Page 1

User Manual

Sterilizer 205

Dry-heat sterilizer

EN

We thank you for your confidence demonstrated by the purchase of this MELAG product. As an owner-run and operated

family concern founded in 1951, we have a long history of successful specialization in hygiene products for practicebased use. Our focus on innovation, quality and the highest standards of operational reliability has established MELAG

as the world’s leading manufacturer in the instrument treatment and hygiene field.

You, our customer are justified in your demand for the best products, quality and reliability. Providing "competence in

hygiene" and "Quality – made in Germany", we guarantee that these demands will be met. Our certified quality

management systems is subject to close monitoring: Our certified quality management systems is subject to close

monitoring: one instrument to this end is our annual multi-day audit conducted in accordance with ISO13485 and

ISO9001. This guarantees that all MELAG products are manufactured and tested in accordance with strict quality

criteria.

The MELAG management and team.

Page 2

Page 3

Contents

Contents

Chapter 1 – General safety information ................................................................................................................................4

Chapter 2 – General Guidelines .............................................................................................................................................5

Formatting rules ...................................................................................................................................................................5

Symbols used.......................................................................................................................................................................5

Formatting rules ...................................................................................................................................................................6

Chapter 3 – Description of the device ...................................................................................................................................7

Scope of delivery..................................................................................................................................................................7

Intended use ........................................................................................................................................................................7

Views of the device ..............................................................................................................................................................8

Loading variations ................................................................................................................................................................9

Chapter 4 – Setup and Installation.......................................................................................................................................10

Requirements of the installation location ...........................................................................................................................10

Chapter 5 – First steps.......................................................................................................................................................... 11

Switching the hot air sterilizer on and off again..................................................................................................................11

Opening and closing the door ............................................................................................................................................12

Changing the mount...........................................................................................................................................................12

Chapter 6 – Sterilization .......................................................................................................................................................13

Preparing the sterilization material.....................................................................................................................................13

Heißluftsterilisator beladen.................................................................................................................................................13

Information regarding routine operation .............................................................................................................................14

Setting the temperature......................................................................................................................................................14

Selecting the sterilization times..........................................................................................................................................14

Removing the sterilized equipment ....................................................................................................................................14

Storing sterile instruments..................................................................................................................................................15

Chapter 7 – Function tests ...................................................................................................................................................16

Periodical checks ...............................................................................................................................................................16

Chapter 8 – Maintenance ......................................................................................................................................................17

Checks and cleaning..........................................................................................................................................................17

Chapter 9 – Malfunctions...................................................................................................................................................... 18

General events...................................................................................................................................................................18

Chapter 10 – Technical Data ................................................................................................................................................19

Chapter 11 – Accessories..................................................................................................................................................... 20

Glossary .................................................................................................................................................................................21

Page 4

Chapter 1 – General safety information

Chapter 1 – General safety information

When operating the device, comply with the following safety instructions as well as those

contained in subsequent chapters. Use the device only for the purpose named in these

instructions. Failure to comply with the set-up conditions can result in malfunctions or

damage to the device and/or human injury.

Power cable and power plug

n Only the power cable included in the scope of delivery may be connected to the device.

n The power cable may not be replaced by a cable determined to be insufficient.

Set-up installation and commissioning

n Only have the device set up, installed, and started up by people authorized by

MELAG.

n In accordance with current VDE specifications, the device is unsuitable for operation in explosive at-

mospheres.

n The device may only be repaired by the manufacturer or an agency which he has authorized to do so

(stockist or customer services).

n Check the device for any damage suffered during transport after unpacking.

n In the case of obvious or suspected damage/defects, the device may not be operated further. In such

cases, the device has to be repaired.

Danger of short circuit

n Liquids may not be permitted to reach the interior of the device. This could result in an electrical shock

or short circuiting.

Preparation and sterilization

n Do not place the objects to be sterilized on material produced from cellulose (e.g., paper, paper tow-

els, staple fiber, bandage material, etc.); this material would produce excessive heat accumulation

which would prevent the required heat equalization in the sterilizer.

n Observe the relevant standards and directives for the preparation of instruments.

Repair

n Never open the housing of the device. Incorrect opening and repair can compromise electrical safety

and pose a danger to the user. The guarantee and warranty are forfeited as soon as the device is

opened by anyone other than a member of a MELAG-authorized technical customer service.

4

Page 5

Chapter 2 – General Guidelines

Chapter 2 – General Guidelines

Please read this operating manual carefully before commissioning the product. The instructions include

important safety information. The functionality and value-retention of this device depend primarily on the

care accorded to it. Make sure to keep the Operating Manual near to the device. It represents a

component of the product.

Formatting rules

Example Explanation

see Chapter 2 Reference to another text section within this document

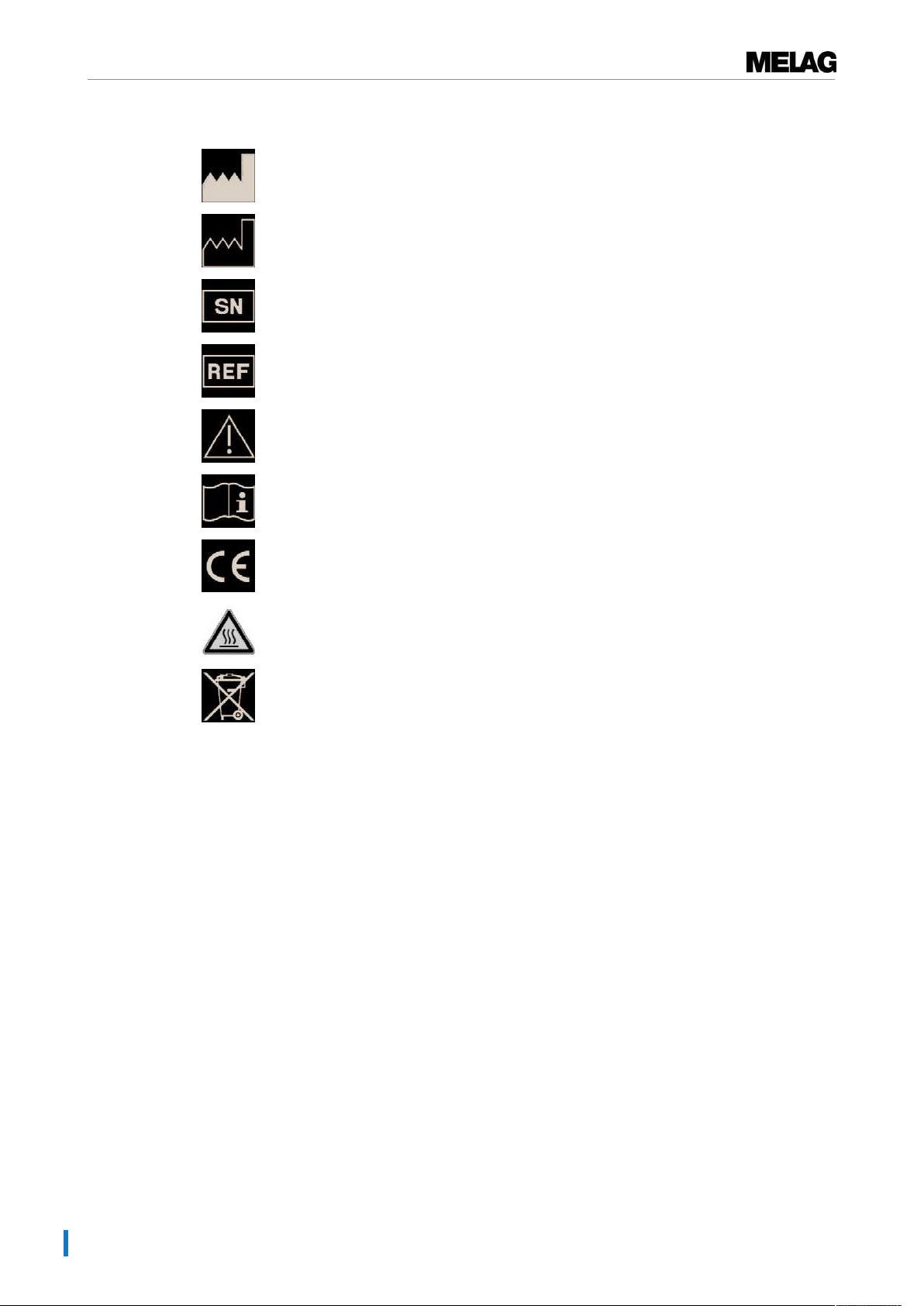

Symbols used

Symbol Explanation

Indicates a dangerous situation, which if not avoided, could entail slight to lifethreatening injuries.

Draws your attention to a situation, which if not avoided, could result in damage to the

instruments, the practice fittings or the device.

Draws your attention to important information.

5

Page 6

Chapter 2 – General Guidelines

Formatting rules

Manufacturer of the product

Date of manufacture of the product

Product serial number from the manufacturer

Article number of the product

The operating manual includes important safety information. Failure to comply with these

instructions can result in injury and material damage.

Please read this user manual carefully before commissioning the device.

In affixing the CE mark, the manufacturer declares that this product fulfils the basic

requirements of the EMC and low voltage directive.

Draws your attention to a hot surface. Should the fan fail, the cooling unit fins can

become hot.

The device may not be disposed as domestic waste. The vendor is responsible for

appropriate disposal of the device - it must be delivered to the vendor to be disposed of.

In affixing this symbol, the manufacturer furthermore declares that he has satisfied all the

legal requirements pertaining to the release, redemption and environmentally sound

disposal of electric and electronic appliances.

MELAG devices are synonymous with long-term quality. When you eventually need to

decommission your MELAG device, we offer a special disposal service. Simply contact

your stockist.

6

Page 7

Chapter 3 – Description of the device

Chapter 3 – Description of the device

Scope of delivery

Please check scope of delivery before connecting the device.

Standard scope of delivery

▪ 1x Sterilizer 205

▪ 1x User manual

▪ 1x Declaration of conformity

▪ 1x Warranty certificate

▪ 1x Power cable

▪ 1x Mount 1 or mount 2 (depending on the order)

Optionally

▪ Tray

▪ Tray jack

▪ Standard tray jack

▪ Standard tray cassette (unperforated)

Intended use

This hot air sterilizer is intended for use in the cosmetics sector, the cosmetic chiropody and the veterinary

sector. It was designed for the sterilization of objects made of non-flammable (inorganic) materials with a

minimum temperature resistance of 220°C (e.g. metal, glass, porcelain, stone or enamel). Comply with

the restricting information from the instrument manufacturer. Porous sterilization material is unsuitable for

hot air sterilization.

7

Page 8

Chapter 3 – Description of the device

2

1

3

4

5

6

7

8

11

9

10

13

12

Views of the device

Fig.1: Fore device view

1 Device foot

2 Temperature controller

3 Indicator lamp heating

4 Thermometer

5 Indicator lamp network

6 On/Off switch and time setting

7 Door handle

8 Door (opens forwards)

9 Fan

10 Type plate

11 Connection for the power supply

and the device fuse

Fig.2: Rear view of the device

12 Mounting

13 Sterilization chamber

Fig.3: View of the interior

8

Page 9

Chapter 3 – Description of the device

Loading variations

The hot air sterilizer is delivered with a mount for the acceptance of trays or standard tray cassettes. If one

or two trays are ordered with the device, the scope of delivery will include a tray jack.

The loading versions with devices with trays and standard tray cassettes are possible in the following

sizes:

▪ Tray (WxHxD): 19x2x36 cm

▪ Standard tray cassette (WxHxD): 19x4x29 cm

Mounting 1

Mount 1 can hold up to six trays.

Mounting 2

Mount 2 can hold three standard tray cassettes or three trays.

Both mounts are easy to replace. Comply with the instructions under point Changing the mount [}page

12] in chapter First steps [}page 11].

9

Page 10

Chapter 4 – Setup and Installation

Chapter 4 – Setup and Installation

Requirements of the installation location

NOTICE

The mains plug and the fuse must be easily accessible.

n Set up the device in such a fashion that the power plug can be disconnected from the mains

quickly following danger and that the fuse is easy to access.

Please observe and comply with the following instructions relating to the set-up.

u Install the device in a dry and dust-protected location.

u Install the device with a minimum clearance of 10 cm to other devices and walls, especially flammable

parts.

u Ensure sufficient ventilation. Ensure sufficient clearance to the top for free removal of the warm air.

The device may not be used as an installation device and not be used in the immediate treatment

area.

u The installation surface must be level and able to support the weight of the unit.

Tests after set-up

Perform a temperature check after setting-up the device using thermo sensors or bio indicators. Place the

test equipment in the area of the sterilization chamber in which the sterilization temperature is reached the

most slowly. This also depends on the arrangement and nature of the sterilization material.

10

Page 11

Chapter 5 – First steps

Chapter 5 – First steps

Switching the hot air sterilizer on and off again.

The hot air sterilizer is activated via the time switch (On/Off switch) and switches itself off after a pre-set

time. The fan comes to standstill after c. 45 seconds.

PLEASE NOTICE

Disconnect the mains plug if the device has not been operated for a long period of time.

Setting the operating time:

u Set the On/Off switch to the required operating time (turn clockwise).

ÊThe control lights network and heating will remain illuminated until the time expires.

ÊThe hot air sterilizer can be set to continuous operation. In this case, the hot air sterilizer must be

switched off manually.

Activating and deactivating continuous operation:

u Switch the On/Off switch to the "I" position (turn anti-clockwise).

ÊThe control lamp will remain illuminated; the control lamp for the heating will switch on and off. The

set temperature will be kept constant by the heating switching on and off.

u Switch the On/Off switch to the "0" position to switch off continuous operation.

ÊThe control lamps network and heating will extinguish.

11

Page 12

Chapter 5 – First steps

Opening and closing the door

ü

The device must always be deactivated before it is opened. Do not open the door or add any objects

after the sterilization procedure has started; this could result in cooling and the object not being sterilized for a sufficient time.

1. Move the On/Off switch to the "0" position to switch off.

2. Open the door forwards to open.

3. Move the door forwards to open.

Changing the mount

The mounts are installed to the left and the right in the sterilization chamber and can be replaced as

follows:

1. Slide the mount upwards from below and pull off to the side.

2. Set the mount with the screws into the larger aperture and press the mount downwards.

CAUTION

Danger of burns from hot metal surfaces

n Allow the device to cool sufficiently before opening.

n Do not touch any hot metal parts.

12

Page 13

Chapter 6 – Sterilization

Chapter 6 – Sterilization

Preparing the sterilization material

Cleaning and disinfection must always have been performed before sterilization. Only in this way is it

possible to guarantee the subsequent sterilization of the Sterilization material. The materials used, the

cleaning fluid and treatment procedures used are of decisive significance.

Please observe the following information before loading:

u Clean, disinfect and dry the instruments before every sterilization.

u Comply with the specifications of the manufacturer’s cleaning and care information when treating the

sterilization material. Only so is it possible to guarantee correct cleaning and disinfection and subsequent sterilization.

u Never place the sterilization material together in blocks, as this will prevent heat equalization.

u Do not place the sterilization material on cellulose, as this can result in a heat build-up.

u Always pack the sterilization material in aluminium containers. Stainless steel is unsuitable due to its

reduced heat conductivity. Do not use any textiles, paper or polyamide film as packaging. This packaging is unsuitable for high sterilization temperatures.

Heißluftsterilisator beladen

Only when correctly loaded is effective sterilization and good drying possible. Ensure the following during

loading:

u Insert trays or standard tray cassettes in the chamber only with their appropriate mount.

u When loading, ensure that air can circulate around the instruments unhindered. Do not load the trays

or standard tray cassettes one-sided and do not stack the sterilized equipment.

Example of a correct load

Tray

Standard tray cassette Standard tray cassette

Example of an incorrect load

Tray

13

Page 14

Chapter 6 – Sterilization

Information regarding routine operation

The sterilization temperature before every sterilization procedure must amount to 180 °C. To this end, the

setting of the sterilization time must take into account the Equilibration time. The pure aborticide time

amounts to 30 minutes at 180 °C.

1. Wait 15 minutes after the thermometer has reached 180 °C.

2. Set the required sterilization time. Comply with the specifications under Selecting the sterilization

times [}page 14] .

3. Check the ventilator noise: ensure that the mechanical air movement is functioning correctly.

Setting the temperature

Set the temperature for the hot air sterilizer as follows:

1. Turn the temperature control to 180 °C.

2. Wait until the thermometer reaches 180°C and allow the device to heat up for 15 minutes.

Ê During this time, the hot air sterilizer heats up the complete sterilization chamber.

3. Set the sterilization time via the “On/Off switch”. Comply with the information of the sterilization times

table.

Selecting the sterilization times

Do not exceed the specified loading quantities. Use only trays and cartridges made of aluminium. When

needing to pack with foil, use aluminium foil.

Table1: Load type and operating time

load Packaging Pre-heating time Operating time

max. of 1 kg, including 2 trays unwrapped 15 min 60 min

max. of 4 kg, including 6 trays unwrapped 15 min 75 min

max. 1 kg inc. 1 standard tray cassette wrapped 15 min 75 min

max. 4 kg inc. 3 standard tray cassettes wrapped 15 min 120 min

Removing the sterilized equipment

CAUTION

Danger of burns from hot metal surfaces

n Allow the device to cool sufficiently before opening.

n Do not touch any hot metal parts.

CAUTION

Unsterile instruments resulting from damaged packaging. This endangers the health of

the patient and the practice team.

n Should the packaging be damaged, re-pack the sterilization material and re-sterilize it.

14

Comply with the following when removing the sterilized equipment:

u Use a tray jack to remove the tray.

u Never touch the sterilized equipment, the device interior or the inside of the the door with unprotected

hands. The components are hot.

Page 15

Chapter 6 – Sterilization

Storing sterile instruments

The maximum storage time is dependent on the packaging and the storage conditions. For standardconform packaged Sterilized equipment – (if protected from dust) it can amount to up to six months.

Comply with the provisions of DIN 58953, part 8 and the criteria specified below for the storage of

sterilized equipment:

u The possible length of storage depends on the type of packaging

u Do not store the Sterilized equipment in the treatment room

u Protected against dust e.g. in a closed instrument cupboard

u Protected from damage to their shiny surfaces

u Protected from significant temperature differences

u Protected from moisture (e.g. from alcohol, disinfection fluids)

15

Page 16

Chapter 7 – Function tests

Chapter 7 – Function tests

Periodical checks

We recommend an annual inspection using bio-indicators, thermocouples or maximum thermometers.

▪ Comply with the valid regional legal specifications.

▪ When performing the spore test using biological indicators, the spore packets are to be clamped under

an instrument in order to prevent the package from being sucked into the fan motor.

16

Page 17

Chapter 8 – Maintenance

Chapter 8 – Maintenance

Checks and cleaning

Check the chamber, including the door seal and chamber sealing face and the mount once a week for

impurities, deposits or damage. If you find any impurities, remove the standard tray cassettes or cartridges

and the mount from the chamber. Clean the soiled components. When cleaning the chamber, the mount

for the load, chamber seal face and the door seal, please comply with the following:

▪ Switch off the steam sterilizer before cleaning and remove the power plug from the socket.

▪ Ensure that the chamber is not hot.

▪ Use a soft, non-fuzzing cloth.

▪ Use a chlorine- and vinegar-free cleaning fluid.

▪ First soak the cloth with the cleaning alcohol or spirit and attempt to remove the impurities with this

method.

▪ Only if the chamber, mount or chamber seal face has persistent soiling should you use a mild stainless

steel cleaning agent, with a pH value between 5 and 8.

▪ To clean the door seal, use a neutral liquid cleaning agent.

▪ You should not allow cleaning fluid to enter the piping coming from the chamber.

▪ Do not use any hard objects such as metal saucepan cleaner or a steel brush.

▪ Check the door seal for damage on a daily basis. Replace the door seal if necessary.

▪ Check the contact pressure of the door The entire surface of the door must be in contact with the frame.

NOTICE

Inappropriately performed cleaning can lead to the scratching of and damage of surfaces

and the development of leaks in sealing surfaces. This creates conditions favourble to

dirt deposits and corrosion in the sterilization chamber.

Comply with all information regarding cleaning of the part affected.

17

Page 18

Chapter 9 – Malfunctions

Chapter 9 – Malfunctions

General events

Incident Possible cause What you can do

The temperature display of

the thermometer deviates

by more than 8 °C than set

on the controller.

The device does not switch

off. The indicator lamp

“network” and “heating”

illuminate.

The temperature displayed

deviates from the set

temperature. The

thermometer displays less

than 180°C or falls from

180°C to c. 150°C within c.

5 min. and continues to fall.

Under circumstances, there

is no audible ventilator

noise.

The device is too hot (over

180°C).

The temperature fluctuates

between 210-240°C. The

indicator lamp network is

illuminated. The indicator

lamp heating is

continuously off or on/off

every 20 seconds.

The control button has

been maladjusted.

The timer is defective or

is set to continuous

operation.

The temperature has

been set too low.

The temperature

controller rotary knob was

unintentionally turned or

mal-adjusted during

unpacking or incorrect

handling e.g. during

cleaning.

The “Temperature

controller” has been set

incorrectly or is defective.

Increase or reduce the temperature by turning

the temperature controller:

Higher temperature: Anti-clockwise

Lower temperature: Clockwise

Check that the "On/Off switch" is set to "I" or "0".

If the timer is defective, inform an authorized

customer services.

The device can be operated provisionally on a

semi-automatic basis by actuating the "On/Off

switch" manually.

Set a higher temperature.

The temperature controller must be readjusted

by a service technician. Inform an authorized

customer services.

Provisionally, turn the temperature controller so

that the desired temperature is displayed on the

device thermometer.

Set the temperature controller to e.g. 180°C

and check whether this temperature has been

reached / is displayed on the thermometer (note

the heating and equilibration time).

Should values deviate, the rotary knob must be

readjusted. Task an authorized customer

services.

If the thermostat is defective, inform an

authorized customer services.

Provisionally, turn the "temperature control"

rotary knob so that the desired temperature is

displayed on the device thermometer.

18

Page 19

Chapter 10 – Technical Data

Chapter 10 – Technical Data

Device type Sterilizer 205

Electrical power 1100 W

Electrical connection 220-240V 50/60 Hz

Device fuse 2 x 6.3 A T

Noise emission 49 dB

Waste heat 1.3 MJ

Weight 17 kg

Please observe the maximum load: 5.5 kg including 6 trays

Maximum mains voltage supply variations: +/- 10 %

Maximum voltage range 207 - 253 V

Relative humidity up to 31°C max. 80% | up to 40°C max. 50%

Degree of protection IP 20

Protection category I

Sterilization chamber (WxHxD)

Dimensions (WxHxD) 31 x 47 x 38.5 cm

Ambient temperature 5°C - 40°C

Volume of the sterilization chamber 14 litres

1

19x 20 x 36 cm

1

with installed mounts

19

Page 20

Chapter 11 – Accessories

Chapter 11 – Accessories

Table2: Accessories

Designation of article Order.-No.

Mounting 1 60030

Mounting 2 60040

Tray 02000

Standard tray cassette 00287

Tray jack 28890

Jack for standard tray cassette 28895

20

Page 21

Glossary

DIN 58953

Standard – sterilization, sterile equipment supply

Equilibration time:

The equilibration time comprises the time required

to to heat all the locations of the device and the

sterilization material to the required temperature of

180 °C.

Sterilization material

Unsterile, sterilizabe material which is still to be

sterilized.

Sterilized equipment

Also referred to as a batch: a load which has

already been sterilized, i.e. is sterile

VDE

German abbreviation "Verband der Elektrotechnik,

Elektronik und Informationstechnik e.V." (Alliance

of the Electronics, Electrotechnical and IT Industry).

Glossary

21

Page 22

MELAG Medizintechnik oHG

Geneststraße 6-10

10829 Berlin

Germany

E-Mail: info@melag.com

Web: www.melag.com

Responsible for content: MELAG Medizintechnik oHG

We reserve the right to technical alterations

Your stockist

BA_Heißluftsterilisator 205_EN.pdf | Rev. 5 - 16/1198 | Modification date: 13.06.2016

Loading...

Loading...