Melag Vacu-23-31 Fault diagnosis

Vacuklav®23-B

Vacuklav®31-B

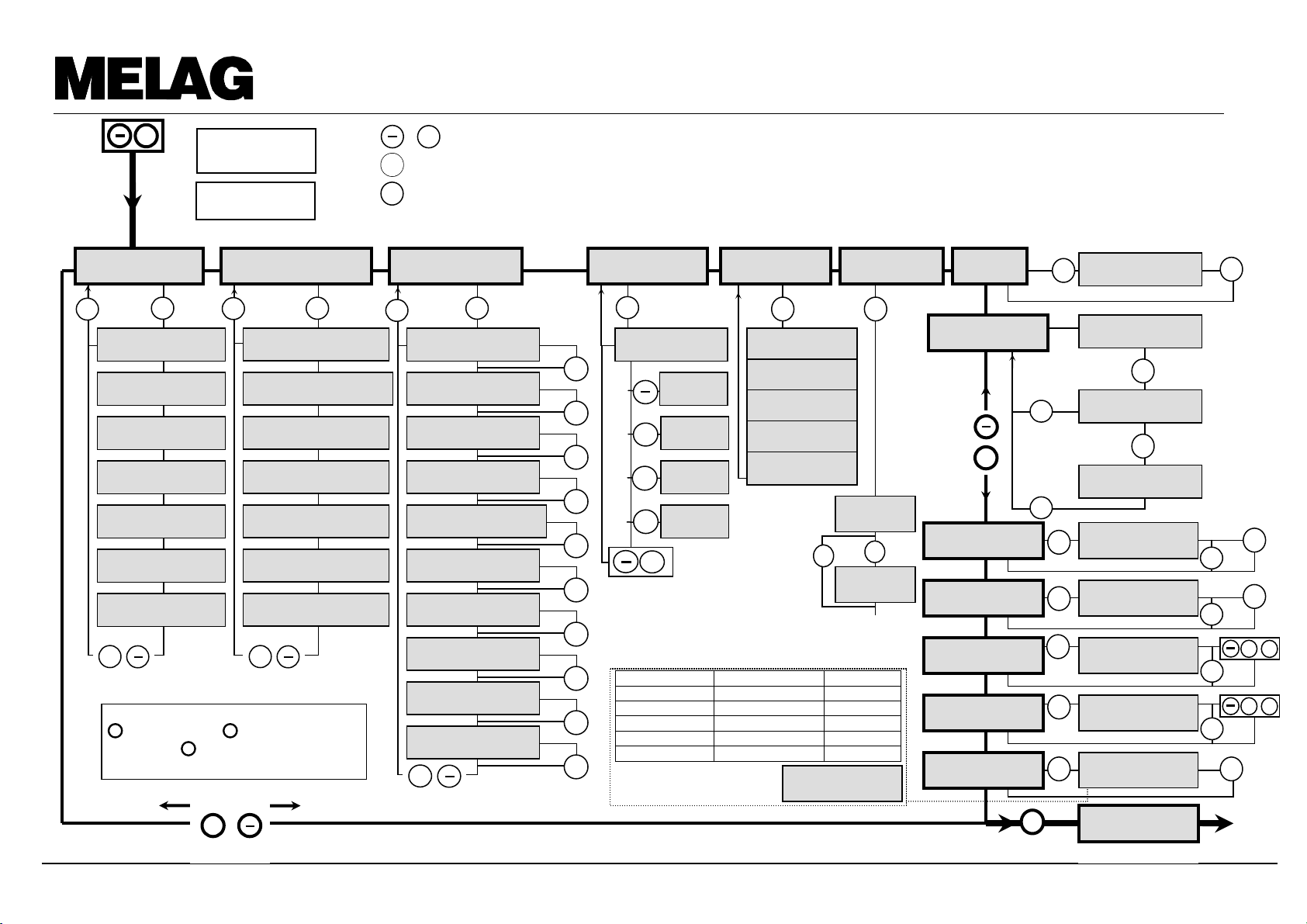

Program-cycle / Diagnosis-program

p

+

Press both buttons

hold and...

... switch on power

P

S

Buttons: „Continue“ in the Menu in the diagnosis-program

+

Button choose program: „Enter / Quit / Input“ in the diagnosis-program

Button Start/Sto

: „Escape / Leave / Interrupt“ in the diagnosis-program

Vacuklav®: 24-B / 30-B / 31-B

Euroklav®: 23-S / 23V-S / 29-S / 29V-S

Diagnosis

Analog-Inputs

S

Temp_Chambr_elec

xx.x °C

Temp_Chambr_Dis

Temp_Chambr_Dis

Pressure_Chamber

Temp_Preht_Cham.

1

2

xxxx mbar

xx.x °C

Reserve

defective

Conductivity

xxx µS/cm

+

Main- und Undermenues can be changed:

+

forward and with - backwards

scrolling and

S

always leaving the loop.

Diagnosis

Digital-Inputs

S

I1: Door contact

I2: OH protector SG

I3: Cooling water

I4: Aqua dem, current

I5: Door locking dev.

I6: Aqua dem swimmer

I7: Reserve

+

P P

closed

closed

closed

open

open

open

open

Diagnosis

Digital-Outputs

S

O1: Steam-generator

x.x bar xx°C (off)

O2: Pre-heating

x.x bar xx°C (off)

O3: Vacuum-pump

x.x bar xx°C (off)

O4: Reserve

O5: Pump/SV aqua dem

O6: SV Vacuum

x.x bar xx°C (off)

O7: SV Press. rel.1

x.x bar xx°C (off)

O8: SV Ventilation

x.x bar xx°C (off)

O9: SV Cool-water

x.x bar xx°C (off)

O10: Door lock

x.x bar xx°C (off)

+

P

(off)

x.x bar xx°C (off)

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

(on)

P

Diagnosis

Keyboard

P

Keyboard

Nr.: 0

Keyboard

Nr.: 10

Keyboard

+

Nr.: 20

Keyboard

P

Nr.: 40

Keyboard

S

Nr.: 80

+

Symbol Meaning example

xxxxklav XX-X Name

typ Type

progvers Programversion

spr Language

parvers Parameterversion

Diagnosis

Self-Test

P

Self-Test

Signal

MELAG-GmbH

Gerätename xxx

Self-Test

Memory-Test OK

Self-Test

Battery OK

Printer is

not ready

P

Vacuklav 30-B

V30-3.16 D01.13

Diagnosis

Leakage-search

P

Leak-Test

0,3 bar 8‘

S

Pressure init.

0,x bar 8‘

Neutral position

Vacuklav 30-B

V30

3.16

D

01.13

Diagnosis

Statistics

Diagnosis

Maintenance-data

+

Diagnosis

Malfunction-mem

Diagnosis

Memory init.

Diagnosis

Backup Parameter

Diagnosis

Delete Backup

Diagnosis

Version

Total: xxxx

P

succesfull.: xxxx

Service: dd.mm.yy

run cycles: xx

P

S

Maintenance-data

Update?

P

Service: dd.mm.yy

run cycles: 0

S

Malfunction-mem

P

P

P

P

P P

print?

Memory init.

Sure?

Backup Parameter

Sure?

Delete Backup

Sure?

xxxxklav XX-X

typ-progvers spr parvers

S

S

S

S

P

+

+

P

P

P

P

+

File: Diagnosis Program.doc Rev: 0-00/104 Seite 1 von 1

S

hh:mm:ss

x.xx bar xx°C

Neutral position

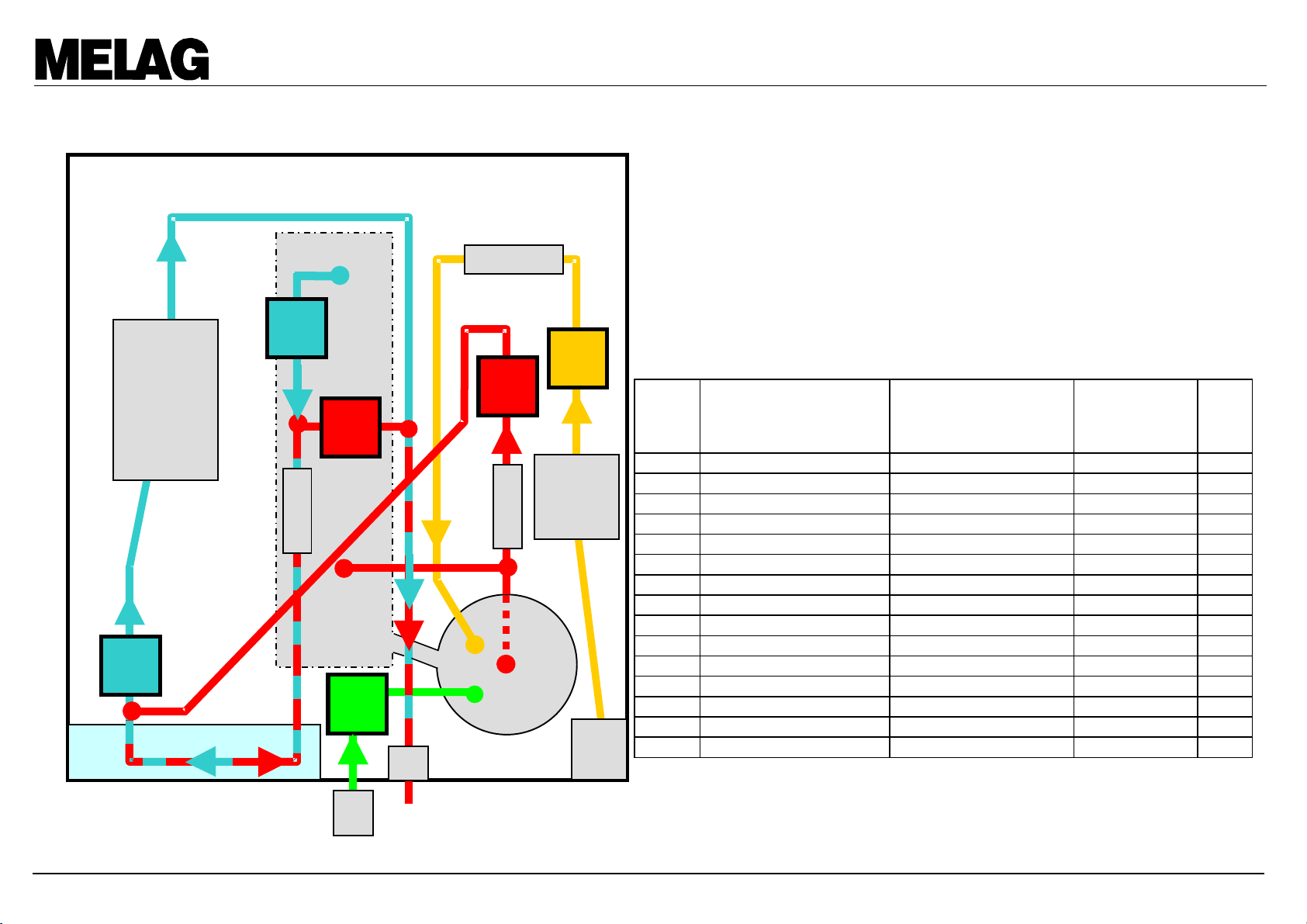

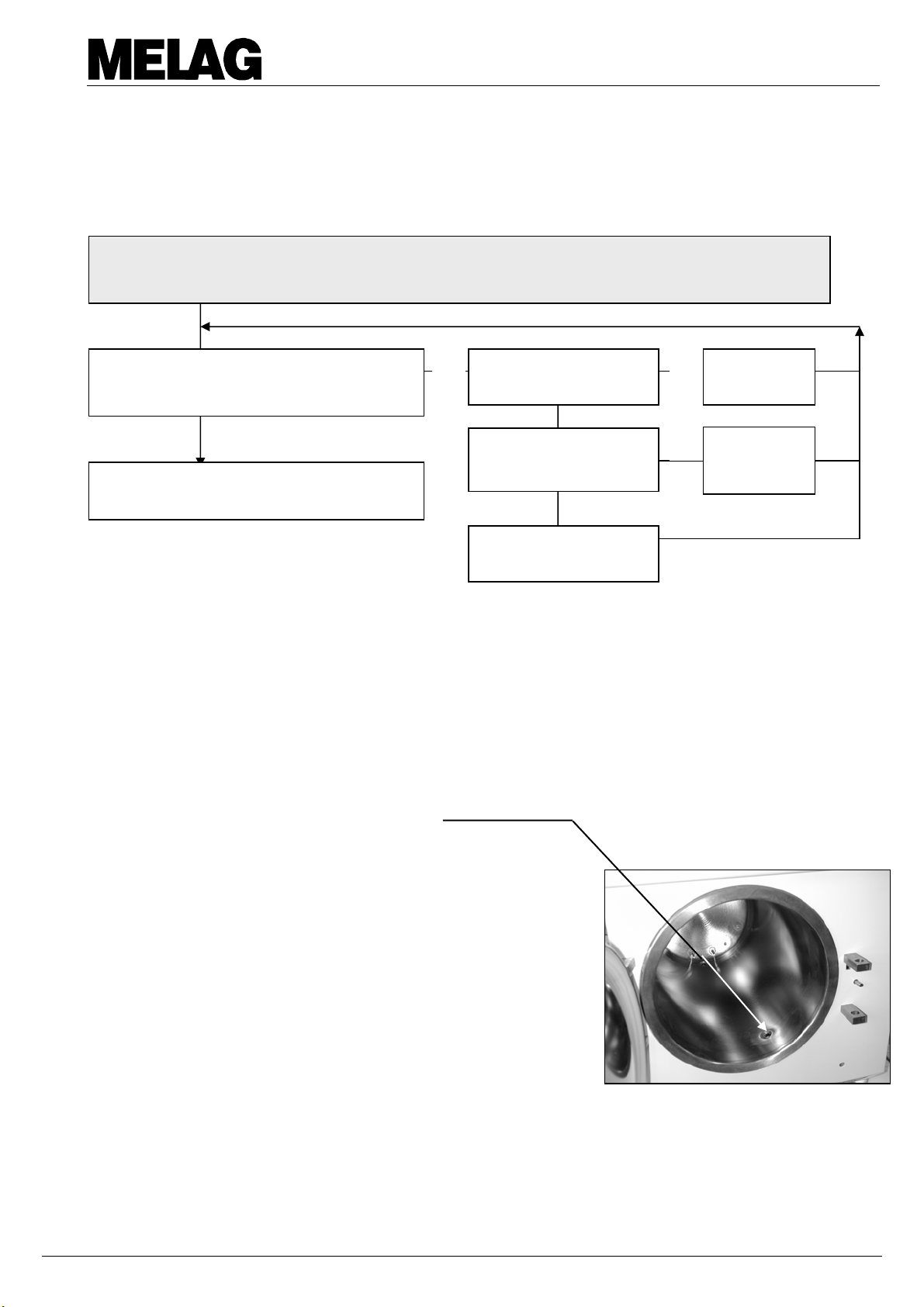

CONFIGURATION OFCOMPONENT GROUPS IN THE AUTOCLAVE

ERROR 1 VACUUM UNIT

VACUKLAV 31-B Configuration of the component

groups in the autoclave

(

TOP VIEW)

FRONT

SQ1

K

VV1

VQ

Fault diagnosis for Vacuklav

®

31-B

Fault 1: Vacuum system

The actual piping plan is contained in Drawing No. 31B-010.

This overview shows a rough schematic of the spatial configuration of the component groups, pipes, and hoses, in the Vacuklav

tions will refer to this overview to help you find the component groups to be checked.

®

31-B. The following error descrip-

C

VV2

PV

VDA1

VDA2

F

K

VB

F

H1

PQ

SLW

F

Item Bezeichnung Description State of valve

when no cur-

rent is applied

(dead)

C

F

H1

K

PQ

PV

SLW

SQ1

V

VV

V

V DA1

V DA2

VV

V

VV

V

VV

V

Kühler cooler 4

Filter filter

Dampferzeuger steam generator 1

Kessel vessel

Pumpe aqua dest pump for distilled water 5

Vakuumpumpe vacuum pump 3

Sensor Leitwert sensor for conductivity

Strömungswächter flow sensor for dist. water

Ventil (Magnet~) valve (solenoid)

B

B

Belüftung ventilation open 8

B

Druckablaß 1 pressure release 1 closed 7

Druckablaß 2 pressure release 2 closed 9

Q

Q

Speisewasser aqua dest feed water (distilled) closed 5

Q

V

1

V

1

Vakuum 1 vacuum 1 closed 6

V

1

V

2

V

2

Vakuum 2 vacuum 2 closed 6

V

2

ACOUT

(power

output)

Seite 1 von 5 Rev.-Nr.:98/0 FAULT_01 for 31B.doc

Fault diagnosis for Vacuklav

Fault 1: Vacuum system

®

Tripping conditions:

Fault conditions may occur if the monitoring time Uet1 was exceeded for achievement of the following:

• The required evacuation pressures for the individual sub-atmospheric pulses

– P37, P38, P40, P41 for cold starts

– P1, P2, P21, P22 for hot starts

• The required evacuation pressure (P17) for the vacuum test

• The required evacuation pressure (P12) for evacuation / pressure relief

• The required minimum pressure for drying (P3).

Causes of the problem / Correction of the problem

Action / checking by operating staff:

• Check for defects and for soiling of the door seal and the sealing surfaces of the sterilization chamber,

and on the round plate around the door of the sterilization chamber. Repair and clean if necessary.

31-B

• Check to make sure that the autoclave is properly set up (it must be installed with a tilt

described in the operating instructions).

• Check to make sure that the condensate drain at the bottom of the sterilization chamber is not stopped.

It can be stopped if instruments, filter paper, etc. fall onto the bottom of the chamber.

• Check for the following:

– If you are using the internal system for supply of demineralised water, check to make sure that the

pressure-release pipe is not stopped.

– If you are using an external waste-water connection that empties into the building waste-water sys-

tem, check to make sure that this drain pipe does not have a kink (make sure the water can flow

freely out).

(at slope), as

Seite 2 von 5 Rev.-Nr.:98/0 FAULT_01 for 31B.doc

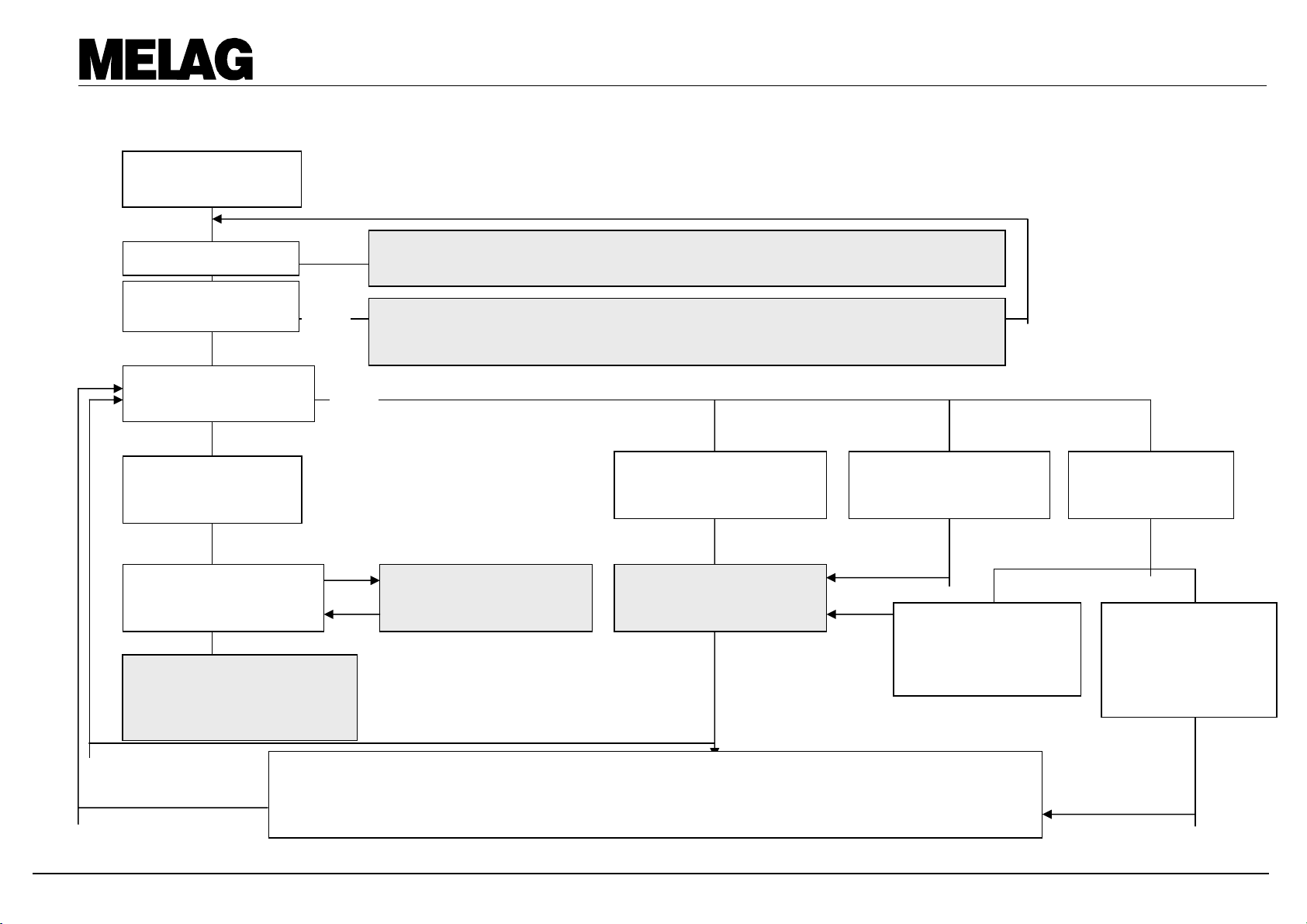

Faults in the autoclave / Correction of faults by technical service personnel

Start the vacuum test

(Leak rate < 1.3 mbar/min)

Special vacuum test OK?

Æ Fault Class: Vacuum fault

Pump system too weak

Correct fault and go on with

normal program start.

Fault 1

Vacuum system

Is the vacuum pump

running?

Yes

Vacuum test OK?

Yes

Vacuum test OK

Leak rate OK

Pressure is stable

(System flag F11 = 1)

(Pressure stable?)

Yes

In the Service Program, raise the evacuation pressure (P17) for the vacuum test by approx. 20 mbar more than

the evacuation pressure reached during the first test. Then repeat the test. (Important: When changing

P17, make sure that P13 is always greater than P17. If necessary, also raise 13 to ensure that P13 >

P17. If this is not done, you will receive the error message “System leak”.)

Note:

No

No

No

Important: All vacuum tests must be conducted with a cold, dry autoclave. Watch the

evacuation pressure achieved here, and the pressure change over time (from the display).

Æ Fault Class: Control fault / faulty pump Please check the following for faults: power

output ACOUT3; fuse F1; possibly defective vacuum pump. Correct the fault, and then go

to next.

Leak rate is too great

(> 1.3 mbar) and permanent

pressure rise

Æ Fault Class: Leak fault

Repair the leak in the intake

line; then next

Æ Fault Class: Leak fault

Stop the leaks and then next

Fehlerdiagnose Vacuklav

Fehler 1: Vakuumanlage

"Fault 31: System leaks"

Pressure rise over P3

(very large leaks)

The sub-atmospheric

pressure achieved is very

weak, or the pressure is

the same as in the room.

®

31-B

"Fault 1: Vacuum

system"

Sub-atmospheric pressure is within the range

of moderate to just less

than the evacuation

pressure (P17).

Seite 3 von 5 Rev.-Nr.:98/0 FAULT_01 for 31B.doc

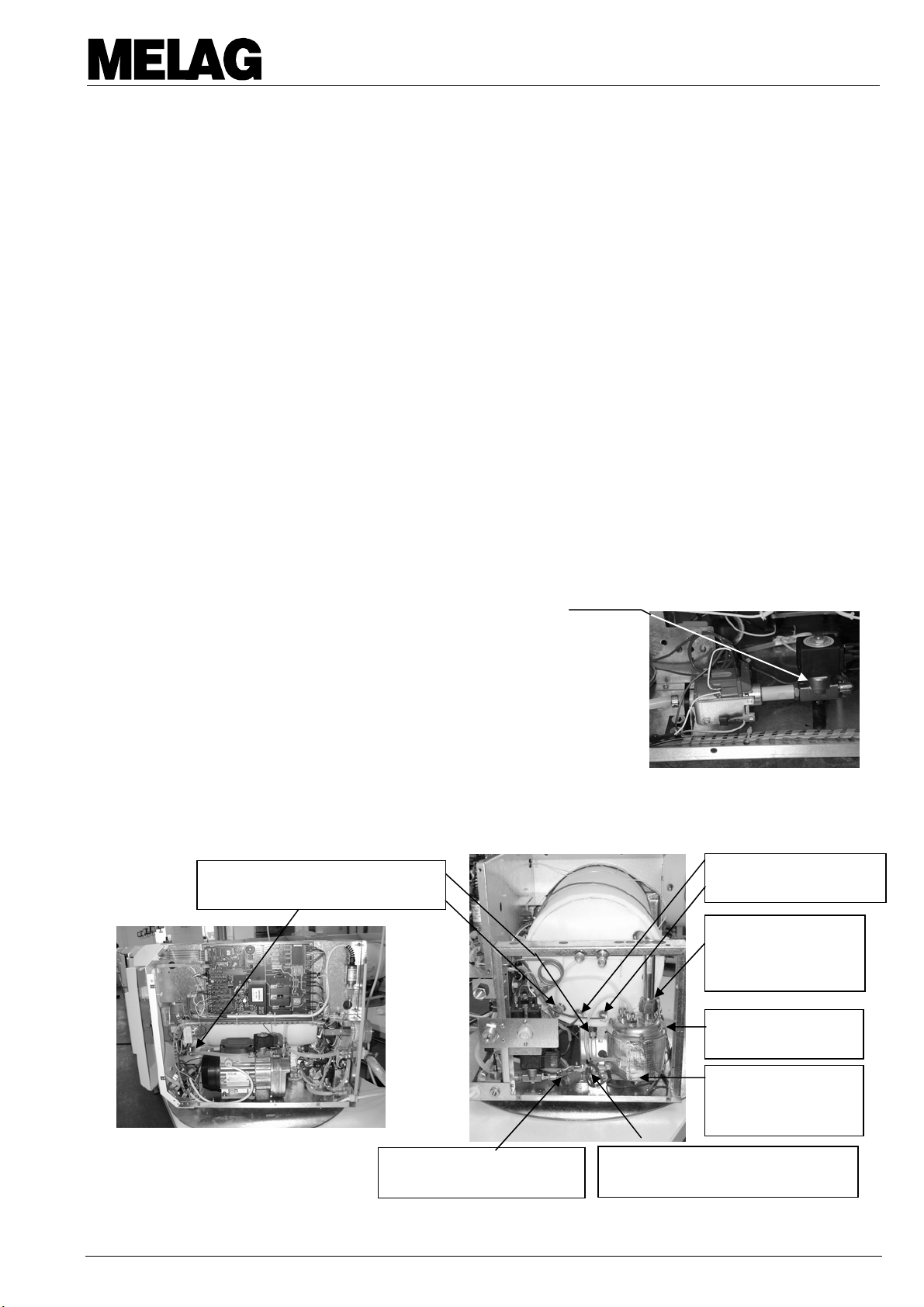

Fault diagnosis for Vacuklav

p

Fault 1: Vacuum system

Æ Fault class: Fault in control system or function of the pump

You can check the input voltage for the vacuum pump, as well as the function of the pump, as follows:

Make sure that the intake side is vented, since the pump will not start against a vacuum. In the Diagnosis

program, switch on the solenoid valves for vacuum 1 + 2 (VV1 + VV2) by switching on the power output

ACOUT 6 (the valves are open when the current is applied).

In the Diagnosis Program, switch on the pump

(PV) by switching the power output ACOUT 3.

Does the pump now run?

Proceed to the next step in the higher-level

fault-analysis plan.

Yes

Æ Fault class: the vacuum performance of the pump system is too weak

► The vacuum solenoid valves 1 + 2 do not open (VV1, VV2)

•

The solenoid valve, or coil, or rectifier plug are defective.

•

The activation for the solenoid valve (output 6) is defective.

Switch on output 6 in the Diagnosis program.

Check the electric control system and the switching behavior of the solenoid valve.

► The flow resistance in the intake line is too high

•

Filter in the intake fitting on the sterilization

chamber is clogged up

► The pressure-sensor signal is defective, or the

processing of this signal is not correct

•

The level of the pressure-sensor signal, or the signal processing,

is too high. See the section “Sensor Fault Group”.

► The suction of the vacuum pump is too weak

No

Check Fuse F1. Is it OK?

Yes

Test the power output

EP2-2 on the circuit board

with a meter. Out

Yes

The pump is defective.

Exchange the pump.

Fault 1: Vacuum system

No

Exchange

fuse F1.

Exchange the

No

circuit board.

ut OK?

®

31-B

Check the vacuum performance of the membrane as follows:

1. Check to see if there are leaks.

2. Make sure that the chamber to be evacuated is empty and dry.

3. If there are no leaks, and if the chamber is empty and dry,

check the performance of the pump. It must be at least

800 mbar in 80 s, or 900 mbar in 180 s.

4. If there are no leaks, and if the chamber is empty and dry, and if the performance of the pump does not meet

the above level (800 mbar in 80 s, or 900 mbar in 180 s), then exchange the pump.

Seite 4 von 5 Rev.-Nr.:98/0 FAULT_01 for 31B.doc

Fault diagnosis for Vacuklav

Fault 1: Vacuum system

®

31-B

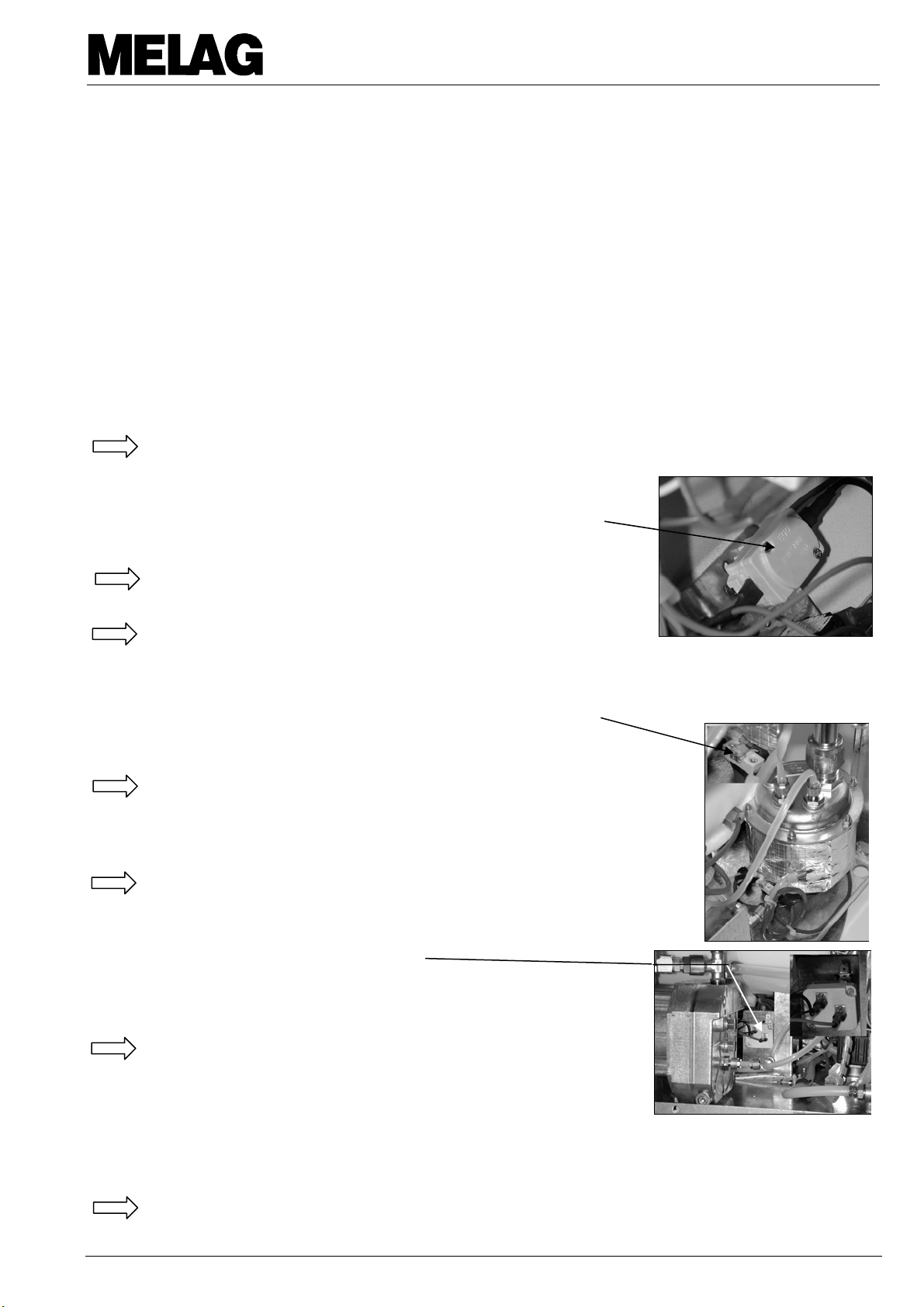

Fault 1: Vacuum system

Fault class: leakages

Leaks in the solenoid valves

► The solenoid valve for the venting (VB) will not close, or it leaks

•

Check the coil, the rectifier plug, and the control at output 8

•

Solenoid valve dirty. Check the plunger / is the seating tight?

Test under sub-atmospheric conditions (Vacuum Test program)

Remove the sterile filter. Cover the opening of the sterile-filter fitting

with the palm of your hand. Then observe the pressure reading.

► The solenoid valve for pressure release 1 + 2 (VDA1, VDA2) has a leak

•

Solenoid valve dirty. Check the plunger / is the seating tight?

Test under sub-atmospheric conditions (Vacuum Test program)

Observe the water column in the hose between the solenoid valve “Pressure release” and the sterile filter.

If there is a leak, water will be pulled in the direction of the solenoid valve.

Loosen the hose on the T-fitting for the cooling-water drain, close with finger, observe the pressure reading.

► The solenoid valve for the vacuum 1 + 2 (VV1 + VV2) has a leak (Vacuum Test program)

•

Solenoid valve dirty. Check the plunger / is the seating tight?

Test under sub-atmospheric conditions (Vacuum Test program):

Observe the water column in the hose between the intake fitting for the chamber and the solenoid valve for the

vacuum. If there is a leak, water will be pulled in the direction of the solenoid valve.

► The solenoid valve for the feed pump (VQ) has a leak

•

Solenoid valve dirty. Check the plunger / is the seating tight?

Test under sub-atmospheric conditions (Vacuum Test program):

Observe the water column in the intake hose leading to the input

of feed water between the conductivity-sensor and the intake fittings

of the pump, and on the pressure side of the pump. If there is a leak,

water will be pulled in the direction of the solenoid valve.

Leaks at the threaded connections and adhesive bonding

Test under sub-atmospheric conditions: start the “Leak search” procedure in the Diagnosis Program (0.3 bar, for

8 min). Or, feed compressed air into the autoclave through the vent-filter fittings (in Diagnosis program, close output 8, “MV vent”). Brush a soapy solution on the points shown below and check to see if there are any air bubbles.

Adhesive-bonded threaded hose

connections at the chamber

Plug of the pressure-release

filter

Adhesive bond for the T-fitting in

the pressure-release filter

Threaded connections

for temperature sensor

Cutting-ring threaded

connection for steam

generator / chamber

Cover seal for

steam generator

Swivelled threaded

connection for the

steam generator

Seite 5 von 5 Rev.-Nr.:98/0 FAULT_01 for 31B.doc

Fault diagnosis Vacuklav

r

®

24-B/24V/30-B/31-B

Fault 2: Steam generato

FAULT 2: Steam generator

Triggered by :

The following monitoring time limits have been exceeded

• Uet2 for the warming-up phases in the fractionations until reaching P5 (warm start), P39 (cold start),

P43 (cold start disinfection) or

• Uet3 for the heating up to the sterilization / disinfection temperature T1-T5

Causes / Remedy

Operating fault / Checks by personnel:

• Maximum load exceeded

• Mains power voltage too low (check mains installation)

Appliance fault / Repair by technical service personnel

► Control steam generator Output ACOUT1 faulty

check in "Diagnosis Program":

Switch on ACOUT1, (the LED for this output lights up),

Measure voltage at output ACOUT1

► Capillary control "2nd Overheating protection for the

Steam Generator" is faulty

• Control unit is permanently open

Check for passage when cold

• Control unit switches too soon

During a program, measure the voltage behind the control unit

with a sufficient water level in the steam generator (check level in the

condensate return) the control unit must not switch

► "3rd Overheating protection for the Steam Generator"

fuse blown on the heating coil of the steam generator

(contact broken )

Measure voltage behind fuse, this will usually be due to a fault at the

output ACOUT1 of the control unit and additionally failure of the 2

overheating protection

nd

► Heating Steam Generator faulty

In the Diagnosis Program switch on output ACOUT1, measure voltage

directly at the connectors of the heating coil of the steam generator

(voltage measured but coil remains cold)

► Capillary level control unit faulty

• Control unit does not open on overheating (water shortage).

Water shortage is not recognised and the overheating protection

switch switches off.

Functional test of the capillary level control unit:

In the "Service Program“/ "switch-times" set z24 = 0,

Start Universal Program with full load, by switching capillary control unit

and the resultant feed of distilled/demineralized feed water should

compensate for the water shortage in the steam generator

(observe condensation return to steam generator)

► Pressure sensor-Signal/ Signal processing faulty

• Pressure sensor signal or the signal processing too low

Steam generator heats until security-valve opens)

Page 1 of 1 Rev.-Nr.:00/0 FAULT_02 for 31B.doc

Loading...

Loading...