Mercury MX 6.2 MPI, 350 MAG MPI Horizon, 350 MAG MPI, MX 6.2 MPI Horizon Installation Manual

Page 1

The following are registered trademarks of

Brunswick Corporation: Merc, MerCathode,

Mercury MerCruiser, Mercury, Mercury

Marine, Quicksilver, RideGuide, Thruster

and Mercury Precision Parts.

GASOLINE ENGINE TOW SPORTS AND

INBOARD MODELS INSTALLATION MANUAL

Models Covered

Inboard

Model Serial Number or Year

Tow Sports

Horizon

Notice

350 MAG MPI

MX 6.2 MPI

Model Serial Number or Year

350 MAG MPI 0M310000 and Above

Model Serial Number or Year

350 MAG MPI Horizon

MX 6.2 MPI Horizon

NOTICE

After completing installation, these instructions should be placed with the

product for the owner’s future use.

0M310000 and Above

0M310000 and Above

Predelivery preparation instructions must be performed before delivering boat

to the product owner.

Page 1 of 77 Printed in U.S.A. - 2002, Mercury Marine 90-864198020 MARCH 2002

NOTICE

Page 2

INSTALLATION MANUAL

Table Of Contents

General Information 3. . . . . . . . . . . . . . . . . . . . . .

Notice to Boat Manufacturer/Installer 3. . . . .

Torque Specifications 4. . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4. . . . . . . . . .

Quicksilver Products 5. . . . . . . . . . . . . . . . . . . . . .

Accessories 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Decal Placement 5. . . . . . . . . . . .

Engine Rotation 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Transmissions 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Velvet Drive Transmissions 6. . . . . . . . . . . . .

ZF / Hurth Transmissions 7. . . . . . . . . . . . . . .

Propeller Rotation 8. . . . . . . . . . . . . . . . . . . . .

Boat Construction 10. . . . . . . . . . . . . . . . . . . . . . .

Engine Bed 10. . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Connections 11. . . . . . . . . . . . . . . . . . . .

Seawater Pickup 11. . . . . . . . . . . . . . . . . . . . . .

Preliminary Connections 14. . . . . . . . . . . . . . . . .

Fuel Inlet Fitting 14. . . . . . . . . . . . . . . . . . . . . .

Inline Fuel Filter 15. . . . . . . . . . . . . . . . . . . . . .

Coolant Recovery System

Connections 17. . . . . . . . . . . . . . . . . . . . . . . .

Engine Mount Pre-Adjustment 18. . . . . . . . . . . .

Engine Preparation 19. . . . . . . . . . . . . . . . . . . . . .

Engine Oil Dipstick Relocation 19. . . . . . . . .

Engine Installation and Initial Engine

Alignment 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models With 8 Degree Down Angle

Transmissions 20. . . . . . . . . . . . . . . . . . . . . .

Models with V-Drive Transmissions 22. . . . .

All Models 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Water Heater Installation 24. . . . . . . . . . .

Exhaust System 26. . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Methods 29. . . . . . . . . . . . . . . .

Exhaust System Hose / Tube

Connections 32. . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 33. . . . . . . . . . . . . . . . . . .

Instrumentation Connections 33. . . . . . . . . . .

Audio Warning System Connections 34. . . .

Fluid Connections 35. . . . . . . . . . . . . . . . . . . . . . .

Coolant Recovery Bottle 35. . . . . . . . . . . . . . .

Final Engine Alignment 36. . . . . . . . . . . . . . . . . .

Throttle Cable Installation and

Adjustment 40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation And Adjustment 40. . . .

Velvet Drive Transmissions 41. . . . . . . . . . . .

ZF / Hurth Transmissions 49. . . . . . . . . . . . . .

Predelivery Preparation 54. . . . . . . . . . . . . . . . . .

Propeller Selection 54. . . . . . . . . . . . . . . . . . . .

Fuel Line Connection 55. . . . . . . . . . . . . . . . .

Battery 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Running Engine 57. . . . . . . . . . . . . . . . . .

Boat In The Water Tests 58. . . . . . . . . . . . . . .

Cold Weather and Extended Storage 59. . . . . .

Draining Instructions 59. . . . . . . . . . . . . . . . . . . . .

Identification 60. . . . . . . . . . . . . . . . . . . . . . . . .

Boat In Water 61. . . . . . . . . . . . . . . . . . . . . . . .

Boat Out Of The Water 65. . . . . . . . . . . . . . . .

All Models 67. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrumentation 68. . . . . . . . . . . . . . . . . . . . . . . . .

ECM 555 EFI System

Engine Wiring Diagrams 70. . . . . . . . . . . . . . . . .

Water Flow Diagrams 74. . . . . . . . . . . . . . . . . . . .

Predelivery Inspection 77. . . . . . . . . . . . . . . . . . .

Page 2 of 77 90-864198020

Page 3

General Information

Notice to Boat Manufacturer/Installer

Throughout this publication, Warnings and Cautions (accompanied by the International

!

Hazard Symbol

concerning a particular service or operation that may be hazardous if performed incorrectly

or carelessly. –– Observe Them Carefully!

These Safety Alerts, alone, cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus common sense operation,

are major accident prevention measures.

Hazards or unsafe practices which could result in severe personal injury or death.

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

IMPORTANT: Indicates information or instructions that are necessary for proper

installation and/or operation.

) are used to alert the manufacturer or installer to special instructions

INSTALLATION MANUAL

WARNING

CAUTION

NOTE: Refer to the Mercury MerCruiser Product Applications Manual - Gasoline Inboard

Models for application recommendations.

This installation manual has been written and published by Mercury Marine to aid the boat

manufacturer (OEM) in the installation of the products described herein.

It is assumed that these personnel are familiar with marine product installation.

Furthermore, it is assumed that they are familiar with, if not trained in, the recommended

installation procedures of Mercury MerCruiser product.

We could not possibly know of or advise the marine trade of all conceivable installations and

of the possible hazards and/or results of each installation. Therefore, the OEM is

responsible for any installation that does not fulfil the requirements of this manual.

It is the responsibility of the boat manufacturer to select the appropriate

engine/transom/drive package (including the correct gear ratio and propeller) for a given

boat. Mercury recommends that any new or unique hull/power package combination be

thoroughly water tested prior to sale, to verify that the boat performs as desired, and that

the engine runs in the appropriate rpm range.

It is recommended that a Mercury Marine Sales Application Engineer (SAE) be contacted

for assistance.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at time of publication. Mercury Marine reserves the right

to make changes at any time without obligation. As required, revisions to this manual will

be sent to all OEM boat companies.

90-864198020 Page 3 of 77

Page 4

INSTALLATION MANUAL

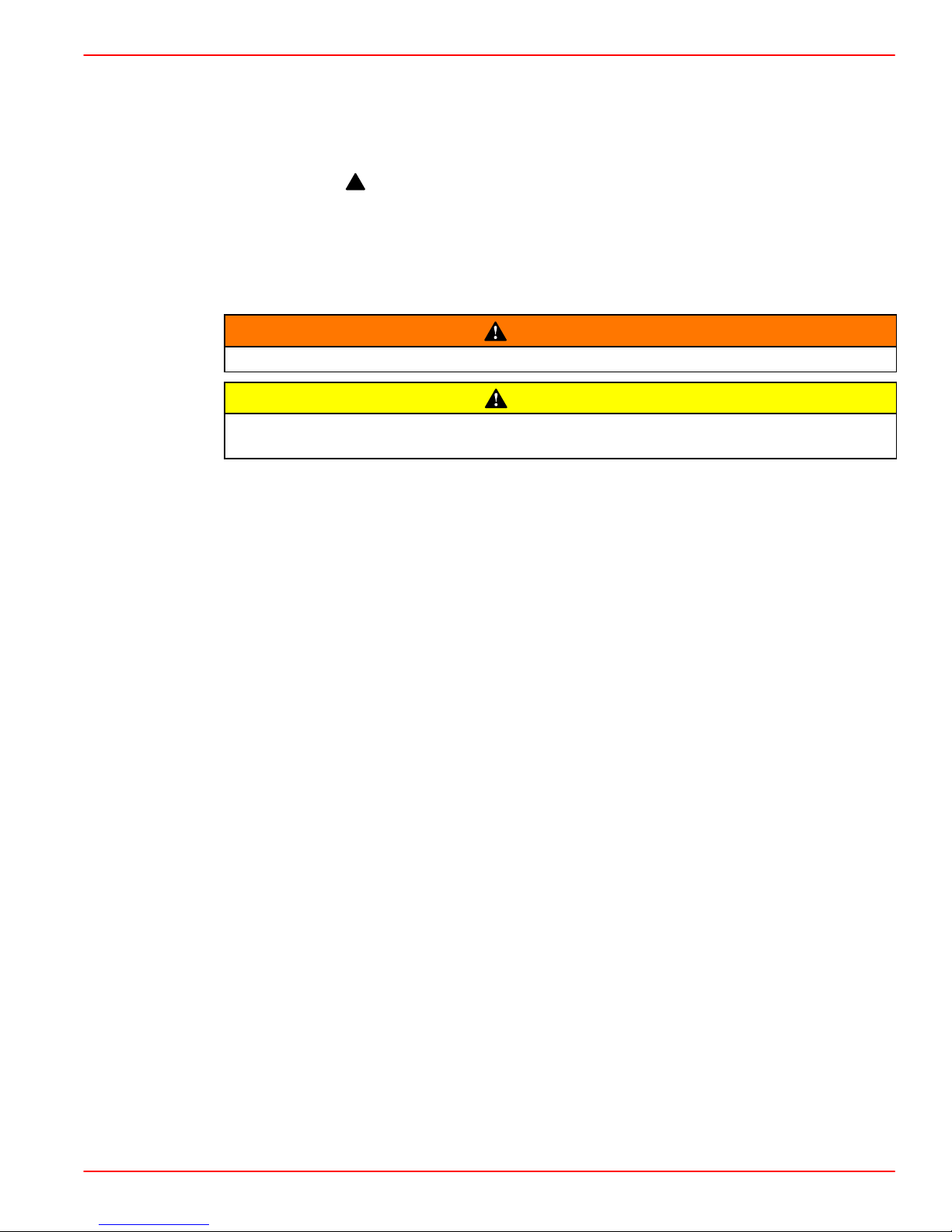

Torque Specifications

NOTE: Securely tighten all fasteners not listed below.

Description

Engine Mount Bracket Screws 64 47

Trunnion Clamping Bolt and Nut 68 50

Propeller Shaft Nut 68 50

Exhaust Manifold Screw 27 20

Coupler Bolts 68 50

1

Refer to Fuel Delivery System.

Lubricants / Sealants / Adhesives

Description Where Used Part Number

Marine Caulking Mounting Surfaces Obtain Locally

Loctite 271 Seawater Pickup Nut 92-809820

Loctite 592 PST

Liquid Neoprene Battery Terminals 92-25711-2

Nm lb-in. lb-ft

Hose Fitting Threads

Plastic Plug Threads

Fuel Inlet Fitting

Obtain Locally

Engine Coupler Spline Grease Coupler Splines 92-816391A4

Page 4 of 77 90-864198020

Page 5

Quicksilver Products

Accessories

Quicksilver gauges, remote controls, steering systems, propellers and other accessories

are available for this product. Mercury MerCruiser recommends the use of Quicksilver parts

on all applications. Refer to Mercury Precision Parts / Quicksilver Accessories Guide for a

complete listing.

This Guide is available from:

Attn: Parts Department

W6250 W. Pioneer Road

Fond du Lac, WI 54936-1939

Outside of U.S.A., order through Distribution Center or Distributor.

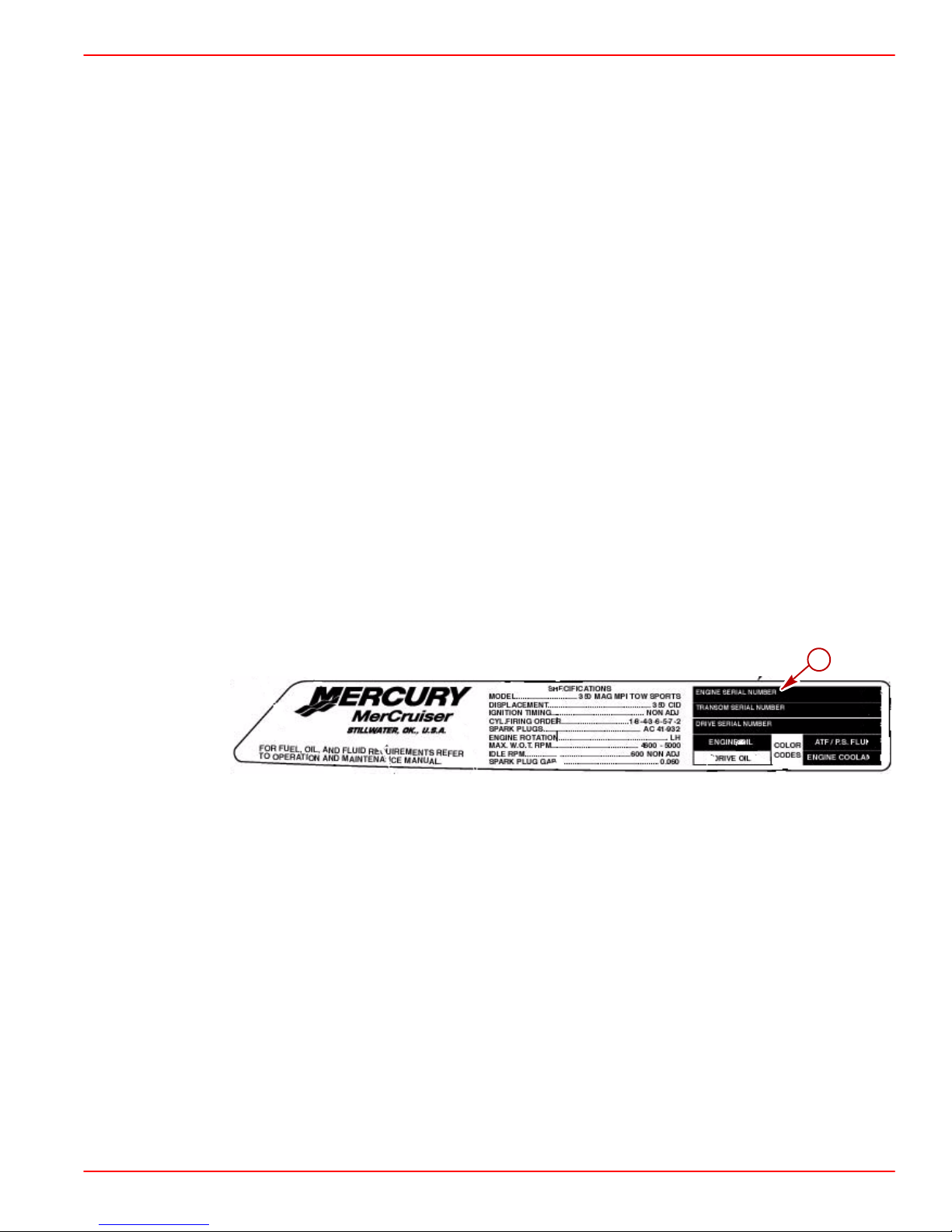

Serial Number Decal Placement

There are three engine serial number decal strips provided with each power package. One

should be used for each of the following:

INSTALLATION MANUAL

Mercury Marine

P.O. Box 1939

• Engine Specification Decal

• Warranty Registration Card

• Operation, Maintenance and Warranty Manual identification page.

Affix engine serial number decal to specification / serial number decal in position shown.

a-Engine Serial Number Location

Engine Rotation

Engine rotation is described when observed from the rear of the engine (transmission end)

looking forward (water pump end). Engine rotation is indicated on engine specifications and

serial number decal.

a

77962

90-864198020 Page 5 of 77

Page 6

INSTALLATION MANUAL

Transmissions

Velvet Drive Transmissions

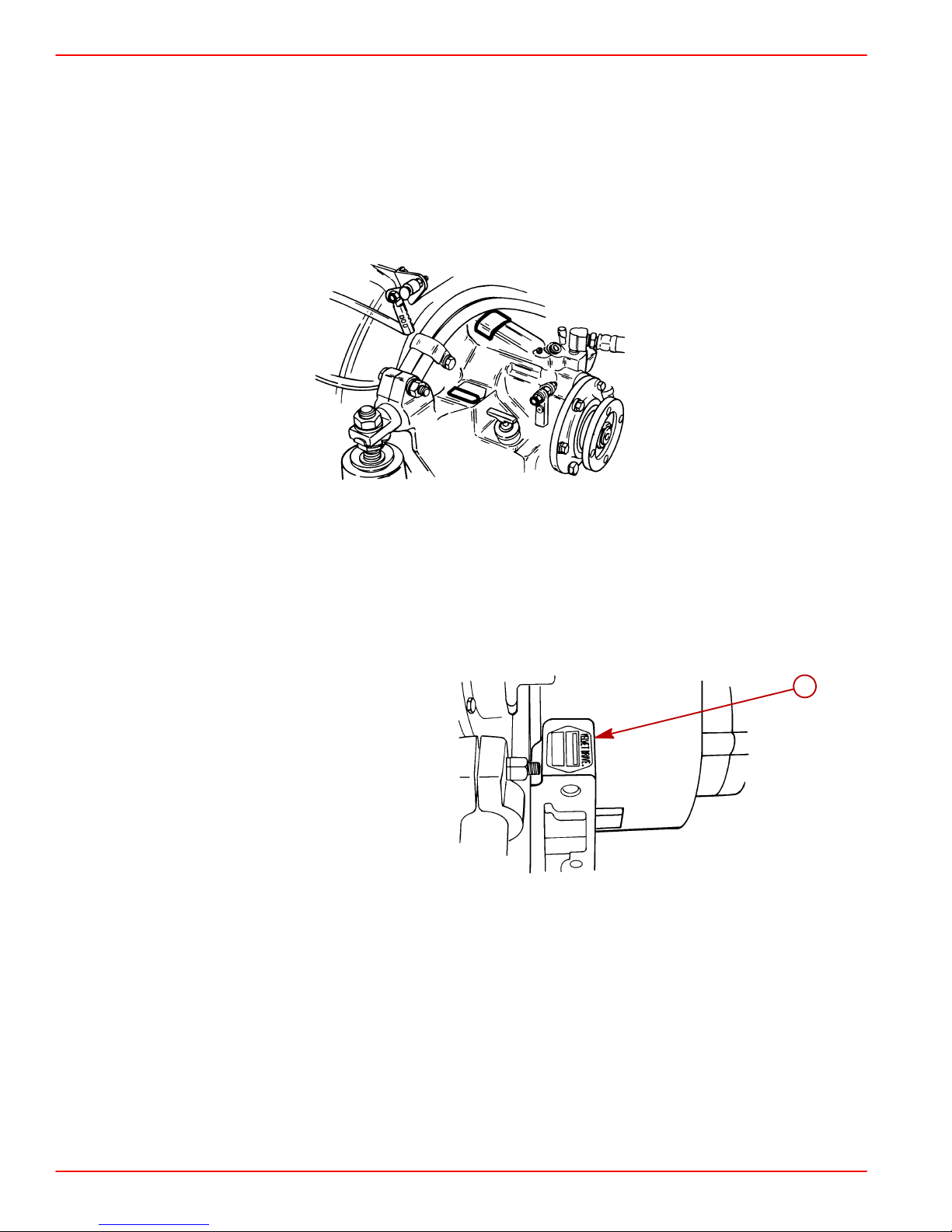

On the Velvet Drive 71C and 72C In-Line and 72C Remote V-Drive Transmissions the gear

ratio (in FORWARD gear) is marked on transmission identification plate. Transmission output shaft rotation and propeller rotation required (in FORWARD gear) are indicated on a decal on the transmission case. Transmission rotation is described when viewed from the rear

of transmission.

22556

In-Line Transmission Shown (Remote V-Drive Similar)

a-Transmission Identification Plate

b-Gear Ratio (In FORWARD Gear)

c-Output Flange Rotation Decal (In FORWARD Gear)

On the Velvet Drive 5000A and 5000V Transmissions the transmission identification plate

indicates gear ratio, serial number and model.

a

71778

Velvet Drive 5000A 8 Degree Down-Angle Transmission Shown (5000V V-Drive

Similar)

a-Transmission Identification Plate

Page 6 of 77 90-864198020

Page 7

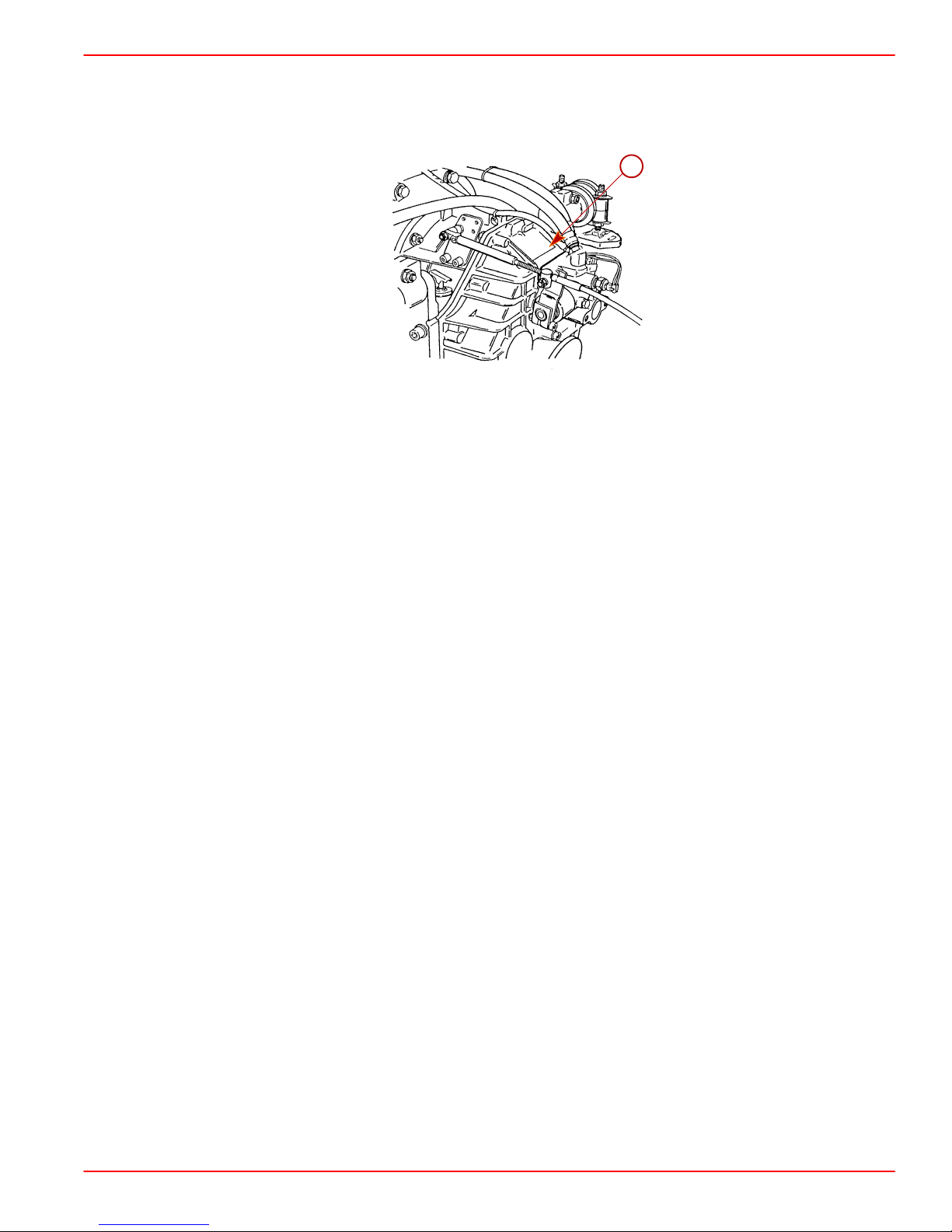

ZF / Hurth Transmissions

On the ZF / Hurth 630A 8 Degree Down-Angle and 630V V-Drive Transmissions the

transmission identification plate indicates gear ratio, serial number and model.

Typical ZF / Hurth Down-Angle Transmission Shown (V-Drive Similar)

a-Transmission Identification Plate

INSTALLATION MANUAL

a

73587

90-864198020 Page 7 of 77

Page 8

INSTALLATION MANUAL

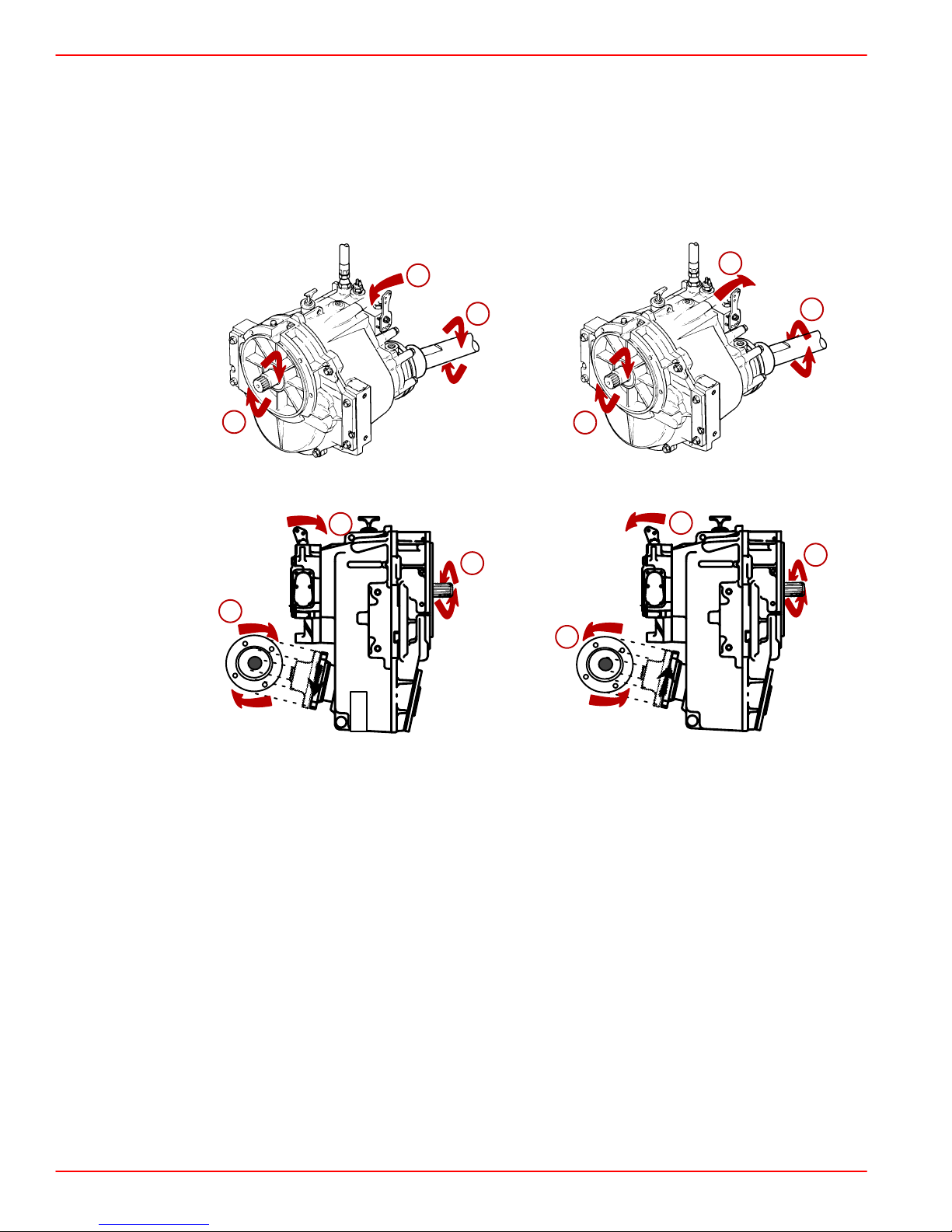

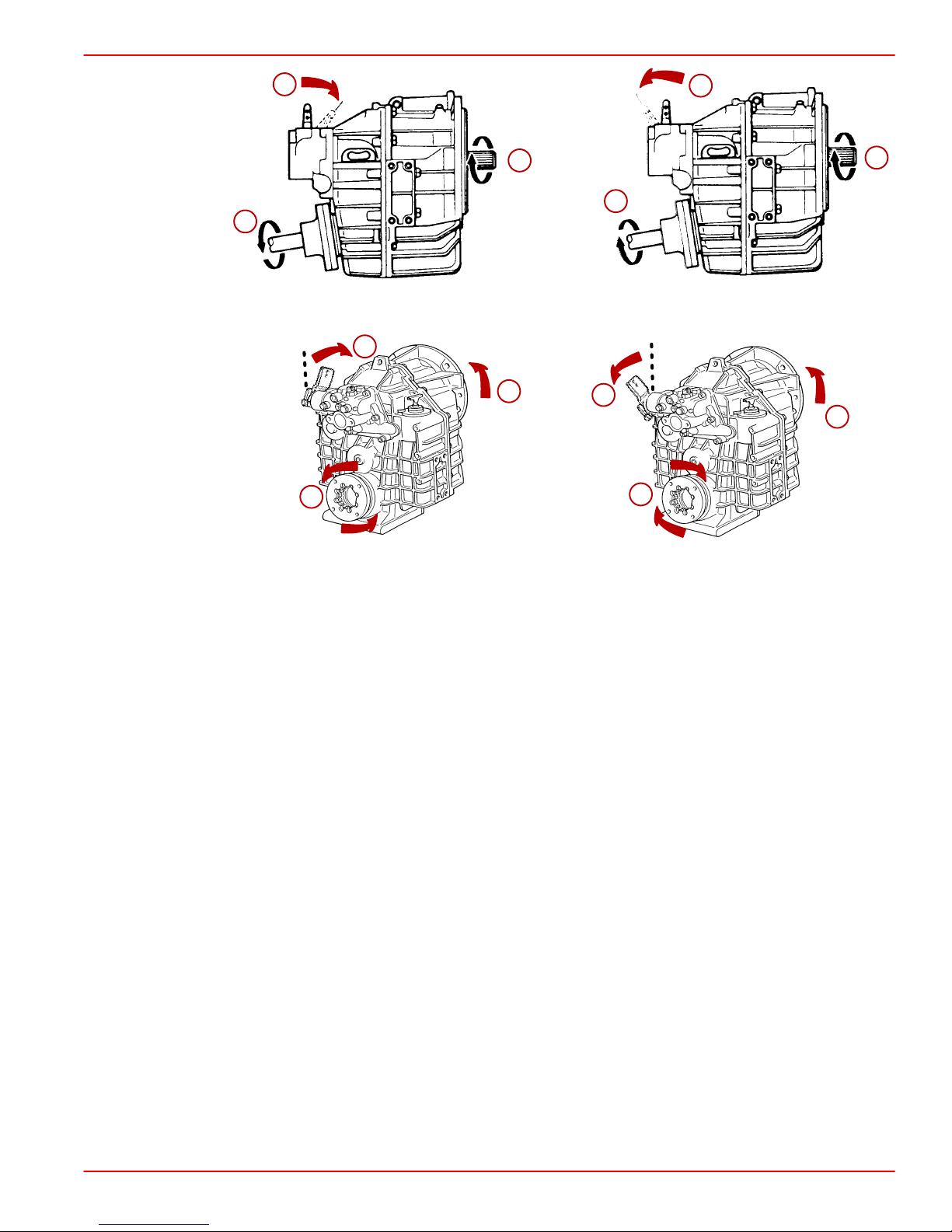

Propeller Rotation

Propeller rotation is not necessarily the same as engine rotation. Refer to the appropriate

following information and drawings for specific information.

These transmissions are full power reversing transmissions, allowing a standard (LH

rotation) engine to be used for both propeller rotations. Propeller rotation (output shaft

rotation) is determined by shift cable attachment at the remote control. Be sure to use

correct rotation propeller and shift cable hook up for direction desired.

a

c

b

Velvet Drive 5000A - 8 Degree Down-Angle Transmission

b

a

b

f

g

d

e

71888

d

b

Velvet Drive 5000V - V-Drive Transmissions

a-Direction of Shift Lever Engagement (Toward Flywheel)

b-Engine/Transmission Input Shaft Rotation Direction (LH)

c-Transmission Output/Propeller Shaft Rotation Direction (LH)

d-Direction of Shift Lever Engagement (Away From Flywheel)

e-Transmission Output/Propeller Shaft Rotation Direction (RH)

f-Transmission Output/Propeller Shaft Rotation Direction (LH as viewed at

propeller)

g-Transmission Output/Propeller Shaft Rotation Direction (RH as viewed at the

propeller)

74604

Page 8 of 77 90-864198020

Page 9

INSTALLATION MANUAL

a

d

b

c

e

ZF / Hurth 630A or 800A - 8 Degree Down-Angle Transmissions

a

b

c

d

e

b

25506

b

72959

ZF / Hurth 630V - V-Drive Transmissions

a-Direction Of Shift Lever Engagement (Toward Flywheel)

b-Engine/Transmission Input Shaft Rotation Direction (LH)

c-Transmission Output/Propeller Shaft Rotation Direction (LH)

d-Direction Of Shift Lever Engagement (Away From Flywheel)

e-Transmission Output/Propeller Shaft Rotation Direction (RH)

90-864198020 Page 9 of 77

Page 10

INSTALLATION MANUAL

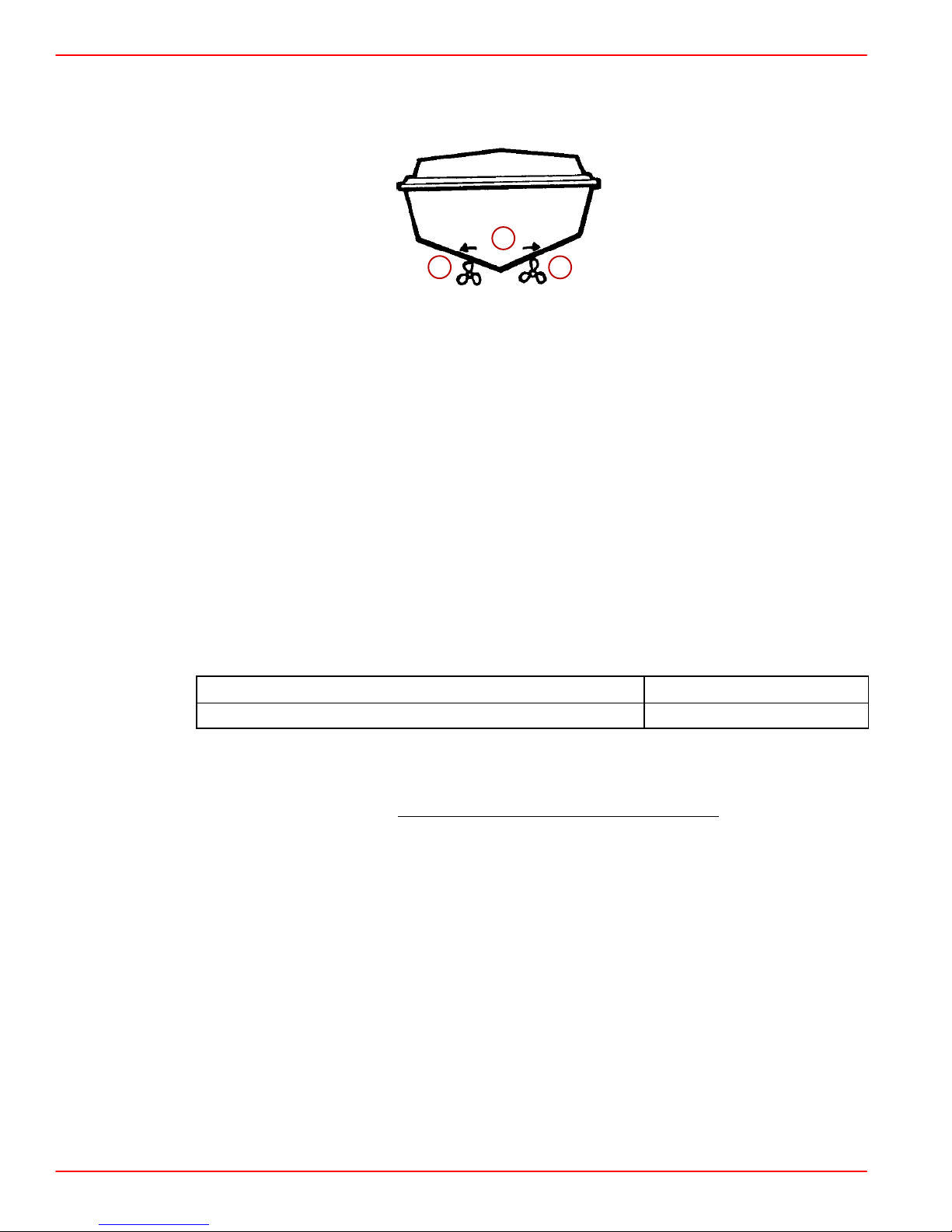

DUAL INSTALLATIONS

Best all-around performance usually is obtained by installing engines so that propellers turn

outboard (looking at the stern).

a

c

a-Outboard Propeller Rotation

b-RH Rotation

c-LH Rotation

b

VELVET DRIVE IN-LINE AND V-DRIVE TRANSMISSIONS (EXCEPT 5000 SERIES)

IMPORTANT: Velvet Drive In-Line and V-Drive Transmissions Only – Use of proper

rotation propeller (specified on transmission output flange rotation decal) is critical

since the transmission must be operated in FORWARD gear selector position only

to drive boat forward. If the wrong rotation propeller is installed and transmission is

operated in REVERSE to propel the boat forward, transmission failure WILL occur.

IMPORT ANT: On engines which are equipped with Velvet Drive In-line transmissions,

a LH propeller is required.

Boat Construction

Engine Bed

Difference Between Starboard and Port Engine Mount 22-1/2 in. (572 mm)

Mount Adjustment Up and Down (minimum) 1/4 in. (6mm)

22457

NOTE: Although the engine mounts allow some adjustment, ensure that the front and rear

mount locations in the vessel are in the same plane and parallel. This may be checked by

tying a string from the left front mount location to the right rear mount location and another

from right front to left rear. The strings should touch where they cross

Page 10 of 77 90-864198020

.

Page 11

Seawater Connections - General Information

NOTICE

Refer to manufacturer’s instructions for information on removal and installation of

other than Quicksilver Seawater Pickups.

IMPORT ANT: Seal the inside edges of any hole made through the hull with a suitable

sealant to prevent water absorption and deterioration.

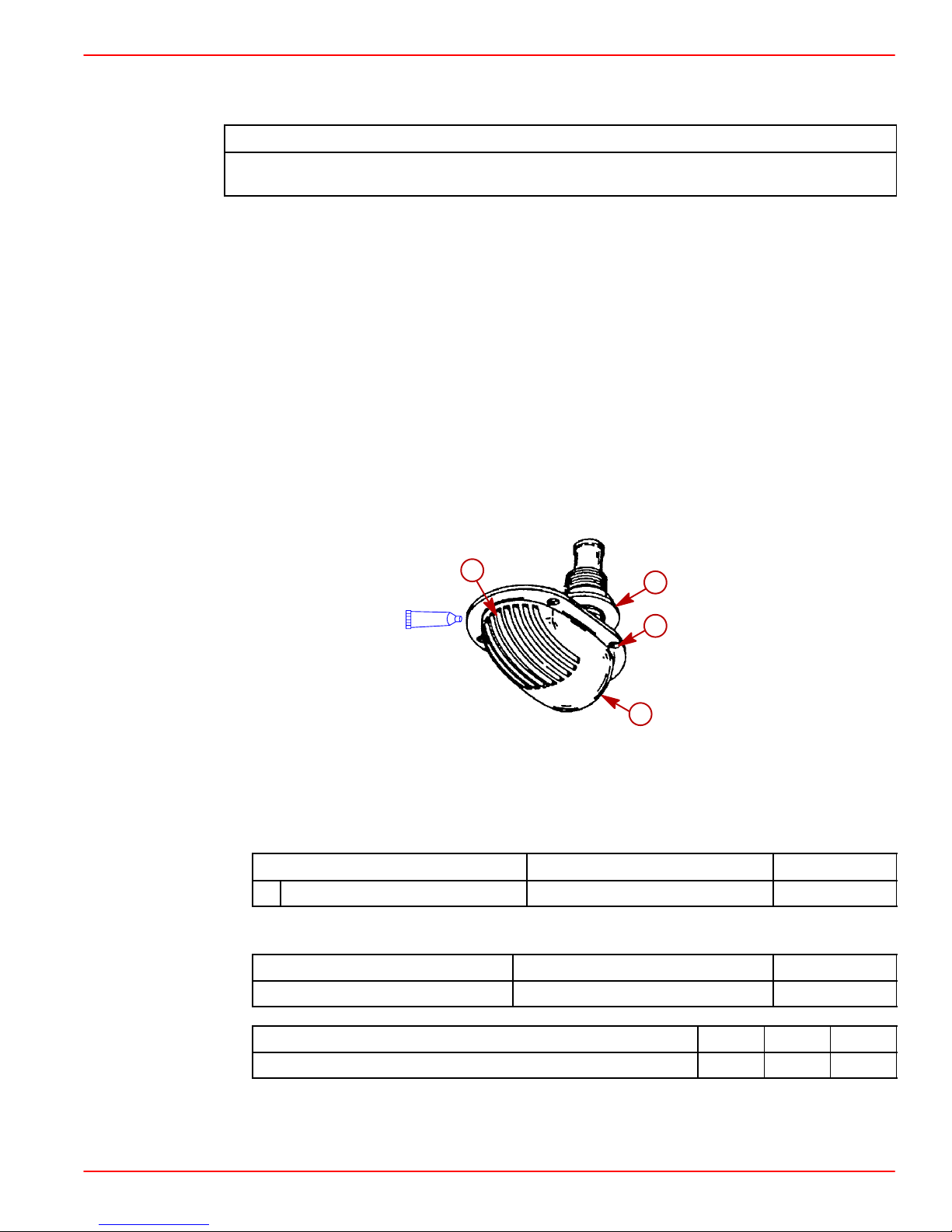

Seawater Pickup

THROUGH THE HULL MOUNTED

1. Seal inside edges of 1-3/4 in. (44 mm) hole in hull using a suitable sealer.

2. Apply marine caulking (sealer) to mounting surface on seawater pickup where hull

contact will occur when installed.

IMPORT ANT: Seawater inlet slots must face forward - parallel with the flow of water .

3. Ensure slots in seawater pickup are facing forward (toward bow of boat) and install

seawater pickup through hull.

4. Fasten pickup with four appropriate mounting screws (if so designed).

INSTALLATION MANUAL

5. Apply marine caulking as needed inside boat.

b

A

a-Seawater Pickup

b-Seawater Inlet Slots

c-Mounting Screw Holes (If Equipped)

d-Nut

Description

A Marine Caulking Mounting Surfaces Obtain Locally

6. Apply sealant to threads of nut and install on pickup on inside of boat and torque nut.

Where Used Part Number

d

c

a

72639

Description

Loctite 271 Seawater Inlet Nut 92-809820

Description Nm lb-in. lb-ft

Nut 42 35

NOTE: If pickup being installed does not have mounting screws on underside where

mounted to hull, be certain, after nut is torqued, that slots are still facing forward.

90-864198020 Page 11 of 77

Where Used Part Number

Page 12

INSTALLATION MANUAL

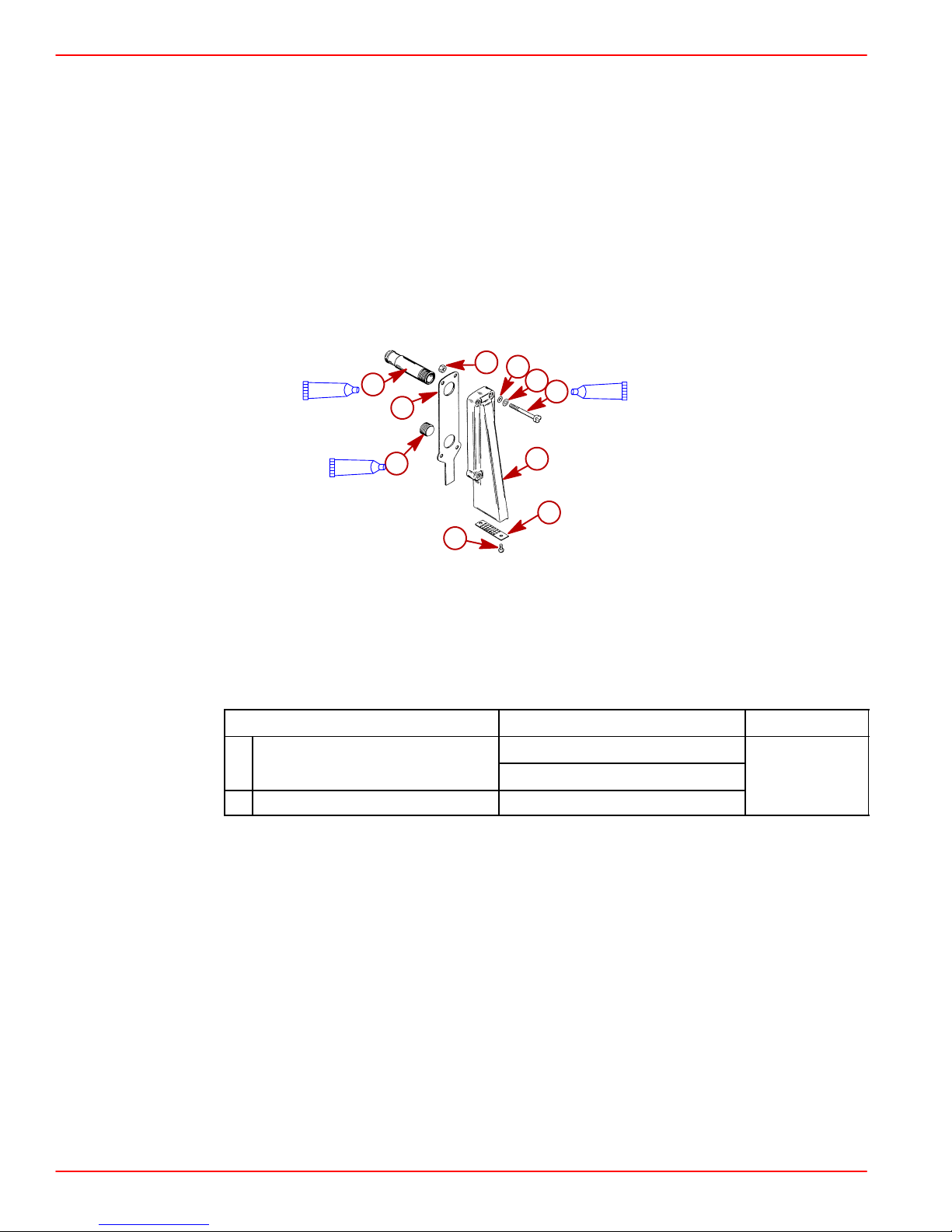

TRANSOM MOUNTED

1. Seal the inside edges of the 1-1/2 in. (38 mm) hole hose fitting.

2. Ensure that the hose fitting and plastic plug are in place and threads have been sealed

prior to tightening each securely.

NOTE: Use a sharp knife or wood chisel to remove excess plastic plug material so that plug

is flush with pickup casting.

3. Position one flat washer and one rubber O-ring on each 5/16 in. x 4 in. (102 mm) long,

round head screw. Coat each screw shaft with sealant.

4. Place new gasket on pickup housing and hold pickup in place on transom. Install four

round head screws (with washers and O-rings in place) into pickup mounting holes and

through drilled 21/64 in. (8 mm) holes in transom.

b

d

A

a

e

B

f

c

g

A

h

i

j

a-Hose Fitting

b-Nut (4)

c-Gasket

d-O-ring (4)

e-Washer (4)

Description

A Loctite 592 PST

B Silicone Sealant Or Equivalent Screw Shaft

Hose Fitting Threads

Plastic Plug Threads

72640

f-Screw (4)

g-Plastic Pug

h-Pickup

i-Screen

j-Screw (2)

Where Used Part Number

Obtain Locally

Page 12 of 77 90-864198020

Page 13

INSTALLATION MANUAL

NOTE: Some installations may have 7/32 in. (5 mm) holes drilled in transom using four 5/16

in. diameter stainless steel lag bolts in place of round head screws. In any case, flat washers

and O-rings are required as outlined.

a

b

72641

Water Pickup Installed on Transom

a-Diagonal Mount - Leading Edge Of Pickup 1/8 in. (3.2 mm) From Boat Bottom.

b-Vertical Mount - Corner Of Leading Edge Of Pickup 1/8 in. (3.2 mm) From Boat

Bottom

5. Secure water pickup from inside with locknuts and washers (unless using lag bolts).

6. Tighten fasteners securely.

90-864198020 Page 13 of 77

Page 14

INSTALLATION MANUAL

Preliminary Connections

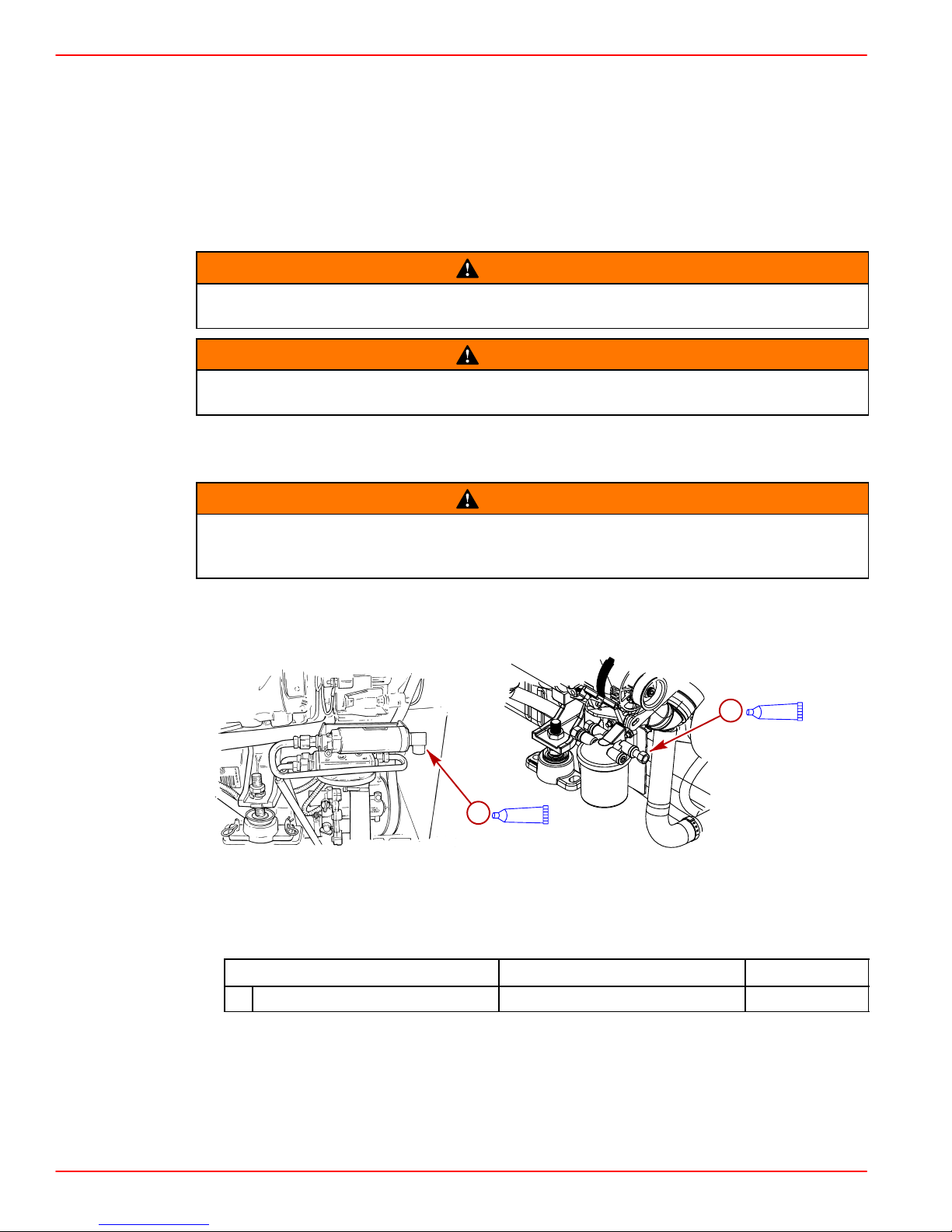

Fuel Inlet Fitting

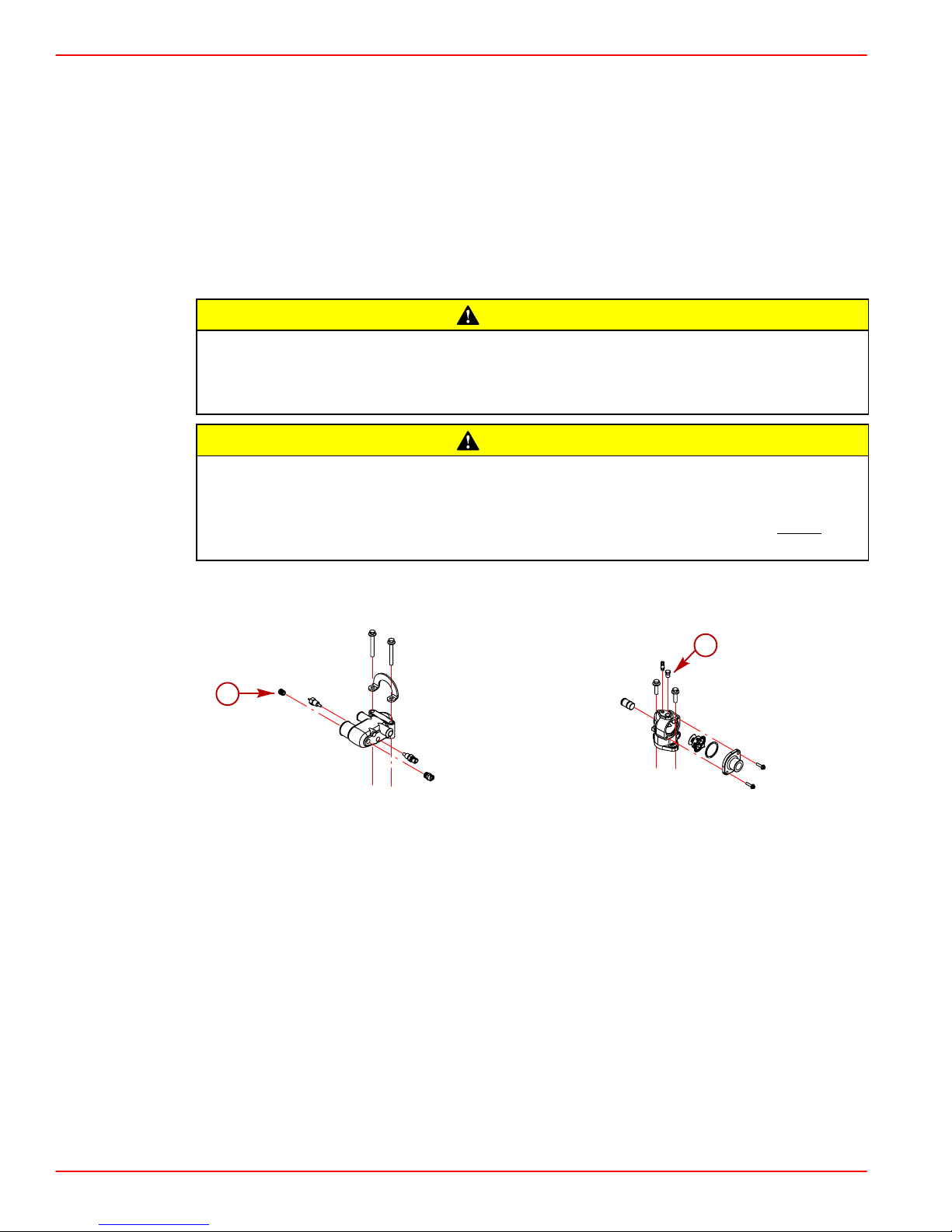

IMPORTANT: The following information is provided to ensure proper installation of

brass fittings or plugs installed into fuel pump or fuel filter base:

• Use #592 Loctite Pipe Sealant with Teflon on threads of fuel inlet fittings or plugs.

DO NOT USE TEFLON TAPE.

Boating standards (NMMA, ABYC and others) and Coast Guard regulations must

be adhered to when installing fuel delivery system.

Avoid gasoline fire or explosion. Improper installation of brass fittings or plugs into

fuel pump or fuel filter base can crack casting and/or cause a fuel leak.

1. Remove plastic plug from fuel inlet hole.

2. Apply sealant to threads of fuel inlet fitting. DO NOT USE TEFLON TAPE.

WARNING

WARNING

WARNING

Overtightening the fuel inlet fitting can lead to fuel leaks, avoid severe personal

injury or death from a gasoline fire or explosion. DO NOT use a power tool (i.e.

impact wrench) to tighten the fuel inlet fitting.

3. Install fuel inlet fitting in fuel pump or filter base. To prevent cracking the casting or

causing fuel leaks, turn fuel inlet fitting in by hand until finger tight. Tighten the fitting an

additional 1-3/4 to 2-1/4 turns with wrench. DO NOT OVERTIGHTEN.

a

a

78276

Models With Boost Pump Models With Out Boost Pump

a-Fuel Inlet Fitting

A

A

77950

Description

A Loctite 592 Fuel Inlet Fitting Obtain Locally

Page 14 of 77 90-864198020

Where Used Part Number

Page 15

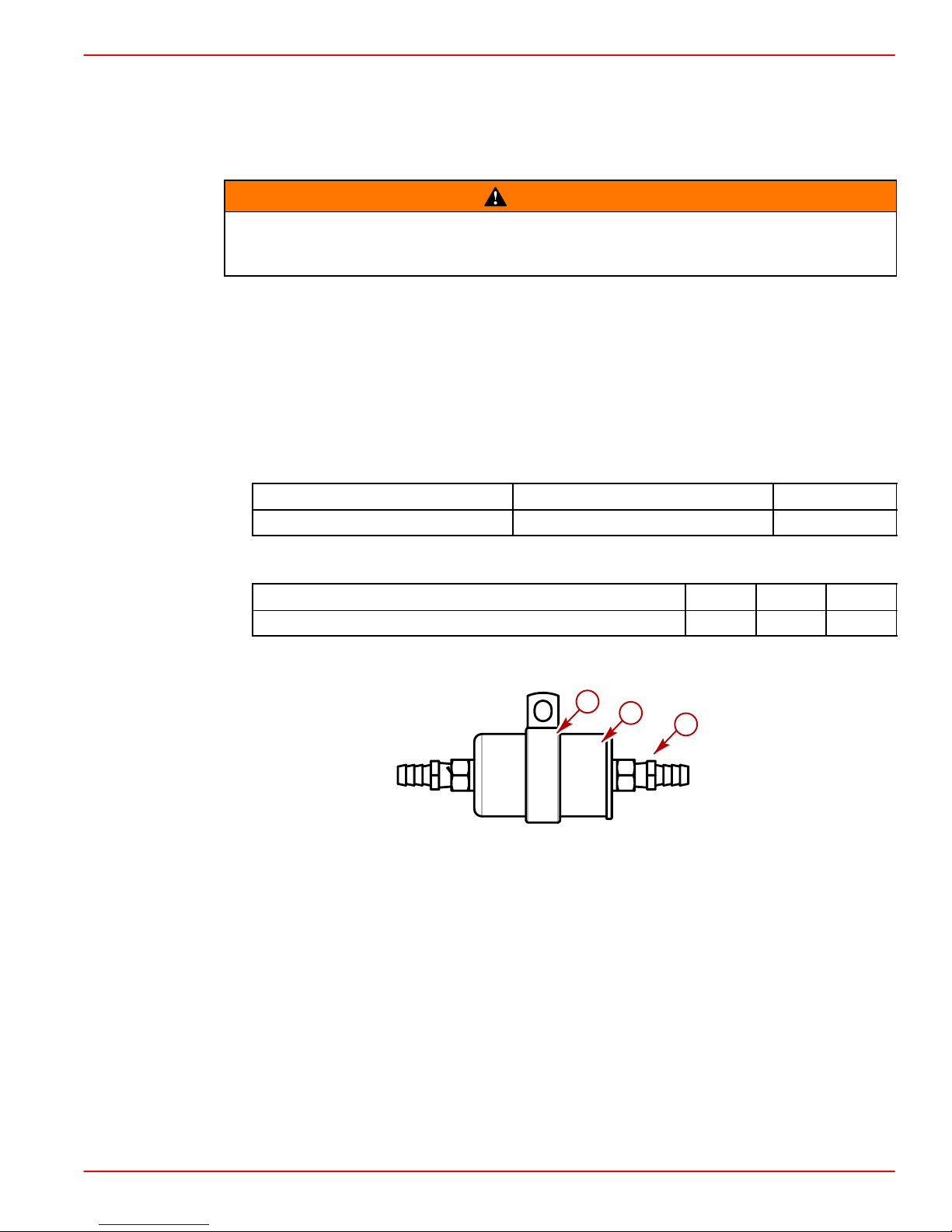

Inline Fuel Filter

INSTALLATION

IMPORTANT: If the engine is equipped with a boost pump, an inline filter must be

installed between the fuel tank and the boost pump.

Avoid injury or death and power package damage from an electrical shock, fire or

explosion. Always disconnect both battery cables from the battery before servicing

the power package.

1. Disconnect both battery cables from the battery.

2. Install boat fuel line from the tank to the engine.

3. With the engine installed, locate a section of the fuel line in a serviceable location,

4. Remove 76 mm (3 in.) of fuel line in mounting location.

5. Select appropriate size connector for the fuel line and install the connector on the filter.

6. Apply sealant to the male pipe threads on the connectors.

INSTALLATION MANUAL

WARNING

leaving enough room for filter, connections and bracket mounting.

Description

Where Used Part Number

Loctite 565 Male Threads Obtain locally

7. Torque connectors.

Description

Nm lb-in. lb-ft

Connectors 19-27 14-20

8. Insert filter into the mounting clip.

c

a

b

a-Inline Filter

b-Connectors

c-Mounting Clip

78289

90-864198020 Page 15 of 77

Page 16

INSTALLATION MANUAL

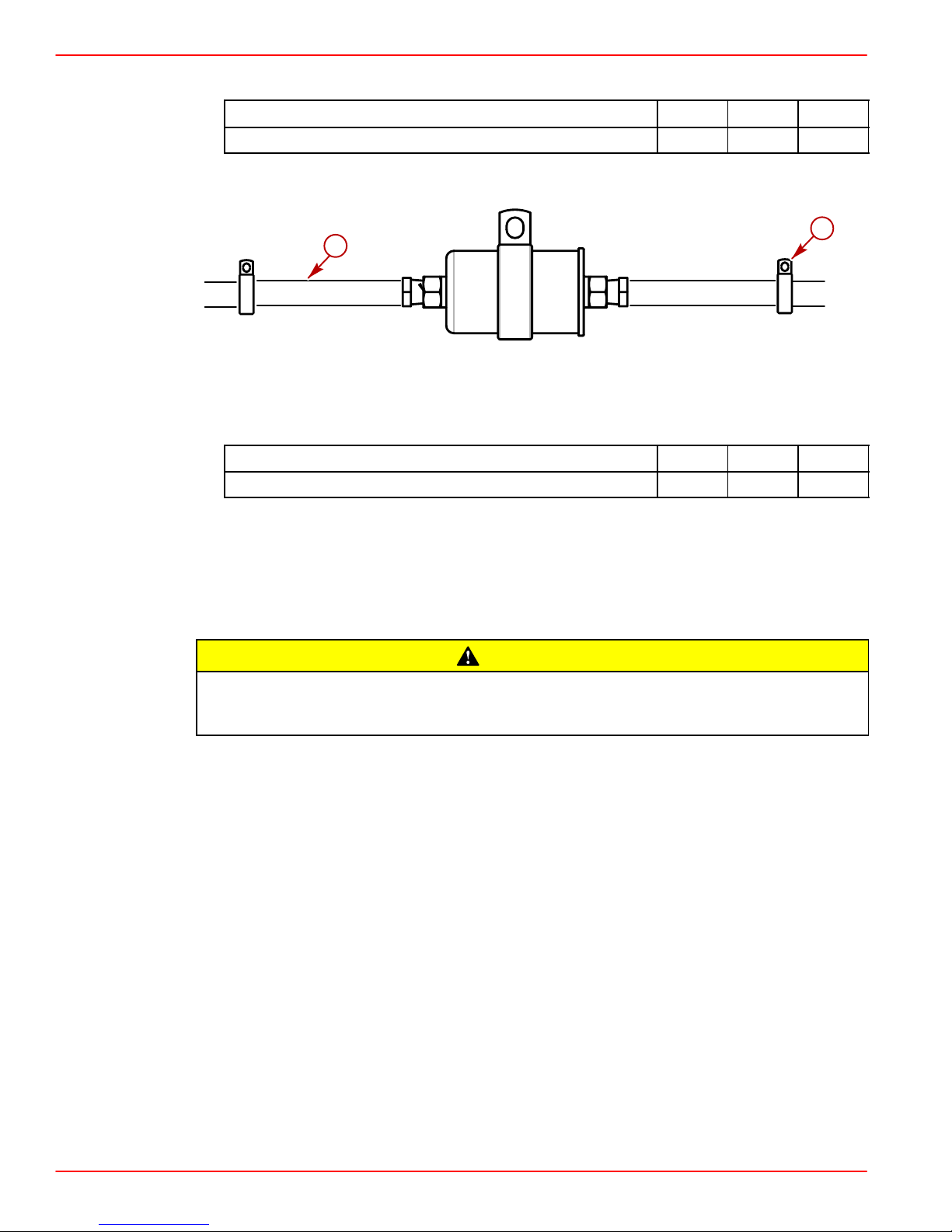

9. Install and torque screw and washer through the mounting clip into the stringer.

Description

Nm lb-in. lb-ft

Screw, Mounting Clip 12.2 9

10. Install and torque hose clamps over hose and insert barbs into hose.

a

b

78289

a-Fuel Line Stringer Clips

b-Fuel Line

Description

Hose Clamps 3.4-6.8 30-60

11. Inspect the fuel line stringer clips to ensure that the recommended length between clips

has not been exceeded. The maximum allowable length is 45.7 mm (18 in.).

Nm lb-in. lb-ft

12. Pressurize the fuel system and check for leaks. Relieve pressure and then check for

leaks again.

SPECIAL INFORMATION ABOUT ELECTRIC FUEL PUMPS

CAUTION

The electric fuel pump and factory installed water separating fuel filter have been

carefully designed to function properly together . Do not install additional fuel filters

and/or water separating fuel filters between fuel tank and engine.

The installation of additional filters may cause:

• Fuel Vapor Locking

• Difficult Warm-Starting

• Piston Detonation Due to Lean Fuel Mixture

• Poor Driveability

Page 16 of 77 90-864198020

Page 17

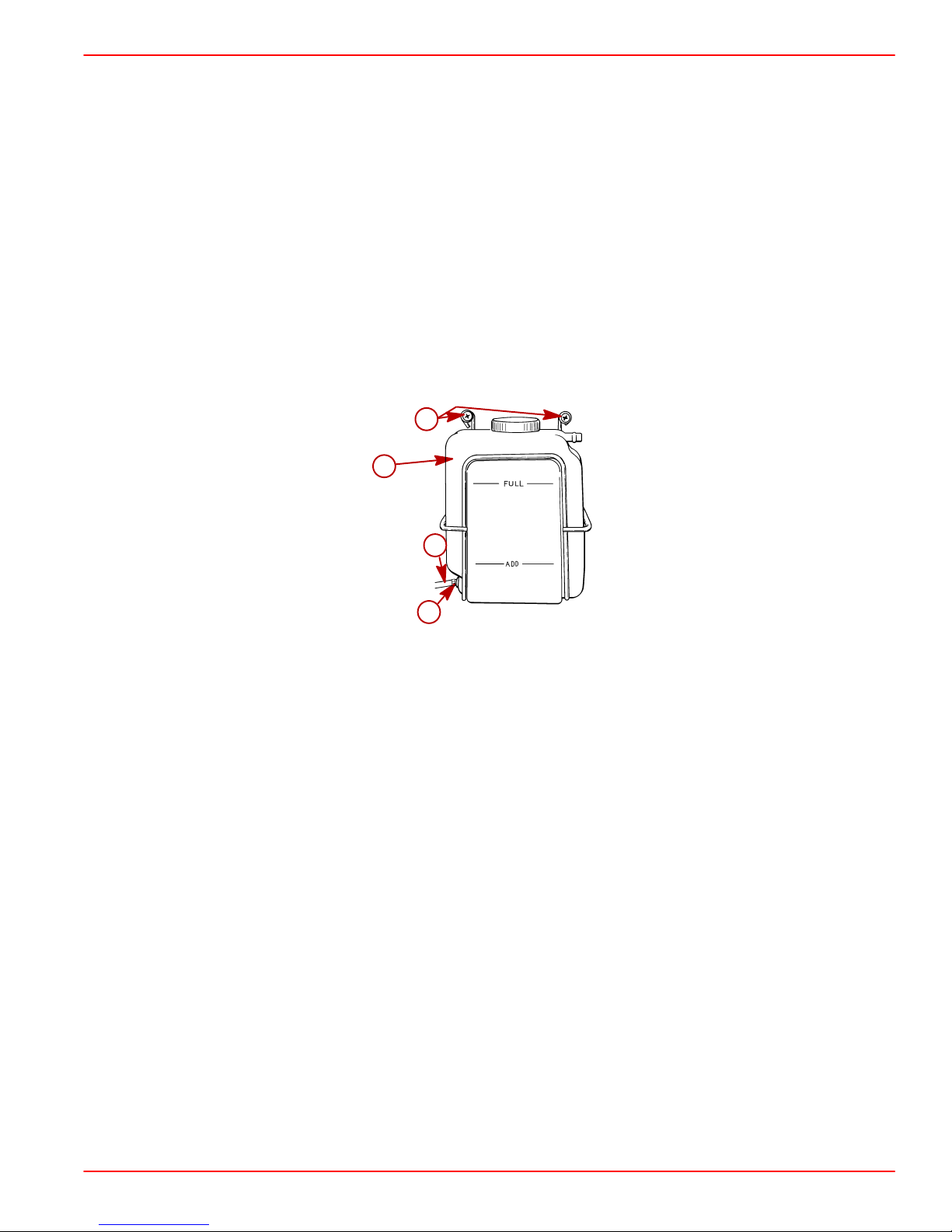

Coolant Recovery System Connections

1. Select a mounting location for coolant recovery bottle and mounting bracket that meets

all of the following:

• Within limits of clear plastic tubing.

• Level with or above the heat exchanger fill neck.

• Accessible for observing coolant level and filling.

2. Mount coolant recovery bottle and mounting bracket in desired location, using two

3/4 in. (19 mm) long screws and flat washers.

3. Route plastic tubing to recovery bottle. Ensure that tubing is positioned away from any

moving parts. Cut plastic tubing as required and connect to bottom connection on recovery bottle and secure with tubing clamp provided.

4. Fasten plastic tubing to boat as necessary, with the 2 hose clips and 1/2 in. (13 mm) long

screws provided.

b

a

INSTALLATION MANUAL

c

d

a-Recovery Bottle And Mounting Bracket

b-Screws And Flat Washers

c-Plastic Tubing

d-Tubing Clamp

70547

90-864198020 Page 17 of 77

Page 18

INSTALLATION MANUAL

Engine Mount Pre-Adjustment

1. Remove hardware holding engine to shipping pallet. Attach a suitable sling to lifting eyes

on engine. Lift engine from pallet with an overhead hoist.

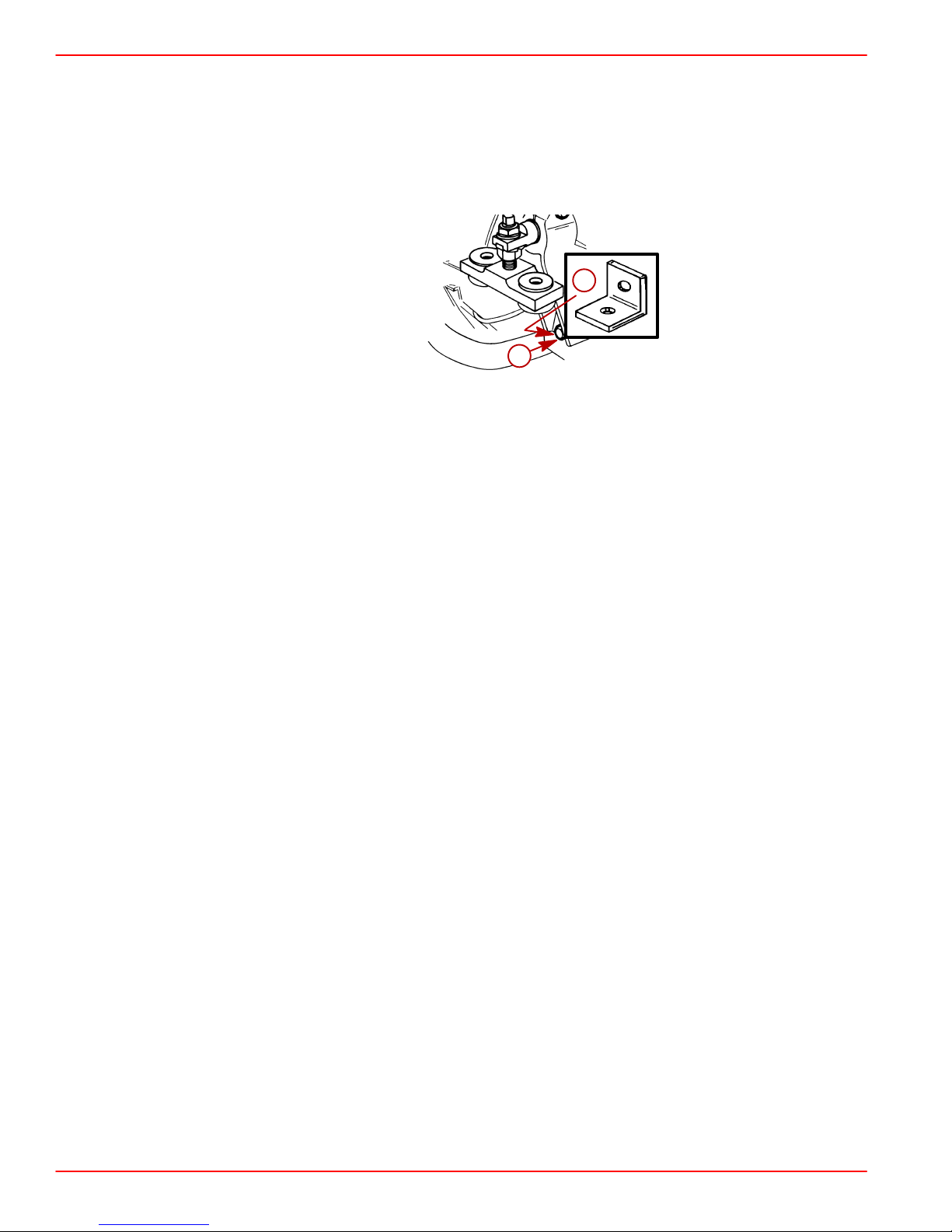

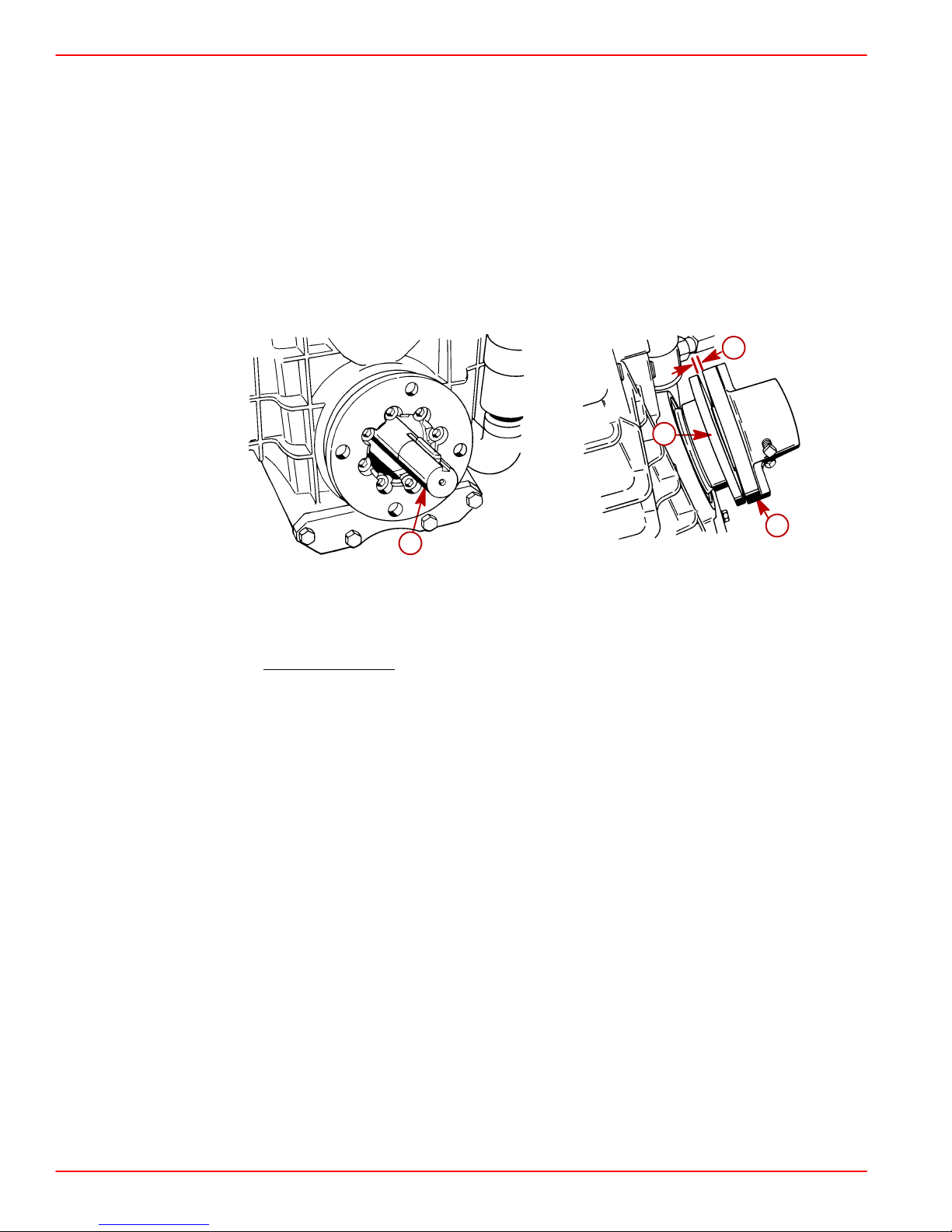

2. Remove L-shaped shipping bracket from both rear (transmission) mounts as shown.

Retorque mount bracket attaching screw to 47 lb-ft (64 Nm).

a

b

74623

Typical

a-L-shaped Bracket

b-Transmission Mount Bracket Attaching Screw

IMPORTANT: Engine mounts must be adjusted, as explained in Steps 3. and 4., to

center mount adjustment and establish a uniform height on all mounts.

3. Check all 4 engine mounts (2 front, 2 rear) to ensure that distance from bottom of mount

to bottom of trunnion is as shown. If not, loosen mount locking nut and turn adjusting nut

in direction required to obtain proper dimension, then retighten locking nut. Be sure to

leave mount positioned so that slot is forward.

4. Loosen clamping bolts and nuts on all 4 engine mount brackets to ensure the following:

• Large diameter of mount trunnion extended.

• Mount base slotted mounting hole forward, if so designed.

• Each mount base is downward. Tighten clamping bolts and nuts slightly to prevent mov-

ing in or out. Mounts must be free to pivot when installing engine.

Page 18 of 77 90-864198020

Page 19

Engine Preparation

1. Remove and read all tags attached to engine.

2. Remove all hardware that secures engine to shipping container.

3. Connect battery cables to engine. Be sure to observe the following:

a. Ensure that grounding stud and starter solenoid terminal are free of paint or any oth-

er material that could cause a poor electrical connection.

b. After battery cables are connected, apply a thin coat of sealant to the terminals.

INSTALLATION MANUAL

Description

Liquid Neoprene Battery Terminals 92-25711-2

c. Be sure to slide rubber boot over positive (+) terminal after making connection.

IMPORTANT: There is a fuse located at the starter solenoid. DO NOT remove this fuse.

The positive battery cable must be connected to the same stud as the fuse.

Where Used Part Number

c

a

b

77001

a-Positive (+) Battery Cable

b-Starter Solenoid

c-90 Amp Fuse - DO

NOT Remove

4. Drape battery cables over top of engine to prevent interference during installation.

Engine Oil Dipstick Relocation (If Equipped)

Engine crankcase oil dipstick can be located on either starboard or port side of engine to

suit installation requirements. To move dipstick, remove dipstick from current location and

install in opposite side. Place rubber cap over the open dipstick tube.

a-Dipstick

90-864198020 Page 19 of 77

a

a

77954

Page 20

INSTALLATION MANUAL

Engine Installation and Initial Engine Alignment

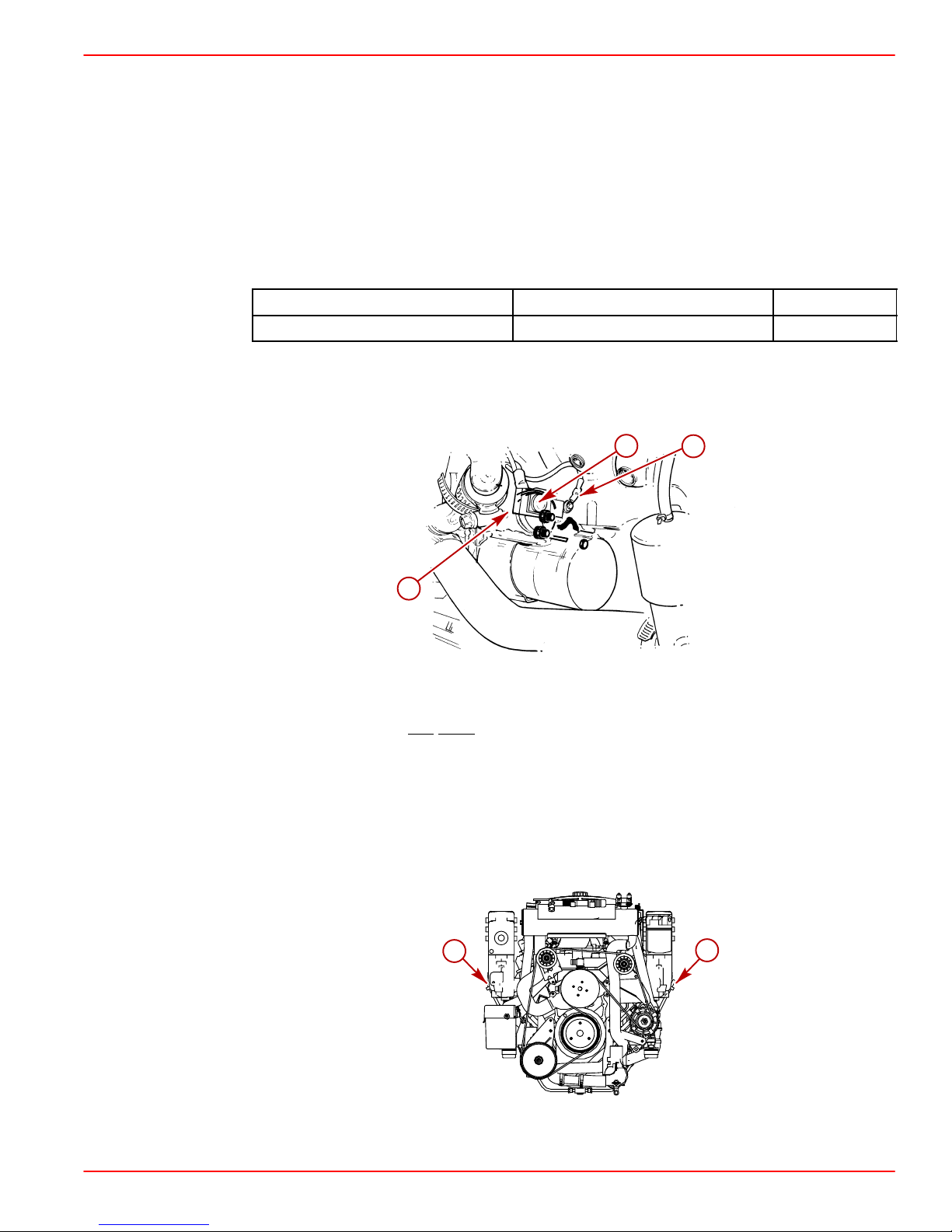

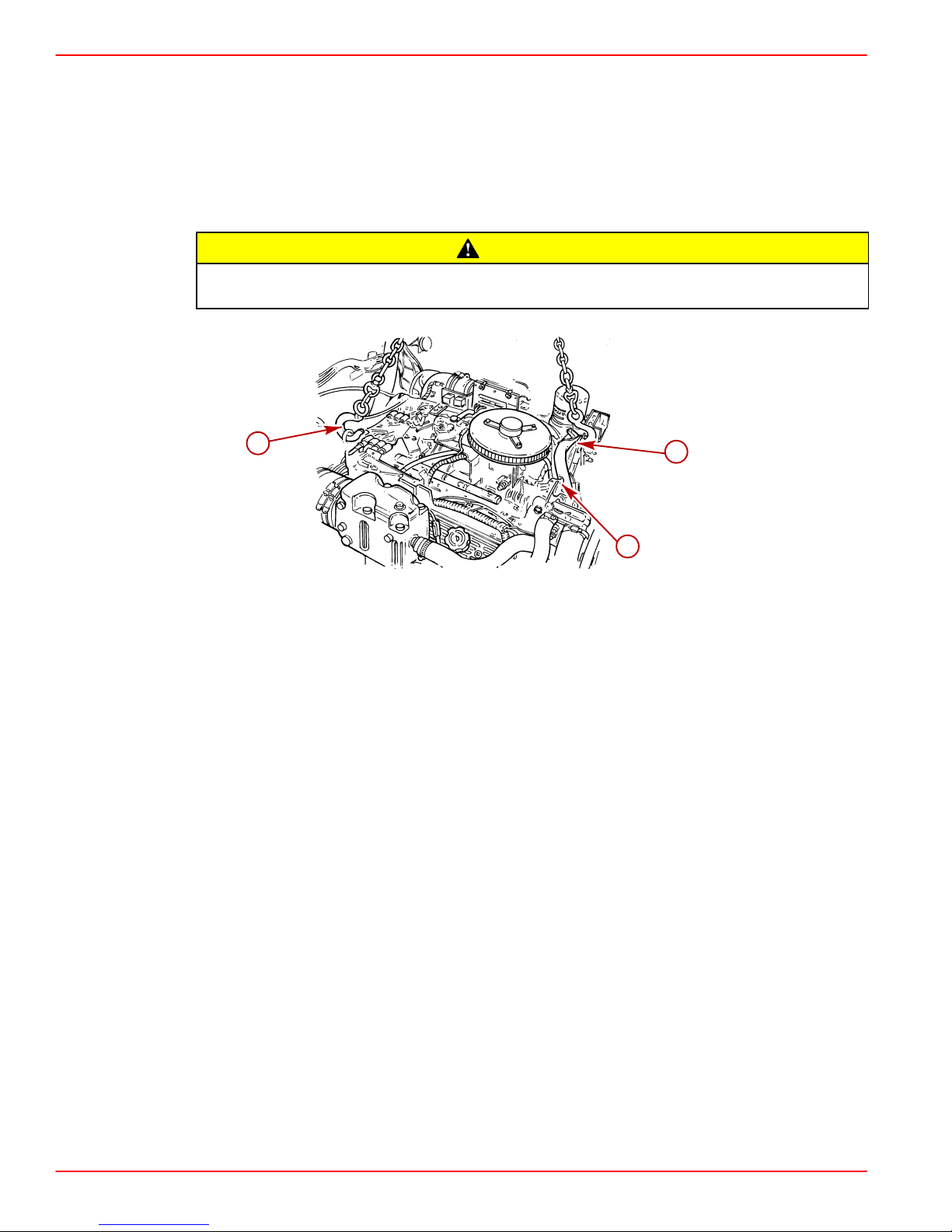

Models With 8 Degree Down Angle Transmissions - Velvet Drive or ZF / Hurth

1. Remove the engine cover.

2. Attach a suitable sling to lifting eyes on engine and adjust so that engine is level when

suspended.

CAUTION

Center lifting eye on top of thermostat housing is used for engine alignment only.

Do not use to lift entire engine.

b

c

a-Front Lifting Eye

b-Rear Lifting Eye

c-Center Lifting Eye

3. Lift engine into position in boat using an overhead hoist.

a

77912

Page 20 of 77 90-864198020

Page 21

INSTALLATION MANUAL

4. Position engine on engine bed so that transmission output flange and propeller shaft

coupler are visibly aligned (no gap can be seen between coupling faces when butted

together). Adjust engine height if necessary to obtain proper alignment. DO NOT use

mount adjustments to adjust engine position at this time.

IMPORTANT: Engine bed must position engine so that a minimum of 1/4 in. (6 mm)

up and down adjustment still exists on all 4 mounts after performing initial alignment.

This is necessary to allow for final engine alignment.

c

b

a

74546

a-Propeller Shaft

b-Propeller Shaft Coupler

c-Transmission Output Flange

5. Ensure quick drain oil fitting is more than 1/2 in. (13 mm) above the boat bottom.

IMPORT ANT: If quick drain oil fitting is within 1/2 in. (13 mm) of boat bottom, remove

fitting and install drain plug from parts bag directly into oil pan.

6. Ensure that all 4 mounts are still positioned properly, then fasten mounts t o engine bed

with 3/8 in. (10 mm) diameter lag bolts (of sufficient length) and flat washers. Tighten

lag bolts securely.

7. Disconnect overhead hoist and remove sling.

90-864198020 Page 21 of 77

Page 22

INSTALLATION MANUAL

Models with V-Drive Transmissions

1. Lift engine into position in boat using an overhead hoist.

2. Install quick drain oil hose plug in oil drain hose.

3. Position engine so that enough propeller shaft protrudes through transmission and output flange for propeller shaft coupler to be attached. Then install coupler and position

engine (no gap can be seen between coupling faces when butted together). Adjust en-

gine height if necessary to obtain proper alignment. DO NOT use mount adjustments

to adjust engine position at this time.

IMPORTANT: Engine bed must position engine so that a minimum of 1/4 in. (6 mm)

up and down adjustment still exists on all 4 mounts after performing final alignment.

This is necessary to allow for final engine alignment.

d

c

a

50608 50608

b

ZF / Hurth 630V (Others Similar)

a-Propeller Shaft

b-Propeller Shaft Coupler

c-Transmission Output Flange

d-No Gap Allowed

4. Ensure quick drain oil fitting is more than 1/2 in. (13 mm) above the boat bottom.

IMPORT ANT: If quick drain oil fitting is within 1/2 in. (13 mm) of boat bottom, remove

fitting and install drain plug from parts bag directly into oil pan.

5. Ensure that all 4 mounts are still positioned properly. Fasten mounts to engine bed with

3/8 in. (10 mm) diameter lag bolts (of sufficient length) and flat washers. Tighten lag bolts

securely.

6. Disconnect overhead hoist and remove sling.

Page 22 of 77 90-864198020

Page 23

All Models

INSTALLATION MANUAL

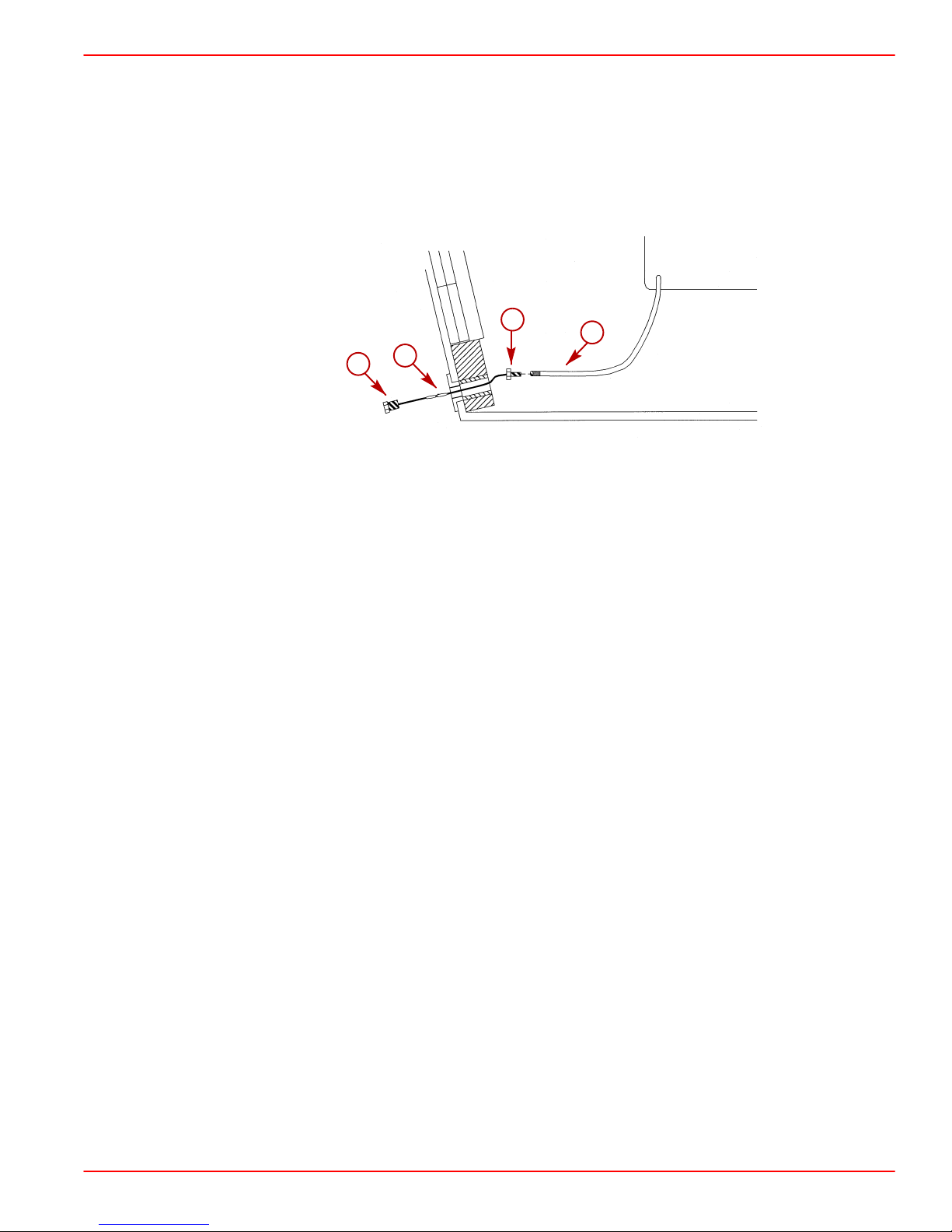

1. Push end of oil drain hose out of boat hull through flange.

2. Pull oil drain hose out until it is 6 in. (152 mm) from the propeller.

3. Move alignment clip on the oil drain hose and squeeze to position it on the hose just in-

side of the boat hull against the flange.

4. Connect bilge drain plug to oil drain hose plug using clip.

b

d

c

a

78002

a-Oil Drain Hose

b-Alignment Clip

c-Clip

d-Bilge Drain Plug

IMPORT ANT: If Quick Drain Oil Fitting is within 1/2 in. (13 mm) of boat bottom, remove

fitting and install drain plug from parts bag directly into oil pan.

5. Push oil drain hose through flange into boat hull.

6. Install bilge drain plug in hull.

90-864198020 Page 23 of 77

Page 24

INSTALLATION MANUAL

Hot Water Heater Installation

IMPORTANT: When connecting a cabin heater or hot water heater:

• Supply hose (from engine to heater) and return hose (from heater to engine)

MUST NOT EXCEED 5/8 in. (16 mm) I.D.

• Make heater connections ONLY at locations shown.

• Refer to manufacturers’ instructions for complete installation information and

procedures.

• Do not reposition engine temperature switch.

Avoid a performance loss and/or possible engine damage. Engine coolant must

flow continuously from the engine intake manifold to the engine water circulating

pump. NEVER close-off or block the coolant flow to or from a heater. All heater

installations must be plumbed in series with the supply and return connections.

Avoid engine overheating which could result in engine damage. On models

equipped with Closed Cooling, an air pocket may form in the closed cooling system

if some coolant is lost from the system and the cabin heater or hot water is mounted

higher than the fill cap on the heat exchanger. Heater must be mounted lower

the fill cap of the heat exchanger on models so equipped.

CAUTION

CAUTION

than

SUPPLY HOSE CONNECTION

NOTE: Some models may be equipped with additional fittings.

a

Seawater Cooled Models Closed Cooled Models

77816

a

77815

Page 24 of 77 90-864198020

Page 25

All Models

a-Location for Hot Water Supply

RETURN HOSE CONNECTION

INSTALLATION MANUAL

77933

a

a

a-Location For Hot Water Return

77954

90-864198020 Page 25 of 77

Page 26

INSTALLATION MANUAL

Exhaust System

It is the responsibility of the boat manufacturer or installing dealer to properly locate the engine and install the exhaust system. Improper installation may allow water to enter the exhaust manifolds and combustion chambers and severely damage

the engine. Damaged caused by the water in the engine will not be covered by Mercury MerCruiser Warranty, unless this damage is the result of defective parts.

MEASURING PROCEDURE

1. Fill all fuel, water, gray water and heater tanks to maximum capacity.

NOTE: Weight can be added in these locations to simulate full loaded condition.

2. Add maximum allowable cargo weight to boat in areas where it will be stowed, including

refrigerator and lockers.

3. Add 190 lb (86 kg) of weight in all locations where each passenger will sit during normal

operation.

4. Measure exhaust elbow height. Refer to Measurement Methods. Also, measure

exhaust system slope on applications with through the hull or through the transom

exhaust.

CAUTION

a

b

Using A Universal Protractor (Inclinometer) To Measure Slope

a-Protractor

b-Exhaust Hose Or Tube

77981

Page 26 of 77 90-864198020

Page 27

INSTALLATION MANUAL

5. Move load weight to bow to simulate greatest bow-down attitude the boat will encounter

in normal operation.

6. Recheck exhaust system slope.

7. Move load weight and cargo weight to stern of boat to stimulate greatest stern-down

attitude the boat will encounter such as when loading.

IMPORTANT: Be sure to consider swim platform loading and personal watercraft.

8. Recheck exhaust system measurements.

Minimum Exhaust Elbow Height from Top of Elbow to Waterline

Model Measurement

All V6 and V8 13 in. (330 mm)

a

b

c

d

a-Top Of Transom

b-Highest Point On Exhaust Elbow

c-Measurement

d-Waterline

Minimum Continuous Downward Slope (Exhaust Hoses, Collector, Etc.)

Model Measurement (degrees)

All Sterndrive 6

77956

90-864198020 Page 27 of 77

Page 28

INSTALLATION MANUAL

9. If measurements are less than specified, exhaust elbow risers must be installed to

achieve proper dimension.

11

9

6

9

14

7

4

12

5

10

3

13

2

1

8

No Riser 3 Inch Riser 6 Inch Riser

1-Exhaust Manifold

2-Restrictor Gasket

3-Exhaust Elbow

4-3 Inch Riser

5-6 Inch Riser

6-Open Gasket

7-Plug

8-Bolt, Manifold-To-Cylinder Head

9-Bolt, Exhaust Elbow-To-Exhaust Manifold

10 - Stud

11 - Nut And Washer, Exhaust Elbow-To-3 Inch Riser

12 - Bolt, 6 Inch Riser-To-Exhaust Manifold

13 - Hose Fitting

14 - Pipe Plug

78489

Page 28 of 77 90-864198020

Page 29

Measurement Methods

STRAIGHT EDGE METHOD

1. Place a straight edge across boat.

2. With the straight edge above the engine and parallel to the water , measure the distances

between the straight edge and the top of the exhaust elbow.

3. With the straight edge above the engine and parallel to the water measure the distance

between the straight edge and the outside waterline.

4. The difference between these two measurements is the exhaust elbow height above the

water line. Refer to Measuring Procedure and compare measurement to Mercury

MerCruiser’s specifications.

c

INSTALLATION MANUAL

b

d

a

a-Waterline

b-Top Of Exhaust Elbow

c-Straight Edge

d-Measurement Between Straight Edge And Top Of Exhaust Elbow

e-Measurement Between Straight Edge And Water Line

e

76859

72700

90-864198020 Page 29 of 77

Page 30

INSTALLATION MANUAL

CLEAR HOSE METHOD

1. Obtain a 5/16 - 3/8 in. (8-10 mm) I.D. hose approximately 15 ft (4.5 m) long. Put a metal

fitting or a weight on one end of the hose to keep that end of the hose below the water

line.

2. Put the weighted end of the hose over the port or starboard side of the boat, keeping

it in line with the engine’s exhaust elbow.

3. Route the remainder of the hose toward the engine’s exhaust manifold and elbow.

Ensure that this open end section of the hose is as vertical as possible from the boat’s

bilge to the top of the exhaust elbow

4. Coil excess hose in bilge of boat, keeping it below the water line.

5. Lower open end of hose and siphon water until it starts to come out of the hose. Put a

finger over the hose and lift open end until it is at the top of the exhaust elbow.

6. Slowly take finger off end of hose to let the water level stabilize. The water will seek the

level of the water outside the boat. Keep hose close to exhaust elbow and as vertical

as possible.

7. The measurement between water in hose and top of exhaust elbow is the exhaust elbow

height. Ensure that boat is level.

c

b

a

a-Waterline

b-Top Of Exhaust Elbow

c-Clear Plastic Hose

d-Weight

e-Measurement - Waterline To Top Of Exhaust Elbow

Minimum Exhaust Outlet Hose Size

Model Single Outlet Dual Outlet

Inboard

350 MAG MPI /

350 MAG MPI Horizon

MX 6.2L MPI /

MX 6.2 MPI Horizon

Tow Sports

4 in. (102 mm) 3 in. (76 mm)

e

76859

a

d

72700

350 MAG MPI 3 1/2 (88.9 mm) Not Applicable

Page 30 of 77 90-864198020

Page 31

INSTALLATION MANUAL

NOTE: A kit is available to reduce from the 4 in. (102 mm) to 3 in. (76 mm). Refer to the

Mercury Precision Parts / Quicksilver Accessories Guide, for kit part number.

d

c

e

Typical Continuously Sloping Exhaust Line

a-Exhaust Elbow

b-Exhaust Hose Or Pipe

c-Muffler (If Equipped)

d-Exhaust Outlet Internal Shutter

e-Exhaust Flapper Valve

f-Waterline

b

b

a

f

a

g

71774

d

c

e

Typical Waterlift Muffler Exhaust System

a-Vent Line [1/4 in. (6 mm)]

b-Transom

c-Water Line

d-Exhaust Hose

e-Drain Fitting

f-Water Lift Muffler

g-Exhaust Elbow

f

71775

CAUTION

Avoid severe engine damage. A 1/4 in. (6 mm) vent hose must be run from the highest point in the seawater system to the exhaust pipe after the water lift muffler to

break the vacuum and prevent water from back-filling the engine.

90-864198020 Page 31 of 77

Page 32

INSTALLATION MANUAL

Exhaust System Hose / Tube Connections

Avoid exhaust hose failure. Discharge water from exhaust elbow must flow around

entire inside diameter of hose to avoid causing hot spots which could eventually

result in burned-through exhaust hoses. Exhaust hoses and/or tubes must be correctly connected to exhaust elbows so that they do not restrict the flow of discharge

water from exhaust elbow.

Correct Connection Incorrect Connection

IMPORTANT: Exhaust hoses/tubes should be secured at each connection with at

least 2 hose clamps.

1. Tighten all exhaust hose and/or exhaust tube clamps securely.

CAUTION

71653

a

a-Hose Clamps

IMPORTANT: S-pipes must be routed under the transmission mounts.

a

b

Tow Sports Models

a-S-pipe

b-Transmission Mount

73961

74832

Page 32 of 77 90-864198020

Page 33

Electrical Connections

Avoid damage to the EFI electrical system components: Refer to the following precautions when working on or around the EFI electrical harness, or when adding other electrical accessories:

• DO NOT tap accessories into engine harness.

• DO NOT puncture wires for testing (Probing).

• DO NOT reverse battery leads.

• DO NOT splice wires into harness.

• DO NOT attempt diagnostics without proper, approved Service Tools.

IMPORTANT: When routing all wire harnesses and hoses, be sure they are routed and

secured to avoid coming in contact with hot spots on engine and to avoid contact

with moving parts.

Instrumentation Connections

We recommend the use of Quicksilver Instrumentation and Wiring Harnesses. On dual station applications, oil pressure and water temperature senders (on engine) must be changed.

Refer to Mercury Precision Parts / Quicksilver Accessories Guide for selection.

INSTALLATION MANUAL

CAUTION

The 4 basic gauges that must be used with the engine are:

• Tachometer

• Oil Pressure

• Water Temperature

• Voltmeter

IMPORT ANT: Connect fused accessory panel (40-amp current draw maximum) must

be connected as shown in the wiring diagrams.

1. Route instrumentation wiring harness back to engine, making sure that harness does

not rub or get pinched. If an extension harness is required, be sure to secure connection

properly.

2. Fasten harnesses to boat at least every 18 in. (460 mm), using appropriate fasteners.

3. Place hose clamp over instrumentation wiring harness.

90-864198020 Page 33 of 77

Page 34

INSTALLATION MANUAL

4. Connect the instrumentation wiring harness to engine harness plug at location shown.

a-Engine Harness Plug

5. Tighten hose clamp to secure wiring harness to engine harness plug.

Audio Warning System Connections

a

78030

WARNING

Alarm is not external ignition-proof, therefore, DO NOT mount alarm in engine or

fuel tank compartments.

1. Select a location for audio warning alarm which meets all of the following:

• alarm can be easily heard, yet is out of sight

• alarm can be easily accessed for installation and maintenance

• alarm will remain dry

• alarm is within length limits of the 18 in. purple alarm wire that connects to the “I” terminal

or 12 volt source on switched side of ignition switch.

NOTE: The terminal to which wire is attached must have no voltage when ignition switch

is in the OFF position.

2. Place alarm in desired location and secure to wire bundle with tie-strap provided.

3. Connect PURPLE wire from alarm to any PURPLE wire terminal on instrument gauge

or ignition switch. Tighten connection securely.

4. Connect TAN/BLUE wire from alarm to TAN/ BLUE wire from instrument harness.

5. Place the small (transparent) decals on the bottom of the water temperature and the oil

pressure gauges.

Page 34 of 77 90-864198020

Page 35

INSTALLATION MANUAL

6. Place the large decal on the instrument panel or other appropriate location in easily

viewed by the operator.

ALARM INDICATES LOW

OIL OR OVERHEATING

a

APPLY THE PROPER DECAL TO THE DASHBOARD

OR OTHER APPROPRIATE LOCATION:

AUDIO WARNING HORN WILL SOUND WHEN:

1. ENGINE OIL PRESSURE IS TOO LOW,

2. ENGINE WATER TEMP. IS TOO HOT, OR

3. TRANSMISSION TEMPERATURE IS TOO HOT.

TO TEST THE AUDIO WARNING HORN:

TURN KEY TO ON POSITION (ENGINE OFF)

a-Small Decal (Transparent)

b-Larger Decal

7. Test audio warning system during Predelivery Preparation section.

Fluid Connections

Coolant Recovery Bottle

Avoid engine overheating and subsequent damage to engine. The coolant recovery

system will not operate properly without proper sealing. Plastic tubing MUST seal

completely at connections.

1. Connect plastic tubing to bayonet fitting on heat exchanger. Secure with tubing clamp

provided.

b

75434

CAUTION

a-Plastic Tubing

b-Tubing Clamp

2. Remove cap from coolant recovery reservoir and fill to FULL mark with coolant solution.

3. Reinstall cap.

90-864198020 Page 35 of 77

b

a

70548

Page 36

INSTALLATION MANUAL

Final Engine Alignment

IMPORTANT: Engine alignment MUST BE RECHECKED with boat in the water, fuel

tanks filled and with a normal load on board.

Engine must be aligned so that transmission and propeller shaft coupling centerlines are

aligned and coupling faces are parallel within .003 in. (0.07 mm). This applies to installations

with solid couplings as well as flexible couplings.

1. Check mating faces on transmission output flange and propeller shaft coupler to ensure

that they are clean and flat.

2. Center propeller shaft in shaft log as follows:

a. Push down and then lift shaft as far as it will move. Then place shaft in the middle

of the movement.

b. Move shaft to port and then to starboard as far as shaft will move. Then place shaft

in the middle of the movement.

c. With shaft in the center of shaft log as determined by above procedures, align engine

to shaft.

a

d

b

c

Typical Down Angle (V-Drive Similar)

a-Up

b-Down

c-Port

d-Starboard

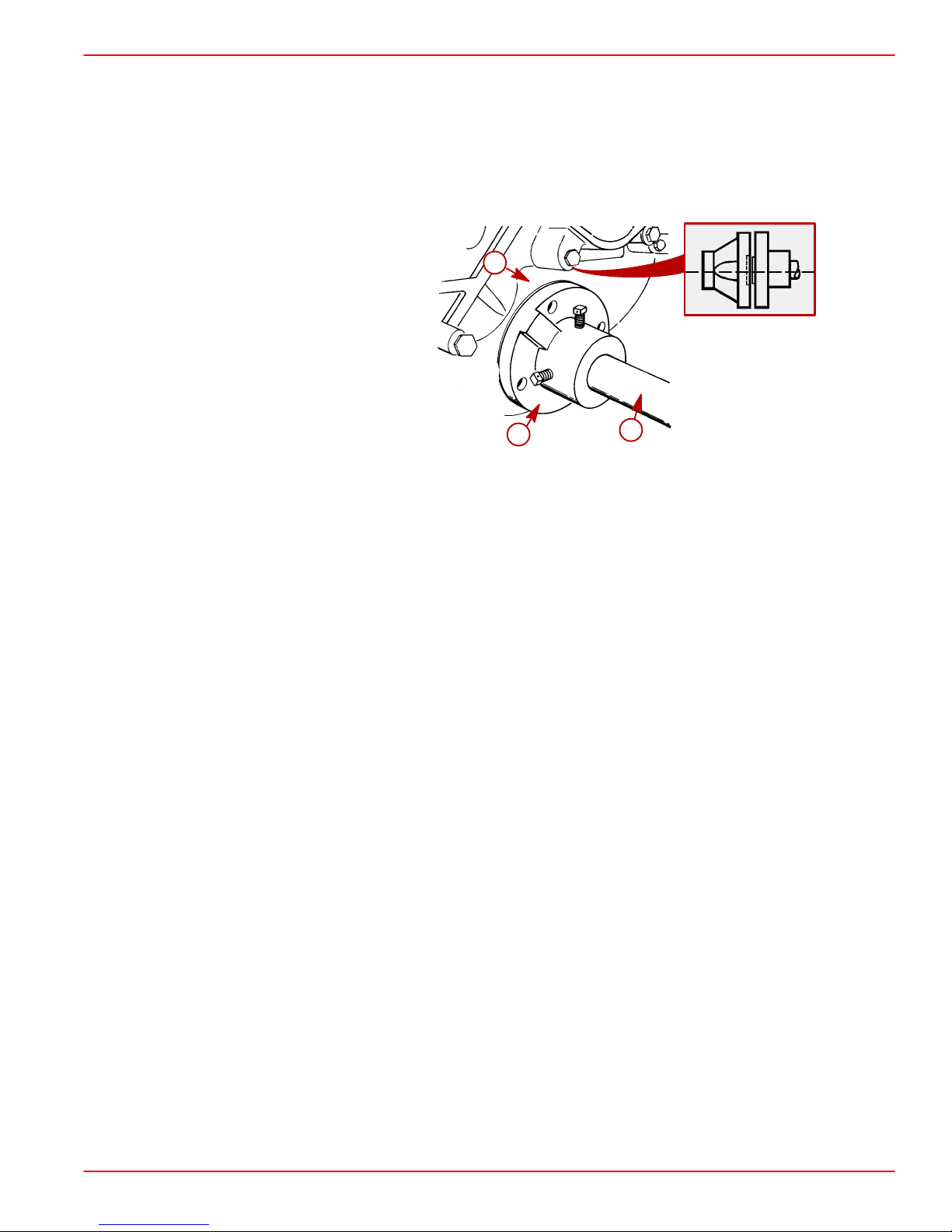

3. Check that coupling centerlines align by butting propeller shaft coupler against transmission output flange. Shoulder on propeller shaft coupler face should engage recess

on transmission output flange face with no resistance.

72595

72597

Incorrect Correct

Page 36 of 77 90-864198020

Page 37

INSTALLATION MANUAL

NOTE: Some propeller shaft couplers may not have a shoulder on mating face. On these

installations, use a straight edge to check centerline alignment.

c

a

b

d

74483

a-Transmission Output Flange

b-Propeller Shaft Coupler

c-Propeller Shaft

d-Straight Edge

4. Check for angular misalignment by hand holding coupling faces tightly together and

checking for a gap between coupling faces with a .003 in. (0.07 mm) feeler gauge. Check

the gap at 90 degree intervals.

a

b

c

75534

Velvet Drive

b

c

a

ZF / Hurth

a-Propeller Shaft Coupler

b-Feeler Gauge

c-Transmission Output Flange

50609

a

c

b

50608

90-864198020 Page 37 of 77

Page 38

INSTALLATION MANUAL

5. If coupling centerlines are not aligned or if coupling faces are more than .003 in.

(0.07 mm) out of parallel, adjust engine mounts.

a. TO ADJUST ENGINE UP OR DOWN: Loosen locking nut on mounts requiring

adjustment and turn adjusting nuts in desired direction to raise or lower.

IMPORTANT: Both front mounts (or rear mounts) adjusting nuts must be turned

equally to keep engine level from side to side.

NOTE: Some rear mounts have one (1) clamping screw and nut on each side.

b. TO MOVE ENGINE TO THE LEFT OR RIGHT: Loosen clamping bolts and nuts on

all 4 mount brackets and move engine to the left or right as necessary to obtain proper alignment. A small amount of adjustment can be obtained with slot on front end

of some mounts. Loosen lag bolts (which fasten mounts to engine bed) and move

engine, as required. Retighten lag bolts securely.

IMPORTANT: Large diameter of mount trunnion MUST NOT extend over 1-3/4 in.

(45 mm) from mount brackets on any of the mounts.

6. After engine has been properly aligned, secure engine mounts.

7. Torque clamping bolts and nuts on all 4 mount brackets.

Description lb-ft lb-in. Nm

Clamping Bolts And Nuts

50 68

8. Tighten locknut on all four mounts.

9. Bend one of the tabs on the tab washer down onto the flat of the adjusting nut.

IMPORTANT: All coupler bolts must be SAE Grade 8 (Metric Grade 10.9) or better, with

a shoulder (grip length) sufficient to pass through the mating face plane of the

couplers.

Page 38 of 77 90-864198020

Page 39

INSTALLATION MANUAL

10. Secure coupling together with bolts, lockwashers and nuts. Torque fasteners.

a

b

75535

a-Bolts

b-Transmission Coupler

Description lb-ft lb-in. Nm

Coupling Bolts And Nuts

a. If propeller shaft coupler has set screws, remove set screws and mark dimple loca-

tions using a transfer punch.

50 68

b. T o drill dimples, remove propeller shaft coupler and drill shallow dimples at locations

marked with punch.

c. Reinstall propeller shaft coupler and torque bolts. Install set screws and tighten se-

curely. Safety wire set screws to ensure they do not loosen.

b

c

d

e

a

50608

a-Propeller Shaft Coupler

b-Bolts

c-Set Screws

d-Safety Wire

e-Transmission Output Flange

Coupling Bolts And Nuts

90-864198020 Page 39 of 77

Description lb-ft lb-in. Nm

50 68

Page 40

INSTALLATION MANUAL

Throttle Cable Installation and Adjustment

IMPORT ANT: When installing throttle cable, be sure that cables are routed in such a

way as to avoid sharp bends and/or contact with moving parts. DO NOT fasten any

items to throttle cable.

1. Place remote throttle lever in idle position and attach cable to throttle body, following

cable manufacturer’s instructions.

2. Install cable end guide on throttle lever , then push cable barrel end lightly toward throttle

lever end. (This will place a slight preload on shift cable to avoid slack in cable when

moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor

plate. Ensure hole in barrel positions cable as shown. Tighten locknut until it contacts

washer, and then loosen 1/2 turn.

a

b

c

a-Cable End

b-Cable Barrel

c-Locknut and Flat Washer

Shift Cable Installation And Adjustment

IMPORTANT: When installing shift cables, be sure that cables are routed in such a

way as to avoid contact with moving parts and/or sharp bends All bends must make

greater than an 8 in. (203 mm) radius. DO NOT fasten any items to shift cables.

Shift cable must be hooked up to remote control before starting installation and adjustment

procedures. Refer to Transmission - Propeller Rotation, as previously outlined in the front

of this manual, for transmission shift lever direction of movement versus propeller shaft

output direction of rotation.

Damage caused to transmission as a result of improper shift lever positioning will not be

covered by warranty.

To ensure proper shift and throttle operation, we recommend the use of a Quicksilver remote

control and cables. Refer to Mercury Precision Parts / Quicksilver Accessories Guide.

Shift Cable Travel

78033

2-3/4 in. (70 mm)

Page 40 of 77 90-864198020

Page 41

Velvet Drive Transmissions

IN-LINE AND REMOTE V-DRIVE

IMPORT ANT: V elvet Drive Transmission Warranty is jeopardized if the shift lever poppet ball or spring is permanently removed, if the shift lever is repositioned or changed

in any manner or if remote control and cable do not position shift lever correctly.

INSTALLATION MANUAL

FNR––

a

d

e

b

F

R

c

22457

a-Transmission Shift Lever

b-Shift Lever MUST BE Over This Letter In FORWARD

c-Shift Lever MUST BE Over This Letter In REVERSE

d-Poppet Ball MUST BE Centered In Detent Hole For Each F-N-R Position

(FORWARD Gear Shown)

e-Install Shift Lever Stud in This Hole, If Necessary, To Center Poppet Ball in

FORWARD And REVERSE Detent Holes

1. Verify shift cable stud is in appropriate stud hole as indicated. Tighten elastic stop nut

securely.

a

50947

a-Shift Cable Anchor Stud Hole

90-864198020 Page 41 of 77

Page 42

INSTALLATION MANUAL

2. Place remote control shift lever and transmission shift lever in NEUTRAL position.

3. Remove nuts and washers from shift cable attaching studs.

4. Locate center of remote control and control shift cable play (backlash), as follows:

a. Ensure that remote control is in NEUTRAL position.

b. Push in on control cable end with enough pressure to remove play and mark position

“a” on tube.

c. Pull out on control cable end with enough pressure to remove play and mark position

“b” on tube.

d. Measure distance between marks “a” and “b,” and mark position “c,” half-way

between marks “a” and “b.”

b

c

a

c

22024

5. Center cable-end play, then adjust cable barrel to align holes in barrel and in cable end

guide, with attaching points on transmission.

6. Temporarily install shift cable. Do not secure at this time.

7. Place remote control shift lever in FORWARD gear position and check position of transmission shift lever. Shift lever must be positioned as previously indicated.

8. Place remote control lever in REVERSE gear position and again check shift lever position. Lever must be positioned as previously indicated.

9. If transmission shift lever will position properly in one gear, but not in the other, recheck

shift cable adjustment. If transmission shift lever will not position properly in either gear,

move transmission shift lever stud, from top hole in shift lever to bottom hole, and recheck for proper positioning. If proper positioning is still not obtained, remote control

does not provide sufficient shift cable travel and must be replaced.

10. Reattach nut and washer to cable end guide stud. T ighten until they contact, then loosen

1/2 turn.

Page 42 of 77 90-864198020

Page 43

INSTALLATION MANUAL

11. Reattach nut and washer to cable barrel stud. Tighten until they contact. Tighten

securely, but DO NOT overtighten.

g

a

b

f

e

c

d

Rear Entry Single Station Installation In-Line And Remote V-Drive

e

g

b

50947

f

a

c

d

Rear Entry Dual Station Installation In-Line And V-Drive

a-Cable End Guide

b-Cable Barrel

c-Cable Barrel Stud

d-Elastic Stop Nut and Washer

e-Spacer

f-Cable End Guide Stud

g-Elastic Stop Nut and Washer

50947

90-864198020 Page 43 of 77

Page 44

INSTALLATION MANUAL

b

d

a

c

g

f

e

Front Entry Single Station Installation In-Line And V-Drive

d

b

a

c

g

e

f

Front Entry Dual Station Installation In-Line And V-Drive

a-Cable End Guide

b-Cable Barrel

c-Cable Barrel Stud

d-Elastic Stop Nut and Washer

e-Spacer

f-Cable End Guide Stud

g-Elastic Stop Nut and Washer

50946

50946

NOTE: For models equipped with a dual station shift bracket such as the one shown, refer

to shift cable manufacturer’s instructions for adjusting the cable. Shift lever must be positioned as stated in the preceding steps.

22457

Dual Station Shift Bracket (Not Quicksilver)

Page 44 of 77 90-864198020

Page 45

5000 SERIES (8 DEGREE DOWN ANGLE AND V-DRIVE)

For Left-Hand Propeller Shaft Rotation: Shift cable hookup at remote control must result

in shift cable end guide moving in direction “A” when remote control handle is placed in

FORWARD position.

For Right-Hand Propeller Shaft Rotation: Shift cable hookup at remote control must

result in shift cable end guide moving in direction “B” when remote control handle is placed

in FORWARD position.

A

B

Remote control must provide a total shift cable travel (at transmission end) of at least

2-3/4 in. (70 mm). This is necessary to position transmission shift lever fully in the FORWARD and REVERSE gear positions. Insufficient shift cable travel will cause transmission

to slip and eventually fail.

INSTALLATION MANUAL

23242

a

72602

a-2-3/4 in. (70 mm) Minimum

IMPORTANT: The distance between studs (Dimension “c”) shown in the following

illustration is factory set at 7-1/8 in. (181 mm).

b

c

b

d

a

73284

8 Degree Down Angle Shown (V-Drive Similar)

a-Shift Lever

b-Anchor Stud

c-Dimension Between Studs - 7-1/8 in. (181 mm)

d-Shift Cable Bracket

90-864198020 Page 45 of 77

Page 46

INSTALLATION MANUAL

WARNING

Avoid serious injury or property damage caused by improper shifting. Anchor stud

for shift cable must be installed in the correct hole.

1. Be certain anchor stud is installed in the front hole as shown in the illustration following.

ab

73284

a-Shift Cable Bracket

b-Anchor Stud In Front Hole

2. Place remote control shift lever and transmission shift lever in NEUTRAL position.

3. Remove nuts and washers from shift cable attaching studs.

4. Locate center of remote control and control shift cable play (backlash) as follows:

a. Check that remote control is in NEUTRAL position.

b. Push in on control cable end with enough pressure to remove play; mark position

“a” on tube.

c. Pull out on control cable end with enough effort to remove play; mark position “b”

on tube.

d. Measure distance between marks “a” and “b;” mark position “c,” half-way between

marks “a” and “b.”

b

c

c

a

72603

5. Center cable-end play, then adjust cable barrel to align holes in barrel and in cable end

guide with attaching points on transmission.

6. Temporarily install shift cable. Do not secure at this time.

7. Place remote control shift lever in gear and check position of transmission shift lever.

Shift lever must be positioned in the desired detent hole.

IMPORT ANT: Transmission is fully in gear when shift lever comes to a stop in either

direction.

Page 46 of 77 90-864198020

Page 47

INSTALLATION MANUAL

IMPORT ANT: V elvet Drive Transmission Warranty is jeopardized if the shift lever poppet ball or spring is permanently removed, if the shift lever is repositioned or changed

in any manner or if remote control and shift cable do not position shift lever exactly

as shown.

CAUTION

Remote control and shift cable must position transmission shift lever exactly as

shown or transmission failure may occur. Do not remove poppet ball or spring.

a

e

b

c

d

73248

Velvet Drive 5000 Series (8Degree Down Angle Shown, V-Drive Similar)

a-Transmission Shift Lever

b-Poppet Ball Must Be Centered In This Detent Hole When Left-Hand Propeller

Shaft Rotation Is Desired

c-Poppet Ball Must Be Centered In This Detent Hole When Right-Hand Propeller

Shaft Rotation Is Desired

d-Poppet Ball Must Be Centered In This Detent Hole For NEUTRAL Position

e-Install Shift Lever Stud In This Hole When Using Quicksilver Shift Cables

8. Place remote control shift lever in opposite gear position and again check transmission

shift lever position. Lever must be positioned in the desired detent hole.

9. If transmission shift lever will not position properly in one gear or both gears, recheck

shift cable adjustment and travel. If proper positioning is still not obtained, remote control

does not provide sufficient shift cable travel and must be repaired or replaced.

10. Install nut and washer to cable end guide stud. Tighten until they contact, then loosen

1/2 turn.

1 1. Install nut and washer to cable barrel stud. Tighten until they contact. Tighten securely,

but DO NOT Overtighten.

90-864198020 Page 47 of 77

Page 48

INSTALLATION MANUAL

e

71780

Typical Single Cable Installation - Rear Entry

a-Cable End Guide

b-Spacer (As Required)

c-Elastic Stop Nut and Washer

d-Bushings

e-Cable Barrel Location

f-Cable Barrel Stud

g-Cable End Guide Stud

b

a

c

g

d

b

c

f

e

71972

e

a

71897

Typical Dual Cable Installation - Rear Entry

a-Cable End Guide

b-Spacer (As Required)

c-Elastic Stop Nut and Washer

d-Bushings

e-Cable Barrel Location

f-Cable Barrel Stud

g-Cable End Guide Stud

g

b

c

d

f

e

50073

Page 48 of 77 90-864198020

Page 49

ZF / Hurth Transmissions

IMPORTANT: These ZF / Hurth transmissions are full reversing transmissions. Direction of output/propeller rotation is determined by hookup of shift cable at remote control.

Shift cable must be hooked up to remote control before starting installation and adjustment

procedures. Refer to “T ransmission - Propeller Rotation”, as previously outlined in the front

of this manual, for transmission shift lever direction of movement versus propeller shaft

output direction of rotation.

For Right Hand Propeller Rotation – Shift cable hookup at remote control must result in

shift cable end guide moving in direction “A” when remote control handle is placed in

FORWARD position.

For Left Hand Propeller Rotation – Shift cable hookup at remote control must result in shift

cable end guide moving in direction “B” when remote control handle is placed in

FORWARD position.

INSTALLATION MANUAL

A

B

23242

WARNING

Avoid serious injury or property damage caused by improper shifting. Anchor stud

for shift cable must be installed in the correct hole.

1. Be certain anchor stud is installed in the correct mount hole as shown by the following

illustration.

a

71020

Shift Cable Bracket - Anchor Stud Positions

a-Cable Bracket

b-Quicksilver Shift Cable Anchor Stud Location - 630A and 630V

c-Quicksilver Shift Cable Anchor Stud Location - 800A

b

c

a

73588

IMPORTANT: When installing shift cables, be sure that cables are routed in such a

way as to avoid contact with moving parts and/or sharp bends All bends must make

greater than an 8 in. ( 203 mm) radius. DO NOT fasten any items to shift cables.

90-864198020 Page 49 of 77

Page 50

INSTALLATION MANUAL

2. Check shift lever positioning as indicated:

IMPORTANT: Check that shift lever is positioned approximately 10 degrees aft of

vertical when in the NEUTRAL detent position and that the distance “c” between

studs in the following is set at 7-1/8 in. (181 mm). If necessary, loosen clamping bolt

and position lever so that dimension “c” is as shown when in the NEUTRAL detent

position and retighten bolt.

b

c

a

d

73587

Typical ZF / Hurth Transmission Shown

a-Shift Lever

b-Lever In NEUTRAL Detent 10 Degrees Aft Of Vertical

c-Dimension Between Studs - 7-1/8 in. (181 mm)

d-Clamping Bolt

3. Place remote control shift lever, and transmission shift lever, in NEUTRAL position.

4. Remove nuts and washers from shift cable attaching studs.

5. Locate center of remote control and control shift cable play (backlash), as follows:

a. Check that remote control is in NEUTRAL position.

b. Push in on control cable end with enough pressure to remove play, and mark

position “a” on tube.

c. Pull out on control cable end with enough pressure to remove play, and mark

position “b” on tube.

d. Measure distance between marks “a” and “b,” and mark position “c,” half-way

between marks “a” and “b.”

b

c

6. Center cable-end play, then adjust cable barrel to align holes in barrel, and in cable end

guide, with attaching points on transmission.

Page 50 of 77 90-864198020

a

c

22024

Page 51

INSTALLATION MANUAL

7. Temporarily install shift cable. Do not secure at this time.

a

73587

Typical

a-Shift Cable End Guide

IMPORT ANT: Transmission is fully in gear when shift lever comes to a stop in either

direction.

8. Place remote control shift lever in FORWARD gear position. Ensure that transmission

is fully in gear, as follows:

a. Hold shift lever in position.

b. Carefully slide shift cable off of anchor points.

c. Attempt to move shift lever further.

9. Place remote control shift lever in the REVERSE gear position. Ensure that transmission

is fully in gear, following same procedure.

10. If transmission shift lever will position properly in one gear, but not in the other, recheck

shift cable adjustment. If transmission shift lever will not position properly in both gears,

move transmission shift lever stud “a,” from top hole in shift lever, to bottom hole, and

recheck for proper positioning. If proper positioning is still not obtained, remote control

does not provide sufficient shift cable travel and must be replaced.

b

c

a-Shift Lever Stud (In Bottom Hole, If Required)

b-Lever in NEUTRAL Detent 10 Degrees Aft of Vertical

c-Shift Lever Top Hole

90-864198020 Page 51 of 77

a

50228

Page 52

INSTALLATION MANUAL

11. Reattach locknut and washer to cable end guide stud. Tighten until they contact, then

loosen 1/2 turn.

12. Reattach locknut and washer to cable barrel stud. Tighten until they contact. Tighten

securely, but DO NOT overtighten.

NOTE: To change cable approach direction on single or dual station installations, only the

spacers/bushings have to be switched to the opposite stud (the studs are identical).

e

73589

Typical Single Cable - Forward Entry

a-Cable End Guide

b-Locknut and Washer

c-Spacer (Fits over Bushings)

d-Bushings

e-Cable Barrel Location

f-Spacer (Fit over Stud)

g-Cable Barrel Stud

h-Cable End Guide Stud

d

c

g

b

e

h

a

f

b

71210

a

f

e

b

h

Typical Single Cable - Rear Entry

a-Cable End Guide

b-Locknut and Washer

c-Spacer (Fits over Bushings)

d-Bushings

e-Cable Barrel Location

f-Spacer (Fit over Stud)

g-Cable Barrel Stud

h-Cable End Guide Stud

Page 52 of 77 90-864198020

73587

d

g

e

c

b

50229

Page 53

INSTALLATION MANUAL

e

f

e

b

d

73590

Typical Dual Cable - Forward Entry

a-Cable End Guides

b-Locknut and Washer

c-Spacer (Fits over Stud)

d-Bushings

e-Cable Barrel Locations

f-Cable Barrel Stud

g-Cable End Guide Stud

c

g

a

b

71211

c

g

e

Typical Dual Cable - Rear Entry

a-Cable End Guides

b-Locknut and Washer

c-Spacer (Fits over Stud)

d-Bushings

e-Cable Barrel Locations

f-Cable Barrel Stud

g-Cable End Guide Stud

73591

b

a

d

f

e

b

50073

90-864198020 Page 53 of 77

Page 54

INSTALLATION MANUAL

Predelivery Preparation

Once the power package installation is complete, the following final steps should be taken

to prepare power package for delivery to the customer. I t i s the boat manufacturer’s responsibility to perform these procedures, or to make arrangement with the dealer to have these

procedures completed.

Propeller Selection

GENERAL INFORMATION

IMPORTANT: Installed propeller must allow engine to run at its specified maximum

WOT rpm. Use an accurate service tachometer to verify engine operating rpm.

It is the responsibility of the boat manufacturer and/or the selling dealer to equip the power

package with the correct propeller. Refer to Quicksilver publication - Everything You Need

To Know About Propellers P/N 90-8614492. Specified engine WOT and operating rpm

range are listed in the Mercury MerCruiser Operation, Maintenance and Warranty Manual

attached to the engine.

Select a propeller that will allow the engine power package to operate at or near the top end

of the recommended wide-open-throttle operating rpm range with a normal load.

If full throttle operation is below the recommended range, the propeller must be changed

to prevent loss of performance and possible engine damage. On the other hand, operating

an engine above the recommended operating rpm range will cause higher than normal wear

and/or damage.

After initial propeller selection, the following common problems may require that the

propeller be changed to a lower pitch.

• Warmer weather and greater humidity cause a loss of rpm.

• Operating in a higher elevation causes a loss of rpm.

• Operating with increased load (additional passengers, pulling skiers) causes a loss of

rpm.

For better acceleration, such as is needed for water skiing, use the next lower pitch

propeller. Do not operate at full throttle when using the lower pitch propeller but not pulling

skiers.

Because of the many variables of boat design, only testing will determine the best propeller

for a particular application. Available propellers are listed in the Mercury Precision Parts /

Quicksilver Accessories Guide.

See BOAT IN THE WATER TESTS, Maximum RPM Test at the back of this manual.

Page 54 of 77 90-864198020

Page 55

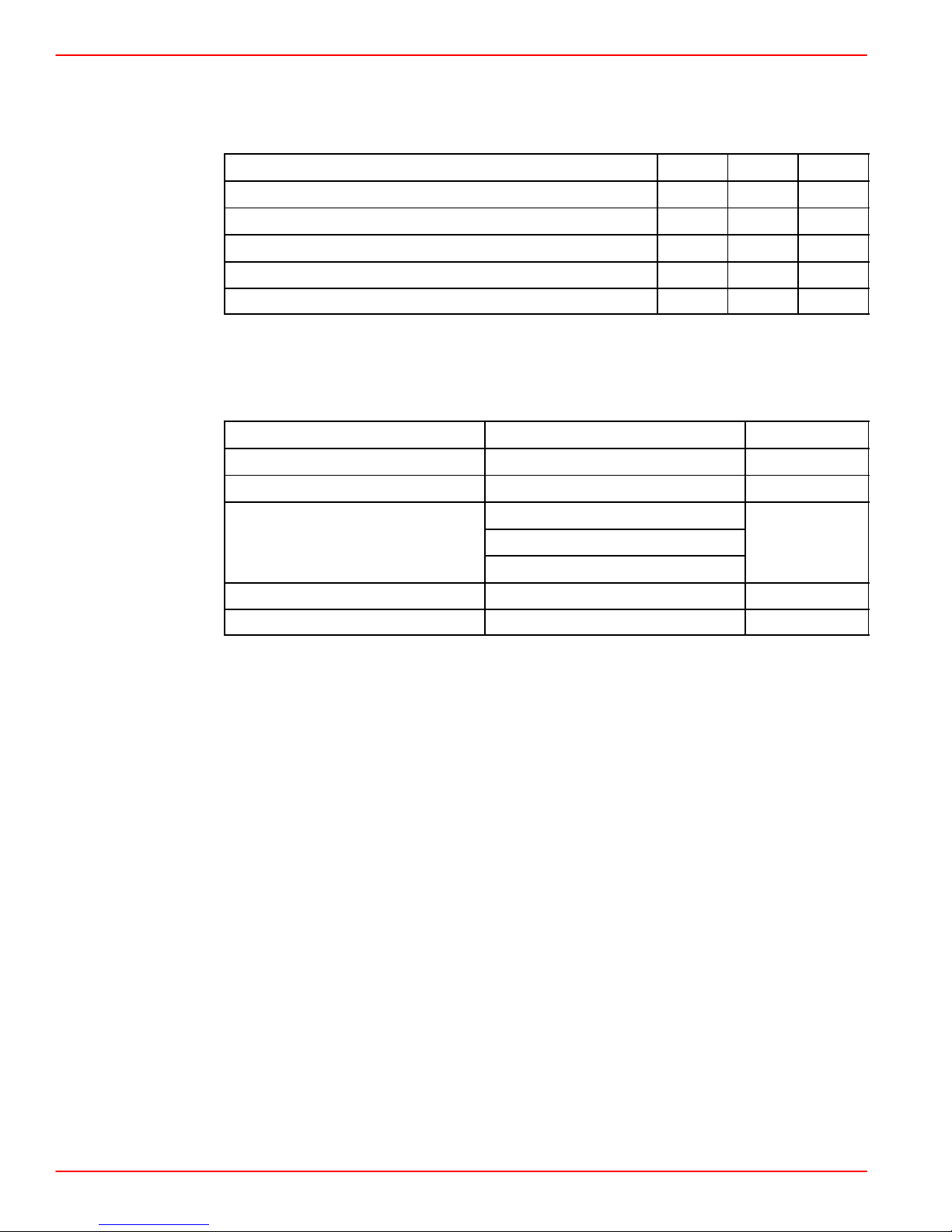

ENGINE REV-LIMITER

IMPORTANT: The engines listed in the following chart are equipped with a rpm revlimiter that is set to an upper (or limited) rpm amount. This limit is slightly above the

normal operating range of the engine and is designed to help prevent damage from

excessive engine rpm. When the engine reaches the rev-limit rpm, the horn will

sound. Once the rpm drop into the recommended operating rpm range, normal engine operation resumes.

INSTALLATION MANUAL

Inboard

350 Mag MPI /

350 Mag MPI Horizon

MX 6.2L MPI /

MX 6.2L MPI Horizon

Tow Sports

350 Mag MPI 4600 - 5000 5150

Fuel Line Connection

Boating standards (NMMA, ABYC and others) and Coast Guard regulations must

be adhered to when installing fuel delivery system.

1. Hold the brass fuel inlet fitting with a suitable wrench and install the fuel line.

Battery

IMPORTANT: Boating industry standards (BIA, ABYC, etc.), federal standards and

Coast Guard regulations must be adhered to when installing the battery. Be sure

battery cable installation meets the pull test requirements and that positive battery

terminal is properly insulated in accordance with regulations.

Model

Engine Recommended

Operating RPM Range

4400 - 4800 4950

4600 - 5000 5150

Rev-Limit RPM Setting

WARNING

IMPORT ANT: It is recommended (required in some states) that battery be installed in

an enclosed case. Refer to regulations for your area.

IMPORTANT: Engine electrical system is negative (–) ground.

1. Select a battery that meets all of the following specifications:

• 12-volt marine type.

• Tapered post connectors or side terminal connectors.

IMPORTANT: Do NOT use a battery with wing nut connectors.

• Battery capacity rating of at least:

Engine

(Cyl./Type)

V8 MPI

V8 MPI

V8 MPI

90-864198020 Page 55 of 77

cid (l) Minimum Required Cranking Battery Size

305 (5.0)

350 (5.7)

377 (6.2)

550 cca/700 mca/120 Ah

Page 56

INSTALLATION MANUAL

BATTERY CABLES

1. Select proper size positive (+) and negative (–) battery cables, using chart. Battery

IMPORTANT: Terminals must be soldered to cable ends to ensure good electrical

contact. Use electrical grade (resin flux) solder only. D O NOT use acid flux solder, as

it may cause corrosion and a subsequent failure.

should be located as close to engine as possible.

Cable Length

Up to 3-1/2 ft. (1.1 m) 4 (25 mm2)

3-1/2 - 6 ft. (1.1-1.8 m) 2 (35 mm2)

6 - 7-1/2 ft. (1.8-2.3 m) 1 (50 mm2)

7-1/2 - 9-1/2 ft. (2.3-2.9 m) 0 (50 mm2)

9-1/2 - 12 ft. (2.9-3.7 m) 00 (70 mm2)

12 - 15 ft. (3.7-4.6 m) 000 (95 mm2)

15 - 19 ft. (4.6-5.8 m) 0000 (120 mm2)

MULTIPLE EFI ENGINE BATTERY INFORMATION

Batteries: Boats with multi-engine EFI power packages require each engine be connected

to its own battery. This ensures that the engine’s Electronic Control Module (ECM) has a

stable voltage source.

Battery Switches: Battery switches should always be positioned so each engine is running

off its own battery . DO NOT operate engines with switches in BOTH or ALL position. In an

emergency, another engine’s battery can be used to start an engine with a dead battery.

Battery Isolators: Isolators can be used to charge an auxiliary battery used for powering

accessories in the boat. They should not be used to charge the battery of another engine

in the boat unless the type of isolator is specifically designed for this purpose.

Cable Gauge

NOTE: Sure Power Industries Inc., Model 32023A meets this design specification.

1. The boat may have two engines connected to a single Model 32023A battery isolator.

2. The Model 32023A battery isolator is connected to two banks of batteries.

3. Each bank contains two batteries with the cranking battery for 1 engine in each bank.

4. The second battery in each bank is connected in parallel to the cranking battery.

5. The Model 32023A battery isolator is designed for this type of use; two battery banks,

two charging sources, 120 amps (maximum alternator output).

6. When the engines are running, either engine’s alternator could be charging either bank

of batteries through the Model 32023A battery isolator.

Any other manufacturer’s battery isolator that is the same type as the Sure Power Inc.,

Model 32023A could also be used.

Generators: The generator’s battery should be considered another engine’s battery.

Page 56 of 77 90-864198020

Page 57

BATTERY CONNECTION

IMPORTANT: Engine electrical system is negative (–) ground.

1. Connect engine positive (+) battery cable (usually RED) to positive (+) battery terminal.

2. Connect engine negative (–) battery cable (usually BLACK) to negative (–) battery termi-

nal.

3. Connect Power T rim pump BLACK (–) battery cable to negative (–) battery terminal and

trim pump RED (+) battery cable to positive (+) battery terminal.

4. Ensure that all battery terminal connections are tight. Then spray terminals with a bat-

tery connection sealant to help retard corrosion.

Test Running Engine

If engine is to be tested with boat out of water, the propeller must be removed to

avoid injury.

IMPORTANT: If engine is to be tested on land, water must be supplied to seawater

pickup pump. DO NOT run engine above 1500 rpm.

INSTALLATION MANUAL

WARNING

WARNING

Do not leave helm unattended when making test with boat in the water.

1. Ensure that cooling system drain plugs, petcocks and hoses are installed and tight.

NOTE: Refer to appropriate Mercury MerCruiser Operation, Maintenance and Warranty

Manual for operating specifications. Refer to appropriate Mercury MerCruiser Service

Manual for fluid capacity information.

2. Check crankcase oil level.

3. Check drive belt tension.

4. Test Audio Warning System in accordance with instructions on instrumentation panel

decal.

5. Start engine and run at idle rpm until water temperature is normal.

6. Watch all gauges for normal readings.

7. Inspect engine compartment for water, oil, fuel and exhaust leaks.

8. Stop the engine and turn the key switch OFF.

90-864198020 Page 57 of 77

Page 58

INSTALLATION MANUAL

Boat In The Water Tests

IMPORTANT: Engine alignment MUST BE CHECKED with boat in the water, fuel tanks

filled, and with a normal load on board.

NOTE: On Tow Sports Applications: If during testing for a particular application, you

experience fuel starvation in sharp high speed turns, baffles or a fuel sump may be needed

in the tank to help correct this condition.

ENGINE IDLE SPEED ADJUSTMENT

Engine should idle at rpm (as specified in appropriate Mercury MerCruiser Operation, Maintenance and Warranty Manual) with boat in the water, drive unit in FORWARD gear and engine at normal operating temperature. If idle speed is incorrect, proceed as follows:

1. Ensure that throttle cable has been adjusted properly.

2. If idle speed is still not correct, it may be necessary to perform EFI System Diagnostic