Members Mark Y0202xc Owner's Manual

Owner's Manual

!

Liquid Propane Gas Grill

MODEL Y0202XC LP

Natural Gas Grill

MODEL Y0202XC NG

MODEL Y0202XC LP SHOWN

Grill Information Center: If you have questions about assembly or grill operation, or if there are damaged or

missing parts when you unpack this unit from the shipping boxes, call us 8am - 4:30 pm CST,

Monday through Friday at: 1-800-770-9769

WARNING:

Read this Owner's Manual carefully and be sure your

gas grill is properly assembled, installed and

maintained. Follow all leak check procedures carefully in this manual prior to grill operation. Do this

even if the grill was store assembled. Failure to

follow these instructions could result in serious bodily

injury and/or property damage. This grill is intended for

outdoor use only and is not intended to be installed in

or on recreational vehicles or boats.

Note to Installer: Leave this Owner's Manual

with the consumer after delivery and/or installation.

Note to Consumer: Leave this Owner's Manual in

a convenient place for future reference.

Important Note: This grill is manufactured to

exact specifications. Model Y0202XC LP is certified

for use with LP gas and Model Y0202CX NG is

certified for use with Natural Gas. You can not

convert this grill from one fuel type to the other.

For your safety, conversion kits are not available.

Any attempt to convert your grill will void your

warranty.

Manufacturer:

Grand Hall Enterprise Co., Ltd.

9th Fl., No.298, Rueiguang Rd., Neihu,

Taipei, Taiwan (114)

P80146046A - Date: 08/12/2003

Table of Contents

Read These Safety Instructions

Warranty.....................................................2

Safety Instructions.....................................2

Natural Gas Safety Instructions...............4

Pre-Assembly Instructions..............................5

Hardware, Parts Diagram and Lists.....6

Rotisserie, Parts Diagram and Lists...10

Assembly Instructions...............................11

Lighting Instructions..................................18

Rotisserie Instructions.............................20

Back Burner, Rotisserie Instructions.......22

Cleaning and Maintenance Instructions....23

Frequently Asked Questions..................25

Cooking Instructions................................26

Cooking Guide and Recipes................27

Member's Mark Grill Warranty

Full 1-Year Warranty on Grill

For one year from the date of purchase, the Manufacturer

will repair or replace, at their option, any grill part (except

for paint loss, rusting, AA batteries) that is defective

in material or workmanship.

Limited Warranty on Selected Grill Parts

From the date of purchase for the designated time

periods stated below, the Manufacturer will replace the

following grill parts if they are defective in material or

workmanship. You will be charged shipping and handling.

• Lifetime of the grill: Stainless steel parts

(except for discoloration due to normal use or

excessive heat, and scratches or dents caused

by normal use and improper maintenance).

Aluminum Castings (except for paint loss)

• 2 Years: Cast-iron Burners

• For Warranty Service: Call our Grill Information

Center 8am - 4:30pm CST, Monday through

Friday at 1-800-770-9769

Warranty Restrictions:

• This warranty does not cover surface rust or

natural oxidation.

• This warranty is void if grill is used for

commercial or rental purposes.

• This warranty applies only when the grill is used

in the United States.

• This warranty gives you specific legal rights, and

you may also have other rights which vary from

state to state. See back cover for warranty details.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your

gas supplier or your fire department.

FOR YOUR SAFETY

Do not store or use gasoline or other flam-

1.

mable vapors and liquids in the vicinity of this

or any other appliance.

An LP gas tank not connected for use shall

2.

not be stored in the vicinity of this or any other

appliance.

!

WARNING

Combustion byproducts produced when

using this product contain chemicals known

to the State of California to cause cancer,

birth defects, or other reproductive harm.

!

WARNING

Failure to comply with these instructions

could result in a fire or explosion that

could cause serious bodily injury, death, or

property damage.

!

WARNING

Your grill will get very hot. Never lean over

the cooking area while using your grill. Do not

touch cooking surfaces, grill housing, grill lid or

any other grill parts while the grill is in

operation, or until the grill has cooled after use.

Failure to comply with these instructions

may result in serious bodily injury.

Grill Installation Codes

This gas grill must be installed in accordance with

all local codes. In areas without local codes, follow

the latest edition of the National Fuel Gas Code

ANSI Z223.1. In Canada, installation must conform

to standard CAN/CGA 1b149.1 or 1-b149.2 (Installation Code for Gas Burning Appliances and

Equipment) and all local codes.

Correct LP Gas Tank Use

LP gas grill models are designed for use with a

standard 20 lb. Liquid Propane Gas (LP gas) tank,

not included with grill box. Never connect your

gas grill to an LP gas tank that exceeds this

capacity. A tank of approximately 12 inches in

diameter by 18-1/2 inches high is the maximum

size LP gas tank to use. You must use an

"OPD" gas tank which offers an Overfill Prevention Device. This safety feature prevents the

tank from being overfilled which can cause malfunction of the LP gas tank, Regulator and/or grill.

The LP gas tank must be constructed and marked

in accordance with specifications of the U.S. Dept.

of Transportation (DOT). In Canada, the LP gas

tank must meet the Canadian Transportation and

Communications (CTC) specifications. Also be sure

to read and follow all LP gas instructions on the

following page.

2

1.

The LP gas tank has a Shut Off Valve,

terminating in an LP gas supply tank valve

outlet, that is compatible with a Type 1 tank

connection device. The LP gas tank must

also have a safety relief device that has a

direct communication with the vapor space of

the tank.

The tank supply system must be arranged

2.

for vapor withdrawal.

The LP gas tank used must have a collar

3.

to protect the tank valve.

Proper Placement and Clearance of Grill

Never use your gas grill in a garage, porch, shed,

breezeway or any other enclosed area. Your gas grill is

to be used outdoors only, at least 24 inches from the

back and side of any combustible surface. Your

gas grill should not be placed under any surface

that will burn. Do not obstruct the flow of ventilation

and combustion air around the gas grill housing.

This outdoor gas grill is not intended to be installed in

or on recreational vehicles and/or boats.

!

WARNING

Failure to comply with these instructions

could result in a fire or explosion that

could cause serious bodily injury, death,

or property damage.

• Never connect an unregulated LP gas tank to

your gas grill. The gas Regulator assembly

supplied with your gas grill is adjusted to have

an outlet pressure of 11" water column (W.C.)

for connection to an LP gas tank.

• Only use the Regulator and Hose Assembly

supplied with your gas grill. Replacement

Regulators and Hose Assemblies must be

those specified by manufacturer.

• Have your LP gas tank filled by a reputable

propane gas dealer and visually inspected and

re-qualified at each filling.

• Never fill the gas tank beyond 80% full.

Have your propane gas dealer check the

release valve after every filling to ensure that it

remains free of defects.

• Always keep LP gas tanks in upright position.

• Do not store (or use) gasoline or other flammable

vapors and liquids in the vicinity of this gas grill.

• An LP gas tank that is not connected for use must

NOT be stored on bottom shelf inside cabinet or in

the vicinity of this or any other gas grill.

• Do not subject the LP gas tank to excessive heat.

• Never store an LP gas tank indoors. If you

store your gas grill in the garage or other

indoor location, always disconnect the LP gas

tank first, store it safely outside.

• LP gas tanks must be stored outdoors in a

well-ventilated area and out of the reach of

children. Disconnected LP gas tanks

must not be stored in a building, garage or

any other enclosed area.

• When your gas grill is not in use the gas

must be turned off at the LP gas tank.

• The Regulator and Hose assembly must be

inspected before each use of the grill. If there

is excessive abrasion or wear or if the hose

is cut, it must be replaced prior to the grill

being used again.

• Keep the gas Regulator Hose away from hot

grill surfaces and dripping grease. Avoid

unnecessary twisting of hose. Visually inspect

hose prior to each use for cuts, cracks,

excessive wear or other damage. If the Hose

appears damaged do not use the gas grill,

call our Grill Information Center for a

replacement, at 1-800-770-9769.

• Never light your gas grill with the Lid closed

or before checking to insure the Burner Tubes

are fully seated over the Gas Valve Orifices.

• Never allow children to operate your grill. Do

not allow children to play near your grill.

!

WARNING

A strong gas smell, or the hissing sound of

gas indicates a serious problem with your

gas grill or the LP gas tank. Failure to

immediately follow the steps listed below

could result in a fire or explosion that could

cause serious bodily injury, death, or property damage.

• Shut off gas supply to the gas grill.

• Turn the Control Knobs to OFF position.

• Put out any flame with a Class B fire

extinguisher.

• Open Grill Lid.

• Get away from the LP gas tank.

• Do not try to fix the problem yourself.

• If odor continues or you have a fire you cannot

extinguish, call your fire department. Do not call

near the LP gas tank because your telephone is

an electrical device and could create a spark

resulting in fire and/or explosion.

NOTE: The normal flow of gas through the

Regulator and Hose Assembly can create a

humming sound. A low volume of sound is

perfectly normal and will not interfere with

operation of the grill. If humming sound is

loud and excessive you may need to purge

air from the gas line or reset the Regulator

excess gas flow device. This purging procedure should be done every time a new LP

gas tank is connected to your grill. For help

call the Grill Information Center.

Grill Information Center, 8:00am-4:30pm

CST, Monday through Friday at:

1-800-770-9769

3

Natural Gas Safety Instructions

• Your Natural Gas Grill is designed to operate on

Natural Gas only, at a pressure of 7" water column

(W.C.) (1/4 psig or 1.75 kpa), regulated at the

residential meter. Check with your gas utility

company for local gas pressure and with your local

municipality for building code requirements. If

your residential gas line pressure has not been

regulated to 7" W.C., contact your local gas

utility company for professional assistance.

• The gas pressure Regulator supplied with this

appliance must be used. This Regulator is set

for an outlet pressure of 4" W.C.

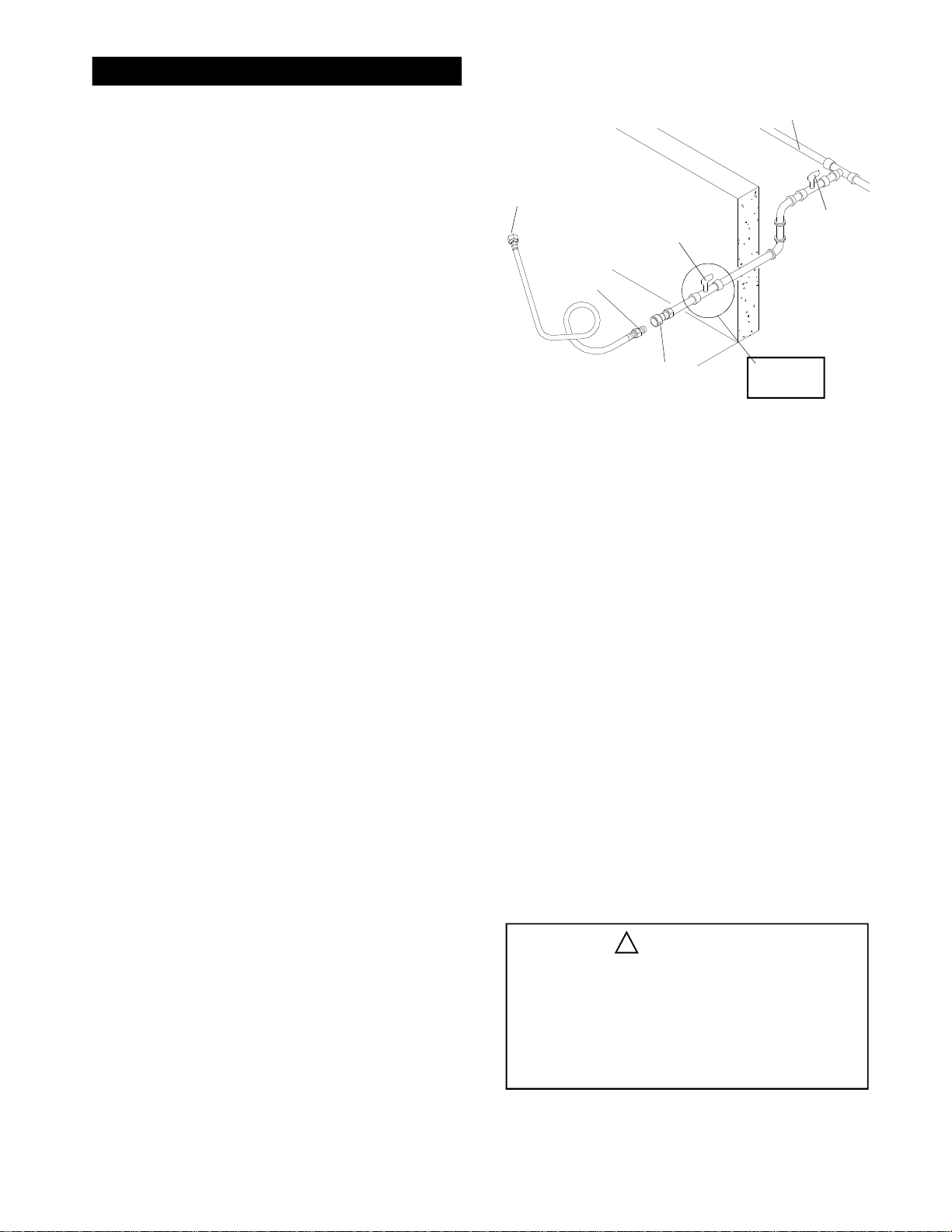

• It is recommended that a Shut Off Valve be installed

at the gas supply source outdoors. Install at a point

after the gas pipe exits the outside wall and before the

Quick Disconnect Hose, or install it at the point

before the gas line piping enters the ground. See

Figure 1.

• Pipe sealing compound or pipe thread tape resistant

to the action of Natural Gas must be used on all male

pipe threads when making the connection.

Figure 1

(For Natural Gas Model Only)

NATURAL GAS SUPPLY

I

N

S

I

D

E

W

A

L

L

A

L

L

LOCKING

GAS

SHUT OFF

VALVE

Additional

Hardware Not

Included

TO NATURAL GAS

REGULATOR

MALE

FITTING

O

U

T

S

I

D

E

W

LOCKING GAS

SHUT OFF VALVE

QUICK

DISCONNECT

Gas Line Piping

If the length of line required does not exceed 50 feet,

use a 5/8" O.D. tube. One size larger should be used

for lengths greater than 50 feet.

• Disconnect your gas grill from fuel source when

the gas supply is being tested at high pressures.

This gas grill and its individual Shut Off Valve must

be disconnected from the gas supply pipe system

during any pressure testing of that system at

pressure in excess of 1/2 psi (3.5kpa).

• Turn off your gas grill when the gas supply is

tested at low pressures. The grill must be isolated

from the gas supply pipe system by closing its

individual Manual Shut Off Valve during any

pressure testing of the gas supply pipe system at

pressures equal to or less than 1/2 psi (3.5kpa).

• The Quick Disconnect connects to a 3/8 inch NPT

thread from gas source. The Quick Disconnect

fitting is a hand operated device that automatically

shuts off the the flow of gas from the source when

it is disconnected.

• The Quick Disconnect fitting can be installed

horizontally, or pointing downward. DO NOT install

the fitting with the opening pointing upward

because the fitting could collect water and debris.

• The Dust Covers (plastic plugs) provided with the

Quick Disconnect help keep the open ends

clean while disconnected.

• The outdoor connector must be firmly attached to

a ridged permanent construction.

• The Quick Disconnect MUST BE installed above

ground.

Gas piping may be copper tubing, type K or L;

polyethylene plastic tube, with a minimum wall

thickness of .062 inch; or standard weight (schedule

40) steel or wrought iron pipe.

Copper tubing must be tin-lined if the gas contains

more than 0.3 grams of hydrogen sulfide per 100

cubic feet of gas.

Plastic tubing is suitable only for outdoor, underground use.

Gas piping in contact with earth, or any other material which may corrode the piping, must be protected

against corrosion in an approved manner.

Underground piping must have a minimum of 18"

cover.

Test Connections

All connections and joints must be thoroughly tested

for leaks in accordance with local codes and all listed

procedures in the latest edition of ANSI Z223.1

!

DANGER

Do not use an open flame to check for

gas leaks. Be sure there are no sparks

or open flames in the area while you

check for gas leaks. This will result in a

fire or explosion which can cause serious

bodily injury or death, and damage to

property.

• WARNING: Do not route the 12 foot Quick

Disconnect Hose under a deck. The hose must be

visible and inspected prior to each grill use.

4

CAUTION: BEWARE OF FLASH-BACK

Pre-Assembly Instructions

CAUTION: Spiders and small insects occa-

sionally spin webs or make nests in the grill

burner tubes during transit and warehousing.

These webs can lead to a gas flow obstruction which could result in a fire in and around

the Burner Tubes. This type of fire is known

as a "FLASH-BACK" and can cause serious

damage to your grill and create an unsafe

operating condition for the user.

Although an obstructed Burner Tube is not the

only cause of "FLASH-BACK", it is the most

common cause.

To reduce the chance of "FLASH-BACK", you

must clean the Burner Tubes before assembling your grill, and at least once a month in

late summer or early fall when spiders are

most active. Also perform this Burner Tube

cleaning procedure if your grill has not been

used for an extended period of time.

To reduce the chance of "FLASH-BACK" (see

CAUTION at left) clean the Burner Tubes and

Burners before fully assembling your grill. Remove the Cotter Pin from the rear underside of

each Burner using a pair of long nose pliers.

Carefully lift each Burner up and away from the

Gas Valve Orifice, then refer to Figure 1 and

perform one of these three cleaning methods:

Bend a stiff wire, (a lightweight coat hanger

1.

works well) into a small hook as shown

below. Run the hook through the Burner

Tube and inside the Burner several times to

remove any debris.

Use a Burner Cleaning Brush, or a bottle

2.

brush with a flexible handle. Run the brush

through the Burner Tube and inside the

Burner several times, removing any debris.

Use an air hose to force air through each

3.

Burner Tube. The forced air should pass

debris or obstructions through the Burner

and out the ports.

Tools Required for Assembly

Phillips Head screw driver

•

Adjustable wrench

•

Long nose pliers - used to remove the

•

Cotter Pin when cleaning the Burners

Open-end wrench (included with Hardware

•

Pack) used to tighten the Casters.

Protective work gloves

•

Eye protection

•

Figure 1

TO CLEAN BURNER TUBE,

INSERT HOOK HERE

GAS COLLECTOR BOX

SPARK ELECTRODE

!

WARNING

The location of the Burner Tube with respect

to the Orifice is vital for safe operation. Check

to ensure the Orifice is inside of the Burner Tube

before using your gas grill. See Figure 2. If the

Burner Tube does not fit over the Valve Orifice,

lighting the Burner may cause explosion

and/or fire.

Figure 2

CONTROL

KNOB

CROSS

SECTION

OF MANIFOLD

BURNER

GAS VALVE

BURNER PORT

SPARK ELECTRODE

GAS COLLECTOR BOX

ORIFICE

ORIFICE

BURNER TUBE

5

Contents for Hardware Pack (Part #P4182A)

Contents for Hardware Pack (Part #P4182A)

Contents for Hardware Pack

The following table illustrates a breakdown of the Hardware Pack. It highlights what components

are used in the various stages of assembly.

Ref.

B.

N.

L.

E.

E.

K.

E.

E.

Q.

K.

E.

U.

K.

U.

Component

1/4" x 2 1/2" Phillips Head Screw

1/4" x 3/4" Phillips Head Screw

1/4" Lock Nut

1/4" x 1/2" Phillips Head Screw

1/4" x 1/2" Phillips Head Screw

3/16" x 1/2" Phillips Head Screw

1/4" x 1/2" Phillips Head Screw

1/4" x 1/2" Phillips Head Screw

M5 x 6mm Phillips Head Screw

(already screwed into Door Handles)

3/16" x 1/2" Phillips Head Screw

1/4" x 1/2" Phillips Head Screw

M4 x 10 Self-Tapping Screw

3/16" x 1/2" Phillips Head Screw

M4 x 10 Self-Tapping Screw

Qty. to use

2

4

4

2

4

4

2

4

4

2

2

1

2

1

Purpose of Component

Attaches Grill Bowl to Cart Leg

Secures Grill Bowl onto the Cart

Attaches LP Fuel Tank Gauge to Side Cart Panel

Attaches Tank Hook and Tank Holder to

LP Fuel Tank Gauge

Secures Rear Panel to Cart

Attaches Door Bracket to the Cart

Attaches Shelf Bracket to Cart Leg

Attaches the Handles onto the Doors

Secures the Rear Wind Shield to the back

of Grill Cart

Secures the Spice Tray to Side Shelf

Secures the Control Panel to Side Burner

and Grill Bowl

U.

M4 x 10 Self-Tapping Screw

E.

1/4" x 1/2" Phillips Head Screw

K.

3/16" x 1/2" Phillips Head Screw

Manual Lighting Stick

R.

Caster Wrench (Part#P05515109E)

V.

"AA" Batteries

S.

(1 For NG Model)

(3 For LP Model)

T.

Door Handles

V.

Caster Wrench

W.

Side Burner Control Knob

X.

Side Burner Control Knob Seat

Y.

Spring

1

4

2

1

1

3

2

1

1

1

1

Attaches Manual Lighting Stick to Side Panel

Secures Side Shelf and Side Burner to

Shelf Brackets

Attaches Natural Gas Regulator to Cart Leg

Attaches to Right Side Panel

Tightens Casters

Powers the Electronic Ignition and LP Fuel

Gauge Display

Attaches to front Doors

Fixing the Casters

Attaches on Side Burner Valve

Attaches on Side Burner Valve

Attaches on Side Burner Valve

6

Contents for Hardware Pack (Part # P06002023A For LP)

Contents for Hardware Pack (Part #P4182A)

Contents for Hardware Pack (Part #P4182A)

(Part # P06002040A For N.G.)

Actual Size and Quantity of Each Hardware Piece:

B. 1/4" x 2 1/2" Phillips Head Screw - QTY 2

E. 1/4" x 1/2"

Phillips Head Screw

QTY. 18 (12 for NG

model)

U. M4 x 10

Self-Tapping Screw

QTY. 3

N. 1/4" x 3/4"

Phillips Head Screw x 4

(found in

door handles)

Q. M5 x 6mm

Phillips Head Screw

QTY. 4

L. 1/4" Lock Nut x 4

K. 3/16" x 1/2"

Phillips Head Screw

QTY. 8 (additional 2 for NG)

R. Manual Lighting Stick (scale 1/2) - QTY. 1 S. "AA" Batteries - QTY. 3

(1 For NG Model)

(3 For LP Model)

T. Door Handle (scale 1/2) - QTY. 2

W. Side Burner Control Knob-QTY. 1

V. Caster Wrench (scale: 1/2)- QTY. 1

Y. Spring-QTY. 1

X. Side Burner Control Knob seat-QTY. 1

Grill Information Center: If you have questions about assembly or grill operation, or if there are damaged

or missing parts when you unpack this unit from the shipping boxes, call us 8am - 4:30 pm CST,

Monday through Friday at: 1-800-770-9769

7

Y0202XC Parts Diagram

Remove all components from both cartons and place within easy reach. Turn the largest carton

upside down and it will provide a comfortable height work surface for grill assembly.

8

10.

11.

12.

13.

14.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

29.

30.

31.

32.

33.

33-1.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

Lid Plate

1.

Lid Side Panel, Left

2.

Lid Side Panel, Right

3.

Temperature Gauge

4.

Name Plate

5.

Lid Handle

6.

Heat-Insulating Spacer

7.

Cooking Grid

8.

Ceramic Flame Tamer

9.

Rack for Flame Tamer

Burner

Gas Collector Box W. Electrode

Cover for Back Burner

Frame for Back Burner

Back Burner

Spark Electrode

Orifice

Gas Tube Assembly

Grease Draining Tray

Grease Receptacle

Burner Bracket

Bowl Side Panel, Left

Bowl Side Panel, Right

Bowl Front Panel

Bowl Rear Panel

Electric Wire Set

Valve/Manifold Assembly (LP)

Valve/Manifold Assembly (NG)

Control Panel

Control Knob (Side Burner)

Control Knob (Main Burner)

Control Knob (Back Burner)

Spring

Control Knob Seat

Electric Ignitor

AA Battery(3 For LP Model)

(1 For NG Model)

Rear Wind Shield

Rear Panel

Side Shelf

Spice Tray

Side Shelf Bracket

Manual Lighting Stick

Caster

Caster Seat

Door Plate

Door Handle

Door Bracket

Door Stop

Bottom Shelf

Cart Legs,Left(LP)

Cart Legs,Left(NG)

Cart Legs,Right

Regulator(LP)

Y0202XC Parts List

QTY.REF#PART#DESCRIPTION

P00129306A

P00105317T

P00106317T

P0618A

P0435C

P0234A

P5573A

P01602029C

P1736A

P1736B

P1925C

P2623B

P06905001B

P80F1A

P1947A

P2515A

P5643A

P3512A

P2738B

P2717A

P0220321AD

P00705407G

P00706407G

P00740266D

P00741266D

P02615047A

Y0060056

Y0060057

P02909233S

P03424241L

P03424231L

P03424251L

P80E3A

P3432A

P02502154C

P8080A

P06906003C

P07701004A

P01107024B

P05206009A

P01215007D

P5540A

P5115B

P4525B

P04313008A

P0247A

P03301014E

P05510089E

P01005019H

P00901021B

P00901055B

P00902021B

P3632N

1

1

1

1

1

1

2

3

6

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

5

5

1

1

1

1

1

4

1

4

4

2

2

1

1

1

1

1

1

1

57a.

57b.

57c.

57d.

57d-1.

57e.

57f.

57g.

57h.

57i.

For the repair or replacement parts you need:

Call our Grill Information Center, 8am - 4:30pm CST,

Monday through Friday at 1-800-770-9769

To make sure you obtain the correct replacement part

(s) for your gas grill please refer to the parts list on

this page. The following information is required to

insure you receive the correct parts:

1. Model and Serial Number (see CSA label on grill)

2. Part Number

3. Description

4. Quantity of parts needed

Please allow sufficient time to process and ship.

IMPORTANT: Keep this Owner's Manual for

convenient referral and for part replacement.

IMPORTANT: Use only factory authorized parts. The

use of any part that is not factory authorized can

be dangerous. This will also void your warranty.

Tank Holder(LP)

54.

Tank Hook(LP)

55.

Tank Gauge(LP)

56.

Side Burner Frame

Side Burner Body

Side Burner Lid

Side Burner Control Panel(LP)

Side Burner Control Panel(NG)

Pot Support

Side Burner

Spark Electrode for Side Burner

Connection Hose(7.3")

Gas Valve for Side Burner(LP)

Gas Valve for Side Burner(NG)

Tank gauge Display(LP)

58.

Regulator (NG)

59.

Hose Kit 12ft.(NG)

60.

Connection Hose (19.8")

61.

Air Shutter (NG)

62.

Owner's Manual

---Hardware Pack (page 7)

---Hardware Pack(NG)

----

QTY.REF#PART#DESCRIPTION

P4042A

P4041A

P80N5A

P01102025B

P02301005B

P1144A

P02904243S

P02904463S

P80E4B

P02002047D

P2632B

P03705024A

P03232064B

P03232065B

P05310031A

Y0080007

P3718A

P03705036A

P80R7A

P80146046A

P06002023A

P06002040A

CSA label located here

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

9

Rotisserie Parts Diagram

3

6

3

8

5

3

2

7

4

9

9

9

Rotisserie Parts List Hardware for Rotisserie

QTY.REF#PART#DESCRIPTION

1

1.

Handle

2.

Bushing

3.

3/8"x1/2" Thumbscrew

4.

Collar

5.

Skewer

6.

Holding Fork

7.

Motor Bracket

8.

AC Rotisserie Motor

9.

#10-24x3/4" Screw

Washer

#10-24 Nut

P8083E

P05508092F

P05508094F

P05508091F

P05508093F

P05508090F

P8083K

P07101010A

Y0100052

1

1

3

1

1

2

1

1

2

9. #10-24x3/4" UNC Screw

QTY. 2

3. 3/8"x1/2" Thumbscrew

QTY. 3

10

9. Washer

QTY. 2

9. #10-24 Nut.

QTY. 2

Cart Assembly Instructions

Remove all cart parts, hardware, and Grill Head from

shipping boxes. Raise the Grill Lid and remove all

packed components. Use the parts list to check that

all necessary parts have been included.

Figure 1

LOCKING SCREW

CART LEG BRACKET

NOTCHED HOLE

Assemble the gas grill on a protective work surface

to avoid scratching grill surfaces. Inspect your grill for

damage as you proceed. Do not assemble or operate

your grill if it appears damaged. If there are damaged

or missing parts when you unpack the shipping boxes,

or you have questions during the assembly process,

call our Grill Information Center 8am - 4:30pm CST,

Monday through Friday at: 1-800-770-9769.

When assembling this grill, we recommend asking for

the assistance of another person when maneuvering

some of the larger, heavier pieces. You will need both

an Adjustable Wrench and Phillips Screw Driver

(not provided) for securing the nuts and screws.

Assembling The Cart

1.

Remove cart assembly from shipping box and place

on a flat and level surface such as a garage floor.

Peel back approximately two inches of the protective

PVC film from the front, back and both ends of the

Bottom Shelf. Unfold both pre-assembled Cart Legs

to an upright position. See Figure 1. Push down

Cart Legs until Locking Screws snap into the notched

holes of the Cart Leg Brackets.

THREADED HOLE FOR

DOOR BRACKET

Figure 2

PIVOT

SCREW

CASTER

2.

Make sure that the Cart Side Panels are flush with

the Bottom Shelf. Use a #2 Phillips Head screw driver

to tighten both Locking and Pivot Screws for each Cart

Leg.

3.

Install the 4 Casters to the bottom of the Cart Legs

by turning the threaded Caster Stem clockwise until

it stops. Tighten securely using the Caster Wrench

(included in Hardware Pack). See Figure 2.

4.

Attach the Rear Panel to the Cart Legs as shown

in Figure 3. Align the holes on panel with the

holes on Cart Legs. Secure loosely using 4 of the

"K" 3/16" x 1/2" Phillips Head Screws provided.

K. 3/16" x 1/2" Phillips Head Screw x 4

Secure the Manual Lighting Stick to the top of the

5.

right Side Panel. Fix firmly by using the "U"

M4 x 10 Self-Tapping Screw packed with the Manual

Lighting Stick.

Figure 3

REAR PANEL

MANUAL

LIGHTING

STICK

U. M4 x 10 Self-Tapping Screw x 1

11

Attach the Door Bracket to Cart Legs. Be sure the

6.

folded strip of the bracket is closest to the Cart

Legs. Then align the holes on both ends of the

bracket with the threaded holes on the Cart Legs.

Attach the Door Bracket using 2 of the "E" 1/4"x

1/2" Phillips Head Screws. Do not tighten screws

yet. Refer to Figure 4.

E. 1/4" x 1/2" Phillips Head Screw x 2

Locate the hinge holes on the Bottom Shelf and Door

7.

Bracket. Insert the Door Hinges into these holes and

holes on Door Bracket. Push the Door Bracket down

to an even level. See Figure 4. Adjust bottom door

stop as necessary to insure that the Door Magnets

contact the stop and the Doors are flush with the

Bottom Shelf. Unscrew the 4 "Q" M5 x 6mm Phillips

Head Screws which were pre-assembled into the

Door Handles. Use these screws and a # 2 Phillips

Head screw driver to attach the Door Handles to

the Door Plate as shown in Figure 4.

Q. M5 x 6mm Phillips Head Screw x 4

(found in door handles)

Figure 4

DOOR

BRACKET

SIDE SHELF

BRACKET

DOOR HANDLE

DOOR PLATE

Insert the 4 Side Shelf Brackets into the open slot

8.

at the top section of each Cart Leg. See Figure 4A.

Secure Brackets using 4 of the "E" 1/4"x 1/2" Phillips

Head Screws. Tighten all 4 Brackets securely.

E. 1/4" x 1/2" Phillips Head Screw x 2

Side Shelf Assembly

Place the stainless steel Side Shelf onto the Side

1.

Shelf Brackets previously attached to the right side

of the Cart. Align the holes on the Side Shelf with

the threaded holes at the end of Shelf Brackets.

Secure firmly using 2 of the "E" 1/4"x1/2" Phillips

Head Screws. See Figure 5.

E. 1/4" x 1/2" Phillips Head Screw x 2

Place the Side Burner onto the Shelf Brackets

2.

previously attached to the left side of the Cart. Align

the holes on the Side Burner with the threaded

holes at the end of Shelf Brackets. Secure firmly

using 2 of the "E" 1/4"x1/2" Phillips Head Screws.

See Figure 5.

Figure 4A

OPEN SLOT OF

CART LEG

Figure 5

SIDE SHELF

BRACKET

SIDE BURNER

SIDE SHELF

E. 1/4" x 1/2" Phillips Head Screw x 2

12

Loading...

Loading...