Melag Vacuklav 41-B, Vacuklav 43-B User manual

User Manual

Autoclave

Vacuklav®41-B

®

Vacuklav

43-B

Dear doctor,

We thank you for your confidence demonstrated by the purchase of this autoclave.

Over 55 years ago, MELAG began as a medium-sized family-run enterprise to specialise in the

manufacture of sterilization equipment for medical practices. In the meantime our company has grown

into one of the world's leading producers of sterilization equipment. Verification of it success has been

the sale of more than 410,000 MELAG units worldwide, attesting to the high quality of our sterilizers,

which are exclusively made in Germany.

This autoclave has also been manufactured and tested according to the most stringent quality criteria.

Nevertheless, please read the Operating Instructions carefully before the initial start-up of the device.

The long-term serviceability and the retention of value of your autoclave depend primarily on the

careful preparation of the instruments and the regular maintenance of the device.

MELAG - General Management and employees

r

For physicians, physician's assistants, and service personnel

Please read this User Manual before you start operation of the autoclave. The

instructions contain important safety precautions. .Make sure to keep the Use

Manual near to the autoclave. The instructions are a part of the product.

User Manual Vacuklav®41-B and Vacuklav®43-B

MELAG Medical Technology Berlin

Valid for Vacuklav

as of software version 2.4x

st

1

edition September 2006

Responsible for the contents: Engineering Department

MELAG Medical Technology

E-mail: info@melag.de

©2006-2009 MELAG Berlin

Document: BA_2_GB_41B_43B.doc/ Revision: 3 – 09/0187

Subjects to technical changes

®

41-B, Vacuklav®43-B

Geneststraße 7–10

10829 Berlin

Germany

www.melag.de

r

r

Foreword

Device name

User Manual The User Manual contains important safety instructions and information

Avoid dangers

Thank you for deciding to buy this premium class MELAG autoclave.

This User Manual describes both the autoclaves Vacuklav

Vacuklav®43-B. They are identical except for their chamber depth and

device depth.

The device name "autoclave" is used in this User Manual to designate the

steam sterilizers Vacuklav

which you need to operate the autoclave. Read these instructions carefully

and thoroughly in proper sequence.

Please read all the safety instructions attentively before using the autoclave.

About this manual

Symbol

Dange

Meaning Explanation

Risk to health

Indicates a dangerous situation which if not avoided

could entail slight to life-threatening injuries.

®

41-B and Vacuklav®43-B.

®

41-B and

Observe

Attention

Notice

Table 1: Meaning of the symbols used in this User Manual

Example of emphasis Meaning Explanation

→Double jacket steam

generato

Universal program

Chapter 6 – Logging

Figure 1/(5)

Table 2: Meaning of the emphasized text within this User Manual

without fail

Important

information

Glossary entry Words or phrases marked with an arrow are explained

Software

citation

Cross-reference Reference to another text section within this User

Cross-reference Reference to a detail in a figure – in the example, to

Indicates a dangerous situation which if not avoided

could entail damage to the instruments, the practice

equipment or the autoclave.

Indicates important information.

in the glossary. The glossary is listed alphabetically. It

can be found at the end of this manual.

Words or phrases appearing on the →display of the

autoclave are marked as software citations.

Manual.

Part No. 5 in Figure 1.

r

r

g

e

d

Safety instructions

To operate the autoclave, pay attention to the following safety instructions

Dange

Instruction

Mains cable and power plug

→Double-jacket steam

generato

Setting up, installation,

commissionin

Preparation and sterilization

of textiles and instruments

Program termination

Removal of the items to b

sterilize

Maintenance

Carrying the autoclave

Errors

given below and in the individual chapters of this User Manual.

■ Do not sterilize any liquids with this autoclave.

■ Never damage or change the mains cable or power plug.

■ Never operate the autoclave if the mains cable or power plug are

damaged.

■ Never pull on the mains cable to take it out of the socket. Always take

hold of the power plug itself.

■ The autoclave remains under pressure after being switched off.

Check the pressure display of the manometer located on the

autoclave lower front side.

■ Only have the autoclave set up, installed, and commissioned by

people →authorized by MELAG.

■ Only operate the autoclave in areas which are not subject to

explosion hazards.

■ The electric connections and connections for feed water and used

water may only be completed by a specialist technician.

■ Follow the instructions of the textile and instrument manufacturers for

preparing and sterilizing textiles and instruments.

■ Observe the relevant standards and directives for the preparation and

sterilization of textiles and instruments, e.g. →RKI [Robert Koch

Institute] and →DGSV [German Society for Sterile Supply].

■ Only use wrapping materials and systems which are suitable for

steam sterilization according to the manufacturer's information.

■ Take heed that when opening the door after terminating a running

program, hot water steam can escape out of the chamber, depending

on when the program was terminated.

■ Depending on the time of the program termination, the load might not

be sterile. Observe the clear instructions shown on the →display of

the autoclave. If necessary, sterilize the affected →objects after

rewrapping.

■ Never open the door by force.

■ Use a tray lifter to remove the tray. Never touch the →sterilized items,

the chamber or the door with unprotected hands. The parts are hot.

■ Check the wrapping of the sterilized objects for damage when

removing them from the autoclave. If a wrapping is damaged, wrap

the object again and re-sterilize it.

■ Have the maintenance done only by →authorized persons.

■ Comply with the predetermined maintenance intervals.

■ Two people are necessary to carry the autoclave.

■ Use a suitable carrying strap to transport the autoclave.

■ If repeated error messages occur while operating the autoclave, turn

the device off.

■ Only have the autoclave repaired by →authorized persons.

Safety instructions

Contents

Chapter 1 – Performance Specification.............. 3

Proper use.............................................................. 3

User benefit ............................................................ 3

Overview of sterilization programs.......................... 5

Chapter 2 – Device Description........................... 6

Scope of delivery .................................................... 6

Equipment views .................................................... 7

Effective capacity.................................................... 8

Mountings for the load ............................................ 8

Switch on autoclave................................................ 9

After switching on ................................................... 9

Control panel ........................................................ 10

Acoustical signals ................................................. 12

Overview of menus and symbols.......................... 13

Supply with feed water ......................................... 14

Close the door ...................................................... 14

Chapter 3 – Initial commissioning .................... 15

Conditions for setting up, installing and

commissioning...................................................... 15

Set-up location requirements................................ 15

Connections required ........................................... 16

Prerequisites for initial commissioning.................. 17

Installation and installation report ......................... 17

Chapter 4 – Sterilization..................................... 18

Setting date and time............................................ 34

Determine format for program log files ................. 34

Reading log files correctly .................................... 35

Finding logs .......................................................... 37

Chapter 6 – Maintenance ................................... 38

Cleaning ............................................................... 38

Avoid formation of spots ....................................... 39

Use qualitatively high-grade feed water................ 39

Oil door spindle..................................................... 40

Maintenance ......................................................... 40

Chapter 7 – Operating pauses........................... 41

Sterilization frequency .......................................... 41

Pause times.......................................................... 41

Decommissioning ................................................. 42

Transport .............................................................. 42

Re-commissioning after change of locality ........... 43

Chapter 8 – Function test................................... 44

Automatic function test ......................................... 44

Manual function test ............................................. 44

Testing in daily operation...................................... 44

Vacuum test.......................................................... 44

Bowie & Dick test.................................................. 45

Validation.............................................................. 45

Create prerequisites ............................................. 18

Prepare items to be sterilized ............................... 18

Load the autoclave ............................................... 20

Select program ..................................................... 22

Start program........................................................ 23

Program is running ............................................... 23

Sterilization phase is finished ............................... 25

Drying phase ........................................................ 26

Program is finished............................................... 26

Display batch number........................................... 26

Remove sterilized items ....................................... 26

Storage of sterilized items .................................... 27

Chapter 5 – Logging........................................... 28

Batch documentation............................................ 28

Plug in and remove CF card................................. 29

Automatic immediate log output ........................... 31

Subsequent output of stored logs ......................... 32

Use log printer as output medium......................... 33

Using the PC as output medium........................... 34

Chapter 9 – Errors .............................................. 46

A warning is not an error ...................................... 46

Messages ............................................................. 46

Warning messages............................................... 46

Error messages .................................................... 46

Before you call...................................................... 47

Bad drying results................................................. 50

Glossary.............................................................. 51

Appendix A – Accessories................................. 54

Appendix B – Symbols on the autoclave ......... 55

r

r

Chapter 1 – Performance Specification

In this chapter you learn

under which conditions and for which purpose you should use this autoclave

what benefit you can achieve by using this autoclave

which sterilization programs you can use

Proper use

Application area The autoclave is intended for use in the medical field, e.g. in general

physician and dental practices.

Sterilization tasks According to →DIN EN 13060 this autoclave is considered a Class B

sterilizer. It is suited as a universal autoclave for demanding sterilization

tasks. For instance, you can sterilize narrow-bore instruments and

transmission instruments – wrapped or unwrapped – and larger quantities

of textiles.

Dange

Attention

Universal use The autoclave sterilizes on the basis of the →fractionated vacuum

Large quantities

Small time expenditure

No pause times

Overheating protection

Clean feed wate

Observe the following instructions for using the autoclave:

■ Do not sterilize any liquids with this autoclave. It is not approved for

the sterilization of liquids.

In case of non-observance, the consequences could be →delayed boiling,

damage to the autoclave and burns.

■ Use the autoclave only for the intended purposes outlined in the

related technical documents and only in connection with the devices

and components recommended by MELAG.

■ The sterilization of instruments and textiles with this autoclave, like the

foregoing instrument sterilization, is only to be done by competent

personnel.

■ Only use instruments, wrappings and textiles which are suitable for

steam sterilization according to the manufacturer's information.

In case of non-observance the consequences can entail damage to the

autoclave and/or to the →items to be sterilized.

User benefit

method. This ensures the complete and effective wetting or penetration of

the →items to be sterilized with saturated steam. This method makes it

possible to sterilize all kinds of loads which occur in a physician's medical

practice.

To generate the sterilization steam, the autoclave uses a →double jacket

steam generator. Once heated up, it provides permanent steam. The walls

of the →sterilization chamber thus have a defined temperature. The

sterilization chamber is protected from overheating and you can

consecutively sterilize large quantities of instruments or textiles very

rapidly and achieve excellent drying results.

The autoclave works with a one-way feed water system. This means that it

uses fresh purified →feed water for every sterilization run. The quality of

the feed water is constantly monitored via integrated →conductivity

3

Chapter 1 – Performance Specification

y

d

d

g

y

k

measurement. This prevents stains on instruments and soiling of the

autoclave, assuming the instruments have been carefully prepared.

Automatic feed water suppl

Optimal drying for wrappe

items to be sterilize

Optimized total operatin

High degree of safety b

extensive safety devices

Additional function chec

Effective batch

documentation

The supply with purified →feed water for the steam production is

automatically provided from an internal supply tank or a water treatment

unit (e.g. MELAdem® 40, MELAdem

®

47).

The →items to be sterilized are dried by the →vacuum. (→vacuum

drying). This way you achieve optimal drying results for wrapped objects

as well.

The autoclave works with an →electronic parameter control. This way the

time

autoclave optimizes the total operating time of a program depending on

the load.

The autoclave checks the pressure and temperature in the sterilization

chamber at all times and does not permit the door to be opened in case of

overpressure in the chamber. The motor-operated automatic door lock

opens the door by slowly turning the locking spindle and holds the door

while it opens. Pressure compensation takes place even if there is any

difference in pressure until the door is completely opened.

The quantity and quality of the →feed water is checked.

A →process evaluation system is integrated in the electronics of the

autoclave. During a program it compares such process parameters as

temperatures, times and pressures with each other. It monitors the

parameters with respect to their limit values at activation and control and

guarantees a safe and successful sterilization.

A monitoring system checks the device components of the autoclave with

respect to their functional reliability and their plausible interaction.

If one or more parameters exceed defined limits, the autoclave issues

warnings or error messages, and if necessary aborts the program. In the

event of an automatic program abort, observe the information on the

display.

You can conduct an additional function check at any time with the help of

test programs.

Use the vacuum test to check the autoclave for leaks in the steam system.

Use the →Bowie & Dick test to check whether there is sufficient steam

penetration for porous material to be sterilized (e.g. textiles).

The autoclave has an internal log memory. All data of the completed

sterilization programs are automatically stored here.

You can read out the internal log memory immediately after the end of the

program, or at a later time. You determine whether the logged data are

issued to one or several different output media (e.g. log printer

MELAprint

®

42, MELAflash CF card, computer).

4

Chapter 1 – Performance Specification

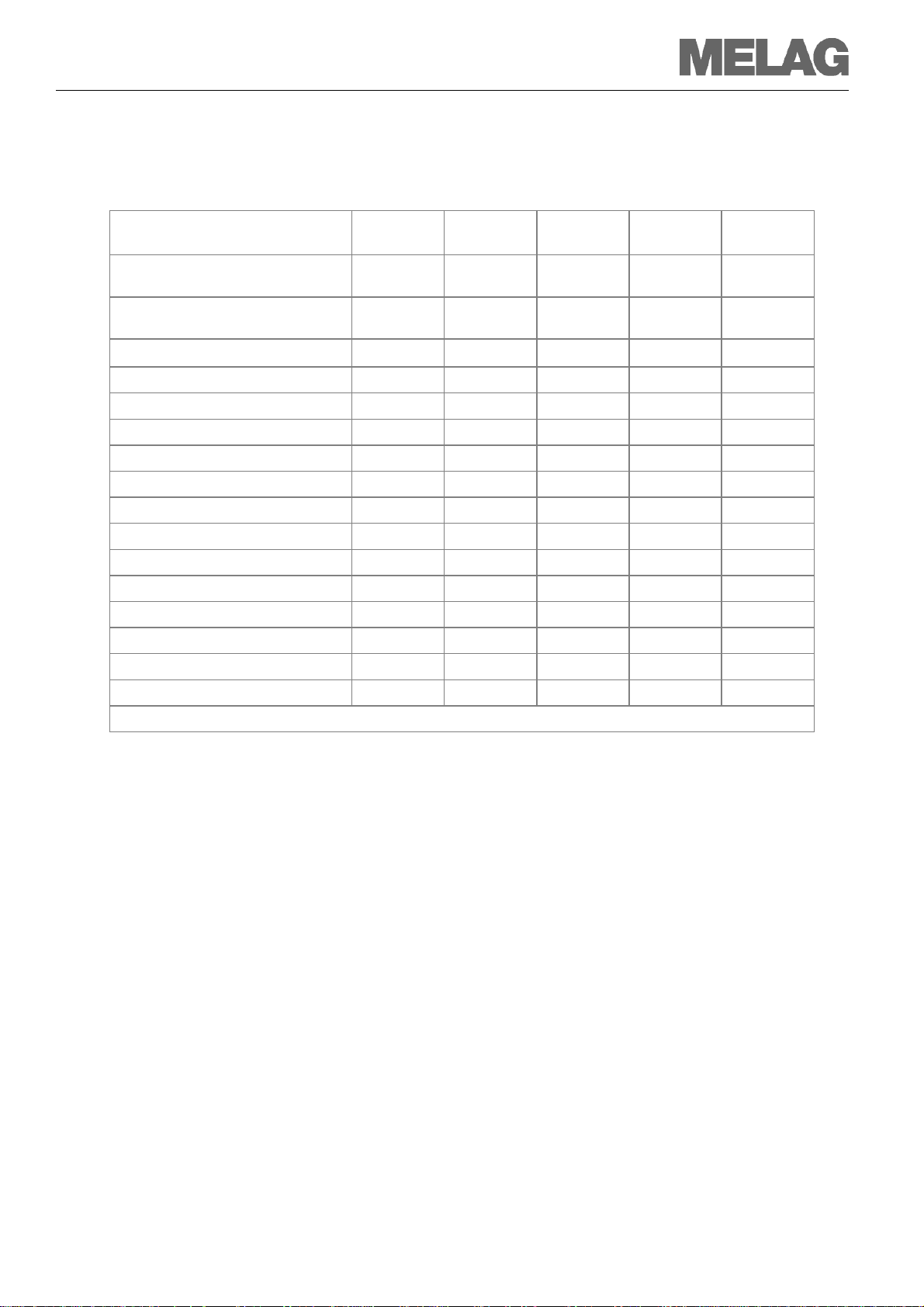

Type tests

Program type as per

→DIN EN 13060

→Dynamic pressure test of the

sterilization chamber

→Air leak X X X X X

→Empty chamber test X X X X X

→Solid load X X X X X

→Porous partial load X X X

→Porous full load X X X

→Hollow body B X X X X X

→Hollow body A X X X X

→Simple wrapping X X X X

→Multiple wrapping X X X

Drying →solid load X X X X X

Drying →porous load X X X

Sterilization temperature 134 ˚C 134 ˚C 134 ˚C 121 ˚C 134 ˚C

Sterilization pressure 2 bar 2 bar 2 bar 1 bar 2 bar

Sterilization time 5.5 minutes 3.5 minutes 3.5 minutes 20.5 minutes 20.5 minutes

X = Conformity with all applicable sections of the standard →DIN EN 13060

Table 3: Overview of sterilization programs

Overview of sterilization programs

UniversalProgram

Type B Type B Type S Type B Type B

X X X X X

QuickProgram B

QuickProgram S

GentleProgram

PrionProgram

5

y

Chapter 2 – Device Description

In this chapter you learn

which components are included in the standard scope of delivery

which components the autoclave contains

what safety devices the autoclave has

how the operating elements are designed and how you should use them

how the menus of the user interface are structured

which acoustical signals the autoclave emits

what kind of water supply the autoclave needs

Standard scope of delivery

Optionall

Scope of delivery

®

Vacuklav

User Manual

Technical Manual

Record of installation and setting up

Warranty certificate

Pressure device directive certificate

Manufacturer’s inspection report

1 Mounting for trays or cassettes

1 hose for draining the internal storage tank

1 Tray lifter

1 Allen wrench for emergency opening of the door

1 Torx wrench to remove the carrying strap

Trays

Standard tray cassette and lifter

Additional tray mounts

MELAflash CF card

MELAflash CF card reader

41-B or Vacuklav®43-B

6

Chapter 2 – Device Description

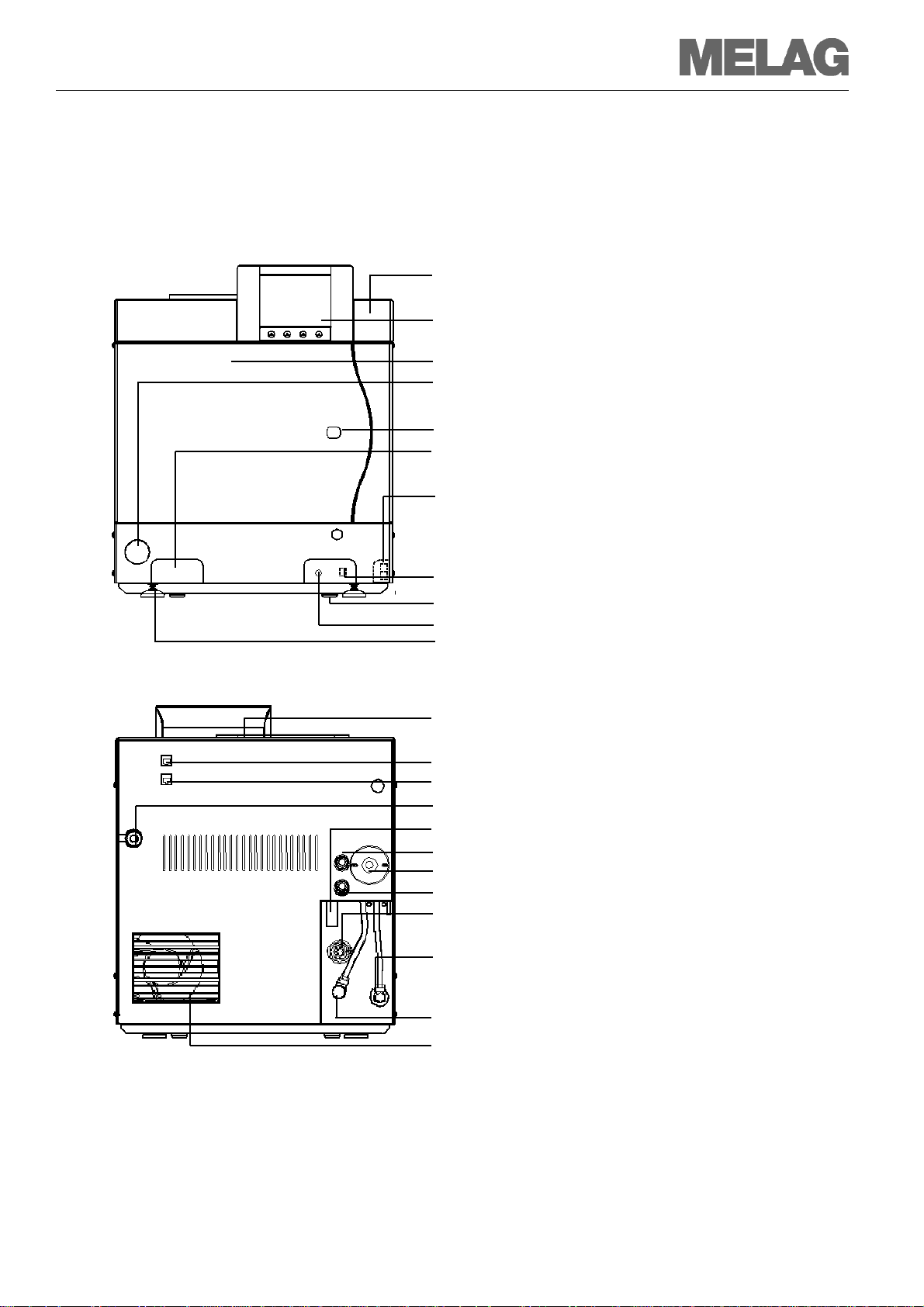

Front view

<

Equipment views

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Protective cap for slot of the →CF card

Control panel

Door (pivots opens to the left)

Protective cap for manometer to display the pressure of

the →double jacket-steam generator

Cap for emergency opening of the door

Draining hose covering of the supply tank

Mains switch (concealed, accessible from the side)

Ethernet-1 data connection*

Back foot of the unit (fixed)

Reset button overheating protection*

Front foot of the unit (adjustable)

*behind covering

Rear view

Figure 1: Front and rear view

Tank filler cap

(12)

Ethernet-2 data connection

(13)

Ethernet-3 data connection* (can be retrofitted)

(14)

Power cable

(15)

Emergency overflow

(16)

Safety valve, chamber

(17)

Sterile filter

(18)

Safety valve, double jacket

(19)

One-way drain

(20)

Purified feed water inlet (for MELAdem®; swivelling

threaded fitting for hose 8x1, alternatively straight)

(21)

Connection pressure discharge

(22)

(23)

Cooler

7

Chapter 2 – Device Description

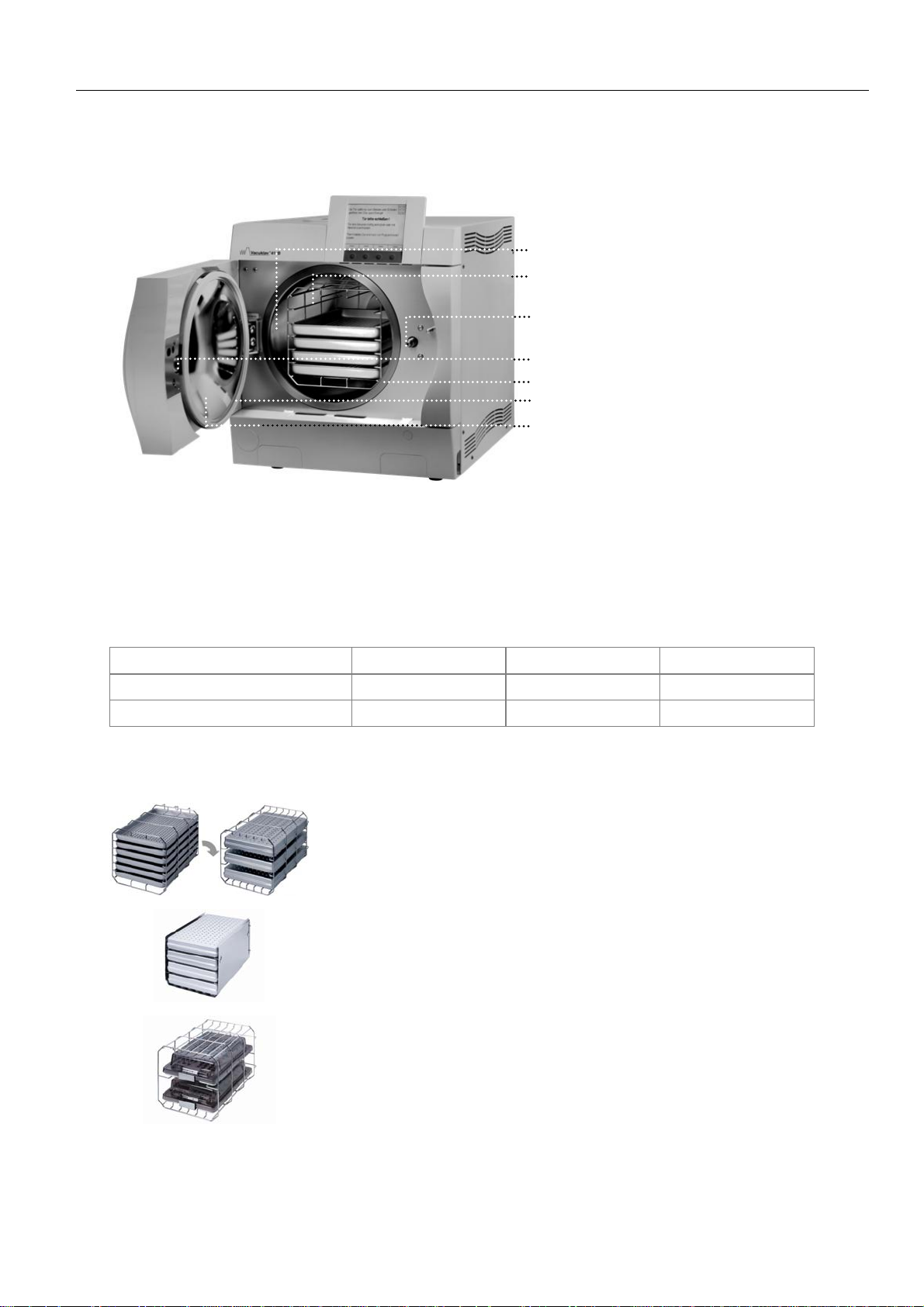

Interior view

Figure 2: Interior view

Chamber

(1)

Mounting to hold the load

(2)

Door spindle

(3)

Threaded bushing

(4)

Chamber sealing surface

(5)

Door seal

(6)

Door plate

(7)

Effective capacity

The autoclaves Vacuklav®41-B and Vacuklav®43-B differ only with respect

to the respective depth of the units. As a result, their effective capacities

are different.

Vacuklav®41-B 25 cm 35 cm 18 litters

Vacuklav®43-B 25 cm 45 cm 22 litters

Table 4: Dimensions of the effective capacity (usable space)

Diameter Depth Volume

Mountings for the load

The autoclave is always delivered with a mounting to hold trays or

cassettes.

The mounting (C) is standard and can hold either six trays or three

standard tray cassettes rotated by 90˚.

Figure 3: CMounting C

Figure 4: Mounting B

The mounting (B) can hold four standard tray cassettes or four trays.

The mounting (D) can hold two high cassettes (e.g. for implants) or four

trays rotated by 90°.

Figure 5: Mounting D

8

Chapter 2 – Device Description

r

e

Dange

Switch on autoclave

Observe the following precautionary measures when handling the mains

cable and power plug:

■ Never splice or modify the mains cable.

■ Never bend or twist the mains cable.

■ Never pull on the mains cable to take it out of the socket. Always take

hold of the power plug itself.

■ Never place any heavy objects on the mains cable.

■ Never run the mains cable over places where it could be squeezed

(e.g. doors or windows).

■ Do not run the mains cable along a heat source.

■ Do not use any nails, staples or similar objects to fixate a cable.

■ If the mains cable or the power plug is damaged, turn off the

autoclave. Mains cables or power plugs may only be replaced by

→authorized persons.

If these points are not observed, the cable or plug can be damaged and/or

a fire or electrical shock might occur. Serious injuries could be the

consequence.

Plug power plug into th

socket

Switch on mains Turn the mains switch on to power the autoclave (page 7, Figure 1/(7))

Preparation time After the autoclave was switched on at the mains switch (page 7, Figure

If the autoclave is still not connected to the supply mains, plug the power

plug into the socket.

After switching on

On the →display you see the start screen Welcome. The →software of the

autoclave is →initialized and its device components are checked.

The level of the →feed water in the →double jacket steam generator is

automatically checked and if necessary maintained by the feed procedure

(feed pump runs). The feed water is preheated for generating steam.

1/(7)), it requires a →heating-up period for the initial preheating of the

→double jacket-steam generator. For normal operation, this time is

Vacuklav®41-B 9 minutes

Vacuklav®43-B 13 minutes

The main menu appears on the →display. As soon as the device is

switched on, the default program selection is Universal-Program.

9

Chapter 2 – Device Description

Control panel

The control panel consists of a display and four membrane keys. The

→display can show 320 x 240 pixels.

(1)

Key 1 – serves primarily for navigation

(2)

Key 2 – serves primarily for navigation

(3)

Key 3 – serves primarily for selecting options

(4)

Key 4 – serves primarily for selecting options

(5)

General display areas

(6)

Key1 Key2 Key3 Key4

Figure 6: Control panel

Key settings You operate the autoclave by pressing the membrane keys. The keys are

differently allocated with functions depending on the operating situation

(soft keys). You can see the current key settings in the display field directly

above a key.

Area for displaying the current allocation of the respective

membrane key directly underneath.

Area with membrane keyboard

(7)

Use key 1 and 2 primarily to navigate within the menu. These keys are

forthwith called "navigation keys".

Keys 1 and 2 can also be used to select additional functions.

Use keys 3 and 4 to select the option displayed directly above this key.

Hot keys Certain →hot keys are defined for individual functions. There are hot keys

for which you are notified on the →display, and other hot keys which are

hidden. These are not shown on the display.

Several of the important hot keys are given below:

10

Chapter 2 – Device Description

y

y

Current operating situation Hot keys Function/explanation

After the operator has terminated the

program

Briefly simultaneously

press key 1

Opens the door after a program termination

(see page 25, Manually terminate program)

(CONFIRM) and key 3

(OPEN)

DOCU Menu/Logging list Press each one of the

keys 1 to 4

Immediately before starting a

program

Immediately before starting a

program

Press key 1 for longer

than one second

Press key 4 (START)

for longer than one

second

In all menus and displays Briefly press key 2 and

3 simultaneously

Sort the list:

Key 1 – by →batch

Key 2 – by date

Key 3 – by program

Key 4 – by success

(see page 33, Logging list

Additional drying (see page 23, Additional

drying

Pre-selection start time (see page 23)

Running program Press key 3

Table 5: Important Hot Keys

Acoustical signals When you press a key, your entry is confirmed by a short acoustical

signal.

Time dela

There can be a very brief time delay between pressing a key and the

corresponding display.

Buffered entr

Despite this time delay you can press the keys quickly after one another,

once you've gained a certain routine with the autoclave. The autoclave has

an input buffer. This buffer registers which key was pressed in what

sequence, and implements the corresponding functions.

Diverse messages

Diverse messages are issued in the right upper corner of the →display.

Several examples are shown below.

Messages

Messages are marked by an envelope icon. Such information supports

you in the operation of the autoclave. Messages are not error messages or

warning messages.

Warning messages

Warning messages help you to ensure a smooth operation and to

recognize undesirable conditions. Warning messages are not error

messages.

Status display;

Display automatically returns to the previously

displayed screen after 30 seconds.

Displays details to the currently running program

11

Chapter 2 – Device Description

Error messages

Reverse (selected) display You can only start programs or change settings if these are marked as

Error messages indicate an error or a malfunction.

selected, indicated by reverse display (highlighted).

Example:

not marked (normal display)

marked (reverse display)

Acoustical signals

The autoclave emits acoustical signals. The signals are meant to catch

your attention and serve as sources of information. The time interval

between two signals is 0.5 seconds.

Signal Meaning

1 x 0.1 seconds Confirms the correct pressing of a key

1 x 0.5 seconds Warning or communication

2 x 0.5 seconds Door is open (sounds every 30 seconds)

3 x 0.5 seconds Attention, program abort or end of abort reached

5 x 0.5 seconds Program successfully finished

8 x 0.5 seconds Program for unwrapped instruments has been started

10 x 0.5 seconds Fault

Table 6: Overview of acoustical signals

12

Chapter 2 – Device Description

Overview of menus and symbols

Menus Symbols

Main menu

├ Universal-Program

├ Quick-Program B

├ Quick-Program S

├ Gentle-Program

├ Prion-Program

├

SPECIAL menu

│ ├ Vacuum test

│ ├ Bowie & Dick test

│ ├ Conductivity measurement

│ ├ Draining

│ ├

│ │ ├ Output of stored logs on

│ │ └ ├ Logging list

│ │ ├ Last log

│ │ ├ Daily log file

│ │ ├ Log files of the week

│ │ ├ Log files of the month

│ │ ├ All program logs

│ │ ├ Last error log

│ │ ├ Error logs for the day

│ │ ├ Error logs for the week

│ │ ├ Error logs for the month

│ │ ├ All error logs

│ │ ├ Legend log file

│ │ ├ Status log

│ │ ├ System log

│ │ └ CF card formatting

│ └ Return to Main Menu

├ SETUP menu

│ ├ Water supply

│ ├ Automatic logging

│ │ ├ CF card

│ │ ├ Computer

│ │ ├ MELAprint

│ │ ├ Immediate output

│ │ ├ Batch format

│ │ └ LAN TCP/IP FTP

│ │ │ └

│ │ └ Graphic logs

│ │ └

│ ├ Date

│ ├ Display contrast

│ ├ Language

│ ├ Energy-saving mode

│ └ DIAGNOSIS+SERVICE…

│ └

└

INFO Menu

└ (many important information texts)

Table 7: Overview of menus and symbols

DOCU menu

Universal-Program

Quick-Program B

Quick-Program S

Gentle-Program

Prion-Program

SPECIAL Menu

Vacuum test

Bowie & Dick test

Conductivity measurement

Draining double jacket

DOCU menu

Return to Main Menu

SETUP menu

INFO menu

Additional drying

Message

Warning message

Error message

Diagnosis and Service

DEMO Mode

13

Chapter 2 – Device Description

l

k

k

5

r

t

7

r

Feed water with interna

storage tan

Internal supply tan

Distilling unit MELAdest

Feed water with wate

treatment uni

Water treatment units

MELAdem

®

MELAdem®4

Notice

Supply with feed water

The autoclave requires →demineralized or →distilled →feed water for

generating steam. The feed water supply is provided either with the

internal supply tank or with a water treatment unit (e.g. MELAdem

MELAdem

If you employ the internal supply tank for the feed water supply, you must

fill it manually from time to time. Employ only water available on the market

according to →VDE 0510 as →feed water.

The internal supply tank holds maximum 5 liters. This quantity of →feed

water suffices for up to 7 sterilizations.

®

6

With the MELAdest®65 distilling unit, you can produce →feed water in the

practice cost effectively.

A water treatment unit is connected to the drinking water grid. It produces

the →feed water required for generating the steam for the autoclave. The

purified feed water connection for the autoclave is directly connected to

the water treatment unit.

If you use a water treatment unit, then there is always sufficient feed water

available. You no longer need to fill the water storage tank.

The water treatment units MELAdem®40 and MELAdem

40 and

optimal purified feed water quality for the autoclave. The selection of the

respective unit depends on the number of sterilizations per day and the

respective loads. Every MELAG autoclave can be supplemented with a

water treatment unit.

Please first consult with MELAG if you would like to use water treatment

units from other manufacturers.

®

47). The autoclave automatically sucks in the feed water.

®

47 produce the

®

40 /

Close the door

When closing the door of the autoclave, observe the following instructions:

Attention

If you don't observe this instruction, you may impair the functional

Locked doo

Notice

■ Do not press the door too hesitantly against the autoclave housing.

■ Hold the door pressed closed for at least 3 seconds.

■ Under no circumstances should you slam the door shut.

reliability of the door lock mechanism.

The autoclave has an automatic motor-driven door lock with threaded

spindle.

In order to lock the door, press it tightly closed.

The door locks pressure-proof once the program is started.

Inputs at the →display of the autoclave are only possible when the

autoclave door is locked.

Leave the door open only for loading and unloading the autoclave. If you

keep the door closed, you will save energy.

14

Loading...

Loading...