Page 1

www.resourcedm.com

PR0018

PR0018-PHI

Mercury Switch User Guide

UK OFFICE

Resource Data Management Ltd

80 Johnstone Avenue,

Hillington Industrial Estate,

Glasgow, Scotland, G52 4NZ, UK

+44(0)141 810 2828

sales@resourcedm.com

US OFFICE

Resource Data Management Inc

100 North Sixth Street,

Suite 820C,

Minneapolis, MN 55403, USA

Tel +1 612 354 2923

Fax +1 612 208 0922

usasales@resourcedm.com

Resource Data Management

Page 2

Revision 2.2 Page 2 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Table of Contents:

THE MERCURY SWITCH ................................................................................................................................... 3

Description ......................................................................................................................................................... 3

Front View .......................................................................................................................................................... 3

Rear View ............................................................................................................................................................ 3

Top View ............................................................................................................................................................. 3

Connection to Mercury Controllers: ................................................................................................................ 4

RS232 Lead Lengths ....................................................................................................................................... 4

Connection to other IP equipment ................................................................................................................... 4

Connection to another Mercury Hub/Switch or Other Ethernet Hub/switch ............................................... 4

Connection to a Data Manager/Director .......................................................................................................... 4

10/100 Base T connectors ................................................................................................................................ 4

Network ID .......................................................................................................................................................... 4

ID for equipment with rotary switches. ........................................................................................................... 4

PR0018-PHI USER GUIDE ................................................................................................................................. 5

Front Panel Features (PR0445) ........................................................................................................................ 5

Setup via Display ............................................................................................................................................... 5

Recommended set-up method ......................................................................................................................... 6

Set/View Type .................................................................................................................................................. 6

Set/View Parameters (This can also be achieved at the network front end) ................................................... 6

ID ...................................................................................................................................................................... 6

Network Configuration ..................................................................................................................................... 6

IP-L (Local IP Address) ................................................................................................................................ 7

IP-r (IP Address issued by the DHCP server) .............................................................................................. 7

Parameters ......................................................................................................................................................... 8

Parameters Description ................................................................................................................................... 9

Input/Output table ............................................................................................................................................ 10

EEV Control Operation .................................................................................................................................... 10

On board 4-20mA Suction Pressure Input Control Application ..................................................................... 10

Remote Suction Pressure Application ........................................................................................................... 10

To disable local transducer ............................................................................................................................ 10

Mercury Switch Type ....................................................................................................................................... 11

Transducer Connection .................................................................................................................................. 11

MOP – Maximum Operating Pressure ........................................................................................................... 11

Humidity Control Operation ........................................................................................................................... 12

GP Timer Set-up ............................................................................................................................................ 12

Trim Heater Control via Mercury Case Controller Range ............................................................................ 12

Network Alarms ............................................................................................................................................... 13

Setup via Webpages ........................................................................................................................................ 13

SPECIFICATION ............................................................................................................................................... 14

Mounting ........................................................................................................................................................... 14

RS232 Cable Lengths ...................................................................................................................................... 14

Ethernet Cable lengths ................................................................................................................................... 14

Disclaimer ......................................................................................................................................................... 14

REVISION HISTORY......................................................................................................................................... 14

Page 3

Revision 2.2 Page 3 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

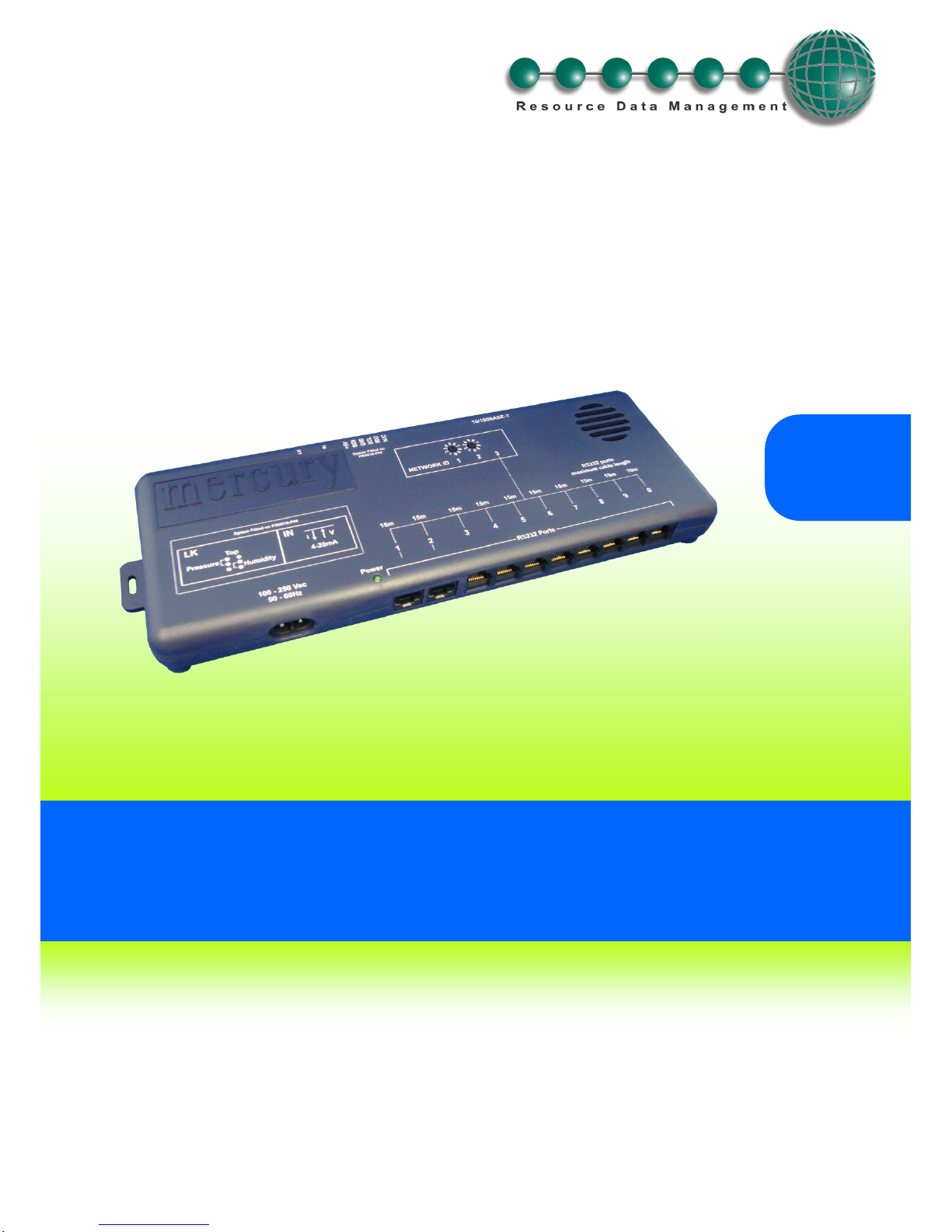

The Mercury Switch

From Resource Data Management

Description

The Mercury Switch (PR0018) is a device that allows up to 10 RDM Mercury controllers to be connected to an IP network, without the

need for individual IP Futura modules. There are 10 RS232 connections for linking to 10 Mercury controllers. There are 3 standard

Ethernet Switch (10/100baseT) connections for other network devices. The Ethernet ports are self configuring for uplinks and standard

10/100 Base T device connections.

As well as the Switch function there is the option for Island EEV control. This control can be achieved by using a transducer connected to

the Mercury Switch 4-20mA input or from a remote Suction pressure reading sent across an IP network from a Mercury Plant Pack

controller. Island trim heater control can also be achieved through the display port using a humidity temperature display (PR0445). To

utilise either of these features then the PR0018-PHI build option would be required.

Software version 2.2 and higher has the capability for CO2 Load shedding.

See RDM Data Manager User Guides for more information on CO2 Load Shedding

Front View

Rear View

Note:- The display port, mA input and mA input selector are fitted on the PR0018-PHI only.The mA input is available for Pressure

applications only, for Humidity please use a PR0445 connected to the display por

Top View

10 x RS232 Ports for direct connection to RDM controllers

Mains connector

3 x IP ports

mA Input

Display port

mA input selector

Page 4

Revision 2.2 Page 4 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

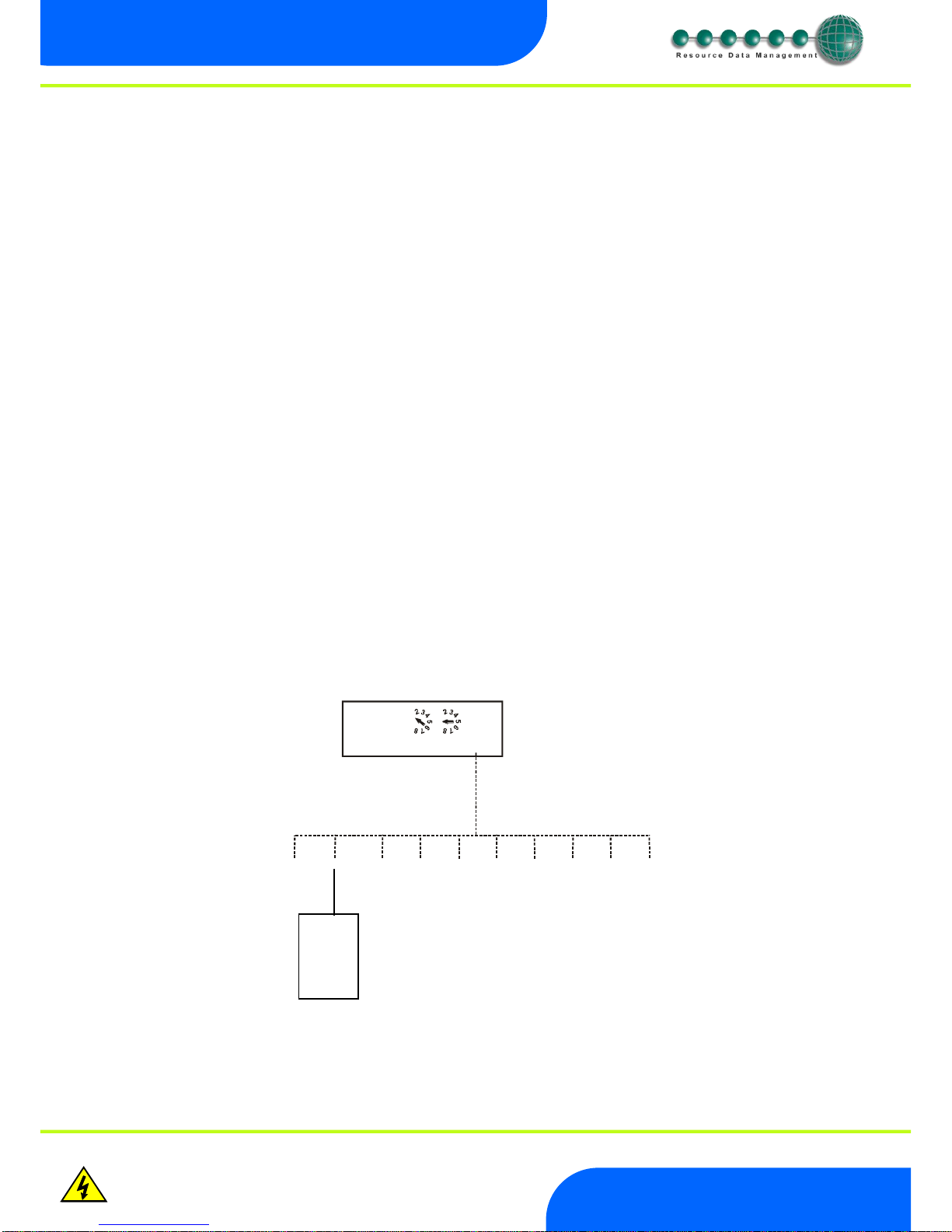

Connection to Mercury Controllers:

Using a standard CAT5 patch lead, connect the serial output of the RDM Controller to one of the RS232 ports of the Mercury Switch.

RS232 Lead Lengths

RS232 patch lead maximum length must not exceed 15 metres. (Ports 1 - 10)

The 3-character address that will be seen on the system front end is determined by the position of the two Network ID rotary switches

and the port the controller has been connected to, unless the connected controller has its own network ID rotary switches, in which case

the controller ID will override the switch settings.

Connection to other IP equipment

Use a standard CAT5 patch lead to connect other IP equipment to the Mercury Switch (such as a Futura IP module) into the 10/100 Base

T ports 1, 2 or 3.

Connection to another Mercury Hub/Switch or Other Ethernet Hub/switch

Use a standard CAT5 patch lead from any of the 3 10/100 Base T ports into any of the 3 10/100 Base T ports on the upstream Mercury

Switch. The 3 10/100 Base T ports are all self configuring.

Connection to a Data Manager/Director

Use a standard CAT5 patch lead and connect the Data Manager or Data Director to one of the 3 10 Base T ports.

10/100 Base T connectors

The three 10/100 Base T connectors have 2 LED’s adjacent to them: The green LED; when static, indicates that the connection to the

device is good, the green LED then flickers when data is being transmitted.

When the amber LED is permanently on it indicates that the connection is full duplex and if there is an error or fault on that channel the

LED flickers.

Network ID

The 3-character network ID is made up from the positions of the 2 rotary switches and the RS232 connector number. We recommend

that the 2 rotary switches are set to the Bay number and that the case sections are plugged into their corresponding RS232 port

numbers.

E.g. Bay 10 case 2:

The 2 rotary switches set to "1" and "0", controller plugged into port 2. The ID then is seen as "102" at the system front end.

Note that case number 10 would plug into RS232 port 0 (right most port) and come through as "100".

ID for equipment with rotary switches.

For RDM products that use the 3 rotary switches for the network ID (such as Mercury Power tray), the ID will follow what is set on the

controller local switches and NOT the port position on the Switch.

1

9

0

1

9

0

NETWORK ID

1 2

3

Vdc

1 2 3 4 5 6 7 8 9 0

Controller

at position 2

Page 5

Revision 2.2 Page 5 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

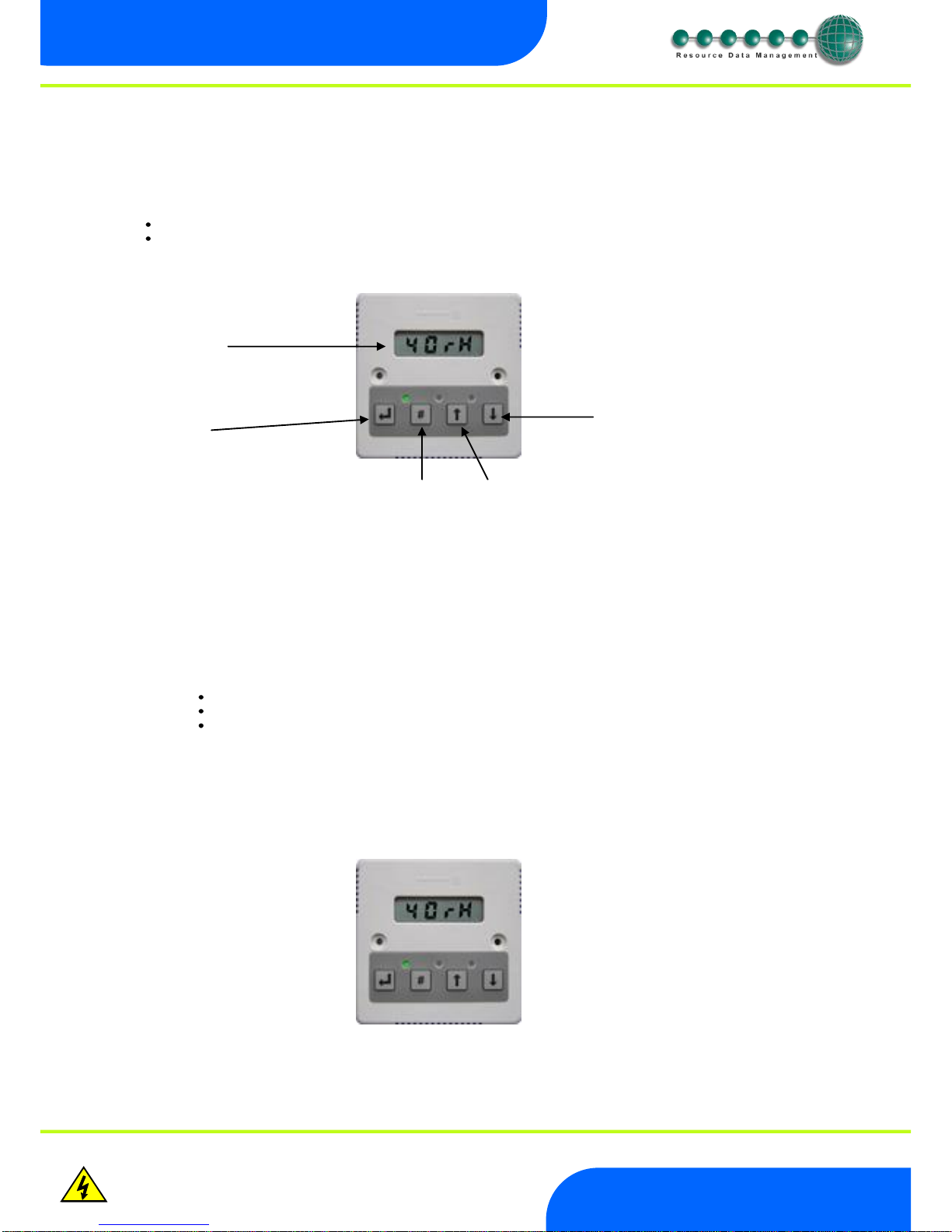

PR0018-PHI User Guide

The PR0018-PHI hardware version of the Mercury Switch allows for EEV Control on an island by island basis. It also allows for the use of

the energy feature Trim Control which pulses the trim relay of a Mercury case controller based on the actual shop floor humidity therefore

minimising energy usage.

Access to configure the Mercury Switch can be achieved by 2 ways.

Through the front mounted buttons on the display (PR0445)

Across an IP network

Front Panel Features (PR0445)

4 Character LCD

Down Button

Enter Button

# Button Up Button

Display: The display fits a standard UK single socket pattress.

Enter Button: Button used to enter/confirm values after a change.

Up Button: When in the software menu, the up button is used to scroll up through the menu items.

Down Button: When in the software menu, the down button is used to scroll down through the menu items

# Button: No function

Network LED:

Green LED used to indicate network Status:

Off No network attached

Flashing Attempting to Log on to network

Steady On-line

Amber LED: No function

Alarm LED: Red LED used to indicate an alarm status.

Setup via Display

To enter the software menu for setup mode, hold the Enter and Down buttons together for approximately 3 seconds until the message

“Ent” appears on the display. Release both buttons and now press the Enter button again to enter the software menu. IO is the first item

to be displayed. Scroll up or down to go through the menu items which are highlighted below.

Page 6

Revision 2.2 Page 6 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

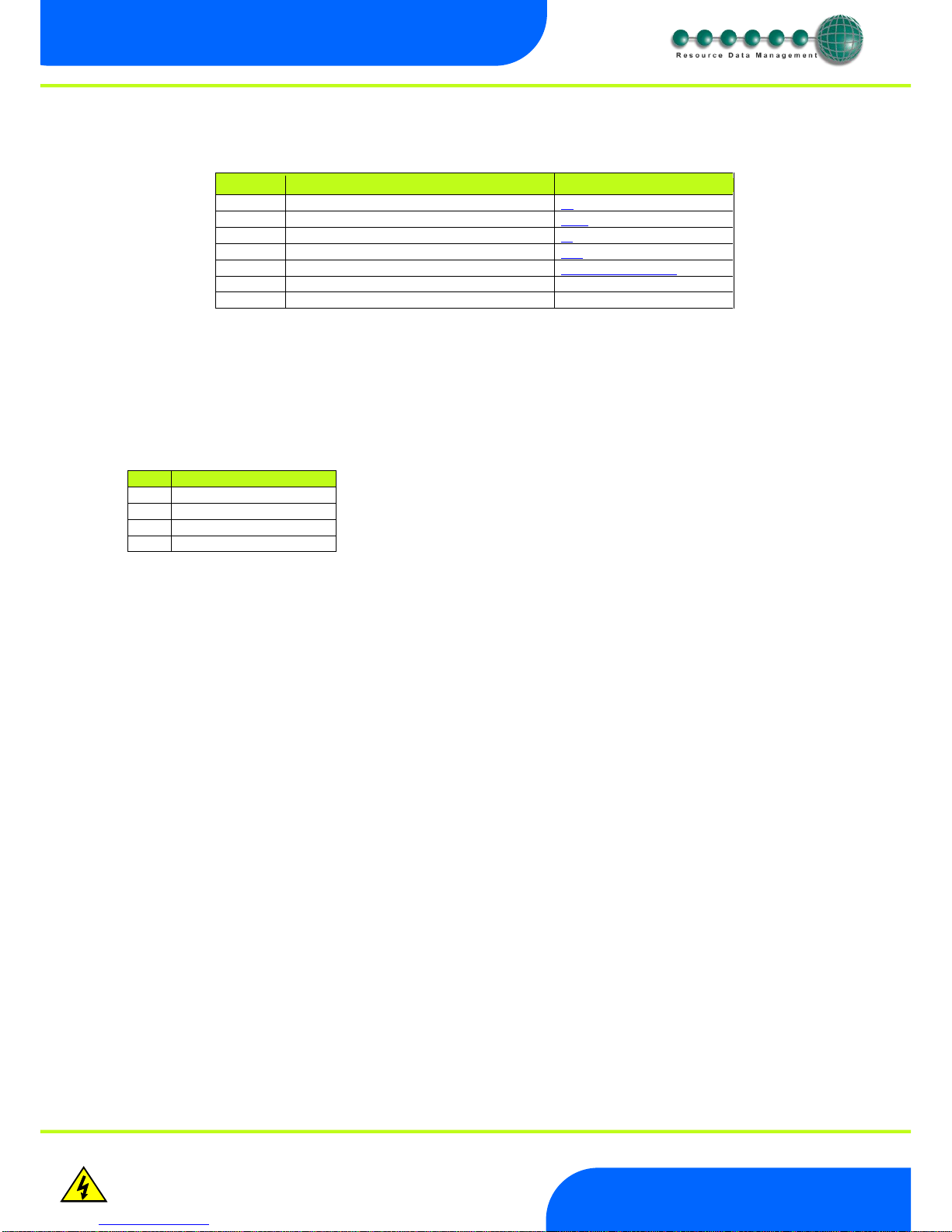

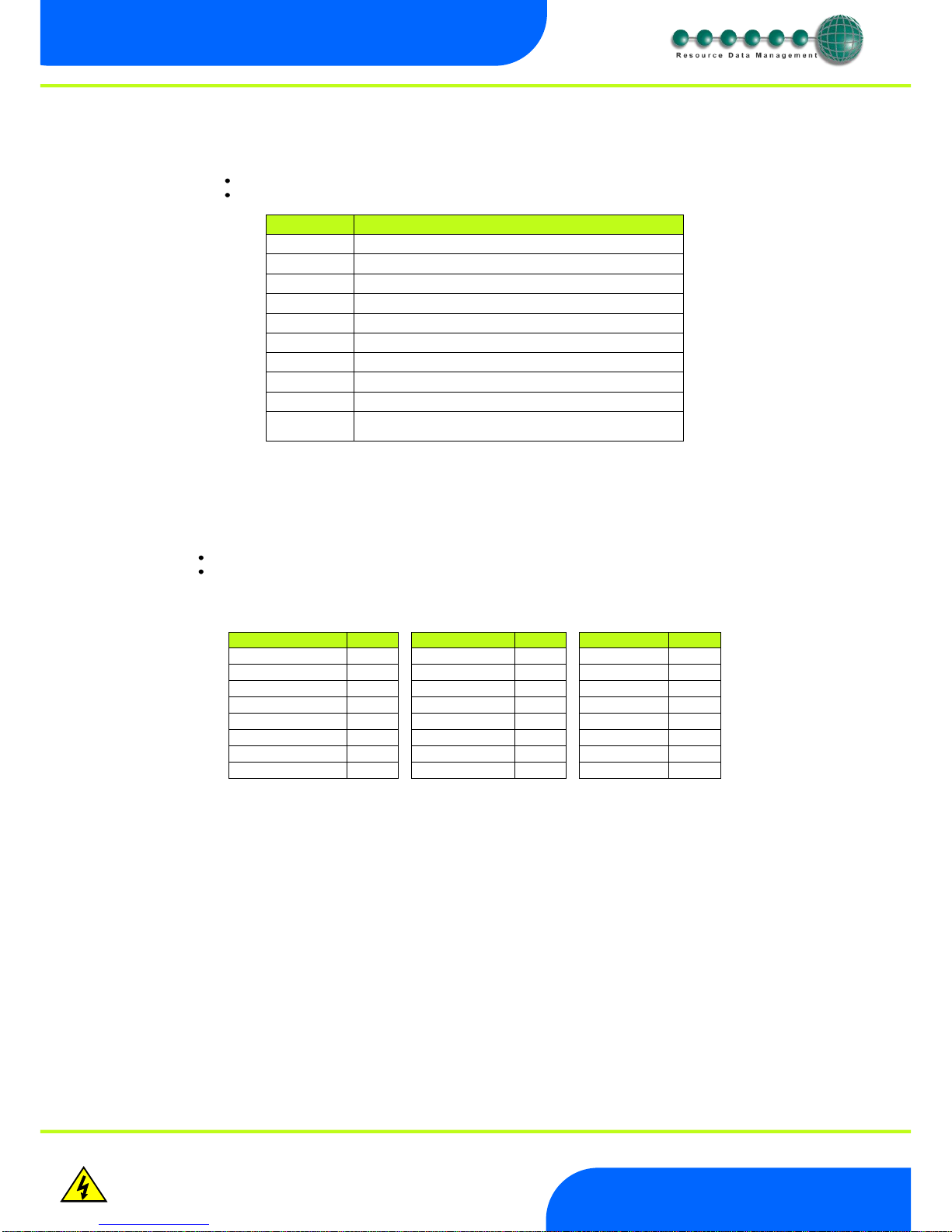

Setup Function Menu

Display

Option

Explained in Paragraph

IO

View Input and Output States

IO

PArA

View or change Parameters

PArA

ID

View or change ID

ID

tyPE

View or change Controller Type

type

nEt

View or change the Network Settings

Network Configuration

SoFt

View the Software version

ESC

Escape the menu

Recommended set-up method

Set/View Type

a. From the function menu scroll to select type and press enter

b. The current type is shown. Use the up/down buttons to scroll through the configuration types.

c. Select the desired number and press enter.

There are 4 types: -

Type

Description

1

Degree C/ Bar

2

Degree C/ PSI

3

Degree F/ Bar

4

Degree F/ PSI

Set/View Parameters (This can also be achieved at the network front end)

a. From the function menu scroll to select PArA

b. Pressing Enter while PArA is displayed will enter the parameter menu. The first parameter option will be displayed as P-

01. Pressing the Up or Down button will present the other parameter options P-02, P-03 etc. See the parameter table to

find what parameter number corresponds to which actual parameter. Pressing the Enter button will show the current

value of the selected parameter. Press Up or Down to modify the value and press Enter again to save the value. The

parameter list number will be displayed again. Two other options are present in the parameter menu – dFLt and ESC.

Selecting ESC will exit setup mode. Selecting dFLt will reset all parameters back to the default values for the current type

of controller.

ID

Allows the user to assign a unique three digit software address to the Mercury Switch. Note this is only required when the Mercury Switch

is in IP-L mode.

a. From the function menu scroll to select Id

b. The current id number will be shown. Use the up/down buttons to scroll through from 000 to 999.

c. Select the desired number and press enter to save.

Network Configuration

Unlike the PR0018 (Standard Mercury Switch version) when this product is used with a Data Manager/Data Director it is registered on

the system as a device. Once the Mercury Switch is on-line, the Switch type and parameters can be set up. The switch comes online with

the ID of the 2 rotary switch settings followed by the letter a. For example with the first rotary switch set to 4 and the second switch set to

8 then the switch would appear as device “48a”. If a DHCP server is present on the IP network set the 2 rotary network switches to an

appropriate setting, the Mercury Switch has an auto-initialise function, which will automatically log the device onto the site network. If the

wrong ID has been entered onto the network, you will have to reset the Switch ID by setting the ID to 0-0, power cycle and then re-enter

the correct ID.

This Switch does not require an external communications module.

Page 7

Revision 2.2 Page 7 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

IP-L (Local IP Address)

To configure the Mercury Switch for IP-L, set both rotary switches to zero.

1. nEt. From the function menu you can now select nEt

Press enter and the display will show “IP-L”, press enter

You can now set the address using the table below

Display

Option

IP-1

IP Address byte 1

IP-2

IP Address byte 2

IP-3

IP Address byte 3

IP-4

IP Address byte 4

nL

Network Mask Length

gt-1

Gateway Address byte 1

gt-2

Gateway Address byte 2

gt-3

Gateway Address byte 3

gt-4

Gateway Address byte 4

ESC

Exit network menu. N.B. this option must be selected to save

any changes made in this menu

IP-r (IP Address issued by the DHCP server)

To configure the Mercury Switch for IP-r, set the two rotary switches to give each controller a unique identifier. The controller should then

be connected to the network.

2. nEt. From the function menu you can now select nEt

Press enter and the display will show “IP-r”, press enter

You can now view only the address given by the DHCP server

To ease setup, a single network mask length value is used. If the address has been specified with a network mask value in dotted IP

format e.g. 255.255.255.0 then the table below gives the conversion:

Mask

Length

Mask

Length

Mask

Length

255.255.254.0

23

255.254.0.0

15

255.255.255.252

30

255.255.252.0

22

255.252.0.0

14

255.255.255.248

29

255.255.248.0

21

255.248.0.0

13

255.255.255.240

28

255.255.240.0

20

255.240.0.0

12

255.255.255.224

27

255.255.224.0

19

255.224.0.0

11

255.255.255.192

26

255.255.192.0

18

255.192.0.0

10

255.255.255.128

25

255.255.128.0

17

255.128.0.0

09

255.255.255.0

24

255.255.0.0

16

255.0.0.0

08

Page 8

Revision 2.2 Page 8 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Parameters

No.

Parameter

Range Bar (psi)

Step

Units

Default Bar (Psi)

P-01

Refrigerant

None (0). R12 (1). R13 (2)

R13b1 (3). R22 (4). R23 (5)

R32 (6). R114 (7). R134a (8)

R142B (9). R227 (10). R401 (11)

R401A (12). R401B (13). R402 (14)

R402A (15). R402B (16). R404A (17)

R407A (18). R407B (19). R407C (20)

R500 (21). R502 (22). R503 (23)

R507 (24). R717 (25)

R290 (Propane) (26)

R744 (27). R407F (28). R410A (29)

N/A

None

P-02

Span

-3.4 to 180.0 (-49.3 to 2610)

0.1

Bar (Psi)

13.8 (200)

P-03

Offset

-3.4 to 180.0 (-49.3 to 2610)

0.1

Bar (Psi)

0.0 (0.0)

P-04

Glide

-15 to 15

0.1

o

C

0.0

P-05

Pressure Type

Absolute (0), Gauge (1)

1 0

P-11

Evap 1 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-12

Evap 2 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-13

Evap 3 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-14

Evap 4 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-15

Evap 5 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-16

Evap 6 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-17

Evap 7 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-18

Evap 8 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-19

Evap 9 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar (Psi)

0.1

P-20

Evap 10 offset

0.0 to 0.5 (0 to 7.2)

0.1

Bar/PSI

0.1

P-31

Transducer Fault Delay

00:00 to 99:00

01:00

Mins

01:00

P-32

Alarm Delay

00:00 to 99:00

01:00

Mins

01:00

P-33

HP Alarm

-3.4 to 180.0 (-49.3 to 2610)

0.1

Bar (Psi)

4.0 (58.0)

P-40

MOP

-3.4 to 180.0 (-49.3 to 2610)

0.1

Bar (Psi)

3.4 (50.0)

P-41

MOP Diff

-3.4 to 180.0 (-49.3 to 2610)

0.1

Bar (Psi)

0.3 (5.0)

P-42

Recovery Count

0 – 10

1 2

P-43

MOP Delay

00:00 to 02:00

00:01

min : sec

00:05

P-50

Humidity Low

0-100 1 rH

20

P-51

Humidity High

0-100 1 rH

60

P-52

Trim Low

0-100 1 %

30

P-53

Trim High

0-100 1 %

100

P-54

Trim Off Level

0-100 1 %

30

P-55

Trim Mode

0 = Off

1 = On

2 = Remote

1 On

P-56

Broadcast ID

0 - 999

1 0

P-57

Evaporator Type

0 = Local

1 = Remote 1

2 = Remote 2

3 = Remote 3

1 0

* Span and Offset allows for the full range of the transducer to be used by the Mercury Switch.

Span is the full range of the transducer

Offset is the value below zero.

An example Transducer setup is: - Danfoss AKS 33 with range: -1 Bar to 12 Bar

Span would be 190 (13 Bar)

Offset would be -15 (-1 Bar)

Page 9

Revision 2.2 Page 9 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

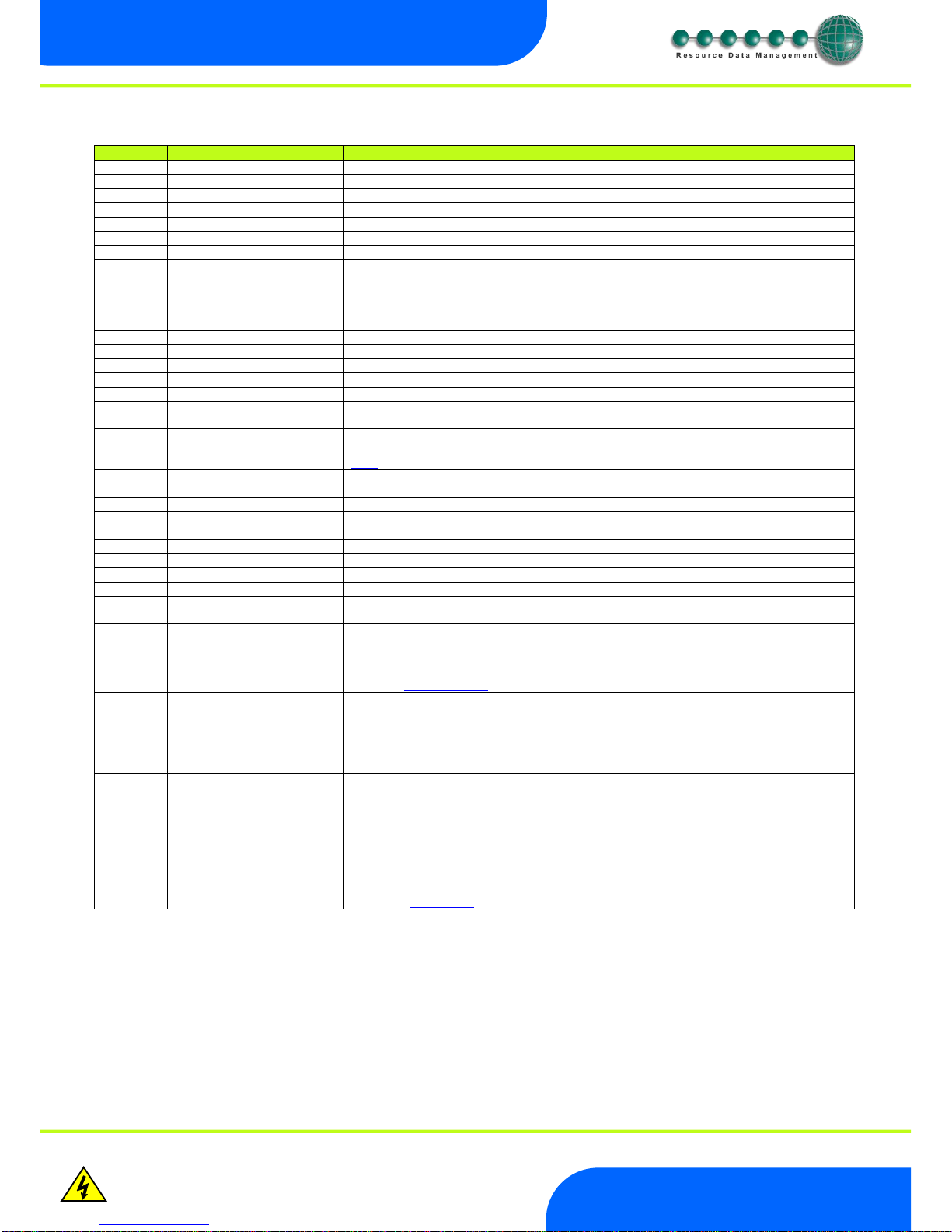

Parameters Description

Number

Parameter

Description

P-01

Refrigerant

Select the gas type used within the refrigeration system.

P-02

Span

Total range of transducer. See: To Disable Local Transducer

P-03

Offset

Value below zero*

P-04

Glide

Allows the calculated temperature to be offset by subtracting the value at P-04

P-05

Pressure Type

Select between Absolute or Gauge pressure

P-11

Evap 1 offset

Pressure difference between suction transducer and evaporator 1

P-12

Evap 2 offset

Pressure difference between suction transducer and evaporator 2

P-13

Evap 3 offset

Pressure difference between suction transducer and evaporator 3

P-14

Evap 4 offset

Pressure difference between suction transducer and evaporator 4

P-15

Evap 5 offset

Pressure difference between suction transducer and evaporator 5

P-16

Evap 6 offset

Pressure difference between suction transducer and evaporator 6

P-17

Evap 7 offset

Pressure difference between suction transducer and evaporator 7

P-18

Evap 8 offset

Pressure difference between suction transducer and evaporator 8

P-19

Evap 9 offset

Pressure difference between suction transducer and evaporator 9

P-20

Evap 10 offset

Pressure difference between suction transducer and evaporator 10

P-31

Transducer Fault Delay

Alarm generated, once transducer fault delay expires, if the transducer fails.

P-32

Alarm Delay

Delay before the HP alarm is generated.

P-33

HP Alarm

If the pressure exceeds this value then a High Pressure alarm is generated once the alarm

delay expires.

P-40

MOP

If the pressure exceeds this value the valves on controllers connected to the Mercury Switch

will closed or be reduced to a predetermined percentage. A MOP alarm is also created. (See

MOP)

P-41

MOP Diff

When the pressure reduces below this value valves on controllers connected to the Switch will

recover to their normal operational

P-42

MOP Delay

Delay after the MOP value has been exceeded before the MOP actions and alarm occurs.

P-43

Recovery Count

When the Switch comes out of MOP, the valves will come on at 1 minute intervals and turn

“this” number of valves on per minute.

P-50

Humidity Low

Sets humidity low level.

P-51

Humidity High

Sets humidity high level.

P-52

Trim Low

Sets trim low level.

P-53

Trim High

Sets trim high level.

P-54

Trim Off Level

When the timer is in the off period the trims will be pulsed at this value. Note if the humidity

sensor fails the trim relays will be pulsed at this level.

P-55

Trim Mode

Off – Pulses the controller trim relays at the Trim Off Level.

On – trim control feature will continuously pulse the controller trim relays dependant

on the measured humidity.

Remote – Uses Data Manager GP Timer channel to determine when to control. See

GP Timer Setup

P-56

Broadcast ID

ID of Plant Controller being used to broadcast Suction Pressure

The Broadcast ID is derived from the Rotary Switch positions set on the Plant controller which

is providing the remote suction pressure.

Note: no two Plant controllers on a local area network can have the same rotary switches

positions set. This will have adverse affects on control.

P-57

Evaporator Type

Select one of the following to determine the source of the pressure value used to calculate the

remote evaporator temperature.

Local – Uses Mercury Switch on board 4-20mA Input

Remote 1 – Uses the Remote Plant controllers Transducer Input 1

Remote 2 – Uses the Remote Plant controllers Transducer Input 2

Remote 3 – Uses the Remote Plant controllers Transducer Input 3

Note: Mercury Switch pressure units must match that of the Plant Pack controller it is mapped

to e.g. both devices have to be set to Bar or PSI

See Note : EEV Control

Page 10

Revision 2.2 Page 10 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Input/Output table

Number

IO

Range Bar (Psi)

Units

I-01

Evap Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-02

Evap 1 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-03

Evap 2 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-04

Evap 3 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-05

Evap 4 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-06

Evap 5 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-07

Evap 6 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-08

Evap 7 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-09

Evap 8 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-10

Evap 9 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-11

Evap 10 Press

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-12

Humidity

0 to 100

rH

I-13

Sensor Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

I-14

Remote 1 Pressure

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-15

Remote 1 Pressure

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

I-16

Remote 1 Pressure

-3.4 to 180.0 (-49.3 to 2610)

Bar (Psi)

O-01

Evap Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-02

Evap 1 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-03

Evap 2 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-04

Evap 3 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-05

Evap 4 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-06

Evap 5 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-07

Evap 6 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-08

Evap 7 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-09

Evap 8 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-10

Evap 9 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-11

Evap 10 Temp

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-21

MOP

Off ( 0 ) or On (1)

O-31

Trim Level

0 to 100 %

%

O-32

Remote Trim

Off ( 0 ) or On (1)

O-33

Remote 1 Temperature

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-34

Remote 2 Temperature

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

O-35

Remote 3 Temperature

-49.0 to 60 (-56.2 to 140.0)

o

C (o F)

EEV Control Operation

Product PR0018-PHI is intended for EEV control on an Island by island basis and can be implemented in two ways.

1. Using the on board 4-20mA Input to measure the suction pressure going to the island.

2. Using a remote suction pressure sent from Mercury Plant Controller (PR0600-PACK) on the same IP network. Note this remote

pressure can be shared by more than one Mercury Switch.

On board 4-20mA Suction Pressure Input Control Application

Ensure parameter P-57 is set to “Local”.

Configure the remaining parameters.

Connect the suction pressure transducer for the Island to the 4-20mA input on the Mercury Switch.

Ensure the transducer is correctly connected and the mA input selector jumper is in the Pressure position.

Ensure each Mercury case controller has been configured to accept the calculated remote evaporator temperature. See

Mercury user guide for further details.

Remote Suction Pressure Application

Ensure parameter P-57, Evaporator Type, is set to Remote 1 or Remote 2 or Remote 3.

Set parameter P-56, Broadcast ID, to match the ID of the desired Plant Pack Controller.

Configure the remaining parameters.

Configure the desired Plant Pack controller to broadcast the Suction pressure. See RDM Plant Controller PR0600 for further

information on how to broadcast pressure.

Note

If the Plant/Intuitive Pack Controller being read from is set to Bar then the Mercury Switch has to be set for Bar (Type 1 or 3)

If the Controller being read from is set to PSI then the Mercury Switch has to be set for PSI (Type 2 or 4).

To disable local transducer

To disable the local pressure input if it is not being used and stop it alarming transducer fault.

Set P-02 (Span) = 0. This only applies to software version 2.1 or higher.

Page 11

Revision 2.2 Page 11 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Operation

Once the Switch has been correctly setup, it will pass values to each of the controllers connected to ports 1 through 10. In an EEV

application the evaporator in temperature probe reading for a case controller can be obtained from the Mercury Switch on which the

controller is connected. A suction pressure transducer is connected from the case Island to the 4-20mA input of the Mercury Switch or

the pressure read from a remote plant controller. This pressure is then converted to a temperature based on the gas type being used by

the system. This temperature is transmitted to each controller connected to the switch and along with the suction temperature probe local

to the controller the superheat is calculated. Please see the Mercury Case controller user document from the RDM website for further

details. (P-51 Minimum valve opening) RDM recommend that this parameter be set to 0% when using Mercury Pressure Switch to

calculate Superheat. Please note that RDM recommend that the evaporator in temperature probe is fitted as the controller will use this to

calculate the superheat in the event of a communication loss with the Mercury Switch. (Or the remote Mercury Plant Controller) The

Mercury Case controllers require to have P17 (Evaporator control) set to 1 (Remote) for this feature to function.

Mercury Switch Type

There are 4 types: -

Type

Description

1

Degree C/ Bar

2

Degree C/ PSI

3

Degree F/ Bar

4

Degree F/ PSI

Transducer Connection

Note:- Pressure/Humidity Link. The mA input is available for Pressure applications only, for Humidity please use a PR0445 connected to

the display port.

MOP – Maximum Operating Pressure

When the MOP alarm is created a valve off command is sent to the 6-5E controllers connected to the Mercury Switch. The percentage

that the valve shuts down to is dependent on the “Div Value” parameter in the Mercury case controller. When the Mercury Switch

generates the MOP alarm the controller reduces the maximum valve opening to this percentage. For example if the Div Value” parameter

is set to 50% and the MOP alarm is generated then the maximum valve opening will be limited to 50%. Therefore as the controller pulses

the valve the maximum the valve will open to is 50%.

If Mercury 6-5M controllers are connected to the Switch then the LLV will be closed when the MOP alarm is created and return to normal

operation when the alarm clears. When the pressure reduces below the MOP diff the valves will revert to normal operation at 1 minute

intervals. The number of controller coming back to normal operation per minute depends on the “recovery count” value.

Link

Top

Pressure

Humididty

+12V loop feed

mA loop return

mA Input

Selector

Page 12

Revision 2.2 Page 12 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Humidity Control Operation

To utilise this feature a Humidity/Temperature Display is required (PR0445). Connect the Humidity/Temperature display to the display

port on the Mercury Switch. The control algorithm will use the humidity reading from the display in calculating the percentage at which the

trim relays are to be pulsed.

When the measured rH is below the “Humidity Low” parameter the Mercury Switch will pulse the Mercury case controller trim relays to

the duration set by the “Trim Low” parameter. When the measured rH is above the “Humidity Low” parameter but below the “Humidity

High” parameter the Mercury Switch will pulse the Mercury case controller trim relays in proportion to the line drawn between the low and

high levels. When rH goes above the “Humidity High” level the Mercury Switch will pulse the Mercury case controller trim relays at the

“Trim High” setting. Setting the trim high parameter to 70% will result in 30 % energy savings as the controller trim relays will never pulse

on for more than 70%. The trims are pulsed over a 5 minute period. Therefore if the Mercury Switch calculates the trim percentage as

50% then the trim relay will be on for 2 and a half minutes and then off for 2 and a half minutes.

GP Timer Set-up

It is possible to set the Mercury Switch humidity control to operate at specific times. For this operation to occur set the parameter “Trim

Mode” to “Remote”. A GP Timer channel must be set up to control the timer on/off periods of the Mercury Switch. For GP Timer set up

please refer to the Data Manager user guide found on the RDM website. The following settings should be followed in the GP setup.

Output Type – This should be set to “General”.

Output Mask – This should match the “Controller Name” e.g. “45a”

Output Channel – Set to “13”. This will allow the GP Timer to control the state of the timer.

When the parameter “Trim Mode” is set to “Remote” and the Data Manager GP timer channel directed to the Mercury Switch is in the on

period the humidity control will operate as described above. During the Data Manager GP timer channel off period the relay will pulse to

the preset “Trim Off Level” parameter. For example if the trim off level is zero then the trims will be completely off. Thus allowing the user

to save energy when the store isn’t trading and the trims are not required.

Note if you wish the Mercury controller trim relay to follow the Data Manager Trim Control feature and not the Mercury Switch settings

then please see the Mercury Controller user document (Parameter P-12).

Trim Heater Control via Mercury Case Controller Range

Energy savings via the Mercury controller range can be achieved in a number of ways. One of which is pulsing the trim heater relay off

for a given period of time. One way to pulse the trim heater relay in the Mercury case controller range is by setting the parameter “Trim

Level”. This sets a percentage level, of a 5-minute period, to pulse the trim heater relay off/on. Using this parameter pulses the trim relay

irrespective of the actual shop floor humidity. For greater energy savings the Data Manager energy feature trim control or the Mercury

Switch trim control feature can be used. These two options pulse the trim relay dependant on the actual shop floor humidity levels. Thus

if the shop floor humidity is relatively low the trim heaters can be pulsed off for longer durations. Please see the relevant user guides for

further details.

RDM recommend that the trim heater pulse module is used in all instances (PR0723). This module is fitted in between the trim heater of

the case and the relay output of the Mercury Controller which is pulsing the heater. The trim heater module output provides a smoother

power distribution, compared to using the relay output direct, as it switches at the zero voltage crossover point. Switching the trim heater

on and off via a normal relay, without using the RDM trim heater pulse module, may damage the trim heater and reduce the operational

life of the heater. Therefore RDM recommend the use of this module in every trim heater control application.

Humidity

Low

Humidity

High

Page 13

Revision 2.2 Page 13 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Network Alarms

The table below shows the text and associated type number that is sent to the system "front end". The type number is normally used to

provide different alarm actions.

Alarm text

Type # (Index)

Transducer Fault

6

High Pressure Alarm

8

MOP Alarm

3

Remote Pressure

6

Setup via Webpages

The Mercury Switch can be configured by navigating to the Mercury Switch WebPages. This can be achieved by using the Controller Info

page in the Data Manager/Data Director. Find the IP address assigned to the Mercury Switch in question from the list. Now connect a

laptop onto the IP network on which the Mercury Switch is connected. Using a web browser navigate to the IP address of the Mercury

Switch. The homepage of the Mercury Switch is shown below: -

Click on “Configure” to set the type: -

Then click “Type”

Use the drop-down selection to select the type required and then click “Set Type”. Parameters can be changed using the connection as

illustrated above or through the normal Data Manager/Director change parameter routes or through the display if fitted (PR0445).

Page 14

Revision 2.2 Page 14 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Ensure that all power is

switched off before

installing or maintaining

this product

Specification

Details

Description

Power requirements

Supply Voltage Range

100 – 240 Vac ±10%

Supply Frequency

50 – 60 Hz

Typical Supply Current

<500mAmps

Maximum Supply Current

650mA

General

Operating Temperature Range

+50C to +500C

Operating Humidity

80% maximum

Storage Temperature Range

-200C to +650C

Environmental

Indoor use at altitudes up to 2000m, Pollution Degree II,

Installation Category II.

Size

300mm (L) x 35mm (H) x 110mm (W)

Weight

300 Grams

Safety

EN61010

EMC

EN 55022

EN 55024

EN 61000-3-2

EN 61000-3-3

Attention this is a Class A product. When used in a domestic environment this device may cause

radio interference, in which case the user may be required to take adequate measures.

Disposal

Please observe local legislation with regards to electrical products.

Origins

Product designed in the UK manufactured in Taiwan.

Ventilation

There is no requirement for forced cooling ventilation

Class 2 Insulation

No protective Earth is required and none should be fitted.

The host equipment must provide a suitable external over-current protection device such as: -

Fuse

1A 240 Vac Antisurge (T) HRC conforming to IEC 60127

Or MCB

1A, 240 VAC Type C conforming to BS EN 60898

Mounting

There is a fixing lug at each end of the Switch, with hole centres 317 mm apart. Use typically Number 6 x 1” Pan head screw with 6mm

washer, torque down to 1.5 Newton metres.

RS232 Cable Lengths

All RS232 connections must not exceed 15 metres/connection.

Ethernet Cable lengths

Port number

Main Powered Switch

1

Refer to Cat5 standard

2

Refer to Cat5 standard

3

Refer to Cat5 standard

Disclaimer

The specifications of the product detailed in this document may change without notice. RDM Ltd shall not be liable for errors or

omissions, for incidental or consequential damages, directly or indirectly, in connection with the furnishing, performance or misuse of this

product or document.

Revision History

Revision

Date

Changes

2.1D

21/02/2012

Current Release

2.2

10/07/2012

Gas type R410A added, Load Shedding feature added

Loading...

Loading...