USE AND INSTALLATION MANUAL EN

PELLET STOVE

FLAT

COMFORT AIR MADE OF CERAMICS

FLAIR

COMFORT AIR MADE OF STEATITE

Translation of original instructions

TABLE OF CONTENTS

TABLE OF CONTENTS .................................................................................................. II

INTRODUCTION ..........................................................................................................1

1WARNINGS AND WARRANTY CONDITIONS .................................................................2

2FUEL .......................................................................................................................6

3INSTALLATION .........................................................................................................7

4FLUE .......................................................................................................................8

5DRAWINGS AND TECHNICAL FEATURES ....................................................................15

6INSTALLATION AND ASSEMBLY ...............................................................................18

7REMOTE CONTROL MAX ..........................................................................................36

8EMERGENCY PANEL ................................................................................................41

9SAFETY DEVICES AND ALARMS ................................................................................44

10MAINTENANCE AND CLEANING..............................................................................48

11PROBLEMS/CAUSES/SOLUTIONS ...........................................................................52

12WIRING DIAGRAMS ..............................................................................................55

II

INTRODUCTION

Dear Customer,

our products are designed and manufactured in compliance with European reference Standards for construction products (EN13240

wood-burning stoves, EN14785 pellet-burning appliances, EN13229 replaces/wood-burning inserts, EN 12815 wood-burning cookers),

with high quality materials and extensive experience in the transformation processes. The products also meet the essential requirements

of Directive 2006/95/EC (Low Voltage) and Directive 2004/108/EC (Electromagnetic Compatibility).

To get the best performance, we suggest you read the instructions in this manual carefully.

This installation and use manual forms an integral part of the product: ensure that the manual is always supplied with the appliance,

even if it changes owner. If the manual is lost, you can request another copy from the local technical service or download it directly from

the company website.

All local regulations, including those regarding national and European regulations, must be observed when the appliance is installed.

In Italy, for the installation of systems with biomass below 35KW, refer to ministerial decree D.M. 37/08, and the qualied installation

technician with the appropriate requisites must issue a certicate of compliance for the system installed. (By system one means

Stove+Chimney+Air inlet).

REVISIONS TO THE PUBLICATION

The content of this manual is strictly technical and the property of MCZ Group Spa.

No part of this manual may be translated into other languages and/or adapted and/or reproduced, even in part, in other mechanical or

electronic forms, photocopies, recordings or other, without the prior written authorisation from MCZ Group Spa.

The company reserves the right to make changes to the product at any time without prior notice. The proprietary company reserves its

rights according to the law.

CARE OF THE MANUAL AND HOW TO CONSULT IT

• Take care of this manual and keep it in an easily accessible place.

• Should the manual be misplaced or ruined, request a copy from your retailer or directly from the authorised Technical Assistance

Department. It can be downloaded from the company website.

• The “text in bold” must be read with particular care.

• The “text in italics” draws attention to other sections in this manual or clarications.

• “NOTE” provides the reader with additional information.

SYMBOLS USED IN THE MANUAL

ATTENTION:

read the relative message carefully as failure to observe the information provided could result in serious

damage to the product and put the persons who use it at risk.

INFORMATION:

failure to comply with these provisions will compromise the use of the product.

OPERATING SEQUENCES:

sequence of buttons to be pressed to access the menus or change settings.

MANUAL

carefully read this manual or the relative instructions.

Technical Dept. - All rights reserved - Reproduction is prohibited

1

1-WARNINGS AND WARRANTY CONDITIONS

SAFETY PRECAUTIONS

• Installation, electrical connection, function test and maintenance must only be carried out by authorised and

qualied personnel.

• Install the product in accordance with all local and national legislation and regulations in force in the region or state.

• Only use the fuel recommended by the manufacturer. The product must not be used as an incinerator. It is strictly forbidden to use

liquid fuel.

• Do not put any fuel other than wood pellets in the hopper.

• The instructions provided in this manual must always be complied with to ensure the product and any electronic appliances

connected to it are used correctly and accidents are prevented.

• The user, or whoever is operating the product, must read and fully understand the contents of this installation guide before

performing any operation. Errors or incorrect settings can cause hazardous conditions and/or poor operation.

• Do not climb on or lean on the product.

• Do not put linen on the product to dry. Any drying racks or the like must be kept at a safe distance from the product. Fire hazard.

• All liability for improper use of the product is entirely borne by the user and relieves the Manufacturer from any civil and criminal liability.

• Any type of tampering or unauthorised replacement with non-original spare parts could be hazardous for the operator’s safety and

relieves the company from any civil and criminal liability.

• Many of the surfaces of the product get very hot (door, handle, glass, smoke outlet pipes, etc.). Avoid coming into contact with

these parts, without adequate protective clothing or suitable implements, such as gloves with thermal protection or

“cold handle” operating systems.

• It is forbidden to operate the product with the door open or the glass broken.

• The product must be powered by an electrical system that is equipped with an eective earthing device.

• Switch the product o in the event of a fault or malfunction.

• Accumulated unburned pellets in the burner after each “failed start-up” must be removed before lighting again. Check that the

burner is clean and positioned properly before lighting again.

• Do not wash the product with water. Water could get inside the unit and damage the electrical insulation and cause electric shocks.

• Do not stand for a long time in front of the product in operation. Do not overheat the room you are in and where the product is

installed. This could cause injuries and health problems.

• Install the product in a location that does not feature a re hazard and is equipped with power and air supplies and smoke extractors.

• In the event of re in the chimney, turn o the device, disconnect it from the mains electricity and do not open the hatch. Then

contact the competent authorities.

• The product and the cladding must be stored in a dry place and must not be exposed to weathering.

• It is recommended not to remove the feet that support the product in order to guarantee adequate insulation, especially if the

ooring is made of ammable materials.

• In the event of a malfunction of the ignition system, do not force it to light by using ammable materials.

• Special maintenance must only be performed by authorised and qualied personnel.

• Assess the static conditions of the surface on which the weight of the product will rest and provide suitable insulation if it is made of

ammable material (e.g. wood, tted carpet or plastic).

2

1-WARNINGS AND WARRANTY CONDITIONS

INFORMATION:

Please contact the retailer or qualied personnel authorised by the company to resolve a problem.

• You must only use the fuel specied by the manufacturer.

• When the product is switched on for the rst time it is normal for it to emit smoke due to the paint overheating for the rst time.

Therefore make sure the room in which it is installed is well ventilated.

• Check and clean the smoke extraction pipes regularly (connection to the chimney).

• The product is not a cooking appliance.

• Always keep the cover of the fuel hopper closed.

• Store this installation and use manual with care as it must accompany the product for the duration of its useful life. If the product is

sold or transferred to another user, ensure the manual is also handed over.

INTENDED USE

The product only works with wood pellets and must be installed indoors.

WARRANTY CONDITIONS

The company guarantees the product, with the exception of elements subject to normal wear listed below, for a period of 2 (two)

years from the date of purchase attested by:

• a document to serve as proof of purchase (invoice and/or receipt) that shows the name of the vendor and the date on which the

purchase was made;

• forwarding of the completed certicate of guarantee within 8 days of purchase.

Furthermore, the product must be installed and started by specialised personnel who must, where provided, issue a declaration of

conformity of the plant and of the proper functioning of the product, for the warranty to be valid and eective.

We recommend testing the product before completion with the relative nishes (claddings, painting of walls, etc.).

Installations that do not meet the current standards, improper use and lack of maintenance as expected by the manufacturer, void the

product warranty.

The guarantee is valid on the condition that the instructions and warnings contained in the use and maintenance manual are observed,

and therefore the product is used correctly.

The replacement of the entire appliance or the repair of one of its components does not extend the warranty period, and the original

expiry date remains unchanged.

The warranty covers the replacement or free repair of parts recognised as faulty at source due to manufacturing defects. To

benet from the warranty, in the event of a fault, the customer must have the warranty certicate and show it with the proof of purchase

document to the Technical Assistance Oce.

Technical Dept. - All rights reserved - Reproduction is prohibited

3

1-WARNINGS AND WARRANTY CONDITIONS

EXCLUSIONS

The guarantee does not cover malfunctions and/or damage to the appliance that arise due to the following causes:

• Damage caused during transportation and/or handling

• all parts that develop faults due to negligence or improper use, incorrect maintenance, installation that does not comply with the

manufacturer’s instructions (always refer to the installation and use manual provided with the appliance)

• incorrect sizing with regard to the use or faults in the installation or failure to adopt the necessary devices to guarantee proper

execution

• improper overheating of the equipment, use of fuels not conforming to the types and quantities indicated in the instructions provided

• further damage caused by incorrect user interventions in an attempt to x the initial fault

• worsening of the damage due to the continued use of the equipment by the user, once the defect has been noticed

• in presence of a boiler, any corrosion, incrustations or breakages caused by water ow, condensation, hardness or acidity of the water,

improperly performed descaling treatments, lack of water, mud or limescale deposits

• ineciency of chimneys, ues or parts of the plant aecting the equipment

• damage caused by tampering with the appliance, atmospheric agents, natural disasters, vandalism, electric shocks, res, faults in

the electric and/or hydraulic system.

The following are also not covered by the warranty:

• parts subject to normal wear such as gaskets, glass, claddings and cast iron grids, painted, chrome-plated or gilded parts, handles

and electric cables, bulbs, indicator lights, knobs, all parts which can be removed from the hearth.

• Variations in colour of the painted or ceramic/serpentine parts and craquelure ceramics as they are natural characteristics of the

material and product use.

• masonry work

• plant parts (if present) not supplied by the manufacturer

Any technical interventions on the product to eliminate the above-said defects and consequent damages must be agreed upon with

the Technical Assistance Centre, who reserves the right to accept the relative appointment or not. However, said interventions will not

be carried out under warranty but as technical assistance to be granted at part of any eventual and specic agreed conditions and in

accordance with the fee in force for the work to be carried out.

The user will also be charged for any costs incurred to remedy the incorrect technical interventions, tampering or damage to the appliance,

not attributable to original faults.

With the exception of the legal or regulatory limits, the warranty does not cover the reduction of atmospheric and acoustic pollution.

The company declines all liability for any damage which may be caused, directly or indirectly, to persons, animals or objects as

a consequence of non compliance with any provision specied in the manual, especially warnings regarding installation, use

and maintenance of the appliance.

4

1-WARNINGS AND WARRANTY CONDITIONS

SPARE PARTS

In the event of a malfunction, consult the retailer who will forward the call to the Technical Assistance Service.

Only use original spare parts. The retailer or service centre can provide all necessary information regarding spare parts.

We do not recommend waiting for the parts to get worn out before having them replaced. It is important to perform regular maintenance.

The company declines all liability if the product and any other accessory is used improperly or modied without

authorisation.

All parts must be replaced with original spare parts.

WARNINGS FOR THE CORRECT DISPOSAL OF THE PRODUCT.

The owner is the sole party responsible for demolishing and disposing of the product. This must be performed in compliance with laws

related to safety and environmental protection in force in his/her country.

At the end of its working life, the product must not be disposed of as urban waste.

It must be taken to a special dierentiated waste collection centre set up by the local authorities or to a retailer that provides this service.

Separating and recycling prevents potential negative eects on the environment and health (often caused by inappropriately disposing of

product parts). It also allows materials to be recovered in order to obtain signicant savings in energy and resources.

Technical Dept. - All rights reserved - Reproduction is prohibited

5

2-FUEL

The instructions in this chapter refer explicitly to the Italian installation regulation UNI 10683. In any case, always observe the regulations

in force in the country of installation.

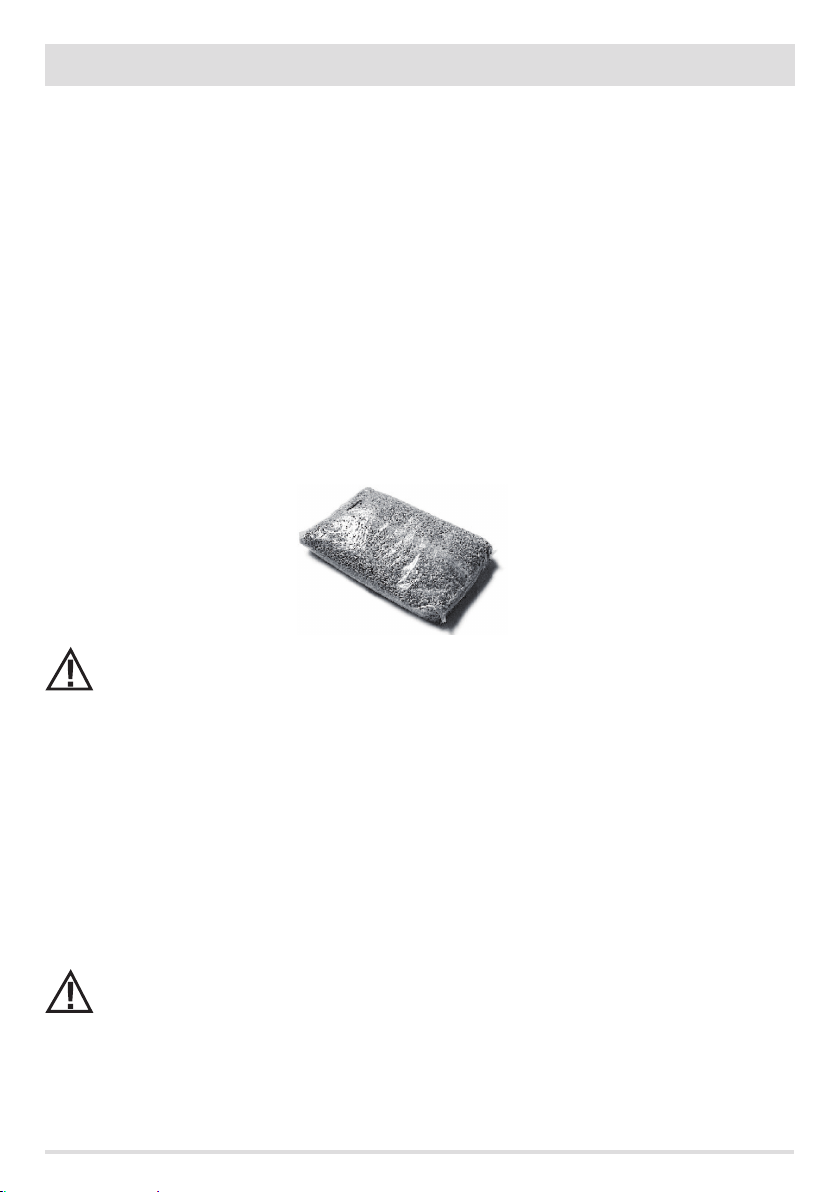

PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the working of natural dried wood. The

compactness of the material is guaranteed by the lignin contained in the wood itself and allows pellets to be produced without glue or

binders.

The market oers dierent types of pellets with characteristics that vary according to the wood mixtures used. The most common

diameter on the market is 6 mm (although 8 mm diameter is available too) with a length, on average, of between 5 and 30 mm. A good

quality pellet has a density of between 600 and 750 or more kg/metres cubed and a water content that accounts for 5 to 8% of its weight.

Pellets have technical advantages besides being an ecological fuel, as the wood residue is used completely, thereby achieving cleaner

combustion than that of fossil fuels.

While good-quality wood has a caloric value of 4.4 kW/kg (15% moisture, after about 18 months of seasoning), whereas that of pellets

is around 4.9 kW/kg. To ensure good combustion, the pellets must be stored in a dry place and protected from dirt. Pellets are usually

supplied in 15 kg bags, therefore, storing them is very convenient.

Good quality pellets guarantee good combustion, thereby decreasing harmful emissions into the atmosphere.

15 Kg BAGS OF FUEL

The poorer the quality of the fuel, the more often the internal parts of the brazier and combustion chamber must

be cleaned.

The main quality certications for pellets currently available on the European market guarantee that the fuel complies with class A1/A2

according to EN14961-2. These certications include, for example, ENPlus, DINplus, Ö-Norm M7135, and in particular, guarantee the

following characteristics:

• caloric value: 4.6 ÷ 5.3 kWh/kg.

• Water content: ≤ 10% of the weight.

• Percentage of ash: max 1.5% of the weight.

• Diameter: 6±1/8±1 mm.

• Length: ≤ 40 mm.

• Content: 100% untreated wood without the addition of binding substances (max 5% bark).

• Packaging: in sacks made from ecologically compatible or biologically decomposing material.

The company strongly recommends using certied fuel for its products (ENplus, DINplus, Ö-Norm M7135).

Poor quality pellets or others that do not comply with the characteristics specied previously may compromise the

operation of your product and can therefore make the guarantee and product liability invalid.

6

3-INSTALLATION

FOREWORD

The installation position must be chosen according to the room, to the smoke extraction system, to the chimney ue. Check with local

authorities whether there are any restrictive regulations in force regarding the combustion air inlet, the smoke outlet system, the

ue or the chimney cap. The manufacturer declines all responsibility in the event of installations that do not comply with the laws in

force, incorrect room air exchange, electrical connection non-compliant with the standards and inappropriate use of the appliance. The

installation must be carried out by a qualied technician, who must issue a declaration of conformity of the system to the purchaser and

will assume full responsibility for nal installation and consequent good operation of the product.

In particular one must ensure that:

• there is a suitable combustion air inlet and smoke outlet in compliance with the type of product installed

• other stoves or devices installed do not cause depression in the room where the product is installed (for sealed appliances only, a

maximum of 15 Pa of depression in the room is allowed)

• when the product is switched on there is no reux of smoke in the room

• fumes extraction takes place in total safety (sizing, smoke seal, distances from ammable materials..).

We especially recommend to check the data tags of the ue for the safety distances that must be observed in presence

of combustible materials and the type of insulating material to be used. These indications must be followed strictly to

prevent serious harm to people and the integrity of the home. The installation of the appliance must ensure easy access to

clean the appliance itself, the smoke outlet pipes and the ue. It is forbidden to install the stove in rooms with a re hazard.

Installation in studio ats, bedrooms and bathrooms is only allowed with sealed or closed appliances equipped with

suitable combustion air ducting directly outside. Always maintain adequate distance and protection in order to prevent

the product from coming into contact with water.

In the event there are several appliances installed, the external air inlet must be sized accordingly.

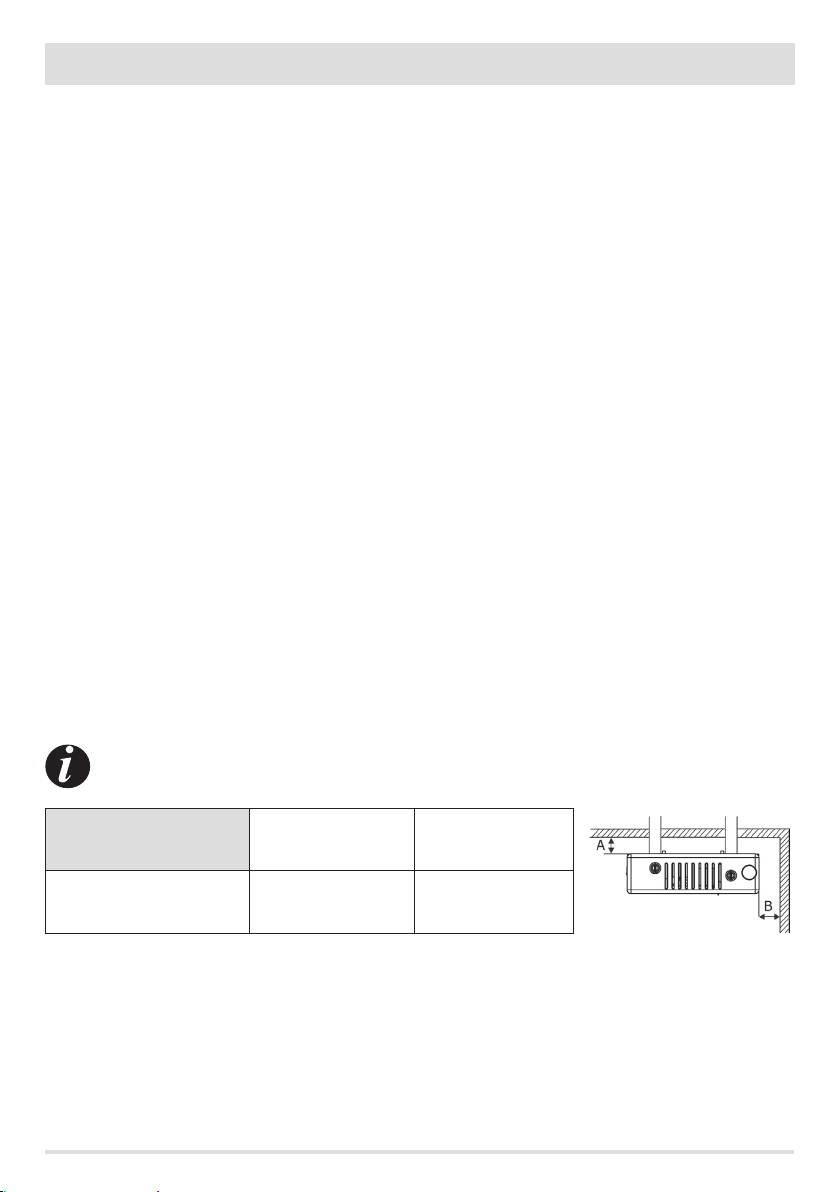

MINIMUM DISTANCES

It is recommended to install the stove detached from any walls and/or furniture, with a minimum clearance to allow eective aeration

of the appliance and a good distribution of heat in the room. Observe the distances from ammable or heat-sensitive objects (sofas,

furniture, wood panelling, etc..) as specied. The front distance from ammable materials must be at least 80 cm.

If particularly delicate objects are present, such as furniture, curtains or sofas, increase the stove clearance accordingly.

If the oor is made of wood, it is recommended to t a oor protection sheet in compliance with the Standards in

force in the country of installation.

FLAT - FLAIR Non-ammable walls Flammable walls

Comfort Air

If the oor is made of combustible material, it is recommended to use protection made of non-combustible material (steel, glass...) that

also protects the front from falling combusted material during cleaning operations.

The appliance must be installed on a oor with adequate load capacity.

If the existing construction does not meet this requirement, one must take appropriate measures (for example a load distribution plate).

Technical Dept. - All rights reserved - Reproduction is prohibited

A = 2 cm

B = 15 cm

A = 2 cm

B = 20 cm

7

4-FLUE

FOREWORD

The Chimney Flue chapter has been drawn up with reference to the provisions of European Standards (EN13384 - EN1443 - EN1856 EN1457).

The chapter provides instructions for installing a chimney ue eciently and properly, but under no circumstances is it a substitute of the

Standards in force, which the qualied technician must be in possession of. Check with local authorities whether there are any restrictive

regulations in force regarding the combustion air inlet, the smoke outlet system, the ue or the chimney cap.

The company declines all liability relating to the poor functioning of the stove if this is due to the use of an insuciently sized ue in

violation of the Standards in force.

CHIMNEY FLUE

The ue or chimney is of great importance for the proper operation of a solid fuel-burning heating appliance with forced draught, as

modern heating appliances have high eciency with cooler ue gasses and consequently less draught, it is therefore essential that the

ue is built up to standard and always kept in perfect order. A ue that serves a pellet/wood fuelled appliance must be at least category

T400 (or greater if the appliance requires so) and resistant to soot res. Smoke must be extracted through a single ue made of insulated

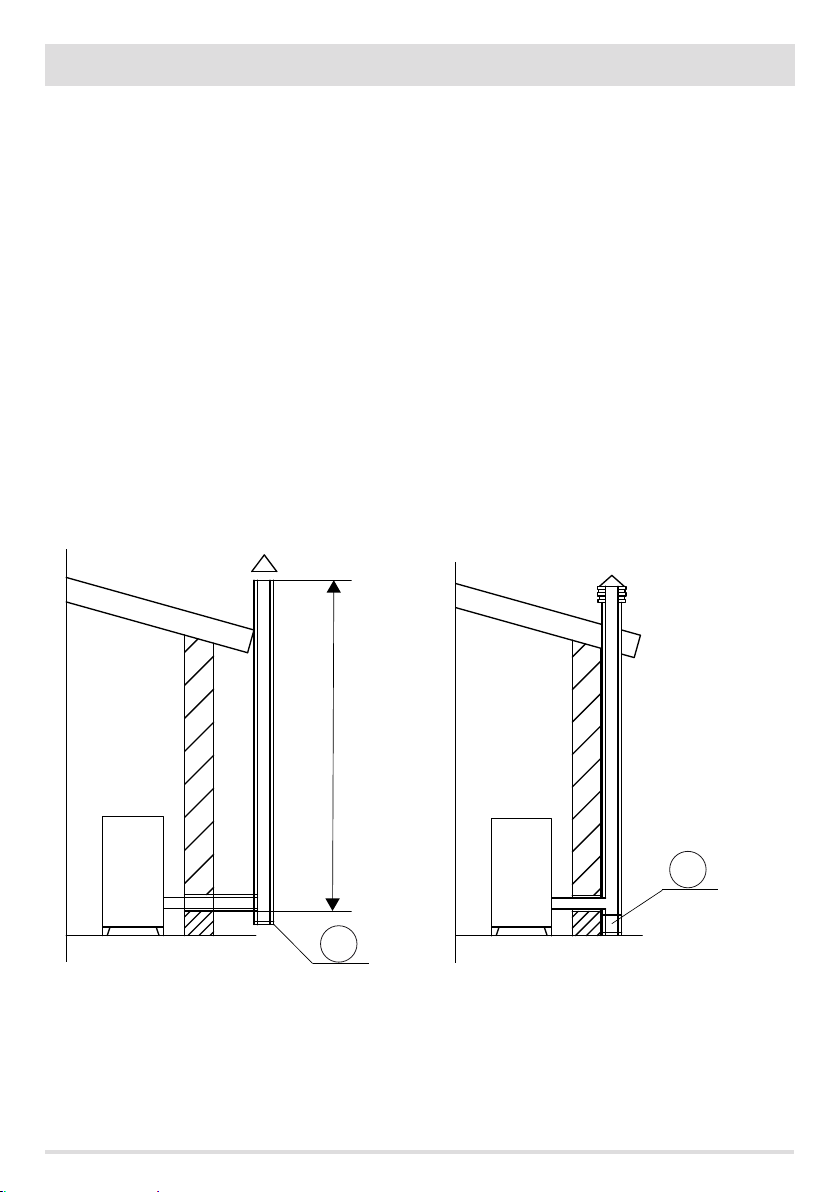

steel (A) or an existing ue that complies with the intended use (B).

A simple air shaft made of cement must be suitably lined. In both solutions there must be an inspection cap (AT) and/or inspection hatch

(AP) - FIG.1.

It is forbidden to connect more than one wood/pellet-burning appliance or of any other kind (vent hoods... ) to the same ue.

min.3,5 metri

AP

(A)

AT

FIGURE 1 SMOKE FLUE

8

(B)

4-FLUE

TECHNICAL CHARACTERISTICS

Have the eciency of the ue checked by an authorised technician.

The ue must be sealed against ue gasses, in a vertical direction without narrowing, be made with materials impermeable to smoke,

condensation, thermally insulated and suitable to resist normal mechanical stress over time (we recommend replaces made of A/316

or refractory material with insulated round section double chamber). Be suitably insulated externally to avoid condensation and reduce

smoke cooling. It should be separated from combustible or ammable materials with an air gap or insulating materials: check the distance

specied by the manufacturer of the replace according to EN1443. The chimney opening must be in the same room as the appliance, or

at most in the adjoining room, and have a soot and condensation collection chamber beneath the opening, and be accessible via a sealed

metal hatch.

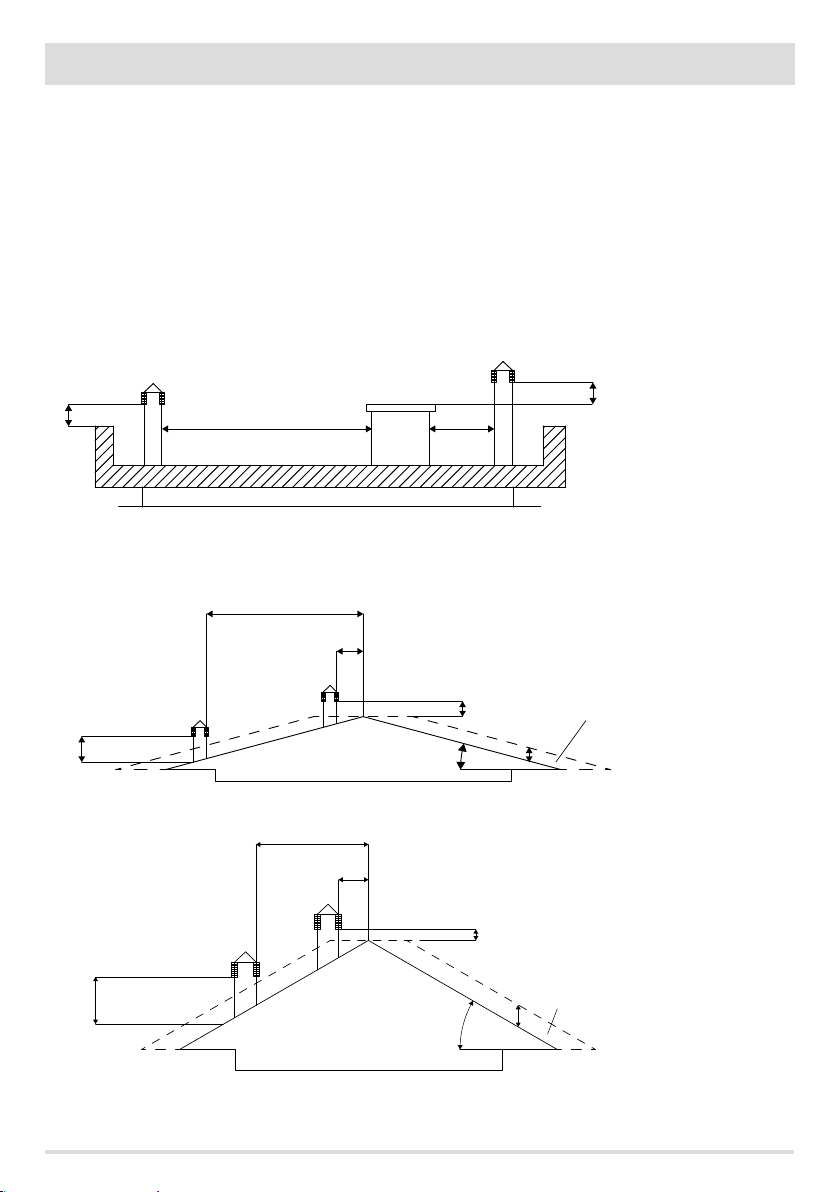

FLAT ROOF

A = 0.50 metres

B = DISTANCE > 2 metres

D

A

ROOF AT 15°

A

B

E

B

C

15°

C

D

E

C = DISTANCE < 2 metres

D = 0.50 metres

E = TECHNICAL VOLUME

FIGURE 2

A = MIN. 1.00 metres

B = DISTANCE > 1.85 metres

C = DISTANCE < 1.85 metres

D = 0.50 metres above highest

point

E = 0.50 metres

F

F = REFLUX AREA

FIGURE 3

ROOF AT 30°

B

C

A

Technical Dept. - All rights reserved - Reproduction is prohibited

30°

A = MIN. 1.30 metres

B = DISTANCE > 1.50 metres

C = DISTANCE < 1.50 metres

D = 0.50 metres ABOVE

D

HIGHEST POINT

E = 0.80 metres

F = REFLUX AREA

F

E

FIGURE 4

9

4-FLUE

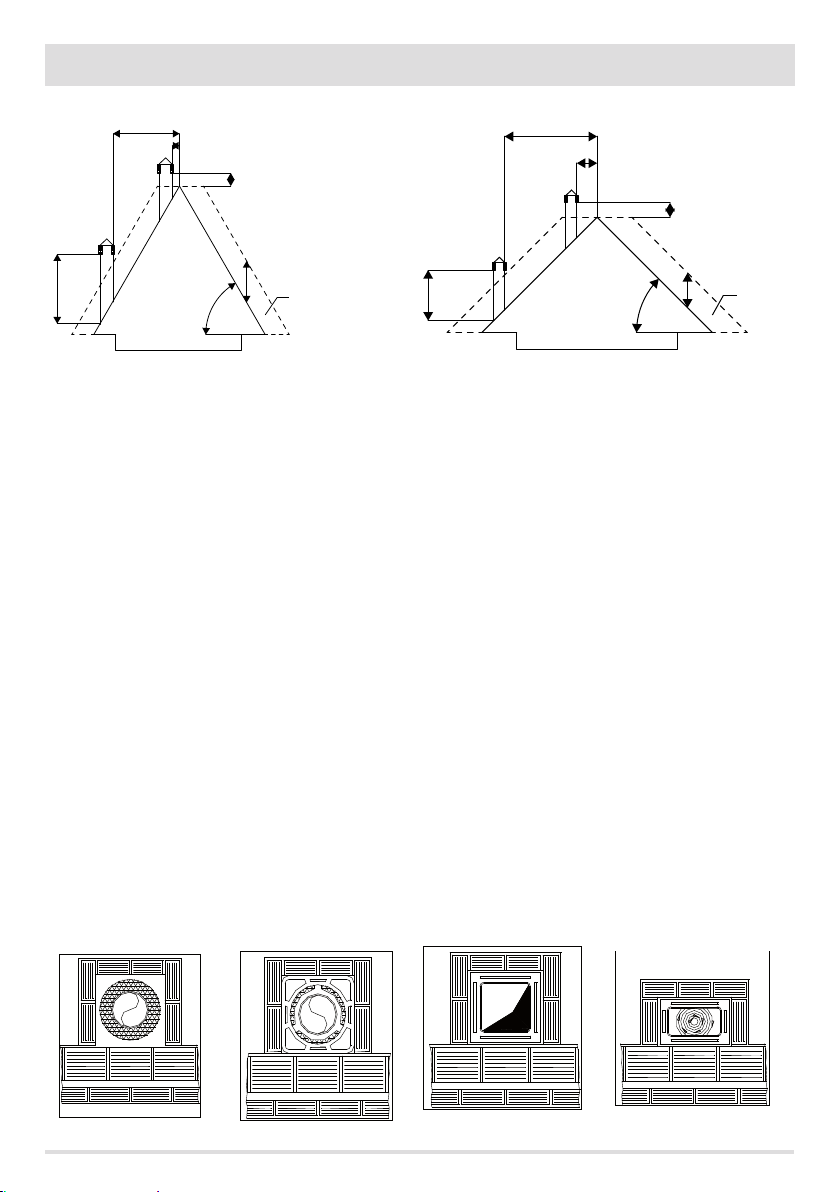

ROOF AT 60° ROOF AT 45°

B

C

D

A

60°

A = MIN. 2.60 metres

B = DISTANCE > 1.20 metres

C = DISTANCE < 1.20 metres

D = 0.50 metres ABOVE HIGHEST POINT

E = 2.10 metres

F = REFLUX AREA

E

F

FIGURE 5 FIGURE 6

A

A = MIN. 2.00 metres

B = DISTANCE > 1.30 metres

C = DISTANCE < 1.30 metres

D = 0.50 metres ABOVE HIGHEST POINT

E = 1.50 metres

F = REFLUX AREA

B

C

D

F

45°

E

SIZING

The depression (draught) of a ue depends on its height. Check the depression with the values indicated in the technical characteristics.

The minimum height of the chimney is 3.5 meters.

The interior cross-section of the ue can be round (best), square or rectangular (the ratio between the internal sides must be ≤1.5) with

the sides joined with a minimum radius of 20 mm. The dimension of the cross-section must be minimum Ø100mm.

The cross-sections/lengths of the chimneys shown in the technical data tables are indications for correct installation. Any alternative

congurations must be correctly sized in accordance with the general method of calculation of UNI EN13384-1 or other proven eciency

methods.

Below is a list of some ues available on the market:

AISI 316 steel chimney with

double chamber insulated

with ceramic bre or equivalent resistant up to 400°C.

Refractory chimney with

double insulated chamber and

external lightweight concrete

cladding with cellular material

such as clay.

Traditional square-section

clay chimney with insulating

empty inserts.

Avoid products with an

internal rectangular section

where the larger side is 1.5

times the smaller side (e.g.

20x40 or 15x30).

EXCELLENT GOOD POOR VERY POOR

10

4-FLUE

MAINTENANCE

The ue must be kept clean, since the deposit of soot or unburned oils reduces the cross-section reducing the draft and thus compromising

the ecient operation of the stove and, if large build-ups accumulate, can catch re. The ue and chimney must be cleaned and checked

by a qualied chimney sweep at least once a year. Once maintenance has been performed, request a written declaration that the system

is safe.

Failure to clean the system jeopardises safety.

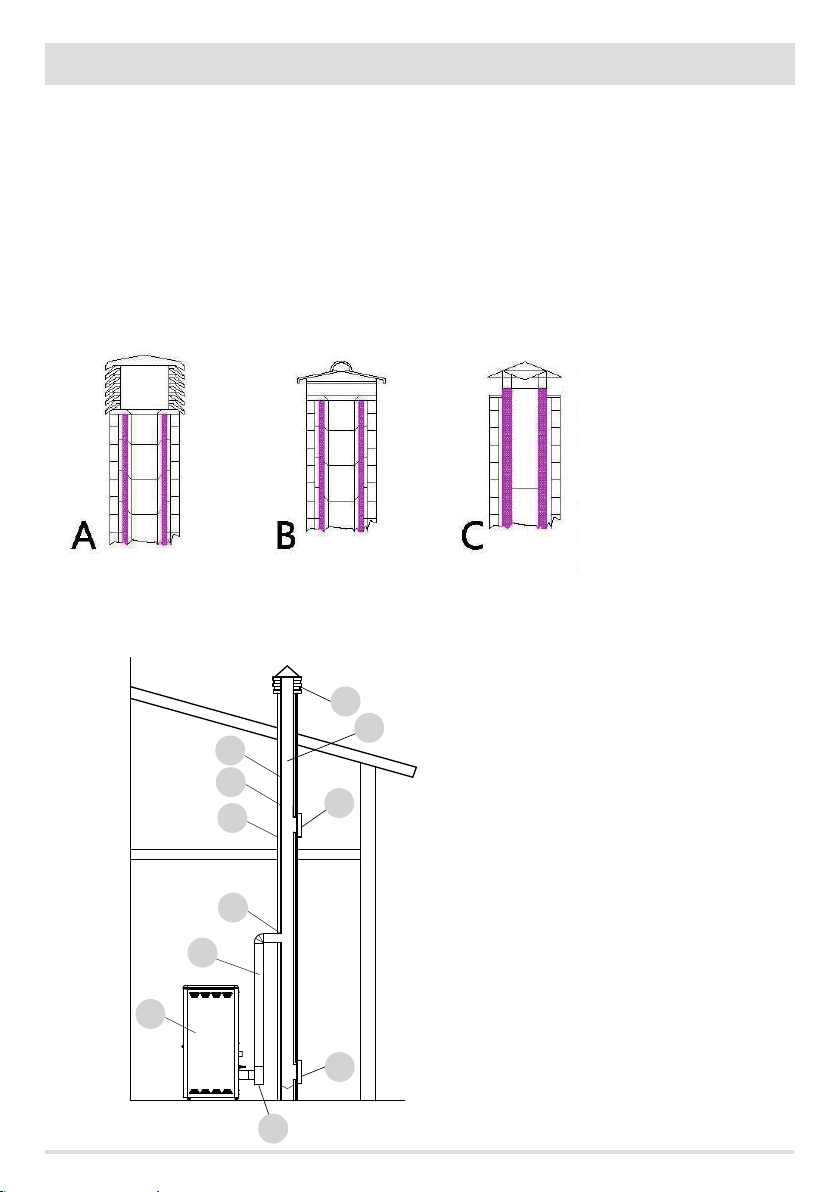

CHIMNEY CAP

The chimney cap is a crucial element for the heating appliance to work properly: we recommend a wind proof chimney cap (A), see Figure

7.

The area of the openings for smoke

extraction must be at least double the

cross-section of the smoke duct/ue

system, and arranged so that smoke

extraction is ensured even in strong

wind. The chimney must prevent rain,

snow or animals from entering the

chimney. The height of outow into

the atmosphere must be beyond the

reux area due to the shape of the roof

or any obstacles near the outlet (see

Figures 2-3-4-5-6).

FIGURE 7

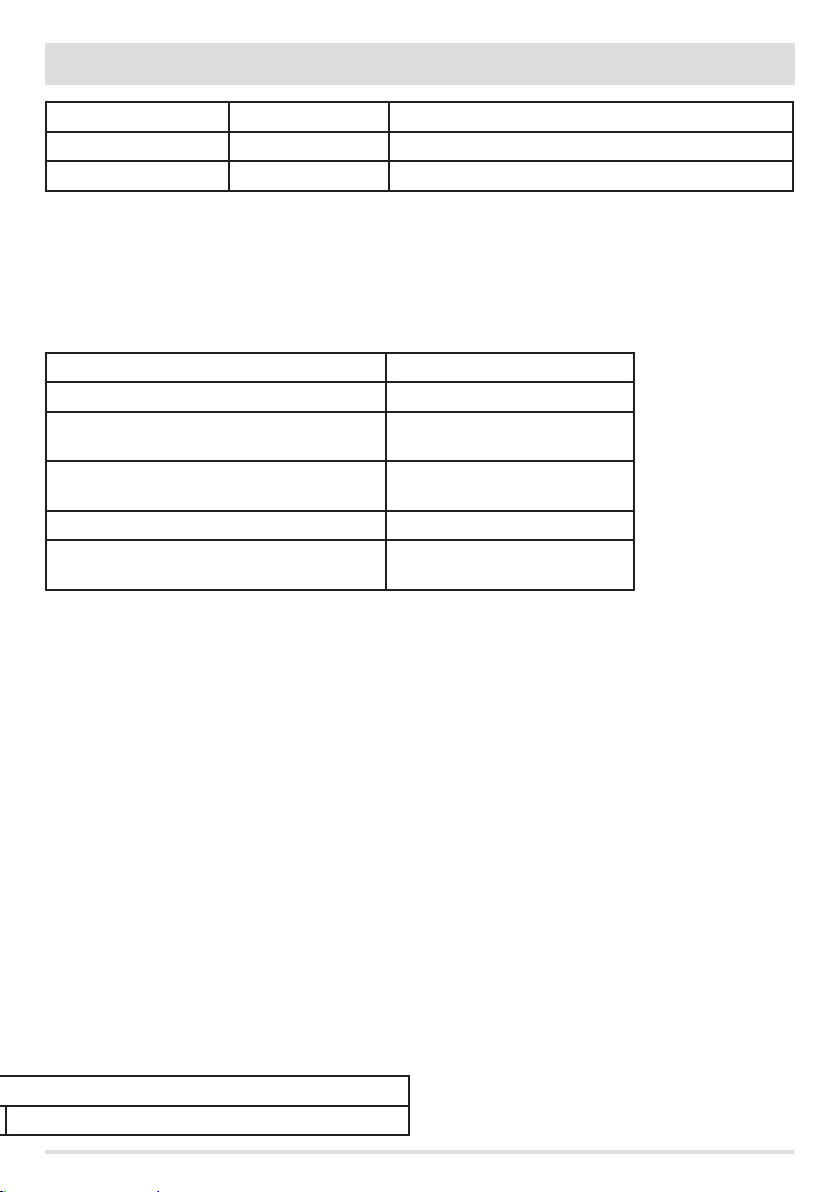

CHIMNEY COMPONENTS

1

2

3

4

5

9

6

7

8

9

9

Technical Dept. - All rights reserved - Reproduction is prohibited

KE Y:

(1) CHIMNEY CAP

(2) REFLUX CHANNEL

(3) SMOKE DUCT

(4) THERMAL INSULATION

(5) OUTSIDE WALL

(6) CHIMNEY CONNECTION

(7) SMOKE CHANNEL

(8) HEAT GENERATOR

(9) INSPECTION ACCESS PANEL

FIGURE 8

11

4-FLUE

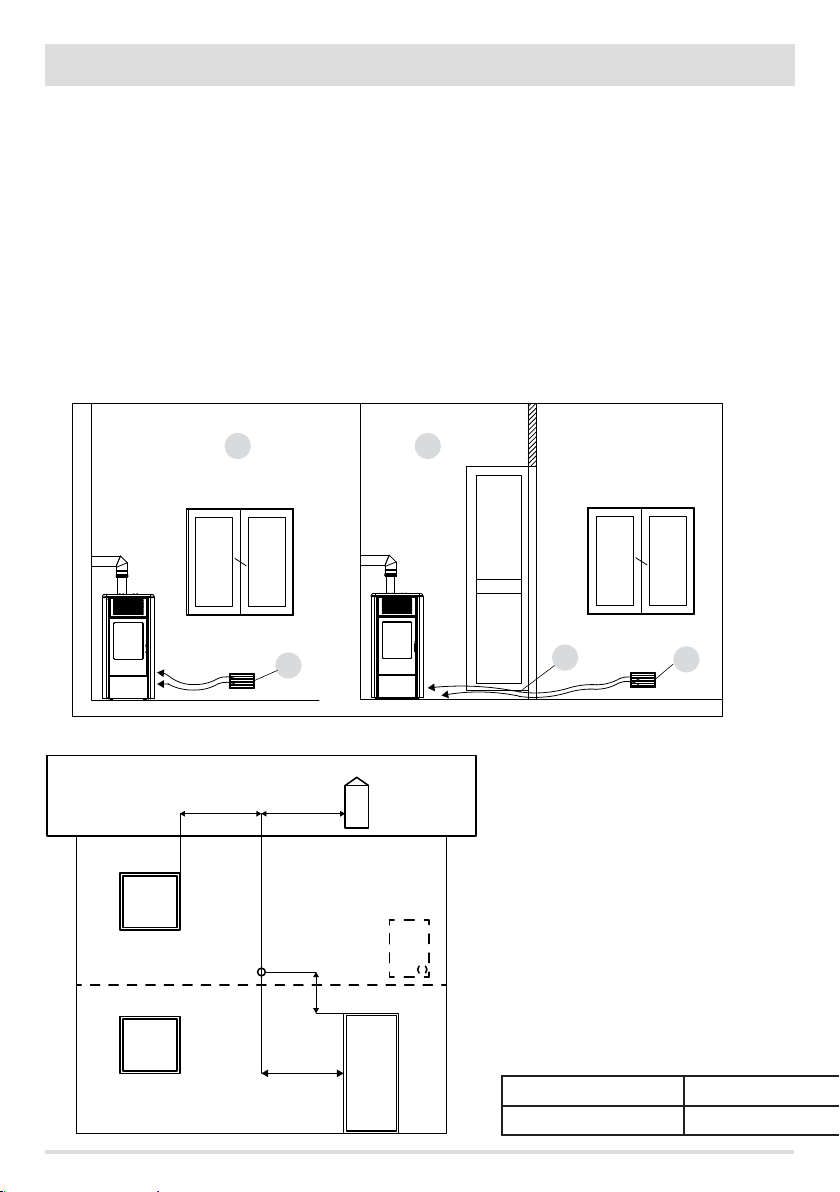

EXTERNAL AIR INLET

It is mandatory to provide an adequate external air intake that supplies the combustion air required for the product to work properly. The

ow of air between the outside and the installation room may be direct, through an inlet in an external wall of the room; or indirect, via

air intake from adjoining rooms and connecting permanently with the installation room (see Figure 9 b). Adjoining areas may not include

sleeping areas, garages or general areas that present a re hazard. During installation one must check the minimum clearances required

for air intake from outside. Take into account the presence of doors and windows that could interfere with the proper ow of air to the

stove (see diagram below).

The air intake must have a minimum total net area of 80 cm2: the surface must be increased accordingly if within the room there are other

active generators (for example: electric fan for stale air extraction, kitchen hood, other stoves, etc...), which could cause cause depression

in the room. One must verify that, with all the equipment on, the pressure drop between the room and the outside does not exceed a value

of 4 Pa. If necessary increase the intake section of the air inlet, which must be made at oor level and always protected with a bird-proof

outer protection grid and in such a way that it cannot be obstructed by any object.

B B

A

FIGURE 9 A DIRECTLY FROM OUTSIDE

It is possible to connect the air required for combustion directly to the outside air inlet, with a pipe of at least Ø50mm, with maximum

MIN.1,5 m MIN.1,5 m

FIGURE 9 B INDIRECTLY FROM THE ADJACENT ROOM

C

A=AIR INLET

B=ROOM TO BE VENTILATED

C=INCREASE OF THE GAP UNDER THE DOOR

A

length of 3linear metres; each pipe bend shall be

considered equivalent to a linear metre. To attach the

pipe see the back of the stove.

For stoves installed in studio ats, bedrooms and

bathrooms (where allowed), it is mandatory to

connect the combustion air outside. In particular for

sealed stoves the connection must be sealed in order

MIN.0,3 m

MIN.1,5 m

not to compromise the overall sealed characteristic of

the system.

DISTANCE (metres) The air inlet must be at a distance of:

FIGURE 10

1.5 m UNDER Windows, doors, smoke outlets, cavities, ....

12

4-FLUE

1.5 m HORIZONTALLY Windows, doors, smoke outlets, cavities, ....

0.3 m ABOVE Windows, doors, smoke outlets, cavities, ....

1.5 m AWAY from smoke outlet

CONNECTION TO THE FLUE

The connection between the ue and the appliance must be via a smoke duct that complies with EN 1856-2. The connecting section must

extend no more than 4 m horizontally, with a minimum slope of 3% and with a maximum of 3 90% bends (accessible for inspection - do

not count the T tting at the appliance outlet).

The diameter of the smoke duct must be equal to or greater than that of the appliance outlet (Ø 80 mm).

TYPE OF SYSTEM SMOKE DUCT

Minimum vertical length 1.5 metres

Maximum length

(with 1 accessible 90° bend)

Maximum length

(with 3 accessible 90° bends)

Maximum number of accessible 90° bends 3

Horizontal sections

(minimum slope 3%)

Use smoke ducts with a diameter of 80mm or 100mm depending on the type of system, with silicone gaskets or similar gaskets that

can withstand the high operating temperatures of the appliance (min. T200 class P1). The use of exible metal hoses made of

bre cement or aluminium is forbidden. For direction changes, we always recommend using a T tting with an inspection

cap allowing easy access to clean the pipes. Always ensure that the inspection cap is put back in place and sealed hermetically with the

relevant seal intact after cleaning.

It is forbidden to connect several appliances to the same smoke duct, or the outlet from the overhead hoods. It is forbidden to extract the

combustion products directly through the wall, whether into indoor spaces or outdoors.

The smoke duct must be at a minimum distance of 400 mm from ammable or heat-sensitive structures.

6.5 metres

4.5 metres

4 metres

Technical Dept. - All rights reserved - Reproduction is prohibited

13

4-FLUE

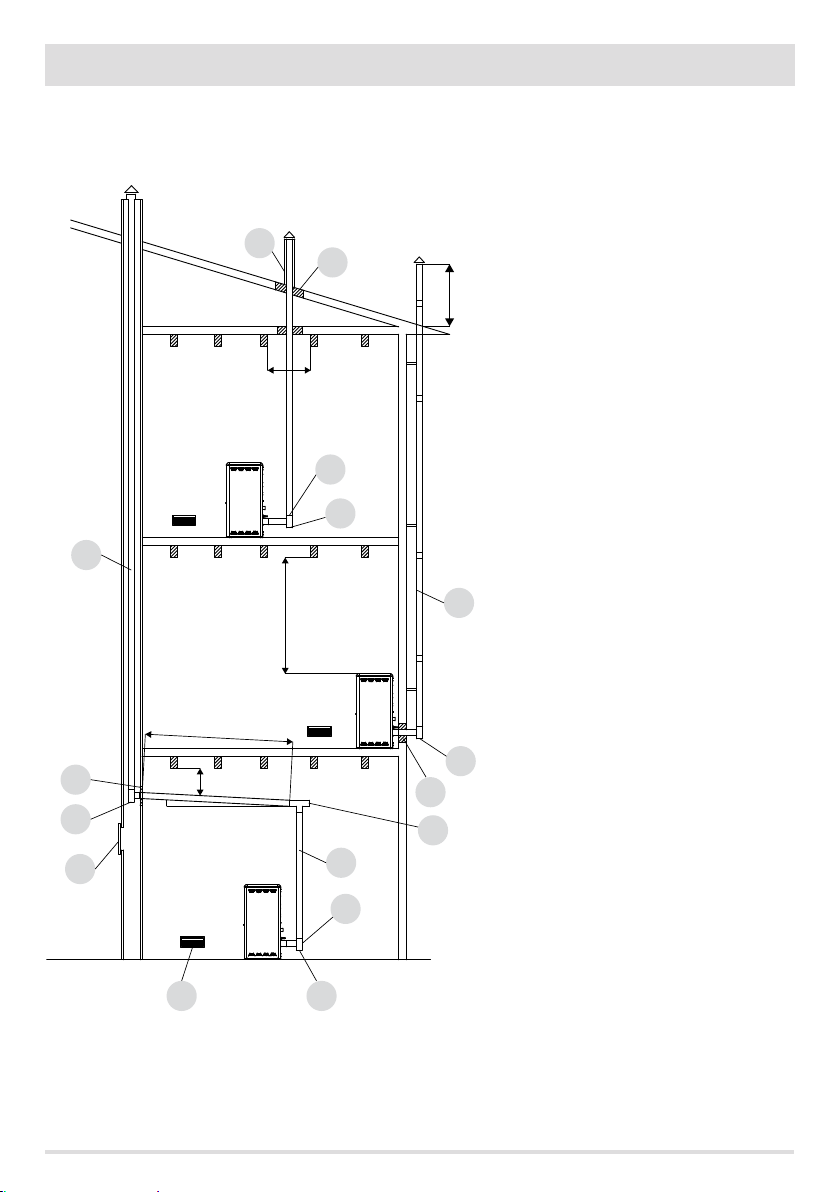

EXAMPLES OF CORRECT INSTALLATION

1

E

2

1. Installation of Ø120mm ue with hole for the passage

of the pipe increased by:

minimum 100mm around the pipe if next to non

ammable parts such as cement, brick, etc.; or

minimum 300mm around the pipe (or as required by data

U

V

I

tags) if next to ammable parts such as wood etc.

In both cases, install suitable insulation between the ue

and the ceiling.

F

Always check and respect the data tags on the ue,

in particular the minimum safety distances from

combustible materials.

The previous rules also apply for holes made in walls.

2. Old ue, minimum pipe Ø100mm with the inclusion of

an external access door for chimney cleaning.

3. External ue made of insulated stainless steel pipes,

i.e. with double walls minimum Ø100mm: all securely

mounted on the wall. With wind-proof chimney cap. See

g. 7 type A.

4. Ducting system using T tting that allow easy access

for cleaning without having to remove the pipes

D

B

U

I

S

A

C

4

T

P

I

3

FIGURE 11

U = INSULATING

I

V = ANY REDUCTION FROM 100 TO 80 MM

U

I

I = INSPECTION CAP

S = INSPECTION ACCESS PANEL

P = AIR INLET

T = T JOINT WITH INSPECTION CAP

A = MINIMUM 40 MM

B = MAXIMUM 4 M

C = MINIMUM 3°

D = MINIMUM 400 MM

E = HOLE DIAMETER

F = SEE FIG.23456

14

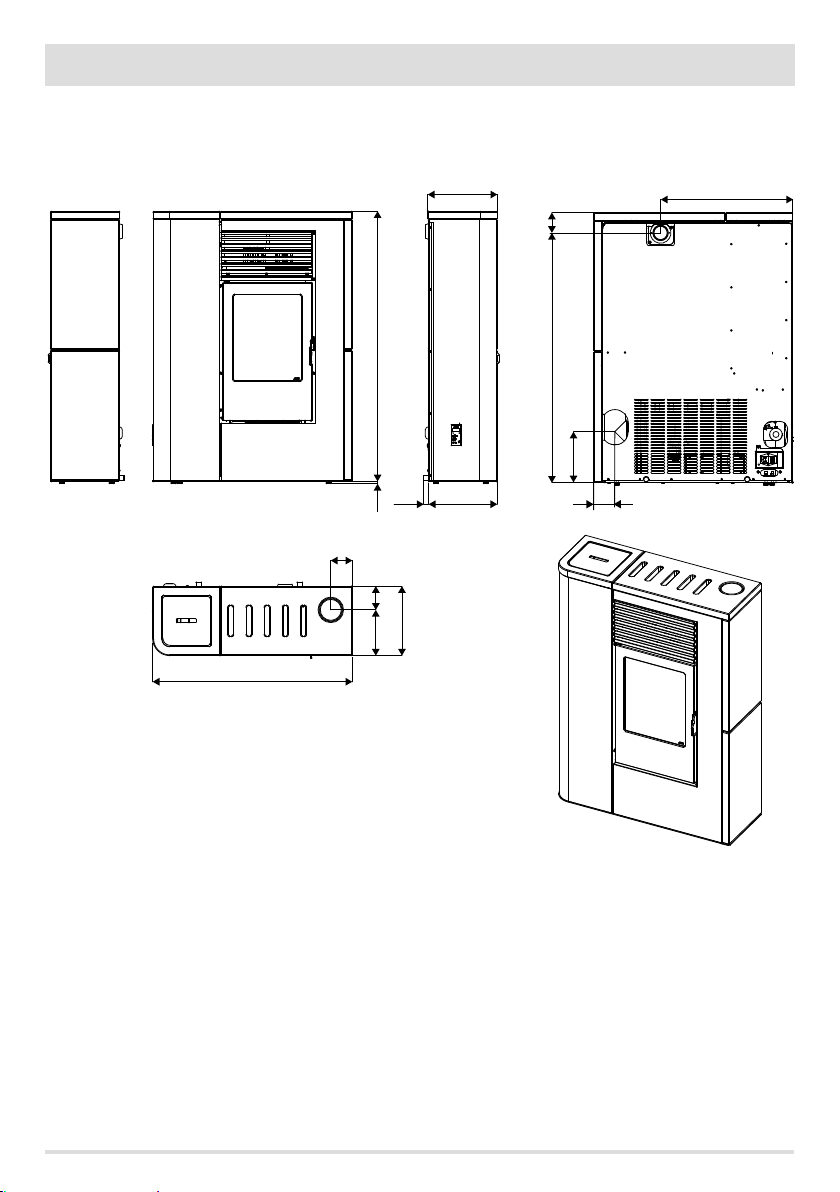

5-DRAWINGS AND TECHNICAL FEATURES

DRAWINGS AND CHARACTERISTICS

FLAT COMFORT AIR DIMENSIONS (in mm)

790

85.5

93

181

1070

9.5

274

20

274

271

291

521.5

80.3

989.3

202

84

Technical Dept. - All rights reserved - Reproduction is prohibited

15

5-DRAWINGS AND TECHNICAL FEATURES

FLAIR COMFORT AIR DIMENSIONS (in mm)

790

85.1

1070

9.5

94

181

20

275

275

271

523.3

80.3

989.3

202

84

16

5-DRAWINGS AND TECHNICAL FEATURES

TECHNICAL CHARACTERISTICS FLAT-FLAIR COMFORT AIR

(Max) nominal output power 8 kw (6880 kcal/h)

Minimum output power 3,2 kw (2752 kcal/h)

Eciency at Max 87,8%

Eciency at Min 93,6%

Temperature of exhaust smoke at Max 160°C

Temperature of exhaust smoke at Min 90°C

Particulate/OGC/Nox (13%O2) 28 mg/Nm3 - 27 mg/Nm3 - 145 mg/Nm

CO at 13% O2 at Min and at Max 0,052 – 0,015%

CO2 at Min and at Max 6,0% - 9,2%

Recommended draught at Max power*** 0,10 mbar - 10 Pa***

Minimum draw allowed for minimum power 0,0 mbar - 0 Pa

Mass of smoke 7 g/sec

Hopper capacity 30 litri

Type of pellet fuel Pellet diameter 6-8 mm and size 5/30 mm

Pellet hourly consumption Min ~ 0,7 kg/h* - Max ~ 1,8 kg/h*

Autonomy At min ~ 29 h* - At max ~ 11 h*

Heatable volume m

Combustion air inlet External diameter 50 mm

Smoke outlet External diameter 80 mm

Air inlet 80 cm

Nominal electrical power (EN 60335-1) Max 320 W - Med. 100 W

Supply voltage and frequency 230 Volt / 50 Hz

Net weight 125 kg

Weight with packaging 135 kg

Distance from combustible material (back) 20 mm

Distance from combustible material (side) 200 mm

3

172/40 – 197/35 – 229/30 **

2

3

* Data that may vary depending on the type of pellets used.

**Heatable volume based on the requested power per m3 (respectively 40-35-30 Kcal/h per m3).

*** Value recommended by the manufacturer (non-binding) for the optimal operation of the product

Tested according to EN 14785 in accordance with Directive 89/106/EEC (Construction Products).

Technical Dept. - All rights reserved - Reproduction is prohibited

17

6-INSTALLATION AND ASSEMBLY

PREPARATION AND UNPACKING

The FL AT stove is delivered on a pallet with several packages (g.1):

• The rst package contains the stove.

• The second package contains the ceramic panels and is stacked on top of the structure package.

FIGURE 1 - FLAT STOVE PACKAGE

•

The FLAIR stove is delivered in two dierent packages (g.2/2A):

• The rst pallet contains the stove.

• The second pallet contains the serpentine panels.

•

Open the package, remove the four brackets from the pallet (2 front and 2 rear), which block the stove to the pallet (g. 3). The brackets

are removed by loosening the two screws and removing the bracket.

Set the stove in the pre-selected place, making sure this complies with the requirements.

The product must always remain in a vertical position and handled solely with a cart. Pay particular attention to the door and its glass,

protecting them from mechanical knocks that would compromise their integrity.

In any case, the product must always be handled with care. If possible, unpack the product near the place of installation. The packaging

materials are neither toxic nor harmful, and therefore no particular disposal measures are required. The end user is responsible for product

storage, disposal or possible recycling in compliance with the regulations in force.

FIGURE 2 - FLAIR STOVE PACKAGE FIGURE 2A - FLAIR STOVE SERPENTINE PACKAGE

18

6-INSTALLATION AND ASSEMBLY

REMOVE THE TWO SCREWS FROM THE FOUR BRACKETS

Technical Dept. - All rights reserved - Reproduction is prohibited

REMOVE THE BRACKETS

FIGURE 3 - REMOVING THE PACKAGE SCREWS

19

6-INSTALLATION AND ASSEMBLY

Position the product without its cladding and connect it to the chimney. Once the connections are complete, assemble the cladding

(ceramic or serpentine sides).

If the product must be connected to an exhaust pipe that goes through the rear wall (to enter the chimney), make sure not to force it in.

Adjust the 4 feet (J) to level the stove for the smoke exhaust and the pipe to be coaxial. The ceramic/serpentine sides must not be tted

when the feet are adjusted as this is carried out inside the cladding. A rear foot is adjusted through the triangular hole on the back of the

product (detail A).

Attention!

Do not use and/or force the smoke exhaust pipe when handling the product as it can be damaged.

1. TURN THE FEET CLOCKWISE TO LOWER THE PRODUCT.

2. TURN THE FEET ANTI-CLOCKWISE TO RAISE THE PRODUCT.

FOOT J.

DETAIL A.

20

6-INSTALLATION AND ASSEMBLY

CONNECTION OF THE SMOKE OUTLET PIPE

You can choose whether to release the smoke on the rear part or upper part of the product.

If you wish to connect the smoke outlet to the upper part, remove the cap with the three screws from under the top. Then insert the

pipe until it engages with the smoke tting.

REMOVE THE CAP FASTENED TO THE STRUCTURE OF THE PRODUCT WITH THREE

SCREWS FROM UNDER THE TOP.

INSERTING THE PIPE FOR THE UPPER SMOKE OUTLET.

Technical Dept. - All rights reserved - Reproduction is prohibited

21

6-INSTALLATION AND ASSEMBLY

If you wish to connect the smoke outlet to the rear part, turn the T-tting towards the rear of the product.

Then connect the pipes.

TURN THE T-FITTING FOR THE REAR SMOKE OUTLET.

22

6-INSTALLATION AND ASSEMBLY

CONNECTING THE HOT AIR DUCTING

The standard product has two fans installed for air distribution with the nozzle directed towards the front part of the stove.

Therefore, the rst important thing to decide is whether to channel the air or not. In line with this, turn the fan (2) for the air to be released

towards the rear part.

Attention: make sure the plug has been disconnected from the socket before performing any operation.

How to turn the fan.

• Remove the ceramic/serpentine top.

• Remove plate A.

• Remove the two screws “B” that fasten the fan to the structure of the product.

• Pull it slightly out from its seat for it to turn (it does not have to be removed!).

• Turn the whole fan 180°.

• Fasten the fan to the structure once again with the two screws “B”.

• Fasten plate “A”.

• Set the top in place and insert the plug.

CERAMIC OR STEATITE TOP.

Technical Dept. - All rights reserved - Reproduction is prohibited

PLATE A.

23

6-INSTALLATION AND ASSEMBLY

FAN 2 TURNED FOR REAR AIR.

FAN 2 ORIGINAL POS.

The air can be channelled by fastening a exible pipe on the rear part of the product with a clamp, in line with the hole on the upper part.

The air can now be released from the front and rear, only from the front or only from the rear.

These channels can also be walled in (SEE OPTIONALS).

Room ventilation can only be set towards the rear wall if there is adequate insulated ducting of the hot air ow.

The air outlet pipe can become very hot, approx. 200°C: therefore, it must be adequately insulated with suitable

material, especially points that could come in contact with ammable surfaces or parts that are aected by heat

(e.g. change in shades, wiring ducts, plasterboard, etc.). Moreover, persons and animals must be protected from

accidental or intentional contact. In any case, comply with the regulations and laws in force in the region where the

product is installed.

24

6-INSTALLATION AND ASSEMBLY

It is recommended to insulate the entire length of the pipe in order to reduce dispersion and increase heat output

in the room.

A - STOVE

B - HOT AIR OUTLET PIPE

C - INSULATION WALL

D - INSULATION

If the wall that is to be drilled through is made of ammable material, the INSTALLER MUST adequately insulate the pipe of the stove that

passes through it, using suitable insulating material (1.3 - 5 cm thick with min. thermal conductivity 0.07 W/m°K).

However, the pipe inserted in the wall must be adequately insulated in order not to disperse heat and soundproof the released air.

Technical Dept. - All rights reserved - Reproduction is prohibited

25

6-INSTALLATION AND ASSEMBLY

ASSEMBLING THE CLADDING

ASSEMBLING THE CERAMIC SIDE PANELS

The product is supplied with the ceramic panels packaged separately, therefore unpack all the parts before proceeding with the assembly.

Follow the sequence below to assemble the panels:

• Flaps “b” on the lower part of the ceramic panel A must be tted into the holes of the structure of the stove. Then fasten the panel to

the structure - pos.c - with the screws supplied (two screws at the top).

b

b

c

c

c

c

A

b

b

c

c

b

b

26

6-INSTALLATION AND ASSEMBLY

• Panel B can be fastened by following the procedures implemented to assemble panel A. The aps on the lower part of the panel -

pos. d - must enter the holes in the structure, whereas two screws on the upper part of the panel, block it to the structure - pos. f.

Panel B rests on the two adjustable screws “e”. Panels A and B could touch or the gap between may be too wide, therefore, adjust

screw “e” to resolve the problem.

•

IMPORTANT!

The “A” and “B” ceramic panels are interchangeable as both the ceramic and metal support are the same.

CERAMIC PANELS (INSIDE VIEW)

A/B = TOP OR BOTTOM PANEL

f

f

Technical Dept. - All rights reserved - Reproduction is prohibited

B

d

e

d

d

27

6-INSTALLATION AND ASSEMBLY

ASSEMBLING THE SERPENTINE SIDE PANELS

The product is supplied with the serpentine panels packaged separately, therefore unpack all the parts before proceeding with the

assembly.

Follow the sequence below to assemble the panels:

• Flaps “b” on the lower part of the stone panel A must be tted into the holes of the structure of the stove. Then fasten the panel to

the structure - pos.c - with the screws and nuts supplied (two screws at the top).

IMPORTANT!

The “A” and “B” serpentine panels are not interchangeable: panel “A” goes only at the bottom and panel “B” only at

the top. The panels are recognisable as there are two aps protruding from the serpentine in the upper part of panel

“A”, whereas upper panel “B”, has two aps in line with the serpentine stone. (see gure next page).

b

b

c

c

A

b

b

e

c

c

28

6-INSTALLATION AND ASSEMBLY

• Panel B can be fastened by following the procedures implemented to assemble panel A. The aps on the lower part of the panel

- pos. d - must enter the holes in the structure, whereas two screws and two nuts on the upper part of the panel, block it to the

structure - pos. f. Panel B rests on the two adjustable screws “e”. Panels A and B could touch or the gap between may be too wide,

therefore, adjust screw “e” to resolve the problem.

Flaps

B

f

A

SERPENTINE PANELS (INSIDE VIEW)

A = BOTTOM PANEL

B = TOP PANEL

f

B

Technical Dept. - All rights reserved - Reproduction is prohibited

d

e

d

d

29

6-INSTALLATION AND ASSEMBLY

ASSEMBLING THE CERAMIC/SERPENTINE TOP

The top does not require particular fastening as it is only placed on the structure of the product in line with the relative vibration dampers.

Therefore, once panels A and B are tted, parts C and D can be assembled with the hopper cover E.

ASSEMBLY OF CERAMIC TOP

ASSEMBLY OF SERPENTINE TOPGROOVE DIRECTION

E

D

C

E

D

C

30

6-INSTALLATION AND ASSEMBLY

HOPPER COVER ORIENTATION

Attention! Tank cover E must rest on component D with the groove placed horizontally compared to the stove.

D

E

D

ED

Technical Dept. - All rights reserved - Reproduction is prohibited

E

31

6-INSTALLATION AND ASSEMBLY

ASSEMBLING THE AIR FILTER

The cylindrical lter is already tted inside the product.

If it must be cleaned, slightly loosen the screw knob on the air inlet pipe, remove the lter, clean it and then set it and block it in place by

tightening the knob.

ATTENTION!

The stove must never be operated without the air lter. The manufacturer cannot be held liable for any damage

caused to the internal components if this requirement is not complied with.

ASSEMBLING/REMOVING THE AIR FILTER.

OPENING/CLOSING THE DOOR

ATTENTION!

The door must be closed properly for the product to work correctly.

The door of the Flat/Flair stove is opened by inserting the cold handle on the opening hook of the door, lifting and pulling.

OPENING THE DOOR.

ELECTRICAL CONNECTION

First connect the power cable to the back of the product and then to a wall socket.

The main switch at the side must only be activated when the stove is used; otherwise, it is advisable to keep it o.

It is recommended to disconnect the power cable when the product is not used.

CABLE TO THE STOVE

I/O SWITCHCONNECTION OF THE POWER

ELECTRICAL CONNECTION

32

6-INSTALLATION AND ASSEMBLY

BEFORE START-UP

GENERAL PRECAUTIONS

Remove all components that could burn from the brazier and the glass (manual, various adhesive labels and any polystyrene).

Check that the brazier is positioned correctly and rests properly on the base.

After a long period of inactivity, remove any pellets left in the hopper (using a vacuum cleaner with a long pipe), as they

could have absorbed moisture, thereby altering their original characteristics and no longer being suitable for combustion.

The rst start-up may not be successful as the feed screw is empty and does not always manage to load the required

amount of pellets in the brazier in time for the re to be regularly ignited.

CANCEL THE FAILED START-UP ALARM STATUS BY BRINGING SELECTOR “D” TO OFF. REMOVE THE PELLETS FROM THE

BRAZIER AND REPEAT START-UP.

If a ame does not ignite after a number of failed start-ups, even though the pellet supply is correct, make sure the brazier is set in place

correctly, which must be interlocked in its seat and clean from any ash deposits. If no anomaly is found during this inspection, there

may be a problem with the product components or installation may not be correct.

REMOVE THE PELLETS FROM THE BRAZIER AND CONTACT AN AUTHORISED TECHNICIAN.

Avoid touching the stove during the initial start-up, as the paint hardens during this phase. If you touch the paint,

the steel surface may be exposed.

If necessary, touch up the paint with the spray can of the specic colour (see “Pellet stove accessories”).

Technical Dept. - All rights reserved - Reproduction is prohibited

33

6-INSTALLATION AND ASSEMBLY

It is good practice to guarantee eective ventilation in the room during the initial start-up, as the stove will emit

some smoke and smell of paint.

Do not stand close to the stove and air the room. The smoke and smell of paint will disappear after about an hour of operation, however,

remember they are not harmful in any case.

The stove will be subject to expansion and contraction during the start-up and cooling phases, therefore light creaking noises may be

heard.

This is absolutely normal as the structure is made of laminated steel and must not be considered a defect.

It is extremely important to make sure the stove is not immediately overheated and the temperature is increased gradually starting from

the low power.

This will prevent damaging the ceramic or serpentine tiles, the welds and the steel structure.

DO NOT EXPECT HEATING EFFICIENCY IMMEDIATELY!

SETTINGS TO BE CARRIED OUT BEFORE THE INITIAL START-UP

Once the power cable is connected in the rear part of the stove, bring the switch to position (I). Switch the stove on and o by pressing key

A on the remote control and LEDs B or C on the emergency panel will light up according to the mode of the stove.

A

34

6-INSTALLATION AND ASSEMBLY

LOADING THE PELLETS

Fuel is loaded by lifting the cover on the upper part of the product. Slowly pour the pellets into the hopper.

Be careful as the cover could become very hot.

LIFT THE COVER.

INSERT THE PELLETS.

No other type of fuel other then pellets, in compliance with above-mentioned specications, is to be inserted into

the hopper.

Technical Dept. - All rights reserved - Reproduction is prohibited

35

A

B

E

C

D

7-REMOTE CONTROL MAX

GENERAL SPECIFICATIONS OF THE LCD REMOTE CONTROL

The remote control works at a transmission frequency of 434.5 MHz.

Power the product with 3 AAA batteries as follows:

• Remove the cover of the battery compartment by pressing and lifting the point indicated by the arrow.

• Insert the batteries with the correct polarity (+) and (-).

• Close the cover of the battery compartment.

The time must be set when the remote control is switched on.

The remote control has a special icon on the display to indicate when the batteries are almost at. If the at battery icon appears, the

batteries are almost at and the remote control is about to go o.

Used batteries must be disposed of separately in special containers.

GRAPHIC APPEARANCE

Reference will often be made to the keys. Always keep the gure at hand for simplicity’s sake.

A

B

D

E

C

36

7-REMOTE CONTROL MAX

LCD REMOTE CONTROL OPERATION

GENERAL RULES

Press key A for 1” to switch the product on and o. All changes are made with keys C. Key E is used to conrm the changes. Key B is used to

select the product operating mode. Key D is used to browse the VENTILATION and SLEEP settings (see “Various settings”).

Whichever the mode is, press key A briey (or leave the keypad idle for 7”) to go back to the initial display.

INITIAL SETTINGS

SETTING THE TIME

The time/day setting is accessed by pressing keys B+E simultaneously for 3”, regardless whether the remote control is on or o.

The hour digits will start to ash, which can be modied with keys C. Press key E to conrm the changes.

The minute digits will then start to ash. Follow the same procedure to modify and conrm the setting and the time display setting (12h

or 24h) will then be accessed and lastly, the day will start to ash. Conrm this data to exit the settings.

NOTE: each time the remote control is powered, the time is reset and the display automatically enters the time setting.

°C -°F SETTING

The unit of temperature measurement is changed from Celsius to Fahrenheit and vice versa by pressing key B for 5” while the product is o.

SETTING THE OPERATING MODE

One of the following 4 operating modes can be set via key B while the remote control is on. The 4 basic displays are shown, respectively,

in gures 1-2-3 and 4:

Manual, Automatic, Timer and Eco mode.

MANUAL MODE (MAN)

This mode allows the ame power (changed directly via keys C) and ventilation to be set manually in 5 levels + auto (see “Various

settings”), Figure 1.

AUTOMATIC MODE (AUTO)

This mode allows the desired room temperature to be set and the appliance will automatically adjust the ame power to reach it. The

ventilation can be adjusted in 5 levels + auto (see “Various settings”), Figure 2.

TU

12:02

MAX

FIGURE 1

MANUAL MODE.

Technical Dept. - All rights reserved - Reproduction is prohibited

31

°C

MAN

TU

12:03

31

FIGURE 2

AUTOMATIC MODE.

°C

35

AUTO

°C

37

8:20

26

FR

20

°C

TIMER

°C

P1

8:20

26

FR

20

°C

TIMER

°C

P1

12:06

31

°C

TU

23

°C

ECO

7-REMOTE CONTROL MAX

TIMER MODE (TIMER)

Select this operating mode to switch the product on and o automatically, according to 6 customised time bands (P1 – P6). The following

can be set for each time band:

• Start-up time.

• Shutdown time.

• Desired room temperature during that time band.

• Days of the week when the time band is to be activated.

Days of the week when the time band is to be activated. When the product is switched on (manually via button A or automatically via a

time band), it operates in the automatic mode, described above. A time band appears automatically when it is active (P1 in gure 3) and

the desired temperature is changed to the value set in the time band. However, the user can always modify this value as desired and in

real time.

Refer to “Timer Settings” to learn how to set the time bands.

FR

°C

P1

20

TIMER

°C

FIGURE 3

TU

8:20

TU

ECO MODE (ECO)

This mode is activated/deactivated by pressing key B for 5” on the remote control while it is switched on.

ECO is an automatic mode with the only dierence that if the set temperature is reached and remains so for the subsequent 20 minutes

(despite ame modulation), the product is switched o and remains on stand by until the room temperature drops 2 degrees below the

desired temperature (and in any case for at least 5 minutes from the last shutdown). The product is then switched on again, Figure 4.

If the room is not suciently insulated, ame modulation does not allow the set temperature to be met for 20 consecutive minutes and

the product will not go o.

NOTE: it is recommended to use the ECO mode only in well-insulated rooms in order to prevent start-up and shutdown from

occurring within short periods of time.

The remote control remains on even when the product is o when in ECO mode, in order to indicate that this shutdown is only temporary.

Obviously, if the product is switched o from key A, ECO mode is exited and the product remains o.

Up to 6 automatic start-up and shutdown time bands (E1 – E6) can also be set in ECO mode, which are independent from those of TIMER

mode (P1 – P6). If they have been activated, TIMER-ECO appears on the display (gure 5) permanently, even if the remote control is

switched o.

Refer to “Timer Settings” to learn how to set the time bands.

NOTE: if the remote control is switched o in TIMER mode, ECO mode can only be re-activated by the user (key A) or when

started-up by the next valid time band. Combined use of TIMER and ECO modes requires a good knowledge of the product

operating logic.

26

12:06

°C

23

°C

31

FIGURE 4 FIGURE 5

ECO

38

12:07

31

°C

23

°C

TIMER

ECO

26

°C

7-REMOTE CONTROL MAX

VARIOUS SETTINGS

ROOM VENTILATION

The room ventilation can be adjusted as desired in all 4 operating modes described earlier on. Simply follow the steps below: press key

D on the initial display to access the VENTILATION setting. Then press key C to set the desired ventilation by selecting one of the 5 levels

available. The “auto” option can also be selected, which automatically links the room ventilation speed to the ame level.

In brief:

ame set to 1 > ventilation set to 1; ame set to 3 > ventilation set to 3; ame set to 5 > ventilation remains set to 3 (for silent operation

as it is in automatic mode).

The speed of each fan (identied with 1 or 2 above the level bars) in products with 2 fans (comfort air models) can be scrolled and set via

key D.

NOTE: if the remote control is replaced with a new one and the default settings must be changed, proceed as follows: press keys

D + E simultaneously for 10 seconds while the remote control is switched on (until the ashing number disappears). Press key

C to select 1 or 2 according to the product to which the remote control is to be paired, and press E to exit.

°C

26

FIGURE 6

SLEEP FUNCTION

The sleep function allows a shutdown time to be set quickly. This function is only available in the MAN and AUTO modes. It is set as

follows: from the VENTILATION setting (press key D - see the previous paragraph), press key D again to access the SLEEP setting.

The shutdown time is set in 10 minute intervals via key C. Conrm via key D or E and the display returns to the initial page on which the

sleep shutdown time remains displayed. Disable the SLEEP function by simply accessing the setting and decreasing the time until dashes

are displayed and then conrm.

FR

OFF

°C

MAN

FIGURE 7

39

21:11

MAX

Technical Dept. - All rights reserved - Reproduction is prohibited

23:00

27

TIMER

6:30

8:00

MO TU WE TH FR SA SU

ON

OFF

20

P1

°C

7-REMOTE CONTROL MAX

TIMER SETTINGS

DISPLAY THE TIMER TIME BANDS

Simply press key D for 2” to display the time bands in TIMER mode. The 6 time bands can be scrolled through with key C, thereby verifying

all the saved settings. Press key D or A to return to the initial display.

MO TU WE TH FR SA SU

ON

6:30

P1

MODIFYING THE TIMER TIME BANDS

Modify a time band by displaying it as described in the previous paragraph and then press key E briey.

The rst parameter that can be set will start to ash, i.e. the room temperature. Press key C to modify the value and key E to conrm and

move on to the next parameter. The parameters of a time band can be set in the following order:

• Room temperature. Can be set between 5° and 35°C. 2 dashes “--” appear if set below 5°C or above 35°C, and if this is conrmed, the

program is deactivated (therefore, the product will not be switched on).

• Start-up time. The value is adjusted in 10 minute intervals (from 00:00 to 23:50).

• Shutdown time. The value is adjusted in 10 minute intervals (from 00:10:00 to 24:00).

• Days of the week when the program is to be activated. Monday (MO) will start to ash, followed by the other days of the week. Use

Press key D at any time to save all the changes made (conrmed by pressing key E), exit the time band editing page and return to the time

bands display. Press key A (or leave the keypad idle for 30”) to go directly to the initial display, saving all the changes made and conrmed

with key E.

key C to activate/deactivate the day. The activated days will be displayed on a dark background. When the Sunday (SU) setting is

complete, press key E to exit the editing page and return to the time bands display.

8:00

20

°C

TIMER

OFF

FIGURE 8

ACTIVATING THE TIMER-ECO TIME BANDS

6 customised start-up and shutdown time bands (E1 – E6) can be activated in the ECO mode: press key D for 2” and the TIMER activation/

deactivation function will appear. If the ON option is conrmed, the 6 TIMER-ECO time bands are accessed and can be modied as

described earlier on for the TIMER. If the OFF option is conrmed, the TIMER is disabled and the product returns to the ECO mode with

no time bands activated.

OFF ON

TIMER

FIGURE 9

ECO

40

8-EMERGENCY PANEL

EMERGENCY PANEL

There is an emergency panel on the product side, designed for any malfunction to be detected and product control if the remote control

should malfunction.

KEY

A

B

C

D

E

F

G

Three-digit display that indicates a variety of product information besides the identication code of any malfunction.

GREEN LED that indicates:

• OFF= The product is o.

• FLASHING ON= The product is starting up.

• FIXED ON= The product is on.

RED LED that indicates:

• OFF= The product is on.

• ON AND FLASHING SLOWLY= The product is shutting down.

• ON AND FLASHING QUICKLY= The product is in alarm status (accompanied by a buzzer for the rst 10 minutes).

• FIXED ON= The product is o.

3-position selector for the following functions:

• OFF= The product is switched o manually without the remote control.

• REMOTE= The product can only be controlled via remote control.

• ON= The product is switched on manually without the remote control.

3-position selector for the power selection:

• MIN= The product runs at MINIMUM power without the remote control and with selector 4 set to ON.

• MED= The product runs at MEDIUM power without the remote control and with selector 4 set to ON.

• MAX= The product runs at MAXIMUM power without the remote control and with selector 4 set to ON.

Button for diagnostic functions regarding the product operation mode.

Button to connect the product to a new remote control.

SELECTOR “D” MUST BE SET TO THE “REMOTE” POSITION FOR THE PRODUCT TO BE REMOTE CONTROLLED.

Technical Dept. - All rights reserved - Reproduction is prohibited

41

8-EMERGENCY PANEL

EMERGENCY PANEL START-UP/SHUTDOWN

If the remote control is faulty or the batteries are at, the product can be operated in safe mode via the rear emergency panel.

In this conguration, the product can only work in manual mode and one of 3 power levels can be selected.

• APPLIANCE START-UP WITHOUT THE REMOTE CONTROL.

Switch the product on by bringing selector “D” to the ON position. The RED LED goes o upon start-up, whereas the GREEN LED starts

to ash until the start-up phase is complete. Once the product runs smoothly, the GREEN LED remains on.

• SELECTING THE POWER WITHOUT THE REMOTE CONTROL.

One of three heating powers MIN-MED-MAX can be selected (selector “E”):

The MINIMUM power corresponds to the 1st power.

The MEDIUM power corresponds to the 3rd power.

The MAXIMUM power corresponds to the 5th power.

• APPLIANCE SHUTDOWN WITHOUT THE REMOTE CONTROL.

Switch the product o by bringing selector “D” to the OFF position.

Once the remote control is restored, remember to set selector “D” back to the “REMOTE” position, otherwise the

product will ignore the remote control commands.

ON

OFF

D

E

42

8-EMERGENCY PANEL

LOAD THE FEED SCREW

This function can only be activated when the stove is o and allows the pellets to be loaded into the feed screw (loading system). It can

be used each time the pellets nish in the feed screw and hopper (see alarm A02). It is useful to prevent failed start-ups (alarm A01) due

to the hopper being empty.

The LOAD FEED SCREW function is ac tivated as follows (with the stove o): bring selector “D” on the emergency panel to OFF and press key

TEST on the same panel three consecutive times. Wait a few seconds and FEED SCREW will ash on the display.

Press the TEST key once again when the pellets begin to fall into the brazier to end the LOAD FEED SCREW function and proceed with the

stove start-up.

ON

TEST

C O C

C A R

OFF

D

E

Technical Dept. - All rights reserved - Reproduction is prohibited

43

9-SAFETY DEVICES AND ALARMS

SAFETY DEVICES

The product is supplied with the following safety devices:

SMOKE TEMPERATURE PROBE

Detects the temperature of the smoke, thereby enabling start-up or stopping the product when the temperature drops below the preset

value.

PELLET HOPPER SAFETY THERMOSTAT

If the temperature exceeds the preset safety value, it immediately stops the product, which must cool down before being restarted.

Selector “D” must be set to “O ” for the product to be restored.

ELECTRICAL SAFETY

The product is protected against sudden changes in current by a main fuse in the power supply panel on the rear part of the product. Other

fuses that protect the electronic boards are found on the latter.

SMOKE FAN FAULT

If the fan stops, the electronic board promptly blocks the supply of pellets and the alarm is displayed.

GEAR MOTOR FAULT

If the gear motor stops, the product continues to work until the minimum cool level is reached.

TEMPORARY POWER CUT

If a power cut occurs during operation, the product automatically sets itself in cooling mode when the power is restored and then restarts.

FAILED START-UP

If no ame is developed during start-up, the product will go into alarm status.

IT IS FORBIDDEN TO TAMPER WITH THE SAFETY DEVICES.

The product can be started-up and the automatic function of the probe restored only after having eliminated the cause that

triggered the safety system. This manual will help you understand which anomaly has occurred, and explain how to intervene

according to the alarm message displayed on the product.

44

9-SAFETY DEVICES AND ALARMS

ALARM ALERTS

If an operating anomaly occurs, the product enters the shutdown phase due to an alarm and informs the user regarding the type of fault

by means of a 3 digit code that remains displayed on the emergency panel.

The alarm is indicated permanently by the relative 3 digit code, a ashing red LED that lights up on the emergency panel and an

intermittent buzzer for the rst 10 minutes. Read the instructions in the following 2 paragraphs to cancel the alarm status and restore

the normal operating mode of the stove. The following table describes the possible alarms indicated by the product, associated to the

respective code that appears on the emergency panel and helpful tips to resolve the problem.

DISPLAY MESSAGE T YPE OF PROBLEM SOLUTION

The re does not ignite. Check the level of pellets in the hopper.

Check that the brazier rests correctly in its seat and has

A01

The re goes o abnormally. Due to the hopper being empty (no fuel).

no visible deposits of unburned pellets. Check whether

the start-up spark plug becomes hot.

A02

A03

A04

A05

A06

A08

A09

The pellet hopper temperature exceeds the

intended safety threshold.

The structure overheats due to reduced heat

dissipation.

The temperature of the exhaust smoke has

exceeded the preset safety limits.

Clogged ue-wind-door open. Check the smoke duct and make sure the door is closed.

The smoke extractor fails to guarantee sucient

primary air, required for a correct combustion.

Faulty smoke fan. Verify whether the smoke fan compartment is clean,

The smoke probe is faulty and does not detect

the exhaust smoke temperature correctly.

The structure is too hot because the product has been

used for too long at the maximum power or due to poor

ventilation or because the air fans are faulty. When

the product is suciently cold, press button B on the

control panel or OFF on the remote control to delete

alarm A03. Once the alarm is deleted, the appliance

can be switched on.

The appliance switches o automatically. Let the

product cool down for a few minutes and then switch

it on again. Check the smoke expulsion and the type of

pellets used.

Insucient draught or clogged brazier.

Verify whether the brazier is clogged and clean it, if

necessary.

Check and if necessary clean the smoke duct and air

inlet.

and particularly if it is blocked by dirt. If this does not

suce, the smoke fan is faulty. Contact an authorised

service centre to have it replaced.

Contact an authorised service centre to have the

component replaced.

Technical Dept. - All rights reserved - Reproduction is prohibited

45

9-SAFETY DEVICES AND ALARMS

Pellet supply fault. Contact an authorised service centre to have the

A11

component replaced.

The remote control has been out of the product

reception range for over 3 hours (or the batteries

are at).

A12

NOTE: the appliance does not enter the

shutdown phase due to an alarm only in such a

case, and continues to work in the mode set by

the remote control via the last command.

General fault in the electronic control unit. Contact an authorised service centre to have the

A13

Faulty air ow rate sensor. This alarm does not block the system and only a

A14

Routine maintenance alert. This ashing message upon start-up indicates that the

SEr

DELETING THE ALARM STATUS

Follow the procedure described below to restore normal product operation after an alarm has been triggered:

• Set selector D on the rear emergency panel to OFF for a few seconds until the 3 digit alarm identication code disappears. The red LED

stops ashing and the alarm buzzer is silenced by performing the steps below.

• Set selector D back to the REMOTE position for product operation to be remote controlled.

• Switch the remote control o and then on again if the product is to be switched on.

Move the remote control within the product reception

range (or change the batteries of the remote control if

they are at). The alarm alerts will disappear as soon

as the appliance receives a new signal from the remote

control. A simple way of forcing signal transmission to

the product is by pressing button 4 (which changes the

operating mode from manual to automatic and vice

versa).

component replaced.

warning screen is displayed. Contact an authorised

service centre to have the component replaced.

preset operating hours before maintenance is due have

elapsed and a qualied technician, recommended by

the manufacturer, must be contacted for maintenance

to be performed.

Only if alarm A12 is triggered (no communication between the remote control and the product), the appliance

remains on according to the last mode set and automatically exits the alarm mode when the rst signal is received

from the remote control.

46

9-SAFETY DEVICES AND ALARMS

BLOCKED PRODUCT

The following may cause the product to be mechanically blocked:

• The structure overheats (“A03”).

• The smoke is overheated (“A04”).

• During product operation, air that has not been controlled in the combustion chamber has entered or the chimney is clogged (“A05”).

SOLUTIONS:

If “A03” appears, the structure is too hot because the product has been used for too long at the maximum power or due to poor ventilation

or because the air fans are faulty.

When the product is suciently cold, press button B on the control panel to delete alarm A03. Once the alarm is deleted, the product can

be switched on.

If “A04” appears, the product will shutdown automatically, let it cool down for a few minutes and then switch it on again. Delete the alarm

and switch the product on again.

If “A05” appears, the door has been left open for too long or a signicant amount of air has entered (e.g. missing smoke fan inspection

cap). If these causes are excluded, check and if necessary clean the smoke duct and chimney.

Only after having eliminated the cause permanently can the product be switched on again.

Technical Dept. - All rights reserved - Reproduction is prohibited

47

10-MAINTENANCE AND CLEANING

EXAMPLE OF A CLEAN BRAZIER EXAMPLE OF A DIRTY BRAZIER

ATTENTION!

All the cleaning operations of all parts must be performed with a completely cold product and the plug disconnected.

The product requires little maintenance if used with certied good quality pellets.

DAILY OR WEEKLY CLEANING PERFORMED BY THE USER

BEFORE EACH START-UP

Clean the ash and any deposits in the brazier that could clog the air passage holes.

If the pellets in the hopper nish, unburned pellets may accumulate in the brazier. Always empty the residue in the brazier before

starting-up.

REMEMBER THAT ONLY A CORRECTLY POSITIONED AND CLEAN BRAZIER CAN GUARANTEE START-UP AND OPTIMAL

OPERATION OF YOUR PELLET PRODUCT.

For the brazier to be cleaned properly, remove it from its housing completely and thoroughly clean all the holes and the grate on the

bottom. If good quality pellets are used, you will normally only need to use a brush to restore the optimal operating conditions of the

component.

CHECKS TO BE PERFORMED EVERY 2/3 DAYS

Clean and empty the ash pan, being careful of hot ashes.

Only if the ash is completely cold can a vacuum cleaner be used to remove it. In this case, use an adequate vacuum cleaner to remove

particles that are not so small. Experience and the quality of the pellets will determine the cleaning frequency required. However, it is

recommended not to exceed 2 or 3 days.

CLEANING THE ASH COLLECTION COMPARTMENT

48

10-MAINTENANCE AND CLEANING

CLEANING THE GLASS

It is recommended to clean the ceramic glass with a dry brush, or if it is very dirty, spray a little specic detergent and clean with a cloth.

ATTENTION!

Do not use abrasive products and do not spray the glass spray cleaner on the painted parts or the door gaskets

(ceramic bre cord).

PERIODIC CLEANING PERFORMED BY A QUALIFIED TECHNICIAN

CLEANING THE HEAT EXCHANGER

The compartment through which the exhaust smoke passes must be cleaned at the of the winter season.

This cleaning process is mandatory in order to facilitate the general removal of all combustion residue, before it becomes very dicult to

remove it due to the humidity compacting it over time.

If necessary, clean it more often.

It is good practice to guarantee eective ventilation in the room while cleaning the product.

CLEANING THE EXCHANGER:

When the stove is cold, open the door, remove pan “M” and brazier “N”; remove the side plates “O” and “P” by turning them slightly

inwards for them to come out of their grooves and then pull them towards you (be careful as they can break easily).

Once the side plates are removed, lift plate “H” slightly, tilt it downwards and remove it.