UNCONTROLLED IF PRINTED

9-1

CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG

9.1 This chapter provides basic and specific cleaning requirements for selected vehicles.

Where there is a specific requirement or need to highlight particular problem areas detailed

cleaning guides are provided as tables and figures in this chapter.

9.2 This Section deals with the cleaning of the basic Unimog vehicle. The section is structured

as follows:

a. external areas;

b. underside;

c. cabin;

d. cabin holes

e. front areas;

f. under tray;

g. tray checker panel;

h. chassis;

i. chassis support tubes;

j. cross members;

k. chassis cross members;

l. chassis cavities;

m. sump;

n. torque tube wiring looms and air lines

o. chassis ai r lines and wiring looms;

p. suspension;

q. engine and transmission;

r. battery box;

s. winch, wire ropes and slings;

t. tarpaulins;

u. camouflage nets; and

v. tyres (new, old and spares).

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-2

External Areas

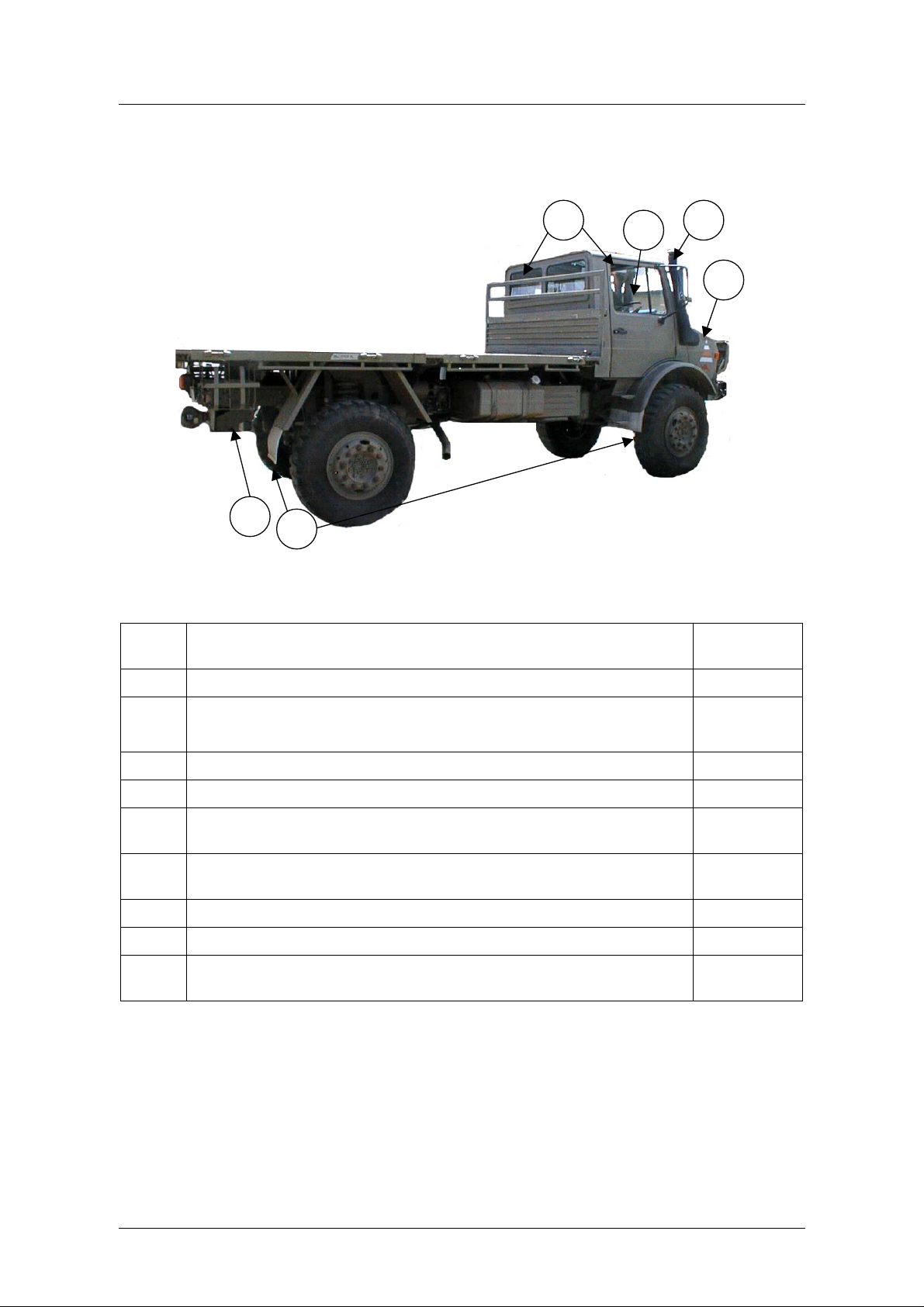

9.3 The cleaning instructions for the Unimog’s external areas, as illustrated in Figure 9-1,

include the points detailed in Table 9-1.

6

5

Figure 9-1: Unimog’s External Areas

Table 9–1: Cleaning Instructions for the Unimog’s External Areas

Serial Comments or Tasks

1

2

3

4

Technical

Time (hours)

1 Clean all rubber seals around the windows and doors.

2 Remove the cabin seats to facilitate cleaning.

Remove the rubber floor matting to clean the cabin floor.

3 Remove the snorkel to facilitate cleaning. 0.5

4 Remove the bonnet to facilitate cleaning.

5 Remove the mudflaps and pay attention to cleaning around the

attachment points.

6 Remove Cupola crash pad and any lining to facilitate cleaning and

inspection.

7 Loosen fuel and air tank retaining straps

8 Remove light covers and flush housing

9 Clean and inspect channel tubing at cargo tie down points on cargo

tray

1.5

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-3

Underside

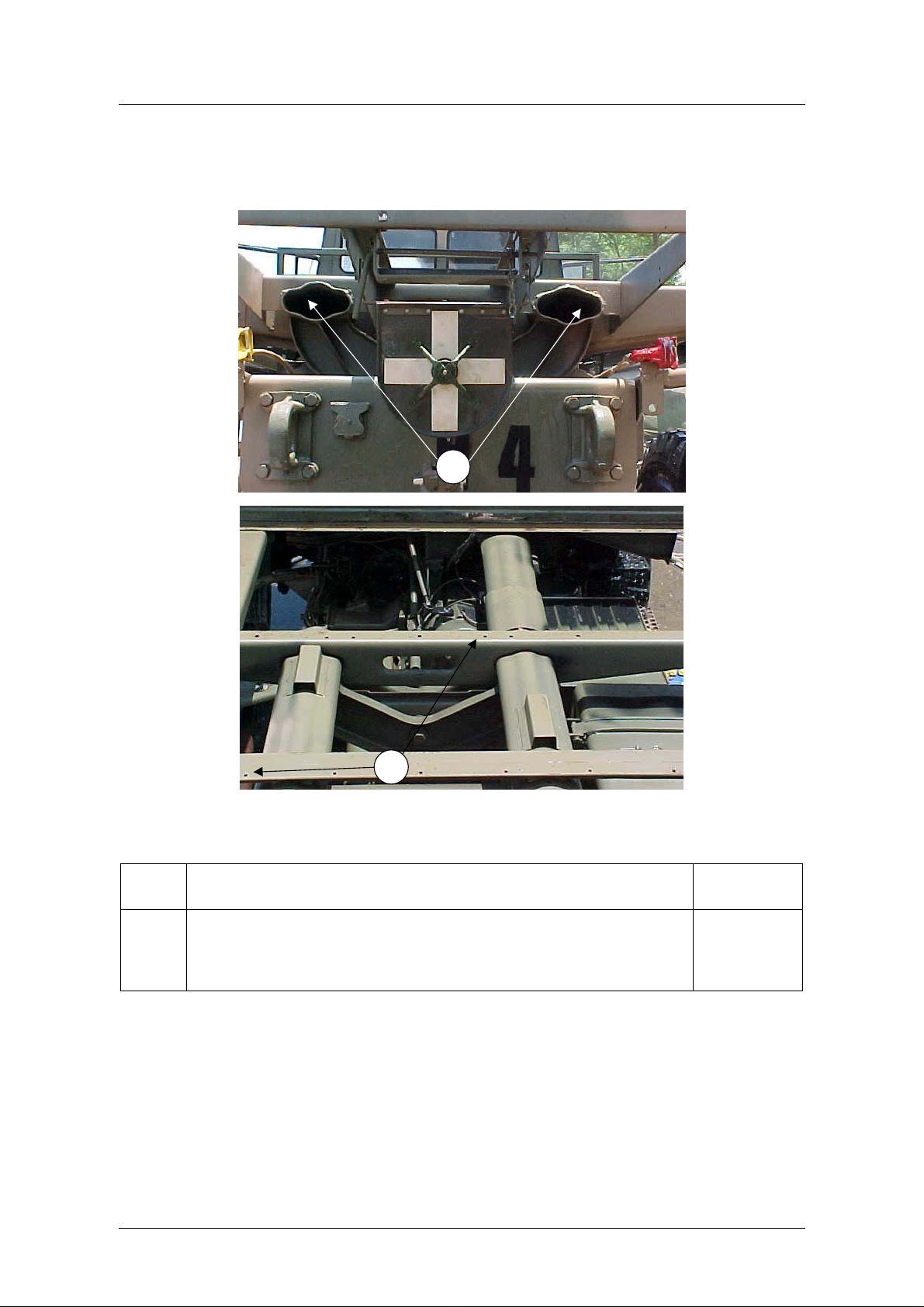

9.4 The cleaning instructions for the Unimog’s external areas, as illustrated in Figure 9-2,

include the points detailed in Table 9-2.

Figure 9-2: Unimog’s Underside Areas

Table 9–2: Cleaning Instructions for the Unimog’s Underside Areas

Serial Comments or Tasks

1 All tools are to be fully removed and extended to facilitate cleaning.

2 All externally fitted items of equipment to be removed and both the

items and the mounting brackets to be cleaned of all QRM

3 Jerry cans are to be removed to facilitate cleaning. 0.5

4 All toolboxes are to be emptied to facilitate cleaning.

If required, remove the toolboxes and Jerry can holders to facilitate

cleaning of soil, plant and insect debris between the items and the

chassis.

5 Spare tyre to be fully removed and to be cleaned as per “tyres”

para.10.9 below.

6 Tyre cover (if fitted) to be fully removed and to be washed and

scrubbed to remove all QRM (refer paragraph 9-23 below).

7 Frame areas are to be washed with high-pressure water utilising a

flexible nozzle.

Technical

Time (hours)

1.5

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-4

Cabin

9.5 The cleaning instructions for the Unimog’s cabin, as illustrated in Figures 9–3 and 9–4,

include the point detailed in Table 9–3.

Figure 9–3: Unimog’s Cabin

Figure 9–4: Unimog’s Doors

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-5

Table 9–3: Cleaning Instructions for the Unimog’s Doors

Serial Comments or Tasks

1 Remove the cabin seats to facilitate cleaning. 1.5

2 Remove the rubber floor matting to clean the cabin floor.

3 Inspect mirror sills and mirrors.

4 Door trims are to be removed and cleaned

5 The window and door rubber seals are to be cleaned of all soil, plant

and insect matter. Seals on the bonnet area are to be cleaned in a

similar fashion.

6 The seats and the floor mats are to be removed and the cabin floor

cleaned.

7 The cabin area is to be vacuumed and air-blown clean.

8 Ventilation ducts are to be unscrewed and air-blown clean.

9 Remove the front cover from the ventilation fan housing and clean the

fan housing. All soil, plant and insect matter are to be removed.

10 Critically inspect the gun mount and manhole (if fitted) to ensure they

are free from dirt, dust, plant and insect material.

Technical

Time (hours)

1.0

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-6

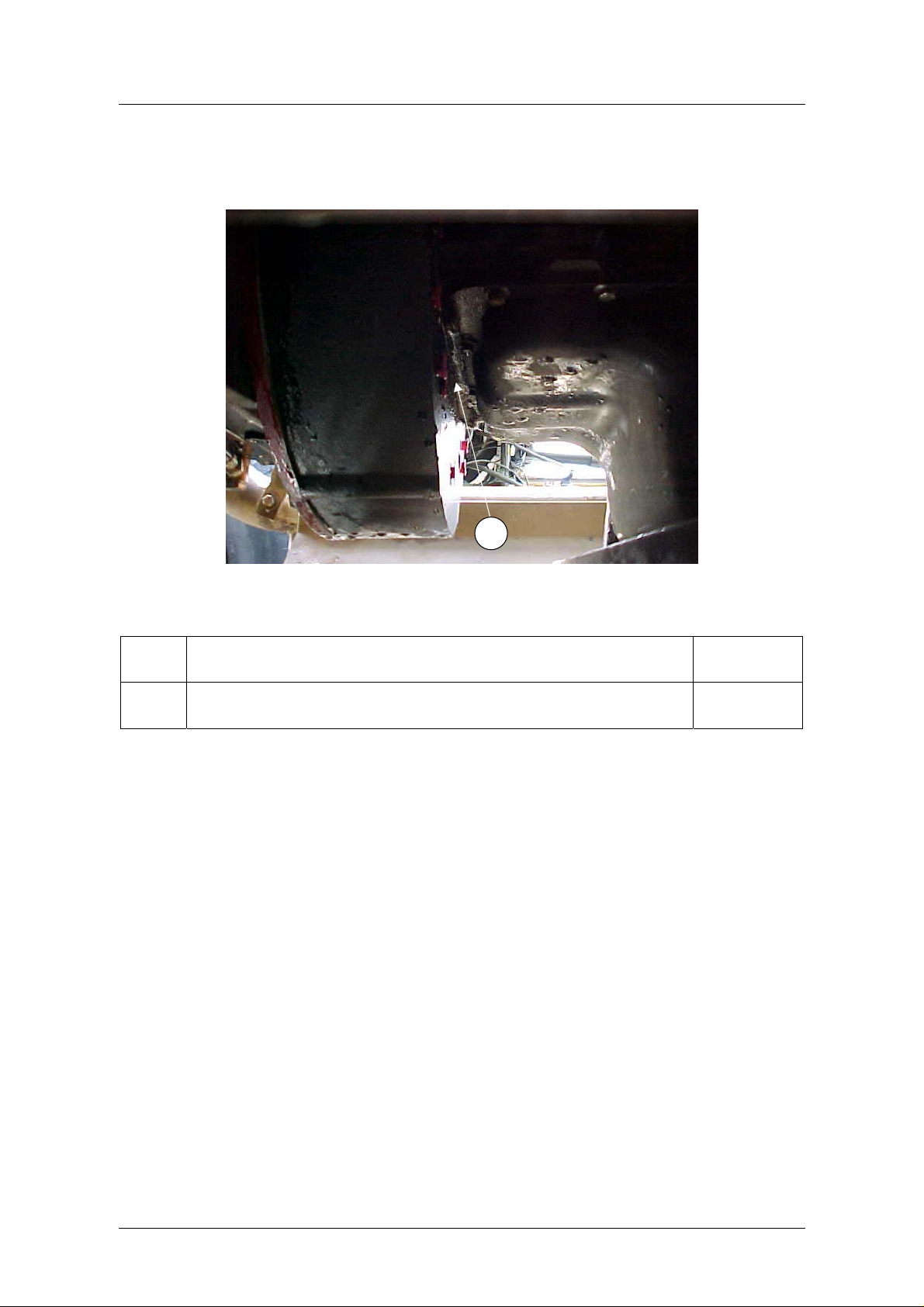

Cabin Holes

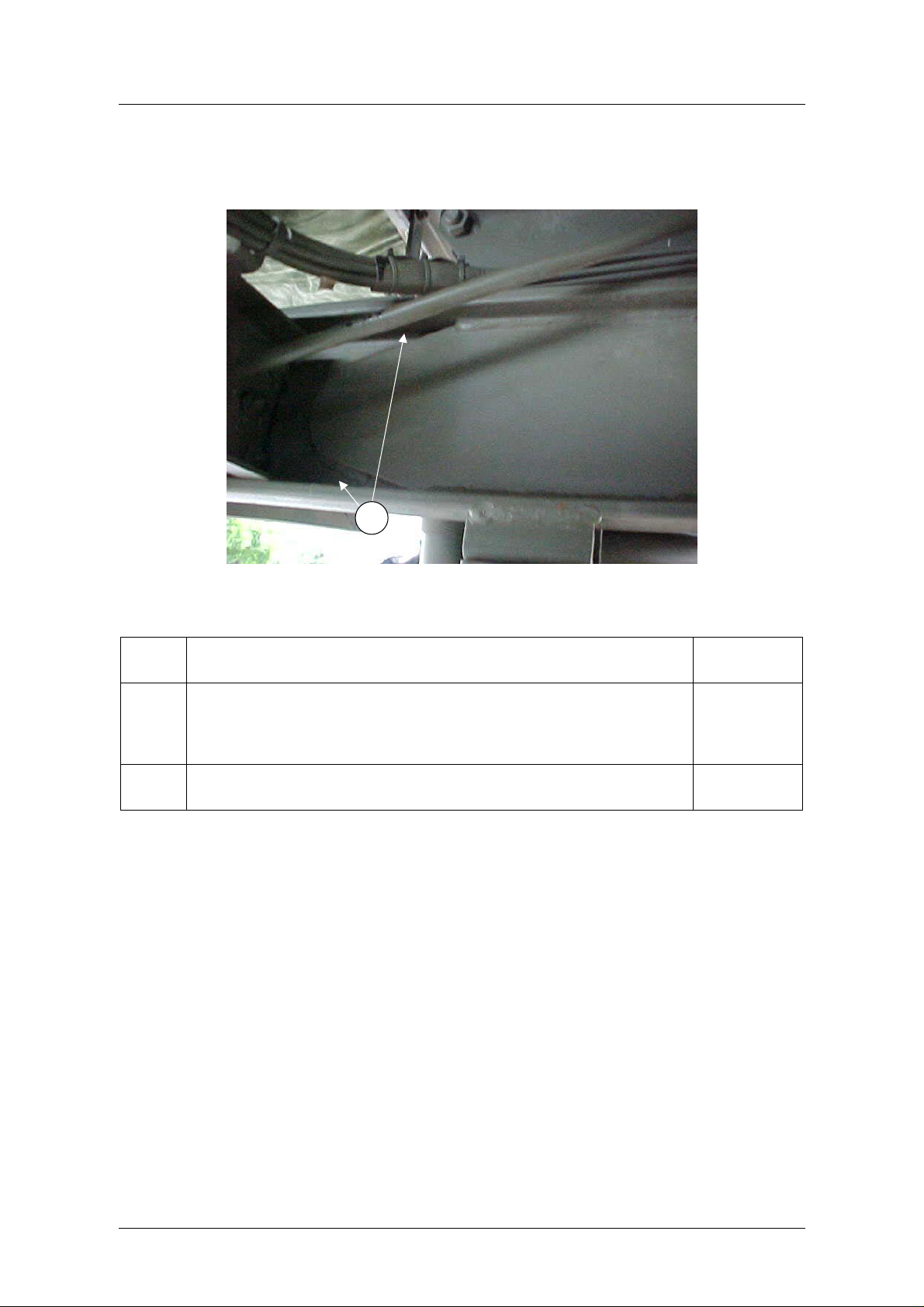

9.6 The cleaning instructions for the Unimog’s cabin holes, as illustrated in Figure 9-5, include

the point detailed in Table 9–4.

1

Figure 9-5: Unimog’s Cabin Holes

Table 9–4: Cleaning Instructions for the Unimog’s Cabin Holes

Serial Comments or Tasks

1 The holes under the cab are to be flushed through to remove all debris.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-7

Front Areas

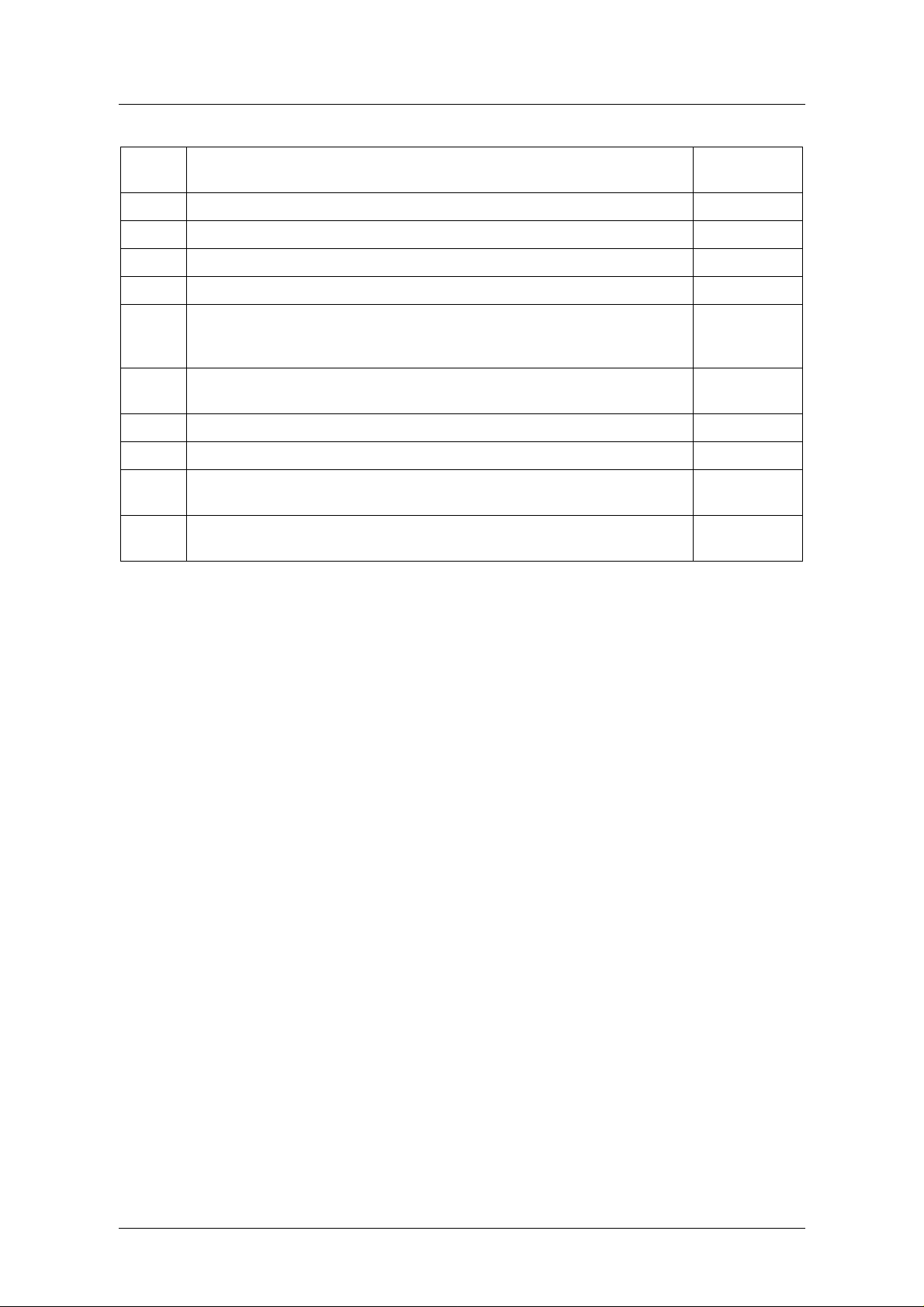

9.7 The cleaning instructions for the Unimog’s front areas as illustrated in Figure 9-6 include

the points detailed in Table 9–5.

3

4

2

1

Figure 9-6: Unimog’s Front Areas

Table 9–5: Cleaning Instructions for the Unimog’s Front Areas

Serial Comments or Tasks

Technical

Time (hours)

1 Headlights are to be removed to facilitate cleaning behind them. 1.0

2 The brush guard is to be removed. 0.25

3 The air cleaner element is to be removed and disposed of in

accordance with AQIS directions.

Clean the ventilation nozzles on the centre top of the dash using low

pressure compressed air.

Remove the ventilation blower assembly filter element, from the front

left-hand side of the cabin, and dispose of in accordance with AQIS

directions. Clean out the ventilation blower assembly housing and

ensure no dirt, seed or plant material remains.

Raise the heating/ventilation flap, on the selected gear indicator panel,

and vacuum clean the discharge cavity to remove dust and other

foreign material.

4 The bonnet is to be removed.

5 Remove the radiator to facilitate cleaning.

The radiator is to be high-pressure air-cleaned to remove seed and

then washed down by a low-pressure water high-volume wash;

Bent radiator grills may require heat treatment to burn any embedded

seed material (using heat shrink guns).

It may be necessary to use brushes or pick insect and seed matter out

from between the veins on the radiators.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-8

Under Tray

9.8 The cleaning instructions for under the Unimog’s tray, as illustrated in Figure 9-7, include

the points detailed in Table 9–6.

1

2

3 4 5 6

Figure 9-7: Under the Unimog’s Tray

Table 9–6: Cleaning Instructions for Under the Unimog’s Tray

Serial Comments or Tasks

Technical

Time (hours)

1 High-pressure water clean around the fittings using a flexible nozzle as

is necessary to get into all areas.

2 Remove the tank straps to facilitate cleaning. 1.0

3 Clean all the supporting members for the floor area.

The wooden floor is to be lifted to allow inspection and to facilitate

cleaning of the chassis cross members and underside of the floor. If

the wooden floor plates are cracked, gouged or damaged, they are to

be disposed of in accordance with AQIS directions.

4 The underside hollow cross members are to be subject to

high-pressure water using a flexible nozzle to remove all soil, plant and

insect matter.

5 Remove the driver’s step to facilitate cleaning where the step attaches

to the vehicle. Additionally, the hollow tube is to be subject to a high-

pressure water clean and, if necessary, drill a hole near the step point

to provide an exit point for water and debris.

2.0

0.5

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-9

Tray Checker Panel

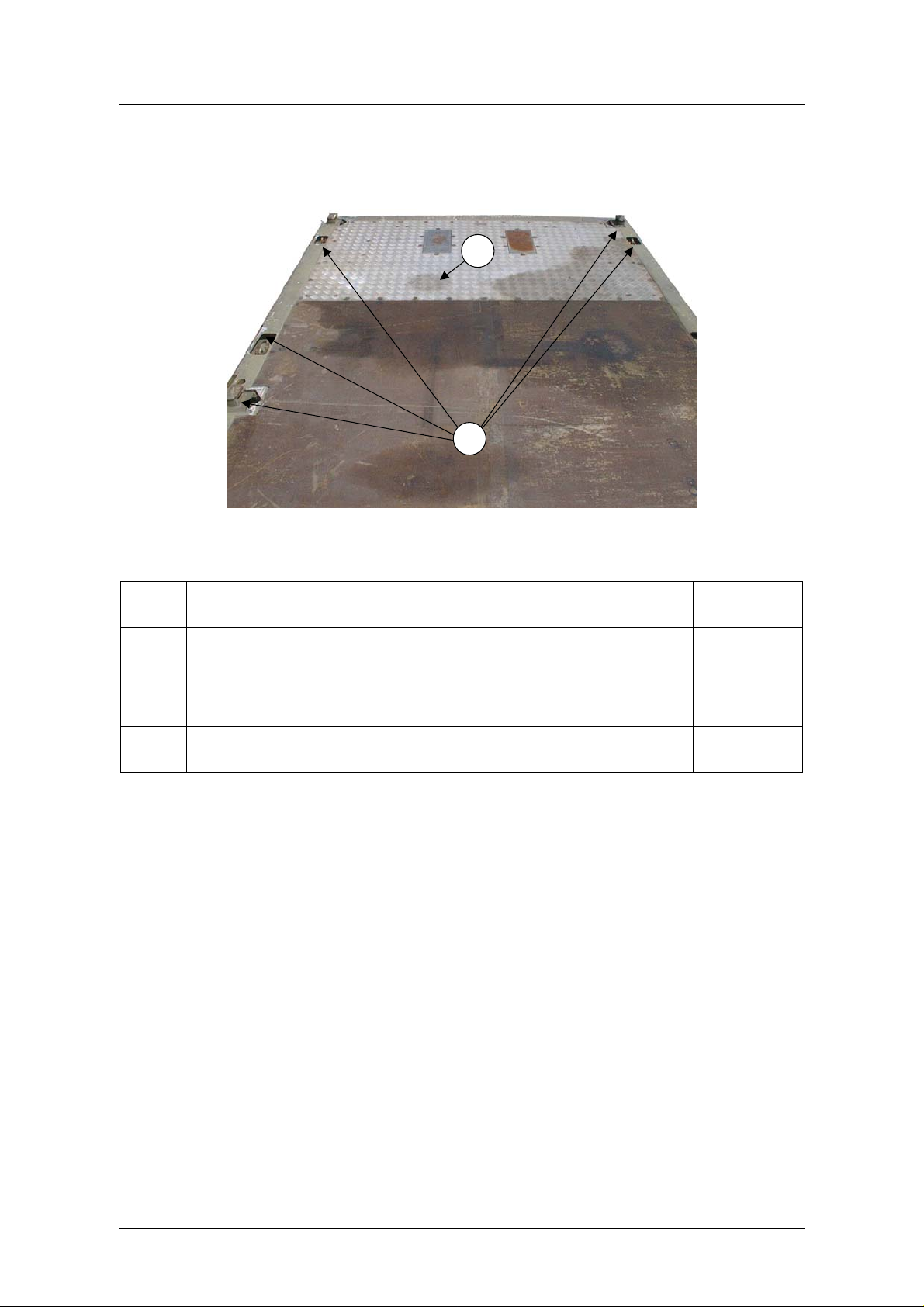

9.9 The cleaning instructions for the Unimog’s tray checker panel, as illustrated in Figure 9-8,

include the points detailed in Table 9–7.

1

2

Figure 9-8: Unimog’s Tray Checker Panel

Table 9–7: Cleaning Instructions for the Unimog’s Tray Checker Panel

Serial Comments or Tasks

1 Where evidence of QRM has been found the checker plate is to be

seperated from the Wooden floor to facilitate cleaning. Remove the

checker plate to facilitate cleaning and an AQIS inspection underneath.

Timber floor panels passed by AQIS inspectors will require fumigation

action upon entry to Australia and will not be refitted to vehicle.

2 Use a high-pressure water clean on the attachment points on the cargo

tray.

Technical

Time (hours)

1.0

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-10

Chassis

9.10 The cleaning instructions for the Unimog’s chassis, as illustrated in Figure 9-9, include the

points detailed in Table 9–8.

1

Figure 9-9: Unimog Chassis

Table 9–8: Cleaning Instructions for the Unimog’s Chassis

Serial Comments or Tasks

1 The chassis rail on the vehicle has open areas which collect deb ris.

The area is to be flushed behind the plate using a flexible nozzle and

moving around to ensure all areas behind the plate are cleaned until

the water is observed to be clear on exit.

2 Loosen and clean air line restraining straps. Foam covering may

require to be disposed of if heavenly contaminated.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-11

Chassis Support Tubes

9.11 The cleaning instructions for the Unimog’s chassis support tubes, as illustrated in

Figure 9-10, include the point detailed in Table 9–9.

1

1

Figure 9-10: Unimog’s Chassis Support Tubes

Table 9–9: Cleaning Instructions for the Unimog’s Chassis Support Tubes

Serial Comments or Tasks

1 The rear view of the chassis support tubes are to be flushed out. The

right-hand tube has a closed end and may require extensive flushing.

Some vehicles have been modified and have drilled holes at the cabin

end of the tube to allow water to drain out.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-12

Cross Members

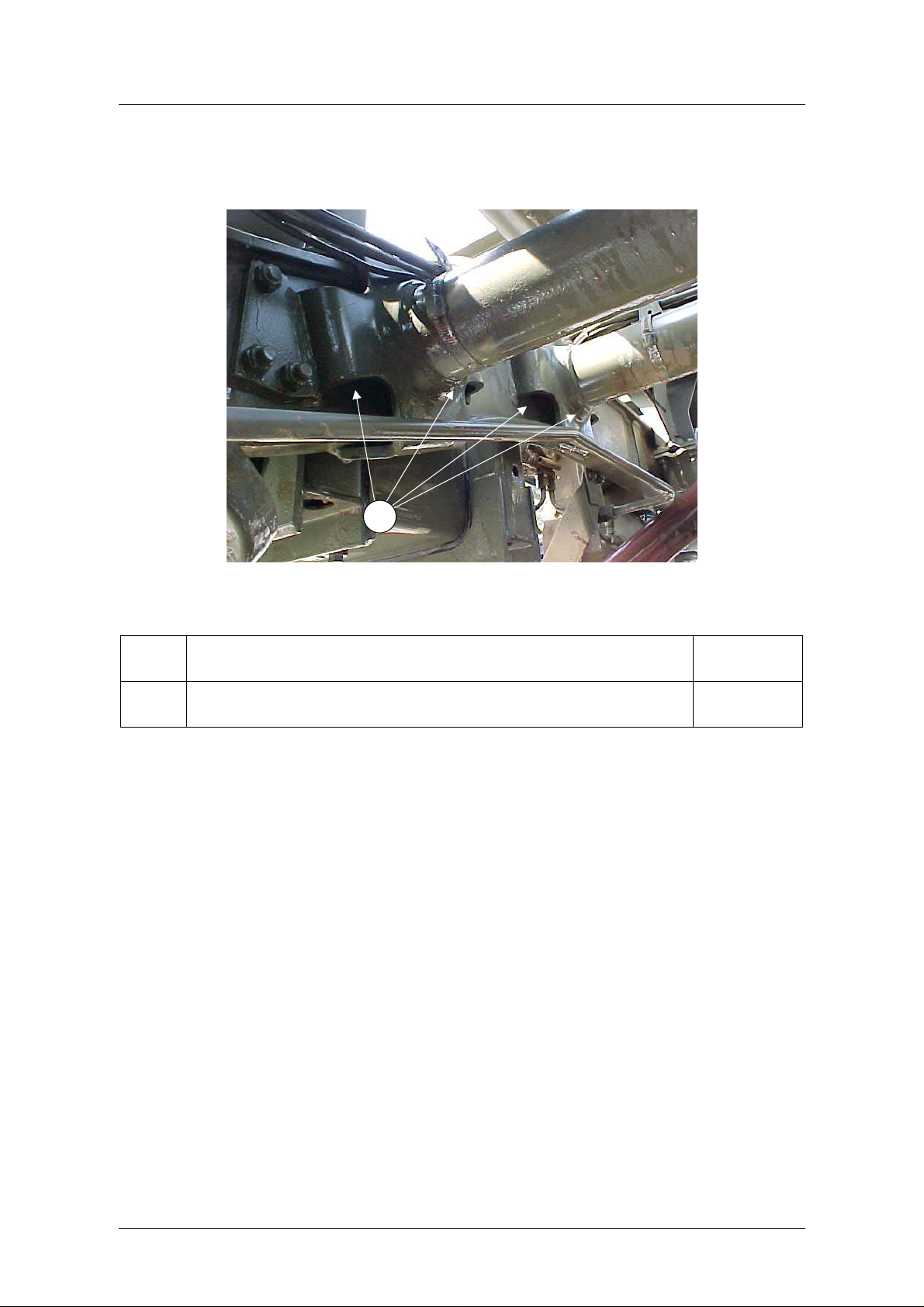

9.12 The cleaning instructions for the Unimog’s cross members, as illustrated in Figure 9-11,

include the point detailed in Table 9–10.

1

Figure 9-11: Unimog’s Cross Members

Table 9–10: Cleaning Instructions for the Unimog’s Cross Members

Serial Comments or Tasks

1 The mounting brackets for the cross members collect debris that

requires flushing using a flexible nozzle.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-13

Chassis Cross Member

9.13 The cleaning instructions for the Unimog chassis cross member, as illustrated in

Figure 9-12, include the point detailed in Table 9–11.

1

Figure 9-12: Unimog Chassis Cross Member

Table 9–11: Cleaning Instructions for the Unimog’s Chassis Cross Member

Serial Comments or Tasks

1 The chassis cross member collects debris that requires flushing usi ng

a flexible nozzle.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-14

Chassis Cavities

9.14 The cleaning instructions for the Unimog chassis cavities, as illustrated in Figure 9-13,

include the point detailed in Table 9–12.

1

Figure 9-13: Unimog’s Chassis Cavities

Table 9–12: Cleaning Instructions for the Unimog’s Chassis Cavities

Serial Comments or Tasks

1 All soil and debris is to be removed from the chassis cavities.

2 Remove plastic ties to expose grouped cables and air lines for

inspection

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-15

Sump

9.15 The cleaning instructions for the Unimog sump, as illustrated in Figure 9-14, include the

point detailed in Table 9–13.

1

Figure 9-14: Unimog Sump

Table 9–13: Cleaning Instructions for the Unimog’s Sump

Serial Comments or Tasks

1 Grease and oil from the front of the sump and on the back of the

flywheel housing is to be removed.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-16

Torque Tube Wiring Looms and Air Lines

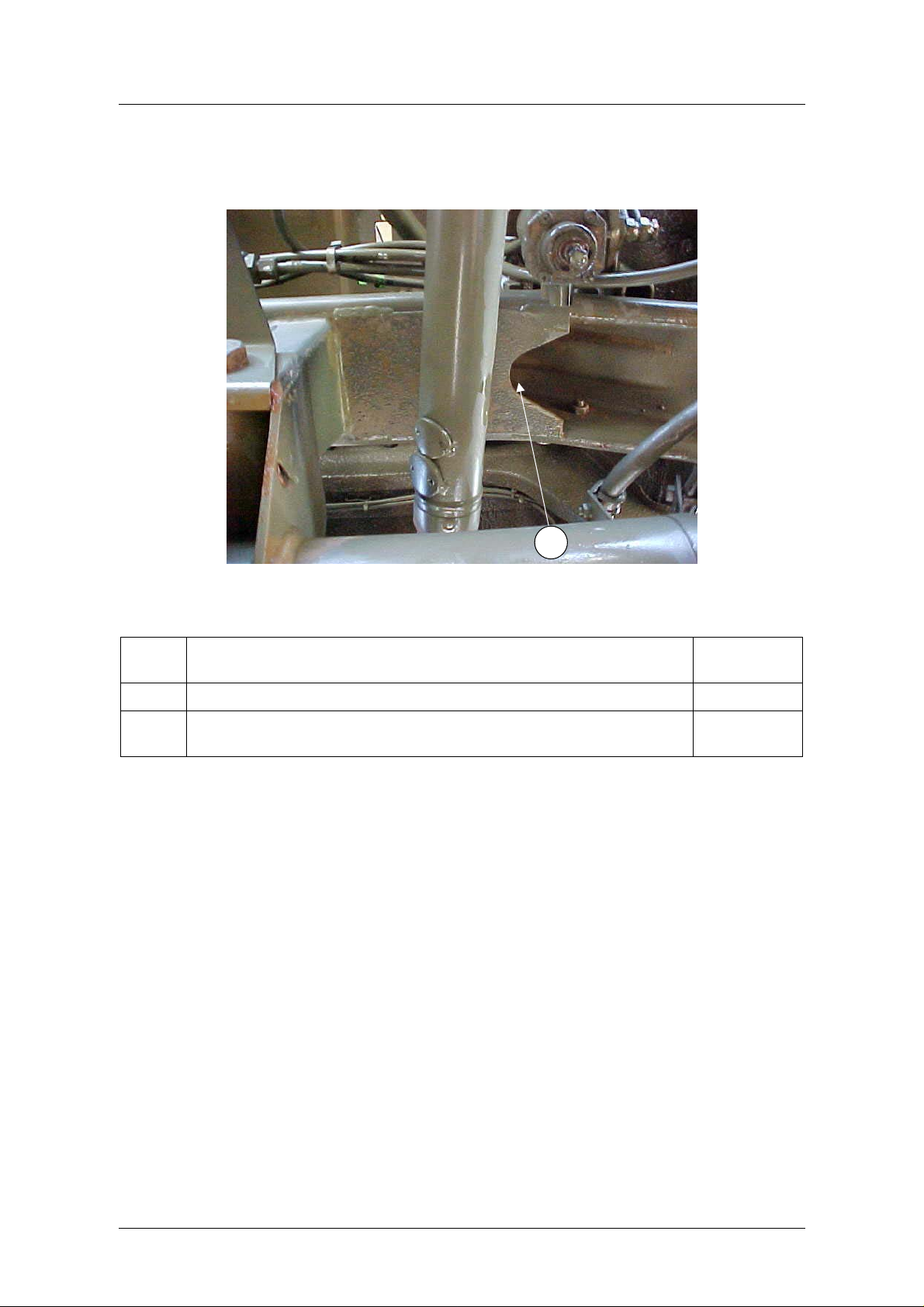

9.16 The cleaning instructions for the Unimog’s wiring looms and air lines, as illustrated in

Figure 9-15, include the point detailed in Table 9–14.

1

Figure 9-15: Unimog’s Wiring Looms and Air Lines

Table 9–14: Cleaning Instructions for the Unimog’s Wiring Looms and Air lines

Serial Comments or Tasks

1 Loosen hose clamps and mounting channels and clean in between all

air lines on the torque tube.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-17

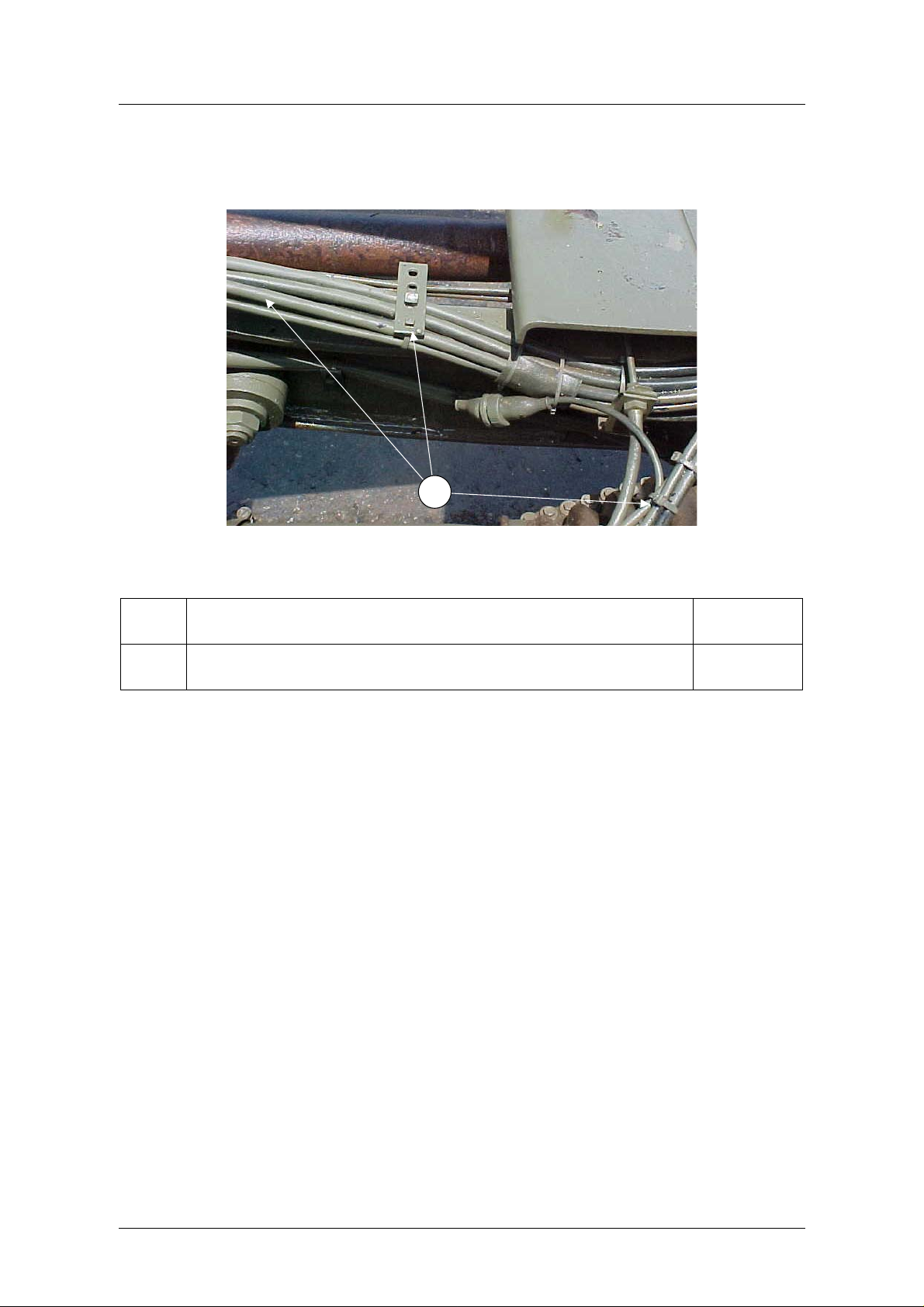

Chassis Air Lines and Wiring Looms

9.17 The cleaning instructions for the Unimog’s cables, as illustrated in Figure 9-16, include the

point detailed in Table 9–15.

1

Figure 9-16: Unimog’s Cables

Table 9–15: Cleaning Instructions for the Unimog’s Cables

Serial Comments or Tasks

1 Clean in between all cables, paying attention to where the cable ties

are located and between the cable and vehicle.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-18

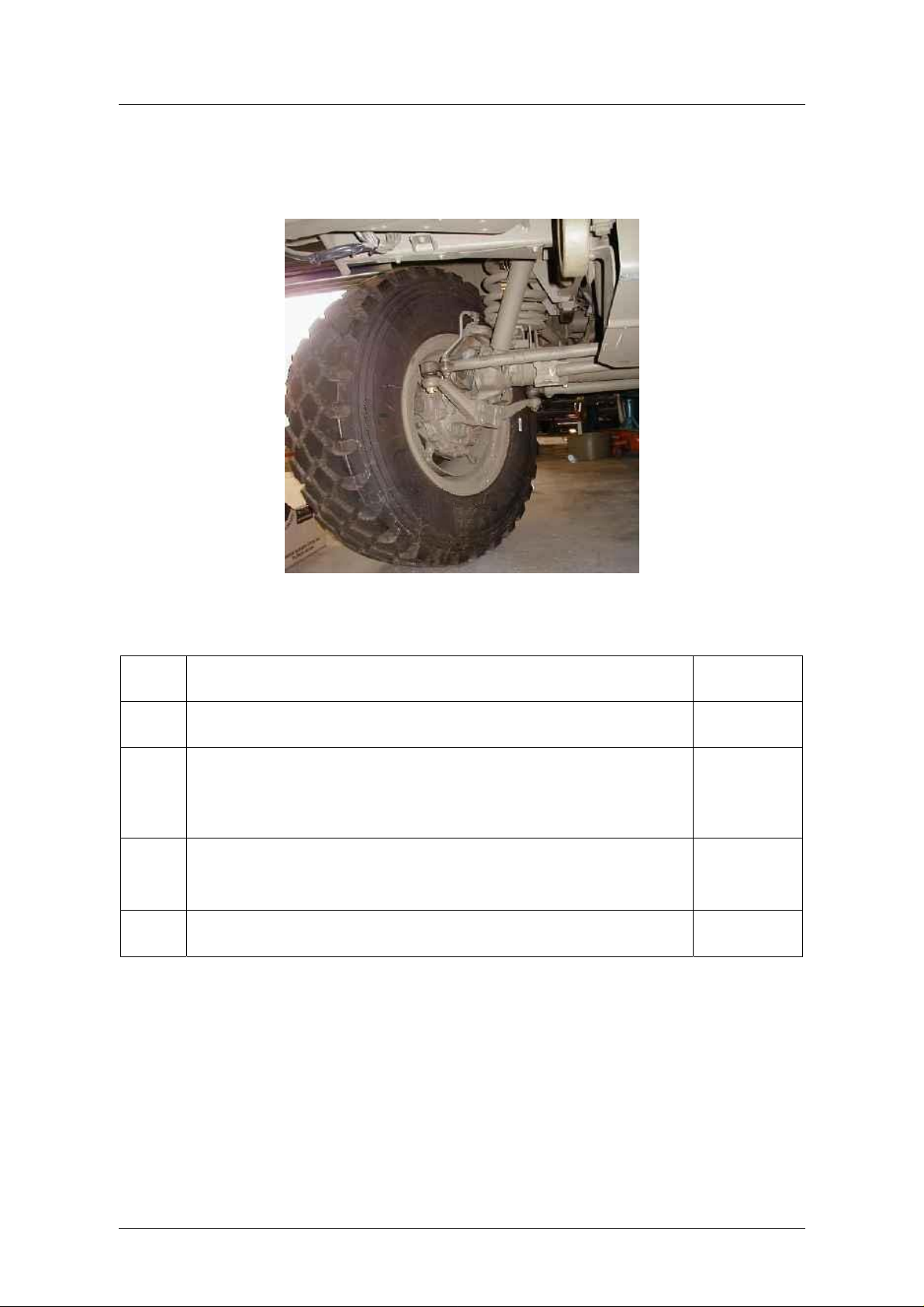

Suspension

9.18 The specific cleaning instructions for Unimog’s suspension include those points detailed in

Figure 9-17 and Table 9–16.

Figure 9-17: Unimog’s Suspension

Table 9–16: Cleaning Instructions for the Unimog’s Suspension

Serial Comments or Tasks

1 Ensure suspension rocker beam mounts on chassis are clean and free

of soil, plant and insect material.

2 Mud and other debris collect in the spring seat, where the spring is

mounted to the axle assembly, and are difficult to remove from the

base of the springs.

Ensure that this area is cleaned well.

3 Mud and other debris collect in the inside area on the inner side of the

wheel.

Ensure that this area is cleaned well.

4 Ensure axles and mounts on chassis are clean and free of soil, plant

and insect material.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-19

Engine and Transmission

9.19 The specific cleaning instructions for Unimog’s engine and transmission include those

points detailed in Figure 9-18 and Table 9–17.

Figure 9-18: Unimog’s Engine and Transmission

Table 9–17: Cleaning Instructions for the Unimog’s Engine and Transmission Compar tment

Serial Comments or Tasks

1 Clean the engine compartment and engine to ensure they are free of

Technical

Time (hours)

dust, built-up dirt and grease, insect and plant material..

2 Ensure any engine openings/breathers are taped or plugged to stop

ingress of water.

3 Ensure the starter motor and alternator are covered and taped to stop

ingress of water.

4 Do not direct high-pressure water jets at any of the engine

openings/breathers, or at any of the electrical/electronic components

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-20

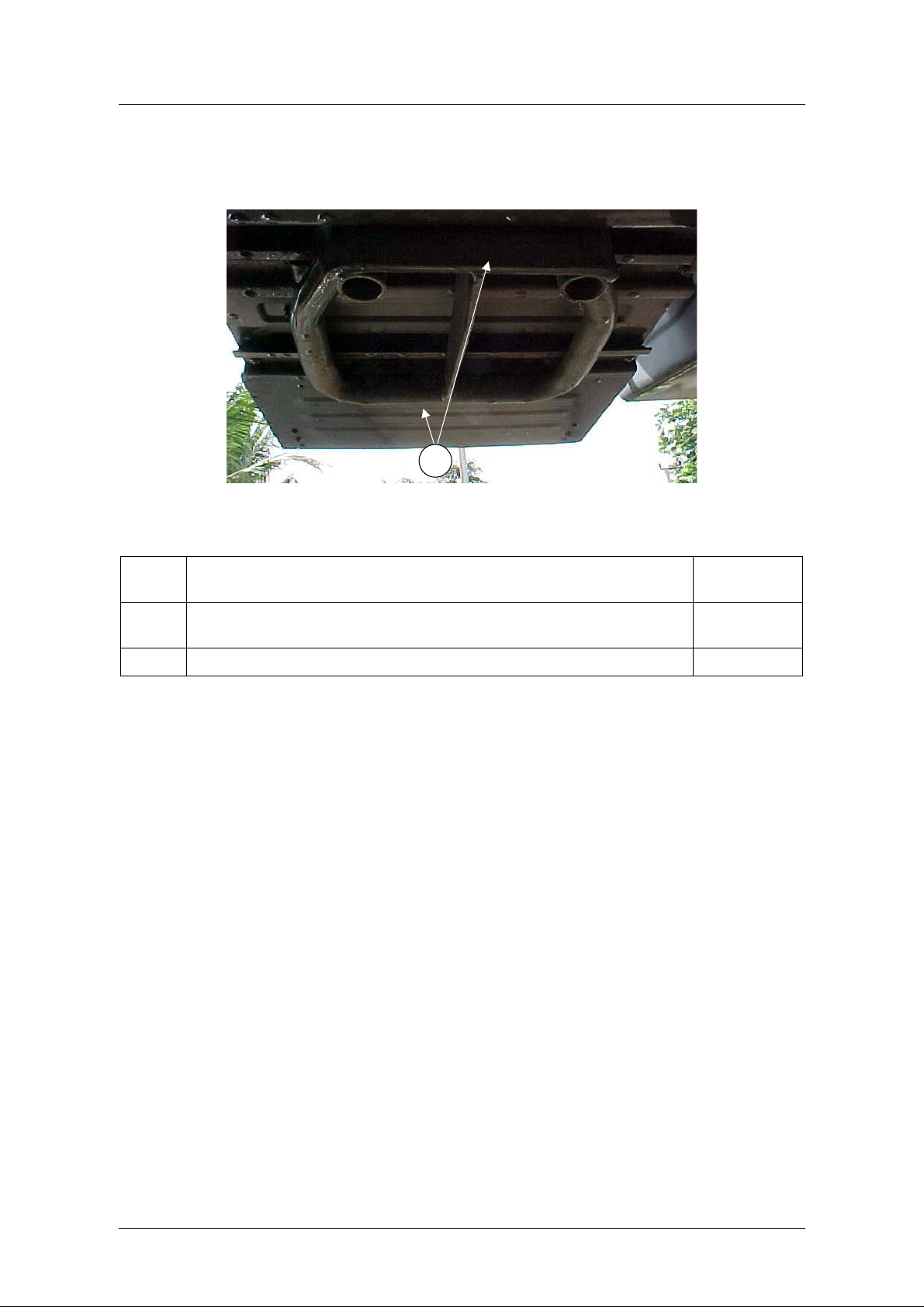

Battery Box

9.20 The cleaning instructions for the Unimog’s battery box, as illustrated in Figure 9-19, include

the point detailed in Table 9–18.

1

Figure 9-19: Unimog’s Battery Box

Table 9–18: Cleaning Instructions for the Unimog’s Battery Box

Serial Comments or Tasks

1 The battery box support member is to be flushed through using a

flexible nozzle until clear water is seen to exit.

2 Flush support bases and tubing underneath battery box.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-21

Winches, Wire Ropes and Slings

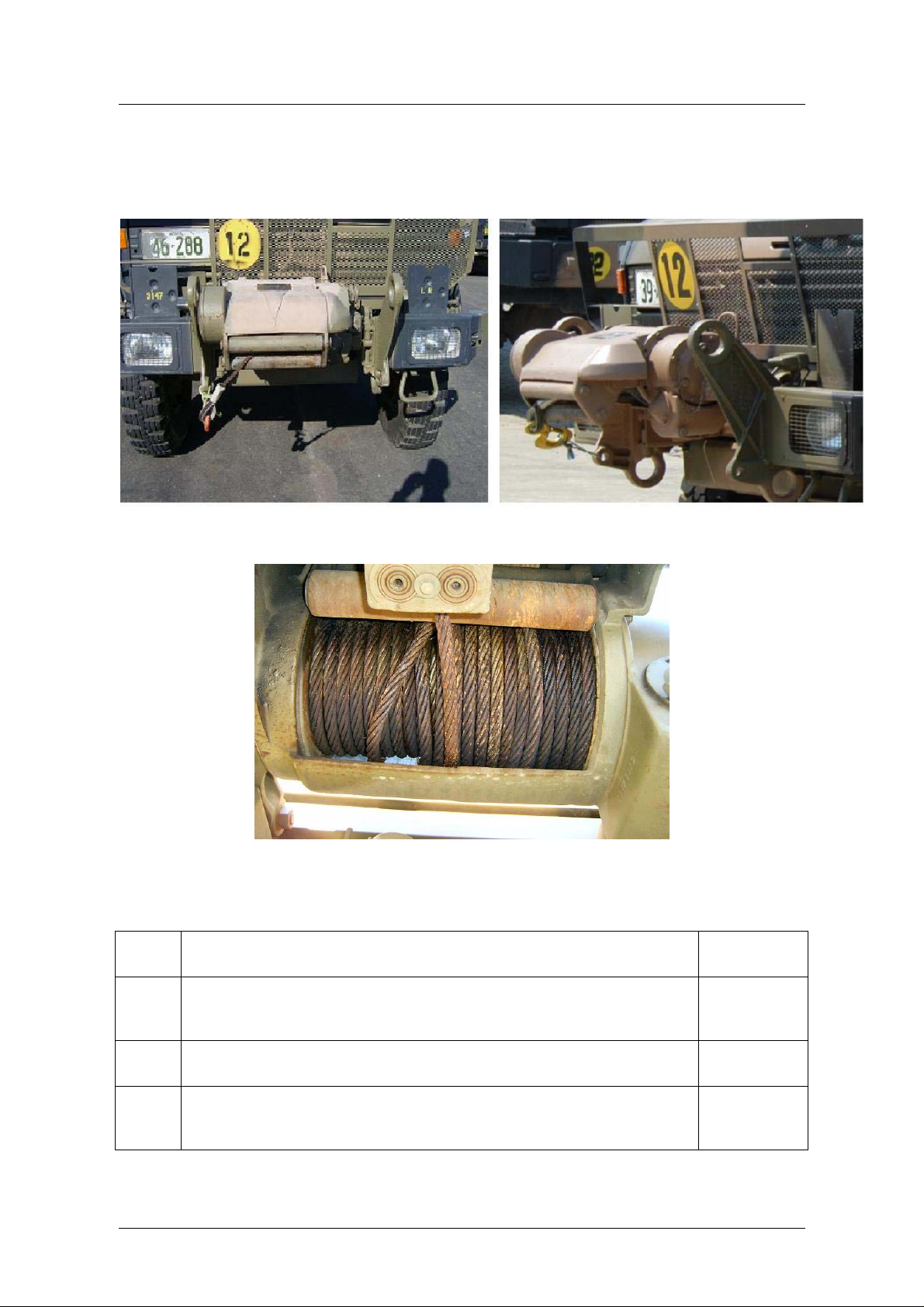

9.21 The cleaning instructions for Winches, Wire Ropes and Slings, as illustrated in Figures 9-

20 and 9-21, include the point detailed in Table 9–19.

Figure 9-20: Unimog’s Winch Assembly

Figure 9-21: Unimog’s Winch Assembly Underside

Table 9–19: Cleaning Instructions for Winches, Wire Ropes and Slings

Serial Comments or Tasks

Technical

Time (hours)

1 All items are to be extended to full length and subject to a high-pressure

water clean using degreaser, if required, to remove all soil, plant and

insect matter

2 The winch drum is also to be degreased and subject to a high-pressure

water clean

3 All winch ropes, wire ropes and slings are to be re-oiled after inspection.

An application of a protective covering (plastic bag) may be required to

protect the refurbished ropes and cables

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-22

Tarpaulins

9.22 The cleaning instructions for the tarpaulins include the points detailed in Table 9-20.

Table 9–20: Cleaning Instructions for the Tarpaulin Areas

Serial Comments or Tasks

1 All tarpaulins are to be given a brush down, brush scrubbing and hose

cleaning, paying particular attention to the seam areas and then

hung so as not to contact the ground for drying

2 All ropes and universal dispatch straps are to be extended to

their full length and wiped or washed clean of all soil, plant and insect

matter

Attention to attachment points and fixtures and tension devices is

required

Personnel are to inspect and remove all twigs, foliage, and so on that

has become embedded in the rope fibres

3 Velcro panels and seams (where fitted) are to be brushed and

washed to ensure all seed, plant and soil material is removed

4 Canvas bags are to be turned inside out and checked for burrs, seeds

and insects;

5 Where fitted, poles, knuckles and pegs are to be subject to a

high-pressure water clean to remove all soil, plant and insect matter

(ants, spiders and mud wasps are of particular concern)

6 If tarpaulins have not been used during the entire deployment,

then the requirement is for all tarpaulins to be unrolled, brushed and

swept clean to ensure no vermin or insect infestation and then

subject to an AQIS inspection

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-23

Camouflage Nets

9.23 The cleaning instructions for camouflage nets include the points detailed in Table 9-21.

Table 9–21: Cleaning Instructions for Camouflage Nets

Serial Comments or Tasks

1 Removal of grass and debris may be achieved by use of a petrol

powered blower/vacuum in the first instance, use of water should be

avoided

2 Heavily soiled camouflage nets may require further scrubbing and a dip

in an approved detergent/ disinfectant (one in 20 solution). This has

been achieved in the past by using trailers with required additive

3 Depending on the degree of contamination and diligence in the

cleaning process, camouflage nets may require three or more trailer

dips to achieve the required AQIS clearance

4 Drying is to be achieved by hanging the camouflage net so that it does

not come into contact with the ground

5 Nets are to be inspected to ensure that all plant material is removed

6 Camouflage poles are to be brushed or swept clean; and metal joiners

are to be removed cleaned and inspected by AQIS officers

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-24

Tyres (New, Old and Spares)

9.24 The cleaning instructions for Tyres (New, Old and Spares), as illustrated in 9-22, include

the points detailed in Table 9-22.

Figure 9-22: Unimog’s Wheel

Table 9–22: Cleaning Instructions for Tyres (New, Old and Spares)

Serial Comments or Tasks

Time (hours)

1 All tyres are to be washed and scrubbed to remove all QRM.

2 Damaged tyres are to be inspected by AQIS, who will determine their

suitability for return to Australia. If necessary, damaged tyres (for

example, perished, cracked or split) are to be removed and dispo s ed of

in accordance with the tyre disposal policy;

3 Cracked tyres have the risk of containing QRM therefore perished tyres

are to be subject to disposal.

4 All tyres are to be treated with an approved residual insecticide

after cleaning

5 Fitted tyres that are damaged should be replaced with new tyres.

6 Used and fitted tyres on rims are to be individually verified that the tyres

are on rims, inflated with beading sealed and that the tyres are clean,

free of water and other quarantine risk material.

Technical

7 Tyres that are not fitted to rims are to be stored in such a

manner that water cannot collect inside the tyre. The preferred AQIS

solution is that tyres are stored within containers. Tyres not fitted on

rims will require fumigation on return to Australia.

8 AQIS considers a Non-Commercial consignment of tyres to contain a

maximum of 8 tyres (inclusive of the wheels on the vehicle) and be

imported with an accompanying vehicle. If tyres are to be transported

back to Australia in containers or crates, please refer to the AQIS

internet site (

http://www.daff.gov.au/) ICON (Import Conditions

Database) for the commodity “tyres”.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9-25

ANNEXES:

A.

C

leaning Instructions – Unimog Dump

B. Cleaning Instructions – Unimog Medium Recovery Vehicle (MRV)

C. Cleaning Instructions – Unimog Tank & Pump Assemblies

D. Cleaning Instructions – Uni mog Maintenance Shelter (UMS)

E. Cleaning Instructions – Unimog Special Forces Long Range Sustainment Vehicle (LRSV)

F. Cleaning Instructions – Unimog Radar

G. Cleaning Instructions – Unimog Gun Tractors

H. Cleaning Instructions – Unimog Cargo Crane Variant

I. Clea ning Instructions – Unimog Troop Carrier

J. Cleaning Checklist – Unimog

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9A-1

ANNEX A TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG DUMP

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog dump’s external areas, as illustrated in Figure

9A–1, include the points detailed in Table 9A–1.

Figure 9A–1: Unimog Dump

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9A-2

Table 9A–1: Cleaning Instructions for the Unimog Dump’s External Areas

Serial Comments or Tasks

1 Remove the mudflaps and pay attention to cleaning around the

Technical

Time (hours)

attachment points.

2 The dump body is to be raised to extend the hydraulic ram for cleaning.

The dump body is to be locked in the raised position.

Clean the chassis rails and exposed vehicle components under the

dump body with high-pressure water.

3 The box section is to be inspected for damage. If damaged, the box

area is to be flushed through with high-pressure water using a flexible

nozzle to ensure all soil, plant and insect matter is removed.

4 The tray face is to be inspected for damage and damaged sections are

to be removed to facilitate an inspection to ensure there is no

compacted soil embedded.

5 Refer to Chapter 9 for detailed cleaning guidelines.

Lower Areas

4. The cleaning instructions for the Unimog dump’s lower areas, as illustrated in Figure 9A–2,

include the points detailed in Table 9A–2.

1

3

2

Figure 9A–2: Unimog Dump’s Lower Areas

Table 9A–2: Cleaning Instructions for the Unimog Dump’s Lower Areas

Serial Comments or Tasks

1 The linkage area for the tailgate is to be cleaned of all grease and

contamination by soil, plant and insect material.

Technical

Time (hours)

2 The ram is to be extended to facilitate cleaning.

3 Electrical tape is to be removed to facilitate cleaning between the

cables.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9A-3

Rear Electrical Cables

5. The cleaning instructions for the Unimog dump’s rear electrical cables, as illustrated in Figure

9A–3, include the point detailed in Table 9A–3.

1

Figure 9A–3: Unimog Dump’s Rear Electrical Cables

Table 9A–3: Cleaning Instructions for the Unimog Dump’s Rear Electrical Cables

Serial Comments or Tasks

1 Electrical tape is to be removed to facilitate cleaning of electrical

cables.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-1

ANNEX B TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG MEDIUM RECOVERY

VEHICLE (MRV)

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

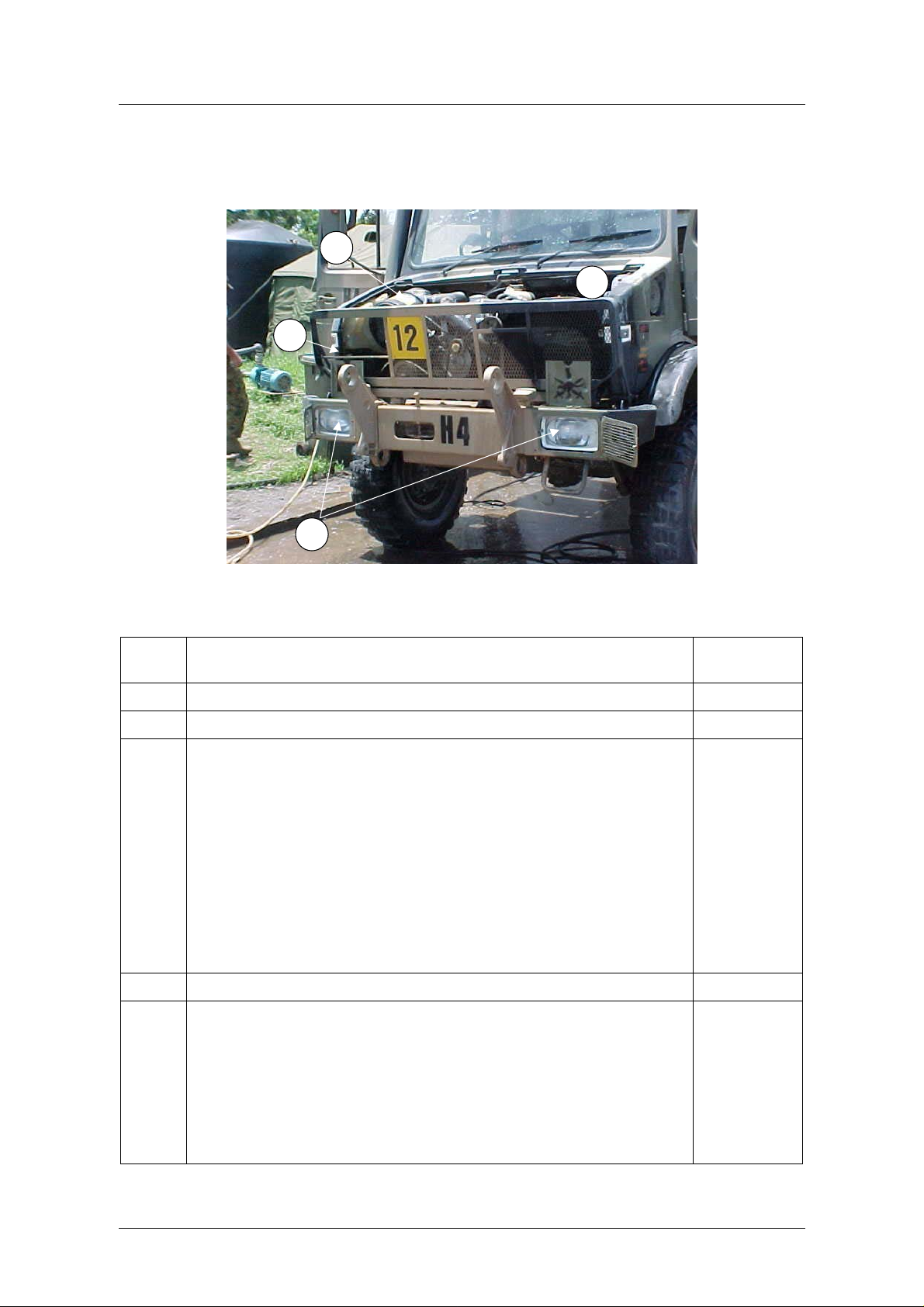

3. The cleaning instructions for the Unimog Medium Recovery Vehicle’s external areas, as

illustrated in Figures 9B–1and 9B–2, include the points detailed in Table 9B–1.

Figure 9B–1: Unimog Medium Recovery Vehicle

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-2

Figure 9B–2: Unimog Medium Recovery Vehicle’s External Areas

Table 9B–1: Cleaning Instructions for the Unimog Medium Recovery Vehicle’s External

Areas

Serial Comments or Tasks

Technical

Time (hours)

1 Refer to Chapter 9 for detailed cleaning guidelines. 1.25

2 Clean all rubber seals around the windows and doors.

3 Remove the cabin seats to facilitate cleaning.

Remove door trims to clean door cavities.

4 Remove the snorkel to facilitate cleaning.

5 Remove the bonnet to facilitate cleaning.

6 Remove the mudflaps and pay attention to cleaning around the

attachment points.

7 Remove the batteries and clean the battery box, terminals and

batteries.

8 Remove the tank straps to facilitate cleaning. 1.5

9 Remove the toolboxes and Jerry can holders to facilitate cleaning of

soil, plant and insect debris between the items and the chassis.

10 The tray is to be raised to extend the hydraulic ram for cleaning.

11 The box section is to be inspected for damage. If da maged, the box

area is to be drilled and flushed through with high-pressure water u sing

a flexible nozzle to ensure all soil, plant and insect matter is removed.

1.5

12 The tray face is to be inspected for damage and damaged sections are

to be removed to facilitate an inspection to ensure there is no

compacted soil embedded.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-3

Palfinger

4. The cleaning instructions for the Unimog Medium Recovery Vehicle’s palfinger, as illustrated in

Figures 9B–3 and 9B–4, include the points detailed in Table 9B–2.

Figure 9B–3: Unimog Medium Recovery Vehicle’s Palfinger 1

Figure 9B–4: Unimog Medium Recovery Vehicle’s Palfinger 2

Table 9B–2: Cleaning Instructions for the Unimog Medium Recovery Vehicle’s Palfinger

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-4

CAUTION

HYDRAULIC COMPONENTS

Do not use high pressure water or steam to clean the hydraulics or

hydraulic control areas unless under the supervision of a qualified

technician

Serial Comments or Tasks

1 The linkage area for the tailgate is to be cleaned of all grease and

contamination by soil, plant and insect material.

2 The ram is to be extended to facilitate cleaning.

3 Electrical tape is to be removed to facilitate cleaning between the

cables.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-5

Recovery Boom

5. The cleaning instructions for the Unimog Medium Recovery Vehicle’s recovery boom, as

illustrated in Figure 9B–5, include the points detailed in Table 9B–3.

Figure 9B–5: Unimog Medium Recovery Vehicle’s Recovery Boom

Table 9B–3: Cleaning Instructions for the Unimog Medium Recovery Vehicle’s Recovery

Boom

CAUTION

HYDRAULIC COMPONENTS

Do not use high pressure water or steam to clean the hydraulics or

hydraulic control areas unless under the supervision of a qualified

technician

Serial Comments or Tasks

1 The linkage area is to be cleaned of all grease and contamination by

Technical

Time (hours)

soil, plant and insect material.

2 The ram is to be extended to facilitate cleaning.

3 Electrical tape is to be removed to facilitate cleaning between the

cables.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-6

Lower Areas

6. The cleaning instructions for the Unimog Medium Recovery Vehicle’s lower areas, as illustrated

in Figure 9B–6, include the points detailed in Table 9B–4.

Figure 9B–6: Unimog Medium Recovery Vehicle’s Lower Areas

Table 9B–4: Cleaning Instructions for the Unimog Medium Recovery Vehicle’s Lower Areas

Serial Comments or Tasks

1 The linkage area for the tailgate is to be cleaned of all grease and

Technical

Time (hours)

contamination by soil, plant and insect material.

2 The ram is to be extended to facilitate cleaning.

3 Electrical tape is to be removed to facilitate cleaning between the

cables.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-7

Battery Box

7. The cleaning instructions for the Unimog’s battery box, as illustrated in Figure 9B-7, include

the point detailed in Table 9B-5.

Figure 9B-7: Unimog MRV Battery Box

Table 9–5: Cleaning Instructions for the Unimog’s Battery Box

Serial Comments or Tasks

1 The battery box support member is to be flushed through using a

flexible nozzle until clear water is seen to exit.

2 Flush support bases and tubing underneath battery box.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-8

Winch Ropes, Wire Ropes and Slings

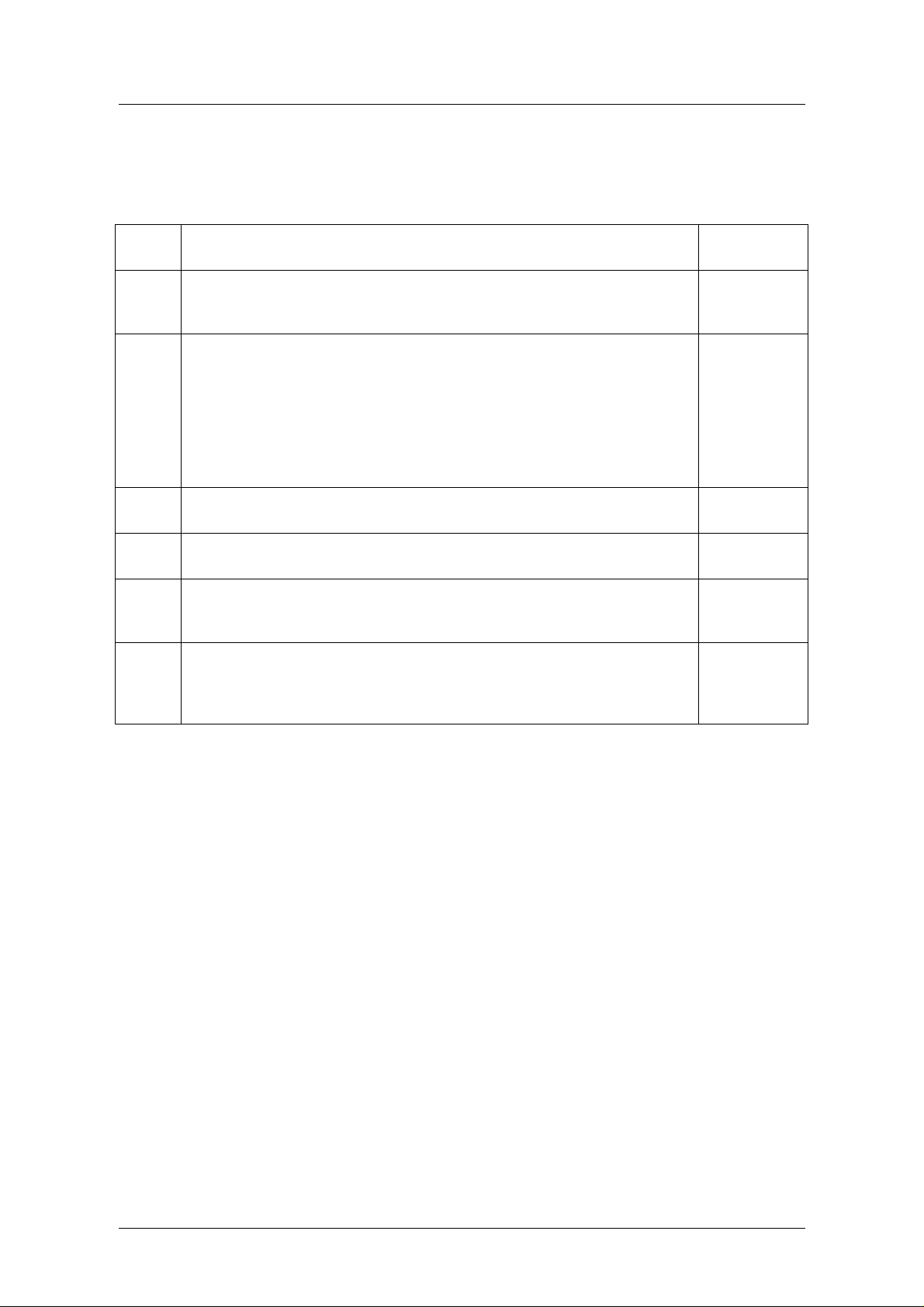

8. The cleaning instructions for Winch Ropes, Wire Ropes and Slings, as illustrated in Figure 9B–

8 to 9B–10; include the points detailed in Table 9B–6.

Figure 9B–8: Unimog Medium Recovery Vehicle’s Winch Cable Pulley System

Figure 9B–9: Unimog Medium Recovery Vehicle’s Winch Drums

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-9

Figure 9B–10: Unimog Medium Recovery Vehicle’s Winch Cable Channel

Table 9B–6: Cleaning Instructions for Winch Ropes, Wire Ropes and Slings

Serial Comments or Tasks

1 All items are to be extended to full length and subject to a high-pressure

water clean using degreaser, if required, to remove all soil, plant and

insect matter

2 The winch drum is also to be degreased and subject to a high-pressure

water clean

3 All winch ropes, wire ropes and slings are to be re-oiled after inspection.

An application of a protective covering (plastic bag) may be required to

protect the refurbished ropes and cables

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-10

Tool Boxes/ Storage Bins

9. The cleaning instructions for the Unimog Medium Recovery Vehicle’s Tool Boxes/Storage Bins,

as illustrated in Figures 9B–11 to 9B–14, include the point detailed in Table 9B–7.

Figure 9B–11: Unimog Medium Recovery Vehicle’s Tool Boxes Drivers Side 1

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9B-11

Figure 9B–12: Unimog Medium Recovery Vehicle’s Tool Boxes Drivers Side 2

Figure 9B–13: Unimog Medium Recovery Vehicle’s Tool Boxes Passengers Side 1

Figure 9B–14: Unimog Medium Recovery Vehicle’s Tool Boxes Passengers Side 2

Table 9B–7: Cleaning Instructions for the Unimog Medium Recovery Vehicle’s Tool

Boxes/Storage Bins

Serial Comments or Tasks

1

Toolboxes and tool bins are to be emptied and brushed, air-blown and

wiped clean.

2

Tools are to be wiped clean and lightly oiled after inspection

3

Clean all rubber seals around the doors.

ADF Force Extraction Cleaning Manual

Technical

Time (hours)

UNCONTROLLED IF PRINTED

9C-1

ANNEX C TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG TANK AND PUMP

ASSEMBLIES

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog tank and pump assemblies’ external areas, as

illustrated in Figures 9C-1 to 9C-3, include the points detailed in Table 9C-1.

1

Figure 9C-1: Unimog Tank and Pump Assemblies’ External Areas

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-2

2

1

3

Figure 9C-2: Unimog Tank and Pump Assemblies’ Rear Angle

Figure 9C-3: Unimog Tank and Pump Assemblies’ Rear

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-3

Table 9C-1: Cleaning Instructions for the Unimog Tank and Pump Assemblies’ External

Areas

Serial Comments or Tasks

1 Remove the tank and pump assembly from the parent vehicle to

facilitate cleaning.

Vehicle to be cleaned as per Chapter 9 - Unimog of this publication

2 Ensure the forklift pockets are free of dirt, plant and other debris.

3 Ensure twist lock recesses are clean and free of plant and insect

material

4 Refer to Chapter 9 for detailed cleaning guidelines.

Technical

Time (hours)

0.7

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-4

Tank and Pump Assembly

4. The cleaning instructions for the Unimog tank and pump assemblies’ rear external areas, as

illustrated in Figures 9C-4 to 9C-10, include the points detailed in Table 9C-2.

Figure 9C-4: Unimog Tank and Pump Assembly Tyne Slots

Figure 9C-5: Unimog Tank and Pump Assembly Connector Hoses

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-5

Figure 9C-6: Unimog Tank and Pump Assembly Top Area

Figure 9C-7: Unimog Tank and Pump Assembly Coupling Connectors

Figure 9C-8: Unimog Tank and Pump Assembly Hose Reel Side-on

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-6

Figure 9C-9: Unimog Tank and Pump Assembly Hose Reels and Controls

Figure 9C-10: Unimog Tank and Pump Assembly Pump - No Grill Variant

Figure 9C-11: Unimog Tank and Pump Assembly Pump - Grill Variant

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9C-7

Table 11N-2: Cleaning Instructions for the Unimog Tank and Pump Assemblies’ Rear

External Areas

Serial Comments or Tasks

1 The top of tank and pump assemblies are to be cleaned, paying

particular attention to areas where foliage may have collected. All

seed, plant, insect and animal matter is to be removed.

2 All hoses are to be unrolled to their full length and wiped clean of all

contaminants to ensure there is no soil, plant or insect material.

3 The equipment area is to be thoroughly cleaned, so removal of some

equipment attachments may be necessary to achieve this.

2 Clean all hose couplings and hose coupling assembly with a high-

pressure water cleaner (refer Figure 10C-7).

3 Unroll all hoses and clean all oil and grease material to ensure there is

no soil, plant or insect matter. Clean hose assembly with a high-

pressure water cleaner (refer Figures 10C-8 and 9C-9).

4 CES bins are to be emptied to facilitate cleaning with high-pressure

water.

4 The pump assembly is to be cleaned and inspected to ensure freedom

from QRM (refer Figures 9C-10 and 9C-11).

5 Remove all panels and doors to allow access to internal areas for

cleaning.

6 Remove covers to clean out all soil, plant, insect matter and to check

for animal nests and presence of animals.

Technical

Time (hours)

7 Linings may need to be disposed of if they cannot be brought to an

acceptable standard

8 The inside radiator to be air-blown and, if necessary, picked clean of all

insect and seed matter.

9 Heat and soundproofing on panels is to be cleaned and wash ed or

removed as necessary to achieve the required standard

10 Clean the exhaust grill of all seed and plant material.

11 Remove air cleaner element and dispose of in accordance with AQIS

directions. Ensure air cleaner housing is clean of dust, soil, insect and

plant material.

12 Replace air cleaner element with new part.

13 Remove the batteries and clean the battery and battery ca sings, cradle

and housing compartment of all soil, plant and insect matter.

14 Hose out or remove the conduit to ensure there is no soil, plant and

insect matter caught between cables.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9D-1

ANNEX D TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG MAINTENANCE SHELTER

(MMS)

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog Shelters’ external areas, as illustrated in Figures 9D-1

and 9D-2, include the points detailed in Table 9D-1.

Figure 9D-1: Unimog Shelters’ External Areas

Table 9D-1: Cleaning Instructions for the Unimog Shelters’ External Areas

Serial Comments or Tasks

1 Clean vehicle as per Chapter 9

2 Remove all external CES and clean individually.

3 Lower rear tray platform (refer Figure 9D-2) and clean all areas

ensuring freedom from QRM.

ADF Force Extraction Cleaning Manual

Technical

Time (hours)

UNCONTROLLED IF PRINTED

9D-2

Figure 9D-2: Unimog Shelters’ Rear Areas

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9D-3

Internal Areas

4. The cleaning instructions for the Unimog Shelters internal areas include the points detailed in

Table 9D-2.

Table 9D-2: Cleaning Instructions for the Unimog Shelters’ Internal Areas

Serial Comments or Tasks

1 Remove all shelving and cupboard frames to ensure there is no seed,

soil or insect debris

2 Toolboxes and tool bins are to be emptied and brushed, air-blown and

wiped clean. Clean individual drawers and frames and ensure there is

no seed, soil or insect debris.

3 Remove floor panels (if applicable) underneath cupboards. Remove

dirt, dust, seed, and plant material that may collect at the point where

the floor panel meets the support members of the module

4 The equipment area is to be thoroughly cleaned: removal of some

equipment attachments may be necessary to achieve this.

5 Floor or bench mounted machinery may need to be removed to ensure

that cavities and areas underneath the bases are free of QRM.

6 Remove all light lenses and covers on and inside the module to ensure

there is no seed, soil or insect debris (refer to Figures 6D-5).

Dispose of damaged lights and lenses in accordance with AQIS

instructions.

7 Critically inspect all rubber dust and weather seals on the shelters side

and rear doors to ensure they are not damaged in any way.

Any damaged seals should be disposed in accordance with AQIS

instructions.

Technical

Time (hours)

Figure 9D-3: Unimog Maintenance Shelter

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9E-1

ANNEX E TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG SPECIAL FORCES LONG

RANGE SUSTAINMENT VEHICLE

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog Special Forces Long Range Sustainment Vehicle’ s

external areas, as illustrated in Figure 9E-1, include the points detailed in Table 9E-1.

Figure 9E-1: Unimog Special Forces Long Range Sustainment Vehicle’s External Areas

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9E-2

Figure 9E-2: Unimog Special Forces Long Range Sustainment Vehicle’s External Areas

Table 9E-1: Cleaning Instructions for the Unimog Special Forces Long Range Sustainment

Vehicle’s External Areas

Serial Comments or Tasks

Technical

Time (hours)

1 Clean all rubber seals around the windows and doors. 1.25

2 WARNING FOR ALL ARMOURED GLASS: Wash by hand with

warm, soapy water ONLY (Directions for cleaning can be found on the

glass)

3 Remove the cabin seats to facilitate cleaning.

Remove door trims to clean door cavities.

4 Remove the snorkel to facilitate cleaning. 1.5

5 Remove the bonnet to facilitate cleaning.

6 Remove the mudflaps and pay attention to cleaning around the

attachment points.

7 Remove the batteries and clean the battery box, terminals and

batteries.

8 Remove the tank straps to facilitate cleaning.

9 Remove the toolboxes and Jerry can holders to facilitate cleaning of

1.5

soil, plant and insect debris between the items and the chassis.

10 The tray is to be raised to extend the hydraulic ram for cleaning.

11 The box section is to be inspected for damage. If damaged, the box

area is to be drilled and flushed through with high-pressure water u sing

a flexible nozzle to ensure all soil, plant and insect matter is removed.

12 The tray face is to be inspected for damage and damaged sections are

to be removed to facilitate an inspection to ensure there is no

compacted soil embedded.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9E-3

Spare Tyre Mount

4. The cleaning instructions for the spare tyre mount include the points detailed in Table 9E-2.

Figure 9E-3: Unimog Long Range Sustainment Vehicle’s Spare Tyre Mount

Table 9E–2: Cleaning Instructions for the Spare Tyre Mount

Serial Comments or Tasks

1 All tools are to be fully removed and extended to facilitate cleaning.

2 Tyre to be fully removed and to be cleaned as per “Tyres (New, Old

and Spares)” below.

3 Tyre cover (if fitted) to be fully removed and to be washed and

scrubbed to remove all QRM.

4 All externally fitted items of equipment to be removed and both the

items and the mounting brackets to be cleaned of all QRM

5 Frame areas are to be washed with high-pressure water utilising a

flexible nozzle.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9E-4

Tool Boxes/ Storage Bins

5. The cleaning instructions for the Unimog Special Forces Long Range Sustainment Vehicle’s

Tool Boxes/Storage Bins include the point detailed in Table 9E-3.

Table 9E-3: Cleaning Instructions for the Unimog Special Forces Long Range Sustainment

Vehicle’s Tool Boxes/Storage Bins

Serial Comments or Tasks

1

Toolboxes and tool bins are to be emptied and brushed, air-blown and

wiped clean.

2

Tools are to be wiped clean and lightly oiled after inspection

3

Clean all rubber seals around the doors.

4

All steel frame-work is to be cleaned.

5

Grip tape on climbing surfaces is to be cleaned and inspected to

ensure freedom from soil, plants and seeds.

6

Nylon bushes and guides are to be inspected for freedom from QRM

7

All tarpaulins fitted for weather protection are to be given a brush

down, brush scrubbing and hose cleaning, paying particular

attention to the seam areas and then hung so as not to contact

the ground

8

All ropes and universal dispatch straps are to be extended to

their full length and wiped or washed clean of all soil, plant and insect

matter

Technical

Time (hours)

Attention to attachment points and fixtures and tension devices is

required

Personnel are to inspect and remove all twigs, foliage, and so on that

has become embedded in the rope fibres

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9F - 1

ANNEX F TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG RADAR

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides

are provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

Unimog Radar Cleaning Instructions

3. The cleaning instructions for the Unimog Radar, as illustrated in Figure 9F-1, include the

points detailed in Table 9F-1.

Figure 9F-1: Unimog Radar

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9F - 2

Table 9F-1: Cleaning Instructions for the Unimog Radar

EXTREME CAUTION

ELECTRICAL COMPONENTS

Do not use water or steam to clean any interiors areas of the radar or

radar controls unless under the supervision of a qualified technician

Serial Comments or Tasks

1 The dish is to be cleaned down with water to remove all soil, plant and

insect matter. Attention is to be paid to small areas where foliage,

seeds and insect material can become lodged.

2 Attachment points and frames are to be cleaned, and attention is to be

paid to the hollow tube areas.

3 Electronic equipment is to be air-hose cleaned and brushed down with

brushes to remove soil and insect debris. Filters are to be removed and

cleaned where fitted. All cables are to be unwound and wiped down,

paying attention to connectors.

4 Mounting frames that are fixed to the floor are to be moved to facilitate

cleaning and inspection. Equipment is to be dismounted to facilitate

cleaning.

5 All multi-pair cable is to be wiped clean over the entire length including

connectors. Conduit is to be cleaned by a high-pressure water clean or

removed to facilitate cleaning and inspection by AQIS.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9F - 3

Hydraulics

4. The specific cleaning instructions for Unimog Radar hydraulics, illustrated in Figure 9F–2,

include those points detailed in Table 9F–2

Figure 9F-2: Unimog Radar Extended

Table 9F–2: Cleaning Instructions for the Unimog Radar hydraulics

CAUTION

HYDRAULIC COMPONENTS

Do not use high pressure water or steam to clean the hydraulics or

hydraulic control areas unless under the supervision of a qualified

technician

Serial Comments or Tasks

1 Lifting rams are to be fully extended and cleaned. 1.0

2 Extend stabilisers, clean the hydraulic cylinder and rod, stabiliser

housing and foot assembly.

3 The hydraulic area is to be cleaned of all grease and oil to ensure there

is no soil, plant or insect matter. Regrease lightly after AQIS inspection

to working surface only.

4 The hydraulic control areas are to be either hand wiped or air-cleaned

unless under the supervision of a qualified technician

Technical

Time (hours)

1.5

5 Check under all hydraulic looming for cleanliness

6 All electrical and hydraulic lines are to be separated and all grease and

soil debris cleaned from in between them.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9F - 4

Supports and Stands

5. The cleaning instructions for the Unimog Radar supports and stands, as illustrated in

Figure 9F–3 include the points detailed in Table 9F–3.

Figure 9F-3: Unimog Radar Stands

Table 9F-3: Cleaning Instructions for the Supports and Stands

Serial Comments or Tasks

Time (hours)

1 Attachment points and frames are to be cleaned, and attention is to be

paid to the hollow tube areas.

2 Supports are to be cleaned with a high-pressure water cleaner.

3 Stands are to be removed and subject to high-pressure water cleaner,

paying attention to the threaded area.

4 Special attention is to be paid to the foot plates which are to be with a

high-pressure water cleaner.

5 Forklift pockets, in the base of the shelter, are to be cleaned and free

of dirt, dust, plant and insect material.

Technical

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9G-1

ANNEX G TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG GUN TRACTOR

1. This Chapter provides specific cleaning requirements for selected vehicles . Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog Gun Tractors’ external areas, as illustrated in Figure

9G-1, include the points detailed in Table 9G-1.

Figure 9G-1: Unimog Gun Tractor’s External Areas

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9G-2

Table 9G-1: Cleaning Instructions for the Unimog Shelters’ External Areas

Serial Comments or Tasks

1 For ease of cleaning and inspection, the personnel and cargo modules

Technical

Time (hours)

are to be removed from the Unimog prior to cleaning.

Refer to Chapter 9 for detailed cleaning guidelines. 0.7

Personnel Module

4. The cleaning instructions for the Unimog Gun Tractor’s Personnel Module, as illustrated in

Figures 9G-2 to 9G-4, include the points detailed in Table 9G-2.

Figure 9G-2: Unimog Gun Tractor’s Personnel Module

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9G-3

Figure 9G-3: Unimog Gun Tractor’s Personnel Seating

Figure 9G-4: Unimog Gun Tractor’s Personnel Seating

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9G-4

Table 9G-2: Cleaning Instructions for the Unimog Gun Tractor’s Personnel Module

Serial Comments or Tasks

Time (hours)

1 Seat cushions are to be removed and cleaned.

Damaged seat cushions are to be disposed of in accordance with

AQIS directions.

2 The hard moulded plastic seats are to be cleaned to ensure freedom

from QRM. (refer Figures 9G-3)

3 Seatbelts are to be fully extended and wiped clean.

4 Ropes fitted for restraint of equipment and to provide handholds

5 Plastic floor matting (if fitted) is to be removed and will require a high-

pressure water clean to remove all soil, plant and insect matter. If the

mat is damaged or badly soiled, disposal in-country is recommended.

6 Grip tape on climbing surfaces is to be cleaned and inspecte d to

ensure freedom from soil, plants and seeds.

7 Foam and rubber weather seals are to be inspected to ensure freedom

from QRM

8 Standard plastic butt boxes and clips for rifles are to be cleaned. for

drying

9 All tarpaulins fitted for weather protection are to be given a brush

down, brush scrubbing and hose cleaning, paying particular

attention to the seam areas and then hung so as not to contact

the ground

Technical

10 All ropes and universal dispatch straps are to be extended to

their full length and wiped or washed clean of all soil, plant and insect

matter

Attention to attachment points and fixtures and tension devices is

required

Personnel are to inspect and remove all twigs, foliage, and so on that

has become embedded in the rope fibres

11 Critically inspect the gun mount and manhole to ensure they are free

from dirt, dust, plant and insect material (refer Figure 9G-4).

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9G-5

Stores Container

5. The cleaning instructions for the Unimog Gun Tractor’s Stores Container, as illustrated in

Figures 9G-5 and 9G-6, include the points detailed in Table 9G-3.

Figure 9G-5: Unimog Gun Tractor’s Stores Container

Figure 9G-6: Unimog Gun Tractor’s Stores Platform and Ladder

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9G-6

Table 9G-3: Cleaning Instructions for the Unimog Gun Tractor’s Stores Container

Serial Comments or Tasks

1 All steel frame-work is to be cleaned. Special attention is to be made to

the access ladder that comes in direct contact with the ground. Ensure

all are washed clean of all soil, plant and insect matter

2 Grip tape on climbing surfaces is to be cleaned and inspecte d to

ensure freedom from soil, plants and seeds.

3 Nylon bushes and guides are to be inspected for freedom from QRM

4 All tarpaulins fitted for weather protection are to be given a brush

down, brush scrubbing and hose cleaning, paying particular

attention to the seam areas and then hung so as not to contact

the ground

5 All ropes and universal dispatch straps are to be extended to

their full length and wiped or washed clean of all soil, plant and insect

matter

Attention to attachment points and fixtures and tension devices is

required

Personnel are to inspect and remove all twigs, foliage, and so on that

has become embedded in the rope fibres

Technical

Time (hours)

ADF FORCE EXTRACTION CLEANING MANUAL

UNCONTROLLED IF PRINTED

9H - 1

ANNEX H TO CHAPTER 9

CLEANING INSTRUCTIONS – CARGO CRANE VARIANT

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog cargo with crane’s external areas, as illustrated in

Figure 9H-1, include the points detailed in Table 9H-1.

Figure 9H-1: Unimog Cargo with Crane

Table 9H-1: Cleaning Instructions for the Unimog Cargo with Crane’s External Areas

Serial Comments or Tasks

1. Refer to Chapter 9 for detailed cleaning guidelines.

ADF Force Extraction Cleaning Manual

Technical

Time (hours)

UNCONTROLLED IF PRINTED

9H - 2

Cargo Crane

4. The cleaning instructions for the Unimog Cargo Crane vehicle’s areas as illustrated in Figure

9H-2, include the points detailed in Table 9H-2.

Figure 9H-2: Unimog Cargo with Crane - Hoist Side

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9H - 3

Table 9H-2: Cleaning Instructions for the Unimog Cargo Crane

CAUTION

HYDRAULIC COMPONENTS

Do not use high pressure water or steam to clean the hydraulics or

hydraulic control areas unless under the supervision of a qualified

technician

Serial Comments or Tasks

Technical

Time (hours)

1 Lifting rams are to be fully extended and cleaned. 1.0

2 Extend stabilisers, clean the hydraulic cylinder and rod, stabiliser

1.5

housing and foot assembly.

3 The hydraulic area is to be cleaned of all grease and oil to ensure there

is no soil, plant or insect matter. Regrease lightly after AQIS inspection

to working surface only.

4 The hydraulic control areas are to be either hand wiped or air-cleaned

unless under the supervision of a qualified technician

5 Check under all hydraulic looming for cleanliness

6 All electrical and hydraulic lines are to be separated and all grease and

soil debris cleaned from in between them.

Supports and Stands

5. The cleaning instructions for the Unimog Cargo with Crane’s Supports and Stands include

the points detailed in Table 9H–3.

Table 9H-3: Cleaning Instructions for the Unimog Cargo with Crane’s Supports and Stands

Serial Comments or Tasks

Technical

Time (hours)

1 Attachment points and frames are to be fully extended prior to

cleaning.

2 Supports are to be cleaned with a high-pressure water cleaner and

attention is to be paid to the hollow tube areas.

3 Stands are to be removed and subject to high-pressure water cleaner,

paying attention to the threaded area.

4 Special attention is to be paid to the foot plates which are to be with a

high-pressure water cleaner.

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9H - 4

Spare Tyre Mount

6. The cleaning instructions for the spare tyre mount include the points detailed in Table 9H-4.

Table 9H–4: Cleaning Instructions for the Spare Tyre Mount

Serial Comments or Tasks

1 All tools are to be fully removed and extended to facilitate cleaning.

2 Tyre to be fully removed and to be cleaned as per “Tyres (New, Old

and Spares)” below.

3 Tyre cover (if fitted) to be fully removed and to be washed and

scrubbed to remove all QRM.

4 All externally fitted items of equipment to be removed and both the

items and the mounting brackets to be cleaned of all QRM

5 Frame areas are to be washed with high-pressure water utilising a

flexible nozzle.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

UNCONTROLLED IF PRINTED

9I - 1

ANNEX I TO CHAPTER 9

CLEANING INSTRUCTIONS – UNIMOG TROOP CARRIER

1. This Annex provides specific cleaning requirements for selected vehicles. Where there is a

specific requirement or need to highlight particular problem areas detailed cleaning guides are

provided as tables and figures in this Annex.

2. The cleaning requirements that follow are in addition to those points for the Unimog vehicle

included in Chapter 9 of this publication.

External Areas

3. The cleaning instructions for the Unimog troop carrier’s external areas, as illustrated in Figure

9I–1, include the points detailed in Table 9I–1.

Figure 9I–1: Unimog Troop Carrier

Table 9I–1: Cleaning Instructions for the Unimog Troop Carrier’s External Areas

Serial Comments or Tasks

1 Remove the mudflaps and pay attention to cleaning around the

attachment points.

2 Refer to Chapter 9 for detailed cleaning guidelines.

ADF Force Extraction Cleaning Manual

Technical

Time (hours)

UNCONTROLLED IF PRINTED

9I - 2

Rear Areas

4. The cleaning instructions for the Unimog Troop Carrier’s rear areas, as illustrated in Figure 9I–

2, include the points detailed in Table 9I–2.

Figure 9I–2: Unimog Troop Carrier’s Rear Areas

Table 9I–2: Cleaning Instructions for the Unimog Troop Carrier’s Rear Areas

Serial Comments or Tasks

1 Remove the canopy and bows and clean.

2 Clean the hollow sections of the canopy bows by using flushing

through the tubes with a pressure washer.

3 The linkage area for the tailgate is to be cleaned of all grease and

contamination by soil, plant and insect material.

2 Remove all seating and frames to ensure there is no seed, soil or

insect debris.

3 Clean area underneath floor panel to ensure there is no dirt, dust,

seed, and plant material.

4 Refer to Chapter 9 for detailed cleaning guidelines.

Technical

Time (hours)

ADF Force Extraction Cleaning Manual

ANNEX J TO CHAPTER 9

CLEANING CHECKLIST – UNIMOG

All serials may not be specific to all Unimog trucks

Vehicle Registration No: ……………………………….

1 The snorkel has been removed to facilitate cleaning.

External Areas

2 The bonnet has been removed to facilitate cleaning.

3 The mudflaps have been removed and attachment points cleaned.

4 The toolboxes and Jerry can holders have been removed to facilitate

cleaning of soil, plant and insect debris between the items and the chassis.

5 Cupola crash pad and any lining removed to facilitate cleaning and

inspection.

6 Fuel and air tank retaining straps loosened and cleaned.

7 Light covers removed and flushed

8 Channel tubing at cargo tie down points on cargo tray cleaned and

inspected

9 Headlights removed to facilitate cleaning behind them.

10 Brush guard removed and cleaned.

11 The air cleaner element removed and disposed of in accordance with AQIS

directions.

12 The ventilation nozzles on the centre top of the dash cleaned using low

pressure compressed air.

13 The ventilation blower assembly filter element removed from the front left-

hand side of the cabin, and disposed of in accordance with AQIS

directions. The ventilation blower assembly housing cleaned and free of

dirt, seed or plant material remains.

14 The heating/ventilation flap raised, on the selected gear indicator panel,

and the discharge cavity vacuumed to remove dust and other foreign

material.

15 The bonnet has been removed and cleaned.

16 All apertures, tie-down points, and twist lock housings in tray body flooring

have been cleaned with high-pressure water from a front and rear aspect

17 Straps on the fuel and air tanks have been loosened and tanks cleaned

18 Batteries and tools have been removed from the battery box and tool

attachment points and cleaned

19 All toolboxes have been emptied and cleaned

20 Air cleaner elements have been removed and disposed of in accordance

with AQIS directions

21 Jerry cans have been removed and cleaned

22 The chassis rail on the vehicle has open areas which collect debris. The

area has been flushed behind the plate using a flexible nozzle all areas

behind the plate are cleaned until the water have been observed to be

clear on exit.

23 Air line restraining straps have been loosened and cleaned. Heavily

contaminated Foam covering has been disposed of.

24 The mounting brackets for the cross members have been flushed using a

flexible nozzle.

25 The chassis cross member have been flushed using a flexible nozzle.

26 All soil and debris is has been removed from the chassis cavities.

27 Plastic ties have been removed to expose grouped cables and air lines for

inspection

28 The rear view of the chassis support tubes have been flushed out. The

right-hand tube has been extensive flushed.

29 All cables where the cable ties are located and between the cable and

vehicle have been cleaned.

1 The holes under the cab have been flushed through to remove all debris.

Cabin

2 Door trims have been removed and cleaned

3 Mirror sills and mirrors have been inspected.

4 Seatbelt assembly has not been removed. The full length of the seatbelt

have been exposed and cleaned by wiping with a dry rag

5 Access panels under cabin seats (including topside of fuel cell) have been

cleaned.

6 Inner door panels from both front doors have been removed and cleaned

7 Door cavity, including the window winding mechanism, have been pressure

washed and cleaned

8 The window frame, channels and fillers have been pressure washed and

cleaned

9 All rubber seals around the windows and doors have been cleaned.

10 The cabin seats have been removed to facilitate cleaning.

11 Rubber floor matting have been removed to clean the cabin floor.

12 All door and window glass channels and fillers have been inspected and

cleaned

1 Grease and oil from the front of the sump and on the back of the flywheel

housing have been removed.

Sump

1 The engine compartment and engine have been cleaned

2 All engine openings/breathers have been taped or plugged to stop ingress

of water

Engine Bay

3 The starter motor and alternator have been covered and taped to st op

A

A

ingress of water

4 No high-pressure water jets were dire cted at any of the engine

openings/breathers, or at any of the electrical/electronic components

5 The brake booster assembly and pedal pivot housing have been removed

and cleaned

6 The clutch pedal pivot housing cover has been rem oved and cleaned

7 Heater assembly has been removed and heater core cleaned

8 Heater/ventilation fan housing has been cleaned

9 The air cleaner flexible line from the air plenum in the right-hand front

mudguard assembly have been removed and cleaned

1 High-pressure water cleaning around the fittings using a flexible nozzle has

occurred

2 The tank straps have been removed to facilitate cleaning.

3 All the supporting members for the floor area have been cleaned.

4 The wooden floor has been lifted to allow inspection and to facilitate

cleaning of the chassis cross members and underside of the floor. Wooden

floor plates cracked, gouged or damaged have been disposed of in

accordance with AQIS directions.

5 The underside hollow cross members have been subject to

high-pressure water using a flexible nozzle to remove all soil, plant and

insect matter.

Underneath Areas

1 The battery box support member has been flushed through using a flexible

nozzle until clear water was seen to exit.

2 The support bases and tubing underneath the battery box have been

flushed.

Battery Box

3

The batteries have been removed and the battery box, terminals and

batteries cleaned.

1 All tarpaulins have been given a brush down, brush scrubbing and hose

cleaning, with particular attention to the seam areas and then hung

so as not to contact the ground for drying

2

3 Attachment points and fixtures and tension devices are free of all soil, plant

4 Personnel are to inspect and remove all twigs, foliage, and so on that has

5 Velcro panels and seams (where fitted) have been brushed and

6

7 Where fitted, poles, knuckles and pegs have been subject to a high-

8 Unused tarpaulins that have not been used during the entire

ll ropes and universal dispatch straps have been extended to their

full length and wiped or washed clean of all soil, plant and insect matter

and insect matter

become embedded in the rope fibres

washed to ensure all seed, plant and soil material is removed

ll canvas bags have been turned inside out and checked for burrs, seeds

and insects;

pressure water clean to remove all soil, plant and insect matter (ants,

spiders and mud wasps are of particular concern)

deployment, have been unrolled, brushed and swept clean to ensure no

Tarpaulins

vermin or insect infestation and then subject to an AQIS inspection

1 All grass and debris have been removed

2 Heavily soiled camouflage nets have been further scrubbing and a

dipped in an approved detergent/ disinfectant (one in 20 solution).

3 Drying has been achieved by the hanging the camouflage net so that it did

not come into contact with the ground

4 All nets have been inspected to ensure that all plant material is removed

5 All camouflage poles have been brushed or swept clean; and metal joiners

have been removed cleaned and then inspected by AQIS officers

Camouflage Nets

1 All tyres have been washed and scrubbed to remove all QRM

2 Cracked/ perished tyres have been assessed for disposal

3 All tyres have been treated with an approved residual insecticide after

cleaning

4 All fitted tyres that were damaged have been replaced with new tyres

Tyres (New, Old and Spares)

5 Used and fitted tyres on rims have been individually verified that the tyres

are on rims, are inflated with beading sealed and that the tyres are clean,

free of water and other quarantine risk material

6 Tyres not fitted to rims have been stored in such a manner that water has

not collected inside the tyre

7 The consignment contains a maximum of 8 tyres and is to be imported with

an accompanying vehicle

The consignment contains more than a maximum of 8 tyres and will not be

imported with an accompanying vehicle

(Delete whichever is not applicable)

Signed ………………………………………. Date: ………………….

Name: ………………………………………

Loading...

Loading...