Page 1

Page 2

Page 3

Introduction

McQuay

charged, tested and ready for installation. Each unit consists of a water-cooled condenser with

integral subcooler, multiple accessible semi-hermetic single screw compressors. replaceable tube

shell-and-tube evaporator. and complete refrigerant piping. Liquid line components included are

manual liquid line

sightglass/moisture

heaters, and an advanced fully integrated microprocessor control system.

automatic operation. (the high and low pressure controls are external from the electrical control

center). Compressors are protected by solid-state overload protection and over temperature

protection.

StarGateTM

The electrical control center includes all safety and operating controls necessary for dependable

Field

water-cooled chillers are completely assembled. factory wired. evacuated.

shutoff valves. charging valves. filter-dryers. liquid line solenoid valves,

indicators. and electronic expansion valves. Other features include compressor

installed fused

disconnect Sw itch (furnished by

others) offers additional protection.

Receiving and Handling

Inspect the unit immediately after receipt for

all claims for handling and shipping damage are

shipping

extreme care when rigging the equipment to prevent damage to the control center. or refrigerant

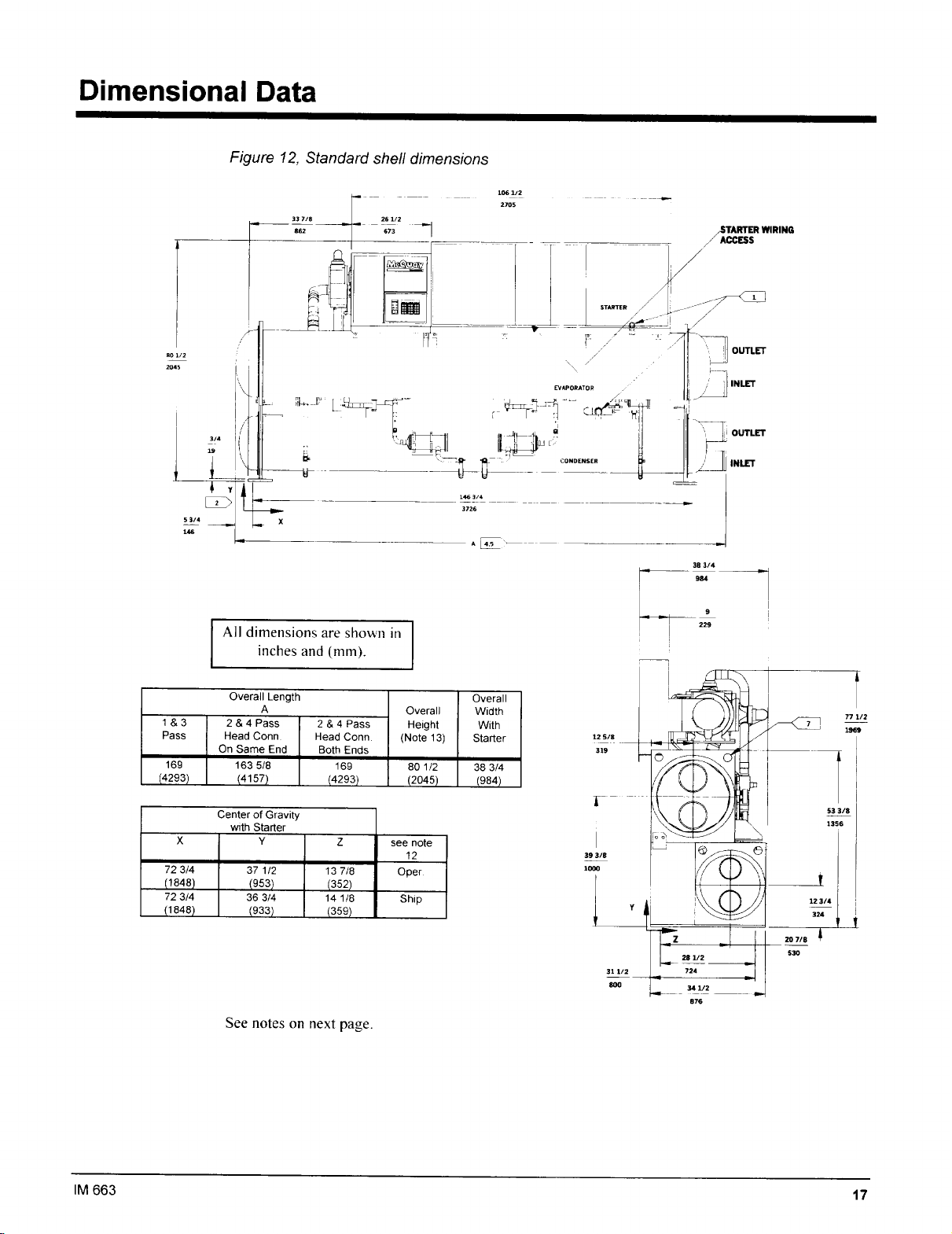

piping. See Dimensional Data for the center

eyes are located (see Figure I ). Use spreader bars between the ri

control center.

skid

in place until the unit is in final position. This will aid in handling the equipment. Use

Lift the unit

by

fastening the ri

gging

Figure I, Rigging Eyes

possible

of gravity of the

hooks to

damage.

the

responsibility

the

four corners of the evaporator where the rigging

The unit is shipped FOB factory and

of the

consignee. Leave the

unit.

gging lines to prevent damage to the

IM

663

Rigging eyes

Rigging eyes

3

Page 4

Installation

Installation must be performed by qualified personnel who are familiar with local codes

regulations, and experienced with this type of equipment

Start-up by

excluding Mexico. Two weeks prior notification of start-up is required. The contractor should obtain

a copy of the Start-up Scheduled Request Form from the sales representative or from the nearest

McQuayService office.

McQuayService

is included on all units sold for installation within North America

Location and Mounting

Mount the unit on a level concrete or steel base. Service clearance (at either end of the unit) is 14 feet

for units with

Evaporator and condenser tubes are rolled into the tube sheets to permit replacement. Clearance at all

other points, including the top, is 3 feet.

Make certain the floor or structural support is adequate to support the full operating weight of the

complete unit. Optional rubber-in-shear pads. or spring isolators can be ordered for use under each

corner of the base members.

although mounting holes are provided in the unit support at the four corners.

12-foot

long standard shells and 18 feet for units with

It is not necessary to bolt the unit to the mounting slab or frame work:

16-foot

long optional shells.

Compressor Condensation

Condensation occurs on the compressor surface when the temperature of the compressor surface is

lower than the ambient dew point temperature. Drain pans with drain connections are provided

underneath each compressor to collect the condensate. The compressor motor housing extends past

the drain pans. Install a floor drain close to the unit to collect condensate from motor housing and

condensate pans.

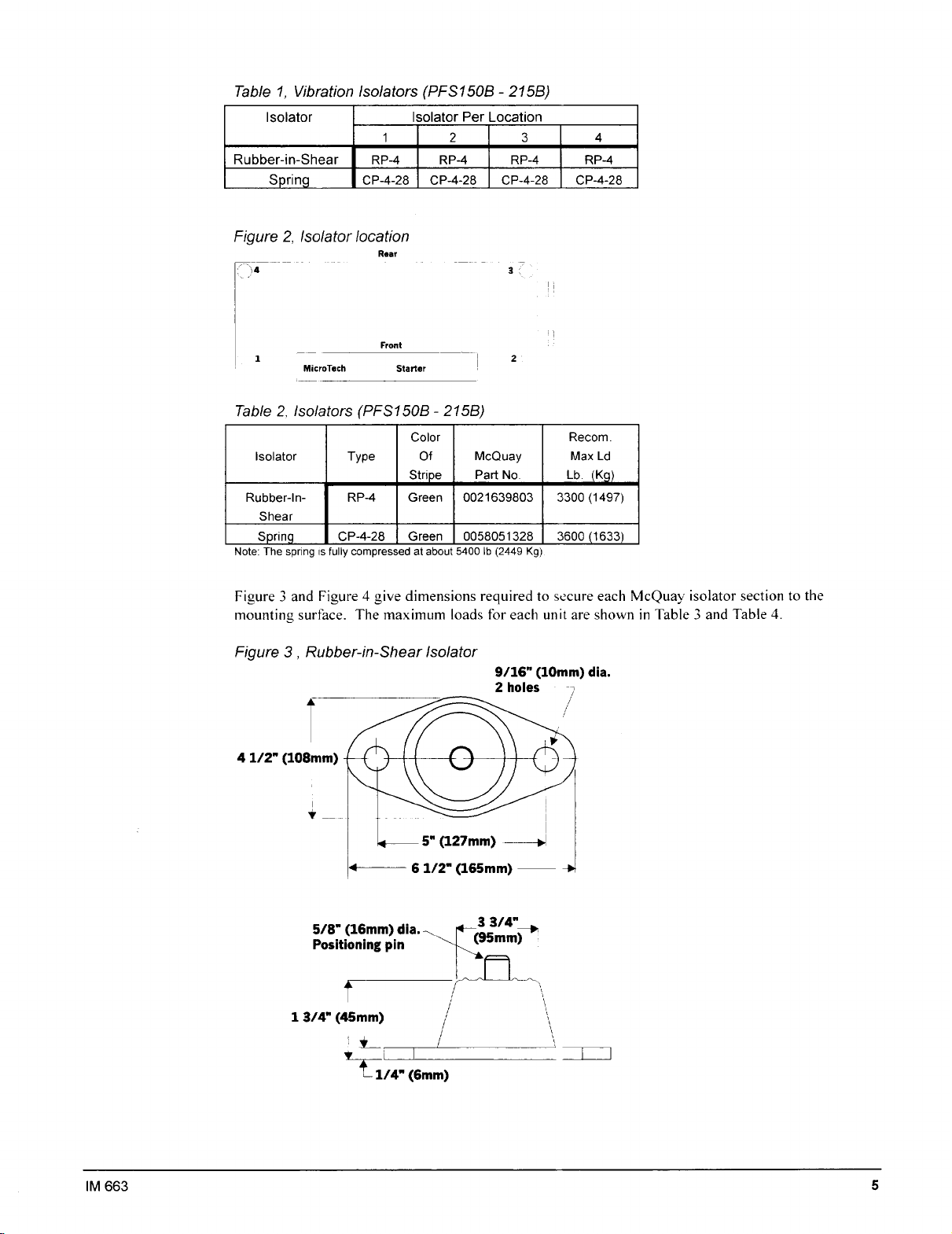

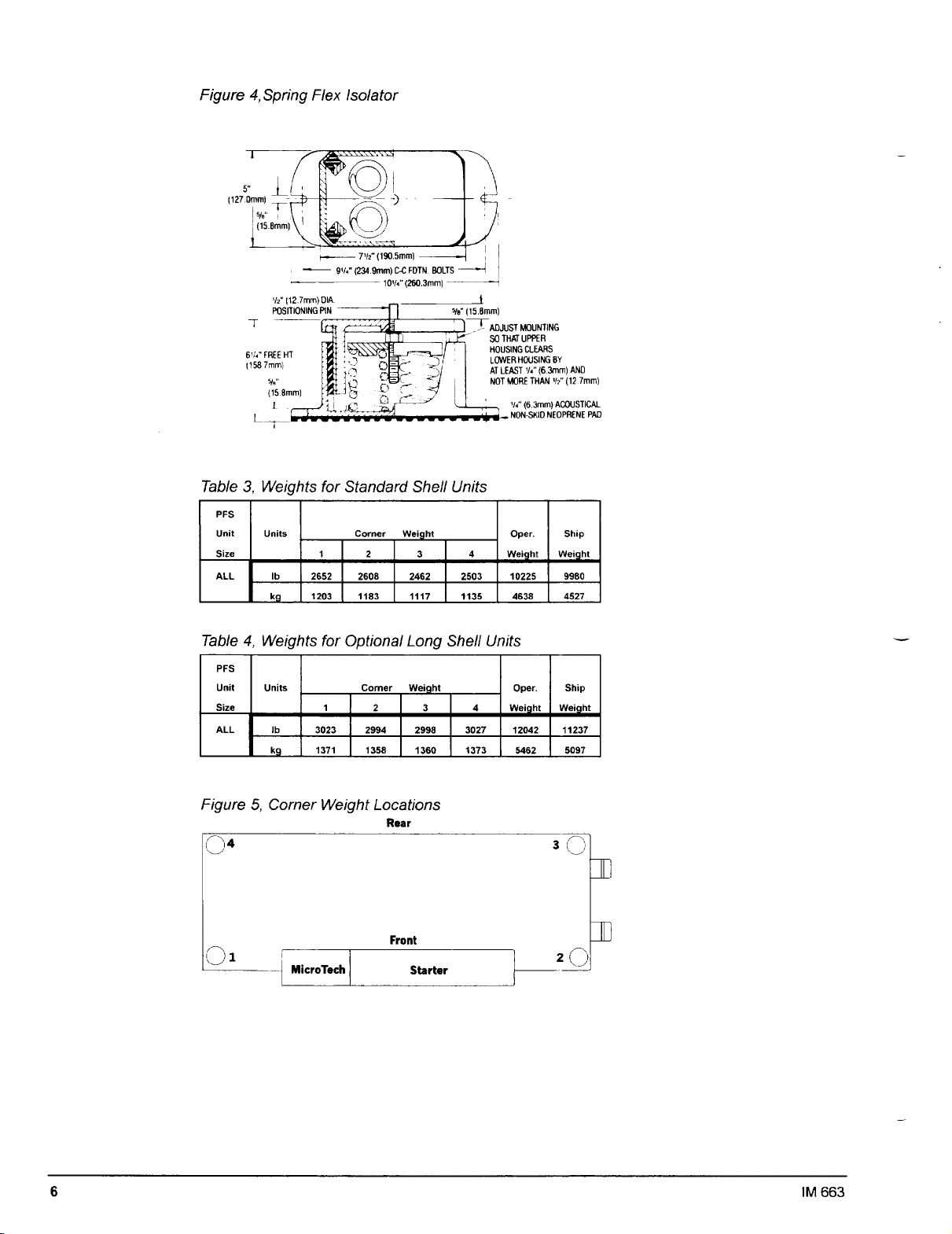

Vibration Isolators

Vibration isolator pads are shipped with the unit for field installation. These pads provide minimal

isolation. Vibration isolators are recommended on all upper level installations where vibration

transmission is a consideration. When vibration isolators are used. install springs under the main unit

supports. Adjust spring so the upper housing clears lower housing by at least

more than

Install vibration eliminators in water piping to reduce piping strain. vibration. and noise. Table

spring and rubber-in-shear isolators for all PFS unit sizes

4

1/2"

(1

3mm).

If hold-down bolts are not used. install a rubber anti-skid under isolators.

1/4"

(6mm) and not

l

lists

IM 663

Page 5

Page 6

Page 7

Evaporator and Condenser Water Piping

PFS evaporators and condensers are equipped with either victaulic or flange connections. The

installing contractor must provide matching connections.

Remove the solid-state temperature sensor and thermostat bulbs from the wells to prevent

damage to those components when welding on the victaulic or flange connections.

Connect the condenser with the inlet

condenser water will discharge from the top connection.

Support piping to reduce weight and strain on the fittings and connections. Be sure piping is

adequately insulated.Install a cleanable

piping. install enough

without draining the complete system.

shutoff

valves

water

entering at the bottom to maximize subcooling. The

20-mesh

to permit draining water from the evaporator or condenser

water strainer in evaporator and condenser water

CAUllUN

Freeze Notice: Neither the evaporator nor the condenser is self-draining. Both must be

blown out.

I

Include thermometers at the inlet and outlet connections and air vents at the high points of piping.

The water heads can be interchanged (end for end) allowing water connections to be made at either

end of the unit. Use new head gaskets when interchanging water heads. When water pump noise is

objectionable, use rubber isolation sections at both the inlet and outlet of the pump. Vibration

eliminator sections in the condenser inlet and outlet water lines are not normally required. Where

noise and vibration are critical, and unit is mounted on spring isolators, flexible piping connections

are necessary.

Water treatment

If unit is operating with a cooling tower, clean and flush cooling tower.

or bleedoff is operating. Atmospheric air contains many contaminants which increases the need for

water treatment. The use of untreated water may result in corrosion, erosion, sliming, scaling, or

algae formation. A water treatment service is recommended.

responsible for damage or faulty operation from untreated or improperly treated water.

McQuay

Make sure tower “blowdown”

International is not

Head pressure control, tower system

The minimum entering water temperature to the condenser must not be lower than 70°F (2

Use a three-way bypass valve around the tower to modulate the condenser water flow.Figure 6 shows

a three-way pressure actuator water regulating valve used for cooling applications. This regulating

valve will assure an adequate condensing pressure if the inlet condenser water temperature falls below

70°F). An optional

valve or a varible speed condenser pump.

IM

663

AOX-4

board located in the

MicroTech

panel will control a cooling tower bypass

I _

1°C).

7

Page 8

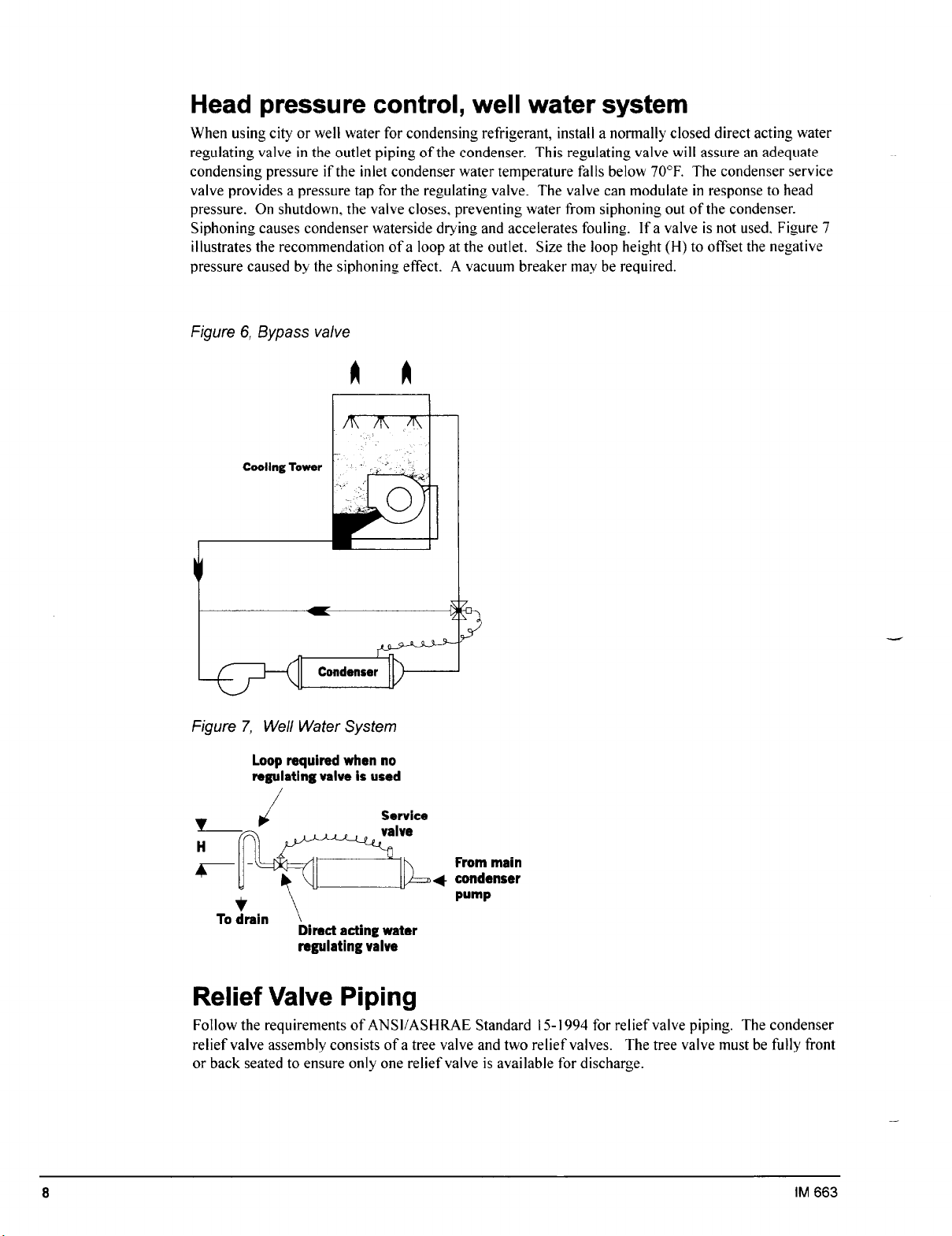

Head pressure control, well water system

When using city or well water for condensing refrigerant, install a normally closed direct acting water

regulating valve in the outlet piping of the condenser. This regulating valve will assure an adequate

condensing pressure if the inlet condenser water temperature falls below 70°F. The condenser service

valve provides a pressure tap for the regulating valve. The valve can modulate in response to head

pressure. On shutdown. the valve closes. preventing water from siphoning out of the condenser.

Siphoning causes condenser waterside drying and accelerates fouling. If a valve is not used, Figure 7

illustrates the recommendation of a loop at the outlet. Size the loop height (H) to offset the negative

pressure caused by the siphoning effect. A vacuum breaker may be required.

Figure 6, Bypass valve

Figure 7, Well Water System

Loop required when no

regulating valve is used

V-d

H

Kl-

r-

ld

f

To drain

/

T

Direct acting water

regulating valve

Service

valve

Y

From main

+ condenser

pump

Relief Valve Piping

Follow the requirements of ANSUASHRAE Standard 15- 1994 for relief valve piping. The condenser

relief valve assembly consists of a tree valve and two relief valves. The tree valve must be fully front

or back seated to ensure only one relief valve is available for discharge.

8

IM 663

Page 9

Temperature and Water Flow Limitations

“F

(-8.9”C)

PFS units are designed to operate in conditions from

temperature on the evaporator side and 70°F (2 I. 1 “C) to 95°F (35°C) entering water temperature on

the condenser side.

Glycol in the evaporator is required on all applications below 40°F (4.4”C) leaving evaporator

fluid temperature. The maximum allowable water temperature to the cooler in a non-operating cycle

is

10j°F (40.6”(Z).

(46.1 “C).

control. Flow rates above the maximum values will result in unacceptable pressure drops. excessive

nozzle and tube erosion and possibly cause tube failure.

The non-operating leaving condenser water temperature maximum is 115°F

Flow rates below the minimum values may cause freeze-up problems, scaling and poor

2 1

to 55°F (1O’C) leaving water

Evaporator Freeze Protection

When freeze protection is a concern, do the following:

1. If the unit will not be operated during the winter. drain and flush the evaporator and chilled water

piping with glycol Drain and vent connections are provided on the evaporator.

2.

When using a cooling tower, add glycol solution to the chilled water system. Freeze point should

be approximately 10°F

Note: Freeze damage is not considered a warranty failure and is not the responsibility of

McQuay

3.

International.

Insulate field water piping. especially on the chilled water side.

(5.6”C) below minimum design ambient temperature.

Condenser Protection and Design Considerations

If pond or river water is used as a condensing medium and the water valves leak, the condenser and

liquid line refrigerant temperature could drop below the equipment room temperature on the

cycle. This problem occurs when cold water continues to circulate through the condenser and the unit

remains off due to satisfied cooling load.If this occurs:

1.

Cycle the condenser pump off with the unit.

2.

Verify the liquid line solenoid valves are operating properly.

“off

Chilled Water Thermostat

The PFS water-cooled chiller is equipped with the MicroTech leaving water controller. Be careful

when working around the unit to avoid damaging lead wires and sensor cables. Check lead wires

before running the unit. Avoid rubbing the lead wires on the frame or other components. Verify the

lead wires are firmly anchored. If the sensor is removed from the well for servicing. do not wipe off

the heat conducting compound supplied in the well.

Refrigerant Charge

All units are designed for use with HCFC-22 and are shipped with a full operating charge. The

operating charge for each unit is shown in the Physical Data Table.

IM

663

9

Page 10

Detection of Loss of Flow

NOTE: Water pressure differential switches are not recommended for outdoor applications

The preferred means for detecting loss of flow is the use of factory-mounted pressure differential

switches for the evaporator and condenser.

A flow switch is available from McQuay (part number 00175033-00).

It is a “paddle” type

switch and adaptable to any pipe size from 3” (76mm) to 8” (203mm) nominal. Two flow switches

are required. Mount the flow switch in either the entering or leaving water line ofthe evaporator and

condenser. Certain minimum flow rates are required to close the switch and are listed in Table 5.

Installation should be as shown in Figure 8.

Figure 8.

and 63. Flow switch contact must be suitable for 23 VAC. low current ( I bma).

Flow Switch

Connect the normally open contacts ofthe flow switch in the unit control center at terminals 62

Table 5, Flow Switch Minimum Flow Rates

Nominal Pipe Size Min. Required Flow to

(inches) Activate Switch - GPM (L/s)

5

6

58.7 (3.7)

79.2 (5)

Note: The procedure

does not specify the

type of glycol. Use

ihe der& factors

found in Table 6 for

corrections when

using ethylene glycol

and those in Table 7

for propylene glycol.

10

Glycol Solutions

Use industrial grade glycols only. Do not use an automotive grade antifreeze. Automotive

antifreeze contains inhibitors that will cause plating on the copper tubes within the chiller

evaporator. The type and handling of glycol used must be consistent with local codes.

To determine flou rate for the evaporator in CPM (L/s). and pressure drop through the cooler, use the

following formulas and tables.

Capacity - Multiply the chiller’s capacity with water b>, the capacity correction factor (Cap) to

1.

tind the chiller’s capacity with glycol.

3

CPM - To determine evaporator GPM (or Delta-T) knowing Delta-T (or GPM) and tons:

-.

Gl~col <iPM =

73 x to/?s( &m/)

llelm - 7‘

x j70M$from talk)

IM 663

Page 11

For metric applications:

L/s - To determine evaporator L/s (or Delta-T) knowing Delta-T (or L/s) and kW:

Glycol L : s = x ,/10lr’ (from tahlc)

3. Pressure Drop - To determine pressure drop through the cooler when using glycol, enter the

appropriate water pressure drop curve (begin on page I2 at the actual glycol flow. Multiply the

water pressure drop found there by pressure drop adjustment factor (PD) to obtain corrected

glycol pressure drop.

4. To determine the unit power consumption, multiply the unit kW/TR with water by the (kW/TR)

factor. Test coolant with a clean. accurate glycol solution hydrometer (similar to that found in

service stations) to determine the freezing point. Obtain percent glycol from the freezing point

table below. A minimum of2590 solution by, weight should be used for protection against

corrosion.

UI’

4. IX x nvllL1 - r

Note: The effect of glycol in the condenser is negligible. As glycol increases in

temperature, its properties approach those of water. For selection purposes, there is no

derate in capacity for glycol in the condenser.

Table 6, Adjustment factors for ethylene glycol

Tab/e 7, Adjustment factors for propylene glycol

IM 663

11

Page 12

Evaporator and Condenser Water Flow and Pressure Drop

Flow rates must fall between the minimum and maximum values shown on the appropriate evaporator

and condenser curves. Flow rates below the minimum values shown will result in laminar flow that

will reduce efficiency, cause erratic operation of the electronic expansion valve and could cause low

temperature cutouts. Flow rates exceeding the maximum values shown can cause erosion on the

evaporator water connections and tubes.

Measure the chilled water pressure drop through the evaporator at field installed pressure taps. It is

important not to include the effect of valves or strainers in these readings.

Do not vary the water flow through the evaporator while the compressor(s) are operating. MicroTech

control setpoints are based on constant flow.

Figure 9 Evaporator pressure drop (2-pass and 3-pass)

Flow Rate (Us)

I

1 Standard Shall B-pass/

12 IM 663

/ I

200 WI3

Flow Rate (GPM)

hi i i i t

a0 saoaoo7moo~lom

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Field Wiring

PFS unit compressors are single direction rotation compressors. For this reason proper

phasing of electrical power is essential. Electrical phasing must be A, B, C clockwise for

electrical phases

power connection and includes one MotorSaver phase failure, phase reversal protective

device that will prevent operation of the unit with incorrect power phasing. The MotorSaver is

factory wired and tested. Do not alter the wiring to the

General Information

Wiring

accordance with specifications.

Copper wire must be used for all wiring

CAUtlON

1,

2 and 3 (A=L1

must

comply with all applicable codes and ordinances. Warranty is void

,B=L2,C=L3)

The unit is supplied with single point factory

MotorSaver.

if wiring

is not in

The PFS is supplied standard with the main power

large power terminal block is provided. Wiring within the unit is sized according to the National

Electrical Code. A single field-mounted disconnect (supplied by others) is required. An optional

factory mounted transformer for the

Main power must enter the control panel at the location indicated on the unit illustration.

1

15

volt control circuit may have been provided.

wiring for single point power connection. A single

IM

663

21

Page 22

Page 23

Page 24

Page 25

Pre-Start-up

1.

Open all electrical disconnects and check electrical connections are tight.

2.

Verify water piping flow directions are correct and properly connected at the evaporator and

condenser.

3.

Using a phase tester,

4.

Verify unit power supply is within

5.

Verify power supply wiring is the correct size and has a minimum temperature insulation rating of

75°C.

6.

Verify all mechanical and electrical inspections have been completed according to local code.

7.

Make certain all

available.

Check all compressor valve connections for tightness.

8.

Open compressor suction valve until backseated. (This is an optional valve)

9.

Open discharge shutoff valve until backseated

10.

I 1.

Vent air from the evaporator and condenser water system piping.

12.

Open all water tlow valves and start chilled water pump.

13.

Check all piping for leaks.

14.

Flush the evaporator and condenser system piping.

verify

auxilliary

electrical phasing is A-B-C clockwise (A=L I, B=L2.C=L3).

10% of nameplate rating.

control equipment is operative and an adequate cooling load is

Sequence of Operation

The following sequence of operation is typical for McQuay models PFS

rotary screw water chillers. The sequence may vary depending on the software revision or various

options that may be installed on the chiller.

Initial Conditions

Before energizing the control box do the following:

1.

Verify the two control circuits are powered through the primary fuses FU1 and

secondary fuse

2.

Verify

the power developed through the transformer CPT in the starter is 120 Vac on the

secondary.

3.

Verify front panel switch is in the off position.

When applying power to the control for the first time do the following:

1.

Open the left door and the top door to each control box.

2.

Observe when power is applied the display lights up and when the Unit Status screen appears the

EXV board lights rapidly sequence closed.

3.

Listen for the stepper motors closing with a ratcheting sound.

FU3.

150B

through

FU2

PFS2 15B

and the

IM 663

25

Page 26

4. The Unit Status Screen on the display should indicate Off: Front Panel SW.

5. Verify the control setup for the network of two control boxes as follows:

*** 1s unit Model size

Move Master control communication connector fi-oni B to A port and disconnect the RSX2

connector (the one with the juniper from pin 2 - pin 6)

Second Screen Nevt Item

Slave Address

Mode= Auto:Local Auto- Network

Note. If address switches were changed then reset power off / on for both boxes

Off Conditions

With power to the controller there are several “off’ states as follows:

Off: Manual When the setpoint in menu “I I Control Mode” is set to the Mode= Manual Off to

change set the Mode= Auto: Network or any other running mode.

Off: Front Panel SW When the panel switch is in the “Stop” position. To change move the switch

to “Auto” position.

Off Alarm Remove the alarm state then clear the alarm to remove this off state.

Alarm

The alarm light on the front panel illuminates when the particular control receives an active alarm

state. That particular control will be locked out of compressor start or operation. The other control

will still be able to start.

26 IM 663

Page 27

Initial Start-up

CAUTION

Initial start-up must be performed by McQuayService personnel.

Set up control as described in the initial conditions.

1.

Turn front panel switch to Auto position (chilled water flow pump relay will energize).

2.

If the field installed flow indicator does not indicate chilled water flow after 30 seconds, the

3.

alarm output wi

The chiller

4.

The controller starts the compressor W ith

5.

the liquid in_jection solenoid and motor coolin

solenoids. and

Suction

6.

The discharge superheat drops below

Absolute Pres. ratio is greater than I.2 ( Abs. Condenser Psia i Abs. Evaporator Psia)

The unit status moves from:

7.

EvapOn-Recirc

Solenoid to Running Min Amp Lim to Running:

If additional cooling capacity is required then the controllers will add capacity by changing the

capacity control solenoids outputs 7. 8. and 9 and maintaining a close balance in amp capacity

between compressors after both compressor are running. The lag compressor will come on after the

lead compressor amps have exceeded the

23 on the master controller).

I l be

will

start w

injection

energized.

hen

the leaving

de-energizes

will turn

**Sec

the

off when

to All Systems Off to MCR Started to Pre-purge to Open

water

temperature is

the

least

starts

g

solenoid. energizes the suction

crank

case

heaters.

the following conditions have been met:

r

“F. the Liquid Presence sensor shows liquid, and the

3

setpoint

to turn on the lag for the defined lag time (see menu

3’F

above the Active Setpoint.

while in auto Iead-lag setting. energizes

%

Cap 50

injection

I

I

Load Recycle

As the load drops. the controls will unload the compressors until the compressors amps drop below

the lag cutoff point for the delay time required. The control will then shut off the lag compressor and

further reduction in load will cause the leaving water ternperature to drop 3

setpoint which will cause the compressor to turn off on Load Recycle and the display will show

Waiting For Load and the chilled water pump will remain on.

’

F below the active

IM

663

27

Loading...

Loading...