Page 1

Pump module

00%

O

MANUAL

Appliance sizes

PM/PMP 29

PM/PMP 49

PM/PMP 101

100% ATMOSAFE.MADE IN GERMANY

1

ATM

www.memmert.com I www.atmosafe.net

Page 2

2

About this manual

Purpose and target audience

This manual, together with the operating manual for the MEMMERT vacuum oven, describes

how to use and put into operation the MEMMERT pump module. Pump modules can be purchased with or without a pre-installed vacuum pump.

The manual contains the original maintenance and operating manual for the membrane vacuum pump, which may have been installed, from the company KNF.

The pump module may only be used in combination with the MEMMERT vacuum oven VO or

VOcool. All information in terms of safety instructions, assembly, function, transport, putting

into operation, operation, troubleshooting, maintenance and decommissioning/disposal can be

found in the operating manual for the vacuum oven VO.

This manual is intended for use by trained personnel of the owner, who have the task of operating and/or maintaining the respective appliance. If you are asked to work on the appliance,

read this manual carefully before starting.

Familiarise yourself with the safety regulations. Only perform work that is described in this manual. If there is something you do not understand, or certain information is missing, ask your

manager or contact the manufacturer. Do not do anything without authorisation.

Other documents to be observed as applicable:

► The operating manual for the MEMMERT vacuum oven VO

► The original maintenance and operating manual for the vacuum pump from KNF

Storage and resale

This operating manual belongs with the appliance and should always be stored where persons working on the appliance have access to it. It is the owner's responsibility to ensure that

persons who are working on or are going to work on the appliance know where to find the

operating manual. We recommend that it is always stored in a protected location close to the

appliance. Make sure that the operating manual is not damaged by heat or humidity. If the

appliance is resold or transported and then set up again at a different location, the operating

manual must remain with it.

The current version of this operating manual in PDF format is also available for download from

http://www.memmert.com/en/service/downloads/user-manual/.

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 3

Safety regulations

WARNING

After removing covers, live parts may be exposed. Touching these can lead to an

electric shock. Disconnect the mains plug before removing any covers. Work on

the electrical system must only be performed by qualifi ed electricians.

WARNING

Toxic gases or vapours may be produced in certain applications. These

can escape from the vacuum pump into the room. This can injure people

nearby. The appliance may only be used for such applications if a suction

is attached to the vacuum pump used, which reliably keeps toxic gases or

vapours away from people. Observe the respective national regu-lations for

occupational safety and environmental protection.

NOTICE

3

The operating manual of the MEMMERT vacuum oven contains important

information and instructions how to use the pump module. Followall possible information from the related operating manual of the vacuum oven

exactly.

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 4

4

Intended use

The appliance may only be used to accommodate and control a vacuum pump by means of a

MEMMERT vacuum oven VO29, VO49 or VO101. Any other use is improper and may result in

hazards and damage.

Changes and alterations

No unauthorised changes or alterations may be made to the appliance. No parts may be added

or inserted which have not been approved by the manufacturer.

Unauthorised changes or alterations result in the CE declaration of conformity losing its validity,

and the appliance may no longer be operated.

The manufacturer is not liable for any damage, danger or injuries that result from unauthorised

changes or alterations, or from non-compliance with the provisions in this manual.

Requirements of the operating personnel

The appliance may only be operated and maintained by persons who are of legal age and have

been instructed accordingly. Personnel who are to be trained, instructed or who are undergoing general training may only work with the appliance under the continuous supervision of an

experienced person.

Repairs may only be performed by qualified specialists. The provisions in the operating and

installation manual from KNF also need to be observed.

Behaviour in case of malfunctions and irregularities

The appliance may only be used in a flawless condition. If you as the operator notice irregularities, malfunctions or damage, immediately take the appliance out of service and inform your

superior.

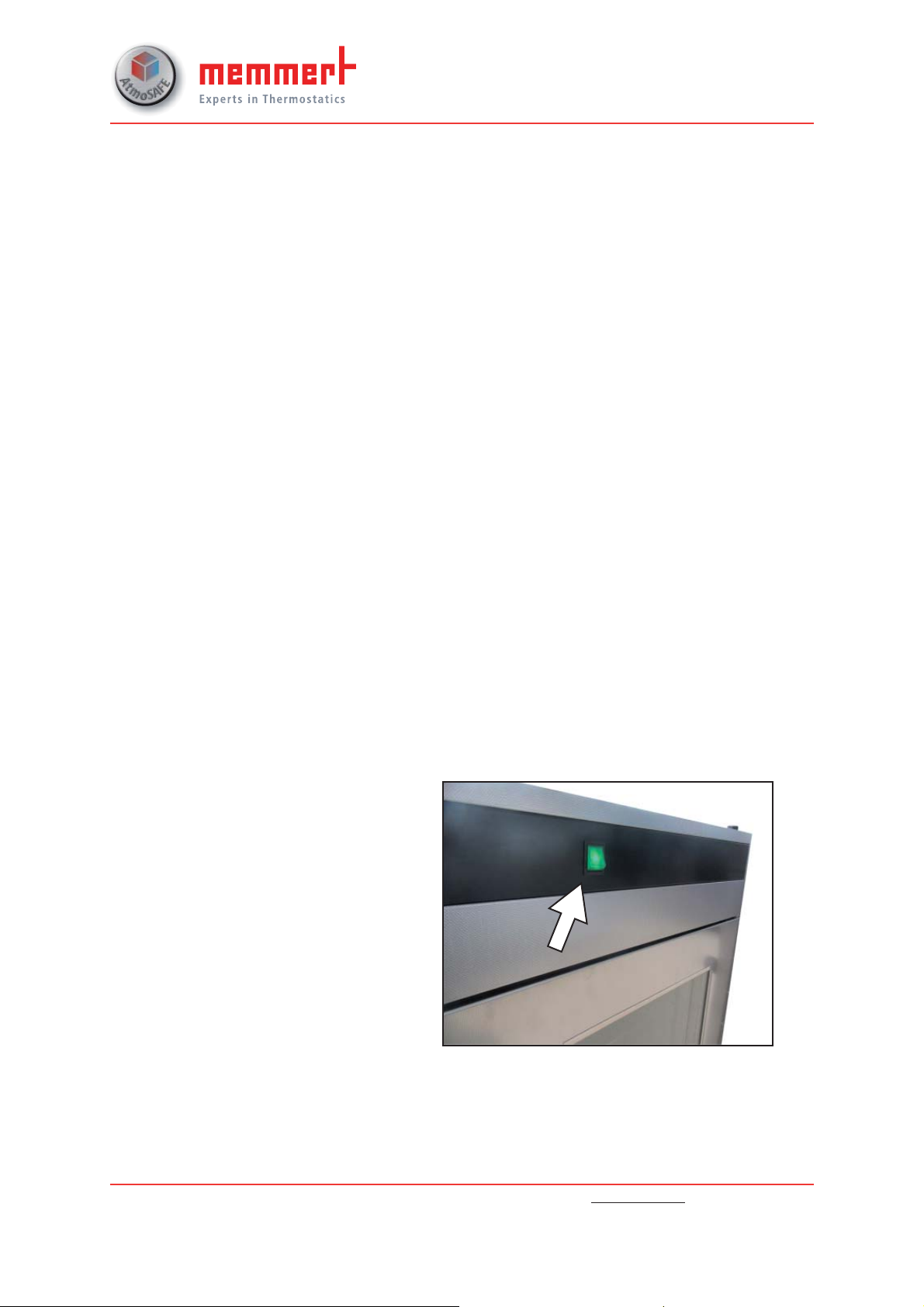

Switching off the appliance in

an emergency

Press the main switch on the pump module.

This disconnects the appliance from the

power supply at all poles.

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 5

5

Putting into operation

When operating the appliance for the first time, do not leave it unattended until it has reached

a steady state.

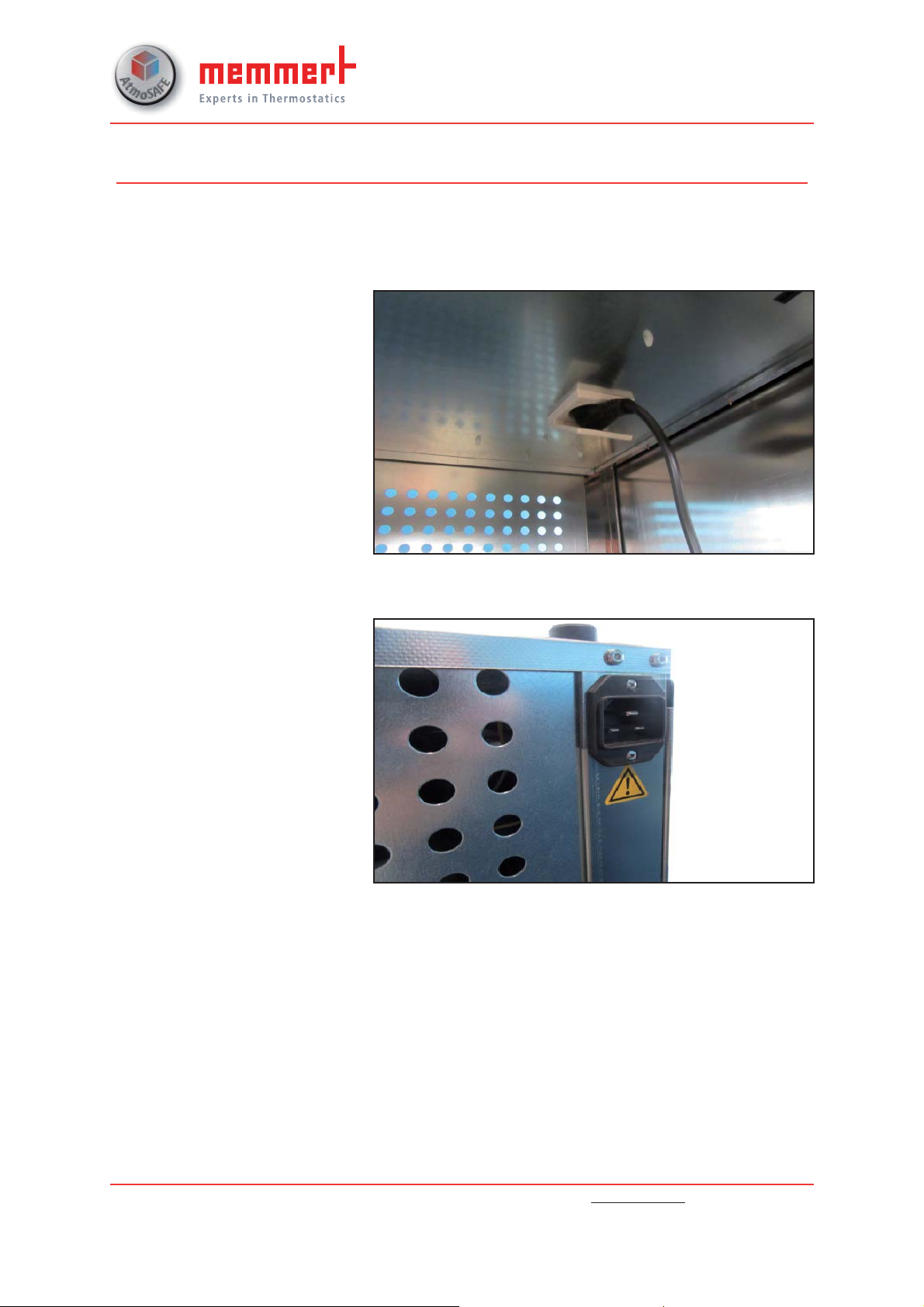

Connecting the vacuum pump

► Connect the vacuum pump's

230 V plug with earthing contact to the internal socket in

the pump module.

Connecting the appliance

Caution:

For connection, please observe

the national regulations. Observe

the connection and power ratings

(see nameplate and technical

data).

Make sure to establish a safe PE

conductor connection.

Place the power cable so that

► it is easily accessible at all times

and can be pulled out quickly,

for example in case of a malfunction or emergency;

► it does not represent a trip

hazard;

► it cannot come into contact

with any hot parts.

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 6

Connecting the vacuum pump to the VO

The connection for the signal lead

(left) and the connection for the

vacuum hose (right) can be found

at the rear of the PM.

Connect the vacuum oven and the

pump module to the signal lead

and the vacuum hose as described

in the operating manual for the

MEMMERT vacuum oven.

Switching on

► Press the main switch for the

vacuum pump.

6

► Press the main switch for the

pump module.

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 7

Maintenance and cleaning

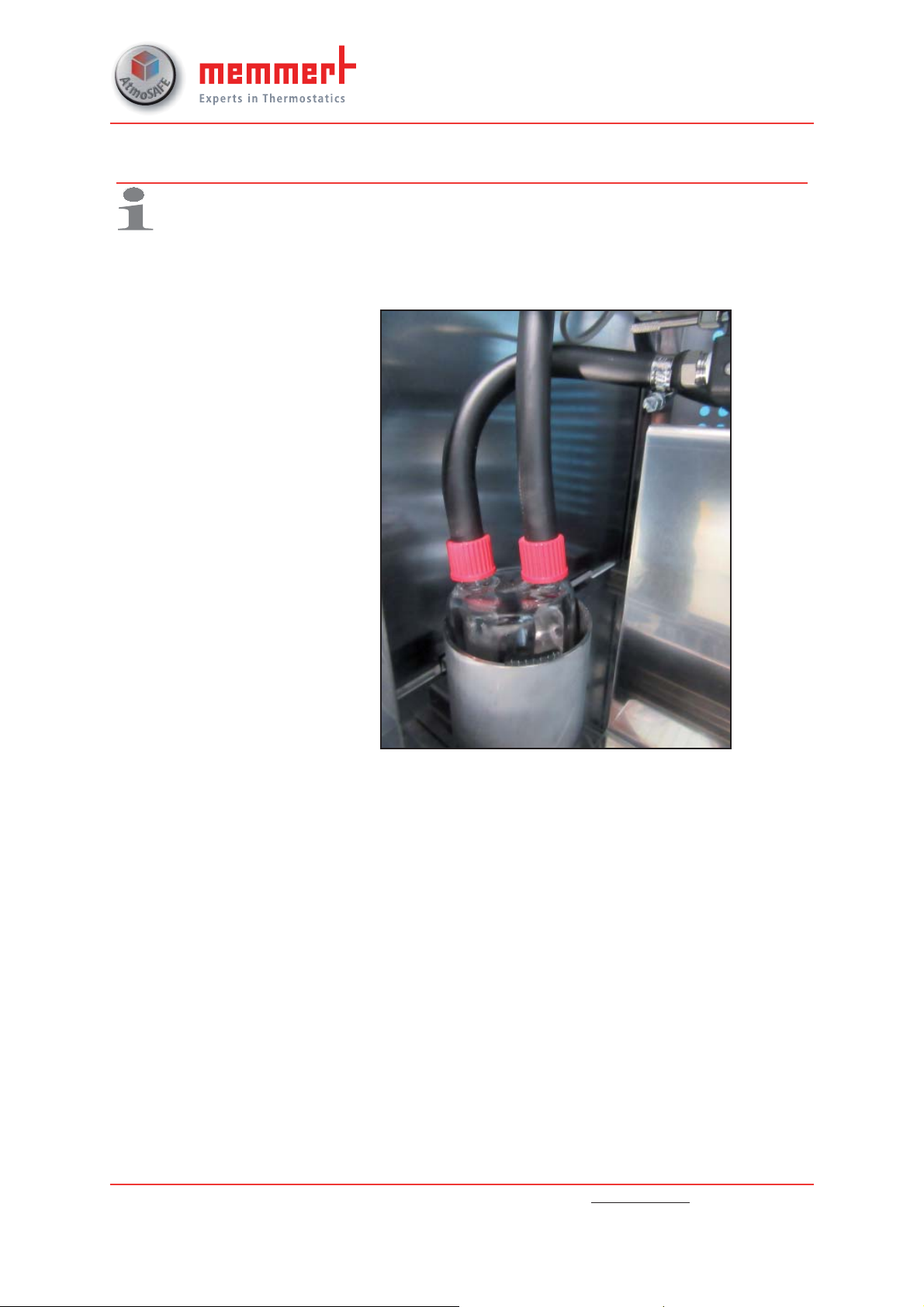

Depending on the customer process, condensate may accumulate in the

collection container of the pump module. No condensate can be sucked in

by the pump. Check and empty the container regularly.

Emptying the collection container

► Unscrew and remove the

ducts from the collection

container.

► Remove the collection con-

tainer from the holder and

empty it.

► Insert the collection container

into the holder and attach

the ducts.

7

MEMMERT GmbH + Co. KG

Willi-Memmert-Strasse 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Fax: +49 (0)9171 9792 979

Email: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 8

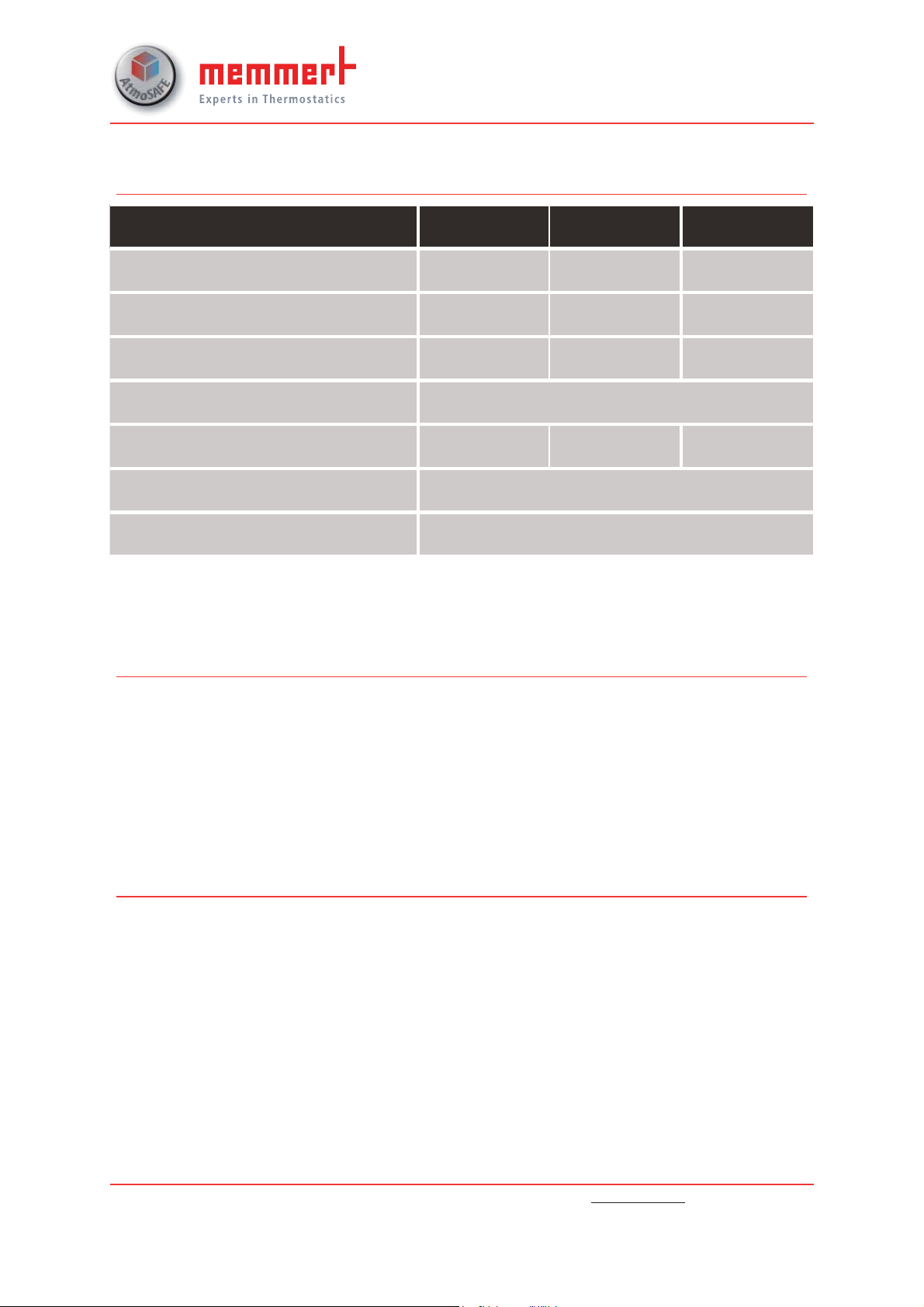

Technical data

Appliance size 29 49 101

Appliance width D [mm] 550 550 710

Appliance height E [mm] 600 680 760

Appliance depth F [mm] 400 480 550

Depth of door lock [mm] 38

Weight without/with pump [kg] 25/33 30/38 41/49

Power [W]* 140

Current consumption [A]* 1.9

8

*All other technical data can be found in the operating and installation manual for the KNF

pump which follows

Spare parts and service

In the event of a malfunction or if the pre-installed membrane vacuum pump requires maintenance or service work, contact the Customer Service department at Memmert.

The spare parts required for complete maintenance of the pump head are available from

Memmert under the following order number:

► E07534 spare parts kit for membrane.

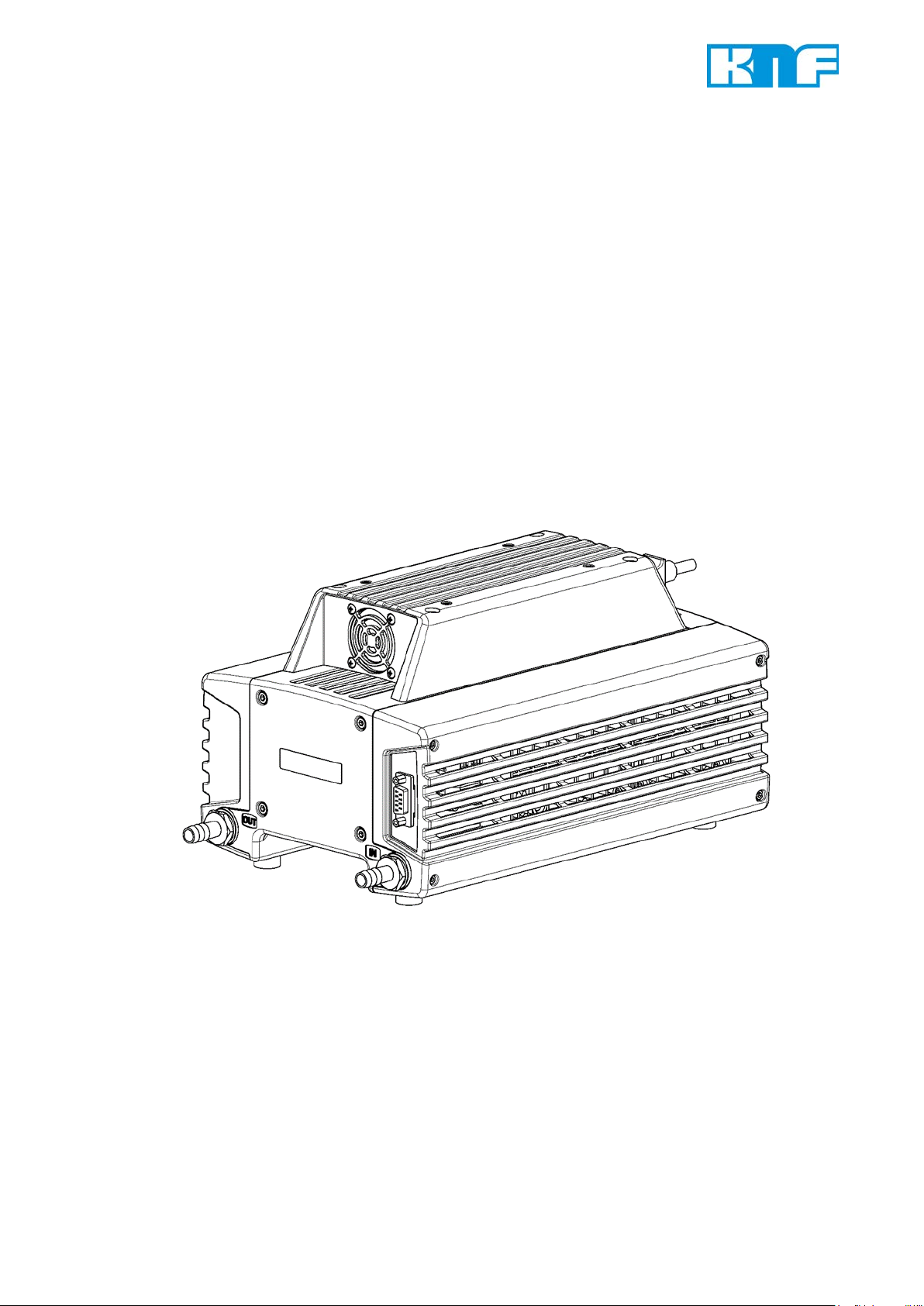

Operating and installation information

Information about the assembly and functionality of the pre-installed KNF vacuum pump

N950.50 KNE-W can be found in the manufacturer's original operating manual (provided).

MEMMERT GmbH + Co. KG

Willi-Memmert-Straße 90-96

D-91186 Büchenbach

Germany

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

Email: sales@memmert.com

Internet: www.memmert.com

Customer service:

Hotline: +49 (0)9171 9792 911

Service fax: +49 (0)9171 9792 979

E-mail: service@memmert.com

© 2018 Memmert GmbH + Co. KG

Page 9

KNF 125530-316634 06/18

LAB

PJ25481-950.50.18

TRANSLATION OF ORIGINAL INSTALLATION

ENGLISH

INSTRUCTIONS

DIAPHRAGM PUMP

Note!

Before operating the pump and the accessories, please read the operating instructions and pay attention to

the safety precautions!

Page 10

KNF Neuberger GmbH

Alter Weg 3

79112 Freiburg

Germany

Phone +49-(0)7664-5909-0

Fax +49-(0)7664-5909-99

E-mail: info@knf.de

www.knf.de

Contents Page

About this document ................................................................. 3

1.

2. Use............................................................................................ 4

3. Safety ........................................................................................ 6

4. Technical Data .......................................................................... 8

5. Design and function ................................................................ 10

6. Installation and connection ..................................................... 11

7. Operation ................................................................................ 15

8. Servicing ................................................................................. 20

9. Troubleshooting ...................................................................... 28

10. Returns ................................................................................. 300

11. Health and safety clearance and decontamination form ...... 311

Page 11

Diaphragm pump PJ25481-950.50.18 About this document

A danger is located here.

Possible consequences of a failure to observe the

warning are

Warning, indicates the danger level.

Signal word

Meaning

Consequences if not observed

DANGER

warns of immedi-

Death or serious injuries and/or

WARNING

warns of possible

Death or serious injuries and/or

CAUTION

warns of a possi-

Minor injuries or damage are

This symbol refers to important inform ation.

1. About this document

1.1. Using the Installation Instructions

The Installation Instructions are part of the pump.

Carefully study the Installation Instructions before using the

pump.

Always keep the Installation Instructions handy in the work

area.

Pass on the Installation Instructions to the next owner.

1.2. Symbols and markings

Warning

WARNING

Measures for avoiding the danger and its conse-

quences are specified here.

Danger levels

ate danger

danger

bly dangerous

situation

Tab. 1

Other information and symbols

An activity to be carried out (a step) is specified here.

1. The first step of an activity to be carried out is specified here.

Additional, consecutively numbered steps follow.

specified here. The signal word, e.g.

serious damage are the consequence.

serious damage are possible.

possible.

Original-Installation Instructions, english, KNF 12553 0-3166 34 06/ 1 8 3

Page 12

Use Diaphragm pump PJ25481-950.50.18

Operating parameter and

Requirements for

Accessories

2. Use

2.1. Proper use

The pumps are exclusively intended for transferring gases and vapors.

Owner’s responsibility

Only install and operate the pumps under the operating parameters

conditions

transferred medium

and conditions described in Chapter 4. Technical Data.

Make sure that the installation location is dry and the pump is pro-

tected against rain, splash, hose and drip water as well as other

pollutions.

The gas-tightness of the connections between the application

pipes and the pump (or the pump connection) must be checked

regularly; with leaky connections, there is a danger that hazardous

gases or vapors may escape from the pump system.

Before using a medium, check whether the medium can be transferred danger-free in the specific application case.

Before using a medium, check the compatibility of the materials of

the pump head, diaphragm and valves with the medium.

Only transfer gases which remain stable under the pressures and

temperatures occurring in the pump.

Laboratory equipment or additional components connected to a

vacuum pump system have to be suitable for use with the pneumatic capabilities of the pump. (see Chapter 4. Technical Data).

4 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 13

Diaphragm pump PJ25481-950.50.18 Use

2.2. Improper use

The pumps may not be operated in an explosive atmosphere.

The pumps are not suitable for transferring dusts.

The pumps are not suitable for transferring liquids.

The pumps are not suitable for transferring aerosol.

The pumps are not suitable for transferring biological and microbio-

logical substances.

The pumps are not suitable for transferring fuel.

The pumps are not suitable for transferring explosive and combus-

tible materials.

The pumps are not suitable for transferring fibers.

The pumps are not suitable for transferring oxidizing agent.

The pumps are not suitable for transferring foodstuffs.

The pumps must not be used to create vacuum and overpressure

simultaneously.

Pumps designed to create either a vacuum or an overpressure

must not be used for these two purposes simultaneously.

An overpressure must not be applied to the suction side of the

pump.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 5

Page 14

Safety Diaphragm pump PJ25481-950.50.18

Note the safety precautions in Chapter 6. Installation and connect

Personnel

Working in a safety

Handling dangerous media

Handling combustible media

3. Safety

conscious manner

The pumps are built according to the generally recognized rules of

the technology and in accordance with the occupat io na l saf et y and

accident prevention regulations. Nevertheless, dangers can result

during their use which lead to injuries to the user or others, or to

damage to the pump or other property.

Only use the pumps when they are in a good technical and proper

working order, in accordance with their intended use, observing the

safety advice within the Installation Instructions, at all times.

Components connected to the pump must be designed to withstand the pneumatic performance of the pump.

Take care that safety regulations are observed when connecting

the pump to the electricity supply.

Make sure that only trained and instructed personnel or specially

trained personnel work on the pumps. This especially applies to

assembly, connection and servicing work.

Make sure that the personnel has read and understood the Installation Instructions, and in particular the “Safety” chapter.

Observe the accident prevention and safety regulations when performing any work on the pump and during operation.

ion and 7. Operation.

Do not expose any part of your body to the vacuum.

Ensure that the pump is separated from the mains and is de-ener-

gized.

The pump heads heat up during operation – avoid contact with

them.

Make sure that there are no hazards due to flow with open gas

connections, noises or hot gases .

Ensure that an EMC-compatible installation of the pump is ensured

at all times and that this cannot lead to a hazardous situation.

When transferring dangerous media, observe the safety regula-

tions when handling these media.

If the diaphragm ruptures, the transferred medium will mix with the

air in the environment.

Take all necessary care to prevent this leading to a dangerous situation.

Be aware that the pumps are not designed to be explosion-proof.

Make sure the temperature of the medium is always sufficiently be-

low the ignition temperature of the medium, to avoid ignition or explosion. This also applies for unusual operational situations.

Note that the temperature of the medium increases when the pump

compresses the medium.

6 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 15

Diaphragm pump PJ25481-950.50.18 Safety

Environmental protection

Standards

Customer service and

Hence, make sure the temperature of the medium is sufficiently below the ignition temperature of the medium, even when it is compressed to the maximum permissible operating pressure of the

pump. The maximum permissible operating pressure of the pump

is stated in the technical specifications (Chapter 4).

If necessary, consider any external sources of energy, such as radiation, that may add heat to the medium.

In case of doubt, consult the KNF customer service.

Store all replacement parts in a protected manner and dispose of

them properly in accordance with the applicable environmental protection regulations. Observe the respective national and international regulations. This especially applies to parts contaminated

with toxic substances.

The pumps conform to the Directive 2011/65/EU (RoHS2).

The pumps conform to the safety regulations of the EC Directive

2014/30/EU concerning Electromagnetic Compatibility and the EC

Directive 2006/42/EC concerning Machinery.

repairs

The following harmonized standards have been used:

DIN EN 61010-1

DIN EN 61326-1 Class A

DIN EN 50581

The pumps correspond to DIN EN 60664-1:

The overvoltage category II

The pollution degree 2

The pump is maintenance-free. But KNF recommends, checking

the pump regularly with regard to conspicuous changes in noise

and vibrations.

Only have repairs to the pumps carried out by the KNF Customer

Service responsible.

Housing with voltage-caring parts may be opened by technical personnel only.

Use only genuine parts from KNF for servicing work.

Use only the original KNF power supply.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 7

Page 16

Technical Data Diaphragm pump PJ25481-950.50.18

Assembly

Material

Diaphragm

PTFE coated

Valve plates

FFPM

O-ring

FPM (head 1-3)

Head plate

PPS

Intermediate plate

PPS

Parameter

Value

Max. permissible operating

-

Ultimate vacuum [mbar abs.]

2.0

Delivery rate at atm. pressure

55.0

Pump type

Value

PJ25481-950.50.18

Hose ID 10

Parameter

Value

Automatic voltage selection

100-240 V

Max. current consumption [A]

1.9

Max. power consumption [W]

140

Maximum permitted mains

± 10%

Protection class Motor

IP 20

Protection class Pump

IP 20

The pump is supplied by a universal power supply with integrated overload

They are protected against overheating by a temperature sensor on the motor board and equipped with overcurrent protection.

If one of these safety functions is triggered, the pump will

shut down and must be manually reset, as follows:

Remove the cause(s) of the fault before restarting.

4. Technical Data

Pump materials

FFPM (head 4)

Tab. 2

Pneumatic values

pressure [bar g]

with closed gas ballast

and 5V control voltage [l/min]*

Tab. 3 *Liters in standard state (1013 mbar)

Pneumatic Connections

Tab. 4

Electrical data

50 – 60 Hz

voltage fluctuations

Tab. 5

8 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Separate pump from mains.

protection.

be

Page 17

Diaphragm pump PJ25481-950.50.18 Technical Data

Pump type

Value

PJ25481-950.50.18

Approx. 7.2 kg

Parameter

Value

Permissible ambient tempera-

+ 10°C to + 40°C

Permissible media tempera-

+ 5°C to + 40°C

Dimensions

See Fig. 3, Chapter 6.1

Maximum permissible ambient

80% for temperatures up to

Max. altitude of site:

2000

Weight

Tab. 6

Other parameters

ture

ture

relative humidity

[m above sea level]

Tab. 7

31°C, decreasing linearl y to

50% at 40°C.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 9

Page 18

Design and function Diaphragm pump PJ25481-950.50.18

1 Inlet (suction side)

1 Outlet valve

5. Design and function

Design

2 Outlet (pressure side)

3 Power switch, removable

mains cable

4 Sub-D-plug (motor control)

2 Inlet valve

3 Transfer chamber

4 Diaphragm

5 Eccentric

6 Connection rod

7 Pump drive

Fig. 1: Design PJ25481-950.50.18

Function Diaphragm Pump

Fig. 2: Pump head

Diaphragm pumps transfer, compress (depending on pump version) and evacuate gases and vapors.

The elastic diaphragm (4) is moved up and down by the eccentric

(5) and the connection rod (6). In the downward stroke it aspirates

the gas to be transferred via the inlet valve (2). In the upward

stroke, the diaphragm presses the medium out of the pump head

via the outlet valve (1). The transfer chamber (3) is hermetically

separated from the pump drive (7) by the diaphragm.

10 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 19

Diaphragm pump PJ25481-950.50.18 Installation and connection

The IP protection class of the pump motor is indicated on the

type plate.

Mounting dimensions

Cooling air supply

Installation location

6. Installation and connection

Only install and operate the pumps under the pneumatic operating

parameters and conditions described in Chapter 4, Technical Data.

Observe the safety precautions (see Chapter 3).

6.1. Installation of the pump

Choose a safe location (flat surface) for the pump.

Before installation, store the pump at the installation location to

bring it up to ambient temperature.

See Fig. 3 for m ounting di mensions.

Fig. 3: Mounting dimensions PJ25481-950.50.18 (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V)

Install the pump so that the motor fan can intake sufficient

cooling air.

Make sure that the installation location is dry and the pump is

protected against rain, splash, hose and drip water as well as

other pollutions.

Make sure, that the installation location is accessible for

maintenance and service.

Install the pump at the highest point in the system to prevent

condensate from collecting in the pump head.

Protect the pump from dust.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 11

Page 20

Installation and connection Diaphragm pump PJ25481-950.50.18

Personal injury and/or damage to property because

of vibration

In conjunction with adjacent components, vibration of

the pump may result in crushing and/or damage to

these components.

Foreign matter protection

Protect the pump against grease and oils.

Protect the pump from vibrations and jolts.

WARNING

Make sure that vibrations of the pump do not re-

sult in hazards associated with adjacent components.

Protect the pump against contact and intrusion of foreign mat-

ter.

12 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 21

Diaphragm pump PJ25481-950.50.18 Installation and connection

Extreme danger from electrical shock

Only have the pump connected by an authorized

The voltage must not vary by more than + 10% and – 10%

from that shown on the type plate.

Ensure sufficient dimensioning of the connection cables.

Personal injury or damages to property by ejected

protective

If the

pump hasn’t been removed, it could be ejected because of the overpressure during operation.

Connected

Pump exhaust

6.2. Electrical connection

specialist.

DANGER

When connecting the device to a power source, the relevant

standards, directives, regulations, and technical standards

must be observed.

Connecting pump

1. Compare the supply data with the data on the motor plate. For

maximum operating current of the pump see pump’s type

plate.

Only have the pump connected when the power

supply is disconnected.

components

2. Insert the mains cable plug into a properly installed shockproof

socket.

6.3. Pneumatic connection

plugs

CAUTION

Only connect components to the pump which are designed for

the pneumatic data of the pump (see Chapter 4, Technical

Data).

If the pump s used as a vacuum pump, safely discharge the

pump exhaust at the pump’s pneumatic outlet.

protective plug at the pressure side of the

Remove the protective plug during the installa-

tion.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 13

Page 22

Installation and connection Diaphragm pump PJ25481-950.50.18

A marking on the pump head shows the direction of flow.

Confusion between suction and pressure sides can lead to

breakage of connected components on the suction and pressure sides.

Connecting pump

1. Remove the protective plugs from the hose connection

threads.

2. Connect the suction line and pressure line (see Chapter 4,

Tab. 7 for mounting dimensions).

3. Lay the suction and pressure line at a downward angle to prevent condensate from running into the pump.

14 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 23

Diaphragm pump PJ25481-950.50.18 Operation

Operational requirements

Pump

All hoses attached properly.

Danger of burns from hot pump parts or hot medium

During or after operation of the pump, some pump

parts may be hot.

Injury of the eyes

During excessive approach to the inlet or outlet of

the pump, the eyes could be injured by the upcoming

vacuum or overpressure.

7. Operation

7.1. Initial start-up

Fan openings not blocked.

Specifications of the power supply corre-

spond with the data on the pump’s t ype plate.

Ensure that the pump outlet is not closed or

constricted.

Tab. 8

7.2. Start up

WARNING

WARNING

Only operate the pumps under the operating parameters and

conditions described in Chapter 4. Technical Data.

Make sure the pumps are used properly (see Chapter 2.1).

Make sure the pumps are not used improperly (see Chapter

2.2).

Observe the safety precautions (see Chapter 3).

Allow the pump to cool after operation.

Take safety precautions against the contact of

hot parts/media.

Don’t look into the pump’s inlet or outlet during

the operation.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 15

Page 24

Operation Diaphragm pump PJ25481-950.50.18

Hazard of the pump head bursting due to excessive

pressure increase

Only throttle or regulate the air or gas quantity in

Excessive pressure (with all of the related hazards) can be prevented by placing a bypass line with a pressure

tween the pressure and suctions sides of the pump. For further

information, contact our technical adviser (contact data: see

www.k

Automatic starting can cause personal injury and

pump damage

When the operation of the pump is interrupted by the

thermal

sors, the pump will restart automatically after cooling

down.

The pump may not start up against pressure during switch-on.

This also applies in operating following a brief power failure.

a

This activates the

overload switch and the pump switches off.

Depending on the applied electrical voltage, initialization of the

electronics may take up to one second before the pump starts.

Pump standstill

Do not exceed max. permissible operating pres -

WARNING

sure (see Chapter

Monitor pressure during operation.

If the pressure exceeds the maximum permissi-

ble operating pressure, immediately switch off

pump and eliminate fault (see Chapter

bleshooting).

the suction line to prevent the maximum permis-

sible operating pressure from being exceeded.

If the air or gas quantity in the pressure line is

throttled or regulated, make sure that the maxi-

mum permissible operating pressure is not ex-

ceeded.

Ensure that the pump outlet is not closed or con-

stricted.

4. Technical Data.

9. Trou-

With the pump at a standstill, open pressure and suction lines to

normal atmospheric pressure.

WARNING

16 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

7.3. Switching Pump on/off

Switching pump on

Make sure that normal atmospheric pressure is present in the

lines during switch-on.

Pumpe am Netzschalter einschalten (siehe Fig. 1/3 in Kapite l

5).

nf.com).

pump starts against pressure, it may block.

-relief valve be-

switch or the trigging device for PTC sen-

Take all necessary care to prevent this leading

to a dangerous situation.

If

Page 25

Diaphragm pump PJ25481-950.50.18 Operation

Elektrische Anschlüsse / Electrical connection

Litzenbelegung / lead assignment

Signalname

5V Ausgangsspannung

Masse

Masse

Ausgangssignal Drehzahl

Versorgung Gasballastventil

Eingangssignal Drehzah lre gel ung

Ausgangssignal Fehler

Eingangssignal Remote EIN/AUS

Masse Gasballastventil

5V Ausgangsspannung U5V / 5V Power supply U5V

Ausgangsspannung DC

Max. Ausgangsstrom

External actuation

Pin Nr. Funktion / function

1

2

3

4

5

6

7

8

9

5V power supply

Ground

Ground

Output signal speed

Supply gas ballast valve

Input signal speed control

Output signal fault

Input signal Remote ON/OFF

Ground gas ballast valve

Output voltage range DC

signal name

U5V

GND

GND

U

Spd

U

+GB

U

Ctrl

U

Flt

U

Rmt

U

-GB

[V] 5 ± 0.2

Max. current output

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 17

[mA] 170

Tab. 9 (part 1): Connection plan motor electronics

Page 26

Operation Diaphragm pump PJ25481-950.50.18

Ausgangssignal Drehzahl U

/ Output signal speed U

Pulse pro Umdrehung

Pulstastverhältnis

PWM-Signal

PWM Frequenz

Ausgangspegel „high“

5

Ausgangspegel „low“

0

Max. Strombelastbarkeit

Ausgangsimpedanz @ 1 kHz

Eingangssignal Drehzahlregelung U

/ Input signal speed control U

Steuerspannungsbereich DC

Steuerspannungsbeschreibung:

min.

max.

Max. Eingangsspannung

Schwellenspannung

PWM Frequenzbereich

100

Eingangspegel „high”

5

Eingangspegel „low”

0

Tastgradbereich

Tastgradbeschreibung:

min.

max.

Eingangsimpedanz @ 1kHz

Analog

Pulses per revolution

Pulse duty cycle

PWM frequency

Output level „high“

Output level „low“

Max. current carrying capacity

Output impedance @ 1 kHz

Control voltage range DC

min. Pumpe min. Förderleistung

max. Pumpe max. Förderleistung

Analog

Contol voltage description

min. pump min. flow

max. pump max. flow

Spd

Ctrl

Spd

[-] 1

[%] 50 ± 1

[Hz] 50 ± 0.5

[V]

[V]

[4.1 … V5V]

[0 … 0.6]

[mA] 10

[kΩ] ≥ 9

Ctrl

[V] 0 … 5

[V]

0.1 5

Max. input voltage

Treshold voltage

PWM frequence range

Input level „high”

Input level „low”

PWM-Signal

Duty cycle range

min. Pumpe min. Förderleistung

max. Pumpe max. Förderleistung

Duty cycle description

min. pump min. flow

max. pump max. flow

Input impedance @ 1kHz

[V] 5.5

[mV] 25 ± 0.5

[Hz]

[V]

[V]

[%] 0 … 100

[%]

[kΩ] ≥ 12

Tab. 9 (part 2): Connection plan motor electronics

[50 … 150]

[4.2 … 5.5]

[0 … 0.9]

2 100

18 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 27

Diaphragm pump PJ25481-950.50.18 Operation

Ausgangssignal Fehler U

/ Output signal fault U

Eingangspegel „high“ Fehler vorhanden

5

Eingangspegel „low“ kein Fehler

0

Max. Strombelastbarkeit

Ausgangsimpedanz @ 1kHz

Eingangssignal Remote EIN/AUS U

/ Input signal Remote ON/OFF U

Eingangspegel „high“ Motor EIN

5

Eingangspegel „low” Motor AUS

0

Eingangsimpedanz @ 1 kHz

Versorgung Gasballastventil U

/ Supply gas ballast valve U

Steuerspannung DC

Max. Stromaufnahme

To start the motor, Pin 5 must be bridged to the ground of the

controller connection.

Adjusting the flow rate

Remote ON/OFF

Vapors as media

Flt

Input level „high“ err or d etec ted

Input level „low“ no er ror

Max. current carrying capacity

Output impedance @ 1kHz

Input level „high“ motor ON

Input level „low” motor OFF

Input impedance @ 1 kHz

+GB

Control voltage DC

Max. current consumption

Tab. 9 (part 3): Connection plan motor electronics

The flow rate can be varied by an external actuation (Sub-D-plug,

see Tab. 9).

Rmt

Flt

[V]

[V]

[3.9 … 5.5]

[0 … 0.9]

[mA] 10

[kΩ] ≥ 9

Rmt

[V]

[V]

[3.9 … 5.5]

[0 … 0.9]

[kΩ] ≥ 1.8

+GB

[V] 24 ± 10%

[mA] ≤ 50

The speed of the pump is controlled by a control voltage.

Please contact our KNF customer service for further information.

Remote ON/OFF is through an 9-pin controller connection (Pin 8,

see Tab. 9).

Please contact our KNF customer service for further information.

Switching off the pump

The life of the diaphragm is prolonged the formation of condensate

is avoided. Therefore the following precautions should be taken:

Run the pump for a few minutes to warm it up before handling

saturated or nearly saturated vapors.

KNF recommends: When transferring aggressive media, flush

the pump prior to switch off (see Chapter 8.2.1) to increase the

service life of the diaphragm.

Switch off pump with power switch (Fig. 1 at Chapter 5).

Restore the system to normal atmospheric pressure (release

pneumatic pressure in pump).

Pull out the pump’s main plug.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 19

Page 28

Servicing Diaphragm pump PJ25481-950.50.18

Component

Servicing interval

Pump - Regular inspection for external

damage or leaks

Hose connections

Regular inspection for external

damage or leaks

Diaphragm and valve

Replace when pumping capacity

Silencer

Change if it is dirty

When cleaning, make sure that no liquids enter the inside of

the housing.

Dangerous substances in the pump can cause a

health hazard.

Depending on the substance transferred, caustic

burns or poisoning are possible.

Danger of burns from hot pump parts

The pump head or motor may be hot even after the

pump has been shut off.

Requirements

8. Servicing

8.1. Servicing schedule

-

-

plates

Tab. 10

8.2. Cleaning

decreases, or sooner

-

8.2.1. Flushing pump

Before switching off the pump, flush it with air (or with inert gas

if required for safety reasons) under atmospheric conditions

(ambient pressure) for about five minutes.

8.2.2. Cleaning pump

Pump disconnected from mains and de-energized.

WARNING

Wear protective clothing if necessary, e.g. pro-

tective gloves.

Take the proper steps to clean the pump.

CAUTION

Solvent should be used for cleaning only if the head materials

are not corroded (ensure compatibility of the material).

If compressed air is available, blow out the parts.

20 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Allow the pump to cool off after operation.

Page 29

Diaphragm pump PJ25481-950.50.18 Servicing

Spare part/tool

Spare parts set according to spare parts list, Chapter 10

Allen key 2-mm (hexagon)

Phillips screwdriver No. 2

Allen key 4-mm (hexagon)

Felt-tip pen

Dangerous substances in the pump can cause a

health hazard.

Depending on the substance transferred, caustic

burns or poisoning are possible.

Danger of burns from hot pump parts

The pump head or motor may be

pump has been shut off.

Requirements

Spare parts/tools

Information on procedure

8.3. Replacing diaphragm and reed valves

Pump disconnected from mains and de-energized

Pump is clean and free of hazardous materials.

Hoses removed from pump’s pneumatic inlet and outlet.

Tab. 11

Always replace diaphragm and valve plates together to main-

tain the pump performance.

WARNING

Wear protective clothing if necessary, e.g. pro-

tective gloves.

Flush the pump before replacing the diaphragm

and valve plates (see Chapter

CAUTION

Allow the pump to cool off after operation.

8.2.1).

hot even after the

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 21

Page 30

Servicing Diaphragm pump PJ25481-950.50.18

1 8x attachment screws

2

3

4

5

6

7

8

9

10

11 2x connection blocks .50

12

13

14

15

16

17

18

19

20

Fig. 4: Exploded drawing PJ25481-950.50.18

(head cover)

4x head screws

16x attachment screws

(head)

4x head plates

8x O-rings (ø24 x 2)

4x intermediate plates

4x diaphragms

1x connection cover

4x attachment screws

(connection cover)

2x O-rings (ø7,65 x1,78)

2x flat seals

2x connection block s .1.2

2x attachment screws

(connection .1.2)

8x valve plates

6x valve plates

6x O-rings (ø18,77 x

1,78)

6x O-rings (ø10 x 2,5)

2x head covers

2x attachment screws

(connection .50)

Removing the pump head

1. Undo the eight screws (Fig. 4/1) and remove the head covers

(20).

2. Undo the connection cover’s (8) attachment screws (Fig. 5/9)

and remove the connection cover.

22 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

3. Remove the head connection’s (11) and (14) screws (10) and

(15) and remove the head connections.

Page 31

Diaphragm pump PJ25481-950.50.18 Servicing

Fig. 5: Disassembling the head connections

4. Remove O-rings (Fig. 6/12) and flat seals (13).

Fig. 6: Marking the pump

5. Head 1 (Fig. 6/I):

Use a felt-tip pen to apply a single mark (M) to the head plate,

intermediate plate, and compressor housing.

6. Head 2 (Fig. 6/II):

Use a felt-tip pen to apply two marks (M) to the head plate, intermediate plate, and compressor housing.

7. Head 3 (Fig. 6/III):

Use a felt-tip pen to apply three marks (M) to the head plate,

intermediate plate, and compressor housing.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 23

Page 32

Servicing Diaphragm pump PJ25481-950.50.18

During re-assembly, refer to the marks on the individual heads

to ensure th

8. Head 4 (Fig. 6/IIII):

Use a felt-tip pen to apply four marks (M) to the head plate, intermediate plate, and compressor housing.

at the parts are properly re-assembled.

9. Undo the 16 attachment screws (Fig. 4/3) on the heads (1 to 4)

and remove the heads (1 and 2 as well as 3 and 4).

10. Pull apart heads 1 (Fig. 7/I) and 2 (II) and heads 3 (III) and 4

(IIII) and remove O-rings (19).

Fig. 7: Removing the o-rings

11. On all four heads, undo the head screw (Fig. 8/2) in the head

plate (4) and remove head plate from the intermediate plate

(6).

24 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 33

Diaphragm pump PJ25481-950.50.18 Servicing

Use caution to prevent the diaphragm spacers (21) located between the diaphragm and the connecting rod from falling into

the pump housing. The diaphragm and the connecting rod from

falling into the housing. The diaphragm spacers (

installed in the same quantity as before in order to ensure th

pump’s pneumatic performance.

Fig. 8: Exploded drawing of pump heads 1 and 2

Replacing the diaphragms and valve plates

1. Manually remove the four diaphragms (Fig. 9/7) by turning

them in the counterclockwise direction.

21) must be

e

Fig. 9: Replacing diaphragm

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 25

Page 34

Servicing Diaphragm pump PJ25481-950.50.18

Before you finally tighten the diaphragms, you are recommended to move the diaphragm to the upper dead center.

The upper and lower sides of the valve plates are identical.

When inserting the O-rings, make sure that they are the correct

size and color (head 4: black O

Refer to for arrangement and alignment of disk springs and the

screw’s washer.

When inserting the O-rings, make sure that they are the correct

size and color (head 4: black O

2. Remove from the intermediate plates (Fig. 8/6) the valve plates

(16) and (17) and the O-rings (5) and (18).

3. Manually screw the ne diaphragms (Fig. 9/7) into the connecting rod’s threads and tighten to hand tightness.

4. Insert the new valve plates (Fig. 8/16) and (17) and the new O-

rings (5) and (18) into the intermediate plates (6).

Install intermediate plates and head cover

1. Place head plate (Fig. 8/4) onto the int ermediate plates (6), observing the felt-tip pen marks (Fig. 6/M).

2. With your hands, caref ull y and lightl y tighte n the head plat e’s

head screw (Fig. 8/2) on all four heads (tightening torque:

60 Ncm).

3. Place three O-rings (Fig. 7/19) into each of the head connection holes.

-rings).

-rings).

Fig. 10: Aligning the

disk spring

4. Press together heads 1 and 2 (Fig. 6/I and II) and heads 3 and

4 (III and IIII).

5. Place heads 1 and 2 and heads 3 and 4 onto the compressor

housing; alternately tighten attachment screws (Fig. 4/3) to

hand-tightness (tightening torque: 3.5 Nm).

6. Insert O-rings (Fig. 6/12) and flat seals (13) into the head connection receiver.

7. Reinstall the head connections:

To do this, manually tighten the head connections’ attachment

screws (Fig. 5/10 and 15).

8. Reinstall the head connection cover (8):

To do this, manually tighten the head connection cover’s attachment screws (9).

9. Reinstall the head covers (Fig. 4/20):

To do this, manually tighten the eight attachment screws (1).

10. Properly dispose of the old diaphragms, valve plates, and Orings.

26 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 35

Diaphragm pump PJ25481-950.50.18 Servicing

Final steps

1. Reconnect suction and pressure line on the pump.

2. Reconnect the pump to the mains.

If you have any questions about servicing, call your KNF technical

adviser (contact data: see www.knf.com).

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 27

Page 36

Troubleshooting Diaphragm pump PJ25481-950.50.18

Extreme danger from electrical shock!

Pump does not transfer

Cause

Fault remedy

Pump not connected to the

Connect pump to the mains.

No voltage in the mains.

Check room fuse and switch on if necessary.

The motor board’s overcur-

Separate pump from the mains.

The pump must be separated from the mains for several

seconds before the electronics will permit restarting.

Connections or hoses are

Check hoses and connections.

External valve is closed or filter

Check external valves and filters.

Condensate has collected in the

Detach the condensate source from the pump.

Diaphragm or valve plates are

Replace diaphragm and valve plates (see Chapter 8.3).

Flow rate, pressure or vacuum too low

Cause

Fault remedy

Condensate has collected in the

Detach the condensate source from the pump.

Presence of positive pressure

Change the pressure conditions.

Cross-section of pneumatic

Disconnect the pump from system and determine output

If applicable, use larger-diameter hoses or connectors.

Leaks in connections, hoses or

Make sure the hoses and connections.

Pump head components are

Clean head components.

9. Troubleshooting

Disconnect the pump power supply before work-

ing on the pump.

DANGER

Check the pump (see Tab. 12 and Tab. 13).

mains.

Make sure the pump is de-energized and se-

cure.

rent protection circuit has

activated.

Maximum temperature of

motor board is exceeded.

Determine and remove the cause of the overcurrent (for ex-

ample: improper pressure, liquid in the pump heads).

Maximum blocking time of

the rotor is exceeded.

blocked.

Remove blockage.

is clogged.

pump head.

Flush the pump (see Chapter 8.2.1).

worn.

Tab. 12

The pump does not achieve the output specified in the Technical data or the data sheet.

pump head.

Flush the pump (see Chapter 8.2.1).

on the pressure side with simultaneous vacuum or positive

pressure on the suction side.

hoses or connectors too narrow

or restricted.

pump head.

values.

Remove restriction (e.g. valve) if necessary.

Remove any parts or particles causing blockages.

soiled.

28 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 37

Diaphragm pump PJ25481-950.50.18 Troubleshooting

Pump head components are

Clean head components.

Diaphragm or valves plates are

Replace diaphragm and valve plates (see Chapter 8.3).

Diaphragm and valve plates

Make sure that the shim rings have been replaced onto the

Check head connection and hose connections for leaks.

soiled.

worn.

have been replaced.

diaphragm screw thread.

Tab. 13

Fault visualization on motor contr oller

The excess of the overcurrent limit, the excess of the maximum

temperature of the motor board or the blocking of the rotor is

shown as a fault. A red LED on the BLDC motor controller signals

the cause of the fault.

Optional settings:

If desired, the motor controller can be programmed so that the error output voltage exhibits the same characteristics as the LED.

With factory settings, only 1 or 0 are logically outputted as voltage

at the fault output.

Fig. 11: LED blinking duration according to different faults

To delete the error condition the motor has to be disconnected

from the mains.

Fault cannot be rectified

If you are unable to identify the cause of the problem, please send

the pump to KNF customer services (contact data: see

www.knf.com).

1. Flush the pump (see Chapter 8.2.1).

2. Clean the pump (see Chapter 8.2.2).

3. Send the pump, together with completed Health and Safety

Clearance and Decontamination Form (Chapter 12), to KNF

stating the nature of the transferred medium.

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 29

Page 38

Returns Diaphragm pump PJ25481-950.50.18

10. Returns

Pumps and systems used in laboratories and process-based

industries are exposed to a wide variety of conditions. This means

that the components contacting pumped media could become

contaminated by toxic, radioactive, or otherwise hazardous substances.

For this reason, customers who send any pumps or systems back

to KNF must submit a Health and safety clearance and decontamination form in order to avoid a hazardous situation for KNF employees. This Health and safety clearance and decontamination

form provides the following information, among other things:

physiological safety

whether medium-contacting parts have been cleaned

whether the equipment has been decontaminated

media that have been pumped or used

To ensure worker safety, work may not be started on pumps or

systems without a signed Health and safety clearance and decontamination form.

For optimal processing of a return, a copy of this declaration

should be sent in advance via e-mail, regular mail, or fax to KNF

Customer Service (co ntac t data: see www.knf.com). In order to

avoid endangering employees who open the shipment’s packaging, despite any residual hazards, the original version of the Health

and safety clearance and decontamination form must accompany

the delivery receipt on the outside of the packaging.

The template for Health and safety clearance and decontamination

form is included with these Operating Instructions and may also be

downloaded from the KNF website.

The customer must specify the device type(s) and serial number(s)

in the Health and safety clearance and decontamination form in order to provide for the unambiguous assignment of the Declaration

to the device that is sent to KNF.

In addition to the customer’s declaration of physiological safety, information about operating conditions and der customer’s application are also of importance to ensure that the return shipment is

handled appropriately. Therefore, the Health and safety clearance

and decontamination form requests this information as well.

.

30 Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18

Page 39

Diaphragm pump PJ25481-950.50.18 Health and safety clearance and decontamination form

11. Health and safety clearance and decon-

tamination form

Translation of original Installation Instructi ons , english, KNF 125530-316634 06/18 31

Page 40

KNF worldwide

Find your

local KNF partner on www.knf.com

Page 41

Experts in Thermostatics

Pump module – PM

D39489

Last updated 09/2018

English

Memmert GmbH+ Co.KG

Willi-Memmert-Straße 90-96 I 91186 Büchenbach

Phone +49 9122 925-0 | Fax +49 9122 14585

E-mail: sales@memmert.com

facebook.com/memmert.family

The expert platform: www.atmosafe.net

Loading...

Loading...