Page 1

Installation and Maintenance Manual IM 835

Enthalpy Energy Recovery Wheel Option

McQuay Applied RoofPak™ Systems

Heating and Cooling Units and Rooftop Air Handlers

Type RPR/RFR/RDR 015C-075C, RAR 800C-802C and 47C

Group: Applied Systems

Part Number: IM 835

Date: March 2006

© 2006 McQuay International

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wheel Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purge and Pressurization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Frost Protection Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Variable Speed Frequency Control . . . . . . . . . . . . . . . . . . . . . 4

Alternate Frost Protection Measures . . . . . . . . . . . . . . . . . . . . 4

Startup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Prestartup Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Servicing Control Panel Components . . . . . . . . . . . . . . . . . . . 6

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Variable Frequency Controller . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Enthalpy Wheel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

MicroTech II Sequence of Operation . . . . . . . . . . . . . .9

Enthalpy Wheel Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exhaust Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Energy Recovery Bypass Damper Control . . . . . . . . . . . . . . 11

Typical Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Twister Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

McQuay and MicroTech are registered trademarks of McQuay International.

DesignFlow, Hi-F, Protocol Selectability, RoofPak, SelectTools, SpeedTrol, SuperMod, UltraSeal, and VaneTrol

Microsoft is a registered trademark of Microsoft Corporation.

Copyright © 2006 McQuay International. All rights reserved throughout the world.

are trademarks of McQuay International.

Windows is a trademark of Microsoft Corporation.

Page 3

Introduction

Introduction

This manual provides installation and maintenance

information about the enthalpy energy recovery wheel option

(“enthalpy wheel”) featured on the following McQuay

Applied RoofPak™ models:

1 RPR/RFR/RDE 015C - 075C Packaged Heating and

Cooling Units

2 RAR 800C - 802C and 47C Rooftop Air Handlers

General installation amd maintenance information on the rest

of the unit is found in the following manuals:

• IM 738 for Packaged Heating and Cooling Units

• IM 487 for Rooftop Air Handlers

• IM 696 for MicroTech™ II Controls

• OM 137 for discharge air control for MicroTech II

Controls

• OM 138 for space comfort for MicroTech II Controls

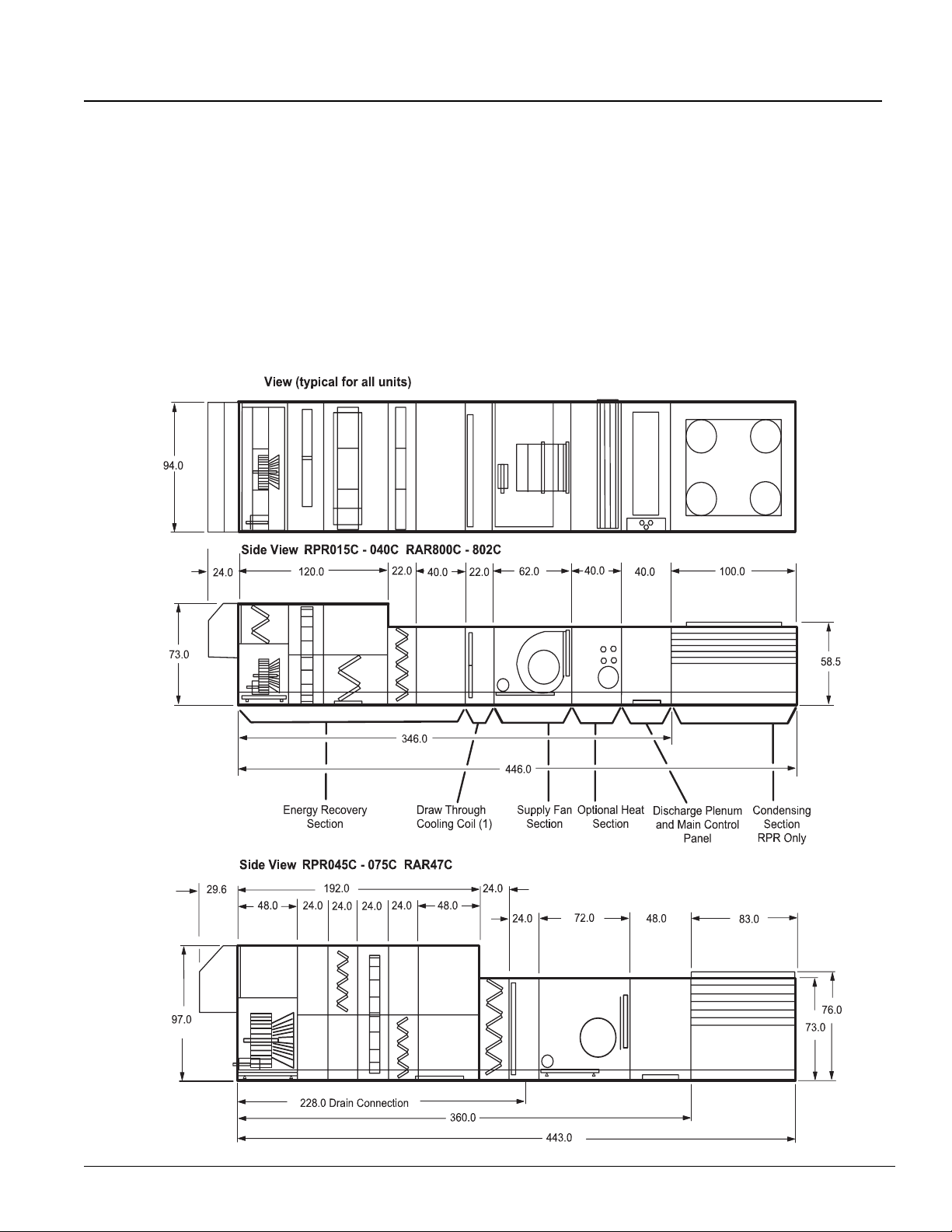

Figure 1: General Layout - (Approximate dimensions which vary with options)

Top

McQuay IM 835 1

Page 4

Introduction

Arrangements

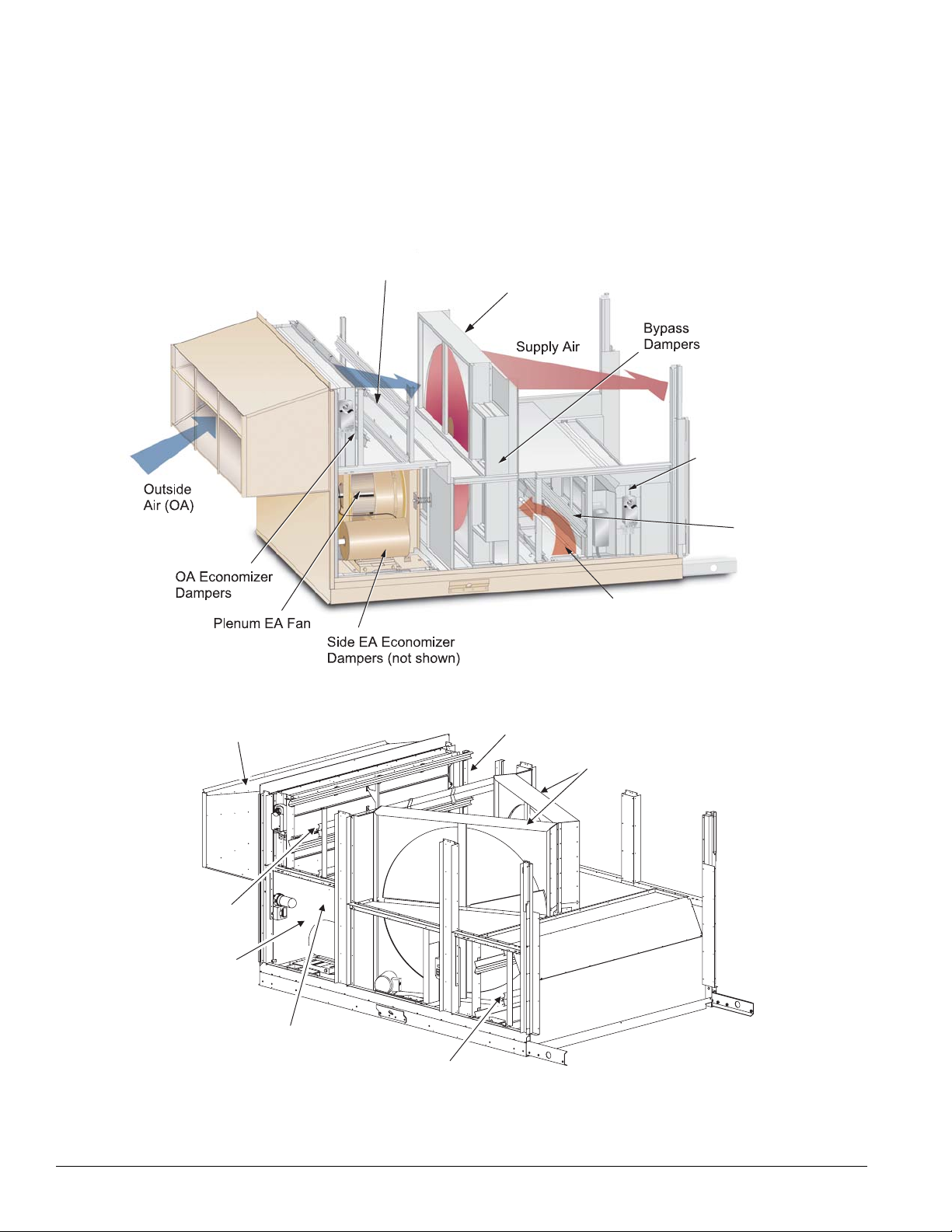

Three arrangements are offered for the enthalpy wheel:

1 Single enthalpy wheel with economizer and bypass (see

Figure 2). This arrangement is available for all units.

2 Single enthalpy wheel without economizer (100% outdoor

air unit) for airflow up to about 7000 CFM. This

Figure 2: Arrangement #1

OA Filter Rack

arrangement is available on sizes 015 - 040C and 800 802C only.

3 Dual enthalpy wheel without economizer (100% outdoor

air unit) for airflow exceeding about 7000 CFM (see

Figure 3). This arrangement is available on sizes 015 040C and 800 - 802C only.

Enthalpy

Wheel

Return Air

Economizer

Dampers

EA Filter Rack

Figure 3: Arrangement #3

OA Hood

OA Filter

Rack

Side EA

Economizer

Dampers

(not shown)

Exhaust Air (EA)

(at negative pressure)

OA Dampers

(2) Enthalpy

Wheels

Plenum EA Fan

EA Filter Rack

2 McQuay IM 835

Page 5

System Description

System Description

When a unit is equipped with an optional enthalpy wheel (see

Figure 2), ener gy recovery is provided by drawing outside air

across half of the enthalpy wheel and drawing exhaust air

across the other half. Latent heat and sensible heat are

transferred from the hotter and moist exhaust air to the colder

and dry outside air during winter conditions. Latent heat and

sensible heat are transferred from the hotter and moist

outside air to the cooler and dry exhaust air during summer

conditions. Energy recovery control consists of starting and

stopping an exhaust fan, modulating the speed of the exhaust

fan, starting and stopping an enthalpy wheel, optionally

controlling the speed of the enthalpy wheel and opening and

closing a set of bypass dampers. The outdoor dampers are

controlled in the normal manner. For more information, refer

to OM 137 or OM 138. Also see “MicroTech II Sequence of

Operation” on page 9.

Wheel Construction

Your McQuay enthalpy wheel is delivered completely

assembled and ready to run. The wheel is built to provide

many years of trouble free service following proper

installation and performance of the minimal maintenance

requirements.

Definitions

The following are descriptions of various components related

to the enthalpy wheel construction (see Figure 4):

Bearing, external - The wheel and bearing rotate on the

shaft, no field lubrication is required.

Brush seal - The seal used for both the circumferential seal

and the inner seal in the cassettes. They are constructed of

nylon brush and configured to seal against the enthalpy

wheel band in the case of the circumferential seal, and

against the wheel face in the case of the inner seal. These

seals are full contact seals, have an integral clip, and they are

clipped to the cassette face panel cutout (concumferential) or

to the (inner) post.

Latent energy - Latent energy, in the context of enthalpy

wheel discussions, is the work done by the wheel to transfer

moisture from one air stream to another. Latent work is

accompanied by humidity changes in the air streams.

Media - The chemical composite part of the enthalpy wheel

which actually performs the latent and sensible exchange.

Outdoor air - The air stream that is brought in from the

outside. Outdoor air becomes supply air after going through

the enthalpy wheel.

Purge - A small segment of supply air defined by the gap

between the inner seal on the outdoor air edge of the center

post and the supply air edge of the center post. The purge

angle is adjustable. The purge captures the small amount of

supply air captive in the enthalpy wheel when the wheel

moves from return to supply and routes it to return to

minimize cross contamination.

Return air - The air stream that is returned from the

building. Return air becomes exhaust air after going through

the enthalpy wheel.

Rotor - The part of an enthalpy wheel that performs the

energy exchange and consists of the wheel media, hub,

spokes and band.

Sensible heat - Sensible energy, in the context of enthalpy

wheel discussion, is the work done by the enthalpy wheel to

transfer heat from one air stream to another. Sensible work is

accompanied by temperature changes in the air stream.

Spoke - Flat metal member used to support the enthalpy

wheel radially.

Supply air - The air stream that is supplied to the building

space. Supply air is outdoor air that has been run through the

enthalpy wheel.

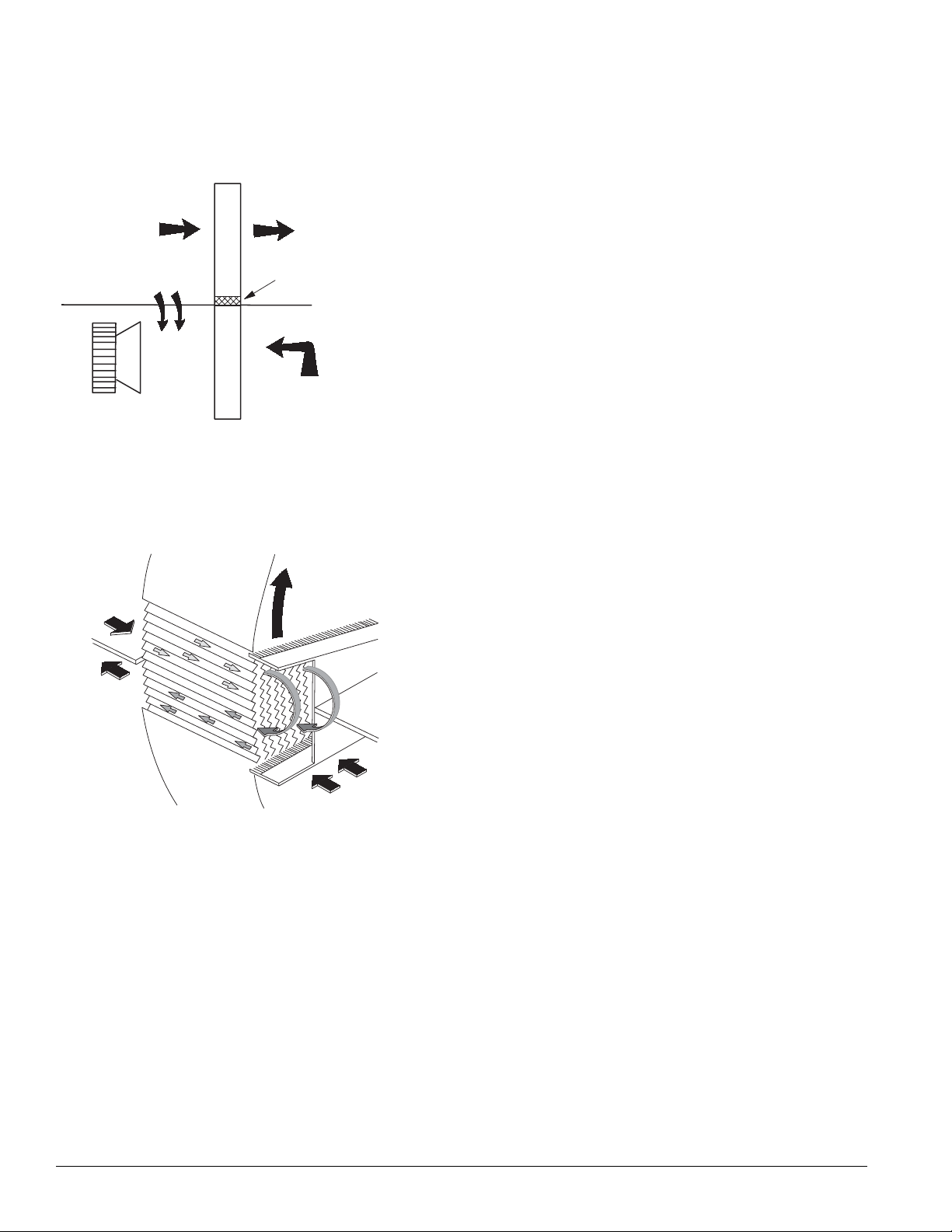

Figure 4: Wheel Construction (Side-by-Side)

Spoke

Hub

Brush Seal

Cassette - The steel structure that houses the rotor. Cassettes

Media

are of punched sheet metal panelized construction.

Enthalpy wheel - A generic name for an energy

conservation wheel. The term “enthalpy” refers to an air

stream’s total energy (temperature and humidity level).

Exhaust air - The air stream that is exhausted to the outside.

Exhaust air is building return air that has been run through

the enthalpy wheel.

Heat wheel - Synonymous with an enthalpy wheel, energy

conservation wheel, or total energy recovery wheel. Some

heat wheels are sensible only wheels and should not be

confused with McQuay total energy recovery wheels.

Hub - The center support of an enthalpy wheel.

McQuay IM 835 3

Enthalpy Wheel

(1) Currently, only the Over-Under configuration is offered on McQuay rooftop

systems and air handlers.

Side-by-Side

Configuration

Purge Location

Cassette

1

Over-Under

Configuration

Purge Location

Drive Belt

Motor

Sheave

1

Page 6

System Description

Purge and Pressurization

Pressurization is critical to minimize crossover from exhaust to

supply and to allow the purge to operate.

Figure 5: Purge and Pressurization

Outside Air at

Atmospheric Pressure

Any leakage must occur

from outside to Exhaust Air

due to pressure gradient

Plenum Exhaust Fan

draws a negative pressure

Figure 6: Purge Detail

Supply Air

Adjustable Purge

(See Detail)

Exhaust Air

NOTE:

Maintain the pressure gradient to

prevent cross contamination from the

Exhaust to Outside Supply Air

Frost Protection Option

During extremely cold winter conditions, exhaust air stream

frost formation becomes a possibility. Frost formation will act

to plug or reduce air flow but it will not hurt the enthalpy

wheel itself.

To circumvent this frost possibility, McQuay offers a factory

installed frost protection option (MicroTech II VFD system)

that will control the speed of the enthalpy wheel for you (see

“Variable Speed Frequency Control” below). The sequence of

operation is detailed in “Variable Speed Enthalpy Wheel” on

page 9.

Variable Speed Frequency Control

A variable frequency drive is included with the frost protection

option and it controls the speed of the enthalpy wheel. The unit

has also been programmed for the recommended range of

wheel speed operation. Typical wheel speed is 45 RPM, but

the programming can allow for wheel speeds above or below

45 RPM. Check all factory settings to make sure they are

consistent with the application.

Enthalpy wheel speed will be controlled by exhaust

temperature measurement.

Adjust purge in this

direction to decrease

OUTSIDE AIR

EXHAUST AIR

capacity and increase

purge

Drive Motor

The enthalpy wheel comes standard with a constant speed

drive motor which is prewired to turn in the proper direction.

Alternate Frost Protection Measures

If you choose not to have the frost protection option factory

installed by McQuay, other frost protection measures must be

considered.

Enthalpy wheel speed control functions to limit frost formation

by reducing wheel performance to a level where the exhaust

air temperature is kept above the dew point. Proper dew point

control of exhaust air is determined by using psychrometrics

(see Figure 8 on page 9):

1 Locate the winter design return air condition and outdoor

air condition and connect the two points on a psychrometric

chart.

2 Determine the dry bulb temperature at which this line

intercepts the saturation curve.

3 Add 2°F and set dew point control at this point and vary

enthalpy wheel speed downward to control at or above this

point.

4 Audit performance of the enthalpy wheel during actual

operation. If frost formation is never evident, it may be

because design conditions are never reached. In such a

case, it may be possible to gradually work dew point

control down.

4 McQuay IM 835

Page 7

Startup and Operation

Startup and Operation

Prestartup Checks

Before starting the unit, check the following:

1 Is the motor rotation correct? This can be checked by

bumping the motor and observing the direction of rotation.

The sheave should be rotating in the direction such that the

enthalpy wheel will rotate per the exterior markings. If not,

rewire the motor.

2 Does the air flow orientation match up to design? See the

identification markings on the cassette and/or refer to the

general arrangement drawing to check the four duct

connections to the unit.

3 Are the belts on correctly and sufficiently tight? For more

information, see “Appendix” on page 13.

4 Check if seals are making good contact and adjust by

moving the brushes closer to the wheel as necessary.

5 Is the optional frost control provided? If not, be aware that

enthalpy wheel capacity and air pressure drop suffer if frost

forms on the wheel.

6 If optional frost control is provided, check the following:

a Check the power supply for proper rating.

b Make sure that the proper jumper orie ntat ion is use d for

specific control input.

c Make sure that the unit is programmed for proper input

voltage and output voltage.

Note – Variable speed units are provided only with the

optional frost protection feature.

7 Has the construction dirt been cleaned? If filters are used to

clean the duct system, leave the exhaust fan off and just

recirculate air through the main filters with the supply fan.

McQuay IM 835 5

Page 8

Maintenance

Maintenance

CAUTION

Installation and maintenance must be performed only by

qualified personnel who are experienced with this type of

equipment and familiar with local codes and regulations.

Seals

The seals are designed to be durable and require no

maintenance other than adjustment. If seals become worn or

damaged they may easily be replaced. The seals are made to

clip onto the cassette or metal post easily.

WARNING

Moving machinery and electrical power hazards. Can cause

severe personal injury or death. Disconnect and lock off all

power before servicing equipment.

CAUTION

Sharp edges are inherent to sheet metal parts, screws, clips,

and similar items. Contact with these edges may cause

personal injury. Exercise caution when servicing equipment.

Servicing Control Panel Components

Disconnect all electric power to the unit when servicing

control panel components. Before servicing, always inspect

units for multiple disconnects to ensure all power is removed

from the control panel and its components.

DANGER

Hazardous voltage. Will cause severe injury or death.

Disconnect electric power before servicing equipment. More

than one disconnect may be required to de-energize the unit.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1-800-37-PARTS or at www.mcquay.com. When contacting

McQuay for service or replacement parts, refer to the model

number and serial number of the unit as stamped on the

nameplate attached to the unit.

Bearings

Enthalpy wheels are provided with "no maintenance" inboard

bearings, requiring no maintenance during the life of the

equipment.

Drive Motor

The drive motor should require no maintenance.

Drive Belts

Belts are multilink with individual links constructed of a high

performance polyurethane elastomer, reinforced with

multiple plies of polyester fabric. This belt provides a strong,

yet flexible belting. The multilink feature provides easy

servicing or replacement. See “Appendix” on page 13 for

belt repair/replacement instructions.

V ariable Frequency Controller

No maintenance should be required on the VFD. Should

problems with the VFD develop, consult the VFD service

manual that accompanied your order.

Wheel

The enthalpy wheel is designed to last the life of the

equipment. It is protected by an ASHRAE 30% filter to keep

dust and dirt from the heat transfer surface. The wheel is

somewhat self cleaning through its normal action of rotating

in and out of countercurrent air flow streams. If the wheel

becomes dirty, it may be cleaned by blowing out the unit with

compressed air (20 psig maximum). In cases of severe dirt,

the wheel may be removed from the cassette and washed

with water following wheel removable procedures outlined

below.

Enthalpy Wheel Removal

The following enthalpy wheel removal procedure is for a

dual wheel design (although much of the procedure is

applicable for a single wheel design).The dual wheel is only

offered for small cabinet 100% O.A. High Flow applications

(no economizer or bypass dampers). There are two removal

procedures depending on the weight of the wheel (see

Table 1) These are described below:

Procedure (size 800 - 802C or 015 - 04 0C)

1 Disconnect electrical power.

2 Put a safety cover over the bottom return opening.

3 Remove divider panels and blockoffs.

4 Remove filter rack and optional inverter mount.

5 Remove cross channel between uprights.

6 Support the wheel from the bottom.(See Table1)

7 Remove end panels from energy wheel cassette.

8 Loosen motor and uncouple the belt.

9 Remove enthalpy wheel supports and bearing from

cassette.

6 McQuay IM 835

Page 9

Maintenance

Note – If the unit is equipped with an external flanged

bearing, loosen the allen screws in the bearing

housing that keeps the shaft affixed in the horizontal

plane on both bearings, front and back. Remove the

shaft clips at the face of the hub from both sides of the

shaft. Unbolt one post completely and remove post

with the bearing completely out. Remove the shaft.

Roll the wheel carefully out.

10 Slide wheel out the front of the cassette.

11 With the enthalpy wheel out, wash the media carefully with

water. Allow wheel to dry completely for several hours.

Figure 7: Enthalpy Wheel Removal Components

Cassette

End

Panel (#6)

12 Reinstall the enthalpy wheel using the reverse procedure,

Run the unit. It may take several hours for the desiccant to

dry and for the wheel to perform normally.

Table 1: Weight of the wheel less sheet metal cassette

Unit Size Weight

55" tall cabinet 300 Lbs.

73" tall cabinet, 6" wide wheel 800 Lbs.

73" tall cabinet, 12" wide wheel 1000 Lbs.

Wheel

Supports/

Bearing (#8)

Wheel (#9)

Cassette

End

Panel (#6)

Channel (#4)

Cross

Divider

Panels/Blockoffs (#2)

Divider

Panels/Blockoffs (#2)

Cross

Channel (#4)

Motor (#7)

Filter Rack/

Optional Inverter

Mount (#3)

Procedure (size 47C or 45 - 75C)

The enthalpy wheels in these larger units are too heavy and

wheel removal, as described above for smaller units, is usually

not practical. If a need arises to remove an enthalpy wheel

from a size 47C or 45-75C, then there are two choices to

consider, depending on the reason for removal:

1 Disconnect electrical power.

2 If the primary need is to clean the wheel:

a Normally the wheel can be cleaned with compressed air

(20 psig maximum) while in place.

b If the wheel cannot be cleaned with compressed air, then

water can be used. A drain pan is provided under the

wheel for collecting the water.

c To clean the wheel with water, first remove the lower

baffle located between the bypass damper and the wheel

blocking the drain pan. Clean the wheel with water

while it is in place, but care must be taken that the water

does not splash outside the drain pan.

d If the wheel cannot be sufficiently cleaned while in

place, then the roof will have to be removed so a crane

can be used to lift out and re-install the wheel. Follow

steps 1-8, 10 and 11 (from the above procedure for size

800-802C or 015-040C) for loosening and reinstalling

the wheel.

3 If the wheel must be replaced:

a Cut the wheel into pieces that can be easily handled and

replace the wheel.

b If using a crane and removing the unit’s roof is not

practical, then replace the existing wheel with a

segmented wheel.

McQuay IM 835 7

Page 10

Maintenance

Troubleshooting

The following table may be used as a quick-reference for

identifying common symptoms and possible causes related to

the recovery wheel.

SYMPTOM CAUSE

Check wheel rotation speed (see “Variable Speed

Frequency Control” on page 4).

Check for wheel integrity and adjust seals or replace

worn seals (see “Prestartup Checks” on page 5 and

Inadequate Wheel

Performance

Improper Wheel

Rotation

“Seals” on page 6).

Check entering air conditions and compare to

design (see “Prestartup Checks” on page 5).

Check ducting for leakage and fix any leaks.

Check media for dirt and clean per cleaning instruc-

tions (see“Wheel” on page 6 and “Enthalpy Wheel

Removal” on page 6).

Check drive belts for engagement with sheave.

Check drive motor.

Check drive motor wiring for proper voltage.

Check VFD programming (provided with optional

frost protection).

High Pressure Drop

Noise

Wheel Will Not

Operate

Check air flow and compare to design.

Check filters and clean/replace as necessary.

Check media for plugging and clean per cleaning

instructions (see “Enthalpy Wheel Removal” on

page 6).

Check seals and adjust as necessary.

Check the bearings for source of noise.

Check the belt for slippage (see “Power T wister Belt”

on page 13).

Check all electrical connections.

If MicroTech II controls are provided, make sure the

building pressure is above setpoint such that the

EAF turns on. The wheel does not operate unless

the EAF is on (see “Exhaust Fan Control” on page

10).

8 McQuay IM 835

Page 11

MicroTech II Sequence of Operation

S

MicroTech II Sequence of Operation

When a unit is equipped with an optional enthalpy wheel,

energy recovery is provided by drawing outside air across half

of the enthalpy wheel and drawing exhaust air across the other

half. Latent and sensible heat is transferred from the hotter

moist exhaust air to the colder dry outside air in winter. Latent

and sensible heat is transferred from the hotter moist outside

air to the cooler dry exhaust air in summer. Energy recovery

control consists of starting and stopping an exhaust fan,

modulating the speed of the exhaust fan, starting and stopping

an enthalpy wheel, optionally controlling the speed of the

enthalpy wheel and opening and closing a set of bypass

dampers. The outdoor dampers are controlled in the normal

manner. Refer to OM 137 or OM 138.The following sections

describe the control of the enthalpy wheel, exhaust fan and

bypass dampers.

Enthalpy Wheel Control

Table 2, below, lists the programmable parameters on the

MicroTech II keypad that affect the operation of the enthalpy

wheel.

Table 2: Enthalpy Wheel Programmable Parameters

Keypad/Display ID

Menu Name Item Name

OA Damper Eff Min OA Pos= ___%

Energy

Recovery

Energy Rec

Setup

Energy Rec= No

Min ExhT Diff= 2°F

Max ExhT Diff= 6°F

Stage Time= 5 min

Min Off Time= 20 min

When the Energy Recovery Control Flag is set to “Yes”, the

enthalpy wheel is turned on whenever the unit exhaust fan is

on and the current OA Damper Pos= parameter in the OA

Damper menu indicates a value within 3% of the Effective

Minimum Outdoor Damper Position Set Point. It is turned off

when the exhaust fan is turned off or the OA Damper Pos=

value is greater than the Effective Minimum Outdoor Damper

Position Set Point by more than 3% (as when the unit is in the

Econo operating state).

Constant Speed Enthalpy Wheel

When the unit is equipped with a constant speed enthalpy

wheel, the wheel is driven to maximum speed whenever the

enthalpy wheel is on.

Parameter Name

Effective Minimum

Outdoor Damper Position

Set Point

Energy Recovery Control

Flag

Minimum Temperature

Difference

Maximum Temperature

Difference

Enthalpy Wheel Stage

Time

Enthalpy Wheel

Minimum Off Time

Variable Speed Enthalpy Wheel

When the unit is equipped with the enthalpy wheel frost

protection option, it has a variable speed enthalpy wheel. The

wheel is driven to maximum speed whenever the enthalpy

wheel is on. The speed of the wheel may be modulated as

described below to prevent wheel frosting.

When there is a threat of frost on the enthalpy wheel, the wheel

is slowed down or stopped so that less enthalpy transfer occurs

and frosting of the wheel is avoided. Frosting can occur on the

enthalpy wheel when the exhaust air leaving the wheel is

saturated. This condition occurs when two lines intersect on a

psychrometric chart, and it does not occur when these two

lines do not intersect (see Figure 8). One of these lines is the

Humidity Ratio versus the dry bulb temperature for saturated

air. The other line is the exhaust air process line. The exhaust

air process is defined by two points on a psychrometric char t.

The first point on this line is the outdoor air temperature at

95% relative humidity (point 1 in Figure 8) and the second

point on the line is the return air temperature at the return air

relative humidity (point 2 in Figure 8). One exhaust air process

line showing frosting conditions and another showing no frost

conditions is shown in Figure 8.

Figure 8: Variable Speed Enthalpy Wheel Frost Protection Psychrometric Chart

aturated Air

Saturated Air

Saturation

Temperature

(Intersection Point)

1

ST

1

Dry Bulb Temperature

ST

2

Enthalpy Wheel

Exhaust Air (No

Frost Conditions)

Enthalpy Wheel

Exhaust Air

(Frost

Conditions)

2

2

Humidity Ration

The controller makes a continuous calculation to determine if

and at what temperatures the saturated air and exhaust air

process lines intersect. When they do not intersect, the

enthalpy wheel runs at full speed. When they do intersect, the

enthalpy wheel is controlled to a slower speed to maintain the

dry bulb temperature of the exhaust air leaving the enthalpy

wheel above the higher of the two intersecting dry bulb

temperatures (point ST

in Figure 8). This is referred to as the

2

“Intersection Point.” This prevents the wheel from operating

under frosting conditions.

McQuay IM 835 9

Page 12

MicroTech II Sequence of Operation

The following describes the details involved in the frost

protection function that affect the speed and start/stop of the

enthalpy wheel.

• When the enthalpy wheel has been operating at maximum

speed for at least the Enthalpy Wheel Stage Time and the

exhaust air temperature leaving the wheel (ER ExhT=) drops

below the Intersection Point plus the Minimum Temperature

Difference, the enthalpy wheel will be slowed to its

minimum speed.

• If the enthalpy wheel has been operating at minimum speed

for at least the Enthalpy Wheel Stage Time and the exhaust

air temperature leaving the wheel (ER ExhT=) is still below

the Intersection Point plus the Minimum Temperature

Difference, the enthalpy wheel will be stopped.

• If the exhaust air temperature leaving the wheel (ER ExhT=)

then rises above the Intersection Point plus the Maximum

T emperature Diff erence and the enthalpy wheel has been of f

for longer than the Enthalpy Wheel Minimum Off Time, the

wheel will be restarted and will run at its minimum speed.

• If the enthalpy wheel has been at minimum speed for longer

than the Enthalpy Wheel Stage Time and the exhaust air

temperature leaving the wheel (ER ExhT=) is still above the

Intersection Point plus the Maximum Temperature

Difference, the wheel will be increased to its maximum

speed.

Exhaust Fan Control

When a unit is equipped with a 0 - 100% modulating

economizer or is 100% OA with a variable capacity discharge

fan, the energy recovery option includes a variable capacity

exhaust fan equipped with a VFD. The MicroTech II

parameters that control the exhaust fan are shown in Table 3

There are two different methods for controlling the exhaust fan

capacity, as described below.

Table 3: Exhaust Fan Progra mma b le Paramete rs

Keypad/Display ID

Menu Name Item Name

BldgSP Spt= 1.00 “WC

Bldg Pressure

BSP Db= 0.080 “WC

OA Damper Eff Min OA Pos=___%

BSP Propbd= 0.400 “WC

Building Static P

Setup

Energy Recovery

Unit Configuration

BSP IntTime= 2.0 sec

BSP Period= 2.0 sec

EF Min Cap= 5%

Energy Rec= No

Min Exh On= 120 sec

Min Exh Off= 120 sec

2nd P Sensor= None

RF/EF Ctrl= Tracking

Rem RF/EF Cap= 25%

Parameter Name

Building Static

Pressure Set Point

Building Static

Pressure Dead Band

Effective Minimum

Outdoor Damper

Position Set Point

Building Static

Pressure Proportional

Band

Building Static

Pressure Integral

Time

Building Static

Pressure Period

Exhaust Fan Minimum

Capacity Value

Energy Recovery

Control Flag

Minimum Exhaust Fan

On Timer

Minimum Exhaust Fan

Off Timer

Second Pressure

Sensor Present Flag

Return/Exhaust Fan

Capacity Control Flag

Remote Return/

Exhaust Fan Capacity

Set Point

1) Building Pressure Control

When the Energy Recovery Control Flag is set to “Yes”, the

Return/Exhaust Fan Capacity Control Flag is set to “BldgPres”

and the Second Pressure Sensor Present Flag is set to “Bldg”,

the exhaust fan is controlled based on the building static

pressure. The exhaust fan is turned on when the discharge fan

is running and the Bldg Press= parameter value is above the

Building Static Pressure Set Point high by more than half the

Building Static Pressure Dead Band for longer than the

Minimum Exhaust Fan Off Timer.

Note – If the unit is 100% OA with a constant volume discharge

fan, the exhaust fan is turned on whenever the outdoor air

dampers are open.

The exhaust fan remains on until either of the following occur:

a The Bldg Press= parameter value drops below the

Building Static Pressure Set Point by more than half the

Building Static Pressure Deadband and the RF/EF Fan

Cap= value has been at the Exhaust Fan Minimum

Capacity Value for longer than the Minimum Exhaust

Fan On Timer.

b The discharge fan is turned off.

10 McQuay IM 835

Page 13

MicroTech II Sequence of Operation

When the exhaust fan is on, its capacity is modulated to

maintain the Bldg Press= parameter value at the Building

Static Pressure Set Point using three PID control loop

parameters. These are the Building Static Pressure

Proportional Band, Building Static Pressure Integral Time and

Building Static Pressure Period. Although these parameters

can be adjusted, for most applications, the factory default

values for these parameters provide the best control. For

detailed information regarding tuning PID control loop

parameters, refer to “MicroTech II DDC Features” in OM 137.

2) Direct Position Control

When the Energy Recovery Control Flag is set to “Yes” and

the Return/Exhaust Fan Capacity Control Flag is set to

“Position”, the exhaust fan is controlled based on Remote

Return/Exhaust Fan Capacity Set Point. This set point can be

adjusted via a network signal. The exhaust fan is turned on

when the discharge fan is running and the exhaust fan capacity

is commanded above the Exhaust Fan Minimum Capacity

Value for longer than the Minimum Exhaust Fan Off Timer.

The exhaust fan remains on until either of the following occur:

a The Remote Return/Exhaust Fan Capacity Set Point is

commanded to the Exhaust Fan Minimum Capacity

Value for longer than the Minimum Exhaust Fan On

Timer.

b The discharge fan is turned off.

Note – If the unit is 100% OA with a constant volume

discharge fan, the exhaust fan is turned on whenever

the outdoor air dampers are open.

Energy Recovery Bypass Damper Control

When a unit is equipped with a 0-100% modulating

economizer, the energy recovery option includes a set of

bypass dampers (see Figure 9) that allow air to bypass the

energy recovery wheel when the wheel is not operating. The

dampers are driven closed for 2 minutes whenever the energy

recovery wheel is turned on, forcing the entering and leaving

air to go through the wheel. When the outdoor air dampers are

driven more than 3% above the effective Minimum Outdoor

Damper Position Set Point (as when the unit enters the

Economizer operating state the wheel is shut off and the

bypass dampers are driven open for 2 minutes allowing the

entering and leaving air to bypass the wheel.

Table 4: Programmable Parameters

Keypad/Display ID

Menu Name Item Name

OA Damper Eff MinOA Pos= ___%

Parameter Name

Effective Minimum

Outdoor Damper

Position Set Point

Figure 9: Bypass Damper Control

O A D a m p e r s

O u t d o o r

A i r

E A a n d O A

P r e - F i l t e r s

P l e n u m E A F

A t m o s p h e r i c

P r e s s u r e

E x h a u s t A i r

B y p a s s D a m p e r ( O p t i o n a l )

S u p p l y

A i r

N e g a t i v e

P r e s s u r e

R e t u r n

A i r

R A E c o n o m i z e r

D a m p e r s ( O p t i o n a l )

McQuay IM 835 11

Page 14

Typical Wiring Diagram

8

Typical Wiring Diagram

The following is a common wiring diagram for the enthalpy

wheel.

P B 1 1

L 1 - 1 2

L 2 - 1 2

L 3 - 1 2

T 1 _ 1 1 5 V A C / 1 . 6 8 T 2 _ 2 4 V A C / 2 . 6 4

1 2 - L 1

1 2 - L 2

1 2 - L 3

S R C

1 - 8

9 1 2 A

2 0 7 ( C L O S E D )

2 0 7 ( O P E N )

C B 6 0

L 1

T 1

L 1

L 2

T 2

L 2

L 3

T 3

L 3

N o r m a l E c o n o m i z e r

C o n t r o l O u t p u t s

j p r s

M C B

B 0 5

2 4 V S R C

5 N O

5

j

p r s

M C B

B 0 6

2 4 V S R C

6 N O

6

H 9 0 3 - 1

H 9 0 4 - 1

H 9 0 5 - 1

G N D 1

H 9 1 2 - 7

9 1 2 B

9 1 2 A

H 9 1 3 - 6

H 9 1 4 - 1 0

9 1 2 A

H 9 1 4 - 1 0

H 9 1 3 - 0

H 9 1 2 - 7

H 9 0 6 - 1

W h e e l

V F D

U 1

V 1

G N D

W 1

+ N B

A C T 3

4

( O A D A M P E R )

C C W

2

2 4 V

( W I T H C C W S P R I N G

3

R E T U R N C L O S E D )

C W

+ N B

A C T 4

2

( R A D A M P E R )

2 4 V

4

C C W

( W I T H C W S P R I N G

3

R E T U R N O P E N )

C W

E n e r g y

H 9 0 3 - 1

U 2

H 9 0 4 - 1

V

2

H 9 0 5 - 1

W 2

P L 1 1

H 9 1 2 - 8

1

C O M

H 9 1 2 - 8

1

C O M

W h e e l

M o t o r

T 1

T 2

9 3 4

M T R

T 3

T 3 _ C O M

T 2 _ C O M / 2 . 4 7

T 1 _ N / 1

. 6

3 0 3 B

T 3 _ 2 4 V

2 4 V

J 1 0

J U M P E R S

B I 7

E N A B L E

B I 9

E N A B L E

B I 1 0

J U S T U N D E R

C O M M . C A R D )

B I 8

B I 1 1

B I 1 2

( C O M P R # 1 )

3

5

6

8

9

3 0 3 A

C O M

1 2

C O M

1 5

1 6

1 7

( C O M P R # 2 )

1 9

9 0 3

1 3

1 1

H 9 5 7 - 8

H 9 5 7 - 1 2

I S O F F T H R O U G H R 6 0

8

P L 1 2

1 2

P L 1 2

9 5 8 A

2 4 C

N 2

N 2 +

B U S

N 2

R E F

B 0 1

D I S A B L E

J 8

B 0 2

D I S A B L E

E R B 1

A I 1

C O M

S V D C

A I 2

C O M

A I 6

A I 3

C O M

S V D C

( J U M P E R

L O C A T E D

E n e r g y

R e c o v e r y

B o a r d

I N P U T S

B I = B I N A R Y

A I = A N A L O G

B O 1

N O

C O M

B O 2

N O

C O M

B O 3

N O

C O M

B O 4

C O M

N O

B O 5

N O

B O 6

C O M

B O 6

N O

N C

B O 7

C O M

N O

B O 8

C O M

N O

B O 9

C O M

N O

+ N B

A F D 6 0

V D F F o r T h e E n e r g y

R e c o v e r y W h e e l

6

1 0

8

O P E N S A N D F O R C E S

T H E V F D T O L O W

S P E E D W H E N T H E

W H E E L M O T O R

( l in e 9 3 4 )

P L 1 2

R 6 0

9 5 8 B

9 5 9 A

5

9

9 3 4

2 0 9 C

2 1 0 C

2 1 1 C

9 3 0 C

9 3 1 C

H 9 3 9 - 4

4

1 4

7

H 9 3 4 - 1

P L 2 2

H 9 4 1 - 2

H 9 5 7 - 7

P L 1 2

W H T

B L K

D R N

W H T

B L K

D R N

+ N B

M T R 1

9 0 3

+ N B

A C T 1 2

( B Y P A S S D A M P E R )

C L O S E

C C W

C W

O P E N

9 2 4 C

9 2 5 C

L 1

P L 1 2

1

9 3 4 C

1

2

4

7

9 4 0 C

1 0

P L 2 2

9 4 1 C

2

1 1

1 3

1 4

9 4 4 C

1 5

9 4 6 C

1 8

2 0

1 2

9

H 9 5 7 - 9

9

W H T

B L K

D R N

+ P P

P L 2 4

H 9 2 4 - 1

1

H 9 2 5 - 2

2

D R N 4

4

+ P P

P L 2 3

H 9 3 0 - 1

1

H 9 3 1 - 2

2

D R N 4

4

( A U X I L I A R Y C O N T A C T O N T H E

W H E E L M O T O R O P E N S W H E N

T H E M O T O R I S O F F )

( B Y P A S S D A M P E R S O P E N

D U R I N G E C O N O M I Z E R

O P E R A T I O N )

H 9 3 9 - 3

C O M

( S P E E D U P A N D S L O W

D O W N O U T P U T R E L A Y S

F O R T H E V F D )

R 5 8 _ 5 9

H 1 D N

H 1 C

H 1 U P

9 6 1

N 2 + A / 2 . 1 1

N 2 + A / 2 . 1 2

R E F A / 2 . 1 2

O p t i o n a l

+ N B

E A T

( E X H A U S T A I R S E N S O R

L E A V I N G W H E

+ N B

E A T

( L E A V I N G A I R S E N S O R

O U T D O O R A I R

L E A V I N G W H E E L )

P L 1 2

H 9 3 4 - 2

T 3 _ C O M

P L 2 2

3

E L )

R 6 0

2

7

8

3 0 3 B

9 5 8 A

H 2 U P H 2 V

( S P E E D U P A N D S L O W D O W N

O U T P U T R E L A Y S F O R T H E V F D )

R 5 8 _ 5 9

H 2 D N

9 4 4

12 McQuay IM 835

Page 15

Appendix

Appendix

Power Twister Belt

The following Power Twist® Belt information offers

instruction on how to measure, disassemble, assemble, and

install the belt.

Belt Length Measurement

The following steps give the correct installed belt length and

will provide optimum belt tension when running.

1 Pull belt tight around sheaves to check hand tight length,

overlapping the last two tabs with two holes in matching

links as shown below.

2 Count the number of links and remove one link for every

24 links.

Note – Every tenth link is designated with an arrow.

3 Rotate belt end with tab 90°.

4 Pull belt end through two links.

Belt Assembly

1 Hold belt with tabs pointing outward.

Belt Disassembly

1 Hold belt upside down. Bend back as far as possible; hold

with one hand. Twist one tab 90° parallel with slot.

2 Pull end of link over tab.

2 Place end tab through two links at once.

3 Flex belt further and insert second tab through end link by

twisting tab with thumb.

McQuay IM 835 13

Page 16

Appendix

4

Ensure tab returns to position across belt. Reverse belt so

tabs run inside.

Belt Installation

1 Disconnect electrical power.

2 Turn belt with tabs to the inside before installing.

3 Determine direction of the drive rotation.

4 Align belt directional arrow with drive rotation.

5 Fit belt in nearest groove of smaller sheave.

6 Roll belt onto larger sheave, turning the drive slowly. Belt

may seem very tight, this is okay; DO NOT JOG MOTOR.

7 Roll belt onto larger sheave, turning the drive slowly. Belt

may seem very tight, this is okay; DO NOT JOG MOTOR.

8 Check to see that all tabs are still in their correct position

and are not twisted out of alignment.

Alternative Belt Installation Method

1 Set motor to mid position of adjustment range and mark

base clearly.

2 Determine required belt length (see “Belt Length

Measurement” on page 13).

3 Push motor forward to minimum center distance.

4 Install belts as in (see “Belt Installation”).

5 Pull motor back to previously marked mid position.

Retensioning

Like all high performance V-belts, PowerTwist

Plus V-Belts

require the maintenance of correct drive tension to operate

efficiently. Experience indicates that drive tension should be

checked after the first 24 hours running at full load. A

retension may be necessary depending on the severity of the

drive. Any initial belt stretch is then taken up. Subsequently,

belt tension should be checked periodically and adjusted when

necessary.

14 McQuay IM 835

Page 17

Page 18

McQuay Training and Development

Now that you have made an investment in modern, efficient McQuay equipment, it s care should be a high priority.

For training information on all McQuay HVAC products, please visit us at www.mcquay.com and click on train ing, or

call 540-248-9646 and ask for the Training Department.

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited Product

Warranty. Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find your

local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date product

information, please go to www.mcquay.com.

13600 Industrial Park Boulevard, Minneapolis, MN 55441 USA (612) 553-5330

Loading...

Loading...