Operating Manual

for the

Autoclave

Vacuklav31 B

Dear Doctor:

Thank you very much for the trust which you have shown by purchasing this autoclave.

For 50 years now, MELAG — a medium-sized family-owned and -operated business —

has specialised in the production of sterilization equipment for medical practice. During

this period, MELAG has succeeded in becoming a leading manufacturer of sterilization

equipment. More than 335,000 MELAG units sold throughout the world testify to the exceptional quality of our products — which are manufactured exclusively in Germany.

As all other MELAG products, this autoclave was manufactured and tested according to

strict quality criteria. Before placing this unit into operation, please carefully read this Operating Manual. The long-term functional effectiveness and the preservation of the value

of your autoclave will primarily depend on careful preparation of instruments before sterilization, and on proper care of the unit.

The staff and management of MELAG

The functional effectiveness and the preservation of

value of this unit depend on:

1. Proper preparation of the instruments to be sterilized

2. Proper care of the autoclave

3. The use of sufficiently pure demineralized / distilled water

DESCRIPTION OF THE UNIT ...........................................................................................................................6

1.1 Views of the unit...................................................................................................................................6

1.2 Technical data......................................................................................................................................6

1.2.1 Primary technical data ..................................................................................................................6

1.2.2 Capacity / weights.........................................................................................................................6

1.2.3 Operating media ...........................................................................................................................6

1.2.4 Operational parameter ..................................................................................................................6

1.2.4.1 Programs / operating times....................................................................................................6

1.2.4.2 Consumption of energy / water..............................................................................................6

1.3 Installation examples............................................................................................................................7

1.4 Control panel........................................................................................................................................8

1.5 Performance features of this autoclave ...............................................................................................8

1.5.1 Preliminary air removal by sub-atmospheric pulsing ....................................................................8

1.5.2 Sterilization and disinfection functions..........................................................................................8

1.5.3 Separate steam generation...........................................................................................................8

1.5.4 One-way system / conductivity measurement / automatic re-supply of water..............................8

1.5.5 Electronic parameter control .........................................................................................................8

1.5.6 Vacuum drying ..............................................................................................................................8

1.5.7 Pre-heating ...................................................................................................................................9

1.5.8 Documentation of results ..............................................................................................................9

2 INSTALLATION ..........................................................................................................................................9

2.1 Requirements for installation................................................................................................................9

2.2 Transport straps ...................................................................................................................................9

2.3 Levelling ...............................................................................................................................................9

2.4 Mains power supply .............................................................................................................................9

2.5 Outlet connection for one-way water .................................................................................................10

2.6 Internal water supply with demineralized / distilled water ..................................................................10

2.7 Connection of a water treatment system ...........................................................................................10

2.8 Emptying the water storage tank........................................................................................................10

3 PLACING THE AUTOCLAVE INTO OPERATION ..................................................................................10

3.1 Printer connection and initialisation (optional) ...................................................................................10

3.1.1 Connection of the MELAprint

3.1.2 Initialisation of the printer / setting for immediate printout ..........................................................10

3.2 Vacuum test .......................................................................................................................................11

3.3 Trial run ..............................................................................................................................................12

3.4 Installation log – sent to MELAG........................................................................................................12

3.5 Safety instructions..............................................................................................................................13

4 FOR EACH STERILIZATION CYCLE ......................................................................................................14

4.1 Water and power................................................................................................................................14

4.1.1 Demineralized / distilled water ....................................................................................................14

4.1.2 Power supply ..............................................................................................................................14

4.2 Preparation of instruments .................................................................................................................14

4.3 Loading the autoclave ........................................................................................................................15

4.4 Closing the door .................................................................................................................................16

4.5 Selection of the program ....................................................................................................................16

4.6 Start of program .................................................................................................................................17

4.7 Program sequence.............................................................................................................................17

Printout of cycle log.......................................................................................................................................19

4.8 Removing the sterilized items ............................................................................................................19

4.9 Sterile storage ....................................................................................................................................19

4.10 Sterilization frequency / interval periods ............................................................................................20

4.11 Manual abort of the program..............................................................................................................20

®

42 ................................................................................................10

Page

2

Operating Manual for the Vacuklav

4.11.1 Aborting during the sterilization / disinfection phases.................................................................20

4.11.2 Interruption of a drying phase .....................................................................................................21

4.13 Response in case of warnings and error messages ..........................................................................22

4.14 Operational shutdowns ......................................................................................................................22

5 PLACING THE AUTOCLAVE OUT OF OPERATION / TRANSPORT /

PUTTING THE AUTOCLAVE BACK INTO SERVICE ....................................................22

6 SPECIAL FUNCTIONS.............................................................................................................................23

6.1 Display of water quality (conductivity) / pre-heat temperature of the sterilization chamber..............23

6.2 Selection for additional drying............................................................................................................23

6.3 Logging / documentation of sterilization + disinfection cycles ...........................................................23

6.3.1 Output of logs..............................................................................................................................23

6.3.1.1 External printer ....................................................................................................................23

6.3.1.1.1 Connection of the external printer Melaprint

6.3.1.1.2 Initialization of the printer...................................................................................................24

6.3.1.2 Connection to an external PC..............................................................................................25

6.3.1.2.1 Installation..........................................................................................................................25

6.3.1.2.2 Initializing the output on your PC.......................................................................................25

6.3.1.3 No printer .............................................................................................................................25

6.3.2 Immediate printout option: YES or NO .......................................................................................25

6.3.3 Printing out stored cycles at a later time.....................................................................................26

6.3.4 Printing out all stored cycles .......................................................................................................27

6.3.5 Displaying the contents of the printer memory ...........................................................................28

6.3.6 Deleting stored cycles from the memory ....................................................................................29

6.3.7 Test printout ................................................................................................................................30

6.4 Setting the date and time of day ........................................................................................................31

6.5 Automatic pre-heating ........................................................................................................................32

6.6 Total-cycle counter.............................................................................................................................33

6.7 Changing the setting for supply of demineralized / distilled water .....................................................34

6.8 Program modifications .......................................................................................................................34

®

42................................................................23

®

31-B

7 FAULTY OPERATION / MALFUNCTIONS..............................................................................................35

7.1 What to do in case of malfunctions ....................................................................................................35

7.2 Malfunctions without an error message .............................................................................................35

7.2.1 An empty display window............................................................................................................35

7.2.2 The autoclave uses too much demineralized / distilled water ....................................................35

7.2.3 Poor drying..................................................................................................................................35

7.3 Warning messages ............................................................................................................................36

7.4 Error messages..................................................................................................................................38

8 PRESERVING THE VALUE OF THIS DEVICE........................................................................................41

8.1 Preparation of instruments .................................................................................................................41

8.2 Drag-in rust (rust brought into the autoclave) ....................................................................................41

8.3 Regular care of the Vacuklav

8.3.1 Cleaning......................................................................................................................................42

8.3.2 Use of demineralized / distilled water .........................................................................................42

8.4 Monitoring the functions of the autoclave ..........................................................................................43

8.4.1 Continuous monitoring of sterilization progress..........................................................................43

8.4.2 Periodical bacteriological monitoring (every 6 months) ..............................................................43

8.4.3 Periodic maintenance recommendation .....................................................................................43

9 ANNEX ......................................................................................................................................................44

9.1 Instructions on drying .........................................................................................................................44

9.1.1 The drying process in sterilization containers.............................................................................44

9.1.2 Textiles........................................................................................................................................45

9.1.3 Instruments .................................................................................................................................46

9.1.4 Loading the autoclave.................................................................................................................46

9.1.5 Loading of containers with soft sterilization packages................................................................46

9.1.6 Stacking of sterilization containers .............................................................................................47

9.1.7 Removing sterilized items...........................................................................................................47

9.1.8 Further improvement of the drying process ................................................................................47

®

31-B....................................................................................................42

10 INDEX........................................................................................................................................................48

Seite 3

Page 4

®

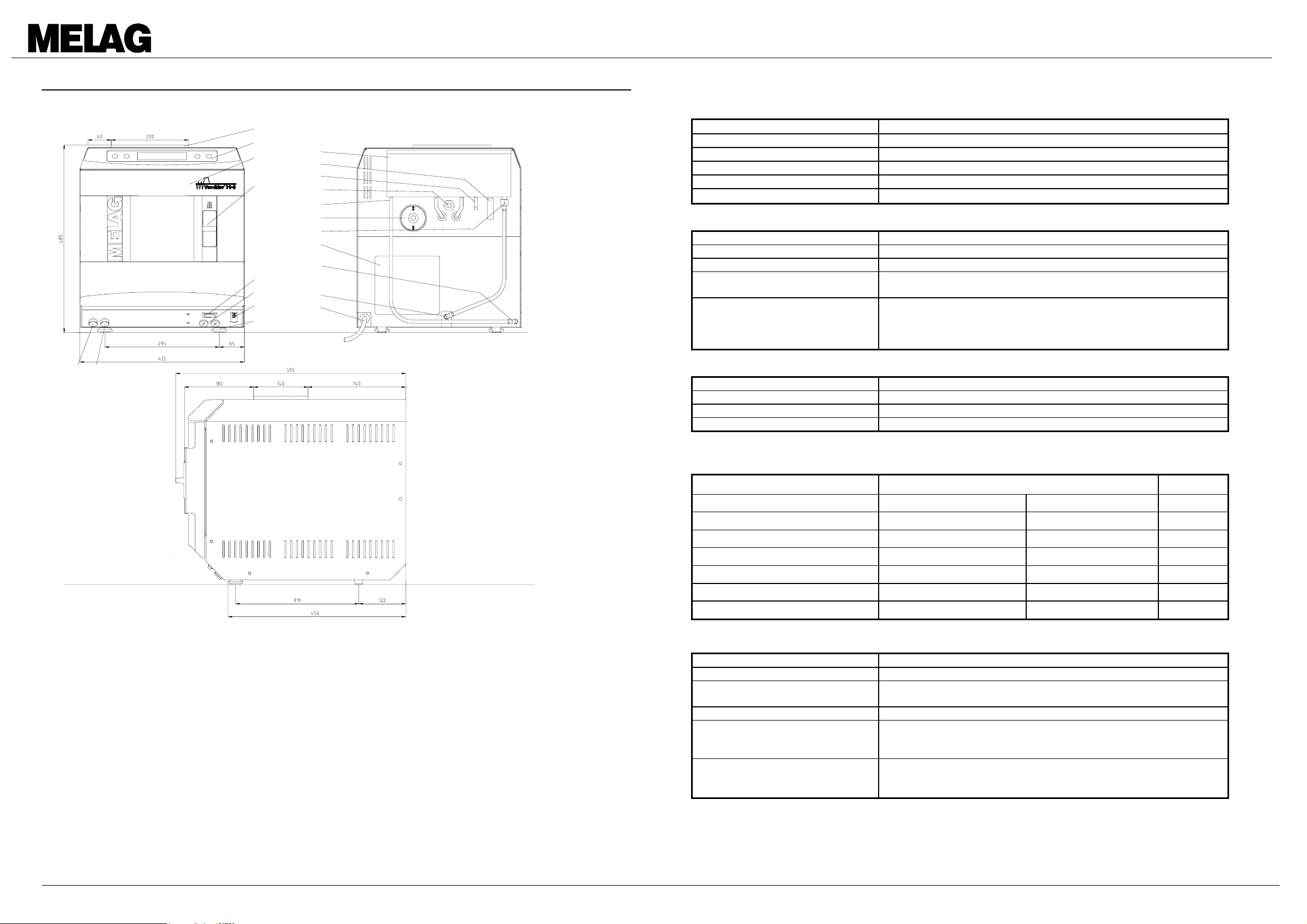

1 Description of the unit

1.2 Technical data _______________________________________________________

1.1 Views of the unit __________________________________________________________

19

20 21

Frontansicht

18

17

16

15

14

13

12

10

11

1

2

Rückansicht

3

4

5

6

7

8

9

1.2.1 Primary technical data _____________________________________________________________

Sterilization chamber ( × depth)

Power ratings

Sterilization pressure / temp.

Disinfection pressure / temp.

Maximum load

Outside dimensions

25 cm × 36 cm

2400 W / 230V AC / 10.4 A / 50 ... 60 Hz

2 bar / 134°C; 1 bar / 121°C

0.3 bar / 105°C

5 kg of instruments or 1.8 kg of textiles

48.5 cm high × 42.5 cm wide × 59.5 cm deep

1.2.2 Capacity / weights_________________________________________________________________

Weight of unit (without load)

43 kg

Volume of chamber 17.6 litre

Maximum loading 5 kg of instruments or 1.8 kg of textiles

Water storage tank (demineralized /

Fresh-water side: 5 litres (approx. 7 cycles); drain side: 3 litres

distilled water)

Loading variations Mount “B” for max. 4 norm tray cassettes or 4 MELAG trays

Mount “C” for max. 3 norm tray cassettes or 6 MELAG trays

MELAG sterilization containers: 28M,G, 23R, 15K,M,G, 17K,R;

MELAG Package Holders

1.2.3 Operating media __________________________________________________________________

Power ratings:

Electricity ratings 230 V AC / 10.4 A / 50 ... 60 Hz

Power ratings 2400 W; fuse = 16 A; RCCB (residual current circuit breaker); 30 mA

aqua dem / aqua dest

Demineralized / steam-distilled water in accordance with VDE 0510

Seitenansicht

Fig. 1 Views of the Vacuklav

31-B

1 Water storage tank 11 Power cable

2 Emergency overflow (OUT) 12 Front adjustable feet of the unit

3 One-way drain (OUT) 13 Serial data and printer interface (RS 232)

4 Spring-operated safety valve 14

5 Connection for demineralized / distilled

Fuses for the unit: 2 × 16 A / FF

15 Power switch

water (OUT)

6 Sterile filter 16 Sliding-lock handle

7 Connection for pressure release for

17 Hinged door (opens to the left)

water storage tank (IN)

8 Cooler 18 Operator’s control and monitoring panel

9 Connection for demineralized / distilled

water (IN) (quick-fitted threaded

connection for 6 × 1 hose)

19 Cover to water tank

20 Drain hose for water tank, drain side (OUT)

21 Drain hose for water tank, demineralized-water side (OUT)

10 Connection for pressure release (OUT)

1.2.4 Operational parameter _____________________________________________________________

1.2.4.1 Programs / operating times_________________________________________________________

Program Operating time (not including drying period) Drying

Hot start; load = 0.5 kg Hot start; load = 5 kg

"Quick program" (134°C, 2 bar) 12 min 20 min 10 min

"Universal program" (134°C, 2 bar) 23 min 38 min 15 min

"Gentle program" (121°C, 1 bar) 41 min 50 min (1,8 kg textiles) 20 min

" Prion Program" (134°C, 2bar ) 40 min 55 min 15 min

"Bowie & Dick" (134°C, 2 bar) 33 min 40 min 5 min

"Vacuum Test" — 18 min (empty) --

1.2.4.2 Consumption of energy / water _____________________________________________________

Power consumption

"Pre-heating"

One-time heating up to pre-heating

approx. 0.12 kWh ( = 0.03 DEM1 )

temperature (134°C)

"Stand by" operation per hour approx. 0.2 kWh ( = 0.05 DEM)

"Program cycle" (including drying) 0.3 kWh (= 0.075 DEM) for “Quick program” / hot start / light load, up

to ...

Consumption of demineralized /

distilled water

1.1 kWh ( = 0.275 DEM) for “Gentle program” / cold start / full load

300 ml ( = 0.06 DEM

500 ml ( = 0.10 DEM) for “Universal program”

2.

) for “Quick program”

600 ml ( = 0.12 DEM) for “Gentle program”

1

Based on following price for one kWh: = 0.25 DEM

2

Based on following price for one litre of distilled water from the MELAdest®65: 0.20 DEM

Page 6

AAA

A

Operating Manual for the Vacuklav

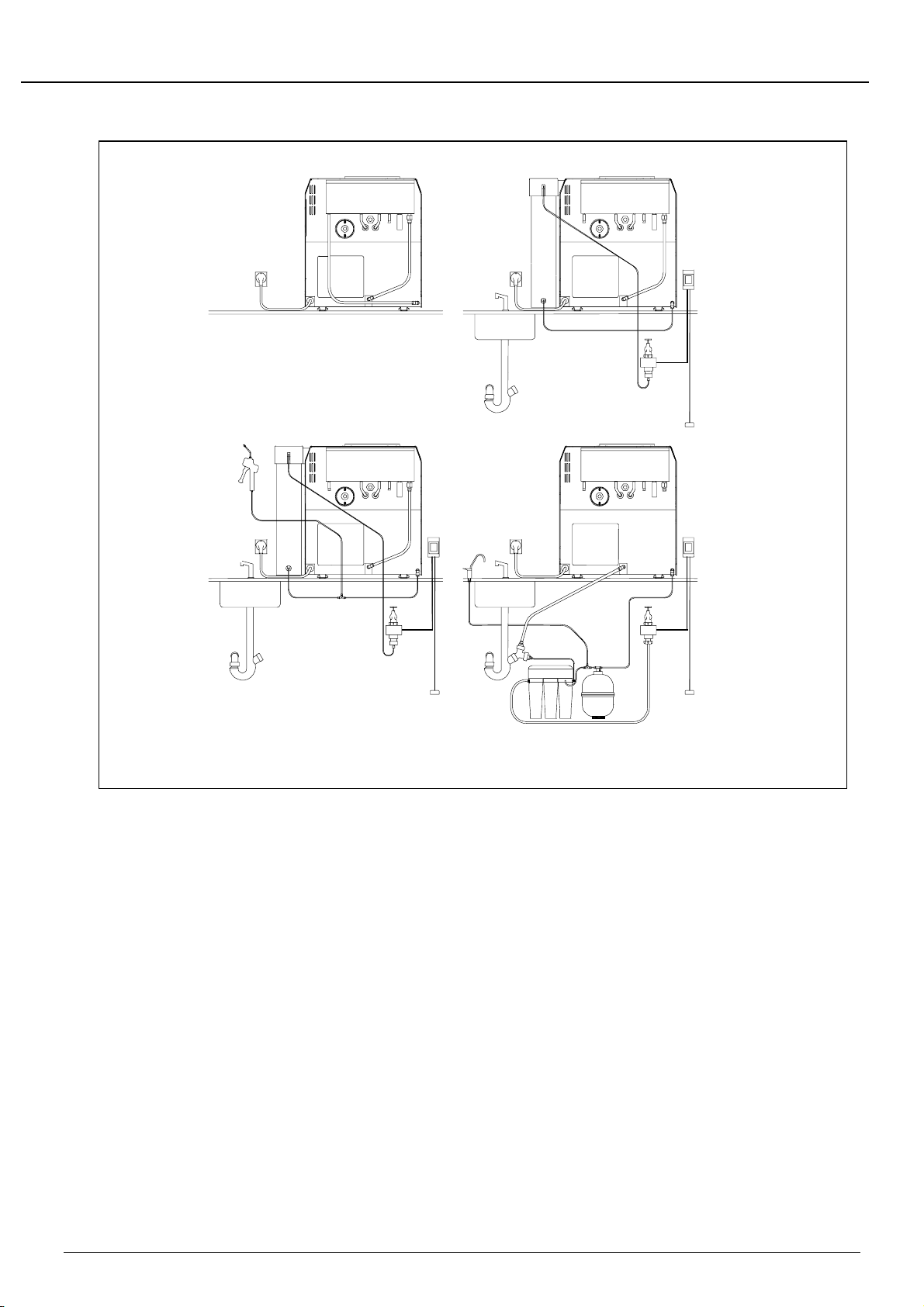

1.3 Installation examples_____________________________________________________

®

31-B

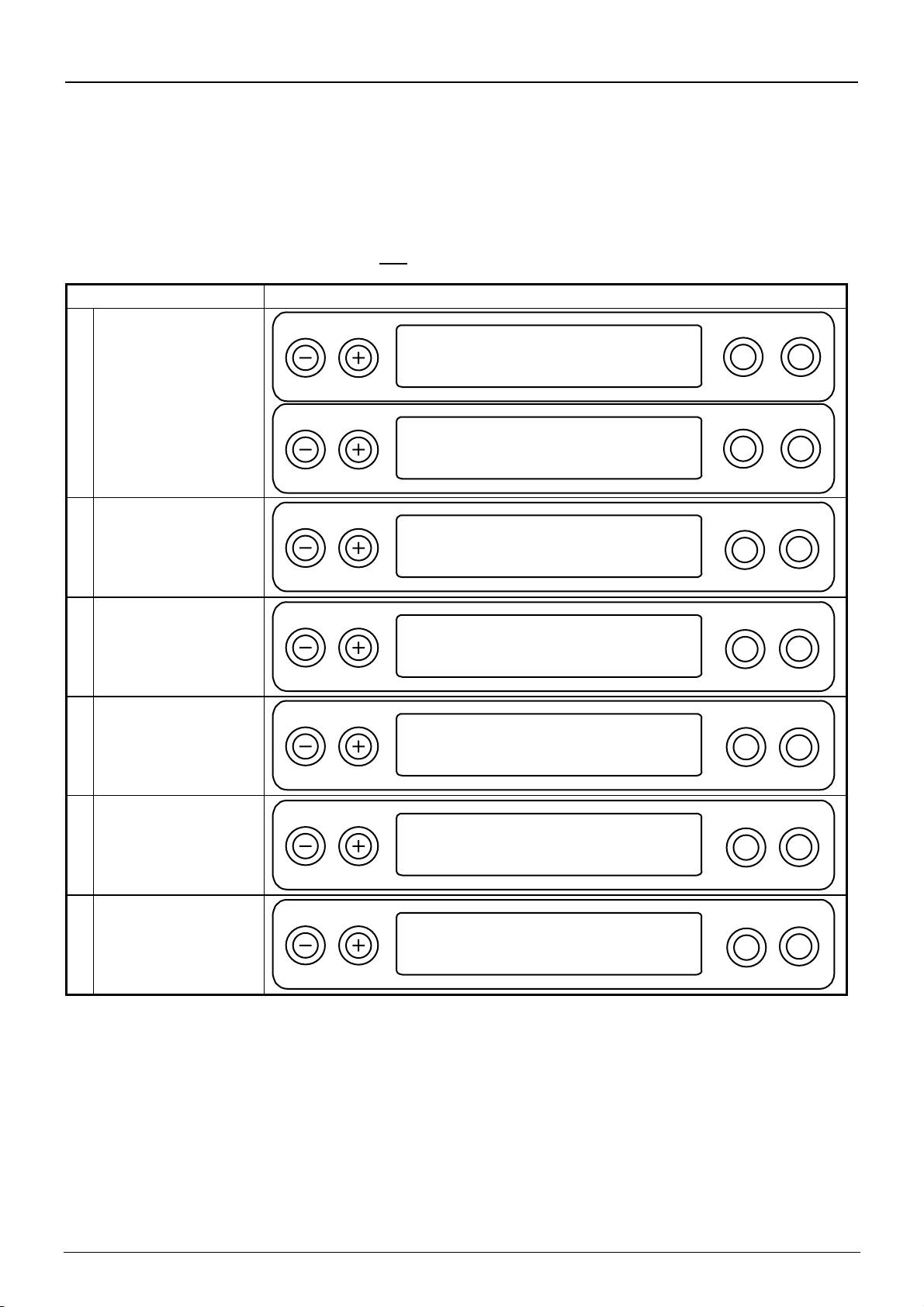

Example 1

Example 3

B

Example 2

B

Example 4

B

Fig. 2. Installation examples for Vacuklav

*1 Alternative: a separate drain with stench trap, instead of the double-chamber trap.

Example 1

Vacuklav31-B rear view

Standard version = version as supplied

(with internal supply of water)

Leak detector with shutoffvalve and sensor

Example 3

Vacuklav31-B rear view

MELAdem

with manual draining of the waste-water tank

MELAjet

Leak detector with shutoff valve and sensor

(optional)

37 (optional), external water supply,

(optional)

(A) with double-chamber trap (B)

Example 2

Vacuklav31-B rear view

MELAdem

with manual draining of the waste-water tank

(optional)

Example 4

Vacuklav31-B rear view

MELAdem

automatically into a double-chamber trap

Leak detector with shutoff valve and sensor

(optional)

37 (optional), external water supply,

47 (optional), with drain of waste water

*1

Page 7

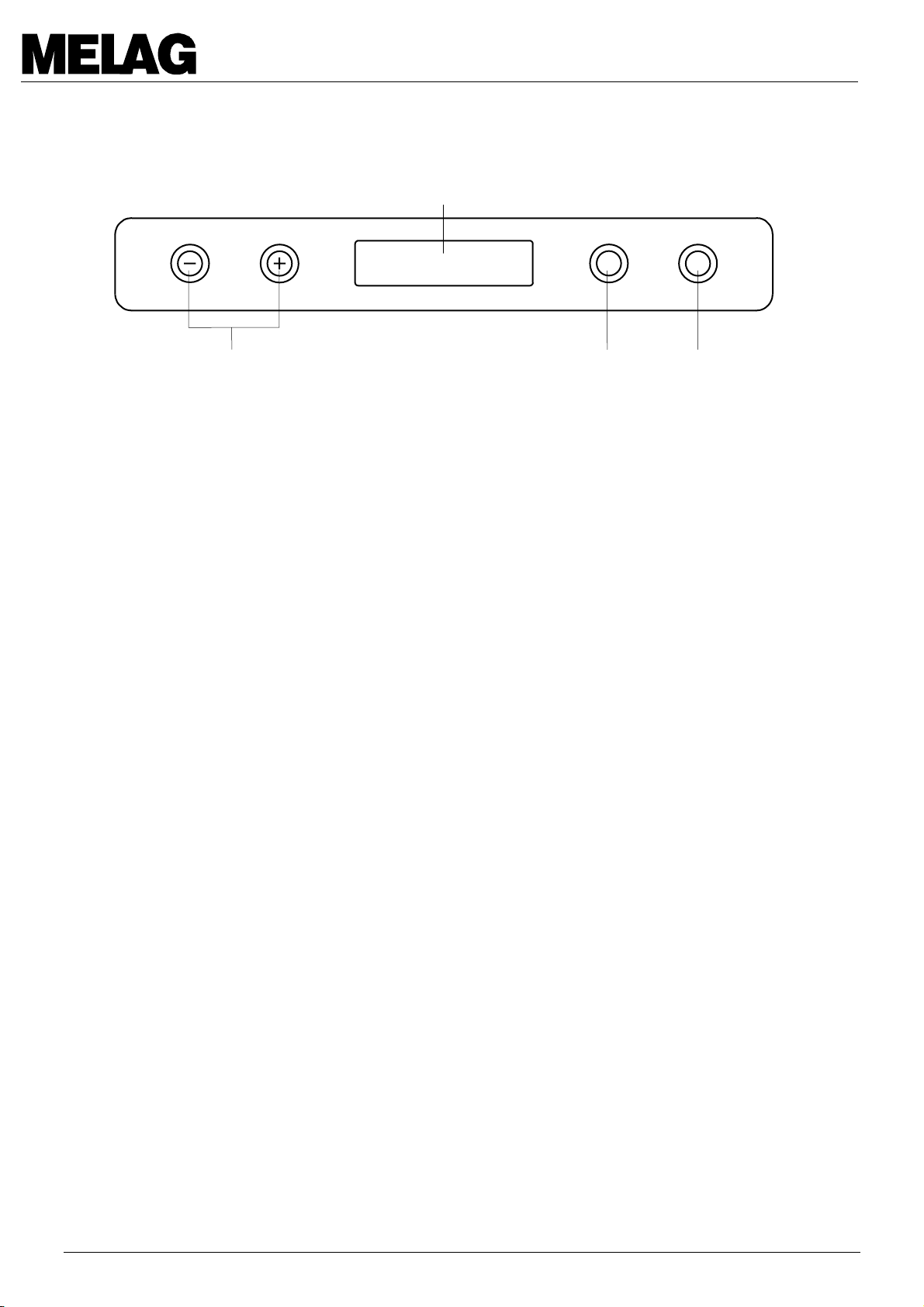

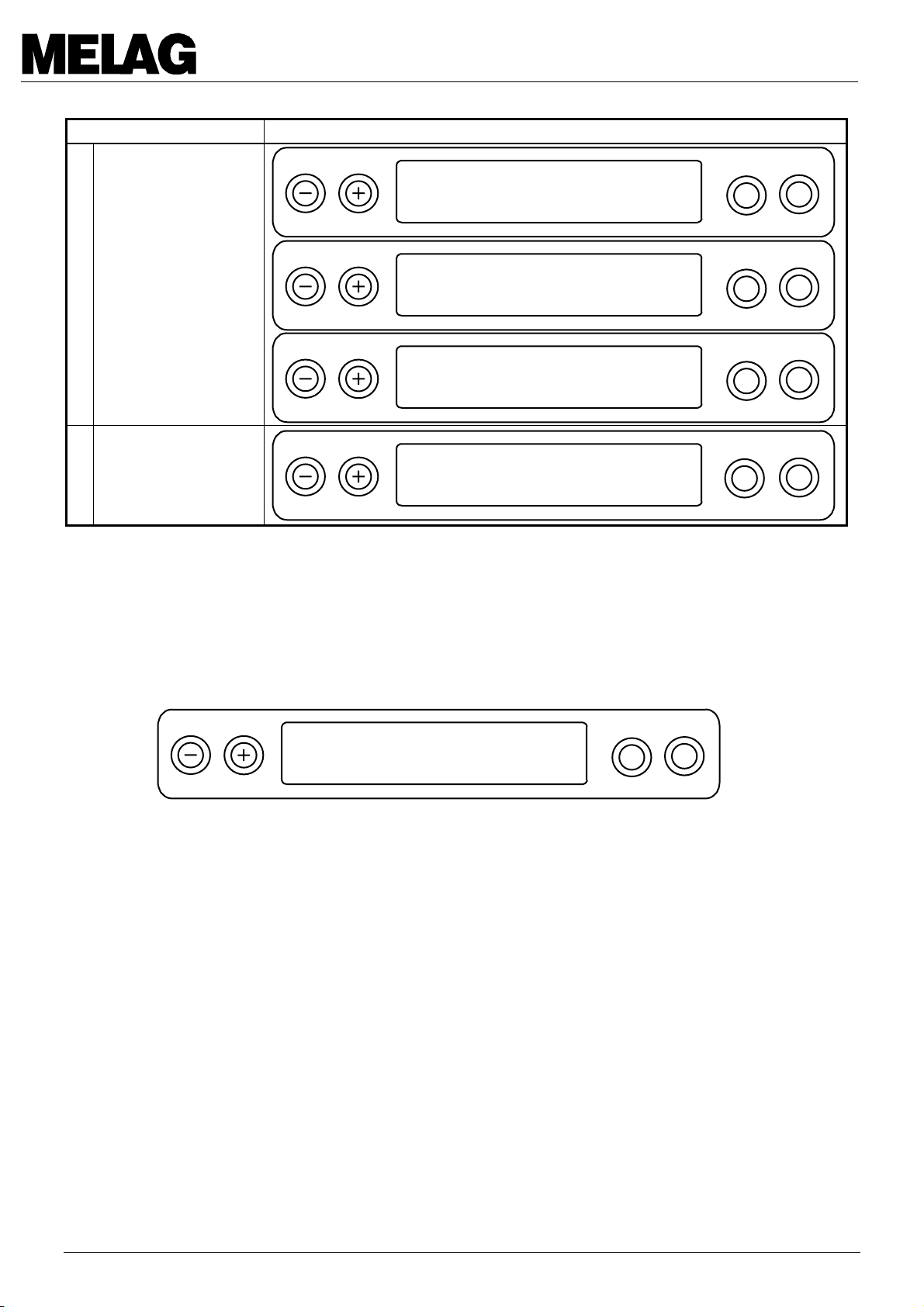

1.4 Control panel ___________________________________________________________

2 x 20-character alphanumeric LED

display For display of program status and

parameters, and for operator for basic and

special functions

Program

Start / Stop

Fig. 3: Vacuklav

Function buttons

For selections, settings, and display of

special functions: printing, date and time of

day, pre-heating, total sterilised loads, water

conductivity, error-report acknowledgement

31-B control panel

For selection of the sterilisation programs and

Program selection button

test programs, and for selection/settings of

options (sub-menus) for the special functions

Start / stop button

For starting and stopping of

programs, drying, and for

control fo special functions

1.5 Performance features of this autoclave______________________________________

1.5.1 Preliminary air removal by sub-atmospheric pulsing ________________________________________

Preliminary air removal by sub-atmospheric pulsing repeatedly evacuates the air from the autoclave and alternately

introduces steam between evacuations: providing the required penetration of the sterilized objects with saturated

steam. This ensures fast and effective execution of difficult sterilization tasks: e.g., instruments with narrow bores

and large amounts of textiles. This autoclave also features a special program for the Bowie & Dick Test (a

recognised procedure used in large-scale sterilization to confirm steam penetration.

1.5.2 Sterilization categories _________________________________________________________________

The Vacuklav

®

31-B features three sterilization programs for temperatures at 134°C: the “Universal Program” (for

wrapped objects), the “Prion Program” (a special Universal Program), the “Fast Program” for unwrapped items, and

the “Gentle Program” (a sterilization program for textiles and rubber articles at 121°C). The user can at any time

perform additional functional checks of the autoclave by running the Bowie & Dick Test for steam penetration, and

the Vacuum Test for leak testing. The additional program "MELAsteam

®

" is available as an option, and functions at

a temperature of 136°C.

1.5.3 Separate steam generation______________________________________________________________

The powerful steam generator outside the actual sterilization chamber makes it possible to sterilize large loads of

instruments or textiles in a short time. No waiting periods are necessary between the sterilization cycles, and

excess temperatures within the sterilization chamber cannot occur.

1.5.4 One-way system / conductivity measurement / automatic re-supply of water ____________________

The Vacuklav

®

31-B operates with the tried-and-proven one-way system: this means that all evaporated water and

all impurities contained in this water are removed from the autoclave upon pressure release. For the following

program cycle, new demineralized / distilled water is therefore used. An integrated conductivity measurement

system monitors the quality of the demineralized / distilled water used in steam generation. For heavy use of the

autoclave, we recommend supply of the demineralized / distilled water by connection of a water-treatment system

such as the MELAdem

®

47 or MELAdem® 37. If the instruments are carefully prepared, this arrangement prevents

spots on the items sterilized, and avoids fouling of the autoclave.

1.5.5 Electronic parameter control ____________________________________________________________

The microprocessor installed in the Vacuklav

®

31-B implements electronic parameter control, which continuously

monitors pressure, temperature, and time in the programs. The process evaluation and monitoring system

contained in the program control system compares momentary process parameters with standard process data and

monitors the process with respect to limit temperatures, limit times, and limit pressures. This function detects

malfunctions in the program cycle and guarantees the security of the sterilization / disinfection results.

1.5.6 Vacuum drying________________________________________________________________________

The vacuum drying feature ensures good drying results, even for wrapped items.

Page 8

Operating Manual for the Vacuklav

1.5.7 Pre-heating___________________________________________________________________________

Activating the pre-heating function warms up the cold autoclave chamber before sterilization, or maintains the

temperature between sterilization cycles. This shortens the duration of cycles and considerably reduces the

formation of condensation, thus optimising drying results.

1.5.8 Documentation of results _______________________________________________________________

The memory of the electronic control system stores records of the previous 40 programs. For effective hard-copy

documentation and for checking purposes a MELAprint

immediately after completion of a program, or to print out records from the memory. By connection of a PC, the

program MELAwin

out these results as needed.

®

can also transfer the records to the PC, for permanent archiving of all results, and for printing

®

42 printer can be connected to print out a record

®

31-B

2 Installation

For the steps required to prepare for and carry out the setting up and installation of this autoclave, see the separate

instructions contained in “Setting up the Vacuklav

2.1 Requirements for installation ______________________________________________

The autoclave should be set up in a dry place which is protected against dust. The base should be stable and

capable of supporting the weight of the appliance (unloaded weight = 43 kg). The space required by the autoclave

can be seen from the external dimensions (see Section 1.2.1 here). A minimum additional space of 10 cm should

be allowed on both sides and above the autoclave in order to ensure that heat can escape.

The electrical power supply should be a separate 230V AC circuit with a 16 A fuse.

This autoclave operates with a blower for the cooling system, on the rear side of the unit. If there is a restriction of

the escape of heat above the unit, this can impair the functioning and shorten the service life of the autoclave.

IMPORTANT: We therefore urgently advise our users not to install the autoclave in an area where there is

not sufficient circulation of air.

If the user decides to install an automatic one-way water system, it is necessary to have a connection to the

wastewater plumbing near the autoclave, preferably a wall outlet (NW 40) or a sink drain (standard length of

outflow pipe = 2 m, with 16 mm diameter). The work surface on which the autoclave stands must be higher than the

outlet, and the outlet pipe must be without bends and twists which could prevent water flowing out freely. At the

same time, the work surface must provide convenient access to the autoclave, and the display must be clearly

visible.

The autoclave can be supplied with demineralized / distilled water from the integrated dual-chamber storage tank,

with freshwater and wastewater chambers. Alternatively, the Vacuklav

water purifier – the MELAdem

note that this will require additional space.

®

47 or MELAdem®37 (or an equivalent water purification system). However, please

®

31-B”.

®

31-B can also be connected to an external

2.2 Transport ribbons _______________________________________________________

Lift the autoclave out of the packaging by using the transport straps. The straps themselves are each removed by

unscrewing the two retaining screws, which must then be screwed firmly back in place without washers.

2.3 Levelling ______________________________________________________________

In order to operate properly, and to allow unimpeded return flow of condensate into the steam generator, the autoclave must be installed so that it definitely slopes toward the rear. First install the autoclave in a horizontal (level)

position, and check that this position is in fact horizontal with a spirit level at the chamber flange. Then extend the

front feet to lift up the front side of the autoclave, by screwing the feet out by at least three (3) turns.

2.4 Mains power supply _____________________________________________________

The electric cable of the appliance must be plugged into a mains socket rated at 230 V / 50 Hz. The power rating of

the autoclave is 2400 W. In order to avoid overloading the building electricity supply, we recommend using a

separate electrical circuit fitted with a 16 A fuse and optionally protected with a type RCCB (residual current circuit

breaker) with a tripping current of 30 mA.

Page 9

2.5 Outlet connection for one-way water _______________________________________

The connection for the one-way water outlet at the back of the unit (3) must be hooked up to the drainage system

of the building by means of the outlet pipe supplied (transparent pipe). It is important that the pipe should have a

steady downward gradient, without twists and kinks. The outlet must be connected to an existing sink drain, or

to a separate NW40 drain pipe with use of the wall-mounted drain (MELAG article no. 37410).

2.6 Internal water supply with demineralized / distilled water ______________________

If the user decides for internal supply of the autoclave with demineralized / distilled water, this water is taken from

the right chamber of the built-in water storage tank. To install the internal system for supply of demineralized /

distilled water, connect the hose at the demineralized / distilled water connection of the supply tank to the swivell

threaded connection at the supply point for demineralized / distilled water on the rear side of the autoclave. For this

variation of water supply, the autoclave is delivered ready for installation. To fill the feed water tank, remove the

cover of the tank and fill the right chamber with demineralized / distilled water up to the maximum mark.

2.7 Connection of a water treatment system ____________________________________

The autoclave can be directly connected to a water treatment system for direct supply with demineralized / distilled

water. Instead of being connected to the water storage tank (as in Section 2.6), the demineralized / distilled water

connection is hooked up directly to the water treatment system. The reverse-osmosis system MELAdem

the ion-exchanger MELAdem

consult the operating manuals of these reverse-osmosis systems for detailed instructions on installation and

placing into operation. If you decide to use water treatment systems made by other

they deliver water with sufficient quality and quantity. Please get in touch with the company MELAG before

connecting such systems made by other manufacturers. In addition, a water stop valve (MELAG article no. 01056)

should be installed upstream of such water treatment systems, in order to satisfy insurance requirements.

®

37 are designed to optimally satisfy the requirements of the Vacuklav®31-B. Please

manufacturers, be sure that

®

47 and

2.8 Emptying the water storage tank __________________________________________

It is easy to completely empty the water storage tank of this autoclave. This is required, for example, to clean or

repair the autoclave, or to place it out of operation. To drain the tank, pull the drain hoses out of the front panel at

the plug (see Fig. 1: drain side [21], and tank side, with demineralized water [22]). Pull out the plugs, and allow the

water to drain into a separate container.

3 Placing the autoclave into operation

3.1 Printer connection and initialisation (optional) _______________________________

3.1.1 Connection of the MELAprint®42 _________________________________________________________

The accessory printer MELAprint

item which is not supplied with the normal scope of delivery for the autoclave. Follow the instructions in Section

6.3.1.1.1 of this manual to connect the printer to the autoclave.

3.1.2 Initialisation of the printer / setting for immediate printout____________________________________

Follow the instructions in Section 6.3.1.1.2 of this manual to initialise the external printer after it has been

connected. This initialisation will log the printer on to the computer control system in the autoclave. Follow the

instructions in Section 6.3.2 of this manual to set the immediate-printout option to "Yes". This means that the

system will automatically print out a report when the system program has come to an end.

®

42 is designed for connection to the autoclave Vacuklav®31-B. This is an optional

Page 10

Operating Manual for the Vacuklav

3.2 Vacuum test ____________________________________________________________

A vacuum test (leak test) should be conducted under the following conditions to assure proper functioning of the

autoclave:

− Once when a new autoclave is set up for the first time

− When the autoclave is being put back into service after a long period of inactivity

− When the autoclave is moved to a new location

− Periodically as part of routine operations.

The vacuum test should be performed on the cold

Operator action:

1. Switch on the autoclave

at the power switch: After

the following message ...

... the display will show the

initial state:

Shown on the display:

autoclave as follows:

Program

Please wait

Door unlocking

Program

14:27:12

®

31-B

Start-Stop

Start-Stop

0.02bar 25°C

2. Press the “Program” button

several times until the program “Vacuum test” appears.

3. Close the door

4. Press the “Start – Stop”

button

5. The vacuum pressure has

been reached. The equilibration time begins to run (waiting time until beginning of

measurement).

6. After the waiting time has

run out (5 min), the measuring time will begin (here:

7 min 52 s).

Program

Start-Stop

Vacuumtest

Program

Start-Stop

Door

closed

Program

Start-Stop

Vacuumtest: Start

Press. = 980mbar

Program

Start-Stop

Vacuumtest 00:00

Press. = 80mbar

Program

Start-Stop

Vacuumtest 07:52

Pressure = 82mbar

Page 11

Operator action:

After the measuring time has

7.

run out (10 min), the cham-

ber is vented, and ...

... then the leak rate is given

(with connected printer and

setting for immediate printout = “Yes”, a record will

now be printed out. After the

message “Please wait –

door unlocking”, the following request will appear:

Shown on the display:

Program

Start-Stop

Ventilate

–0.56 bar 25 °C

Program

Start-Stop

Leak rate = 0.2 mbar

Program

Start-Stop

Open door

please

8. Open the door.

Program

Start-Stop

Vacuum test

If the leak rate determined is greater than the maximum permissible value, the following will appear in the display

and on the printed log: “Test not successful”. In such a case, follow the instructions given in this manual under

Section 7.3.

3.3 Trial run _______________________________________________________________

To continue the functional check of the autoclave, carry out the trial run by loading the autoclave with a typical load

for your daily work, and then run the program “Universal program, 134°C, wrapped”. Load the autoclave and use

the “Program” button to select this program. Then press the button “Start – Stop”. If the program runs correctly

(also see Section 4.7 here), the following message will appear at the end of the program:

Universal program

run successfully

Program

This display will also show the maximum values achieved for pressure and temperature. If a printer is connected,

and with setting for immediate printout = “Yes”, a record will now be printed out.

3.4 Installation log – sent to MELAG ___________________________________________

As documentation that the autoclave has been set up properly, an installation record should be produced by an

authorised person and a copy sent to MELAG. This is important in the event that you wish to make claims under

warranty provisions.

Start-Stop

Page 12

Operating Manual for the Vacuklav

3.5 Safety instructions ______________________________________________________

®

31-B

* Danger: Be careful when opening the door of the autoclave, especially if you are

interrupting a drying cycle. Small amounts of residual steam can escape through the door

and can burn operating personnel.

* Warning: After opening the autoclave door, do not touch exposed hot metal parts.

Warning: These parts can burn operating personnel. Be sure to use a MELAG or standard

tray handle to remove still-hot trays from the autoclave. Be sure to use suitable hand

protection (for example, potholders or gloves) when removing other sterilizing containers.

* We recommend the installation of a leak monitor in the water supply line (see Section 2,

Installation, for instructions).

* If you wish to connect to this autoclave water-treatment systems which are made by other

equipment manufacturers, get in touch with the MELAG company before you install this

equipment.

* This device is not suitable for the sterilization of liquids.

* According to presently valid regulations published by the Society of German Electrical

Engineers (VDE), this device is not suitable for operation in hazardous areas which are

endangered by the possibility of explosion (for example, in hazardous atmospheres).

* Important: Empty the water supply tank before moving the autoclave. If the autoclave has

water inside, do not tip it.

* This device may be repaired only by the company MELAG or by persons authorised by

MELAG (specialist personnel or customer-care staff). These persons must use original

spare parts and must observe the instructions for service published by MELAG.

* Danger: Do not open the enclosure to this device before disconnecting the electrical power

plug from its outlet.

* This autoclave will properly sterilize only if the operating personnel observe the instructions

in this Operating Manual – especially the instructions for loading the autoclave in

accordance with the program required.

Page 13

4 For each sterilization cycle

4.1 Water and power _______________________________________________________

4.1.1 Demineralized / distilled water__________________________________________________________

This autoclave automatically checks to make sure that there is enough demineralized / distilled water, and it checks

that the quality of the demineralized / distilled water is sufficient for starting a program. In order to start a program

without delay, to avoid error messages, and to prevent a program from stopping before it is finished (see Sections

7.3 and 7.4), please make sure to carry out the following:

1. Before starting the first sterilization cycle of a day, check to make sure that there is enough water in the right

side of the dual-chamber water supply tank (this applies if you are using the system’s own internal supply: i.e., if

you are not using a connected water-treatment system). If there is not enough water in the tank, fill with water of

sufficient quality (see Section 8.3.2 of this manual).

2. If you use a direct water supply from the MELAdem

to the autoclave is open in time. If the pressure tank is empty, this feed must be opened at least one

starting a program. This step is not necessary if the water supply remains open continuously .

4.1.2 Power supply________________________________________________________________________

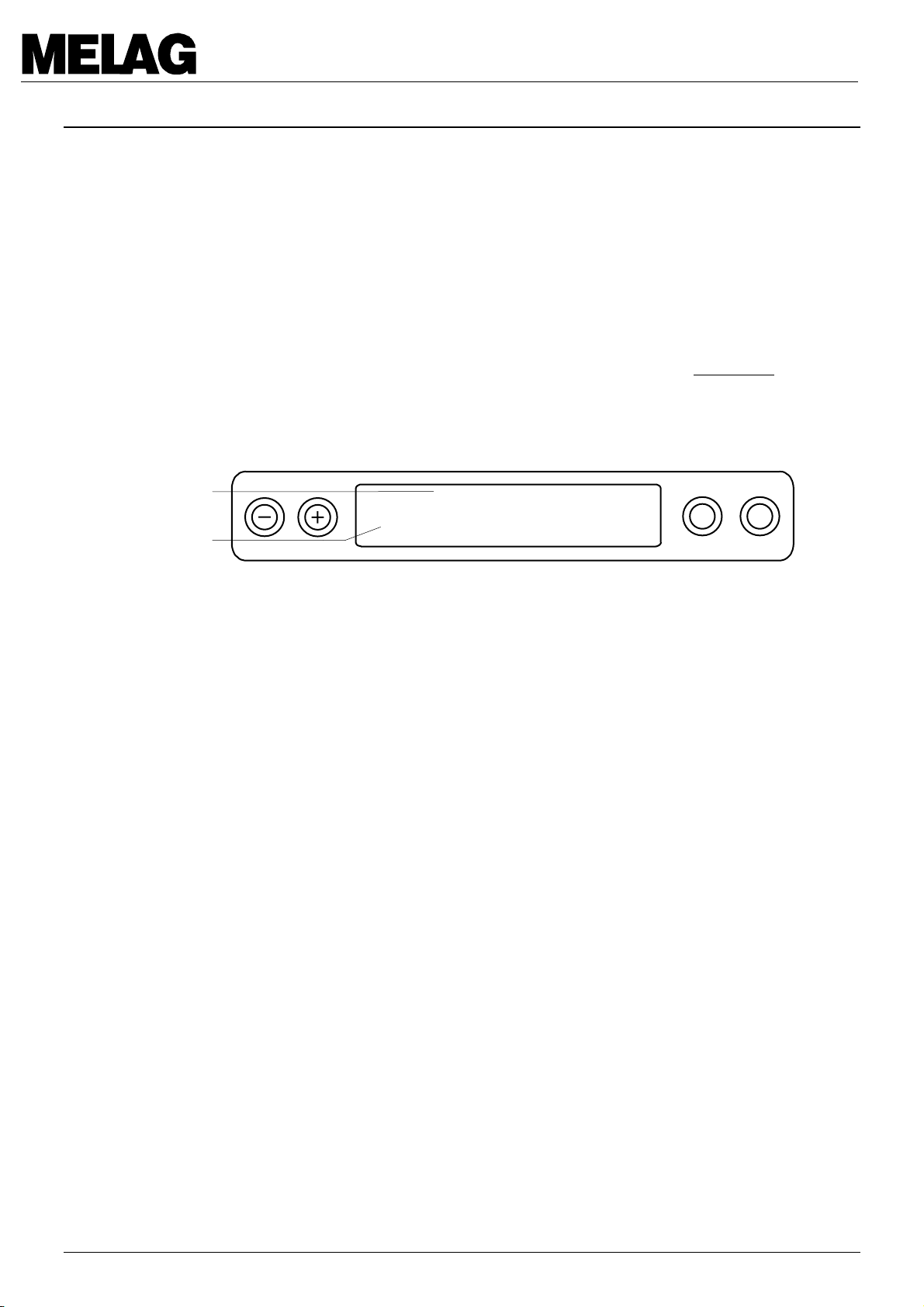

Switch on the power switch at the bottom right of the front of the autoclave. The message “Please wait – Door

unlocking” will appear in the display. After approx. 15 s, the device will then be in its initial state.

Time of day (h:min:s)

Chamber pressure (bar)

Temperature (steam) (°C)

®

47 water-treatment system, make sure that the water feed

hour before

Program

Start-Stop

14:27:12

0.02bar 25°C

4.2 Preparation of instruments ________________________________________________

MELAG — use of non-rusting materials for parts which come into contact with steam

All parts of the Vacuklav

sterilization chamber and the chamber door are of stainless steel, steam lines are Teflon

connections and solenoid valves are brass.

Drag-in rust

The non-rusting parts used in the Vacuklav

cases in which rust has developed on the autoclave or on the sterilized items inside, investigations have

consistently shown that this rust has been dragged into the autoclave from the outside by rusty instruments. We

must point out that rust can form on stainless-steel instruments made by even the best manufacturers.

One main cause of instrument rusting is improper treatment with chemical cleaning and disinfecting agents during

preparation for sterilization.

Preparation of instruments for sterilization

The problem of drag-in rust shows how important it is to properly prepare items for sterilization. It is urgently

necessary to observe the following procedures:

1. Clean and prepare (for example, by oiling) handpieces and contra angles as described in the instructions

provided by the manufacturers of these items.

2. Immediately after their medical use, all other instruments must be placed in a disinfection and/or cleaning

solution in accordance with UVV/VBG 103 and properly cleaned and disinfected there.

3. Always be sure to use the correct dosage of disinfection and/or cleaning agents in these solutions.

4. Important: Be sure to carefully follow the instructions for the length of time that the instruments must soak in

the solutions.

5. We also recommend the use of ultrasonic equipment, recommended cleaning and care equipment for

handpieces and contra angles, as well as thermal disinfecting techniques.

6. The proper cleaning of instruments is also essentially important in preventing particles of soiled matter from

separating from the instruments during sterilization and from clogging the filters, nozzles, and valves of the

autoclave. It is extremely important to use a brush to very carefully clean the locks, joints, and hinges of the

instruments before sterilization.

7. Important: Use a brush under running water to completely rinse all cleaning and disinfecting agents from

instruments before placing them in the autoclave. Residue of chemical cleaning and disinfecting agents

must by no means be allowed to enter the autoclave, since they will cause corrosion there.

8. As a final step before placing the instruments into the autoclave, rinse them with demineralized water, and dry

them well.

9. Be sure to use oil (as indicated in the manufacturers’ instructions) to prepare turbines and handpieces for

sterilization, in order to ensure their long service life.

®

31-B which come into contact with steam are made of non-rusting materials. The

®

31-B ensure that the autoclave itself cannot cause rust to form. In any

®

, and threaded

Page 14

Operating Manual for the Vacuklav

Instruments new from the factory:

Be sure also to follow the above-described pre-cleaning procedure even for instruments new from the factory.

Often there are small amounts of oil, grease, and impurities still on new instruments, from their production.

Important

procedures which are provided by manufacturers of instruments.

4.3 Loading the autoclave ____________________________________________________

The correct loading of the autoclave is essentially important in guaranteeing the sterilization effectiveness and the

proper drying of the items being sterilized. Be sure to observe the following basic instructions in loading the

autoclave:

Tray mounts:

There are 2 different tray mounts for the Vacuklav

1. Tray mount “B” (MELAG art.-no. 40234) for loading of either a maximum of 4 trays, or 4 standard tray cassettes

2. Tray mount “C” (MELAG art.-no. 40232) for loading of either a maximum of 6 trays, or 3 standard tray

In normal cases the autoclave should always be operated with a tray mount, since this ensures optimal steam

penetration and drying. In exceptional cases, it may be possible to remove the tray mount and place the suitable

containers directly into the sterilization chamber (for example, with use of sterilization containers of other

manufacturers). But please check with your specialist dealer or with MELAG before attempting this solution.

For sterilization of instruments sealed in see-through sterilization packaging, we recommend the use of the MELAG

Package Stand (MELAG article no. 22410). The Package Support considerably improves the results of the drying

process for instruments wrapped in this way.

Trays:

Trays used for the loading of sterilized items must be perforated, in order to allow the condensate to run out.

MELAG trays fulfil this requirement. We cannot advise the use of non-perforated trays or bowls (e.g., unperforated

standard-tray supports), since they do not allow proper trying.

Closed sterilization containers:

Closed sterilization containers must be perforated on at least one side (preferably the bottom), or they must have

valves, in order to allow the steam to properly penetrate and the condensate to flow out. All MELAG sterilization

containers satisfy this requirement, with perforations on two sides and with a sterile filter cloth insert. We cannot

recommend sterilization with sterilization containers with holes only on the top, since they do not allow proper

drying.

See-through sterilization packaging:

If you use see-through sterilization packaging (for example, MELAfol

tray for sterilization. We recommend the use of MELAG Foil Holders (MELAG article no. 22410).

Important: Do not stack the see-through sterilization packages horizontally on top of each other. If the sealing

seam of the package breaks during sterilization, please use a longer sealing pulse on the MELAG MELASEAL

Package Sealing Device, or seal with a double seam.

If standard tray cassettes are sealed in MELAfol

side seam and to prevent it from breaking open. In addition, be sure to press excess air out of the package before

sealing it.

Multiple packaging:

Air removal by sub-atmospheric pulsing allows multiple-wrapping.

Loading limits:

Be careful not to exceed the prescribed maximum loading amounts: 5kg of instruments or 1.8kg of textiles.

Mixed loads of textiles and instruments:

If you are sterilizing textiles and instruments at the same time, place the textiles above the instruments and do not

allow the textiles to come into direct contact with the instruments. Do not sterilize textiles and instruments in the

same sterilization container. Important: Do not by any means allow the textiles to come into direct contact with the

wall of the sterilization chamber. Please observe the following instructions for different types of packaging in one

sterilization cycle:

Place the see-through sterilization packaging and paper packing on the top (but if you are using a combination with

textiles: then arrange these packages on the bottom)

Sterilization of liquids:

Danger: The Vacuklav

: It is absolutely necessary to carefully follow the instructions for preparation and re-sterilization

®

31-B:

cassettes.

Both of these tray mounts are also designed to support the following MELAG sterilization containers:

Types 15K,M,G; Type 17K,R; Type 23R, Type 28M,G.

®

), these should be placed vertically on the

®

(250 mm wide), clamps or tape must be used to reinforce the

®

31-B is not suitable for the sterilization of liquids.

®

31-B

Page 15

Loading...

Loading...