Page 1

Operating manual

for the autoclaves

MELAtronic15EN

MELAtronic

MELAtronic23EN

with device software version 3.33 ff.

17EN

Dear Doctor:

Thank you very much for the trust which you have shown by purchasing this autoclave.

For more than 50 years now, MELAG — a medium-sized family-owned and -operated

company — has specialized in the production of sterilization equipment for medical

practice. During this period, MELAG has succeeded in becoming a leading manufacturer

of sterilization equipment. More than 355 000 MELAG units sold throughout the world

testify to the exceptional quality of our sterilizers — which are manufactured exclusively in

Germany.

As all other MELAG products, this autoclave was manufactured and tested according to

strict quality criteria. Before placing this unit into operation, please read this Operating

Manual carefully. The long-term functional effectiveness and the preservation of the value

of your autoclave will depend on careful preparation of instruments before sterilization,

and on proper care of the unit.

The staff and management of MELAG

Page 2

To ensure the functional effectiveness of this

unit and to preserve its value:

1. Prepare the instruments to be sterilized carefully

2. Take proper care of the autoclave

3. Use only pure distilled or demineralized water

CONTENTS

1

DESCRIPTION OF THE UNIT....................................................................................................................4

1.1 Views of the unit...................................................................................................................................4

1.2 Control - Panel .....................................................................................................................................5

1.3 Technical data......................................................................................................................................6

1.4 Performance features of this autoclave ...............................................................................................6

1.4.1 Conformity to european standard.................................................................................................6

1.4.2 Fractionated Gravity system.........................................................................................................6

1.4.3 Operating range for sterilization....................................................................................................6

1.4.4 Integrated steam generation.........................................................................................................6

1.4.5 One-way / Closed-loop system / Conductivity measurement.......................................................7

1.4.6 Electronic Parameter Control EPS ...............................................................................................7

1.4.7 Pre-heating / Drying......................................................................................................................7

1.4.8 Documentation..............................................................................................................................7

2 INSTALLATION..........................................................................................................................................8

2.1 Setting up the autoclave.......................................................................................................................8

2.2 Transport ribbons.................................................................................................................................8

2.3 Levelling...............................................................................................................................................8

2.4 Mains power supply .............................................................................................................................8

2.5 Filling the water storage tank...............................................................................................................8

2.6 Connecting the external Condensate container (option) .....................................................................9

3 INITIAL START-UP.....................................................................................................................................9

3.1 Initialising the printer............................................................................................................................9

3.1.1 Connecting the external MELAprint®42 printer.............................................................................9

3.1.2 Initialising the printer / Immed. print-out? Yes/No.........................................................................9

3.2 Test run................................................................................................................................................9

3.3 Safety instructions..............................................................................................................................10

4 INSTRUCTIONS FOR ALL STERILIZATION PROCEDURES................................................................10

4.1 Electricity and water supplies.............................................................................................................10

4.1.1 Feed water aqua dest / aqua dem..............................................................................................10

4.1.2 Power supply ..............................................................................................................................11

4.2 Preparing instruments for sterilization................................................................................................11

4.3 Loading the autoclave........................................................................................................................12

4.4 Closing the door.................................................................................................................................13

4.5 Program selection ..............................................................................................................................13

4.6 Program start......................................................................................................................................14

4.7 Program progress ..............................................................................................................................14

4.8 Print-out record...................................................................................................................................15

4.9 Removing the sterilized items............................................................................................................16

4.10 Sterile storage / Drying.......................................................................................................................16

4.11 Sterilization frequency / pauses.........................................................................................................16

4.12 Manual termination of program..........................................................................................................17

4.12.1 Termination of sterilization..........................................................................................................17

4.13 Reaction to warnings / error messages .............................................................................................18

4.14 Operational pauses............................................................................................................................18

Page 2

5 CLOSING DOWN / TRANSPORT / REINSTALLATION..........................................................................18

Page 3

®

Operating manual for MELAtronic

6

SPECIAL FUNCTIONS.............................................................................................................................19

6.1 Water quality (conductivity) / Chamber preheating temperature .......................................................19

6.2 Records / Load documentation..........................................................................................................19

6.2.1 Record print-out..........................................................................................................................19

6.2.1.1 External Printer....................................................................................................................19

6.2.1.1.1 Connecting the external printer MELAprint®42..................................................................19

6.2.1.1.2 Initialising the printer..........................................................................................................20

6.2.1.2 Connection to an external PC..............................................................................................21

6.2.1.2.1 Installation..........................................................................................................................21

6.2.1.2.2 Initialising the file transmission to the PC..........................................................................21

6.2.1.3 No printer.............................................................................................................................21

6.2.2 Immed. print-out? Yes / No.........................................................................................................21

6.2.3 Printing out stored records..........................................................................................................22

6.2.4 Print all stored cycle records.......................................................................................................23

6.2.5 Display printer memory status ....................................................................................................24

6.2.6 Deleting cycle records.................................................................................................................25

6.2.7 Test print-out...............................................................................................................................26

6.3 Setting date and time.........................................................................................................................27

6.4 Automatic preheating.........................................................................................................................28

6.5 Total batch counter ............................................................................................................................29

6.6 Program modifications .......................................................................................................................29

15 / 17 / 23EN

7 OPERATORS FAULTS/ MALFUNCTIONS..............................................................................................30

7.1 What to do if the autoclave malfunctions...........................................................................................30

7.2 Malfunctions without display messages.............................................................................................30

7.2.1 No Display...................................................................................................................................30

7.2.2 Door locking function ..................................................................................................................30

7.2.3 Leaks in the door ........................................................................................................................30

7.2.4 Excessive water consumption.....................................................................................................30

7.2.5 Poor drying..................................................................................................................................31

7.3 Warning messages ............................................................................................................................31

7.4 Malfunction messages .......................................................................................................................33

8 TAKING CARE OF YOUR AUTOCLAVE.................................................................................................36

8.1 Preparation of instruments.................................................................................................................36

8.2 Rust formation = Drag-in rust.............................................................................................................36

8.3 Taking care of the MELAtronic15EN, 17EN and 23EN....................................................................37

8.3.1 Cleaning the autoclave ...............................................................................................................37

8.3.2 Instructions for checking and caring for the door and door-lock components............................38

8.3.3 Use of demineralized or distilled water.......................................................................................39

8.4 Checking the operation of the autoclave............................................................................................39

8.4.1 Safety with automatic monitoring................................................................................................39

8.4.2 Periodical bacteriological testing (twice a year)..........................................................................39

8.4.3 Maintenance recommendations..................................................................................................39

9 ANNEX......................................................................................................................................................40

9.1 Capacity / Weight...............................................................................................................................40

9.2 Performance of the sterilization programs according to EN 13060 ...................................................40

9.3 Additional technical data....................................................................................................................41

Page 3

Page 4

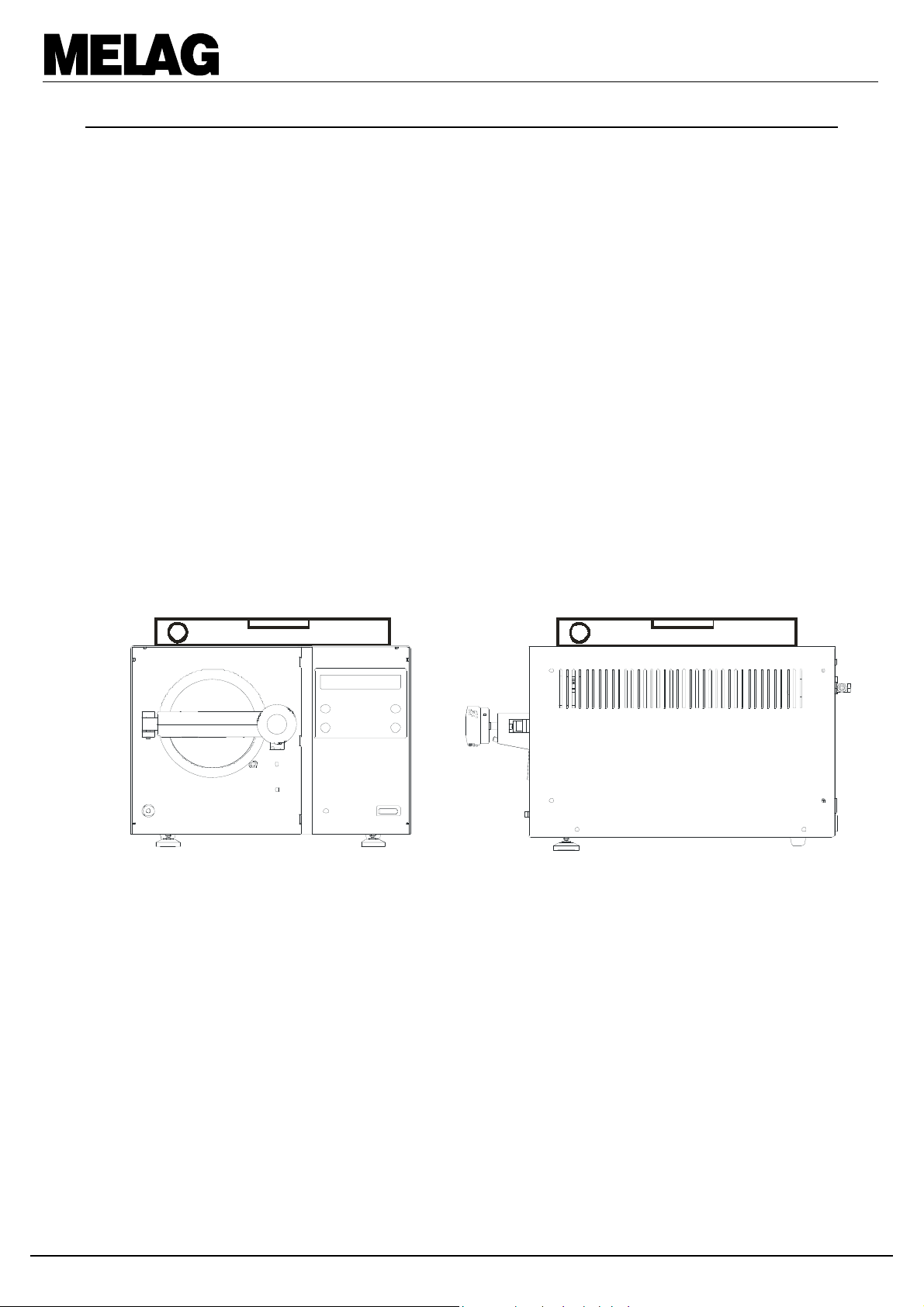

1 Description of the unit

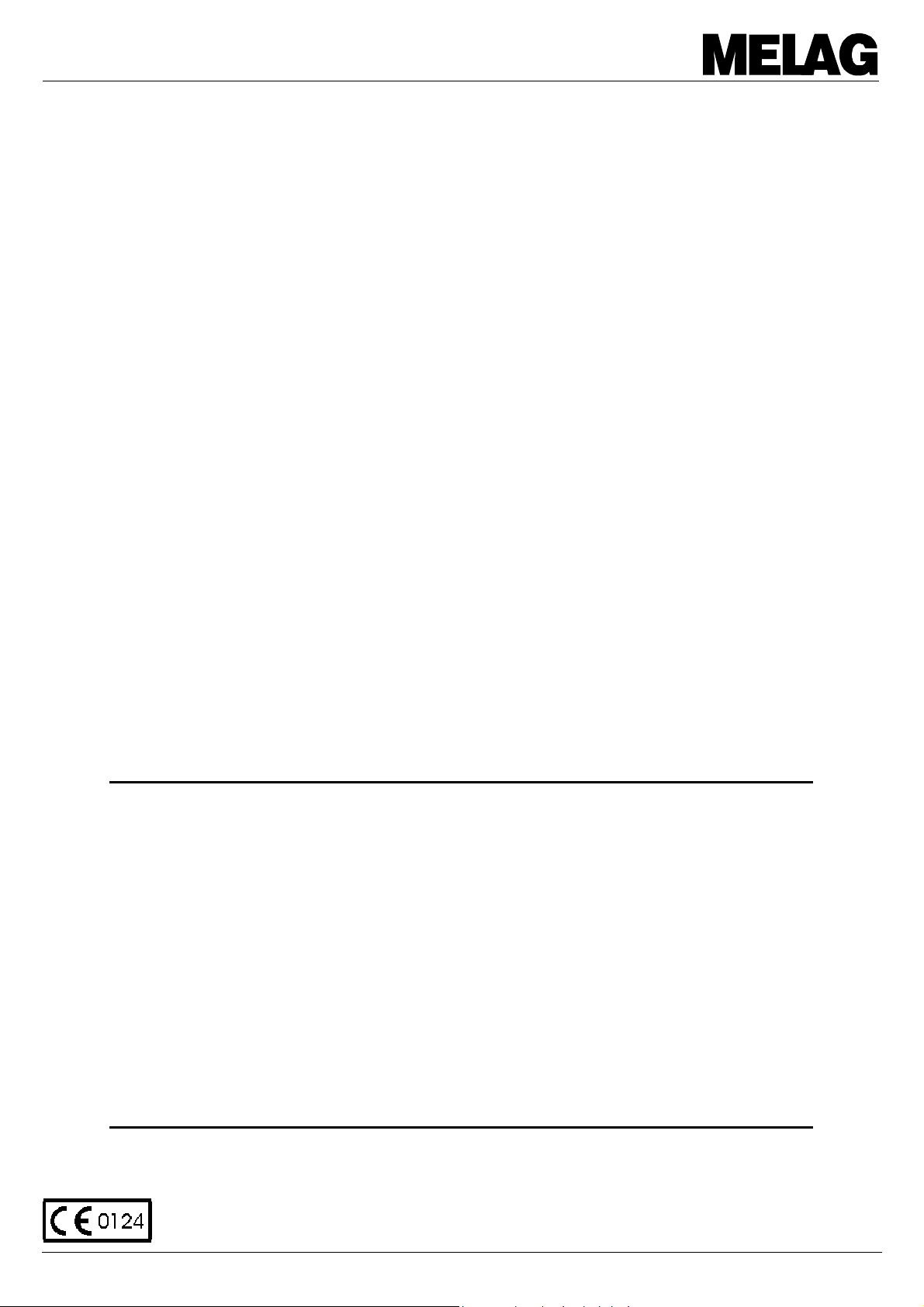

1.1 Views of the unit

7

6

Fig. 1 Views of the MELAtronic

3

A

5

____________________________________________________

13

C

D

E

27

28

23

1

B

4

2

3

19

18

17

16

15

14

®

15EN / 17EN / 23-EN

11

12

10

10

9

8

22

21

20

26

25

24

Page 4

Page 5

t

Pos.

Operation panel

1

Power switch

2

Adjustable front feet

3

Reset bottom for the overheating protection of

4

the steam generator

Door contact switch

5

Water drain tap

6

Door

7

Back feet

8

Mains power cable

9

Fuses: 2 x 16 A / FF

10

Connector for external condensate container

11

Serial data and printer port (RS 232)

12

Aeration of the water storage tank

13

Conductivity sensor

14

Dimensions

Operating manual for MELAtronic

Pos.

Safety valve

15

„MAX“- mark

16

Water supply filter

17

Condensate loop „Pressure release“

18

Connector for condensate loop

19

Door locking bolt

20

Door grip

21

Locking latch

22

Tray

23

Tray mount

24

Door gasket

25

Water storage tank

26

Housing cover with slides

27

Lid of water storage tank

28

®

15 / 17 / 23EN

tronic

®

15EN

MELA

MELAtronic®17EN

MELAtronic®23EN

Width Height Depth C Depth D Depth E

43.5cm 32.5cm 50cm 46cm 62.5cm

46cm 35cm 54.5cm 51cm 67cm

52cm 38cm 58.5cm 55cm 71cm

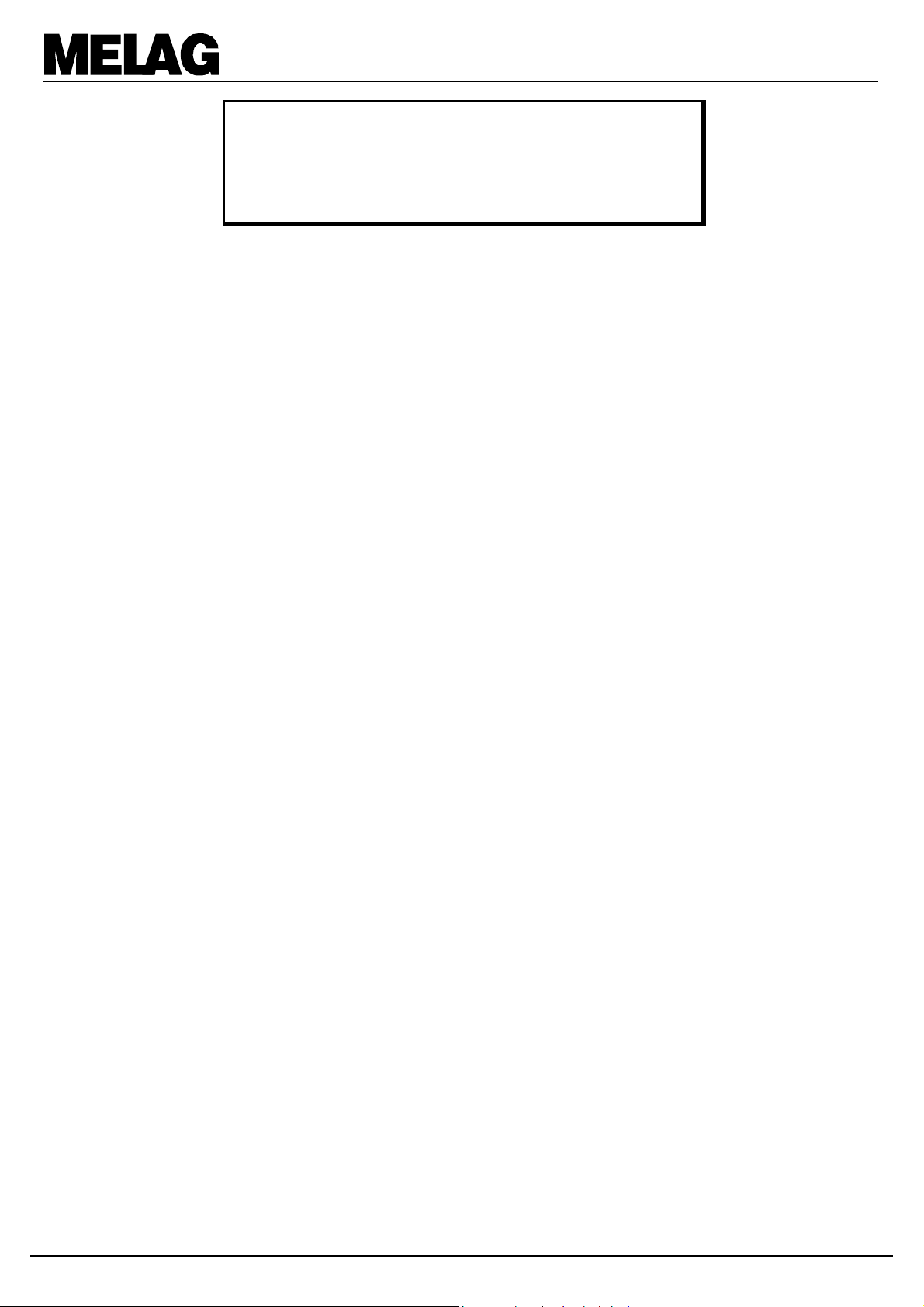

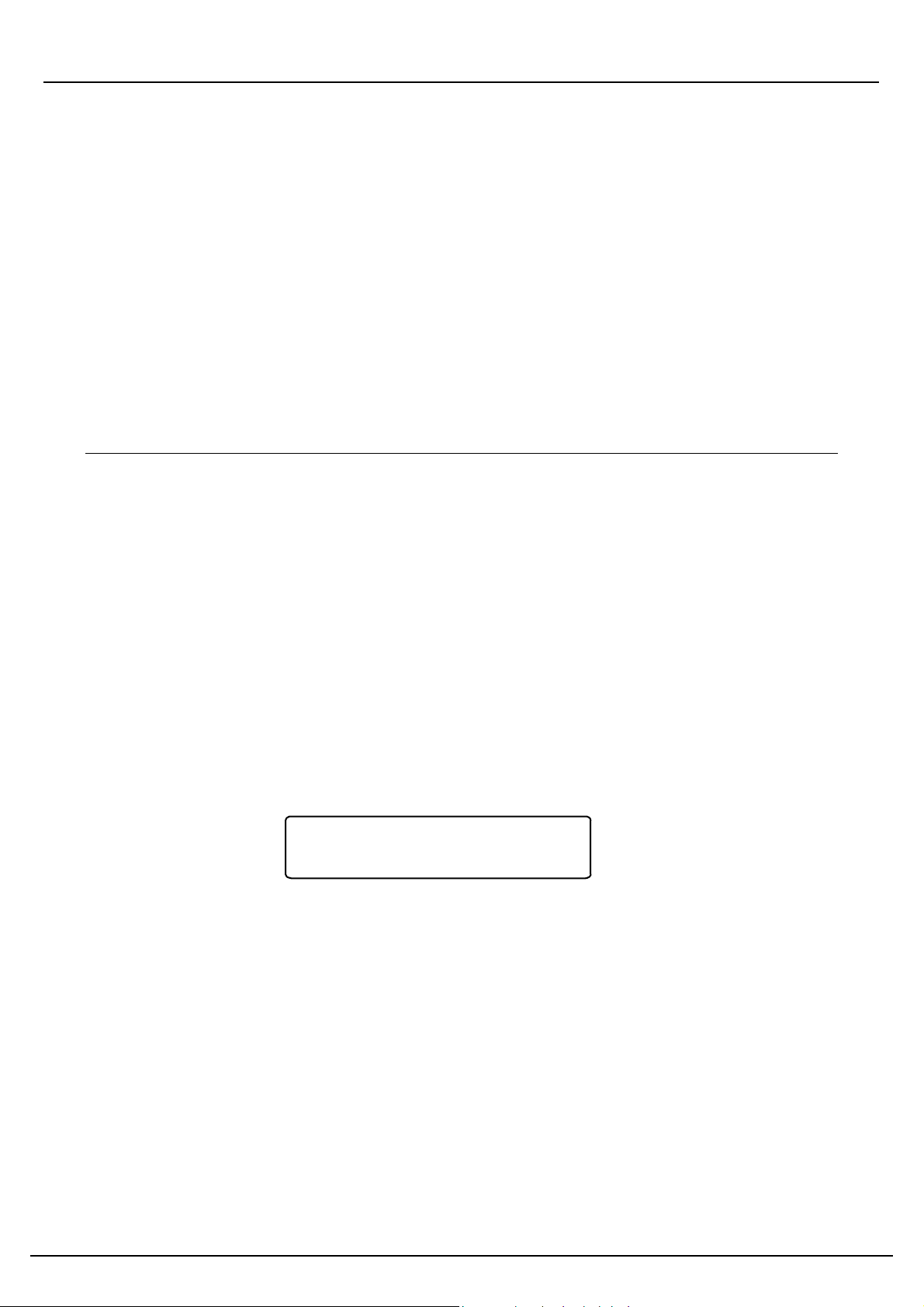

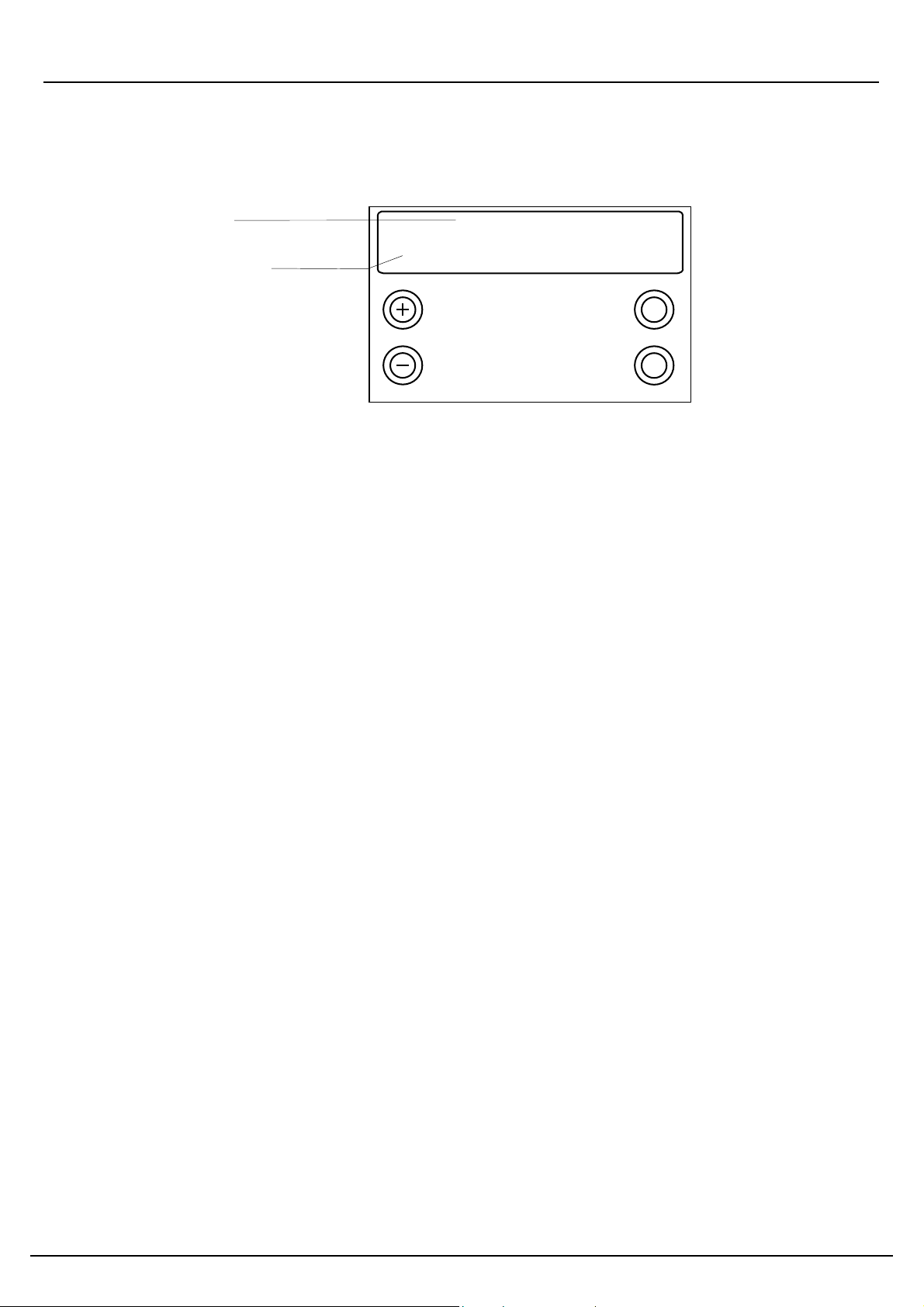

1.2 Control - Panel

______________________________________________________

Buttons for selecting, adjusting and

displaying special functions:

Printing, date / time, pre-heating,

total loads, conductivity, re-setting

Fig. 2 Control panel of MELAtronic

15EN / 17EN / 23-EN

Programm

Start - St o p

2 x 20- alphanumeric LED-display, showing

program status, and parameters for basic

and special functions

Program selection for:

Sterilization programs/ test programs

and for selecting options (sub-menus) of the

special functions

Start - stop buttons to star

and interrupt programs,

drying, and to control special

functions

Page 5

Page 6

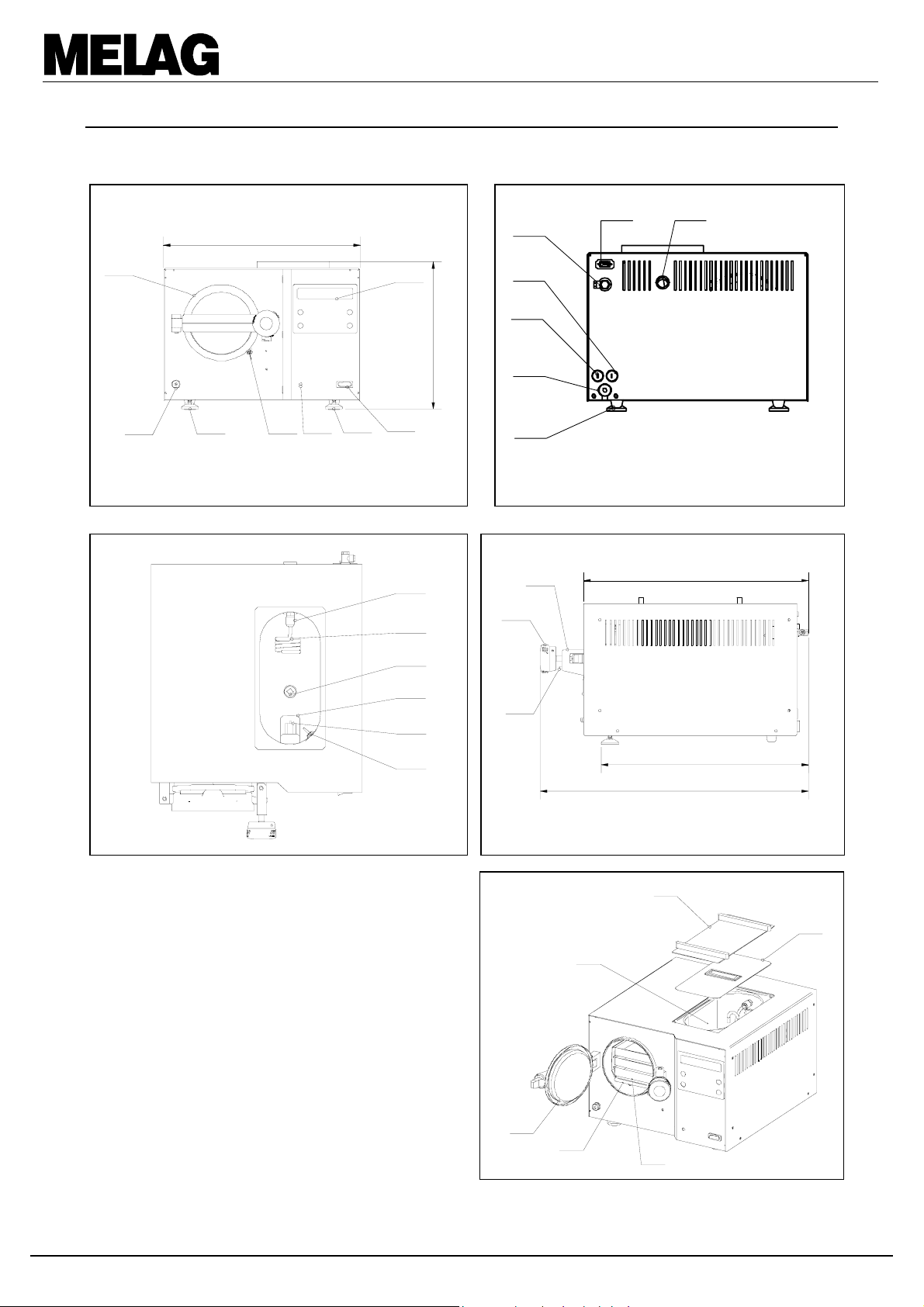

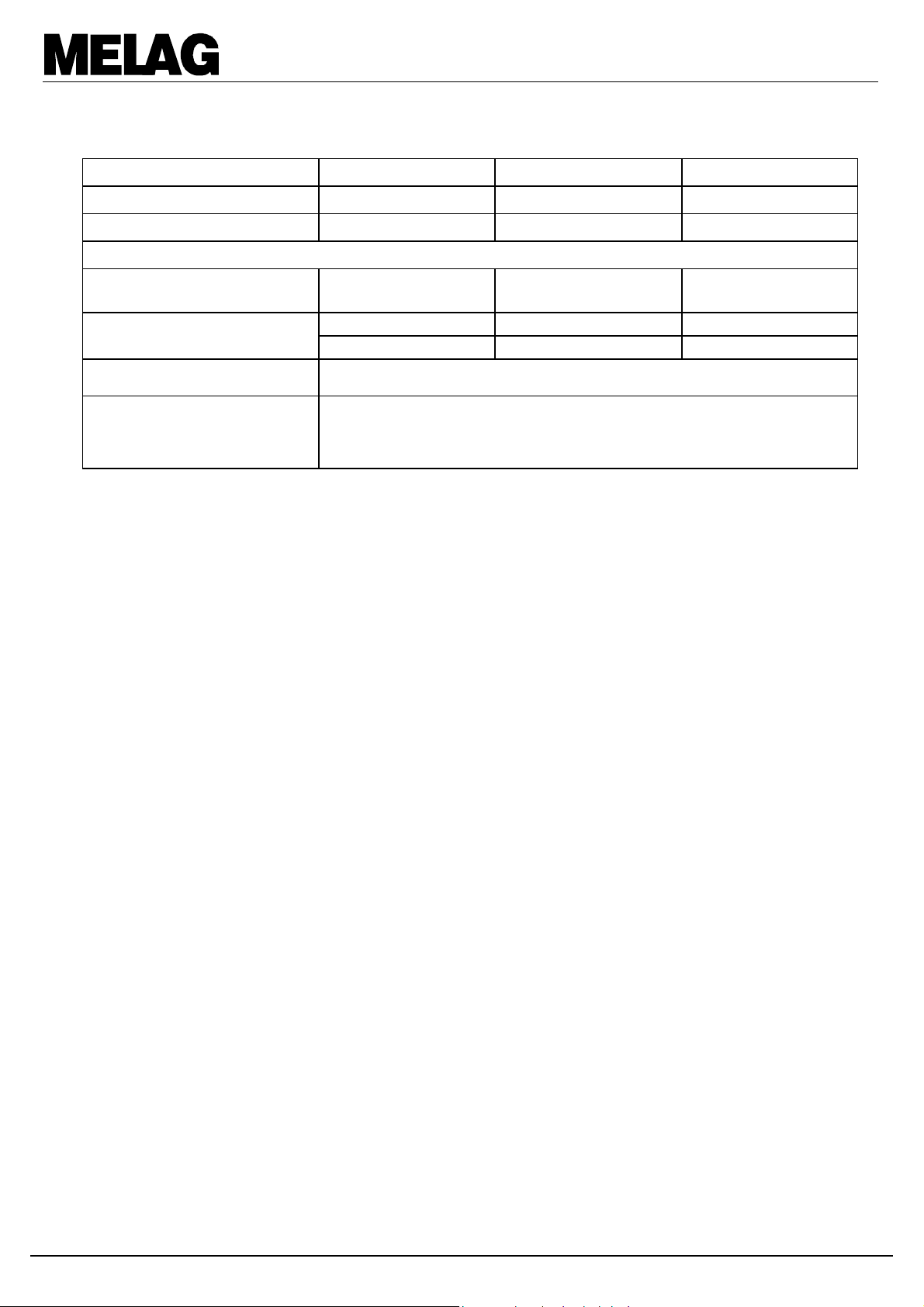

1.3 Technical data

Chamber ( ∅ x Depth), Volume

Electric power supply 230V / 50Hz, 1500W 230V / 50Hz, 1500W 230V / 50Hz, 1600W

Maximum load:

Instruments

Wrapped / unwrapped

Textiles wrapped

unwrapped

Parameters

Gentle - Programm

Parameters

Universal-program ,

Quick - programm ,

Prionen - Programm

Further technical details are included in the Annex

1.4 Performance features of this autoclave

______________________________________________________

MELAtronic®15EN MELAtronic®17EN MELAtronic®23EN

15 x 38 cm, 7 Litres 18 x 42 cm, 11 Litres 23 x 45 cm, 19 Litres

2 Kg 3 Kg 4 Kg

100 Gr. 150 Gr. 200 Gr.

150 Gr. 300 Gr. 500 Gr.

121 °C, 1bar, Sterilization time: 20 min

134 °C, 2bar, Sterilization time: 5 min

_________________________________

1.4.1 Conformity to european standard____________________________________________________

The autoclaves MELAtronic

Steam Sterilizers EN 13060 for autoclaves with sterilization cycle of the type „S“ and „N“ (see section .4.5

and 9.2) .

Regarding the sterilization performance the autoclaves MELAtronic

the sterilization of unwrapped and solid instruments, for the sterilization of single wrapped solid instruments

and also for the sterilization of small amounts of single wrapped textiles. Thermo – electrical Tests according

EN 13060 and additional bacteriological tests have approved this perfomance.

1.4.2 Fractionated Gravity system________________________________________________________

With the fractionated gravity system which is used steam flows into and then out of the autoclave to ensure

effective penetration of the items to be sterilized by saturated steam.

This makes it possible to carry out demanding sterilization tasks rapidly and reliably, such as for example the

sterilization of wrapped instruments or textiles.

1.4.3 Operating range for sterilization_____________________________________________________

The autoclaves MELAtronic

134°C: the “Universal Program” (for wrapped objects), the “Prion Program” (a special Universal Program),

the “Quick Program” for unwrapped items. The “Gentle Program” is a sterilization program for textiles and

rubber articles at 121°C.

1.4.4 Integrated steam generation ________________________________________________________

The powerful steam generation in the sterilization chamber makes it possible to sterilize large loads of

instruments or textiles in a short time. This system of steam generation means that excess temperatures in

the sterilized chamber are not possible.

15EN, 17EN und 23EN fulfill the stipulations of the european standard for Small

15EN, 17EN and 23EN are usable for

®

15EN, 17EN and 23EN feature three sterilization programs for temperatures at

Page 6

Page 7

®

Operating manual for MELAtronic

1.4.5 One-way / Closed-loop system / Conductivity measurement______________________________

The autoclaves MELAtronic

circulatory water system. This means that the water evaporated during each sterilization process is

condensed and returned to the water storage tank. This takes place during sub-atmospheric pulsing, and

during pressure release. This type of operation is effective for sterilization rates of approx. 2 … 3 sterilization

cycles per work day, if sufficiently long pauses between sterilization are observed. In work with a circulatory

water system, however, it is very important to ensure that the instruments to be sterilized have been

especially carefully cleaned and rinsed before sterilization. In addition, the water should be checked for dirt

and debris every day, and the water must be changed at least once a week.

If the sterilizer is used often, the water in the water storage tank becomes extremely hot, so that complete

condensation in the tank is not possible, and steam will exit from the vent openings (Fig. 1, Pos. 13) on the

back wall of the autoclave. Under these conditions, an external condensate tank (MELAG article no. 00356)

can be connected to the autoclave, and the condensing coil (Fig. 1, Pos. 18) can be removed from the water

storage tank. The autoclave will now operate with a single-use (non-reusable) water system, and the

evaporated water for each sterilization will be condensed in the external condensate tank. This configuration

has the advantage that the water in the storage tank will not become too hot, and the steam will not be

ejected from the autoclave. Another advantage of this installation alternative is that impurities dissolved in

the steam will not get into the water of the storage tank – and this means that clean distilled or demineralized

water will once again be used for sterilization in the following program cycle.

An integrated electrical conductivity sensor monitors the quality of the demineralized or distilled water used

to generate the steam. Using the recommended one-way operation for the autoclave, the increased

consumption of demineralized or distilled water can be provided by using a water purifier such as the

MELAdem

®

40, MELAdem®47 or the MELAdest®65.

Provided that the instruments are prepared carefully for the sterilization, stains on the load and soiling of the

autoclave itself can be prevented.

®

15EN, 17EN and 23-EN operate in the standard installation mode, as a

15 / 17 / 23EN

1.4.6 Electronic Parameter Control EPS ___________________________________________________

The microprocessor used in the MELAtronic

®

15EN, 17EN and 23EN makes it possible to monitor pressure,

temperature and time continuously during a program by Electronic Parameter Control The overall operating

time can then be optimised according the load and the temperature of the autoclave.

The process assessment and monitoring system in the program control compare current process parameters

with standard process data and monitors the process relative to limit values for temperatures, times and

pressures. This makes it possible to identify faults as they occur, and provides quality assurance for the

sterilization process.

1.4.7 Pre-heating / Drying _______________________________________________________________

By activating the "pre-heating" function, the cold autoclave chamber can be warmed up before sterilization,

or the temperature can be maintained between sterilization runs. This reduces the duration of cycles and

considerably reduces the formation of condensation, thus improving drying results with slightly opened door.

1.4.8 Documentation ___________________________________________________________________

The memory of the electronic control system stores records of the previous 40 programs.

For effective hard-copy documentation and for checking purposes a MELAprint

to print out a record immediately after completion of a program, or to print out records from the memory.

By connection of a PC, the program MELAwin

®

can also transfer the records to the PC, for permanent

®

42 printer can be connected

archiving of all results, and for printing out these results as needed.

Page 7

Page 8

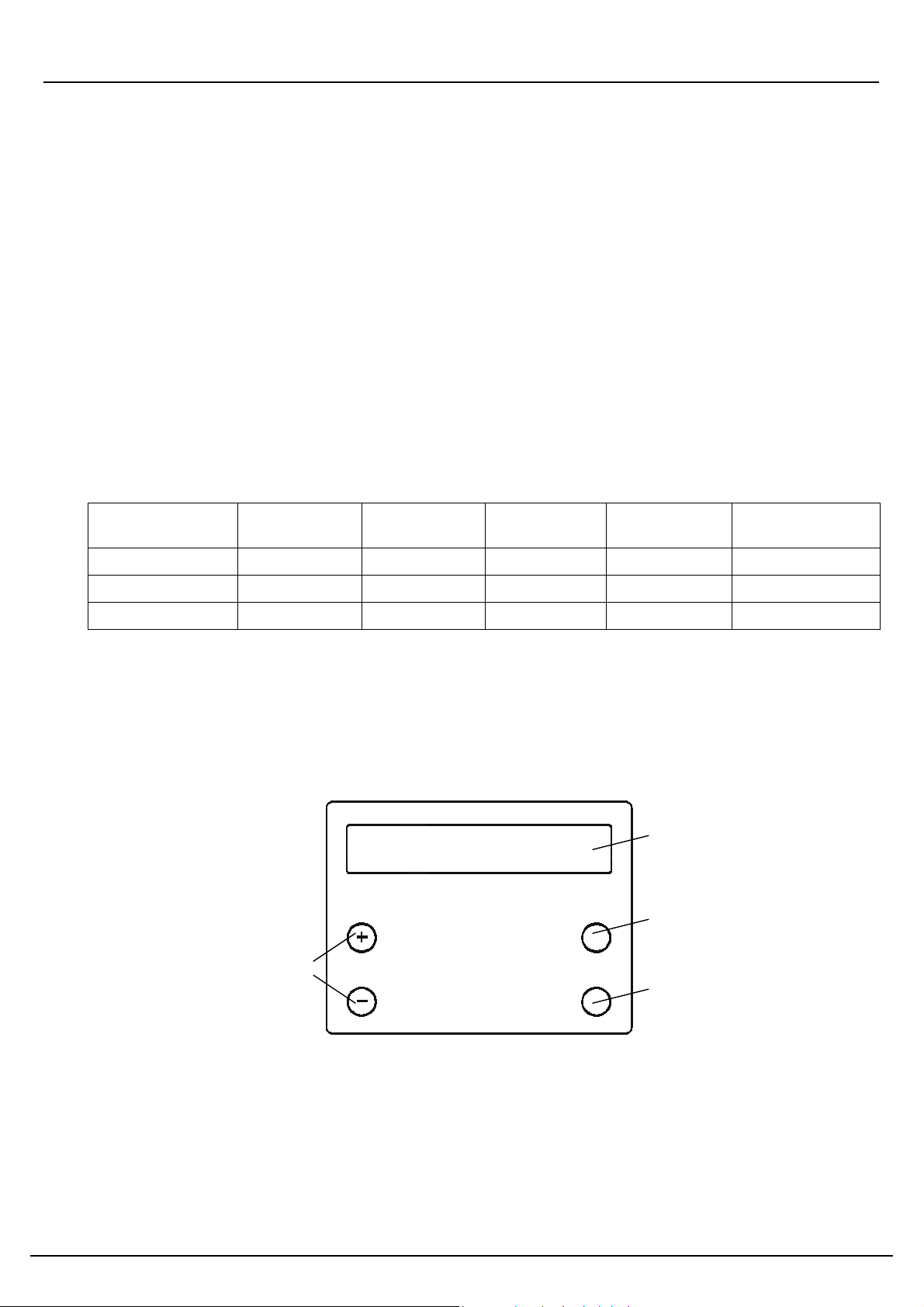

2 Installation

2.1 Setting up the autoclave

The autoclave should be set up in a dry place which is protected against dust.

The base should be stable, and able to support the weight of the autoclave. At the same time, the work

surface must provide convenient access to the autoclave, and the display must be clearly visible.

The space required by the autoclave can be seen from the external dimensions (as in Section 1.1). A

minimum additional space of 5 cm should be allowed on either side and above the autoclave in order to

ensure that heat can escape. If the additional condensate container shall be connected to the autoclave you

need an adequate space below the autoclave for the container.

The electrical power supply should be a separate 230V AC circuit with a 16 A fuse and optionally protected

with a 30 mA circuit breaker.

Should it be decided at some stage to install an automatic one-way water system, it is necessary to connect

the condensate container as an option. The condensate container must stand below the autoclave and the

outlet pipe must be without bends and twists which could prevent water flowing out freely.

For the supply with demineralized / distilled water from the integrated water storage tank (Fig. 1 Pos. 26) you

need at least a space of 30cm or more above the autoclave.

______________________________________________

2.2 Transport ribbons _____________________________________________________

Take the autoclave out of the packaging by means of the transport ribbons. The blue ribbons themselves are

each removed by undoing two retaining screws, which must then be screwed firmly back in place without

washers. Therefore you need the TORX-key, delivered with the autoclave

2.3 Levelling_____________________________________________________________

In order to ensure that the autoclave will work reliable, the autoclave should be installed in a horizontal

position (this should be checked with a spirit level at the chamber flange) as shown in the pictures below.

Fig. 3 Levelling the autoclave with a spirit level

2.4 Mains power supply

_________________________________________________

Page 8

The electric cable of the appliance is plugged into a mains socket rated at 230 V, 50 Hz. The power rating of

the MELAtronic

avoid overloading the electricity supply, we recommend using a separate electrical circuit fitted with a 16 A

fuse and optionally protected with a 30 mA circuit breaker.

®

15EN and the MELAtronic®17EN is 1500W, of the MELAtronic®23EN 1600W. In order to

2.5 Filling the water storage tank__________________________________________

Remove the lid of the housing (Fig.1 Pos 27) and the lid of the water tank (Fig.1 Pos. 28) below. Fill the

water tank with ca. 3 Litres of aqua dest / aqua dem. Do not fill more water into the tank than up to the "MAX"

mark (Fig.1 Pos. 16). The cooling coils in the water storage tank should always be covered with water. This

will allow the steam flowing out to condense. It will also prevent and problems from the steam, and will

eliminate excessive consumption of distilled or demineralised water. For this reason, be sure to top up with

distilled or demineralised water as soon as necessary. Or, better: drain out the remaining water through the

water drain tap (Fig. 1, Pos. 6) and refill with fresh distilled or demineralised water up to the MAX mark.

Page 9

®

Operating manual for MELAtronic

15 / 17 / 23EN

2.6 Connecting the external Condensate container (option)

To operate the autoclave with a single-use (non-reusable) water system (one-way system), and to avoid

discharge of steam during frequent sterilization work, an external condensate tank (MELAG article no.

00356) can be connected to the autoclave. This external condensate tank is not part of the equipment

provided originally with the autoclave. Please proceed as follows to connect the condensate tank to the

autoclave:

Remove the blind cap from the connection point for the external condensate tank (Fig. 1, Pos. 11), on the

back wall of the autoclave. Connect the drain pipe (supplied with the external condensate tank) to the

connection point, and tighten it securely with the coupling ring. Fill up the external condensate tank up to the

MIN mark with ordinary tap water, and place the tank under the autoclave.

Insert the free end of the drain pipe, as far as it will go, onto the plug-on coupling in the top of the external

condensate tank. The drain pipe should not have any kinks or dips, and it should lead continuously

downward (without any upward loops).

Finally, remove the condensing coil for the pressure release (Fig. 1, Pos. 18) in the water storage tank.

Remove this coil by pressing toward the rear the locking ring of the plug-in conne ctor for the condensate loop

(Fig. 1, Pos. 19). After removing this coil, store it safely where you can find it easily.

____________________

3 Initial start-up

3.1 Initialising the printer

3.1.1 Connecting the external MELAprint®42 printer _________________________________________

In order to document the progress of the sterilization programs, the printer MELAprint

to the MELAtronic

For the connection of the printer to the autoclave see section 6.2.1.1.1.

®

15EN / 17EN / 23EN. This printer is not included by delivery.

________________________________________________

®

42 can be connected

3.1.2 Initialising the printer / Immed. print-out? Yes/No ______________________________________

The initialising of the external printer (Registration in the electronic of the autoclave) is described in section

6.2.1.1.2. For the selection “ Immed. print-out? Yes (Preferred selection, after a cycle the print-out is made

automatically) see the description in section 6.2.1.3.

3.2 Test run______________________________________________________________

In order to check the operation of the autoclave under realistic conditions, a test run should be carried out

with the "Universal Program, 134°C wrapped" and a relevant load. After loading the autoclave and selecting

the program with the "Program" button, sterilization is started by pushing the "Start/Stop“ button. If the

program runs correctly, the following message will appear on the display (see Section 4.7):

with the values for the maximum values for pressure and temperature. If the immediate printout option has

been selected for an external printer a record of the program run will be printed.

Universal-Program

Run sucessfully

Page 9

Page 10

3.3 Safety instructions

__________________________________________________

When opening the door, particularly after interrupting the drying process, residual steam can escape

from the autoclave chamber.

After opening the door, do not touch any metal surfaces - these will be hot! Danger of burns. Always use

the tray lifter to remove trays, or wear suitable hand protectors when taking out other items.

IMPORTANT: If you connect an external condensate tank to the autoclave, be sure to remove the

condensing coil for pressure relief (Fig. 1 Pos. 1) from the water storage tank. Check the level of water in

the condensate tank every day, and empty this tank to prevent water from overflowing and causing

damage to the room. IMPORTANT: There is no automatic monitor for the level of condensate water.

The appliance is not suitable for sterilizing liquids.

Under current VDE-regulations, this appliances is not suited for use in areas where there are risks of

explosion.

The appliance must only be serviced and repaired by MELAG or by its authorised representatives

(specialist dealers or customer services) using only original parts and following service instructions.

Before opening the housing always disconnect from the mains power supply!

In order to ensure effective sterilization with the autoclave observe the instructions in this operating

manual, and in particular ensure that the loading of the autoclave is appropriate for the program

selected.

This device is designed to be operated outside the patient’s surroundings. This means that there must

be an interval of at least 1.5 metres between the device and the area where patients are being treated,

or where they otherwise stand or sit.

If error messages repeatedly occur during operation of the autoclave, then do not use the autoclave until

it has been repaired by authorized service personnel.

If the power cable is damaged, do not use the autoclave. Call authorized service personnel and have

them replace the damaged cable by an especially prepared cable.

4 Instructions for all sterilization procedures

4.1 Electricity and water supplies

4.1.1 Feed water aqua dest / aqua dem___________________________________________________

The autoclave automatically monitors the availability of cooling water and purified water, as well as the

quality of the distilled / demineralized water before starting a program.

In order to allow an immediate program start and to avoid error reports or interruptions of programs check

before the first sterilization at the start of the working day, that the internal water supply has sufficient water

in the water storage tank. If necessary, refill with water of appropriate quality (see Section 8.3.3).

Before the first sterilization the quality of the feed water has to be checked by pressing the button „-“ after the

autoclave is switched on. Is the conductivity of the water higher than 65 µS/cm, the feed water has to be

exchanged and fresh aqua dest / aqua dem has to be filled into the water storage tank..

If the water storage tank is dirty, the water has to be drained and the water storage tank must be cleaned

bevor refilling the tank with fresh aqua dest / aqua dem (see also section 8.3.3).

________________________________________

Page 10

Page 11

®

Operating manual for MELAtronic

4.1.2 Power supply ___________________________________________________________________

Switch on the power using the switch on the front of the autoclave (Fig.1 Pos.2). The autoclave is in the start

status:

Time (h:min:s)

Pressure of chamber (bar)

(Steam)-Temperature (°C)

14:27:12

0,02bar 25°C

Programm

Start-Stop

15 / 17 / 23EN

4.2 Preparing instruments for sterilization

MELAG - rust-free materials

All parts of the MELAtronic

rusting materials: the pressure chamber and the door of stainless steel, steam pipes of Teflon, and screws

and magnet-valves of bronze.

Film rust

The use of these materials means that no parts of the autoclave can initiate rust formation. Where rust does

attack the autoclave or instruments sterilized in it, tests repeatedly show that this has been brought into the

autoclave on instruments (film rust).

Even top-quality stainless steel instruments can form rust if they are not handled properly, e.g. if they are

treated with the wrong chemical cleaning or disinfecting agents.

Preparing items for sterilization

The example of the formation of film rust shows how important it is to prepare items properly before

sterilization.

Handpieces and contra-angles must be cleaned before sterilization and maintained (e.g. by oiling).

Other instruments must be disinfected and cleaned immediately after use in accordance with UVV/VBG 103,

or similarly strict national codes of practice in a disinfectant and / or cleaning solution at the correct

concentration for the correct length of time.

MELAG recommends the use of cleaning aids such as ultrasonic baths, cleaning and maintenance

equipment for handpieces for contra-angles, as well as thermo-disinfecting devices.

It is essential that the instruments are well cleaned in order to avoid dirt and contamination being separated

from the load in the autoclave and clogging filters, valves, and nozzles. In particular locks, joints, and hinges

must be cleaned thoroughly with a brush before sterilization. No traces of cleaning and disinfecting agent s

should be allowed to enter into the sterilization chamber of the autoclave, since this can give rise to

corrosion! The instruments should be swilled off with demineralized water and then dried off before bei ng

loaded in the autoclave. Turbines and handpieces must be oiled in accordance with the manufacturer's

instructions in order to ensure their long working life.

Brand-new instruments

The cleaning procedures described above must also be followed before sterilizing brand-new instruments.

These often carry small amounts of grease, oil and soiling from the manufacturing process.

Important: Carefully follow all instructions provided by manufacturers of instruments for the preparation of

their products for first-time sterilization and for subsequent sterilizations.

®

15EN / 17EN / 23EN which come into contact with steam are made on non-

__________________________________

Page 11

Page 12

4.3 Loading the autoclave

It is of crucial importance for effective sterilization and good drying that the autoclave is loaded properly: In

the annex you will get information how to load the autoclave.

When loading the autoclave, take account of the following points:

Tray rack

Normally, the autoclave should be used in conjunction with a tray rack, since this ensures that steam

penetration and drying are as good as possible. In exceptional situations (e.g. when using sterilization

containers from other manufacturers), and after consultation with your specialist dealer or with MELAG, the

tray rack can be removed and the container can be placed directly in the autoclave chamber.

Trays

Trays for objects which are to be sterilized must be perforated, in order to get safe sterilization results and to

allow condensation to run away. MELAG-trays are recommended. If you use dishes or trays without

perforations, then the sterilization will not be safe and the autoclave will not dry properly.

Enclosed sterilization containers

Enclosed sterilization containers must be perforated on at least one side (preferably underneath) or must

have valves, in order to ensure that steam can penetrate and condensate can run out. All MELAGsterilization containers meet these requirements with perforations on two sides a nd filter-cloth- inlays.

Sterilization containers which only have perforations on the top only allow limited drying and are not for the

use in the MELAtronic

If sterilization containers are stacked in the autoclave, it is important to ensure that the perforations are not

blocked.

Transparent sterilization packaging

If you use transparent sterilization packaging, such as MELAfol

vertically on the tray. For the MELAtronic

The packagings should never be laid flat one on top of the other.

If seals split open during sterilization it may be necessary to increase the length of the impulse on the sealing

device or to use a double-seal.

Standard tray-cassettes sealed in MELAfol

ensure that the side-seals do not split open.

Maximum loads

Do not exceed the maximum loads of the autoclave.

Mixed loads

If mixed loads of textiles and instruments are to be sterilized, then as far as possible the textiles should be

above the instruments and direct contact with the instruments should be avoided.

Inclusion of textiles and instruments in the same sterilization container is not desirable.

Textiles should never come into direct contact with the walls of the chamber.

If different types of packaging are included in a load, then:

• Instruments and sterilization containers should be at the bottom

• Transparent and paper sterilization packaging should be at the top (but lower than textiles)

Liquids

The appliance is not suitable for the sterilization of liquids!

Suitability for sterilization

Relevant information provided by manufacturers of instruments and textiles about sterilization should be

strictly observed.

®

15EN / 17EN / 23-EN

_______________________________________________

®

®

15EN the foil holders (MELAG-Art.-No.: 00283) should be used.

®

(250 mm wide) must be taped and clasped additionally to

, then the items should if possible be stood

Page 12

Page 13

®

Operating manual for MELAtronic

15 / 17 / 23EN

4.4 Closing the door

The door is closed by putting the door latch over the door beam and turning the door grip until the door is

closed. The display shows the message:

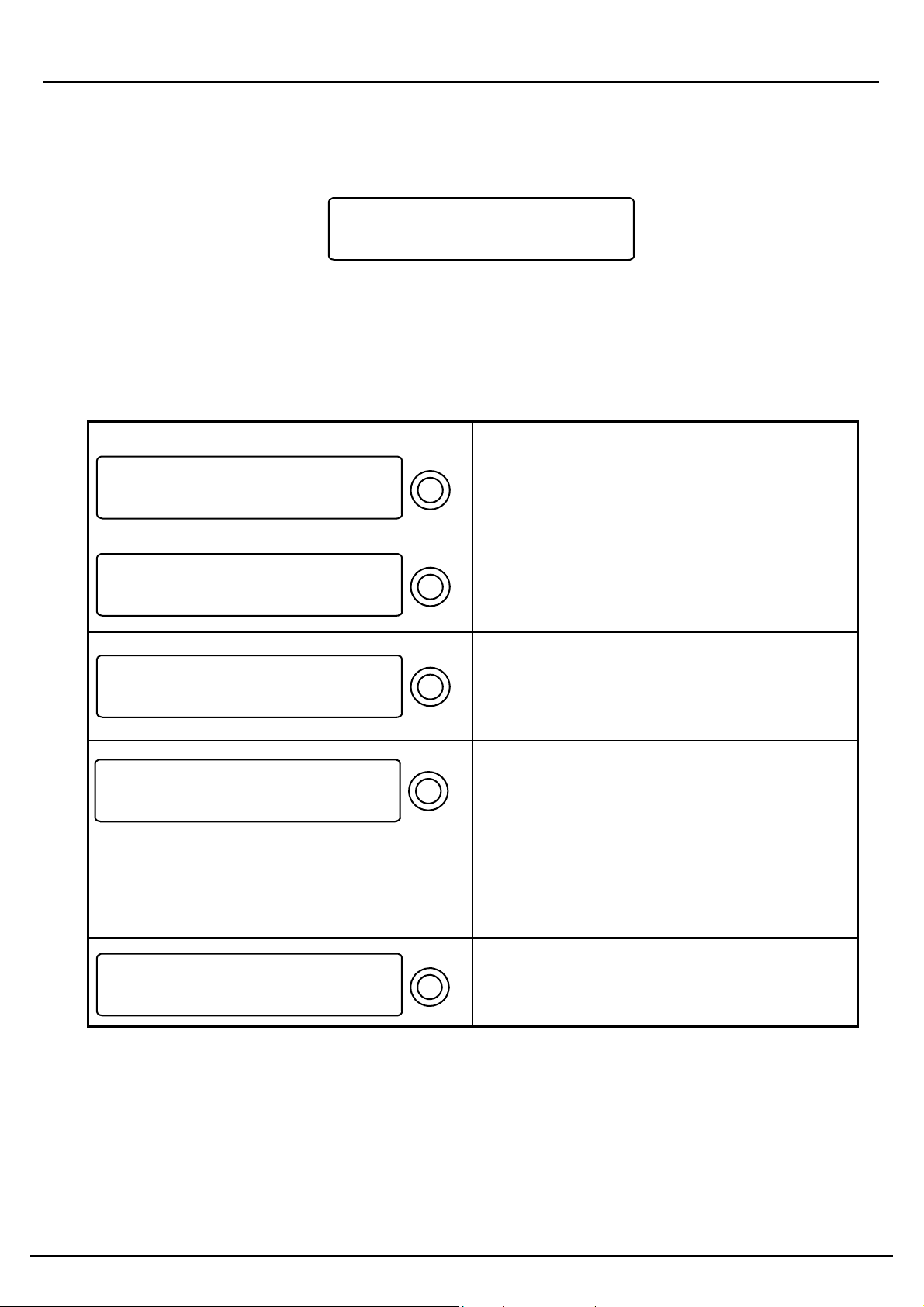

4.5 Program selection

A program should be selected which is appropriate for the physical properties of the items being sterilized

(and in particular their heat resistance) and the type of packaging (if any part of the load is wrapped, then

either the "Universal Program" or the "Gentle Program" must be used).

By pressing the "Program selection" button it is possible to review the display of the following programs for

selection:

Program name/Display message Parameter/Application

Universal program at 134°C, 2 bar, and a

Universal - Program

134°C wrapped

Quick Program at 134°C, 2 bar and a sterilization

Quick - Program

134°C unwrapped

Gentle Program at 121°C, 1 bar, sterilization time

Gentle - Program

121°C wrapped

Prion - Program

134°C wrapped 20'

Basic display (no program selected)

____________________________________________________

Door

Closed

___________________________________________________

Programm

Programm

Programm

Programm

Programm

sterilization time of 3.5 min for the sterilization of

wrapped items, in particular solid instruments (no

hollows), or mixed loads (unwrapped / wrapped). The

maximum loads in section 1.3 must not be exceeded.

time of 5 min for the sterilization only of unwrapped

and solid instruments (no hollows, no textiles) for

rapid re-use (drying can be interrupted manually). The

maximum loads in section 1.3 must not be exceeded.

20 min for the sterilization of all types of wrapped and

solid instruments items (no hollows), textiles or

thermolabile materials (plastic, rubber), or mixed loads

(wrapped/unwrapped) The maximum loads in section

1.3 must not be exceeded.

Prion Program (a special Universal Program) at

134°C, 2 bar, and with sterilization time extended to

20 min, for sterilization of wrapped items, especially

instruments and/or mixed loads (i.e., packed and

unpacked). This program is recommended for

sterilization of instruments used in situations in which

the danger of infection by pathologically modified

proteins is suspected: for example, Creutzfeld-Jacob

and BSE).

The maximum loads in section 1.3 must not be

exceeded.

15:31:33

0,02bar 22°C

Page 13

Page 14

4.6 Program start

Press the "Start-Stop" button once the desired program is shown on the display. The availability of feed

water will be checked automatically, with a conductivity measurement.

At the start of the quick program there will be an additional message "Warning: Only unwrapped

instruments". This message must be acknowledged by pressing "Start" again.

4.7 Program progress

After starting the program, it will then progress automatically. The display shows the current program status

as follows:

Program status

1.

Phase 1 and following

Depending on the program chosen and the temperature of the

chamber at the start of the program, a number of cycles of steam

inflow and outflow follow to ensure adequate penetration of superheated steam into the items being sterilized.

2.

Heating phase

A heating-up phase follows. The continuous introduction of steam

raises pressure and temperature in chamber to the values needed

for the program

_______________________________________________________

Start

___________________________________________________

Display message

1. Fractionation

0,69 115°C

Heat up

1,80 bar 117°C

3.

Sterilization phase

When the required pressure and temperature have been reached

the sterilization proper then begins.

The display shows alternately the pressure and temperature and

the time remaining.

4.

Pressure release

After completion of the sterilization time, the pressure is released

and the steam generator emptied.

Pressure and temperature fall.

6.

Program end

After ventilation of the chamber the program is completed.

After the unlocking of the door you can open the door.

If a printer is attached and print-out "yes" is selected, the record will

be printed-out immediately.

Sterilization

2,18 bar 135°C

Sterilization

noch 2 min, 12s

Pressure release

0,85 bar 96°C

Universal - Program

Run sucessfully

Door

Open please

Page 14

Page 15

®

Operating manual for MELAtronic

15 / 17 / 23EN

4.8 Print-out record

_____________________________________________________

The print-out record contains the following information:

----------------------------------------- MELAG MELAtronic 23-EN

------------------------------------------

Program : Universal-Program

134°C wrapped

Date : 03.03.2005

Time : 11:18:06 (Start)

Charge No.: 5

------------------------------------------

Preheating 118.5 °C

Conductivity 7 µS/cm

Program step Press. Temperat. Time

bar °C min

Start 0.03 62.9 00:00

1. Fractionation

Steam entry 1.01 80.9 04:07

Pressure release 0.19 83.8 04:32

2. Fractionation

Steam entry 1.01 111.4 06:34

Pressure release 0.19 101.6 07:17

3. Fractionation

Steam entry 1.00 117.0 08:51

Pressure release 0.20 105.1 10:05

4. Fractionation

Steam entry 1.01 119.5 11:36

Pressure release 0.20 105.8 12:57

Heat up 2.05 134.2 17:28

Steril. begin 2.05 134.2 17:28

Steril. end 2.19 136.0 22:28

Pressure release 0.49 113.1 22:28

End 0.50 112.9 22:38

------------------------------------------

Temperature : 135.5 +0.2 /-0.2 °C

Pressure : 2.19 +0.03/-0.03 bar

Steriliz. time : 5 min 00 s

Time : 11:45:52 (End)

==========================================

276 200501258 3.33 1.12

PROGRAM PROPERLY EXECUTED!

Selected Programm

Date

Time of start

Batch number of the day

Preheating temperature

Conductivity of the aqua dest / aqua dem

Program phases with the values for steam

pressure and temperature, and time (relative

to program start)

Final report

Mean sterilization temperature / deviations

Mean sterilization pressure / deviations

Duration of sterilization

Time at end of program

Info-line with total number of loads,

Works number and software version.

Page 15

Page 16

4.9 Removing the sterilized items

After opening the door the sterilized items can be removed.

Be careful when removing the sterilized items! Touching the metal surfaces can lead to burns. Always use

the appropriate aids to lift the trays (MELAG-tray lever, standard tray-lifter) or wear suitable hand protection.

4.10 Sterile storage / Drying

After removing wrapped sterile items, the wrapping should be checked for any signs of damage. If it is

defective (e.g. split seals) then the sterilization of the items must be repeated after the items have been rewrapped.

It is important for sterile storage that the items have been properly dried. The

MELAtronic

completion and the autoclave has been properly loaded (see Section 4.3). Directly after sterilization there

may still be residual condensation on the items or the container. Because the items are hot on removal, this

will usually evaporate quickly. The German industrial standard DIN 58953 Part 7 Section 7 contains the

following comment about residual moisture on paper wrapping or transparent sterilization paper after

sterilization: "...small amounts of water on the wrapping are unproblematic, provided they have evaporated

within 30 minutes after removal from the steam sterilizer....."

After cooling, wrapped sterilized objects should be stored in a place where they are protected from dust

(e.g. instrument cupboard). Given proper storage, DIN 58953 Part 7 gives the following guidelines for the

maximum storage periods for sterilized objects: in basic wrapping (e.g. transparent sterilization foil) up to 6

weeks; in double-wrapping up to 6 months.

®

15EN / 17EN / 23EN provide very good drying if the program has not been interrupted before its

_______________________________________________

4.11 Sterilization frequency / pauses

After a sterilization cycle, the autoclave can be reloaded and started immediately. However, continuous

operation can lead to increased development of water vapour from the aeration rifle at the back of the

autoclave housing. This is not harmful for the MELAtronic

space around it for ventilation and it is not fully enclosed (e.g. in a cupboard). In order to reduce formation of

water vapour it is advisable to connect the external condensate container.

_________________________________________

________________________________________

®

15EN / 17EN / 23EN provided there is sufficient

Page 16

Page 17

®

Operating manual for MELAtronic

15 / 17 / 23EN

4.12 Manual termination of program

4.12.1 Termination of sterilization _________________________________________________________

A program can be terminated at any time by pressing the "Start-Stop" button. If the program has not yet

reached the drying phase then the items will be non-sterile!

Warning! Steam may escape when the autoclave door is opened.

If the sterilization phase of the program had not been completed, then it is advisable to carry out an empty

sterilization run before reusing the autoclave.

Operation

1. Press the "Start-Stop" button

2. If confirmation is given then the program stops.

To confirm, press the "Start-Stop" once again within 5 seconds.

If no confirmation is given then the program resumes normally.

The pressure inside the autoclave will

then be equalised by pressure release.

________________________________________

Display message

Stop program?

Press ‚STOP‘

Program

stopped

Pressure release

1.52 bar 112°C

3. After pressure equalisation, the display will alternately show the

messages "Terminated" and an offer to quit the program

termination.

4. To acknowledge the program termination, press the " - " button.

After a short time the door is unlocked and the display shows the

selected program.

Stop / End

0,02 bar 88°C

Acknowledge

with ‚-‘

Universal - Program

121°C wrapped

Page 17

Page 18

4.13 Reaction to warnings / error messages____________________________________

The MELAtronic®15EN, 17EN and 23 EN have a number of safety features and an extensive integrated

control and monitoring system, in order to ensure the greatest possible level of safety for the sterilization

process, and to eliminate risks for the patients and operators.

Various aspects of the operation of the autoclave, such as pressure and temperature sensors are

automatically checked when the autoclave is switched on.

The quantity and quality of the feed water is checked before each program start.

A successful program start is followed in the next stages by the monitoring of all parameters of relevance for

the sterilization. If any limit values for the individual program phases are exceeded then there is a

malfunction report and the program is automatically interrupted.

In addition to messages, warnings or malfunction reports on the display, if a printer is connected then a printout will provide details of the type of malfunction and when it occurred.

If any such warning message occurs then you should consult Section 7, which provides detailed advice and

possible operational errors.

4.14 Operational pauses

In general, the door should only be leant to during operational pauses in order to reduce wear on the door

seal and to avoid premature failure or sticking.

In the event of longer breaks, such as during vacations, the water storage tank should be drained. If the

condensate container is connected, the container should be emptied, too.

__________________________________________________

5 Closing down / Transport / Reinstallation

When closing down and transporting the autoclave you should proceed as follows:

Switch off the power.

Disconnect from the mains, allow the autoclave to cool down.

Empty the internal water storage tank.

Disconnect and empty the condensate container, if connected.

Fasten the transport ribbons to the autoclave.

If transporting the autoclave with trays and tray rack assemblies in place, then protect the inside surface

of the door by including a sheet of foam or similar material.

o Warning! To avoid damage use the original packaging when transporting the autoclave.

If the appliance may be exposed to frost in transit then follow the relevant service

instructions!

When setting the appliance up for reuse after transport or repairs then proceed in accordance with

Sections 2 and 3.

Page 18

Page 19

6 Special functions

Operating manual for MELAtronic

®

15 / 17 / 23EN

6.1 Water quality (conductivity) / Chamber preheating temperature

By repeatedly pressing the "-" button, the preheating temperature of the chamber and the conductivity of the

purified feed water used for steam generation can be displayed alternately.

Operation

1. Press down the "-" button to display the conductivity of the feed

water µS/cm

Release the "-" button to return to the basic display (as shown

here) or the program status

Press the "-" button repeatedly and hold down: Display shows

the pre-heating temperature of the chamber.

Display message

Conductivity

15 µ S/cm

14:27:12

0,02bar 25°C

Temp_Preht_Chamb.

120°C

6.2 Records / Load documentation

In order to document the progress of the sterilization program, then the processor memory stores records of

the last 40 cycles. These records can be downloaded at a later stage via the serial interface (RS232).

When the memory is full (40 program runs) then before the start of the next run the oldest record will

automatically be overwritten. If an external printer is connected (and operable) and the option "Immed. printout? No" has been selected, then confirmation will be requested before the oldest record is overwritten (see

Section 7.3).

Hardware details and the nature of the print-out documentation is provided in the following sub-sections.

________________________________________

_____________

6.2.1 Record print-out_________________________________________________________________

6.2.1.1 External Printer

6.2.1.1.1

In order to connect a printer to the autoclave then a printer cable should be connected between the 9-pole

socket on the front of the autoclave (see Fig.1 Pos. 3) and the 25-pole on the back of the printer (ensuring a

good connection and tightening the locking screws).

The power supply to the printer is provided by the power unit supplied with the printer, which connects to the

socket on the rear of the printer.

The printer is ready for operation when the voltage lamp "P" shines and the status display (On line / Off line)

"SEL". The operating manual of the printer includes further details, including the assembly of an external

paper feed, inserting paper, and the general operation of the printer.

Connecting the external printer MELAprint®42

Page 19

Page 20

6.2.1.1.2

After connecting the printer to the autoclave it must be registered with the autoclave processing unit

(initialised). Proceed as follows:

Operation

1. Switch on autoclave Display shows:

2. Hold down "+" button and also press "-" button.

3. Press "Program" button,

4. Press "Program" button,

Initialising the printer

1. Line: Time

2. Line: Pressure of chamber

Temperature inside chamber

The "Function"-menu with the sub-menu "Print" is shown

Select "Print" menu sub-menu "File transmission »

Select "File transmission"

Display shows current status e.g. "No printer"

Anzeige am Display

0,02bar 25°C

File transmission

File transmission

14:27:12

Function:

Print

Print

No printer

5. Press "+" (or "-") button until display shows

"External printer"

6. Press "Program" button,

Confirm the setting, return to "Print" menu

7. Press "Start-Stop" button,

return to the "Function" menu

8. Press "Start-Stop" button,

Quit the "Function" menu and return to the initial display

File transmission

External Printer

Print

File transmission

Function:

Print

14:27:30

0,02bar 25°C

Page 20

Page 21

®

Operating manual for MELAtronic

6.2.1.2 Connection to an external PC

6.2.1.2.1

Records and archives can also be kept by using an external PC. This require s a suitable connection between

the serial port of the PC and the printer port of the autoclave.

For data transfer and data processing to a PC you must first install the program MELAwin

Installation

15 / 17 / 23EN

®

on the PC.

6.2.1.2.2 Initialising the file transmission to the PC

When the autoclave has been connected to the PC the file transmission of the autoclave has to be set on

"External PC". The initialising of this has to be done as described in section 6.2.1.1.2 but under 5. the

selection "External PC" with the buttons "+" or "-" has to be made.

6.2.1.3 No printer

In order to select the option "No printer", proceed as described as in Section 6.2.1.1.2. Under Point 5,

however, use the "+" or "-" button to reach the setting "No printer".

6.2.2 Immed. print-out? Yes / No

When an external printer is fully installed, a print-out can be produced automatically at the end of each

program run by selecting the following options after switching on the autoclave:

Operation

1. Hold down "+" button and also press "-" button.

Select "Function" menu, sub-menu "Print"

Display message

Function:

2. Press "Program" button,

Select "Print" menu sub-menu "File transmission"

Print

Print

File transmission

3. Press "+" button, select sub-menu "Immed. print-out?" Display

shows current option, here e.g. "No"

4. The button "Program" can be used to switch between "Yes"

and "No" Press "Program" button,

Select "Yes" option

5. Press "Start-Stop" button,

Confirm the setting and return to "Function" menu, sub-menu

"Print"

6. Press "Start-Stop" button,

Quit the "Function" menu and return to the initial display

Immed. Printout

No

Immed. Printout

Yes

Function:

Print

14:27:30

0,02bar 25°C

Page 21

Page 22

6.2.3 Printing out stored records

When an external printer is fully installed, a print-out of selected records from the memory can be produced

by selecting the following options after switching on the autoclave:

Operation

1. Hold down "+" button and also press "-" button.

Select "Function" menu,

submenu "Print"

Display message

Function:

Print

2. Press "Program" button,

Select "Print" menu, submenu "File transmission"

3. Press "+" (or "-") until the submenu "Print last cycle"

appears on the display

4. Press "Program" button, the cycle record number flashes

5. To select another number, press the "-" or "+" b utton until

the right number is reached, e.g. here No. 25

6. Press "Program" button to start the print-out of the

selected record,

(or to terminate press "Start-Stop" and return to the

"Function" menu)

Print

File transmission

Last cycle

print: no. 40

Last cycle

print: no. 40

Last cycle

print: no. 25

Printout

Page 22

7. If you wish to print further records then return to Point 4,

or...

8. ... to terminate press "Start-Stop" and return to the

"Function" menu

9. Press the "Start-Stop" button to return to the initial display

Last cycle

print: no. 40

Function:

Print

14:27:30

0,02bar 25°C

Page 23

®

Operating manual for MELAtronic

15 / 17 / 23EN

6.2.4 Print all stored cycle records

In order to print-out all stored cycle records (with a fully installed external printer) then select the following

options after switching on the autoclave:

Operation

1. Hold down "+" button and also press "-" button.

2. Press "Program" button,

3. Press "+" (or "-") until the submenu "Print all cycles" appears

4. Press "Program" button to start the print-out of all the stored

Select "Function" menu,

submenu "Print"

Select "Print" menu, submenu "File transmission"

on the display

records (up to 40!), or to terminate press "Start-Stop" and

return to the "Function" menu

(Once printing has started termination is only possibly by

switching off the power!)

Display message

File transmission

Function:

Print

Print

Print

all cycles

Print

5. When the print-out is complete, the display again shows the

submenu :

6. Press the "Start-Stop" button to return to the "Function"

menu...

7. ...and then press "Start-Stop" again to return to the initial

display

Print

all cycles

Function:

Print

14:27:12

0,02bar 25°C

Page 23

Page 24

6.2.5 Display printer memory status _____________________________________________________

With a fully installed external printer, the status of the printer memory can be displayed as follows::

Operation

1. Hold down "+" button and also press "-" button.

Select "Function" menu,

submenu "Print "

Display message

Function:

2. Press "Program" button,

Select "Print" menu, submenu "File transmission"

3. Press "+" (or "-") button until the display shows the memory

status, e.g.:

4. Press the "Start-Stop" to return to the "Function" menu

5. and press "Start-Stop" again to return to the starting display

Print

Print

File transmission

Allocated: 40

Free: 0

Function:

Print

14:27:12

-0,02bar 25°C

Page 24

Page 25

®

Operating manual for MELAtronic

6.2.6 Deleting cycle records

In order to delete cycle records (e.g. in the event of the warning message "Printer memory full", with the

option "Immed. print-out? No", selected (see Section 7.3), then after switching on the appliance proceed as

follows:

Operation

1. Hold down "+" button and also press "-",

Select "Function" menu,

submenu "Print"

Display message

Function:

Print

15 / 17 / 23EN

2. Press "Program" button,

Select "Print" menu, submenu "Data transfer".

3. Press "+" (or "-") until the display shows "Delete all cycles".

4. Press the "Program" button to delete all records

(or press "Start-Stop" to terminate).

5. Then press "Start-Stop" to return t o "Function" menu...

6. ...and press "Start-Stop" again to return to the starting display

Print

File transmission

All cycles

delete

Allocated: 0

Free: 40

Function:

Print

14:27:12

-0.02bar 25°C

Page 25

Page 26

6.2.7 Test print-out ___________________________________________________________________

In order to check the printer and its connection to the autoclave, a test print-out can be made as follows:

Operation

1. Hold down "+" button and also press "-",

Select "Function" menu,

submenu "Print"

Display message

Function:

2. Press "Program" button,

Select "Print" menu, submenu "File transmission"

3. Press "+" (or "-") until the display shows "Test print-out"

4. Then press the "Program" button for a test print-out (or

press "Start-Stop" to terminate)

5. Then press "Start-Stop" to return to the "Function" menu

6. and press "Start-Stop" again to return to the starting

position

Print

Print

File transmission

Test print-out

Print-out

Function:

Print

14:27:12

-0,02bar 25°C

Page 26

Page 27

®

Operating manual for MELAtronic

15 / 17 / 23EN

6.3 Setting date and time

The date and time can be reset if necessary (e.g. winter time / summer time) as follows:

Operation

1. Hold down "+" button and also press "-" button.

2. Press "+" (or "-"), until the display shows the submenu

Select "Function" menu,

submenu "Print"

"Date/Time".

_______________________________________________

Display message

Function:

Print

Function:

Date / Time

3. Press "Program", the display shows the current hour (24hour clock) (here for example 17.00)

Date / Time

Hour : 17

4. by pressing the "+" (or "-") button the following options

can be selected

Date / Time

Minute : 23

5. After finding the required option, e.g. "Minute", press the

"Program" button and the current value flashes

6. Press "+" or "-" to increase or reduce the value:

Date / Time

Second : 13

Date / Time

Day : 14

Date / Time

Month : 05

Date / Time

Year : 19

Date / Time

Minute : 23

Date / Time

7. Press "Program" to confirm the new value, which then

stops flashing.

If more adjustment are necessary, return to Point 4 and

begin again,...

Minute : 28

Date / Time

Minute : 28

Page 27

Page 28

Operation

8. ...or press "Start-Stop" to return to the "Function" menu,

and

Display message

Function:

9. Press "Start-Stop" again to return to the starting display

Date / Time

14:27:12

-0,02bar 25°C

6.4 Automatic preheating ________________________________________________

The MELAtronic®15EN / 17EN / 23EN have a preheating function by means of which the autoclave chamber

can be heated to the necessary temperature before a program starts, or can be maintained at this

temperature between cycles. This not only shortens the time for each cycle but also reduces condensation

on the walls of the chamber which helps to provide very good drying performance.

If the automatic preheating is activated, then this begins as soon as the power is switched on.

In the default setting on delivery the automatic preheating is on.

The current setting for the automatic preheating can be changed as follows:

Operation

1. Hold down "+" button and also press "-" button.

Select "Function" menu, sub-menu "Print"

Display message

Function:

Print

2. Press "+" (or "-") until the display shows the submenu "autom.

preheating".

3. Press "Program", and the display shows the current option,

here "Preheating Yes"

4. Pressing the "Program" button now alternates between the

options "Preheating Yes/No", here e.g. "No"

5. W hen the desired option has been selected press "Start-Stop"

and return to the "Function" menu, then...

6. ...press "Start-Stop" again to return to the starting display

Function:

auto. preheating

auto. preheating

Yes

auto. preheating

No

Function:

auto. preheating

14:27:12

Page 28

-0,02bar 25°C

Page 29

®

Operating manual for MELAtronic

6.5 Total batch counter

The MELAtronic®15EN / 17EN / 23EN have a counter of the total number of cycles that have been started,

and this be displayed as follows:

Operation

1. Hold down "+" button and also press "-", select "Function"

menu,

submenu "Print"

__________________________________________________

Anzeige am Display

Function:

15 / 17 / 23EN

2. Press "+" (or "-") until the display shows the submenu "Sum

batch number".

3. Press "Program", the display shows the current total load count,

e.g.:

4. Close by pressing "Start-Stop", and return to the "Function"

menu, then

5. Press "Start-Stop" again to return to the starting display

Print

Function:

Sum batch number

Sum batch number

367

Function:

Sum batch number

14:27:12

-0,02bar 25°C

6.6 Program modifications

The standard programs are designed to meet most practical operational needs (pulsed flow, heating,

sterilization, pressure release, drying, and ventilation) and to display the parameters of most interest

(pressure, temperature, time).

The operator is responsible for ensuring that the autoclave is not overloaded, and that the load is arranged

properly to ensure good drying.

There are two standard options "Automatic preheating" and "Additional drying".

Any further program modification to suit specific individual requirements should only be carried out by

authorised personnel, after consultation with your dealer or with the experts at MELAG.

_______________________________________________

Page 29

Page 30

7 Operators faults/ Malfunctions

7.1 What to do if the autoclave malfunctions

If the autoclave does not seem to be working properly (e.g. poor drying, warnings, or error reports) then

follow these instructions in order to exclude possible operational errors. Following these instructions continue

to work with the autoclave. If the malfunction occurs repeatedly then contact our dealer, and authorised

MELAG customer service or contact MELAG directly. You should describe the problem precisely and include

the works number of your appliance.

7.2 Malfunctions without display messages

7.2.1 No Display_______________________________________________________________________

After switching on the autoclave, the display should show the initial setting .

If there is no display: Check:

1. Is the power cable plugged into the mains?

2. Is the mains supply OK.? (if necessary check with another appliance).

3. Exchange the two power fuses (Fig. 1, Pos. 10) on the back of the autoclave as following:

Disconnect the power cable and remove the screw cap over the fuses using a screwdriver or a coin.

Exchange the fuses (two reserve fuses are delivered with the autoclave) then replace the screw cap

and reconnect the autoclave to the power supply. If there is still no display when the autoclave is

switched on, or if the display blacks out repeatedly, please inform your specialist dealer. If you

exchange the fuses, order two new spare fuses through your dealer (MELAG-Art. No. 57592 ).

7.2.2 Door locking function _____________________________________________________________

®

The autoclaves MELAtronic

This function will disable the twist handle of the door lock during the sterilization program, and after

occurrence of any malfunction (until the malfunction has been acknowledged by the operator). This doorlocking function is also effective if no power is supplied: this means than the twist handle will also be blocked

if necessary, even after the autoclave has been switched off. After the power switch is turned back on, and at

the end of a program, the system will automatically pull the door locking bolt (Fig. 1 Pos. 20) to the rear –

which will release the twist handle.

In certain positions of the twist door handle, the door locking bolt may jam and it cannot be pulled to the rear.

The operator will notice this when a quiet hum or buzzing sound can be heard. This is not

release the locking bolt, simply turn the twist handle slightly.

If the locking bolt repeatedly blocks the twist handle, then report this fault to your specialist dealer or

authorized service personnel.

15EN, 17EN, and 23EN are equipped with an electric door-locking function.

________________________________

_________________________________

a malfunction. To

7.2.3 Leaks in the door _________________________________________________________________

If – after the start of the program, and upon beginning of pressure build-up – leaks in the door occur and

steam discharges from the door area, then proceed as follows: Check the door gasket and the collar of the

sterilization chamber for dirt and debris. Clean if necessary. If the door gasket is visibly damaged, replace it.

Before starting a program, be sure to turn the door handle tightly and securely lock the autoclave –

regardless of the display (even if “Door closed” appears).

If you cannot stop the leak by the above measures, then report this fault to your specialist dealer or

authorized service personnel.

7.2.4 Excessive water consumption ______________________________________________________

The autoclave can be operated in a mode with a water-circulation system. This means that an external

condensate tank has not been connected. Any loss of water in this mode will be the result of evaporation

losses by incomplete condensation in the water storage tank. This loss is caused by very frequent use of the

autoclave, and the resulting heating of the water.

When the external condensate tank is connected, the autoclave operates with a single-use (non-reusable)

water system. This means that the water used for each sterilization cycle is not condensed and returned to

the water storage tank, but is collected in an external condensate tank. In this case, the consumption of

water will depend on the program and the loading of the autoclave.

If your autoclave is consuming considerably more water than the amounts given in the attached annex, first

check to make sure that the autoclave has been set up perfectly level (horizontal). If the autoclave is level,

and if it still uses excessive amounts of water on a long-term basis, then report this fault to your specialist

dealer or authorized service personnel.

Page 30

Page 31

®

Operating manual for MELAtronic

7.2.5 Poor drying ______________________________________________________________________

Good drying depends only on the correct operation of the autoclave, but also on the way the autoclave is

loaded. If drying is not satisfactory:

1. Open the door after a sterilization cycle slightly so the load can be dried effectively with the

activated preheating function.

2. Check that the autoclave has been set up correctly so that condensate can flow out of the

chamber.

3. Check that the condensation outflow is not blocked by dropped, instruments, filter paper, etc. on

the floor of the pressure chamber.

4. Check that the maximum load has not been exceeded (particularly for textiles), that the autoclave

has been loaded properly (no direct contact with the walls of the pressure chamber), and that the

appropriate tray-rack assembly has been used (see Section 4.3).

5. If none of these measures help to reduce water consumption, please inform your specialist dealer.

15 / 17 / 23EN

7.3 Warning messages

For the following warning messages, please observe the comments made and restart the program in

question. If the warning occurs repeatedly please consult your specialist dealer.