Page 1

Mealstream

SERVICE

ALL CTM3 MODELS & TIM HORTON'S COMBINATION OVEN

MANUFACTURED FROM JANUARY 2003

CAUTION MICROWAVE EMISSIONS

DO NOT BECOME EXPOSED TO EMISSIONS FROM THE MICROWAVE GENER ATOR

OR PARTS CONDUCTING MICROWAVE ENERGY

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 1

SERVICE MANUAL

Page 2

TABLE OF CONTENTS

Microwave safety precautions ................................................. 3

Safety code ............................................................................. 4

Product specifications ............................................................. 5

Installation instructions............................................................ 6

Main features ....................................................................... 7-8

Principal components: LHS ..................................................... 9

Principal components: RHS .................................................. 10

Principal components: Top.................................................... 11

Principal components: Back view.......................................... 12

Principal components: door, roof and heater element ..........13

Principal components: Cavity Parts & External Panels ......... 14

Principal components: Electronic control panel assembly .... 15

Principal components: Tim Hortons Control panels .............. 16

Principal components: ( not shown in main views ) ............. 17

Principal components: Input wiring details ............................ 18

Principal components: Part no. identification charts ........ 19-21

Procedure for Microwave leakage test ............................. 22-23

Procedure for Power output measurement ........................... 24

Procedures for Principal Component tests ......................25-26

Procedure for Door interlock adjustment and test .......... 27-29

Procedure for building and fitting the door ....................... 30-34

Procedure for replacing door seal assembly.................... 35-36

Procedure for removing shelf runners & element cover ........ 37

Procedure for replacing Heater Element...............................38

Procedure for replacing Hot air Motor assembly................... 39

Procedure for replacing Magnetron assembly .................40-41

Procedure for Testing Membrane panel circuit ................ 42-43

Circuit diagrams ..............................................................44-47

Error codes and diagnostics.................................................. 48

Appendix 1: Test Procedure for Tim Hortons........................ 49

Appendix 2: MenuKey® Download procedure ...................... 50

Appendix 3: Temperature Sensor resistance data ................ 51

Manual corrections and modifications................................... 52

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 2

Page 3

MICROWAVE SAFETY

CAUTION

WARNING TO SERVICE TECHNICIANS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before

activating the magnetron or other microwave source , and make repairs

as necessary:

1) interlock operation.

2) proper door closing.

3) seal and sealing surfaces (arcing, wear, and other damage).

4) damage to or loosening of hinges and latches.

5) evidence of dropping or abuse.

(c) Before turning on microwave power for any service test or inspection

within the microwave generating compartments, check the magnetron,

wave guide or transmission line, and cavity for proper alignment,

integrity and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door

seal, and microwave generation and transmission systems shall be

repaired, replaced, or adjusted by procedures described in this manual

before the oven is released to the owner.

(e)(i) A microwave leakage check to verify compliance with the Federal

Performance Standard should be performed on each oven prior to

release to the owner. For U.S.A.

(e)(ii) A microwave leakage check to verify compliance with the Canadian

Regulation, HEALTH AND WELFARE, SOR/79 920 should be

performed on each oven prior to release to the owner. For CANADA.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 3

Page 4

SAFETY CODE

This manual is designed to assist engineers who have been on a recognised product

familiarisation and training course run by Garland. It has been prepared to offer technical

guidance for the Mealstream range of Combination Microwave Ovens.

Please remember that it is wiser not to attempt a service task if you are unsure of being able to

complete it competently, quickly, and above all safely.

To avoid injury to yourself, and to protect the appliance from possible damage, please follow this

Safety Code when servicing these ovens.

Before attempting to repair the oven, check it for microwave leakage.

Check that the oven is not emitting microwaves, even when supposedly not in

operation.

Check that the oven is not operating continuously, whether the display indicates

cooking or not.

Always discharge the HT capacitors before working on the oven using a suitably

insulated 10 MΩ Resistor.

Before removing any covers from the oven, do all of the following.

• Switch off the mains supply and remove the plug from the wall socket.

or

• If the oven is hard wired, ensure that the power is turned off at the isolator switch.

Note:

The On/Off switch on the oven is not adequate protection against electric

shock, as it does not isolate all of the internal wiring from the mains.

Upon completion of a service on a Mealstream oven, or before reconnecting the appliance to the

electrical supply for testing, check all of the following points:

• All internal electrical connections are correct (see wiring diagram Page 44-47).

• All wiring insulation is correct and is not touching a sharp edge.

• All grounding connections are electrically and mechanically secure.

• All door safety interlocks are secure and mechanically sound.

• The door operation is smooth, and the arms run freely in the slots.

• The door activates all three of the door interlock switches in the correct order

(see pages 27-29).

• The temperature sensor is correctly connected to the Power PCB.

Before finishing a service call, recheck the following points:

• All of the electronics are functioning correctly, and all of the touch pads are working.

• Microwave emissions are below permissible limit - 4 mW/cm².

• The power output of the oven is checked in accordance with page 24.

• Oven has correct 2 inch ( 50mm ) air gap all round and 2 inch ( 50mm ) above.

Air flow should not be restricted. (see page 6).

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 4

Page 5

PRODUCT SPECIFICATIONS

Model Number: + Voltage + Frequency + Phases + Controls + Country

Model No. CTM3

Voltage

Frequency

Phases

Control Type

Country

Customer Variant

Power

Requirements

208Volts

240Volts

Power Output Microwave 100%

Convection

Combination

External

Dimensions

Height

Width

Depth

208V 20

240V 24

50Hz 50

60Hz 60

Single 1

Three 3

Series 5 S5

UK UK

N.America A

N.America TH = Tim Hortons

208V ac 60Hz 30Amp 2P & G

240V ac 60Hz 40Amp 2P & G

1425W

3000W

1425W + 3000W

30 inches ( 765mm )

29.5 inches ( 770mm )

25 inches ( 635 mm)

Manufacturers

recommended

clearances

Height

Width

Depth

Internal

Dimensions

Height

Width

Depth

Capacity

Weight Nett

Gross packed

Construction Cavity

Casework

Settings Microwave

Temperature

Timer

Programs

Mealstream Ovens Pt. No. 32Z3403 Issue 15

32 inches ( 815 mm )

31.5 inches ( 795 mm )

27 inches ( 685 mm)

10.2 inches ( 260mm )

19.3 inches ( 490mm )

14.2 inches ( 360mm )

1.62 ft³ ( 45.86 litres )

198 lb.s ( 90 kg )

227 lbs ( 103 kg )

304 Stainless Steel

100%,75%,50%,25%, Convection only

Off, 300°F, 350°F, 400°F, 440°F, 480°F

Up to 30 minutes per stage

Cook Programs can have 3 cooking stages of up to 30

minutes for each stage

Page 5

Page 6

INSTALLATION INSTRUCTIONS

Installation Instructions for Mealstream Combination Ovens

Power Supply Requirements

The Mealstream Series should be connected to a suitable electricity supply, which can cope

with the switching-on surge that occurs with certain types of catering equipment, including

microwaves. Because of this requirement, we strongly recommend that a separate, suitably

rated supply is installed for the oven.

The supply for the oven should be fitted with a Type "C" or Time Delay circuit breaker,

rated at:

50 Amp for 208V electrical supply ( 2PH + GND )

50 Amp for 240V electrical supply ( 2PH + GND )

30 Amp for 208V electrical supply ( 2PH + GND )

30 Amp for 240V electrical supply ( 2PH + GND )

If the oven is hard-wired to the supply, a double-pole isolator switch with a contact gap of at

least 1/8 inch ( 3 mm ) should be fitted.

Grounding requirement

This appliance must be connected to a grounded, metallic, permanent wiring system, or an

equipment grounding conductor should be run with the circuit conductors and connected to the

equipment grounding terminal or lead on the appliance.

Canada models

US models

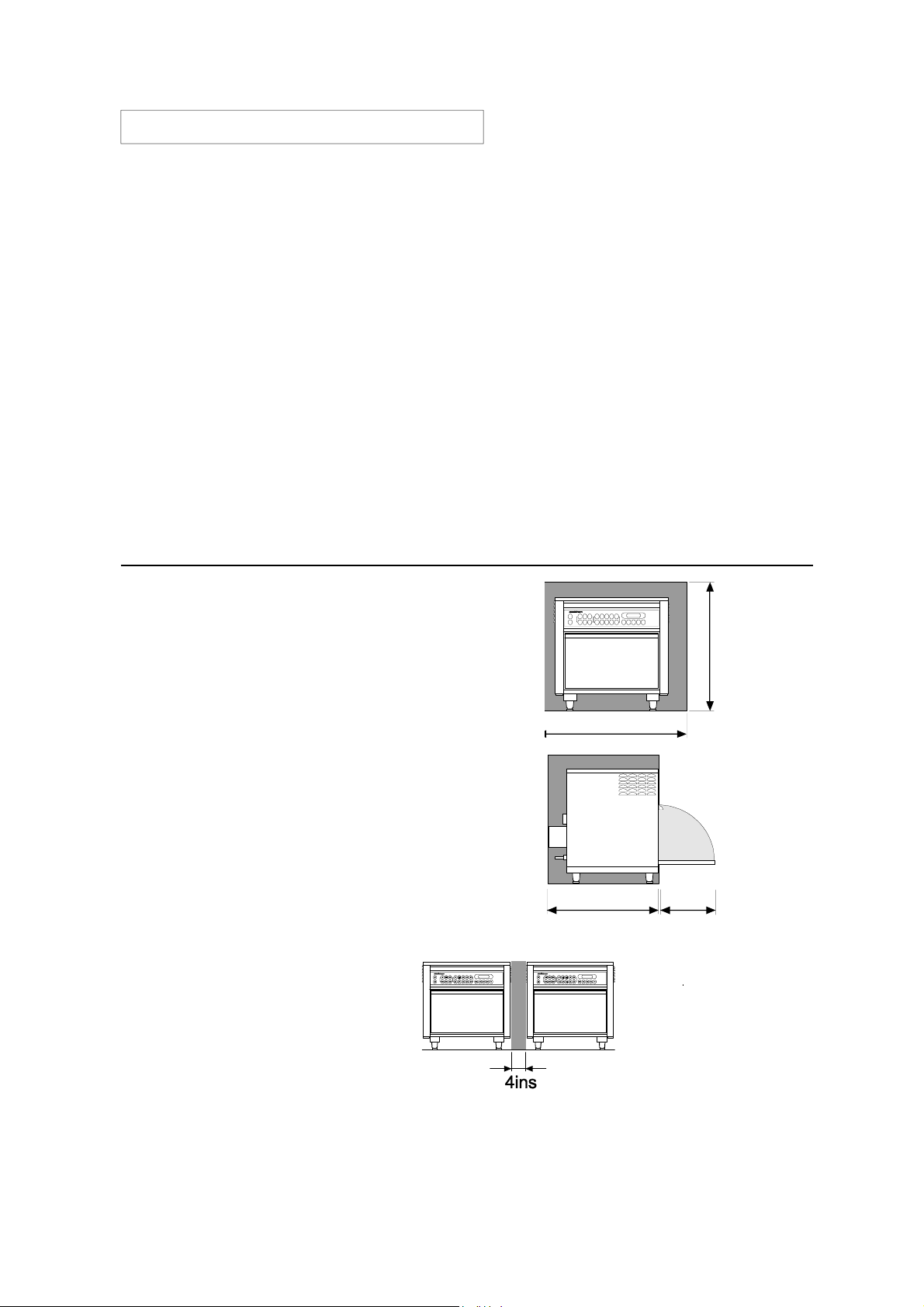

Positioning the Oven

In order to maintain adequate ventilation for air intake

and exhaust, and to allow access for cleaning filters,

you must allow a minimum of 2 inches ( 50 mm )

clearance at the sides and rear of the oven,

and at least 2 inches ( 50 mm ) above.

Air intake temperature should not exceed 110°F/45°C

excessive temperature will lead to reduced operating

duty cycle, or premature ageing of internal components.

Failure to comply with these conditions will invalidate

the warranty.

NEVER Install an oven above fryers,

grills, griddles or any other

major heat source.

NEVER Stack machines on top of

each other. Always use a

double stand or a separate

shelf.

ALWAYS Place containers in the cavity

carefully - impact damage

may chip the vitreous enamel

coating on the runners and

baffle plate.

Note:

The minimum recommended

clearance required for air flow

31.5ins

27ins

32ins

16ins

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 6

Page 7

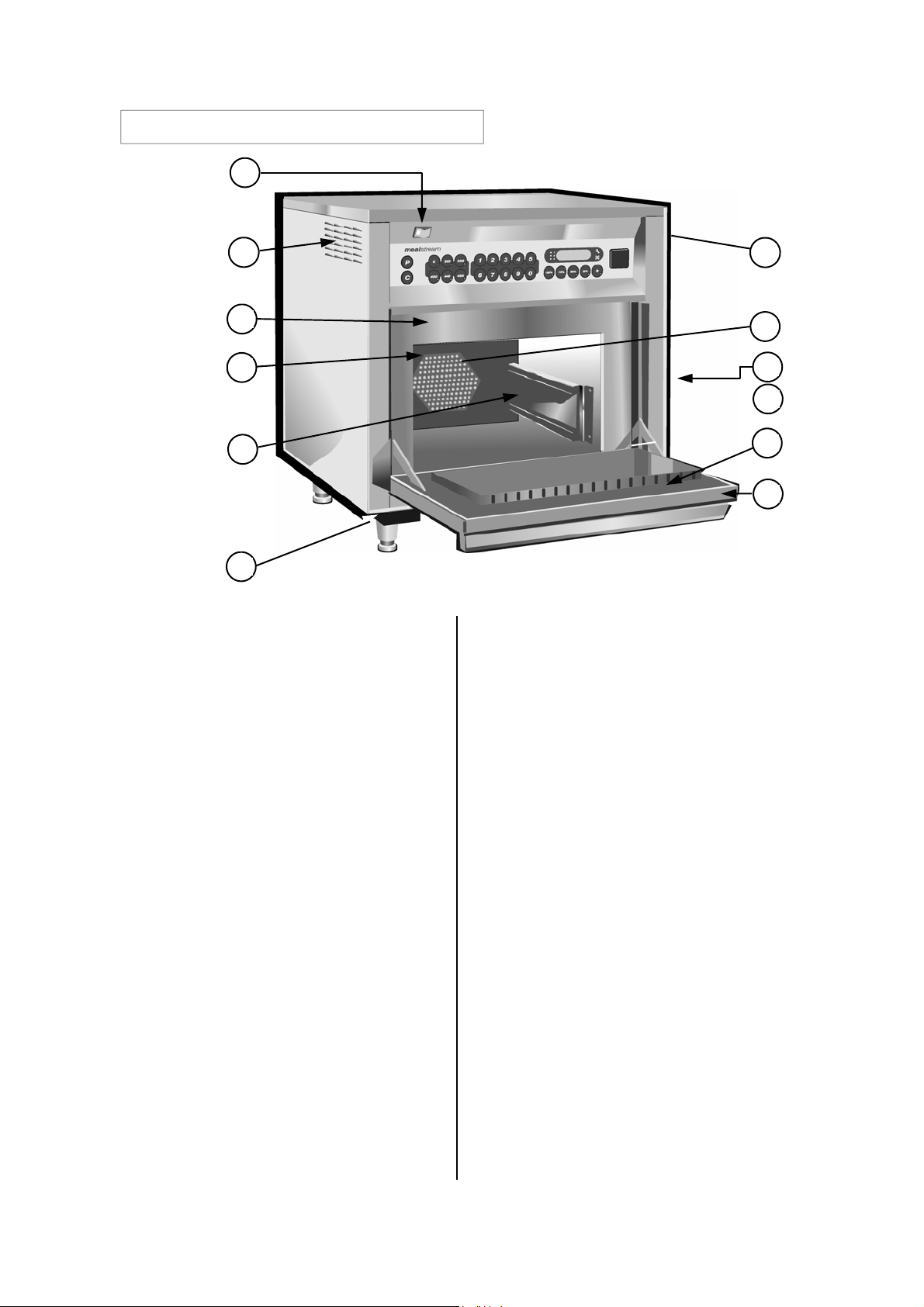

MAIN FEATURES

a

b

c

d

e

k

a

On/Off SWITCH

This is used to turn the oven On or Off.

IT DOES NOT ISOLATE INTERNAL

WIRING FROM THE MAINS SUPPLY.

EXHAUST VENTS

b

Allows exhausted air from the magnetron

cooling system to escape.

f

HOT AIR FAN

Situated behind the baffle plate, and

circulates the hot air through the baffle

plate, over the heating element, and around

the edge of the baffle plate back into the

cavity.

g

RATING PLATE

b

f

g

j

i

h

OVEN CAVITY

c

The oven cavity is mainly constructed

from stainless steel panels. It must be

kept clean.

BAFFLE PLATE

d

Forms the inside rear of the oven and

covers the hot air circulation fan. This

must be cleaned on a regular basis, and

kept free of debris.

RUNNERS

e

These are mounted on each side of the

oven cavity to support the rectangular

racks or oven trays.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

The rating plate is situated on the rear of

the oven, and states the Model, Serial

Number, Electrical Ratings and

Manufacturers telephone number.

h

DOOR

The door consists of a thermally insulated

inner section, and an additional air gap

provided by a twin skinned door front to

lower the surface temperature.

i

DOOR SEAL

ELECTRICAL SUPPLY CORD

j

Electrical supply cord is situated on the rear

of the oven,

AIR FILTER

k

Main intake for cooling air for internal

components. Must be clear of obstructions.

Page 7

Page 8

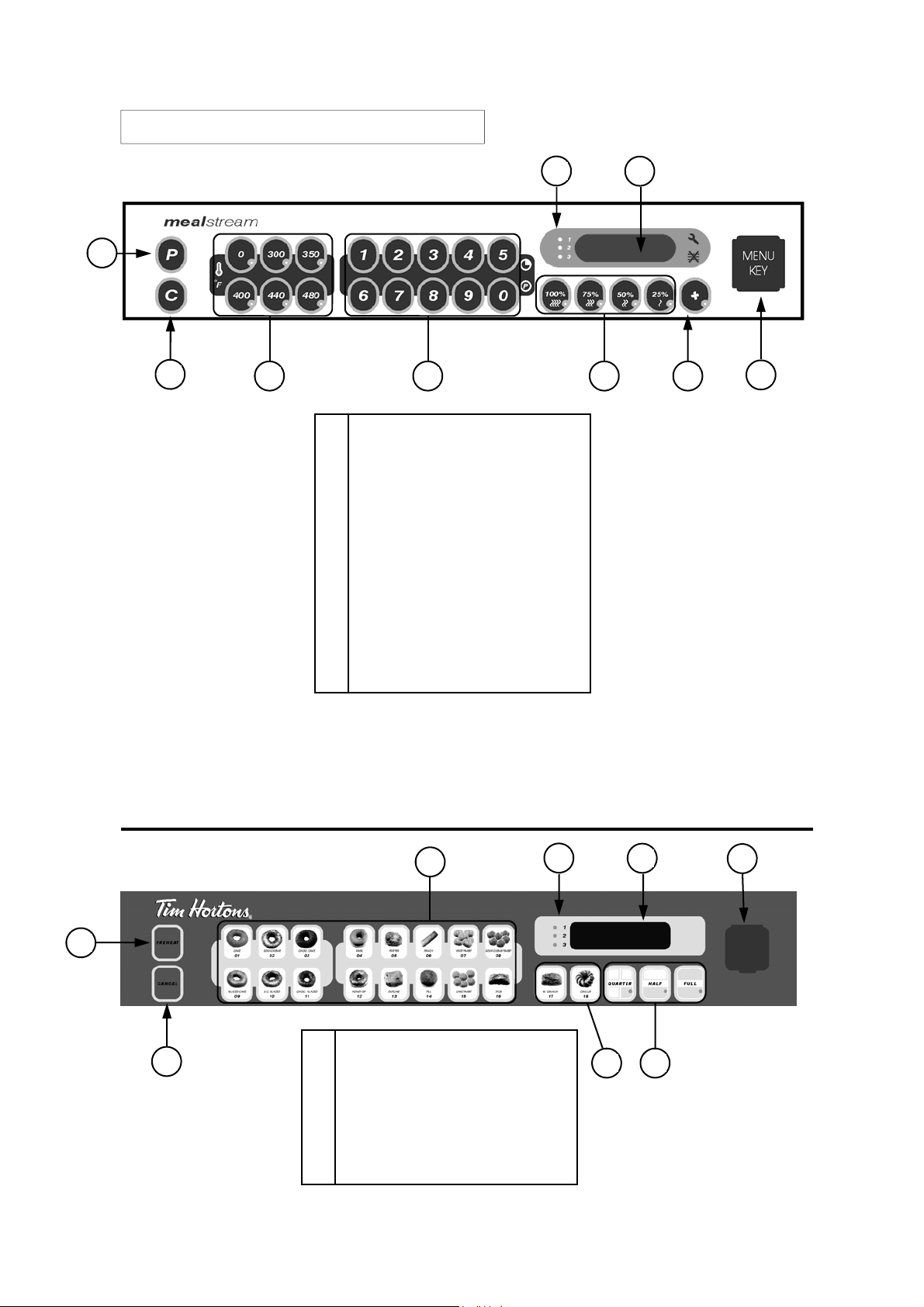

MAIN FEATURES

Electronic control panel

j

i

h e

Stage LED's

a

Program & Time Display

b

Convection Pad

e

Power Pads

f

Time / Preset Pads

g

Temperature Set Pads

h

Cancel / Callback Pad

i

a

b

f g

N

K

j

N

Tim Hortons control panel

Preheat

K

L

L

Cancel

Program Pad

Menukey™

M

a

M

b

O

N

MENU

KEY

Icon Cook Pads

M

MenuKey™

N

Quarter, Half & Full Batch Load

O

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 8

Page 9

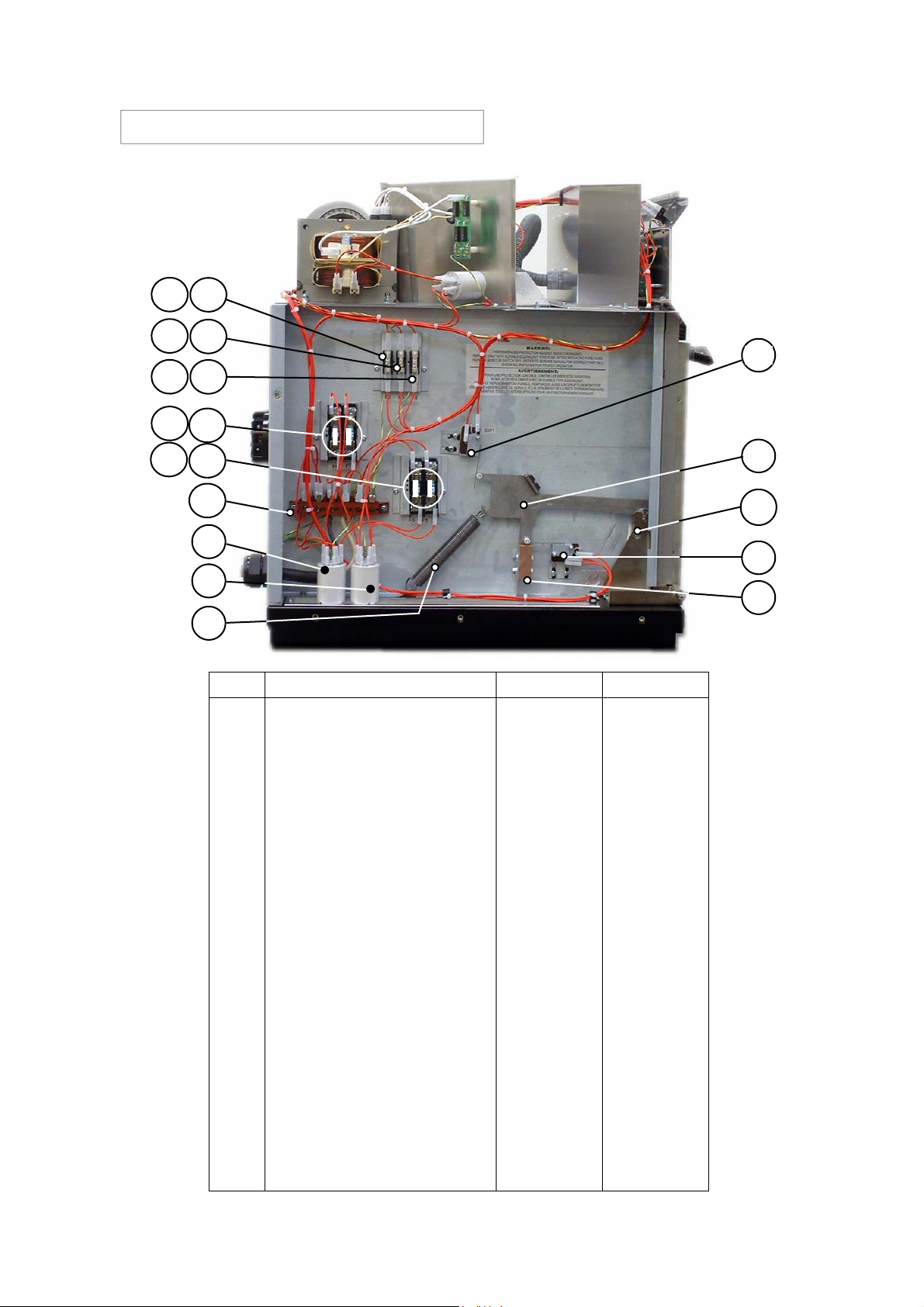

PRINCIPAL COMPONENTS

Left side

1

1A

2

2A

3A

3

4

4A

14

5

5A

6

7

8

9

No Description 208V 240V

1 Fuse holder 30Z0231 30Z0231

1A Fuse 10 amp 30Z0217 30Z0217

2 Fuse holder 30Z0231 30Z0231

2A Fuse 10 amp 30Z0217 30Z0217

3 Fuse holder 30Z0285 30Z0285

3A Fuse 1 amp 30Z0957 30Z0957

4 Fuse holder 30Z1178 30Z1178

4A Fuse 20 amp 30Z1177 30Z1177

5 Fuse holder 30Z1178 30Z1178

5A Fuse 20 amp 30Z1177 30Z1177

6 Electrical supply terminal block 31Z0149 31Z0149

7 Filter ( Heater circuit ) 30Z0997 30Z0997

8 Filter ( Microwave circuit ) 30Z0997 30Z0997

9 Door spring (short type) 520000 520000

9 Door spring( Long )A 40C1141 40C1141

10 Door arm stop assembly 11C0279 11C0279

11 Microswitch ( Primary ) 30Z0240 30Z0240

12 Door hinge assembly ( LH )B 11C0167 11C0167

13 Door arm assembly 11C0300 11C0300

14 Microswitch ( Monitor ) 30Z0240 30Z0240

13

12

11

10

Note A

Ovens after

June 2003

Note B

See page 17

for parts

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 9

Page 10

PRINCIPAL COMPONENTS

Right side

95

22

59

15

16

17

19 18

No Description 208V 240V

15 Door arm assembly 11C0300 11C0300

16 Door hinge assembly ( RH )

B

11C0166 11C0166

17 Micro-switch ( Secondary ) 30Z0240 30Z0240

18 Door arm stop assembly 11C0279 11C0279

21

20

90

Note B

See page 17

for parts

19 Door spring 520000 520000

Door spring( Long )A 40C1141 40C1141

19

20 Steam pipe 40C1023 40C1023

21 Steam vent guard 790061 790061

22 Temperature sensor 50E123 50E123

59 Rubber stop 31Z1150 31Z1150

90 Cavity Vent Pipe 40C1013 40C1013

95 Diode Board assy. with leads 11M0325 11M0325

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 10

Note A

Ovens after

June 2003

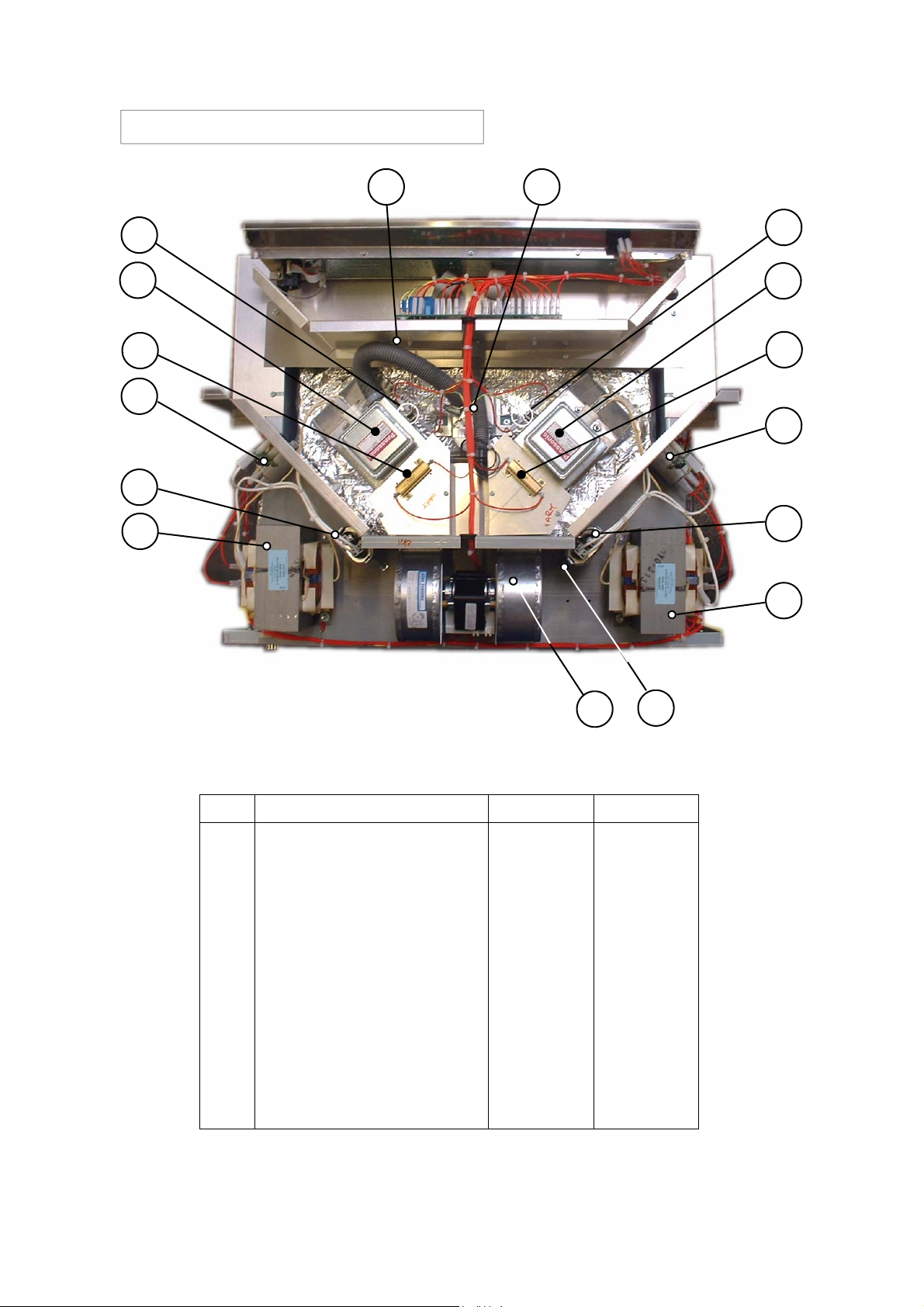

Page 11

PRINCIPAL COMPONENTS

Top view

87

23

24

63

26

27

60

61

87

23

24

63

26

27

28

No Description 240V

23 Magnetron (Panasonic) 30Z1171

24 Resistor 470 R 30Z0283

26 Capacitor 0.88µf (2300V)A 30Z0861

26 Capacitor 0.88µf (2500V) Kit 10C0192

27 Transformer 30Z1191

28 Twin blower motor

60 25mm OD Flexible conduit

61 20mm OD Flexible conduit

62 Capacitor clip (99mm)

63 Filter 30Z0997

87 Magnetron Thermal Trip 2571016

Note A: This Capacitor is replaced with 0.88µf 2500V and 2 x 109mm clips

included in a service kit Part No. 10C0192

208V

30Z1171

30Z0283

30Z0861

10C0192

30Z1139

30Z1145

314402

314401

31Z0176

62

30Z1067

314402

314401

31Z0176

N/A

2571016

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 11

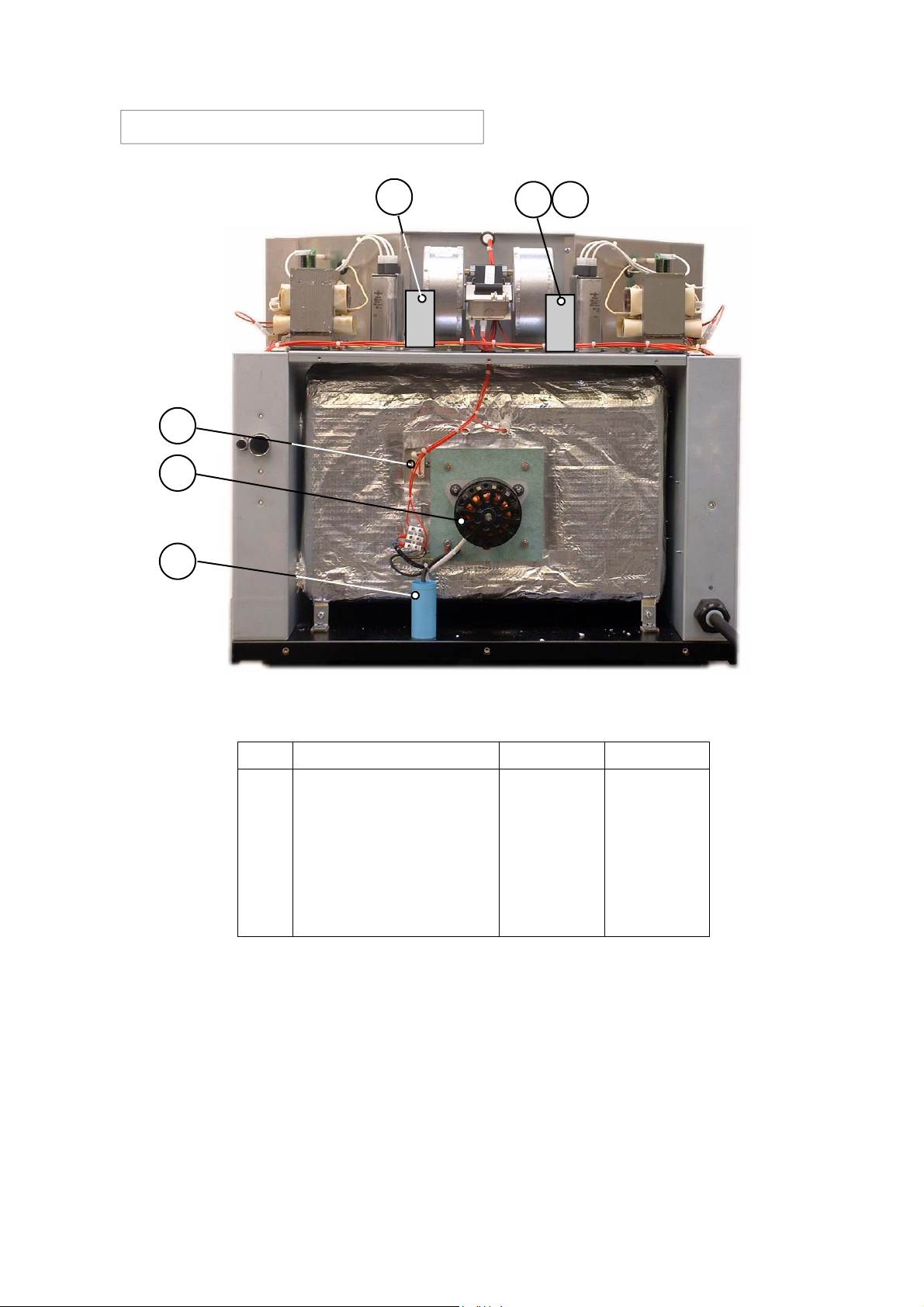

Page 12

PRINCIPAL COMPONENTS

Back view

94

88

64

65

104 105

No Description 208V 240V

64 Hot air motor assembly 11C0312

65 Capacitor 6µF 30Z1148

88 Overheat Safety Thermostat 30Z1024

94 Hot Air motor Resistor 50R N/A

104 Twin Blower Resistor 39R N/A

105 Twin Blower Resistor 50R N/A

11C0312

30Z1148

30Z1024

30Z1165

30Z1164

30Z1165

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 12

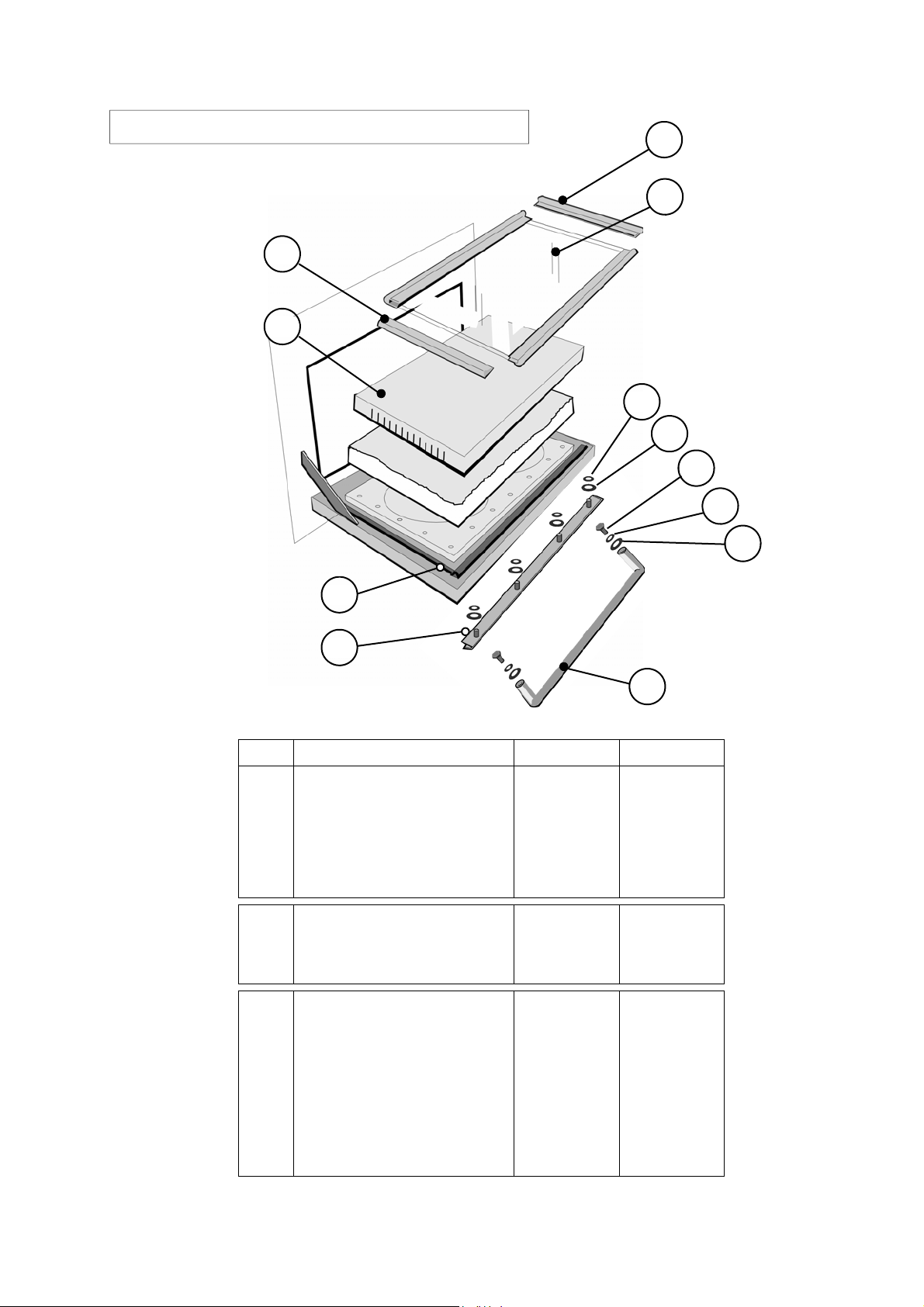

Page 13

PRINCIPAL COMPONENTS

Door and cavity roof

86

72

86

67

106

107

77

108

109

71

89

76

No Description 208V 240V

53 M5 Hex/hd s/s Screw 101825 101825

67

71 Door seal kit 11C0292 11C0292

72 Door choke 790007 790007

86 Cavity roof seal (short) 790052 790052

93

76 Door Handle Towel Rail 32Z1064 32Z1064

77 Bolt 1/4" 20 UNC 3/4" Hex 109050 109050

Stirrer glass assy. ( inc. long seals )

Door Assembly Garland 11C0336 11C0336

Door Assembly Tim Hortons 11C0380 11C0380

Door Assembly Unbranded 11C0418 11C0418

11C0319 11C0319

89 Door Handle 40C1020 40C1020

106 Flat Washer S/S M5 x 20 104036 104036

107 Nylon Washer 104250 104250

108 Spring Washer 31Z5005 31Z5005

109 Flat Washer S/S M6 x 20 104054 104054

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 13

Page 14

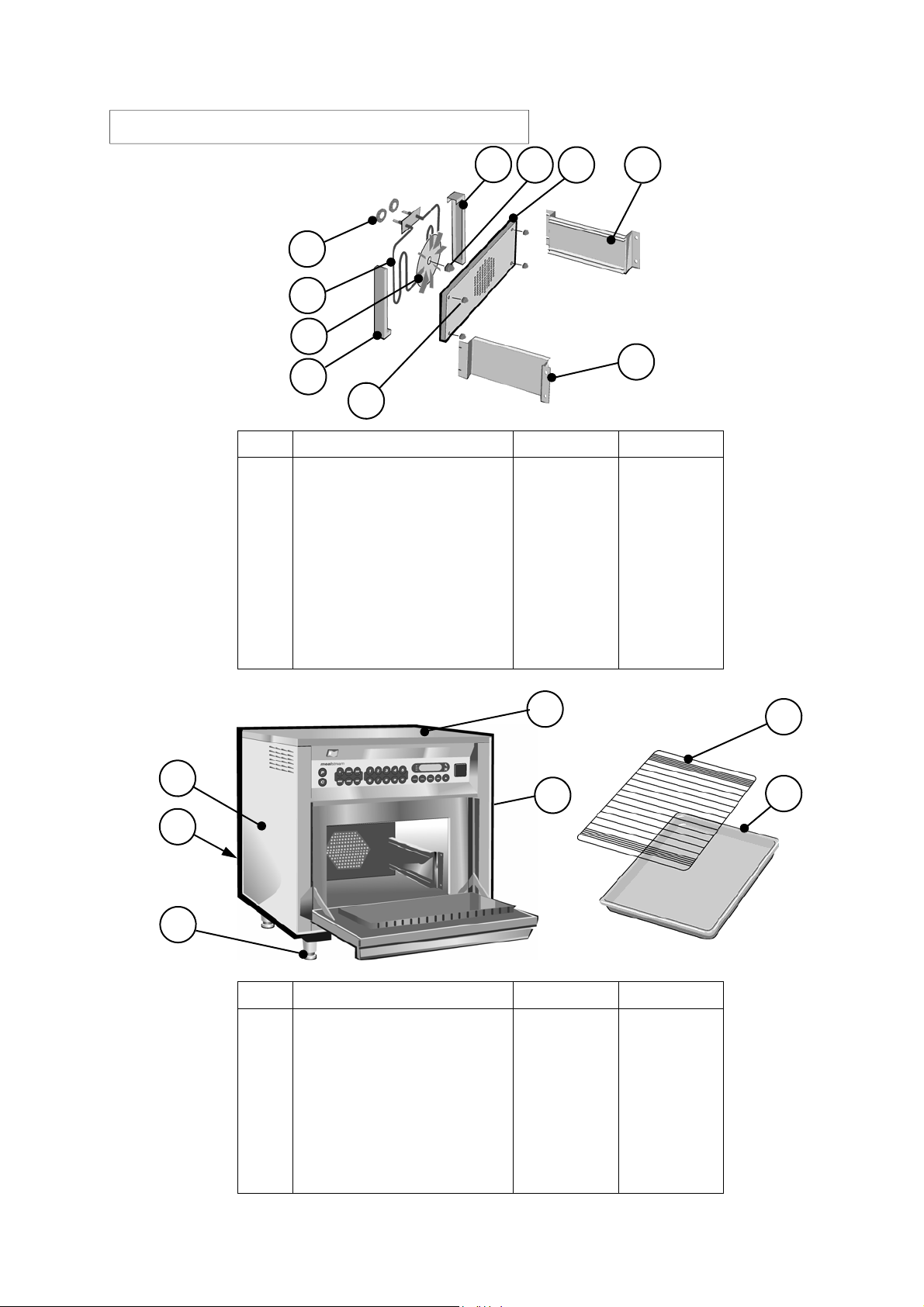

PRINCIPAL COMPONENTS

Heater Element and Cavity parts

57

68

102

70

85

No Description 208V 240V

57 Mesh washer 31Z5044 31Z5044

68 Heater element 40C0949 40C0948

69 Heater element cover plate 790047 790047

70 Baffle 11C0311 11C0311

85 Dome Nut 80X7025 80X7025

92 Tray Support 40C0950 40C0950

102 Hot Air Impeller MC3111 MC3111

103

Hot Air Impeller Securing Nut

70

69

103

105065 105065

92

92

External Parts and accessories

96

110

99

No Description 208V 240V

96 Side Panel Left Side 790002 790002

97 Side Panel Right Side 790003 790003

98 Top Panel 790005 790005

99 Foot 32Z1052 32Z1052

100 Wire Rack 40C1011 40C1011

101 Crumb Tray RBR290X02 RBR290X02

110 Rear Outer Panel 40C0951 40C0951

98

97

100

101

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 14

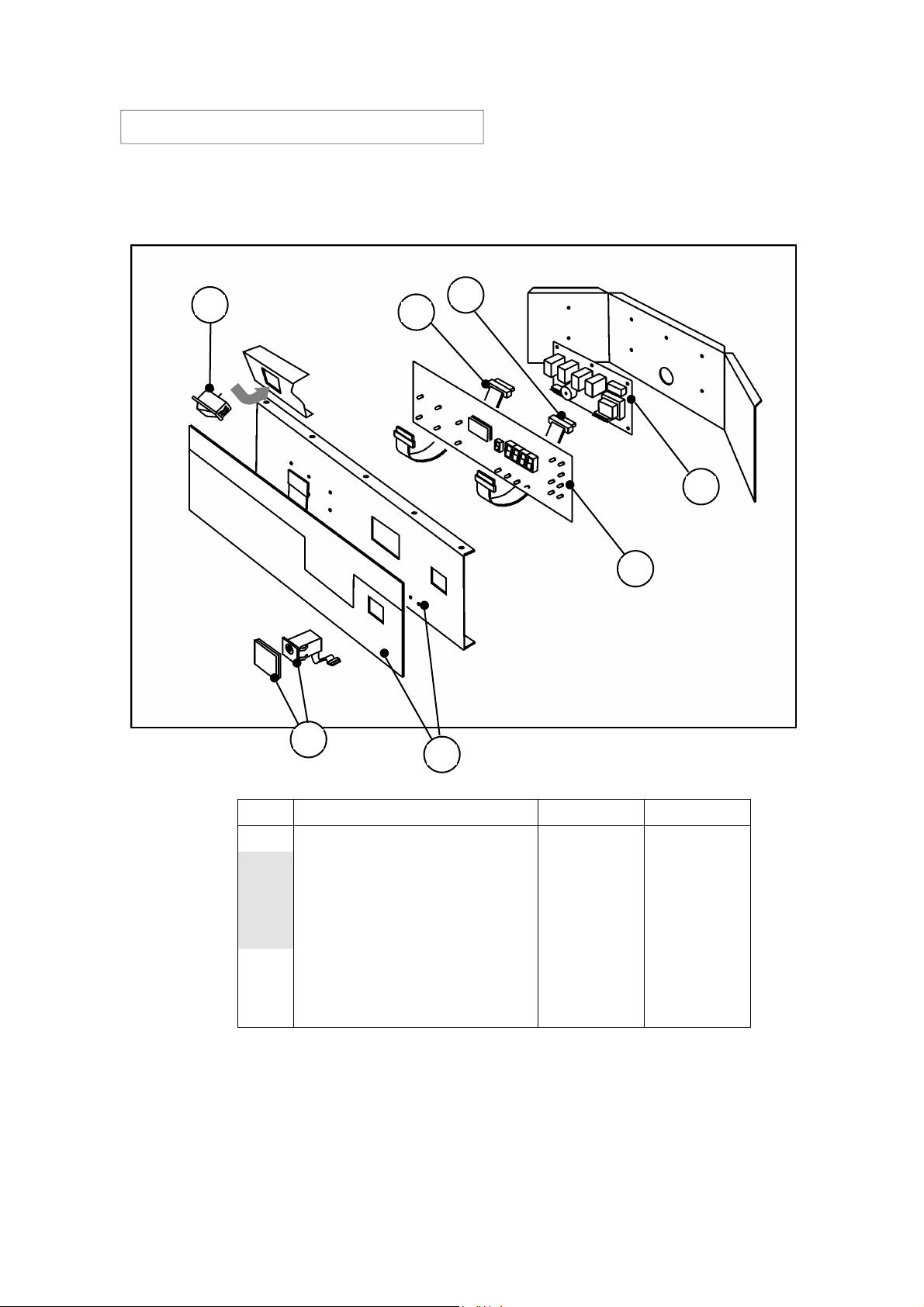

Page 15

PRINCIPAL COMPONENTS

Electronic Control Panel Assembly

29

34

33

32

31

73

30

Tim Hortons

See page 16

No Description 208V 240V

29 On/Off Switch 30Z0503 30Z0503

30 Control Panel Assy with Menukey

(except Tim Hortons)

31 Logic Board (except Tim Hortons) 11C0377 11C0377

32 Relay Board (except Tim Hortons) 11C0316 11C0212

33 AC Ribbon connector 11M0116 11M0116

34 DC Ribbon connector 11M0117 11M0117

73 MenuKey Assembly 10C0148 10C0148

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 15

11C0379 11C0379

Page 16

TIM HORTONS CONTROL PANEL

US/ English

No Description 208V 240V

30 Control Panel Assy with Menukey 11C0332 11C0332

31 Logic Board 11C0331 11C0331

32 Relay Board 11C0316 11C0212

US/ English 1/4 Load

No Description 208V 240V

30 Control Panel Assy with Menukey 11C0412 11C0412

31 Logic Board 11C0411 11C0411

32 Relay Board 11C0402 11C0403

French Canadian

No Description 208V 240V

30 Control Panel Assy with Menukey 11C0413 11C0413

31 Logic Board 11C0411 11C0411

32 Relay Board 11C0402 11C0403

Unbranded

No Description 208V 240V

30 Control Panel Assy with Menukey 11C0414 11C0414

31 Logic Board 11C0411 11C0411

32 Relay Board 11C0402 11C0403

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 16

Page 17

PRINCIPAL COMPONENTS

( not shown in main views )

Left Hand Door Hinge

12

54

53

Motor shaft screen and

seal assembly

Assembly

52

51

55

58

Right Hand Door Hinge

16

52

51

56

Stirrer motor assembly

Assembly

54

53

49

50

No. Description All models

12 Door Hinge Assembly LH 11C0167

16 Door Hinge Assembly RH 11C0166

49 Motor shaft screen 40C1005

50 Hot air motor damper/seal 40C1008

51 Pin 790027

52 Roller 40C0752

53 M5 Hex/hd s/s Screw 101825

54 M5 stainless steel Nut 80X7003

55 LH Hinge bracket 790024

56 RH Hinge bracket 790025

58 Stirrer motor assembly 11C0162

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 17

Page 18

PRINCIPAL COMPONENTS

Input wiring details

Green/Yellow

6

L1 L2

48 46

No Description All models

Green

Black

White

47

6 Electrical Supply Terminal Block 31Z0149

46 Cable Gland 31Z0500

47 Gland Nut 31Z0499

48 Electrical Supply Cord 3 Core 30Z1162

91 Electrical Supply Plug 50Amp

(Canada)

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 18

31Z0298

Page 19

PRINCIPAL COMPONENTS: Part Number Identification Chart 1

No

1

1A Fuse 10 amp 30Z0217 30Z0217 9

2 Fuse holder 30Z0231 30Z0231 9

2A Fuse 10 amp 30Z0217 30Z0217 9

3 Fuse holder 30Z0285 30Z0285 9

3A Fuse 1 amp 30Z0957 30Z0957 9

4 Fuse holder 30Z1178 30Z1178 9

4A Fuse 20 amp 30Z1177 30Z1177 9

5 Fuse holder 30Z1178 30Z1178 9

5A Fuse 20 amp 30Z1177 30Z1177 9

6 Electrical supply terminal block 31Z0149 31Z0149 9/18

7 Filter ( Heater circuit ) 30Z0997 30Z0997 9

8 Filter ( Microwave circuit ) 30Z0997 30Z0997 9

9

10 Door arm stop assembly 11C0279 11C0279 9

11 Microswitch ( Primary ) 30Z0240 30Z0240 9

12 Door hinge assembly ( LH ) 11C0167 11C0167 9/17

13 Door arm assembly 11C0300 11C0300 9

14 Microswitch ( Monitor ) 30Z0240 30Z0240 9

15 Door arm assembly 11C0300 11C0300 10

16 Door hinge assembly ( RH ) 11C0166 11C0166 10/17

17 Microswitch ( Secondary ) 30Z0240 30Z0240 10

18 Door arm stop assembly 11C0279 11C0279 10

19 Door spring 520000 520000 10

20 Steam pipe 40C1023 40C1023 10

21 Steam vent guard 790061 790061 10

22 Temperature sensor 50E123 50E123 10

23 Magnetron 30Z1171 30Z1171 11

24 Resistor 470 R 30Z0283 30Z0283 11

25 HT diode 11C0266 11C0266 11

26 Capacitor 0.88µf (2300V) 30Z0861 30Z0861 11

26 Capacitor 0.88µf (2500V) Kit 10C0192 10C0192 11

27 Transformer 30Z1139 30Z0992 11

28 Twin blower motor 30Z1145 30Z1067 11

29 On/Off Switch 30Z0503 30Z0503 15

30 Control Panel Assembly (Except Tim Hortons) 11C00379 11C0379 15

31 Logic Board (Except Tim Hortons) 11C0377 11C0377 15

Description

Fuse holder 30Z0231 30Z0231 9

Door spring 520000 520000 9

Door spring( Long ) 40C1141 40C1141 9

Door spring( Long )A 40C1141 40C1141 10

Control Panel Assembly US Tim Hortons 11C0412 11C0412 16

Control Panel Assy. French C. Tim Hortons 11C0413 11C0413 16

Control Panel Assy. UnBranded Tim

Hortons

Logic Board Tim Hortons 11C0411 11C0411 16

Part No

208V 240V

11C0414 11C0414 16

Page No

Note A

Ovens after

June 2003

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 19

Page 20

PRINCIPAL COMPONENTS: Part Number Identification Chart 2

No

46 Cable Gland 31Z0500 31Z0500 18

47 Gland Nut 31Z0499 31Z0499 18

48 Mains Cable 3 Core 30Z1162 30Z1162 18

49 Motor shaft screen 40C1005 40C1005 17

50 Hot air motor damper/seal 40C1008 40C1008 17

51 Pin 790027 790027 17

52 Roller 40C0752 40C0752 17

53 M5 Hex/hd s/s Screw 101825 101825 13/17

54 M5 stainless steel Nut 80X7003 80X7003 17

55 LH Hinge bracket 790024 790024 17

56 RH Hinge bracket 790025 790025 17

57 Mesh washer 31Z5044 31Z5044 14

58 Stirrer motor assembly 11C0162 11C0162 17

59 Rubber stop 31Z1150 31Z1150 10

60 25mm OD Flexible conduit 314402 314402 11

61 20mm OD Flexible conduit 314401 314401 11

62 Capacitor clip (99mm) 31Z0176 31Z0176 11

63 Filter 30Z0997 N/A 11

64 Hot air motor assembly 11C0312 11C0312 12

65 Capacitor (Motor starter) 30Z1148 30Z1148 12

67 Stirrer glass assy. 11C0319 11C0319 13

68 Heater element 40C0949 40C0948 14

69 Element cover plate 790047 790047 14

70 Baffle 11C0311 11C0311 14

71 Door seal kit 11C0292 11C0292 13

72 Door choke 790007 790007 13

73 Menu-Key Assembly 10C0148 10C0148 15

76 Handle 32Z1064 32Z1064 13

77 Bolt 1/4" 20 UNC 3/4" Hex 109050 109050 13

85 Dome Nut 80X7025 80X7025 13

86 Cavity roof seal (short) 790052 790052 13

87 Magnetron Thermal Trip 2571016 2571016 10

88 Cavity Overheat Thermostat 30Z1024 30Z1024 12

89 Door Handle 40C1020 40C1020 13

90 Cavity Vent Pipe 40C1013 40C1013 10

91 Electrical Supply Plug (50A Canada) 31Z0298 31Z0298 18

92 Tray Support 40C0950 40C0950 13

93

94 Hot Air motor Resistor 50R N/A 30Z1165 12

95 Diode assy with leads 11M0325 11M0325 10

Description

Door Assembly Garland 11C0336 11C0336 13

Door Assembly Tim Hortons 11C0380 11C0380 13

Door Assembly Unbranded 11C0418 11C0418 13

208V 240V

Part No

Page No

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 20

Page 21

PRINCIPAL COMPONENTS: Part Number Identification Chart 3

No

96 Side Panel Left Side 790002 790002 14

97 Side Panel Right Side 790003 790003 14

98 Top Panel 790005 790005 14

99 Foot 32Z1052 32Z1052 14

100 Wire Shelf 40C1011 40C1011 14

101 Crumb Tray RBR290X02 RBR290X02 14

102 Hot Air Fan MC3111 MC3111 14

103 Hot Air Fan Securing Nut 105065 105065 14

104 Twin Blower Resistor 39R N/A 30Z1164 12

105 Twin Blower Resistor 50R N/A 30Z1165 12

106 Flat Washer S/S M5 x 20 104036 104036 13

107 Nylon Washer 104250 104250 13

108 Spring Washer 31Z5005 31Z5005 13

109 Flat Washer S/S M6 x 20 104054 104054 13

110 Door Spacer Kit 10C0171 10C0171 28

111 Rear Outer Panel 40C0951 40C0951 14

Description

208V 240V

Part No

Page No

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 21

Page 22

PROCEDURE FOR MICROWAVE LEAKAGE TEST (1)

Warning

Check for radiation leakage after servicing. Should the leakage be more than 4mW/cm² Inform

Garland service centre immediately. After repairing or replacing any radiation safety device, keep

a written record for future reference, as required by D.H.H.S. and Health and Welfare Canada

regulation.

This requirement must be strictly observed. In addition, the leakage reading must be recorded on

the service repair documentation while in the customer’s premises.

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools.

Tools required for microwave leakage test

Tim Hortons

600ml glass beaker

Supply of cold water

Microwave leakage meter

To carry out this test the Icon Pads

need to be switched to

ENGINEERING MODE PROGRAMS

See Appendix 1

Read and understand all of these notes and procedure before carrying out this operation.

Note before measuring.

• Make sure that the survey meter you are using has been calibrated and is suitable for

measuring frequencies of 2,450 MHz.

• Do not exceed meter full scale deflection, leakage meter should initially be set to the

highest scale, then adjusted down as necessary to ensure that low readings are measured

on the most sensitive range.

• To prevent false readings, hold the probe on the grip provided and move along the areas

indicated on the following page. The probe should be moved at 1 inch/second (2.5cm).

• With any casework removed the leakage should not exceed 4mW/cm².

• When measuring the leakage, always hold the probe at 2” (50mm) from the test area using

the probe supplied with the instrument.

• Always hold the probe at right angles to the oven and point of measurement.

Procedure

1 Place 275ml of cold water in the 600ml glass beaker.

2 Place the 600ml glass beaker in the centre of oven.

3 Close the door and set time for 30 seconds then press Power pad 100%

(change water every 30 seconds to prevent boiling).

Tim Hortons: In ENGINEERING MODE (see Appendix 1 ) press Pad 01 then any Load pad

(QUARTER, HALF, FULL) watch time display and open door at 30 seconds.

4 Set the leakage meter to the appropriate scale/range.

5 Move the survey meter probe along the areas indicated in (Figures 1 to 4 page 23).

6 Remember to change the water after 30 second since water that boils will result in

inaccurate readings.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 22

Page 23

PROCEDURE FOR MICROWAVE LEAKAGE TEST (2)

• Readings must be below 4mW/cm². If a level greater that 4mW/cm² is observed,

this should be reported to Garland Service Division immediately.

• In any case, notes should be kept of the leakage that is observed. In terms of level and

position on the oven. This should be kept with the service documentation.

Control Panel - Figure 2

Door Perimeter - Figure 2

Rear and Side Covers - Figure 1, 3 & 4

Left & right Side Air Filters. - Figure 3 & 4

Test for microwave leakage at all points marked with a

Fig. 1

Fig. 3

Fig. 2

Fig. 4

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 23

Page 24

PROCEDURE FOR POWER OUTPUT MEASUREMENT

The power output specification, 1425W on this model is established under IEC 705 standard

method. This method is only workable in Laboratory controlled conditions.

An approximate method is as follows.

Tim Hortons Ovens

To carry out this test the Icon Pads need to be switched to ENGINEERING MODE PROGRAMS

See Appendix 1

1 Fill one beaker ( glass or plastic ) with one litre ( 1.78 pints ) of tap water ( at about 68ºF/

20ºC ) and measure the water temperature.

( Use a thermometer with a

2 Place the beaker in the centre of the cavity.

3

General Market Models

Set Time to 1 minute 3 seconds and Power to 100%

Wait until the counter reaches zero.

Tim Hortons Ovens

With the oven in ENGINEERING MODE ( see Appendix 1) Press Pad 01 (Cake) and any

Load Pad ( Quarter, Half, Full ) Wait until the counter reaches zero.

4 Take the beaker out immediately stir the water with a plastic implement and measure the

water temperature.

5 Calculate the temperature rise of water in the beaker. The temperature rise of the water

should be within the following range:

Temperature Rise

27ºF ( 15ºC ) Minimum

36ºF ( 20ºC ) Maximum

Power Output is affected by the line voltage under load.

For correct Power Output measurement, the line voltage under load must be correct.

1

/10, 0.1 degree gauge ).

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 24

Page 25

PROCEDURES FOR PRINCIPAL COMPONENTS TEST (1)

1. Power Transformer Test

You will need:

A Digital Multi-meter (D.M.M.)

A Megger or similar resistance meter using 500V d.c.

WARNING: High voltages and large currents are present at the secondary winding

and filament winding of the Power Transformer. It is very dangerous to

work near this part when the oven is on. NEVER make any voltage

measurements at the High Voltage circuits, including the magnetron

filament.

WARNING: Even when the oven is not cooking, the Power Transformer has High

Voltages present because of the Soft Start circuit. Isolate the oven

before testing.

See Safety Code ( Page 4 )

1 Isolate the oven from the mains supply.

2 Ensure that the High Voltage Capacitor is discharged before commencing work.

3 Remove all connections from the Power Transformer.

4 Using a D.M.M., check the resistance of the windings. Results should be as follows:

Mains winding (between tags)

High Voltage winding (between tag and chassis)

Filament winding (between terminals)

5 Using a Megger, test the insulation resistance between:

Primary winding and chassis

Filament winding and chassis

One end of the High Voltage winding is connected to the chassis, so this is not tested.

Approximately 1.1 Ω

Approximately 60 Ω

Less than 1 Ω

Pass if over 10 MΩ

Pass if over 10 MΩ

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 25

Page 26

PROCEDURES FOR PRINCIPAL COMPONENTS TEST (2)

2. High Voltage Capacitor Test

You will need:

A Digital Multi-meter (D.M.M.)

A Megger or similar resistance meter using 500V d.c.

WARNING: High voltages and large currents are present at the High Voltage Capacitor.

It is very dangerous to work near this part when the oven is on. NEVER make any voltage

measurements at the High Voltage circuits, including the magnetron filament.

WARNING: Even when the oven is not cooking, the High Voltage Capacitor has High

Voltages present because of the Soft Start circuit. Isolate the oven before testing.

See Safety Code ( Page 4 )

1 Isolate the oven from the mains supply.

2 Ensure that the High Voltage Capacitor is discharged before commencing work.

3 Remove all connections from the High Voltage Capacitor.

4 Using a D.M.M., check for continuity between the terminals & compare results with table

Between Terminals

Pass if approximately 10 MΩ

Between Terminals and Case Pass if open circuit

5 Using a Megger, test the insulation resistance between the terminals and the case.

Between Terminals and Case

3. High Voltage Rectifier Test

You will need:

Pass if over 100 MΩ

A Megger or similar resistance meter using 500V d.c.

WARNING: High voltages and large currents are present at the High Voltage Rectifier.

It is very dangerous to work near this part when the oven is on. NEVER make any voltage

measurements at the High Voltage circuits, including the magnetron filament .

WARNING: Even when the oven is not cooking, the High Voltage Rectifier has High

Voltages present because of the Soft Start circuit. Isolate the oven before testing.

See Safety Code ( Page 4 )

1 Isolate the oven from the mains supply.

2 Ensure that the High Voltage Capacitor is discharged before commencing work.

3 Remove all connections from the High Voltage Rectifier.

4 Using the Megger, test for continuity in both directions. Compare results with following

Open Circuit both ways

Conducts one way only

Short Circuit both ways

Conducts one way, leaks the other

Mealstream Ovens Pt. No. 32Z3403 Issue 15

FAIL

PASS

FAIL

FAIL

Page 26

Page 27

PROCEDURE FOR DOOR INTERLOCK ADJUSTMENT AND TEST (1)

The door on the Mealstream oven is monitored by three microswitches. These are used in the

conventional “Primary, Secondary and Monitor” switch arrangement shown below.

The switches operate as follows:

Door Interlock Arrangement

Switches shown in Door Closed position

L1

Power In

L2

1. Monitor switch ( 14 ,Top left-hand Side ). The Monitor switch will produce

a short circuit across the mains supply if the Primary interlock switch is

faulty, when the door is opened, thus blowing the microwave fuse and

rendering the oven inoperative.

2. Primary Interlock ( 11 , Bottom left-hand ) and Secondary Interlock

( 17 , Bottom right-hand ) Switches. Operate simultaneously.

The Primary switch will cut off the microwave emissions from the oven when

the door is opened by breaking the electrical supply circuit to the

transformers. The Secondary interlock switch will cut off the microwave

emission if the Primary switch have failed.

Note:

If operation of the Monitor switch has caused the Microwave Fuse to blow,

the Primary and Monitor microswitches must be changed, as they may have

been damaged by the high short-circuit currents involved.

Primary switch

11

17 Secondary switch

Power Out

14 Monitor switch

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 27

Page 28

PROCEDURE FOR DOOR INTERLOCK ADJUSTMENT AND TEST (2)

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools and parts.

Continuity Meter

Door Spacer Kit

Part No. 10C0171

Spacer No. required Part No.

S10 Door Spacer 10mm

S5 Door Spacer 5mm

S1 Door Spacer 1mm

2 40C1119

2 40C1118

2 40C1114

WARNING

Before starting this test procedure please make sure that the oven is disconnected

from the electrical supply and that the oven power switch (ON/OFF) is in the OFF

position.

After each step check that the interlocks are operating in the correct order using a

continuity meter.

See Safety Code ( Page 4 )

Disconnect the microswitches and check for the continuity of the switches with a continuity meter

Step 1: Set the interlock so that they activate in the following order.

When closing the door.

Interlock Order

SW1 (Monitor) 1st

SW2 (Primary) 2

SW3 (Secondary) 2

When opening the door.

Interlock Order

SW1 (Monitor) 3rd

SW2 (Primary) 1

SW3 (Secondary) 1

nd

Note both SW2 and SW3 activate together

nd

Note both SW2 and SW3 activate together

st

Note both SW2 and SW3 activate together

st

Note both SW2 and SW3 activate together

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 28

Page 29

PROCEDURE FOR DOOR INTERLOCK ADJUSTMENT AND TEST (3)

Step 2: Insert S10 10mm spacer into door.

(See figure 1 below for inserting spacer

correctly).

Step 3: Remove S10 10mm spacer and insert S1 1mm

spacer into the door and close the door.

Step 4: Remove S1 1mm spacer and insert S5 5mm

spacer into the door and close the door.

If an oven fails this sequence

then check the microswitches are functioning

Interlock Order

SW1 (Monitor) CLOSED

SW2 (Primary) OPEN

SW3 (Secondary) OPEN

Interlock Order

SW1 (Monitor) OPEN

SW2 (Primary) CLOSED

SW3 (Secondary) CLOSED

Interlock Order

SW1 (Monitor) OPEN

SW2 (Primary) OPEN

SW3 (Secondary) OPEN

correctly and repeat steps 1 to 4.

After carrying out this procedure make sure that the interlock monitor switch is properly connected

according to the circuit diagram on pages 44-46.

Figure 1

Door side seal

Door top seal

Door spacer

The door spacer must always be

located on the point where the side

seals and top seals meet.

Please note.

It is very important after completing this procedure to carry out a

microwave leakage test procedure. See pages 22-23.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 29

Page 30

PROCEDURE FOR BUILDING AND FITTING MEALSTREAM DOOR

Parts required for door fitting

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools and parts.

Item No. Description Part No. Quantity

1 RHS door hinge assy 11C0166 1

2 M5 x 10mm 101820 4

3 M5 flat washer 31Z5008 29

4 M5 shake proof washer 31Z5012 29

5 Spacer 790084 2

6 M5 x 16mm hex screw 101876 2

7 Door frame assy 11C0303 1

8 LHS door hinge assy 11C0167 1

9 Door arm assy 11C0300 2

10 Door arm Pivot Pin 790010 2

11 Door spring 520000 or 40C1141 2

12 Door Stop 40C0854 2

13 Door stop spring clip 31Z5047 2

14 M5 stainless steel full nut 80X07003 23

15 Door seal set of 4 11C0292 1

16 CAF 30 Adhesive 31Z0186 As required

17 Door insulation set 40C0942 1

18 Outer Door Skin Check Oven Model 1

19 M3 counter sunk screw 31Z3094 7

20 Choke Plate 790007 1

21 SPACER KIT 10C0171 1

Tools required for door fitting

M5 Nut runner Door Spacers S325 & 3 off S215

Flat head screw driver Long nose pliers

5mm open-ended spanner Adhesive skeleton gun

Engineers rule

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 30

Page 31

PROCEDURE FOR BUILDING AND FITTING MEALSTREAM DOOR

1. Visually check all parts to be used.

2. Fit right hand side (RHS) Hinge assy. to base

assy. loosely fit in place with bottom bolts, 2

off M5 x 10mm, 2 off M5 flat washer, 2 off M5

shockproof washer.

Fit spacer to fill gap between Hinge assy and

Inner side panel, loosely fit spacer in place

with 1 off M5 bolt x 16mm, 1 off M5 flat

washer, 1 off M5 shakeproof washer.

3. Insert (RHS) Pivot pin of door frame into

(RHS) Hinge assy. Place door frame against

cavity face and slide on (LHS) Hinge assy to

the (LHS) Pivot pin of door frame,

Spacer

Hinge

fixings

4. Fit right hand side (RHS) Hinge assy to base

assy, loosely fit in place with bottom bolts, 2

off M5 x 10mm, 2 off M5 flat washer, 2 off M5

shockproof washer. Fit spacer to fill gap

between Hinge assy. and Inner side panel,

loosely fit spacer in place with 1 off M5 bolt x

16mm, 1 off M5 flat washer, 1 off M5

shakeproof washer.

Pivot

pin

Pivot pin

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 31

Page 32

PROCEDURE FOR BUILDING AND FITTING MEALSTREAM DOOR

5. Fit door frame assembly (including seals

and cage nuts) firmly against cavity and

tighten all fixing bolts to secure (RHS)

and (LHS) Hinge assy.

Hinge

6. Position door frame central by using the

following method.

Measure the distance between the side of the

door and the TDK Mounting Strip on both

sides with the door in the closed position.

Add these two measurements together and

divide by 2. Adjust hinge adjustment bolt so

the door is the distance calculated from the

TDK Mounting Strip and lock in position with

lock nut.

TDK

Mount

Door

7. Fit (RHS) and (LHS) door arms through slots

in cavity and insert door arm pivot pins

through door arms into door frame.

Door arm pivot pin

8. Fit door springs to door arms and to the hook

at base of inner side panels. Check operation

of door and remove (LHS) spring.

Door hinge adjustment

Spring clips

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 32

Page 33

PROCEDURE FOR BUILDING AND FITTING MEALSTREAM DOOR

9. Position door choke to Door Frame Assembly

making sure it is in the correct orientation (the

top of door choke is marked with ‘T‘ on the

underside).

‘T’

Mark

10. Loosely fit 3 off M5 flat washers, 3 off M5

shockproof washers, and 3 off M5 stainless

steel full nuts.

11. Tape choke Spacer S325 to the cavity base and

tape choke Spacers S215 to sides and top of

door choke.

Close the door and centralise the door choke.

Fit the remaining 20 M5 washers and nuts

tighten the fixings evenly.

Stage 1

3

Stage 2

1

4

1 Cavity base S325

2 Choke fingers Top S215

3 Choke fingers Left S215

4 Choke fingers Right S215

Remove spacing pieces and check door

operation.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

2

Page 33

Page 34

PROCEDURE FOR BUILDING AND FITTING MEALSTREAM DOOR

12. Fold the square piece oven insulation in half

and place it in the recess in the oven door.

Place the rectangular piece into the remainder

of the door (foil facing out).

13. Place the outer skin over the door frame

assembly and fix with 7 of M3x12 counter sunk

screws around the LHS, RHS and top of the

door.

Please note.

It is very important after completing this procedure,

to carry out a Door interlock adjustment and test procedure.

See pages 27-29.

Stage 1

Stage 2

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 34

Page 35

PROCEDURE FOR REPLACING DOOR SEAL ASSEMBLY (1)

Parts required for replacing carbon loaded door seals

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools and parts.

Item Description Part Number Quantity

1 Door seal set of 4 11C0292 1

2 CAF 30 ( Black ) 31Z0186 As required

Tools required for replacing carbon loaded door seals

Long nose pliers

Adhesive skeleton gun

Flat head screw driver

Please note.

Before proceeding with this procedure ensure that the oven is disconnected

from the power supply.

If the oven has been operating recently please allow time for the oven to cool.

Removing Door seal

1 Open the oven door.

2 Use a pair of long nose pliers to unclip one end of the seal. (See figure 1 page 36)

3 Peel back the door seal assembly and unclip at the other end. (See figure 2 page 36)

4 Remove the residue CAF 30 adhesive with a flat head screw driver. (See figure 3 page 36)

5 Visually inspect the vitreous enamel to ensure that it is undamaged.

Fitting a New Seal

1 Clip on end of the door seal in place. Using a pair of long nose pliers, stretch the door seal

and connect the other end in place. (See figure 4, 5 & 6 page 36)

2 Visually inspect that the door seal is sitting in the rebate provided.

3* Perform door interlock set-up procedure (See page 27-29)

4* Perform a microwave leakage test procedure. (See page 22-23)

5 Lift the seal and applied a thin line of CAF 30 adhesive along the length of the rebate and

push the seal down. (See figure 7 page 36)

6 Seal the ends of the door seal with CAF 30 (See figure 8 page 36)

Leave the door in the open position to allow the adhesive to set.

* It is very important to carry out these procedures

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 35

Page 36

PROCEDURE FOR REPLACING DOOR SEAL ASSEMBLY (2)

Figure 1

Figure 3

Figure 2

Figure 4

Figure 5

Figure 7

Figure 6

Figure 8

Please note.

It is very important after completing this procedure,

to do a Door interlock adjustment and test procedure.

See pages 27-29.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 36

Page 37

PROCEDURE FOR REMOVING SHELF RUNNERS AND ELEMENT COVER PLATE

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools.

Tools required for removing shelf runners and element cover plate.

M6 nut runner

M5 nut runner

M6 x 12mm

stainless steel Hex

Head screw

Pt No. 80T7133

Shelf runner

1. Loosen the rear fixings screws of both shelf runners with M6 nut runner.

2. Remove the front fixings screws of both shelf runners with M6 nut runner.

3. Pull the shelf runners forwards away from the rear screws.

4. Remove the 4 off M5 dome nut securing the Element cover plate.

5. Lift the Element cover plate out taking care to not damage the temperature sensor pocket.

M5 stainless steel

dome nut

Pt. No. 80X7025

Element cover plate

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 37

Page 38

PROCEDURE FOR REPLACING HEATER ELEMENT

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following part and tools.

Parts required for replacing heater element.

Item Description Part Number Quantity

1 Heater Element 208 volt 40C0949 / 240 volt 40C0948 1

2 Mesh Washer 31Z5044 3

Tools required for replacing heater element.

M5 nut runner

1. Disconnect or isolate oven from mains supply.

2. Remove outer covers.

3. Remove shelf runners and element cover plate

( See page 37 ).

4. Disconnect wires from heater element terminals at rear of

oven.

5. Remove M5 screw securing heater element.

6. Remove heater element.

7. Refit new heater element with new mesh

washers fitted over each terminal and 3 off

M5 Flat washer over the M5 screw (this is

very important to prevent microwave

leakage).

8. Tighten M5 screw and check that the

heater element is not touching the

cavity or protruding to much that it

will not touch the element cover plate.

9. Reconnect wires to heater element terminals

at rear of oven.

10. Replace element cover plate and shelf runners.

11. Perform Microwave Leakage procedure

(see page 22-23) checking carefully around

the heater element terminals at rear of oven.

12. Replace outer covers and fully test oven.

Heater Element

M5 x 25mm Hex head

S/S screw Pt. No. 101825

3x M5 Flat

Washers

Mesh

Washers

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 38

Page 39

PROCEDURE FOR REPLACING HOT AIR MOTOR ASSEMBLY

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following part and tools.

Parts required for replacing hot air motor assembly.

Item Description Part Number Quantity

1 Hot Air Motor Assembly 11C0312 1

Tools required for replacing hot air motor assembly.

M5 nut runner

1. Disconnect or isolate Oven from mains supply.

2. Remove outer covers.

3. Remove shelf runners and element cover plate (See page 37).

4. Remove fan blade securing nut and remove fan blade.

5. Disconnect motor connection at terminal block.

(Note: which wire colour goes to which terminal).

6. Disconnect Motor Earth tag then undo all securing nuts from the

motor mounting plate and remove the fan motor assembly.

7. Check the position and condition of the hot air motor damper/seal

(this a important microwave leakage seal) in the motor shaft

screen. (See page 17).

8. Fit new hot air motor assembly, and fit all securing washers and

nuts, ensure it is aligned centrally into the hole in the cavity, and

tighten all securing nuts. Make sure the ground wire is connected.

9. Reconnect motor connection at terminal block.

(Note: correct position of each wire colour).

10. Refit fan blade and fan blade securing nut, and ensure that the

fan/motor rotates free by hand.

11. Refit shelf runners and element cover plate.

12. Perform Microwave Leakage procedure (see pages 22-23),

checking carefully around the hot air motor assembly at rear

of oven.

13. Replace outer covers and fully test oven.

Fan blade securing nut

Fan blade

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 39

Page 40

PROCEDURE FOR REPLACING MAGNETRON ASSEMBLY (1)

Parts required for replacing magnetron

Please Note

DO NOT attempt to carry out the following procedure

unless you have the following tools and parts.

Item Description Part Number Quantity

1 Magnetron 30Z1171 1

Tools required for replacing magnetron

Philips screw driver

M5 nut runner

WARNING

Before proceeding with this procedure ensure that the oven

is disconnected from the power supply,

And the high voltage capacitors are discharged

See Safety Code ( Page 4 )

1. Remove the top and side casing from the oven.

2. Remove the air duct cover plate.

(See figure 1 page 41)

3. Disconnect the 2 wires and earth wire from the over temperature stat and the 3 wires from

the magnetron connection block.

(See figure 2 page 41)

4. Remove the 4 nuts from the magnetron fixing.

(See figure 3 page 41)

5. Remove the magnetron.

(See figure 4 page 41)

6. Remove the 2 screws form the over temperature stat on the magnetron and remove.

(See figure 4 page 41)

7. Visually inspect the new magnetron making sure that the wire mesh gasket seal is in place

and undamaged. Check the outer casing for any damage such as dents.

(See figure 5 page 41)

8. Attach the oven temperature stat to the new magnetron.

(See figure 5 page 41)

9. Visually inspect the magnetron mount in the wave guide making sure that it is undamaged

and that there is no debris that may obstruct the new magnetron when fitted.

(See figure 5 page 41)

10. Place the new magnetron in position making sure it is in the correct orientation.

11. Replace the 4 fixing nuts making sure that they are tightened equally.

12. Reconnect the wiring to the over temperature stat.

13. Reconnect the wiring to the magnetron.

14. Replace the air duct cover.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 40

Page 41

PROCEDURE FOR REPLACING MAGNETRON ASSEMBLY (2)

Figure 1 - 6

Figure 1

Screw

Figure 3

Temperature

Stat.

Figure 2

Temperature

Stat.

Figure 4

Magnetron

connection

block

4 x Magnetron

screw fixings

Figure 5 Figure 6

Temperature

Stat.

Screws

Wire mesh

Magnetron mount

Please note.

After completing this procedure do a microwave leakage test.

See page 22-23.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 41

Page 42

PROCEDURE FOR TESTING MEMBRANE PANEL CIRCUIT

You will need:

A Digital Multi-meter (D.M.M.)

1. The oven isolate from the electrical supply.

2. Remove the Logic Assembly from the Control Panel Housing.

3. Unplug the membrane “tail” from the Logic PCB Assembly.

4. Using a D.M.M., check for continuity between the correct terminals when the pads are

pressed.

5. When the panel has been tested, re-assemble and re-test the control circuit.

1 10

Mealstream 501 US

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 42

Page 43

PROCEDURE FOR TESTING MEMBRANE PANEL CIRCUIT (2)

Mealstream 501 US Tim Hortons & Unbranded Variant

Note:PINS 1-4 Lower Layer & Pins 5-10 upper layer

Mealstream 501 US Tim Hortons French (Canada)

Note:PINS 1-4 Lower Layer & Pins 5-10 upper layer

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 43

Page 44

CIRCUIT DIAGRAM: ALL MODELS BEFORE 05.28.02

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 44

30Z1177

30Z1177

30Z1177

30Z1177

Page 45

CIRCUIT DIAGRAM: ALL MODELS AFTER 05.28.02-11.10.02

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 45

Page 46

CIRCUIT DIAGRAM: ALL MODELS AFTER 11.11.02

1

3.0 KW

RHS

MAG 2

CAVITY HEAT

D

C

2

(3)U

3

NOTE

REVERSE

PHASING

N(4)

C

T2

(1)U

L(2)

MAG 1

LHS

D

T1

30Z0124

HS1

300°C

572°F

OVER HEAT

GOLD

RESISTOR

10 AMP 10 AMP

FUSE FUSE

F2 F3

11

1

A

9

of

11Monday, Nove mber 11, 2002

1

40C0952

50E123

A1

MERRYCHEF LTD

STATION ROAD WEST

ASH VALE, ALDERSHOT

HANTS GU12 5XA

TEL:+44 (0)1252 371000 FAX:+44 (0)1252 37100

Size Document Number Rev

Date: Sheet

11C0402 208V

11C0403 240V

RELAY PCB

CAVITY SENSOR

11C0291

MEMBRANE

LOGIC PCB

2

3

(3)U

4

MF3 MF4

**

BLUE

BROWN

RED

YELLOW

5

INTERLOCK

123

NO COLOR

4

TEST 3

TEST POINTS

MONITOR

6

(1)U

FILTER 3 FILTER 4

L(2)

N(4)

OVERHEAT

MAGNETRON

MS1 MS2

SECONDARYPRIMARY

OMIT

GRA1 AND GRA2

50W

GOLD

RX1 RX2

RESISTOR

ON 208V VERSION

39R

SEE NOTE 1

TEST 4

8

GRA2

39R50R

GRA1

A

15

DOOR

PSU

VOLTAGE

4

5

6

SW1

SHOWN IN DOOR

SW2 SW3

(3)U

MF1

FILTER 1

(1)U

MF2

7

(1)U

FILTER 2

OPEN POSITION

MAGNETRON

CONVECTION

COOLING FANFAN

BROWN

M4

6uF

BLUE

A

14

B

15

STIRRER

MOTOR

7

13 14 15 1097 127 32 54 166

NOTE 1: ON 240V 60HZ VERSION ONLY - 208V MAGNETRON COOLING FAN IS SUPPLIED VIA

SERIES 39R AND 50R RESISTOR AS SHOWN. ON 208V 60HZ VERSION NO RESISTORS ARE FITTED

MEALSTREAM SERIES 5 WIRING DIAGRAM 2POLE/3POLE + GND (NORTH AMERICA) FROM NOV 2002

F6

F7

N(4)

L(2)

FUSE

F1

FUSE

8

EARTH

TB1

FUSE

L1

TEST 1

L3

LINK

FOR

2POLE

D D

L(2)

N(4) (3)U

F5

FUSE

TEST 2

L2

F4

FUSE

SW4

MERRYCHEF

PART No.

30Z0217

30Z0217

30Z1177

= 20A

F1F2F3F4F5F6F7

C C

B B

FUSE RATING

= 10A

= 10A

30Z1177

30Z1177

= 1A 30Z0957

= 20A

= 20A

30Z1177

= 30Z0240

SW1

= 20A

= 30Z0240

= 30Z0240

SW2

SW3

8

OMIT FILTER 3 & 4

FOR 240V VERSION

*

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 46

Page 47

CIRCUIT DIAGRAM: ALL MODELS AFTER 04.06.03

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 47

Page 48

ERROR CODES AND DIAGNOSTICS

The Mealstream will identify some of the most common problems by flashing an error message

code in the time display window.

These are the error messages, and suggestions for repairing them.

Door not fully shut.

1

Possible electrical fault

2

Magnetron overheating.

3

Close door fully.

Door switch inoperative.

Check air filters.

Check location, air inlet

temperature and air filters.

No time has been set.

1

Invalid time has been

2

set.

Invalid program has

3

been set.

TIM HORTONS

4

No cook program

assigned to selected pad

Oven not heating up.

1

Possible Heater fault.

2

Oven Cavity overheating. Confirm heater relay is

1

Set a time.

Set a valid time.

Use call-back to check program.

Ensure correct Menukey is

installed (switch oven off then

on to show key No. )

Check heater fuse.

Confirm operation of heater

circuit.

operating.

Check sensor.

Oven is not at correct

1

temperature to start

program.

Remove food.

Allow oven to reach correct

temperature.

If the key is removed before

the download is complete or

the process is interrupted

the display shows EPS

then FAIL then REDO

Switch oven off and begin the

MenuKey download again.

See Appendix 2.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 48

Page 49

APPENDIX 1

Tim Hortons variants: Power Test and Microwave Leakage Test (Pages 22-24)

Engineering Mode programs

In order to carry out the Power Test and Microwave Leakage Test on Tim Hortons

variant Ovens, the Icon Pad programs on the control panel need to be switched to

Engineering Program Mode.

Engineering Mode does not affect the current Menukey program settings for the Icon

pads and the current Menukey programs are automatically restored when the oven is

next switched on.

To switch to Engineering Mode Programs:

1 With the oven switched off hold down the CANCEL ( ANNULER ) Pad and switch the oven

ON, the display shows the current Menukey Code, continue to hold the CANCEL

( ANNULER ) Pad for approximately 10 seconds until the display shows

indicating the oven is now in engineering mode

2 Programs will be set as follows:

EE 00:00

Program Number Time Temp Power

Pad 01 1 minute 3 secs Off 100%

Pad 02 3 minutes Off 100%

Pad 03

Pad 04

All other programs will be blank

3 Follow the Leakage Check Procedure as detailed on pages 22-23, using Program 01

( Cake ) to give the required 1 minute 3 seconds at 100% Microwave Power setting.

4 Follow the Power test procedure as detailed on Page 24 using Program Pad 01 ( Cake) to

give the required 1 minute 3 seconds at 100% Microwave Power setting.

5 On completion the current Menukey programs are automatically restored when the oven is

next switched on.

Stage 1 30 minutes 480 °F 100%

Stage 2

59 minutes 59secs 480 °F None

29 minutes 59 secs 480 °F 50%

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 49

Page 50

APPENDIX 2: MenuKey™ DOWNLOAD PROCEDURE

The MenuKey™ System automatically changes all the

cooking programs on the numbered icon pads with the

turn of a key.

To change the menus on the oven:

Ensure the power switch is off.

1

Lift the MenuKey™ cover in the top panel

2

of the oven and put the key in the keyhole

Turn the key clockwise to the stop

( ¼ turn ).

Do not remove the key at this stage.

3

Switch the power switch on.

The oven will now go through the program

download sequence by displaying the

following:

The Key Code

The number of

programs and each

program number on the key.

When the display shows 0:00, the cavity

lights up and the fans start.

Remove the key and close the cover and

the oven is ready to use with the new

programs.

To confirm the download is successful

Switch off the oven.

Switch on and the display briefly will show the following:

1. The new key code

2. 0:00 (oven ready to use)

example: Key 01

example: 38 programs

EPS-FAIL-REDO

If the key is removed before

the download is complete or

the process is interupted the

display shows EPS then FAIL

then REDO

Switch oven off and begin the

MenuKey download again.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 50

Page 51

APPENDIX 3: TEMPERATURE SENSOR RESISTANCE DATA

Temperature Sensor Resistance

Temp °F Temp °C Min. Rate

kΩ

212 100 11.490 13.060 14.810

302 150 2.803 3.161 3.434

392 200 0.950 1.000 1.050

482 250 0.3572 0.3865 0.4171

Standard

Rate kΩ

Max. Rate

kΩ

R(200)°C = 1 kΩ ± 5%

Note:

These resistances will only be apparent in a stable cavity temperature as the

sensor has a slow response time.

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 51

Page 52

MANUAL CORRECTIONS AND MODIFICATIONS

Whilst every effort has been made to ensure that the information contained in this manual is

accurate and complete, if you believe that an error has been made, or if you have any

suggestions for how the manual could be improved, please fill in and return this form. A review of

any forms returned will be made on a regular basis, and the manual will be updated if required.

Name

Address

Page number on which error occurs (if applicable) - Mealstream Garland

Description of error

Suggestion for improvement to manual

Please return this form to:

Garland Commercial Industries

1177 Kamato road

Mississauga

Ontario L4W 1X4

CANADA

Attn : Service Department

Or Fax it on 800-361-7745

Mealstream Ovens Pt. No. 32Z3403 Issue 15

Page 52

Loading...

Loading...