Page 1

Installation Instructions For

CENTRIFUGAL WATER CHILLERS

LESS CONDENSERS

Models

13600 Industrial Park Blvd., P 0. Box 1551,

PLH

046,

079,

Minneapolis

048,

087,

MN 55440

050,

100

063

Page 2

Page 3

Page 4

GENERAL

The less condenser chiller unit is partially factory assembled, wired and checked. Installation (by others) will require piping, power, and control interlock connections to the

machine. Factory mounted and wired compressor motor

starters are available as an optional accessory. All units are

shipped with a holding charge of refrigerant.

All rigging, installation, power and control wiring and refrigerant piping are the responsibility of the installer. Recommendations for the installation of the less condenser unit are provided in the paragraphs following.

IMPORTANT: The responsibility and/or duties of the

installer and McQuay at the time of startup are detailed in the startup section on page 11. It is important

that the installer be aware of the limits of this responsibility since McQuay startup services beyond these

limits will only be performed after written authorization

has been obtained from the owner and/or installer.

Do not under any circumstance make final power

connections to the unit mounted starter (when supplied)

or to the compressor terminals when a remote starter

is used. The compressor cannot be put in operation until the the McQuay service technician has checked the

unit installation and electrical phase sequence for proper compressor rotation.

McQuay equipment when applied to perform the duty for

which it has been designed, and when it is operated within

limits of the design specifications, will provide safe and dependable service.

CAUTION

DO NOT ABUSE THE EQUIPMENT.

MODEL NOMENCLATURE

PLH -

0635 - AE - 30R I E2212 - GB - 2RA

Nomenclature Change: The 2-letter model code

new code for PE chillers less condenser

IO12

(“L”

at the end of

“PL”

is a

the old model number signified less condenser). The letter

“H”

has been added behind the first two digits of the model

code to signify a hermetic compressor motor. Model PLH is

synonymous with model PE-L.

UNIT NAMEPLATE

Whenever requesting information or assistance on the model

PLH water chilling unit, the unit model number, shop order

number and serial number should be copied from the unit

nameplate. A reproduction of this nameplate is shown in

Figure 3.

Figure 3. Unit Nameplate

Do not step on any piping or climb over the machine.

Do not exceed test pressures. Be sure to verify

allowable test pressure for the McQuay unit and

other items in the piping system.

Be sure all pressure relief devices are correctly installed. When vent piping to the outside is utilized,

be sure piping has a flexible connection and a drain

to prevent buildup of rain water or condensate. See

Figure 7.

Do not use oxygen to purge or apply pressure to a

unit or system for any reason.

RECEIVING THE EQUIPMENT

1. CHECK EQUIPMENT before removing it from the ship-

ping vehicle. The unit nameplate contains the unit model

number, serial number, etc. Figure 3 indicates the infor-

mation

contained on the nameplate. Check the nameplate

data against shipping papers and job information. Pay

careful attention to voltage characteristics. (Check voltage

on compressor nameplate.)

HOLDING

CHARGE

ONLY

MODEL

STYLE

SERIAL

S.O. NO.

\

I

PLH~J

1

PE5210-GO1

5NAl23~500 ~~

PE-5210

FACTORY CHARGED

_

LBS. REFRIGERANT=

LEAK TEST PRESSURE

MOTOR - COMPRESSOR CONTROLLER

AND OVERLOAD PROTECTION FIELD

SUPPLIED. SEE SPEC. PE-D4

19SP1Wi01-A MADE IN U.S.A.

100 PSIG.

2. INSPECT the unit while it is still on the shipping vehicle,

record any damage and note whether or not unit has been

torn from the shipping skid. In the event that the unit has

lost the refrigerant holding charge, look for damage to

refrigerant lines and connections. See testing and

evacuation section on page 9. Have all damage checked by the

transportation inspector or their representative before

Page 4

/

IM 310

Page 5

removing the unit from the vehicle. Promptly forward claim

forms directly to the carrier. Notify the nearest McQuay

sales office or representative of any item missing from the

shipment.

NOTE: All equipment furnished by McQuay is

shipped F.O.B. factory and all claims for handling

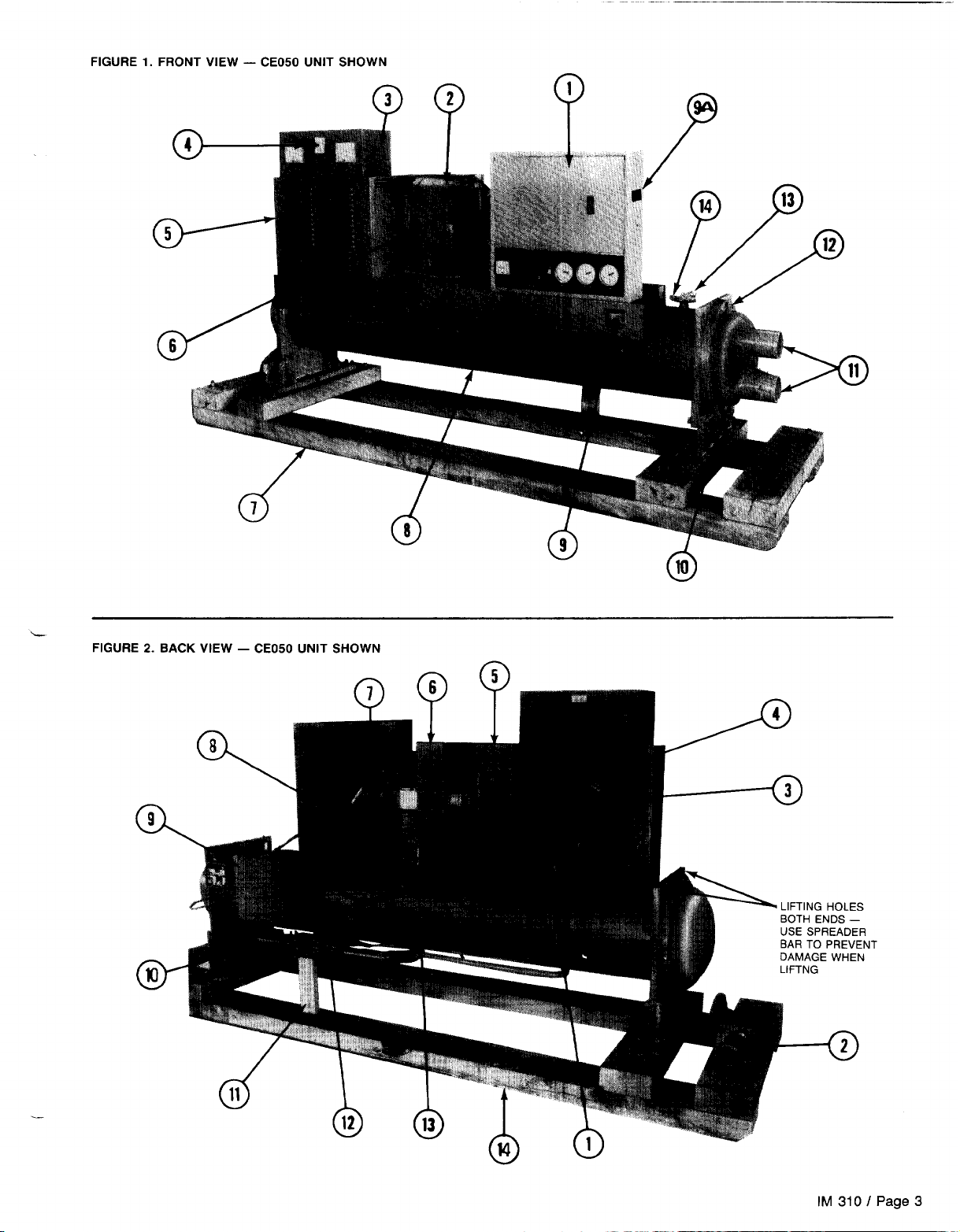

3. RIGGING. Lift unit only from points indicated in Figure 2.

Where required, use a spreader bar to prevent damage

to the unit. Be sure rigging equipment and procedures

INSTALLATION

followed are adequate to handle the unit weight. When

skidding the unit, be sure a minimum of 3 rollers are

used. Under no circumstances should the unit be

dragged with or without the skid.

PROTECTION. The unit assembly and starter (where

separate) must be adequately protected against dirt,

moisture and freezing during construction.

Chillers are drained of water before leaving the factory.

The chiller is not self-draining and must be blown out to

remove water if water has been added at the jobsite. When

the unit will be exposed to low temperatures during construction, a small amount of antifreeze should be put in

the chiller to protect it from freezing.

1.

CLEARANCES. A clearance for chiller tube removal at one

end of the unit must be provided. This clearance is

for shells with

1

2-foot

tubes. For all other unit sides and top, a clearance

8-foot

tubes and 14 feet for shells with

10 feet

of 3 feet is required.

2. UNIT SUPPORT. The floor or structural support must be

level and adequate to handle the full operating weight of

the unit. Operating weights for units are shown in Table

3. VIBRATION ISOLATION

a. “lsomode” or “Shearflex” pads are supplied with the

unit for installation under each corner of the

Unit

base

members.

It is not normally necessary to attach the unit to the

concrete slab or framework, but should this be

desirable,

1%” diameter holes are provided as shown

on the submittal drawings for the unit.

Figure

4. Typical Installation of Standard Isolation

UNIT TUBE

SHEET SUPPORT

r

ISOMODE

FURNISHED

WITH

PAD

“NIT

Note: Pads are shipped stored

in the switch section

of the control center.

Spring Isolators supplied by others may be placed

b.

under base support plates on both ends of the unit. Job

information should contain details on type and arrangement. Figure 5 shows a typical installation of spring

isolators. Spring isolation is not generally required but

1.

may be necessary if the unit is installed on the upper

floor of a building.

Table 1. Rigging 81 Operating Weights (Less Condenser)

(For weights of other

EYmtm

OODE

combinations,

RfQKOIWQ

WT.

(MS.)

cp

see certified drawings)

OPERATtAKS

WT.

OD

(LB%)

luooeLI tI4@, 048, oao

El 606-A’

-0’

E2006-1

l

-2’

E2012-C’

E2212-G’

E1612.1

I

I

-D’

-E’

-J’

I

2102

2203

2637

2726

3060

3262

3416

3533

3633

McBaEL

3399

I

I

033

I

2616

2697

3401

3470

4210

4372

4566

4665

5145

4088

LEVEL SUPPORT

BASE

Figure 5. Typical Installation of Spring Isolators

llN,T

BASE

ATTACH SECURELY

TO VIBRATION

\

LEVEL FLOOR

OR SUPPORT NEOPRENE PAD

SUPPORl

-4 4426

E2016-1

-2

-3 4959

-4 5065

E2212-1

-2 4536

-3 4637

E2216-1

-2

-3

-4 6823

r&m% m

MOlM&tia7..‘.....,.

f#%@kL

%

Rigging Weight: Unit Weight + Holding Charge of Refrigerant

0

Operating Weight: Rigging Weight + Water Weight + Operating Charge

of Refrigerant

. . . . . . . . .

toO .

. . . . . I. .

4619

4671

4457

4894

6539

6665

Add

35s Fb8.

to

Add

11@6 Lb. to osl)

*

Add

1972 Lbs. to 003

063 Evaporator WsiQhts

Evaporator Weights

Evaporator

5450

5915

6167

6255

6381

5675

5756

5655

6334

9103

9229

9387

WelaMs

IM 310 I Page 5

Page 6

PIPING

General - Chiller water and refrigerant piping connections

to the unit are required and good piping practice must be

followed during installation. All piping should be installed per

specific job piping drawings and details covered by these

drawings. In addition, the details and provisions following

below must be considered.

Adequate attention must be paid to the support and isola-

tion of piping particularly when spring type vibration mount-

ings are used.

WATER PIPING

NOTE: Chiller inlet and outlet connections are

marked. Do not reverse these connections or the unit

cooling capacity will be reduced.

Chiller connections will accommodate grooved piping con-

1.

nections or weld type flanges, or if ordered, the unit can

be factory supplied with flanges installed. See job details

for specific arrangement. Chiller water heads can be interchanged end for end. If this is done, new gaskets must

be used.

Offset piping flanges (see Figure 6) to permit removal of

2.

the pipe sections between the evaporator stubs and the

pipe flanges for general maintenance or to permit head

removal for tube inspection.

Air vents should be installed at high points to remove air

3.

from the system which, if not removed, can cause erosion

and other problems.

Chilled water flow switch or pressure differential switch,

4.

when used, must have a vapor tight construction. The flow

switch must be installed in a horizontal run a minimum

of five pipe diameters from any bend and must be located

in a vertical position at the top of the pipe.

Water Pump Noise. Avoid two pole (3600 rpm) water

5.

pumps. This design of pump can quite often operate with

objectionable noise and vibration. It is also possible to

create a “frequency beat” because of the slight vibration

difference between the pump motor and centrifugal compressor. We encourage the use of 1740 rpm (four pole)

motors on water pumps whenever possible.

6.

Water Flow. Located on the chiller heads are

l/B”

test

cocks for venting and draining. Chiller pressure drop information is available through your McQuay sales representative.

1.

UIL COOLER PIPING

Model PLH

046,048,050

and 063 units include a refrigerant

cooled oil cooler piped into the chiller system as standard.

This oil cooler does not require field piping connections.

Model PLH 079,087 and 100 units are supplied as standard

with a water cooled oil cooler. (A refrigerant cooled oil cooler

is available as an optional accessory.)

The water cooled oil cooler is factory mounted with all oil

piping provided. Water piping to this cooler must be field supplied and installed. The installation of water piping should

follow accepted good piping practice. Piping should include

inlet and outlet shutoff valves, a cleanable strainer (40 mesh

maximum), a balancing valve, a solenoid operated shutoff

valve (field wired into the unit control circuit as indicated on

the unit wiring information), and a drain valve or removable

plug.

Water for the oil cooler can be obtained from any of the

following sources.

1. The chilled water circuit. This water source is preferred

and is strongly recommended.

2. An independent water source such as city water or other

domestic source.

3. Cooling tower makeup water circuit. Note: The use of condenser water from a cooling tower is not recommended

because of the dirt and contamination contained in such

water.

Oil cooler water piping must be sized using not less than

the gpm shown in the table below. At the time the centrifugal

Figure 6.

NOTES:

1.

Offset piping flanges to allow removal of water head(s) for tube cleaning or maintenance.

2.

Install air vents at high points in water piping.

3.

Locate flow switch in horizontal pipe run. Switch should be in vertical

position a minimum of five (5) pipe diameters from any bend. if

ferential pressure switch is used in lieu of a flow switch, it should be

installed across the chilled water vessel, not across the water pump.

4.

Be sure water flow is into unit through nozzle marked “inlet.” Some

vessels require water inlet on the bottom nozzle; some on the top.

INSTALL

l/8”

Et

DRAIN VALVES

VENT

dif-

GROOVED TYPE

COUPLINGS OR

CHILLER

CONNFLTIONS

SUITABLE FOR

COUPLlNtiS

OR

GROOVEU

WELDFO / LDb.<,t’

NOTE

F, ANGEI‘I

PIPE

THEY

cITTINf,S ARE

MAY

BE SCREWED

SHDWN

CONNECTIONS IF SIZING PERMITS

Page 6 / IM 310

Page 7

unit is checked out and started, the McQuay technician will

adjust the water flow through the oil cooler to maintain oil

temperature leaving the cooler at an acceptable level.

Water Flow Rate for Oil Cooler Pipe Siring’

should the oil cooler be piped in parallel with a single pass

evaporator.

Units are available with oil cooler water solenoid valves fac-

tory supplied and mounted. On units where the solenoid valve

is field supplied, the solenoid valve recommended is an ASCO

type 8210827 (McQuay part

alternate

valve

is considered it should be of comparable quali-

#350A484H45).

If the use of an

ty and McQuay approved.

*CAUTION: Water temperatures entering the oil cooler

should not exceed 90 o F unless the application has been

approved by McQuay.

Recommended oil cooler piping is illustrated in Figure 7.

On some applications, where chiller water is used for oil cool-

ing and the unit is shut down for extended periods of time

over a weekend or for other reasons, the chilled water loop

temperature can substantially increase above the normal

chilled water temperature. Should this occur, the use of a

temperature actuated modulating water valve or other con-

trol means may be required to adjust water flow when the

unit is restarted. The purpose of this control is to compen-

sate for the effect of the different water temperatures on oil

temperature leaving the oil cooler when the unit starts and

after it has run and dropped the chilled water temperatures.

Figure 7.

r

Oil Cooler Connected Across Pump

RELIEF VALVE PIPING

The

ANSI/ASHRAE

Standard

15-1978

specifies that pressure

relief valves on vessels containing Group 1 refrigerants (R-12

and R-500) “shall discharge to the atmosphere at a location

not less than 15 feet above the adjoining ground level and

not less than 20 feet from any window, ventilation opening

or exit in any building.” The piping must be provided with

a rain cap at the outside terminating point and a drain at the

low point on the vent piping to prevent water buildup on the

atmospheric side of the relief valve. In addition, a flexible pipe

section should be installed in the line to eliminate any piping

stress on the relief valve(s).

The size of the discharge pipe from the pressure-relief valve

shall not be less than the size of the pressure relief outlet.

When two or more vessels are piped together, the common

header and piping to the atmosphere shall not be less than

the sum of the area of the relief valve outlets connected to

the header. Fittings should be provided to permit vent piping to be easily disconnected for inspection or replacement

of the relief valve. Larger size piping may be required if the

piping length is long. If in doubt, contact the local inspector.

Note: Provide adequate fittings in piping to permit repair or

replacement of relief valve.

Figure

8. Relief Valve Vent Piping

CAP

Independent Water Source

WATER LEAVING

OIL COOLER CAN

\GO

OR ‘VNVE

L

TO OPEN SIGH

DRAIN OR INTO

COOLING TOWER

T

When the oil cooler is piped into the chilled water circuit,

the oil cooler water piping system should be connected across

the chilled water pump so that full pump pressure differen-

tial is maintained across the oil cooler at all times the pump

is running. For those systems where it may be desirable to

pipe the cooler in parallel with the evaporator, it can only be

done when the evaporator water pressure drop is equal to

or greater than the pressure drop through the oil cooler water

piping system.

On installations utilizing an independent water source such

as city water makeup to a cooling tower, the water must be

piped from the oil cooler to the cooling tower where it must

enter at a point above the highest possible water level. If the

water is not utilized in the cooling tower then it must be dis-

posed of through an open drain. Under no circumstances

FO

CONDENSAilON

PITCH TO

OUTSIDE

I

FLEXIBLE CONNECTION

INSTALL AS CLOSE AS

POSSIBLE TO

VALVE

RELiEF

7

REFRIGERANT

EVAPORATOR

m

kv

OUTSIDE

WALL

3.

EVAPORATOR

-RELIEF

VALVE

FACTORY SUPPLIED

MOUNTED AT EVAPORATOR

VENT

I

15FT

MINIMUM

CLEARANCE

TO GROUND

LEVEL

ISEE

ADJACENl

INFORMATION1

IM 310 I Page 7

Page 8

Page 9

nished with grooves on one end and will have to be connected to the unit before piping connections are made.

The discharge connection at the unit is shipped capped.

Before attaching the discharge line section, relieve the

refrigerant pressure, remove the cap and use the same

grooved coupling to secure the discharge line in place.

Discharge and liquid line connections to the unit can be

run in either copper or steel.

Remote air or evaporative condensers must have an

adequate means for controlling head pressure. Operating

head pressure’should not be permitted to drop below 75

psig on units utilizing either R-12 or R-500 refrigerant or

erratic expansion valve operation can be expected.

IMPORTANT

The expansion valve supplied with the unit requires

a 45 psig minimum pressure difference across it for

proper operation. Provisions must be made to

assure this during periods of low outside temperatures.

IMPORTANT

Figure 9 is applicable to systems where the condenser is above or on the same level as the centrifugal chiller. When the unit is above the condenser, the liquid lift from the condenser to the

chiller is limited to 20 feet. When liquid lifts greater

than 20 feet are necessary, liquid subcooling from

an auxiliary source will be required. Contact your

McQuay sales representative for recommendations.

The McQuay Applications Department is available to assist

on piping questions.

3. Refrigerant Lines. The job data should contain detailed

information on refrigerant line sizes and runs. McQuay

refrigerant line sizing data

is available

where refrigerant

lines must be sized or checked. In addition, McQuay Applications Department personnel are available for consultation on piping details where required.

The liquid line piping must contain a refrigerant drier

with removable cores. The cores should be left in the line

until there are no traces of abnormal moisture levels. The

cores should then be removed. Piping should be arranged to permit bypassing the drier or valving it off for

core removal. See Figure 9.

Where an evaporative condenser is used, a subcooing

coil and an operating liquid receiver are required to contain adequate system refrigerant for both full load and part

load operation.

Oil circulation in centrifugal systems is negligible. The

use of double risers is not generally required. A

typical

piping arrangement for a remote air cooled or evaporative

type condenser is shown in Figure 9.

4. Hot Gas Lines. Pressure drop in the hot gas line should

be limited to the equivalent of

1

to 2 degrees. A hot gas

check valve (with low pressure drop) should be installed

in the discharge line just ahead of the condenser inlet gas

connection to limit refrigerant migration during periods

when the compressor is not operating.

If refrigerant velocity noise may be a problem, or if the

piping will be run in, or near, an occupied space, the use

of a steel discharge line is recommended.

The McQuay Applications Department is available to

assist on piping questions.

5. Pressure Testing. No pressure testing is necessary

unless damage was incurred during shipment or rigging.

Damage may be determined by a visual inspection of the

exterior piping assuming no breakage has occurred or fit-

tings have loosened. Panel gauges should show a positive

pressure. If no pressure is evident on the gauges, a leak

has probably occurred releasing all or part of the

refrigerant charge. In this case, the unit should be leak

tested.

6

Leak Testing. If the refrigerant holding charge is lost, the

unit should be checked for leaks prior to charging the complete system. Leak testing can be accomplished by charging enough refrigerant into the unit to build the pressure

to approximately 10 psig and adding sufficient dry nitrogen

to bring the pressure to a maximum of 125 psig. The unit

should then be leak tested with a Halide or electronic leak

detector. Water flow through the chiller should be maintained any time refrigerant is added or removed from the

system. CAUTION: Do not use oxygen to build up

pressure. A serious explosion could result.

A pressure

regulating valve should always be utilized on the drum being used to build up the system pressure. The regulating

valve must be set not to exceed the 125 psig test pressure.

When the test pressure is reached, disconnect the gas

cylinder to prevent an accidental further increase in

pressure.

If the leaks are found in welded or brazed joints or it

is necessary to replace a gasket, relieve the test pressure

in the system before proceeding. For copper joint repair,

the use of silver solder is recommended.

After making any necessary repairs, the system should

be evacuated as described in the following paragraphs.

7

Evacuation. After it has been determined that the unit is

tight and there are no refrigerant leaks, the unit should

be evacuated. The use of a vacuum pump with a pumping capacity of approximately 3 cu. ft./min. and the ability

to reduce the vacuum in the unit to at least 1 millimeter

(1000 microns) is recommended.

a.

A mercury manometer, electronic or other type of

micron gauge should be connected to the unit at a point

remote from the vacuum pump. For readings below 1

millimeter, an electronic or other micron gauge should

be used.

b.

The triple evacuation method is recommended and is

particularly helpful if the vacuum pump is unable to obtain the desired 1 millimeter of vacuum. The system

is first evacuated to approximately 29 inches of mercury. Enough refrigerant vapor is then added to the

system to bring the pressure up to zero pounds.

C.

Then the system is once again evacuated to approximately 29 inches of mercury. This is repeated three

times. The first pulldown will remove about 90% of the

non-condensables, the second about 90% of that remaining from the first pulldown, and after the third only one-tenth of 1% of the non-condensables will remain.

8.

Charging the System. Less condenser units are leak

tested at the factory and shipped with a holding charge

of refrigerant.

a. After all refrigerant and water piping is complete and

the system has been leak tested and evacuated,

refrigerant charging can proceed as described in the

following paragraphs. (Do not under any circumstance

start the compressor.)

b. Turn on the condenser fans (on evaporative type con-

densers also turn on the spray pump), chilled water

pump and the main system fans. (It will be necessary

to manually close the chilled water pump starter.)

c. Connect the refrigerant drum to the purge valve located

ahead of the filter-drier and purge the charging line be-

tween the refrigerant cylinder and the valve (Check the

position of the valves at the liquid receiver.) If the

system is under a vacuum, stand the refrigerant drum

with the connection up and open the valve on the

IM 310

/

Paae

9

Page 10

refrigerant drum to the mid-position and break the

vacuum with refrigerant gas.

With system gas pressure higher than the equivalent

of a freezing temperature, invert the charging cylinder

and elevate the drum above the purge valve. With the

drum in this position, valves, open, water pumps and

system fans operating, liquid refrigerant will flow into

the system. Approximately 25% of the total requirement

estimated for the unit can be charged in this manner.

After 25% of the required charge has entered the

system, reconnect the refrigerant drum and charging

line to the

compressor. Again purge the connecting line; stand the

drum with the connection up and place the service

valve in the open position. The charge can be raised

to approximately 50% in this manner. Once approximately 50% of the system charge has been installed,

shut off the drum and disconnect the charging line.

5/B”

service valve on the suction line at the

ELECTRICAL

All wiring must, as a minimum, satisfy the requirements of

the National Electrical Code and where necessary local code

requirements. Motor starters must meet the McQuay starter

specifications contained in Certified Drawing 461451Y (copies

will be supplied on request).

IMPORTANT

At this point the charging procedure should be

interrupted and prestart checks made before at-

tempting to complete the refrigerant charge. The

compressor must not be started at this time.

Preliminary checks as covered by the

checklist on page 12 must be completed.

When these checks have been completed and

your McQuay sales representative is notified, he

will request a McQuay technician to do the actual startup.

IMPORTANT

If any

unit

out by a McQuay technician the unit warranty

may be voided.

Wiring connections to a unit mounted starter or

compressor terminal studs must be made with copper lugs and copper wire.

is started before it has been checked

CAUTION:

POWER SUPPLY

Voltage supplied to this unit must be held within the allowable

variation of

Nameplate rating =

253V,

balance between phases cannot exceed 3%. A voltage un-

balance of only 3.5% will cause an increase of approximate-

ly 25% in motor winding temperature. It is most important

that the phase voltage unbalance be held to 3% or less.

Power Wiring

tory wired and mounted compressor motor starters (starters

are Star-Delta type open or closed transition as required by

the job specifications), or less starters for use with a free

standing starter.

It is important that the proper phase sequence be maintained in the power wiring with a phase sequence of l-2-3.

The proper motor rotation is clockwise when facing the motor

end of the compressor.

When a free standing starter is used which requires field

supplied wiring, care must be taken to be sure the right phase

sequence is carried through the starter to the compressor

motor terminals.

With the phase sequence l-2-3 and

and T6, L2 connected to T2 and T4 and L3 connected to T3

and T5, rotation is correct. See the diagram in the terminal

box cover of the compressor motor.

Phase sequence may be determined using a G.E.

#546703265 phase sequence meter or equal. Before connecting the starter load leads to the compressor terminals, and

while checking the field connection wiring, the transition timer

in the starter should be adjusted to make the transition from

Star to Delta connection in approximately 6 to 15 seconds

from initial start. This should be rechecked when the com-

pressor is put on the line. The timer should be adjusted to

actuate (disconnect Star winding connection and connect

Delta) when the motor has come up to speed and before any

speed reduction occurs.

f

10% of the unit nameplate rating. Example:

minimum allowable voltage =

23OV,

maximum allowable voltage =

-

Less condenser units are available with fac-

207V.

Ll

connected to

Voltage un-

Tl

IMPORTANT:

Do not make final power connections to the starter un-

til wiring has been checked and approved by an

authorized McQuay service representative. Under no

circumstances should the compressor be brought up

to speed unless proper phase sequence and rotation

have been established.

The McQuay startup technician will make this check

as part of the startup procedure.

CONTROL WIRING

The unit control circuit is designed for operating on a separate

power circuit. When factory mounted and wired, starters are

supplied as part of the unit assembly, a 2 KVA control

transformer is included and a separate power source to the

unit control center is not required.

Where separate free standing starters are used, a

115V160Hz

center is required. This power source can be provided through

a control transformer installed in the motor starter. The

transformer should have a rating not less than 2

a minimum inrush rating of 12.5 KVA at 80% power factor

and 95% secondary voltage. Transformers should have multiple taps to provide

For control wire sizing, refer to Table 3 or the National Electrical Code, Article 215 and 310.

Either power source should be properly fused with 20

amperes dual element fuses, or with a circuit breaker selected

for motor duty. (The oil pump motor is in this control circuit.)

When starters are factory mounted, adequate control power

and circuit protection will be included.

If the control transformer or other power source for the control panel is remote from the unit, conductors must be sized

for a maximum voltage drop of 3% (see Table 3). The control circuit ampacity rating is 20 amperes at 115 volts.

or 1

lOV150Hz

*

power source to the unit control

KVA,

10% voltage variation of the transformer.

with

Page 10

/

IM 310

Page 11

CAUTION: The control power disconnect switch

must be tagged to prevent power interruption. It

must remain on at all times to keep oil heaters

operative and to prevent refrigerant from accumulating in the oil.

L

The control center on-off switch should be turned to the

OFF position whenever compressor operation is not wanted.

Table 3. Maximum Conductor

*Maximum length is distance conductor will traverse between control power

source and the unit control panel. Wire size based on voltage drop not to exceed 3%.

Panel terminal connectors will accommodate wire size up to IO AWG; larger

conductors will require an intermediate junction box.

Length’

CONTROL INTERLOCKS

An open section has been provided in the unit control panel

for the installation of interlock contacts (see unit electrical

diagram for location). The purpose of the open section is to

prevent the compressor from operating until external devices

necessary for the proper operation of the unit are functioning.

The condenser fans (and spray pump if used) must cycle

with the unit and the fans must be interlocked in the control

circuit to prevent the compressor from operating until the condenser fans are running. Relay CFR (field supplied) on the

unit electrical diagram identifies the condenser fan interlock

relay which must have a set of normally open contacts in-

stalled in series with the MCR coil located in the compressor

motor starter or with the panel mounted protective relay in

the control panel. In addition to the CFR relay contacts, the

use of a flow or pressure differential switch located in the

chilled water piping is recommended. The contacts of this

flow switch must be wired in series with the CFR contacts

in the interlock circuit. The volt ampere rating of the CFR coil

must not exceed 25 VA.

NOTE: All interlock contacts must be rated for a minimum

of 10 inductive amperes. If an alarm circuit relay is utilized

and is connected into the section provided for the alarm circuit in the control panel, it must be rated for 115 volts and

its operating coil should draw not more than 100 volt amperes.

CONTROL CIRCUIT TESTING

After the power and control wiring has been completed, the

control circuit should be tested “functionally.” During this

testing the compressor must not be started. Power wire

connections to the unit mounted starter must not be made

or when a remote starter is used the load side wiring from

the starter to the compressor motor must be disconnected.

1.

In cases where a separate control voltage source is fur-

nished, it is only necessary to energize the control circuit

with the compressor disconnect switch open.

2. The McQuay startup technician will check the setting and

operation of all unit safety and operating controls at the

time of unit checkout and startup.

3. All field interlock connections should be checked for proper operation by stopping each pump in order. The motor

control relay (MCR) should de-energize at the same time.

4. Stop the water pump. This also should open the starter

circuit.

When all of the checklist items are complete, the services

of a McQuay startup technician will be furnished at no charge

to start the unit. If the startup time required to place the unit

in operation exceeds 24 consecutive normal working hours,

or if repeated calls are required through no fault of McQuay,

charges for such extended services will be invoiced.

NOTE: THE MOST COMMON PROBLEMS DELAYING

STARTUP AND AFFECTING UNIT RELIABILITY ARE:

Compressor motor power supply leads too small. Check

with the McQuay sales representative to obtain proper wire

size.

A 115 volt field supplied relay (CFR) must be used to start

and stop condenser fans on most applications. Provisions

have been made in the control center for connecting the

CFR relay. The relayoperating coil must not have a rating

in excess of 25 VA.

CAUTION: Be sure all items on the checklist are complete and the unit is ready to be checked out and

started. If the startup technican is required to leave the

job and return because owner/contractor items of

responsibility are not complete and the unit cannot be

started, the excess time and expense will be billed at

McQuay’s

standard hourly service rate plus in-

curred expenses.

IM

310 / Page 11

Page 12

PRE-START SYSTEM CHECKLIST

(By Installing Contractor)

DIRECT EXPANSION

Piping complete

Main air system fans operable

Controls - dampers, solenoid valves, variable volume boxes, etc., operable

..................................................

........................................

NOT

APPLICABLE

E

L

...

CHILLED WATER

Piping complete

Water system filled, vented

Pumps installed, (rotation checked) strainers cleaned

Controls (3-way, face and bypass dampers, bypass valves, etc.) operable

Water system operated and flow balanced to meet unit design requirements

CONDENSER

Condenser flushed, filled and vented (if evaporative type), air cooled coils clean

Pumps installed, (rotation checked) strainers cleaned

Controls (bypass valves, etc.) operable

Water system operated and flow balanced to meet unit requirements

ELECTRICAL

115 volt service completed, but not connected to control panel

‘Power leads connected to starter: load leads run to compressor

ready for connection when service engineer is on hand for startup

(Do not connect to starter or compressor terminals)

All interlock wiring complete between control panel and complies with specifications

Starter complies with specifications

Pump starter and interlock wired

Cooling tower fans and controls wired

Wiring complies with National Electrical Code and local codes

*Condenser pump starting relay (CWR) installed and wired

MISCELLANEOUS

Oil cooler water piping complete. (Units with water cooled oil coolers only)

Relief valve piping complete

Thermometer wells, thermometers, gauges, control wells, controls, etc., installed.

Minimum system load of 25% of machine capacity available for testing and adjusting controls

Refrigerant piping system has been evacuated and leak tested

Approximately 50% of refrigerant charge has been added to system

Additional refrigerant available on jobsite to complete charging system

................................................

............................................

...............................

.......................................

.........................................

.....................................

...........................................

........................

......................

................

................

...................

.......................

..........

.........

..........

..........

........

........

.....

...........

...........

...........

...........

0

q

q

q

0

0

n

q

q

........

STARTUP DUTIES OF McQUAY

1.

Inspect and check unit; verify all valves in operating position.

2.

Control circuit energized.

3.

Oil heaters operating a minimum of 24 hours and oil hot. (Ap-

proximately 130 to 140F)

Oil level correct.

4.

Water flow to condenser correct (if applicable).

5.

6.

Check, set and adjust safety controls.

7.

Check that wire size and type is correct.

Phase sequence correct.

8.

NOTES:

When all of the checklist items are complete, the services of a McQuay startup technician will be furnished at no charge to start the unit.

If the startup time required to place the unit in operation exceeds 24 consecutive normal working hours, or if repeated calls are required

through no fault to McQuay, charges for such extended services will be invoiced.

NOTE: THE MOST COMMON PROBLEMS DELAYING STARTUP AND AFFECTING UNIT RELIABILITY ARE:

1.

Compressor motor power supply leads too small. Check with the McQuay sales representative to obtain proper wire size.

2.

A 115 volt field supplied relay (CFR) must be used to start and stop condenser fans on most applications. Provisions have been made

in the control center for connecting the CFR relay. The relay operating coil must not have a rating in excess of 25 VA.

3.

CAUTION: Be

is required to leave the job and return because owner/contractor items of responsibility are not complete and the unit cannot

be started, the excess time and expense will be billed at

sure all items on the checklist are complete and the unit is ready to be checked out and started. If the startup technican

McQuay’s

9.

Check voltage and phase unbalance.

Wiring connections correct.

10.

11.

All wiring connections right and made with copper connectors

and lugs.

12.

Check that starter parts move freely and contacts meet evenly.

13.

Motor overloads correct and filled with dashpot oil.

14.

Supervise topping off refrigerant charge.

15.

Start unit; check operation.

16.

Instruct owner personnel.

standard hourly service rate plus incurred expenses.

Loading...

Loading...