og enhver sveiseoppgave. De

kan blant annet kjennes igjen på den typisk sum

mende lysbuelyden.

Hvis man avviker for mye fra de optimale verdiene,

er det ikke mulig å få til perfekt sveising.

-

-

Innkopling av apparatet

Innstilling av apparatet skal skje ved hjelp av sveisespenningsbryteren i forbindelse med Max-Min-

Den riktige sveisefugen

I tabellen finner du anvisninger for forming av fuger.

Fugeform Utførelse Platetyk-

kelse

s (mm)

I-fuge ensidig < 1,5

I-fuge tosidig

V-fuge

25

s

b

s

b

> 1,5

2 – 4 < 2

3 – 6 < 1

3 – 6 < 1

Fugbredde

b (mm)

0

< 2

K-fuge

Dobbel K-fuge

MIG/MAG 140/160

s

> 0,6 –

0,6 – 1,5 –

> 0,6 –

3.4

Page 20

Hjørneskjøt

Fugeform Utførelse Platetyk-

kelse

s (mm)

> 1 –

s

Fugbredde

b (mm)

Stell og vedlikehold

Apparatet er for en stor del vedlikeholdsfritt.

Fare – elektrisk spenning!

B

Før ethvert vedlikehold og enhver feilretting

skal støpselet trekkes ut!

x Fremtrekkshjulet, mottrykksrullen og innløpsdy-

sen skal kontrolleres regelmessig med hensyn

til tilsmussing, om nødvendig må de rengjøres.

x Med jevne mellomrom må den komplette bren-

nerslangepakken rengjøres fordi det avsettes

avslitte partikler og støv innvendig.

x Brennerens kontaktdyse er en slitedel. Når hul-

let er blitt for stort, må den byttes.

x På innerveggene i brennerens gasskappe setter

det seg fast små metallpartikler. Disse må evt.

fjernes. Et skillemiddel letter dette arbeidet og

forebygger at splintene kleber seg fast.

x Skadede ledninger må straks skiftes ut.

Feilretting

Mekaniske feil viser seg for det meste ved ujevnt

sveisetrådfremtrekk eller ved at fremtrekket er blok

kert.

Elektriske feil fører til at apparatet faller ut helt eller

delvis.

Fare – elektrisk spenning!

B

Feilsøking i den elektriske delen av apparatet

og alle arbeider på det elektriske anlegget

skal utelukkende foretas av autorisert elektro

installatør.

Videre feilsøking er mulig i henhold til vedlagte koplingsskjema.

Feilsøkingen må først skje når apparatet er i spenningsløs tilstand og i følgende rekkefølge:

1. Det må kontrolleres at nettilkoplingen og de

andre tilkoplingene ved bryterne, trafoen og

drosselen* samt stikkontaktene og loddede forbindelser sitter fast.

2. Kontroll av sikringen med hensyn til passasje og

kontakt.

3. Optisk kontroll med hensyn til evt. kortslutninger

eller overbelastning av viklinger (misfarging).

-

-

Feil, årsak Retting

• Urolig eller ustabil lysbue?

Gal sveisespenningsstilling

For mye / for lite sveisetråd

Arbeidsstykkeklemmen løs eller stor overgangsmotstand (rust,

lakk)

Kontaktdyse slitt eller

gal diameter

Gassmengde galt innstilt

Arbeidsstykket urent i

sømområdet

Effektdel defekt Bring apparatet til service-

Inntrekksspiralen tilsmusset

Feil ved fremtrekket Se nedenfor

• Mye sprut ved sveisingen?

For mye sveisetråd Drei trådfremtrekksregulato-

For høy sveisespenning

Arbeidsstykket urent Rengjør det

• Fremtrekksmotoren går ikke?

Ingen nettspenning Kontroller nettilkoplingen

Nettspenningsbry-

teren står på null

Brennerbryter ikke slått påSlå på brennerbryteren

Sikring La en autorisert elektro-

Motor defekt Bring apparatet til service-

Korriger på spenningstrinnbryteren

Reguler på trådfremtrekksregulatoren

Sørg for at det er god kontakt mellom arbeidsstykket

og arbeidsstykkeklemmen

Bytt den

Still inn gassmengden

Fjern lakk, rust, fett osv.

verksted

Rengjør og skift den

ren tilbake

Still spenningstrinnbryteren

tilbake

Still inn spenningstrinnet

installatør skifte den

verksted

3.5

MIG/MAG 140/160

Page 21

• Ingen sveisetrådtransport?

Mottrykksrullen for løs Øk mottrykket på bladfjæren

ved hjelp av fingerskruen

Sveisetråden brukket

av ved fremtrekket

Rille i fremtrekkshjulet

nedslitt

Tråd brent fast på

kontaktdysen

Rett ut innløpsdysen

Bytt fremtrekkshjul

Bytt kontaktdyse, hvis tråden er deformert, reduser

mottrykket

• Apparatet koples ut, overbelastningsindikatoren

lyser?

Innkoplingsvarighet

(ED) overskredet

Effektdel defekt Bring apparatet til service-

La apparatet kjøles ned,

overhold ED iht. typeskiltet

verksted

Tekniske data

MIG/MAG 140 MIG/MAG 160

Tilkoplingsspenning 1 x 230 V, 50/60 Hz 1 x 230 V, 50/60 Hz

Tilkoplingseffekt maks. 5,1 kVA 5,3 kVA

Tilkoplingsstrøm maks. 22 A 23 A

Sikring (treg) 16 A 16 A

Tomgangsspenning 17,5 – 28 V 19 – 30 V

Innstillingsområde 30 – 140 A 30 – 160 A

Maks. innkoplingsvarighet (40°C) 4 % 8 %

Trinn 4 4

Sveisetrådfremtrekk 1,0 – 12 m/min 1,0 – 12 m/min

Elektrodediameter 0,6 – 0,8 mm 0,6 – 0,8 mm

Kapslingsklasse IP 21 IP 21

Lengde x bredde x høyde 590 x 260 x 420 mm 590 x 260 x 420 mm

Vekt 21 kg 26,5 kg

Justeringsområde for strøm

Posisjon MIG / MAG 140 MIG / MAG 160

130A30A

250A60A

380A100A

4140A160A

MIG/MAG 140/160

3.6

Page 22

XS0028B.fm

4Suomi/ Finland

Käyttöohjeet

1

2

3

4

5

1 Hitsauspolttimen liityntä (+) napa

2 Hitsausvirran kytkentä/katkaisu

3 Langansyötön säädin

4 Ylikuormituksen merkkivalo

5 Maadoituspuristimen liityntä (–) napa

Hyvä asiakas

Parhaat onnittelumme tämän korkealaatuisen MIG/

MAG-hitsauskoneen hankinnan johdosta. Taataksemme turvallisuutesi ja laitteen turvallisen käytön,

pyydämme sinua lukemaan käyttöohjeet kokonaan

ennen koneen käyttöä ja noudattamaan kaikkia

kohtia.

Perustietoa käyttäjälle

MIG/MAG hitsauskone on vaihtovirtalähteellä ja

yhdistetyllä langansyöttölaitteella varustettu hitsauskone, joka on tarkoitettu yksinomaan MIG- ja

MAG-kaarihitsaukseen.

Kaikki tämän koneen muu käyttö on vaarallista, eikä

ole sallittua.

Hitsauskonetta tulee käyttää vain koneen arvokilvessä mainitulla pääjännitteellä. Kytkentä verkkoon

tulee tehdä pätevän sähköasentajan asentaman

maadoitetun pistokkeen kautta. Verkko tulee olla

suojattu sulakkeella tai pienoisvirtakytkimellä.

Riippuen virran kytkennästä kytkentäpisteessä hitsausvirtalähde voi aiheuttaa häiriöitä muille virrankuluttajille. Tarkista oma tehonkäyttösi ennen verkkoon kytkeytymistä. (CISPR 11, luokka A)

Pidä hitsauskone lasten ulottumattomissa.

Ota huomioon hitsaukseen liittyvät vaaratekijät ja

noudata kaikkia työhön ja palonestoon liittyviä määräyksiä.

Hitsauskone ei sovellu ulkokäyttöön sateessa. Säilytä kone kuivassa paikassa.

Laite ei sovi putkien sulattamiseen.

Varoitus:

A

henkilön, jolla on sydämentahdistaja, tulee

neuvotella lääkärinsä kanssa ennen tämän

hitsauskoneen käyttöä.

Turvallisuustietoa ja onnettomuuksien torjunnasta

x Pidä hitsauskone lasten ulottumattomissa.

x Noudata kaikkia työsuojelu- ja palontorjuntaoh-

jeita työskennellessäsi tällä hitsauskoneella.

x Noudata kaikkia soveltuvia onnettomuuden

esto-ohjeita. Hitsaukseen liittyy paljon erilaisia

vaaroja, mitkä voivat olla terveysriskejä tietyissä olosuhteissa.

x Käytä hitsatessa aina sopivia, kuivia haalareita

(suositellaan tulenkestäviä hitsaajan haalareita), tukevia eristettyjä saappaita, hitsaajan

maskia ja nahkaisia hitsaajan käsineitä.

x Synteettisistä aineista valmistetut vaatteet ja

kengät eivät ole suositeltavia.

Kuivat, eristävät käsineet molemmissa käsissä

suojaavat sähköiskuilta (hitsausvirtapiirin tyhjäkäyntijännite), vaaralliselta säteilyltä (lämpö- ja

ultraviolettisäteily) sekä hehkuvalta metallilta ja

kuonaroiskeilta. Ultraviolettisäteilystä tulee

auringonpolttovaikutus iholle.

Huurut - höyryt - savu

x Hitsauksen aikana kehittyy vaarallisia savuja ja

metallipölyjä. Hitsaajan työsuojelun takia suo

sittelemme voimakkaasti hitsaushuurujen poistoa ja hitsaamista ainoastaan kunnolla tuuletetuissa tiloissa.

x Suljetuissa tiloissa tulee käyttää tehostettua

tuuletusta, joka sijoitetaan hitsausalueen alapuolelle.

x Hitsattavassa materiaalissa ei saa olla halogee-

niliuottimia tai rasvanpoistoaineita, jottei niistä

muodostuisi myrkyllisiä höyryjä.

x Lyijyllä, grafiitilla, kadmiumilla, sinkillä, elohope-

alla tai berylliumilla päällystetyt tai niitä sisältävät metallit voivat muodostaa paljon savuja hitsauksen aikana.

x Hitsaus muodostaa otsonia, joka voi ärsyttää tai

vioittaa hengityselimiä.

x Rasvanpoistoaineet, kuten trikloorietyleeni, tet-

rakloorietyleeni jne höyrystyvät hitsauksen

aikana ja muuttuvat kemiallisesti fosgeeniksi

(karbonyylikloridi). Fosgeeni on myrkyllistä!

-

4.1

MIG/MAG 140/160

Page 23

UV-säteily

x Kaaren säteily voi aiheuttaa silmävaurioita ja

ihon palamista.

x Kipinöiltä, lämmöltä, näkyvältä ja näkymättö-

mältä säteilyltä suojauee käyttää soveltuvaa silmäsuojainta (hitsausmaskia tai kypärää, jossa

on standardinmukainen suodattava suojalasi,

hitsausvirrasta riippuen luokat 10 B 15 DIN 4647

mukaisesti).

x Älä katso suojaamattomin silmin kaareen

(sokeutumis- ja paloriski). Näkymätön ultraviolettisäteily aiheuttaa, jos silmäsuojaus on riittämätön, hyvin kivuliaita, vasta tuntien päästä

ilmeneviä seuraamuksia.

x Hitsaa vain silloin, kun on näköetäisyys muihin,

että voit saada apua hätätilanteessa.

x Avustajien tai muitten lähelläolevien tulee olla

tietoisia vaaroista ja heillä tulee olla tarvittavat

suojavarusteet.

x Viereisten työpaikkojen tulee eristetty toisistaan

säteilysuojaverhoilla.

x Sisällä hitsattaessa tulee olla riittävä tuuletus.

Tulipalo

Varoitus!

A

Kaaren lämpötila on noin 2400 °C.

Ennen hitsauksen aloittamista noudata seuraavaa:

x Poista kaikki palava materiaali ja esineet 5 m

säteellä hitsauspaikasta.

x Materiaali, jota ei voi poistaa 5 m säteellä, tulee

suojata peittämällä se metallilevyillä, märillä

kankailla tms.

x Kaikki seinäaukot, halkeamat jne tulee peittää ja

tiivistää lentäviltä roiskeilta.

x Pidä palotorjuntalaitteet, kuten sammutin, vesi-

astia jne käsillä.

x Pidä mielessä, että palon leviäminen hitsaus-

paikasta voi alkaa peitetyistä osista tai muista

huoneista.

x Hitsaustyön lopettamisen jälkeen tarkista useita

kertoja 6 - 8 tunnin aikana, ettei ympäristössä

ole lämmön johtumista, palavia pisteitä, piilossa

olevat palopesäkkeitä jne.

Suojakaasupullojen käsittely

x Noudata kaasupullojen käsittelyä koskevia

määräyksiä. Vaarallisen korkean paineen

vuoksi (jopa 200 bar) suojakaasupulloja tulee

erityisesti suojata mekaanisilta vaurioilta, putoamiselta tai kaatumiselta, lämpenemiseltä (max.

50 °C), pitkäaikaiselta auringon säteilyltä tai

kovalta pakkaselta.

x Mikäli hitsauskone varustetaan liian suurella

kaasupullolla, siitä tai epätasaisesta perustasta

voi seurata hitsaus- koneen kaatuminen.

Estääksesi tällaisesta johtuvat hitsauskoneen

tai kaasupullon vauriot, käytä ainoastaan sopivan kokoisia kaasupulloja (10l / 20l pulloja).

x Pullojen täyttö tulee tehdä vain valtuutetuilla

täyttöasemilla.

Sähkövaarat

x Hitsauskoneen kytkeminen verkkoon ja huolto

tulee tehdä VDE-säännöksien tai muitten maahan soveltuvien standardien mukaan.

x Varmista kunnollinen syöttöpiirin suojakytkentä.

x Varmista työpenkin suojakytkentä.

x Vain pätevä henkilöstö saa tehdä huolto- tai

kunnossapitotöitä.

x Vaihda vialliset tai vahingoittuneet polttimen

osat tai polttimen johtimet välittömästi.

x Kone saadaan kytkeä periatteessa vain maa-

doitettuun liitäntään. Ainoastaan pätevän sähköasentajan asentamat maadoitetut liittimet, ml.

ulosotot, jatkokaapelit maadoitetuilla pistokkeilla ja maajohtimilla ovat sallittuja.

x Sähkösyötön suojasulakkeen tulee olla paikal-

listen määräyksien mukainen. Näitten määräyksien mukaan tulee asentaa sulakkeet tai pienoiskytkimet johtimen poikkipinnan mukaisesti.

Ampeerimäärältään liian suuren sulakkeen

asentaminen voi aiheuttaa sähkölinjaan palo

vaaran ja rakennukseen palovahinkoja.

x Vaihda vioittunut polttimen eriste tai vioittuneet

hitsauskaapelit välittömästi.

x Vioittuneen voimakaapelin, - tulpan jne vaihta-

minen ja hitsauskoneen sähköisten komponenttien korjaus tulee jättää pätevälle sähköasentajalle.

x Hitsauspoltinta ei tule kiinnittää käteen tai sillä

tavoin että virta voi johtua suoraan hitsaajaan.

Katkaise virta pitempien työkatkoksien ajaksi.

x Kytke kone pois verkosta, kun työ on valmis, tai

kun siirrät konetta. Onnettomuustilanteessa

irroita hitsausvirtalähde heti verkosta.

-

Koneen yleiskuvaus

MIG/MAG-hitsauskone muodostuu muuntajasta,

sarjaan kytketystä piitasasuuntaajasta (staattinen

ominaiskäyrä), hitsausvirran kuristimesta ja langansyöttöyksiköstä.

Hitsauskone sopii erilaisten hitsauslankojen suojakaasuhitsaukseen (mm teräslangan, ks "Tekninen

määrittely") suojakaasun ollessa CO2:ta, seoskaa

sua tai argonia.

Kone on varustettu tuulettimella ja ylikuormasuojalla.

-

MIG/MAG 140/160

4.2

Page 24

Symbolit laitteella

Vaara!

Seuraavien varoitusten laiminlyönti

voi johtaa vakaviin vammoihin.

Lue ohjekirja ennen käyttöönottoa.

Langansyöttönopeus

Älä käytä laitetta sateessa

Hitsauslaite sopii hitsaamiseen ympäristössä, jossa vallitsee tavallista suurempi

sähköinen vaara.

Ylikuumeneminen

Käyttöönotto

Mukana toimitettavat osat

Kaikki mukana toimitettavat osat ovat langansyöttöyksikön sisällä ja voidaan ottaa esille, kun langansyöttöyksikön kansi on irroitettu.

Asennus

x Suojakaasuhitsauslaite tulee sijoittaa kuivaan

ympäristöön, jossa on jäähdytyksen tarvitsema

määrä vapaata tilaa.

x Jos laite sijoitetaan vinolle alustalle, sen kaatu-

minen tulee estää: aseta laite suoran pinnan

muodostavalle kiilamaiselle alustalle.

x Laite on suunniteltu käytettäväksi katetuissa

tiloissa. Ulkona ei saa hitsata sateella.

Tiedot tyyppikilvellä:

6

6 Valmistaja

7 Laitenimitys

8 Sarjanumero

9 Normiohje - Tämä laite täyttää mainitun normin

10 CE-merkki – Tämä laite täyttää EU-direktiivit vaa-

11 Hävityssymboli – Laite voidaan hävittää valmista-

12 Sähköiset tiedot

13 Valmistusvuosi

78910

1213

vaatimukset

timuksenmukaisuusvakuutuksen mukaisesti

jan kautta

11

Verkkoon kytkentä

x Tarkista, että liitäntäjännite vastaa koneen arvo-

kilven jännitettä.

x Aseta koneen hitsauskytkin asentoon "0" ennen

verkkoon kytkemistä.

Suojakaasupullon liitäntä

x Aseta suojakaasupullo hitsauskoneen pulloteli-

neeseen ja lukitse pullo paikalleen koneen takaosassa olevalla ketjulla. Irroita pullon hattu ja

avaa pulloventtiiliiä hiukan poispäin itsestäsi.

x Ruuvaa paineenalennin kaasupullon venttiiliin.

Vedä kaasuletku paineenalentimesta koneen

kaasuliitäntään.

x Suositeltava kaasunvirtaus vedottomassa

tilassa on: 5-10 l/min.

x Käytettäessä säädettävää paineenalenninta

aseta virtaus kellossa olevan virtausasteikon

mukaan T-ruuvilla. Vääntämällä T-ruuvia

sisään kaasunvirtaus lisääntyy ja vääntämällä

sitä ulos virtaus vähenee.

x Säädettäessä kaasunvirtausta, kone tulee olla

kytkettynä päälle ja hitsauspolttimen liipasinta

tulee pitää alaspainettuna, niin että kaasuvent

tiilin solenoidi on auki. Jotta hitsauslankaa ei

kuluisi turhaan, käännä langansyöttöyksikön

lehtijousi sivulle.

Paineenalentimen muutokset ja korjaukset ovat

ehdottomasti kiellettyjä asiaan liittyvien vaarojen

vuoksi. Lähetä vialliset paineenalentimet huoltoon

korjattaviksi.

-

4.3

MIG/MAG 140/160

Page 25

Maadoituksen liitäntä

Kiinnitä hitsauskoneen maadoituskaapelin puristin

mahdollisimman lähelle hitsauskohtaa. Varmista

hyvä metallikosketus.

Hitsisauman valmistelu

Hitsisauman alue työkappaleessa tulee olla puhdistettu maalista, metallipinnoitteista, liasta, ruosteesta, rasvasta ja kosteudesta.

Hitsisauman valmistelu tulee tehdä noudattaen hitsin suunnittelumääräyksiä.

Hitsaustekniikan ja koneen säätövihjeitä

Koneen kytkeminen päälle

Kone kytketään päälle yhdistetyllä ON/OFF B hitsauskytkimellä. Kytkimen asennossa "0" kone on sähköisesti irti sähkösyötöstä.

Koneeseen on kytketty lämpötunnistin, joka kytkee

koneen poispäältä lämpötilan noustessa liian korkealle.

Lämpöylikuorma näkyy koneen etupanelissa olevasta merkkivalosta. Hitsausvirtalähde ja langansyöttö eivät toimi. Jäähtymisen jälkeen hitsausvirtalähde ja langansyöttö kytkeytyvät automaattisesti

päälle ja merkkivalo sammuu.

Hitsausarvojen säätö

Hitsauskoneen valmistelujen jälkeen hitsaus voi

alkaa.

Hitsausjännitteen ja langansyöttönopeuden tulee

olla työhön sopivia. Kun langansyöttönopeus kasvaa, kasvaa hitsausvirta vastaavasti.

Jokaista langanhalkaisijaa ja jokaista hitsaustehtävää kohti löytyy optimiarvot. Ne voi tunnistaa mm.

tyypillisestä surisevasta kaaren äänestä.

Mikäli arvot poikkeavat liian paljon optimiarvoista,

hitsaus ei onnistu tyydyttävästi.

Oikea liitos

Allaolevassa taulukossa on informaatiota hitsisauman suunnittelusta.

Hitsisauman muoto Tyyppi Materiaalin

paksuus

s (mm)

1 x I-railo < 1,5

2 x I-railo

V-railo

Piena

25

s

b

s

b

> 1,5

2 – 4 < 2

3 – 6 < 1

3 – 6 < 1

> 0,6 –

s

0,6 – 1,5 –

Kaksoispiena

> 0,6 –

Juuren

avaus

b (mm)

0

< 2

Kulma

MIG/MAG 140/160

> 1 –

s

4.4

Page 26

Hoito ja kunnossapito

Kone on lähes huoltovapaa.

Vaara - jännittellinen

B

Kytke kone irti sähköverkosta ennen huoltoa!

x Tarkista syöttörulla, painerulla ja polttimen lan-

kajohdin-suutin säännöllisin väliajoin, puhdista

mikäli tarpeen.

x Sopivin väliajoin tulee puhdistaa koko hitsaus-

poltin mukaanlukien johtimet, kumiosat ja sisäpuolelle tulevat pölykertymät.

x Polttimen kontaktisuutin on kuluva osa. Reiän

suurennuttua suutin tulee vaihtaa.

x Paikalleen työnnettävään kaasusuuttimeen ker-

tyy roiskeita. Nämä tulee tarvittaessa poistaa.

Roiskeenestospray helpottaa työtä ja estää

roiskeita tarttumasta suuttimeen.

x Vaihda vioittuneet kaapelit välittömästi.

Vianetsintä

Mekaaniset viat ilmenevät useimmiten epäsäännöllisenä tai kokonaan keskeytyvänä langansyöttönä.

Sähköviat aiheuttavat laitteeseen virhetoimintoja,

joko yksittäiseen komponenttiin tai koko laitteeseen.

Vaara - jännittellinen

B

Sähkövikojen etsintä tulee jättää pätevälle

sähköasentajalle.

Se voidaan tehdä mukana olevan sähkökaavion

avulla.

Vikojen etsinnän tulee alkaa virran kytkemisellä pois

koneesta ja sitten seuraavassa järjestyksessä:

1. Tarkista sähkön syöttökaapelin liitäntä ja kaikki

kytkimien liitännät, muuntaja ja kuristin sekä

kaikki pistokkeiden ja tulppien liitännät ja juotet

tujen liitäntöjen tiukkuus.

2. Tarkista sulakkeen johtavuus ja kontakti.

3. Tarkista silmämääräisesti käämien ylikuormitus

tai puutteet (värittyminen).

-

Todennäköinen syy Korjaus

• Äänekäs tai epästabiili kaari

Väärä hitsausjännite Korjaa hitsauskytkimellä

Liikaa/liian vähän lan-

gansyöttöä

Maadoituspuristin löy-

sällä tai suuri vastus

kontaktissa (ruoste,

maali)

Kontaktisuutin kulunut

tai väärä halkaisija

Väärä kaasuvirtauksen

asetus

Työkappale likainen

sauma-alueella

Virtalähde viallinen Tarkastuta kone huollossa

Spiraalijohdin likainen Puhdista tai vaihda

Langansyöttö viallinen Ks alla