Melag Euroklav 23-29 Service manual

Technical Manual

Autoclave

Euroklav®23 VS+

®

Euroklav

as of software version V4.06

29 VS+

For users and personnel

Please read the accompanying Technical Description before you start operation of

the autoclave. The instructions contain important safety precautions. Make sure to

keep the Technical Manual together with the Technical Description near the

autoclave. The instructions are part of the product.

Foreword

This manual has been created for the autoclaves Vacuklav®23 VS+ and Vacuklav®29 VS+. They are identical

except for their chamber depth and device depth.

The device name "autoclave" is used to designate the steam sterilizers Vacuklav

You also receive a Technical Description with the autoclave. It contains important safety instructions and

information which you need to operate the autoclave. Read the Technical Description completely through in

proper sequence before beginning operation with the autoclave.

This Technical Manual includes declarations of conformity, suitability statements and recommendations,

instructions for setting up, installing and initial start-up of the autoclave including installation record, extended

technical information on the software and hardware and other technical data. The Technical Manual is meant for

interested persons and service personnel.

®

23 VS+ and Vacuklav®29 VS+.

Technical Manual Euroklav®23 VS+, Euroklav®29 VS+

MELAG Medical Technology Berlin

Valid for Euroklav

as of software version 4.06

1st Edition October 2007

Responsible for the contents: Engineering Department

MELAG Medical Technology

Document: TH_2_GB_23VS+_29VS+.doc/Revision: 1 – 07/1064

Subject to technical changes

®

23 VS+, Euroklav®29 VS+

Geneststraße 9-10

10829 Berlin

Germany

E-mail: info@melag.de

www.melag.de

© 2007 MELAG Berlin

Technical Manual Euroklav®23 VS+ and Euroklav®29 VS+

CONTENTS

Foreword ...................................................................................................................................................... II

Declaration of conformity according to the EC-guide lines for medical devices 93/42/EWG......................... 4

Device views.......................................................................................................................................................... 5

Installation and setting up.................................................................................................................................... 6

Removal from the packaging........................................................................................................................ 6

Space requirements ..................................................................................................................................... 6

Installation surface ....................................................................................................................................... 6

Electrical connections................................................................................................................................... 7

One-way drain.............................................................................................................................................. 7

Supply with feed water ................................................................................................................................. 7

Installation material ...................................................................................................................................... 7

Installation examples.................................................................................................................................... 8

Record of installation and setting up ................................................................................................................ 12

Device and installation data ....................................................................................................................... 12

Executed work............................................................................................................................................ 13

Program modifications................................................................................................................................ 14

Electromagnetic compatibility............................................................................................................................ 15

Electromagnetic environment..................................................................................................................... 15

Recommended protective distances .......................................................................................................... 16

Technical tables................................................................................................................................................... 17

Nominal value tolerances ........................................................................................................................... 17

Pressure-Time-Charts ................................................................................................................................ 17

Quality of the feed water ............................................................................................................................ 19

Brief instructions................................................................................................................................................. 20

Emergency door opening in case of power failure ..................................................................................... 20

Replace device fuses ................................................................................................................................. 21

Program overview : MAIN menu......................................................................................................................... 22

Program overview: SETUP menu: Function...................................................................................................... 23

Technical Manual Euroklav®23 VS+ and Euroklav®29 VS+

Declaration of conformity according to the EC-guide line s for medical devices 93/ 42/EWG

Declaration of conformity

Euroklav®23 VS+

Euroklav

In accordance with the EC-guidelines for medical devices 93/42/EWG

Manufacturer: MELAG oHG

Address: Geneststraße 9 – 10

10829 Berlin

Country: Germany

Product: Steam sterilizer (autoclave)

Type of classification: Euroklav®23 VS+/ Euroklav®29 VS+

Classification: Class 2a

®

29 VS+

We herewith declare that the above designated product conforms to the following

guideline:

Appendix I of the EC-guidelines for medical devices 93/42/EWG.

Notified body: DEKRA Certification Services GmbH

Handwerkstraße 15

70565 Stuttgart

No. of registration: 50199-Z3-00

The cited medical device is designated with the CE sign since 19-10-2007.

Berlin, 19-10-2007

……………………………………

General Management

Evidence Based Sterilization

4

Quality – Made in Germany

www.melag.de

Technical Manual Euroklav®23 VS+ and Euroklav®29 VS+

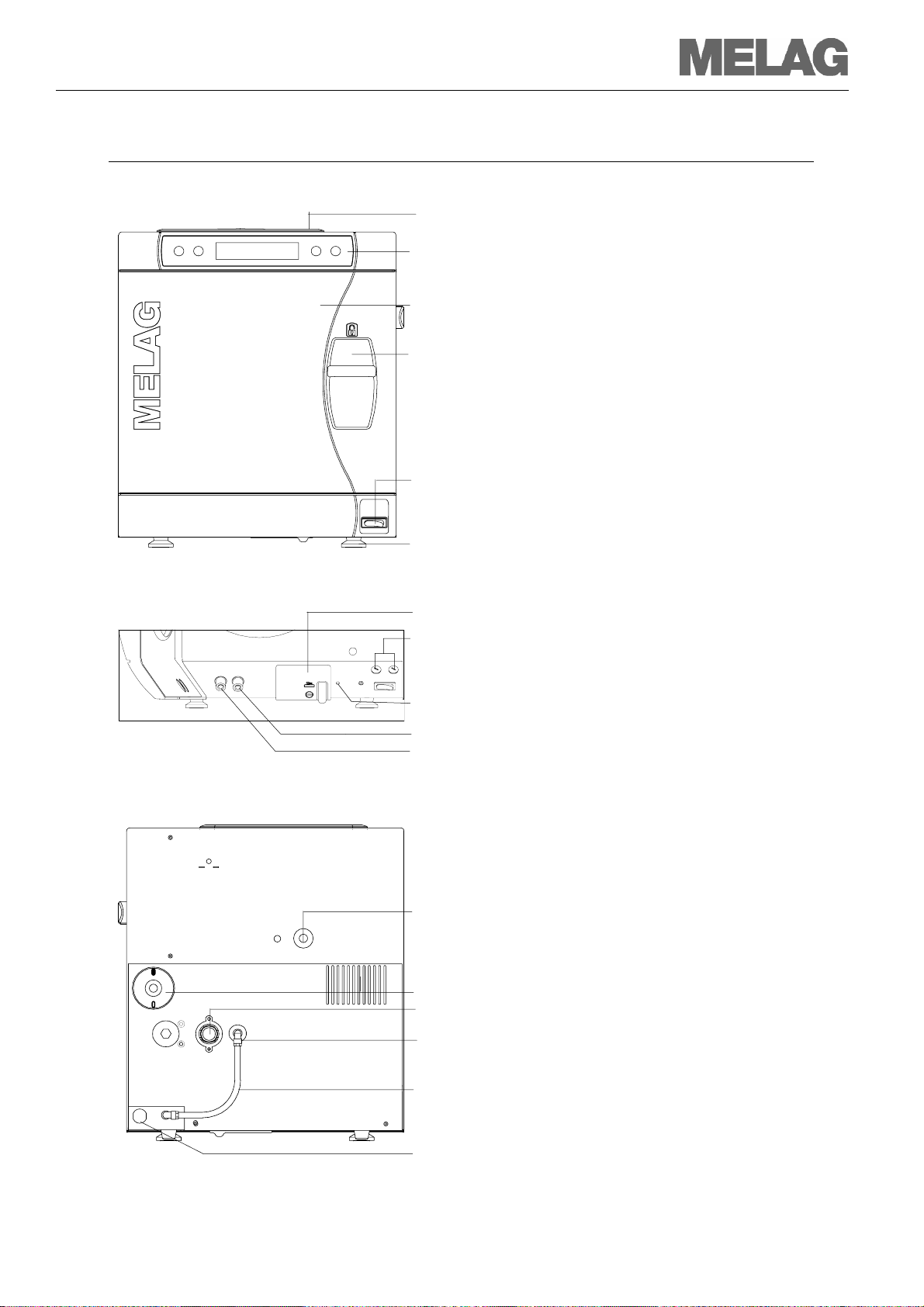

Device views

Front side

(1) Tank cap

Front side below with opened door

(7) Serial data and printer connection (RS232)

Back side

Figure 1: Device views

(2)

(3)

(4)

(5)

(6)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

Operating and display field

Door (pivots opens to the left)

Sliding closure grip

Mains switch

Front of the unit (adjustable)

Device fuses – 2x 16A/ gRl

Reset button for overheating protection

Connection for emptying the storage tank – feed water

Connection for emptying the storage tank – waste water

*hidden behind the white cover

Safety valve

Sterile filter

One-way drain

Purified feed water inlet via internal storage tank

Hose bridge for internal feed water supply

Power cable

5

Technical Manual Euroklav®23 VS+ and Euroklav®29 VS+

y

Installation and setting up

Warning!

The autoclave sterilizes on the basis of the →pre-vacuum method

Please read the Technical Description of the autoclave and the

water treatment unit before setting up the autoclave.

combined with the fractionated flow method. A piston pump used to create

the vacuum combines the advantages of great efficacy with extreme

robustness in continuous operation. Thus the autoclave can be

immediately put into operation without additional installation work, apart

from providing the necessary power supply. For the optional connection of

the one-way drain and an external water treatment unit please follow the

water main and general information for the proper installation which must

be observed when setting up the device.

Removal from the packaging

Unpack autoclave

Remove carrying strap

After switching on

Lift the autoclave out of the carton with the carrying strap.

To remove the carrying strap, unscrew the four screws on each side of the

housing. Retighten these screws firmly without the washers. Keep the

carrying strap and the washers.

After switching on the autoclave and before initial start-up, open the door

and remove the trays and the accessories from the chamber.

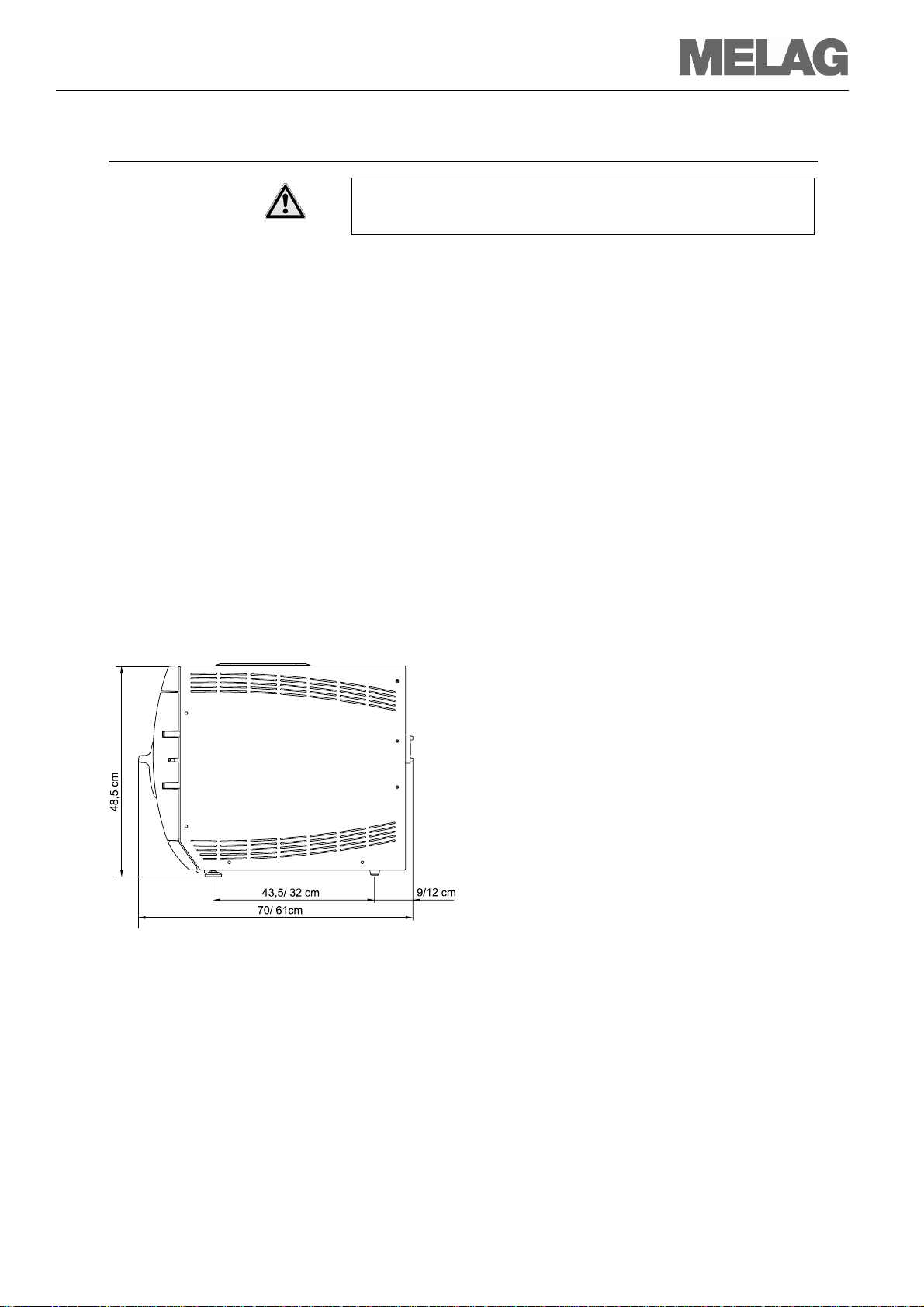

Space requirements

The space requirements for the autoclave

corresponds to its dimensions plus at least 10 cm on

both sides.

The autoclave should be freely accessible from

above, or easy filling of the storage tank and to

ensure proper ventilation.

The autoclave is not suitable for incorporation

into existing furnishings.

Dimensions of Euroklav

Figure 2: Dimensions Euroklav®23 VS+/ Euroklav®29 VS+

For →Feed water suppl

In case of external feed water supply there is additionally required space

for the water treatment unit MELAdem

Installation surface

®

23 VS+/Euroklav®29 VS+

®

40 or MELAdem

®

47.

Flat and level

Load capacity

6

Place the autoclave on a flat and level surface.

The Euroklav®23 VS+ weighs without load and without feed water 45 kg.

The Euroklav

®

29 VS+ weighs without load and without feed water 42 kg

Installation and setting up

r

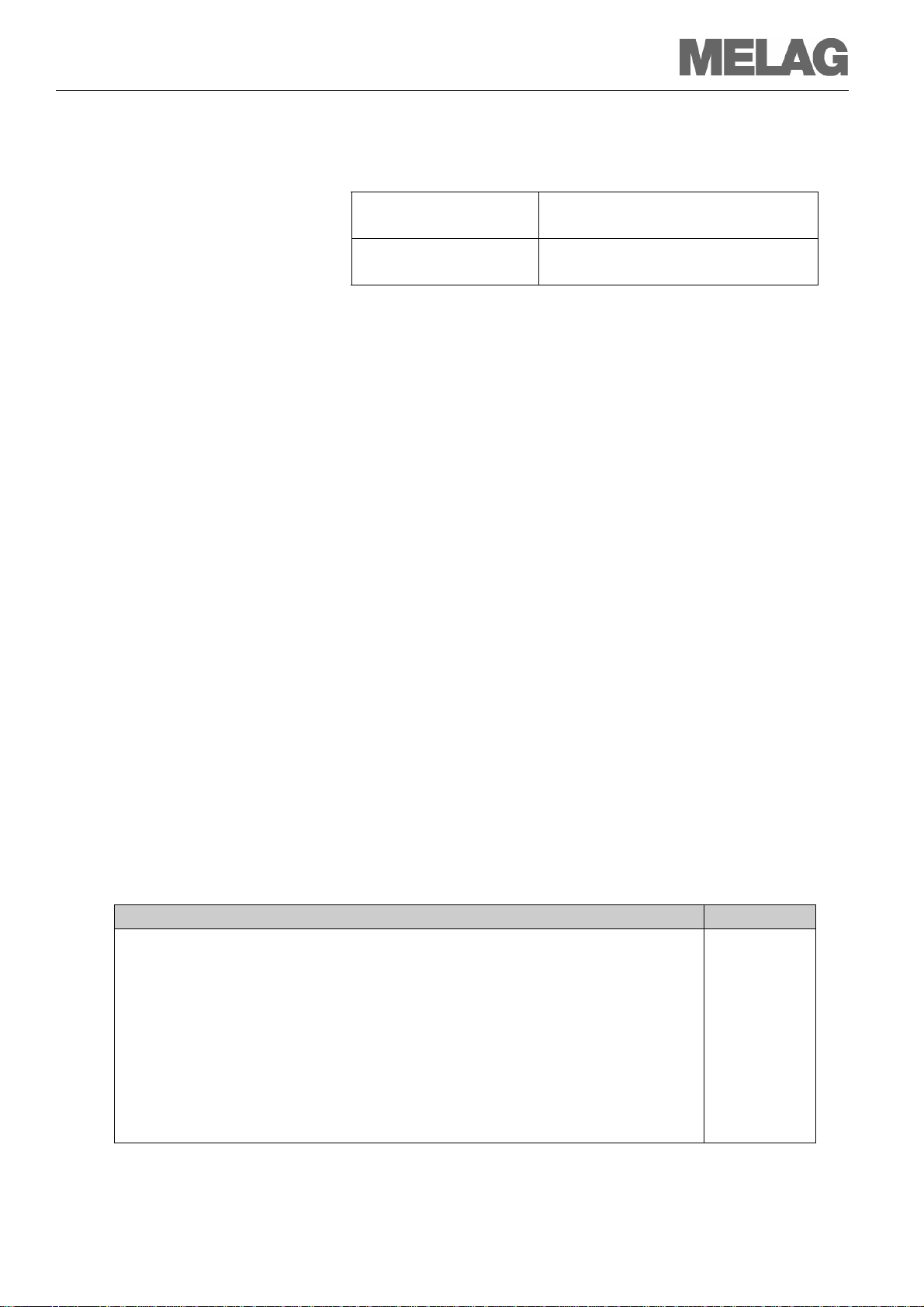

Electrical connections

Power socket

connected load

Power cable

Log printer

MELAprint

220V-240V, 50/ 60Hz; separate fuse protection 16 A,

protection from leakage current 30 mA

as of software version 4.07 2600 W for Euroklav®23 VS+

software version V4.06 3000 W for Euroklav®23 VS+

The power cable is 1.35 m long.

If you want to connect a log printer to the autoclave, you need another

®

42

socket for its power supply.

One-way drain

Wall drain or

siphon drain

Wastewater hose

A wall drain, nominal DN40 or a siphon drain (sink drain) is required for the

one-way drain.

A wastewater hose with a length of 2 metres (MELAG Art. No. 36585) can

be ordered from MELAG to connect the autoclave to the waste water.

The drain must be located at least 30 cm beneath the autoclave and be

installed dip-free with continuous descent.

Supply with feed water

2100 W for Euroklav

2400 W for Euroklav

®

29 VS+

®

29 VS+

Feed water One-way and

Circulatory-

flow system

Quality of

feed wate

The autoclave works both according to the feed water one-way system as

well as the feed water circulatory flow system. In the one-way system, it

uses fresh purified feed water for every sterilization run. In the feed water

circulatory flow system, the autoclave works in a more water-conserving

manner, since the feed water is used for several sterilization runs.

provided the instruments have been carefully prepared, that means

cleaned and rinsed (e.g. in a thermal disinfector).

The autoclave gets the feed water either from the internal storage tank,

which the practice team has refilled e.g. with distilled water from the

MELAdest

treatment unit MELAdem

The Quality of the →distilled or demineralized feed water for the steam

generation must be at least VDE 0510.

®

65. Or it gets the feed water fully automatically from the water

®

40 or MELAdem

®

47.

Installation material

Additional material, that can be ordered MELAG Art. No.

1 One-way drain hose, 2 m 36585

1 Surface mounted siphon with double hoze nozzle 37410

1 Double hose nozzle with anti-flooding flap for connection to an available siphon drain 37400

1 Water tap 3/4“ with safety combination 37310

1 Additional water tap with return flow inhibitor and pipe aerator (to attach to an available angle

valve)

1 Leak monitor (water stop) with shut-off valve and probe 01056

1 Feedwater filter MELAdem

1 Safeguard combination, consisting of return flow inhibitor and pipe aerator according to EN

1717

®

48240

58130

48660

7

Loading...

Loading...