Melag Vacuklav 30 B User manual

Operating Manual

for the

Autoclave

Vacuklav30 B

Dear Doctor:

Thank you very much for the trust which you have shown by purchasing this autoclave.

For 50 years now, MELAG — a medium-sized family-owned and -operated company —

has specialized in the production of sterilization equipment for medical practice. During

this period, MELAG has succeeded in becoming a leading manufacturer of sterilization

equipment. More than 335 000 MELAG units sold throughout the world testify to the

exceptional quality of our sterilizers. — which are manufactured exclusively in Germany.

As all other MELAG products, this autoclave was manufactured and tested according to

strict quality criteria. Before placing this unit into operation, please read this Operating

Manual carefully. The long-term functional effectiveness and the preservation of the value

of your autoclave will depend on careful preparation of instruments before sterilization,

and on proper care of the unit.

The staff and management of MELAG

To ensure the functional effectiveness of this

unit and to preserve its value:

1. Prepare the instruments to be sterilized carefully

2. Take proper care of the autoclave

3. Use only pure distilled or demineralised water

1 Description of the unit................................................................................................................. ..................4

1.1 Views of the unit .................................................................................................................. ....................4

1.2 Control panel ............................................................................................................................................ 5

1.3 Technical data ............................................................................................................................ ..............5

1.4 Performance features of this autoclave ............................................................................................. ....5

1.4.1 Fractionating pulsed vacuum procedure ................................................................................... ........5

1.4.2 Programs for sterilization / disinfection ............................................................................ ..................5

1.4.3 Separate steam generation .................................................................................... ..........................5

1.4.4 One-way system/ Conductivity measurement/ Automatic water supply ............................................5

1.4.5 Electronic Parameter Control (EPS) ................................................................................. .................6

1.4.6 Vacuum drying ....................................................................................................................... ............6

1.4.7 Pre-heating ......................................................................................................................... ...............6

1.4.8 Documentation ...................................................................................................... ...........................6

2 Installation................................................................................................................................... ...................6

2.1 Setting up the autoclave .................................................................................................. ......................6

2.2 Transport ribbons ....................................................................................................................... .............6

2.3 Levelling the autoclave ...................................................................................................... .....................7

2.4 Power supply ................................................................................................................... .......................8

2.5 Cooling water inlet connection ............................................................................................................ ..8

2.6 Cooling water outlet connection ........................................................................................ ...................8

2.7 Connection of the feed water storage container ................................................................................ ..8

2.8 Connection of a water purification system ........................................................................................... 8

3 Initial start-up ...................................................................................................................... ..........................8

3.1 Printer connection/ Initialisation (optional) ............................................................................... ............8

3.1.1 Connecting the MELAprint®42 ...................................................................................... ....................8

3.1.2 Initialisation of the printer / Setting up immediate print-out ............................................ ...................8

3.2 Vacuum test ................................................................................................................. ............................8

3.3 Test run ........................................................................................................................................... .......10

3.4 Installation record .............................................................................................................................. ...10

3.5 Safety instructions ..................................................................................................... ..........................10

4 Instructions for all sterilization procedures .................................................................................... ..........11

4.1 Electricity and water supplies .............................................................................................................. .11

4.1.1 Cooling water and purified feed water ......................................................................................... ....11

4.1.2 Power supply ........................................................................................................... .......................11

4.2 Loading the autoclave ............................................................................................................ ...............11

4.3 Closing the door ................................................................................................................ ...................12

4.4 Program selection ....................................................................................................... .........................12

4.5 Basic display (no program selected)Program start .................................................................. .........13

4.6 Program progress .............................................................................................................................. ...13

4.7 Print-out record ................................................................................................................................... ..16

4.8 Removing the sterilized items ........................................................................................... ..................16

4.9 Sterile storage ................................................................................................................................ .......16

4.10 Sterilization frequency / pauses .......................................................................................... ..............17

4.11 Manual termination of program ....................................................................................... ...................17

4.11.1 Termination of sterilization/ disinfection .................................................................................... ......17

3.To undo the program termination, press the " - " button. ................................................................... ...17

4.11.2 Terminate drying ................................................................................................ ...........................18

4.12 4This is followed by ventilation of the autoclave chamber................................................... ............20

4.13 Disinfection ........................................................................................................................ ..................21

4.14 Reaction to warnings / error messages ................................................................................. ...........21

4.15 Operational pauses ................................................................................................... ..........................21

5 Closing down / Transport / Reinstallation ........................................................................................ .........21

6 Special functions ............................................................................................................ ............................22

6.1 Water quality (conductivity)/ Chamber temperature .................................................................. ........22

Page 2

Operating manual - Vacuklav

®

30-B

6.2 Selecting extra drying ..................................................................................................... .....................22

6.3 Records / Load documentation ......................................................................................... ...................22

6.3.1 Record print-out ................................................................................................................... ...........23

6.3.2 Immed. print-out? Yes/No ........................................................................................... ....................24

6.3.3 Printing out stored records .......................................................................................................... ....25

6.3.4 Print all stored cycle records ....................................................................................................... ....26

6.3.5 Display printer memory ........................................................................................................... ........27

6.3.6 Deleting cycle records ........................................................................................... .........................28

6.3.7 Test print-out ........................................................................................................................ ............29

6.4 Resetting date and time .................................................................................................. ......................29

6.5 Automatic preheating ............................................................................................................... .............31

6.6 Total load count ............................................................................................................... .....................32

6.7 Program modifications ...................................................................................................................... ....32

7 Operational errors / Malfunctions .................................................................................................. ............32

7.1 What to do if the autoclave malfunctions ............................................................................... ............32

7.2 Malfunctions without display messages ....................................................................... ......................33

7.2.1 No display .............................................................................................................................. .........33

7.2.2 Excessive water consumption .............................................................................. ...........................33

7.2.3 Poor drying ................................................................................................................ .....................33

7.3 Warning messages ............................................................................................................. ..................33

7.4 Error reports .......................................................................................................................................... .36

8 Taking care of your autoclave......................................................................................................... ............39

8.1 Preparation of instruments ...................................................................................................... ............39

8.2 Rust formation = Drag-in rust .................................................................................................... ..........40

8.3 Taking care of the Vacuklav®30-B ..................................................................................................... ...40

8.3.1 Cleaning ............................................................................................................... ..........................40

8.3.2 Use of demineralised or distilled water ........................................................................ ...................40

8.4 Checking the operation of the autoclave ........................................................................................ .....41

8.4.1 Safety with automatic monitoring ........................................................................................ ............41

8.4.2 Periodical bacteriological testing (twice a year) ............................................................... ................41

8.4.3 Maintenance recommendations ................................................................................................. .....41

9 Annex ..................................................................................................................................... ......................42

9.1 Installation options ...................................................................................................................... .........42

9.2 Additional technical data ........................................................................................... ..........................43

9.2.1 Capacity/Weight ............................................................................................................................ ..43

9.2.2 External supplies ..................................................................................................... .......................43

9.2.3 Operational parameters ..................................................................................................... ..............43

9.3 Instructions on drying ................................................................................................................. ..........44

9.3.1 Drying in sterilization containers .................................................................................... .................44

9.3.2 Textiles ........................................................................................................................................ .....45

9.3.3 Instruments ............................................................................................................................ ..........46

9.3.4 Loading the autoclave ................................................................................................................... ..46

9.3.5 Loading containers with soft sterilization packing material .................................... .........................46

9.3.6 Stacking sterilization containers ......................................................................... ............................47

9.3.7 Removing the sterilized items ............................................................................................... ..........47

9.3.8 Improving the drying ..................................................................................................... ..................47

Page 3

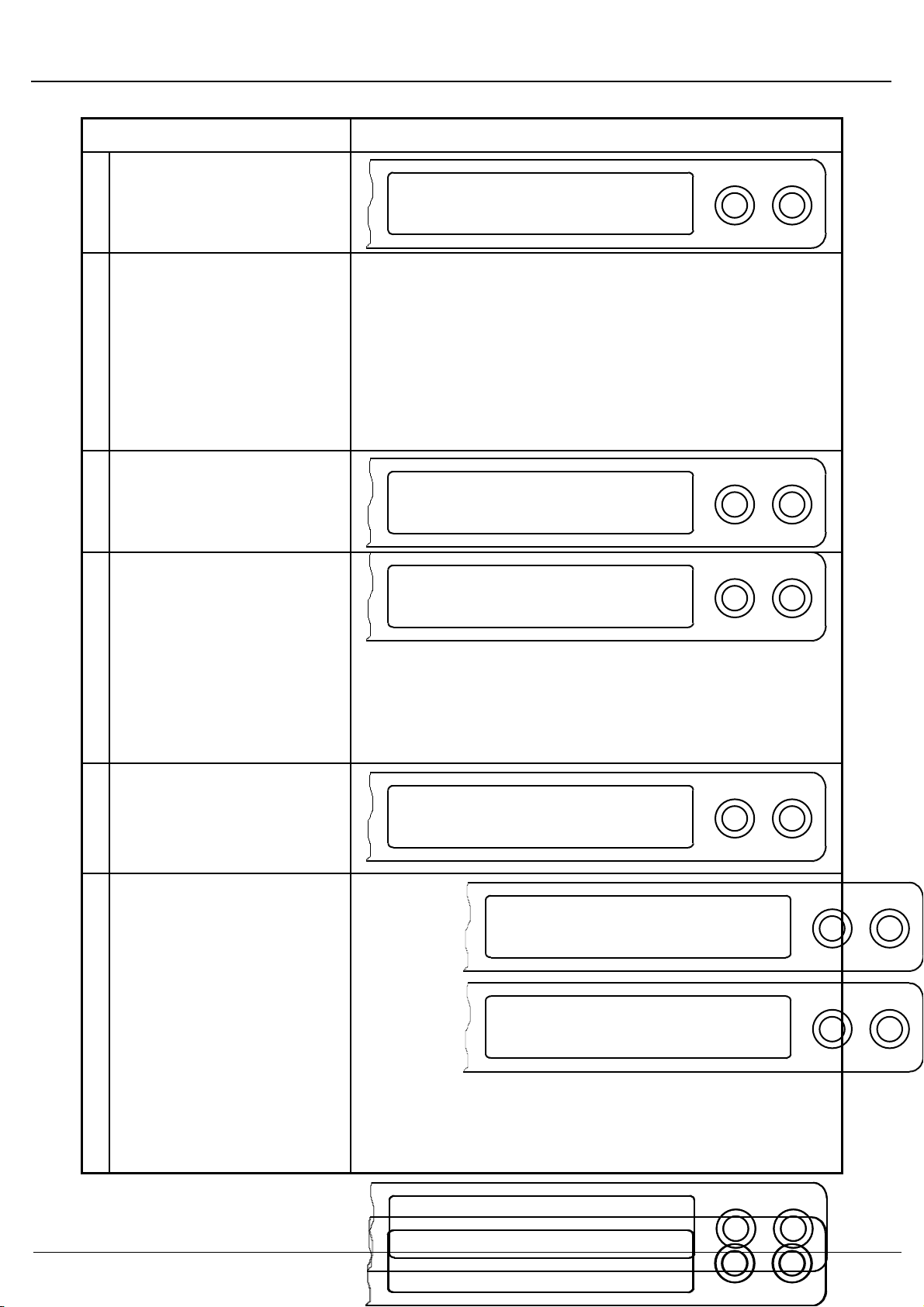

1 Description of the unit

1.1 Views of the unit_______________________________________________________

1 Safety valve 9 Fuses - 2 x 16 A / FF

2 Sterile filter 10 Power switch

3 Cooling water inlet (3/4" external thread) 11 Motor circuit breaker (vacuum pump)

4 Cooling water outlet (3/4" external thread) 12 Sliding door lock

5 Purified water inlet

(Swivel connection for 6x1 pipe)

13 Door (left-side hinge)

14 Control panel

6 Mains power cable

7 Adjustable front feet

8 Serial data and printer port

( RS 232 )

Page 4

Fig. 1 Views of the Vacuklav®30-B

Operating manual - Vacuklav

®

30-B

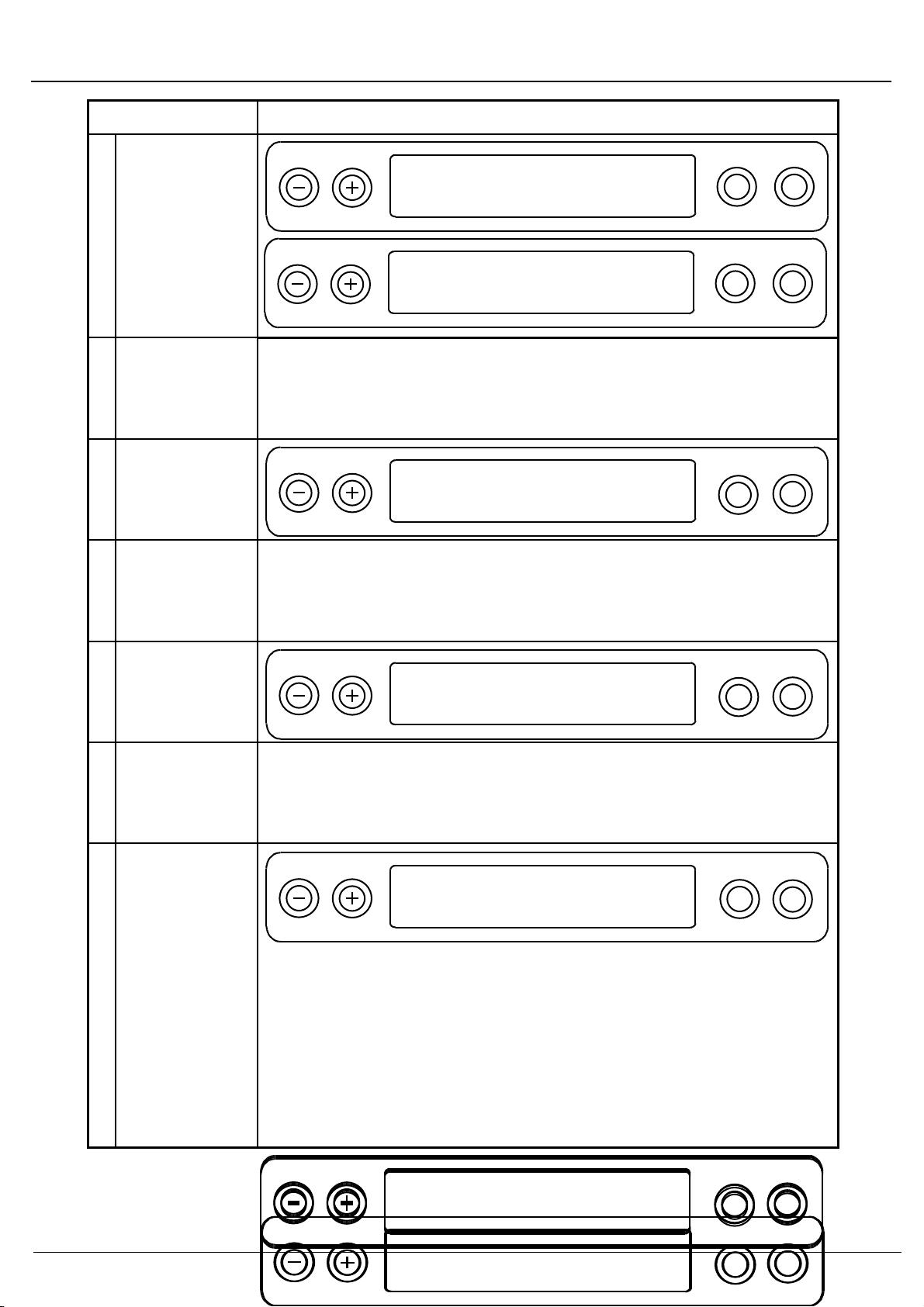

1.2 Control panel_________________________________________________________

Fig. 2 Control panel Vacuklav30-B

1.3 Technical data________________________________________________________

Sterilization space (diameter x depth ) : 25cm x 36cm

Electric power supply : 2400W / 230V AC / 10.4A / 50....60Hz

Sterilization pressure / temperature : 2bar/134°C; 1bar/121°C

Disinfection pressure/ temperature : 0.3 bar/105°C

Maximum load: : 5kg instruments or 2kg textiles

Further technical details are included in the Annex

1.4 Performance features of this autoclave___________________________________

1.4.1 Fractionating pulsed vacuum procedure _______________________________________________

A fractionating pulsed vacuum method involved the repeated evacuation of the sterilization chamber,

alternating with the introduction of steam in order to ensure the necessary penetration of the items undergoing

sterilization with superheated steam.

This means that even demanding sterilization tasks, involving for example intricate instruments or large

amounts of textiles can be completed quickly and reliably.

Steam penetration can be demonstrated using the established Bowie & Dick Test, for which a special test

program can be implemented.

1.4.2 Programs for sterilization / disinfection________________________________________________

The Vacuklav® 30-B has two sterilization programs, the "universal program" at 134°C: for packed utensils and

the "fast program" for unpacked utensils, as well as a sterilization program for textiles and rubber articles at

121°C, and a disinfection program at 105°C. In addition, it is possible to check at any time that the autoclave is

functioning properly by using the test program for steam penetration (the Bowie & Dick Test Program), as well

as to test for leaks (the Vacuum Test Program).

1.4.3 Separate steam generation __________________________________________________________

The generation of steam by a high-performance unit outside the sterilization chamber makes it is possible to

sterilise large loads of instruments or textiles quickly. It is not necessary to have any pauses between the

sterilization runs, and overheating in the sterilization chamber is impossible.

1.4.4 One-way system/ Conductivity measurement/ Automatic water supply ______________________

The Vacuklav® 30-B operates with a reliable one-way system, in which all the condensate from a sterilization,

including any impurities which this may contain is completely eliminated and purified water used for the next

program run.

An integrated conductivity measurement system monitors the quality of the distilled or demineralised water

used for the steam generation.

For frequent operations, the larger demand for purified water can be met by a water purifier, e.g. MELAdem®47

or MELAdem® 37, which can be directly connected to the autoclave.

Provided the instruments to be sterilized are then also prepared carefully, stains on the load and soiling of the

autoclave itself can be prevented.

Page 5

Program

Start - Stop

Buttons for selecting, adjusting and

displaying special functions:

Printing, date/time, pre-heating,

total loads, conductivity, re-setting

Program selection

for sterilization programs/ test programs

and for selecting options (sub-menus) of the

special functions

Start - stop buttons to start

and interrupt programs,

drying, and to control special

functions

2 x 20- alphanumeric LED-display, showing

program status, and parameters for basic

and special functions

1.4.5 Electronic Parameter Control (EPS)____________________________________________________

The microprocessor in the Vacuklav® 30-B makes it possible to monitor pressure, temperature and time

continuously during a program by Electronic Parameter Control The overall operating time can then be

optimised according the load and the temperature of the autoclave.

The process assessment and monitoring system in the program control compare current process parameters

with standard process data and monitors the process relative to limit values for temperatures, times and

pressures. This makes it possible to identify faults as they occur, and provides quality assurance for the

sterilization and disinfection processes.

1.4.6 Vacuum drying_____________________________________________________________________

Vacuum drying ensures the best possible drying results for packed utensils.

1.4.7 Pre-heating________________________________________________________________________

By activating the "pre-heating" function, the cold autoclave chamber can be warmed up before sterilization, or

the temperature can be maintained between sterilization runs. This reduces the duration of cycles and

considerably reduces the formation of condensation, thus improving drying results.

1.4.8 Documentation____________________________________________________________________

The electronic memory stores records of the previous 40 programs.

For effective hard-copy documentation and for checking purposes a MELAprint®42 printer can be connected to

print out a record immediately after completion of a program or to print out records from the memory.

2 Installation

When setting-up and installing the autoclave, please consult the separate instructions leaflet "Installing the

Vacuklav® 30-B".

2.1 Setting up the autoclave _______________________________________________

The autoclave should be set up in a dry place which is protected against dust.

The base should be stable, and able to support the weight of the appliance (unloaded weight 43 kg).

The space required by the autoclave can be seen by the external dimensions (as in Section 1.1). A minimum

additional space of 10 cm should be allowed on either side and above the autoclave in order to ensure that

heat can escape.

The electrical power supply should be a separate 230V AC circuit with a 16 A fuse.

The cooling water should be obtained from a mains water supply, to which the autoclave is connected by

means of a water tap or stop cock with a 3/4" external thread. This water supply should be accessible close to

point where the autoclave is set up. (The standard connection pipe supplied is 2 m long).

The disposal of the cooling water outflow requires either a wall-outlet (NW 40) or a sink outflow, and this

should also be situated close to the autoclave (the standard 16 mm connection pipe provided is 2m long). The

outflow must be lower than the working surface on which the autoclave stands, so that the outflow pipe can be

installed without bends and kinks, ensuring a constant downward flow. The autoclave should set-up at a level

which allows easy loading and at which the display can be read clearly without bending.

The autoclave must also be supplied with purified water for steam generation. The distilled or demineralised

water can come either from a storage container (MELAG Art.-No. 244) or directly from the container in which

purchased water is supplied. This should also be situated close to the autoclave (length of feed pipe supplied

1.5m, maximum height difference 1.5 m). If the purified water comes directly from a water purification system

MELAdem®47 or MELAdem®37 (or another purification system) then a storage container is not necessary, but

space must be allowed to accommodate the water purification system.

2.2 Transport ribbons_____________________________________________________

Take the autoclave out of the packaging by means of the transport ribbons. The ribbons themselves are each

removed by undoing the two retaining screws, which must then be screwed firmly back in place without

washers.

Page 6

Operating manual - Vacuklav

®

30-B

2.3 Levelling the autoclave________________________________________________

In order to ensure that condensate can drain out of the autoclave (which is important if it is to operate properly)

the appliance must have be clearly higher at the front than at the back. The autoclave should first be installed

in a horizontal position (this should be checked with a spirit level at the chamber flange) and then the front feet

should be extended by giving them at least five (5) turns.

5

3211

78916410

210x230

340

Fig. 3 Typical installation of the Vacuklav30-B with storage container for distilled/demineralised water, with a

wall-mounted trap

1

Vacuklav30-B rear view

2 Cooling water inlet pipe (pressure pipe)

3 Cooling water outlet pipe DN16

4 Water stop cock with safety combination in accordance with DIN 1988 (MELAG Art.-No.: 37310)

5 Leak detector with stop valve and sensor (MELAG Art.-No.: 1056)

6 Wall- mounted trap (MELAG- Art.- No.: 37410)

7 Wall outlet (NW 40)

8 Storage container for distilled or demineralised water (MELAG Art.-No. : 244)

9 Feed water intake with filter

10 Y-junction with non-return valve (included in (6) )

11 Power connection

Page 7

2.4 Power supply ________________________________________________________

The electric cable of the appliance is plugged into a mains socket rated at 230 V, 50 Hz. The power rating of

the autoclave is 2400 W. In order to avoid overloading the electricity supply, we recommend using a separate

electrical circuit fitted with a 16 A fuse and optionally protected with a 30mA circuit breaker.

2.5 Cooling water inlet connection __________________________________________

The connection for the cooling water inlet at the back of the appliance is connected to the mains water supply

using the pressure pipe supplied (see page 7, Fig. 3.). Make sure that the washers are fitted correctly.

In order to avoid water damage in the event of leaks, we also recommend the installation of a leak detector

("Water-stop", MELAG-Art.-No.:1056).

2.6 Cooling water outlet connection __________________________________________

The connection for the cooling water outlet at the back of the appliance is connected to the drainage system of

the building by means of the outlet pipe supplied (textile-reinforced transparent pipe, DN16). It is important that

the pipe should have a steady downward gradient, without twists and kinks.

When connecting to an existing sink outflow, the use of the double-chamber trap supplied helps to reduce

noise due to water discharging.

When connecting to a separate outflow pipe NW40, a wall-mounted trap should be used (MELAG Art.-No.

37410 ,see Fig. 3).

2.7 Connection of the feed water storage container ____________________________

If the autoclave is to be supplied with distilled or demineralised water from a storage container (see Fig. 3)

then this will be drawn up through the suction pipe. The one end of the pipe is attached to the inlet at the rear

of the autoclave, either directly or by means of the swivel connection. The pipe is then fed into the storage

container until its other end with the inlet filter reaches the bottom.

If you use the MELAG storage container (MELAG Art.-No.: 244) you will find the necessary instructions on the

label. This container has a volume of 11.5 litres, enough for an average of 25 sterilization cycles.

2.8 Connection of a water purification system ________________________________

The autoclave can be connected directly to a water purification unit which provides the demineralised or

distilled water required (see page 39, Fig. 4). Instead of connecting the feed water inlet to a storage container,

it is simply connected directly to the water purification unit.

The reverse-osmosis systems MELAdem®47 and MELAdem®37 are ideally suited to provide the quantity and

quality of water needed for the Vacuklav®30-B.

Detailed instructions on the installation of these water purification units are provided in their operating

manuals.

When connecting water purification systems from other manufacturers it is very important to ensure that they

are able to provide sufficient amounts of water at the required purity. You are generally advised to consult

MELAG first.

3 Initial start-up

3.1 Printer connection/ Initialisation (optional)________________________________

3.1.1 Connecting the MELAprint®42________________________________________________________

The autoclave can be connected to an external printer, the MELAprint®42. This is not supplied as standard

with the autoclave.

In order to connect the printer to the autoclave follow the description in Section 6.3.1.1.1.

3.1.2 Initialisation of the printer / Setting up immediate print-out ________________________________

Initialise the external printer (registering with the processing unit of the autoclave) as described in Section

6.3.1.1.2. In order to select the immediate print-out option, which means that a record of each sterilization is

printed out automatically as soon as it has finished, proceed as described in Section 6.3.1.3.

3.2 Vacuum test__________________________________________________________

In order to check the operation of the autoclave in the course of the initial start-up, after long periods without

being used, or after moves, as well as periodically during routine use, a vacuum test should be carried out to

check for leaks.

The vacuum test should be carried out as follows, preferably on the cold autoclave:

Page 8

Operating manual - Vacuklav

®

30-B

Operation Display message

1.

S

wit

ch

on

po

we

r,

2.

Pr

es

s

th

e

"P

ro

3.

Cl

os

e

th

e

do

or

4.

Pr

es

s

"St

art

St

op

"

bu

tto

n

5.The evacuation pressure has been reached.6.After waiting for the equalisation (5 min) the measuring period starts (running

here e.g. for 7min 52s)7.After the measuring period (10 min) the chamber is ventilated and

Page 9

Program

Start-Stop

Leak rate 0. 2 m b a r

Program

Start-Stop

V e n t i l a t i o n - 0 . 5 6 b a r

2 5 ° C

Program

Start-Stop

V a c u u m t e s t

Program

Start-Stop

D o o r c l o s e d

Program

Start-Stop

V a c u u m t e s t :

S t a r t P r e s s u r e

Program

Start-Stop

V a c u u m t e s t 0 0 : 0 0

P r e s s u r e 8 0 m b a r

Program

Start-Stop

V a c u u m t e s t 0 7 : 5 2

P r e s s u r e 8 2 m b a r

O p e n d o o r p l e a s e

Program

Start-Stop

Program

Start-Stop

P l e a s e w a i t D o o r

u n l o c k i n g

Program

Start-Stop

1 4 : 2 7 : 1 2 0 . 0 2 b a r

2 5 ° C

Operation Display message

8. Open door

If the leakage rate is above the limit value, then the display (and the print-out) will also show "Test

unsuccessful". In this case, follow the instruction in Section 7.3.

3.3 Test run _____________________________________________________________

In order to check the operation of the autoclave under realistic conditions, a test run should be carried out with

the "Universal Program, 134°C wrapped" and a relevant load. After loading the autoclave and selecting the

program with the "Program" button, sterilization is started by pushing the "Start/Stop“ button. If the program

runs correctly, the following message will appear on the display (see Section 4.6 ):

with the values for the maximum values for pressure and temperature. If the immediate printout option has

been selected for an external printer a record of the program run will be printed.

3.4 Installation record ____________________________________________________

As documentation that the autoclave has been set-up properly, an installation record should be produced by

an authorised person and a copy sent to MELAG. This is important in the event that you wish to make claims

under warranty provisions.

3.5 Safety instructions ____________________________________________________

• When opening the door, particularly after interrupting the drying process, residual steam can escape from

the autoclave chamber.

• After opening the door, do not touch any metal surfaces - these will be hot! Danger of burns. Always use

the tray lifter to remove trays, or wear suitable hand protectors when taking out other items

• We recommend the installation of a water leak detector (see installation details Section 2).

• If you intend to install a water purification unit from another manufacturer, then consult MELAG before you

do so.

• The appliance is not suitable for sterilising liquids.

• Under current VDE-regulations, this appliances is not suited for use in areas where there are risks of

explosion.

• The appliance must only be serviced and repaired by MELAG or by its authorised representatives

(specialist dealers or customer services) using only original parts and following service instructions.

• Before opening the housing always disconnect from the mains power supply!

• In order to ensure effective sterilization with the autoclave observe the instructions in this operating manual,

and in particular ensure that the loading of the autoclave is appropriate for the program selected.

Page 10

Program

Start-Stop

Vacuumtest

Universal-progr.run

successfully

Program

Start-Stop

Operating manual - Vacuklav

®

30-B

4 Instructions for all sterilization procedures

4.1 Electricity and water supplies___________________________________________

4.1.1 Cooling water and purified feed water _________________________________________________

The autoclave automatically monitors the availability of cooling water and purified water, as well as the quality

of the distilled / demineralised water before starting a program.

In order to allow an immediate program start and to avoid error reports or interruptions of programs (see

Sections: 7.3 and 7.4) :

• Before the first sterilization at the start of the working day, check that the water supply is turned on (stop

cock)

• If purified feed water is drawn from a storage container, check the water level, and if necessary fill up with

purified water of appropriate quality (see Section 8.3.2)

• If the feed water is drawn directly from a MELAdem

®

47 water purifier, check that its water supply is turned

on in good time (this may be up to an hour before starting a sterilization program), if the water supply has

been turned off over night, for example.

4.1.2 Power supply _____________________________________________________________________

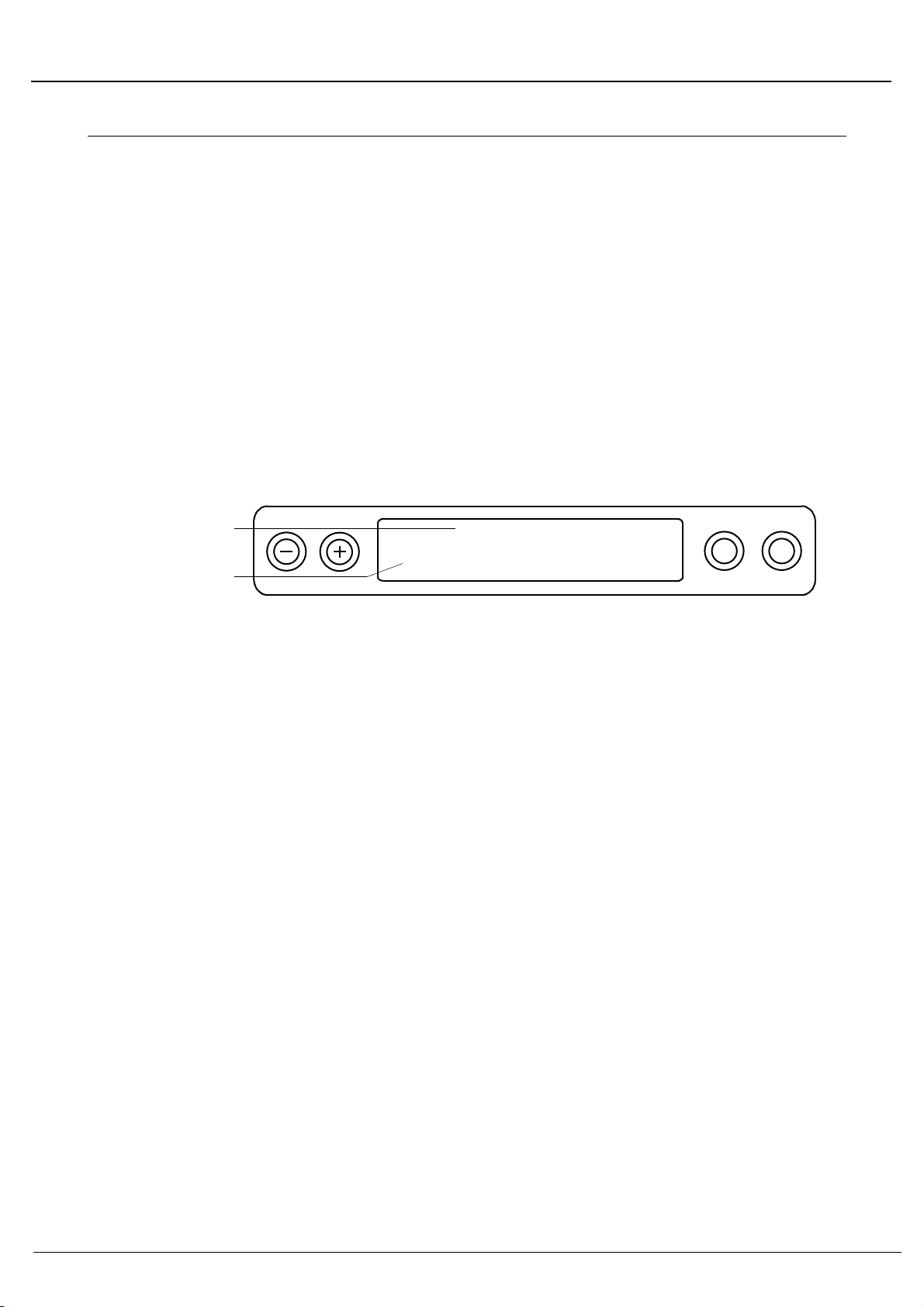

Switch on the power using the switch on the front of the autoclave (bottom right). About 15 seconds after the

message "Please wait Door release“ the appliance is in the start status :

4.2 Loading the autoclave_________________________________________________

It is of crucial importance for effective sterilization and good drying that the autoclave is loaded properly:

Tray rack

For the Vacuklav® 30-B there are 2 types of tray rack:

Type "A" (MELAG-Art.-No.: 40231) for up to 6 trays and

Type "B" (MELAG-Art.-No.: 40234) for up to 4 trays or 4 standard tray-cassettes.

Both types of tray rack are also suitable for the MELAG-sterilization containers Type 15K,M,G; Type 17 K,M,G;

Type 17R; Type 23R, Type 28 M, Type 28G).

Normally, the autoclave should be used in conjunction with a tray rack, since this ensures that steam

penetration and drying are as good as. In exceptional situations (e.g. when using sterilization containers from

other manufacturers), and after consultation with your specialist dealer or with MELAG, the tray rack can be

removed and the container can be placed directly in the autoclave chamber.

Trays

Trays for objects which are to be sterilized must be perforated, in order to allow condensate to run away.

MELAG-trays are recommended. If you use dishes or trays without perforations, then the objects being

sterilized will not dry properly.

Enclosed sterilization containers

Enclosed sterilization containers must be perforated on at least one side (preferably underneath) or must have

valves, in order to ensure that steam can penetrate and condensate can run out. All MELAG-sterilization

containers meet these requirements with perforations on two sides and filter-cloth- inlays.

Sterilization containers which only have perforations on the top only allow limited drying.

If sterilization containers are stacked in the autoclave, it is important to ensure that the perforations are not

blocked.

Transparent sterilization packaging

If you use transparent sterilization packaging, such as MELAfol® , then the items should if possible be stood

vertically on the tray, or sterilized in foil holders (MELAG-Art.-No.: 238). They should never be laid flat one on

top of the other.

If seals split open during sterilization it may be necessary to increase the length of the sealing impulse or to

use a double-seal.

Page 11

Program

Start-Stop

1 4 : 2 7 : 1 2 0 . 0 2 b a r

2 5 ° C

Time (24-hour)

Chamber pressure (bar)

(steam)-temperature (°C)

Standard tray- cassettes sealed in MELAfol® (250 mm wide) must be taped and clasped additionally to ensure

that the side-seals do not split open.

Multiple wrapping

The pulsed vacuum method means it is possible to use multiple wrapping.

Maximum loads

Loads should not exceed 5kg of instruments or 2kg of textiles.

Mixed loads

If mixed loads of textiles and instruments are to be sterilized, then as far as possible the textiles should be

above the instruments and direct contact with the instruments should be avoided.

Inclusion of textiles and instruments in the same sterilization container is not desirable.

Textiles should never come into direct contact with the walls of the chamber.

If different types of packaging are included in a load, then:

• Instruments and sterilization containers should be at the bottom

• Transparent and paper sterilization packaging should be at the top (but lower than textiles)

Liquids

The appliance is not suitable for the sterilization of liquids!

Suitability for sterilization

Relevant information provided by manufacturers of instruments and textiles about sterilization should be

strictly observed.

4.3 Closing the door _____________________________________________________

The door is closed by lightly applying pressure in the direction of the chamber flange and at the same time

pressing down the sliding door catch.

The display shows the message:

4.4 Program selection ____________________________________________________

A program should be selected which is appropriate for the physical properties of the items being sterilized (and

in particular their heat resistance) and the type of packaging (if any part of the load is wrapped, then either the

"Universal Program" or the "Gentle Program" must be used).

By pressing the "Program selection" button it is possible to review the display of the following programs for

selection:

Program name/Display message Parameter/Application

Universal-progr. at 134°C, 2 bar, and a sterilization

time of 3.5 min

Sterilization of all types of wrapped items, in

particular instruments, or mixed loads

(unwrapped/wrapped)

Quick-program at 134°C, 2bar and a sterilization

time of 3.5 min

Sterilization only of unwrapped instruments (no

textiles) for rapid re-use (drying can be interrupted

manually)

Page 12

Program

U n i v e r s a l - p r o g r .

1 3 4 ° C

Program

Q u i c k - p r o g r a m

1 3 4 ° C u n w r a p p e d

Program

Start-Stop

D o o r c l o s e d

Operating manual - Vacuklav

®

30-B

Gentle-program at 121°C, 1bar and a sterilization time of 15min

Program name/Display message

Parameter/Application

Disinfection program at 105°C, 0.3 bar and a

disinfection time of 8 min for steam-pressure

disinfection of materials with physical properties which

mean that they cannot be sterilized.

Warning this is not sterilization!

Bowie&Dick Test Program at 134°C, 2 bar and a

sterilization time of 3.5 min

Used to check the operation of the autoclave

(Steam penetration of special indicators)

Vacuumtest-program

Used to check the autoclave for leaks,

from a cold start

4.5 Basic display (no program selected)Program start_________________________

Press the "Start-Stop" button once the desired program is shown on the display. The availability of cooling

water, and feed water will be checked automatically, with a conductivity measurement.

At the start of the quick program there will be an additional message "Warning: Only unwrapped instruments“,

at the start of the disinfection program the warning "Warning - Not sterilization“. These messages must be

acknowledged by pressing "Start“ again.

4.6 Program progress ____________________________________________________

After starting the program, it will then progress automatically. The display shows the current program status as

follows:

Page 13

G e n t l e - p r o g r a m

1 2 1 ° C w r a p p e d

Program

D i s i n f e c t i o n

1 0 5 ° C 0 . 3 b a r 8 ‘

Program

B o w i e & D i c k T e s t

1 3 4 ° C 2 . 2 b a r 3 . 5 m i n ‘

Program

V a c u u m t e s t

Program

Start-Stop

S t a r t

Program

1 5 : 3 1 : 3 3

0 . 0 2 b a r 2 2 ° C

Program

Program status Display message

1. Phase 1 consisting of evacuation

(removal of air) until the appropriate

evacuation pressure is reached, followed

by steam introduction up to slightly above

atmospheric pressure.

Display show pressure in chamber and

steam temperature

2.

Ph

as

e

2

an

d

fol

lo

wi

ng

De

pe

ndi

ng

on

th

e

pr

og

ra

m

ch

os

en

an

d

th

e

te

m

pe

rat

ur

e

of

th

e

ch

a

m

be

r

at

th

e

sta

rt

of

th

e

te

m

pe

rat

ur

e,

ad

diti

on

al

cy

cle

s

m

ay

be

ne

ce

ss

ar

y

Page 14

Program Start-Stop

1 . s u b - a t m . p u l s i n g

- 0 . 0 8 5 b a r 2 2 ° C

Program Start-Stop

2 . s u b - a t m . p u l s i n g

- 0 . 8 5 b a r 7 0 ° C

Operating manual - Vacuklav

®

30-B

Program status Display message

3.

He

ati

ng

ph

as

e

A

he

ati

ng

up

ph

as

4.

St

eri

liz

ati

on

ph

as

e

W

he

n

th

e

re

5.

Pr

es

su

re

rel

ea

se

A

fte

r

co

m

ple

tio

n

of

th

e

ste

rili

zat

6. Drying phase

After pressure release the drying phase begins.

At this point it is possible to stop the program without this leading to a fault being

reported, since the sterilization itself is now completed. However, with the exception of

the "Quick Program", the drying phase should be allowed to run to completion.

7. Ventilation 8. Program end

Page 15

Program Start-Stop

V e n t i l a t i o n

- 0 . 1 2 b a r 6 0 ° C

Program Start-Stop

O p e n d o o r

p l e a s e B i t t e T ü r

Program Start-Stop

Q u i c k - p r o g r a m

R u n s u c c e s s f u l l y

Program Start-Stop

H e a t u p

0 . 7 6 b a r 1 1 7 ° C

Program Start-Stop

S t e r i l i z a t i o n

S t i l l 2 m i n 1 2 s e c

Program Start-Stop

S t e r i l i z a t i o n

2 . 1 8 b a r 1 3 5 ° C

Program Start-Stop

P r e s s u r e r e l e a s e

0 . 8 5 b a r 9 6 ° C

Program

Start-Stop

I m m e d i a t e r e m o v a l

P r e s s S T O P

Program Start-Stop

V a c u u m - d r y i n g

1 ' - 0 . 9 b a r 9 9 ° C

Program Start-Stop

P l e a s e w a i t

D o o r u n l o c k i n g

Loading...

Loading...