Page 1

Installation & Maintenance Data

Group: PTAC

Part No.: 910109975

Date: July 2010

EnerSaver™ Packaged Terminal

Air Conditioners and Heat Pumps with R-410A Refrigerant

Model PNES3 “A” Design

IM 1079

Table of Contents

Receiving Equipment .....................................................................2

Model Nomenclature ......................................................................3

Installation Instructions

Louver Frame ..................................................................................3

Wall Sleeve Extension ....................................................................4

Subbase ...........................................................................................5

Wall Guard Flange ..........................................................................6

Hydronic Piping ..............................................................................7

Room Cabinet/Wall Sleeve .............................................................8

Condensate Drain Kit ......................................................................9

Chassis ..........................................................................................10

Front Panel ....................................................................................11

Climate Director Plenum ..............................................................11

© 2010 McQuay International

Unit Start-up

Electrical Connections ..................................................................12

Outside Air Damper ......................................................................12

Check, Test & Start Form ...................................................... 13-14

Unit Maintenance and Operation ..............................................15

Specic Operating Conditions ..................................................16

Typical Schematics .......................................................................16

Wall Thermostat Adjustment ......................................................18

AC Retrot With HP Chassis ......................................................18

Troubleshooting ...................................................................... 19-21

Page 2

Receiving Equipment

Before signing the freight bill, carefully examine the units and

note any shortages or damages on the freight bill. The purchaser

is responsible for ling the necessary claims with the carrier.

Concealed damage which was not discovered until after unloading

should be reported to the carrier within 15 days after receipt.

McQuay’s responsibility ceases upon delivery of material in

good order to a carrier.

To help avoid concealed damage, the units must be shipped,

handled, and stored right side up as clearly marked on the

container. If the units must be stored prior to installation, they

should be stored within the carton in a clean, dry, protected area.

When ready for installation, save the carton and use the carton

shell to protect the cabinets until construction, painting, etc., is

completed.

A complete EnerSaver unit is normally shipped in two cartons:

one carton contains the cabinet/wall sleeve, front panel, louver

and subbase; the other carton contains the integrated chassis.

Cabinet/ Wall Sleeve

The EnerSaver cabinet/ wall sleeve is available in two sizes, 37½"

(952mm) or 41½" (1054mm) long. This one-piece cabinet/wall

sleeve functions as both the wall box as well as the room cabinet

once the front panel is in place. Units with hydronic heat always

utilize the long cabinet. The hydronic coil is factory mounted

to the cabinet/ wall sleeve. Electric heat models are available in

either size cabinet. Units ordered with either the stamped or the

extruded aluminum louver are shipped with the louver factory

mounted. Stamped anged louvers must be eld mounted after

the room cabinet/wall sleeve is in place.

Chassis

The chassis is a completely self-contained, integrated

heating/ cooling/ ventilation center. It houses the refrigeration

components , air handling components, electric heater

(if applicable), and controls. A single integrated chassis requires

less on-site handling during installation and service periods.

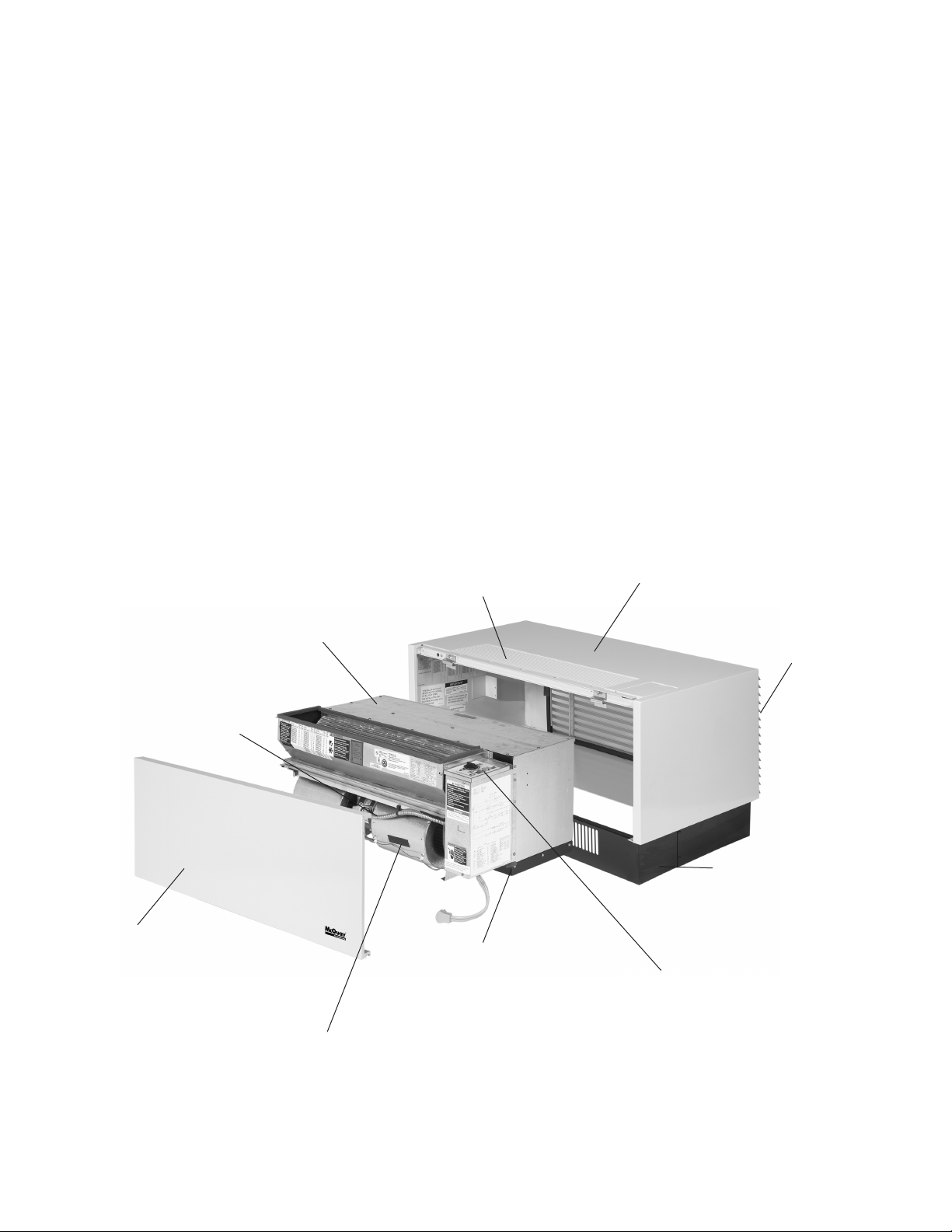

Figure 1: EnerSaver Features

Ventilation Control

Manual damper standard on

electric and heat pump chassis.

Motorized damper standard

on hydronic chassis.

Fan Motors

Both indoor and outdoor fan motors

are PSC for superior quality and

greater reliability.

Front Access Panel

Heavy gauge steel with

powder paint coating provides

maximum scratch and dent

resistance and minimizes

vibration for quieter operation.

Indoor Fan Wheels

Large diameter to provide

improved airow and quiet operation.

Heavy Duty Grille

Factory mounted,

“pencil proof” bar stock

discharge grille.

Base Pan

One-piece base pan and

one-piece bulkhead provide

weather tightness and water

integrity.

Room Cabinet/Wall Sleeve

Heavy gauge steel with

powder paint coating provides maximum

scratch and dent protection and resists

corrosion.

Outside Air Louver

Factory mounted

extruded aluminum

to resist weathering.

Subbase

Heavy duty steel with

powder coated paint

to resist corrosion.

Electro-mechanical Controls

Reliable and easy to operate.

Easily adaptable to energy

management systems.

IM 1079 / Page 2 of 24

Page 3

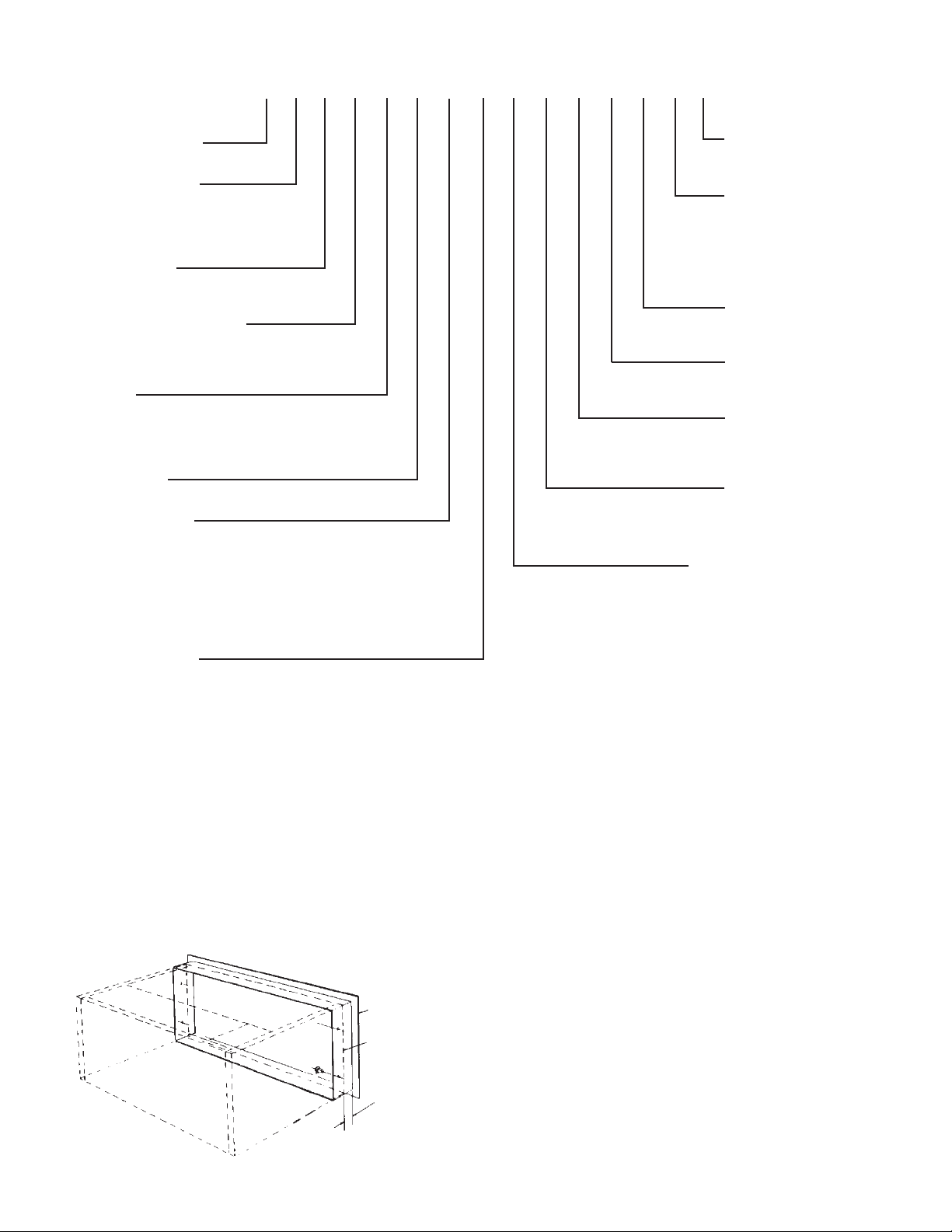

Model Nomenclature

P NES 3 009 C Z 35 Z 12 AR 14 C 1 A 1

Model

Product Category

P= PTAC

Product Style

1 = 1st Style Change

Product Identier

NES = Enersaver Air Conditioner w/

Electric or Hydronic Heat

NHS = Enersaver Heat Pump

w/ Electric Heat

Design Series

3 = A design - Enersaver

4 = B design Enersaver

Nominal Capacity - Btuh

009 = 9,000

012 = 12,000

015 = 15,000 (AC Only)

Voltage

A = 115 - 60 - 1 (Hydronic AC Only)

C = 208 - 60 - 1

G = 230 - 60 - 1

J = 265/277 - 60 - 1

Coil Options

Z = None

Heating Options

00 = None

35 = 2.5 kW nominal

41 = 3.5 kW nominal

44 = 4.0 kW nominal

62 = Hydronic - Normally Open Valve (hot water or steam)

for EnerSaver “A” Design

63 = Hydronic - Normally Closed Valve (hot water or steam)

for EnerSaver “B” Design

Hand Orientation

Z = Not Applicable

SKU

A = Stock

B = Standard

Delivery

C = Extended

Leadtime

Color

1 = Antique Ivory

Power Connection

C = Cord

Return Air/

Outdoor Air

14 = Bottom

Discharge

AR = Flat Top

Controls

12 = Unit Mounted Manual

Changeover (MCO)

13 = Remote Thermostat Setup

24 = Unit Mounted Manual

Changeover (MCO)

& Night Setback (NSB)

Note: Availability of voltages, heating options, and controls may vary amongst unit sizes. Consult your McQuay representative.

Installation Instructions

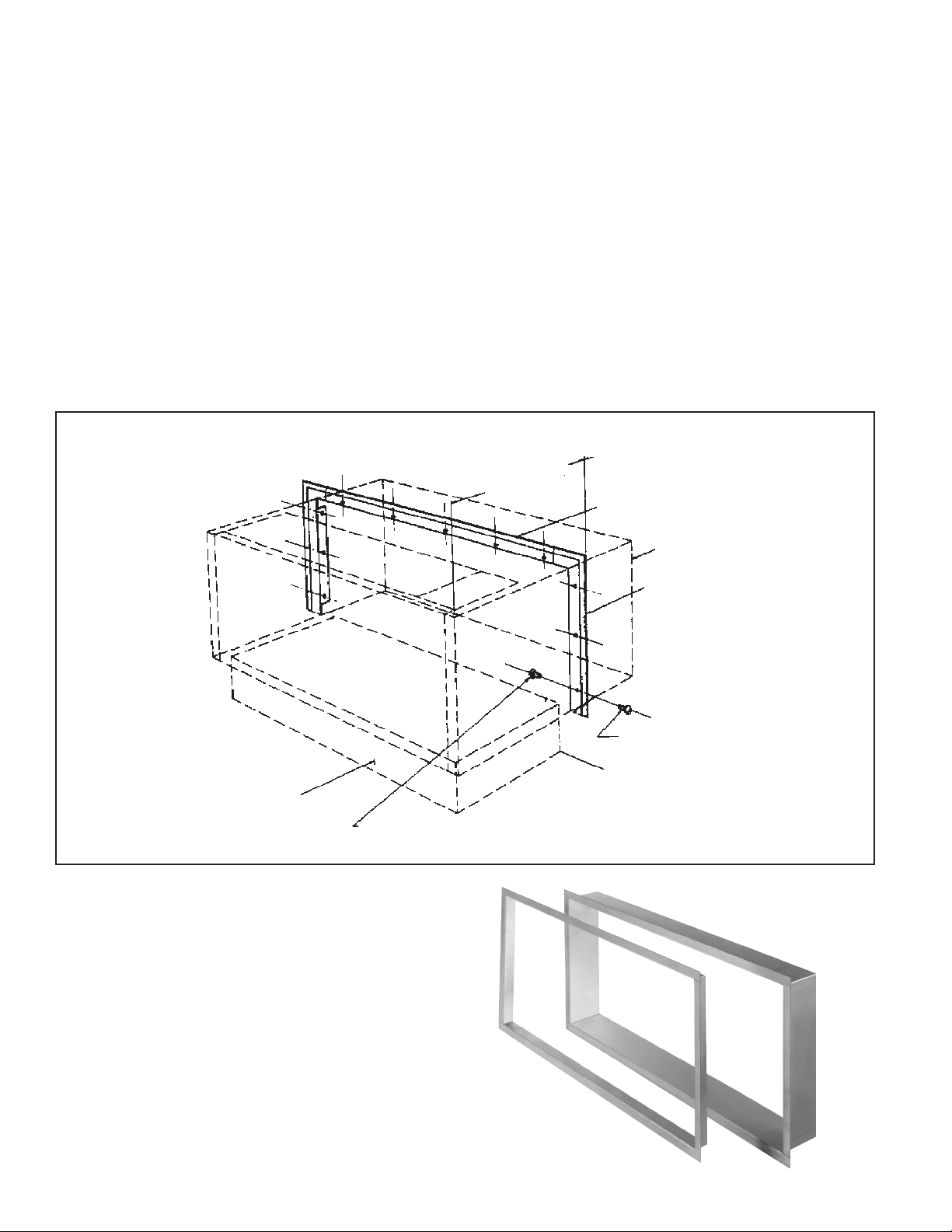

Louver Frame

When a louver frame is used, it must be installed prior to the

room cabinet/ wall sleeve, and it must be level and square (see

Figure 2). If the louver frame is to be installed in a panel wall,

install it at the same time as the room cabinet/wall sleeve.

1. Apply caulking compound on the surfaces of the louver

frame’s four anges which will come in contact with the

wall. Add caulking as required for weather tight seal.

Figure 2: Louver Frame Installation

Intake Collar

Cabinet/Wall Sleeve

2. Place the louver frame in the wall opening from the

exterior of the building, and apply rm pressure so that

the caulked frame anges are snug against the exterior

of the building. Secure the louver frame to the wall if

desired.

3. Secure the louver frame to the wall through the sides and

top. Never secure the frame through the bottom as it can

cause leaks.

4. Coordinate the remaining instructions with the room cabinet/wall sleeve installation instructions.

5. Drill four (4) 1/8" (3mm) diameter holes through the sides

of the wall sleeve and through the ange of the louver

frame. Attach the collar with four (4) #8 x 3/8 self-tapping

screws provided. Do not drill holes in the bottom of the

wall sleeve.

6. Caulk the seam between the louver frame and the wall

watertight.

3" (76mm)MAX

IM 1079 / Page 3 of 24

Page 4

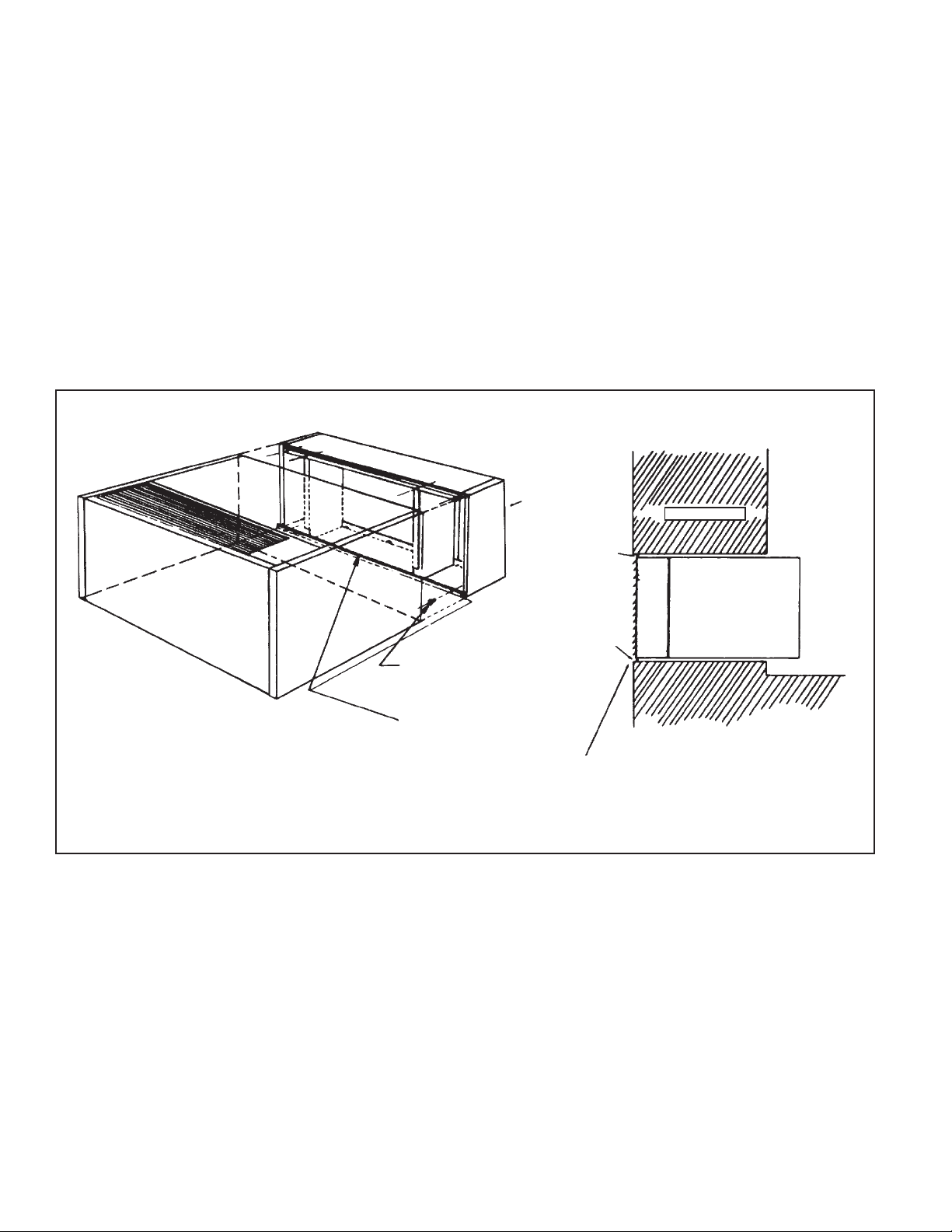

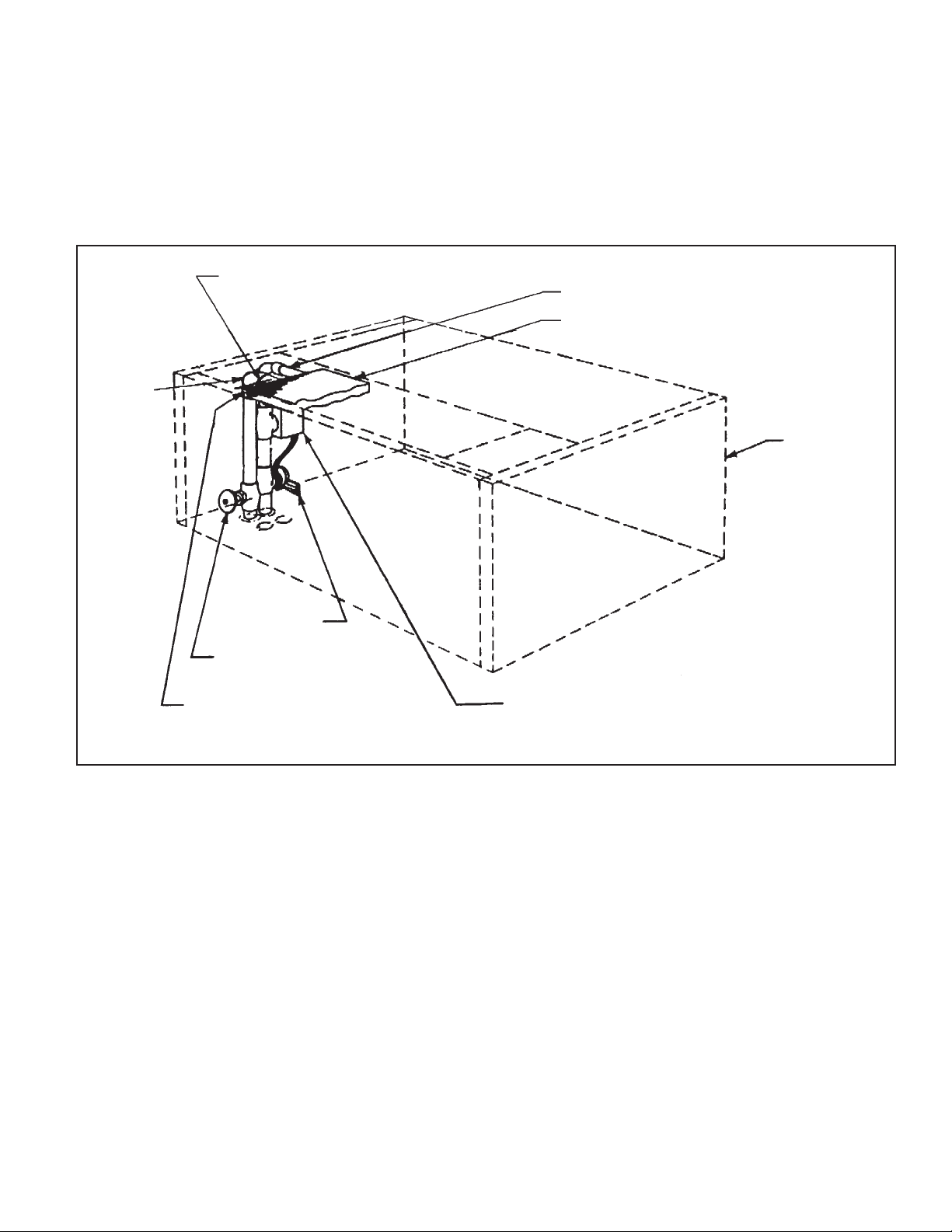

Wall Sleeve Extension

1. When a wall sleeve extension is used, assemble it and the

wall sleeve, then place them in the wall as a unit.

2. In cases where the louver is already installed in the

cabinet/wall sleeve, remove it from the wall sleeve before

installing the extension.

3. Check the tagging of the wall sleeve extension to be sure

it corresponds with the correct unit location.

4. Before attaching the wall sleeve extension to the wall

sleeve, run a bead of caulking around the outside ange

of the wall sleeve where it attaches to the extension,

making a watertight seal.

Figure 3: Wall Sleeve Installation

5. Align the predrilled mounting holes of the wall sleeve

extension with those of the wall sleeve (the louver mounting holes), and rmly attach these two parts with the six

(6) self-tapping screws provided with the wall sleeve

extension.

6. Recheck caulking to ensure that all seams are watertight.

7. Refer to the wall sleeve installation instructions on page

8 for installation of the wall sleeve and extension into the

wall.

Wall Sleeve

Extension

Wall Depth

Caulk (by others)

Caulk (by others)

1. Attach the extension with the self

tapping screws provided, through

the slots in the rear of the cabinet/

wall sleeve.

2. Caulk the inside perimeter of

the cabinet/wall sleeve/extensionwatertight.

3. After installation, caulk the

exterior perimeter of the

extension/wall watertight.

Cabinet/Wall

Sleeve

Extension

IM 1079 / Page 4 of 24

Page 5

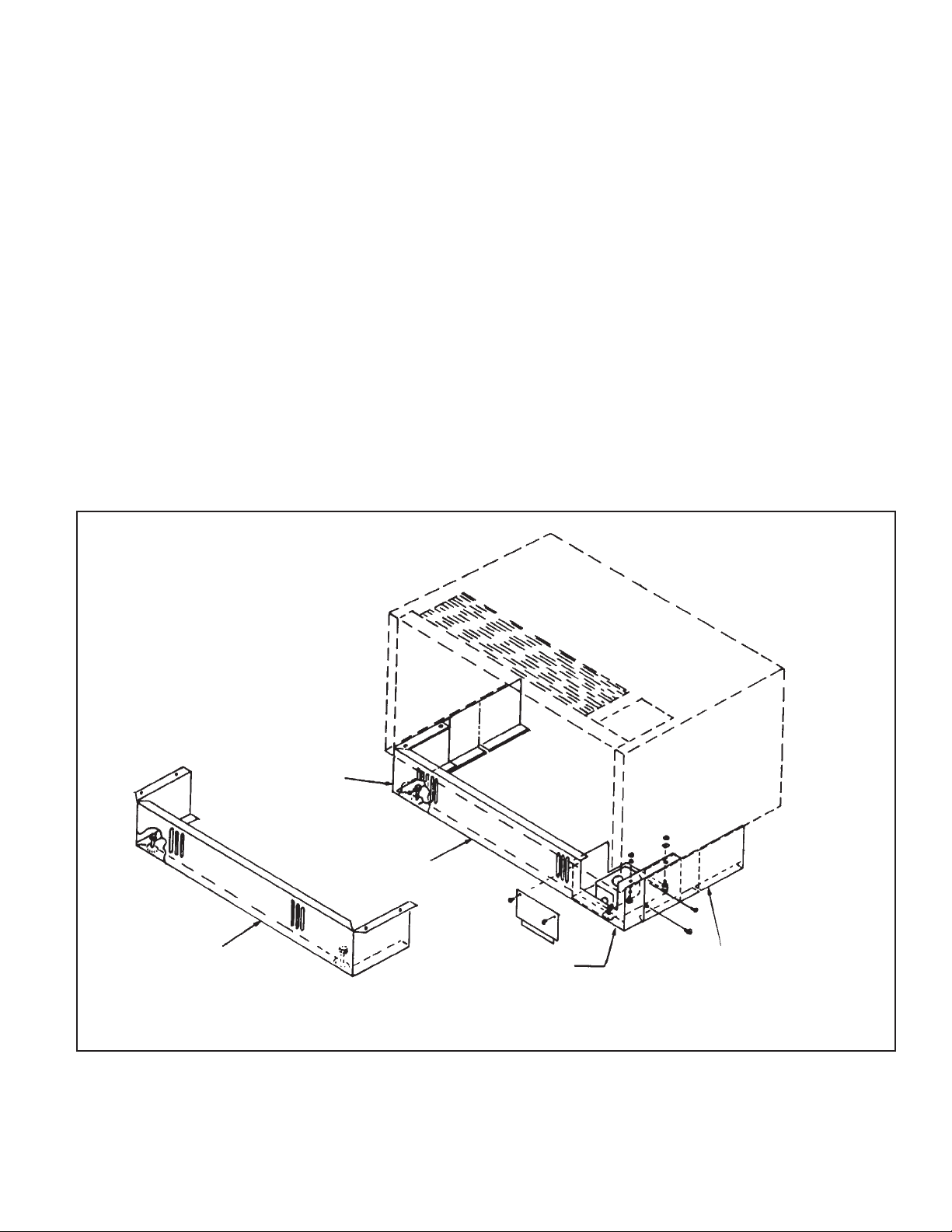

Subbase

When a subbase is used, it must be installed prior to the room

cabinet/wall sleeve. Consult the instructions shipped with the

subbase for proper installation.

1. When removing the subbase from the shipping carton

remove the two (2) shipping bolts and sheet metal nuts.

Do not throw away the shipping bolts; they are used as

subbase leveling bolts.

2. The electrical subbase assembly contains the unit receptacle and junction box. Therefore, before installing the

subbase to the cabinet/wall sleeve, it will be necessary to

run the power wiring from the stub-in and attach it to the

subbase receptacle.

3. The subbase assembly comes in two (2) parts:

a. A front section which bolts to the cabinet/wall sleeve.

b. End ller pieces, which telescope to t ush

against the wall.

Figure 4: Subbase Installation

4. Attach the front section of the subbase to the cabinet/wall

sleeve with the furnished nuts, screws and lock washers

using holes provided as attachment points. Install the two

(2) star washers provided as shown in the illustration to

provide a ground path between the cabinet/wall sleeve

and the subbase.

5. Coordinate the remaining instructions with the room cabinet/wall sleeve installation instructions.

6. After the cabinet/wall sleeve is fastened in the wall,

position the end ller pieces so they are tight against the

wall. Then, using the two (2) holes as a template, drill two

(2) 11/64" (4.4mm) diameter holes into the front section

of the subbase. Attach the two end llers, using the selftapping screws provided.

Standard Subbase

Leveling Bolts

Electrical Subbase

Attach Front of Subbase to

Cabinet/Wall Sleeve Using

Holes Provided

(See item 4 above)

Attach Rear Section with

(2) #10- 24 × 3/8" Self-Tapping Screws

Provided (See item 6 Above)

IM 1079 / Page 5 of 24

Page 6

Wall Guard Flange

1. The wall guard ange is shipped disassembled and is

normally taped to the inside of the cabinet/wall sleeve.

2. Mounting the wall guard ange before the cabinet/wall

sleeve is installed:

a. Locate the rear edge of the wall guard ange at the

position that corresponds to the inside nished wall line.

b. Using the holes in the wall guard ange as a template,

drill eleven (11)1/8" (3mm) diameter holes in the cabinet

wall sleeve and attach the wall guard ange to the

cabinet/wall sleeve with the eleven (11) #8 x 3/8 selftapping screws furnished.

Figure 5: Wall Guard Flange Installation

3. Mounting the wall guard ange after the cabinet/wall

sleeve is installed:

a. Position the wall guard ange so that the rear edge is

tight against the inside nished wall surface.

b. Measure the distance from the front of the cabinet/

wall sleeve to the front edge of the wall guard ange

and add 1/2" (13mm). At this dimension from the

front of the cabinet/wall sleeve, drill eleven (11)1/8"

(3mm) diameter holes from the inside of the cabinet/

wall sleeve through the angle of the wall guard ange

spacing them approximately 6" to 8" (153mm to

203mm) as shown. Attach the wall guard ange to

the cabinet/wall sleeve with the eleven (11) #8 x 3/8

self-tapping screws provided.

Locate the Rear Edge of the Wall

Guard Flange Top and End Sections

at the Finished Wall Line

20" (508mm) Max.

8" (203mm) Min.

Top Wall Guard Flange

Optional Subbase

Cabinet/Wall Sleeve

End Wall Guard Flange

Note 2

Note 3

Wall Guard Flange

(Flange for Interior Wall Finish)

IM 1079 / Page 6 of 24

Intake Collar

(Flange for Exterior Wall Opening)

Page 7

Hydronic Piping

1. Stub hot water or steam piping through oor prior to

installation of room cabinet/wall sleeve.

3. Install valve. Use soft solder only. Refer to the installation

instructions packed with each valve.

2. After the room cabinet/wall sleeve is installed, complete

the piping. Piping must not extend to the right beyond the

chassis guide rail in the bottom of the cabinet/wall sleeve.

Figure 6: Hydronic Piping Installation

Air Vent if Required

(by others)

Return

4. After all piping is complete and chassis is installed,

connect wiring to the valve. Plug connection is provided

on wiring which hangs from the left side of the chassis.

Supply

Hydronic Coil (Factory Mounted in Cabinet/Wall Sleeve)

Cabine/Wall Sleeve

Wire Harness

Shutoff Valves (by others)

Coil Supply and Return Connections

are 5/8" O.D. Female Sweat

Motorized Valve (AAF). Standard Piping For Hot Water Shown. For Steam

System, Steam Trap By Others Required in Return Line.

IM 1079 / Page 7 of 24

Page 8

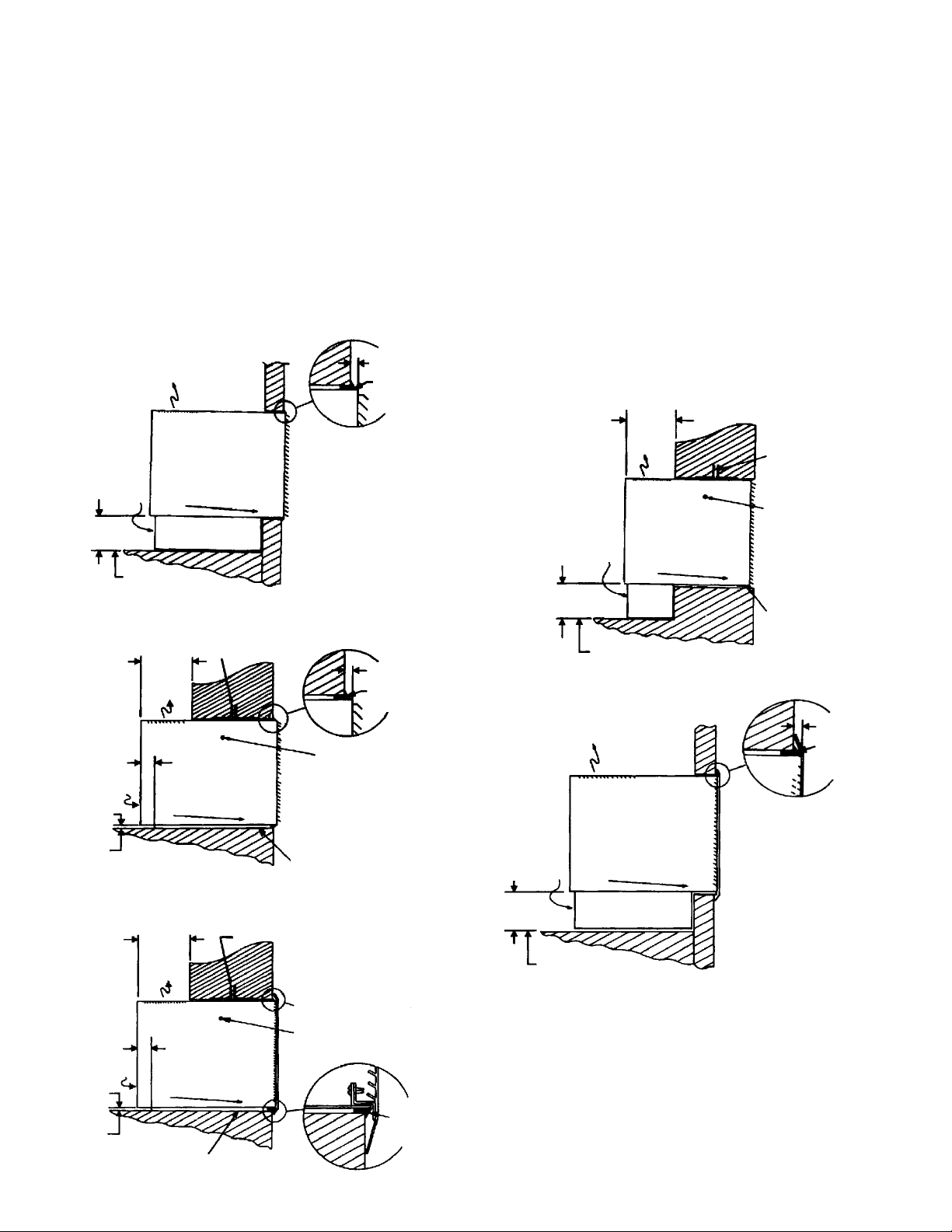

Room Cabinet/ Wall Sleeve

1. Where applicable, install the louver frame, wall sleeve

extension, subbase, and/or wall guard ange as per prior

installation instructions.

2. For masonry installations, set the room cabinet/wall

sleeve in soft mortar.

3. Position the room cabinet/wall sleeve in the wall opening.

Where applicable, align with louver frame. See Figures

7 through 11 and associated notes for various installations.

4. Where applicable, level the subbase with the leveling

bolts provided.

Figure 7: Panel Construction, Bottom Inlet, Extruded Louver

Discharge

Return

Air

Inlet

5"(127mm)

Min.

Finished Floor Line

Slope 1° Max.

Subbase

(See Note 3)

Figure 8: Masonry Construction, Front Inlet, Extruded Louver

Masonry Lintels

8"

Min.

3" (76mm)

Slope 1° Max.

By Others

See

Note 4

Fasteners By Others

Standard Louver

Installation Shown

Mortar Bed or Rigid Insulation

Board

(203mm)

Discharge

Return

Air Inlet

See Note 5

Finished

Floor Line

1/4" (6mm) Min.

Caulk

By Others

1/4" (6mm)

Min. Caulk By

Others

5. After the room cabinet/wall sleeve is installed and

leveled, secure the louver frame to the wall with screws

driven through the sides and top of the room cabinet/wall

sleeve outward through the louver frame. Never secure

the frame through the bottom, as it can cause leaks.

6. Caulk the outdoor joint between the room cabinet/wall

sleeve and the louver frame: top, bottom, and both sides.

Do not permit caulking to block the weep holes.

7. Install the outdoor louver. Holding the louver with a wire

loop, or other similar means, push the louver out through

the rear opening in the room cabinet/wall sleeve and pull

the louver back to the rear face so that the louver studs

pass through the holes in the room cabinet/wall sleeve

ange. Attach the louver with the washers and nuts

provided, and securely tighten the louver in place.

Figure 10: Masonry Construction, Bottom Inlet, Extruded

Louver

Return

Air

Inlet

5"(127mm)

Min.

Finished Floor Line

Figure 11. Panel Construction, Bottom Inlet, Stamped

Flanged Louver

Discharge

Return

Air

Inlet

8"

(203mm)

Min.

Discharge

Slope 1° Max.

Subbase

(Optional)

Slope 1° Max.

Masonry Lintels

By Others

Fasteners By Others

Flush Louver

Installation Shown

1/4" (6mm)

Min. Caulk

By Others

See

Note 4

Standard Louver

Installation Shown

Figure 9: Masonry Construction, Front Inlet, Stamped

Flanged Louver

(203mm)

Min.

Discharge

Return

Air Inlet

See Note 5

Finished

Floor Line

Mortar Bed or Rigid Insulation Board

IM 1079 / Page 8 of 24

8"

3" (76mm)

Slope 1° Max.

Masonry Lintels By Others

See Detail

Fasteners By Others

Caulk By

Others

5"(127mm)

Min.

Finished Floor Line

Notes:

1. Recommended wall openings are 16½" x 38" (419mm x 965mm) for short

cabinets and 16½" x 42" (419mm x 1067mm) for long cabinets.

2. Set the cabinet level side to side and level to no more than 1° slope

downward toward outside, front to back.

3. Fasten the cabinet/wall sleeve to the wall when possible. Do not fasten the

cabinet/wall sleeve through its bottom.

4. Regardless of the type of wall construction, the cabinet/wall sleeve must be

eld caulked to the wall around the top, bottom, and both sides, to form an

airtight and watertight weather seal. For ush louver installation, if the wall

material at the opening is not watertight, framing or ashing must be provided

around the wall opening (by others) to prevent penetration of water into the wall.

5. 1/2" (13mm) minimum for power cord (short cabinet only). Caution: If the

conditioned space is carpeted, increase this dimension to 3/4" (19mm)

minimum for long cabinets or to 1¼" (38mm) minimum for short cabinets.

Subbase

(See Note 3)

Page 9

Heat Pump Condensate Drain Kit (P/N 105542401)

Install the condensate drain kit at the same time as the chassis

is being installed.

1. If the application requires a drain exit through the bottom

of the wall sleeve, punch through the knockout provided.

2. Holes in the cabinet/wall sleeve, other than the knockout,

must be provided by others.

3. Slip the 5/8" (16mm) rubber tube over the end of the

drain tube elbow, locate the drain tube in the desired

position, and slip the open end of the rubber tube over the

chassis drain pan elbow. The rubber tube must engage the

copper elbows a minimum of 1/2" (13mm). Installation of

the drain piping must allow clearance for the lter which

ts under the drain connection.

Figure 12: Heat Pump Condensate Drain Connection

Left Side of

Cabinet/

Wall Sleeve

23/32" 18mm)

71/4" (184mm)

Long Cabinet (411/2")

31/4" (83mm)

Short Cabinet (371/2")

Lower Left-Hand Front View

(Front Panel Removed)

Condensate

Drain

4. Maintain a downward pitch in the drain line, away from

the drain pan.

5. Connect drain pipe to condensate removal piping system

or extend to exterior of building.

6. Test drain operation by pouring approximately (2) quarts

of water into drain and assure proper removal.

7. The drain valve is thermostatically controlled: full open at

60°F (1600), full closed at 80°F (2700).

Figure 13: Condensate Drain Connection Detail

3/4" (19mm) Dia. Hole (by

others) 1/2" (13mm) Up from

Bottom Caulk Water Tight When

Drain is Thru Rear of Cabinet

5/8" Copper Tube Assembly

Thru End Panel into Wall

(Hole by others)

Down Thru Wall

Knockout

Provided

5/8" Rubber Tube

(Hole by others)

Drain Pan Elbow

Lintel By Others

(13mm)

Extruded

Louver

Shown

1/2"

Condensate Drain

Left End View

Finished Wall Surface

8"

(203mm)

Min.

1¾"

(44mm)

7¼"

(184mm)

Optional

Subbase

3/4" (11mm)

1½" (38mm)

Chassis

Cabinet Front

Panel

23/32" (18mm)

Return Air

Inlet

Trap By Others

Notes:

1. Condensate drain piping must be connected to the condensate drain as shown

in Figure 13.

2. A condensate piping kit is available from McQuay.

3. Condensate piping must be disconnected for removal of the chassis.

4. The drain valve is thermostatically controlled: full open at 60°F (16°C); full

closed at 80°F (27°C).

5. The condensate line must be slightly pitched below the chassis for proper

drainage.

IM 1079 / Page 9 of 24

Page 10

Chassis

Important: The chassis must be fully seated to provide a

proper weather seal. When properly installed, the front edge

will line up with the front edge of the cabinet/wall sleeve

1. Remove the chassis from the carton and check for

damage.

2. Compare the nameplate information to the job requirements and check the voltage supplied to the unit before

installing the chassis.

3. Remove all debris from the cabinet/wall sleeve and check

to see that the rear seal strip is securely attached.

4. Spin the condenser and room air fan wheels to make sure

they rotate freely, and they are tight. Check the copper

tubing in the compressor compartment. If required, bend

carefully to eliminate contact with other tubing or the

compressor shell.

5. Remove the two (2) hex nuts from the weld studs on the

cabinet and remove the two (2) clips.

6. Install the chassis in the wall sleeve. Check the seal where

the gasket on the discharge plenum seals against the

ange on the wall sleeve. The seal should be in complete

contact with the wall sleeve ange.

7. Attach the drain kit (if provided) or other suitable drain

provisions to the tting on the chassis. Required on

heat pumps only. See condensate drain kit installation

instructions.

10. Install the clips removed in Step #5.

11. Install the lter before operating the unit. If the optional

louvered front panel is furnished, install the lter in the

brackets on the back of the front panel and install the

bottom blockoff in the cabinet/wall sleeve.

12. If applicable, install Climate Director plenum system. See

Climate Director installation instructions.

13. Install the front panel before operating the unit. Fasten the

panel at the lower corners using the screws provided. See

front panel installation instructions.

14. See Figure 14 to check the weather seal.

Cleaning compounds can permanently damage unit. Do not spray

cleaning compounds onto the discharge grille, return air opening or

unit controls. Clean unit by wiping with a damp cloth. When using

cleaning compounds on carpets, oors or walls, turn the unit off

to avoid drawing vapors into the packaged terminal unit.

Figure 14: Perimeter Weather Seal

!

CAUTION

Cabinet/Wall Sleeve Weather Seal

8. Test drain operation by pouring approximately (2) quarts

of water into drain and assure proper removal.

9. Connect the main power, the control wiring (if furnished),

and the motorized valve wire harness (hydronic heat

model only).

Figure 15: Chassis Installation

Inside View (Rear

View of Wall Sleeve)

Note: Check the weather seal around the entire

perimeter for proper adhesion to the cabinet/wall sleeve.

IM 1079 / Page 10 of 24

Page 11

Front Panel

Install the front inlet blockoff as shown in Figure 16. Install

the front panel on the cabinet/wall sleeve by placing the

notches in the bottom of corners of the panel over the raised

tabs on the cabinet (see Figure 17). Place the ange on the top

inside of the panel in the slot on the cabinet and carefully push

down until the cabinet and the front panel align. The panel

may be secured in place by installing screws in each lower

corner.

Figure 16: Front Inlet Blockoff Installation

Climate Director Plenum

1. Visually inspect room cabinet/wall sleeve to ensure that it

was ordered and delivered without the standard grille and

access door.

2. For proper placement of the accessory discharge ple-

num, a minimum distance of 10½" (267mm) must exist

between the wall and the cabinet front panel.

3. Remove the discharge plenum from its carton and position

5/8" (16mm) from the front of the previously installed

room cabinet. Discharge plenum must not interfere with

removal of the front panel. See Figure 18.

4. Using the plenum as a template, mark the locations of the

four mounting holes in each corner. Remove the plenum

and drill holes in the top of the room cabinet for 1/4"

fastening bolts.

5. Replace the discharge plenum and fasten to the room

cabinet with the four (4)1/4" bolts and nuts provided.

6. Install end cap which clips into discharge plenum as

required.

7. Optional duct sections are shipped in two-piece “L”shaped sections. Pieces t together using a locking seam

method. Press pieces together to form a tight t.

Figure 17: Front Inlet Blockoff Detail

Figure 18: Climate Director Plenum and Duct Installation

Discharge Grille

Three grilles and three blockoffs provided with each plenum install blockoffs

at same end as duct

Discharge Plenum

Install with (4) 1/4" diameter

bolts and nuts provided with

plenum

Access Door

8. Attach 4-inch (102mm) or 3-foot (91.5cm) duct sections

to discharge plenum. Duct sections clip onto plenum.

9. A maximum of ve sections, 15 feet (4.56 meters), may

be used on one unit in a straight run only. No elbow

congurations of any type are acceptable. Sections may

be eld cut. Multiple sections must be supported every

3 feet (91.5cm) by the contractor. Multiple sections are

attached with a trim angle at the connecting seam. Attach

trim angle to both sections with the four (4) #8 x 3/8

screws provided.

10. Install grilles on ends of duct sections.

11. Install discharge grilles on discharge plenum. Three (3)

grilles and three (3) blockoffs are provided with each

plenum. Install blockoffs at same end as duct.

Optional Trim Angle

Use to attach two or more 3 ft. duct sections

together. Attach with (4) #8 x 3/8" screws

provided with trim angle

Note Position of Locking Seams

Note: Discharge Plenum Must Not Interfere

with Removal of Unit Front Panel

Optional 4" (102mm) Duct

May be installed at left end

or right end of plenum

Cabinet/Wall Sleeve

Unit Front Panel

End Cap Install Right or Left End

1/4" Diameter Bolt and Nut

IM 1079 / Page 11 of 24

Page 12

Unit Start-up

(Complete the, Check, Test and Start Form on page 13 and 14)

Figure 20: Subbases

Electrical Connections

The 37½" short cabinet is used for applications that utilize

electric resistance or reverse cycle/heat pump heating

technologies. The EnerSaver chassis power cord is designed

to plug directly into an electrical receptacle that is hard wired

and concealed within the subbase of the room cabinet/wall

sleeve (see Figure 19).

The 41½" long cabinet is used when the hydronic (hot water

or steam) heat option is chosen. Included with this room

cabinet is a junction box designed to house an electrical

receptacle that is hard wired to the facilities respective circuit.

In all cases, the electric receptacle is supplied by either the

factory or by others.

1. The electrical installation must be in accordance with

the job wiring diagram and comply with the National

Electrical Code and all local electrical codes.

Figure 19: Receptacle Location for Permanently

Connected Units

Receptacle

2. Permanently connected units may utilize time delay

fuses or HACR type circuit breakers (where applicable)

for branch circuit protection. Cord connected units may

utilize time delay fuses or circuit breakers for branch

circuit protection.

Standard 5" adjustable

depth Subbase

Short Cabinet Subbase

with Electrical Box

Condensate Drain

Test drain operation by pouring approximately (2) quarts of

water into drain and assure proper removal.

Outside Air Damper

Three outside air damper arrangements are available: a manual

damper, a motorized damper, and no damper.

The manual air damper is operated by removing the front

panel and then placing the lever in the desired position.

Pushing the lever opens the damper; pulling the lever closes it.

Units equipped with motorized air dampers are controlled by

removing the front panel and then placing the damper control

switch in the auto or closed position. The concealed switch on

the motorized damper is to help prevent unwanted tampering

with damper control. When this switch is in the auto position,

the damper will be open and remain open while the unit is on.

If the unit is turned off, the damper will automatically close.

Placing the damper control switch in the closed position will

keep the damper closed at all times.

Figure 21: Manual Outside Air Damper

3. Optional factory mounted circuit breakers, when fur-

nished, are not offered as branch protection.

4. Since all chassis have identical dimensions, regardless of

heating and cooling capacities, pay careful attention to

the branch circuit amperage requirement for each unit to

avoid electrical mismatching of chassis and permanently

connected branch circuits during eld installation.

5. Unit supply voltage must be as follows:

Nameplate Voltage

120V

208V

230V

277/265V

IM 1079 / Page 12 of 24

Minimum

108

187

207

249

Maximum

132

228

253

304

Figure 22: Motorized Damper

Page 13

McQuay International PTAC Check, Test & Start

Date Report — Audit

Job Name _________________________________________________ City ______________________ State ______________________

Installer ______________________________________________________________________________ Total No. of Units ___________

ISO#/GO#

Unit Type(s)

Date of Final CTS Start-up ____________________________________________________________

Manufacturers’ Representative Name ____________________________________________________

Suite II Type K

Type EA Type J

Enersaver

Other

ESSENTIAL ITEMS CHECK

A. Voltage Check __________________ Volts (measured)

B. Yes No Condition Yes No Condition

Filters Clean Operates in Heating

Evaporator Coils/Drain Pans Clean Operates in Cooling

Wall Boxes Sealed To Wall, No Leaks Operates in Fan Only (if so equipped)

Wall Box Pitch Satisfactory Hi-Lo Fan Speed Operational (if so equipped)

Chassis Installed Completely into Wall Box Fans Rotate Freely

Condensate Drains Installed Damper Working Properly (Manual or Automatic)

Air Discharge Free of Obstruction Test Drain Pan Operation

Note: “No” answers above require notice to installer by memorandum (attached copy).

Please include any suggestions or comments: ___________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

Above System is in Proper Working Order FOR INTERNAL USE

Release:

________________________________________ SM _______________________

CTS_______________________

Date

T _________________________

Note: This form must be completed and returned to the Warranty Adminis-

Signature for Sales Representative

Signautre for Customer

Service Manger Approval

trator before any CTS, rst year monies can be released for payment. Failure to complete this form may cause unnecessary interruption in job site warranty.

Date

FORM No. PT-CTS-1206

IM 1079 / Page 13 of 24

Page 14

PTAC Check, Test and Start Worksheet

(For additional units copy this page) Page _____ of ___________

Cooling Heating Damper Amp

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

Model Serial # Room # Installation OK

Check

Check

Working

High Fan Low Fan

Check

IM 1079 / Page 14 of 24

Page 15

Unit Maintenance and Operation

With today’s high energy and labor rates, a sound preventive

maintenance policy is a very good investment. Clogged

and restricted air lters and coils can impede the ow of air

through the unit and can cause inefcient operation. Such

conditions only increase operating costs.

Poorly maintained equipment is an open invitation to short

unit life and frequent repair charges.

Filters — EnerSaver units are available with either a permanent lter or a disposable charcoal lter. Clean lters are

essential to proper airow through the unit. Utilities are

currently recommending lter inspection and replacement at

least once per month.

Vacuum permanent lters to remove loose dust. Then wash

the lter in a warm, mild soap solution to remove trapped

material. Rinse the lter and allow it to dry. Do not operate the

unit without both the lter and the unit front panel in place.

Evaporator Fan Motor — All Fan Motors are permanently

lubricated by the manufacturer. They do not require further

oiling.

Gaskets and Seals — It is extremely important that all

gaskets and seals be in place and intact. A loose or missing

gasket will prevent correct seating of the chassis in the

cabinet/wall sleeve, allowing inltration of outside air and

water into the room space. See Figure 24 for gasket and seal

location and arrangement.

Figure 24: Gasket and Seal Location

Seals

Removing Chassis — It is not necessary to remove the

chassis to perform most of the general maintenance proce-

dures just outlined. However, if the chassis requires removal,

use the following procedure:

1. Remove front panel by lifting upward from bottom.

Condenser Fan Motor — All Fan Motors are permanently

lubricated by the manufacturer. They do not require further

oiling.

Coil Surfaces — Clean coil surfaces are essential to efcient

heat transfer. A dirty coil can severely impede the operation of

a unit.

Visually inspect and clean the condenser and evaporator coil

surfaces annually. Inspect and vacuum the hydronic heating

coils before the beginning of each heating season.

Condensate Removal System — Condensate forms on

the evaporator coil during normal operation of the unit. An

internal system is provided to dispose of this condensate. It

is necessary to keep the drain pan and condensate line

clean to keep the system functioning correctly. Cleaning

the condensate pan is most convenient when it is done at the

same time as the annual coil inspection. See Figure 23 for the

location and removal of the drain pan and line.

Figure 23: Evaporator Drain Pan Cover Removal

2. Disconnect power to the unit by unplugging the control

box power cord from the unit receptacle/junction box (or

room receptacle on cord-connected units).

3. For units with remote controls, disconnect low voltage

lines connecting the control box with the wall thermostat.

4. For hydronic heating units, disconnect the motorized

valve from the control circuit. To do so, disconnect the

plastic connector at the left side of the chassis.

5. Remove chassis support brackets.

6. For PTHP units, disconnect the condensate drain kit rubber tube from the chassis drain connection.

7. After all wiring has been disconnected, place ngertips

under chassis removal ange and slowly pull chassis out

of the cabinet/wall sleeve. See Figure 25. Take care not

to allow the back of the chassis to “fall out” of the sleeve.

Damage can result if this happens. Some drain pans can

contain a small amount of water. Take care (i.e., drop

cloth, etc.) to prevent spills from staining carpet or oors.

Figure 25: Chassis Removal Flange

IM 1079 / Page 15 of 24

Page 16

Specic Operating Conditions

Familiarity with the correct operation of the units will allow

you to spot potential problems before they become serious. The

following list details specic operating conditions which you

should be aware of to help identify a unit malfunction.

1. Units with low ambient lockout should not operate on

cooling below 40°F (4°C) outside air temperature.

2. Frequent cycling of the compressor can reduce life expectancy of your unit. This could be caused by an over-

sized unit, poor location of the wall thermostat (when

used), low supply voltage to the unit, low refrigerant

charge, or outside air inltration.

3. Compressor failures are sometimes related to condenser

fan motor failures. If the condenser fan motor fails, the

4. Operating the units during low voltage periods can

damage the unit. If a brownout occurs, or local utilities

warn of voltage cutbacks, it is best to turn off the units.

The compressor is protected against voltage variations

and phase loss to the extent covered by U.L. Standard 484

for Room Air Conditioners.

5. Keep the discharge and return air grilles clean and

unobstructed. Do not use the cabinet/wall sleeve as a shelf

or table, since this restricts the ow of air from the unit.

6. During building construction periods, units should not be

used as temporary heating or cooling sources.

7. Remove any paper and other foreign material from the

unit before operating it.

compressor will continue to run and will operate at high

head pressures and temperatures which will eventually

cause the compressor to fail. To help prevent this, check

8. Test drain operation by pouring approximately (2) quarts

of water into drain and assure proper removal.

for proper operation of the condenser fan motor whenever

routine maintenance is scheduled.

Typical Schematics

Figure 26: Enersaver PNES with Unit-Mounted Thermostat, Electric Heat, No Setback, Manual Changeover

Note: See page 17 for schematic Legend.

IM 1079 / Page 16 of 24

Outdoor Air Motor Wires

Unit Size Color

009B (208) RED

009B (230/265) BLK

012B-015B

(208/230)

012B-015B (265) BLK

Room Air Motor Wires

Unit Size Hi Lo

009B (120/265) BLK RED

009B (208) BLK BLU

009B (230) ORG RED

012B (208/265) BLK BLU/RED

015B BLK BLU

RED/BLK

Page 17

Figure 27: Enersaver PNHS with Unit-Mounted Thermostat, Electric Heat, No Setback, Manual Changeover

Legend

Field Connection

Option Wire

Field Wire

Quick Connect

C1/3 Capacitor

CB Circuit Breaker (Option) (120/265V-1 Pole) (208/230V-2 Pole)

HL Hi Limit

HTR Electric Heater

M1 Motor-Room Air

M2 Compressor

M3 Motor-Outdoor Air Fan

M4 Motor-Vent (Option)

OL Compressor Overload

P1 Plug-Chassis

P2 Plug-Low Voltage

Wire Nut

HP High Pressure Cutout

P5 Plug-HP Cutout

R7 Relay-HP Cutout

Outdoor Air Motor Wires

Unit Size Color

009B (208) RED

009B (230/265) BLK

012B-015B (265) BLK

Unit Size Hi Lo

009B (120/265) BLK RED

009B (208) BLK BLU

009B (230) ORG RED

012B (208/265) BLK BLU/RED

015B BLK BLU

R2 Relay-Cooling

R3 Relay-Heating

R4 Relay-Fan

R5 Relay-Setback

R6 Relay-Interlock

RV Valve-Reversing

S1 Switch-Push Button

S2 Switch-Damper

T Transformer-Class 2

TB1 Terminal Block

TC1 Thermostat-Room Air

TC2 Thermostat-Setback

DOB Relay-DOB

TC4 Thermostat-Low Limit

TC5 Thermostat-Freeze

TD2 Relay-Time Delay

TC3 Thermostat-Low Ambient Lockout

TD1 Relay-Remote Setback (Option)

TB3 Terminal Block

012B-015B

(208/230)

RED/BLK

Room Air Motor Wires

IM 1079 / Page 17 of 24

Page 18

Wall Thermostat Adjustment

The wall thermostats used on EnerSaver units have a built-in

anticipator. In order to obtain even, comfortable heating in a

conditioned space, it is absolutely essential that the thermostat

anticipator is properly adjusted.

The anticipator is a small, adjustable resistor through which

the low voltage control current passes. On heating demand, the

thermostat closes and the unit operates on heating; the anticipator

heats up, giving the thermostat a false signal. If the thermostat

has to wait for the heat from the heating unit to reach it, the room

would have a tendency to overheat. The anticipator prevents

this by raising the temperature at the thermostat and stopping

the unit early.

There are two ways to set the anticipator. Take the control circuit

current draw, if it is known, and adjust the anticipator to this

value. This method will work satisfactorily in the majority of

cases. If the control wiring is oversized, the control voltage low,

or additional components are operated from the control circuit,

then the anticipator must be calibrated for each thermostat.

Remove the thermostat exposing the subbase, connect an ammeter

between the hot 24 volt terminals and the heating lead terminal.

The ammeter should be capable of reading accurately from 0.1

to 4.0 ampere. Record the value and adjust the anticipator to the

value recorded.

Typical recommended thermostat heat anticipator settings are

shown in the table below.

AC Retrot with HP Chassis

EnerSaver Heat Pump units are an excellent replacement for

Air Conditioning units. The chassis dimensions are identical,

allowing the H/P chassis to t into the A/C wall sleeve. The

major addition required is that of a condensate removal system.

On single-story applications, the condensate drain line may be

routed through the rear of the cabinet/wall sleeve allowing the

line to project out of the unit. Caulking around this notch will

prevent entrance of water into the sleeve. Multistory buildings

should utilize a more sophisticated condensate removal system

to prevent excessive drainage down exterior walls.

Note: Check cabinet/wall sleeve level of installation. For

condensate to drain properly, the sleeve must be set and

leveled from side to side. Then level the unit front to back

with no more than 1° slope downward toward the outside.

A nal consideration when retrotting an A/C wall sleeve

with an H/P chassis is branch circuit ampacity. The units

must be the same voltage, and have an ampacity equal

to or less than the A/C unit it is replacing.

Unit Type Anticipator Settings

Cooling Heat — Wet Heat — All Voltages .13

Cooling Heat — Electric Heat — All Voltages .15

Heat Pump — All Unit Types & Voltages .37

The anticipator should now be properly adjusted and very little

uctuation in room temperature should be noticed. The room

should be allowed to stabilize for 48 hours before checking the

effect of the anticipator adjustment. If complaints are still received,

small readjustments may be required due to the conguration

of the space.

The adjustment of the anticipator is a eld adjustment which

must be made by the installing contractor. In all cases, when

there are complaints of uneven heating in a space, ensure that all

anticipators are properly set. Optimum performance and comfort

cannot be expected unless anticipators are set correctly.

IM 1079 / Page 18 of 24

Page 19

Troubleshooting

The following troubleshooting guide should aid in detecting

unit malfunctions.

!

WARNING

Troubleshooting can present risks of equipment damage, severe

personal injury or death. Troubleshooting must be done by trained

experienced technicians only.

Complaint Probable Cause

Entire unit does not

operate.

Electric shock from

equipment.

Evaporator blower

assembly operates,

but is noisy.

Evaporator blower

assembly operates,

but compressor does

not start.

1. Power failure.

2. Push button.

1. Improper grounding of electric circuit.

1. Motor mounts.

2. Fan wheel.

3. Motor bearings.

1. Power.

2. Unit mounted manual change over thermostat.

3. Unit mounted automatic change over thermostat.

4. Wall mounted manual change over thermostat.

5. Wall mounted automatic change over thermostat.

6. Unit control panel.

7. Low ambient lockout.

8. Run capacitor defective.

9. Stuck compressor.

Checks and Corrections

1. Check for blown fuses or tripped circuit breaker. Check fuse sizes. Check

wiring connections and check for both high and low voltage.

2. Check for push button operation. Check for loose terminals, broken wires,

or defective push button. Replace if necessary.

1. Provide proper ground. Check for short circuits.

1. Check motor mounts; they might be loose. If so tighten. They could have

become bent in transit. Reposition and retighten.

2.

Check for proper alignment in fan housing. Check for tightness on motor

shaft. Check for foreign material in fan wheel or housing; e.g., construction debris, paper, plaster. Clean and retest. Check the electrical exible

conduit; it may be rubbing against fan assembly or unit front panel.

3. Check motor bearings. Replace if necessary.

1. Check for proper voltage at compressor terminals. See page 12 for compressor voltage range. At the power source check for proper wire size.

2. Turn unit temperature control knob to normal. Then push “High Speed”

button and push “Cool” button. The unit should turn on. If not, move the

thermostat knob clockwise to the end of its travel. If no contact is made,

hold thermostat bulb rmly in hand for a few minutes. If no reaction, check

wiring and continuity at terminals 1 and 2 at back of thermostat. If open

circuit when bulb is warm, remove and replace thermostat.

3. Turn unit temperature control knob as above. Press “High” or “Low” button.

The unit should turn on provided the setting on the thermostat is lower than

actual room temperature. If not, move thermostat setting to the coldest

point; it no contact, hold thermostat bulb rmly in hand for a few minutes.

If no reaction, check wiring and continuity at terminals 4 and 5 on back of

thermostat, If no continuity, remove and replace.

4. Set unit on “High” or “Low” speed push button. Then push on cool switch

on wall stat. Turn temperature lower than actual room temperature. Cooling relay should energize and compressor should start. If cooling relay

is chattering or humming, check for 24 volts supply at relay (should not

be lower than 18 volts). Caution should be exercised in the length of the

24V wire run from the unit to the stat. If run is excessive for gauge of wire

used, there may be a natural voltage drop. If compressor not running,

place jumper wire at subbase between terminal “Y” and “R”. If no voltage

at relay, check wiring at transformer.

5. Make sure jumper wire between RH and RC (On subbase) has been eld

wired. Set unit on “High” or “Low” speed. Then move lever (cooling) at

thermostat to temperature lower than actual room temperature. Cooling

relay should become energized. If compressor is not running, check for

wiring at transformer.

6. On unit using 24 volt transformer, check for low voltage open circuit;

check 24 volt transformer for burnout, check contacts (relays may be dirty

or binding); check for loose wires if below 18 volts. Caution should be

exercised in the length of the 24V wire run from the unit to the stat. If run

is excessive for gauge of wire used, there may be a natural voltage drop.

Disconnect and replace providing the primary voltage is within specied

limit (10%). Check for loose terminals or connections. They will change

color indicating the presence of heat. If so, change terminal.

7. If outside temperature at time of complaint was below 40OF (4OC), unit was

probably okay but was locked out on low ambient protection. If not, apply

heat by palm of hand to lock out control and warm up to a minimum of

60OF (16OC). and check for continuity. If open, remove and replace.

8. Check for overvoltage and light load. Reduce line voltage to value given

on page 12. In general, voltage should not exceed 10% over and above

nameplate voltage, If capacitor is suspected to be defective, test it with an

ohmmeter Check for water dripping over terminal, or for terminals shorting

together causing a dead short, If water dripping is suspected, nd traces

of water or condensation and make correction.

9. Before attempting this next checkout, ensure that the run capacitor is

not defective. Try an auxiliary capacitor momentarily, If the compressor

starts but the problem reoccurs on starting, install an auxiliary hard start

kit (referred to as PTC, Positive Temperature Coefcient Resistor) and a

correctly sized capacitor.

IM 1079 / Page 19 of 24

Page 20

Complaint

Evaporator blower

assembly operates, but

compressor does not start

(cont’d).

Compressor starts, but

does not switch “off” start

winding.

Unit short cycling.

Unit is running, but no air

is being delivered to room.

Insufcient cooling.

Too much cooling.

Evaporator blower

operates, but no heating

(electric heat).

Probable Cause

10. Compress or motor grou nded or has an

open winding.

1. Improperly wired.

2. Low line voltage.

1. Thermostat.

2. Wiring.

3. Control contacts uttering.

4. High amperage draw.

5. Refrigerant overcharge.

6. Compressor runs hot and cuts on overload

protection.

1. Evaporator airow restricted.

2. Evaporator coil iced up.

1. Evaporator airow restricted.

2. Automatic expansion not functioning properly.

3. Compressor efciency down.

4. Outside air entering room.

5. Unit too small.

1. Thermostat set low.

2. Defective thermostat.

1. Power at heating element.

2. Overheat switch.

Checks and Corrections

10. If the compressor temperature is above 130OF (54OC) the internal overloads

may not have reset yet. Allow the compressor to cool down before checking

the unit again (compressors cool slowly so cooling may take over an hour). If

the compressor is cool and does not start, test the motor windings. Remove the

electrical connections from the compressor and measure the resistance across

the Run and Start windings and/or the Start winding alone. If no resistance is

read, the windings are open and the compressor should be replaced.

1. Check against wiring diagram and correct if incorrectly wired.

2. Check voltage at compressor. Place voltmeter leads at common and run

terminals. Start compressor, read voltage. If below tolerance, check electrical

installation for proper sizing of wires and length of run of wiring for extreme

voltage drop.

1. If remote wall mounted thermostat check for proper heat anticipator setting as

described on page 16.

2. Check for loose terminal or connections in the electrical circuit. Trace and

repair.

3. Check control contact points. If pitted or corroded, remove and replace. Do not

le or clean with abrasive material.

4. Check compressor amperage draw at full load condition. If abnormally high

amperage, check condenser fan operation; fan should always be on when

compressor is running. Also check for refrigerant overcharge as outlined in

the next procedure.

5. Since there is no access valve to the refrigeration circuit, the “Frost Back”

method can be used, described as follows. While compressor is running,

observe the suction line from evaporator to compressor shell. If heavy frost

appears on the line, there is a possibility of an overcharge. To correct, use a

piercing valve on compressors processing tube and bleed off refrigerant slowly

until the frost line backs up 3" or 4" (76mm or 102mm) from compressor shell.

Caution: This method of checking the refrigerant charge is acceptable for this

situation. It is not acceptable for recharging a unit, in which case the amount

charged must be determined by either a graduated charging cylinder or by

weighing.

6. Check condenser coil in back of chassis. If there is excessive buildup of dirt,

clean the coil. Check for condenser fan. Also, either a high amp draw condition

(as described above) or this condition can be caused by short circuiting of the

condenser discharge air into the inlet airstream.

1. Dirty lter; change or clean. Obstruction in unit; remove. Dirty evaporator coil;

clean.

2. Check evaporator fan. If running, check expansion valve operation. If okay for

rst row of tubes at evaporator coil but frozen on remaining rows, clear off frost

and measure actual superheat 3 or 4 inches away from compressor ’s shell (on

suction line). If superheat exceeds +20OF (+11OC), low charge can be suspected

and unit should be evacuated and recharged by weight to nameplate data.

1. Dirty lter; change or clean. Obstruction in unit: remove. Dirty evaporator coil;

clean. Evaporator fan motor not up to adequate speed; fan wheel slipping on

shaft; tighten setscrews.

2. Check suction and/or proper opening at right pressure. Wrap expansion valve

with hot damp cloth, If pressure is restored by this method, then there is indication of moisture in the refrigeration circuit. Discharge refrigerant. Dehydrate

system with a deep vacuum pump and recharge according to procedure. If any

indication of moisture in system or a burn out, a lter-drier should be installed,

If problem still exists, remove expansion device and replace with new one.

3. Check for warm suction (high superheat) and slightly warm discharge. Check

actual temperature and pressure. If discharge pressure low and suction pressure high, may be compressor. Check with factory for procedure.

4. Check for open doors, windows or other openings and improper unit caulking.

5. Recheck heat gain, add additional insulation, shading, etc., or add additional

units.

1. Turn to higher setting.

2. Replace.

1. Check for proper voltage at heating element. Check for broken wires or loose

terminals at element, If broken, do not try to repair. Remove and replace complete element.

2. Overheat switch could be defective. Check continuity through switch when

switch is cooled down to approximately 235OF (113OC) and lower, it should

show continuity and should be open circuit at approximately 260OF (127OC)

IM 1079 / Page 20 of 24

Page 21

Complaint

Evaporator blower operates,

but no heating (electric heat)

(cont’d).

Evaporator blower operates,

but no heating (hot water or

steam).

Unit operates on cooling, but

water is dripping from unit.

El ec tr ic he ating el em en t

operates, but room side fan

does not operate.

PT HP uni t only pr ovide s

heating (no cooling).

PTHP unit not heating below

4OOF (4OC) outdoor ambient.

PT HP rev ers ing val ve no t

shifting from cool to heat or

heat to cool.

PTHP reversing valve starts to

shift, but does not complete

reversal.

Noisy operation.

Probable Cause Checks and Corrections

3. Push button device.

4. Thermostat.

1. Hot water valve or steam valve.

1. Chassis not properly installed in wall sleeve.

2. Condensate hose obstructed.

3. Evaporator drain pan not draining.

4. Air bypass at top of unit.

1. Motor capacity.

2. Loose terminals or broken wire.

3. Push button.

4. Defective motor.

1. Reversing valve not energizing.

2. Defective thermostat.

1. Fault low temperature at stat.

2. Check auxiliary heat.

1. Electric circuit: low solenoid coil voltage.

2. Refrigerant charge: low charge.

3. Defective compressor.

1. Insufcient pressure or both ports of pilot open.

1. Evaporator fan motor bearings.

3. Check contacts through push button (selector switch). If no contact

after switch has been pushed, check for loose wires or loose terminals, If

all connections okay but still does not operate, remove push button switch

and replace.

4. Move thermostat knob to highest setting. If unit still does not heat, check

through thermostat contacts. If no continuity when above set point, remove

and replace thermostat.

1. Check for proper water or steam circulating valve. Check water temperature. Check for continuity across valve motor. If defective, remove and

replace.

1. Cabinet should be set level side to side and level to no more than 1° slope

downward toward outside, front to back. If not, reinstall wall sleeve. Check

for proper gasketing between wall sleeve and chassis. Check that chassis

rmly installed in sleeve so that gasketing on discharge is compressed.

2. Check for dirt and foreign material in condensate hose running from

evaporator drain pan to exterior pan in condensing section.

3. Make sure access cover on drain pan is well placed on top of drain pan.

If not, press rmly into position. If okay, check and clean drain pan and

drain hole.

4. Check for proper chassis installation in wall sleeve. Make sure that gasket around air discharge on chassis is well pressed against top of wall

sleeve, and chassis support clips are in place. This will prevent cold air

from evaporator cabinet outlet to hit the back of cabinet front panel, thus

creating condensation.

1. Test capacitor with an ohmmeter; replace if necessary.

2. Check for loose connection or broken wire. Refer to page 14.

3. Check for continuity when push button is pressed. If defective, replace.

4. Check for continuity or ground at motor. If so, remove and replace.

1. Faulty solenoid or loose wiring at solenoid terminals.

2. Replace thermostat.

1. Replace.

2. See electric, hot water or steam heat procedures above.

1. Check voltage at solenoid with voltmeter. Replace if necessary.

2. Check for leaks. Recharge system.

3. Replace.

1. Check unit operating pressure and charge. Raise head pressure, operate

solenoid. If not shift, replace valve.

1. Check motor bearings. If loose or damaged, replace complete motor.

2. Evaporator fan wheel hitting fan housing.

3. Loose blower wheel.

4. Copper tube vibration or rattling.

5. Contacts.

6. Compressor internal mounts distorted.

7. Compressor internal damage.

8. Liquid refrigerant in compressor crankcase.

2. Relocate wheel in center of blower housing. Check for bent motor shaft.

3. Tighten setscrews on blower wheel to shaft.

4. Adjust by bending slightly to rm position.

5. Contactor noise would be due to control voltage being less than 18 volts.

Check for low voltage supply, low transformer output or extra long runs of

thermostat wires. If the contactor contacts are pitted or corroded, replace

contactor. Never le contacts. If holding coil is defective, replace.

6. Often referred to as “compressor off mounting springs", which in most

cases is highly improbable. If unit was rough handled in transit the internal

mounts might have been distorted and compressor main casting is touching

the dome or shell.

7. Make sure the compressor is not in direct contact with the base or sides of

chassis. The compressor should oat free in its isolation mounts. Excessive noise will occur it the compressor has a broken valve or loose internal

discharge tube. If so, replace compressor.

8. After a prolonged period of non-operation, compressor might produce

abnormal noise on start-up. This could be due to liquid refrigerant being

mixed with oil in compressor crankcase. After a short delay this noise

should disappear.

IM 1079 / Page 21 of 24

Page 22

IM 1079 / Page 22 of 24

Page 23

IM 1079 / Page 23 of 24

Page 24

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited Product Warranty. Consult your local McQuay Representative for warranty details. Refer to Form

933-43285Y. To find your local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

Products Manufactured in an ISO Certified Facility.

© 2010 McQuay International • www.mcquay.com • (800) 432-1342 IM 1079 (7/10)

Loading...

Loading...