Page 1

PLANING MACHINES

WORK MADE PLANE EASY.

Whether you are a professional or an ambitious do-

it-yourself enthusiast, Metabo provides you with the

right planer for your requirements. You can use Metabo

planers for low-dust dressing and planing without

harmful vibrations. Even thick boards cause no pro-

blems due to the anti planer cut patent. There is even

more great technology such as the safety switch, the

automatic workpiece feed and the conversion from

surface planing to thickness planing without tools.

e.g. HC 300 Coated, solid aluminium die cast

dressing plate with 1200 mm length

Therefore even long timbers

can be guided well.

Automatic, even

workpiece feed

during thickness

planing due to high

quality steel rollers.

Precise thickness planing

by bench thicknesser table

on 8 bearings.

Built-in socket

for connecting

a suction unit.

for dust-free trimming

Suction hood

and thickness planing.

Simple conversion

from planer to bench

thicknesser without tools.

Anti-planer cut (snipe) patent

for ideal planing results. Minimal planer

cut on the workpiece by patented special

suspension of the rollers.

Planing of inclined surfaces

The stop can be inclined by up to 45°.

Sturdy substructure

for safe working at ideal

operating height.

Precise thickness planing

by bench thicknesser table on

8 bearings. Automatic, even

workpiece feed.

278 |

Page 2

EQUIPMENT FEATURES

Ideal for mobile use due to low weight

Lateral depth stop adjustment

Large table length

Powerful universal motor for powerful lugging drive

and even planing result

Precise thickness adjustment for quick and exact planing

Large supply and delivery tables support the

conveyance of long materials; for ideal planing results

BENCH THICKNESSER

Planing locking mechanism prevents unintentional

adjustment of the chip removal setting and guarantees

precise work results

For single phase alternating current

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

DH 330

Bench Thicknesser

DH 330

Comparative device characteristics

Dimensions L x W x H 579 x 857 x 574 mm

Chip removal

- Thickness planing 0 - 3 mm

Material

- Thickness table Cast aluminium /

special steel aluminium

Thickness table L x W 840 x 330 mm

Passage height/width 152 mm/330 mm

Feed rate 7 m/min

Diameter of blade shaft 47 mm

Number of blades 2

Blade shaft speed 9.800 /min

Rated input power 1,8 kW

Weight 35 kg

Standard equipment 2 integrated HSS reversible

planer blades, push stick,

extraction nozzle

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

Type DH 330

Order no. 0200033000

0200033038

0200033039

GB

GB

230 V

110 V

| 279

COMPRESSED

AIR SYSTEMS

Page 3

PLANING MACHINES

COMMON FEATURES

For precise angular trimming of raw wood

Sturdy feedgear mechanism

Thickness table made of solid, non-abrasive grey cast iron

Convenient height adjustment with crank handle

Dressing plate made of cast aluminium

Planer blade with double edge

Trimming fence, swivelling 90°-45°

Extensive range of accessories

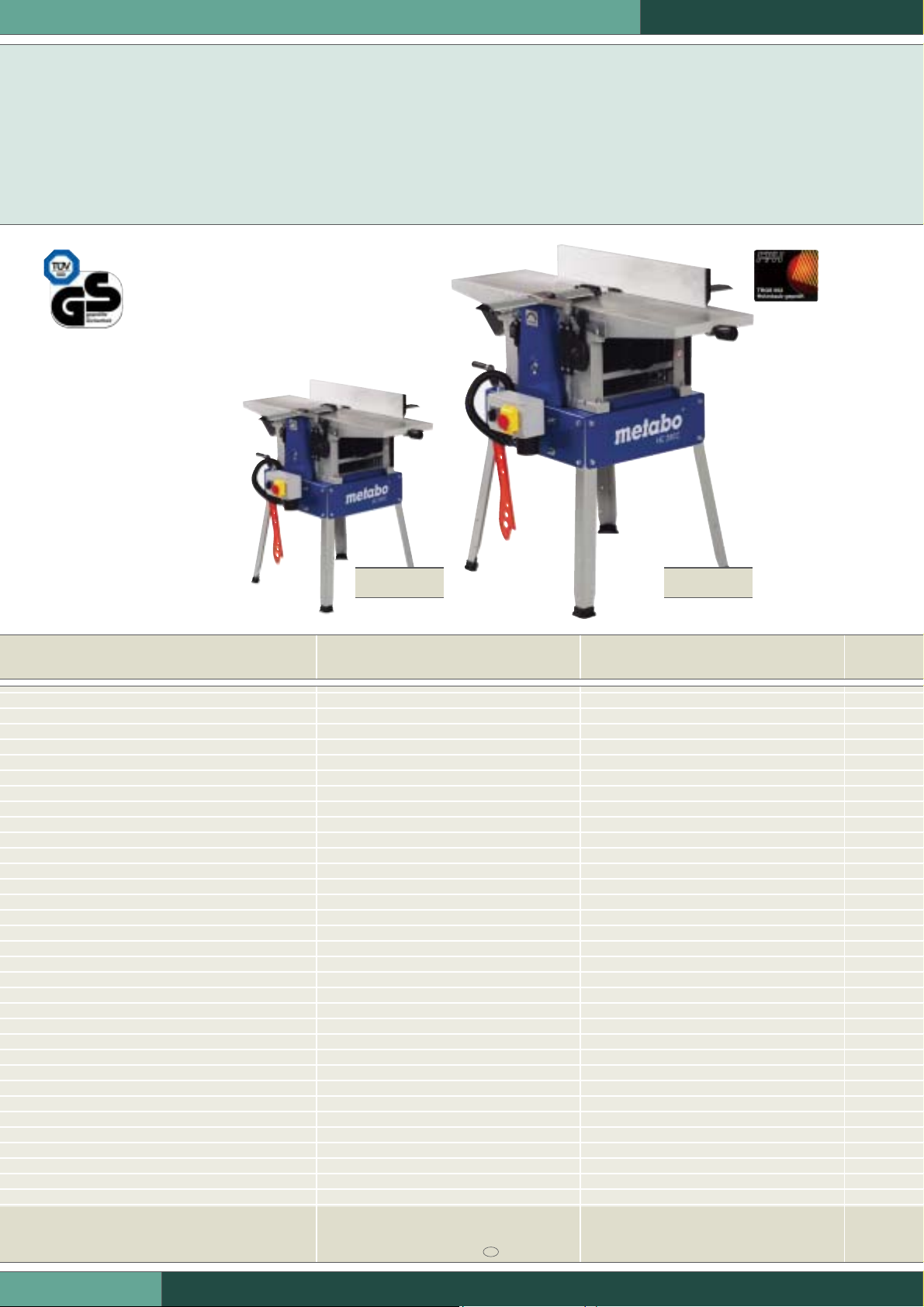

HC 260 C -

2,2 WNB

Planing Machine

HC 260 C -

2,2 WNB

HC 260 C -

2,8 DNB

Planing Machine

HC 260 C -

2,8 DNB

Special advantages

Dustproof according to TRGS 553 by FPH

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 1.110 x 620 x 960 mm 1.110 x 620 x 960 mm

Dressing plates L x W 1.040 x 260 mm 1.090 x 260 mm

Chip removal

- Planing 0 - 3 mm 0 - 3 mm

- Thickness planing 0 - 3 mm 0 - 3 mm

Material

- Dressing plates Cast aluminium Cast aluminium

- Thickness table Grey cast iron Grey cast iron

Thickness table L x W 400 x 260 mm 400 x 260 mm

Passage height/width 160 mm/260 mm 160 mm/260 mm

Feed rate 5 m/min 5 m/min

Diameter of blade shaft 63 mm 63 mm

Number of blades 2 2

Blade shaft speed 6.500 /min 6.500 /min

Rated input power 2,2 kW 2,8 kW

Output power 1,6 kW 2 kW

Weight 71 kg 71 kg

Standard equipment Integrated disposable reversible planer

blades, short, swivelling jointing fence, chip

ejection hood, push stick, extraction nozzle

Integrated disposable reversible planer

blades, short, swivelling jointing fence, chip

ejection hood, push stick, extraction nozzle

Type HC 260 C - 2,2 WNB HC 260 C - 2,8 DNB

Order no. 0114026000 0114026100

GB

0114026038

230 V

280 |

Page 4

COMMON FEATURES

High stability due to the powder-coated, closed machine stand

Slot boring machine can be attached to the side (accessory)

For precise angular trimming of raw wood

Sturdy feedgear mechanism

Thickness table with special steel support

Convenient height adjustment with crank handle

PLANING MACHINES

Dressing plate made of cast aluminium

Trimming fence, swivelling 90°-45°

Dustproof according to TRGS 553 by FPH

Extensive range of accessories

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

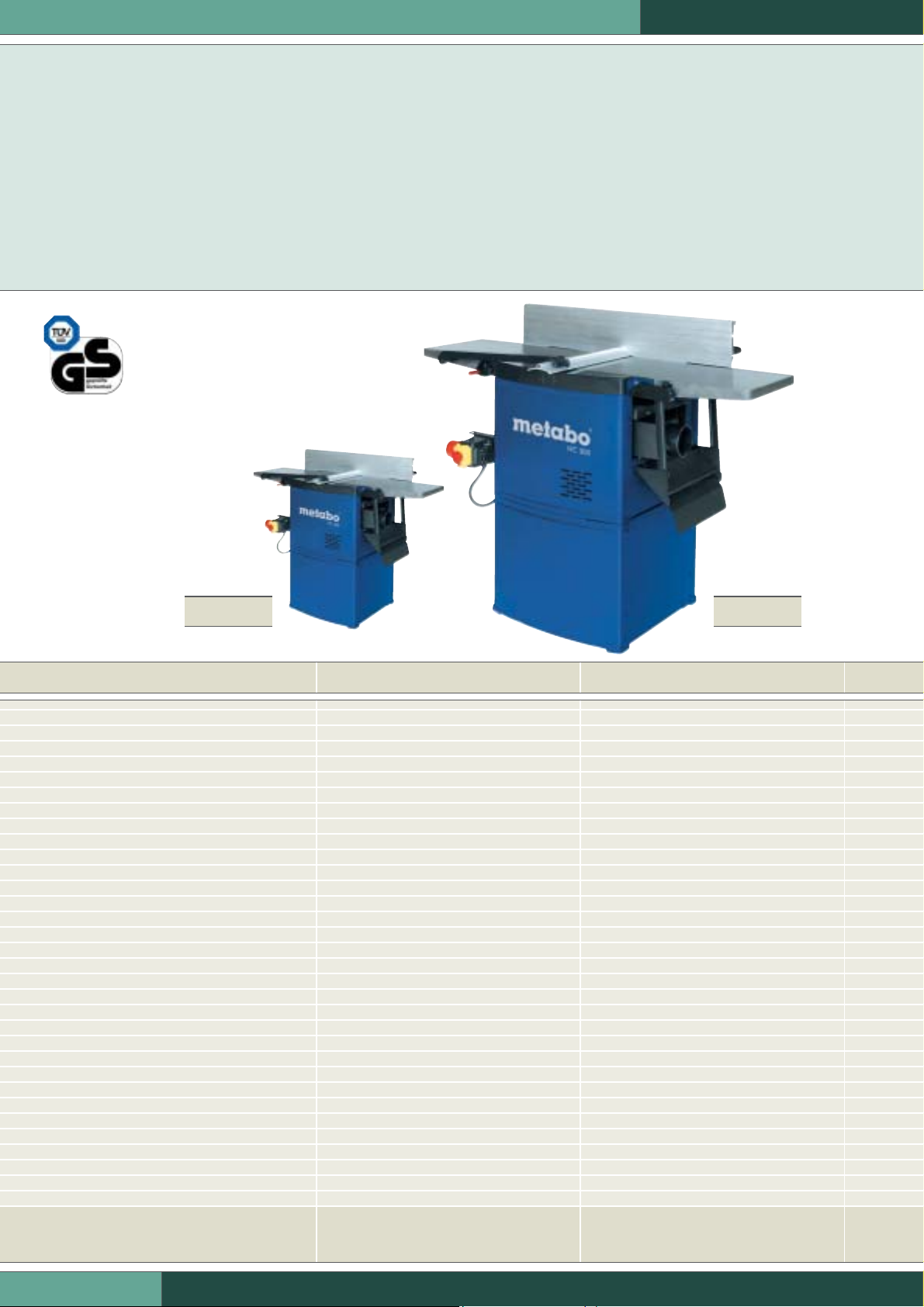

HC 260 K -

3,1 WNB

Planing Machine

HC 260 K -

3,1 WNB

HC 260 K -

4,2 DNB

Planing Machine

HC 260 K -

4,2 DNB

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 1.090 x 540 x 410 mm 1.090 x 540 x 410 mm

TECHNOLOGY

WOOD-PROCESSING

Dressing plates L x W 1.090 x 260 mm 1.090 x 260 mm

Chip removal

- Planing 0 - 3 mm 0 - 3 mm

- Thickness planing 0 - 4 mm 0 - 4 mm

Material

- Dressing plates Cast aluminium, hardened Cast aluminium, hardened

- Thickness table Cast aluminium / special steel aluminium Cast aluminium / special steel aluminium

Thickness table L x W 400 x 260 mm 400 x 260 mm

Passage height/width 160 mm/260 mm 160 mm/260 mm

TECHNOLOGY

WATER-/PUMP

Feed rate 5 m/min 5 m/min

Diameter of blade shaft 63 mm 63 mm

Number of blades 2 2

Blade shaft speed 6.500 /min 6.500 /min

Rated input power 3,1 kW 4,2 kW

Output power 2 kW 2 kW

Weight 72 kg 72 kg

Standard equipment 2 integrated HSS reversible planer blades,

short, swivelling jointing fence, chip ejection

hood, push stick, extraction nozzle

2 integrated HSS reversible planer blades,

short, swivelling jointing fence, chip ejection

hood, push stick, extraction nozzle

Type HC 260 K - 3,1 WNB HC 260 K - 4,2 DNB

Order no. 0112026053 0112026061

0112026096 (mounted)

| 281

WELDING

COMPRESSED

TECHNOLOGY

AIR SYSTEMS

Page 5

PLANING MACHINES

COMMON FEATURES

Anti-planer cut patent for ideal planing results

(minimum feed and extraction levels on the workpiece)

Robust machine housing for high stability and extensive

vibration-free work

Simple conversion from surface planer to bench thicknesser

without tools

Automatic, even workpiece feed

Thickness table on four ball bearings

Dressing plate made of coated, solid aluminium

die cast for good guidance of long wood

With lockable switch

Sturdy support for safe work at ideal operating height

For precise angular trimming of raw wood

Thickness table made of solid, non-abrasive grey cast iron

Convenient height adjustment with crank handle

Planer blade with double edge

Trimming fence, swivelling 90°-45°

Dustproof according to TRGS 553 by FPH

Extensive range of accessories

HC 300 W -

1,85 W

Planing Machine

HC 300 W - 1,85 W

Planing Machine

HC 300 D - 2,8 D

HC 300 D -

2,8 D

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 1.200 x 580 x 1.010 mm 1.200 x 580 x 1.010 mm

Working height 850 mm 850 mm

Dressing plates L x W 1.200 x 300 mm 1.200 x 300 mm

Chip removal

- Planing 0 - 3 mm 0 - 3 mm

- Thickness planing 0 - 3 mm 0 - 3 mm

Material

- Dressing plates Cast aluminium Cast aluminium

- Thickness table Grey cast iron Grey cast iron

Thickness table L x W 500 x 300 mm 500 x 300 mm

Passage height/width 165 mm/300 mm 165 mm/300 mm

Feed rate 5 m/min 5 m/min

Diameter of blade shaft 60 mm 60 mm

Number of blades 2 2

Blade shaft speed 6.000 /min 6.000 /min

Rated input power 1,85 kW 2,8 kW

Output power 1,3 kW 2,2 kW

Weight 85 kg 85 kg

Standard equipment 2 integrated HSS planer blades, gauge for

setting the planer blades, large, swivelling

jointing fence, chip ejection hood, push stick,

extraction nozzle

2 integrated HSS planer blades, gauge for

setting the planer blades, large, swivelling

jointing fence, chip ejection hood, push stick,

extraction nozzle

Type HC 300 W - 1,85 W HC 300 D - 2,8 D

Order no. 0113030000 0113030100

282 |

Page 6

COMMON FEATURES

Optimum draw-in rollers, rubber-coated extraction rollers

for best contact pressure

Four chrome-plated self-cleaning transport columns,

on 8 ball bearings

High own weight for excellent stability

Dressing plate made of solid, non-abrasive grey cast iron

Robust machine housing for high stability and extensive

vibration-free work

Simple conversion from surface planer to bench thicknesser

without tools

Automatic, even workpiece feed

PLANING MACHINES

Thickness table on four ball bearings

Sturdy support for safe work at ideal operating height

Slot boring machine can be attached to the side (accessory)

For precise angular trimming of raw wood

Thickness table made of solid, non-abrasive grey cast iron

Convenient height adjustment with crank handle

Planer blade with double edge

Trimming fence, swivelling 90°-45°

Dustproof according to TRGS 553 by FPH

Extensive range of accessories

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

HC 333 G -

2,5 WNB

Planing Machine

HC 333 G - 2,5 WNB

HC 333 G -

2,8 DNB

Planing Machine

HC 333 G - 2,8 DNB

Special advantages

For single phase alternating current

For three phase current

TECHNOLOGY

Comparative device characteristics

WOOD-PROCESSING

Dimensions L x W x H 1.240 x 560 x 1.010 mm 1.240 x 560 x 1.010 mm

Working height 850 mm 850 mm

Dressing plates L x W 1.240 x 340 mm 1.240 x 340 mm

Chip removal

- Planing 0 - 3 mm 0 - 3 mm

- Thickness planing 0 - 3 mm 0 - 3 mm

Material

- Dressing plates Grey cast iron Grey cast iron

- Thickness table Grey cast iron Grey cast iron

TECHNOLOGY

WATER-/PUMP

Thickness table L x W 550 x 310 mm 550 x 310 mm

Passage height/width 180 mm/307 mm 180 mm/307 mm

Feed rate 5 m/min 5 m/min

Diameter of blade shaft 64,5 mm 64,5 mm

Number of blades 2 2

Blade shaft speed 6.300 /min 6.300 /min

Rated input power 2,5 kW 2,8 kW

Output power 1,9 kW 2,2 kW

Weight 140 kg 140 kg

Standard equipment 2 integrated HSS reversible planer blades,

large, swivelling jointing fence, gauge for

setting the planer blades, chip ejection hood,

push stick, extraction nozzle

2 integrated HSS reversible planer blades,

large, swivelling jointing fence, gauge for

setting the planer blades, chip ejection hood,

push stick, extraction nozzle

WELDING

TECHNOLOGY

Type HC 333 G - 2,5 WNB HC 333 G - 2,8 DNB

Order no. 0113033355 0113033380

GB

0113033363

230 V

| 283

COMPRESSED

AIR SYSTEMS

Page 7

PLANING MACHINES

EQUIPMENT FEATURES

Powder-coated, sturdy and torsion-free welded construction

Sturdy feedgear mechanism that can be shut off

Swivelling switch terminal

Guide shafts, drive shafts and screwed joints are protected

against corrosion permanently by galvanised coating

Thickness table made of grey cast iron; guided by central

spindle

Optimum draw-in rollers, rubber-coated extraction rollers

for best contact pressure

High own weight for excellent stability

Dressing plate made of solid, non-abrasive grey cast iron

Robust machine housing for high stability and extensive

vibration-free work

Simple conversion from surface planer to bench

thicknesser without tools

With lockable switch

Sturdy support for safe work at ideal operating height

Slot boring machine can be attached to the

side (accessory)

For precise angular trimming of raw wood

Convenient height adjustment with crank handle

Planer blade with double edge

Trimming fence, swivelling 90°-45°

Dustproof according to TRGS 553 by FPH

Extensive range of accessories

For three phase current

HC 410 G -

5,5 DNB

Planing Machine

HC 410 G - 5,5 DNB

Comparative device characteristics

Dimensions L x W x H 1.700 x 820 x 1.070 mm

Working height 850 mm

Dressing plates L x W 1.700 x 410 mm

Chip removal

- Planing 0 - 5 mm

- Thickness planing 0 - 5 mm

Material

- Dressing plates Grey cast iron

- Thickness table Grey cast iron

Thickness table L x W 670 x 405 mm

Passage height/width 230 mm/405 mm

Feed rate 7 m/min

Diameter of blade shaft 82 mm

Number of blades 3

Blade shaft speed 5.500 /min

Rated input power 5,5 kW

Output power 3,2 kW

Weight 250 kg

Standard equipment 3 integrated planer blades, gauge for setting the planer blades,

phase inverter, large, swivelling jointing fence,

chip ejection hood, push stick, extraction nozzle

Type HC 410 G - 5,5 DNB

Bestell-Nr. 0113041013

284 |

Page 8

PLANING MACHINES

Planer blades

DimensionsmmReversib-

le planer

Suitable for

Packing

unit

Order no.

blades

HSS planer blade

For all soft woods and hard woods

Regrindable

18% tungsten = increased tool life

332 x 12 x 1,5

334 x 16 x 2

260 x 20 x 3

304 x 25 x 3 HC 300 2

310 x 20 x 3 HC 333 G 2

410 x 25 x 3 HC 410 G 3

410 x 14 x 2,55

DH 330, DH 316 0911063549

DH 330 2 0911062119

HC 260 C 2),

HC 260 M 2), HC 260 K

2 0911030721

1)

0911060167

0911053179

0911050390

HC 410 G 3 0911051150

Disposable reversible planer blades

For all soft woods

260 x 18,6 x 1

HC 260 C 1),

2 0911030713

HC 260 M 1), HC 260 K

Carbide planer blade

For all hard woods, especially exotic woods, laminated

wood, hard paper, fabric reinforced laminates

Panel materials and plastics

Regrindable, long tool life

260 x 20 x 3

HC 260 C 2),

HC 260 M 2), HC 260 K

2 0911030730

1)

304 x 25 x 3 HC 300 2 0911060175

310 x 20 x 3 HC 333 G 2 0911053160

410 x 25 x 3 HC 410 G 3 0911050366

Planer blade and retaining strip conversion set

260 HC 260 C, HC 260 M 2 0911030845

1)

Standard equipment of the planing machines

2)

Also requires planer blade and retaining strip conversion set 0911030845

Planer blade adjusting devices

Order no.

Planer blade adjusting device

Suitable for all blade shafts

Simple handling and exact cutter

0911016397

projection

In wooden case

Scope of delivery: 2 magnet

planer blade adjusting devices,

3 setting plates for blade

excess length

Not suitable for: HC 310

ACCESSORIES FOR DH 330

Order no.

Universal machine stand

For ideal working height

0910057529

and secure base

Can also be used

on uneven surfaces

Collapsible, with height

compensation

ACCESSORIES FOR HC 260 C, HC 260 K, HC 260 M

Order no.

Wheel set

For easy transportation

Suitable for: HC 260 C,

HC 260 M

Wheel set

For easy transportation

Suitable for: HC 260 K

0911003783

0911007100

1)

1)

1)

ACCESSORY FOR HC 300

Wheel set

For easy transportation

ACCESSORIES FOR HC 333 G

Slot boring machine

For the moulding/routing of

peg holes and oblong holes

For oblong holes up to 60 mm

deep and 125 mm long

With 2 hand lever operation

for longitudinal and

transverse motion

Including geared chuck,

extraction nozzle and

1 clamping device

Clamping table: 400 x 130 mm

Working height: 800 mm

Length adjustment: 125 mm

Drilling depth: 60 mm

Height adjustment: 130 mm

Chuck capacity: 1 - 10 mm

Extraction nozzle Ø: 100 mm

Suitable for: HC 260 M,

HC 260 K

Eccentric clamping device

without stand

For clamping the

workpiece

Clamping stand for slot boring

machine

Required for mounting the

eccentric clamping device

Ø 20x200mm thread M

20x1.5mm

Suitable for: HC 260 M,

HC 260 K

Mortising bit set

All mortising bits can be

clamped in the geared chuck

With two straight cutters and

chip breaker grooves

Right-hand cutting

Ø 6, 8, 10 and 12 mm

Packing unit: 4

Suitable for: HC 260 M,

HC 260 K

Wheel set

For easy transportation

Table length extension

For the secure

supporting of long

workpieces

With height adjustable

support leg and

auxiliary fence rail

Eccentric clamp - easy to

mount and dismount

Front/rear mounting

on the base support

system

HC 333: Mounting

possible on both sides

of the dressing plates

Length: 1.000 mm

Width: 200 mm

Auxiliary fence/stop

For precise guiding with

narrow workpieces

Collapsible

Order no.

0911003791

0910009680

0911009811

0911030497

Order no.

0911060205

Order no.

0911053195

0910018469

0911053594

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

AIR SYSTEMS

COMPRESSED

| 285

Page 9

PLANING MACHINES

Slot boring machine

For the moulding/routing

of peg holes and oblong

holes

With 1 hand lever

operation for longitudinal

and transverse motion

Rapid mounting and

dismounting via two

eccentric levers

Separate height

adjustment

Including geared chuck,

clamping device and

mounting set

Clamping table:

300 x 150 mm

Working height: 810 mm

Length adjustment: 110 mm

Drilling depth: 110 mm

Height adjustment: 110 mm

Chuck capacity: 1 - 14 mm

Extraction nozzle Ø: 100 mm

Suitable for: HC 333 G

Mortising bit set

All mortising bits

can be clamped in

the geared chuck

With two straight cutters

and chip breaker grooves

Right-hand cutting

Ø 6, 8, 10 and 12 mm

Packing unit: 4

ACCESSORIES FOR HC 410 G

wheel set

For easy transportation

With 2 steering rollers

and 2 support rollers

Digital display

The display clock enables

you to set and read the

height with a precision

up to a tenth of a

millimetre when

thickness planing

Suitable for: HC 320 up to

model year 99, HC 410 G

Slot boring machine

For the moulding

/routing of peg holes

and oblong holes

For oblong holes

up to 120 mm deep

and 200 mm long

With 1 hand lever

operation for longitudinal

and transverse motion

Separate height

adjustment

Including geared chuck,

clamping device and

mounting set

Clamping table:

400 x 190 mm

Working height: 870 mm

Length adjustment: 200 mm

Drilling depth: 120 mm

Height adjustment: 120 mm

Chuck capacity: 2,5 - 16 mm

Extraction nozzle Ø: 100 mm

Suitable for: HC 314 up to

model year 99, HC 320 up to

model year 99, HC 410 G

286 |

Order no.

0911053187

0911030497

Order no.

0911014203

0911013983

0911014211

Mortising bits

All mortising bits can be clamped

in the geared chuck

With two straight cutters and chip

breaker grooves

Length

mm

Right-hand cutting

Diameter

mm

Order no.

130 8 0911014394

140 10 0911014408

150 12 0911014416

150 14 0911014424

170 16 0911014432

OTHER ACCESSORIES FOR THE PLANING MACHINES

Push block

Order no.

Push block

For the safe feed of short

workpieces while planing

Roller stands

For supporting long workpieces when sawing,

moulding/routing, planing and drilling

Sturdy, height-adjustable and foldable

RS 420

With smooth-rolling special steel

rollers with a high load capacity

Width: 400 mm

Base weight: 100 kg

Height: 640 - 1.015 mm

RS 420 G

With smooth-rolling chromium-plated

ball bearings

Also permits lateral movements

Ideal for panel material

Width: 520 mm

Base weight: 100 kg

Height: 640 - 1.015 mm

RS 420 W

With smooth-rolling chromium-plated

ball bearings

Adjustable ball bearing gib

Also permits lateral movements

Ideal for panel material, round or

square workpieces

Width: 420 mm

Base weight: 100 kg

Height: 640 - 1.015 mm

Anti seize paste

To help the wood slide well on the dressing plate

and the thickness table

Waxilit 70 g

Weight: 70 g

Waxilit 1,000 g

Weight: 1 kg

Spray for maintenance and care

Spray for maintenance and care

0911060213

Order no.

0910053353

0910053345

0910053361

Order no.

0911001071

4313062258

Order no.

0911018691

Page 10

ALL IN ONE.

Metabo combo-machines can do just everything. You

can use them as table saw, surface planer, bench

thicknesser, spindle moulder or for mortising. But

e.g. Multi 260 S

Large spindle moulder

fence

fence with aluminium

die cast pressing fixture.

Sturdy table-top

made of sheet steel.

Infinitely variable height

adjustment during

thickness planing.

COMBO-MACHINES

best of all: con version from one function to the next is

possible quickly without any tools. Is there anything else

you need?

Trimming slide

on ball bearings;

ideal for cutting

head boards.

Large rip or

planer fence

with aluminium

die cast pressing

fixture.

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

Lockable main switch.

Multi 260 S as table saw with

standard carbide-tipped saw blade

and trimming slide.

Welded machine stand

for maximum precision

and stability.

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

Multi 260 S as surface planing and

thickness planing device or as

spindle moulder with mortising

device.

The fence with clamp for firm grip.

| 287

COMPRESSED

AIR SYSTEMS

Page 11

COMBO-MACHINES

COMMON FEATURES

Five-in-one combo-machines: can be used as table

saw, surface planer, bench thicknesser, as bench

milling cutter and for mortising (with accessory)

Easy conversion of various units without special tool

Infinitely variable height adjustment while thickness

planing, steel-corrugated extraction roller

Lockable main switch

Large adjustable fence with pressure appliance made

of sturdy aluminium die cast.

Sturdy sheet steel table-top, grey cast iron thickness

table

Max. tool diameter in the adjustable fence 180 mm,

in the table 150 mm

Trimming slide on ball bearing - ideal for moulding/

routing head boards

Slot boring machine can be attached to the

side (accessory)

With extensive range of accessories for versatile use

MULTI 260 S - DMULTI 260 S - D

Combo-Machine

MULTI 260 S - W

Combo-Machine

MULTI 260 S - D

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

As table saw

Table size 1.040 x 400 mm 1.040 x 400 mm

Cutting height 90/45° 90 mm/58 mm 90 mm/58 mm

Saw blade swivel range 0 - 45 ° 0 - 45 °

Maximum cutting width 420 mm 420 mm

Speed 4.600 /min 4.600 /min

Cutting speed 60 m/s 60 m/s

Sliding table 1.080 x 140 mm 1.080 x 140 mm

- Cross-cut guide, length 800 mm 800 mm

- Swivel range, cross-cut guide (right/left) 45 °/45 ° 45 °/45 °

- Cutting width in front of/behind saw blade 720/1.250 mm 720/1.250 mm

As surface planer

Table length 1.040 mm 1.040 mm

Planing width 260 mm 260 mm

Max. chip removal 4 mm 4 mm

Shaft diameter 62 mm 62 mm

Shaft speed 6.300 /min 6.300 /min

As bench thicknesser

Thickness table L x W 590 x 260 mm 590 x 260 mm

Passage height/width 150 mm/260 mm 150 mm/260 mm

Max. chip removal 4 mm 4 mm

Feed rate 7 m/min 7 m/min

As spindle moulder

Spindle speed 4.300/8.500 /min 4.300/8.500 /min

Diameter of spindle 30 mm 30 mm

Spindle height adjustment (maximum) 125 mm 125 mm

Dimensions L x W x H 1.080 x 880 x 850 mm 1.080 x 880 x 850 mm

Rated input power 2,2 kW 2,2 kW

Output power 1,5 kW 1,5 kW

Weight 166 kg 166 kg

Standard equipment HSS planer blade (regrindable), carbide saw

blade Ø 250 mm, trimming slide on ball

bearing, extraction nozzle Ø 100 mm,

wheel set

HSS planer blade (regrindable), carbide saw

blade Ø 250 mm, trimming slide on ball

bearing, extraction nozzle Ø 100 mm,

wheel set

Type MULTI 260 S - W MULTI 260 S - D

Order no. 0290026008 0290026016

GB GB

288 |

Page 12

COMMON FEATURES

Five-in-one combo-machines: can be used as table

saw, surface planer, bench thicknesser, as bench

milling cutter and for mortising (with accessory)

Easy conversion of various units without special tool

Infinitely variable height adjustment while thickness

planing, steel-corrugated extraction roller

Three motors with powerful lugging capacity

Lockable selector switch for all three motors

Maximum work safety by additional safety end switch

Heavy die cast iron table-tops

Max. tool diameter in the adjustable fence 180 mm,

in the table 150 mm

Trimming slide on ball bearing - ideal for moulding/

routing head boards

Trimming slides with sturdy swivel arm base

Slot boring machine can be attached to the

side (accessory)

With extensive range of accessories for versatile use

Combo-Machine

MULTI 310 G - W

COMBO-MACHINES

MULTI 310 G - DMULTI 310 G - W

Combo-Machine

MULTI 310 G - D

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

As table saw

Table size 1.080 x 435 mm 1.080 x 435 mm

Cutting height 90/45° 82 mm/56 mm 82 mm/56 mm

Saw blade swivel range 0 - 45 ° 0 - 45 °

Maximum cutting width 450 mm 450 mm

Speed 4.200 /min 4.200 /min

Cutting speed 54 m/s 54 m/s

Sliding table 1.080 x 140 mm 1.080 x 140 mm

- Cross-cut guide, length 800 mm 800 mm

- Swivel range, cross-cut guide (right/left) 45 °/45 ° 45 °/45 °

- Cutting width in front of/behind saw blade 680/1.250 mm 680/1.250 mm

As surface planer

Table length 1.400 mm 1.400 mm

Planing width 310 mm 310 mm

Max. chip removal 4 mm 4 mm

Shaft diameter 62 mm 62 mm

Shaft speed 6.200 /min 6.200 /min

As bench thicknesser

Thickness table L x W 550 x 310 mm 550 x 310 mm

Passage height/width 200 mm/310 mm 200 mm/310 mm

Max. chip removal 5 mm 5 mm

Feed rate 7,5 m/min 7,5 m/min

As spindle moulder

Spindle speed 4.300/6.750/8.500 /min 4.300/6.750/8.500 /min

Diameter of spindle 30 mm 30 mm

Spindle height adjustment (maximum) 130 mm 130 mm

Dimensions L x W x H 1.400 x 890 x 890 mm 1.400 x 890 x 890 mm

Rated input power 2,6 kW 2,8 kW

Output power 1,8 kW 2,2 kW

Weight 355 kg 355 kg

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

Standard equipment HSS planer blade (regrindable), carbide saw

blade Ø 250 mm, trimming slide on ball

bearing, extraction nozzle Ø 100 mm

HSS planer blade (regrindable), carbide saw

blade Ø 250 mm, trimming slide on ball

bearing, extraction nozzle Ø 100 mm

Type MULTI 310 G - W MULTI 310 G - D

Order no. 0290031001 0290031010

GB GB

| 289

COMPRESSED

AIR SYSTEMS

Page 13

COMBO-MACHINES

ACCESSORIES FOR THE COMBO-MACHINES

Wheel sets

Wheel set

For easy transportation

Suitable for: Multi 310

Table length extensions

Table length extension

For the secure

supporting of

long workpieces

With height-adjustable

support leg

Eccentric clamp:

easy to mount

and dismount

Can be mounted

at the front or

the rear

Suitable for: Multi 260

Length: 1.000 mm

Width: 150 mm

FOR SAWING

Sliding table width extensions

Sliding table width extension

For enlarging the

supporting surface

Mounted and dismounted

without tools

Length: 350 mm

Width: 262 mm

Length guides

Length guide

For use with the

cross-cut guide of

the sliding table

Enables the cutting

to length of workpieces

of up to 1,700 mm

Extractable

Length 1,100 mm

Order no.

0920054102

Order no.

0920053947

Order no.

0920054072

Order no.

0920054110

Circular saw blades

Top cutting results thanks to teeth

ground on all sides and high accuracy

of flatness and concentric running

Tungsten carbide blades: long tool

life thanks to use of unmixed carbide

Can be reground repeatedly

Made in Germany

Material DimensionsmmTooth

Version Order no.

pitch

Tungsten

carbide

Tungsten

carbide

250 x 2,8 x 30 24 Alternately bevel-

ground tips

250 x 2,8 x 30 34 Alternately bevel-

ground tips,

6.28012

6.28045

Combo secondary

hole holder

Tungsten

carbide

250 x 2,8 x 30 42 Alternately bevel-

ground tips,

6.28046

Combo secondary

hole holder

Tungsten

carbide

250 x 2,8 x 30 60 Alternately bevel-

ground tips,

6.28049

Combo secondary

hole holder

Tungsten

carbide

250 x 3,2 x 30 60 Alternately bevel-

ground tips,

6.28050

Combo secondary

hole holder

Tungsten

carbide

250 x 2,8 x 30 80 Alternately bevel-

ground tips,

6.28087

Combo secondary

hole holder

Tungsten

carbide

250 x 2,8 x 30 80 Flat tooth/

trapezoidal

6.28088

tooth,

5° negative

FOR PLANING

HSS planer blade

For all soft woods and hard woods

Regrindable

18% tungsten = increased tool life

Dimensions

mm

260 x 20 x 2,5 Multi 260 2 0920054030

310 x 20 x 2,5 Multi 310 2 0920054048

Planer blade adjusting devices

Push block

Suitable for Packing unit Order no.

Order no.

Planer blade adjusting device

Suitable for all blade shafts

Simple handling and

0911016397

exact cutter projection

In wooden case

Scope of delivery:

2 magnet planer blade

adjusting devices,

3 setting plates for

blade excess length

Order no.

Push block

For the safe feed of short

0911060213

workpieces while planing

290 |

Page 14

COMBO-MACHINES

Anti seize paste

To help the wood slide well on the dressing plate

and the thickness table

Order no.

Waxilit - anti seize paste

To help the wood slide

0911001071

well on the dressing plate

and the thickness table

Weight: 70 g

Waxilit - anti seize paste

To help the wood slide

4313062258

well on the dressing plate

and the thickness table

Weight: 1 kg

FOR MOULDING/ROUTING

Tenon benches

Order no.

Tenon bench

Prevents the workpiece

from being pulled from

the router bit into the

housing

Particularly when

moulding/routing

short chocks

Support surface:

440 x 150 mm

Arc milling fences

Arc moulding guide

Enables the moulding/

routing of curved

and similarly shaped

workpieces

Suction connection

Ø 100 mm

Including arc

milling fence

Carbide straight bit

For grooving all kinds of wood

and panel materials

Carbide-tipped straight bit

Groove depth max. 25 mm

Groove widthmmDiameter

PA-wood tested

mm

Bore

mm

4 100 30 0914031095

6 100 30 0914031117

8 100 30 0914031125

10 100 30 0914031133

12 100 30 0914031141

14 100 30 0914031150

16 100 30 0914031168

18 100 30 0914031176

20 100 30 0914031184

0920054080

Order no.

0920054099

Order no.

FOR MORTISING

Slot boring machines

Order no.

Slot boring machine

For the moulding/

routing of peg holes

and oblong holes

With one-hand

lever operation for

longitudinal and

transverse motion

Including geared chuck

and clamping device

Clamping table:

300 x 150 mm

Working height: 830 mm

Length adjustment:

110 mm

Drilling depth: 110 mm

Height adjustment: 80 mm

Chuck capacity: 2 - 14 mm

Extraction nozzle Ø: 100 mm

Suitable for: Multi 260

Slot boring machine

For the moulding/

routing of peg holes

and oblong holes

With one-hand

lever operation for

longitudinal and

transverse motion

Rapid attachment

and removal via two

eccentric levers

Separate height

adjustment

Including geared chuck,

clamping device and

mounting set

Clamping table:

300 x 150 mm

Working height: 810 mm

Length adjustment:

110 mm

Drilling depth: 110 mm

Height adjustment: 110 mm

Chuck capacity: 2 - 14 mm

Extraction nozzle Ø: 100 mm

Suitable for: Multi 310

Mortising bits

All mortising bits can be clamped

in the geared chuck

With two straight cutters and

chip breaker grooves

Left-hand cutting

Length

mm

Diameter

mm

Packing unit Order no.

150 14 1 0911055830

160 16 1 0911055848

Mortising bit sets

All mortising bits can be clamped

in the geared chuck

With two straight cutters and

chip breaker grooves

Left-hand cutting

Mortising bit set

Consisting of mortising

bits Ø 6, 8, 10 and

12 mm (1 each)

0920054056

0920054064

Order no.

0911055821

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

AIR SYSTEMS

COMPRESSED

| 291

Page 15

BAND SAWS

CUTTING EDGE PRECISION.

A Metabo band saw provides you with top features that

nobody else can offer. Whether you make models, small

pieces of furniture or whether you are interested in pro-

fessional applications, a Metabo band saw is always the

right choice. All of our band saws are equipped with pre-

cision three-pulley guides, have sturdy, low-vibration

e.g. BAS 317 Precision

Safety cut out switch

Immediate shut down

when a door is opened.

grey cast iron tables and high quality length stops that

enable clean and precise working, whatever you are

doing. Safety limit switches, blade clamp indicators and

quick-release levers offer more safety but also more

comfortable working.

Quick-action lever

Simple adjustment of the

blade tension by hand wheel.

Indicator for the fast reading

of the blade tension.

Professional parallel stop

With eccentric clamping and

exact scale with built-in magnifying glass. Can be used on both

sides of the saw blade.

"Sawdust-tested"

in compliance with

TRGS 553 by FPH

Precision three-

pulley guide

For optimum guidance

and long service life of

the band saw blade.

Torsion-resistant grey

cast iron saw table

For more precision and at the

same time less vibrations.

Convenient angle adjustment

from –2° to 45° by soft handle

and patented toothed ring guide.

High precision operation

with maximum operating comfort.

Best cutting results are no coincidence.

Metabo. Work. Don’t play.

292 |

By shifting the V-belts

to the lower roller box, four different speeds

can be preset for ideal adjustment to the

material to be cut.

High stability

The combination of torsion-resistant

grey cast iron table and professional

belt guide is the basis for ideal cutting

results in wood, plastic or nonferrous

metal for the professional.

Page 16

EQUIPMENT FEATURES

Door opening without tools; protection by safety end switches

Light saw blade guard stop via hand wheel

Precision three-pulley guide with HPHSS rollers and

brass counter nuts; adjustable without tools

Parallel guide/ripping fence with long profile, clamped at

the front. Can be used on both sides, with built-in magnifier

Mitre guide with soft handle and improved T-slot guide,

for optimum grip while working

Radius cutting with circle sawing attachment (accessory)

Large cutting height with height indicator

BAND SAWS

Sturdy design due to steel sheet construction

Large swivelling grey cast iron saw table

Simple and easy-to-use table fixing via large thumb screw

Suction adapter for all conventional Metabo suction

hose diameters

Support base for optimum stability

Large range of accessories

For single phase alternating current

ACCESSORIES FOR BAS 260 SWIFT

Circle cutting attachments

Circle cutting attachment

For circular cuts

or tapered cuts

(with inclined table)

Diameter from 120 to 280 mm

Band saw blade 6 mm

required for curve sawing

Order no.

0909031249

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

BAS 260 Swift

Band Saw

BAS 260 Swift

Comparative device characteristics

Dimensions L x W x H 525 x 425 x 840 mm

Support surface 340 x 335 mm

Working height without stand 374 mm

Working height with stand

Saw tabel swivel range 0 - 45 °

Cutting height 100 mm

Passage width 245 mm

Cutting speed 690 m/min

Saw belt length 1.712 mm

Saw belt width 6,4 - 12,7 mm

Rated input power 0,35 kW

Output power 0,26 kW

Weight 32,5 kg

Standard equipment A6 universal band saw blade,

support base, parallel guide/

ripping fence, mitre guide,

precision three-pulley guide,

suction adapter (suitable for

Ø 44, 58, 100 mm)

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

Type BAS 260 Swift

Order no. 0090025100

0090025138

GB

230 V

| 293

COMPRESSED

AIR SYSTEMS

Page 17

BAND SAWS

COMMON FEATURES

High precision and cutting output

Two cutting speeds for various applications and materials

Quick-release lever for quick saw blade change and easy

conversion to belt grinder

Door opening without tools; protection by safety end switches

Light saw blade guard stop via hand wheel

Blade clamp indicator with scale for easy reading of actual blade

tension

Precision three-pulley guide with HPHSS rollers and brass counter

nuts; adjustable without tools

Parallel guide/ripping fence with long profile, clamped at the back

and front. Can be used on both sides, with built-in magnifier

Mitre guide with soft handle and improved T-slot guide, for

optimum grip while working

Radius cutting with circle sawing attachment (accessory)

GS dustproof

Large cutting height with height indicator

Sturdy design due to steel sheet construction

Comfortable and precise angle adjustment of saw table from

-2° to 45° due to soft handle and patented toothed ring guide

Suction adapter for all conventional Metabo suction hose

diameters

Large range of accessories

BAS 317

Precision WNB

Band Saw

BAS 317 Precision WNB

BAS 317

Precision DNB

Band Saw

BAS 317 Precision DNB

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 665 x 795 x 1.600 mm 665 x 795 x 1.600 mm

Support surface 548 x 400 mm 548 x 400 mm

Working height

Working height without stand 510 mm 510 mm

Working height with stand 985 mm 985 mm

Saw tabel swivel range -2 - 45 ° -2 - 45 °

Cutting height 165 mm 165 mm

Passage width 305 mm 305 mm

Cutting speed 370/800 m/min 370/800 m/min

Saw belt length 2.240 mm 2.240 mm

Saw belt width 6 - 20 mm 6 - 20 mm

Rated input power 0,9 kW 0,9 kW

Output power 0,57 kW 0,64 kW

Weight 70,5 kg 72 kg

Standard equipment A6 universal band saw blade, stand,

parallel guide/ripping fence, mitre guide,

precision three-pulley guide, suction adapter

(suitable for Ø 44, 58, 100 mm)

A6 universal band saw blade, stand,

parallel guide/ripping fence, mitre guide,

precision three-pulley guide, suction adapter

(suitable for Ø 44, 58, 100 mm)

Type BAS 317 Precision WNB BAS 317 Precision DNB

Order no. 0090317000 0090317100

0090317038

GB

230 V

294 |

Page 18

COMMON FEATURES

High precision and cutting output

Asynchronous motor - sturdy, durable and low-noise

Integrated disc sanding function; ideal for regrinding

Sanding disc bench can be inclined up to 45°

Quick sandpaper change due to Velcro-faced surface

Sturdy parallel guide/ripping fence

Radius cutting with circle sawing attachment (accessory)

GS dustproof

Large capacity for wide workpieces but still with

compact machine dimensions

Grey cast iron base for high stability and quiet running,

with levelling option and assembly bores for stand

BAND SAWS

Sturdy construction due to heavily ribbed aluminium

die cast housing

Sturdy saw table made of die cast aluminium, swivelling

Large range of accessories

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

BAS 380 W BAS 380 D

Band Saw

BAS 380 W

Band Saw

BAS 380 D

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 510 x 900 x 920 mm 510 x 900 x 920 mm

Support surface 600 x 400 mm 600 x 400 mm

Working height

Working height without stand 360 mm 360 mm

Working height with stand 988 mm 988 mm

Saw tabel swivel range -2 - 45 ° -2 - 45 °

Cutting height 160 mm 160 mm

Passage width 380 mm 380 mm

Cutting speed 910 m/min 910 m/min

Saw belt length 2.225 mm 2.225 mm

Saw belt width 3 - 13 mm 3 - 13 mm

Speed of grinding plate 1.450 /min 1.450 /min

Dimensions of the grinding table-top 168 x 413 mm 168 x 413 mm

Grinding plate Ø 200 mm 200 mm

Grinding table swivel range -2 - 45 ° -2 - 45 °

Rated input power 0,74 kW 0,74 kW

Output power 0,5 kW 0,5 kW

Weight 45 kg 45 kg

TECHNOLOGY

WOOD-PROCESSING

TECHNOLOGY

WATER-/PUMP

WELDING

TECHNOLOGY

Standard equipment A6 universal band saw blade,

parallel guide/ripping fence, mitre guide,

extraction nozzle (Ø 100 mm)

A6 universal band saw blade,

parallel guide/ripping fence, mitre guide,

extraction nozzle (Ø 100 mm)

Type BAS 380 W BAS 380 D

Order no. 0090380000 0090380100

| 295

COMPRESSED

AIR SYSTEMS

Page 19

BAND SAWS

COMMON FEATURES

High precision and stability for professional applications

High precision and cutting output

Four cutting speeds for various applications and materials

Door opening without tools; protection by safety end switches

Light saw blade guard stop via hand wheel

Blade clamp indicator with scale for easy reading of actual

blade tension

Precision three-pulley guide with HPHSS rollers and brass

counter nuts; adjustable without tools

Large counterbalanced band saw rollers, rubber coated

Sturdy parallel guide/ripping fence

Radius cutting with circle sawing attachment (accessory)

GS dustproof

Large cutting height with height indicator

Sturdy design due to steel sheet construction

Grey cast iron saw table according to DIN EN 1807, infinitely

swivellable by up to 20°

Large swivelling grey cast iron saw table

Large range of accessories

BAS 505 G DNBBAS 505 G WNB

Band Saw

BAS 505 G WNB

Band Saw

BAS 505 G DNB

Special advantages

For single phase alternating current

For three phase current

Comparative device characteristics

Dimensions L x W x H 834 x 639 x 1.860 mm 834 x 639 x 1.860 mm

Support surface 536 x 640 mm 536 x 640 mm

Working height without stand 925 mm 925 mm

Saw tabel swivel range 0 - 20 ° 0 - 20 °

Cutting height 280 mm 280 mm

Passage width 440 mm 440 mm

Cutting speed 68/176/375/967 m/min 68/176/375/967 m/min

Saw belt length 3.380 mm 3.380 mm

Saw belt width 6 - 25 mm 6 - 25 mm

Rated input power 1,5 kW 1,9 kW

Output power 1,1 kW 1,5 kW

Weight 146 kg 146 kg

Standard equipment A6 universal band saw blade, parallel guide/

ripping fence, precision three-pulley guide,

extraction nozzle (Ø 100 mm)

A6 universal band saw blade, parallel guide/

ripping fence, precision three-pulley guide,

extraction nozzle (Ø 100 mm)

Type BAS 505 G WNB BAS 505 G DNB

Order no. 0090505000 0090505100

0090505038

GB

230 V

296 |

Page 20

BAND SAWS

ACCESSORIES FOR BAS 317 PRECISION

Wheel Sets

Wheel set

For easy

transportation

Suitable for:

BAS 317 Precision

Circle cutting attachments

Circle cutting

attachment

For circular cuts

or tapered cuts

(with inclined table)

Diameter from

120 to 280 mm

Band saw blade

6 mm required for

curve sawing

Belt sanding attachment

Belt sanding attachment

For regrinding surfaces

and curved sawing cuts

Comes with two sanding

belts

Order no.

0910063570

Order no.

0909031249

Order no.

0909031230

Fine sawing attachments

Order no.

Fine sawing attachment

For the sawing of small radii

0909060230

3 mm band saw blade required

(order no. 0909060257)

Circle cutting attachments

Order no.

Circle saw attachment

For circular cuts or tapered cuts

0909060249

(with inclined table)

Diameter from 80 to 240 mm

Band saw blade required for

curve sawing

Cloth sanding belts

Grit Dimensions

Packing unit Order no.

mm

P 60 20 x 2.205 3 0909060290

P 80 20 x 2.205 3 0909060303

P 100 20 x 2.205 3 0909060311

P 150 20 x 2.205 3 0909060320

Cling-fit sanding sheets

SAWS

MACHINES

SPECIAL-PURPOSE

SYSTEMATIC

ORGANISATIONGARDEN

Cloth sanding belts

Grit Dimensions

Packing unit Order no.

mm

P 80 20 x 2.240 3 0909030528

P 120 20 x 2.240 3 0909030536

ACCESSORIES FOR BAS 380

Stands

Order no.

Stand

For ideal working

height and secure

base

With rollers and

level compensation

Working height:

988 mm

0909060222

Grit Diameter

Packing unit Order no.

mm

P 60 200 5 0909060338

P 80 200 5 0909060346

P 100 200 5 0909060354

ACCESSORIES FOR BAS 505 G

Wheel Sets

Order no.

0909000505

Order no.

0910008048

Mitre guides

Wheel set

For easy

transportation

Consisting of:

2 wheels, fastening

elements and

handle bar

Mitre guide

For precise cross cuts and

angular cuts

With workpiece bearing

made of aluminium

Infinitely variable, both sides

adjustable, 90°-45°

WOOD-PROCESSING

WATER-/PUMP

WELDING

COMPRESSED

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

AIR SYSTEMS

| 297

Page 21

BAND SAWS

Circle cutting attachments

Order no.

Circle cutting attachment

For circular cuts or tapered cuts

0909031249

(with inclined table)

Diameter from 120 to 280 mm

Band saw blade 6 mm

required for curve sawing

Belt sanding attachment

Order no.

Belt sanding attachment

For regrinding surfaces and

0909031087

curved sawing cuts

Comes with two sanding belts

Cloth sanding belts

Grit Dimensions

Packing unit Order no.

mm

P 80 25 x 3.380 3 0909030544

P 120 25 x 3.380 3 0909030552

Band saw blades

Carbon steel with inductively hardened teeth points

Very economical due to its long useful life

Dimensions

Tooth pitch Material suitability Order no.

mm

For BAS 260 Swift

1.712 x 6 x 0,36 A4 helical tooth Wood, plastic –

0909057175

curve cuts

1.712 x 12 x 0,36 A6 peg tooth Wood, plastic –

0909057183

universal cuts

1.712 x 12 x 0,36 A2 rake tooth Non-ferrous metal,

0909057191

foamed materials

For BAS 317 Precision

2.240 x 6 x 0,5 A4 helical tooth Wood, plastic –

0909029252

curve cuts

2.240 x 12 x 0,5 A6 peg tooth Wood, plastic –

0909029244

universal cuts

2.240 x 15 x 0,5 A6 peg tooth Wood, plastic –

0909029260

straight cuts

2.240 x 15 x 0,5 A2 rake tooth Metal, foamed

0909029279

materials

For BAS 380

2.225 x 3 x 0,5 A2 helical tooth Wood, plastic – small

0909060257

radii, For circular cuts

using the fine sawing

attachment

2.225 x 6 x 0,36 A4 helical tooth Wood, plastic –

0909060265

curve cuts

2.225 x 9 x 0,36 A6 peg tooth Wood, plastic –

0909060273

universal cuts

2.225 x 13 x 0,36 A6 peg tooth Wood, plastic –

0909060281

straight cuts

For BAS 505 G

3.380 x 6 x 0,5 A4 helical tooth Wood, plastic –

0909029180

curve cuts

3.380 x 13 x 0,65 A2 rake tooth Non-ferrous metal,

0909029228

steel frames

3.380 x 15 x 0,5 A2 rake tooth Wood, nailproof,

0909029210

foamed materials

3.380 x 15 x 0,5 A6 peg tooth Wood, plastic

0909029171

– universal cuts

3.380 x 25 x 0,5 A6 peg tooth Wood, plastic

0909000416

– straight cuts

3.380 x 25 x 0,5 A18 peg tooth Wood, firewood 0909000424

DESIGNATION OF THE BAND SAW BLADES

Example:

T. tip ind. hard. 2240 x 6 x 0,5/A – 4 (14/1")

T. tip ind. hard. = Tooth tip induction hardened

Carbon steel with inductively hardened tooth tips;

very economical due to its long service life

2240 = band length mm

6 = band width mm

0,5 = band thickness mm

A – 4 = clearance of tooth tips mm

14/1" = A2 = number of teeth per inch unit

1,3/1" = A18 = number of teeth per inch unit

DESIGNATION OF BAND SAW BLADES

Helical tooth for small radius

Wood, plastic,

fine sawing attachment

required

Helical tooth for curved cuts

Wood, plastic

Peg tooth for universal cuts

Wood, plastic

Peg tooth for straight cuts

Wood, plastic

Peg tooth for straight cuts

Wood, plastic

▼

▼

18

▼

25

▼

Peg tooth for straight cuts

Firewood

Rake tooth for universal cuts

Aluminium, copper, brass, foams

Rake tooth for universal cuts

Aluminium, copper, brass, steel

A 2

A 4

A 6

A 6

A 6

A 18

A 2

14/1"

298 |

Loading...

Loading...