Page 1

Page 2

Page 3

Introduction

I

Refer to Installation and Maintenance Bulletin 549 for additional information on the MicroTech controller.

General Description

McQuay

plete, self-contained automatic refrigerating unitsthat include

the latest in engineering components arranged to provide a

compact and efficient unit. Each unit is completely assembled,

factory wired, evacuated, charged, tested and comes complete and ready for installation. Each unit consists of twin

water cooled condensers with integral subcooler sections,

multiple accessible semi-hermetic single screw compressors, replaceabletubedual circuit shell-and-tubeevaporator,

and complete refrigerant piping. Liquid line components

included are manual liquid line shutoff valves, charging valves,

StarGateTM

water cooled water chillers are com-

Nomenclature

filter-driers, liquid line solenoid valves, sightglass/moisture

indicators, and electronic expansion valves. Other features

include compressor heaters, automatic one time pumpdown

of refrigerant circuit upon circuit shutdown, and an advanced

fully integrated microprocessor control system.

The electrical control center includes all safety and operating controls necessary for dependable automatic operation,

(the high and low pressure controls are external from the

electrical control center). Compressors are protected by

state overload protection and over temperature protection.

Field installed fused disconnect offers additional protection.

solid-

PFS-XXXA

TTT IT

Watercooled

Dual

Screw

compressor

When the equipment is received, all items should be carefully

checked against the bill of lading to insure a complete

shipment. All units should be carefully inspected for damage

upon arrival. All shipping damage must be reported to the

carrier and a claim must be filed with the carrier. The unit

serial plate should be checked before unloading the unit to

2

1

1

( (

Inspection

150=150

165=165

180=180

190=190

200=200

be sure that it agrees with the power supply available.

Physical damage to unit after acceptance is not the

sibility of McQuay International.

Note: Units shipping and operating weights are available

in the physical data table on page 15.

tons

tons

tons

tons

tons

respon-

IM 609 / Page 3

Page 4

Installation & Start-up

Note:

Start-up by McQuay Service is included on all units sold for

installation within North America excludinq Mexico. Two

weeks prior notification of start-up is required. The contractor should obtain a copy of the Start-up Scheduled Request

Form from the sales representative or from the nearest office

of McQuayService.

Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment.

Handling

Care should be taken to avoid rough handling or shock due

to impact or dropping the unit. Do not push or pull the unit

from anything other than the base.

Never allow any part of the unit to fall during unloading or

moving as this may result in serious damage.

Every PFS is shipped with a full refrigerant charge. For

shipping reasons, thechargewill be stored in the condensers

and is isolated by the manual condenser liquid valve and the

Moving the Unit

The PFS water chiller is shipped mounted on heavy wooden

skids to protect the unit from accidental damage and permit

easy handling, and moving.

It is recommended that all moving and handling be

performed with the skids under the unit when possible and

that the skids not be removed until the unit is in the final

location.

When moving the unit, dollies or simple rollers can be

used under the skids.

Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on skids

only and not to the piping or shells. A long bar

the unit easily. Avoid dropping the unit at the end of the roll.

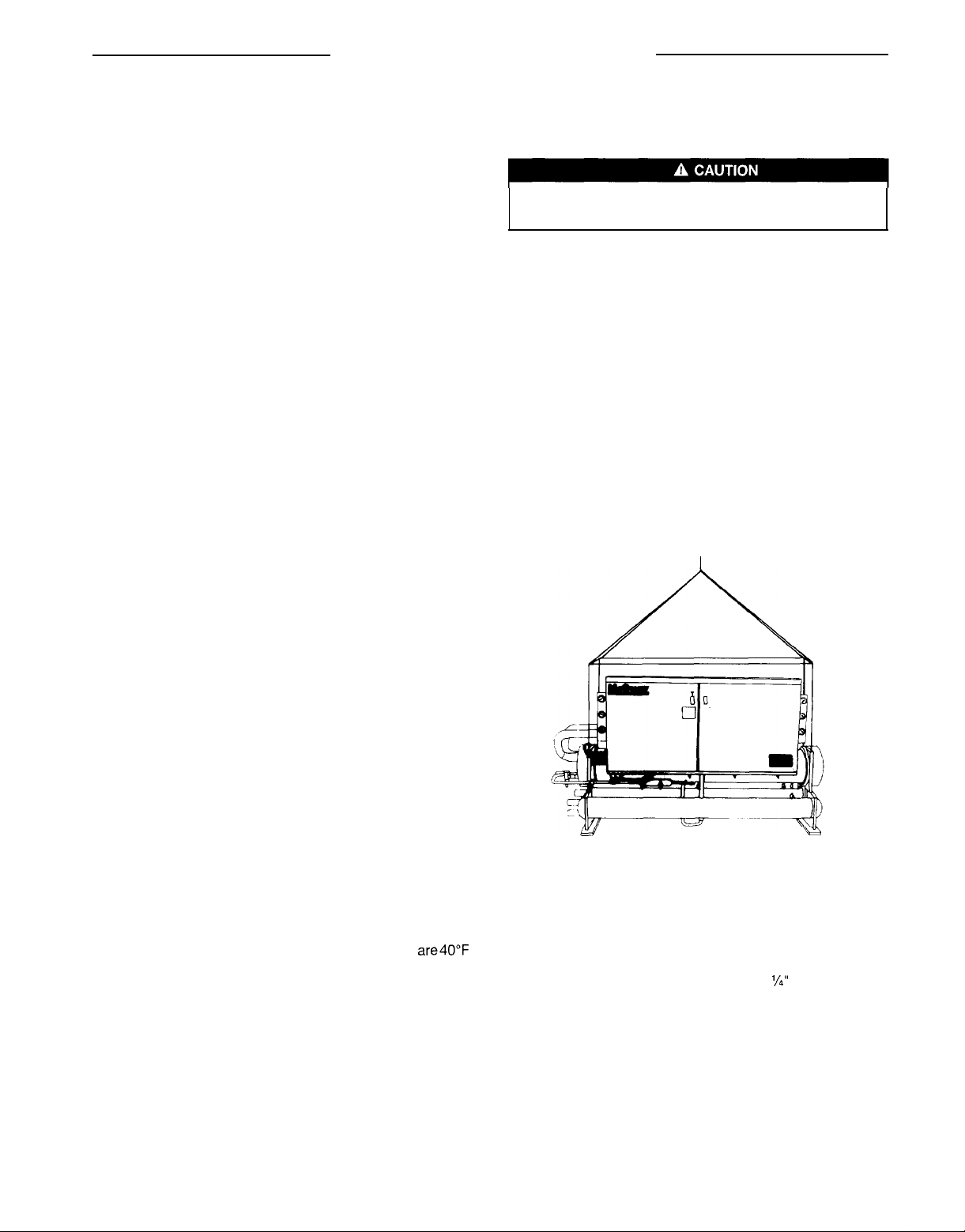

If the unit must be hoisted, it is necessary to lift the unit

by attaching cables or chains at the lifting holes in the

evaporator tube sheets. Speader bars must be used to

protect the control cabinet and other areas of the chiller (see

Figure 1).

Do not attach slings to piping or equipment. Move unit in

the upright horizontal position at all times. Set unit down

gently when lowering from the trucks or rollers.

will

help move

Sharp edges are a potential injury hazard. Avoid contact

with them.

discharge valve.

Should the unit be damaged, allowing the refrigerant to

escape, there may be danger of suffocation in the equipment

area since the refrigerant will displace the air. Be sure to

review Environmental ProtectionAgency(EPA) requirements

should unit damage occur. Avoid exposing an open flame to

refrigerant.

Figure 1. Suggested lifting arrangement

Location

Unit is designed for indoor application and must be located in the control box is supplied as standard fortemporary protecan area

(4°C) or above. A good rule of thumb is to place the unit where

ambients are at least 5°F (3°C) above the leaving evaporator

water temperature.

because of the electrical control devises. A plastic cover over

where the

The unit should not be exposed to the elements (weather)

surrounding ambient temperatures

are40”F tion during shipment.

The PFS should be mounted on a solid and level founda-

tion. The foundation must be level [within

length and width] and able to support the unit’s operating

weight. If necessary, additional structural members should be

provided to transferthe weight of the

‘/a”

(6mm) over its

unit to

the nearest beam.

Compressor Condensation

Screw compressors, sealed by means of liquid injection,

separate at very cold surface temperatures. Where those

temperatures are below the ambient dew point temperatures,

I

Page 4

IM 609

condensation occurs. If condensation is excessive, provisions

must be made to drain off the accumulation. A drain

connection may be required.

Page 5

Clearances

Service access to the evaporator, compressors, condensers,

electrical control panel and piping components must be

provided as per the following limitations: The chilled water

piping for all units enters and leaves the cooler from the rear,

with the control box being on the front side of the unit. A

clearance of 3 to 4 feet (914 to 1219mm) should be provided

for this piping and for replacing the filter-driers, for servicing

the solenoid valves or changing the compressors, in the

unlikely case where this would be required.

The condenser water piping enters and leaves the shell

from the ends. Work space must be provided in the casewater

regulating valves are being used and for general servicing.

Clearance should be provided for cleaning condenser

tubes or removing cooler tubes on one end of the unit as

specified in Table 1. It is also necessary to leave a

worK

area

on the end opposite which is used for replacement of a cooler

tube.

Table 7. Clearance

Notes:

1.

Dimension B

and replacement of evaporator and condenser tubes (either end).

2.

Electrical disconnect is required. It should not be located where it

with component service.

and D reflect the minimum clearance required for the removal

will

Interfere

Figure 2. Clearance requirements

Front

Control B

OX

1

Disconnect all power to the unit while servicing compressor motors. Failure to do so may cause bodily injury or death.

Vibration Isolators

It is recommended that isolators are used on all upper level

installations where vibration transmission is a consideration.

When spring isolators are required, install springs running

under the main unit supports. Adjust spring type mounting so

‘/4”

the upper housing clears lower housing by at least

and not more than

5%”

(13mm). A rubber anti-skid should be

(6mm)

used under isolators if hold-down bolts are not used. Vibra-

tion eliminators in all water piping are recommended to avoid

straining the piping and transmitting vibration and noise.

Table 2 lists spring and rubber-in-shear Isolators for all PFS

unit sizes. Figure 2 shows isolator locations in relation to the

unit control center.

I

20

I

Table 2. Vibration isolators (PFS

Table 3. Isolators

Note: The spring is fully compressed at approximately 3900 Ibs. (1769 kg).

(PFS150A - 200A)

75OA - 200A)

Figure 3. Rubber-in-shear isolator

L 5”

(127mm) ,I

6%” (165mm)

?/IS”

(1

Omm)

dla

IM 609 / Page 5

Page 6

Figures 3 and 4 gives dimensions that are required to

secure each McQuay isolator section to the mounting surface. Table 4 shows the isolator loads at each location as

shown in Figure 5. The maximum loads for each McQuay

selection are shown in Table 3.

Tab/e 4. Weights

.s__._-

UN’TS

f$iZE

,!

105A

‘fc--

BOA

z

Ibs

jDA11

ko

il

Ibs

kg 1015 1050 1010 975 4050

Ibs

WA

ka 1 1015 1 1050 1 1015 1 975 1 4055 I 3916

1-1

Ibs

kq

Ibs1 2238 1 2325 / 2238 1 2161 1 8960 1 8650

xIA kg]L1015 1 1050 / 1015 1

__ . . . . _..

1

1

2

1

2227

1

2315 1

I

I

1

ioifl

I

.-

2236 2315 2227 2150 8930

2238

,

1

1

2230

1

1

1015

1

--_._...

1 3 1

2227

1

/

1050

---

2315 2238 2150 8940

2315

1050

I

I

1010

I

I

1

/

2238

1

1

1015

1

_. _. . .

4

WEIGHT

2150

1I8920

975

I

4046

I

2161

1

8950

980

1

4059

960 1

4064 I 3924

__.-.

WEIGHT

8610

I

I

3YO5

?620

3910

a630

I

1

8640

1

3919

Figure 4. Spring flex isolator

6

9)/r’

6”

(1

1

Figure 5. Corner weight locations

7%“(196:6mm)

(234

9mm)

C-C FOTN Bolt

10%” (266.70mm)

-

t

Mounting so that Upper

6 3mm)

and Not More Than

Acoustical Non-skld

Water Piping

Due to the variety of piping practices, it is advisable to follow

the recommendations of local authorities. They can supply

the installer with the proper building and safety codes re-

quired for a safe and proper installation.

Basically, the piping should be designed with a minimum

number of bends and changes in elevation to keep system

cost down and performance up. It should contain:

1.

All piping should be installed and supported to prevent

the unit connections from bearing any strain

the system piping.

2.

Vibration eliminators to reducevibration and noise trans-

mission to the building.

Shutoff valves to isolate the unit from the piping system

3.

during unit servicing.

Manual or automatic air vent valves at the high points of

4.

the system. Drains should be placed at the lowest points

in the system.

5.

Some means of maintaining adequate system water

pressure (e.g., expansion tank or regulating valve).

Temperature

6.

and

pressure Indicators located within 3

feet (0.9 meters) of the inlet and outlet of the vessels to

aid in unit servicing.

or weight

of

Control Box

A strainer or some means of removing foreign matter

7.

from the water before it enters the pump is recom-

mended. It should be placed far enough upstream to

prevent cavitation at the pump inlet (consult pump

manufacturerforrecommendations).Theuseofastrainer

will prolong pump life and thus keep system perfor-

mance up.

A cleanable strainer should aiso be placed in the water

8.

lines

just

prior to the inlets of the evaporator and condenser. This will aid in preventing foreign material from

entering and decreasing the performance of the evaporator and condenser.

water

9

Any

prevent

piping to the unit must be protected to

freezing.

Consult the

ASHRAE

handbook for

standard industry practice.

10.

If the unit

IS used as a replacement chiller on a previously

existing piping system, the system should bethoroughly

flushed prior to unit installation and then regular water

analysis and chemical water treatment on the evapora-

tor and condenser is recommended immediately at

equipment start-up.

The total quantity of water in the system should be

11

suffic

ient to prevent frequent “on-off” cycling. The total

Page 6

/

IM 609

Page 7

quantity of water, in the system, turnover rate should not

be less than 15 minutes.

12. In the event glycol is added to the water system, as an

afterthought for freeze protection, recognize that the

refrigerant suction pressure will be lower, cooling performance less, and water side pressure drop is greater.

If the percentage of glycol is large, or if propylene is

employed instead of ethylene glycol, the added pressure drop and loss of performance could be substantial.

Reset the freezestat and low leaving water alarm tem-

Figure

6. Typical field evaporator water piping

peratures. The freezestat is factory set to default at 36°F

(2.2%). Reset the freezestat setting to approximately

4”-5°F (2.3”-2.8%) below the leaving chilled water

setpoint temperature. See the section titled “Glycol

Solutions” for additional information concerning glycol.

13. A preliminary leak check of the water piping should be

made before filling the system.

A water flow switch or pressure differential switch

must be mounted in the water lines to the evaporator

assuring water flow before starting the unit.

Note:

1. Chilled water piping should be insulated.

Chilled water piping

The system water piping must be flushed thoroughly

making connections to the unit evaporator. It is recommended that a strainer of 40 mesh be installed in the return

water line before the inlet to the chiller. Lay out the water

piping so the chilled water circulating pump discharges into

the evaporator inlet.

The return water line must be piped to the evaporator inlet

connection and the supply water line must be piped to the

evaporator outlet connection. If the evaporator water is

piped in the reverse direction, which is not recommended, a

substantial decrease in capacity and efficiency of the unit will

be experienced.

A flow switch must be installed in the horizontal piping of

the supply (evaporator outlet) water line to assure water flow

before starting the unit.

Drain connections should be provided at all low points in

the system to permit complete drainage of the system. Air

vents should be located at the high points in the system to

purge air out of the system.

of the evaporator vessel, permits the purging of air out of the

evaporator. Air purged from the water system prior to unit

start-up insures adequate flow through the vessel and prevents safety cutouts on the freeze protection. System pres-

Avent

connection, located on top

prior to

sures can be maintained by using an expansion tank as a

combination pressure relief and reducing valve.

Pressure gauges should be installed in the inlet and outlet

water lines to the evaporator. Pressure drop through the

evaporator should be measured to calculate proper gpm

(Ips) as specified in Table 8. Vibration eliminators are recom-

mended in both the supply and return water lines.

Chilled water piping should be insulated to reduce heat

loss and prevent condensation. Complete unit and system

leak tests should be performed prior to insulating the water

piping. Insulation with a vapor barrier would be the recommended type of insulation. If the vessel is insulated, the vent

and drain connections must extend beyond the proposed

insulation thickness for accessibility. Chillers not run in the

wintershould havetheirwatersystemsthoroughlydrainedto

protect against freezing. If the chiller operates year-round, or

if the system is not drained for the winter, the chilled water

piping exposed to outdoor ambient should be protected

against freezing by wrapping the lines with a heater cable.

Also, an adequate percentage of glycol should be added to

the system to further protect the system during low ambient

periods.

IM 609

/

Page 7

Page 8

Condenser Water Piping

Arrange the condenser water so the water enters the bottom

connection of the condenser. The condenser water will discharge the condenser from the top connection. Failing to

arrange the condenser water as stated above

affect the capacity and efficiency.

Pressure gauges should be installed in the inlet and outlet

water lines to the condenser. Pressure drop through the condenser should be measured to calculate proper gpm (Ips) as

specified in Figure 12. Vibration eliminators are recommended in both the supply and return water lines.

Water cooled condensers may be piped for use with

cooling towers or well water applications. Cooling tower

applications should be made with consideration to freeze

protection and scaling problems. Contact the cooling tower

manufacturer for equipment characteristics and limitations

for the specific application.

will

negatively

Head pressure control, tower system

Some means of operating head pressure control must be

provided. Fan cycling and/or modulating discharge dampers

on the cooling towers is often used; sometimes a three-way

bypass valve around the tower is used. The minimum acceptable condensing temperature is 80°F (27°C). The minimum entering tower condenser water temperature is 60°F

(156°C).

a three-way pressure actuator water regulating valve used

for cooling applications. In Figure 8 the capacity of the cooling tower is controlled through damper and/or fan modulation. These typical systems, depending on the specific application, must maintain a constant condensing pressure, regardless of temperature conditions and must assure enough

head pressure for proper thermal expansion valve operation.

Note that both systems assure full water flow to the tower.

Figures 7 and 8, are typical systems. Figure 7 shows

Figure 7. 3-Way water valve

J-WAY WATER

REGULATlhlG

Figure 8. Fan modulation

VALVES

Head pressure control, well water system

When using city or well water for condensing refrigerant, a

direct acting water regulating valveshould be installed in the

outlet piping of each condenser (see Figure 9). The condenser purge valve provides a convenient pressure tap for

the regulating valve. The valve can modulate in response to

head pressure. On shutdown it closes, preventing water from

siphoning out of the condenser. Siphoning causes con-

denser waterside drying and accelerates fouling. Figure 9

illustrates the recommendation of a loop at the outlet end

when no valve is used.

Figure 9. Well water cooling system

LOOP RECURED

REGULATING

WHEN NO

VALVE IS

USED

Page 8 / IM 609

Page 9

Relief Valve Piping

The

ANSI/ASHRAE

sure relief valves on vessels containing Group 1 refrigerant

(R-22) “shall discharge to the atmosphere at a location not

less than 15 feet (4.6 meters) above the adjoining ground

level and not less than 20 feet (6.1 meters) from any window,

ventilation opening or exit in any building.” The piping must

be provided with a rain cap at the outside terminating point

and a drain at the low point on the vent piping to prevent

water buildup on the atmospheric side of the relief valve. In

addition, a flexible pipe section should be installed in the line

to eliminate any piping stress on the relief valve(s).

The size of the discharge pipe from the pressure relief

valve shall not be less than the size of the pressure relief

outlet. When two or more vessels are piped together, the

common header and piping to the atmosphere shall not be

less than the sum of the area of the relief valve outlets

connected to the header. Fittings should be provided to

permit vent piping to be easily disconnected for inspection or

replacement of the relief valve.

Note: Provide adequate fittings in piping to permit repair

or replacement of the relief valve(s).

Standard 15-l 978 specifies that pres-

Figure 10. Relief valve piping

RELIEF

VALVE

(SET AT 450

PSI)

(3104

kPa)

Note: The above drawing reflects one circuit only. Each condenser is

equipped

with

a relief valve requiring field piping.

Temperature and Water Flow Limitations

PFS units are designed to operate in conditions from 40°F

(4.4%) to 50°F (10°C) leaving water temperature on the

evaporator side and 60°F (15.6%) to 105°F (40.6%) entering

water temperature on the condenser side.

On the evaporator side, the maximum water pressure is

225 psig (1552

kPa).

Glycol in the evaporator is required on

all applications below 40°F (4.4%) leaving evaporator water

temperature. The maximum allowable water temperature to

the cooler in a non-operating cycle is 105°F (40.6%). The

maximum entering evaporator water temperature in the

operating cycle is 90°F (32.2%) for start-up purposes.

The maximum condenser water pressure is 250 psig

(1724

kPa).

The non-operating leaving condenser water

Evaporator Insulation Considerations

The presence of humidity and condensation may become an

issue on the evaporator of a water cooled chiller. Insulation

Evaporator Freeze Protection

Evaporator freeze protection can be a concern in some water

cooled chiller applications. The following practices may

want to be incorporated in the system design:

Drain and flush the evaporator and chilled water piping

withglycoliftheunitwillnotbeoperatedduringthewinter.

Drain and vent connections are provided on the evaporator to facilitate draining.

In some applications such as matching the chiller with a

cooling tower, adding glycol solution to the chilled water

system will provide freeze protection. Freeze point should

be approximately 10°F (5°C) below minimum design ambient temperature.

Bypass water from the heating system through the evaporator when the unit is shutdown during the winter months.

temperature maximum is 115°F (46.1%). The minimum

en-

tering condenser water temperature is 60°F (15.6%).

The minimum and maximum evaporator flow rates are

given in Table 8. Flow rates below the minimum values may

result in laminar flow causing freeze-up problems, scaling

and poor control. Flow rates above the maximum values will

result in unacceptable pressure drops, excessive nozzle and

tube erosion and potentially lead to tube failure. The mini-

mum and maximum condenser flow is shown in Table 9.

Note: When operating with a higher evaporator and condensertemperature a less than nominal water gpm (Ips) is not

recommended.

is applied to the evaporator of the PFS as a standard factory

feature. This insulation will alleviate evaporator sweating.

This can be accomplish by using a small circulating

pump arranged to operate independent of the heating

system. Pipe the pump to maintain a small flow of water

continuously through the evaporator.

4. Field water piping, especially on the chilled water side,

can be insulated to reduce condensation on the piping.

It is the responsibility of the installing contractor and/or

on-site maintenance personnel to insure this additional

protection is provided. Routine checks should be made to

insure adequate freeze protection is maintained.

Failure to do so may result in damage to unit compo-

nents. Freeze damage is not considered a warranty failure or

the responsibility of McQuay International.

IM

609 I Page 9

Page 10

Condenser Protection and Design Considerations

Applications exist where low temperature pond and river

water are utilized as a condensing medium. If the water

valves leak, the condenser and liquid line refrigerant temperature could drop below the equipment room temperature

on the “off” cycle opening the expansion valve. This problem

occurs when cold water continues to circulate through the

condenser and the unit remains off due to satisfied cooling

Chilled Water Thermostat

The PFS water cooled chiller is built with the MicroTech

leaving water controller. Refer to IM Bulletin 549 for proper

setup and calibration of the MicroTech controller. Care

should be taken working around the unit to avoid damaging

leadwires and sensor cables. Check leadwires, before

run-

Refrigerant Charge

All units are designed for use with HCFC-22 and are compat-

ible with HCFC alternatives and are shipped with a full

Flow Switch

A water flow switch must be mounted in either the entering

or leaving water line to insure that there will be adequate

waterflowtotheevaporatorbeforetheunit

safeguard against slugging the compressors on start-up.

Also, it serves to shut down the unit in the event that water

flow is interrupted to guard against evaporator freeze-up.

A flow switch is available

from McQuay under part number

0017503300. It is a “paddle” type switch and adaptable to

any pipe size from 1” to 6” (25mm to 152mm) nominal.

Certain minimum flow rates are required to close the switch

can start. This will

load. If this occurs:

1.

Cycle the condenser pump off with the unit.

2. Verify that the liquid line solenoid valves are operating

properly. If the valves are closing liquid tight as designed,

no recycling of pumpdown should occur.

ning

the

unit,

to avoid rubbing the leadwires on the frame or

other components. Verify the leadwires are firmly anchored.

If the sensor is removed from the well for servicing, do not

wipe off the heat conducting compound supplied in the well.

operating charge. The operating charge for each unit is

shown in the Physical Data Table on page 15.

and are listed in Table 5. Installation should be as shown in

Figure 11.

Electrical connections in the unit control center should be

made at terminals 62 and 63. The normally open contacts of

the flow switch should be wired between these two termi-

nals. Flow switch contact quality must be suitable for 24

VAC, low current (16ma). Flow switch wire must be in

separate conduit from any high voltage conductors (115

VAC and higher).

_

Figure

11.

Flow switch

Flow

Direction

Marked on

5” Pipe Dia. - Minimum

After Switch

L 5”

Pipe Dia.

After Switch

Minimum

Switch

L

Glycol Solutions

The system glycol capacity, glycol solution flow rate for the

evaporator in gpm (Ips), and pressure drop through thecooler

may be calculated using the following formulas and table.

Note: The procedure below does not specify the type of

glycol. Use the derate factors found in Table 6 for corrections

when using ethylene glycol and those in Table 7 for propylene

glycol.

Table 5.

Note:

1.

1.

Flow switch minimum flow rates

NOMINAL

Water pre ssure differential switches are not recommended for outdoor

applications.

Capacity

PIPE SIZE

(inches)

5

6

-

Cooling capacity is reduced from that with

MIN> REQUIRED

ACTIVATE

58.7 (3.7)

79.2 (5)

FLOW TO

SWITCH - gpm (lps)

plain water. To find the reduced value multiply the chiller’s

water system tonnage by the capacity correction factor

(Cap) to find the chiller’s capacity in the glycol system.

2,

GPM -To determine evaporator gpm (or

hT)

knowing

(or gpm) and tons:

Glycol gpm = 24 x tons

(Glvcol) x Flow (from table)

AT

AT

Page 10 / IM 609

Page 11

For metric applications:

LPS -To determine evaporator Ips (or

Ips) and

Glycol Ips =

kW:

kW

4.18

x Flow (from table)

x/IT

LIT)

knowing

LIT

(or

Pressure Drop -To determine pressure drop through the

cooler, when using glycol, enter the water pressure drop

curve (Figure 12) at the actual glycol gpm (Ips). Multiply

the water pressure drop found there by (PD) to obtain

corrected glycol pressure drop.

To determine glycol system power

system power

kW

by the (Power) factor.

kW,

multiply the water

Test coolant with a clean, accurate glycol solution

hydrometer (similar to that found in service stations) to

determine the freezing point. Obtain percent glycol from

the freezing point table below. On glycol applications it is

normally recommended by the glycol supplier that a

minimum of 25% solution by weight be used for protection against corrosion.

Note: The effect of glycol in the condenser is negligible. As glycol increases in temperature, its characteristics have a tendency to mirror those of water. Therefore

for selection purposes, there is no derate in capacity for

glycol in the condenser.

Table 6. Adjstment factors for ethylene glycol

Table 7. Adjustment factors for

propylene

glycol

Do not use an automotive grade antifreeze. Industrial grade glycols must be used. Automotive antifreeze contains

inhibitors that will cause plating on the copper tubes within the chiller evaporator. The type and handling of glycol used

must be consistent with local codes.

Evaporator and Condenser Water Flow and Pressure Drop

Balance the water flow through the evaporator and condenser. The flow rates must fall between the minimum and

maximum values shown on the appropriate evaporator and

condenser curves. Flow rates below the minimum values

shown will result in laminar flow that will reduce efficiency,

cause erratic operation of the electronic expansion valve and

could cause low temperature cutouts. On the other hand,

flow rates exceeding the maximum values shown can cause

erosion on the evaporator water connections and tubes.

McQuay encourages a minimum glycol concentration of

25% be provided on all glycol applications. Glycol concentrations below 25% have too much dilution in the inhibitor

content that is necessary for long-term corrosion protection

of ferrous metals.

Measure the chilled water pressure drop through the

evaporator at field installed pressure taps. It is important not

to include valves or strainers in these readings.

It is not recommended varying the water flow through the

evaporatorwhilethecompressor(s) areoperating.

MicroTech

control setpoints are based upon a constant flow and variable temperature.

Figure 12. Pressure drop - (PFS 150 -

Flow (LPS)

40

30

25

20

10

9

8

6

5

2OOA)

90

75

60

45

30

27

24

21

18

15

P

zi

8

G

?!

;

I

p‘

3

2

200 300

Flow (GPM)

400 500600

800 1000

IM

609/Page

11

Page 12

Page 13

Page 14

Field Wiring

General Information

Wiring must comply with all applicable codes and ordinances. Warranty is voided if wiring is not in accordance with

specifications.

An open fuse indicates a short, ground, or overload.

Before replacing a fuse or restarting a compressor, the

trouble must be found and corrected.

Copper wire is required for all power lead terminations at

the unit and copper must be used for all other wiring to the

unit.

Interlock Wiring - Condenser Pump Starter

Provisions are made for interlocking a condenser pump

starter (MA, MB) to cycle with the compressor(s) as shown in nals 11 and 16. This allows the condenser pump to operate

Figure 13. Coil voltage must be 115 volts with a maximum of when either compressor is operating.

20VA.

or two

One

one circuit is required, jumper terminals 11 and 12, on

Figure 13. Typical interlock schematic

pumps can be interlocked with the PFS. When

The PFS is supplied standard with the main power wiring

for single point power connection. A single large power

terminal block is provided and wiring within the unit and sized

in accordance with the National Electrical Code. A single field

supplied disconnect is required. An optional factory mounted

transformer for the 115 volt control circuit may have been

provided.

Main power must enter the control panel at the location

indicated on the unit illustration.

(TB2),

terminal block

Whentwocircuitsarerequired, connectthestarterforthe

first circuit between 11 and 16. The starter for the second

circuit must be connected between terminals 12 and 16.

and connect the starter between

termi-

FUSED

CONTROL

TRANSFCRMER

OPTION

Legend

Field Connection Terminal

Factory Wiring

Field Wiring

MA, MB Pump Starter (Max. 20VA each)

PFS unit compressors are single direction rotation compressors. For this reason proper phasing of electrical power is

important. Electrical phasing must be A, B, C for electrical phases 1,2 and 3 (A=L1

single point factory power connection and includes one MotorSaver phase failure, phase reversal protective device that

will prevent operation of the unit with incorrect power phasing. The MotorSaver is factory wired and tested. Do not alter

the wiring to the MotorSaver.

CIRCUIT

,B=L2,C=L3).

The unit is supplied with

Page 14

/ IM

609

Page 15

Page 16

Page 17

Page 18

Page 19

Unit Layout and Principles of Operation

Control Center

All electrical controls are enclosed in a weatherproof control

center with keylocked, hinged access doors. The control

center is composed of two separate compartments, high

voltage and low voltage. All of the high voltage components

are located in the compartment on the right side of the unit.

Figure 74. Control center layout

E

The low voltage components are located on the left side

with the 115 VAC terminals located behind the deadfront

panel. This protects service personnel from 115 VAC

nals when accessing the adjustable and resettable controls.

termi-

Sequence of Operation

The following sequence of operation is typical for McQuay

models

The sequence may vary depending on the software revision

or various options that may be installed on the chiller.

PFS140A

through

PFS2OOA

screw water chillers.

Off conditions

With power supplied to the unit, 115 VAC power is applied

through the control fuse

circuit transformer and Output Board Relays 12 and 13. The

MicroTech Controller will energize or de-energize the compressor heaters

the software. Note: Before start-up, the compressor heat-

ers must be on for at least 12 hours or until both circuit

compressor heaters are de-energized by the MicroTech

Controller. The 24V transformer provides power to the

MicroTech controller and related components. With 24V

power applied, the controller will check the position of the

front panel system switch. If the switch is in the “Stop”

position the chiller will remain off and the display will indicate

the operating mode to be OFF: System S

(HTR1

F1

to the primary of the 24V control

, HTR2) based on set parameters in

W. If the system

Ice Mode

For operations requiring ice mode feature, logic in MicroTech

will adjust the freezestat to a pressure equivalent to

(7.5%) below the leaving evaporator water temperature.

However, if a different freezestat pressure value is desired,

the freezestat can be manually changed through MicroTech.

Refer to IM 549 for additional information.

13.5”F

switch is in the “Auto” position the controller will then check

the pumpdown switches. If any of the switches is in the

“stop” position, that circuit’s operating mode will be displayed as OFF: PumpDwnSw. If the switches for both

circuits are in the “Stop” position the unit status will display

OFF:

PumpdownSw’s.

open, the chiller will be OFF: RemoteSw. The chiller may

also be commanded off via communications from a separate

communicating panel such as the Remote Monitoring and

Sequencing Panel or an Open Protocol interface. The display will show OFF: RemoteComm if this operating mode is

in effect. If an alarm condition exists which prevents normal

operation of both refrigerant circuits, the chiller will be

disabled and the display will indicate OFF: Alarm. If the

control mode on the keypad is set to “Manual Unit Off,” the

chiller will be disabled and the unit status will display OFF:

ManualMode. Assuming none of the above stop conditions

are true, the controller will examine the internal time schedule to determine whether the chiller should be permitted to

start. The operating mode will be

schedule indicates time remaining in an “off” time period.

If the remote start/stop switch is

OFF:

TimeClock

if the time

Operation

Alarm

The alarm light on the MicroTech will be illuminated when

one or more of the cooling circuits have an active alarm

condition that results in the circuit being locked out of

operation. Unless the alarm condition affects all circuits the

remaining circuits will operate as required. Refer to IM 549

for additional details.

IM 609

/

Page

19

Page 20

Start-up

If none of the above “off” conditions are true, the MicroTech

controller will initiate a start sequence and energize the

chilled water pump output relay. The chiller will remain in the

WaitForFlow mode until the field installed flow switch indicates the presence of chilled water flow. If flow is not proven

within 30 seconds, the alarm output will be turned on, the

keypad display will be WaitForFlow and the chiller will

continue to wait for proof of chilled water flow. Once flow is

established, the controller will sample the chilled water

temperature and compare it against the Leaving Chilled

Water Setpoint, the Control Band, and the Start-up Delta

Temperature, which have been programmed into the

controller’s memory. If the leaving chilled water temperature

is

above the

Band plus the adjustable Start-up Delta Temperature, the

controller will select the refrigerant circuit with the lowest

number of starts as the lead circuit and energize the first

stage of the Cool Staging mode. The controller will start the

compressor and energize the compressor liquid injection

solenoid along with the main liquid line solenoid. The controller will delay the opening of the electronic expansion

valve until the evaporator pressure decreases to a preset

value. This is the evaporator prepurge mode and the display

will show Pre-Purge. The valve will then open allowing

refrigerant to flow through the expansion valve and into the

evaporator and the display will show Opened EXV. If additional cooling capacity is required, the controller will energize the additional cooling capacity by activating the first

compressor’s capacity control solenoids. As the system

load increases, the controller will start the lag refrigerant

circuit in the same manner after the interstage timers is

satisfied. The compressors and capacity control solenoids

will automatically be controlled as required to meet the

cooling needs of the system. The electronic expansion

Leaving Chilled Water Setpoint plus the Control

valves are operated by the MicroTech controller to maintain

precise refrigerant control to the evaporator at all conditions.

Condenser control

The condenser pumps will be started in conjunction with the

first compressor to provide head pressure control.

Pumpdown

As the system chilled water requirements diminish, the

compressors will be unloaded. As the system load continues

to drop, the electronic expansion valves will be stepped

closed and the refrigerant circuits will go through a

sequence. As the evaporator pressure falls below the

pumpdown pressure setpoint while pumping down, the

compressor(s) will stop. The unit has a one time pumpdown

control logic; therefore, if the evaporator pressure rises while

the refrigerant circuit is in a pumpdown mode, the controller

will not initiate another pumpdown sequence. The controller

will keep the unit off until

pumpdown control section in IM 549 for additional details.

The chilled water pump output relay will remain energized

until the time schedule’s “on” time expires, the remote stop

switch is opened, the system switch is moved to the stop

position, or a separate communications panel such as the

Remote Monitoring and Sequencing Panel or an Open Protocol interface disables the chiller.

Separate pumpdown switches are provided for each

circuit and will initiatea pumpdown and stop sequence when

moved to the pumpdown and stop position to allow for

manual operation or servicing of the unit. For service

pumpdown below the standard pressure setting refer to full

pumpdown procedures as desired under the filter-drier section found on page 24.

acall

for cooling occurs. Refer to the

pumpdown

Refrigerant Piping Schematic

COMPRESSOR ENVELOPE

Page 20 / IM 609

Page 21

Start-up and Shutdown

To assure correct compressor rotation, field power supply leads must be properly phased prior to start-up.

1.

With all electric disconnects open, check all screw or lug

type electrical connections to be sure they are tight for

good electrical contact.

2.

Inspect all water piping for flow direction and correct

connections at the evaporator and condenser.

Using a phase tester, check that electrical phasing to

3.

each compressor circuit is A-B-C for phases

L3 respectively.

4.

Check the voltage of the unit power supply and verify it

is within the allowed

ance between phases must be within +3%.

5.

Check the unit power supply wiring for adequate ampacity and a minimum insulation temperature rating of 75°C.

6.

Verifythat all mechanical and electrical inspections have

been completed per local codes.

7.

See that all auxiliary control equipment is operative and

that an adequate cooling load is available for initial stat--

up.

a.

Check all compressorvalve connections fortightness to

avoid refrigerant loss at start-up. Although all factory

connections are tight before shipment, some loosening

may result from shipping vibration. Open the compressorsuction and dischargeshutoff valves until backseated.

Open the liquid line shutoff valves until backseated.

Always replace valve seal caps.

tlO%

tolerance. Voltage unbal-

L1, L2,

Pre Start-up

9.

Makesuresystem switch S1

pumpdown switches PS1 and

and Stop”, throw the main power and control disconnect switches to “on”. This will energize crankcase

heaters. Wait a minimum of 12 hours or until both circuit

compressor heaters are de-energized by the MicroTech

and

Controller before starting up unit. Turn compressor

circuit breakers to “off” position until ready to start unit.

10.

Vent the air from the evaporator and system piping.

Open all water flow valves and start the chilled water

pump. Check all piping for leaks. Flush the evaporator

and system piping to obtain clean, noncorrosive water in

the evaporator circuit.

Most relays and terminals in the unit control center are

powered when

disconnect is on. Therefore, do not close

for start-up.

Initial start-up must be performed by McQuayService

personnel. Do not proceed with start-up until IM 549 has

been read.

is in the "Stop” position and

PS2

are on “Pumpdown

S1

is closed and the control circuit

Sl

until ready

1.

Double check that the compressor suction and discharge shutoff valves are backseated. Always replace

valve seal caps.

Insure that the ball valves are open on the lines entering

2.

the evaporator.

Insure that the manual liquid line shutoff valve at the

3.

outlet of the subcooler is open.

Adjust the leaving chilled watertemperature setpoint on

4.

the MicroTech controller to the desired chilled water

temperature. The control band is preset for a 10°F (6°C)

DT between the entering and leaving evaporator water

temperature at full load. If the DT is outside an

(4”-7°C) range, at full load, reset the control band as per

the instructions found in the MicroTech IM Bulletin 549.

Start the auxiliary equipment for the installation by

5.

turning on the time clock, and/or remote on/off switch,

and chilled water pump.

6.

Checktoseethat pumpdown switches PS1 and

in the “Pumpdown and Stop”(open) position. Throw the

S1

switch to the “auto” position.

7.

Under menu 13 of the keypad place the unit into the

automatic cool mode.

Start-up

8”-12°F

PS2

are

Start the system by moving pumpdown switch PS1 to

8.

the “auto” position.

Repeat steps 8 for

9.

circuit.

Superheat is factory adjusted to maintain between 6”

10.

and 12°F (3” and 7°C).

The superheat should be between 6” and 12°F (3” and

7”C),

with the liquid line sightglass full, once the sys-

tem temperatures have stabilized at the MicroTech

setpoint temperatures.

11.

After system performance has stabilized, it is necessary

that the “Compressor Equipment Warranty Form” be

completed to obtain full warranty benefits. This form is

shipped with the unit, and after completion, should be

returned to McQuayService through your sales representative.

PS2

and the second refrigerant

IM 609 / Page 21

Page 22

Temporary Shutdown

Move pumpdown switches PSl and PS2 to the “Pumpdown

and Stop” position. After the compressors have pumped

down, turn off the chilled water pump. Caution: Do

the unit off using the

PS1 and PS2 to the “Stop” position, unless it is an

emergency as this will prevent the unit from going through

a pumpdown.

It

is important that the water flow to the unit is not inter-

rupted before the compressors pump down to avoid freeze-

up in the evaporator.

If all power is turned off to the unit the compressor heaters

will become inoperable. Once power is resumed to the unit it

is important that the compressor heaters are energized a

minimum of 12 hours or until both circuit compressor heaters

are de-energized by the MicroTech controller before attempting to start the unit. Failure to do so could damage the

compressors due to excessive accumulation of liquid in the

compressor.

"S1"

switch, without first moving

not turn

Start-up After Temporary Shutdown

1. Insure that the compressor heaters have been energized

for at least 12 hours or until both circuit compressor

heaters are de-energized by the MicroTech controller

prior to starting the unit.

2. Start the chilled water pump.

The unit has one time pumpdown operation. When PS1

and PS2 are in the “Pumpdown and Stop” position the unit

will pumpdown once and not run again until the PSI and

PS2 switches are moved to the auto position. If PS1 and

PS2 are in the auto position and the load has been

satisfied the unit will go into one time pumpdown and will

remain off until MicroTech senses a call for cooling and

starts the unit.

The unit must not be cycled off by using the evaporator

pump or the disconnect switch.

S1

3. With system switch

pumpdown switches PS1 and PS2 to the “auto” position.

4. Observe the unit operation until the system has stabilized.

in the “on” position, move

Extended Shutdown

Move the PSI and PS2 switches to the manual pumpdown 5.Close the compressor suction and discharge valves as

1.

position.

2. After the compressors have pumped down, turn off the

chilled water pump.

3. Turn off all power to the unit and to the chilled water

pump.

Move the emergency stop switch S1 to the “off” position.

4.

well as the liquid line shutoff valves.

6.

Tag all opened disconnect switches to warn against start-

up before opening the compressor suction and discharge

valves and liquid line shutoff valves.

If glycol is not used in the system drain all water from the

7.

unit evaporator and chilled water piping if the unit is to be

shut down during winter. Do not leave the vessels or

piping open to the atmosphere over the shutdown

period.

Start-up After Extended Shutdown

10.

1.

Inspect all equipment to see that it is in satisfactory

operating condition.

2.

If matched with a cooling tower, remove all debris that

has collected near the tower.

3.

Open the compressor suction and discharge valves

until backseated. Always replace valve seal caps.

4.

Open the manual liquid line shutoff valves.

Check circuit breakers. They must be in the “off” posi-

5.

tion.

Check to see that the pumpdown switch PSI and PS2

6.

are in the “manual shutdown” position and the control

system switch

7.

Throw the main power and control circuit disconnects to

the “on” position.

Allow the crankcase heaters to operate for a least 12

8

hours or until both circuit compressor heaters are deenergized by the MicroTech controller prior to stat--up.

Start the chilled water pump and purge the water piping

9.

as well as the evaporator in the unit.

S1

is in “off” position.

Start the auxiliary equipment for the installation by

turning on the time clock, ambient thermostat and/or

remote on/off switch.

Adjust the dial on the temperature controller to the

11.

desired chilled water temperature.

Check resets of all safety controls.

12.

Switch the unit circuit breakers to “on.”

13.

Start the system by pushing the system switch

14.

“on.” Caution: Most relays and terminals in the control

center are hot with

nect on.

Throw pumpdown switches PS1 and PS2 to the “auto”

15.

position for restart and normal operation.

After running the unit for a short time, check the oil level

16.

in each compressor crankcase and for flashing in the

refrigerant sightglass.

S1

and the control circuits discon-

S1

to

Page 22

/

IM 609

Page 23

System Maintenance

General

On initial start-up and periodically during operation, it will be

necessary to perform certain routine service checks. Among

these are checking the liquid line sightglasses and taking

condensing and suction pressure readings. Through the

MicroTech keypad, check to see that the unit has normal

Compressor

Since the compressor is semi-hermetic requiring no oil tained as closely as possible to the load of the original test.

separator, oil heaters and pumps, no yearly maintenance is

normally required. However, vibration is an excellent check compressor and when performed routinely can give a warn-

for proper mechanical operation. Compressor vibration is an

indicator of the requirement for maintenance and contributes the factory for minimum vibration of

to a decrease in unit performance and efficiency. It is recom-

mended that the compressor be checked with a vibration

analyzer at or shortly after start-up and again on an annual

basis. When performing the test the load should be main- opened for servicing.

Electrical

All power electrical terminals, for compressors, should be

retightened every six months, as they tend to loosen in

service due to normal heating and cooling of the wire.

superheat and subcooling readings.

A Periodic Maintenance Log is located on page 00 of this

manual. It is suggested that the report be completed on a

monthly basis. The log will serve as a useful tool for a service

technician in the event service is required.

Maintenance

The vibration analyzer test provides a fingerprint of the

ing of impending problems. The compressor is checked at

0.14”/second (3.56mm/

second) at 3500 rpm (2917 rpm).

The compressor is supplied with a lifetime oil filter. It is a

good policy to replace this filter anytime the compressor is

Terminals

Electric shock hazard. Turn off all power before con-

tinuing with following service.

Refrigerant

The refrigerant sightglasses should be observed periodically. (A weekly observation should be adequate.) A clear

glass of liquid indicates that there is adequate refrigerant

charge in the system to insure proper feed through the

expansion valve. Bubbling refrigerant in the sightglass, dur-

ing stable run conditions, indicates that the system may be

short of refrigerant charge. Refrigerant gas flashing in the

sightglass could also indicate an excessive pressure drop in

the liquid line, possibly due to a clogged filter-drier or a

restriction elsewhere in the liquid line. If subcooling is low

Lead-Lag

Afeatureof all McQuay PFS watercooled chillers is a system

for alternating the sequence in which the compressors start

to balance the number of starts and run hours. Lead-lag of

the refrigerant circuits is accomplished automaticallythrough

the MicroTech controller. When in the auto mode the circuit

Crankcase Heaters

The compressors are equipped with crankcase heaters.

Crankcase heaters keep the temperature in the crankcase

high enough to prevent refrigerant from migrating to the

crankcase and condensing in the oil during the off-cycle.

Whenasystemisto bestartedupinitially, thepowertothe

heaters should be turned on at least 12 hours or until both

circuit compressor heater are de-energized

by the

MicroTech

Sightglass

add charge to clear the sightglass. If subcooling is normal

10”

to 15°F (6” to

the sightglass check the pressure drop across the

drier.

An element inside the sightglass indicates the moisture

condition corresponding to a given element color. If the

sightglass does not indicate a dry condition after about 12

hours of operation, the unit should be pumped down and the

filter-driers changed.

with the fewest number of starts will be started first. If both

circuits are operating and a stage down to one circuit is

required, the circuit with the most operating hours will cycle

off first. The operator may override the MicroTech controller,

and manually select the lead circuit as circuit

controller before the compressor is started. The crankcase

temperature should be at least 80°F (26.7%) before the

system is started minimizing lubrication problems of liquid

slugging.

When the crankcase is below 80°F

the sightglass will be full. Allow additional time for the oil to

heat up before starting the compressor.

13”C),

at full load, and flashing is visible in

#l

(26.7%), the oil level in

or circuit

filter-

#2.

IM 609

/

Page 23

Page 24

Service

Service on this equipment is to be performed by qualified refrigeration personnel familiar with equipment operation,

maintenance, correct servicing procedures, and the safety hazard inherent to this work. Causes for repeated tripping of

safety controls must be investigated and corrected.

Disconnect all power before doing any service inside the unit.

Anyone servicing this equipment shall comply with the requirements set forth by the EPA concerning refrigerant

reclamation and venting.

,

Compressor Solenoids

The PFS unit screw compressors are equipped with 3 solenoids to control compressor capacity. The solenoids are

controlled by MicroTech outputs. See unit wiring diagrams.

The solenoids are energized at various compressor load

conditions as indicated in Table

Table 75. Solenoid status

Note:

1.

Bottom Front - towards compressor

2. Bottom Rear

-

towards motor

15

below.

Filter-Driers

A replacement of the filter-drier is recommended during

scheduled service maintenance of the unit, any time exces-

sive pressure drop is read across the filter-drier and/or when

bubbles occur in the sightglass with normal subcooling, A

partially clogged filter can also cause trips on the no liquid run

sensor. The maximum recommended pressure drop across

the filter-drier at 75% to 100% circuit loading is 10 psig (69

kPa).

The maximum recommended pressure drop across the

filter-drier at 25% to 50% circuit loading is 5 psig (35

Also, the filter-drier should be changed if the moisture

indicating liquid line sightglass indicates excess moisture by

the wet system color indicators.

During the first few months of operation the filter-drier

replacement may be necessary if the pressure drop across

the filter-drier exceeds the values listed in the paragraph

above. Any residual particles from the unit heat transfer

tubing, compressorand miscellaneouscomponents are swept

by the refrigerant into the liquid line and are caught by the

filter-drier.

The following is the procedure for changing the filter-drier

core:

This procedure is slightly different from a typical reciprocating compressor unit due to the use of a liquid injection

feature on the PFS screw compressor unit. Anytime the

compressor contactor is closed liquid from the liquid line is

kPa).

Location of the solenoids is as follows:

The top solenoid

discharge end.

The bottom solenoids are on the lower side of the compressor on the opposite side from the terminal box. The

bottom front solenoid is the one closest to the discharge end

of the compressor. The bottom rear solenoid is the one

closest to the motor end of the compressor.

If the compressor is not loading properly check the

solenoids to see if they are energized per the above chart. A

complete check will include a check of the MicroTech output,

the wiring to the solenoid and the solenoid coil itself.

injected into the screw for cooling and sealing. This liquid

injection also occurs during normal pumpdown and limits

how low a pumpdown can be achieved.

The standard unit pumpdown is set to stop pumpdown

when 34 psig (235

pump down a circuit beyond 34 psig (235

purposes a “Full Pumpdown” service mode can be activated

using the keypad. Go to Menu 23 on the MicroTech keypad,

step through the menu items until “FullPumpDwn” is displayed. Change the setting from “No” to “Yes.”

The next time either circuit is pumped down the pumpdown

will continue until the evaporator pressure reaches 2 psig (14

kPa)

or 60 seconds have elapsed, whichever occurs first.

Upon completing the pumpdown, the

setpoint is automatically changed back to “No.”

The procedure to perform a full service pumpdown for

changing the filter-drier core is as follows:

1. Perform a normal pumpdown to 34 psig (235

moving the pumpdown switch to the “Pumpdown” position. This step will pump down the evaporator with compressor liquid injection still active.

2.

Close the liquid line shutoff valve above the filter-drier, on

the circuit to be serviced.

i.s

on top of the compressor near the

kPa)

suction pressure is reached. To fully

kPa)

for service

“FullPumpDwn”

kPa)

by

Page 24

/

IM 609

Page 25

3. Under Keypad Menu 23, change the “FullPumpDwn”

setpoint from “No” to “Yes.”

4. The circuit status should be “0ff:PumpDwnSw”. Move

the circuit pumpdown switch from “Pumpdown and

Stop” to “Auto.” Also clear the anti-cycle timers through

the MicroTech keypad.

5. The compressor should pump down the circuit until the

kPa)

evaporator pressure reaches 2 psig (14

onds has elapsed, whichever occurs first.

6. Upon completing the full pumpdown per step

“FullPumpDwn” setpoint is automatically changed back

to “No” which reverts back to standard 34 psig (235

stop pumpdown pressure.

7.

If the

pumpdown

attempt, one more attempt can be made by repeating

does not go to 2 psig (14

or 60 sec-

kPa)

on the first

5.,

the

kPa)

Liquid Line Solenoid Valve

The liquid line solenoid valves, that shut off refrigerant flow

in the event of a power failure, do not normally require any

maintenance. They may, however, require replacement of

the solenoid coil or of the entire valve assembly. (The

Electronic Expansion valve, on a sudden power failure,

remains open to the position it was at when the power failure

occurred. During normal operation the EXV closes for auto-

matic pumpdown and the liquid line solenoid valve closes

only when the compressor stops.)

The solenoid coil can be checked to see that the stem is

magnetized when energized by touching a screwdriver to

the top

of the stem. If there is no magnetization eitherthe coil

is bad or there is no power to the coil.

steps

3,4

and 5 above. Do not repeat

more than once to avoid excessive screw temperature rise under this abnormal condition. A no liquid

start alarm and shutdown may occur during this

procedure. Proceed as noted in step number 8.

The circuit is now in the deepest pumpdown that can

8.

safely be achieved by the use of the compressor. Any

remaining refrigerant must be removed from the circuit

by the use of a refrigerant recovery unit.

Remove and replace the filter-drier(s). If the refrigerant

circuit IS opened for more than 10 minutes evacuate the

lines through the liquid line manual shutoff valve(s) to

remove noncondensables that may have entered during

filter replacement. A leak check is recommended before

returning the unit to operation.

The solenoid coil may be removed from the valve body

without opening the refrigerant piping after first moving

pumpdown

pumpdown” position and opening the

sonal safety shutoff and lockout the unit power.

The coil can then be removed from the valve body by

simply removing a nut or snap-ring located at the top of the

coil. The coil can then be slipped off its mounting stud for

replacement. Be sure to replace the coil on its mounting stud

before returning pumpdown switches PS1 and PS2 to the

“auto pumpdown” position.

To replace the entire solenoid valve follow the steps

involved when changing a filter-drier.

.

switches

PS1

and PS2 to the “manual

“FullPumpDwn”

S1

switch. For per-

Liquid Injection Solenoid Valve

Liquid injection is required during compressor operation to

seal and cool the screw. A liquid injection sensor is installed

on the compressor to assure that liquid injection occurs

whenever the compressor is running. A failure of the liquid

injection solenoid valve to open will cause the compressorto

shut down due to lack of liquid injection.

The liquid injection solenoid valve, like the liquid line

Electronic Expansion Valve

The electronic expansion valve is located adjacent to the

compressor motor housing and is piped so the refrigerant

passes through the electronic expansion valve motor housing, cooling the motor, before going into the evaporator.

Refer to the refrigerant piping schematic found on page 20.

The pressure within the motor housing is at an intermediate

pressure between the condenser pressure and the evaporator pressure.

The expansion valve is responsible for allowing the proper

amount of refrigerant to enter the evaporator to match the

cooling load. It does this by maintaining a constant super-

heat. (Superheat is the difference between refrigerant temperature of the vapor as it leaves the evaporator and the

solenoid valve, only closes when the compressor stops.

Since this valve is open during pumpdown the refrigerant in

the line will

138

body can be removed as in the same procedure as the liquid

line solenoid valve but it is important that the

opened first.

saturation temperature corresponding to the evaporator

pressure.) All PFS chillers are factory set for between

12°F (4°C and 7°C) superheat at 75% to 100% load and

between 6°F and 10°F (3°C and 6°C) below 75% load. The

superheat is controlled by the microprocessor and is not

adjustable.

The expansion valve, like the solenoid valve, should not

normally require maintenance, but if it requires replacement,

the unit must be pumped down by following the steps

involved when changing a filter-drier.

If the problem can be traced to the electric motor only, it

can be unscrewed from

valve but only after pumping the unit down.

cause the

kPa)

after shutdown occurs. The solenoid coil and valve

suction pressure to rise 1 O-20 psig (69-

S1

the valve

body without removing the

IM

switch be

8”Fand

609 / Page 25

Page 26

Electronic Expansion Valve Operation

There are three colored indicator

located in the control panel on the electronic expansion

valve

(EXV)

the microprocessor will automatically step the valve to the

fully closed (shut) position and the indicator lights on the EXV

will blink in sequence. The valve can also be heard closing as

it goes through the steps. The valve will take approximately

14 seconds to go from a full open position to a full closed

position.

The position of the valve can be viewed at any time by is

using the MicroTech keypad through menus 5 and 6 (circuit

pressures). There are a total of 760 steps between closed

and full open.

A feature of the electronic expansion valve is a maximum

operating pressure setting (MOP). This setting limits the load

on the compressor during start-up periods where high return

evaporator water temperatures may be present. The valve

will limit the maximum suction pressure at start-up to approximately 85 psig (586

necessary to maintain the 85 psig (586

the superheat will rise above 12°F

12°F (6.7%) until the suction pressure drops below 85 psig

(586

to 85 psig (586

decreases to approximately

When the circuit starts the valve opens as soon as the

evaporator pressure decreases to 40 psig (276

end of the cooling cycle the valve closes to cause the system

to pump down. The valve closes at the rate of approximately

55 steps per second, or from full open to full closed in

approximately 14 seconds. The valve closing during

pumpdown will occur in approximately 20-30 seconds after

the pumpdown switch is moved to the “Pumpdown and

Stop” position.

board. When the control panel is first powered

kPa).

kPa).

The valve will maintain evaporator pressure close

kPa)

until the evaporator water temperature

LEDs

(green, red, yellow)

The valve will close to a point

kPa).

(6.7”C)

55”-60°F (12.8”-15.6%).

During this time

and not drop below

kPa).

At the

Figure 15. Electronic Expansion Valve

I

v

Extended Copper

Piston

Bottom

d

‘a,

Raintight Flex

Connector

Motor

Housing)

stops

A

Bonnet

Valve Body (Brass)

(Aluminum

Evaporator

The evaporator is of the direct expansion, shell-and-tubetype

with refrigerant flowing through the tubes and water flowing

through the shell over the tubes. The tubes are internally

finned to provide extended surface as well as turbulent flow

of refrigeration through the tubes. Normally no service work

is required on the evaporator. There may be instances where

a tube will leak refrigerant into the water side of the system.

In the cases where only one or two tubes leak, the problem

can best be solved by plugging the tube at both ends. When

the tube must be replaced, the old tube can be removed and

replaced.

the

down. Follow the steps involved when changing a filter-drier.

These steps will insure a minimum amount of refrigerant loss

when the evaporator is opened up. The tubes are mechani-

cally expanded into the tube sheets (see figure below) at

each end of the cooler. In order to remove the tubes, it is

necessary to break this bond by collapsing the tube. After

doing this at both ends of the shell,

for replacement. The new tube can then be inserted and

expanded into the tube sheet.

ant tight. This bond must be produced by applying Locktite

(red) to the tube and rolling it into the tube sheet.

refrigerant should be introduced by momentarily opening

the manual liquid line valve. A leak check should then be

performed on the evaporator.

Follow the requirements set forth by the EPA for

pumpdown

To remove a tube, the unit should betemporarily pumped

Note: The bond produced by expansion must be refriger-

After reassembling the evaporator, a small amount of

and recovery of refrigerant.

the tube

can be removed

re-

Tube removal can only take place

located. One method is to subject each tube to air pressure

by plugging each end and with a pressure gauge attached to

one of the end plugs, observing if there is a loss of air

pressure over a period of a minute or two.

Anothermethodistoplaceacorkplugineachtubeon both

ends of the cooler and applying pressure to the shell of the

cooler. After a period of time the pressure will leak from the

shell into the leaking tube or tubes and pop out the cork plug.

Figure 16.

Top View of Typical Dual Circuit Shell and Tube

Evaporator

Liquid Connections

after the

leaking tube is

Page 26

/ IM

609

Page 27

Condenser

The condenser is of the shell-and-tube type with water

flowing through the tubes and refrigerant in the shell. External finned condenser tubes are rolled into steel tube sheets.

Integral subcoolers are incorporated on all units. All con-

Refrigerant

PFS water cooled screw chillers are shipped factory charged

with a full operating charge of refrigerant but there may be

times that a unit must be recharged at the jobsite. Follow

these recommendations when field charging. Refer to the

unit operating charge found in the physical data table on

page 12.

PFS water cooled screw chillers are more sensitive to

undercharging than to overcharging.

Therefore, it is preferable to be slightly overcharged rather

than undercharged on a circuit. The optimum charge is the

charge that allows the unit to run with a solid stream of liquid

in the liquid line at all operating conditions. When the liquid

line temperature does not drop with the addition of 5-10 Ibs.

(2.3-4.5 kg) of charge then the subcooler is nearly full and

proper charge has been reached. If the liquid line temperature does not drop and the discharge pressure goes up 3-5

psig (21-35

added the correct maximum charge has been reached.

Unit charging can be done at any steady load condition.

Unit must be allowed to run 5 minutes or longer.

Once the subcooler is filled extra charge will not

liquid temperature and does not help system capacity or

efficiency. However, a little extra charge,

kg) will make the system less sensitive.

Note:

should recover within several minutes and should never

show below 6°F

condition. Subcooling will vary somewhat with evaporator

leaving water temperature and suction superheat. As the

evaporator superheat goes lower the subcooling will drop

slightly.

Excessive refrigerant losses can also leak oil from the

system. When adding charge, if there is visible evidence of a

significant oil leakage, and an additional oil charge equivalent to 0.04 pints x the Ibs. (189

charge required. (Example: for every

refrigerant charge add

Oil should be charged into the line between the compres-

sor motor outlet and the evaporator inlet.

A leak in the unit could be very small and have little effect

on system operation or could be severe enough to cause the

unit to shut down on a safety trip.

One of the following three scenarios will be

experienced with an undercharged unit:

1.

If the unit is slightly undercharged the unit will show

bubbles in the sightglass. Recharge the unit as described

in the charging procedure below.

2.

If the unit is moderately undercharged the unit will most

likely trip on freeze protection. Recharge the unit as

described in the charging procedure below.

kPa)

as 5-10 ibs. (2.3-4.5 kg) of refrigerant is

10-15

As the

unit changes load thesubcooling will vary but

(3.4X)

subcooling at any steady state run

mL

x the kg) of refrigerant

10

Ibs. (4.5 kg) of

.4

pints (189

mL)

of oil.)

lower the

Ibs. (4.5-6.8

densers are equipped with 450 psig (3104

Either end on the condenser can be easily removed in the

field.

kPa)

relief valves.

Charging

3.

If the unit is severely undercharged the unit will trip off due

to lack of liquid injection. In this case either remove the

remaining charge by means of a proper reclamation

system and recharge the unit with the proper amount of

refrigerant as is stamped on the unit nameplate, or add

refrigerant through the suction valve on the compressor.