Page 1

Page 2

Table of

.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Receiving Inspection . . ...’..... . . . . . . . . . . . . . . . ...3

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Typical Component Locations., . . . . . . . . . . . . . . . . ...4

Typical Unit Sections,...,.,., . . . . . . . . . . . . . . . . ...7

Control Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8

Control Panel Locations, . . . . . . ., . . . . . . . . . . . . . ...9

Controls, Settings, and Functions . . . . . . . . . . . . . ...11

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . ...13

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . ...13

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13

Roof Curb Assembly and Installation . . . . . . . . . . . ...15

Post and Rail Mounting, . . . . . . . . . . . . . . . . . . . . ...16

Rigging and Hand[ing . . . . . . . . . ., . . . . . . . . . . . . ...16

Split Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...17

Reassembly of Split Units..,.. . . . . . . . . . . . . . . ...17

Installing Ductwork, . . . . . . . . . . . . . . . . . . . . . . . . ...21

Installing Duct Static Pressure Sensor Taps ., .,....21

Installing Building Static Pressure Sensor Taps . . ...22

Condensate Drain Connection ., . . . . . . . . . . . . . . ...23

Field Refrigerant Piping and Charging of DX Coils ..24

Unit Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26

Vestibule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...29

Damper Assemblies . . . . . . . . . ., . ., . . . . . . . . . . ...31

Cabinet Weatherproofing . . . . . . . . . . . . . . . . . . . . ...34

Electrical installation, . . . . . . , . . . . . . . . . . . . . . . . ...35

Field Power Wiring . . . . . . . . . . . , . . . . . . . . . . . . . ...35

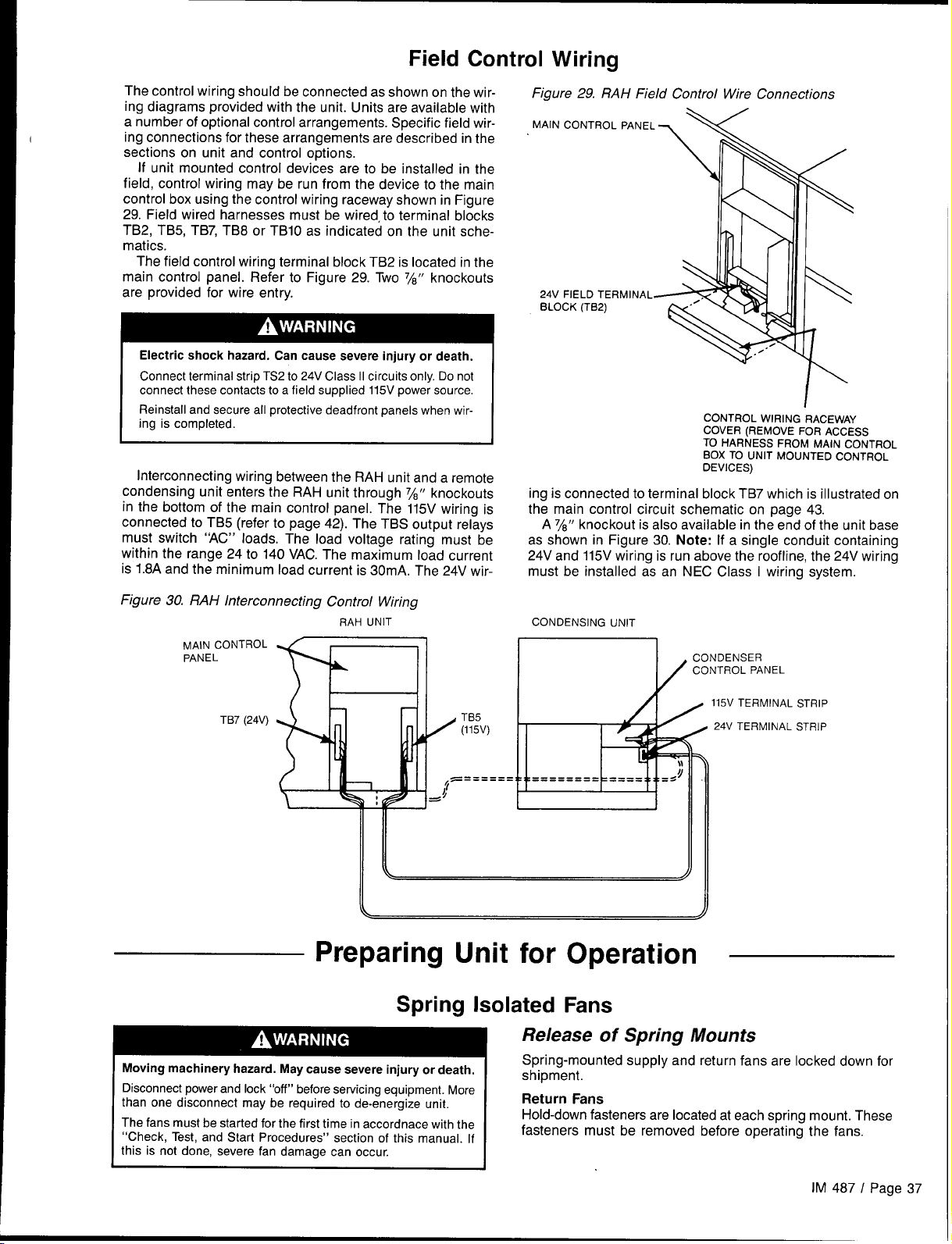

Field Control Wiring, ..,....., ., . . . . . . . . . . . . ...37

Preparing Unit for Operation. . . . . . . . . . . . . . . . . . ...37

Release of Spring Mounts . . . . . . . . . . . . . . . . . . . ...37

Adjustment of Supply Fan Thrust Restraints . . . . . ...38

Adjustment of Spring Mounts,.. . . . . . . . . . . . . . . ...38

Seismic Restraints . . . . . . . . . . . . . . . . . . . . . . . . . ...38

Sequences of Operation . . . . . . . . . . . . . . . . . . . . . ...39

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...39

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...39

Economizer Operation . . . . . . . . ., . . . . . . . . . . . . ...40

Heating Operation . . . . . . . . . . . . . . . . . . . . . . . . . . ...40

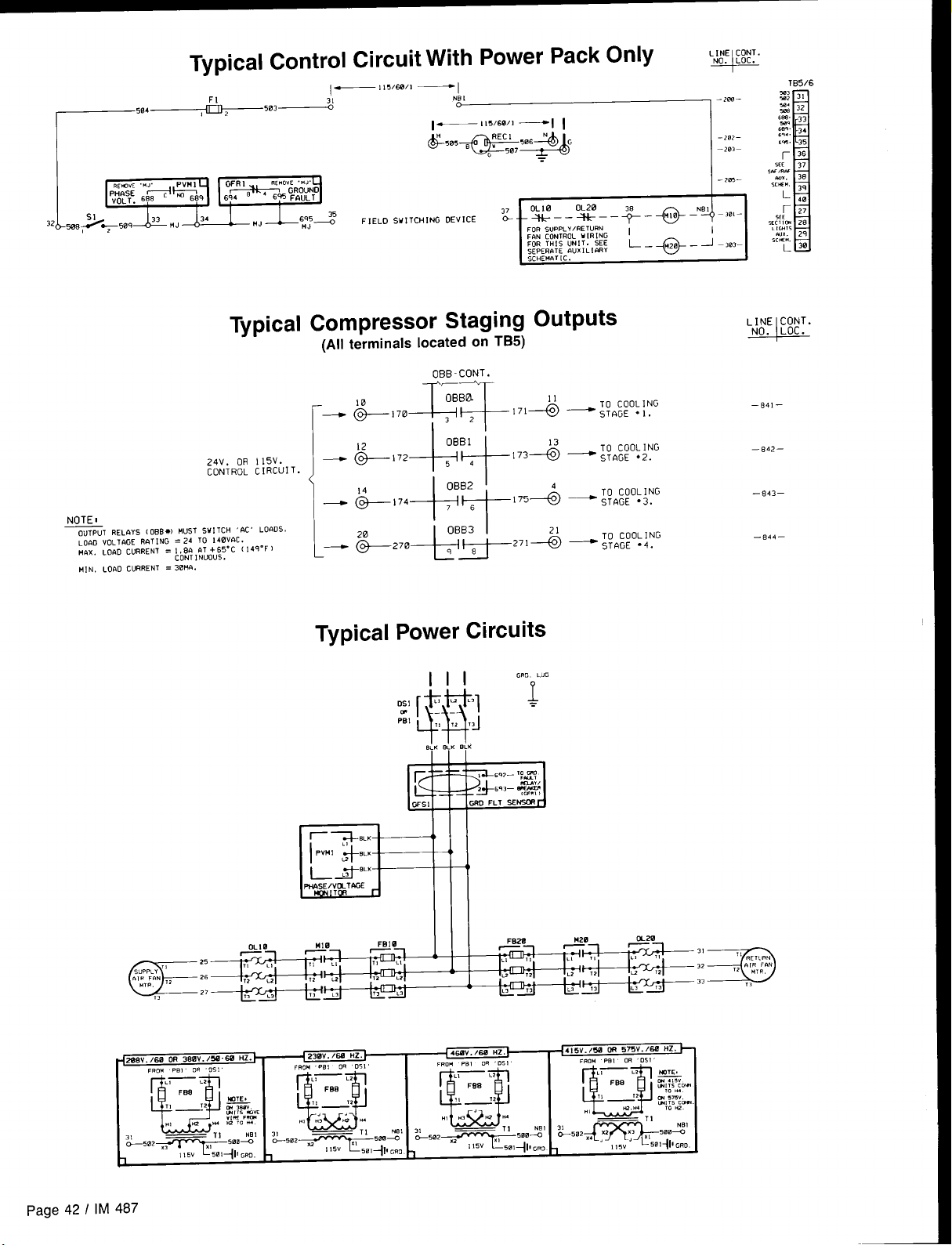

Typical Compressor Staging Outputs. . . . . . . . . . . ...42

Typical Power Circuits With Controls . . . . . . . . . . . ...42

Typical Main Control Circuit (VAV Units) . . . . . . . . ...43

Typical Main Control Circuit (CAV-ZTC Units) ,. . . ...44

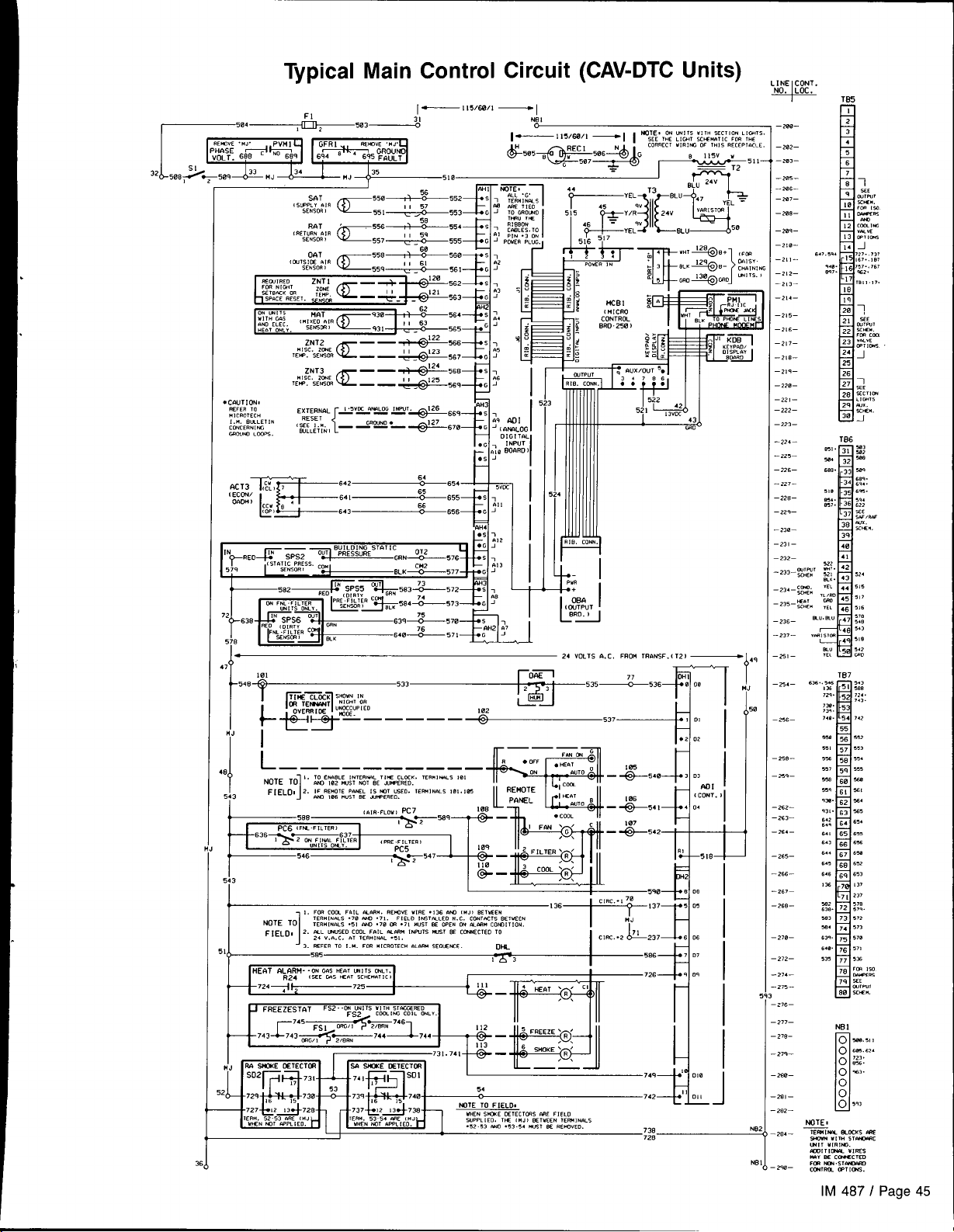

Typical Main Control Circuit (CAV-DTC Units) . . . . ...45

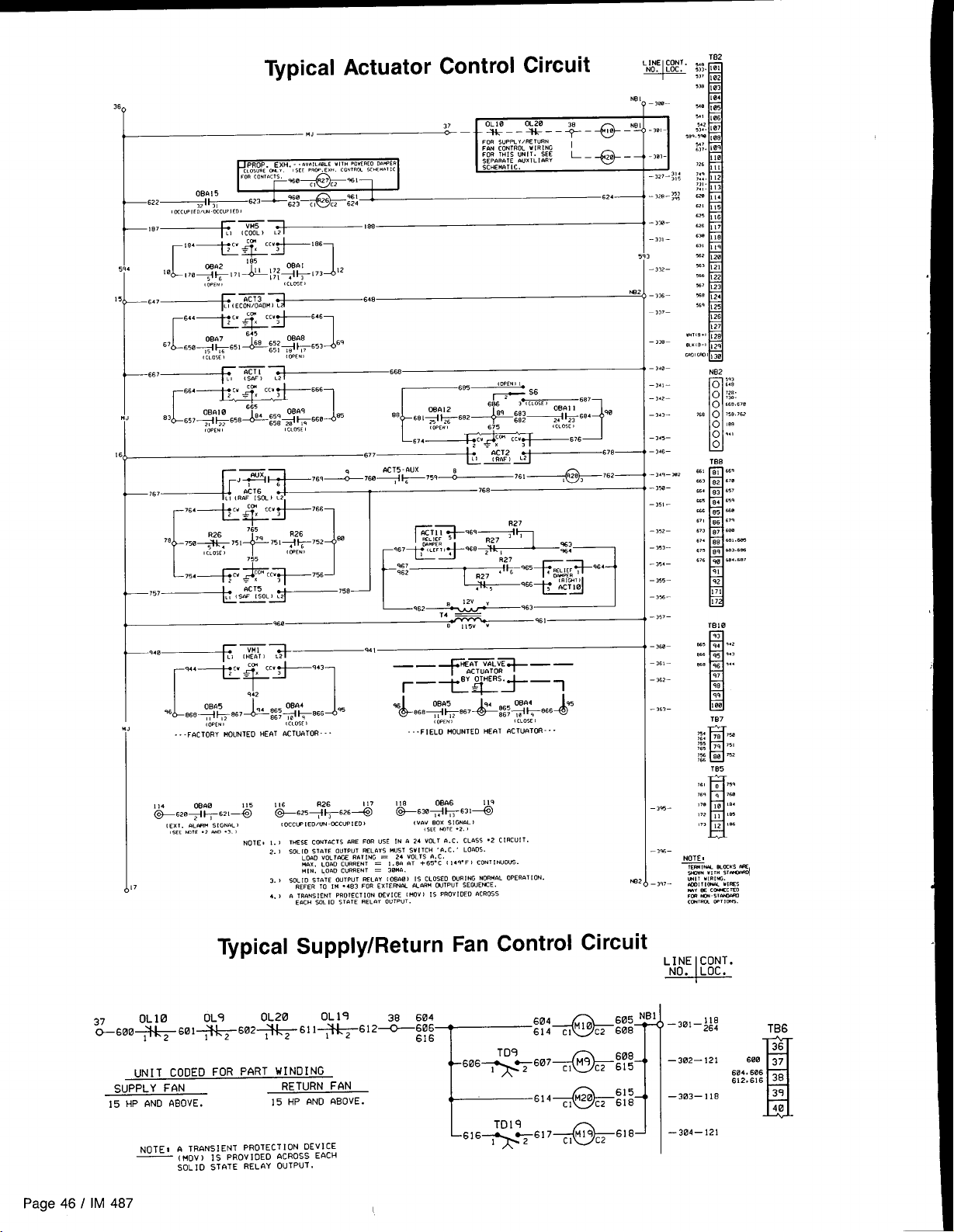

Typical Actuator Control Circuit . . . . . . . . . . . . . . . ...46

TypicalSupply/Return Fan Control Circuit, . . . . . . ...46

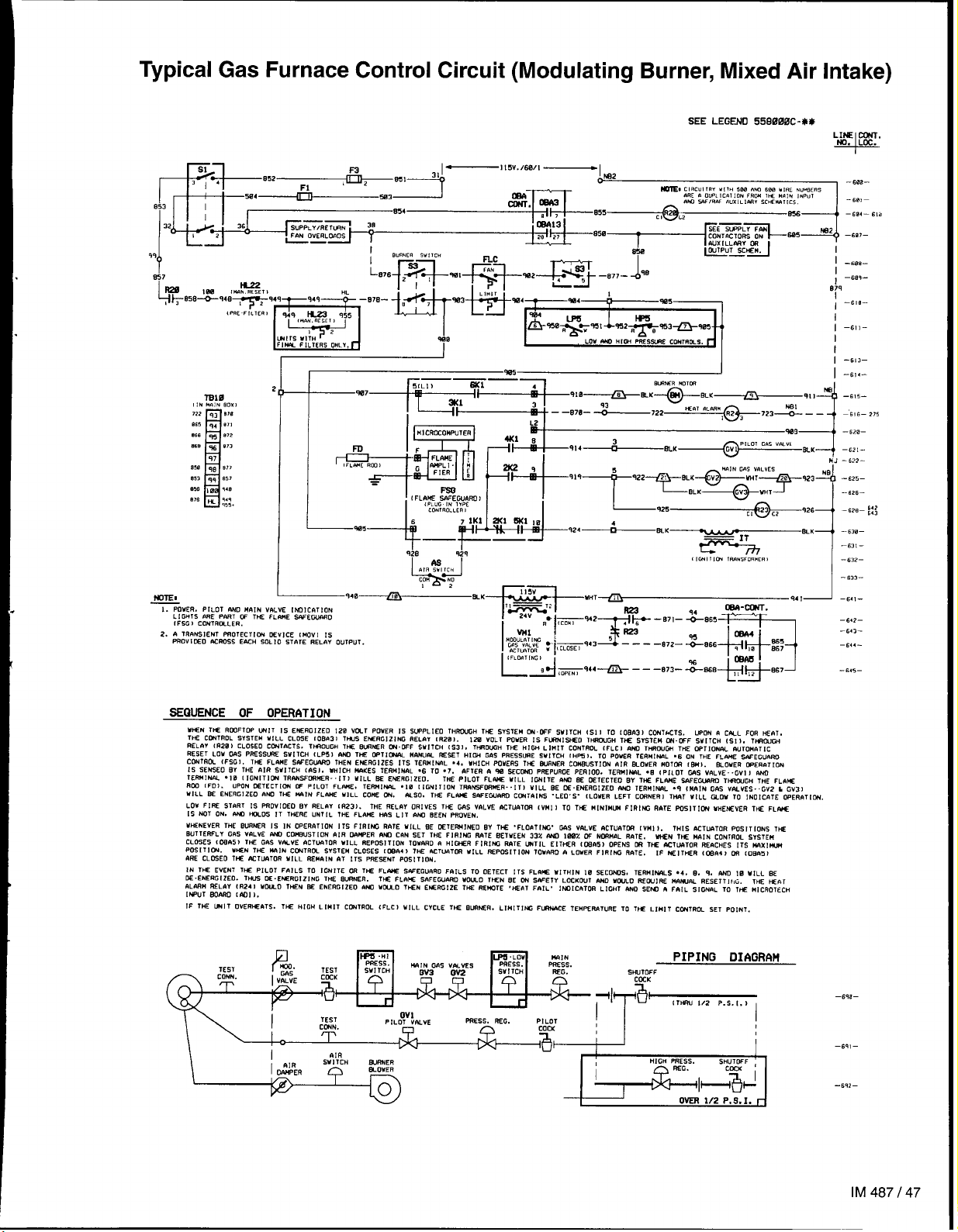

Typical Gas Furnace Control Circuit

(Modulating Burner, Mixed Air Intake) . . . . . . . . ...47

Typical Electric Heat Control Circuit (Multistage) . ...48

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Enthalpy Control . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Part Winding Start. , .,......, . . . . . . . . . . . . . . . ...49

Ground Fault Protection . . . . . . . . . . . . . . . . . . . . . ...49

Phase Voltage Monitor . . . . . . . . . . . . . . . . . . . . . . ...49

Optional Remote Monitoring and Control Panel . . ...50

Remote Monitor Panel . . . . . . . . . . . . . . . . . . . . . . ...50

External Time Clock, . . . . . . . . . . . . . . . . . . . . . . . ...50

Smoke Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . ...50

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . ...50

Duct High Pressure Limit . . . . . . . . . . . . . . . . . . . . ...51

Variable inlet Vanes . . . . . . . . . . . . . . . . . . . . . . . . ...51

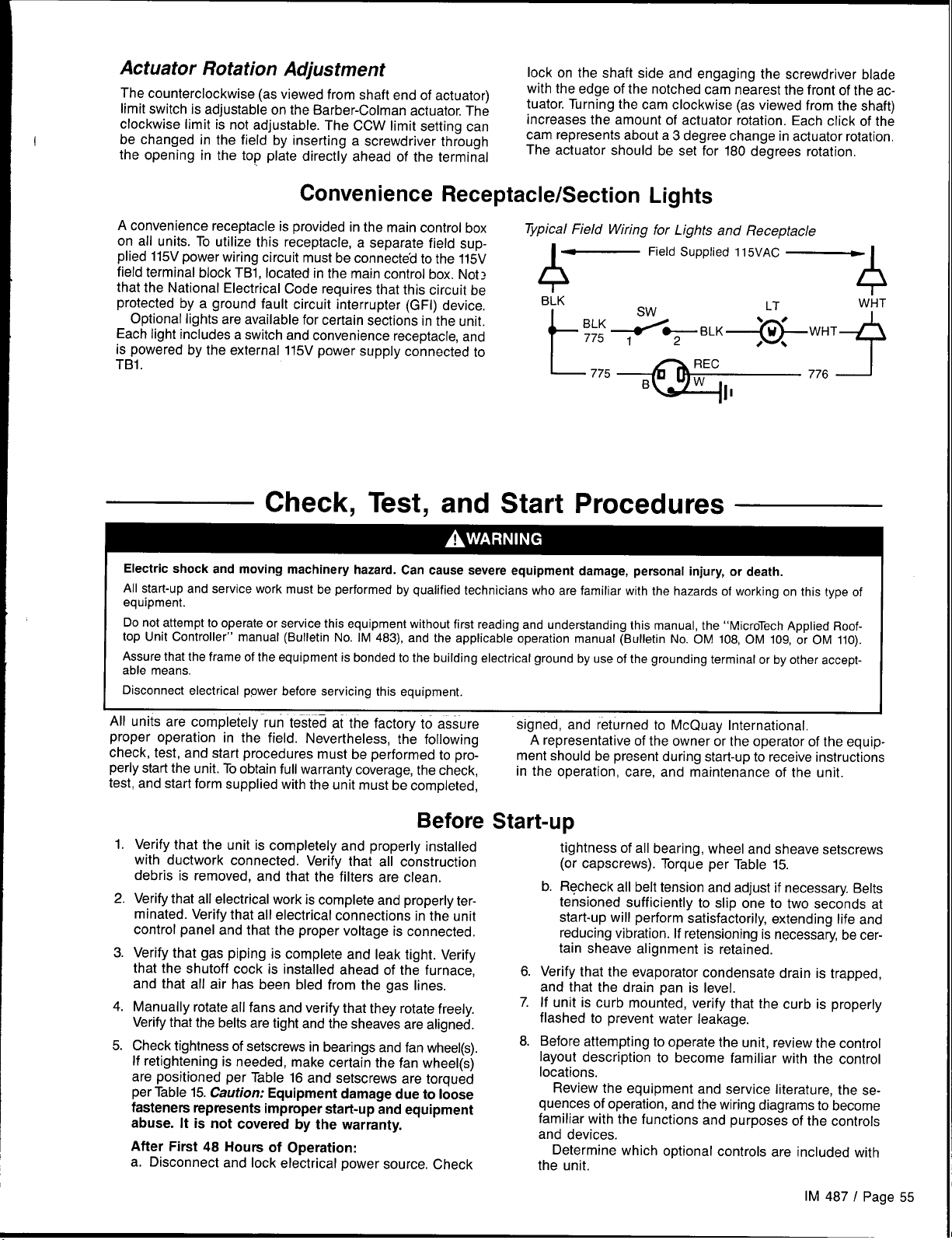

ConvenienceReceptacle/SectionLights . . . . . . . . ...55

Check, Test, and Start Procedures . . . . . . . . . . . . . ...55

Before Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...55

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...56

Fan Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...56

Economizer Start-up . . . . . . . . . . . . . . . . . . . . . . . . ...56

Heating System Start-up. . . . . . . . . . . . . . . . . . . . . ...57

Cooling System Start-up.....,.. . . . . . . . . . . . . . ...57

Adjusting MicroTech Controls&Servicing . . . . . . . ...57

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...58

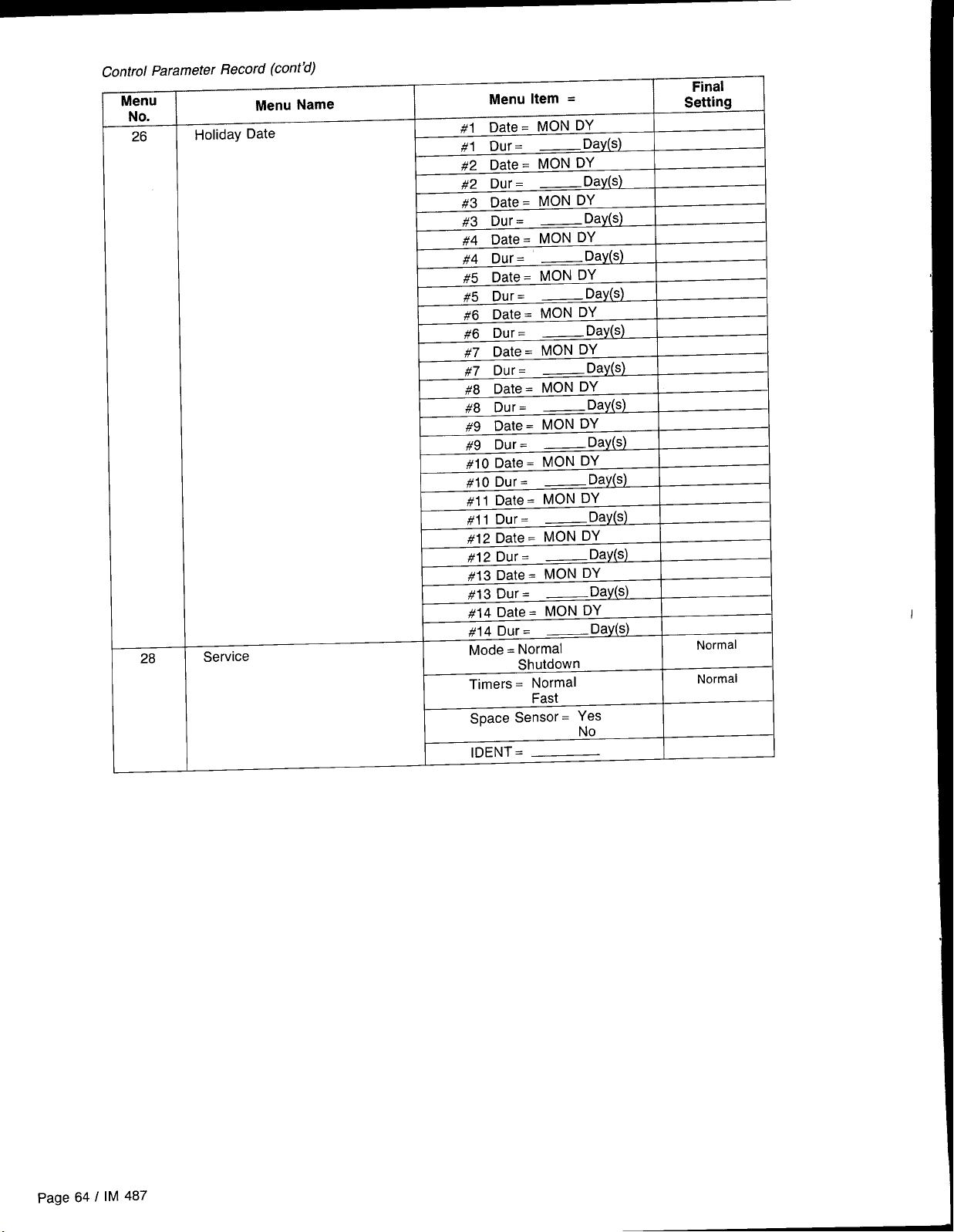

Final Control Settings . . . . . . . . . . . . . . . . . . . . . . . ...60

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...65

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . ...65

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...65

Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...65

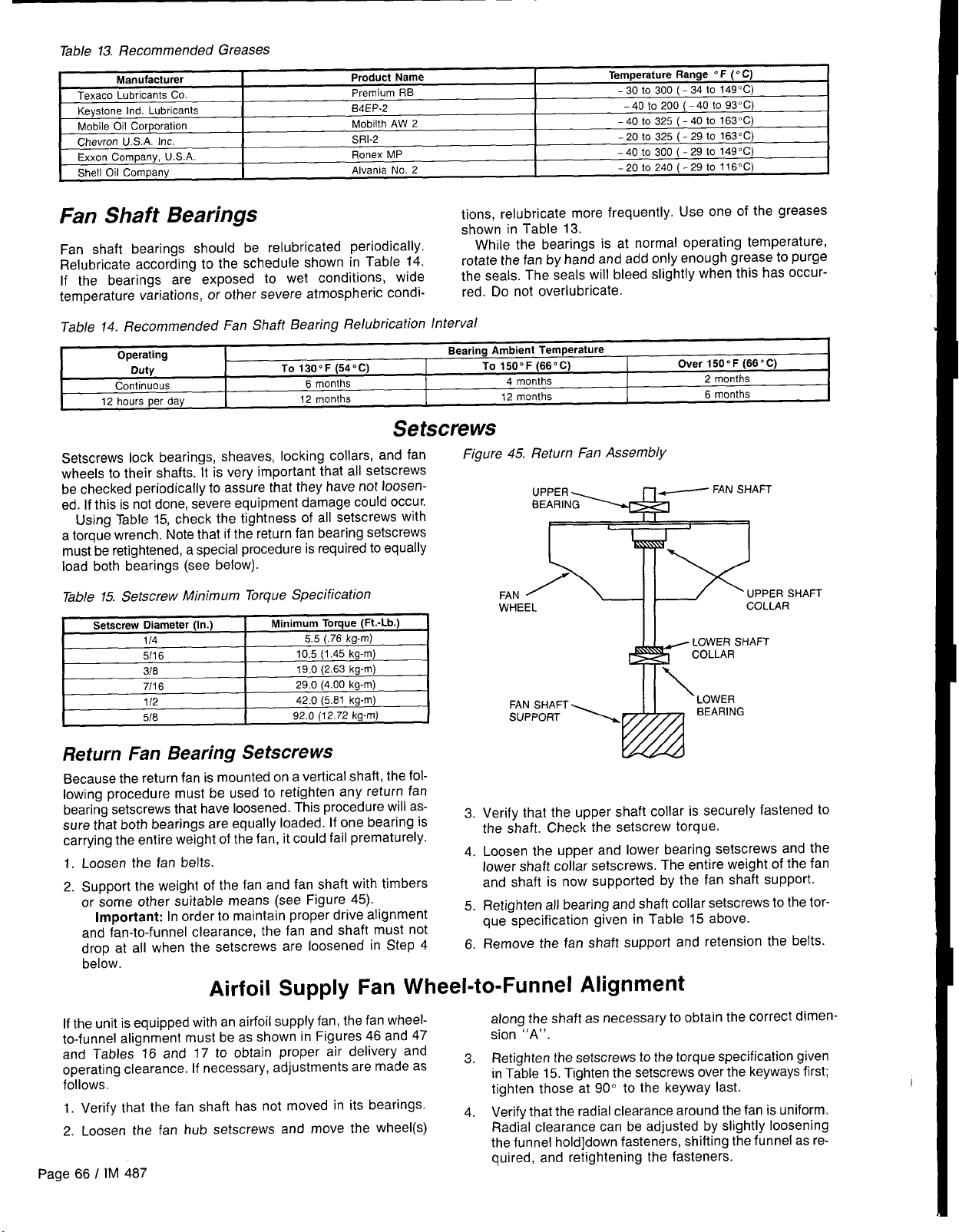

Bearing Lubrication, .,....... . . . . . . . . . . . . . . . ...65

Setscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...66

Airfoil Supply Fan Wheel-to-Funnel Alignment . . . ...66

Winterizing Water Coils. ..,.... . . . . . . . . . . . . . . ...67

Wiring Diagrams . . . . . . . . . . . ., . . . . . . . . . . . . . . . ...41

Legend, . . . . . . . . . . . . . . . . . . . . ., . . . . . . . . . . . . ...41

Typical Power Circuit With Power Pack Only. ,. . . ...42

Installation and maintenance are to be performed only by qualified personnel who are familiarwith local codes

and regulations, and experienced withthistypeof equipment. Caution: Sharpedgesand coilsurfacesare apotential

injury hazard. Avoid contact with them.

Page2/lM487

Service and Warranty Procedure . . . . . . . . . . . . . . ...67

In-Warranty Return Material Procedure . . . . . . . . . ...67

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . ...67

Product Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . ...68

Page 3

Introduction

This manual provides general information about the “C” vintage McQuay RoofPak applied rooftop unit, model RAH. In ad-

I

dition to an overall description of the unit, it includes mechanical and electrical installation procedures, commissioning procedures, sequence of operation information, and maintenance

instructions. For further information on the optional forced draft

gas fired furnace, refer to Bulletin No. IM 484.

The MicroTech Applied Rooftop Unit Controller is available

on “C” vintage roof mounted air handlers. For a detailed description of the MicroTech components, input/output configurations, field wiring options and requirements, and service procedures, refer to Bulletin No. IM 483, “MicroTech Applied Roof-

R AH

RoofPak

~~~~~e= [-

047 (Small Cabinet)

077 (Large Cabinet)

top Unit Controller.” For a description of operation and information on using and programming the MicroTech unit controller,

refer to the appropriate operation manual (see Table 1).

Table 1. Applied Rooftop Unit Operation Manual Literature

Variable Air

Constant Air Volume, Zone

Temperature Control (CAV-ZTC)

Constant Air Volume, Discharge

Temperature Control (CAV-DTC)

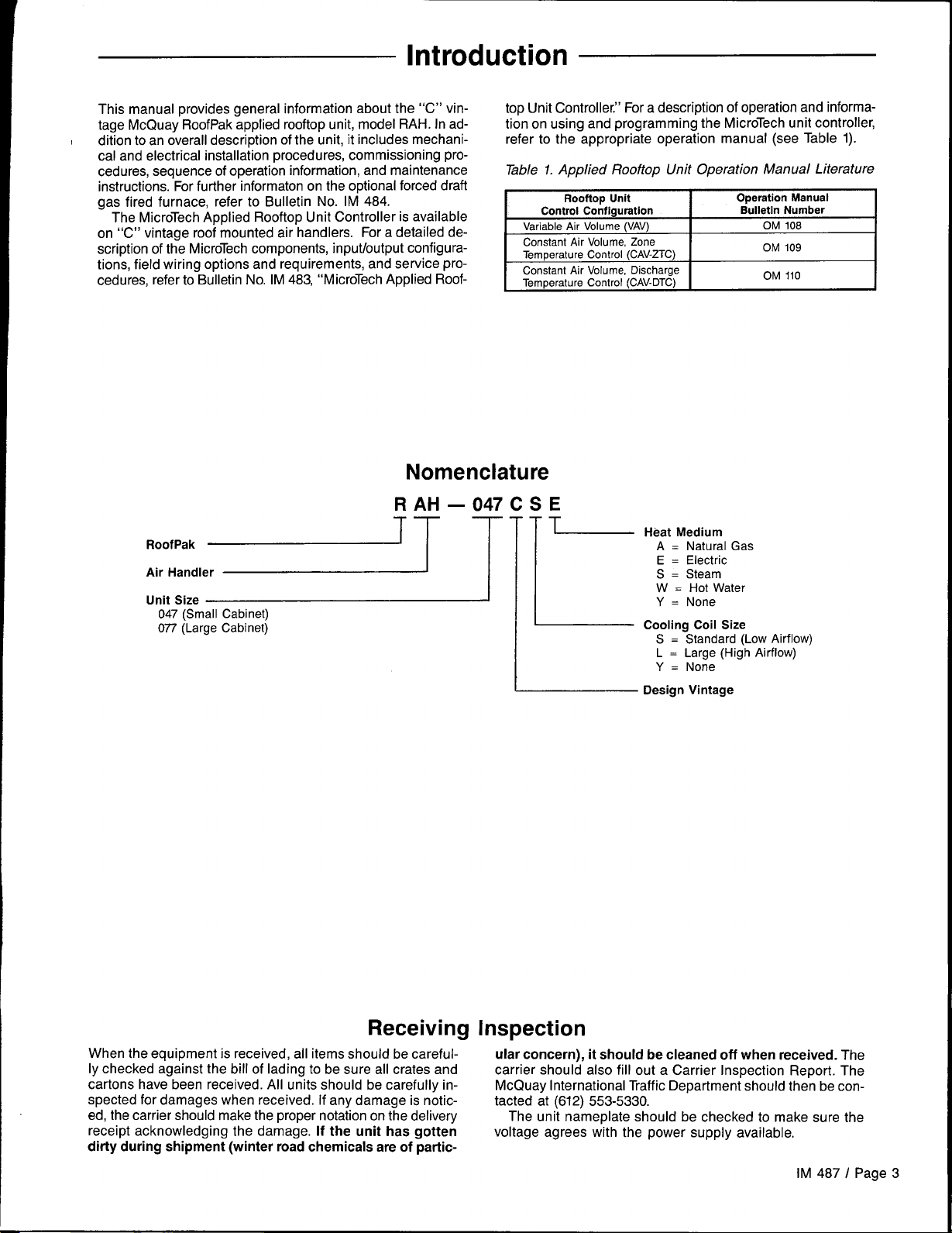

Nomenclature

–047CSE

1

~ Designvintage

Rooftop Unit

Control Configuration

Volume (VAV)

Operation Manual

Bulletin Number

OM 108

OM 109

OM 110

Heat Medium

A = Natural Gas

E = Electric

S .

Steam

W = Hot Water

Y = None

Cooling Coil Size

S = Standard (Low Airflow)

L = Large (High Airflow)

Y = None

Receiving

When the equipment is received, all items should be carefully checked against the bill of lading to be sure all crates and

cartons have been received. All units should be carefully inspected for damages when received. If any damage is noticed, the carrier should make the proper notation on the delivery

receipt acknowledging the damage.

dirty during shipment (winter road chemicals are of partic-

If the unit has gotten

Inspection

ular concern), it should be cleaned off when received. The

carrier should also fill out a Carrier Inspection Report. The

McQuay International Traffic Department should then be con-

tacted at (612) 553-5330.

The unit nameplate should be checked to make sure the

voltage agrees with the power supply available.

IM 487 I Page 3

Page 4

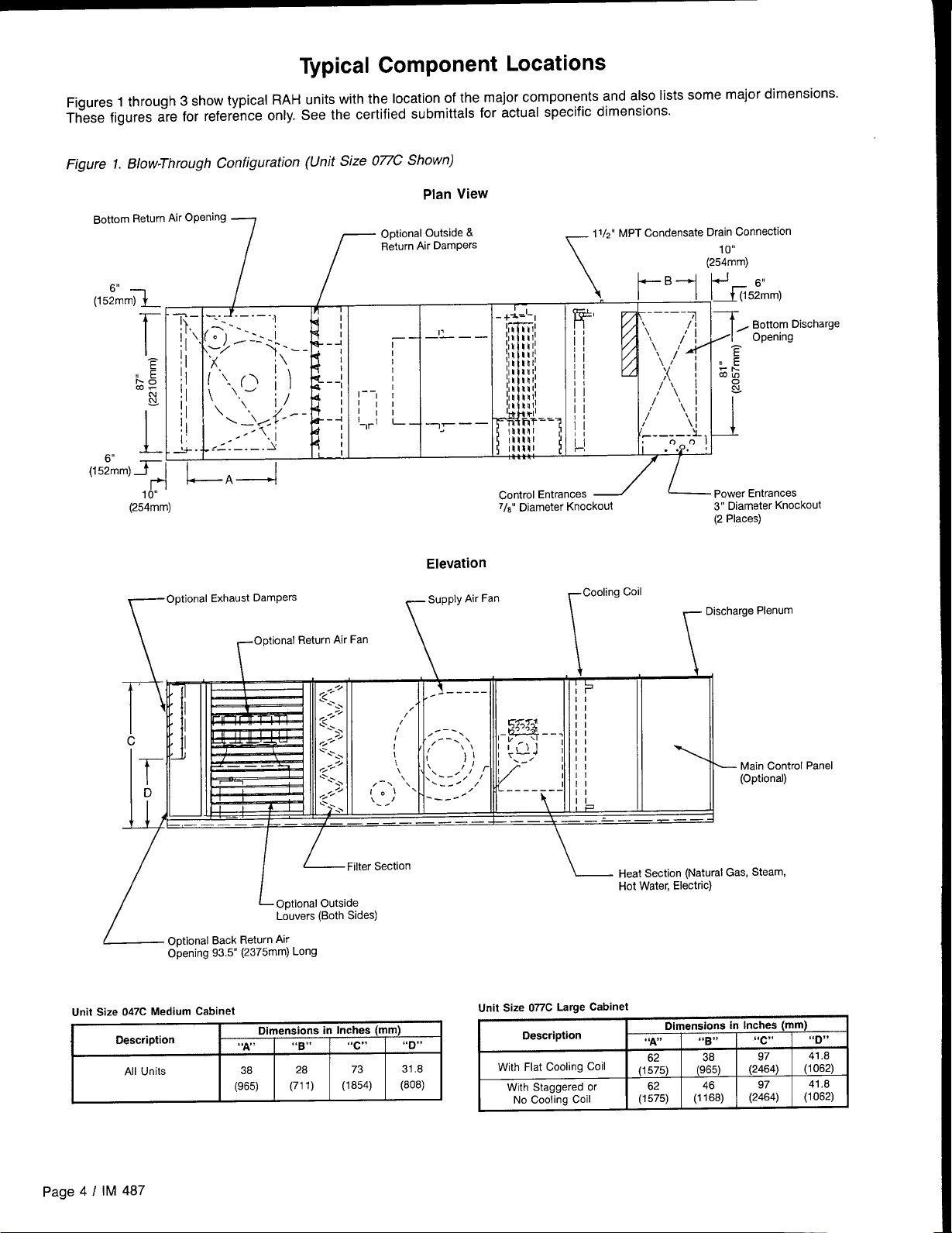

Typical Component Locations

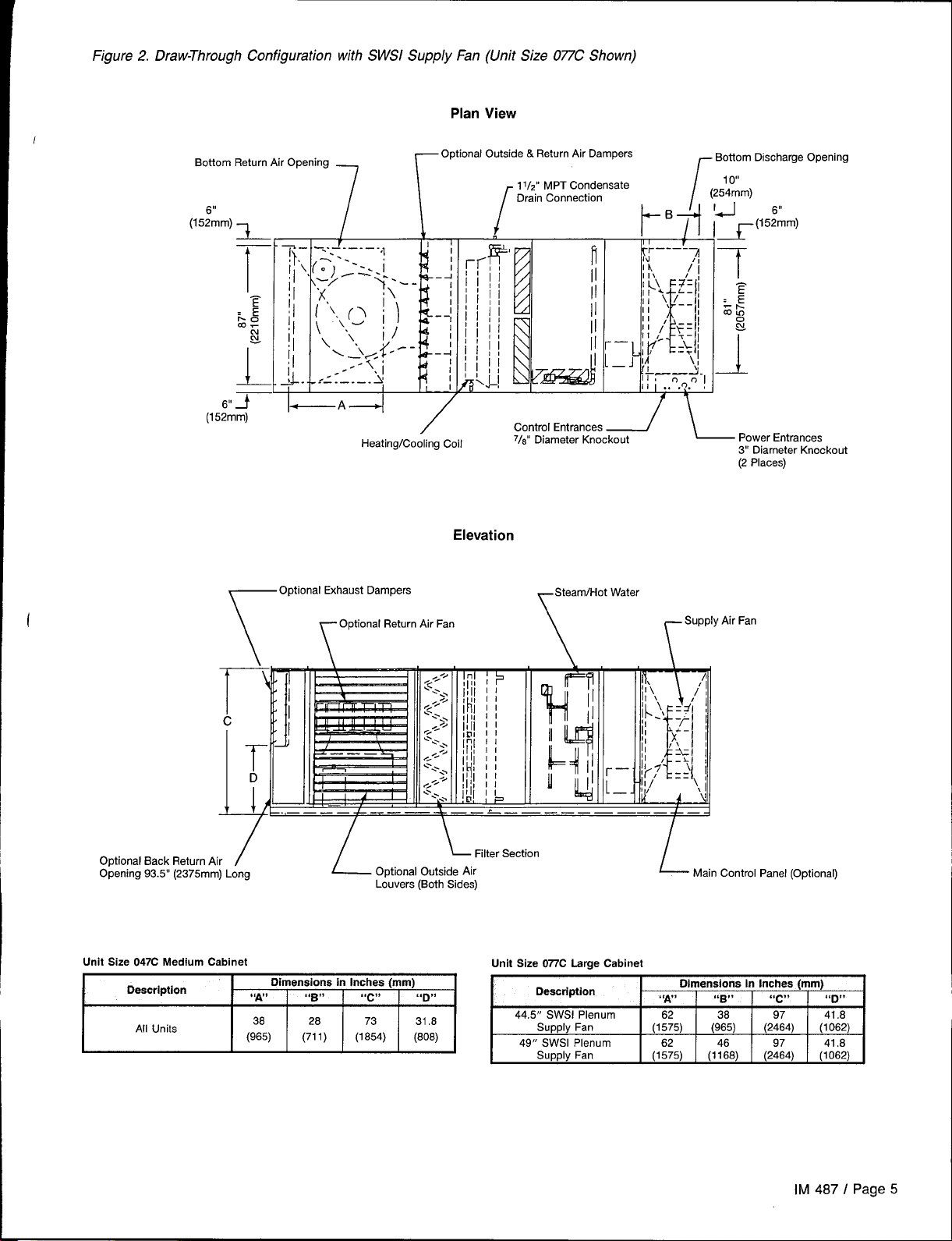

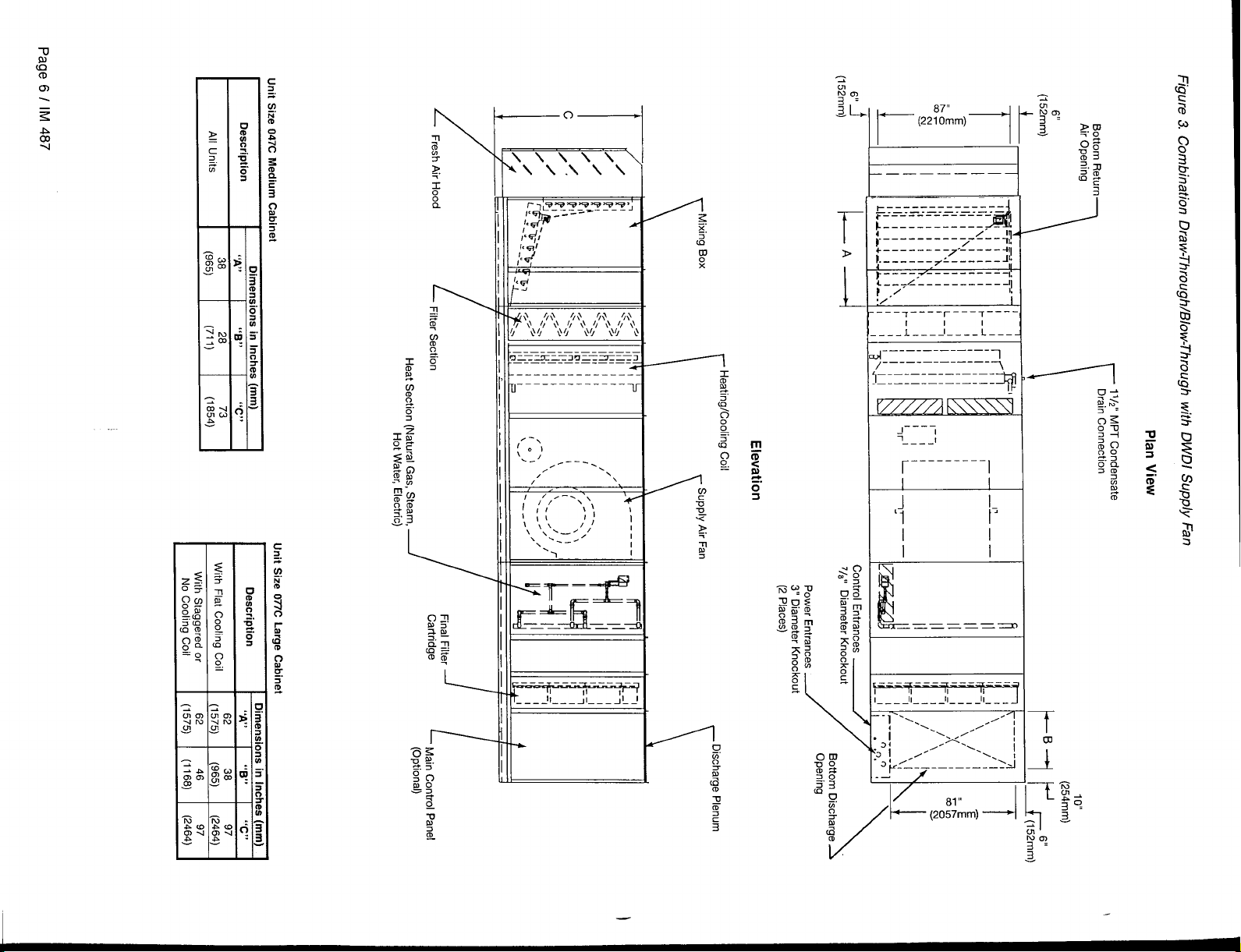

Figures 1 through 3 show typical RAH units with the location of the major components and also lists some major dimensions.

These figures are for reference only. See the certified submittals for actual specific dimensions.

Figure 1. Blow-Through Configuration (Unit Size 077C Shown)

Plan View

Bottom Return ~r Openin9 -

,,

(15;mm~

L

,!

(15;mm) ~

(254mm)

10“

r

I--A--I

optional Outside &

Return Air Dampers

f

11

—— —.

r

I

I

,-_l ~

l,,

l,,

I

-r’

-_——

L

Control Entrances _

7/*1’ Diameter Knockout

11/# MPTcondensateDrain Connection

‘I

/’

/’

/

j

(2J’mm)

L powerEntrances

3“ Diameter Knockout

(2 Places)

,,

, Bottom Discharge

Opening

Optional Exhaust Dampers

r

\ ‘r

,’

+ llL-==L=-1~

/

~ Optional Back Return Air

Unit Size 047C Medium Cabinet

II

/

Opening 93.5” (2375mm) Long

Optional Return Air Fan

,,./

g.

-.,

,,+

[<

.’.,

~,.,

-.

<.. .,

.,:/

G

/

L~i,tese.tiofl

L

Optional Outside

Louvers (Both Sides)

Elevation

supply Air Fan

T ‘i-

\

Cooling Coil

r

+

~.—----

.

/

i’

Unit Size 077C Large Cabinet

Description

With Flat Cooling Coil

Wth Staggered or

No Cooling Coil

II

,,

\

Heat Section (Natural Gas, Steam,

Hot Water, Electric)

“A”

(1$5)

(1:5)

Discharge Plenum

Main Control Panel

(Optional)

Dimensions in Inches (mm)

“B”

(::5)

(1%8)

“c.

(2%4)

(2:4)

“D,*

41.8

(1062)

41.6

(1062)

page 4 I IM 487

Page 5

Figure 2. Draw-Through Configuration with SWSI Supply Fan (Unit Size 077C Shown)

Plan View

Optional

Bottom Return Air Opening

1

r

Outside & Return Air Dampers

1Ilz” MPT Condensate

Drain Connection

r

Bottom 13scharge Opening

r

10’”

(254mm)

I

~Bfl ‘~(15.%m)

~——~.

11,

II . .

~.o.

01

\

l-]

c

1[

7“’

Optional Back Return Air

Opening 93.5” (2375 mm) Long

Heating/Cooling Coil

Optional Exhaust Dampers

Optional Return Air Fan

\

T

D

I

/

r

.——_———.——_.—————————

L

/

Elevation

\ I

L ~lter section

Optional Outside Air

Louvers (Both Sides)

Control Entrances _

718”Diameter Knockout

-+-t

Water

\

Supply Air Fan

Power Entrances

3“ Diameter Knockout

(2 Places)

r

.

L-

Main Control Panel (Optional)

Lrnit siZe 047C Medium Cabinet

~

Unit Size 077’CLarge Cabinet

~

IM 487 I Page 5

Page 6

——— ————— .

~_____-–––-––__

—.—.—.—.—.—.—.—

*-------------

L------------, - !

;-----

----– –,- Z--114

+--- ___7______4,,4,,

>

L______7L__-_--Jlo

F--–-.+-––-----1!

Jai!

w

:/’

L

-––7----r–_–T____

---1--__l–---:____

~.–-– -—————-—-

,-—-—-—

~_-–- —_—-—-———-

-—-—

J

1

-—--

~---- —----

I

7’

—————

—————.

IL

—---—- -—-

II

l_–__ll____ll____ll____

I

!

1, 11

q

+

I

I

I

=x

-—--

I

T

al

v

q-

5

I/

I

—

Page 7

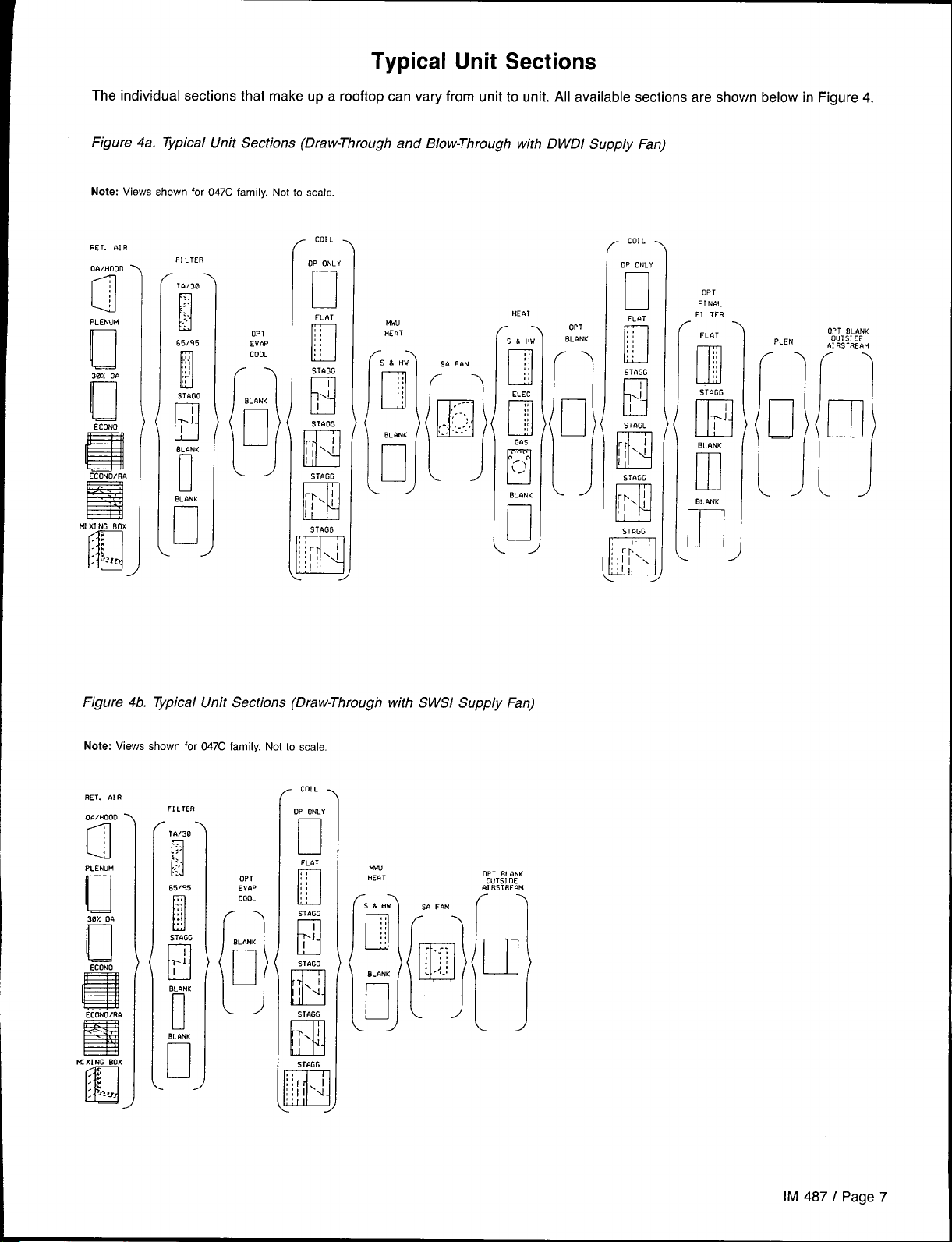

Typical Unit Sections

—

The individual sections that make up a rooftop can vary from unit to unit. All available sections are shown below in Figure 4.

Figure 4a. Typical Unit Sections (Draw-Through and Blow-Through with DWDI Supply Fan)

Note: Views shown for 047C family. Not to scale

RET.&lR

0~/HOOD‘

a

PLENUM

u

30L DA

II

ECONO

s

ECONO/R&

R

MlXlNCBOX

,:

.:

: !0,,

n

OPT

EV&P

COOL

8LANK

n

[:

?- . ...,

!. /---

❑

[1

S6 FfiN

,----

,-,

--

II

---

PLEN

J

Figure 4b. ~pical Unit Sections (Draw-Through with SWSI Supply Fan)

Note: Views shown for 047C family. Not to scale.

FILTER

-.

TA/30

:>

:.

,:

i

65/95

,!

“$;

,,

.,

,,

[

STAGG

pl

I

OL~NK

[

OLONK

u

OPT

EVR?

COOL

.

BLANK

u

1

.

/

h-w

HEbT

IM 487 I Page 7

Page 8

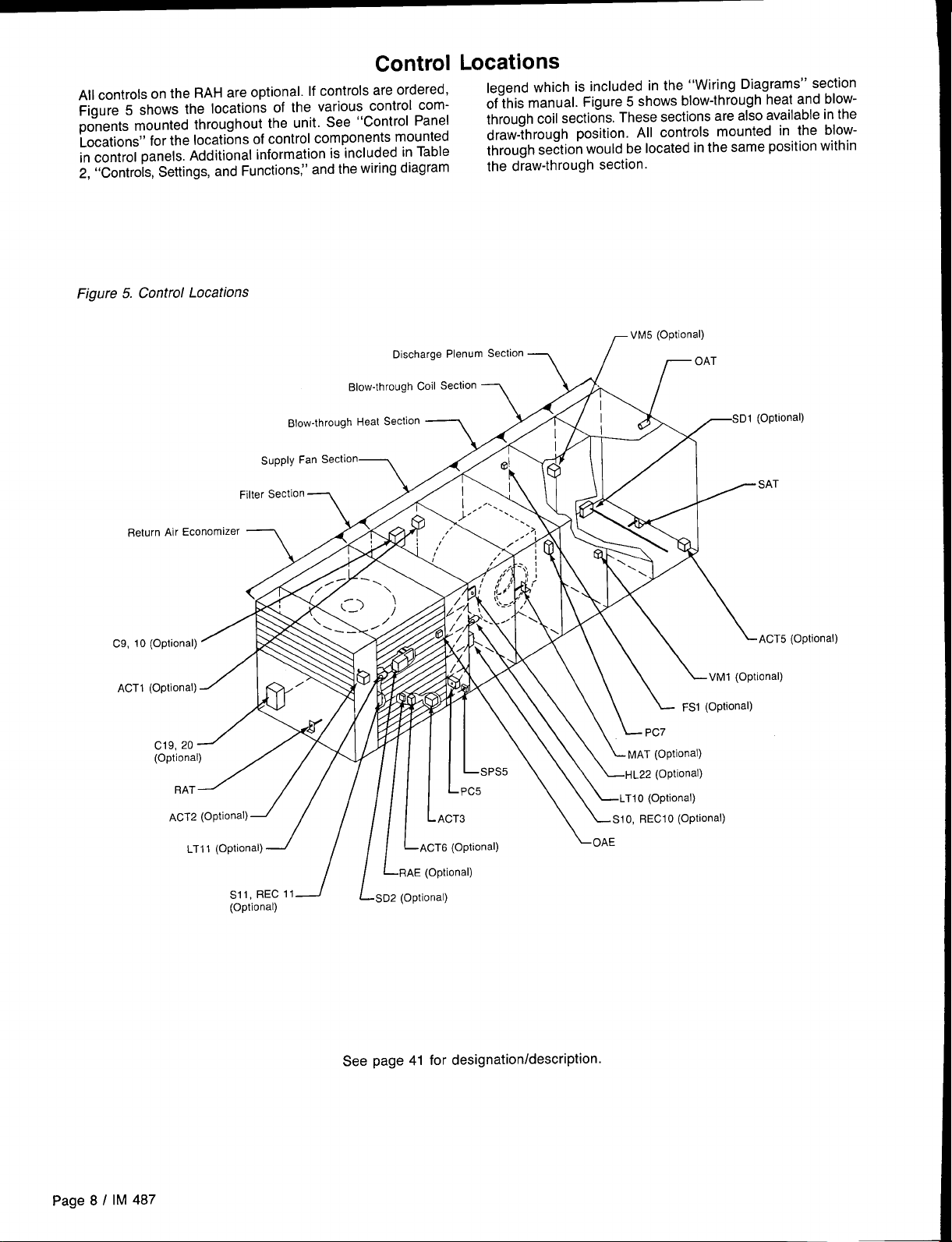

Control Locations

All controls on the RAH are optional. If controls are ordered,

Figure 5 shows the locations of the various control components mounted throughout the unit. See “Control Panel

Locations” for the locations of control components mounted

in control panels. Additional information is included in Table

2, “Controls, Settings, and Functions,” and the wiring diagram

Figure 5. Control Locations

Oischarge Plenum Section

Blow-through coil SeCtiOn

legend which is included in the ‘rWiring Diagrams” section

of this manual. Figure 5 shows blow-through heat and blowthrough coil sections. These sections are also available in the

draw-through position. All controls mounted in the blowthrough section would be located in the same position within

the draw-through section.

Return Air Economizer _

C9, 10 (Optional)

ACT1 (Optional)

C19, 20

(Optiona

RAT

ACT2

LTI 1 (OptiOnal)

SUpply Fan Section

Filter SeCtiOn

-/

SII, REC1l

(Optional)

Blow-through Heat

7

Fka

1 [[

Section

SD2 (Optional)

L

ACT6 (Optional)

RAE (Optional)

\\l v-’\ \ \

\oA,

SD1 (Optional)

~ SAT

\~cT~

VM1 (Optional)

Optional)

(Optional)

Page 8 / IM 487

See page 41 for designationldescription.

Page 9

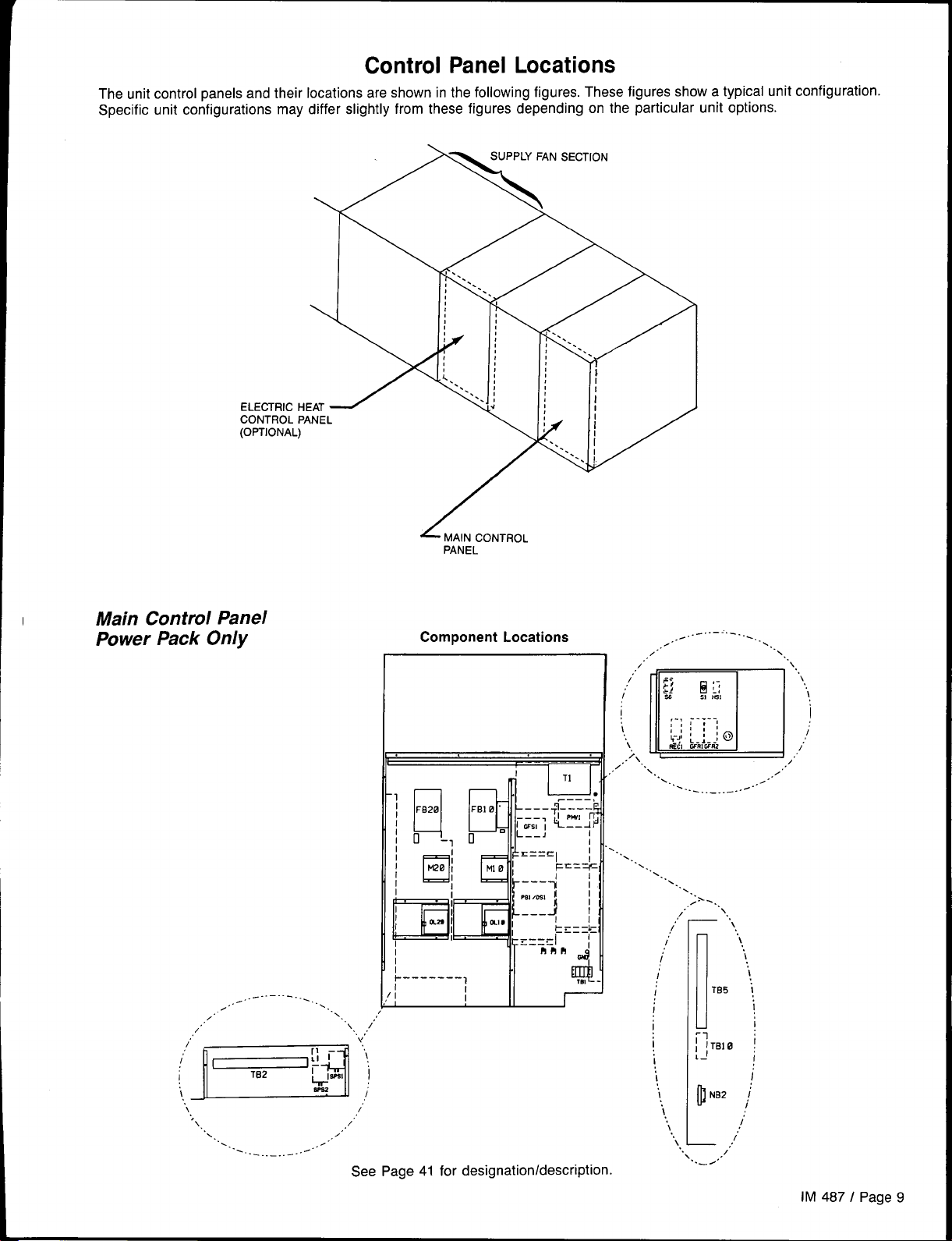

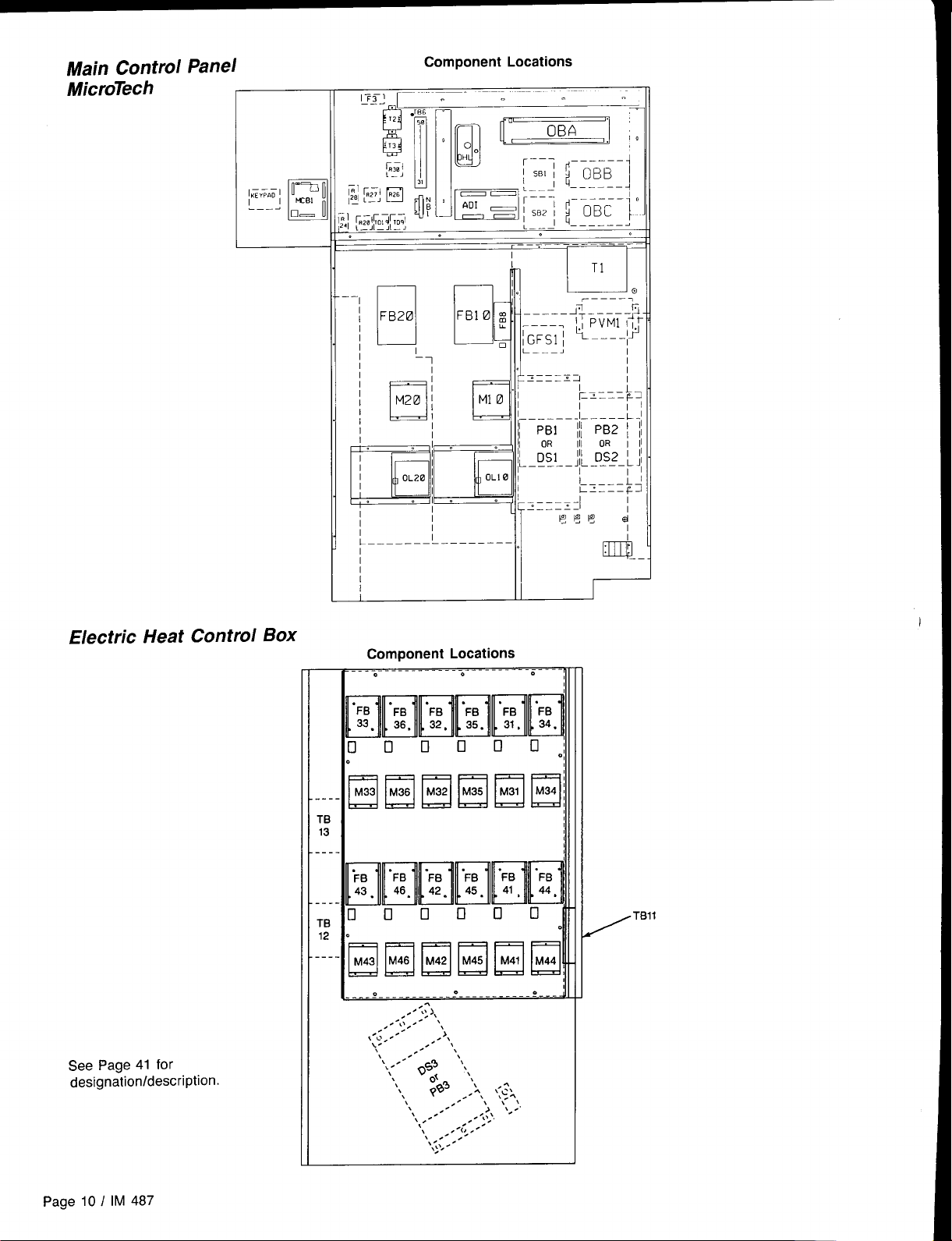

Control Panel Locations

The unit control panels and their locations are shown in the following figures. These figures show a typical unit configuration.

Specific unit configurations may differ slightly from these figures depending on the particular unit options.

Main Control Panel

Power Pack Only

..-” ”— ”---- . ..

/.”.

~~

(bii‘“

\ /’

‘>\

,.

,.

.. .

.. ... ... ..- ... .

PANEL

Component Locations

.

..

1’

\

~,.,

\,

‘ “.

;

/’

,,

,/

./.

See Page 41 for designationldescription.

~..-.. —-----

”

.,.

,/’

./

/’ --

fj

i

%

,., . . . . .

\

‘.lm

,/’” ..

,! ::;

,,

+-.!:-:--: @)

\

RE61WRIWM

~\

x.

.,. ,

. ..

I

i

I

I

1,

“..b /

\

. ... ... ..-

\

1 ~

\

..

\

----

~;,

rB5 I

rBl 0 !

,./

,./

. .

.,

..

..-

\

\

\

I

I

I

;

;

...

‘\

,.

\

\

I

i

/’

/’

,.

/

IM 487 I Page

9

Page 10

Main Control Panel

---

IKE”P.D/

.——.

‘L

0===[

❑ —

Component Locations

I r

T1

. .

M2@

I

u

c

u

Control

Box

—

Component Locations

.

..-

Elmml!q

TB

13

---

..TB

12

---

I

.

II

I

I

I

/“”

See Page41 for

designation/description.

Page 10 / IM 487

\- “,

‘.””’”OS: ‘N,

\

\

\

pf$’ ,,.1, ‘-’

\

\

\

,.

\

,.

\

.,. -

,.-,[:, .

\

‘,,(; , .

.

\

\

. ~,

,.’ ;’. ,

‘,::’-,

\z.,

Page 11

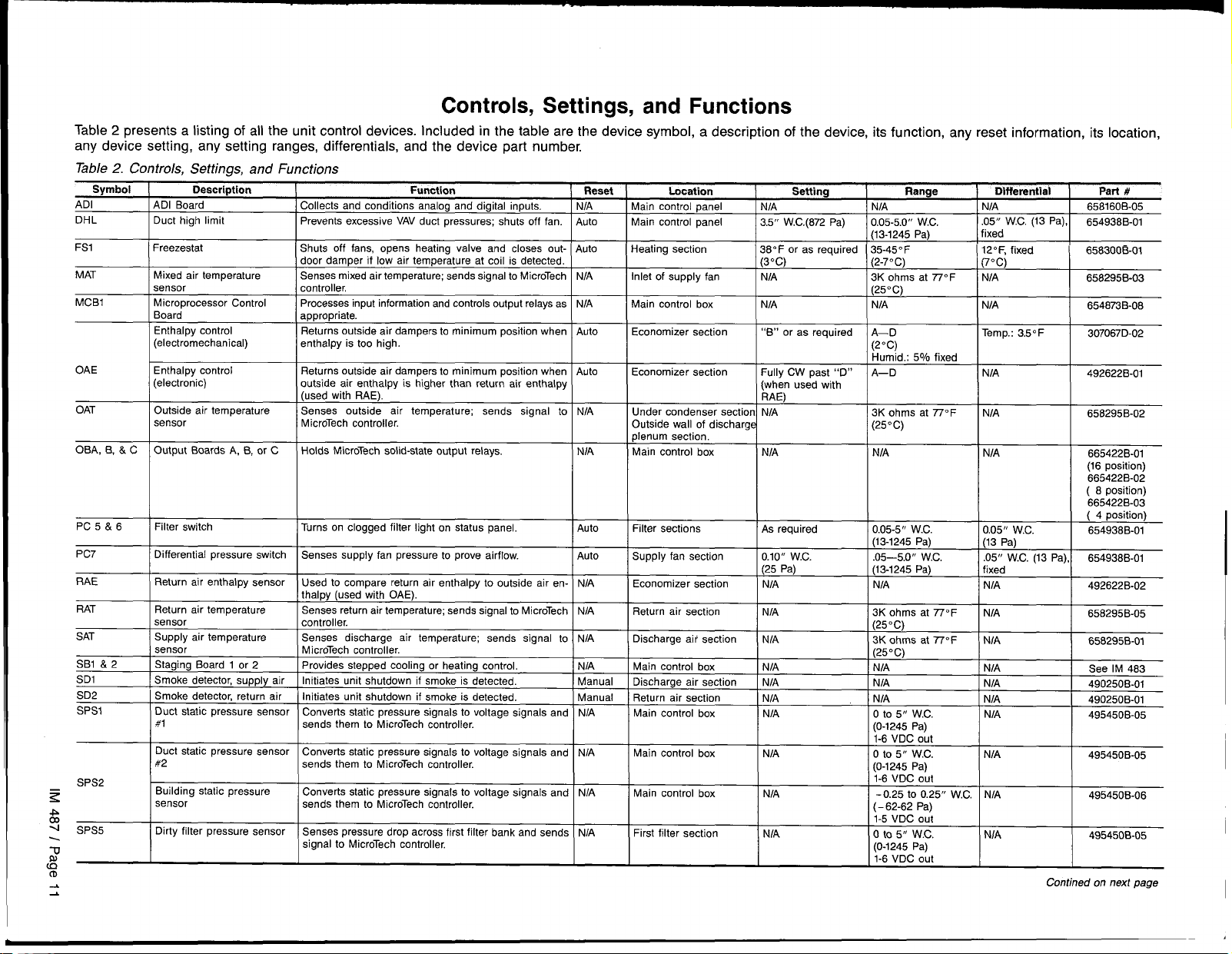

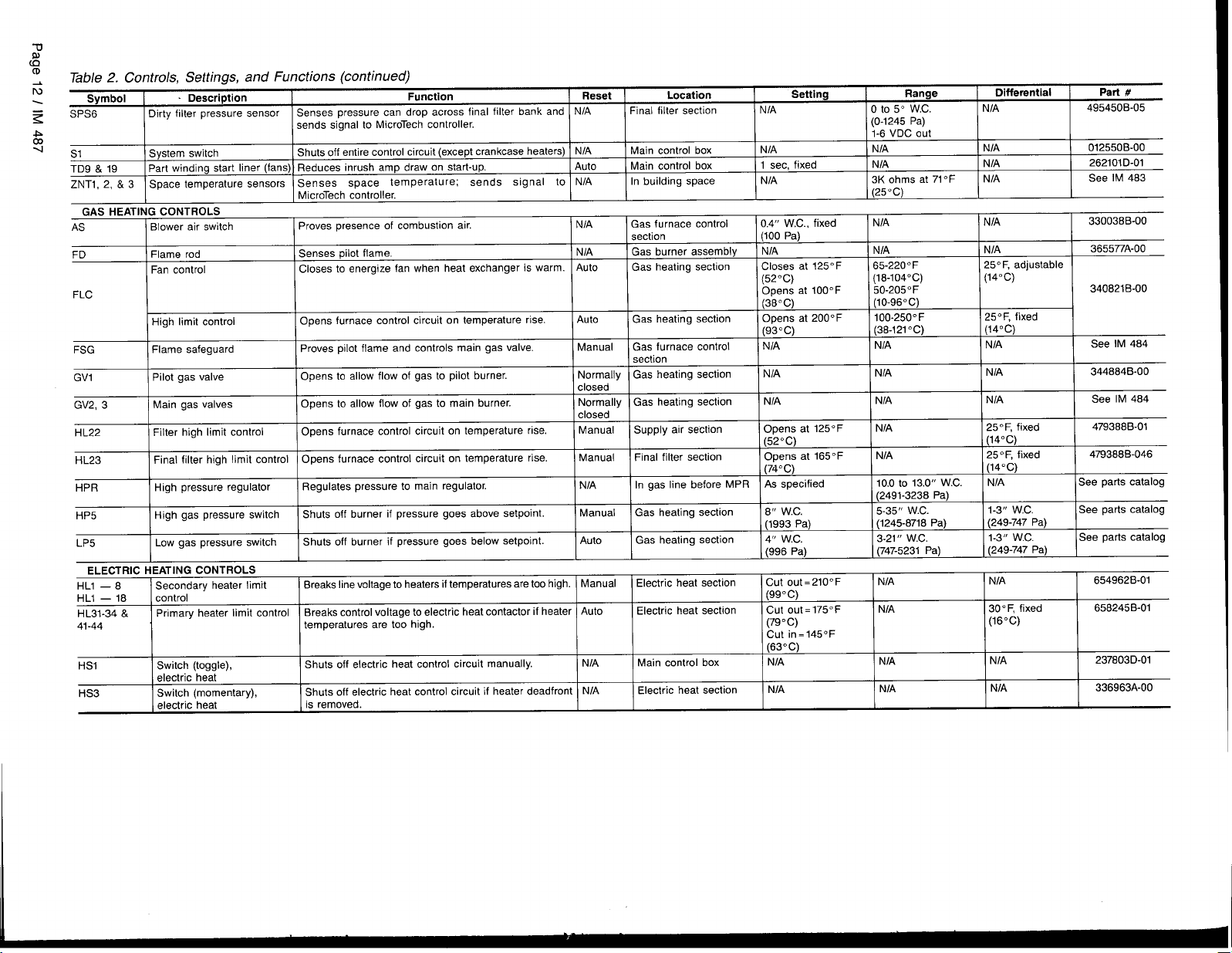

Controls, Settings, and Functions

Table 2 presents a listing of all the unit control devices. Included in the table are the device symbol, a description of the device, its function, any reset information, its location,

any device setting, any setting ranges, differentials, and the device part number.

Table 2. Controls, Settings, and Functions

Symbol

ADI

DHL

FS1

MAT

MCB1

OAE

OAT

OBA, B, & C

PC 5&6

PC?

Description

ADI Board

Duct high limit

Freezestat

Mixed air temperature

sensor

Microprocessor Control

Board

Enthalpy control

(electromechanical)

Enthalpy control

(electronic)

Outside air temperature

sensor

Output Boards A, B, or C

Filter switch

Differential pressure switch

Function

Collects and conditions

Prevents excessive VAV duct pressures; shuts

Shuts off fans, opens heating valve and closes outdoor damper if low air temperature at coil is detected.

Senses mixed air temperature; sends signal to MicroTech

controller,

Processes input information and controls output relays as

appropriate.

Returns outside air dampers to minimum position when Auto

enthalpy is too high.

Returns outside air dampers to minimum position when Auto

outside air enthalpy is higher than return air enthalpy

(used with RAE).

Senses outside air temperature; sends signal to

MicroTech controller.

Holds MicroTech solid-state output relays.

Turns on clogged filter light on status panel.

Senses supply fan pressure to prove airflow.

analog and digital inputs. NIA

off fan. Auto

Auto

NIA

NIA

NIA

NIA

Auto

Auto

Reset

I

Location

Main control

Main control panel

Heating section

I

Inlet of supply fan

Main control box

Economizer section

Economizer section

Under condenser section N/A

Outside wall of discharge (25”C)

plenum section.

Main control box

panel NIA

Setting

NIA

3.5” W.C.(872 Pa)

38° F or as required

(3”C)

NIA 3K ohms at 77° F

I N/A

“B” or as required A—O

Fully CW past “D” A—D

(when used with

RAE)

NIA NIA

0.05-5.0” W.c,

(13-1245 Pa)

35-450 F

(2-7oC)

(25”C)

I NIA

(20c)

Humid.: 50/o fixed

3K ohms at 77° F

Range

Dlfferentisl

UIA

05” W.C. (13 Pa),

ixed

+

+

+

NIA

0.05” WC.

Part #

858160B-05

654938B-01

665422B-01

(16 position)

665422B-02

( 8 position)

665422B-03

( 4 position)

654936B-01

RAE

RAT

SAT

SB1 & 2

SD1

SD2

SPS1

SPS2

z

*

co

+

SPS5

\

-o

&

CD

Return air enthalpy sensor

Return air temperature

sensor

Supply air temperature

sensor

Staging Board 1 or 2

Smoke detector, supply air

Smoke detector, return air

Duct static pressure sensor Converts static pressure signals to voltage signals and

#1

Duct static pressure sensor COMKMS static pressure signals to voltage signals and

#2

Building static pressure

sensor

Dirty filter pressure sensor

Used to compare return air enthalpy to outside air en-

thalpy (used with OAE).

Senses return air temperature; sends signal to MicroTech NIA

controller.

Senses discharge air temperature; sends signal to

MicroTech controller.

Provides stepped cooling or heating control.

Initiates unit shutdown if smoke is detected.

Initiates unit shutdown if smoke is detected.

sends them to MicroTech controller.

sends them to MicroTech controller.

Converts static pressure signals to voltage signals and NIA

sends them to MicroTech controller.

Senses pressure drop across first filter bank and sends NIA

signal to MicroTech controller,

NIA

NIA

NIA

Manual

Manual

NIA

NIA

Return air section

Discharge air section

Main control box

Discharge air section

Return air section

Main control box

Main control box

I I

I NIA I 3K ohms at 770F

I NIA

NIA NIA

NIA

I NIA I NIA

] N/A

NIA o to 5 ‘f WC.

I (25”C)

13K ohms at 7T” F

(25oC)

NIA

Io to 5“ WC.

(0-1245 Pa)

1-8 VDC out

N/A

NIA

N[A

NIA

I 6582!35B-05

I

658295B-01

I

495450B-05

I

1

495450B-05

I

Contined on next page

Page 12

CD

Table 2. Controls, Settings, and Functions (continued)

N

z

.P

co

4

Symbol

SPS6

S1 System switch

TD9 & 19 Part winding start liner (fans) Reduces inrush amp draw on start-up.

ZNT1, 2, & 3 Space temperature sensors Senses space temperature; sends signal to

GAS HEATI

NG CONTROLS

AS

FD

FLC

FSG Flame safeguard Proves pilot flame and controls main gas valve.

GV1 Pilot gas valve Opens to allow flow of gas to pilot burner.

GV2, 3

HL22 Filter high limit control Opens furnace control circuit on temperature rise.

HL23 Final filter high limit control Opens furnace control circuit on temperature rise.

HPR High pressure regulator Regulates pressure to main regulator.

HP5 High gas pressure switch Shuts off burner if pressure goes above setpoint.

LP5 Low gas pressure switch

Description Function

Dirty filter pressure sensor Senses pressure can drop across final filter bank and

air switch

Blower

Flame rod

Fan control Closes to energize fan when heat exchanger is warm. Auto

High limit control

Main gas valves Opens to allow flow of gas to main burner.

sends signal to MicroTech controller.

Shuts off entire control circuit (except crankcase heaters)

MicroTech controller.

Proves presence of combustion air.

Senses pilot flame.

Opens furnace control circuit on temperature rise.

Shuts off burner if pressure goes below setpoint.

ELECTRIC HEATING CONTROLS

HL1 — 8

HL1 — 18

HL31-34 & Primary heater limit control

41-44 temperatures are too high.

HS1

HS3 Switch (momentary), Shuts off electric heat control circuit if heater dead front

Secondary heater limit

control

Switch (toggle),

electric heat

electric heat is removed.

Breaks line voltage to heaters if temperatures are too high.

Breaks control voltage to electric heat contactor if heater

Shuts off electric heat control circuit manually.

Reset Location

NIA

NIA

Auto

NIA

N/A

N/A Gas burner assembly

Auto Gas heating section

Manual

Normally Gas heating section

closed

Normally Gas heating section

closed

Manual Supply air section Opens at 125° F

Manual

N/A

Manual

Auto Gas heating section

Manual

Auto

N/A

N/A

Final filter section NIA

Main control box

Main control box 1 see, fixed

In building space N/A

Gas furnace control 0.4” WC., fixed

section

Gas heating section Closes at 125° F

Gas furnace control

section

Final filter section

In gas line before MPR

Gas heating section 6“ W.C,

Electric heat section Cut out=210° F

Electric heat section Cut out=175° F

Main control box NIA

Electric heat section

Setting

N/A

(100 Pa)

N/A

(52”C)

Opens at 100” F

(36oC)

Opens at 200” F

(93”C)

NIA

NIA

N/A

(52°C)

Opens at 1650F

(74”C)

As specified

(1993 Pa)

4“ W.c.

(996 Pa)

(99”C)

(79”C)

Cut in=145° F

(63oC)

NIA

Range

o to 5“ W.c.

(0-1245 Pa)

1-6 VDC out

NIA

N/A

3K ohms at 71° F

(25”C)

N/A

NIA NIA

65-220” F

(18-104°C)

50-205° F

(10-96oC)

100-2500 F

(38-121”C)

NIA N/A

N/A

NIA

N/A

N/A

10.0to 13.0” W.c.

(2491-3238 Pa)

5-35 ‘c W.c.

(1245-8718 Pa) (249-747 Pa)

3-21“ W.C.

(747-5231 Pa)

N/A

NIA

NIA

NIA

Differential Part #

N/A 495450B-05

NIA 012550B-00

N/A

NIA

NIA

25° F, adjustable

(14”C)

250 F, fixed

(14”C)

N/A 344864B-00

N/A See IM 484

250 F, fixed 479388B-01

(14”C)

25” F, fixed 479388 B-046

(14”C)

NIA See parts catalog

1-3” WC, See parts catalog

1-3“ W.c. See parts catalog

(249-747 Pa)

NIA

300 F, fixed 658245B-01

(16”C)

NIA

NIA 336963A-00

262101D-O1

See IM 483

330036B-00

365577A-00

340821B-00

See IM 484

654962B-01

237803D-01

Page 13

Mechanical Installation

The installation of this equipment shall be in accordance with

the regulations of authorities having jurisdiction and all applicable codes. It is the responsibility of the installer to determine and follow the applicable codes.

Unit Clearances

Service Clearance

Sharp edges are inherent to sheet metal parts, screws,

clips, and similar items. Can cause personal injury.

This equipment is to be installed and operated only by an experienced installation company and fully trained personnel.

Exercise caution when servicing equipment.

I

I

I

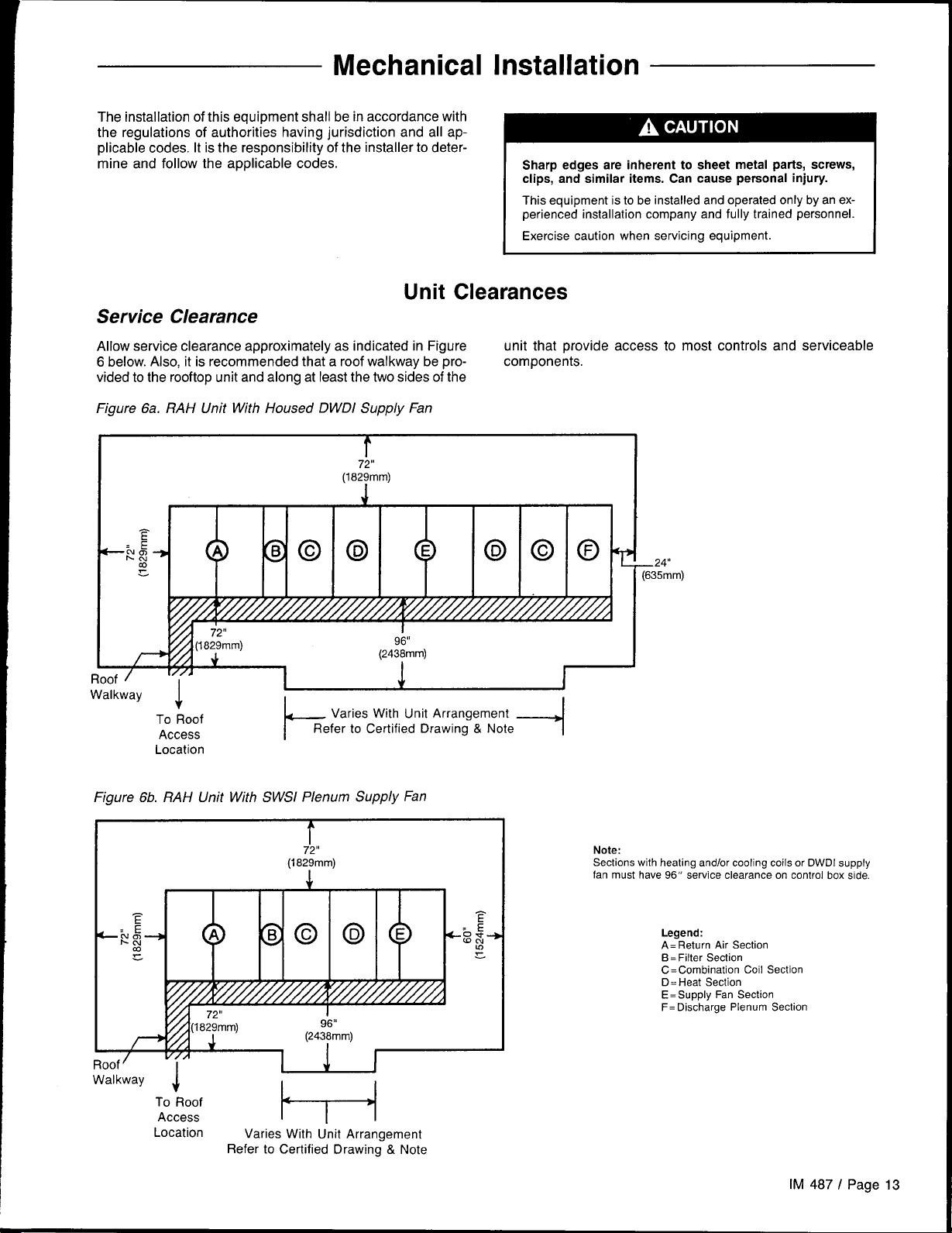

Allow service clearance approximatelv as indicated in Figure

6 below. Also, it is recommended that a roof walkway bepro-

vialed to the rooftop unit and along at least the two sides of the

Figure 6a. RAH Unit With Housed DWDI Supply Fan

r

,!

(18~mm)

Location

unit that provide access to most controls and serviceable

components.

—24”

[635mm)

Figure 6b. RAH Unit With SWSI Plenum Supply Fan

I r

1 1 I I I I I

F

:E

—No

hLu-

m

g

?

/ Y//////////M//////////&

(18~m)

-WI

r V..

m—_’ / I 1~

rluwl

Walkway

TO Roof

Access

Location

v//4

.

i

8 G 0

Varies With Unit Arrangement

Refer to Certified Drawing & Note

T

,,

(24$mm)

v

1

I I

P

I

‘1

Note:

Sections

with heating and/or cooling coils or DWDI supply

fan must have 96” service clearance on control box side.

Legend:

A= Return Air Section

B=Filter Section

C=Combination Coil Section

D=Heat Section

E=Supply Fan Section

F= Discharge Plenum Section

IM 487 I Page 13

Page 14

Ventilation Clearance

Following are minimum ventilation clearance recommendations. The system designer must consider each application

and assure adequate ventilation. If this is not done, the unit

will not perform properly.

Unit(s) surrounded by a screen or fence:

The bottom of the screen or fence should be at least one

1.

foot above the roof surface.

2. The distance between the unit and the screen or fence

should be as described in “Service Clearance” above.

3. The distance between any two units within the screen or

fence should be at least 120 inches (3048mm).

Unit(s) surrounded by solid walls:

1, If there are walls on one or two adjacent sides of the unit,

the walls may be any height, If there are walls on more

than two adjacent sides of the unit, the walls should not

be higher than the unit.

2. The distance between the unit and the wall should be at

least 96 inches (2438 mm) on all sides of the unit.

3. The distance between any two units within the walls should

be at least 120 inches (3048mm).

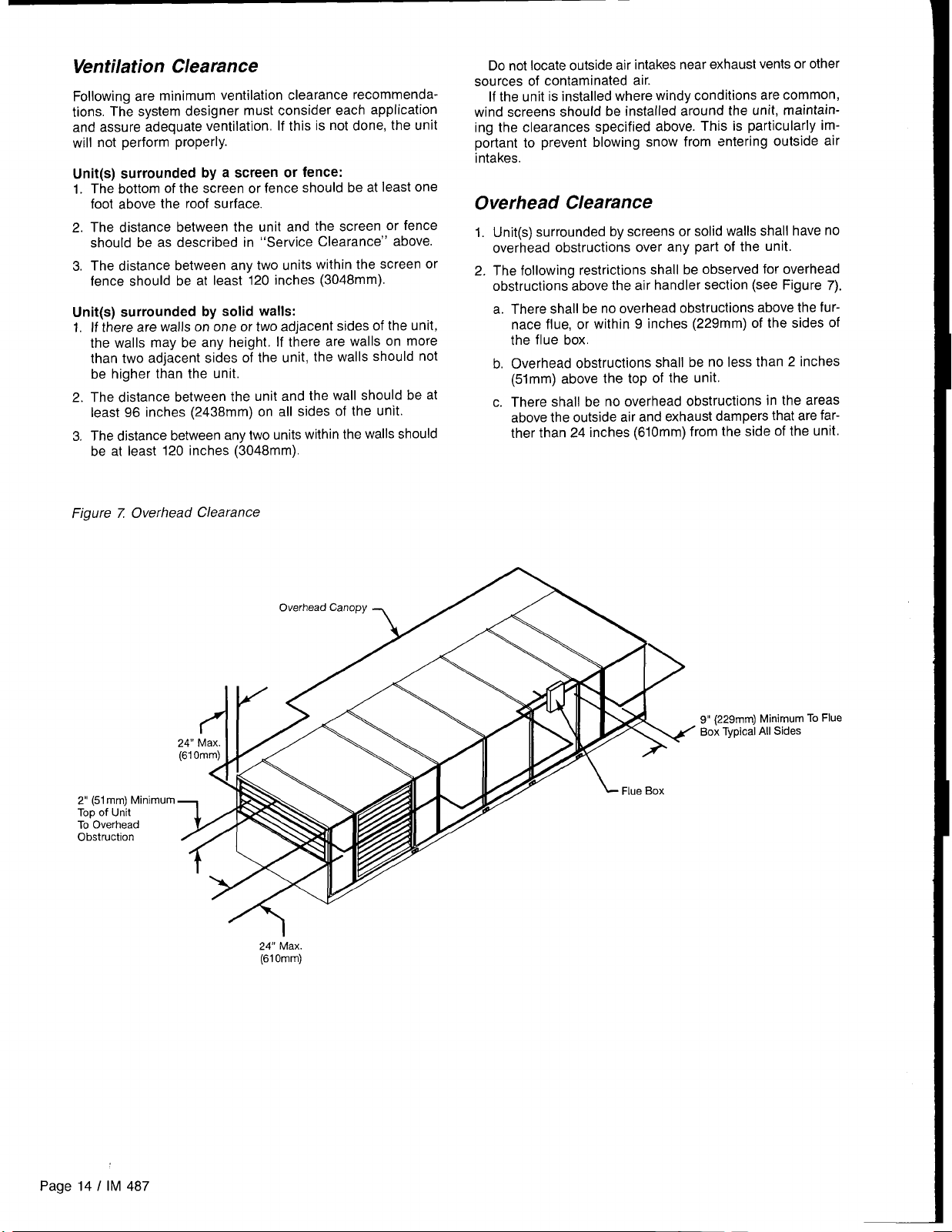

Figure z Overhead Clearance

Do not locate outside air intakes near exhaust vents or other

sources of contaminated air.

If the unit is installed where windy conditions are common,

wind screens should be installed around the unit, maintain-

ing the clearances specified above. This is particularly important to prevent blowing snow from entering outside air

intakes.

Overhead Clearance

1. Unit(s) surrounded by screens or solid walls shall have no

overhead obstructions over any part of the unit.

2. The following restrictions shall be observed for overhead

obstructions above the air handler section (see Figure 7).

a. There shall be no overhead obstructions above the fur-

nace flue, or within 9 inches (229mm) of the sides of

the flue box.

b. Overhead obstructions shall be no less than 2 inches

(51mm) above the top of the unit.

c. There shall be no overhead obstructions in the areas

above the outside air and exhaust dampers that are farther than 24 inches (610mm) from the side of the unit.

2“ (51mm) Minimum

Top of Unit

To Overhead

Obstruction

24” Max.

(61Omm)

9“ (229mm) Minimum To Flue

Box Typical All Sides

Page 14 / IM 487

Page 15

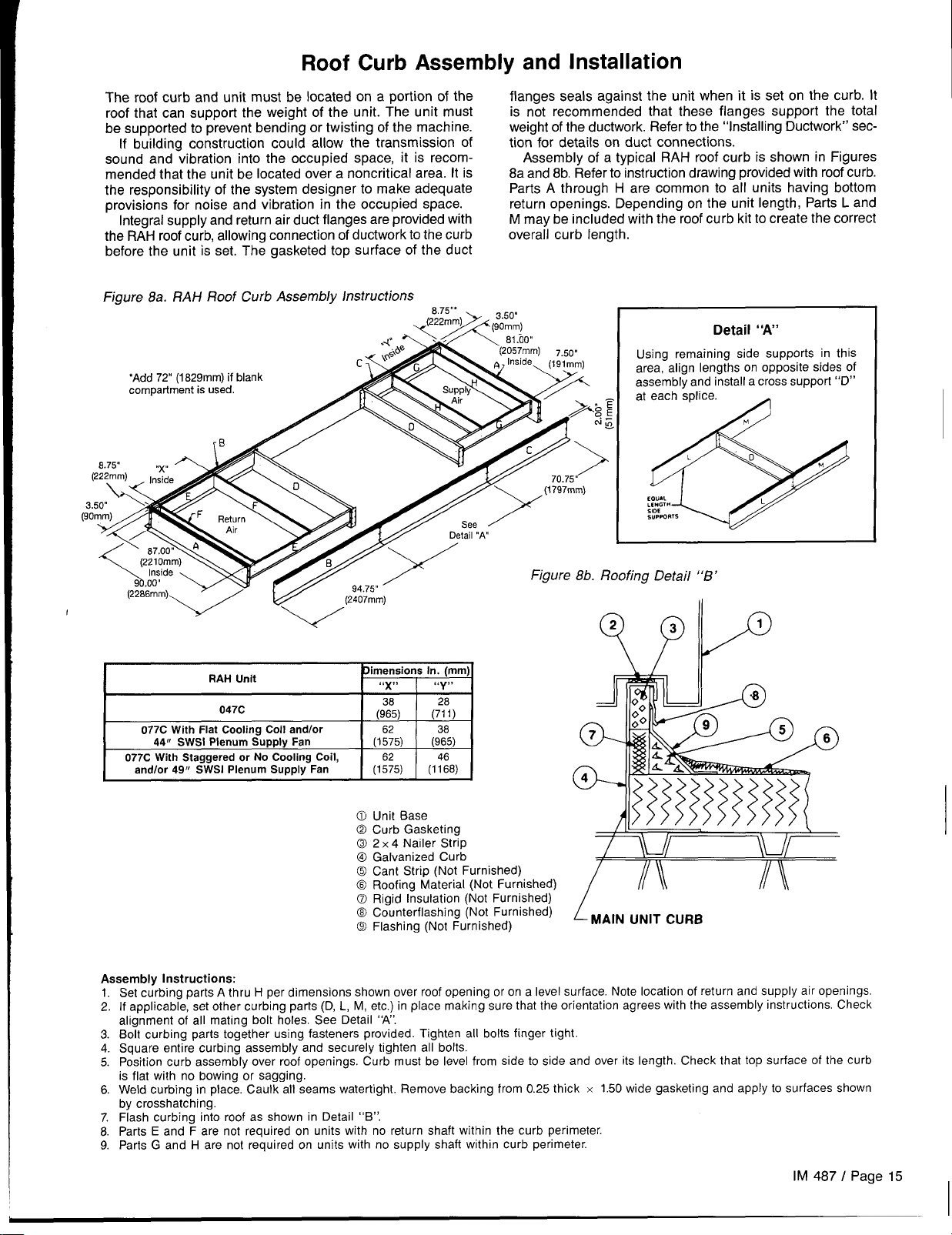

Roof Curb Assembly and Installation

I

The roof curb and unit must be located on a portion of the

roof that can support the weight of the unit. The unit must

be supported to prevent bending or twisting of the machine.

If building construction could allow the transmission of

sound and vibration into the occupied space, it is recommended that the unit be located over a noncritical area. It is

flanges seals against the unit when it is set on the curb. It

is not recommended that these flanges support the total

weight of the ductwork. Refer to the “installing Ductwork” section for details on duct connections.

Assembly of a typical RAH roof curb is shown in Figures

8a and 8b. Refer to instruction drawing provided with roof curb.

the responsibility of the system designer to make adequate Parts A through H are common to all units having bottom

provisions for noise and vibration in the occupied space.

Integral supply and return air duct flanges are provided with

the RAH roof curb, allowing connection of ductwork to the curb

before the unit is set. The gasketed top surface of the duct

Figure 8a. RAH Roof Curb Assembly Instructions

,,.

(Z!i;;m>+ ~jo~m)

return openings. Depending on the unit length, Parts L and

M maybe included with the roof curb kit to create the correct

overall curb Iength.

.

Detail “A’

Using remaining side supports in this

area, align lengths on opposite sides of

assembly and install a cross support “D”

at each splice.

EOUAL

:W[GT “

SUPPORTS

A

RAH Unit

047C

077C With Flat Cooling Coil and/or

4411 SWSI Plenum Supply Fan

077C With Staggered or No Cooling Coil,

and/or 49fI SWSI Plenum Supply Fan

Assembly Instructions:

1.

Set c;rbing parts A thru H per dimensions shown over roof opening or on a level surface. Note location of return and SU!JDIVair oReninW

If applicable, set other curbing parts (D, L, M, etc.) in place making sure that the orientation agrees with the assembly instrfictions. Ch[ck

2.

alignment of all mating bolt holes. See Detail “A’.

Bolt curbing parts together using fasteners provided. Tighten all bolts finger tight.

3.

Square entire curbing assembly and securely tighten all bolts.

4.

Position curb assembly over roof openings. Curb must be level from side to side and over its length. Check that top surface of the curb

5.

is flat with no bowing or sagging.

Weld curbing in place. Caulk aH seams watertight. Remove backing from 0.25 thick

6.

by crosshatching.

Flash curbing into roof as shown in Detail “B”.

7.

Parts E and F are not required on units with no return shaft within the curb perimeter.

8.

Parts G and H are not required on units with no supply shaft within curb perimeter.

9.

3imensions in. (mm)

“x”

(::5)

(1:5)

(1%5) (1%8)

Unit Base

Curb Gasketing

2 x 4 Nailer Strip

Galvanized Curb

Cant Strip (Not Furnished)

Roofing Material (Not Furnished)

Rigid Insulation (Not Furnished)

C&nterflashing (Not Furnished) ~ ~A,N “NIT CURB

Flashing (Not Furnished)

“y,.

(;: )

(::5)

x 1.50 wide gasketing and apply to surfaces shown

IM 487 I Page 15

Page 16

Post and Rail Mounting

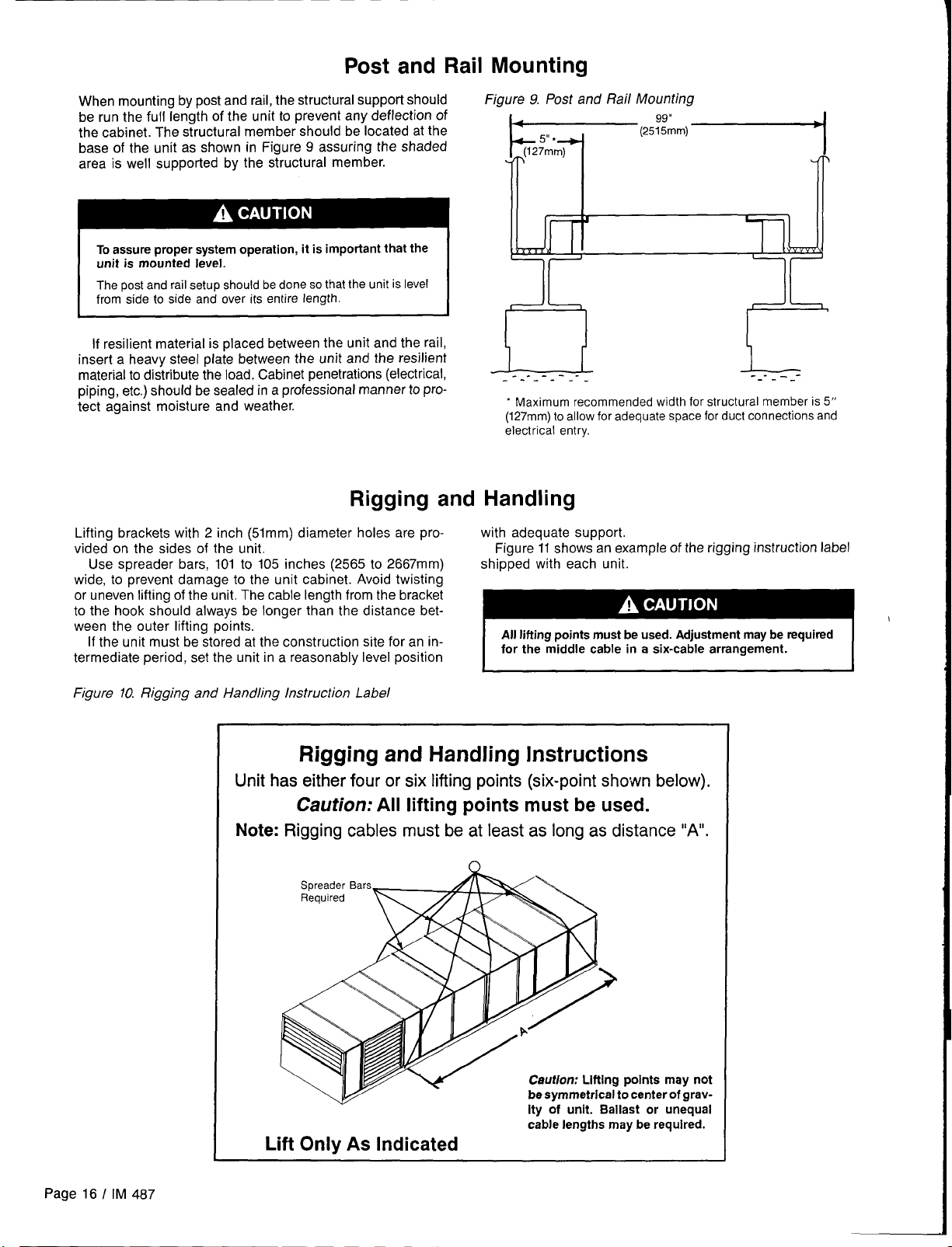

When mounting by Post and rail, the structural support should

run the full length of the unit to prevent any deflection of

be

the cabinet. The structural member should be located at the

base of the unit as shown in Figure 9 assuring the shaded

area is well supported by the structural member.

Figure 9. Post and Rail Mounting

4

,,

(12~m’m)

‘2’;;”)-

l’rl T

To assure proper system operation, it is important that the

unit is mounted level.

The post and rail setup should be done so that the unit is level

from side to side and over its entire length.

If resilient material is placed between the unit and the rail,

insert a heavy steel plate between the unit and the resilient

material to distribute the load. Cabinet penetrations (electrical,

piping, etc.) should be sealed in a professional manner to pro- tect against moisture and weather.

Rigging and Handling

Lifting brackets with 2 inch (51mm) diameter holes are pro-

vialed on the sides of the unit. Figure 11 shows an example of the rigging instruction label

Use spreader bars, 101 to 105 inches (2565 to 2667mm)

wide, to ‘prevent damage to the unit cabinet. Avoid twisting

or uneven lifting of the unit. The cable length from the bracket

to the hook should always be longer than the distance between the outer lifting points.

If the unit must be stored at the construction site for an in-

termediate period, set the unit in a reasonably level position

!l_l!!l_

------ ----

“ Maximum recommended width for structural member

(127mm) to allow for adequate space for duct connections and

electrical entry

with adequate support.

shipped with each unit.

All lifting points must be used. Adjustment maybe required

for the middle cable in a six-cable arrangement.

-------

is 5“

Figure 10. Rigging and Handling Instruction Label

Rigging and Handling Instructions

Unit has either four or six lifting points (six-point shown below),

Caution: All lifting points must be used.

Note: Rigging cables must beat least as long as distance “A”.

Sprea

Requi

/v

Lift Only As Indicated

Caution: Lifting points may not

be symmetrical to center of gravity of unit. Ballast or unequal

cable lengths may be required.

Page 16 / IM 487

Page 17

I

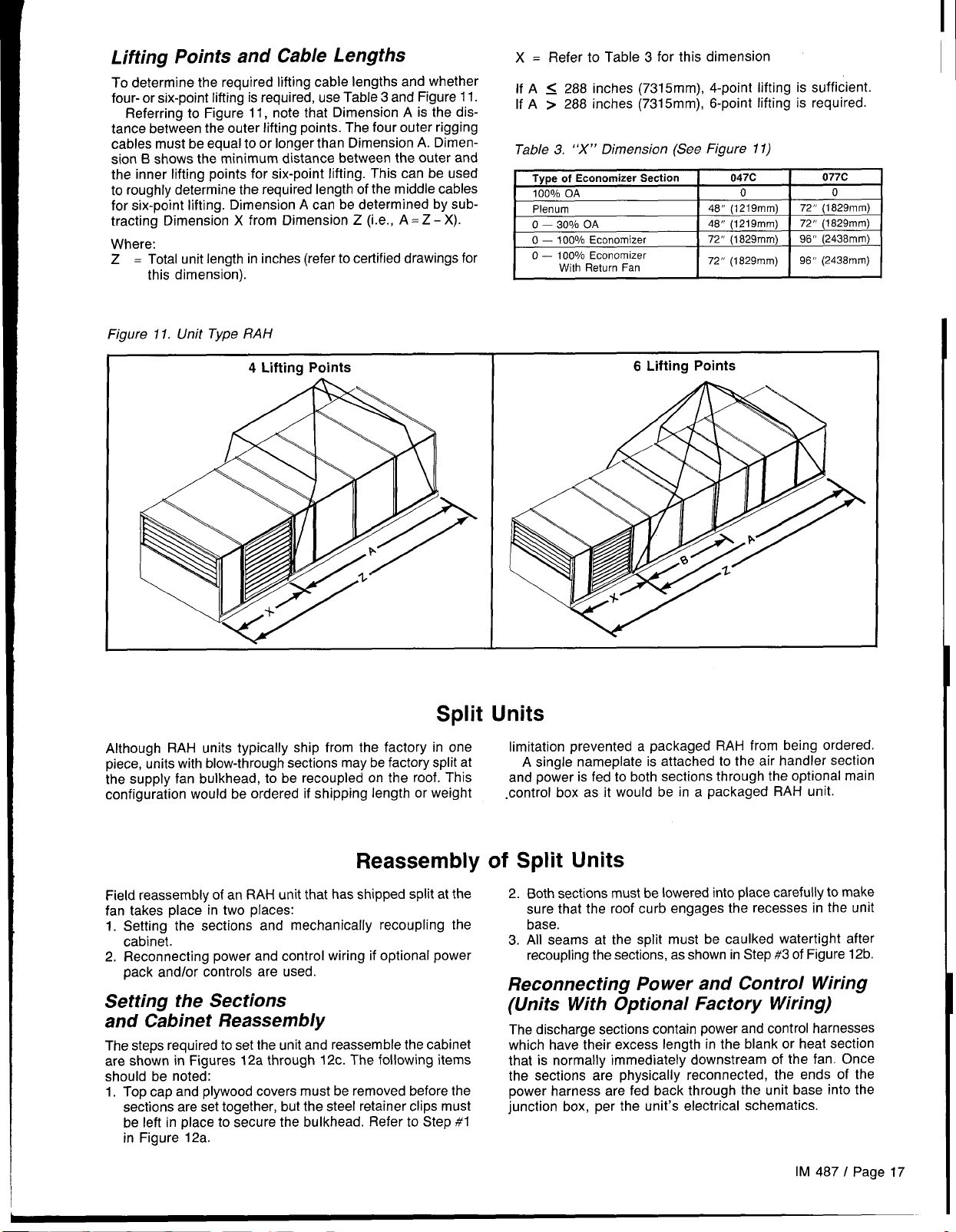

Lifting Points and Cable Lengths

To determine the required lifting cable lengths and whether

four- or six-point lifting is required, use Table 3 and Figure 11.

Referring to Figure 11, note that Dimension A is the distance between the outer lifting points. The four outer rigging

cables must be equal to or longer than Dimension A. Dimen-

sion B shows the minimum distance between the outer and

the inner lifting points for six-point lifting. This can be used

to roughly determine the required length of the middle cables

for six-point lifting. Dimension A can be determined by sub-

tracting Dimension X from Dimension Z (i.e., A = Z - X).

Where:

Z = Total unit length in inches (refer to certified drawings for

this dimension).

Figure 11. Unit Type RAH

4 Lifting Points

X = Refer to Table 3 for this dimension

If A < 288 inches (7315mm), 4-point lifting is sufficient.

If A > 288 inches (7315mm), 6-point lifting is required.

Table 3. “X” Dimension (See Figure 11)

Type of Economizer Section

100%OA

Plenum

O —

2.00/o OA

O — 100°/0 Economizer

O — 100°10 Economizer

With Return Fan

I

6 Lifting Points

047C

o

48” (1219 mm)

48” (1219 mm)

72” (1829mm)

72” (1829 mm)

72” (1829mm)

72” (1829 mm)

96” (2438 mm)

96” (2438 mm)

077C

0

Split Units

Althouqh RAH units typically ship from the factory in one

piece, units with blow-through sections maybe factory split at

the supply fan bulkhead, to be recoupled on the roof. This

configuration would be ordered if shipping length or weight

Reassembly

Field reassembly of an RAH unit that has shipped split at the

fan takes place in two places:

1. Setting the sections and mechanically recoupling the

cabinet.

2. Reconnecting power and control wiring if optional power

pack and/or controls are used.

Setting the Sections

and Cabinet Reassembly

The steps required to set the unit and reassemble the cabinet

are shown in Figures 12a through 12c. The following items

should be noted:

1. Top cap and plywood covers must be removed before the

sections are set together, but the steel retainer clips must

be left in place to secure the bulkhead. Refer to Step #1

in Figure 12a.

limitation prevented a packaged RAH from being ordered.

A single nameplate is attached to the air handler section

and power is fed to both sections through the optional main

control box as it would be in a packaged RAH unit.

of Split Units

2. Both sections must be lowered into place carefully to make

sure that the roof curb engages the recesses in the unit

base.

3. All seams at the split must be caulked watertight after

recoupling the sections, as shown in Step #3 of Figure 12b.

Reconnecting Power and Control Wiring

(Units With Optional Factory Wiring)

The discharge sections contain power and control harnesses

which have their excess length in the blank or heat section

that is normally immediately downstream of the fan. Once

the sections are physically reconnected, the ends of the

power harness are fed back through the unit base into the

junction box, per the unit’s electrical schematics.

IM 487 I Page 17

Page 18

Care must be exercised to connect the proper power block

and maintain proper phasing.

I

When reconnection of the power wires is complete, the inner raceway cover in the blank or heat section must be

reinstalled. Step #4 of Figure 12c shows a typical installation

of the raceway cover.

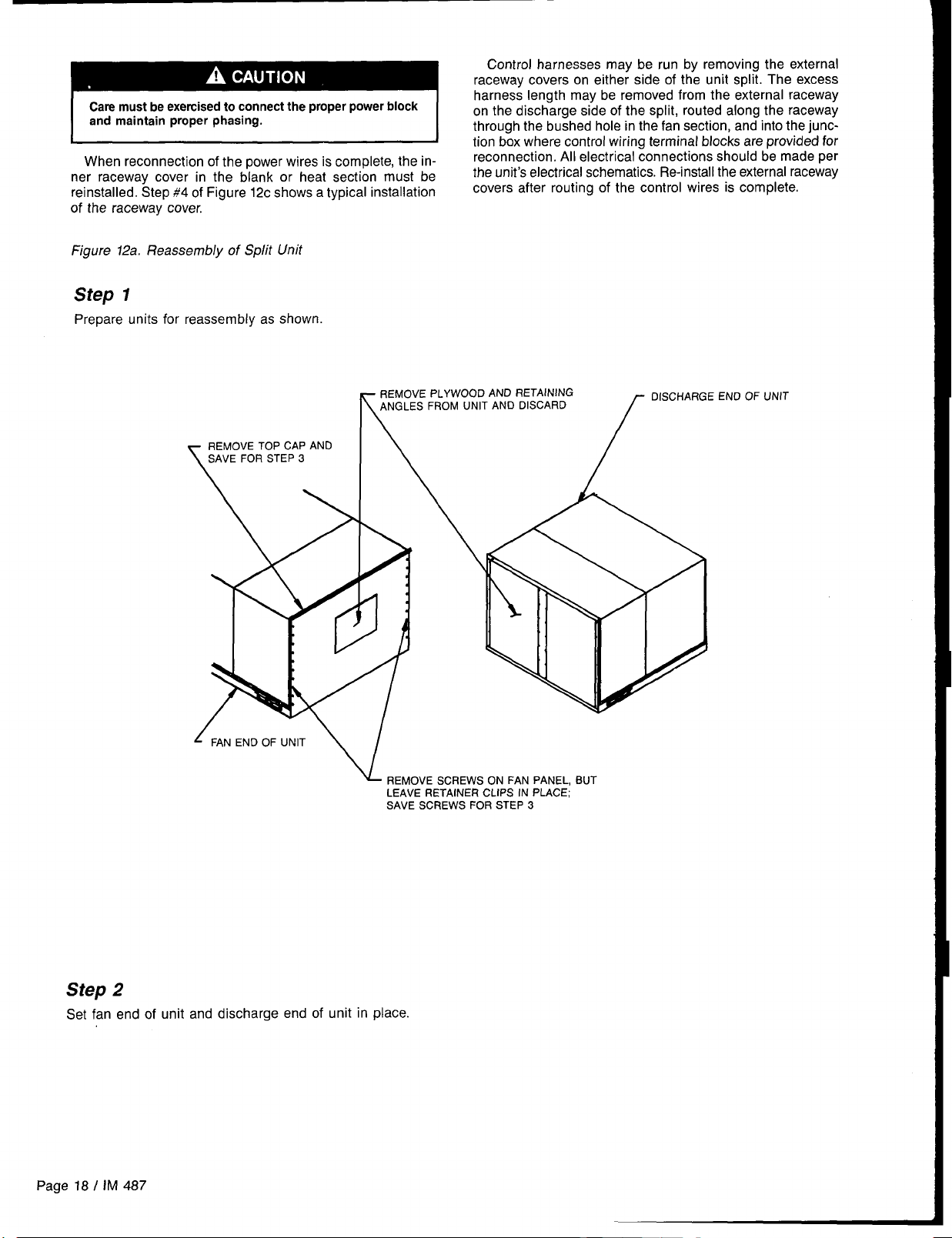

Figure 12a. Reassembly of Split Unit

Step 1

Prepare units for reassembly as shown.

Control harnesses may be run by removing the external

raceway covers on either side of the unit split. The excess

harness length may be removed from the external raceway

on the discharge side of the split, routed along the raceway

I

through the bushed hole in the fan section, and into the junc-

tion box where control wiring terminal blocks are provided for

reconnection. All electrical connections should be made per

the unit’s electrical schematics. Re-install the external raceway

covers after routing of the control wires is complete.

REMOVE PLYWOOD AND RETAINING

ANGLES FROM UNIT AND DISCARD

k

L

REMOVE SCREWS ON FAN PANEL, BUT

LEAVE RETAINER CLIPS IN PLACE;

SAVE SCREWS FOR STEP 3

OISCHARGE END OF UNIT

f

Step 2

Set fan end of unit and discharge end of unit in place.

Page 18 I IM 487

Page 19

r

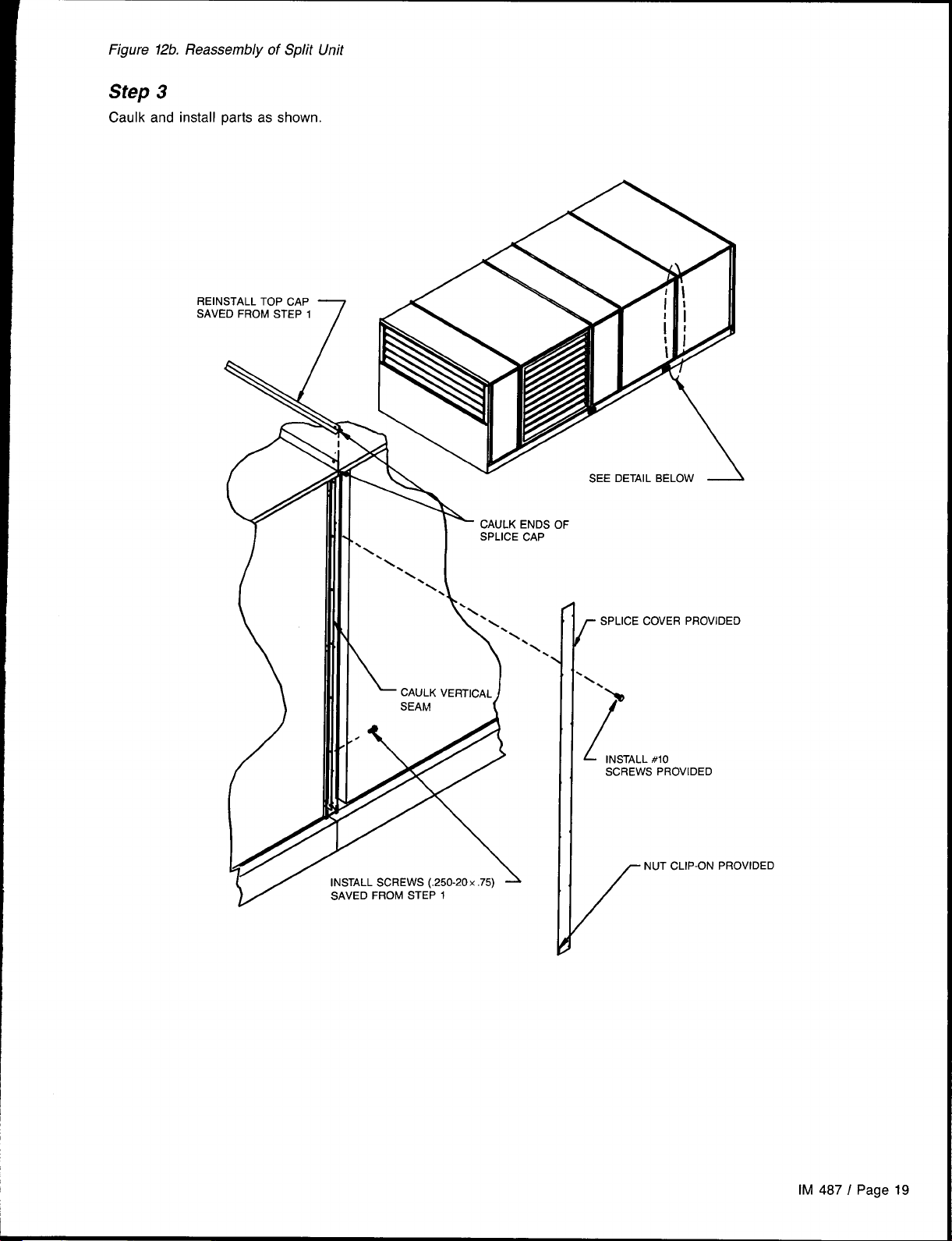

Figure 12b. Reassembly of Split Unit

Step 3

Caulk and install parts as shown.

\

CAULK VERTICAL

SEAM

SPLICE COVER PROVIDED

f

‘\

)

“%

[

INSTAL

SCREWS PROVIDED

NUT CLIP-ON PROVIDED

#lo

/

IM 487 / Page 19

Page 20

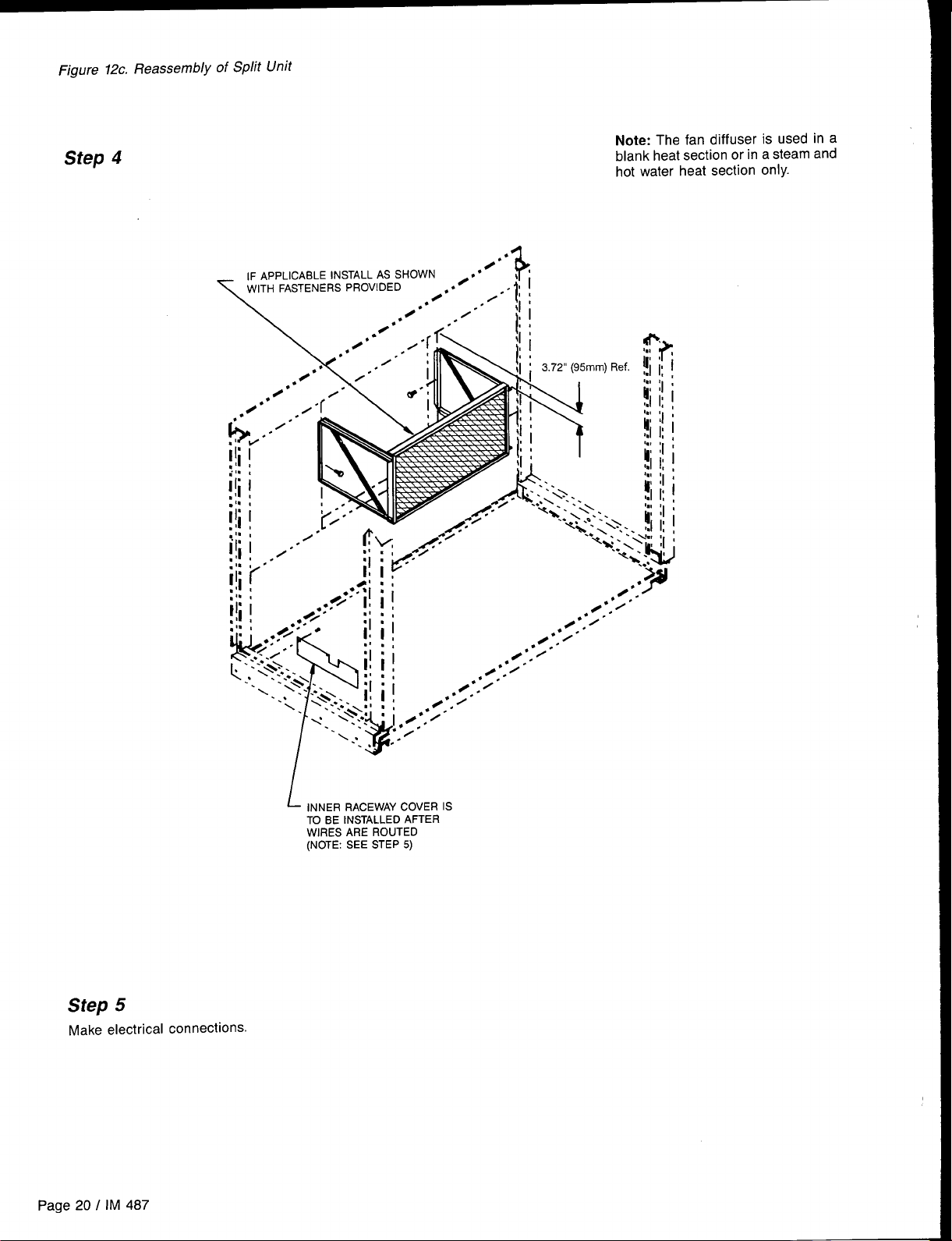

Figure 12c. Reassembly of Split Unit

Step 4

Note: The fan diffuser is used in a

blank heat section or in a steam and

hot water heat section only.

A

Step 5

Make electrical connections.

Page 20 I IM 487

~ INNER RACEWAY COVER IS

TO BE INSTALLED AFTER

WIRES ARE ROUTED

(NOTE: SEE STEP 5)

Page 21

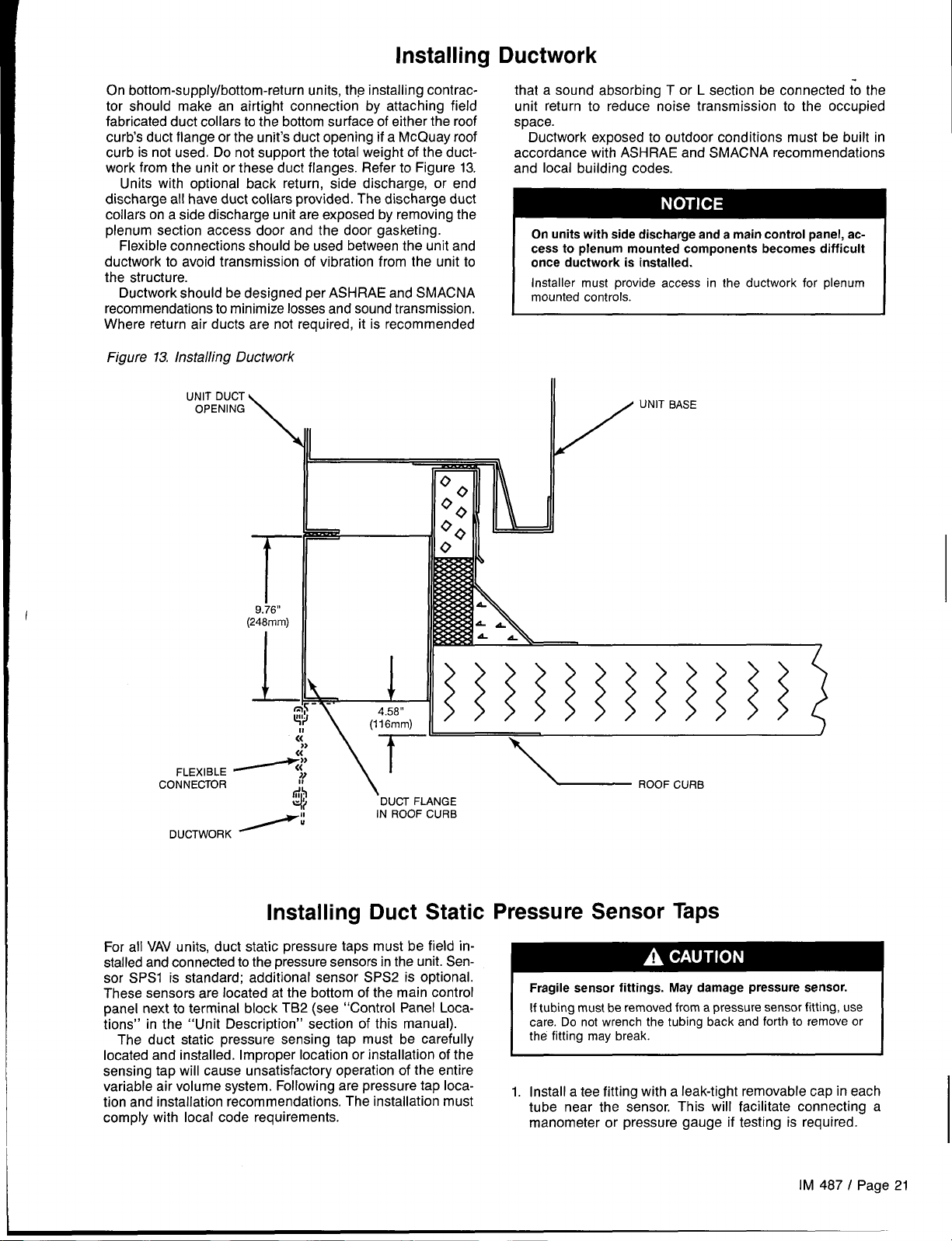

Installing

Ductwork

On bottom-supply/bottom-return units, the installing contractor should make an airtight connection by attaching field

fabricated duct collars to the bottom surface of either the roof

curb’s duct flange or the unit’s duct opening if a McQuay roof

curb is not used. Do not support the total weight of the ductwork from the unit or these duct flanges. Refer to Figure 13.

Units with optional back return, side discharge, or end

discharge all have duct collars provided. The discharge duct

collars on a side discharge unit are exposed by removing the

plenum section access door and the door gasketing.

Flexible connections should be used between the unit and

ductwork to avoid transmission of vibration from the unit to

the structure.

Ductwork should be designed per ASH RAE and SMACNA

recommendations to minimize losses and sound transmission.

Where return air ducts are not required, it is recommended

Figure 13. Installing Ductwork

UNIT DUCT

OPENING

\ll

that a sound absorbing T or L section be connected tO the

unit return to reduce noise transmission to the occupied

space.

Ductwork exposed to outdoor conditions must be built in

accordance with ASH RAE and SMACNA recommendations

and local building codes.

On units with side discharge and a main control panel, access to plenum mounted components becomes difficult

once ductwork is installed.

Installer must provide access in the ductwork for plenum

mounted controls.

I

UNIT BASE

/

I

T‘

9.76”

(248mm)

I

CONNECTOR

For all VAV units, duct static pressure taps must be field installed and connected to the pressure sensors in the unit. Sensor SPSI is standard; additional sensor SPS2 is optional.

These sensors are located at the bottom of the main control

panel next to terminal block TB2 (see “Control Panel Locations” in the “Unit Description” section of this manual).

The duct static pressure sensing tap must be carefully

located and installed. Improper location or installation of the

sensing tap will cause unsatisfactory operation of the entire

variable air volume system. Following are pressure tap location and installation recommendations. The installation must

comply with local code requirements.

fi’

Ii!,$

Installing

\

.DUCT FLANGE

IN ROOF CURB

Duct Static Pressure Sensor Taps

~ ROOF CURB

Fragile sensor fittings. May damage pressure sensor.

If tubing must be removed from a pressure sensor fitting, use

Do not wrench the tubing back and forth to remove or

care.

the fitting may break.

1. Install a tee fitting with a leak-tight removable cap in each

tube near the sensor. This will facilitate connecting a

manometer or pressure gauge if testing is required.

IM 487 / Page 21

Page 22

2.

Use different colored tubing for the duct pressure (Hi) and

reference pressure (LO) taps, or tag the tubes.

Locate the duct pressure (Hi) tap near the end of a long

3.

duct to ensure that all terminal box take-offs along the run

will have adequate static pressure.

4.

Locate the duct tap in a nonturbulent flow area of the duct.

Keep it several duct diameters away from take-off points,

bends, neckdowns, attenuators, vanes, or other irregulari-

ties.

5.

Use a static pressure tip (Dwyer A302 or equivalent) or the

bare end of the plastic tubing for the duct tap. (If the duct

is lined inside, use a static pressure tip device.)

6.

Install the duct tap so that it senses only static pressure

(not velocity pressure). If an L-shaped pressure tip device

is used, the point must face the airstream. If a bare tube

end is used, it must be smooth, square (not cut at an

angle), and perpendicular to the airstream (see Figure 14).

7.

Locate the reference pressure (LO) tap somewhere near

the duct pressure tap within the building (see Figure 14).

If the reference tap is not connected to the sensor, un-

satisfactory operation will result.

8.

Route the tubes between the curb and the supply duct,

and feed them into the unit through the knockout in the

bottom of the control panel (see Figure 15). Connect the

tubes to the appropriate 1/4inch fittings on the sensors.

Assure that the sensors do not support the weight of the

tubing; use tube clamps or some other means.

14. Duct Static Pressure Tap Installation

Figure

TO SENSOR

TO SENSOR

“LO” INPUT

RUBBER

TUBE CLA

PRESSU

TUBING

TUBING EXTENDS ~

THRU APPROX, 1~”

ROMMET

Installing Building Static Pressure Sensor Taps

If a unit has direct building static pressure control capability,

static pressure taps must be field installed and connected to

pressure sensor SPS2 in the unit. This sensor is located at

the bottom of the main control panel next to terminal block

TB2 (see “Control Panel Locations” in the “Unit Description”

section of this manual).

The two static pressure sensing taps must be carefully

located and installed. Improper location or installation of the

sensing taps will cause unsatisfactory operation. Following

are pressure tap location and installation recommendations

for both building envelope and lab, or “space within a space;’

pressure control applications. The installation must comply

with local code requirements.

Fragile sensor fittings. May damage pressure sensor.

If tubing must be removed from a pressure sensor fitting, use

care. Do not wrench the tubing back and forth to remove or

~

Building Pressurization Applications

1.Install a tee fitting with a leak-tight removable cap in each

tube near the sensor. This will facilitate connecting

manometer or pressure gauge if testing is required.

Figure 15. Static Pressure Tubing Entrance Locations

Locate the building pressure (Hi) tap in the area that re-

2.

quires the closest control. Typically, this is a ground level

floor that has doors to the outside.

Locate the building tap so that it is not influenced by any

3.

source of moving air (velocity pressure). These sources

may include air diffusers or outside doors.

4.

Route the building tap tube between the curb and the

supply duct, and feed it into the unit through the knockout

in the bottom of the control panel (see Figure 15). Connect the tube to the 1/4 inch HI fitting on sensor SPS2.

Assure that the sensor does not support the weight of the

tubing; use tube clamps or some other means.

Locate the reference pressure (LO) tap on the roof. Keep

5.

it away from the condenser fans, walls, or anything else

that may cause air turbulence. Mount it high enough above

the roof so that it is not affected by snow. If the reference

tap is not connected to the sensor, unsatisfactory operation will result.

6.

Use an outdoor static pressure tip (Dwyer A306 or

equivalent) to minimize the adverse effects of wind. Place

some type of screen over the sensor to keep out insects.

Loosely packed cotton works well.

7.

Route the outdoor tap tube out of the main control panel

a

through a small field-cut opening in the edge of the control wiring raceway cover (see Figure 15). Cut this “mouse

hole” in the vertical portion of the edge. Seal the penetra-

WIRING

COVER

\

Page 22 / IM 487

Page 23

tion to prevent water from entering, Connect the tube to 4,

L

inch LO fitting on sensor SPS2.

the 1/4

Lab Pressurization Applications

1.

Install a tee fitting with a leak-tight removable cap in each

tube near the sensor. This will facilitate connecting a

manometer or pressure gauge if testing is required.

2.

Use different colored tubing for the controlled space 6

pressure (Hi) and reference pressure (LO) taps, or tag the

tubes.

Regardless of whether the controlled space is positive or 7.

3.

negative with respect to its reference, locate the HI pres-

sure tap in the controlled space. (The setpoint can be set

between -0.2 and 0.2” W.C. [-50 and 50 Pa])

Locate the reference pressure (LO) tap in the area sur-

rounding the controlled

connected to the sensor, unsatisfactory operation will

result.

5.

Locate both taps so that they are not influenced by any

source of moving air (velocity pressure), These sources

may include air diffusers or doors between the high and

low pressure areas.

Route the tap tubes between the curb and the supply duct,

and feed them into the unit through the knockout in the

bottom of the control panel (see Figure 15).

Connect the tubes to the appropriate 1/4 inch fittings on

SPS2. Assure that the sensor does not support me

sensor

weight of the tubing; use tube clamps or some other

means,

space. If the reference tap is not

. .

Condensate Drain

The unit is provided with a 1.50” male NPT condensate drain

connection. Refer to certified drawings for the exact location.

The unit and drain pan must be level side to side and a Ptrap must be installed for proper drainage.

RAH units may have positive or negative pressure sections.

It is recommended that traps are used in both cases with care

given to negative pressure sections. In Figure 16, dimension

“A” should be a minimum of 8“ (203mm). As a conservative

measure to prevent the cabinet static pressure from blowing

or drawing the water out of the trap and causing air leakage,

dimension “A’ should be two times the maximum static

sure encountered in the coil section in inches W.C.

Drainage of condensate directly onto the roof may be acceptable; refer to local code. It is recommended that a small

drip pad of either stone, mortar, wood or metal be provided

to protect the roof against possible damage.

If condensate is to be piped into the building drainage

system, the drain line should be pitched away from the unit

at a minimum of 1/8” per foot (3mm per 254mm). The drain

line must penetrate the roof external to the unit, Refer to local

codes for additional requirements. Sealed drain lines require

venting to assure proper condensate flow.

Figure 16. Condensate Drain Connection

STATIC PRESSURE P, IN W.C.

pres-

Connection

Where the cooling coils have intermediate condensate pans

on the face of the evaporator coil, copper tubes near both

ends of the coil provide drainage to the main drain pan, Check

that the copper tubes are in place and open before the unit

is put into operation.

On units with staggered cooling coils, the upper drain pan

drains into the lower coil drain pan through a copper tube near

the center of the drain pan, Check that this tube is open before

putting the unit into operation and as part of routine maintenance.

Because drain pans in any air conditioning unit may have

some moisture in them, algae, etc. will grow, Periodic cleaning is necessary to prevent this build-up from plugging the

drain and causing the drain pan to overflow, Also, the drain

pans should be kept clean to prevent the spread of disease.

Cleaning should be performed by qualified personnel.

Biological hazard. May cause disease.

Cleaning should be performed by qualified personnel.

I

T’

4“ (102mm)

MINIMUM

T

“A”

(8” [203mm] MINIMUM

OR2XP)

t

DRAIN PAN

VIEW A

L

--ii

NOTE: DRAIN LINE MUST

NOT BE RUN HIGHER

THAN THIS LEVEL.

((

II

MINIMIZE THIS

DIMENSION

““’ 3

\\\

\

VIEW ‘W’

4

- COPPER TUBE

(ONE EACH END OF COIL)

IM 487 I Page 23

Page 24

Field Refrigerant Piping and Charging of DX Coils

RAH units that ship from the factory with DX coils installed

do not include refrigerant piping or refrigerant controls. The

coil assembly is ready for field connections at the distributors

and at the suction headers. Piping kits that provide the

necessary liquid and hot gas piping and control components

are available for field installation.

Field installed refrigerant piping may exit the unit cabinet

at one of the following locations:

1. Through the floor of the unit.

2. Through the discharge and bulkhead of the unit.

3. Through a cabinet door near the DX coil that is not required

for service areas.

Caution: For any of the above cabinet penetrations, the hole

must be tightly sealed to prevent water or air leakage.

In preparing for field piping, the plastic plugs on the distribu-

tors must be removed and the copper caps at the suction

header connections must be unsweated.

Piping design, sizing, and installation information presented

in ASH RAE handbooks should be followed in the design and

installation of interconnecting piping. The DX coil and condensing unit are intended to be set at the same elevation,

as close as possible to each other to minimize refrigerant

pressure drop. The piping must be designed and installed to

prevent liquid refrigerant carryover to the compressor and to

assure a continuous return of compressor oil from the system.

5.

Suction lines within the unit cabinet must be insulated to

prevent dripping of condensation.

6.

The liquid line should be sized for a pressure drop not to

exceed the pressure equivalent of 20F (-17C) for R-22 (6

psi [41 kPa]) saturated temperature. The RAH unit includes

a factory installed filter-drier, solenoid valve, and sightglass

in each liquid line, upstream of the thermal expansion

valve,

Table 4. Minimum Tonnage (R-22) to Carry Oil L@ Suction

Riser at 40 OF Saturated Suction

Line Size

O.D. (In.)

Minimum

Tons

Note: When compressor minimum tonnage is less than shown in the above

table for a given line size, double suction risers will be required.

11A

1,50

13h

2.50

15h

3.80

2% 2%

7.60

13.10

31A 35h

20.4

41~

29.7 41.3

Leak Testing

The field piping system should be checked for leaks prior to

charging. Leak testing must be performed to current EPA

standards and regulations. After making any necessary re-

pair, the system should be evacuated as described in the

following paragraphs.

The pounds of refrigerant in the system may exceed the

capacity of the condenser, depending on the amount of

refrigerant in the liquid lines between the DX coil and the

condensing unit. Refer to condenser manufacturer for information about refrigerant capacity. Suitable means of

containing the refrigerant is required.

On systems with optional hot gas bypass, it is important

the bypass solenoid valve be located at the condensing

unit and not at the DX coil to prevent liquid return and

~

Piping Recommendations

1. Use type K or L clean copper tubing. All joints should be

thoroughly cleaned and brazed with high temperature

solder.

2. Piping sizes should be based on temperature/pressure

limitations as recommended in the following paragraphs.

Under no circumstances should pipe size be based strictly upon the coil or condensing unit piping connection size.

3. Suction line piping pressure drop should not exceed the

pressure equivalent of 2° F (-17C) for R-22 (3 psi [21 kPa])

per 100 feet (30.5m) of equivalent pipe length. After the

suction line size has been determined, the vertical suction risers should be checked to verify that oil will be car-

ried up the riser and back to the compressor. The suction

line(s) should be pitched in the direction of refrigerant flow

and fully insulated between the evaporator(s) and the

compressor.

4. Vertical suction risers should be checked using Table 4

to determine the minimum tonnage required to carry oil

up suction risers of various sizes.

A serious explosion could result from using oxygen to

build up pressure resulting in severe personal injury or

death.

I Do not use oxygen to build up pressure.

Evacuation

After it has been determined that the unit is tight and there

are no refrigerant leaks, the system should be evacuated. The

use of a vacuum pump with a pumping capacity of approximately 3 cu. ft./rein. (1.4 L/see.) and the ability to reduce the

vacuum in the unit to at least 1 millimeter (1000 microns) is

recommended.

A mercury manometer or an electronic or other type of

1.

micron gauge should be connected to the unit at a point

remote from the vacuum pump. For readings below 1

millimeter, an electronic or other micron gauge should be

used.

2.

The triple evacuation method is recommended and is particularly helpful if the vacuum pump is unable to obtain

the desired 1 millimeter of vacuum. The system is first

evacuated to approximately 29 inches (737mm) of mercury.

Enough refrigerant vapor is then added to the system to

bring the pressure up to O pounds.

Then the system is once again evacuated to 29 inches

3.

(737mm) of vacuum. This procedure is repeated three

times. This method can be most effective by holding system

pressure at O pounds for a minimum of 1 hour between

evacuations. The first pulldown will remove about 90% of

the noncondensables, the second about 90% of that re-

maining from the first pulldown, and after the third, only

1/10 of 1% noncondensables will remain.

I

Page 24 I IM 487

Page 25

Table 5 below shows the relationship between pressure, microns, atmospheres, and the boiling point of water.

Table 5. Pressure-Vacuum Equivalents

Absolute Pressure Above Zero

Microns

o 0 760.00

50 0.001

100

150 0.003 759.85

200 0,004 759.80

300

500 0.009

1,000 0,019

2,000 0.039

4,000 0.078

6,000 0.117

8,000 0.156

10,000 0.193

15,000 0.290

20,000

30,000

50,000

100,000

200,000

500,000

E==

7Gr-1 mm

EB=t

Vacuum Below one Atmosphere

Psia

0.002

0.006 759.70

0.387

0.580

Mercury

(mm)

759.95

759.90

759.50

759.00

758.00

756.00

754.00

752.00

750.00

745.00

740.00

730.00

710.00

660.00

560.00

260.00

n o

Mercury

(Inches) One Atmosphere

29.921

29.920

29.920 117,600

29.920 1/5,100

29.910 113,800

29.910 112,500

29.900 Ill ,520

29.880

29.840

29.760

29.690

29.600 1/95

29.530 1176

29.330

29.130 1138

28.740 1125

27.950

25.980 2115

22.050

10.240 2/3

Approximate Boiling

Fraction of of HzO at Each

—

CJnn

,L””

1/15,:

11760

11380 15 (-9”C)

1/169 29 (-2°C)

1/127 39 (4” c)

1/50 63 (170C)

1/15

114

1 Atmosphere 212 (loo”c)

Pressure 0F (0 C)

1

Point

– W-1 (. A6. C)

=- , ,- -,

-40 (-40” C)

-33 (-36 ‘C)

-28 (-33° C)

-21 (-29oC)

-12 (-240C)

1 (-17” C)

46 (80C)

52 (I IoC)

72 (220C)

84 (29oC)

101 (380C)

125 (52” C)

152 (67”C)

192 (89oC)

—

I

Charging the System

1.

After all refrigerant piping is complete and the system has

been evacuated, it can be charged as described in the

paragraphs following. Connect the refrigerant drum to the

gauge port on the liquid shutoff valve, and purge the charging line between the refrigerant cylinder and the valve.

I

Then open the valve to the midposition.

2.

If the system is under a vacuum, stand the refrigerant drum

with the connection up, open the drum and break the

Note: It is

circuit be stamped on the unit nameplate for future reference.

Refrigerant Charge

Factory installed DX coils in RAH units are designed for use

with R-22. The total system charge is the sum of three values:

1. Condensing unit charge—refer to manufacturer’s data.

2. Evaporator coil charge—refer to Table 6.

3. Charge for length of interconnecting piping installed by

vacuum with refrigerant gas.

With a system gas pressure higher than the equivalent

3.

of a freezing temperature, invert the charging cylinder and

elevate the drum above the condenser. With the drum in

this position and the valves open, liquid refrigerant will flow

into the condenser. Approximately 75% of the total requirement estimated for the unit can be charged in this manner.

4.

After 75% of the required charge has entered the condenser, reconnect the refrigerant drum and charging line

to the suction side of the system. Again purge the connecting line, stand the drum with the connection side up, and

place the service valve in the open position.

Important: At this point, the charging procedure should be

interrupted and prestart checks made before attempting to

complete the refrigerant charge.

Note: Factory installed DX coils are intended for two refriger-

ant circuits containing identical weights of refrigerant. The

values shown in Tables 6 and 7 are for each circuit.

Note: The total operating charge per circuit should not ex-

ceed the pumpdown capacity per circuit, specified by the condensing unit manufacturer.

Table 6. Approximate DX Coil Refrigerant Charge Per Circuit

Unit DX Coil R-22 Chsrge (Lbs./Circuit)

Size

047C 3x No. Of DX ROWS

077C

recommended that the total operating charge per

field—refer to Table 7.

Flat Coil

5 x No. of DX flOWS 6.5 X No. Of DX ROWS

Staggered Coil

3.5 x No. of DX flowS

Table 7. Weight of Refrigerant R-22 in Copper Lines (Pounds Per 100 Feet of Type L Tubing)

O.D. Line Size

%

V2 0.100 7.12

518

‘/8

11/s

1% 0.872

15/8 1.237

27/s

278

3% 4.728

35/, 6,398 456.0 24.000

41~

Volume Per 100 Feet

in Cubic Feet

0.054 3.84 .202 .052

0.162 7,12 .605 .158

0.336 24.0 1.260

0.573 40.8 2.140

2.147 153.0 8.040

3.312 236.0 12.400

8.313 592.0 31.100

Liquid @ 100” F

62.1 3.260

88.0 4.620

336,0 17.700

Weight of Refrigerant, Lbs./100 Feet

Hot GSS @ 120” F Suction Gaa (Superheated to 85” F)

Cond.

.374 .098 .143

20” F 40” F

,323 .480

.550 .820

.839 1.250

1.190 1.770

2.060

3.180

4.550

6.150 9.140

8.000

.077

.232

3.060

4.720

6.750

11.190

IM 487 / Page

25

Page 26

Unit Piping

Gas Piping

See the “installation” section of the gas fired furnace installation manual, Bulletin No. IM 484.

Piping for Steam, Hot WateR

and Chilled Water Coils

Factory installed chilled water coils are installed in a combina-

tion coil section which is also designed to accept a factory

installed heating coil immediately upstream. The combination

coil section may be ordered in either the draw-through or blowthrough position. All chilled water piping can be done inter-

nal to the unit without requiring a piping vestibule.

Steam and hot water coils may be factory installed in either

a heat section, or in the combination coil section. These sections may be located either in the draw-through or blowthrough position. When a steam or hot water coil is installed in

the heat section, all piping may be done internal to the unit

without requiring a piping vestibule. Refer to Figures 17 and

18.

When a steam or hot water coil is installed in the combination coil section, the coil connections project to the inside surface of the door panel. Holes maybe cut in the door panels for

the piping to be connected to the coils, or an accessory piping

vestibule may be added to the unit to provide piping space.

Refer to the section on vestibule assembly instructions. The

piping may then be routed back within the unit as shown in

Figure 17.

To avoid piping penetrations through the roof external to the

curb, holes may be cut through the floor of the unit at the locations specified on the certified drawings. Caution; All holes

in the unit floor must be sealed to prevent water leakage into

the building.

Coil freeze possible. ,May damage equipment.

Carefully read instructions for mixing antifreeze solution used. Some products will have higher freezing points in their

natural state than when mixed with water. The freezing of coils

is not the responsibility of McQuay International.

Refer to “Winterizing Coils” in the “Maintenance” section of

the manual.

valve. Field piping connections are of the same NPT size as

the valve—male threads at the supply connection, female

threads at the return connection.

Note: The valve actuator spring returns to a stem down position upon power failure. This allows full flow through the coil.

Figure 17 Hot Water Heat Section

(Shown With Factory Valve and Piping)

SUPPLY

Steam Piping (All Units)

The steam heat section consists of two stacked coils (pitched

at 1/8“ per foot [3mm per 30cm]), as shown in Figure 18. When

no factory piping or valve is included, the coil connections

are 2.50” male NPT iron pipe.

Refer to the sections on steam coil piping and trap recom-

mendations for additional information.

Figure 18. Steam Heat Section

(Shown With Factory Valve and Piping)

Hot Water Piping (All Units)

Note: If an iron valve is installed

in the unit, connecting to a

copper piping system will likely cause galvanic corrosion to

occur and the valves will not last. All coils have vents and

drains factory installed.

Hot water coils are not normally recommended for use with

entering air temperatures below 40 F (40C), No control

system can be depended on to be 100% safe against freezeUP with water coils. Glycol solutions or brines are the only

freeze-safe media for operation of water coils for low entering air conditions. Refer to the “Maintenance” section of this

manual for more on winterizing coils. The hot water section

consists of two stacked coils, as shown in Figure

no factory piping or valve is included, the coil connections

are 2.12” ODM copper.

Hot Water Piping to Coils in the Heat Section

Hot water coils are provided without valves for field piping, or

piped with three-way valves with actuator motors.

With the factory piping and valve package, the two coils are

piped in parallel and controlled through a single three-way

Page 26 I IM 487

17. When

Page 27

Steam Piping to Coils in the Heat Section

Steam coils are provided without valves for field piping, or

piped with two-way valves and actuator motors.

With the factory piping and valve package, the two coil supplies are piped in parallel and controlled through a single twoway valve. The field supply connection is of the same female

NPT size as the valve. Field return connections are made at

the 2.50” male NPT fittings on each of the two stacked coils.

Note: The valve actuator spring returns to a stem up posi-

tion upon power failure. This allows full flow through the coil.

Pipinq Recommendations (Steam Coils)

1.”

Be-certain that adequate piping flexibility is provided.

Stresses resulting from expansion of closely coupled pip-

ing and coil arrangement can cause serious damage.

2.

Do not reduce pipe size at the coil return connection. Carry

return connection size through the dirt pocket, making the

reduction at the branch leading to the trap.

3.

It is recommended that vacuum breakers be installed

all applications to prevent retaining condensate in the coil.

Generally, the vacuum breaker is to be connected between

the coil inlet and the return main. However, if the system

has a flooded return main, the vacuum breaker should be

open to the atmosphere and the trap design should allow

venting of the large quantities of air.

Do not drain steam mains or take-offs through coils. Drain

4.

mains ahead of coils through a steam trap to the return line.

Do not attempt to lift condensate when using modulating

5.

or on-off control.

Pitch all supply and return steam piping down a minimum

6.

of 1 inch per 10 feet (3mm per 305cm) in direction of flow.

Steam Trap Recommendations

1.

Size traps in accordance with manufacturers’ recommendations. Be certain that the required pressure differential

will always be available. Do not undersize.

2

Float and thermostatic or bucket traps are recommended

for low pressure steam. Use bucket traps on systems with

on-off control only.

Locate traps at least 12 inches (305mm) below the coil

3.

return connection.

4.

Always install strainers as close as possible to the inlet side

of the trap.

!5.

A single trap may generally be used for coils piped in

parallel, but an individual trap for each coil is preferred.

Freeze Conditions (Steam Coils)

(Entering air temperature below 350 F [20 C])

1. 5 PSI (34.5 kPa) steam must be supplied to coils at all

times.

2. Modulating valves are not recommended. Control should

be by means of face and bypass dampers.

As additional protection against freeze-up, the trap should

3.

be installed sufficiently far below coil to provide an adequate hydrostatic head to ensure removal of condensate

during an interruption on the steam pressure. Estimate 3

feet (914mm) for each 1 PSI (6.9 kPa) of trap differential

required.

4.

If the unit is to be operated in environments with possible

freezing temperatures, an optional freezestat is recom-

mended. Refer to “Freeze Protection” in the “Unit Options”

section of this manual.

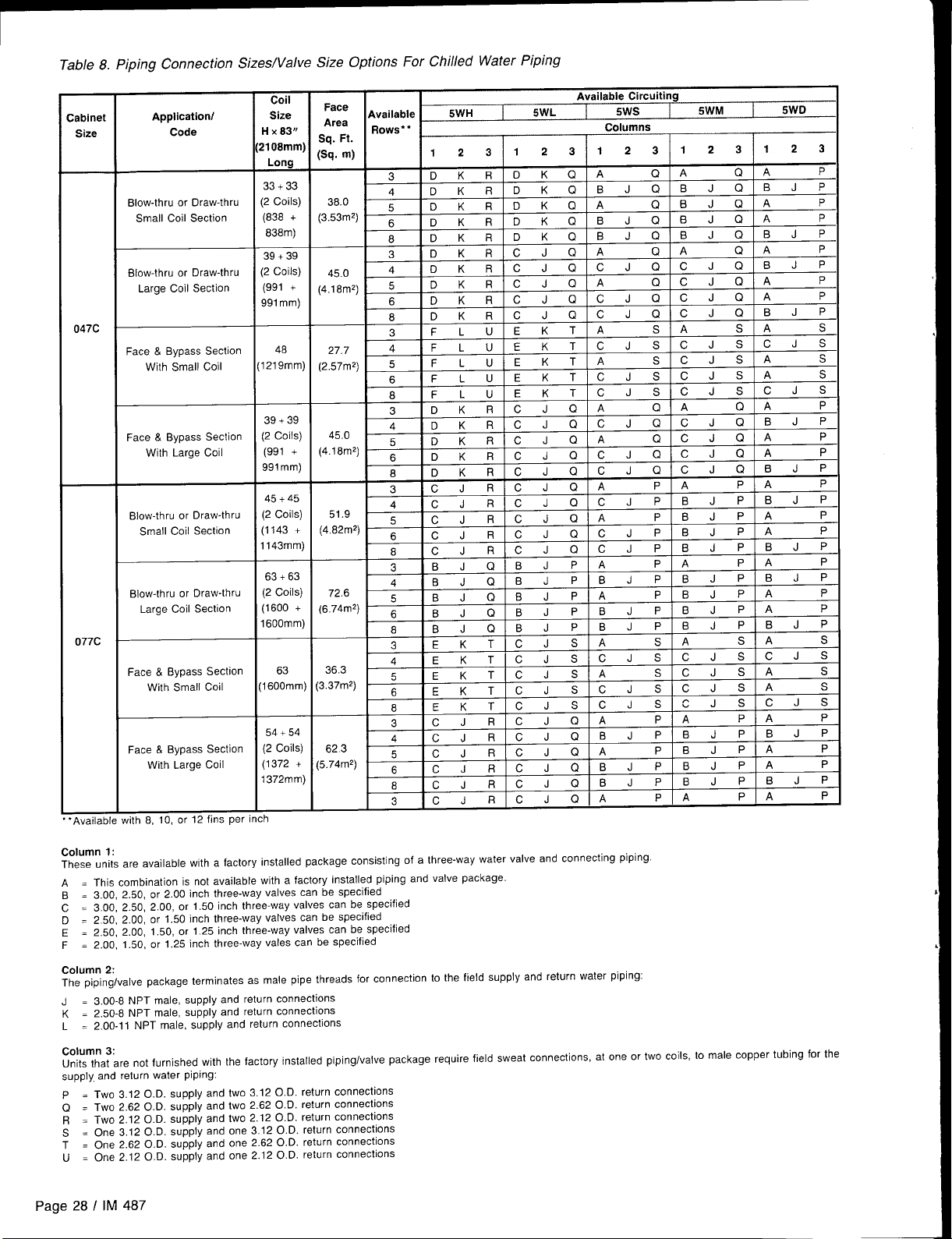

Chilled Water Piping

on

Chilled water coils are provided without valves for field piping, or piped with three-way valves with motor actuators. Table

8 provides information on units with factory installed piping

and valve packages. The table also provides field sweat connection information for units not furnished with factory installed

piping and valve packages.

With the factory piping and valve package, the coil assembly

is controlled through a single three-way valve. When two coils

are included in the assembly, they are piped in parallel. Field

connections are male NPT, sized as shown in Table 8. Refer

to Figure 20 for a typical cooling coil with factory valve and

piping.

Fiaure 20. Chilled Water Coil

(Shown With Factory Valve and Piping)

Figure 19. Heating Coil Piping With Vestibule

IM 487 I Page 27

Page 28

Table 8. Piping Connection SizeslValve Size Options For Chilled Water Piping

:abinet

Size

047C

077C

“Available with 8, 10, or 12 fins per

Application/

Code

Blow-thru or Draw-thru

Small Coil Section

Blow-thru or Draw-thru

Large Coil Section

Bypass Section

Face &

With Small Coil

Face & Bypass Section

With Large Coil

Blow-thru or Draw-thru

Small Coil Section

Blow-thru or Draw-thru

Large Coil Section

Face & Bypass Section

With Small Coil

Face & Bypass SeCtiOn

With Large Coil

y

Hx83° i

2108mm)’

Long

33+ 33

(2 Coils)

(838 +

838m)

39+ 39

(2 Coils)

(991 +

991 mm)

48

1219mm)

39+ 39

(2 Coils)

(991 +

991 mm)

45

45+

(2 Coils)

(1143 +

1143mm)

63+ 63

Coils)

(2

(1600 +

1600mm)

63

1600mm)

54+ 54

(2 Coils)

(1372 +

1372mm)

Face

Available

Area

Sq. Ft.

(Sa. m)

(3.53mZ)

(4.18mZ)

(2.57m2)

(’$18M2)

(4.82m2)

(6.74m2)

3.37mZ)

Rows*”

3

38.0

45.0

27.7

45.0 “~KRICJQ 1A

51.9

72.6

36.3

4

5

6

8

3

4

5

6

8

3

4

5 FLU

6

8

m

?.

I A nKRICJQ CJQ

~lDKRICJQICJ ;l;~QIA

3

4 CJR CJQIC

; ~JR

8

3

4

5

~

8

“ r ,/ T PI

4

5

6

8

3

5WH

123 123 1z3

DKR DKQ A

DKR DKQ

DKR DKQ A

DKR DKQ

DKR

DKR CJQ A

DKR CJQ

DKR

DKR

DKR CJQ

FLU EKT A

FLU EKT

FLU EKT

FLU EKT cJs cJs CJS

I DKRICJ

,

CJR cJQ IA

JR CJI

CJR CJQ

BJQ BJp A

BJQ BJp B

BJQ BJp A

BJQ BJp

BJQ BJ

,,,

.

EKTICJS

EKTICJS A

K

E

EKTICJS

CJRICJQ A

5WL

DKQ BJQ BJQ BJP

CJQ A

CJQ cJQ CJQ A

EKT

RIC

TICJ

J

CJQ

I

r. Ic. IRIc JQIBJ PIBJp BJP

62.3 ; ;;

:5.74mZ)

6

8

3

CJR CJQ

CJR CJQ

CJR CJQ A

RICJQIA

Available Circuiting

5WS

Columns

5WM

123 123

Q A

Q A