Page 1

INSTALLATION MANUAL

75/90/115 OPTIMAX

Important Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Fuel Pump 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boat Horsepower Capacity 2. . . . . . . . . . . . . . . . . . . . . . . .

Start in Gear Protection 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Accessories For The Outboard 2. . . . . . . . . . . .

Fuel Tank Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting Outboard 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Cable 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Recommended Outboard Mounting

Height 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Outboard 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTICE TO INSTALLER: After completing assembly, these instructions should be

placed with the product for the owner’s future use.

IMPORT ANT: If the boat is to be water tested, the operator should be familiar with the

operation procedures in the Operation and Maintenance Manual.

Electrical, Fuel Hose and Control Cables 8. . . . . . . . . . . .

Front Cover Assembly 8. . . . . . . . . . . . . . . . . . . . . . . . .

Remote Wiring Harness 9. . . . . . . . . . . . . . . . . . . . . . . .

Battery Cable Connections 10. . . . . . . . . . . . . . . . . . . .

Fuel Hose Connection 11. . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation 12. . . . . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation 14. . . . . . . . . . . . . . . . . . . . .

Filling Fuel System 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling the Oil Injection Tank 15. . . . . . . . . . . . . . . . . . . . . . .

Priming the Oil Injection Pump 16. . . . . . . . . . . . . . . . . . . .

Propeller Installation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trim-In Stop Adjustment 18. . . . . . . . . . . . . . . . . . . . . . . . .

Important Information

Before Starting Engine

Before starting engine for the first time, prime the oil injection pump. Procedure on page 16.

Prevent possible engine damage, Prime the oil injection pump before starting engine for the first time.

Required Fuel

Do not use pre-mixed gas and oil in this engine. Use a clean and fresh recommended

gasoline during engine break-in and after engine break-in.

Recommended Oil

Mercury or Quicksilver Optimax/DFI 2-Cycle engine oil is recommended for your engine. If Optimax/DFI 2-Cycle engine oil i s not a vailable, we r ecommend u sing Mercury o r Q uicksilver TC-W3

Premium Plus 2-Cycle Oil. Severe engine damage may result from use of an inferior oil.

Avoiding Fuel Flow Restrictions

IMPORTANT: Adding components to the fuel supply system as in filters, valves, fittings, etc. may restrict the fuel flow and could cause engine stalling at low speed, and/

or a lean fuel condition at high RPM, that could cause engine damage.

CAUTION

Electric Fuel Pump

If an electric fuel pump is used, the fuel pressure must not exceed 4 psig at the engine. If

necessary, install a pressure regulator to regulate the pressure.

Page 1 of 18 Printed in U.S.A. - 2004, Mercury Marine 90-10209050 JANUARY 2004

Page 2

75/90/115 OPTIMAX

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

Do not overpower or overload the boat. Most boats will carry a required capacity plate indicating the maximum acceptable power and load as determined by the manufacturer following certain federal guidelines. If in doubt, contact your dealer or the boat manufacturer.

Using an outboard that exceeds the maximum horsepower limit of a boat can: 1.

cause loss of boat control 2. place too much weight at the transom, altering the designed flotation characteristics of the boat or 3. cause the boat to break apart, particularly around the transom area. Overpowering a boat can result in serious injury ,

death, or boat damage.

WARNING

Start in Gear Protection

The remote control connected to the outboard must be equipped with a start-in-gear protection device. This prevents the engine from starting in gear.

WARNING

Avoid serious injury or death from a sudden unexpected acceleration when starting

your engine. The design of this outboard requires that the remote control used with

it must have a built in start-in-gear protection device.

Selecting Accessories For The Outboard

Genuine Quicksilver Parts and Accessories have been specifically designed and tested for

this outboard.

Some accessories not manufactured or sold by Quicksilver are not designed to be safely

used with this outboard or outboard operating system. Acquire and read the Installation, Operation, and Maintenance manuals for all selected accessories.

Fuel Tank Installation

PORTABLE FUEL TANK

Select a suitable location in boat within engine fuel line length limitations and secure tank

in place.

PERMANENT FUEL TANK

These should be installed in accordance with industry and federal safety standards which

include recommendations applicable to grounding, anti-siphon protection, ventilation, etc.

Page 2 of 18

Page 3

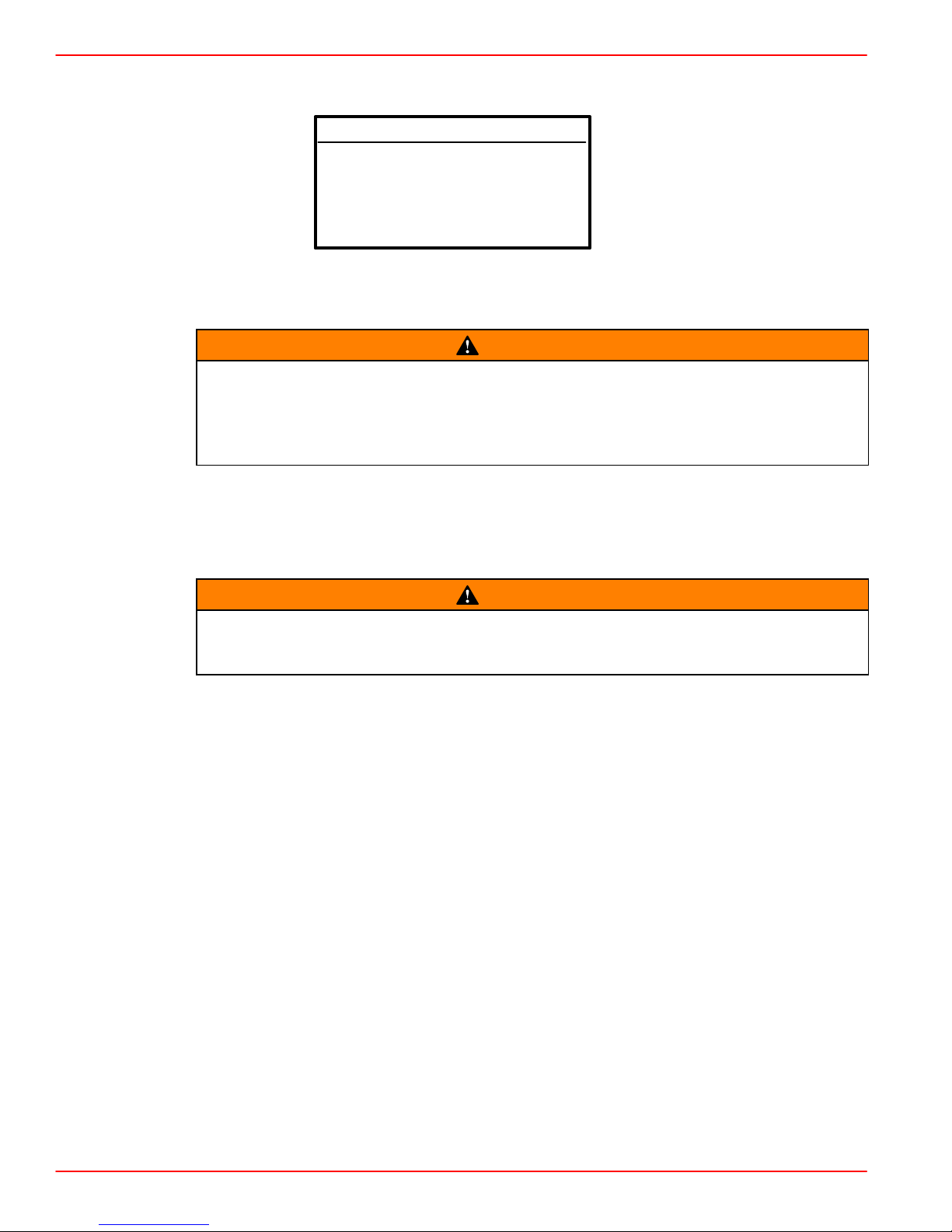

Installation Specifications

a

a – Transom Opening – Minimum

Single Engine (Remote) – 33-3/8 in. (848 mm)

Dual Engines – 59-3/4 in. (1518 mm)

75/90/115 OPTIMAX

a

b

b – Engine Center Line For Dual Engine

26 in. (660mm) Minimum

Lifting Outboard

Use Flywheel Puller/Lifting Eye (91-83164M).

Page 3 of 18

Page 4

75/90/115 OPTIMAX

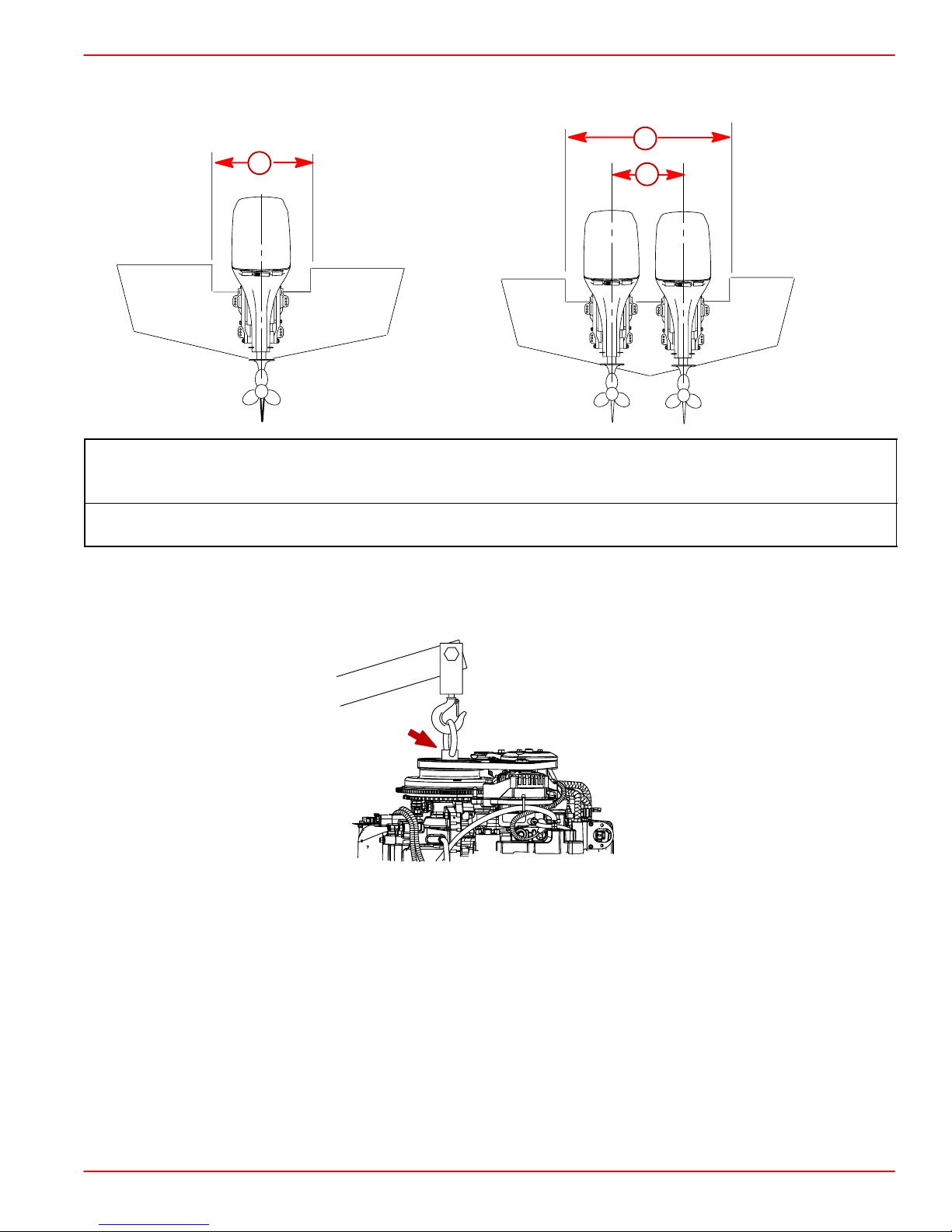

Steering Cable

STARBOARD SIDE ROUTED CABLE

1. Lubricate O-ring seal and entire cable end.

95

95

2-4-C With Teflon (92-825407A12)

2. Insert steering cable into tilt tube.

3. Torque nut to 35 lb. ft. (47.5 N·m).

Page 4 of 18

Page 5

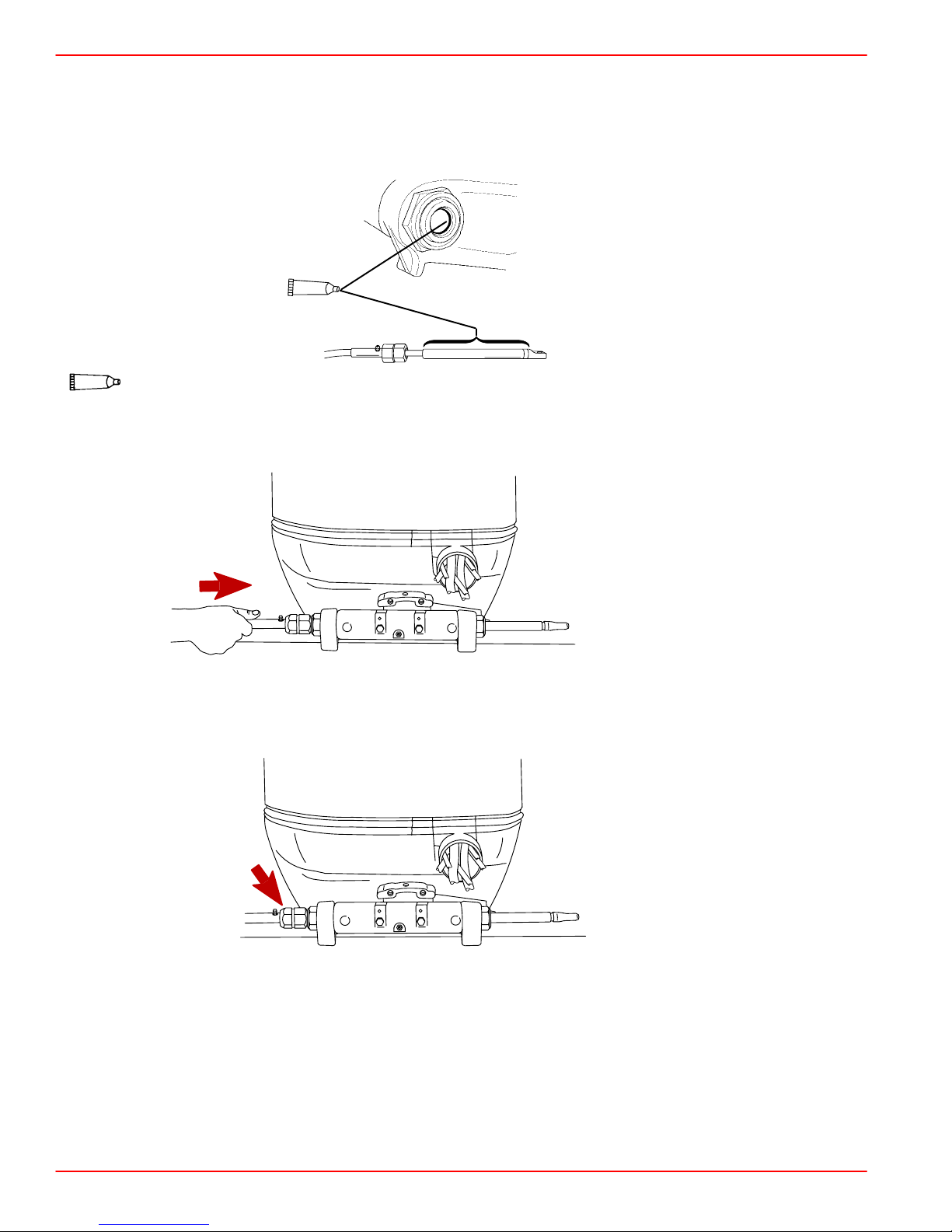

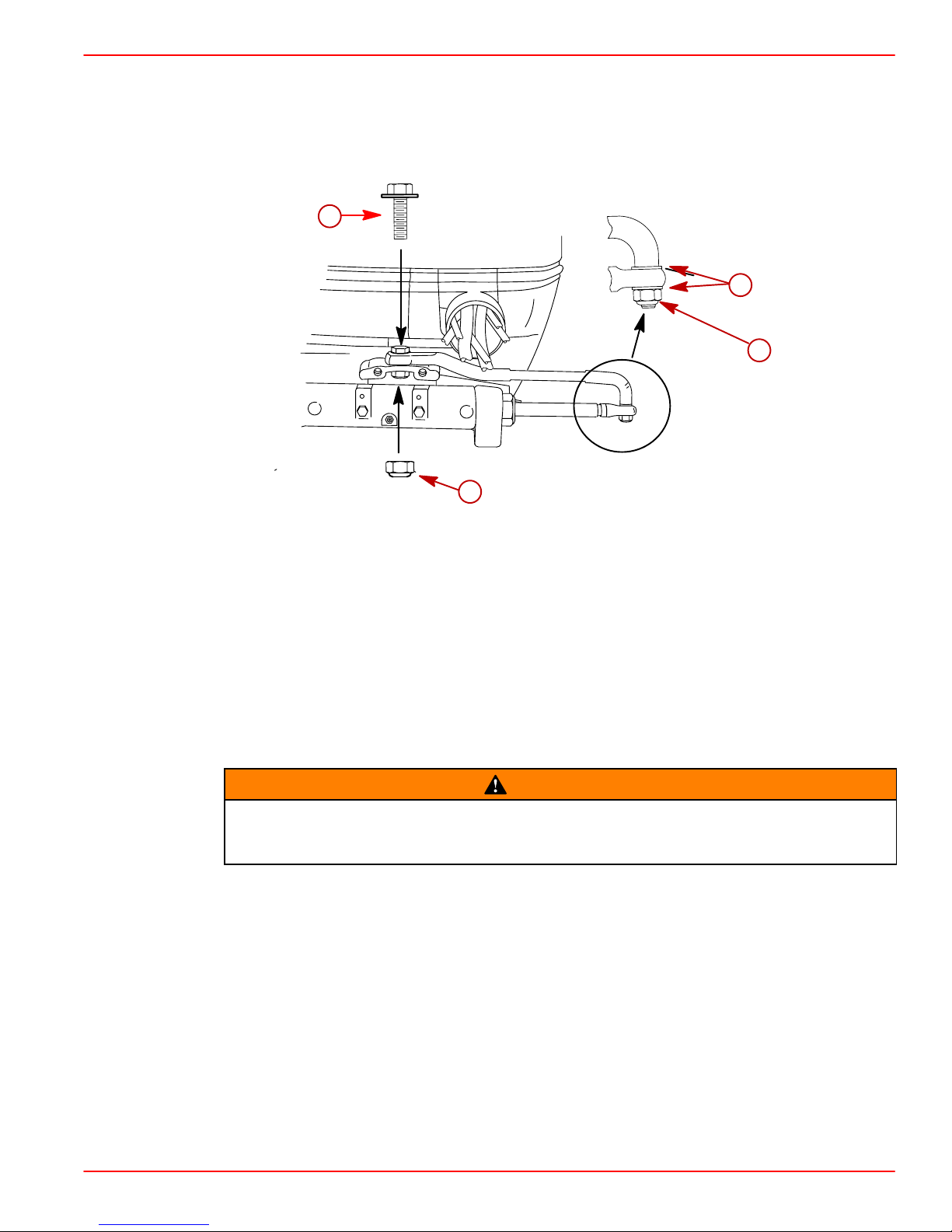

Steering Link Rod

1. Install steering link rod per illustration.

75/90/115 OPTIMAX

a

c

d

b

a-Special Bolt (10-849838) Torque to 20 lb. ft. (27 N·m)

b-Nylon Insert Locknut (11-34863) Torque to 20 lb. ft. (27 N·m)

c-Flat Washer (2)

d-Nylon Insert Locknut (11-34863) Tighten Locknut Until it Seats, Then Back Nut

Off 1/4 Turn

IMPORTANT: The steering link rod that connects the steering cable to the engine

must be fastened using special bolt (“a” - Part Number 10-848838) and self locking

nuts (“b” & “c” - Part Number 1 1-34863). These locknuts must never be replaced with

common nuts (non locking) as they will work loose and vibrate off, freeing the link

rod to disengage.

WARNING

Disengagement of a steering link rod can result in the boat taking a full, sudden,

sharp turn. This potentially violent action can cause occupants to be thrown overboard exposing them to serious injury or death.

Page 5 of 18

Page 6

75/90/115 OPTIMAX

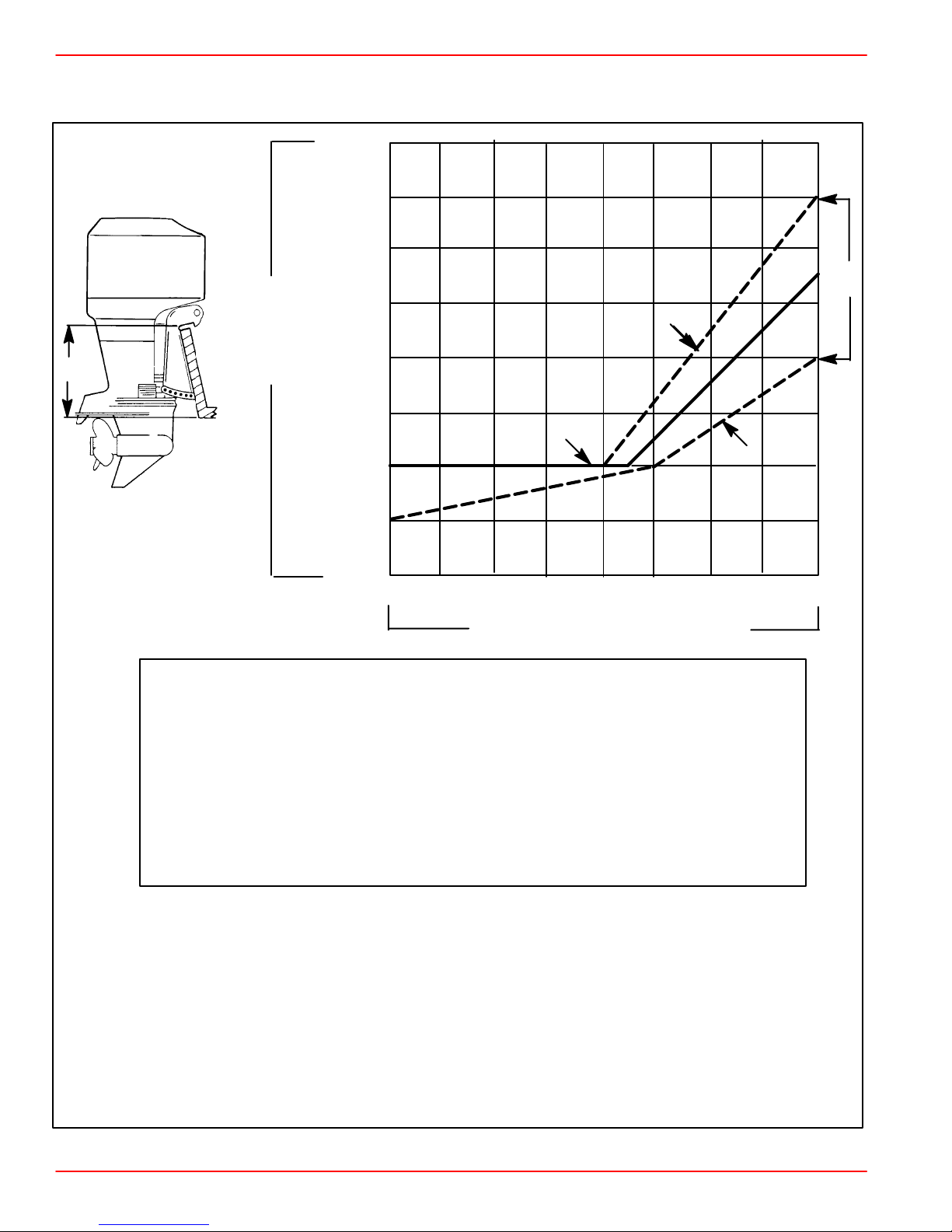

Determining Recommended Outboard Mounting Height

26 in.

(660mm)

25 in.

(635mm)

24 in.

(609mm)

(e)

Outboard

Mounting

Height (See

e

NOTE Below)

23 in.

(584mm)

22 in.

(560mm)

21 in.

(533mm)

20 in.

(508mm)

c

a

d

b

19 in.

(482mm)

NOTE: Add 5 in. (127mm) for XL models to the listed outboard mounting

height.

IMPORTANT

NOTICE TO INSTALLER

1. The outboard should be mounted high enough on the transom so that the exhaust

relief hole will stay at least 1 in. (25.4 mm) above the water line when the engine is

running at idle speed. Having the exhaust relief hole above the water line will prevent

exhaust restriction. Exhaust restriction will result in poor performance at idle.

2. However, keep in mind that the mounting height (e) of the outboard must not exceed

25 in. (635 mm) for L models, 30 in. (762 mm) for XL models. Mounting the outboard

higher may cause damage to the gear case components.

This solid line is recommended to determine the out-

a.

board mounting height.

IMPORTANT: Increasing the height of outboard generally will provide the following: 1) Less steering torque,

2) more top speed, 3) greater boat stability , but, 4) will

cause more prop “break loose” which may be particularly noticeable when planing off or with heavy load.

These broken lines represent the extremes of known

b.

successful outboard mounting height dimensions.

10

20 30 40 50 60 70 80

Maximum Boat Speed Anticipated

c.

This line may be preferred to determine outboard

mounting height dimension, if maximum speed is the

only objective.

d.

This line may be preferred to determine outboard

mounting height dimension for dual outboard installation.

Outboard mounting height (height of outboard transom

e.

brackets from bottom of boat transom). For heights over

22 in. (560mm), a propeller, that is designed for surfacing operation is usually preferred.

Page 6 of 18

Page 7

Installing Outboard

1. Use transom drilling fixture (91-98234A2) or attach (tape) engine mounting template (located in this manual) to boat transom.

2. Mark and drill four 17/32 in. (13.5mm) mounting holes.

75/90/115 OPTIMAX

3. Refer to “Determining Recommended Outboard Motor Mounting Height,” preceding and

install outboard to the nearest recommended mounting height.

4. Fasten outboard with provided mounting hardware shown.

d

b

a

c

e

a-1/2 in. Diameter Bolts (4)

b-Flat Washers(4)

c-Locknuts (4)

d-Flat Washers (4)

e-Marine Sealer - Apply to Shanks

of Bolts, Not Threads

Page 7 of 18

Page 8

75/90/115 OPTIMAX

Electrical, Fuel Hose, and Control Cables

IMPORT ANT: Warning Horn Requirement – The remote control or key switch assembly must be wired with a warning horn. This warning horn is used with the engine

warning system.

Front Cover Assembly

REMOVAL

Pull up the cowl seal and remove the cover from the bottom cowl.

a

b

a

INSTALLATION

d

a-Screws (2)

b-Cover

IMPORTANT: Sufficient slack must exist in engine wiring harness, battery cables,

fuel hose, and routed between clamp and engine attachment point, to relieve stress

and prevent hoses from being kinked or pinched.

1. Route the fuel hose, wiring and cables through the front cover opening.

2. Route flush hose (if equipped) through front cover opening.

3. Place the neoprene wrap around the wiring, hoses, and control cables as shown. Reinstall the cover and cowl seal.

b

b

c

a

a-Neoprene Wrap

b-Screws (2)

c-Cover

d-Flush Hose (if equipped)

Page 8 of 18

Page 9

Remote Wiring Harness

1. Connect wiring. Push the retainer over the ends of the connectors. This will hold the con-

nectors together. Place the harness connection and retainer into the cable holder located in the bottom cowl has shown.

75/90/115 OPTIMAX

d

e

BLU/WHT

GRN/WHT

TAN

BRN/WHT

a-Power Trim Connections

b-Wire Connection For Analog Water Temp Gauge – Not Supported by this En-

gine

c-Connection For Non SmartCraft Analog Trim Gauge

d-Retainer – Push Over Connector Ends

e-Cable Holder

BLU/WHT

GRN/WHT

TAN

BRN/WHT

a

b

c

Page 9 of 18

Page 10

75/90/115 OPTIMAX

Battery Cable Connections

SINGLE OUTBOARD

a

(+)

b

DUAL OUTBOARDS

Connect a common ground cable (wire size same as engine battery cables) between negative (–) terminals on starting batteries.

(–)

a-Red Sleeve (Positive)

b-Black Sleeve (Negative)

c-Starting Battery

(–)

c

d

(–)

d-Ground Cable (Same Wire Size As Engine Battery Cable) – Connect Between

Negative (–) Terminals

Page 10 of 18

Page 11

75/90/115 OPTIMAX

Fuel Hose Connection

PORTABLE FUEL TANK

Select a suitable location in boat within engine fuel line length limitations and secure tank

in place.

PERMANENT FUEL TANK

These should be installed in accordance with industry and federal safety standards which

include recommendations applicable to grounding, anti-siphon protection, ventilation, etc.

FUEL HOSE SIZE

Minimum fuel line inside diameter (I.D.) is 5/16 in. (8mm), with separate fuel line/fuel tank

pickup for each engine.

FUEL HOSE CONNECTION

Fasten remote fuel hose to fitting with hose clamp.

Water Pressure Tubing Connection (Models without SmartCraft Water PSI Gauge)

Make the water pressure gauge hose connection to this tubing as shown.

a

b

c

e

f

d

g

a-Fuel Hose

b-Hose Clamp – Secure Remote Fuel Hose

c-Water Pressure Tubing (Gray Color)

d-Water Pressure Tube – Insert into Coupler, Pull on Tube to Verify That it is

Locked

e-Coupler (859747) – Push In on End of Coupler to Disconnect Plug or Tubing

f-Plug (if equipped) – Remove when Making Coupler Connection

g-Barb Hose Fitting (859731) Provided with Outboard – Install this fitting into Cou-

pler, if a Rubber Hose Connection is Required

Page 11 of 18

Page 12

75/90/115 OPTIMAX

Shift Cable Installation

Install cables into the remote control following the instructions provided with the remote control.

NOTE: Install the shift cable to the engine first. The shift cable is the first cable to move when

the remote control handle is moved out of neutral.

1. Position remote control into neutral.

2. Shift outboard into neutral.

3. Measure the distance (a) between pin and center of barrel pocket.

N

a

c

F

NR

a-Distance Between Pin And Center of Barrel Pocket

b-Pin

c-Barrel Pocket

b

Page 12 of 18

Page 13

75/90/115 OPTIMAX

4. Push in on the shift cable end (d) until resistance is felt. Adjust the cable barrel (e) to

attain distance (a) taken in Step 3.

e

d

d-Shift Cable End

e-Cable Barrel

5. Place cable barrel into pocket. Fasten cable with locknut and flat washer.

h

g

f

f-Place Barrel Into Barrel Pocket

g-Locknut – Tighten locknut then back off locknut 1/4 turn.

h-Flat Washer

6. Check shift cable adjustments as follows:

a. Shift remote control into forward. The propeller shaft should be locked in gear . If not,

adjust the barrel closer to the cable end.

b. Shift remote control into neutral. The propeller shaft should turn freely without drag.

If not, adjust the barrel away from the cable end. Repeat steps a and b.

c. Shift remote control into reverse while turning propeller. The propeller shaft should

be locked in gear. If not, adjust the barrel away from the cable end. Repeat steps a

thru c.

d. Shift remote control back to neutral. The propeller shaft should turn freely without

drag. If not, adjust the barrel closer to the cable end. Repeat steps a thru d.

Page 13 of 18

Page 14

75/90/115 OPTIMAX

Throttle Cable Installation

Install cables into the remote control following the instructions provided with the remote control.

1. Position remote control into neutral.

2. Install throttle cable to the throttle arm with washer and locknut.

3. Adjust the cable barrel so that the installed throttle cable will hold the throttle arm against

the idle stop.

4. Place cable barrel into retainer.

5. Lock the retainer and cables in place with the cable latch.

N

c

d

a

b

e

a-Flat Washer

b-Locknut – Tighten lock-

nut then back off locknut 1/4 turn

c-Barrel Retainer

d-Cable Barrel

e-Cable Latch

Page 14 of 18

Page 15

Filling Fuel System

NOTE: For initial start of a new engine or for an engine that ran out of fuel, or was drained

of fuel, the fuel system should to be filled as follows:

•

Squeeze the fuel line primer bulb until it feels firm.

•

Turn the ignition key switch to the ON position for three seconds. This operates the electric fuel pump.

•

Turn the ignition key switch back to the OFF position, and squeeze the primer bulb again

until it feels firm. Turn the ignition key switch to the “ON” position again for three seconds.

Continue this procedure until the fuel line primer bulb stays firm.

Filling The Oil Injection Tank

75/90/115 OPTIMAX

NOTE: The oil tank capacity is 5 qt. (4.72 liters).

1. Open the cowl cap. Turn the oil fill cap to the left and remove.

a

a-Cowl Cap

b-Oil Fill Cap

2. Use the chain on the fill cap to check oil level. First ball marker (a) is 1 quart (.94 liters)

low and second ball marker (b) is 2 quart (1.89 liters) low.

3. Slowly fill the oil tank with the specified oil. Do Not overfill

the oil level up to the bottom of the fill neck (a).

4. Install oil filler cap and re-tighten. Reinstall the cowl cap.

a

b

– add only enough oil to bring

c

d

a-1 Quart (.94 liters) Low Marker

b-2 Quart (1.89 liters) Low Marker

c-Full Line

d-Oil Fill Cap

b

Page 15 of 18

Page 16

75/90/115 OPTIMAX

Priming the Oil Injection Pump

Before starting engine for the first time, prime the oil injection pump. Priming will remove

any air that may be in the pump, oil supply hose, or internal passages.

a

a-Oil Injection Pump

b-Oil Supply Hose

b

CAUTION

To prevent damage to the fuel pumps, fill the engine fuel system with fuel. Otherwise the fuel pumps will run without fuel during the priming process.

Prime the oil injection pump as follows:

1. Fill the engine fuel system with fuel. Connect fuel hose and squeeze primer bulb until

it feels firm.

2. Turn the ignition key switch to the “ON” position.

3. Within the first 10 seconds after the key switch has been turned on, move the remote

control handle from neutral into forward gear 3 to 5 times. This will automatically start

the priming process.

NOTE: It may take a few minutes for the pump to complete the priming process.

Page 16 of 18

N

F

Page 17

Propeller Installation

If the propeller shaft is rotated while the engine is in gear, there is the possibility that

the engine will crank over and start. To prevent this type of accidental engine starting and possible serious injury caused from being struck by a rotating propeller,

always shift outboard to neutral position and remove spark plug leads when you

are servicing the propeller.

IMPORT ANT: Propellers used on this product require the Mercury Marine Flo-Torq lll

type hub 835257A9 or equivalent.

75/90/115 OPTIMAX

WARNING

Flo-Torq lll Drive Hub Propellers

Flo-Torq lll

e

d

c

a-Forward Thrust Hub

b-Replaceable Drive Sleeve

c-Rear Thrust Hub

d-Propeller Nut Retainer

e-Propeller Nut

4. Tighten propeller nut to 55 lb-ft (75 Nm). Bend tabs against nut.

b

a

a

a-Propeller Nut - Torque To 55 lb- ft (75 Nm)

b-Bend Tabs Into Grooves

b

Page 17 of 18

Page 18

75/90/115 OPTIMAX

Trim-In Stop Adjustment

Some outboard boats, particularly some bass boats, are built with a greater than normal

transom angle which will allow the outboard to be trimmed further “in” or “under”. This greater trim “under” capability is desirable to improve acceleration, reduce the angle and time

spend in a bow high boat attitude during planing off, and in some cases, may be necessary

to plane off a boat with aft live wells, given the variety of available propellers and height

range of engine installations.

However, once on plane, the engine should be trimmed to a more intermediate position to

avoid a bow-down planing condition called “plowing”. Plowing can cause “bow steering” or

“over steering” and inefficiently consumes horsepower. In this condition, if attempting a turn

or encountering a diagonal, moderate wake, a more abrupt turn than intended may result.

In rare circumstances, the owner may decide to limit the trim under. This can be accomplished by purchasing a stainless steel tilt pin (P/N 17-49930A1) and inserting it through

whatever pin hole is desired. The non-stainless steel shipping bolt should not be used in this

application other than on a temporary basis.

Avoid possible serious injury or death. Adjust outboard to an intermediate trim position as soon as boat is on plane to avoid possible ejection due to boat spin-out.

Do not attempt to turn boat when engine is trimmed extremely under or in.

WARNING

a-Tilt Pin

a

Page 18 of 18

Loading...

Loading...