Page 1

115/135/150/175

OptiMax

Direct Fuel Injection

Starting Model Year 2000

Starting Serial Number OG960500

Starting Model Year 2000

Starting S/N OG960500

115/135/150/175 OptiMax

Page 2

Notice

Throughout this publication, “Dangers”, “Warnings” and “Cautions” (accompanied by the International HAZARD Symbol

cerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly. OBSERVE THEM CAREFULLY!

These “Safe t y A l e rts” alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus “Common Sense” operation,

are major accident prevention measures.

) are used to alert the mechanic to special instructions con-

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with the servicing procedures of these products, or like or similar products manufactured and marketed by Mercury Marine, that they

have been trained in the recommended servicing procedures of these products which includes the use of mechanics’ common hand tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service trade of all conceivable procedures

by which a service might be performed and of the possible hazards and/or results of each

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the products safety will be endangered by the

service procedure selected.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition

system are capable of violent and damaging short circuits or severe electrical shocks. When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

90-859494R1 JUNE 2000 Page i

Page 3

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use radial

lines for this purpose, while most American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury. Therefore, fasteners removed should be saved for reuse in the same locations whenever possible. Where the fasteners are not satisfactory for re-use, care should be taken to

select a replacement that matches the original.

Cleanliness and Care of Outboard Motor

A marine power product is a combination of many machined, honed, polished and lapped

surfaces with tolerances that are measured in the ten thousands of an inch/mm. When any

product component is serviced, care and cleanliness are important. Throughout this manual, it should be understood that proper cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is considered standard shop practice

even if not specifically stated.

Whenever components are removed for service, they should be retained in order. At the

time of installation, they should be installed in the same locations and with the same mating

surfaces as when removed.

Personnel should not work on or under an outboard which is suspended. Outboards should

be attached to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products de-

scribed in this manual.

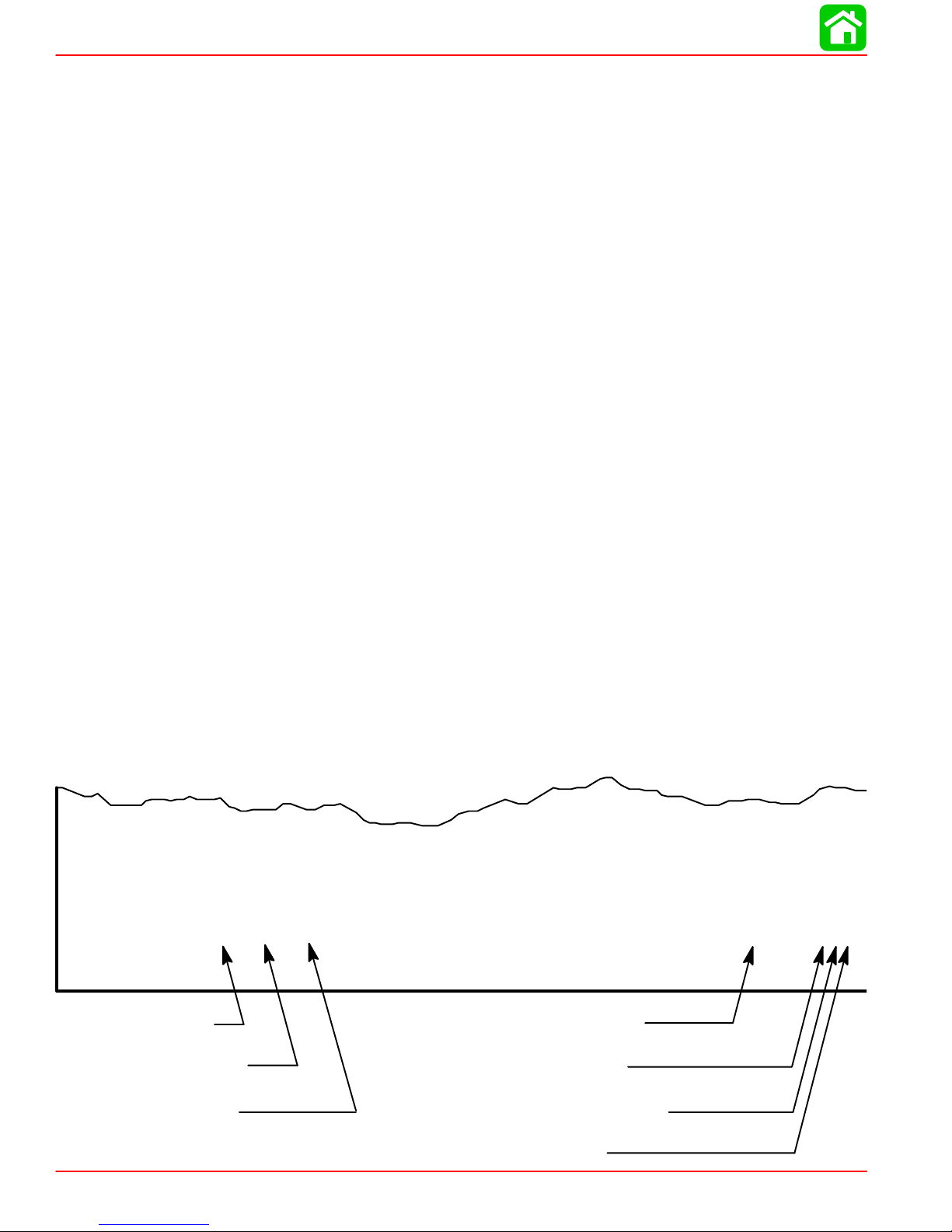

Page Numbering

Two number groups appear at the bottom of each page. The example below is self-explanatory.

90-859494 R1 MAY 2000

EXAMPLE:

LOWER UNIT - 6A-7

Revision No. 1

Month of Printing

Year of Printing

Page ii 90-859494R1 JUNE 2000

Section Description

Section Number

Part of Section Letter

Page Number

Page 4

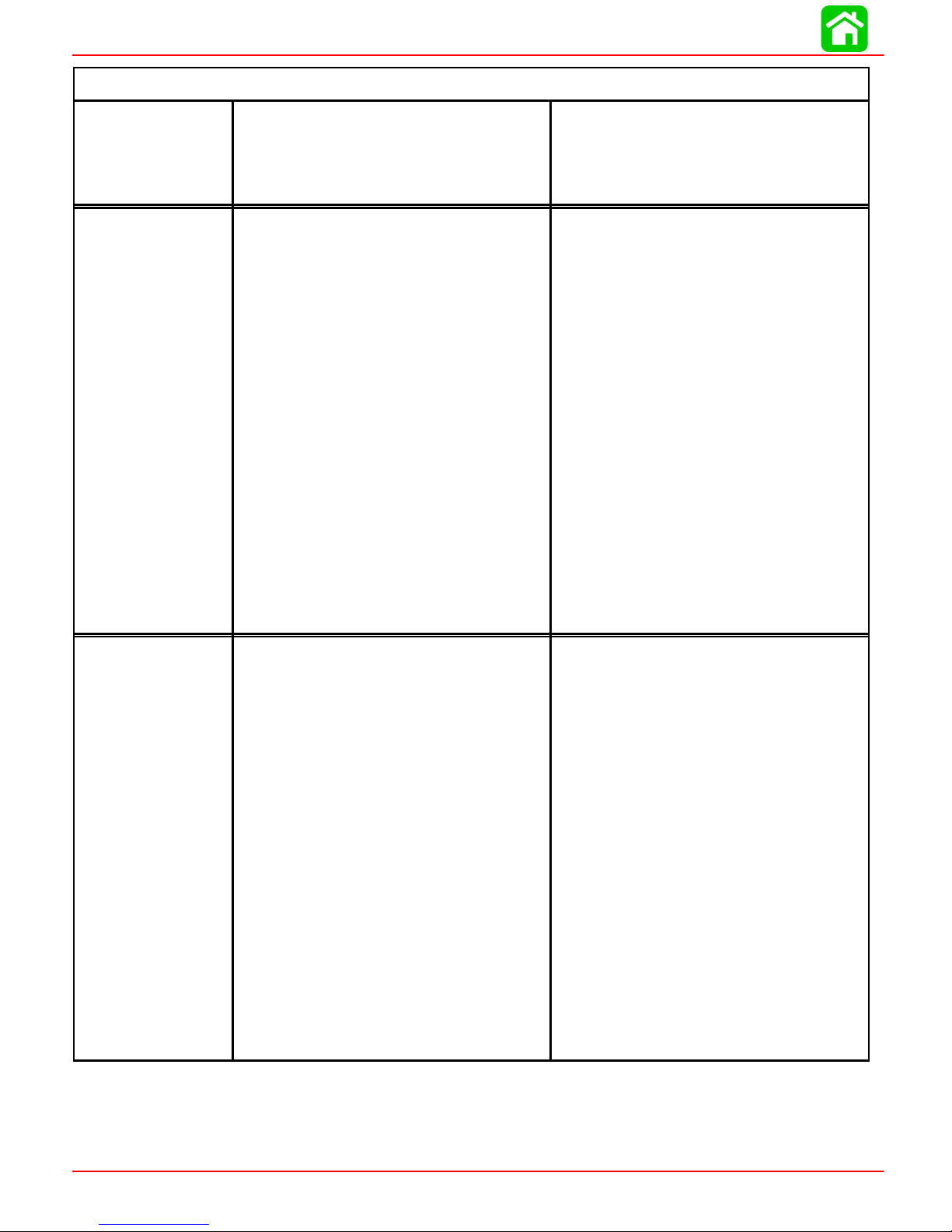

Service Manual Outline

Section 1 - General Information & Specifications

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Fuel Pump

B - Direct Fuel Injection

C - Oil Injection

D - Emissions

Section 4 - Powerhead

A - Powerhead

B - Cooling

Section 5 - Mid-Section

A - Clamp/Swivel Brackets & Drive Shaft Housing

B - Power Trim – Design I (Showa)

C - Power Trim – Design II (Oildyne)

Section 6 - Gear Housing

A - Right Hand (Standard) Rotation Non-Ratcheting

B - Left Hand (Counter) Rotattion Non-Ratcheting

Section 7 - Attachments/Control Linkage

Section 8 - Color Diagrams

General Information

& Specifications

Ignition System

Fuel System

Powerhead

Mid-Section

Gear Housing

Attachment/Control Linkage

Color Diagrams

1

2

3

4

5

6

7

8

90-859494R1 JUNE 2000 Page iii

Page 5

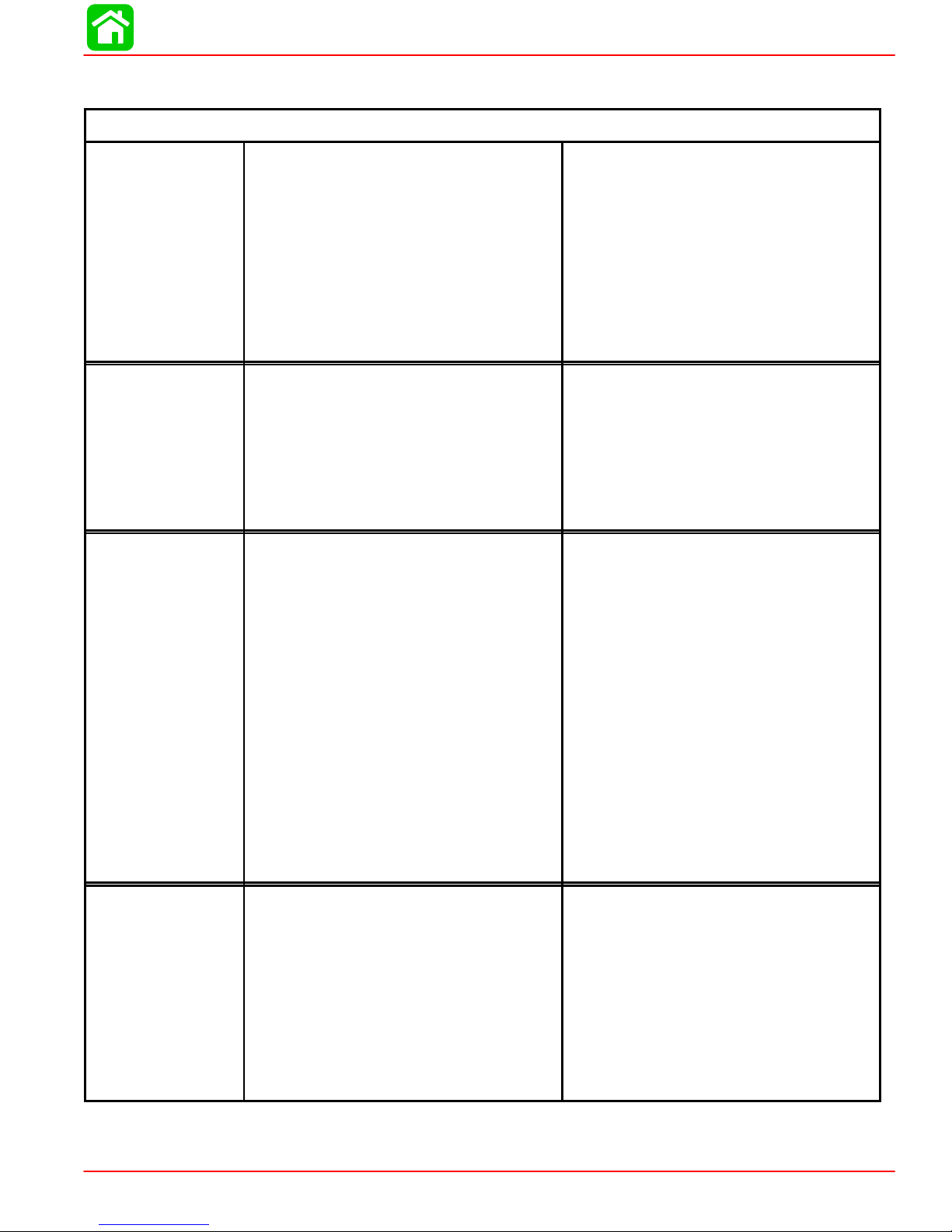

SPECIFICATIONS

IMPORTANT INFORMATION

Section 1A - Specifications

Table of Contents

Master Specifications 1A-1. . . . . . . . . . . . . . . . . . . . . . . . .

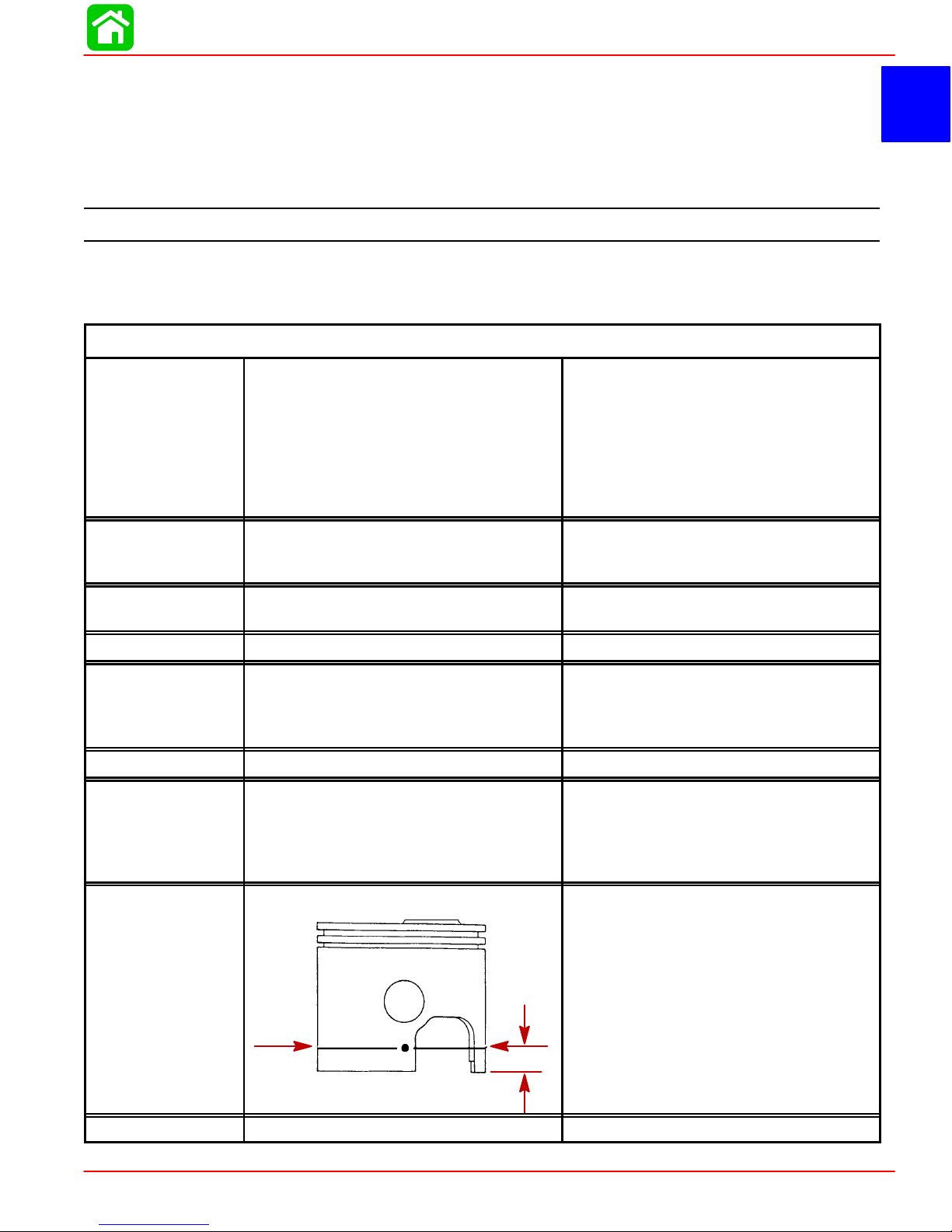

Master Specifications

Model 135/150 DFI

HORSEPOWER

(KW)

OUTBOARD

WEIGHT

Model 135

Model 150

Full Throttle RPM (135/150)

Idle RPM (In Gear) (135/150)

RPM Limiter

1998 Model 135/150

1999 Model 135

1999 Model 150

Model 135/150

– 20 in. (50.8cm) Shaft

– 25 in. (63.5cm) Shaft

1

A

135 (100.7 kw)

150 (111.8 kw)

5000 - 5600

550 ± 25

5750

5750

5950

440.0 lbs. (200.0 kg)

452.0 lbs. (206.0 kg)

CYLINDER

BLOCK

STROKE Length (All Models) 2.65 in. (67.3 mm)

CYLINDER

BORE

CRANKSHAFT Maximum Runout 0.006 in. (0.152 mm)

PISTON Piston Type

PISTON

DIAMETER

Type

Displacement

Diameter (Std)

Diameter 0.015 in. Oversize

Taper/Out of Round/Wear Maximum

Bore Type

Diameter Standard

Diameter 0.015 in. Oversize

Dimension

“A” at Right

Angle (90

to Piston

Pin

°)

.700

17.78mm

V-6 Cylinder, Two Cycle, Direct Injected

153 cu. in. (2508 cc) 60° Vee

3.501 in. (88.925 mm)

3.516 in. (89.306 mm)

0.003 in. (0.076 mm)

Cast Iron

Aluminum

3.4925 in. ± .0005 in. (88.7095 mm ±

0.0127 mm)

3.5075 in. ± 0.0005 in.

(89.0905 mm ± 0.0127 mm)

3.4925 in. ± .0005 in.

(88.7095 mm ± .0127 mm)

Using a micrometer, measure dimension

“A” at location shown. Dimension “A”

should be 3.4925 in. ± .0005 for a STAN-

DARD size piston (new) Dimension “A”

will be 0.001 – 0.0015 less if coating is

worn off piston (used)

REEDS Reed Stand 0pen (Max.) 0.020 in. (0.50 mm)

90-855347R1 JANUARY 1999 Page 1A-1

Page 6

SPECIFICATIONS

Model 135/150 DFI

MID

SECTION

GEAR

HOUSING

Power Trim (Total Tilt Range)

Power Trim (Tilt Range)

Steering Pivot Range

Tilt Pin Adjustment Positions

Allowable Transom Thickness

Gear Ratio

Standard Ratio – 135

Standard Ratio – 150

Optional High Altitude Ratio

– 135

– 150

Gearcase Capacity

Pinion Height

Forward Gear Backlash

– 1.87:1

– 2.00:1

– 2.30:1

Reverse Gear Backlash

– Standard/Counter Rotation

Water Pressure @ RPM

73°

19°

60°

4

2-3/8 in. (6.03 cm)

2.00:1 12/24 Teeth

1.87:1 15/28 Teeth

2.30:1 13/30 Teeth

2.00:1 12/24 Teeth

22.5 fl. oz. (665.4 ml)

0.025 in. (0.635 mm)

.

0.017 in. – 0.028 in.

(0.431 mm – 0.711 mm)

0.015 in. – 0.022 in.

(0.381 mm – 0.558 mm)

0.018 in. – 0.023 in.

(0.460 mm – 0.584 mm)

0.030 in. to 0.050 in.

(0.076 mm to 0.127 mm)

12 PSI Minimum @ 5500 RPM

DIRECT

INJECTION

Injectors

– Quantity

– Injectors are Crank Angle Driven

by ECM

– #2 Cylinder

– #4 Cylinder

– #6 Cylinder

– #1 Cylinder

– #3 Cylinder

– #5 Cylinder

Fuel Line Pressure @ Injectors

Air Pressure

High Pressure Electric Fuel Pump

Amperage Draw

Low Pressure Electric Fuel Pump

Amperage Draw

Low Pressure Electric Fuel Pump

Output

Fuel Injector Ohm Resistance

Direct Injector Ohm Resistance

Fuel/Air Differential

6

WHT/RED + RED/WHT Leads

WHT/YEL + YEL/WHT Leads

WHT/PPL + PPL/WHT Leads

WHT/BRN + BRN/WHT Leads

WHT/ORG + ORG/WHT Leads

WHT/DRK BLU + DRK BLU/WHT

Leads

89 ± 2 psi (613.5 ± 13.8 kPa)

79 ± 2 psi (544.0 ± 13.8 kPa)

5 – 9 Amperes

1 – 2 Amperes

6 – 9 psi (41.37 – 62.04 kPa)

1.8 ± 0.1 Ω

1.3 ± 0.3 Ω

10 psi (68.5 kPa)

Page 1A-2 90-855347R1 JANUARY 1999

Page 7

Master Specifications

SPECIFICATIONS

Model 135/150 DFI

FUEL

SYSTEM

STARTING

SYSTEM

IGNITION

SYSTEM

Fuel

Recommended Gasoline

Recommended Oil

Gasoline/Oil Ratio

– @ Idle

– @ WOT

Fuel Pressure

Crankcase Pump

– @ Idle

– @ WOT

Electric Start – All Models

Starter Draw (Under Load)

Starter Draw (No Load)

Minimum Brush Length

Battery Rating

Type

Spark Plug Type

Spark Plug Gap

Maximum Timing

Idle Timing

Throttle Position Sensor 1 (Inner

TPS)

@ Idle

@ W.O.T

Throttle Position Sensor 2 (Outer

TPS)

@ Idle

@ W.O.T

Crank Position Sensor

Air Gap

Gasoline w/Oil Injection

Unleaded 87 Octane Minimum

Quicksilver TC-W3 Premium Plus 2

Cycle Outboard Oil

300 – 400:1

60:1

2 psi (13.8 kPa)

8 psi (55.2 kPa)

165 Amperes

30 Amperes

0.25 in. (65.4 mm)

1000 (Minimum) Marine Cranking Amps

(MCA)

750 (Minimum) Cold Cranking Amps

(CCA)

Digital Inductive

NGK PZFR5F-11

NGK ZFR5F-11 or

Champion RC12MC4

0.040 in. (1.0 mm)

Not Adjustable; Controlled by ECM

Not Adjustable; Controlled by ECM

3.70 – 4.90 VDC

0.30 – 1.80 VDC

0.10 – 1.50 VDC

3.20 – 4.90 VDC

0.025 in. – 0.040 in.

(0.635 mm – 1.01 mm)

CHARGING

SYSTEM

*Amperage listed is when battery is in a discharged state. If battery is fully charged, amperage readings will

be less.

90-855347R1 JANUARY 1999 Page 1A-3

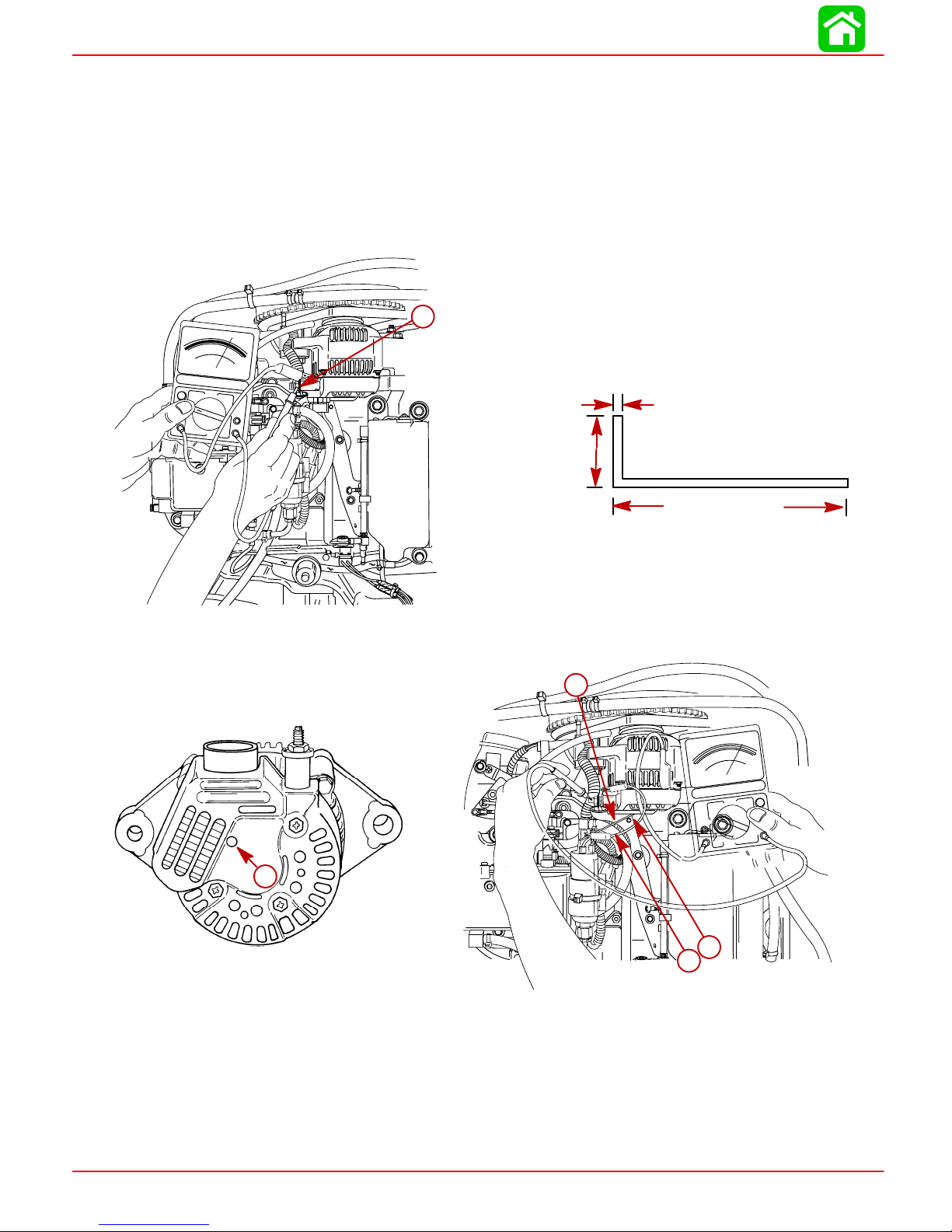

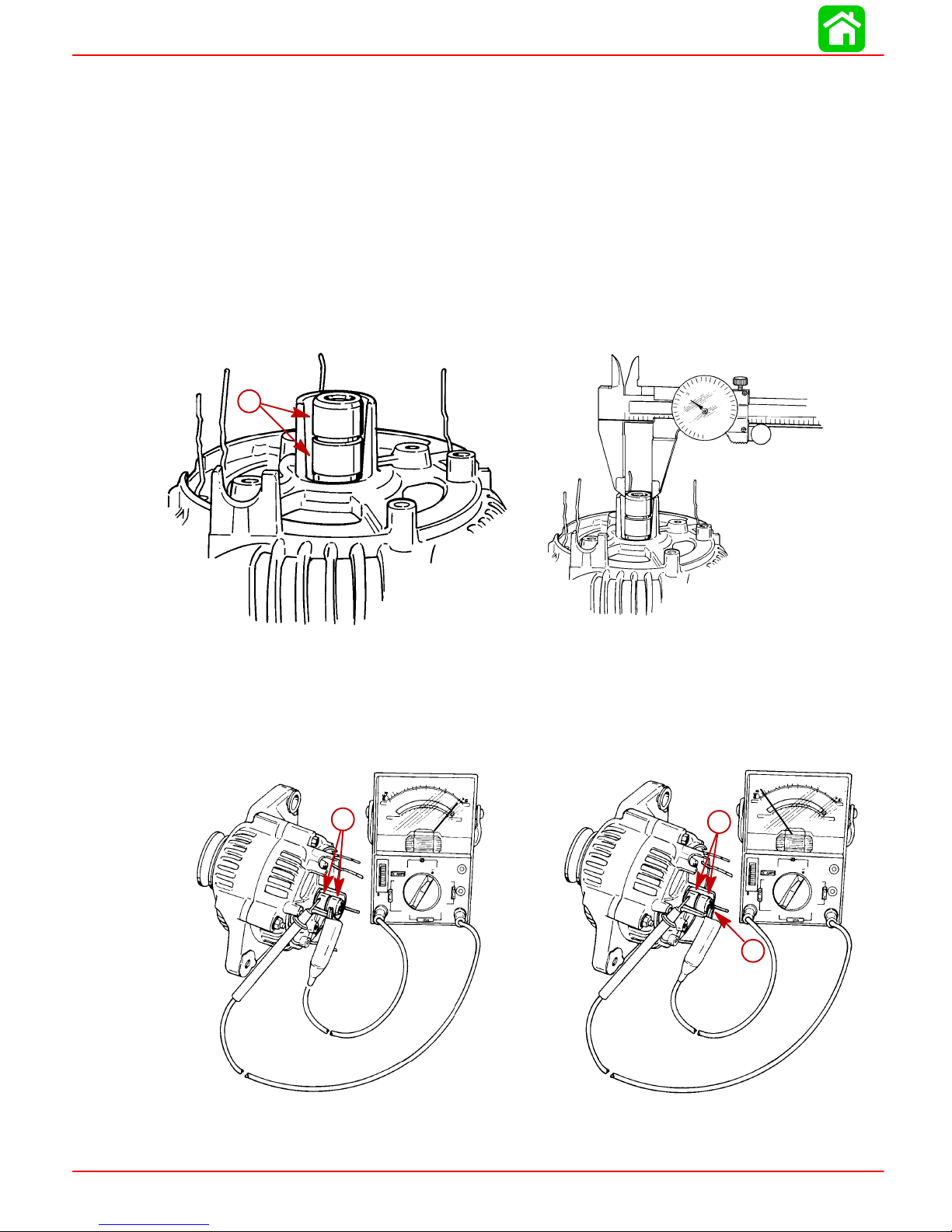

Alternator Output (Regulated)

Brush Length

Voltage Output

Regulator Current Draw

32 - 38 Amperes @ 2000 RPM

@ Battery*

52 - 60 Amperes @ 2000 RPM

@ Alternator

Std Exposed Length:

0.413 in. (10.5 mm)

Min. Exposed Length:

0.059 in. (1.5 mm)

13.5 to 15.1 Volts

0.15 mA (Ign. Switch Off)

30.0 mA (Ign. Switch On)

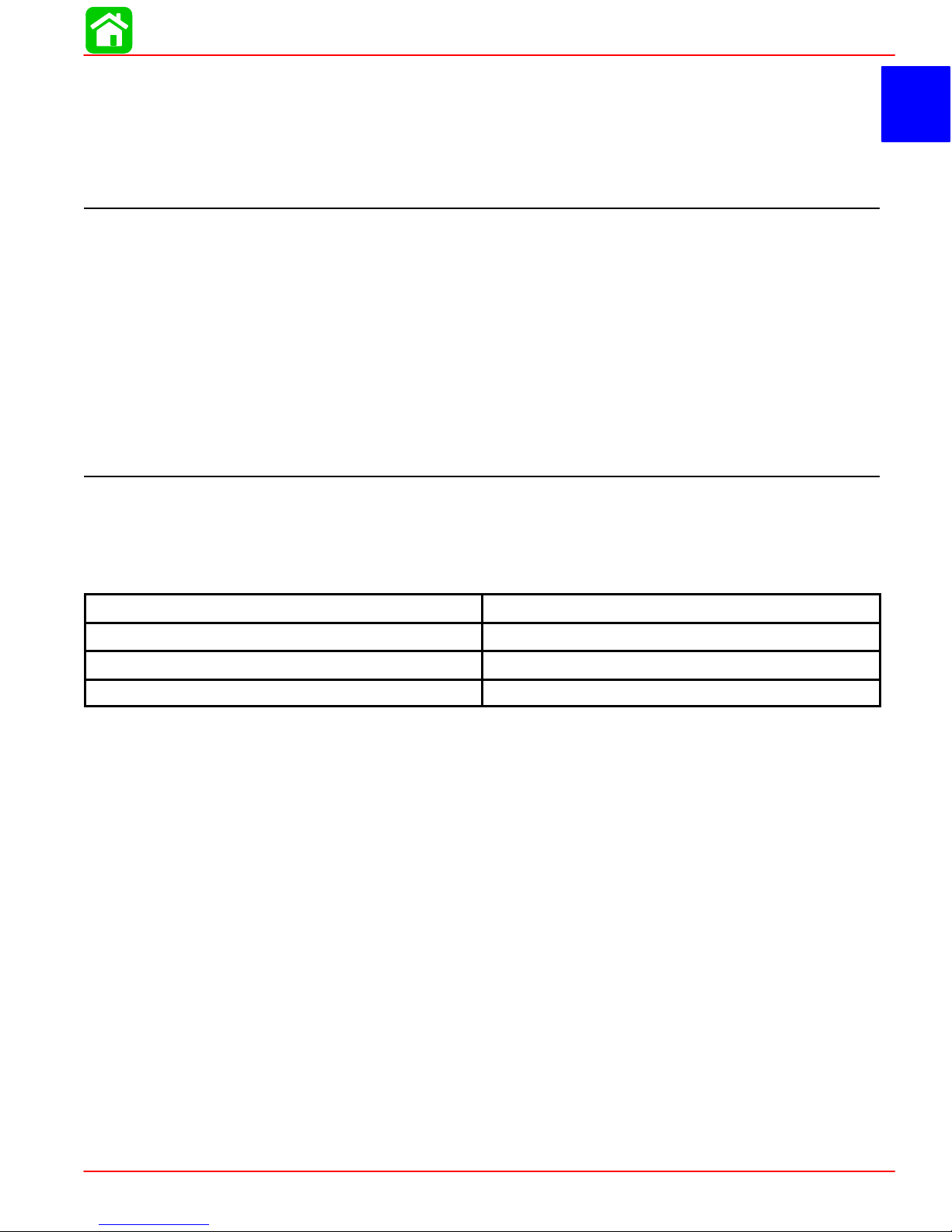

Page 8

MAINTENANCE

IMPORTANT INFORMATION

Section 1B - Maintenance

Table of Contents

Specifications 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-1. . . . . . . . . . . . . .

Special Tools 1B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quicksilver Lubricant/Sealant 1B-2. . . . . . . . . . . . . . . . . .

Inspection and Maintenance Schedule 1B-4. . . . . . . . . .

Before Each Use 1B-4. . . . . . . . . . . . . . . . . . . . . . . . . .

After Each Use 1B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Every 100 Hours of Use or Once yearly,

Whichever occurs first 1B-4. . . . . . . . . . . . . . . . . . . . .

Flushing Engine 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Cooling System – Using Cowl

Flush Plug 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Cooling System – Using Flushing

Attachment 44357A2 1B-5. . . . . . . . . . . . . . . . . . . . . .

Specifications

1

B

Fuel System 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Line Inspection 1B-6. . . . . . . . . . . . . . . . . . . . . . .

Water Separating Fuel Filter 1B-6. . . . . . . . . . . . . . . .

Corrosion Control Anode 1B-7. . . . . . . . . . . . . . . . . . . . . .

Spark Plug Inspection 1B-7. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Inspection 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse Replacement 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor Air intake Filter 1B-9. . . . . . . . . . . . . . . . . . .

Removal 1B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication Points 1B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Power Trim Fluid 1B-11. . . . . . . . . . . . . . . . . . .

Gear Case Lubrication 1B-12. . . . . . . . . . . . . . . . . . . . . . .

Storage Preparation 1B-13. . . . . . . . . . . . . . . . . . . . . . . . .

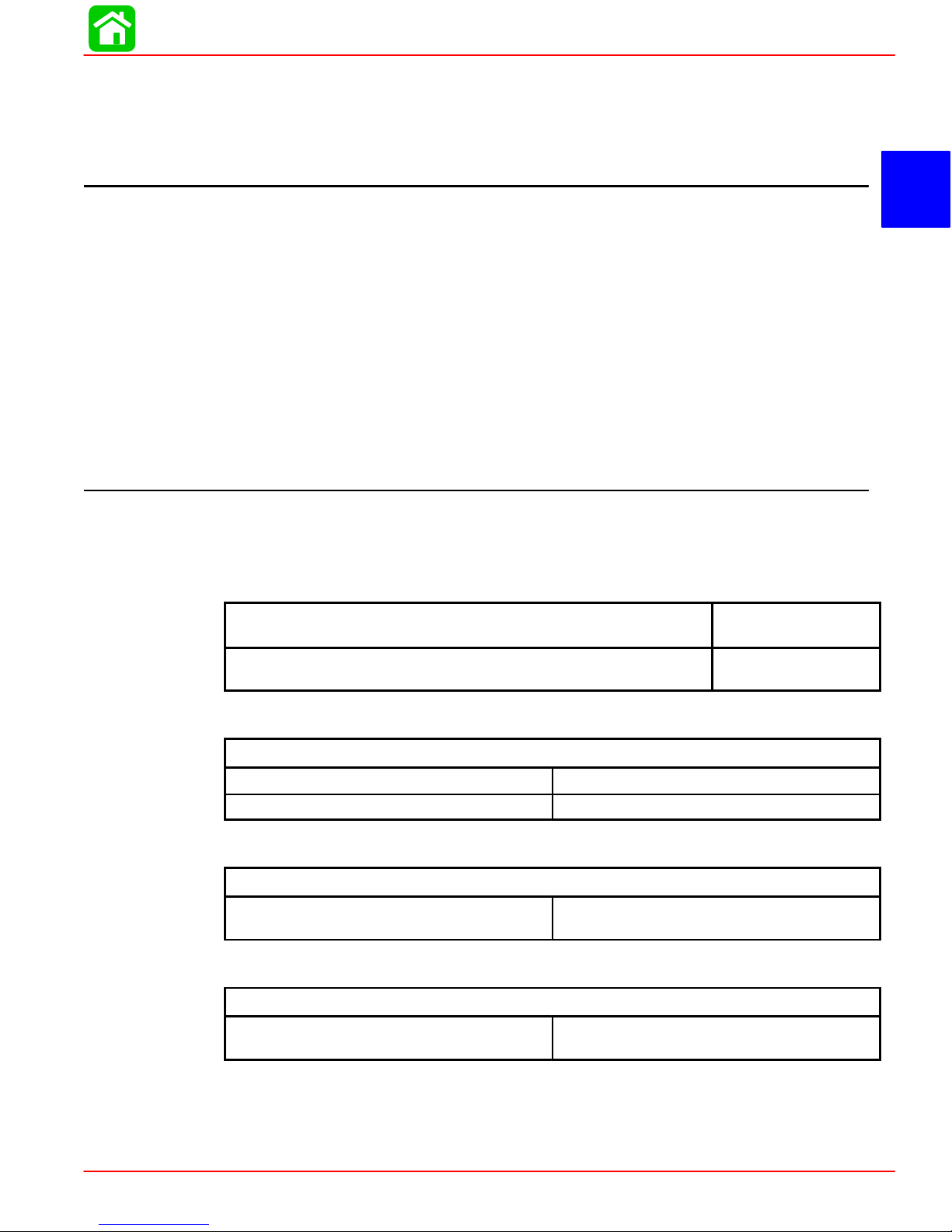

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

1.87:1

2.00:1

2.30:1

22.5 fl. oz. (665ml)

22.5 fl. oz. (665ml)

22.5 fl. oz. (665ml)

90-855347R1 JANUARY 1999 Page 1B-1

Page 9

MAINTENANCE

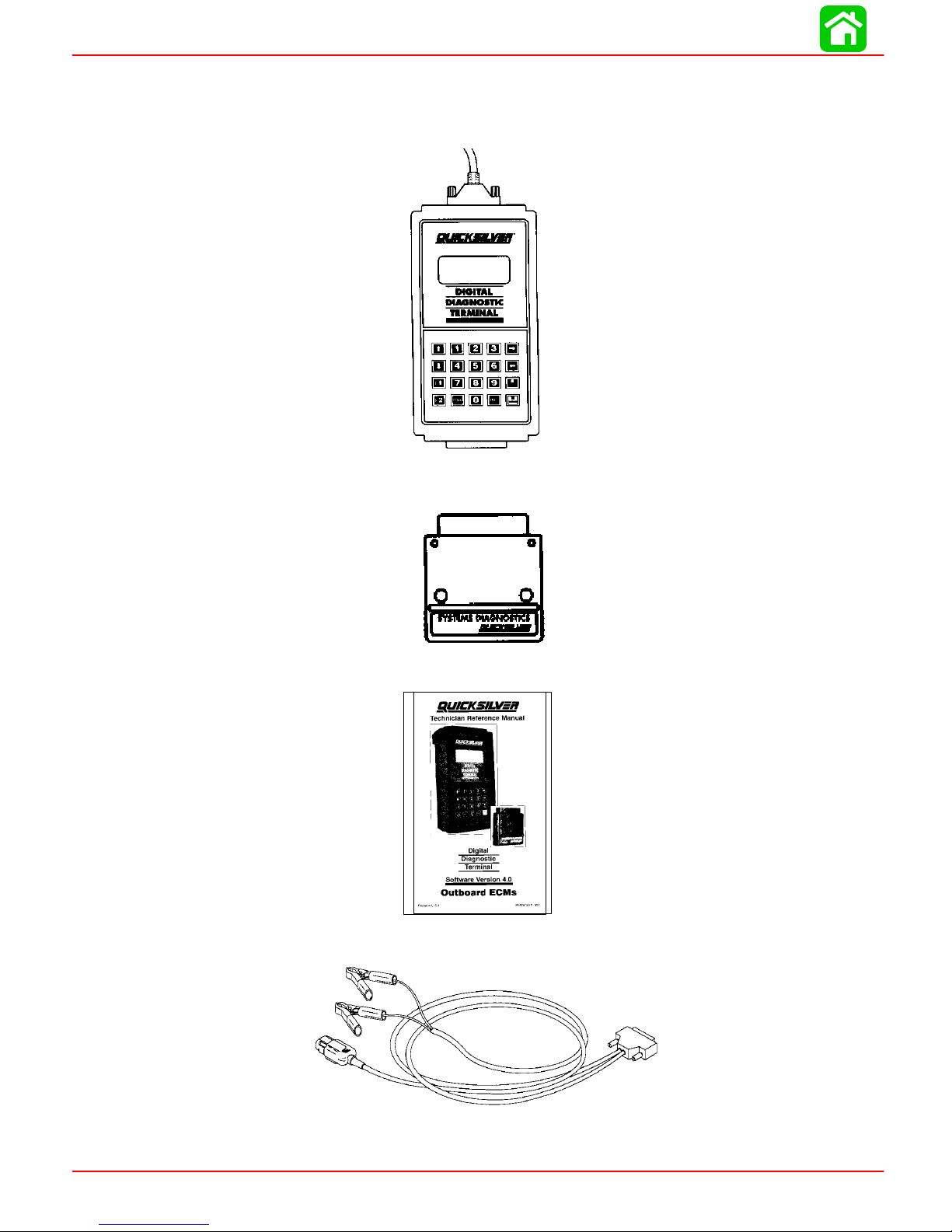

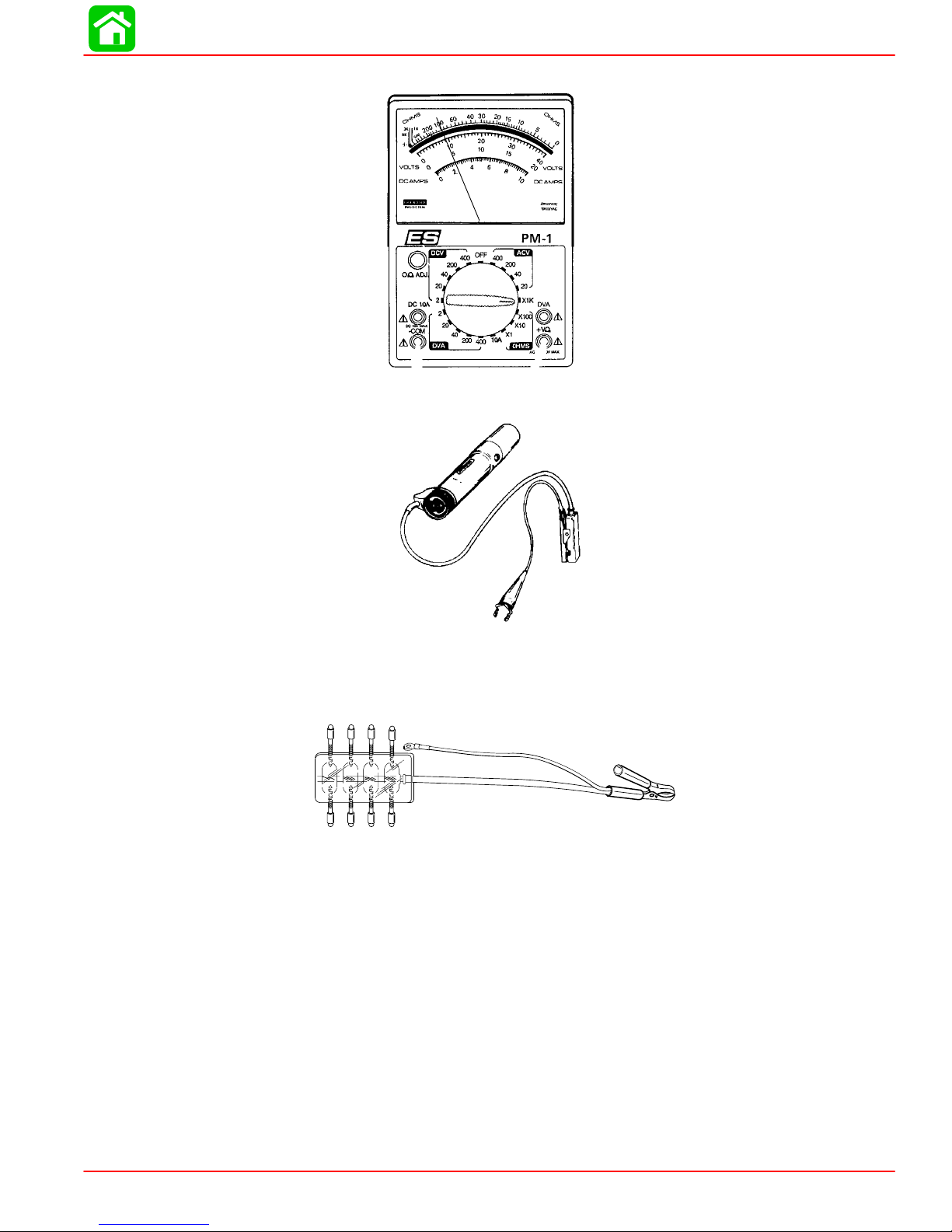

Special Tools

1. Grease Gun 91-37299A1

2. Flushing Attachment 44357A2

Quicksilver Lubricant/Sealant

1. Gear Lubricant - Premium Blend 92-19007A24

Page 1B-2 90-855347R1 JANUARY 1999

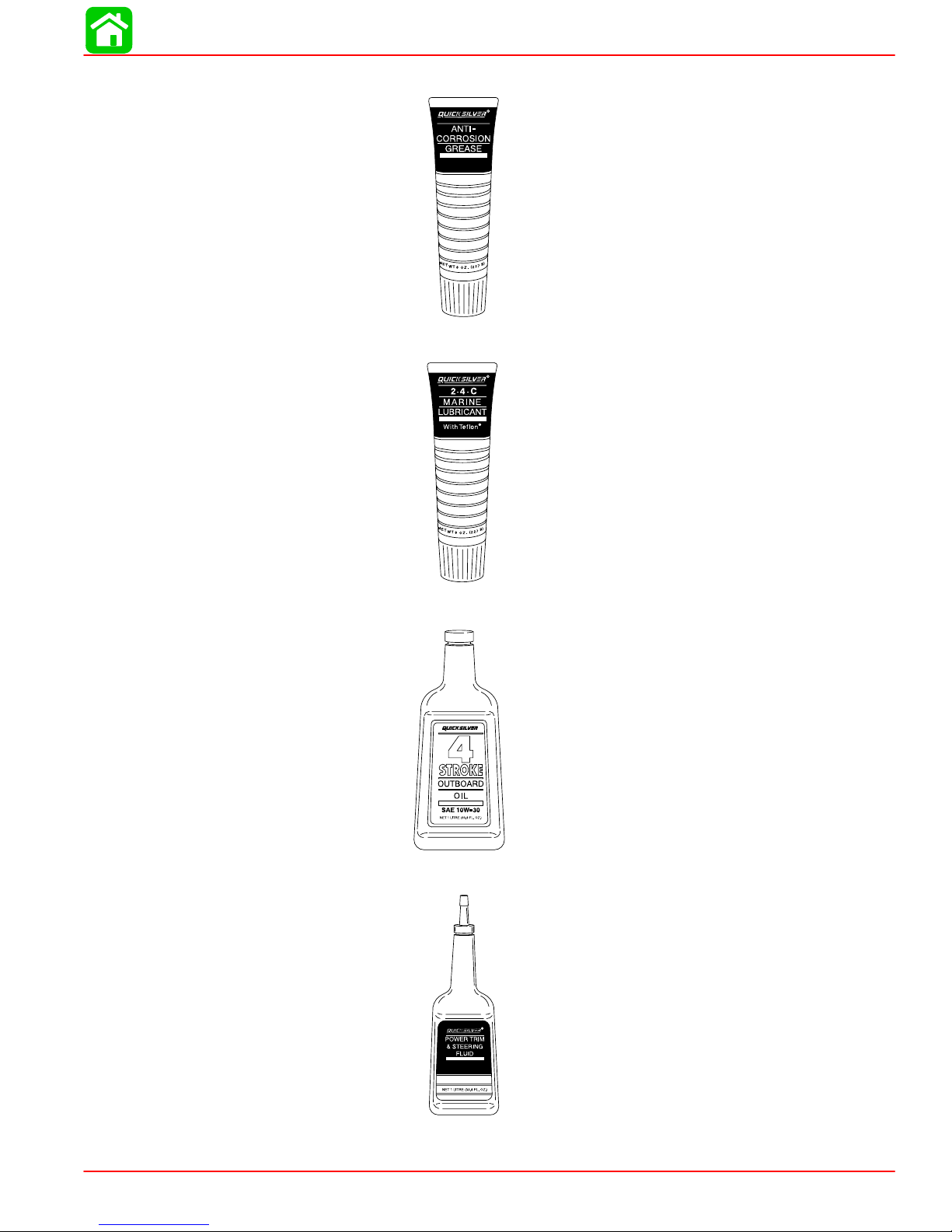

Page 10

2. Anti-Corrosion Grease 92-78376A6

3. 2-4-C Marine Lubricant with Teflon 92-825407A12

MAINTENANCE

4. SAE 30W Motor Oil (Obtain Locally)

5. Quicksilver Power Trim and Steering Fluid 91-90100A12)

90-855347R1 JANUARY 1999 Page 1B-3

Page 11

MAINTENANCE

Inspection and Maintenance Schedule

Before Each Use

1. Check that lanyard stop switch stops the engine.

2. Visually inspect the fuel system for deterioration or leaks.

3. Check outboard for tightness on transom.

4. Check steering system for binding or loose components.

5. Visually check steering link rod fasteners for proper tightness.

6. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operating in salt or polluted water.

2. Wash off all salt deposits and flush out the exhaust outlet of the propeller and gear

case with fresh water if operating in salt water.

Every 100 Hours of Use or Once yearly, Whichever occurs first

1. Lubricate all lubrication points. Lubricate more frequently when used in salt water.

2. Inspect and clean spark plugs.

3. Replace water separating fuel filter

4. Replace compressor air intake filter.

5. Check corrosion control anodes. Check more frequently when used in salt water.

6. Drain and replace gear case lubricant.

7. Lubricate splines on the drive shaft.

8. Check power trim fluid.

9. Inspect battery.

10. Check control cable adjustments.

11. Remove engine deposits with Quicksilver Power Tune Engine Cleaner.

12. Check tightness of bolts, nuts, and other fasteners.

13. Replace water pump impeller (more often if overheating occurs or reduced water

pressure is noted).

These items should be serviced by an authorized dealer.

∗

∗

∗

∗

Page 1B-4 90-855347R1 JANUARY 1999

Page 12

Flushing Engine

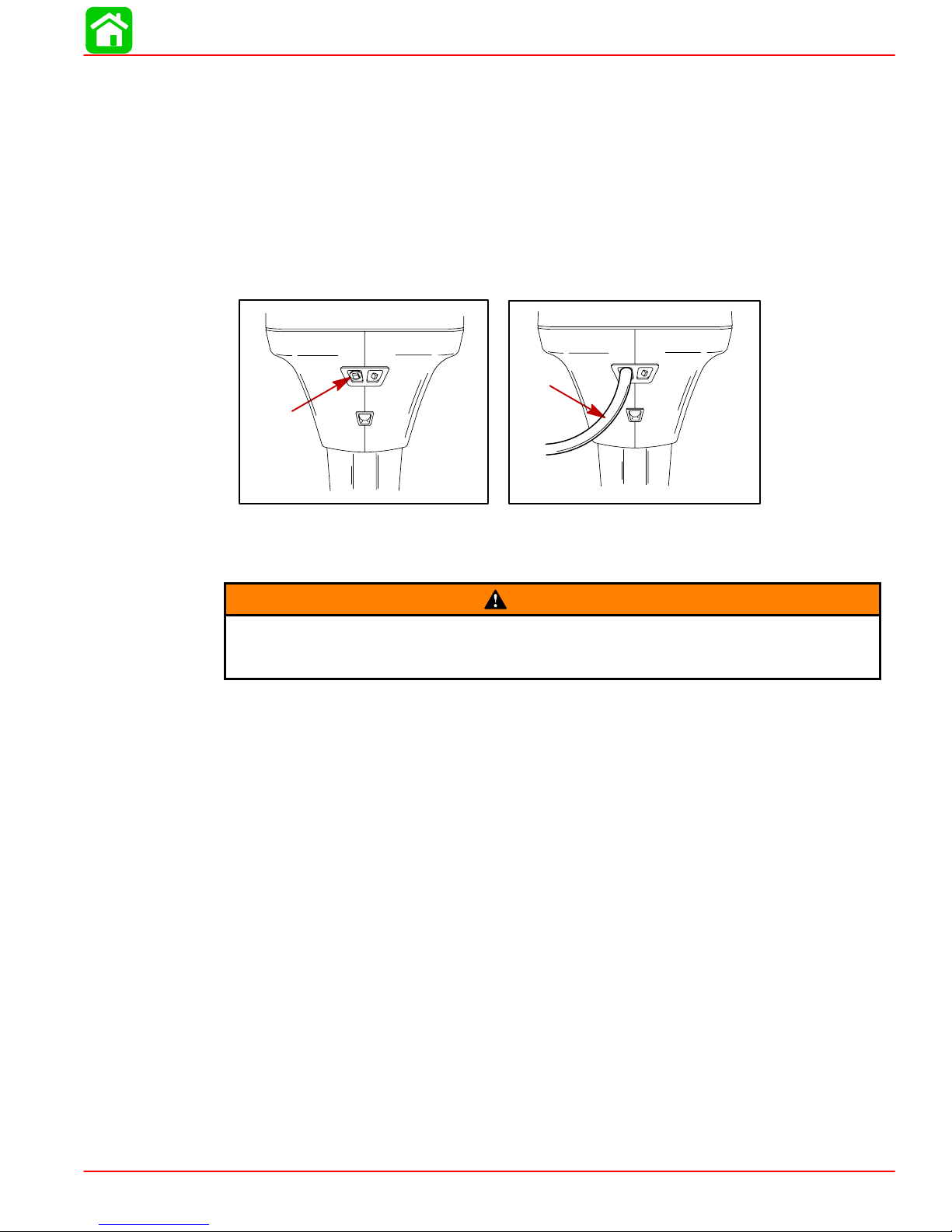

Flushing Cooling System – Using Cowl Flush Plug

Flush the internal water passages of the outboard with fresh water after each use in salt,

polluted or muddy water. This will help prevent a buildup of deposits from clogging the

internal water passages.

NOTE: Engine can be stopped or running at idle speed when flushing the cooling system.

Do not flush engine using a water system that exceeds 45 psi.

1. Remove the plug from fitting in the bottom cowl.

MAINTENANCE

2. Attach a water hose to the fitting. Turn water on and flush for 3 to 5 minutes.

Flushing Cooling System – Using Flushing Attachment 44357A2

WARNING

When flushing, verify that area in vicinity of propeller is clear and that no person

is standing nearby – to avoid possible injury . It is recommended to remove propeller as a precautionary measure.

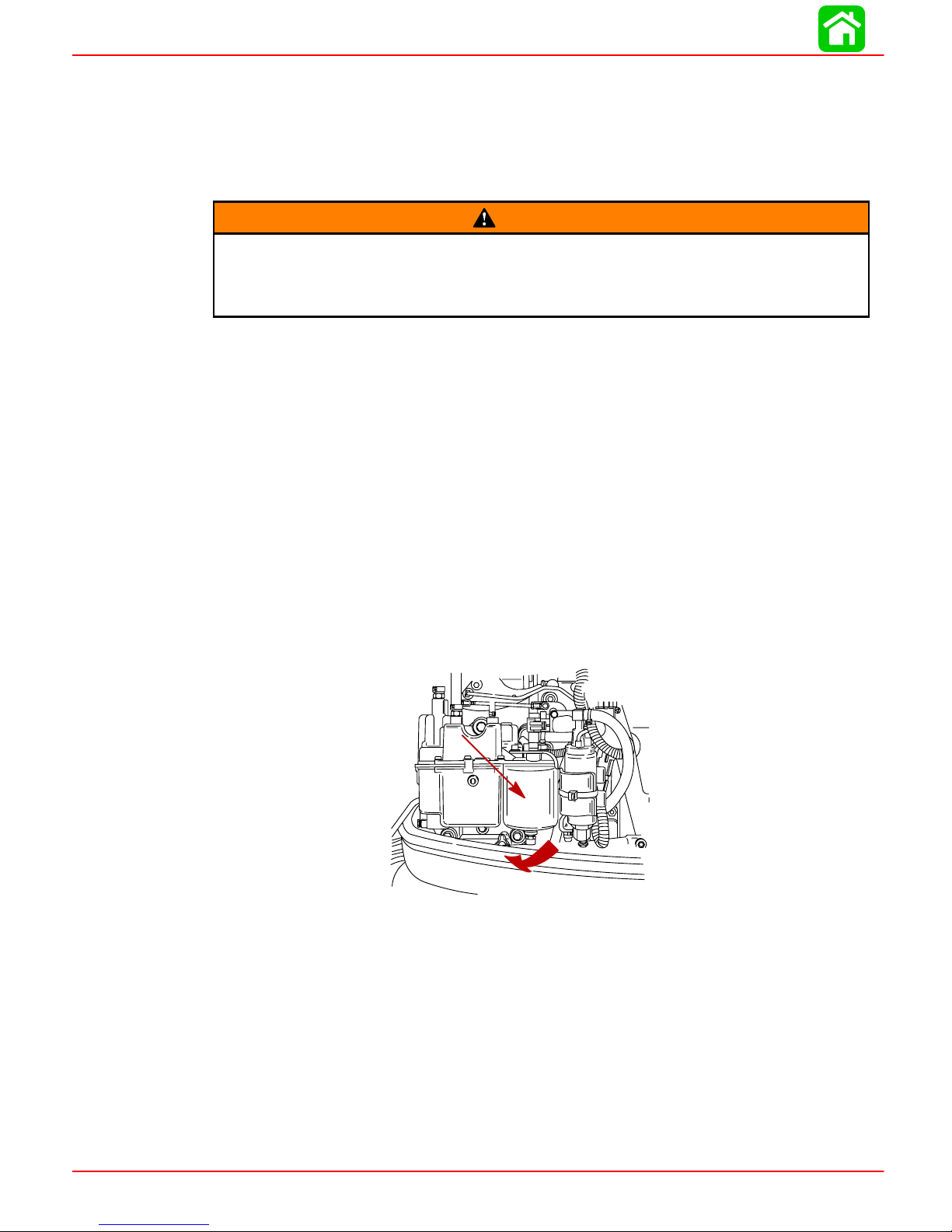

1. Install Quicksilver Flushing Attachment 44357A2 (or equivalent tool) on the gear

housing from the FRONT side, positioning the rubber cups over the water intake

openings.

2. Connect hose [1/2 in. (12.7mm) I.D. or larger] between flushing attachment and water

tap.

IMPORTANT: To prevent water pump damage, do not start or run engine unless

cooling water is flowing.

3. With the outboard in the normal operating position (vertical), partially open water tap

(IT IS NOT NECESSARY to use full water pressure) and adjust water flow so that

there is a significant water loss around the rubber cups.

4. Start engine and idle in NEUTRAL. Increase engine speed, not to exceed 2500 RPM.

5. Flush or service engine as required. Verify adequate cooling water is provided.

a. Water must be discharged thru “tell tale.”

IMPORT ANT: Prevent engine overheating. If water flow is insufficient, stop engine

and determine cause before continuing.

b. Flush until discharge water is clear. In salt-water areas, run outboard 3 to 5 min-

utes.

c. Stop engine before turning off water.

6. Stop engine, turn water off and remove flushing attachment from gear housing.

90-855347R1 JANUARY 1999 Page 1B-5

Page 13

MAINTENANCE

IMPORTANT: While and after flushing, keep outboard in upright position until all

water has drained from drive shaft housing to prevent water from entering the powerhead via drive shaft housing and exhaust ports.

Fuel System

Avoid serious injury or death from gasoline fire or explosion. Carefully follow all

fuel system service instructions. Always stop the engine and DO NOT smoke or

allow open flames or sparks in the area while servicing any part of the fuel system.

Before servicing any part of the fuel system, stop engine and disconnect the battery . Drain

the fuel system completely . Use an approved container to collect and store fuel. Wipe up

any spillage immediately . Material used to contain spillage must be disposed of in an approved receptacle. Any fuel system service must be performed in a well ventilated area.

Inspect any completed service work for sign of fuel leakage.

Fuel Line Inspection

Visually inspect the fuel line and primer bulb for cracks, swelling, leaks, hardness, or other

signs of deterioration or damage. If any of these conditions is found, the fuel line or primer

bulb must be replaced.

WARNING

Water Separating Fuel Filter

NOTE: The warning system will turn on when water in the fuel filter reaches the full level.

1. This filter removes moisture and also debris from the fuel. If the filter becomes filled

with water, the water can be removed. If the filter becomes plugged with debris, the

filter must be replaced with a new filter.

Remove and replace filter as follows:

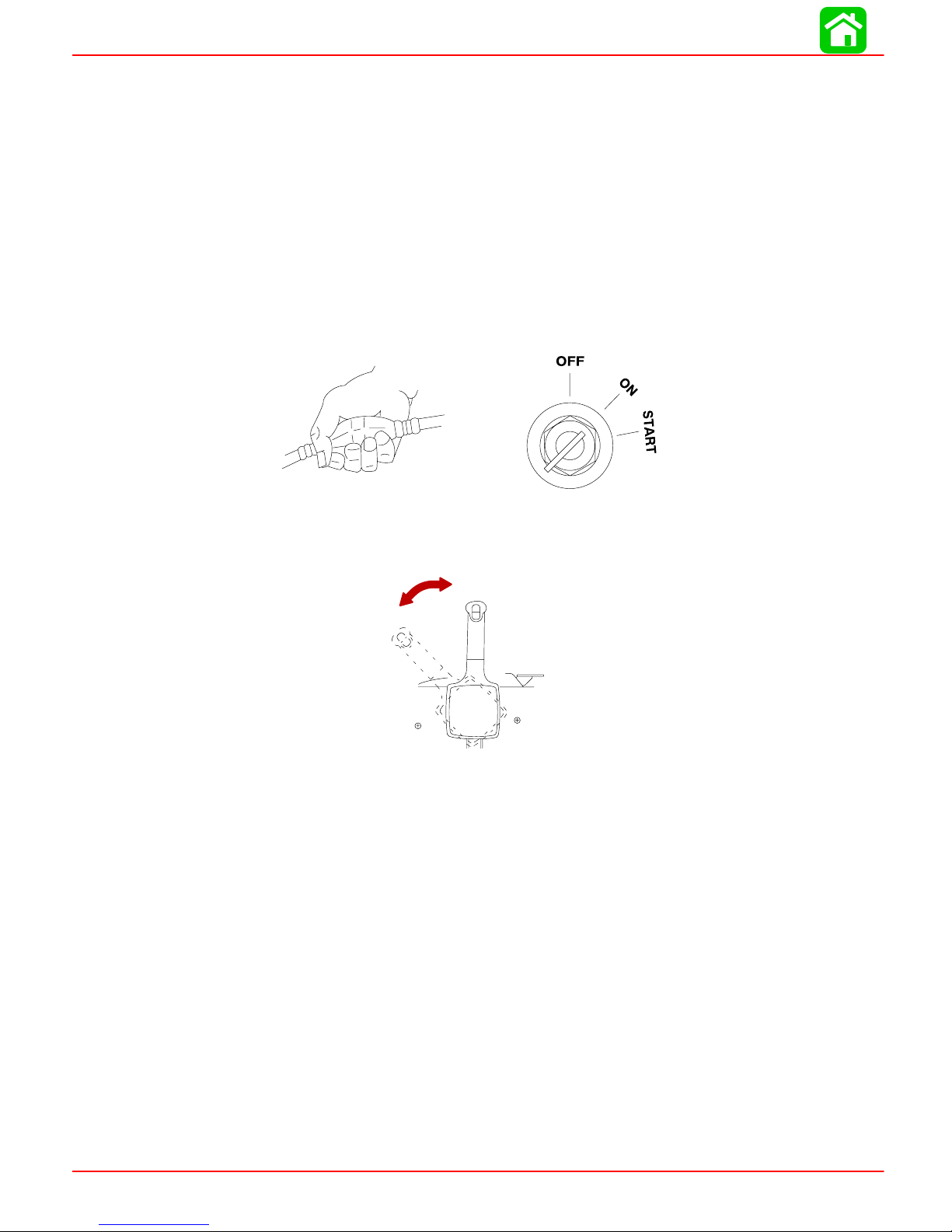

a. Turn ignition key switch to OFF position.

b. Disconnect wire at bottom of filter.

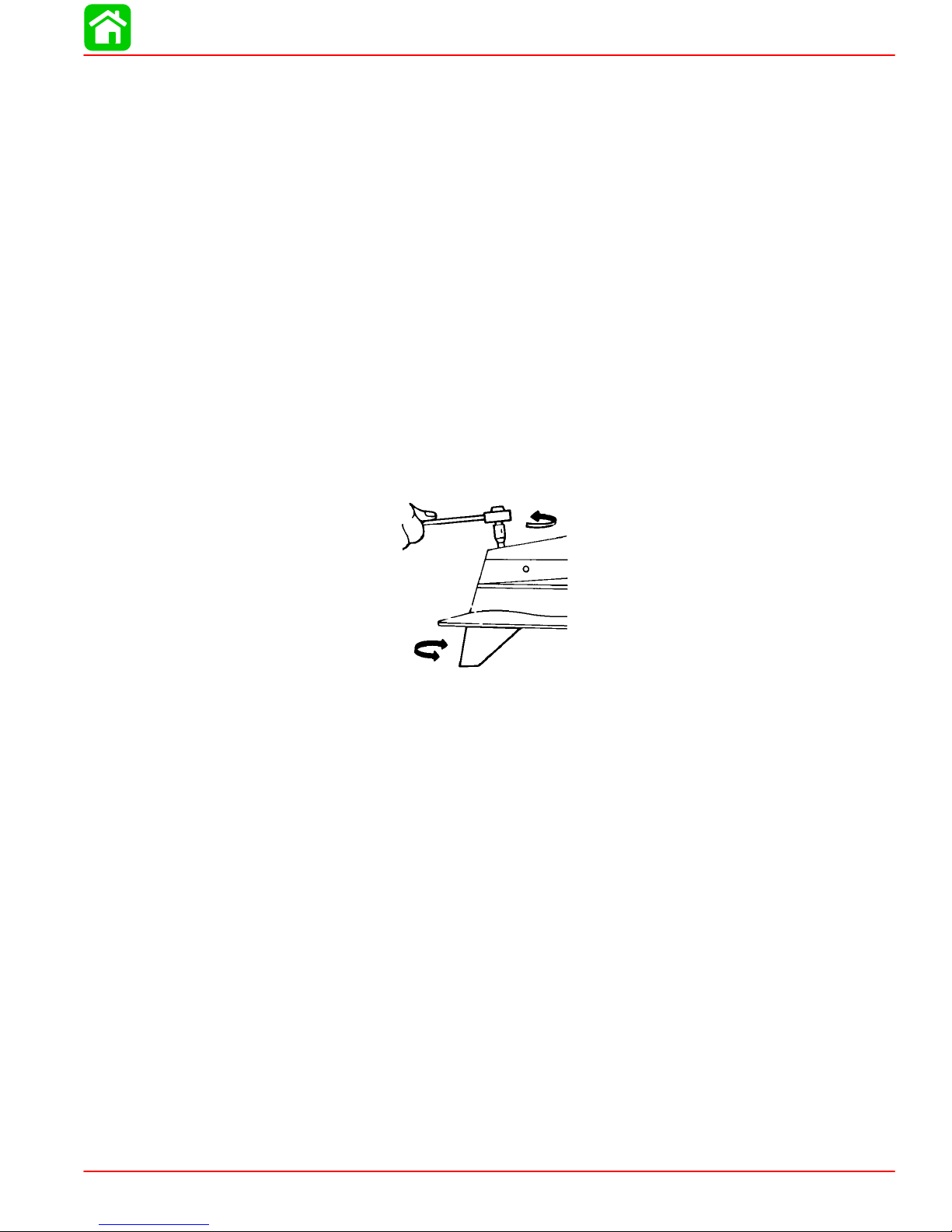

c. Remove filter by turning the filter in the direction of the arrow (clockwise). Tip the

filter to drain fluid in a suitable container.

d. Lubricate the sealing ring on the filter with oil. Thread on the filter and tighten se-

curely by hand. Reconnect the wire to the filter.

IMPORT ANT : Visually inspect for fuel leakage from the filter by squeezing the primer bulb until firm, forcing fuel into the filter.

Page 1B-6 90-855347R1 JANUARY 1999

Page 14

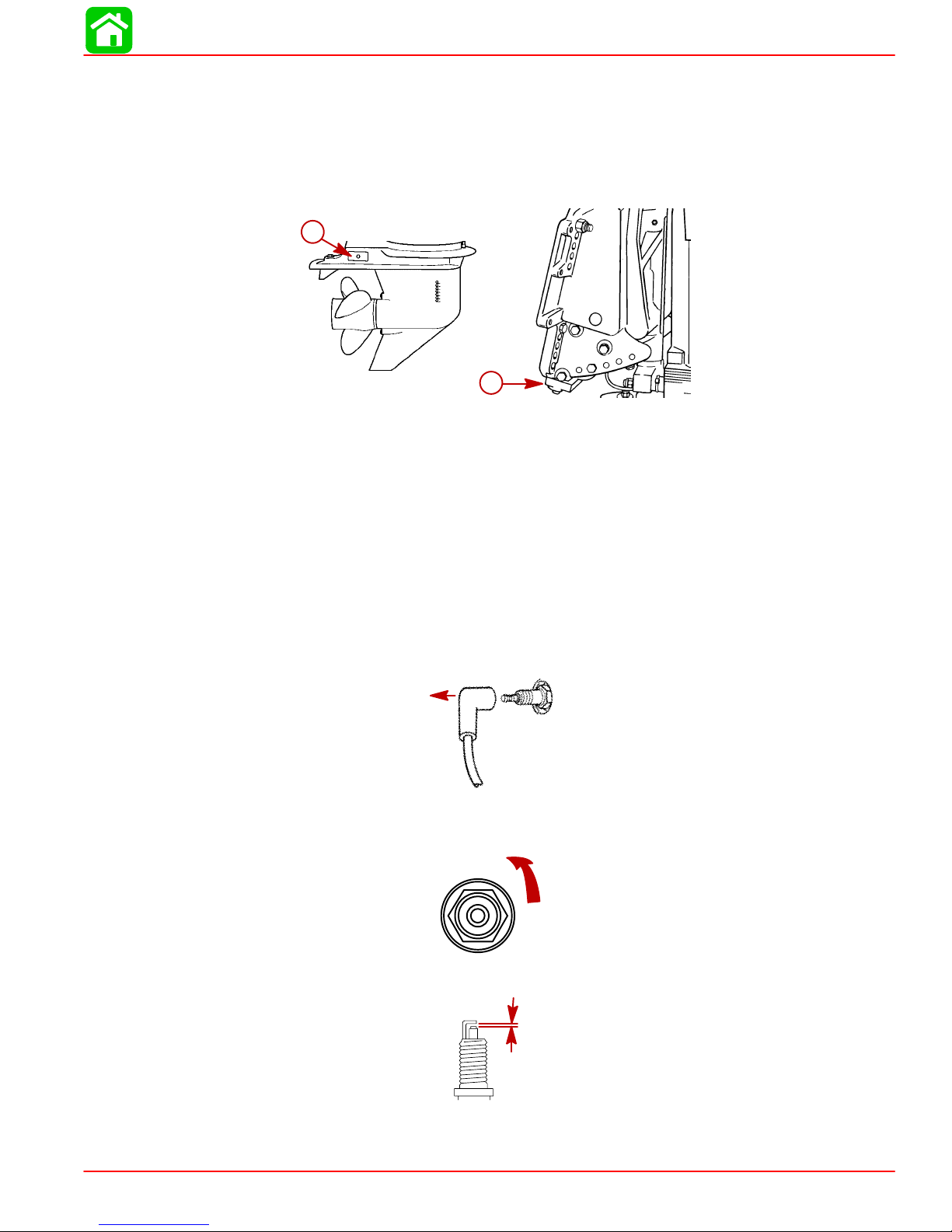

Corrosion Control Anode

The gear case has two corrosion control anodes (a). Another anode (b) is installed on the

bottom of the transom bracket assembly. An anode helps protect the outboard against

galvanic corrosion by sacrificing its metal to be slowly eroded instead of the outboard

metals.

a

Each anode requires periodic inspection especially in salt water which will accelerate the

erosion. T o maintain this corrosion protection, always replace the anode before it is completely eroded. Never paint or apply a protective coating on the anode as this will reduce

effectiveness of the anode.

MAINTENANCE

b

Spark Plug Inspection

Inspect spark plugs at the recommended intervals.

1. Remove the spark plug leads by twisting the rubber boots slightly and pull off. Inspect

spark plug boots and replace if cracked.

2. Remove the spark plugs to inspect and clean. Replace spark plug if electrode is worn

or the insulator is rough, cracked, broken, blistered or fouled.

3. Set the spark plug gap. See Specification Chart in General Information Section.

4. Before reinstalling spark plugs, clean away dirt on the spark plug seats. Install plugs

finger tight, and tighten 1/4 turn or torque to 20 lb. ft. (27 N·m).

90-855347R1 JANUARY 1999 Page 1B-7

Page 15

MAINTENANCE

Battery Inspection

The battery should be inspected at periodic intervals to ensure proper engine starting

capability.

IMPORTANT: Read the safety and maintenance instructions which accompany

your battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Battery cable terminals should be clean, tight, and correctly installed. Positive to positive and negative to negative.

5. Make sure the battery is equipped with a nonconductive shield to prevent accidental

shorting of battery terminals.

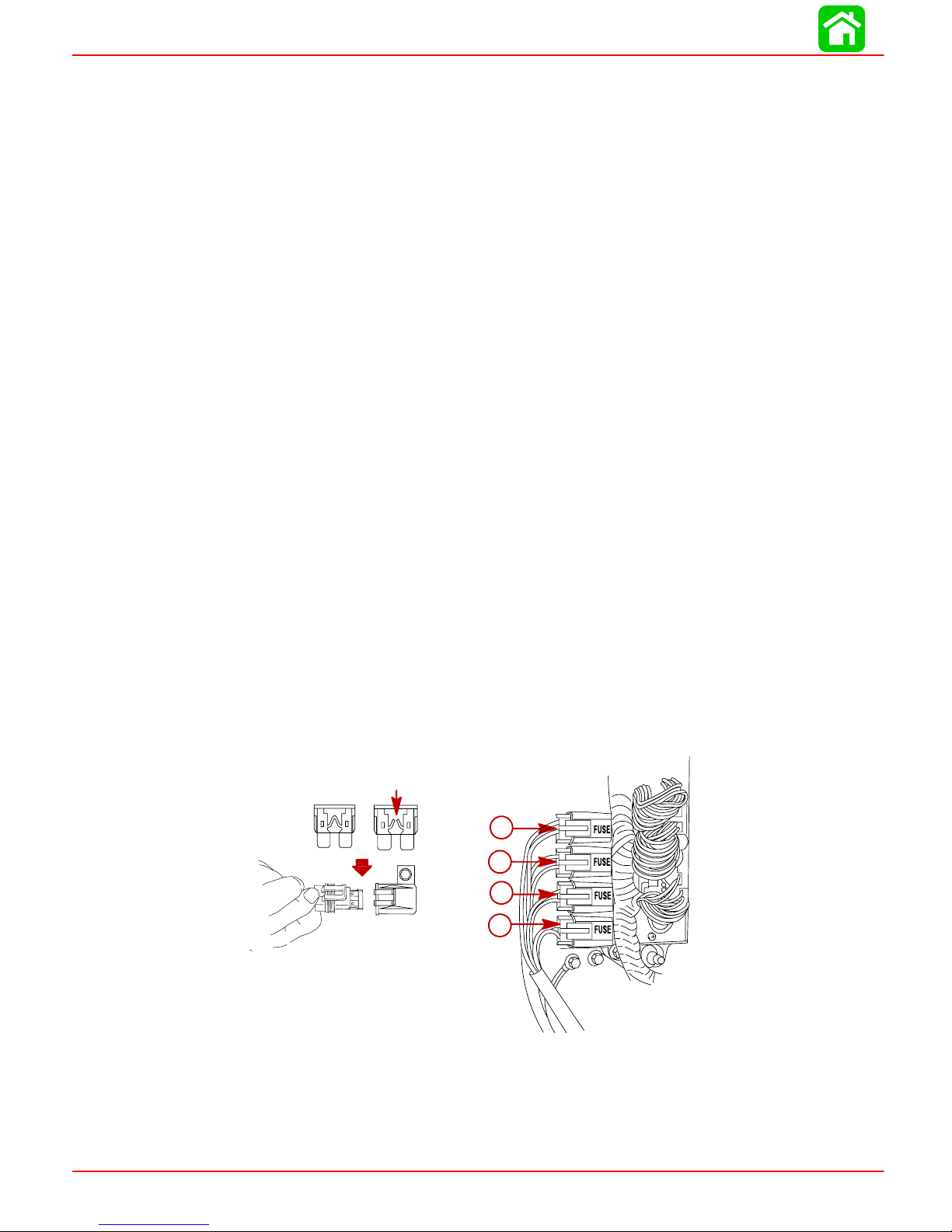

Fuse Replacement

IMPORTANT: Always carry spare SFE 20 AMP fuses.

The electrical wiring circuits on the outboard are protected from overload by fuses in the

wiring. If a fuse is blown, try to locate and correct the cause of the overload. If the cause

is not found, the fuse may blow again.

1. Open the fuse holder and look at the silver colored band inside the fuse. If band is

broken, replace the fuse. Replace fuse with a new fuse with the same rating.

2. The fuses and circuits are identified as follows:

a. Electric Fuel Pump Circuit – SFE 20 AMP Fuse.

b. Fuel/Air Injector Circuits – SFE 20 AMP Fuse.

c. Starting Circuit – SFE 20 AMP Fuse.

d. Ignition Coil/Oil Pump Circuit – SFE 20 AMP Fuse.

a

b

c

d

Page 1B-8 90-855347R1 JANUARY 1999

Page 16

Compressor Air intake Filter

The filter should be changed every 100 hours of operation, or once a season. Never run

the engine without the air filter.

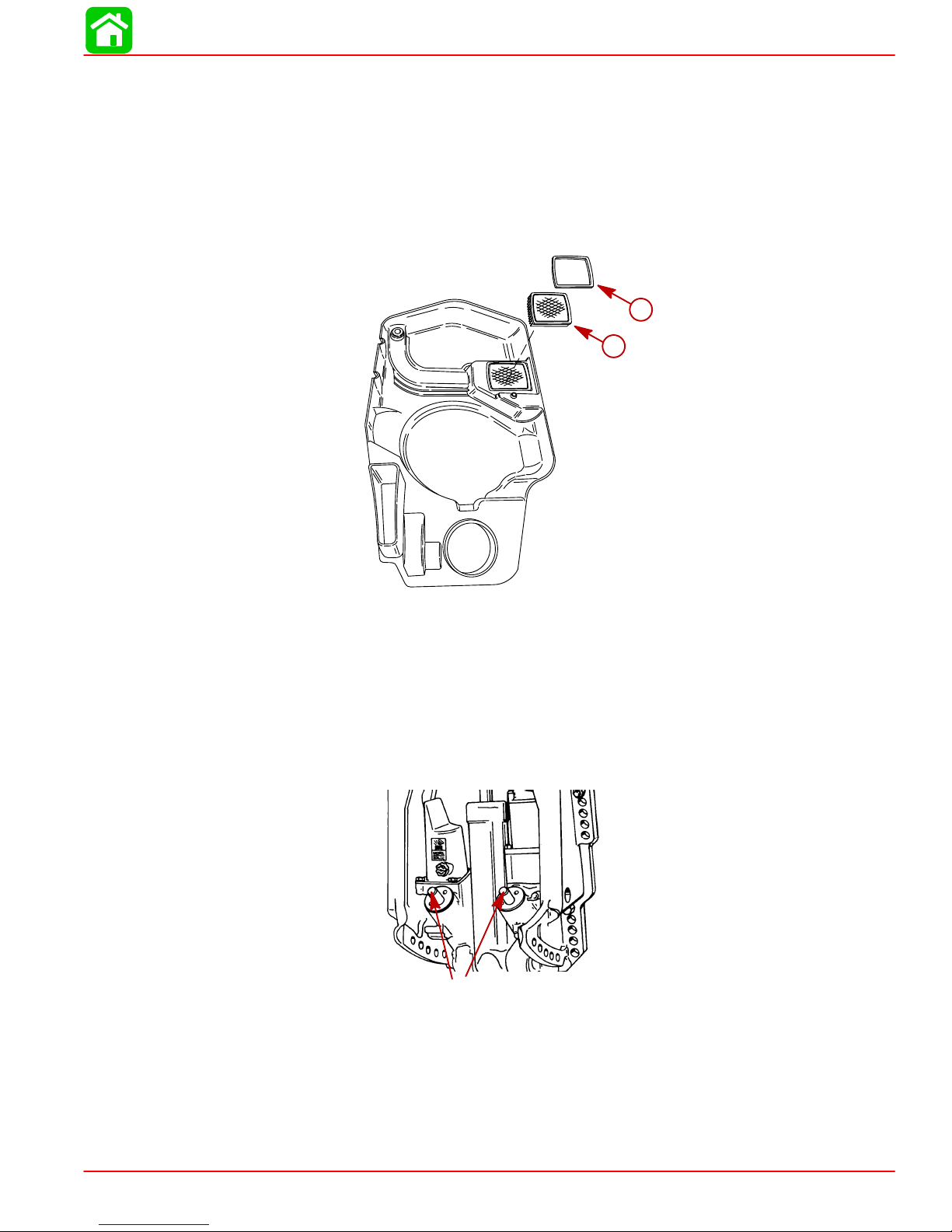

Removal

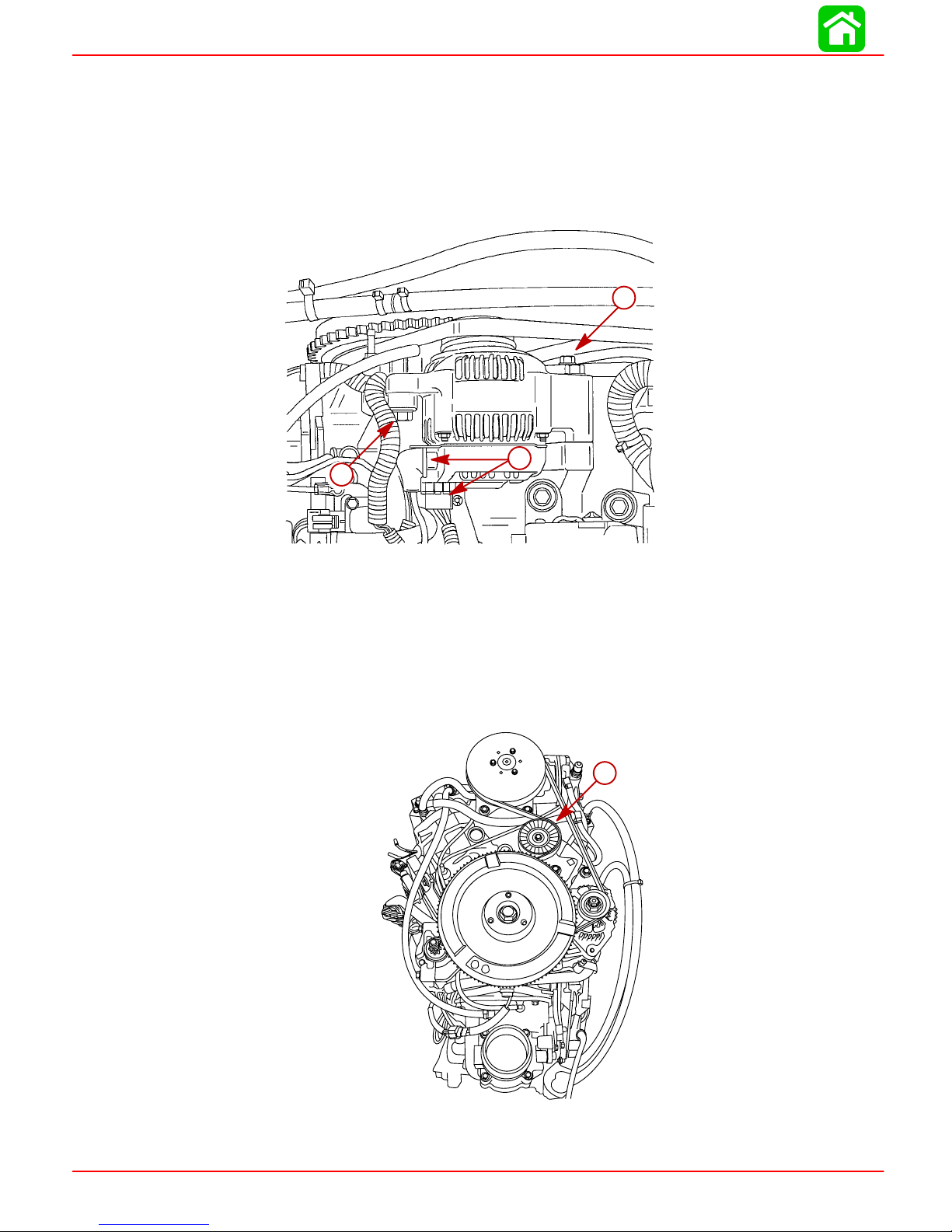

1. Remove flywheel cover from the engine. Snap out the retainer (a) and remove filter

(b).

MAINTENANCE

a

b

Installation

Install filter (b) into the cover. Secure filter into cover with retainer (a).

Lubrication Points

Lubricate Point 1 with Quicksilver Special Lubricant 101.

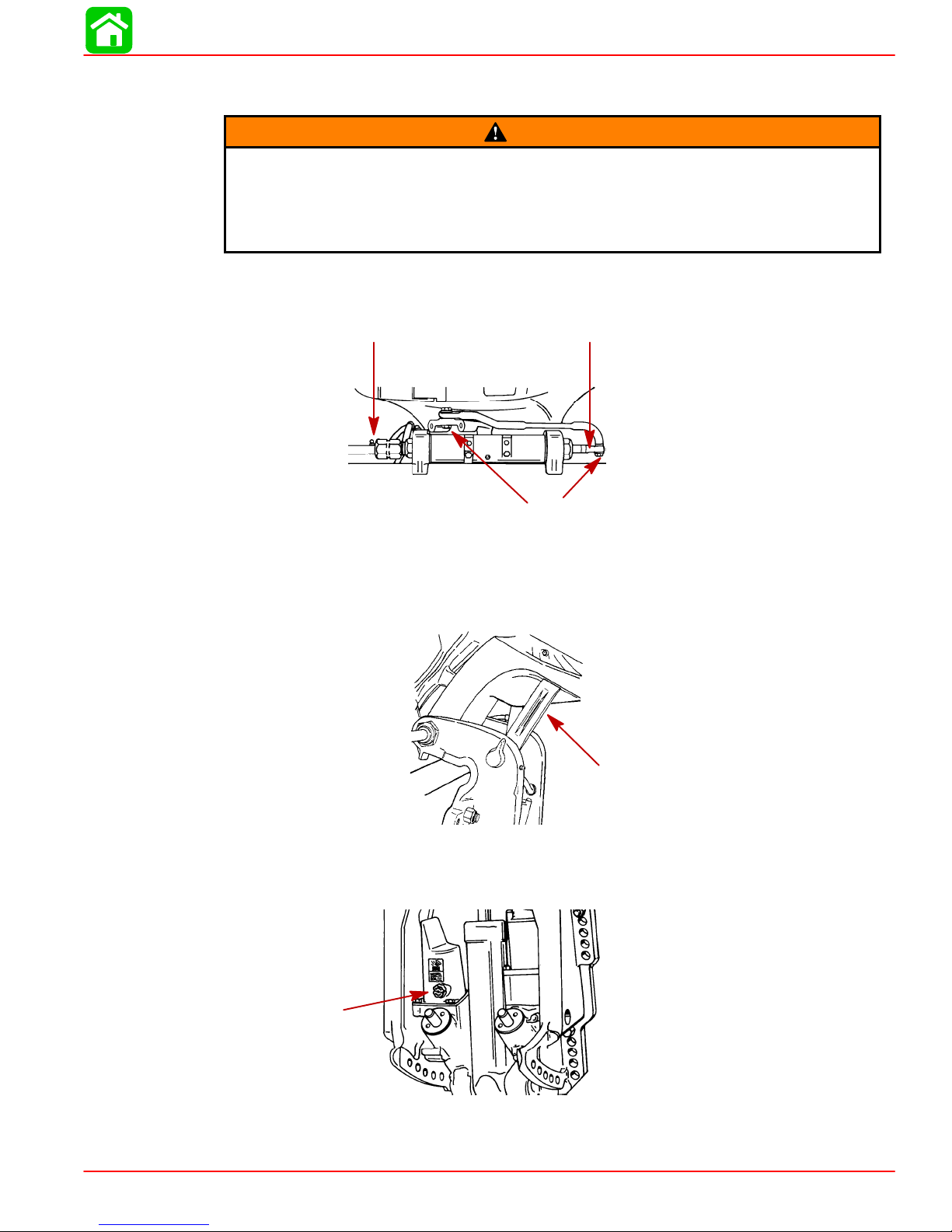

1. Trim Rod Ball Ends – Turn the ball ends to work the lubricant into the ball sockets.

1

90-855347R1 JANUARY 1999 Page 1B-9

Page 17

MAINTENANCE

Lubricate Point 2 with Quicksilver Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

2. Propeller Shaft – Refer to Propeller Replacement for removal and installation of the

propeller. Coat the entire propeller shaft with lubricant to prevent the propeller hub

from corroding and seizing to the shaft.

2

Lubricate Points 3 thru 6 with Quicksilver 2-4-C Marine Lubricant with Teflon or Special

Lubricate 101.

3. Swivel Bracket – Lubricate through fitting.

4. Tilt Support Lever – Lubricate through fitting.

5. Tilt Tube – Lubricate through fitting.

5

3

4

Page 1B-10 90-855347R1 JANUARY 1999

Page 18

6. Steering Cable Grease Fitting (If Equipped) – Rotate steering wheel to fully retract the

steering cable end (a) into the outboard tilt tube. Lubricate through fitting (b).

The end of the steering cable must be fully retracted into the outboard tilt tube

before adding lubricant. Adding lubricant to steering cable when fully extended

could cause steering cable to become hydraulically locked. An hydraulically

locked steering cable will cause loss of steering control, possibly resulting in serious injury or death.

Lubricate Points 7 With Light Weight Oil.

7. Steering Link Rod Pivot Points – Lubricate pivot points.

MAINTENANCE

WARNING

6-b

Checking Power Trim Fluid

8. Tilt outboard to the full up position and engage the tilt support lock.

6-a

7

8

9. Remove fill cap and check fluid level. The fluid level should be even with the bottom

of the fill hole. Add Quicksilver Power Trim & Steering Fluid. If not available, use automotive (ATF) automatic transmission fluid.

90-855347R1 JANUARY 1999 Page 1B-1 1

9

Page 19

MAINTENANCE

Gear Case Lubrication

When adding or changing gear case lubricant, visually check for the presence of water

in the lubricant. If water is present, it may have settled to the bottom and will drain out prior

to the lubricant, or it may be mixed with the lubricant, giving it a milky colored appearance.

If water is noticed, have the gear case checked by your dealer.W ater in the lubricant may

result in premature bearing failure or, in freezing temperatures, will turn to ice and damage

the gear case.

Whenever you remove the fill/drain plug, examine the magnetic end for metal particles.

A small amount of metal filings or fine metal particles indicates normal gear wear. An excessive amount of metal filings or larger particles (chips) may indicate abnormal gear

wear and should be checked by an authorized dealer.

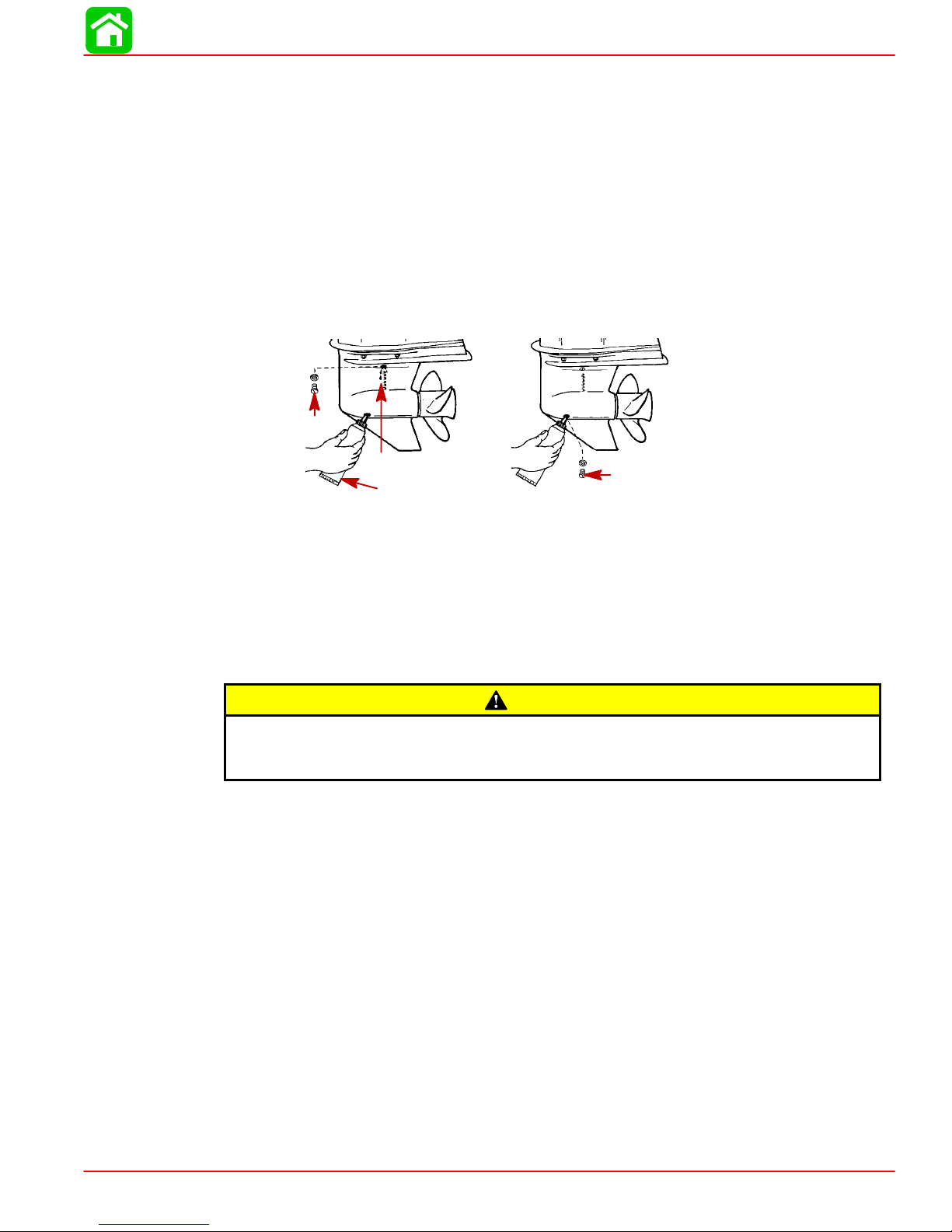

DRAINING GEAR CASE

NOTE: Some models may have the vent and fill/drain plugs on the opposite side.

1. Place outboard in a vertical operating position.

2. Place drain pan below outboard.

3. Remove vent plug and fill/drain plug and drain lubricant.

3

2

GEAR CASE LUBRICANT CAPACITY

Gear case lubricant capacity is approximately 22.5 fl. oz. (666 ml).

1

Page 1B-12 90-855347R1 JANUARY 1999

Page 20

CHECKING GEAR CASE LUBRICANT LEVEL AND REFILLING GEAR CASE

NOTE: Some models may have the vent and fill/drain plugs on the opposite side.

1. Place outboard in a vertical operating position.

2. Remove vent plug (a).

3. Place lubricant tube (b) into the fill hole and add lubricant until it appears at the vent

hole (c).

IMPORTANT: Replace sealing washers if damaged.

4. Stop adding lubricant. Install the vent plug and sealing washer (a) before removing

the lubricant tube.

5. Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer (d).

a

MAINTENANCE

c

1-5

b

STORAGE PREPARATION

The major consideration in preparing your outboard for storage is to protect it from rust,

corrosion, and damage caused by freezing of trapped water.

The following storage procedures should be followed to prepare your outboard for out of

season storage or prolonged storage (two months or longer).

Never start or run your outboard (even momentarily) without water circulating

through all the cooling water intake holes in the gear case to prevent damage to

the water pump (running dry) or overheating of the engine.

FUEL SYSTEM

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause a formation of acid during storage and can damage the fuel system. If the gasoline being used contains alcohol, it is advisable to drain as much of the remaining gasoline as possible from the fuel tank, remote fuel line, and engine fuel system.

d

CAUTION

Fill the fuel system (tank, hoses, fuel pumps, and fuel injection systems) with treated (stabilized) fuel to help prevent formation of varnish and gum. Proceed with following instructions.

1. Portable Fuel T ank – Pour the required amount of Quicksilver Gasoline Stabilizer (follow instructions on container) into fuel tank. Tip fuel tank back and forth to mix stabilizer with the fuel.

2. Permanently Installed Fuel Tank – Pour the required amount of Quicksilver Gasoline

Stabilizer (follow instructions on container) into a separate container and mix with approximately one quart (one liter) of gasoline. Pour this mixture into fuel tank.

90-855347R1 JANUARY 1999 Page 1B-13

Page 21

MAINTENANCE

3. Place the outboard in water or connect flushing attachment for circulating cooling

water. Run the engine at 2000 rpm for 25 minutes to allow treated fuel to fill the fuel

system.

PROTECTING INTERNAL ENGINE COMPONENTS

NOTE: Make sure the fuel system has been prepared for storage.

1. Remove the spark plugs and add approximately one ounce (30ml) of engine oil into

each spark plug hole. Rotate the flywheel manually several times to distribute the oil

in the cylinders. Reinstall spark plugs.

2. Remove the water separating fuel filter and empty contents into a suitable container.

Refer to Maintenance Section for removal and installation of filter. Replace fuel filter

annually , or every 100 Hours of operation, or if large amount of fuel contamination is

present.

PROTECTING EXTERNAL OUTBOARD COMPONENTS

1. Lubricate all outboard components listed in the Inspection and Maintenance

Schedule.

2. Touch up any paint nicks. See your dealer for touch-up paint.

3. Spray Quicksilver Corrosion Guard on external metal surfaces (except corrosion control anodes).

GEAR CASE

Drain and refill the gear case lubricant (refer to maintenance procedure).

POSITIONING OUTBOARD FOR STORAGE

Store outboard in an upright (vertical) position to allow water to drain out of outboard.

If outboard is stored tilted up in freezing temperature, trapped cooling water or

rain water that may have entered the propeller exhaust outlet in the gear case

could freeze and cause damage to the outboard.

BATTERY STORAGE

1. Follow the battery manufacturers instructions for storage and recharging.

2. Remove the battery from the boat and check water level. Recharge if necessary.

3. Store the battery in a cool, dry place.

4. Periodically check the water level and recharge the battery during storage.

CAUTION

Page 1B-14 90-855347R1 JANUARY 1999

Page 22

GENERAL INFORMATION

IMPORTANT INFORMATION

Section 1C - General Information

Table of Contents

Serial Number Location 1C-1. . . . . . . . . . . . . . . . . . . . . . .

Conditions Affecting Performance 1C-2. . . . . . . . . . . . . .

Weather 1C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boat 1C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trim 1C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 1C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Compression 1C-6. . . . . . . . . . . . . . . . . . . . . . .

Following Complete Submersion 1C-7. . . . . . . . . . . . . . .

Salt Water Submersion 1C-7. . . . . . . . . . . . . . . . . . . . .

Submerged While Running 1C-7. . . . . . . . . . . . . . . . .

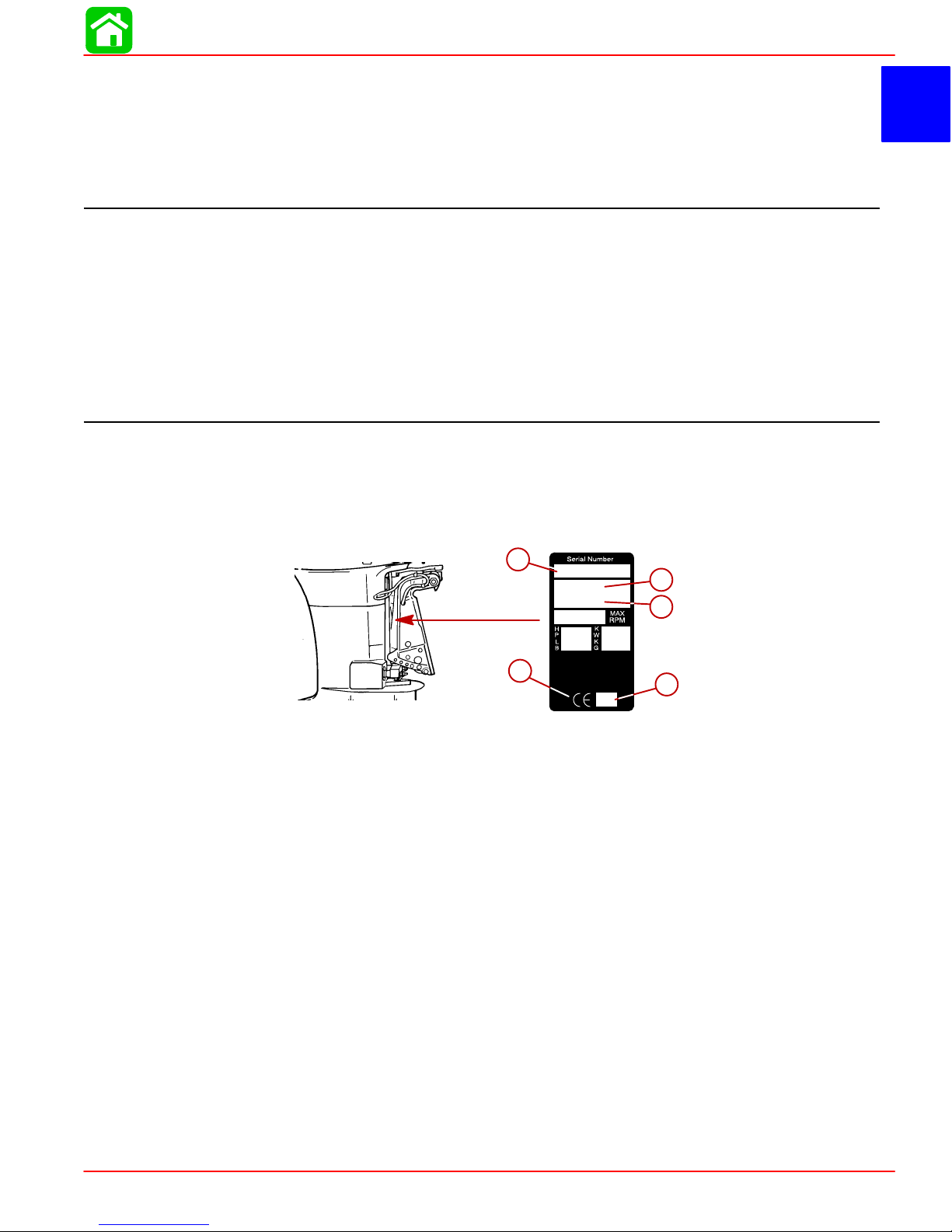

Serial Number Location

The engine serial number is located on the lower starboard side of the engine block. A

serial number is also located on the starboard side of the swivel bracket.

1

C

Model 135/150 DFI Powerhead Front View 1C-9. . . . . .

Model 135/150 DFI Powerhead Starboard View 1C-10

Model 135/150 DFI Powerhead Port View 1C-11. . . . . .

Model 135/150 DFI Powerhead Top View 1C-12. . . . . .

Model 135/150 DFI Powerhead Aft View 1C-13. . . . . .

Painting Procedures 1C-14. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning & Painting Aluminum Propellers & Gear

Housings 1C-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Application 1C-15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Removal 1C-15. . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions for “Wet” Application 1C-15. . . . . . . . . .

a-Serial Number

b-Model Year

c-Model Description

d-Year Manufactured

e-Certified Europe Insignia

a

OGXXXXXX

19XX

XXXX

b

c

e

XX

d

90-855347R1 JANUARY 1999 Page 1C-1

Page 23

GENERAL INFORMATION

Conditions Affecting Performance

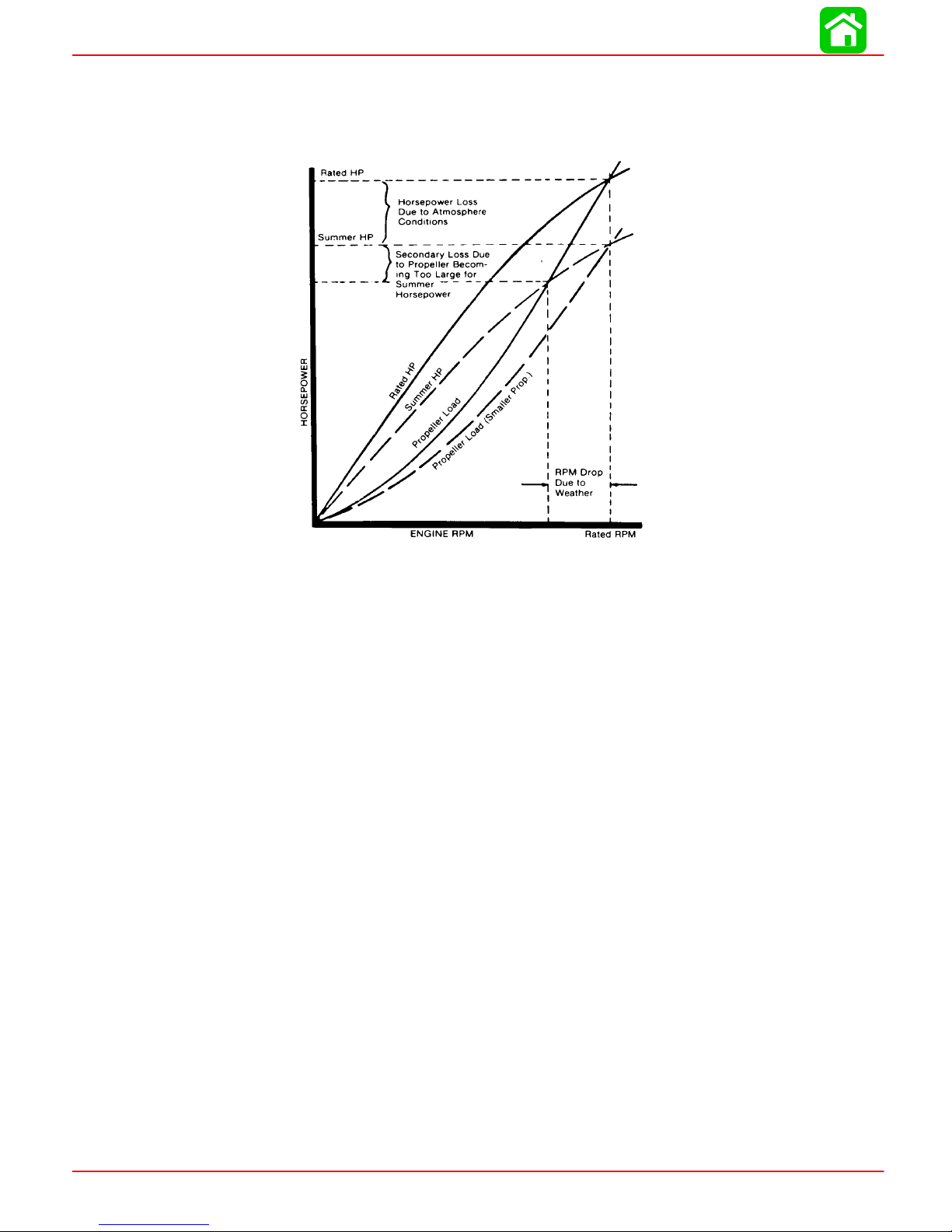

Weather

Weather conditions exert a profound effect on power output of internal combustion engines. Established horsepower ratings refer to the power that the engine will produce at

its rated RPM under a specific combination of weather conditions.

Corporations internationally have settled on adoption of I.S.O. (International Standards

Organization) engine test standards, as set forth in I.S.O. 3046 standardizing the computation of horsepower from data obtained on the dynamometer, correcting all values to the

power that the engine will produce at sea level, at 30% relative humidity at 77° F (25°C)

temperature and a barometric pressure of 29.61 inches of mercury.

Summer conditions of high temperature, low barometric pressure and high humidity all

combine to reduce engine power. This is reflected in decreased boat speeds – as much

as 2 or 3 mph. Nothing will regain this speed for the boater but the coming of cool, dry

weather.

In pointing out the consequences of weather effects, an engine – running on a hot, humid

summer day – may lose as much as 14% of the horsepower it would produce on a dry,

brisk spring or fall day. The horsepower that any internal combustion engine produces

depends upon the density of the air that it consumes and this density is dependent upon

the temperature of the air, its barometric pressure and water vapor (or humidity) content.

Accompanying this weather-inspired loss of power is a second but more subtle loss. At

rigging time in early spring, the engine was equipped with a propeller that allowed the

engine to run within its recommended RPM range at full throttle. With the coming of the

summer weather and the consequent drop in available horsepower, this propeller will, in

effect, become too large. Consequently, the engine operates at less than its recommended RPM.

Due to the horsepower/RPM characteristics of an engine, this will result in further loss of

horsepower at the propeller with another decrease in boat speed. This secondary loss

can be regained by switching to a smaller pitch propeller that allows the engine to run

again at recommended RPM.

Page 1C-2 90-855347R1 JANUARY 1999

Page 24

To obtain optimum engine performance under changing weather conditions, the engine

MUST be propped to allow it to operate at or near the top end of the recommended maximum RPM range at wide-open-throttle with a normal boat load.

This will allow the engine to develop full power while operating in an RPM range that discourages damaging detonation.

Boat

WEIGHT DISTRIBUTION

1. Proper positioning of the weight inside the boat (persons and gear) has a significant

effect on the boat’s performance, for example:

a. Shifting weight to the rear (stern)

b. Shifting weight to the front (bow)

GENERAL INFORMATION

(1.)Generally increases top speed.

(2.)If in excess, can cause the boat to porpoise.

(3.)Can make the bow bounce excessively in choppy water.

(4.)Will increase the danger of the following wave splashing into the boat when

coming off plane.

(1.)Improves ease of planing off.

BOTTOM

(2.)Generally improves rough water ride.

(3.)If excessive, can make the boat veer back-and-forth (bow steer).

1. Boat Bottom: For maximum speed, a boat bottom should be nearly a flat plane where

it contacts the water and particularly straight and smooth in fore-and-aft direction.

a. Hook: Exists when bottom is concave in fore-and -aft direction when viewed from

the side. When boat is planing, “hook” causes more lift on bottom near transom

and allows bow to drop, thus greatly increasing wetted surface and reducing boat

speed. “Hook” frequently is caused by supporting boat too far ahead of transom

while hauling on a trailer or during storage.

b. Rocker: The reverse of hook and much less common. “Rocker” exists if bottom

is convex in fore-and-aft direction when viewed from the side, and boat has strong

tendency to porpoise.

c. Surface Roughness: Moss, barnacles, etc., on boat or corrosion of motor’s gear

housing increase skin friction and cause speed loss. Clean surfaces when necessary .

d. Gear Housing: If unit is left in the water, marine vegetation may accumulate over

a period of time. This growth MUST be removed from unit before operation, as it

may clog the water inlet holes in the gear housing and cause the engine to overheat.

90-855347R1 JANUARY 1999 Page 1C-3

Page 25

GENERAL INFORMATION

Trim

TRIMMING OUTBOARD “OUT” (“UP”)

Excessive trim “out” also may reduce the stability of some high speed hulls. T o

correct instability at high speed, reduce the power GRADUALL Y and trim the outboard “in” slightly before resuming high speed operation. (Rapid reduction in

power will cause a sudden change of steering torque and may cause additional

momentary boat instability.)

1. Will lift bow of boat, generally increasing top speed.

2. Transfers steering torque harder to left on single outboard installations below 23 in.

(584mm) transom height.

3. Increases clearance over submerged objects.

4. In excess, can cause porpoising and/or ventilation.

5. If trimmed out beyond the water pickup, reduced water supply can cause overheating

resulting in engine damage.

WARNING

Page 1C-4 90-855347R1 JANUARY 1999

Page 26

TRIMMING OUTBOARD “IN” (“DOWN”) CHARACTERISTICS

WARNING

Excessive speed at minimum trim “in” may cause undesirable and/or unsafe

steering conditions. Each boat should be tested for handling characteristics after

any adjustment is made to the angle (trim adjustment bolt relocation.)

1. Will help planing off, particularly with a heavy load.

2. Usually improves ride in choppy water.

3. In excess, can cause boat to veer to the left or right (bow steer).

4. Transfers steering torque harder to right (or less to the left) on single outboard installations.

5. Improves planing speed acceleration (by moving trim adjustment bolt one hole closer

to transom).

WATER ABSORPTION

It is imperative that all through hull fasteners be coated with a quality marine sealer at time

of installation. Water intrusion into the transom core and/or inner hull will result in additional boat weight (reduced boat performance), hull decay and eventual structural failure.

CAVITATION

GENERAL INFORMATION

VENTILATION

Cavitation is caused by water vapor bubbles forming either from a sharp edge or angle

on the gear case or from an irregularity in the propeller blade itself. These vapor bubbles

flow back and collapse when striking the surface of the propeller blade resulting in the erosion of the propeller blade surface. If allowed to continue, eventual blade failure (breakage) will occur.

Ventilation occurs when air is drawn from the water’s surface (excessive trim out angle)

or from the engine exhaust flow (wrong propeller/propeller hardware installed or gear

case labyrinth seal worn) into the propeller blades. These air bubbles strike the propeller

blade surface and cause erosion of the blade surface. If allowed to continue, eventual

blade failure (breakage) will occur.

90-855347R1 JANUARY 1999 Page 1C-5

Page 27

GENERAL INFORMATION

Engine

DETONATION

Detonation in a 2-cycle engine resembles the “pinging” heard in an automobile engine.

It can be otherwise described as a tin-like “rattling” or “plinking” sound.

Detonation is an explosion of an unburned portion of the fuel/air charge after the spark

plug has fired. Detonation creates severe shock waves in the engine, and these shock

waves often find or create a weakness: The dome of a piston, cylinder head/gasket, piston

rings or piston ring lands, piston pin and roller bearings.

A few of the most common causes of detonation in a marine 2-cycle application are as

follows:

• Over-advanced ignition timing.

• Use of low octane gasoline.

• Propeller pitch too high (engine RPM below recommended maximum range).

• Lean fuel mixture at or near wide-open-throttle.

• Spark plugs (heat range too hot – incorrect reach – cross-firing).

• Inadequate engine cooling (deteriorated cooling system).

Detonation usually can be prevented if:

1. The engine is correctly set up.

2. Diligent maintenance is applied to combat the detonation causes.

Engine Compression

Engine compression should be checked with engine block warm, throttle shutter wide

open, all spark plugs removed and using a fully charged battery . Normal compression for

all cylinders should be 1 10 to 130 psi (758.5 to 896.4 kPa). Cylinders should not vary more

than 15 psi (103.4 kPa) between one another. A variance of more than 15 psi would indicate the need for a power head inspection/disassembly.

51115

Page 1C-6 90-855347R1 JANUARY 1999

Page 28

Following Complete Submersion

Salt Water Submersion

Due to the corrosive effect of salt water on internal engine components, complete disassembly is necessary before any attempt is made to start the engine.

Submerged While Running

When an engine is submerged while running, the possibility of internal engine damage

is greatly increased. If, after engine is recovered and with spark plugs removed, engine

fails to turn over freely when turning flywheel, the possibility of internal damage (bent connecting rod and/or bent crankshaft) exists. If this is the case, the powerhead must be disassembled.

SUBMERGED ENGINE (FRESH WATER)

IMPORT ANT: Engine should be run within 2 hours after recovery, or serious internal damage may occur. If unable to start engine in this period, disassemble engine

and clean all parts. Apply oil as soon as possible.

NOTE: If sand has entered the air intake on the engine, do not attempt to the start the

engine. Sand will cause internal engine damage. disassembly is required to clean all internal engine components of sand.

GENERAL INFORMATION

1. Recover engine from water as quickly as possible.

2. Remove cowling.

3. Clean the exterior of the outboard with fresh water.

4. Dry all wiring and electrical components using compressed air.

5. Drain water from fuel system as follows:

a. Disconnect remote fuel hose from engine.

b. Remove drain plug from vapor separator and drain fuel/water. Reinstall plug after

draining.

c. Remove the fuel hose from bottom of port side fuel rail and drain fuel/water. Rein-

stall hose.

d. Remove the water separating fuel filter and empty contents.

6. Drain water from air compressor system as follows:

a. Dry or replace the air filter for the compressor.

b. Remove air outlet hose for the air compressor and drain water from compressor

and hose. Reinstall hose.

c. Remove the air hose from bottom of port side fuel rail and drain water. Reinstall

hose.

7. Drain water from engine as follows:

a. Remove air sensor from front of the air plenum. Tilt up the outboard and drain wa-

ter out of the air plenum through the air sensor mounting hole. Reinstall Sensor.

b. Remove spark plugs from engine.

c. Rotate flywheel manually to blow out any water from the cylinders.

d. Add approximately one ounce (30ml) of engine oil into each spark plug hole. Ro-

tate the flywheel manually several times to distribute the oil in the cylinders. Rein-

stall spark plugs.

90-855347R1 JANUARY 1999 Page 1C-7

Page 29

GENERAL INFORMATION

8. Drain water from the oil injection system as follows:

a. Remove remote oil hose (black without blue stripe) from pulse fitting on starboard

side of engine.

b. Drain any water from hose and reconnect.

c. If water was present in hose, check for water in the remote oil tank. Drain tank if

water is present.

9. Disassemble the engine starter motor and dry components.

10. Prime the oil injection pump as follows:

a. Fill the engine fuel system with fuel. Connect fuel hose and squeeze primer bulb

until it feels firm.

b. Turn the ignition key switch to the “ON” position.

c. Within the first 10 seconds after the key switch has been turned on, move the re-

mote control handle from neutral into forward gear 3 to 5 times. This will automatically start the priming process.

N

F

NOTE: Audible click from the oil pump will tell you the pump is priming. It may take a few

minutes for the pump to complete the priming process.

1 1. Attempt to start engine, using a fresh fuel source.If engine starts, it should be run for

at least one hour to eliminate any water in engine.

12. If engine fails to start, determine cause (fuel, electrical or mechanical).

Page 1C-8 90-855347R1 JANUARY 1999

Page 30

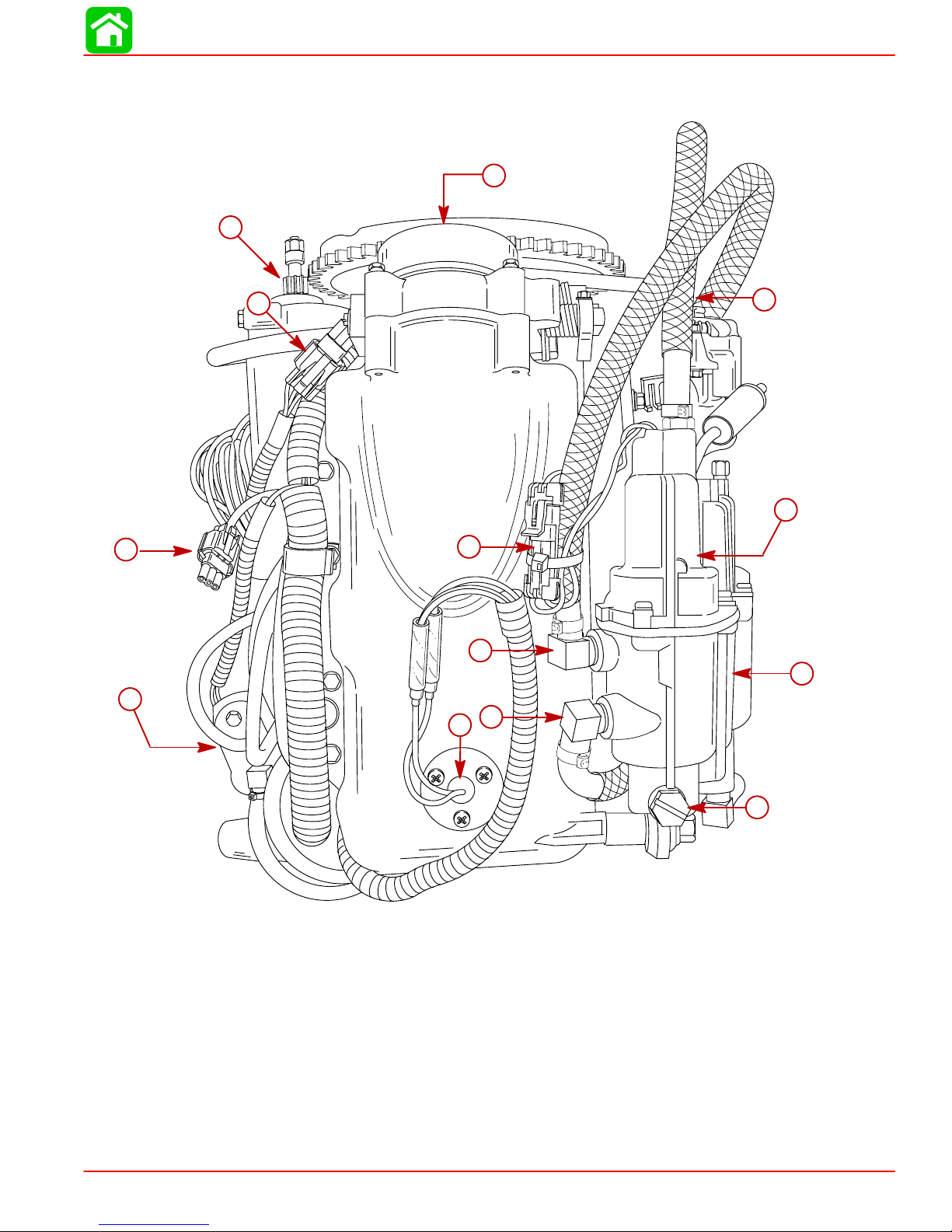

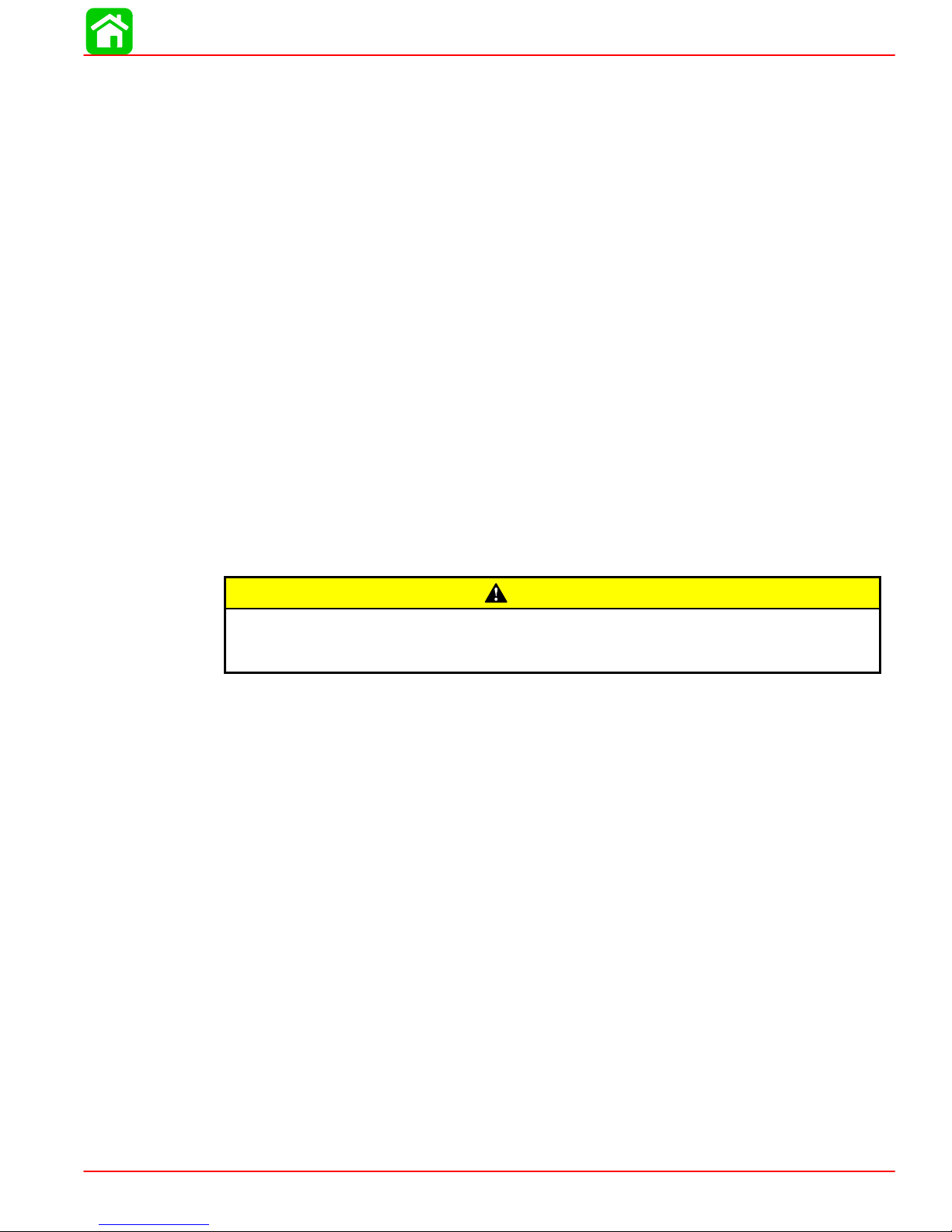

Model 135/150 DFI Powerhead Front View

12

11

GENERAL INFORMATION

10

13

1

9

7

6

2

8

5

4

1-High Pressure Electric Fuel Pump (Inside Vapor Separator)

2-Vapor Separator

3-Vapor Separator Drain Plug

4-Air Temperature Sensor

5-Fuel Hose Outlet from Low Pressure Electric Fuel Pump

6-Fuel Return Hose from Fuel Cooler

7-Electric Fuel Pump Harness Connection

8-Electric Oil Pump (Hidden)

9-Digital Diagnostic Terminal Harness Connection

10 - Crank Position Sensor Harness Connection

11 - Starter Motor

12 - Throttle Plate Assembly

13 - Fuel Hose Out to Fuel Rails (High Pressure)

90-855347R1 JANUARY 1999 Page 1C-9

3

57314

Page 31

GENERAL INFORMATION

Model 135/150 DFI Powerhead Starboard View

24

23

25

2

4

1

11

3

12

18

17

13

16

15

5

20

14

6

22

19

21

10

1-Fuel Pressure Test Valve

2-Air Compressor Oil Return Line

3-Crank Position Sensor

4-Throttle Plate/Air Plenum Assembly

5-Digital Diagnostic Terminal Connector

6-Oil Hose from Oil Reservoir to Oil Pump

7-Oil Pump

8-Main Power Relay(1998 Model)*

9-Trim DOWN Relay

10 - Trim UP Relay (1998 Model)*

11 - Temperature Sensor

12 - Electronic Control Module

13 - Starter Motor

NOTE: *The location for 1999 Model Main Power Relay and T rim UP Relay are reversed.

7

8

9

57317

14 - Starter Solenoid

15 - Oil Pump Fuse

16 - Harness Fuse (20 Ampere)

17 - ECM Fuse (20 Ampere)

18 - Electric Fuel Pump Fuse (20 Ampere)

19 - Air Hose

20 - Starboard Fuel Rail

21 - Fuel Hose

22 - #5 Fuel Injector

23 - #3 Fuel Injector

24 - #1 Fuel Injector

25 - Air Hose from Air Compressor

Page 1C-10 90-855347R1 JANUARY 1999

Page 32

Model 135/150 DFI Powerhead Port View

GENERAL INFORMATION

4

2

3

31

18

6

5

7

8

23

24

19

9

10

31

1

29

26

25

21

20

13

15

11

17

32

30

27

28

22

1-High Pressure Electric Fuel Pump

2-Fuel Out (90 psi)

3-Crank Position Sensor

4-Fuel Return from Fuel Cooler

5-Water Out (tell-tale) from Air Compressor

6-Air Restrictor/Air Inlet to Air Compressor

7-Air Compressor

8-Air Pressure Out from Air Compressor

9-Temperature Sensor (Air Compressor)

10 - #2 Fuel Injector

11 - #4 Fuel Injector

12 - #6 Fuel Injector

13 - Excess Air to Adaptor Plate

14 - Water Inlet to Fuel Cooler from Adaptor Plate

15 - Port Fuel Rail

16 - Water Out to Poppet Valve

12

14

16

57312

17 - Excess Fuel Return to Fuel Cooler

18 - Air Pressure Test Port

19 - 40 psi Check Valve

20 - Fuel Cooler

21 - Oil Reservoir

22 - Neutral Shift Interrupt Switch

23 - 60 Ampere Alternator

24 - Throttle Position Sensor (2 each)

25 - Low Pressure Electric Fuel Pump

26 - Fuel/Water Separator

27 - Fuel/Water Sensor

28 - Low Pressure Fuel Pump Inlet Hose

29 - Vapor Separator

30 - Vapor Separator Drain Plug

31 - Vent Canister

32 - Idle Stop Screw

90-855347R1 JANUARY 1999 Page 1C-11

Page 33

GENERAL INFORMATION

Model 135/150 DFI Powerhead Top View

20

18

19

1

2

13

14

17

12

15

16

11

21

23

7

3

5

6

8

22

4

1-Air Compressor Inlet Nozzle

2-Water Outlet (Tell-Tale) Hose

3-Thermostat Outlet Hose to Adaptor Plate

4-Fuel (90 PSI) to Fuel Rails

5-40 psi Check Valve

6-Fuel Return to Vapor Separator

7-Belt Tensioner

8-60 Ampere Alternator

9-Electric Fuel Pump

10 - Throttle Plate Assembly

11 - Crank Position Sensor

Page 1C-12 90-855347R1 JANUARY 1999

9

10

57313

12 - MAP Sensor Hose

13 - Oil Return Hose from Air Compressor

14 - Starter Motor

15 - Oil Hose from Oil Pump to Air Compressor

16 - Serial Number Plug

17 - Fuel Pressure Test Valve

18 - Air Hose (80 PSI) to Fuel Rail

19 - Check Valve

20 - Air Compressor

21 - Starboard to Port Thermostat Hose

22 - Vent Canister

23 - Throttle Plate Adjustment Screw

Page 34

Model 135/150 DFI Powerhead Aft View

GENERAL INFORMATION

26

25

28

2

4

1

5

3

6

7

18

9

8

19

27

21

17

20

11

10

24

16

23

22

14

1-Air Compressor Restrictor/Air Inlet

2-Water Out (tell-tale) from Air Compressor

3-Air Compressor Oil Inlet from Oil Pump

4-Air Compressor

5-Air Pressure Out (80 psi)

6-Fuel Pressure Test Valve

7-Check Valve

8-Excess Oil Return from Air Compressor

9-#1 Fuel Injector

10 - Starboard Fuel Rail

11 - #3 Fuel Injector

12 - #5 Fuel Injector

13 - Tell-Tale Outlet

14 - Flush Plug

15

13

15 - #5 Ignition Coil

16 - #3 Ignition Coil

17 - #1 Ignition Coil

18 - Water Inlet to Air Compressor

19 - #2 Ignition Coil

20 - MAP Sensor

21 - #4 Ignition Coil

22 - #6 Ignition Coil

23 - #6 Fuel Injector

24 - Air Regulator

25 - Port Fuel Rail

26 - #4 Fuel Injector

27 - Fuel Regulator

28 - #2 Fuel Injector

12

57315

90-855347R1 JANUARY 1999 Page 1C-13

Page 35

GENERAL INFORMATION

Painting Procedures

Cleaning & Painting Aluminum Propellers & Gear Housings

WARNING

Avoid serious injury from flying debris. Avoid serious injury from airborne particles. Use eye and breathing protection with proper ventilation.

PROPELLERS

1. Sand the entire area to be painted with 3M 120 Regalite Polycut or coarse ScotchBrite, disc or belts.

2. Feather edges of all broken paint edges. Try not to sand through the primer.

3. Clean the surface to be painted using PPG Industries DX330 Wax and Grease Remover or equivalent (Xylene or M.E.K.).

4. If bare metal has been exposed, use Quicksilver’s Light Gray Primer.

5. Allow a minimum of 1 hour dry time and no more than 1 week before applying the finish

coat.

6. Apply the finish coat using Quicksilver’s EDP Propeller Black.

GEAR HOUSINGS

The following procedures should be used in refinishing gear housings. This procedure will

provide the most durable paint system available in the field. The materials recommended

are of high quality and approximate marine requirements. The following procedure will

provide a repaint job that compares with a properly applied factory paint finish. It is recommended that the listed materials be purchased from a local Ditzler Automotive Finish Supply Outlet. The minimum package quantity of each material shown following is sufficient

to refinish several gear housings.

Procedure:

1. Wash gear housing with a muriatic acid base cleaner to remove any type of marine

growth, and rinse with water, if necessary.

2. Wash gear housing with soap and water, then rinse.

3. Sand blistered area with 3M 180 grit sandpaper or P180 Gold Film Disc to remove

paint blisters only. Feather edge all broken paint edges.

4. Clean gear housing thoroughly with (DX-330) wax and grease remover.

5. Spot repair surfaces where bare metal is exposed with (DX-503) alodine treatment.

IMPORT ANT : Do not use any type of aerosol spray paints as the paint will not properly adhere to the surface nor will the coating be sufficiently thick to resist future

paint blistering.

6. Mix epoxy chromate primer (DP-40) with equal part catalyst (DP-401) per manufacturers instructions, allowing proper induction period for permeation of the epoxy primer and catalyst.

7. Allow a minimum of one hour drying time and no more than one week before top coating assemblies.

8. Use Ditzler Urethane DU9000 for Mercury Black, DU34334 for Mariner Grey, and

DU35466 for Force Charcoal, and DU33414M for Sea Ray White. Catalyze all four

colors with Ditzler DU5 catalyst mixed 1:1 ratio. Reduce with solvents per Ditzler label.

Page 1C-14 90-855347R1 JANUARY 1999

Page 36

Be sure to comply with instructions on the label for ventilation and respirators.

Using a spray gun, apply one half to one mil even film thickness. Let dry , flash off

for five minutes and apply another even coat of one half to one mil film thickness.

This urethane paint will dry to the touch in a matter of hours, but will remain sensitive to scratches and abrasions for a few days.

9. The type of spray gun used will determine the proper reduction ratio of the paint.

IMPORTANT: Do not paint sacrificial zinc trim tab or zinc anode.

10. Cut out a cardboard “plug” for trim tab pocket to keep paint off of mating surface to

maintain good continuity circuitry between trim tab and gear housing.

Decal Application

Decal Removal

1. Mark decal location before removal to assure proper alignment of new decal.

2. Carefully soften decal and decal adhesive with a heat gun or heat blower while removing old decal.

GENERAL INFORMATION

CAUTION

3. Clean decal contact area with a 1:1 mixture of isopropyl alcohol and water.

4. Thoroughly dry decal contact area and check for a completely cleaned surface.

Instructions for “Wet” Application

NOTE: The following decal installation instructions are provided for a “Wet” installation.

All decals should be applied wet.

TOOLS REQUIRED

1. Plastic Squeegee*

2. Stick Pin

3. Dish Washing Liquid/Detergent without ammonia** “Joy” and “Drift” are known to

be compatible for this process.

** Automotive Body Filler Squeegee

** Do not use a soap that contains petroleum based solvents.

SERVICE TIP: Placement of decals using the “Wet” application will allow time to

position decal. Read entire installation instructions on this technique before proceeding.

TEMPERATURE

IMPORTANT: Installation of vinyl decals should not be attempted while in direct

sunlight. Air and surface temperature should be between 60°F (15°C) and 100°F

(38°C) for best application.

SURFACE PREPARATION

IMPORT ANT: Do not use a soap or any petroleum based solvents to clean application surface.

Clean entire application surface with mild dish washing liquid and water. Rinse surface

thoroughly with clean water.

90-855347R1 JANUARY 1999 Page 1C-15

Page 37

GENERAL INFORMATION

DECAL APPLICATION

1. Mix

NOTE: Leave protective masking, if present, on the face of decal until final steps of decal

installation. This will ensure that the vinyl decal keeps it’s shape during installation.

2. Place the decal face down on a clean work surface and remove the paper backing

3. Using a spray bottle, flood the entire “adhesive side” of the decal with the pre-mixed

4. Flood area where the decal will be positioned with wetting solution.

5. Position pre-wetted decal on wetted surface and slide into position.

6. Starting at the center of the decal, “lightly” squeegee out the air bubbles and wetting

7. Wipe decal surface with soft paper towel or cloth.

8. Wait 10 - 15 minutes.

9. Starting at one corner, “carefully and slowly” pull the masking of f the decal surface at

1

/2 ounce (16 ml) of dish washing liquid in one gallon (4 l) of cool water to use as

wetting solution.

from “adhesive side” of decal.

wetting solution.

solution with overlapping strokes to the outer edge of the decal. Continue going over

the decal surface until all wrinkles are gone and adhesive bonds to the cowl surface.

a 180° angle.

NOTE: T o remove any remaining bubbles, pierce the decal at one end of the bubble with

stick pin and press out the entrapped air or wetting solution with your thumb (moving toward the puncture).

Page 1C-16 90-855347R1 JANUARY 1999

Page 38

OUTBOARD MOTOR INSTALLATION

IMPORTANT INFORMATION

Section 1D - Outboard Motor Installation

Table of Contents

Installation Specifications 1D-1. . . . . . . . . . . . . . . . . . . . . .

Lifting Outboard 1D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Outboard to Boat Transom 1D-2. . . . . . . . . . . .

Determining Recommended Outboard Mounting

Height 1D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Outboard 1D-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Drilling Outboard Mounting Holes 1D-3. . . . . . . . . . . .

Securing Outboard To Boat Transom 1D-4. . . . . . . . .

Steering Cable 1D-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod 1D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical, Hoses and Control Cables 1D-6. . . . . . . . . . .

Installation Note 1D-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Wiring Harness 1D-6. . . . . . . . . . . . . . . . . . . .

Warning Gauge Harness 1D-7. . . . . . . . . . . . . . . . . . .

Battery Cables 1D-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Outboard 1D-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

1

D

Dual Outboard 1D-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable 1D-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Counter Rotation Outboards 1D-9. . . . . . . . . . . . . . . .

Installation 1D-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Cable 1D-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1D-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Clamp Reassembly 1D-13. . . . . . . . . . . . . . . . .

Filling Fuel System 1D-14. . . . . . . . . . . . . . . . . . . . . . . . .

Oil Injection Set-Up 1D-14. . . . . . . . . . . . . . . . . . . . . . . . .

Filling 1D-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priming the Oil Injection Pump 1D-15. . . . . . . . . . . .

Purging Air From the Engine Oil Tank 1D-16. . . . . .

Trim “In” Angle Adjustment 1D-16. . . . . . . . . . . . . . . . . .

Trim Tab Adjustment 1D-17. . . . . . . . . . . . . . . . . . . . . . . .

Models Without Power Steering 1D-17. . . . . . . . . . .

Models With Power Steering 1D-17. . . . . . . . . . . . . .

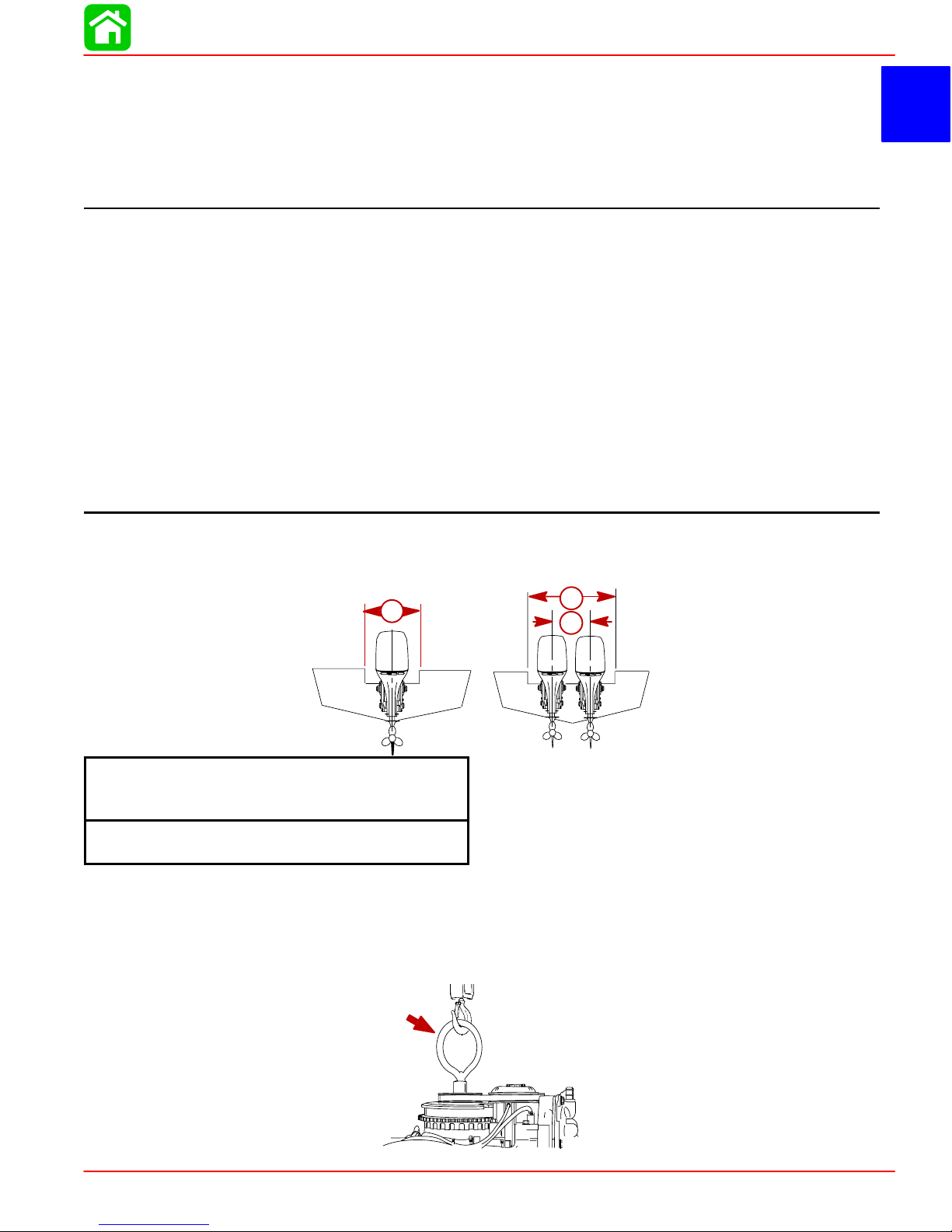

Installation Specifications

a

a

a – Transom Opening – Minimum

Single Engine – 33-3/8 in. (848 mm)

Dual Engines – 59-3/4 in. (1518 mm)

b – Engine Center Line For Dual Engine

26 in. (660mm) Minimum

Lifting Outboard

Electric Start Models – Remove plastic cap from flywheel hub. Thread lifting ring into

flywheel a minimum of 5 turns. Replace plastic cap after installation.

a

a

b

90-855347R1 JANUARY 1999 Page 1D-1

Page 39

OUTBOARD MOTOR INSTALLATION

Installing Outboard to Boat Transom

Determining Recommended Outboard Mounting Height

26 in.

(660mm)

(635mm)

(609mm)

e

Outboard

Mounting

Height (See

NOTE Below)

(584mm)

(560mm)

e

(533mm)

(508mm)

(482mm)

NOTE: Add 5 in. (127mm) for XL models and 10 in. (254mm) for XXL models

to listed outboard mounting height.

25 in.

24 in.

23 in.

22 in.

21 in.

20 in.

19 in.

10

b

c

b

a

d

20 30 40 50 60 70 80

Maximum Boat Speed Anticipated

NOTICE TO INSTALLER:

1. The outboard should be mounted high enough on the transom so that the exhaust

relief hole will stay at least 1 in. (25.4 mm) above the water line when the engine is

running at idle speed. This will prevent exhaust restriction.

2. The mounting height (e) of the outboard must not exceed 25 in. (635 mm) for L models, 30 in. (762 mm) for XL models and 35 in. (889 mm) for XXL models. Mounting the

outboard higher may cause damage to the gear case components.

a. This solid line is recommended to determine the outboard mounting height. In-

creasing the height of outboard generally will provide the following: 1) Less steering torque, 2) more top speed, 3) greater boat stability , but, 4) will cause more prop

“break loose” which may be particularly noticeable when planing off or with heavy

load.

b. These broken lines represent the extremes of known successful outboard mount-

ing height dimensions.

c. This line may be preferred to determine outboard mounting height dimension, if

maximum speed is the only objective.

d. This line may be preferred to determine outboard mounting height dimension for

dual outboard installation.

e. Outboard mounting height (height of outboard transom brackets from bottom of

boat transom). For heights over 22 in. (560mm), a propeller, that is designed for

surfacing operation is usually preferred.

Page 1D-2 90-855347R1 JANUARY 1999

Page 40

Installing Outboard

Drilling Outboard Mounting Holes

1. Attach (tape) engine mounting template (located with the installation manual) to boat

transom.

IMPORTANT: If using “Transom Drilling Fixture” (part number 91-98234A2), use

drill guide holes marked “A” when drilling outboard mounting holes.

OUTBOARD MOTOR INSTALLATION

b

a

a-Centerline of Transom

b-Transom Drilling Fixture (91-98234A2)

2. Mark and drill four 17/32 in. (13.5mm) mounting holes.

90-855347R1 JANUARY 1999 Page 1D-3

Page 41

OUTBOARD MOTOR INSTALLATION

Securing Outboard To Boat Transom

1. Refer to “Determining Recommended Outboard Motor Mounting Height”, preceding

and Install outboard to the nearest recommended mounting height.

2. Fasten outboard with provided mounting hardware shown.

a

a-1/2 In. Diameter Bolts (4)

b-Flat Washers (4)

c-Locknuts (4)

d-Marine Sealer - Apply to Shanks of Bolts, Not Threads

Steering Cable

STARBOARD SIDE ROUTED CABLE

1. Lubricate O-ring seal and entire cable end.

b

c

b

c

a

d

95

95

Page 1D-4 90-855347R1 JANUARY 1999

2-4-C With Teflon (92-825407A12)

Page 42

2. Insert steering cable into tilt tube.

3. Torque nut to 35 lb. ft. (47.5 N·m).

OUTBOARD MOTOR INSTALLATION

Steering Link Rod

1. Install steering link rod per illustration.

a-Special Bolt (10-90041) Torque to 20 lb-ft (27 N·m)

b-Nylon Insert Locknut (11-34863) Torque to 20 lb-ft (27 N·m)

c-Flat Washer (2)

d-Nylon Insert Locknut (11-34863) Tighten Locknut Until it Seats, Then Back

Nut Off 1/4 Turn

IMPORTANT: The steering link rod that connects the steering cable to the engine

must be fastened using special washer head bolt (“a” – Part Number 10-14000) and

self locking nuts (“b” & “c” – Part Number 11-34863). These locknuts must never

be replaced with common nuts (non locking) as they will work loose and vibrate

off freeing the link rod to disengage.

a

c

d

b

Disengagement of a steering link rod can result in the boat taking a full, sudden,

sharp turn. This potentially violent action can cause occupants to be thrown

overboard exposing them to serious injury or death.

90-855347R1 JANUARY 1999 Page 1D-5

WARNING

Page 43

OUTBOARD MOTOR INSTALLATION

Electrical, Hoses and Control Cables

IMPORTANT: Warning Horn Requirement – The remote control or key switch assembly must be wired with a warning horn. This warning horn is used with the engine warning system.

Installation Note

Open the front clamp assembly.

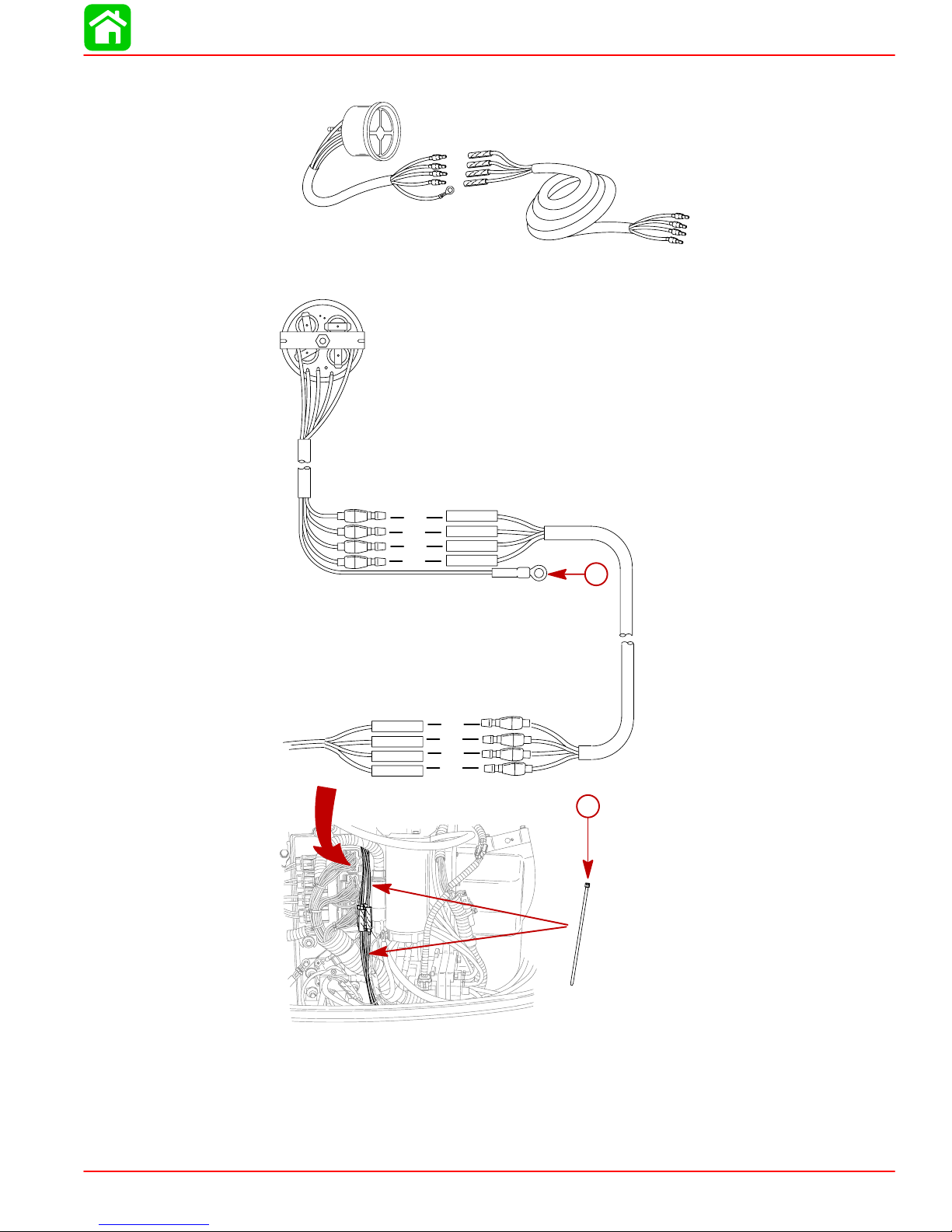

Remote Wiring Harness

1. Connect wiring. Place harness into the holder.

BLU/WHT

GRN/WHT

TAN

BRN/WHT

BLU/WHT

GRN/WHT

a

a-Power Trim Connections

Page 1D-6 90-855347R1 JANUARY 1999

Page 44

Warning Gauge Harness

Connect the harness extension to gauge and engine.

OUTBOARD MOTOR INSTALLATION

1

6

4

3

2

5

a

b

c

d

e

a

b

c

d

a-TAN/BLACK

b-TAN/WHITE

c-PINK/LT. BLUE to PINK/LT. BLUE

d-ORANGE

e-Connect PURPLE to 12 Volt Source or Adjacent Gauge

f-Sta-Straps – Fasten Wiring to Prevent Catching on Cowl

90-855347R1 JANUARY 1999 Page 1D-7

f

Page 45

OUTBOARD MOTOR INSTALLATION

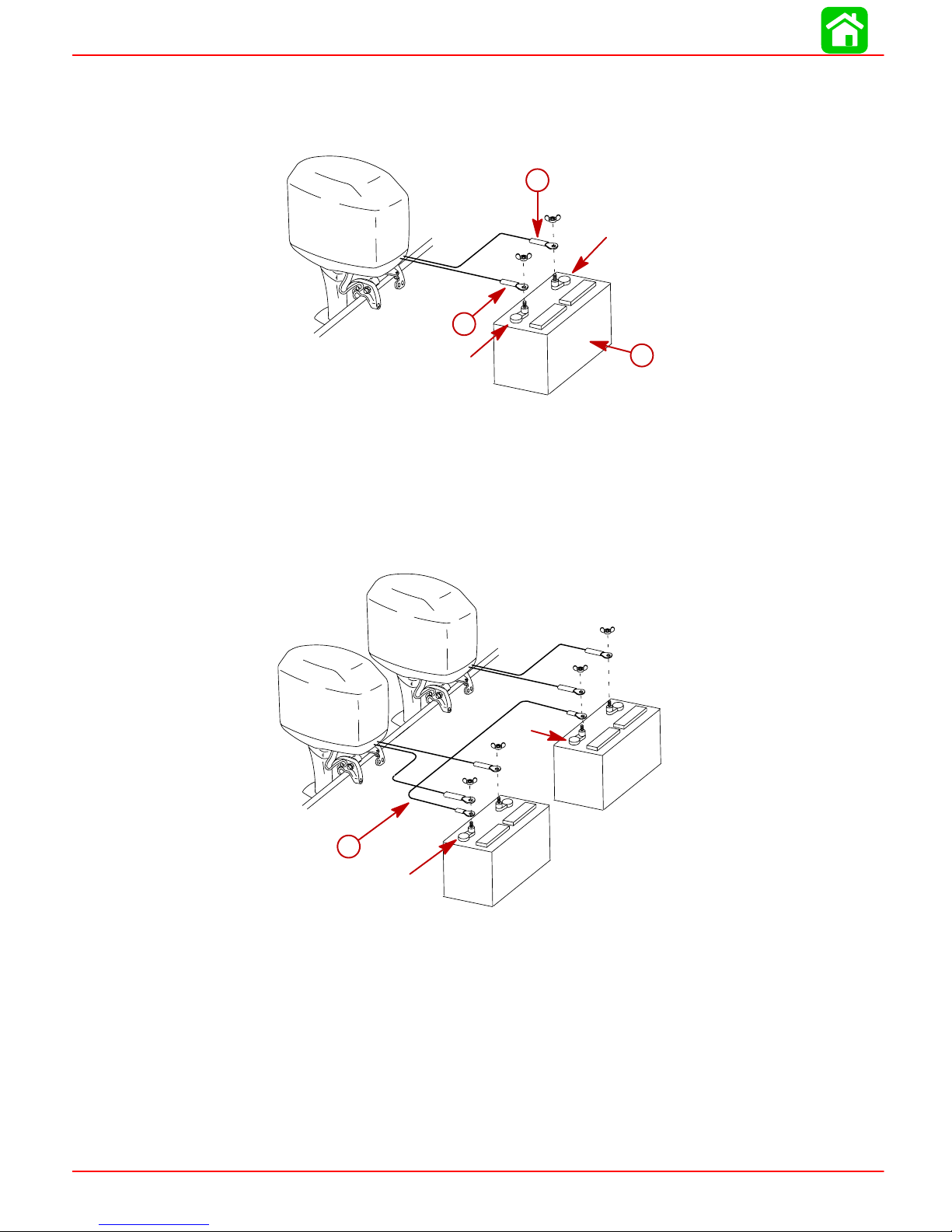

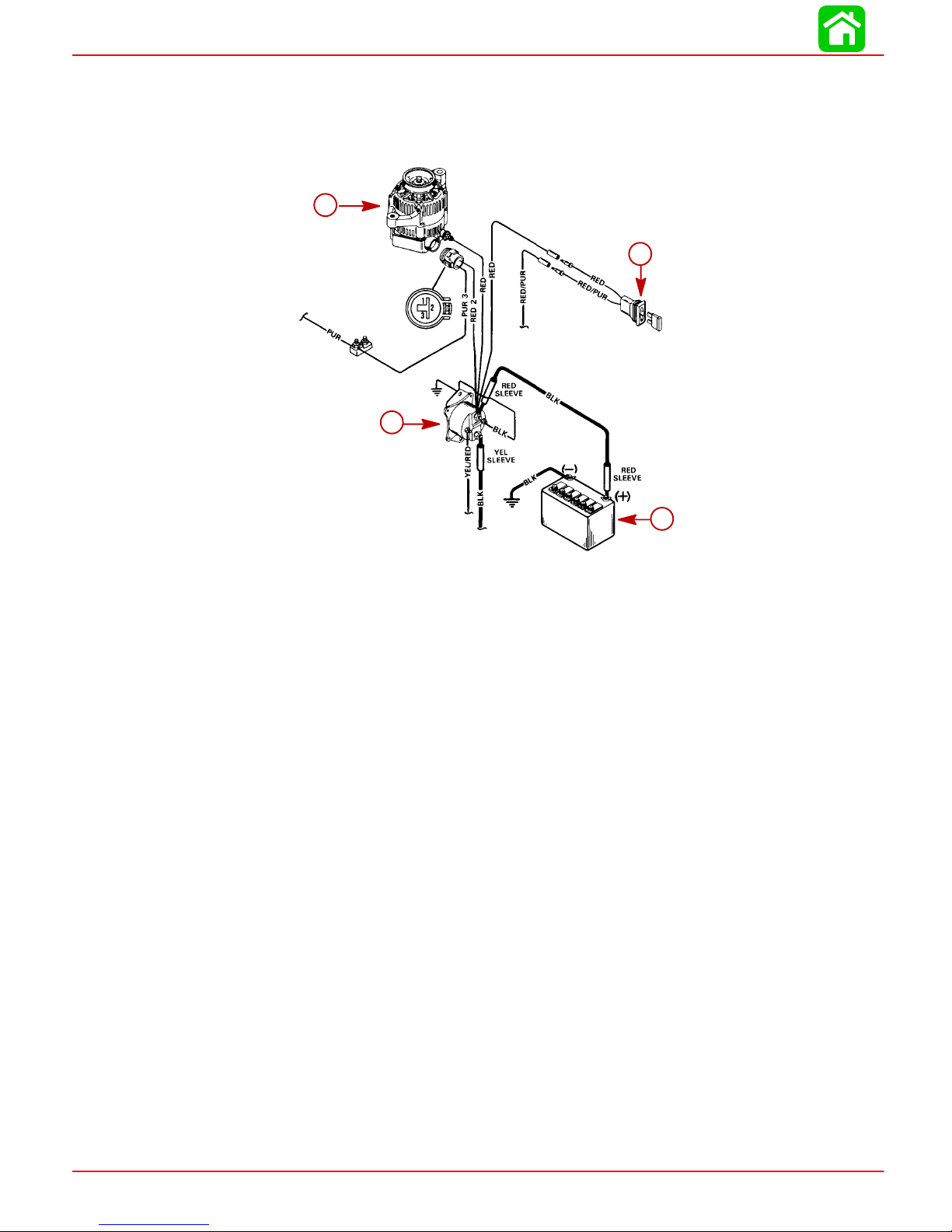

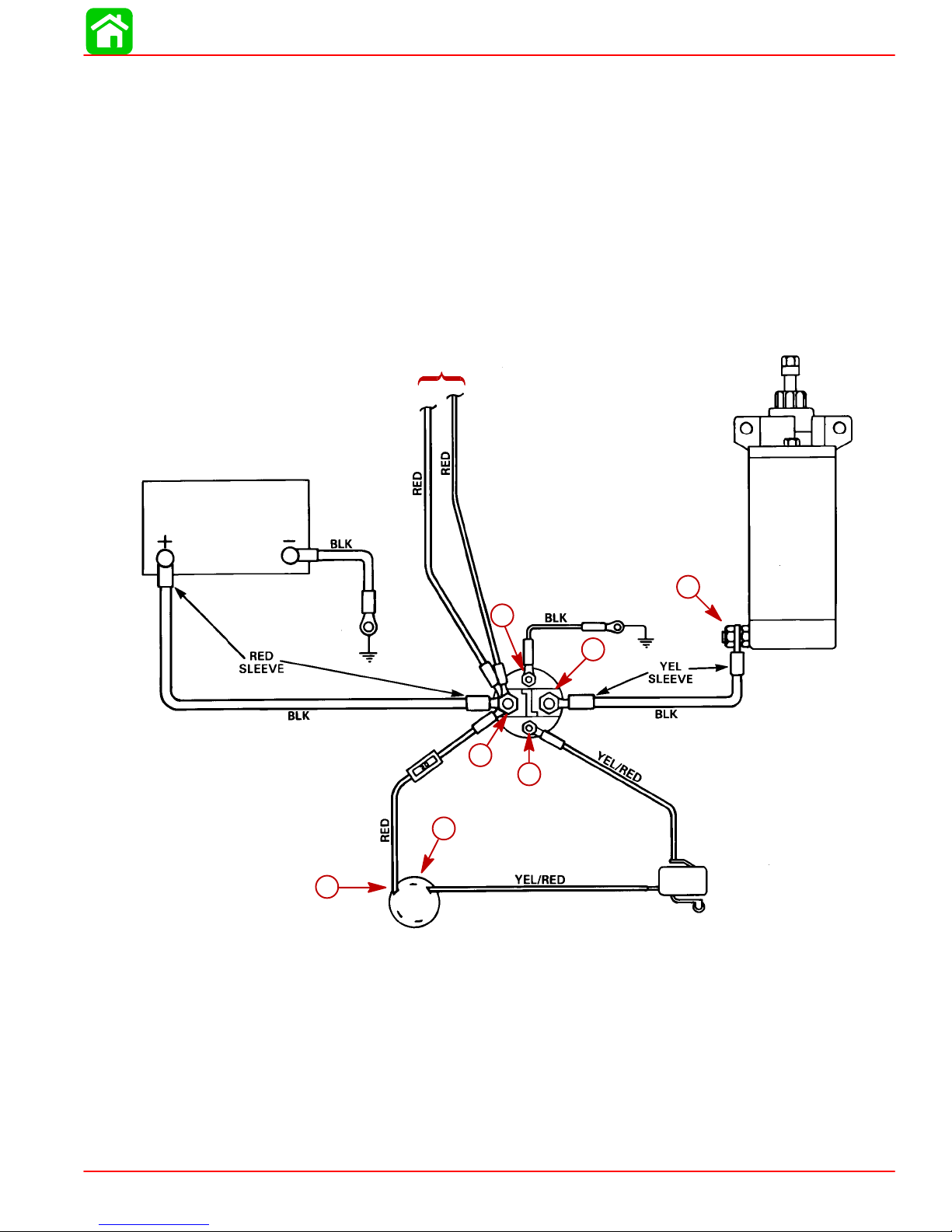

Battery Cables

Single Outboard

a

(+)

b

Dual Outboard

(–)

a-RED Sleeve (Positive)

b-BLACK Sleeve (Negative)

c-Starting Battery

Connect a common ground cable (wire size same as engine battery cables) between

NEGATIVE (–) terminals on starting batteries.

c

(–)

d-Common Ground Cable

Page 1D-8 90-855347R1 JANUARY 1999

d

(–)

Page 46

Shift Cable

Install cables into the remote control following the instructions provided with the remote

control.

NOTE: Install the shift cable to the engine first. The shift cable is the first cable to move

when the remote control handle is moved out of neutral.

COUNTER ROTATION OUTBOARDS

Counter rotating (left hand) gear cases can be identified by a “L” stamped into the end of

the propeller shaft.

The Quicksilver Dual Engine Console Mount Control, P/N 88688A22 or 88688A52, is required to shift the counter rotation outboard. The installation instructions shipped with the

control explain the procedure required to connect this control to a counter rotation outboard.

IMPORTANT: If the counter rotation outboard is rigged similar to a standard rotation outboard OR if a standard rotation outboard is rigged similar to a counter rotation outboard, the reverse gear and bearing in the gear case must function as forward gear. THE REVERSE GEAR/BEARING ARE NOT DESIGNED TO CARRY THE

SUST AINED LOADS THAT ARE GENERA TED WHEN RUNNING UNDER CONST ANT

HIGH RPM AND THRUST CONDITIONS.

OUTBOARD MOTOR INSTALLATION

OUTBOARD SHIFTING DIRECTION

On counter rotation outboards, the shift linkage moves in the opposite direction compared

to a standard rotation outboard.

STANDARD ROTATION GEAR OUTBOARDS

Forward Gear

COUNTER ROTATION OUTBOARDS

Reverse Gear

Reverse Gear

Forward Gear

90-855347R1 JANUARY 1999 Page 1D-9

Page 47

OUTBOARD MOTOR INSTALLATION

Installation

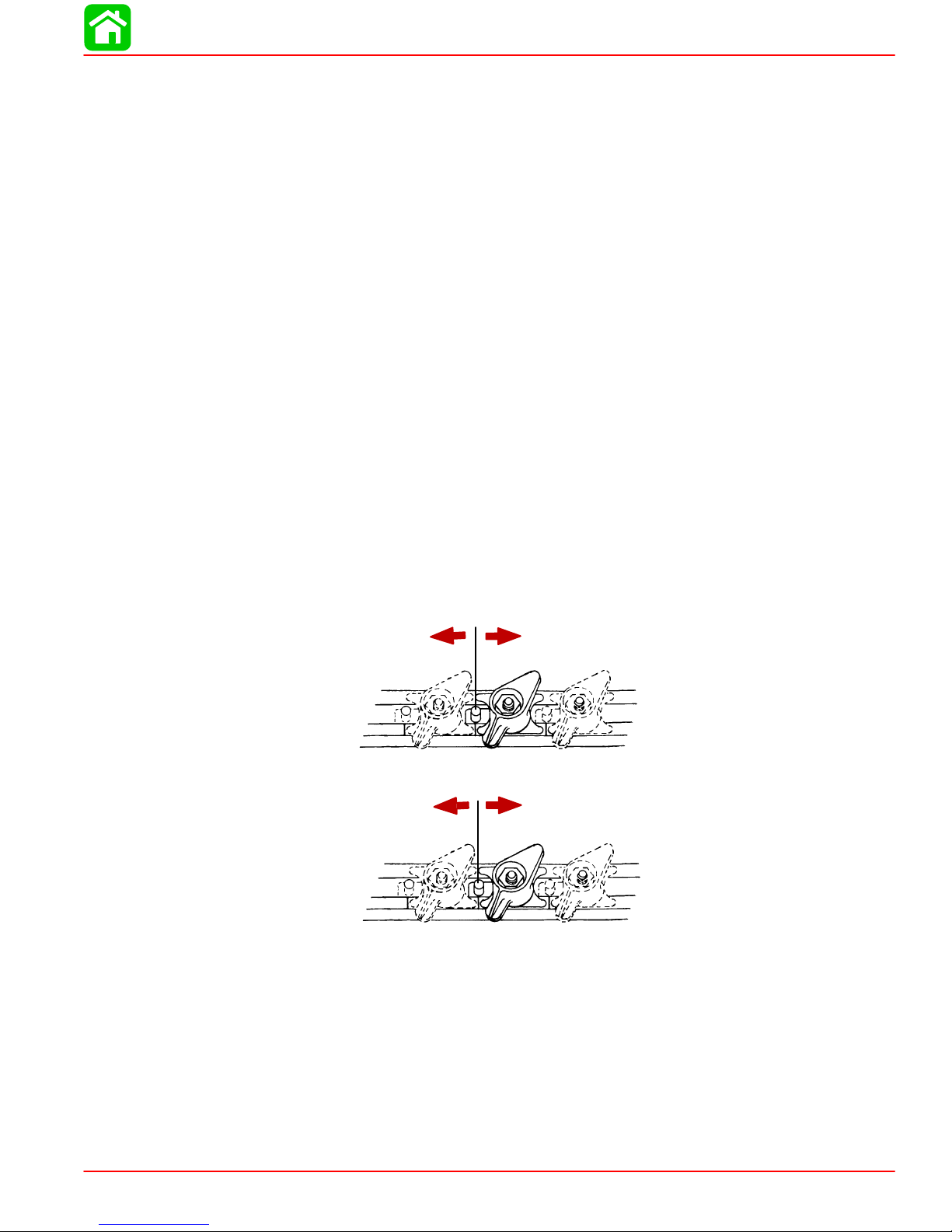

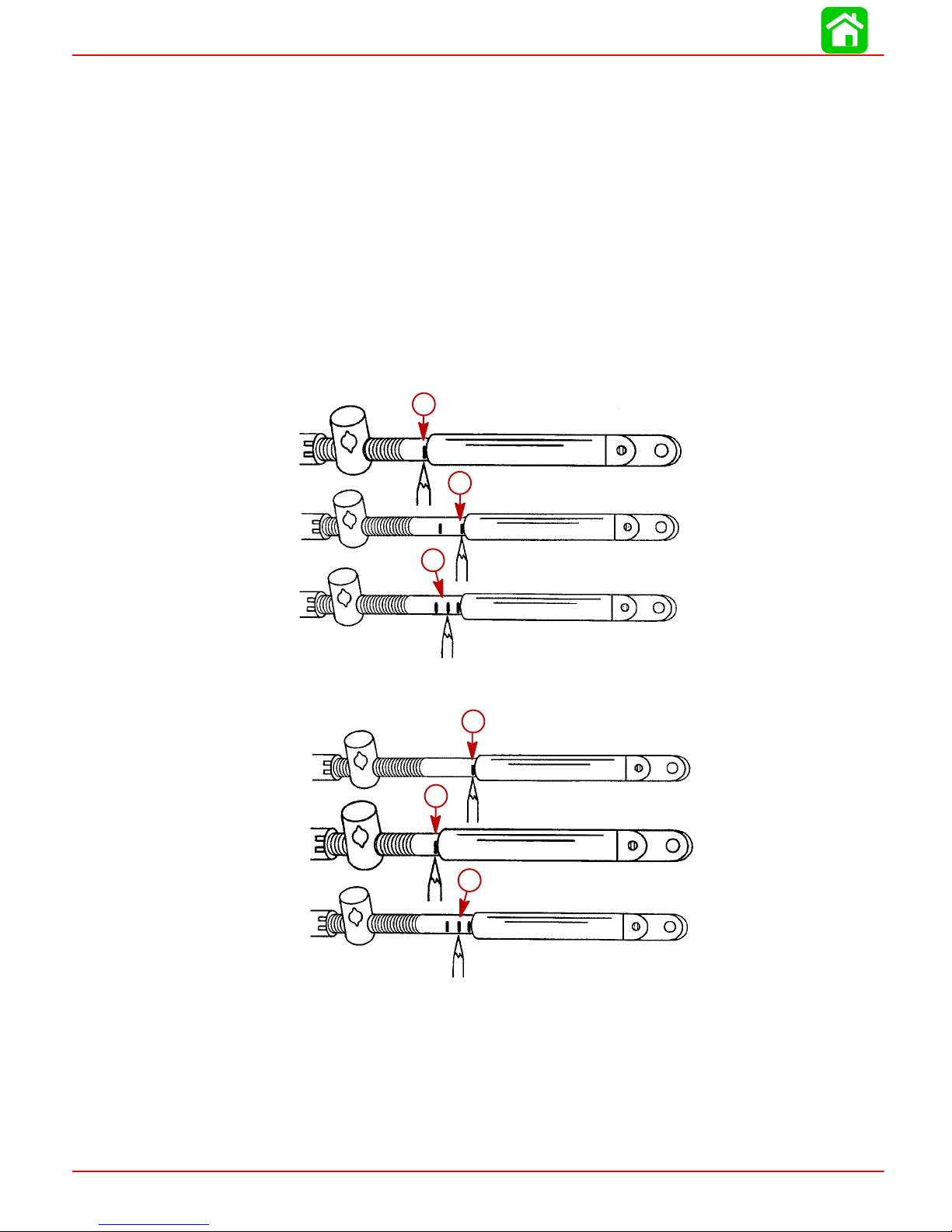

IMPORTANT: Step 1 must be followed for proper adjustment of the shift cable.

1. Locate the center point of the slack or lost motion that exists in the shift cable as follows:

a. Move the remote control handle from neutral into forward and advance the handle

to full speed position. Slowly return the handle back to the neutral. Place a mark

(a) on the cable against the cable end guide.

b. Move the remote control handle from neutral into reverse and advance the handle

to full speed position. Slowly return the handle back to the neutral. Place a mark

(b) on the cable against the cable end guide.

c. Make a center mark (c), midway between marks (“a” and “b”). Align the cable end

guide against this center mark when installing cable to the engine.

STANDARD ROTATION OUTBOARDS

a

b

COUNTER ROTATION OUTBOARDS

c

a

b

c

Page 1D-10 90-855347R1 JANUARY 1999

Page 48

OUTBOARD MOTOR INSTALLATION

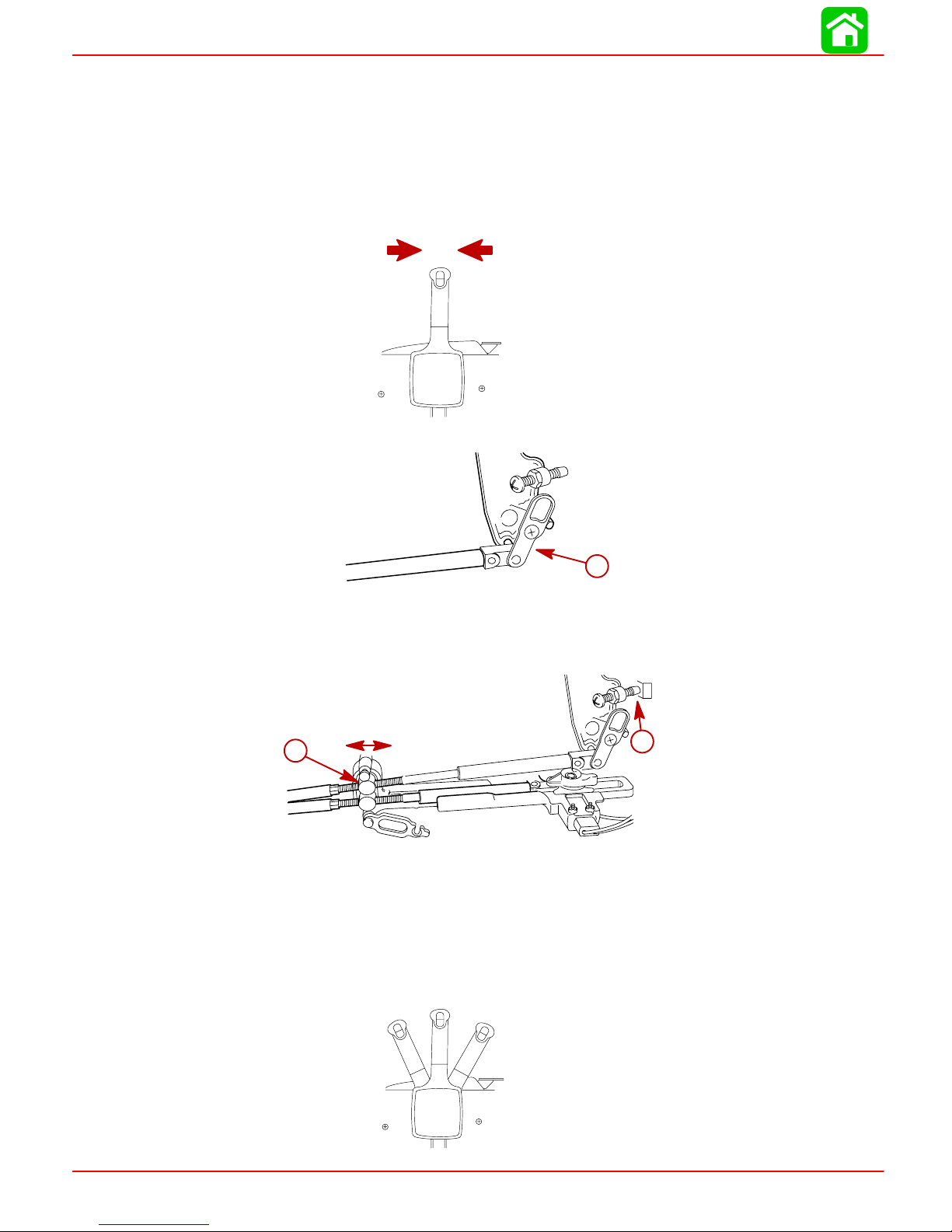

2. Position remote control and outboard into neutral.

N

3. Slide the shift cable retainer forward until resistance is felt, then slide cable anchor

toward rear until resistance is felt. Center the anchor pin between resistance points.

a

b

a-Shift Cable Retainer

b-Anchor Pin

4. Align the shift cable end guide with the center mark as instructed in Step 1.

5. Place shift cable on anchor pin. Adjust cable barrel so it slips freely into the barrel

holder.

6. Secure shift cable with shift cable retainer.

b

a

a-Cable Barrel

b-Shift Cable Retainer

7. Check shift cable adjustments as follows:

a. With remote control in forward, the propshaft should lock solidly in gear. If it does

not, adjust cable barrel closer to cable end guide.

b. Shift remote control into neutral. The propshaft should turn freely without drag. If

not, adjust barrel away from cable end guide. Repeat steps a and b.

c. Shift remote control into reverse while turning propeller. The propshaft should lock

solidly in gear. If not, adjust barrel away from cable end guide. Repeat steps a thru

c.

90-855347R1 JANUARY 1999 Page 1D-11

Page 49

OUTBOARD MOTOR INSTALLATION

d. Return remote control handle to neutral. The propeller should turn freely without

drag. If not, adjust barrel closer to cable end guide. Repeat steps a thru d.

Throttle Cable

INSTALLATION

1. Position remote control into neutral.

2. Attach throttle cable to the throttle lever. Secure with latch.

N

a

a-Latch

3. Adjust the cable barrel so that the installed throttle cable will hold the idle stop screw

against the stop.

a

a-Cable Barrel – Adjust To Hold Idle Stop Screw Against Stop

b-Idle Stop Screw

4. Check throttle cable adjustment as follows:

a. Shift outboard into gear a few times to activate the throttle linkage. Make sure to

rotate the propeller shaft while shifting into reverse.

F

N

R

b

Page 1D-12 90-855347R1 JANUARY 1999

Page 50

OUTBOARD MOTOR INSTALLATION

b. Return remote control to neutral. Place a thin piece of paper between idle adjust-

ment screw and idle stop. Adjustment is correct when the paper can be removed

without tearing, but has some drag on it. Readjust cable barrel if necessary.

IMPORTANT: The idle stop screw must be touching the stop.

a-Idle Stop Screw

b-Idle Stop

5. Lock the barrel holder in place with the cable latch.

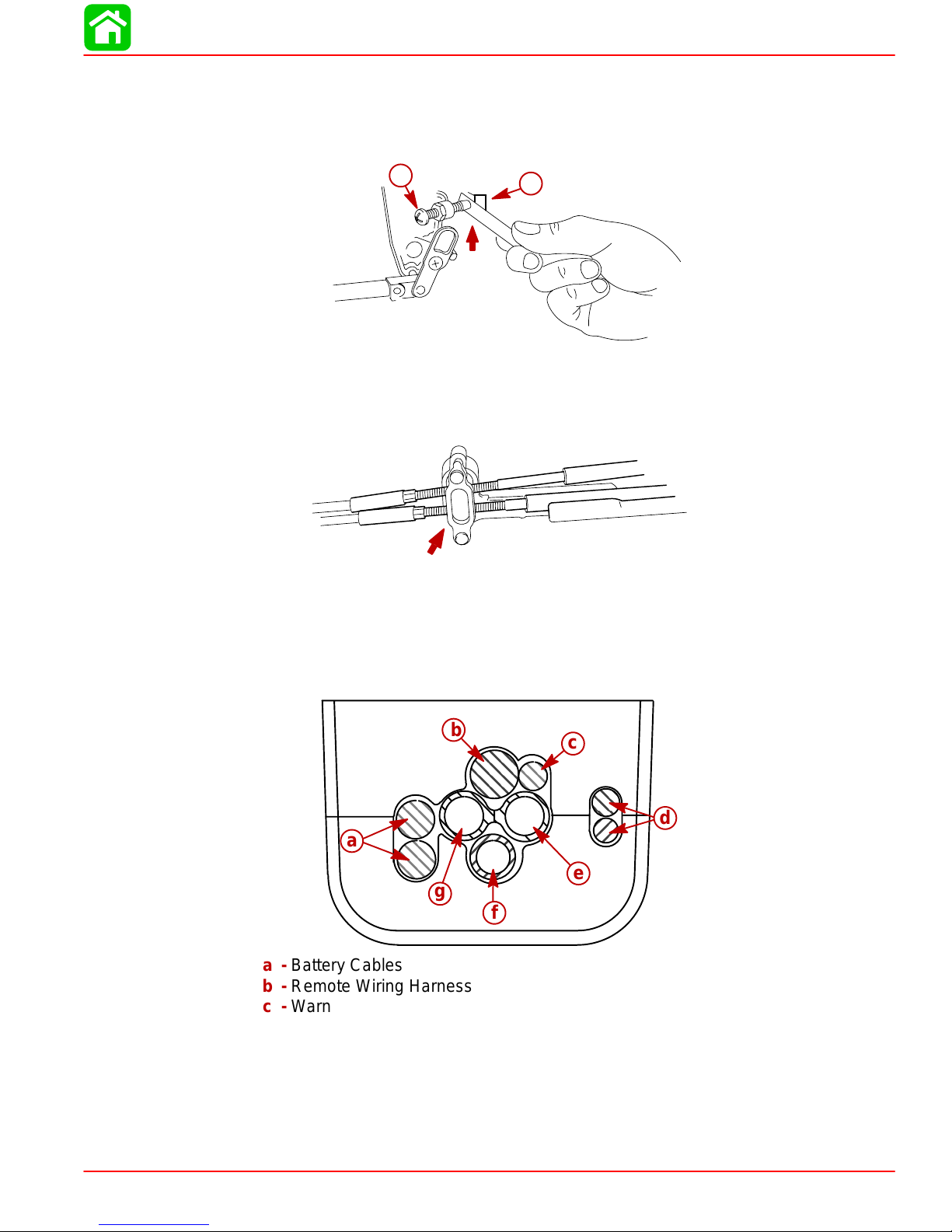

Front Clamp Reassembly

IMPORT ANT: Sufficient slack must exist in engine wiring harness, battery cables,

fuel hose, and oil hoses routed between clamp and engine attachment point, to relieve stress and prevent hoses from being kinked or pinched.

a

b

1. Place the clamp over the wiring, hoses, and control cables as shown.

b

c

d

a

e

g

f

a-Battery Cables

b-Remote Wiring Harness

c-Warning Gauge Wiring Harness

d-Control Cables

e-Oil Hose with Blue Stripe

f-Fuel Hose

g-Oil Hose

90-855347R1 JANUARY 1999 Page 1D-13

Page 51

OUTBOARD MOTOR INSTALLATION

2. Fasten clamp together with two screws.

a-Screws

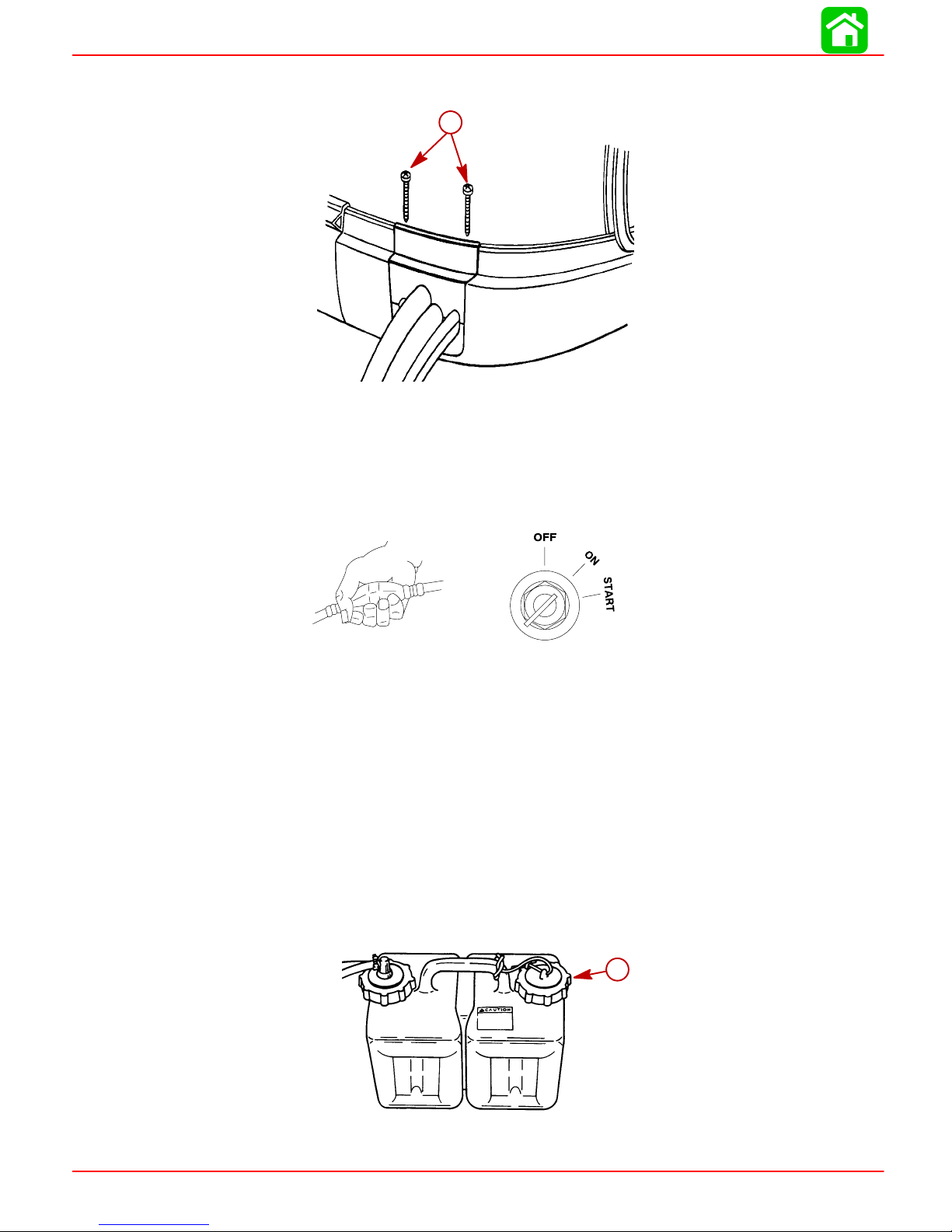

Filling Fuel System

NOTE: For initial start of a new engine or for an engine that ran out of fuel, or was drained

of fuel, the fuel system should to be filled as follows:

a

•

Squeeze the fuel line primer bulb until it feels firm.

•

Turn the ignition key switch to the ON position for three seconds. This operates the

electric fuel pump.

•

Turn the ignition key switch back to the OFF position, and squeeze the primer bulb

again until it feels firm. T urn the ignition key switch to the “ON” position again for three

seconds. Continue this procedure until the fuel line primer bulb stays firm.

Oil Injection Set-Up

Filling

1. Fill remote oil tank with the recommended oil listed in the Operation and Maintenance

Manual. Tighten fill cap.

a

a-Fill Cap

Page 1D-14 90-855347R1 JANUARY 1999

Page 52

2. Remove cap and fill engine oil tank with oil. Reinstall the fill cap.

a-Engine Oil Tank

b-Fill Cap

Priming the Oil Injection Pump

Before starting engine for the first time, prime the oil injection pump. Priming will re-

move any air that may be in the pump, oil supply hose, or internal passages.

a

OUTBOARD MOTOR INSTALLATION

b

a

b

a-Oil Injection Pump

b-Oil Supply Hose

CAUTION

T o prevent damage to the fuel pumps, fill the engine fuel system with fuel. Otherwise the fuel pumps will run without fuel during the priming process.

Prime the oil injection pump as follows:

1. Fill the engine fuel system with fuel. Connect fuel hose and squeeze primer bulb until

it fells firm.

2. Turn the ignition key switch to the “ON” position.

3. Within the first 10 seconds after the key switch has been turned on, move the remote

control handle from neutral into forward gear 3 to 5 times. This will automatically start

the priming process.

90-855347R1 JANUARY 1999 Page 1D-15

N

F

Page 53

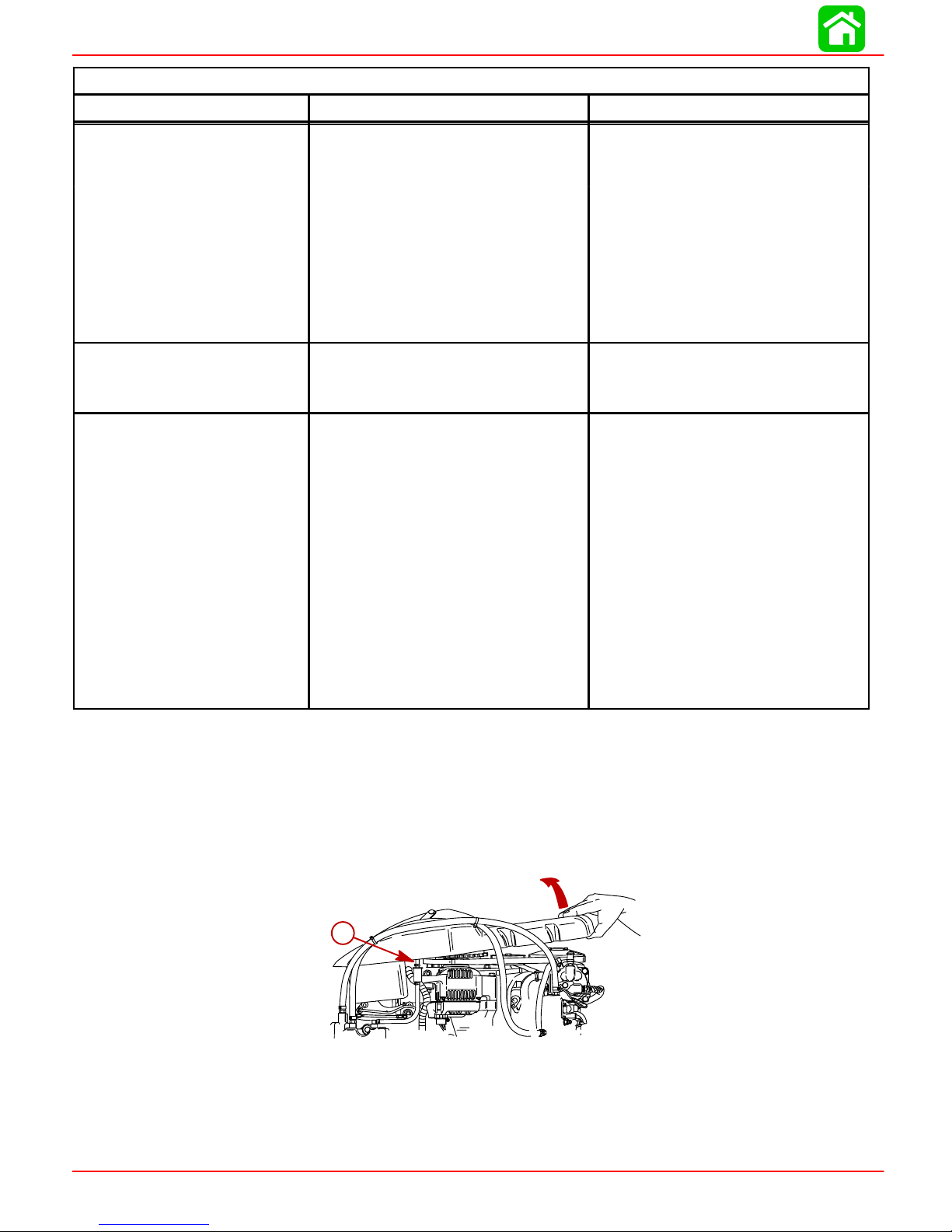

OUTBOARD MOTOR INSTALLATION

NOTE: It may take a few minutes for the pump to complete the priming process.

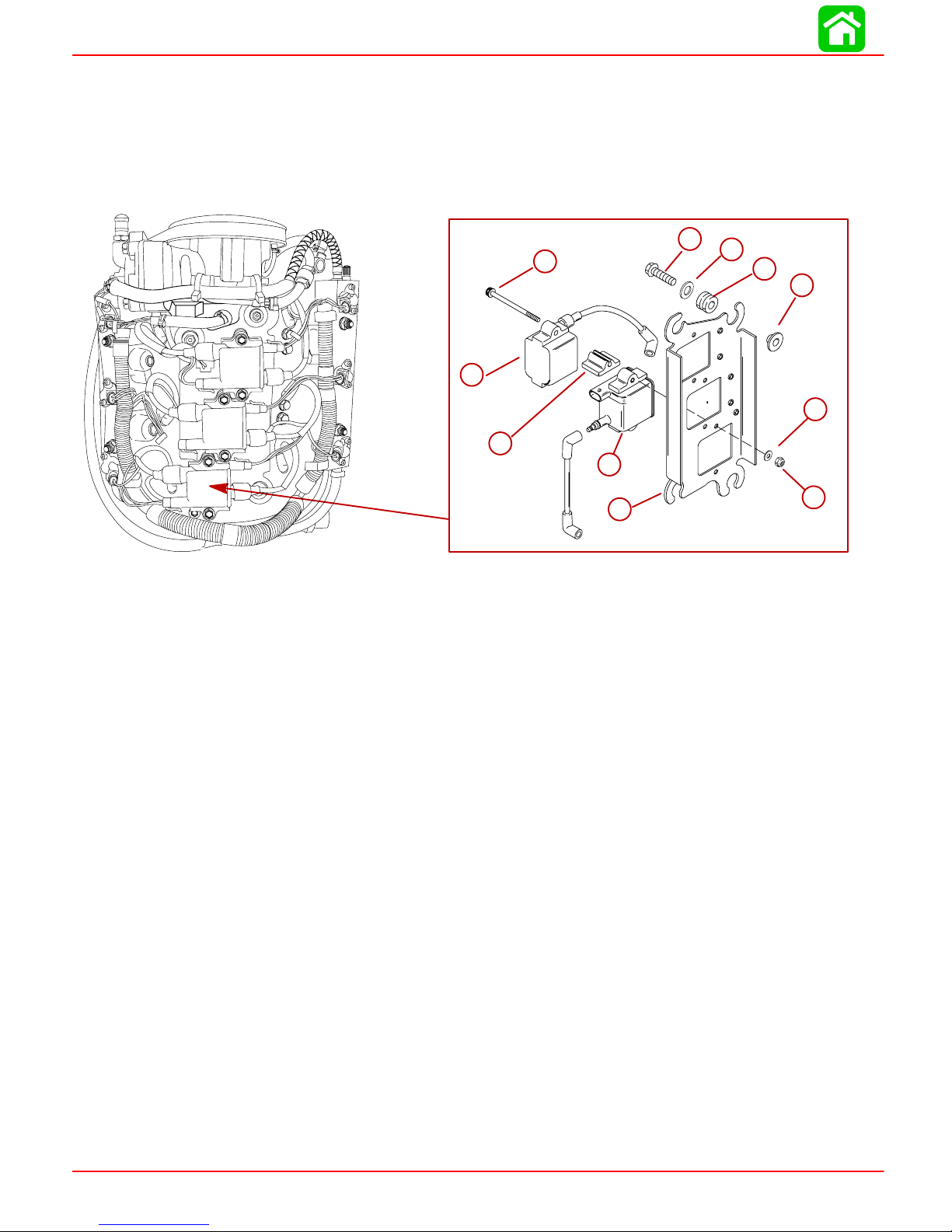

Purging Air From the Engine Oil Tank