Page 1

GA 18 LTX

GA 18 LTX G

GE 710 Compact

GE 710 Plus

GE 950 G Plus

en Operating Instructions 4

fr Mode d'emploi 11

www.metabo.com Made in Germany

es Instrucciones de manejo 19

Page 2

9

B

A

1

2

1

2

3

6

8

7

6

7

14

12

13

11

10

9

6

7

14

12

13

11

10

9

6

8

7

1

2

4

4

6

8

7

GE 710 Compact

GE 710 Plus

GE 950 G Plus

GA 18 LTX G

GA 18 LTX

2

Page 3

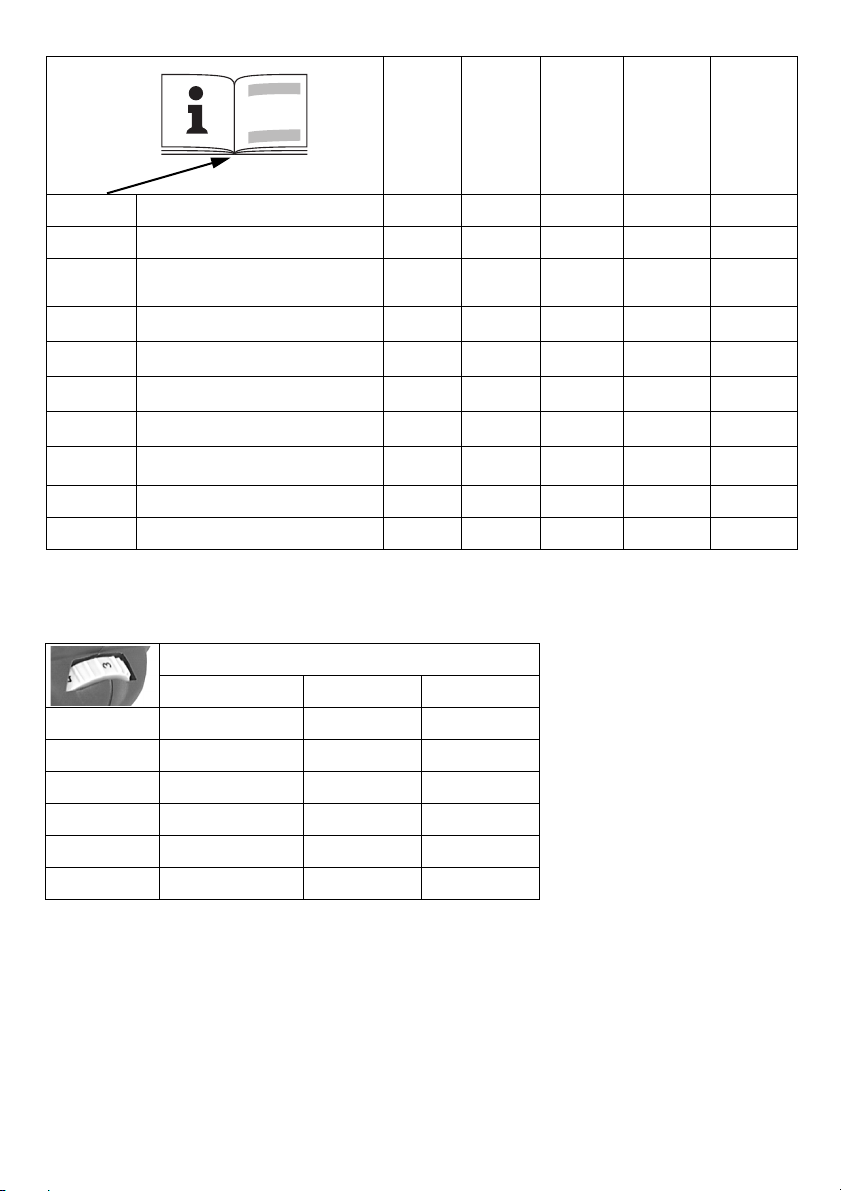

GA 18 LTX

12.

GA 18 LTX G

GE 710 Compact

GE 710 Plus

GE 950 G Plus

S-●● - ●●

U V 18 18 - - -

n /min 25000 6000

n

I

120 V

P

P

D

1

1

2

max

/min - - 24000 24000 7200

A - - 6.4 6.4 8.5

W - - 710 710 950

W - - 430 430 510

in (mm)

7

1

/8 (48) 2 5/32 (55) 111/

13000 -

34000

16

(43)

10000 -

30500

2 (50)

2500 -

8700

2 5/32 (55)

d in (mm) 1/4“ (6) 1/4“ (6) 1/4“ (6) 1/4“ (6) 1/4“ (6)

m lbs (kg) 4.6 (2,1) 4.9 (2,2) 3.1 (1,4) 3.6 (1,6) 3.8 (1,7)

n (/min)

GE 710 Compact GE 710 Plus GE 950 G Plus

1 13000 10000 2500

2 18000 14000 4000

3 23000 18500 5500

4 27000 22000 7000

5 30500 26000 8000

6 34000 30500 8700

Metabowerke GmbH

Postfach 1229

Metabo-Allee 1

D-72622 Nuertingen

Germany

3

Page 4

ENGLISHen

en

Operating Instructions

1. Specified conditions of use

The straight grinders are designed...

- ... for fine grinding work with abrasive points on

metal.

- ... for fine cutting work with small cutting wheels on

metal.

- ... for routing with end mill cutters on non-ferrous

metals, plastics, hardwood, etc.

- ...for working with paint and round wire brushes

- ...for working with polishing bobs

- ...for working with felt polishing tools

- ...for working with lamellar grinding wheels

The machine is not suitable for working with

polishing bells.

The user bears sole responsibility for any damage

caused by improper use.

Generally accepted accident prevention regulations and the enclosed safety information must be

observed.

2. General safety instructions

For your own protection and for the

protection of your electrical tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Reading the operating instructions will reduce the risk of injury.

Pass on your electrical tool only together with these

documents.

General Power Tool Safety Warnings

WARNING – Read all safety warnings and

all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference! The term "power tool" in the warnings

refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

2.1 Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2.2 Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching out-

lets will reduce risk of electric shock.

4

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

2.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

2.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

Page 5

power tool will do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool's operation. If damaged, have

the power tool repaired before use. Many acci-

dents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

2.5 Battery tool use and care

a) Recharge only with the charger specified by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of fire

when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery

packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery terminals

together may cause burns or a fire.

d) Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If

contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause irri-

tation or burns.

2.6 Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

ENGLISH en

3. Special Safety Instructions

3.1 Safety Warnings Common for Grinding,

Sanding, Wire Brushing, Polishing or

Abrasive Cutting-Off Operations:

Use

a) This power tool is intended to function as a

grinder, sander, wire brush, polisher or cut-off

tool. Read all

illustrations and specifications provided with

this power tool. Failure to follow all the instructions

may result in electric shock, fire and/or serious

injury.

b) Do not use any accessories that are not

specifically designed and recommended by the

tool manufacturer. Just because the accessory

can be attached to your power tool, it does not

assure safe operation.

c) The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fly apart.

d) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized acces-

sories cannot be adequately guarded or controlled.

e) The arbour size of wheels, flanges, backing

pads or any other accessory must properly fit

the spindle of the power tool. Accessories with

arbour holes that do not match the mounting hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

f) Do not use damaged accessories. Before

each use, inspect accessories such as abrasive wheels for chips and cracks, backing pad

for cracks, tear or excess wear, wire brush for

loose or cracked wires. If a power tool or

accessory is dropped, check it for damage or

install an undamaged accessory. After

inspecting and installing an accessory, position yourself and bystanders away from the

plane of the rotating accessory and run the

power tool at maximum no-load speed for one

minute. Damaged accessories will normally break

apart during this test time.

g) Wear personal protective equipment.

Depending on application, use a face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors,

gloves and workshop apron capable of stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping

flying debris generated by various operations. The

dust mask or respirator must be capable of filtering

particles generated by your operation. Prolonged

exposure to high intensity noise may cause hearing

loss.

h) Keep bystanders a safe distance away from

the work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may fly away and cause injury beyond immediate

area of operation.

safety warnings,

instructions,

5

Page 6

ENGLISHen

i) Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. A cutting acces-

sory that comes in contact with a "live" wire may

render exposed metal parts of the power tool "live"

and give the operator an electric shock.

j) Position the cord clear of the spinning acces-

sory. If you lose control, the cord may be cut or

snagged and your hand or arm may be pulled into

the spinning accessory.

k) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grip the surface and pull

the power tool out of your control.

l) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

m) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

n) Do not operate the power tool near flam-

mable materials. Sparks could ignite these materials.

o) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

3.2 Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or any

other accessory. Pinching or snagging causes rapid

stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite to the accessory’s rotation at

the point of jamming.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward or

away from the operator, depending on direction of

the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use the auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kick-

6

back will propel the tool in a direction opposite to the

wheel’s movement at the point of snagging.

d) Use special care when working around

corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or

bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades create

frequent kickback and loss of control.

3.3 Safety Warnings Specific for Grinding

and Abrasive Cutting-Off Operations:

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

b) Wheels must be used only for recommended

applications. For example: do not grind with

the side of the cut-off wheel. Abrasive cut-off

wheels are intended for peripheral grinding, side

forces applied to these wheels may cause them to

shatter.

c) Always use undamaged wheel flanges that

are the correct size and shape for your selected

wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel flanges.

d) Do not use worn down wheels from larger

power tools. Wheels intended for larger power

tools are not suitable for the higher speed of a

smaller tool and may burst.

3.4 Additional Safety Warnings Specific for

Abrasive Cutting-Off Operations:

a) Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to make

excessively deep cuts. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback or wheel breakage.

b) Do not position your body in line with and

behind the rotating wheel. When the wheel, at the

point of operation, is moving away from your body,

the possible kickback may propel the spinning

wheel and the power tool directly at you.

c) If the wheel jams or if you interrupt a cut for

any reason, switch off the power tool and hold

the power tool motionless until the wheel

comes to a complete stop. Never attempt to

remove the cut-off wheel from the cut while the

wheel is in motion, otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of the wheel jam.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may jam,

walk up or kickback if the power tool is restarted in

the workpiece.

e) Support panels or any oversized workpiece

to minimise the risk of wheel pinching and kick-

Page 7

back. Large workpieces tend to sag under their own

weight. Supports must be placed under the workpiece near the line of cut and near the edge of the

workpiece on both sides of the wheel.

f) Use extra caution when making a "pocket

cut" into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

3.5 Safety Warnings Specific for Sanding

Operations:

a) Do not use oversized sanding disc paper.

Follow manufacturer's recommendations when

selecting sanding paper. Larger sanding paper

extending beyond the sanding pad presents a

laceration hazard and may cause snagging, tearing

of the disc or kickback.

3.6 Safety Warnings Specific for Polishing

Operations:

a) Loose parts on the polishing guard, especially the fastening cords, are not permitted.

Tuck away or shorten the fastening cords.

Loose, spinning fastening cords may make contact

with your fingers or become caught in the workpiece.

3.7 Safety Warnings Specific for Wire Brushing Operations:

a) Be aware that wire bristles are lost by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work load

and centrifugal forces.

3.8 Additional Safety Instructions

WARNING – Always wear protective

goggles.

Use elastic cushioning layers if they have been

supplied with the abrasive and if required.

Observe the specifications of the tool or accessory

manufacturer! Protect the discs from grease or

impacts!

Abrasives must be stored and handled with care in

accordance with the manufacturer's instructions.

Never use parting grinder discs for roughing work.

Do not apply pressure to the side of parting grinder

discs.

The workpiece must lay flat and be secured against

slipping, e.g. using clamps. Large workpieces must

be supported adequately.

Engage the spindle locking button (4) only when the

motor is inoperative. (GA 18 LTX, GE 710 Plus,

GA 18 LTX G, GE 950 G Plus)

Keep hands away from the rotating tool! Remove

chips and similar material only when the machine is

at a standstill.

ENGLISH en

Prior to use, ensure that the coated abrasive is

properly fitted and secured. Run the tool in idling for

60 seconds in a safe position and bring to a standstill immediately if there are significant vibrations or

if other deficiencies are determined. If such a situation occurs, check the machine to determine the

cause.

Ensure that sparks produced during work do not

constitute a risk to the user or other personnel and

are not able to ignite inflammable substances.

Endangered areas must be protected with flameresistant covers. Make sure that fire-risk areas are

always provided with suitable fire extinguishers.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in

conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is recommended.

Follow national requirements for the materials you

want to work with.

Materials that generate dusts or vapours that may

be harmful to health (e.g. asbestos) must not be

processed.

When working in dusty conditions, ensure that

ventilation openings are not blocked. If it becomes

necessary to remove dust, first disconnect the

power tool from the mains supply (use non-metallic

objects) and avoid damaging internal components.

Damaged, eccentric or vibrating tools must not be

used.

In the interests of safety, ensure that the rubber

sleeve (3) or additional handle is fitted while

working (5).

3.9 Special safety instructions for mains

powered machines:

Pull the plug out of the plug socket before any

adjustments, conversions or servicing are

performed.

During machining, of metals in

deposits inside the machine. This can lead to the

transfer of electrical energy onto the machine

housing. This can mean a temporary danger of

electric shocks. This is why it is necessary when the

machine is running to blow compressed air through

the rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine must

be held firmly.

We recommend using a stationary extractor system

and connecting a residual current circuit-breaker

(RCD) upstream. When the machine is shut down

via the FI circuit-breaker, it must be checked and

particular, conductive dust can form

7

Page 8

ENGLISHen

cleaned. For information on cleaning the motor, see

chapter 7. Cleaning.

3.10 Special safety instructions for cordless

machines:

Remove the battery pack from the machine before

any adjustments, conversions or servicing are

performed.

Protect battery packs from water and moisture!

Do not expose battery packs to naked flame!

Do not use faulty or deformed battery packs!

Do not open battery packs!

Do not touch or short-circuit battery packs!

Slightly acidic, flammable fluid may leak from

defective li-ion battery packs!

If battery fluid leaks out and comes into

contact with your skin, rinse immediately

with plenty of water. If battery fluid leaks out

and comes into contact with your eyes, wash them

with clean water and seek medical attention immediately.

SYMBOLS ON THE TOOL:

...........Class II Construction

V...............volts

A...............amperes

Hz............. hertz

W.............. watts

~

..............alternating current

.......... direct current

rpm ......... revolutions per minute

.../min ..... revolutions per minute

n ............. rated speed

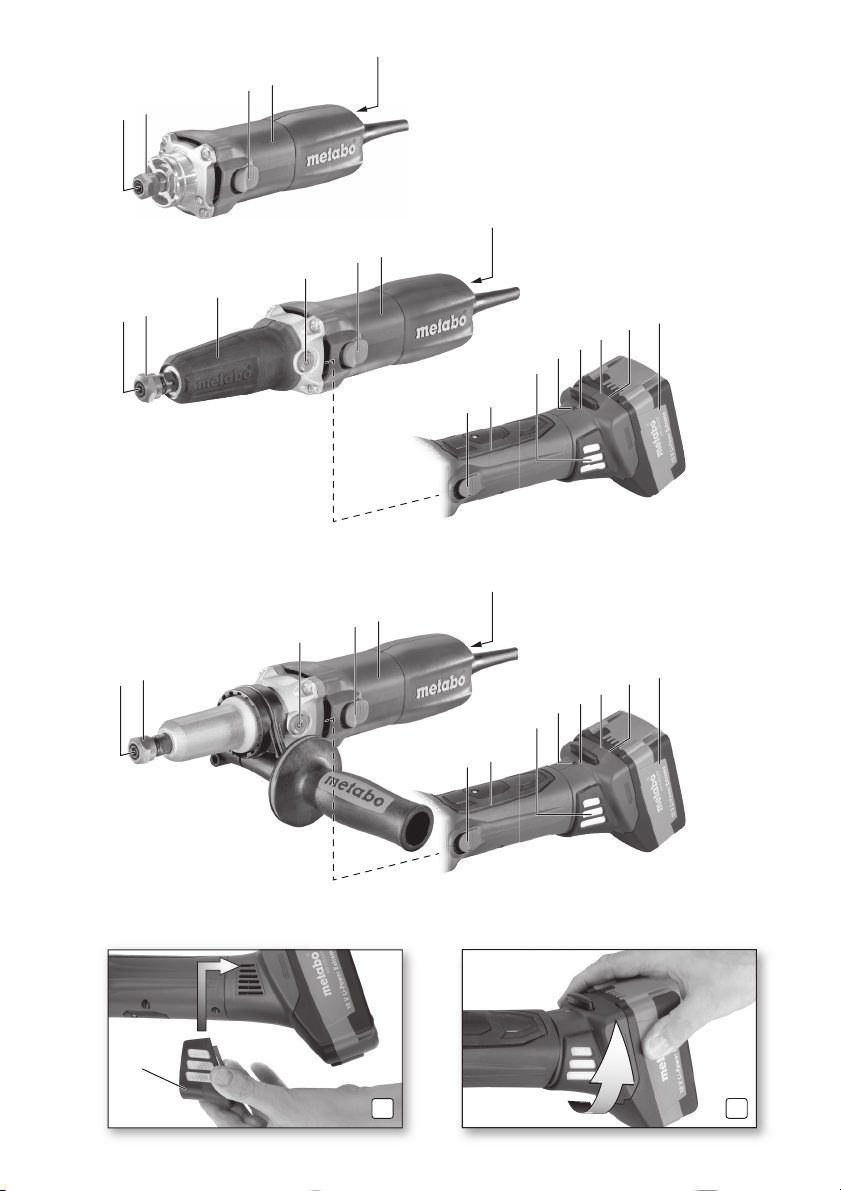

4. Overview

See page 2.

1 Collet chuck

2 Collet chuck nut

3 Rubber sleeve *

4 Spindle locking button*

5 Additional handle *

6 Sliding switch

7 Main handle

8 Setting wheel for speed adjustment *

9 Dust filter

10 Electronic signal indicator*

11 B

12 Capacity indicator button *

13 Capacity and signal indicator *

14 Battery pack*

*

equipment-specific

8

*

attery pack release button *

5. Initial Operation

5.1 For mains powered machines only

Before plugging in the device, check to see

that the rated mains voltage and mains

frequency, as specified on the rating label, match

your power supply.

5.2 For cordless machines only

Dust filter

Always fit the dust filter if the surroundings are

heavily polluted (9).

The machine heats up faster when the dust

filter is fitted (9). It is protected by the electronics system from overheating (see chapter8.).

To fit:

See page 2, illustration A.

Fit the dust filter (9) as shown.

To remove:

edges, raise it slightly and then pull it downwards

and remove.

Rotating battery pack

See illustration B on page 2.

The rear section of the machine can be rotated 270°

in three stages, thus allowing the machine's shape

to be adapted to the working conditions. Only

operate the machine when it is in an engaged position.

Battery pack

Charge the battery pack before use (14).

If performance diminishes, recharge the battery

pack.

The ideal storage temperature is between 10°C and

30°C.

"Li-Power" li-ion battery packs have a capacity and

signal indicator: (13)

- Press the button (12), the LEDs indicate the

charge level.

- If one LED is flashing, the battery pack is almost

flat and must be recharged.

Removing and inserting the battery pack

To remove:

(11) and pull the battery pack (14) downwards

To fit:

Holding the dust filter (9) by the upper

Press the battery pack release button

.

Slide in the battery pack (14) until it engages.

6. Use

6.1 Collet chucks

The tool's shank diameter must correspond

exactly to the collet bore of the collet chuck (1)!

Various collet chucks are available for different

shank diameters. See Accessories section.

6.2 Fitting the tools

Pull the mains plug from the socket.

Only use tools that are suited to the no-load

speed of your machine. See Technical Specifications.

Page 9

The tool's shank diameter must correspond

l

o

exactly to the collet bore of the collet chuck (1)!

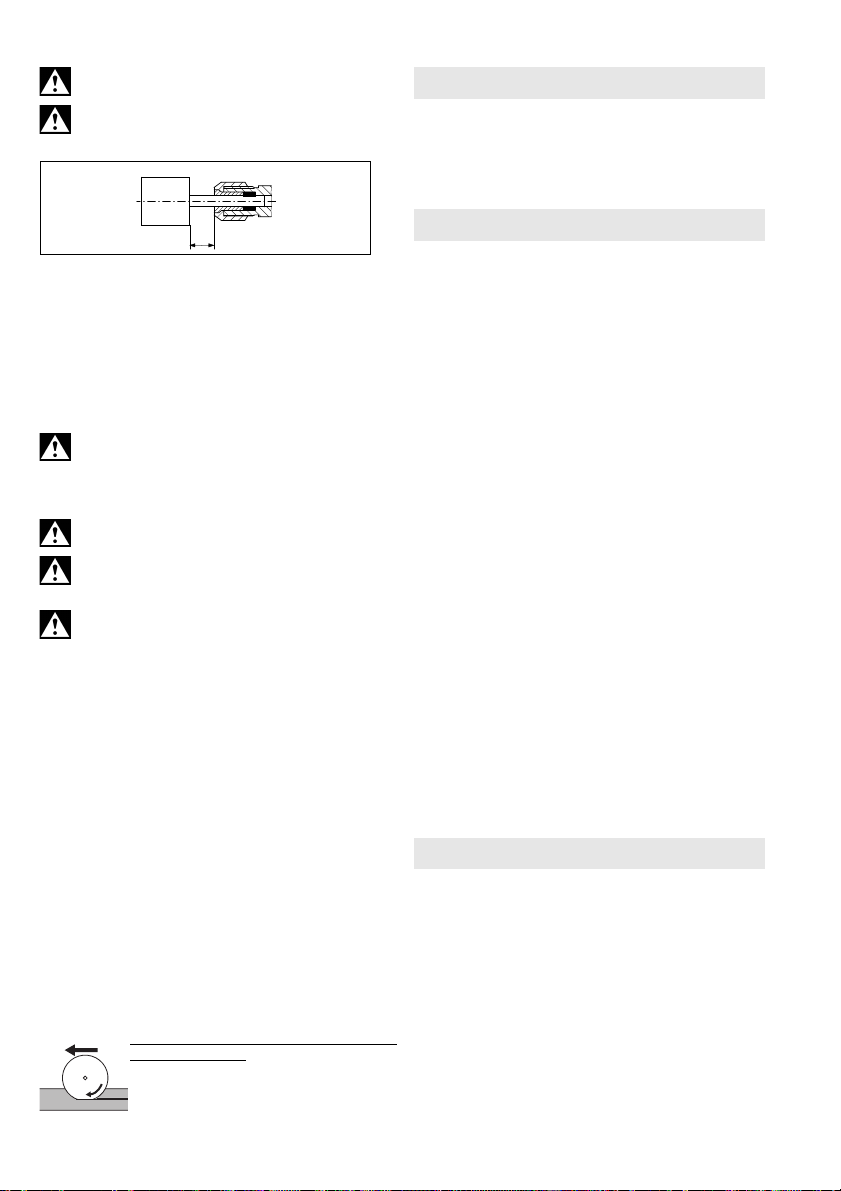

For abrasive points, you must never exceed

the maximum open shank length specified by

the manufacturer l

.

0

ENGLISH en

7. Cleaning

7.1 Motor cleaning

To clean the motor, apply jets of compressed air

through the rear ventilation slots of the machine

regularly, frequently and thoroughly. Here, the

machine must be held firmly.

8. Troubleshooting

Insert the tool (with the full length of the shank) in the

collet chuck (1).

Bring the spindle to a standstill. (For the

GE 710 Compact, use the 13-mm spanner provided

for this purpose. For the GA 18 LTX, GE 710 Plus,

GA 18 LTX G and GE 950 G Plus, press the spindle

locking button (4)).

Using the 19-mm spanner, tighten the collet chuck

nut (2).

If there is no tool inserted in the collet chuck,

you can tighten the collet chuck manually

rather than with the spanner.

6.3 Switching On and Off

Switch on first, then guide the

towards the workpiece.

Avoid inadvertent starts: always switch the

tool off when the plug is removed from the

mains socket or if there has been a power cut.

In continuous operation, the machine

continues running if it is forced out of your

hands. You must th erefore always hold the machine

with both hands using the handles provided (3), (5),

(7), stand in a safe position and concentrate while

working.

Switching on: Push the slide switch (6) forward.

For continuous activation, now tilt downwards until

it engages.

Switching off: Press the rear end of the slide

switch (6) and release.

6.4 Adjusting speed (mains powered

machines only)

The speed can be preset using the setting wheel (8)

and is infinitely variable. For a list of speeds, see the

table on page 3.

6.5 Working instructions

Grinding, sanding, polishing or using wire

brushes: Press down the machine evenly and

move it from side to side over the surface.

Routing: Press down the machine evenly.

Separating:

able for the material being processed. Do not tilt,

apply excessive force or sway from side to side.

Always work against the run of the disc

(see illustration). Otherwise there is

the danger of the machine kicking

back from the cut out of control. Guide

the machine evenly at a speed suit-

accessory

8.1 Mains powered machines:

- Overload protection: There is a MAJOR

reduction in load speed. The motor temperature

is too high! Allow the machine to run at idle speed

until it has cooled down.

- Overload protection: There is a SLIGHT

reduction in load speed. The machine is overloaded. Reduce the load before continuing to

work.

- Metabo S-automatic safety shutdown: The

machine was SWITCHED OFF automatically. If

the slew rate of the current is too high (for

example, if the machine suddenly seizes or kickback occurs), the machine switches off. Switch off

the machine at the slide switch (6). Switch it on

again and continue to work as normal. Try to

prevent the machine from seizing. See section

3.2.

- Restart protection: The machine does not

start. The restart protection is active. If the mains

plug is inserted with the machine switched on, or if

the current supply is restored following an interruption, the machine does not start up. Switch the

machine off and on again.

8.2 Cordless machines:

- The electronic signal display (10) lights up

and the load speed decreases. The tempera-

ture is too high! Run the machine in idling until the

electronics signal indicator switches off.

- The electronic signal display (10) flashes and

the machine does not start. The restart protection is active. The machine will not start if the

battery pack is inserted while the machine is on.

Switch the machine off and on again.

9. Accessories

Use only genuine Metabo accessories.

Use only accessories which fulfil the requirements

and specifications listed in these operating instructions.

Fit accessories securely. Secure the machine if it is

operated in a bracket. Loss of control can cause

personal injury.

A Collets (including nut)

dia.

3 mm = 6.31947

dia.

1/8“ = 6.31948

dia.

6 mm = 6.31945

dia.

1/4“ = 6.31949

dia.

8 mm = 6.31946

B Clamping frame 6.27354 for clamping during

work with flexible shafts (tighten clamping

9

Page 10

ENGLISHen

screw), including:

C Clamping bracket 6.27107 for safe securing to

the work bench (tighten clamping screw).

D Battery chargers: ASC 15, ASC 30 and others.

E Battery packs: 4.0 Ah (6.25527); 3.0 Ah (6.25455)

For a complete range of accessories, see

www.metabo.com or the catalogue.

10. Repairs

Repairs to electrical tools must be carried out

by qualified electricians ONLY!

If you have Metabo electrical tools that require

repairs, please contact your Metabo service centre.

For addresses see www.metabo.com.

You can download spare parts lists from

www.metabo.com.

11. Environmental Protection

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

Special instructions for cordless machines:

Battery packs must not be disposed of with regular

waste. Return faulty or used battery packs to your

Metabo dealer!

Do not allow battery packs to come into contact with

water!

Before disposal, discharge the battery pack in the

power tool. Prevent the contacts from shortcircuiting (e. g. by protecting them with adhesive

tape).

12. Technical Specifications

Explanation of details on page 3. Subject to

changes serving technical progress.

U =Voltage of battery pack

S = Spindle lock for easy tool changes

n = No-load speed (maximum speed)

n

=On-load speed

1

I

= Current at 120 V

120 V

P

=Nominal power input

1

P

=Power output

2

D

=maximum grinding wheel diameter

max

d = Collet bore of the collet chuck

m =Weight with smallest battery pack/weight

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

Electromagnetic disturbances:

In individual cases, the speed may fluctuate temporarily if the machine is exposed to extreme external

electromagnetic disturbances or the electronic

restart protection may respond. In this case, switch

the machine off and on again.

10

without cord

Wear ear protectors!

Page 11

Mode d'emploi

1. Utilisation conforme aux

prescriptions

Les meuleuses droites sont conçues...

- ... pour des travaux de meulage fin sur métaux

avec meules sur tige.

- ... pour des travaux de tronçonnage fin sur métaux

avec petites meules à tronçonner.

- ... pour le fraisage avec des fraises à queue sur

métaux non-ferreux, plastiques, bois dur, etc.

- ... pour des travaux avec brosses métalliques

circulaires ou en forme de pinceau

- ... pour des travaux avec corps de polissage de

forme

- ... pour des travaux avec corps de polissage à

feutre

- ... pour des travaux avec meules à lamelles

Ne sont pas appropriées pour des travaux avec des

cloches à polir.

L'utilisateur est entièrement responsable de tous

dommages résultant d'une utilisation non conforme

aux prescriptions.

Il est impératif de respecter les directives de

prévention des accidents reconnues et les

consignes de sécurité ci-jointes.

2. Consignes de sécurité

générales

Pour des raisons de sécurité et afin de

protéger l'outil électrique, respecter les

passages de texte marqués de ce

symbole !

AVERTISSEMENT – Lire la notice d'utilisation afin d'éviter tout risque de blessure.

Remettre l'outil électrique uniquement accompagné

de ces documents.

Avertissements de sécurité généraux pour

l'outil

AVERTISSEMENT – Lire tous les avertissements de sécurité et toutes les instruc-

tions. Ne pas suivre les avertissements et instruc-

tions peut donner lieu à un choc électrique, un

incendie et/ou une blessure sérieuse.

Conserver tous les avertissements et toutes

les instructions pour pouvoir s'y reporter ultérieurement! Le terme «outil» dans les avertisse-

ments fait référence à votre outil électrique alimenté

par le secteur (avec cordon d'alimentation) ou votre

outil fonctionnant sur batterie (sans cordon

d'alimentation).

2.1 Sécurité de la zone de travail

a) Conserver la zone de travail propre et bien

éclairée. Les zones en désordre ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner les outils électriques en atmosphère explosive, par exemple en

présence de liquides inflammables, de gaz ou

FRANÇAIS fr

de poussières. Les outils électriques produisent

des étincelles qui peuvent enflammer les poussières ou les fumées.

c) Maintenir les enfants et les personnes

présentes à l'écart pendant l'utilisation de

l'outil. Les distractions peuvent vous faire perdre le

contrôle de l'outil.

2.2 Sécurité électrique

a) Il faut que les fiches de l'outil électrique

soient adaptées au socle. Ne jamais modifier la

fiche de quelque façon que ce soit. Ne pas utiliser d'adaptateurs avec des outils à branchement de terre. Des fiches non modifiées et des

socles adaptés réduiront le risque de choc électrique.

b) Eviter tout contact du corps avec des surfaces reliées à la terre telles que les tuyaux, les

radiateurs, les cuisinières et les réfrigérateurs.

Il existe un risque accru de choc électrique si votre

corps est relié à la terre.

c)

Ne pas exposer les outils à la pluie ou à des

conditions humides. La pénétration d'eau à l'inté-

rieur d'un outil augmentera le risque de choc électrique.

d) Ne pas maltraiter le cordon. Ne jamais utiliser le cordon pour porter, tirer ou débrancher

l'outil. Maintenir le cordon à l'écart de la chaleur, du lubrifiant, des arêtes ou des parties en

mouvement. Des cordons endommagés ou em-

mêlés augmentent le risque de choc électrique.

e) Lorsqu'on utilise un outil à l'extérieur, utiliser un prolongateur adapté à l'utilisation extérieure. L'utilisation d'un cordon adapté à l'utilisation

extérieure réduit le risque de choc électrique.

f) Si l'usage d'un outil dans un emplacement

humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD). L'usage d'un RCD réduit le risque

de choc électrique.

2.3 Sécurité des personnes

a) Rester vigilant, regarder ce que vous êtes en

train de faire et faire preuve de bon sens dans

votre utilisation de l'outil. Ne pas utiliser un

outil lorsque vous êtes fatigué ou sous

l'emprise de drogues, d'alcool ou de médicaments. Un moment d'inattention en cours d'utilisa-

tion d'un outil peut entraîner des blessures graves

des personnes.

b) Utiliser un équipement de sécurité. Toujours

porter une protection pour les yeux. Les équipe-

ments de sécurité tels que les masques contre les

poussières, les chaussures de sécurité antidérapantes, les casques ou les protections acoustiques

utilisés pour les conditions appropriées réduiront

les blessures de personnes.

c) Eviter tout démarrage intempestif. S'assurer

que l'interrupteur est en position arrêt avant de

brancher l'outil au secteur et/ou au bloc de

batteries, de le ramasser ou de le porter. Porter

11

Page 12

FRANÇAISfr

les outils en ayant le doigt sur l'interrupteur ou brancher des outils dont l'interrupteur est en position

marche est source d'accidents.

d) Retirer toute clé de réglage avant de mettre

l'outil en marche. Une clé laissée fixée sur une

partie tournante de l'outil peut donner lieu à des

blessures de personnes.

e) Ne pas se précipiter. Garder une position et

un équilibre adaptés à tout moment. Cela

permet un meilleur contrôle de l'outil dans des situations inattendues.

f) S'habiller de manière adaptée. Ne pas porter

de vêtements amples ou de bijoux. Garder les

cheveux, les vêtements et les gants à distance

des parties en mouvement. Des vêtements

amples, des bijoux ou les cheveux longs peuvent

être pris dans des parties en mouvement.

g) Si des dispositifs sont fournis pour le raccordement d'équipements pour l'extraction et la

récupération des poussières, s'assurer qu'ils

sont connectés et correctement utilisés. Utiliser

des collecteurs de poussière peut réduire les

risques dus aux poussières.

2.4 Utilisation et entretien de l'outil

a) Ne pas forcer l'outil. Utiliser l'outil adapté à

votre application. L'outil adapté réalisera mieux le

travail et de manière plus sûre au régime pour

lequel il a été construit.

b) Ne pas utiliser l'outil si l'interrupteur ne

permet pas de passer de l'état de marche à

arrêt et vice versa. Tout outil qui ne peut pas être

commandé par l'interrupteur est dangereux et il faut

le réparer.

c) Débrancher la fiche de la source d'alimentation en courant et/ou le bloc de batteries de

l'outil avant tout réglage, changement d'accessoires ou avant de ranger l'outil. De telles

mesures de sécurité préventives réduisent le risque

de démarrage accidentel de l'outil.

d) Conserver les outils à l'arrêt hors de la

portée des enfants et ne pas permettre à des

personnes ne connaissant pas l'outil ou les

présentes instructions de le faire fonctionner.

Les outils sont dangereux entre les mains d'utilisateurs novices.

e) Observer la maintenance de l'outil. Vérifier

qu'il n'y a pas de mauvais alignement ou de

blocage des parties mobiles, des pièces

cassées ou toute autre condition pouvant

affecter le fonctionnement de l'outil. En cas de

dommages, faire réparer l'outil avant de

l'utiliser. De nombreux accidents sont dus à des

outils mal entretenus.

f) Garder affûtés et propres les outils permettant de couper. Des outils destinés à couper

correctement entretenus avec des pièces

coupantes tranchantes sont moins susceptibles de

bloquer et sont plus faciles à contrôler.

g) Utiliser l'outil, les accessoires et les lames

etc., conformément à ces instructions, en

tenant compte des conditions de travail et du

travail à réaliser. L'utilisation de l'outil pour des

12

opérations différentes de celles prévues pourrait

donner lieu à des situations dangereuses.

2.5 Utilisation des outils fonctionnant sur

batteries et précautions d'emploi

a) Ne recharger qu'avec le chargeur spécifié

par le fabricant. Un chargeur qui est adapté à un

type de bloc de batteries peut créer un risque de feu

lorsqu'il est utilisé avec un autre type de bloc de

batteries.

b) N'utiliser les outils qu'avec des blocs de

batteries spécifiquement désignés. L'utilisation

de tout autre bloc de batteries peut créer un risque

de blessure et de feu.

c) Lorsqu'un bloc de batteries n'est pas utilisé,

le maintenir à l'écart de tout autre objet métallique, par exemple trombones, pièces de

monnaie, clés, clous, vis ou autres objets de

petite taille qui peuvent donner lieu à une

connexion d'une borne à une autre. Le court-

circuitage des bornes d'une batterie entre elles peut

causer des brûlures ou un feu.

d) Dans de mauvaises conditions, du liquide

peut être éjecté de la batterie; éviter tout

contact. En cas de contact accidentel, nettoyer

à l'eau. Si le liquide entre en contact avec les

yeux, rechercher en plus une aide médicale. Le

liquide éjecté des batteries peut causer des irritations ou des brûlures.

2.6 Maintenance et entretien

a) Faire entretenir l'outil par un réparateur

qualifié utilisant uniquement des pièces de

rechange identiques. Cela assurera que la sécu-

rité de l'outil est maintenue.

3. Consignes de sécurité

particulières

3.1 Consignes de sécurité communes pour

le meulage, le ponçage au papier de

verre, les travaux avec brosses métalliques, le polissage et le tronçonnage par

meule :

Application

a) Cet outil électrique est conçu pour une utili-

sation en tant que meuleuse, ponceuse au

papier de verre, brosse métallique, polisseuse

et outil à tronçonner. Observer toutes les

consignes de

tions et spécifications fournies avec cet outil

électrique. La non-observation de toutes les

consignes ci-dessous peut provoquer un choc électrique, un incendie et/ou des blessures graves.

b) Ne pas utiliser d’accessoires qui n'ont pas

été conçus et recommandés spécialement par

le fabricant pour cet outil électrique. Le simple

fait que l’accessoire puisse être fixé à votre outil

électrique ne garantit pas un fonctionnement en

toute sécurité.

c) La vitesse de rotation admissible de l'acces-

soire doit être au moins aussi élevée que la

vitesse de rotation maximale indiquée sur

sécurité

, instructions, illustra-

Page 13

l'outil électrique. Les accessoires tournant plus

vite que leur vitesse admissible peuvent se rompre

et être projetés.

d) Le diamètre extérieur et l’épaisseur de

l'accessoire doivent correspondre aux indications de dimensions de votre outil électrique.

Les accessoires dimensionnés de façon incorrecte

ne peuvent pas être protégés ou contrôlés de

manière appropriée.

e) Les meules, flasques, patins de ponçage ou

tout autre accessoire doivent s'adapter avec

précision à la broche porte-meule de votre outil

électrique. Les accessoires qui ne s'adaptent pas

avec précision à la broche porte-meule fonctionnent de façon irrégulière, vibrent excessivement

et peuvent conduire à une perte de contrôle.

f) Ne pas utiliser d’accessoires endommagés.

Avant chaque utilisation, contrôler les accessoires tels que les meules pour détecter la

présence éventuelle traces d'effritement et de

fissures, les patins de ponçage pour détecter

des traces éventuelles de fissures ou d’usure

excessive, ainsi que les brosses métalliques

pour détecter des fils détachés ou rompus. Si

l’outil électrique ou l’accessoire a subi une

chute, examiner les dommages éventuels ou

utiliser un accessoire non endommagé. Après

le contrôle et le montage d’un accessoire,

maintenir toutes les personnes présentes à

distance du plan de l’accessoire en rotation et

faire fonctionner l’outil électrique à vitesse

maximale à vide pendant une minute. Les

accessoires endommagés seront normalement

détruits pendant cette période d’essai.

g) Porter un équipement de protection indivi-

duelle. En fonction de l’application, utiliser un

masque intégral, une protection oculaire ou

des lunettes de sécurité. Le cas échéant,

utiliser un masque antipoussières, une protection acoustique, des gants de protection ou un

tablier spécial contre les particules abrasives

ou les particules de matière. Les yeux doivent

être protégés contre les corps étrangers projetés

produits par les diverses opérations. Le masque

antipoussières ou le masque de protection respiratoire doit être capable de filtrer les particules

produites lors des travaux. L’exposition prolongée

aux bruits de forte intensité peut provoquer une

perte de l’audition.

h) Maintenir les personnes présentes à une

distance de sécurité par rapport à la zone de

travail. Toute personne entrant dans la zone de

travail doit porter un équipement de protection

individuelle. Des fragments de pièce à usiner ou

d’un accessoire cassé peuvent être projetés et

provoquer des blessures en dehors de la zone de

travail immédiate.

i) Lors de travaux où l'outil risque de rencontrer

des conducteurs électriques non apparents,

voire son câble d'alimentation, tenir l'outil électrique exclusivement par les côtés isolés des

poignées. Le contact avec un conducteur élec-

trique sous tension peut également mettre les

parties métalliques de l'outil sous tension et provoquer un choc électrique.

FRANÇAIS fr

j) Garder le câble d'alimentation à distance de

l’accessoire en rotation. En cas de perte de

contrôle de l'appareil, le câble d'alimentation peut

être sectionné ou être happé et votre main ou votre

bras peut être tiré dans l’accessoire en rotation.

k) Ne jamais reposer l’outil électrique avant

l'arrêt complet de l’accessoire. L’accessoire en

rotation peut parvenir en contact avec la surface de

dépôt et vous risquez de perdre le contrôle de l’outil

électrique.

l) Ne pas faire fonctionner l’outil électrique

pendant que vous le portez. Un contact accidentel avec l’accessoire en rotation pourrait happer

vos vêtements et l’accessoire pourrait se planter

dans votre corps.

m) Nettoyer régulièrement les orifices d’aéra-

tion de l’outil électrique. Le v entil ateur du mo teur

attire la poussière à l’intérieur du boîtier et une

accumulation excessive de poussières métalliques

peut provoquer des dangers électriques.

n) Ne pas faire fonctionner l’outil électrique à

proximité de matériaux inflammables. Des étincelles pourraient enflammer ces matériaux.

o) Ne pas utiliser d’accessoires qui nécessitent

des réfrigérants fluides. L’utilisation d’eau ou

d’autres réfrigérants fluides peut conduire à une

électrocution ou un choc électrique.

3.2 Rebonds et consignes de sécurité correspondantes

Le rebond est une réaction soudaine dû à l’accrochage ou au blocage d'une meule, d'un patin de

ponçage, d'une brosse métallique, etc. L'accrochage ou le blocage conduit à un arrêt brusque de

l'accessoire en rotation. De ce fait, un outil électrique incontrôlé est accéléré dans le sens contraire

au sens de rotation normal de l'accessoire au point

de blocage.

Si par exemple une meule reste accrochée ou est

bloquée dans la pièce à usiner, le bord de la meule

qui plonge dans la pièce peut rester accroché et

occasionner une rupture de la meule ou un rebond.

La meule se déplace alors en direction de l'opérateur ou dans le sens opposé, selon le sens de rotation de la meule au point de blocage. Les meules

peuvent également se rompre dans ces conditions.

Le rebond est la conséquence d'une utilisation

incorrecte de l'outil électrique et peut être évité en

prenant les précautions appropriées spécifiées cidessous.

a) Maintenir fermement l’outil électrique et

placer le corps et les bras de manière à pouvoir

résister aux forces de rebond. Toujours utiliser

une poignée auxiliaire, si disponible, pour une

maîtrise maximale du rebond ou de la réaction

de couple au cours du démarrage. L’utilisateur

peut maîtriser les couples de réaction ou les forces

de rebond, si les précautions qui s’imposent sont

prises.

b) Ne jamais placer la main à proximité de l’outil

en rotation. L’accessoire peut effectuer un rebond

sur votre main.

13

Page 14

FRANÇAISfr

c) Ne pas vous placer dans la zone où l’outil

électrique se déplacera en cas de rebond. Le

rebond entraîne l’outil électrique dans le sens

opposé au mouvement de la meule au point de

blocage.

d) Travaillez avec une précaution particulière

dans la zone des coins, des arêtes vives, etc.

Eviter les rebonds de l'accessoire de la pièce et

par conséquent un blocage. L'accessoire en

rotation a tendance à se bloquer dans les coins, au

niveau des arêtes vives ou en cas de rebond. Ceci

occasionne une perte de contrôle ou un rebond.

e) Ne pas utiliser de lame de scie à chaîne ou de

lame de scie dentée. De telles lames provoquent

des rebonds fréquents et des pertes de contrôle.

3.3 Consignes de sécurité spécifiques aux

opérations de meulage et de tronçonnage :

a) Utiliser exclusivement des meules admissibles pour votre outil électrique et le capot de

protection prévu pour ces meules. Les meules

pour lesquelles l’outil électrique n’a pas été conçu

ne peuvent pas être protégées de façon satisfaisante et sont dangereuses.

b) Les meules doivent être utilisées unique-

ment pour les applications recommandées. Par

exemple : ne pas meuler avec le côté d'une

meule à tronçonner. Les meules à tronçonner

sont conçues pour un enlèvement de matière avec

le bord de la meule. Tout effort latéral sur ces

meules peut les briser.

c) Toujours utiliser des flasques de serrage

non endommagés qui sont de taille et de forme

adaptées à la meule choisie. Des flasques de

meule appropriés supportent la meule et réduisent

la possibilité de rupture de la meule. Les flasques

pour les meules à tronçonner peuvent être différents des autres flasques de meule.

d) Ne pas utiliser de meules usées d’outils élec-

triques plus grands. Les meules pour des outils

électriques plus grands ne sont pas conçues pour

des vitesses de rotation plus élevées d'outils électriques plus petits et peuvent se briser.

3.4 Consignes de sécurité complémentaires

spécifiques aux opérations de tronçonnage :

a) Eviter un blocage de la meule à tronçonner

ou une pression d'appui trop forte. Ne pas

tenter d’exécuter une profondeur de coupe

excessive. Une surcharge de la meule augmente

la sollicitation et la probabilité de coincement ou de

blocage de la meule et par conséquent la possibilité

de rebond ou de rupture de la meule.

b) Ne pas se placer dans l’alignement de la

meule en rotation ni derrière celle-ci. Lorsque la

meule s'éloigne de votre corps dans la pièce à

usiner, un éventuel rebond peut propulser la meule

en rotation et l'outil électrique directement sur vous.

c) Si la meule se bloque ou en cas d'interrup-

tion du travail, mettre l’outil électrique hors

tension et le immobile jusqu’à ce que la meule

soit à l’arrêt complet. Ne jamais tenter de retirer

14

la meule encore en rotation du plan de coupe,

sinon il peut en résulter un rebond. Déterminer

et éliminer la cause du blocage.

d) Ne pas remettre l'outil électrique en marche

tant qu'il se trouve dans la pièce à usiner.

Laisser la meule à tronçonner atteindre sa

pleine vitesse de rotation avant de poursuivre

la coupe avec précaution. Sinon la meule peut se

coincer, sauter hors de la pièce à usiner ou occasionner un rebond.

e) Supporter les plaques ou les pièces à usiner

de grande taille pour minimiser le risque de

rebond ou de blocage de la meule. Les pièces à

usiner de grande taille ont tendance à fléchir sous

leur propre poids. La pièce à usiner doit être

su pport ée des deu x côté s de la meu le, et ceci a ussi

bien à proximité du plan de coupe que du bord de la

pièce.

f) Etre particulièrement prudent lors d'une

"coupe en retrait" dans des parois existantes

ou dans d’autres zones sans visibilité. Lors de

la coupe, la meule plongeante peut occasionner un

rebond au contact de conduites de gaz ou d'eau, de

câbles électriques ou d'autres objets.

3.5 Consignes de sécurité spécifiques aux

opérations de ponçage au papier de

verre :

a) Ne pas utiliser de papier abrasif trop surdimensionné pour les disques de ponçage.

Suivre les recommandations des fabricants

lors du choix du papier abrasif. Un papier abrasif

plus grand s'étendant au-delà du patin de ponçage

peut occasionner des blessures ainsi qu'un

blocage, un déchirement de l'abrasif ou un rebond.

3.6 Consignes de sécurité spécifiques aux

opérations de polissage :

a) Ne laisser aucune pièce flottante du capot de

polissage, particulièrement les cordons

d'attache. Ranger ou couper les cordons

d'attache. Les cordons d'attache flottants,

entraînés en rotation peuvent happer vos doigts ou

se coincer dans la pièce à usiner.

3.7 Consignes de sécurité spécifiques aux

opérations avec brosses métalliques :

a) Garder à l’esprit que des brins métalliques

sont rejetés par la brosse même au cours d’une

opération ordinaire. Ne pas soumettre à une

trop grande contrainte les fils métalliques en

appliquant une charge excessive à la brosse.

Les brins métalliques peuvent aisément pénétrer

dans des vêtements légers et/ou la peau.

b) Si l’utilisation d’un capot de protection est

recommandée, éviter tout contact entre le

capot de protection et la brosse métallique. Le

diamètre des brosses plates et des brosses boisseaux peut s'agrandir sous l'effet de la pression

d'appui et des forces centrifuges.

3.8 Autres consignes de sécurité :

AVERTISSEMENT – Toujours porter des

lunettes de protection.

Page 15

Utiliser des intercalaires souples s'ils ont été fournis

avec l'accessoire de meulage et que leur utilisation

s'impose.

Respecter les indications du fabricant de l'outil ou

de l'accessoire ! Protéger les disques des graisses

et des coups !

Les abrasifs doivent être conservés et manipulés

avec soin, conformément aux instructions du fabricant.

Ne jamais utiliser de meule à tronçonner pour les

travaux de dégrossissage ! Ne pas appliquer de

pression latérale sur les meules à tronçonner.

La pièce à usiner doit être fermement fixée de sorte

à ne pas glisser, par exemple à l'aide de dispositifs

de serrage. Les pièces à usiner de grande taille

doivent être suffisamment soutenues.

N'actionnez le système de blocage de la broche (4)

qu'une fois le moteur à l'arrêt (GA 18 LTX,

GE 710 Plus, GA 18 LTX G, GE 950 G Plus).

Ne pas toucher l'outil en rotation lorsque la machine

est en marche ! Eliminer les copeaux, etc. uniquement lorsque la machine est à l'arrêt.

Veillez à ce que la meule soit correctement positionnée et fixée avant la mise en route et laissez-la

tourner pendant 60 secondes à vide dans une position sans danger ; l'arrêter immédiatement si des

vibrations importantes ou d'autres problèmes sont

constatés. Si cet état se produit, contrôler la

machine afin d'en déterminer la cause.

Veiller à ce que les étincelles produites lors de l'utilisation ne provoquent aucun risque, p. ex. celui

d'atteindre l'utilisateur ou d'autres personnes, ou un

risque d'incendie de substances inflammables.

Toute zone à risque doit être protégée par des revêtements difficilement inflammables. Tenir prêt un

moyen d'extinction adéquat dans les zones à risque

d'incendie.

Les poussières de matériaux tels que les peintures

au plomb, certains types de bois, de minéraux et de

métaux peuvent s'avérer nocives pour la santé. Le

fait de toucher ou d'inhaler ces poussières peut

entraîner des réactions allergiques et/ou des

maladies respiratoires chez l'utilisateur ou les

personnes se trouvant à proximité.

Certaines poussières provenant par exemple de

chêne ou de hêtre sont considérées comme étant

cancérigènes, particulièrement lorsqu'elle sont

associées à des adjuvants de traitement du bois

(chromate, produit de protection du bois). Seuls des

spécialistes sont habilités à traiter les matériaux

contenant de l'amiante.

- Utiliser autant que possible un système d'aspiration des poussières.

- Veiller à une bonne aération du poste de travail.

- Il est recommandé de porter un masque antipoussières avec filtre de classe P2.

Respecter les directives nationales en vigueur relatives aux matériaux à traiter.

Le sciage de matériaux générant des poussières ou

des vapeurs nocives (p. ex. amiante) lors de la

découpe est proscrit.

Si le travail à effectuer génère des poussières,

veiller à ce que les orifices d'aération soient

FRANÇAIS fr

dégagés. S'il devient nécessaire d'enlever la poussière, déconnecter tout d'abord l'outil électrique du

secteur (à l'aide d'objets non métalliques) et éviter

d'endommager des pièces internes.

Ne pas utiliser d'outils endommagés, présentant

des faux-ronds ou des vibrations.

Pour des raisons de sécurité, travailler toujours

avec la manchette en caoutchouc (3) ou la poignée

additionnelle (5) fixée.

3.9 Consignes de sécurité spéciales pour

machines fonctionnant sur secteur :

Débrancher le cordon d'alimentation de la prise de

courant avant toute opération de réglage, de changement d'accessoire, de maintenance ou de

nettoyage.

En cours de travail, et surtout s'il

des poussières conductrices s'accumulent dans la

machine. Il se peut alors qu'il y ait un transfert

d'énergie électrique sur le corps de machine. Ainsi,

par moment il pourra y avoir un risque d'électrocution. Pour cette raison, il est impératif de nettoyer la

machine régulièrement, fréquemment et soigneusement, en soufflant de l'air comprimé à travers les

fentes d'aération à l'arrière pendant que la machine

tourne. Veiller à bien maintenir la machine à cette

occasion.

Il est recommandé d'installer un système

d'aspiration fixe et de prévoir un disjoncteur à

courant de défaut (FI). Lorsque la machine est

arrêtée par le biais du disjoncteur de protection FI,

elle doit être vérifiée et nettoyée. Nettoyage du

moteur, voir chapitre 7. "Nettoyage".

3.10 Consignes de sécurité spéciales pour

machines sans fil :

Retirer le bloc batterie de l'outil avant toute opération de réglage, de changement d'accessoire, de

maintenance ou de nettoyage.

Ne pas utiliser de blocs batteries défectueux ou

déformés !

Ne pas ouvrir les blocs batteries !

Ne jamais toucher ni court-circuiter entre eux les

contacts d'un bloc batterie !

yeux, les laver à l'eau claire et consulter immédiatement un médecin !

SYMBOLES SUR L’OUTIL:

...........Construction de classe II

V...............volts

A...............ampères

s'agit de métaux, il est possible que

Protéger les blocs batteries de l'humidité !

Ne pas exposer les blocs batteries au feu !

Un bloc batterie défectueux Li-Ion peut

occasionner une fuite de liquide légèrement

acide et inflammable !

En cas de fuite d'acide de la batterie venant

en contact avec la peau, rincer abondamment à l'eau. En cas de projection dans les

15

Page 16

FRANÇAISfr

l

o

Hz.............hertz

W..............watts

~...............courant alternatif

.......... courant continu

rpm........... révolutions par minute

.../min .......révolutions par minute

n ............. vitesse à vide

4. Vue d'ensemble

Voir page 2.

1Pince de serrage

2 Ecrou de la pince de serrage

3 Manchette en caoutchouc *

4 Blocage de broche*

5 Poignée additionnelle *

6 Interrupteur coulissant

7 Poignée principale

8 Molette pour réglage de la vitesse *

9 Filtre antipoussières

10 Témoin électronique

11 B

outon de déverrouillage du bloc batterie *

12 Touche de l'indicateur de capacité *

13 Indicateur de capacité et de signalisation *

14 Bloc batterie *

*

suivant équipement

*

*

5. Mise en service

5.1 Spécialement pour machines fonction-

nant sur secteur

Avant la mise en service, vérifier que la

tension secteur et la fréquence secteur indiquées sur la plaque signalétique correspondent aux

caractéristiques de votre réseau de courant.

5.2 Spécialement pour machines sans fil

Filtre antipoussières

En cas d'environnement fortement encrassé,

toujours monter le filtre antipoussières (9).

Lorsque le filtre antipoussières (9) est monté,

la machine s'échauffe plus rapidement. L'électronique protège la machine contre la surchauffe

(voir chapitre 8.).

Fixation :

Fixer le filtre antipoussières (9) comme illustré.

Retrait :

(9) aux bords supérieurs et le retirer vers le bas.

Bloc batterie tournant

Voir page 2, illustration B.

La partie arrière de la machine peut être tournée

selon 3 niveaux de 270° et adapter ainsi la forme de

la machine aux conditions de travail. Ne travailler

qu'en position enclenchée.

Bloc batterie

Charger le bloc batterie avant utilisation (14).

En cas de baisse de puissance, recharger le bloc

batterie.

16

voir page 2, figure A.

Soulever légèrement le filtre antipoussières

La température de stockage optimale se situe entre

10 °C et 30 °C.

Les blocs batteries Li-Ion "Li-Power" sont pourvus

d'un indicateur de capacité et de signalisation : (13)

- Presser la touche (12) pour afficher l'état de

charge par le biais des voyants LED.

- Si un voyant LED clignote, le bloc batterie est

presque épuisé et doit être rechargé.

Retrait et mise en place du bloc batterie

Retrait :

pr ess er le bou to n de déverrouillage du bloc

batterie (11) et retirer le bloc batterie (14) vers le

bas.

Insertion :

l'enclenchement.

Faire glisser le bloc batterie (14) jusqu'à

6. Utilisation

6.1 Pinces de serrage

Le diamètre de la tige de l'outil doit exactement correspondre à l'orifice de serrage de la

pince de serrage (1) !

Des pinces de serrage pour différents diamètres de

tige sont disponibles. Voir chapitre "Accessoires".

6.2 Insertion des outils

Débrancher la fiche secteur de la prise de

courant !

Utiliser uniquement des outils qui sont appropriés pour la vitesse de rotation à vide de votre

machine ! Voir caractéristiques techniques.

Le diamètre de la tige de l'outil doit exactement correspondre à l'orifice de serrage de la

pince de serrage (1) !

Dans le cas de meules sur tige, la longueur de

tige ouverte l

par le fabricant ne doit pas être dépassée !

Insérer l'outil sur toute la longueur de la tige dans la

pince de serrage (1).

Bloquer la broche (pour GE 710 Compact, avec la

clé à fourche de 13 mm fournie ; pour GA 18 LTX,

GE 710 Plus, GA 18 LTX G et GE 950 G Plus, en

act ionnant le disposi tif de bl ocage de la broche (4)).

Serrer l'écrou de la pince de serrage (2) avec la clé

à fourche de 19 mm.

Si aucun outil n'est inséré dans la pince de

serrage, ne pas serrer la pince de serrage

avec la clé, mais uniquement la visser à la main !

6.3 Marche/arrêt

Mettre la machine en marche avant

tionner sur la pièce à usiner.

Eviter les démarrages intempestifs : l'outil doit

toujours être arrêté lorsque le connecteur est

maximale admissible indiquée

0

de la posi-

Page 17

débranché de la prise de courant ou après une

coupure de courant.

Lorsque l'outil est en position de marche

continue, il continue de tourner s'il échappe

des mains. Pour cette raison, toujours tenir la

machine des deux mains au niveau des poignées

(3), (5), (7) prévues à cet effet, veiller à un bon équilibre et travailler de manière concentrée.

Mise en marche : pousser l'interrupteur coulissant

(6) vers l'avant. Pour un fonctionnement en continu,

le basculer ensuite vers le bas jusqu'à l'enclenchement.

Arrêt : appuyer sur l'arrière de l'interrupteur coulissant (6), puis relâcher.

6.4 Réglage de la vitesse de rotation (uni-

quement machines fonctionnant sur secteur)

La molette (8) permet de présélectionner la vitesse

de rotation en continu. Vitesses de rotation, voir

tableau sur la page 3.

6.5 Consignes pour le travail

Meulage, ponçage au papier de verre, travaux

avec brosses métalliques, polissage : presser la

machine de façon modérée et effectuer des mouvements de va-et-vient sur la surface.

Fraisage : presser la machine de façon modérée

Tronçonnage :

une avance mesurée, adaptée au matériau à

usiner. Ne pas positionner la machine de travers, ne

pas l'appuyer ni l'osciller.

lors des travaux de tronçonnage,

toujours travailler en sens opposé (voir

l'illustration). Sinon, la machine risque

de sortir de la ligne de coupe de façon

incontrôlée. Toujours travailler avec

7. Nettoyage

7.1 Nettoyage du moteur

Nettoyer la machine régulièrement, fréquemment et

soigneusement, en soufflant de l'air comprimé à

travers les fentes d'aération à l'arrière. Veiller à bien

maintenir la machine à cette occasion.

8. Dépannage

8.1 Machines fonctionnant sur secteur :

- Protection contre les surcharges : la vitesse

en charge est FORTEMENT réduite. La tempé-

rature du moteur est trop élevée ! Laisser fonctionner la machine à vide jusqu'à ce que la

machine soit refroidie.

- Protection contre les surcharges : la vitesse

en charge est LEGEREMENT réduite. La

machine est surchargée. Continuer de travailler à

charge réduite.

- Coupure de sécurité Metabo S-automatic : la

machine a été ARRETEE automatiquement.

Lorsque la vitesse d'accroissement du courant est

trop élevée (comme c'est le cas par exemple lors

d'un blocage soudain ou d'un rebond), la machine

FRANÇAIS fr

est désactivée. Arrêter la machine par le biais de

l'interrupteur coulissant (6). Ensuite, la redémarrer

et reprendre le travail normalement. Eviter tout

autre blocage. Voir chapitre 3.2.

- Protection contre le redémarrage : la machine

ne démarre pas. La protection contre le redémarrage a déclenché. Si la fiche secteur est branchée alors que la machine est en marche, ou si

l'alimentation est rétablie après une coupure de

courant, la machine ne démarre pas. Arrêter et

redémarrer la machine.

8.2 Machines sans fil :

- Le témoin électronique (10) s'allume et la

vitesse en charge diminue. La température est

trop élevée ! Laisser fonctionner la machine à vide

jusqu'à ce que le témoin électronique s'éteigne.

- Le témoin électronique (10) clignote et la

machine ne fonctionne pas. La protection

contre le redémarrage a déclenché. Si le bloc

batterie est introduit lorsque la machine est en

marche, la machine ne démarre pas. Arrêter et

redémarrer la machine.

9. Accessoires

Utiliser uniquement des accessoires d'origine

Metabo.

Utiliser exclusivement des accessoires, qui sont

conformes aux exigences et aux données caractéristiques indiquées dans la présente notice d'utilisation.

Monter correctement les accessoires. Si la machine

est utilisée dans un support : fixer correctement la

machine. En cas de perte de contrôle, il y a un

risque de blessures.

A Pinces de serrage (y compris écrous)

Ø

3 mm = 6.31947

Ø

1/8“ = 6.31948

Ø

6 mm = 6.31945

Ø

1/4“ = 6.31949

Ø

8 mm = 6.31946

B Support de serrage 6.27354 pour le serrage

lors de travaux avec des arbres flexibles

(serrage de la vis de blocage), avec cela :

C Etrier de serrage 6.27107 pour la fixation sûre sur

l'établi (serrage de la vis de blocage).

D Chargeurs : ASC 15, ASC 30, etc.

E Blocs batteries : 4,0 Ah (6.25527) ; 3,0 Ah

(6.25455)

Gamme d'accessoires complète, voir

www.metabo.com ou catalogue.

10. Réparations

Les travaux de réparation sur les outils électriques ne peuvent être effectués que par un

spécialiste !

Pour toute réparation sur un outil Metabo, veuillez

contacter votre agence Metabo. Voir les adresses

sur www.metabo.com.

Les listes des pièces détachées peuvent être téléchargées sur www.metabo.com.

17

Page 18

FRANÇAISfr

11. Protection de l'environnement

Observer les réglementations nationales concerna nt la m ise au reb ut dan s le respe ct de l 'en viron nement et le recyclage des machines, emballages et

accessoires.

Consignes spéciales pour machines sans fil :

Les blocs batteries ne doivent pas être jetés avec

les ordures ménagères ! Ramener les blocs batteries défectueux ou usagés à un revendeur Metabo !

Ne pas jeter les blocs batteries dans l'eau.

Avant d'éliminer l'outil électrique, décharger son

bloc batterie. Protéger les contacts contre les courtcircuits (p. ex. les isoler à l'aide de ruban adhésif).

12. Caractéristiques techniques

Explications concernant les indications de la page 3

. Sous réserve de modifications allant dans le sens

du progrès technique.

U =tension du bloc batterie

S = blocage de la broche pour un change-

n = Vitesse de rotation à vide (vitesse de rota-

n

1

I

120 V

P

P

D

d = orifice de serrage de la pince de serrage

m =poids avec bloc batterie le plus petit /

Les caractéristiques techniques indiquées sont

soumises à tolérance (selon les normes en vigueur

correspondantes).

ment d'outil simplifié

tion maximale)

=vitesse en charge

=Courant sous 120 V

=puissance absorbée nominale

1

=puissance débitée

2

=diamètre de meule maximal

max

poids sans câble d'alimentation

Porter un casque antibruit !

Dérangements électromagnétiques :

des dérangements électromagnétiques extrêmes

provenant de l'extérieur peuvent entraîner au cas

par cas des fluctuations momentanées de la vitesse

de rotation ou déclencher la protection contre le

redémarrage. Dans ce cas, arrêter et remettre en

marche la machine.

18

Page 19

Instrucciones de manejo

1. Aplicación de acuerdo a la

finalidad

Las rectificadoras han sido concebidas...

- ... para el amolado de precisión en metales con

barritas de abrasivo.

- ... para el tronzado de precisión en metales con

pequeños discos tronzadores.

- ... para fresar con fresas frontales de metales no

ferrosos, plásticos, maderas resinosas, etc.

- ...para trabajar con cepillos de alambre y de

alambre redondo

- ...para trabajar con cuerpos de pulido de forma

- ...para trabajar con cuerpos de pulido fieltro

- ...para trabajar con rueda de afilar para laminillas

No desarrollada para el trabajo con campanas de

pulición.

Los posibles daños derivados de un uso inadecuado son responsabilidad exclusiva del usuario.

Deben observarse las normas sobre prevención de

accidentes aceptados de forma general y la información sobre seguridad incluida.

2. Instrucciones generales de

seguridad

Para su propia protección y la de su

herramienta eléctrica, observe las partes

marcadas con este símbolo.

ADVERTENCIA: Lea el manual de instrucciones para reducir el riesgo de accidentes.

Si entrega su herramienta eléctrica a otra persona,

es imprescindible acompañarla de este documento.

Instrucciones generales de seguridad para

herramientas eléctricas

¡ATENCIÓN! Lea íntegramente estas

instrucciones de seguridad. La no observa-

ción de las instrucciones de seguridad siguientes

puede dar lugar a descargas eléctricas, incendios

y/o lesiones graves.

¡Guarde estas instrucciones en un lugar

seguro! El término "herramienta eléctrica"

empleado en las siguientes instrucciones se refiere

a su aparato eléctrico portátil, ya sea con cable de

red, o sin cable, en caso de ser accionado por

acumulador.

2.1 Puesto de trabajo

a) Mantenga limipo y bien iluminado su puesto

de trabajo. El desorden y una iluminación defi-

ciente en las áreas de trabajo pueden provocar

accidentes.

b) No utilice la herramienta eléctrica en un

entorno con peligro de explosión, en el que se

encuentren combustibles líquidos, gases o

material en polvo. Las herramientas eléctricas

ESPAÑOL es

producen chispas que pueden llegar a inflamar los

materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras

personas de su puesto de trabajo al emplear la

herramienta eléctrica. Una distracción le puede

hacer perder el control sobre el aparato.

2.2 Seguridad eléctrica

a) El enchufe de la herramienta eléctrica debe

corresponder a la toma de corriente utilizada.