Mercedes-Benz 405 Service Manual

Daimler AG · Technical Information and Workshop Equipment (GSP/OR) · D-70546 Stuttgart

Introduction of the New Unimog

Generation

Model Series 405

Introduction into Service Manual

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Preface |

3 |

|

|

Overview |

4 |

Vehicle concept |

4 |

Model designation system |

5 |

Model codes |

6 |

Code system |

7 |

|

|

Overall vehicle |

9 |

Innovations |

9 |

|

|

Drive |

13 |

Technical data |

13 |

Engine OM 934 |

14 |

Engine OM 936 |

16 |

Model codes |

18 |

Mechanical power take-offs |

19 |

Radiator system |

20 |

Exhaust aftertreatment |

22 |

Diesel particulate filter regeneration |

27 |

|

|

Transmission |

29 |

Main transmission |

29 |

EAS |

31 |

|

|

New hydrostatic drive |

33 |

Overview |

33 |

System components |

35 |

Design |

36 |

|

|

Hydraulic components |

38 |

Overview |

38 |

Plug connections |

40 |

Distribution |

41 |

Joystick |

42 |

Work hydraulics |

43 |

2-cell work hydraulics |

44 |

3-cell work hydraulics |

45 |

4-cell work hydraulics |

46 |

Power hydraulics |

47 |

Fan hydraulics |

49 |

Tilting hydraulics |

50 |

Data overview |

51 |

|

|

Chassis |

52 |

Overview |

52 |

New axles of U200/U300 |

53 |

Mechanical sliding caliper disk brake |

54 |

Introduction of the New Unimog Generation | Model Series 405 |

1 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Design |

56 |

Cab exterior |

56 |

Cab interior |

58 |

Instrument cluster |

59 |

Multifunction steering wheel |

60 |

Center console |

61 |

|

|

Networking |

62 |

Overall network |

62 |

Pin assignment of equipment socket |

70 |

Control unit network |

71 |

Central gateway (CGW) |

72 |

|

|

Lights |

73 |

Exterior lights |

73 |

|

|

Driving assistance systems |

75 |

Tire pressure control system |

75 |

|

|

Comfort |

76 |

Heating and climate control |

76 |

|

|

Audio and communications |

78 |

Radio unit |

78 |

Tachograph |

79 |

|

|

Maintenance |

80 |

Maintenance |

80 |

Operating fluids |

85 |

Diagnosis |

86 |

|

|

Special tools |

87 |

Engine OM 934/936 |

87 |

|

|

Annex |

95 |

Abbreviations |

95 |

Index |

98 |

Information and copyright |

100 |

2 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Preface

Dear Reader,

This Introduction into Service Manual presents the new Unimog generation of model series 405.

This brochure is intended for the use of technical personnel familiar with service and maintenance. It is assumed here that the reader is already familiar with the Mercedes-Benz model series currently on the market.

In terms of the contents, the emphasis in this Introduction into Service Manual is on presenting new and modified components and systems.

All of the data in this brochure correspond to the technical status as of the copy deadline in March 2013 and may therefore differ from the current production configuration.

We will publish modifications and new features in the relevant WIS documents only. Individual details in this brochure may therefore differ from more up-to-date versions published in WIS.

Daimler AG

Mercedes-Benz Global Service & Parts (GSP/ORR)

70546 Stuttgart/Germany

BBNote

Information about the vehicles and about operating the vehicle functions can also be found in the interactive owner's manual on the Internet at: www.mercedes-benz.de/betriebsanleitung

This Introduction into Service manual is also available in digital form as a PDF in SDmedia.

Introduction of the New Unimog Generation | Model Series 405 |

3 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Overview

Vehicle concept

General

The product features of the new BlueTec 6 Unimog implement carrier with Euro VI emissions level have been completely revised for its market launch. The advantages of this compact and highly maneuverable implement carrier have been further improved. The vehicle concept has been weightoptimized in order to compensate for the additional weight of the Euro VI components.

The exhaust aftertreatment system with BlueTec 6 is based on the combination of a closed particulate filter and the Mercedes-Benz SCR system including AdBlue® injection, which has been used successfully for many years. This innovation allows nitrogen oxide and particulate emissions to be reduced by 90 %. The term "BlueEfficiency Power" not only encompasses the environmentally friendly and cost-efficient nature of the vehicle, but also the improved power ratings of the new engine generation.This technological leap in the area of performance, user-friendliness, traction drive, ergonomics and safety further underlines the unique selling proposition of the new Unimog implement carrier compared to trucks and tractors.

The new hydrostatic drive is revolutionary. It is an intelligent concept which integrates the hydrostatic drive with the manual transmission in a practical manner.

G00.20-3127-00

The new BlueTec 6 Unimog implement carrier

4 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Model designation system

The new model designation system is a continuation/extension of the previous system.

Model designation system

BBNote

Model series remains the same, serial number increases.

Euro V |

|

|

Euro VI |

|

|

|

|

405 . 101 |

|

|

405 . 104 |

|

|

|

|

405 |

101 |

405 |

104 |

|

|

|

|

Model series |

Serial no. |

Model series |

Serial no. |

|

|

|

|

Model codes in model designation system

Model code |

Model designation |

Wheelbase (mm) |

Load stages (t) |

Engine power (kW) |

|

|

|

|

|

U 216 |

405.090 |

2.800 |

7,5/8,5/10 |

115 |

|

|

|

|

|

U 218 |

405.090 |

2.800 |

7,5/8,5/10 |

130 |

|

|

|

|

|

U 318 |

405.104 |

3.000 |

7,5/8,5/10/11 |

130 |

|

|

|

|

|

U 423 |

405.105 |

3.000 |

11,99/13/13,8 |

170 |

|

|

|

|

|

U 427 |

405.110 |

3.150 |

11,99/13/13,8 |

200 |

|

|

|

|

|

U 430 |

405.110 |

3.150 |

11,99/13/13,8 |

220 |

|

|

|

|

|

U 423 |

405.125 |

3.600 |

11,99/13/13,8 |

170 |

|

|

|

|

|

U 427 |

405.125 |

3.600 |

11,99/13/13,8 |

200 |

|

|

|

|

|

U 430 |

405.125 |

3.600 |

11,99/13/13,8 |

220 |

|

|

|

|

|

U 527 |

405.202 |

3.350 |

11,99/15,5/16,5 |

200 |

|

|

|

|

|

U 530 |

405.202 |

3.350 |

11,99/15,5/16,5 |

220 |

|

|

|

|

|

U 527 |

405.222 |

3.900 |

11,99/15,5/16,5 |

200 |

|

|

|

|

|

U 530 |

405.222 |

3.900 |

11,99/15,5/16,5 |

220 |

|

|

|

|

|

Introduction of the New Unimog Generation | Model Series 405 |

|

|

5 |

|

Overview

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Overview

Model codes

The new model codes point to a completely revised product range with the introduction of the "New Unimog Generation" including new engine technology and allow for differentiation from the old/existing model series.

Model codes

Old model code |

|

New model code |

|

|

|

|

|

Euro V |

|

Euro VI |

|

|

|

|

|

|

UNIMOG |

|

|

|

|

|

|

Implement carrier Euro V |

|

Implement carrier Euro VI |

|

|

|

|

|

U 400 |

|

U 423 |

|

|

|

|

|

Previously without code number for engine power |

|

U 4 |

23 |

|

|

|

|

|

|

Code number for size class |

Code number for engine |

|

|

(same as U 400) |

power (230 hp) |

|

|

|

|

6 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Code system

With the introduction of the new generation of BlueTec 6 Unimog implement carrier, the codings of the special versions have been matched to the new codings of the truck model series. This has necessitated the complete rearrangement

of some letter groups. A third of the codes have stayed the same, a third of the codes have been matched to the truck changes and a third have been added due to the new technology.

The special equipment codes still have three digits but now have the sequence "letter - number - letter". The codes are made up of the installation location, function and logical usage. Codes that belong together have the same number. For example: all front axles start with A1, rear axles with A2, etc. The range of numbers "9" in the code groups is reserved for preinstallations and/or omitted items.

Overview

Design of new code system

1st digit |

2nd digit |

3rd digit |

Code group |

|

|

|

|

|

Capital letter (A...Z) |

Number (0...9) |

Capital letters (A...Z) |

|

|

|

Example

A |

1 |

W |

|

|

|

Axles/suspension |

Front axle |

Front axle differential lock |

|

|

|

Introduction of the New Unimog Generation | Model Series 405 |

7 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Overview

Code system

Overview of code groups

A |

Axles/suspension |

N |

Power take-offs |

|

|

|

|

B |

Brakes |

O |

Internal system control |

|

|

|

code |

|

|

|

|

C |

Chassis |

P |

Platform/dumper |

|

|

|

|

D |

Cab interior |

Q |

Spring/crossmember/trai- |

|

|

|

ler hitch/fifth wheel |

|

|

|

coupling |

|

|

|

|

E |

Electrical system |

R |

Wheels/spare wheel hol- |

|

|

|

der/wheel lifts |

|

|

|

|

F |

Cab exterior |

S |

Safety |

|

|

|

|

G |

Transmission/clutch |

T |

Unused |

|

|

|

|

H |

Hydraulic components |

U |

Unused |

|

|

|

|

I |

Internal code |

V |

Unused |

|

|

|

|

J |

Instruments/ |

W |

Weight variants |

|

communication |

|

|

|

|

|

|

K |

Fuel system/exhaust |

X |

Miscellaneous |

|

system |

|

|

|

|

|

|

L |

Lighting system/lamps |

Y |

Accessories |

|

|

|

|

M |

Engine |

Z |

Internal system control |

|

|

|

code |

|

|

|

|

8 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Innovations

Numerous optimizations and new features have been phased into the new Unimog generation. As a result, solutions have had to be found for the reduction in installation space available. The manoeuvrability and compact dimensions (2.15 m wide) of the vehicle have nevertheless been retained and existing implements can therefore still be used almost without modification.

The holistic rework of the product features of the new BlueTec 6 implement carrier is described below under brief headings:

The cooling system has been adapted to the new technology. As a result of the uprated engines with cooled exhaust gas recirculation, cooling power requirements have also increased. The development of the modified cooling system was based on the aim of retaining the compact vehicle concept while integrating larger radiators at the same time.

The following concept was therefore put in place:

•Arrangement of radiator and A/C condenser on left-hand side of vehicle. This reduces radiator soiling during working operations.

•Cleanfix reversible fan with automatic control and highspeed fan drive as special equipment for dirt-intensive operations (in preparation).

•Swiveling A/C condenser in combination with a widemeshed radiator core and smooth radiator slats for easy cleaning of the radiator unit.

•Charge air cooler decoupled from the radiator and located under the engine hood.

•Greater efficiency of fan hydraulics due to variable displacement pump and demand-based, separate control of both fans. The benefit results from the reduced energy requirement and optimized driving and working performance, including under extreme conditions.

Integrated exhaust management

With respect to exhaust aftertreatment, the new engine generation uses the BlueTec 6 technology which has already proven its effectiveness in practical use on mass-produced heavy duty engines.

The exhaust management system ensures that filter regeneration is carried out according to requirements.

•The cooled exhaust gas recirculation system reduces the proportion of oxygen in the combustion mixture. This results in the production of less nitrogen oxide during combustion.

•The camshaft adjustment function for increasing the exhaust temperature supports active regeneration of the diesel particulate filter during operation.

BBNote

In parallel to the Unimog Euro VI, the U 400.103/123 will still also be produced with Euro III/V engines.

Overall vehicle

Introduction of the New Unimog Generation | Model Series 405 |

9 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Overall vehicle

Innovations

High-performance engine brake

The engine brake developed by Mercedes-Benz significantly reduces the wear on the wheel brake systems and makes a significant contribution to the cost-efficiency of the vehicle. The engine brake is designed as a dual-pulsed decompression brake and provides a high level of brake power.

• Each cylinder in the engine has its own engine brake unit.

Fan hydraulics with variable displacement pump

The fan hydraulics are included in the basic scope of all vehicles.

•Greater efficiency of fan hydraulics due to variable displacement pump and demand-based, separate control of both fans.

Tilting hydraulics based on fan hydraulics

The tilting hydraulics allow the vehicle tilt cylinder to be adjusted and can be extended to allow the adjustment of external consumers (e.g. rail guide or auxiliary rear axle steering) (but not permanent consumers).

•Simple tilting hydraulics for the vehicle tilt cylinder (code HE1)

•Tilting hydraulics with additional connection option for external adjustment operations (code HE2) e.g. trailer with tilt system.

Working/municipal hydraulics (circuit I and circuit II)

The working hydraulics allow an implement to be adjusted or a permanent consumer to be supplied. On the 1-circuit hydraulic system one circuit is available for this, while on the 2-circuit hydraulic system, two independent circuits are available, each with its own fixed displacement pump.

This allows adjustment operations to be carried out and a permanent consumer to be supplied simultaneously. On the 2-circuit hydraulic system, the volumetric flow rates can be swapped over via the volume switchover function or added together via flow summation.

Changes compared to the hydraulic system of Euro V vehicles:

•Fully proportional working hydraulics at connections of cells 1–4 (connections 1-8)

•Integrated pressure filter

•Control of consumers during adjustment operations via the vehicle joystick (social distribution) with diagonal movement of vehicle joystick. Due to the omission of link motion, two adjustment operations can be carried out simultaneously. Example: Raise front loader and tilt shovel simultaneously

•Hydraulic connection possibility on valve block (e.g. for roll stabilization)

•Electrical interface for actuation of hydraulic valve block (circuit I) e.g. for external actuation of front and/or rear power lift

•Joystick with rocker switch for forward/reverse shifting of manual vehicle transmission

10 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Innovations

Power hydraulics (circuit III and IV)

The power hydraulics allow rotating consumers to be powered (e.g. cutting roller, wood chipper etc.). Both circuits are designed as open circuits with a maximum pressure of 280 bar. Code HL4 includes one circuit while code HL5 includes two power hydraulics circuits.

The power hydraulics are located in the platform intermediate frame and can be removed if necessary (e.g. for winter service operations). They are powered by a propeller shaft on the engine power take-off, code N05. The hydraulic couplings are located at the vehicle rear above the end crossmember. Front hydraulic connections are also optionally available, either for one circuit or for both circuits.

System concept of new hydrostatic drive G34:

The new hydrostatic drive system: code G34 combines a modified hydrostatic drive major assembly concept with the cruise control operating and control concept. The previous hydrostatic drive system (code G33) has now been superseded with the launch of the new BlueTec 6 Unimog implement carrier. The new hydrostatic drive (code G34) allows fully hydrostatic driving at up to 50 km/h and, in combination with EAS, also allows mixed hydrostatic/transmission-powered driving and can be controlled with the normal driving controls (accelerator pedal, brake, gear selector lever, steering wheel cruise control buttons). In addition, the gearshifting, cruise control and travel direction functions are supported by a left additional control lever (code DG1). The vehicle can also be accelerated and decelerated via the hydraulic joystick in "driving joystick active" mode.

Modified suspension

The capabilities of the suspension have been retained in their entirety and continue to underline the advantages of the Unimog concept.

•Weight optimization measures: Cutouts in the frame, use of high-strength steels, greater proportion of light alloys and plastics

•The portal axles have also been reinforced which means that the permissible gross vehicle weight is above the previous level

•The additional major assembly weight has been overcompensated for with additional components

•Pneumatic disk brakes on model series U2xx/U3xx

Standardized mounting points

On the current Euro V model series of the Unimog implement carrier, mounting points were defined which have proven effective across all areas of usage. The new Unimog generation will continue to use these standardized interfaces and dimensions. This applies to the front mounting plate, front power take-off, the ball mounting points on the platform and the mounting brackets at the rear end.

Improved ergonomics

•Steering column with adjustable height and inclination (not on vehicles with transferable steering)

•Reduced steering wheel control force and steering capability at standstill

•Multifunction steering wheel

•Improved cab steps

•Transmission control via right multifunction control lever

•EQR operation on hydraulics joystick

•Engine speed adjustment function

•Driving and function controls within primary (400 mm - 600 mm) area of reach of driver

•Modular positioning of hydraulics joystick

•Hydraulics joystick within optimal reach area

•Improved accessibility of switches of center console

Overall vehicle

Introduction of the New Unimog Generation | Model Series 405 |

11 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Overall vehicle

Innovations

New design of exterior/interior

•Hood

•Roof-mounted wiper system

•Headlamps

•Aluminium rims (optional, code R2T)

•Multifunction steering wheel

•CD radio with Bluetooth® hands-free system

•Instrument cluster

•Controls

•Center console

•Higher output heating/cooling system with improved air distribution

4-channel ABS

If a wheel is tending towards locking up, the pressure in the wheel cylinder is corrected depending on the road surface condition and load condition. This ensures safe handling characteristics during braking. Driving stability and steerability are maintained in the process, which reduces the risk of accident.

The ABS can be switched to off-road mode, which allows the wheels to lock up to a certain extent in order to build up a wedge of earth. The ABS off-road program must be deactivated on public roads and firm ground.

The 4-channel ABS system is installed on all model designations and has been tested on mass-produced models. It provides a high level of safety through separate actuation of each wheel on the front and rear axle.

Further changes and improvements

•Electrical interface EN 16330 for demountable implements in preparation => code ES6

•Parameterizable special module (PSM) as standard

•Combinations of 0 to 2 trailers are possible without special measures for turn signal failure detection.

•Front camera with monitor (available optionally with code EM3). This improves visibility of the road surface and implements. Up to three additional cameras can be connected via a connecting point in the cab.

•160 kW instead of 150 kW will now be available at the front power take-off (limitation of engine torque to 850 Nm instead of 800 Nm previously)

•Increase in permissible load values, particularly on model series U318 to up to 11000 kg and on U400 to up to 14000 kg

•Due to the optimized frame concept, front skids are not required for assembly frames for heavy bodies (e.g. crane). This makes the frames shorter, simpler, lighter and more cost-effective. It also simplifies assembly.

12 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

|

|

|

|

|

Technical data |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Unit |

OM 934 |

OM 936 |

||

|

|

|

|

|

|

|

|

Displacement |

cm3 |

5100 |

7700 |

|

|

|

|

|

|

|

|

|

|

Cylinder number/arrangement |

|

4/inline |

6/inline |

||

|

|

|

|

|

|

|

|

Valve timing |

|

DOHC |

DOHC |

||

|

|

|

|

|

|

|

|

Number of valves per cylinder (intake/exhaust) |

|

2/2 |

|

2/2 |

|

|

|

|

|

|

|

|

|

Idle speed |

rpm |

720 |

|

720 |

|

|

|

|

|

|

|

|

|

Output |

kW |

115 |

(code M1H) |

200 (code M2C) |

|

|

|

|

130 |

(code M1I) |

220 (code M2D) |

|

|

|

|

170 |

(code M1K) |

|

|

|

|

|

|

|

|

|

|

Torque |

Nm |

650 |

|

1100 |

|

|

|

|

750 |

|

1200 |

|

|

|

|

900 |

|

|

|

|

|

|

|

|

|

|

|

Compression ratio |

|

17,6/1 |

17,6/1 |

|

|

|

|

|

|

|

|

|

|

Stroke |

mm |

135 |

|

135 |

|

|

|

|

|

|

|

|

|

Cylinder bore |

mm |

110 |

|

110 |

|

|

|

|

|

|

|

|

|

Rail pressure max. |

bar |

2400 |

2400 |

|

|

|

|

|

|

|

|

|

Drive

Introduction of the New Unimog Generation | Model Series 405 |

13 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Engine OM 934

The OM 934 is a 4-cylinder inline engine with a displacement of 5.1 l with turbocharger and cooled exhaust gas recirculation. The OM 934 is available in the following power categories:

•115 kW, 650 Nm (code M1H)

•130 kW, 750 Nm (code M1I)

•170 kW, 900 Nm (code M1K)

The excellent characteristics of the engines, in particular their low fuel consumption in relation to their high power, have been achieved with a range of technical innovations:

•The Common Rail injection system reduces the fuel quantity required for combustion to a minimum.

•The engine brake provides greater performance and is now designed as a decompression brake which replaces the constant throttle and exhaust flap brake.

•The engines fulfill the Euro VI emission standard with Selective Catalytic Reduction (SCR), cooled and regulated exhaust gas recirculation and diesel particulate filters.

G01.10-3133-00

Engine OM 934.972

14 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Engine OM 934

Drive

G01.10-3135-00

Engine power (kW)

|

|

|

G01.10-3136-00 |

Torque (Nm) |

|

Introduction of the New Unimog Generation | Model Series 405 |

15 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Engine OM 936

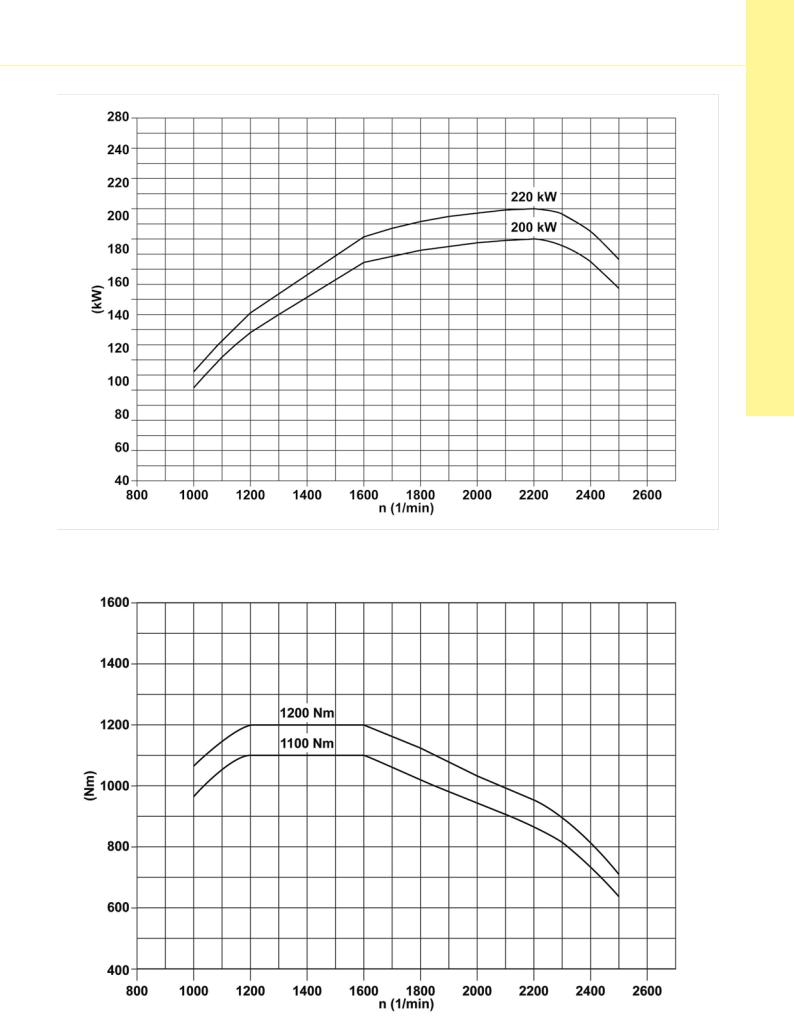

The OM 936 is a 6-cylinder inline engine with a displacement of 7.7 l with turbocharger and cooled exhaust gas recirculation. The OM 936 is only available in Euro VI and the following power categories:

•200 kW, 1100 Nm (code M2C)

•220 kW, 1200 Nm (code M2D)

The excellent characteristics of the engines, in particular their low fuel consumption in relation to their high power, have been achieved with a range of technical innovations:

•The Common Rail injection system reduces the fuel quantity required for combustion to a minimum.

•The engine brake provides greater performance and is now designed as a decompression brake which replaces the constant throttle and exhaust flap brake.

•The engines fulfill the Euro VI emission standard with Selective Catalytic Reduction (SCR), cooled and regulated exhaust gas recirculation and diesel particulate filters.

G01.10-3134-00

Engine OM 936.972

16 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Engine OM 936

Drive

G01.10-3137-00

Engine power (kW)

|

|

|

G01.10-3138-00 |

Torque (Nm) |

|

Introduction of the New Unimog Generation | Model Series 405 |

17 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

18

405 Series Model | Generation Unimog New the of Introduction – 2013 / 03 Status: .service update the by recorded be not will printout This –

Vehicle |

|

|

Engine |

|

|

|

|

Exhaust box (AGN) |

|

|

|

|

|

|

|

|

|

|

|

Model code |

Model |

Wheelbase |

Model |

Engine power |

Code |

Cylinder |

Charging |

Model |

Length (mm) |

|

designation |

(mm) |

designation |

(kW) |

|

|

|

designation |

|

|

|

|

|

|

|

|

|

|

|

U 216 |

405.090 |

2.800 |

934.971 |

115 |

M1H |

4 |

1-stage |

930.728 |

806 |

|

|

|

|

|

|

|

|

|

|

U 218 |

405.090 |

2.800 |

934.971 |

130 |

M1I |

4 |

1-stage |

930.728 |

806 |

|

|

|

|

|

|

|

|

|

|

U 318 |

405.104 |

3.000 |

934.971 |

130 |

M1I |

4 |

1-stage |

930.728 |

806 |

|

|

|

|

|

|

|

|

|

|

U 423 |

405.105 |

3.000 |

934.972 |

170 |

M1K |

4 |

2-stage |

930.728 |

806 |

|

|

|

|

|

|

|

|

|

|

U 427 |

405.110 |

3.150 |

936.971 |

200 |

M2C |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 430 |

405.110 |

3.150 |

936.971 |

220 |

M2D |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 423 |

405.125 |

3.600 |

934.972 |

170 |

M1K |

4 |

2-stage |

930.728 |

806 |

|

|

|

|

|

|

|

|

|

|

U 427 |

405.125 |

3.600 |

936.971 |

200 |

M2C |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 430 |

405.125 |

3.600 |

936.971 |

220 |

M2D |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 527 |

405.202 |

3.350 |

936.971 |

200 |

M2C |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 530 |

405.202 |

3.350 |

936.971 |

220 |

M2D |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 527 |

405.222 |

3.900 |

936.971 |

200 |

M2C |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

U 530 |

405.222 |

3.900 |

936.971 |

220 |

M2D |

6 |

1-stage |

930.728 |

856 |

|

|

|

|

|

|

|

|

|

|

Drive

codes Model

|

Mechanical power take-offs |

|

|

Engine power take-off |

|

The engageable engine power take-off (code N05) (engage- |

BBImportant |

able only with engine off) is driven by the crankshaft of the |

The power take-off (code N05) is only approved for |

engine via intermediate gears. The flange output is located |

powering hydraulic or water pumps. Direct mechani- |

at the rear of the engine and is activated via an engageable |

cal drive (e.g. mechanical rear power take-off) is not |

dog clutch. The engine power take-off (code N05) may only |

permissible. |

be used in combination with a flexible coupling to insulate it |

|

from engine vibrations. |

|

The essential features of the engine power take-off are:

•Integrated into gear drive of engine

•Drive of power hydraulics (code HL4 or HL5) via a propeller shaft (clockwise rotation direction)

Technical data:

•i = 0.933

•Maximum available continuous output 148 kW

•Maximum available torque (continuous) 600 Nm

Drive

G26.45-3227-00

OM 936.972 with engine power take-off

1)Fan drive variable displacement pump, engine power take-off additional dumper function (code N05)

2)Engine power take-off (code N05)

Introduction of the New Unimog Generation | Model Series 405 |

19 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Radiator system

The radiator system is located in the frame, behind the cab. This concept allows space for a windshield which extends far down towards the engine hood and provides an optimal view of the working area. The large radiator is designed for high outside temperatures and slow vehicle speeds to ensure a high level of operational reliability.

The radiator system can be folded out without the use of tools, which makes it very accessible for cleaning.

In order to increase the efficiency of the radiator, a radiator grille is installed to hold back coarse dirt particles.The radiator system is located on the left in the direction of travel and is thus located in an area which has a low susceptibility to soiling.

The hydrostatic fan drive provides optimal cooling output throughout the entire rpm range in any driving situation. It does so by adjusting the rpm of the fan drive according to demand and uses as little energy as possible.

G20.20-3242-00

Radiator system

20 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

|

Radiator system |

|

|

|

|

Rapid radiator cleaning system |

|

|

|

|

|

The Clean-Fix rapid radiator cleaning system (code M74) pro- |

BBNote |

|

vides effective cleaning of a soiled radiator by turning the fan |

On vehicles with code M74, a safety insert is also |

|

blades about their own axis and raising the rpm. This ensures |

installed in the air filter housing in addition to the air |

|

that the optimal cooling output is available in every situation. |

filter. This must also be replaced with every third air |

|

|

filter replacement. |

|

Activation of the reversible fan can be performed while dri- |

|

|

ving or working using a button on the center console. |

|

|

It is also possible to activate an intermittent switching func- |

|

|

tion (automatic start-up every 10 min). |

|

|

|

|

|

|

|

|

|

|

|

Drive

G09.10-3152-00

Safety insert in air filter housing

G20.20-3249-00

Clean-Fix fan (code M74)

1)Cooling

2)Switchover

3)Cleaning

Introduction of the New Unimog Generation | Model Series 405 |

21 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Exhaust aftertreatment

Due to the stricter Euro VI emissions regulations, additional system components for exhaust aftertreatment are required to meet the emissions regulations.

Overview

As a result of the technical implementation of Euro VI, a modified arrangement of the components on the chassis was necessary. This is known as the "Euro VI packaging".

The Euro VI vehicle package differs fundamentally from the package of Euro III and Euro IV/V vehicles and new model designations have been assigned.

Model |

Euro III model designation |

Euro IV/V model |

Euro VI model |

|

|

designation |

designation |

|

|

|

|

U200 |

|

|

405.090 |

|

|

|

|

U300k |

405.100 (production up to |

405.101 |

405.104 |

|

11/2006) |

|

|

|

|

|

|

U300l |

405.120 (production up to |

405.121 |

Discontinued |

|

11/2006) |

|

|

|

|

|

|

U400k |

405.102 |

405.103 |

405.105 |

|

|

|

|

U400 |

|

|

405.110 |

|

|

|

|

U400l |

405.122 |

405.123 |

405.125 |

|

|

|

|

U500k |

405.200 (production up to |

405.201 |

405.202 |

|

11/2006) |

|

|

|

|

|

|

U500l |

405.220 (production up to |

405.221 |

405.222 |

|

11/2006) |

|

|

|

|

|

|

22 |

|

Introduction of the New Unimog Generation | Model Series 405 |

|

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Exhaust aftertreatment

Euro 6 technology and vehicle packaging

In order to meet the requirements of the Euro VI legislation and customer demands for minimal fuel consumption, new engines and a new exhaust aftertreatment system were developed. The engines feature Common Rail injection and exhaust gas recirculation and are designed for minimal consumption. The new exhaust aftertreatment system removes particulates and nitrogen oxides.

The exhaust aftertreatment system consists mainly of:

•Oxidation catalytic converter (DOC)

•Diesel particulate filter (DPF)

•SCR catalytic converter

•Slip catalytic converter

The system also includes the AdBlue® metering unit with various sensors, the ACM electronic unit (Aftertreatment Control Module) and the fuel (HC) metering system. Low-sulfur fuel is required. The fuel may contain up to 7% biodiesel.

Function description:

•The exhaust first flows through the oxidation catalytic converter. This converts the hydrocarbons and carbon monoxide present into carbon dioxide and water. Furthermore, part of the nitric oxide (NO) is oxidized to nitrogen dioxide (NO2).

•The particles are separated through adhesion and collected in the porous filter structure of the diesel particulate filter (DPF). In the particulate filter, the NO2 reacts with the stored soot to produce NO und CO2. The deposits are broken down and the system regenerates itself: "passive regeneration". In order to achieve complete filter regeneration, the "passive regeneration" is coupled with "active regeneration". In the case of active regeneration, a reaction takes place between O2 and soot at temperatures above the passive regeneration range. In order to reach the temperatures required for this, the exhaust

temperatures are increased by injecting HC in the form of diesel fuel. The HC reacts exothermically in the oxidation catalytic converter and increases the temperature of the exhaust.

•SCR catalytic converter: The BlueTec diesel technology reduces the proportion of nitrogen oxide in the exhaust through the addition of AdBlue® (aqueous urea solution). The aqueous AdBlue® solution is injected into the hot exhaust via a metering valve.

Drive

Introduction of the New Unimog Generation | Model Series 405 |

23 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Exhaust aftertreatment

Exhaust gas recirculation |

Diesel particulate filter |

Selective Catalytic Reduction |

|

|

|

(AGR) |

(DPF) |

(SCR) |

|

|

|

|

|

|

|

|

|

G49.20-3104-00

Mode of operation of Euro 6 |

|

|

|

1) |

Charge air cooler |

6) |

Pressure sensor |

2) |

Exhaust gas recirculation cooler |

7) |

NOx sensor |

3) |

Turbocharger |

8) |

Exhaust |

4) |

Temperature sensor |

9) |

AdBlue® metering |

5) |

Fuel injection |

10) |

AdBlue® tank |

24 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

|

|

Exhaust aftertreatment |

|

|

|

|

|

|

The AdBlue® tank is always located on the right-hand side of |

|

|

|

|

|

|

|

the vehicle ahead of the exhaust box (except on model series |

BBNote |

|

|

U200). On the U200, the AdBlue® tank is located on the left- |

On all predecessor vehicles, the upward exhaust |

|

|

hand side of the vehicle ahead of the fuel tank. |

(code C87) was special equipment. Exhaust tailpipe |

|

|

|

positioned between the axles (code K7Q). |

|

|

Two variants of the exhaust system are available: |

|

|

|

• Exhaust system, upward tailpipe (code K7A) - standard |

|

|

|

• Exhaust system, downward outlet (code K7Q) - SA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive

G49.10-3191-00

Standard exhaust system (upward exhaust)

Introduction of the New Unimog Generation | Model Series 405 |

25 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Drive

Exhaust aftertreatment

AdBlue® supply

The AdBlue® is supplied via a heated tank. The AdBlue® is supplied via the intake line to the supply unit and from there to the metering unit on the exhaust system via the pressure line. AdBlue® can be diverted from the metering unit directly back to the AdBlue® tank via the return line. A special tank fitting with reduced diameter prevents the AdBlue® tank from being filled incorrectly with diesel fuel. The tank size is 18 l for the U200 and 25 l for all U300/U400/U500 models.

The AdBlue® intake line between the AdBlue® tank and pump module and the AdBlue® pressure line between the pump module and metering unit are heated electrically by the heating elements integrated in the line sections.

Rear muffler with integrated oxidation catalytic converter, diesel particulate filter and SCR catalytic converter

A corresponding catalytic converter volume is required depending on the vehicle's engine. Only the following AGN boxes (exhaust aftertreatment boxes) are installed ex factory:

•806 mm long on engine OM 934

•856 mm long on engine OM 936

G14.00-3313-00

Exhaust box without cover

26 |

Introduction of the New Unimog Generation | Model Series 405 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Diesel particulate filter regeneration

Regeneration

Soot from diesel combustion and engine oil ash is continuously stored in the closed diesel particulate filter. In order to allow longer filter change intervals and a long filter service life, regular regeneration of the diesel particulate filter is required.

High exhaust temperatures pack the soot and engine oil ash and store it in compressed form at the end of the filter. This keeps the required exhaust back pressure within the permissible limits. Since the exhaust temperatures are not sufficient for passive regeneration in every driving situation, active regeneration may be carried out depending on the driving situation.

The system initiates regeneration automatically once a certain quantity of soot or ash is stored.

Passive regeneration

•Continuously, at exhaust temperatures > 250 °C

•Without additional diesel injection

•Initiated automatically, no action required from driver

Active regeneration

•Is required if the exhaust temperature is too low e.g. vehicle at standstill or slow driving

•Additional diesel injection to increase exhaust temperature

•Can be stopped at any time using the inhibit switch to suit the type and location of vehicle operation

•Initiated automatically, no action required from driver

Drive

|

|

|

G54.25-3464-00 |

G54.30-3843-00 |

|

Inhibit switch |

1) Information field for regeneration messages |

|

Introduction of the New Unimog Generation | Model Series 405 |

27 |

|

– This printout will not be recorded by the update service. Status: 03 / 2013 –

28 |

Diesel particulate filter regeneration |

Message

This – |

|

"DPF regeneration" |

|

be not will printout |

|

"High particulate filter fill level" |

|

update the by recorded |

|

||

|

"Particulate filter full" |

||

03 Status: .service |

|

||

Introduction |

"Particulate filter full" |

||

of / |

|||

–2013 |

Newthe |

||

+ |

|||

|

Unimog |

"Output reduction" |

|

|

|

||

|

Generation| |

"Particulate filter full" |

|

|

Model |

+ |

|

|

"Service Required" |

||

|

405 Series |

|

|

What must be done?

No action required: Active regeneration in progress. Pay attention to high exhaust temperatures, comparable to those with wide open throttle, at the exhaust pipes. Do not interrupt regeneration if possible.

Action required within the next hours depending on fuel consumption and driving profile: Perform an extended trip using significant engine power (freeway, mountain route etc.) or perform manual regeneration. (Duration approx. 30 minutes)

Action required depending on fuel consumption and driving profile: Perform an extended trip using significant engine power (freeway, mountain route etc.) or perform manual regeneration at standstill. (Duration approx. 30 minutes)

Immediate action required: Perform manual regeneration at standstill. (Duration approx. 30 minutes)

Immediate action required: Visit a workshop and have the DPF filter replaced. It is only possible to drive to the next workshop under reduced power. Regeneration is no longer possible.

Drive

regeneration filter particulate Diesel

|

Main transmission |

|

|

|

|

The manual transmission is equipped with double-cone syn- |

|

|

|

|

|

chronization for all main gears and the reversing group and |

BBNote |

|

features a new transmission control system with 8 forward |

Pay attention to the engine code for replacement part |

|

and 6 reverse gears to ensure optimal vehicle speeds for |

orders. |

|

working deployments and transport journeys. Due to the fine |

|

|

graduations of the lower gears, it is possible to individually |

|

|

adjust the vehicle speed during working deployments. |

|

|

The synchronized reversing group (EQR), for direct shifting |

|

|

between forward and reverse gears, enables quick reversing |

|

|

and can be used to rock the vehicle free. |

|

|

Depending on the requirements, the transmission can be ex- |

|

|

|

|

|

tended with a working group or crawler group and thus offers |

|

|

optimal gear-ratio steps for any usage profile. |

|

|

The transmission model of the Euro IV/V vehicles has not |

|

|

changed for the |

|

|

Euro VI vehicles. The technical differences of the transmissi- |

|

|

ons are controlled via the engine code. |

|

|

Transmission

Introduction of the New Unimog Generation | Model Series 405 |

29 |

– This printout will not be recorded by the update service. Status: 03 / 2013 –

Loading...

Loading...