Page 1

USED ON ALL PE, PH. PJ, PG

TPE, TPF, TPH, TPJ MODELS

THROUGH DECEMBER

31,1982

USED ON ALL

AND PF UNITS SINGLE AND DUAL

MODELS THROUGH DECEMBER

PE046W-06OW

31,1982

Page 2

GENERAL

Prior to January 1, 1982 a number of different control

panels were utilized on the model PE and PF centrifugal water chilling units. None of these panels are

now in production, this bulletin will provide general

information on these superseded panels to assist service personnel in understanding the operating sequence as well as providing control settings and

functions.

Each unit control oanel contained necessarv

operating

and

1.

Leaving Water Cycling Thermostat (CT or LRT)

2.

Guardistor Motor Protection

High Pressure Cutout (HP)

3.

4.

Low Pressure Cutout

5.

Oil Pressure Differential Switch (OD)

6.

High Oil Temperature Thermostat (OT or HOT)

7.

Vane Closed Switch (VD)

8.

Low Pressure Override Switch

9.

Oil Pump Time Delay Relay (OTD)

10.

Oil Pump Motor Capacitor

11.

Oil Pump Motor Contactor

Oil Pump Motor Overload Relays (OL)

12.

Electronic Control Module (Temperature and

13.

Current)

Generally, control item identifications and identifying

symbols on wiring diagrams were maintained the same

from panel to panel; however, there were cases where

a control with the same function did carry a different

symbol than had been used on similar panes of an

earlier design. The table of operating and safety controls starting on page 14 will identify controls and also

show where differences did exist.

Notes

1.

2.

3.

-

The information following is of a general nature

and applies to all control panels illustrated on

pages 4 through 6, except for the temperature/

motor load control modules. Details on the different control modules which were used are presented starting on page 7.

When functions covered by a specific control panel

differ from the write-up below, these differences

will be covered with the control panel details on

pages 4 through 6.

A control summary table is presented starting on

page 14, the summary contains the control identifications and other details of protection and operating controls used in the panels.

controls.

All panels basically included:

(GR)

(LP)

(LPO)

(1

M)

protective

OPERATING SEQUENCE

The following operating sequence generally applies to

control panels built through January 1, 1982. Informa-

/l/82

tion on panels utilized after 1

rent product manuals.

Assuming all interconnecting control and power wiring

connections to the panel are complete and the

off” switch is in the “on” position, the operating

controls will be allowed to call for unit operation.

is contained in cur-

“on-

NOTE

If power to the control panel is supplied

by a separate transformer, it should be

rated 2KVA with an inrush rating of

The disconnect switch in the power lines

supplying this transformer must be marked

to prevent the switch from being opened

and de-energizing the control circuit. Oil

heaters are required whenever the unit is

shut down. It is most important that power

is available to the heaters at all times the

unit is not operating.

An open section in the control circuit has been

provided for connection of chilled and condenser

water pump starter interlocks and flow switches.

The purpose of these interlocks is to prevent the

compressor from starting unless both chilled and

condenser water pumps are running and flow has been

established.

The cycling thermostat with its control bulb located in

the leaving chilled water line will, when cooling is required, close its contacts and energize the starting

sequence built into the control panel (assuming the

chilled water pump is running and flow has been established) closing of the cycling thermostat contacts will

first call for oil pump operation by energizing the pump

motor contactor and the oil cooler solenoid valve

through the clutch coil contacts on the oil time delay

relay (OTD).

Once the oil pump is running, two switches and a

timing relay must be satisfied before the compressor

will be allowed to start.

1.

The oil pressure differential switch will close when

the oil/suction pressure difference is 50 psig or

greater. If adequate oil pressure is not developed,

this switch will not close and the compressor will be

prevented from starting.

Before the compressor can start, the inlet guide

vanes must be closed. The vane closed position is

sensed by a pressure switch which is activated

when the unloader piston has moved the guide

vanes to the fully closed position

capacity). Until the vanes are in the minimum

load position, the compressor starting position in

the control circuit will not be energized.

The control circuit also incorporates a timing relay

(OPT) which will stop the oil pump if adequate oil

pressure is not developed or the compressor does

not start within 60 seconds from the closing of the

cycling thermostat.

Once adequate oil pressure has been developed and

the oil differential and vane closed switches have

closed, the condenser pump will be energized by the

condenser pump relay contacts (HWR). The condenser pump must cycle with the compressor. A

second set of condenser pump relay contacts com-

plete a circuit to the motor control relay(s) (MCR),

energizing it or them and as a result energizing the

compressor motor starter to bring the compressor on

line.

Once the compressor is running, the temperature

control module will direct the opening or closing of

the compressor suction inlet guide vanes as requirements for more or less cooling are relayed by the

sensor located in the leaving chilled water line.

12KVA.

(10

percent

2

Page 3

In addition to temperature, the current section of the

control module is constantly monitoring the amount of

current being drawn by the compressor motor. The

current limit is manually set for the required current

limit level (percent of rated load amperes). Regardless

of demands for added cooling capacity, the current

sensing section of the module will not permit the

compressor vanes to open beyond the point where

added capacity will require a value of motor current

which would exceed the current limit setting.

When load conditions change and the need for less

cooling is relayed to the temperature control section

through the sensor in the leaving chilled water, compressor capacity will be reduced as the building

load drops. When the compressor has been unloaded

to 10 percent and the load continues to fall, leaving

chilled water temperature will also drop until the

setting of the cycling thermostat is reached

below design leaving water temperature), at this point

the contacts in the cycling thermostat will open and

the following sequence will take place:

1.

The condenser pump relay will be de-energized

and the condenser pump will stop.

The motor control relay will be de-energized,

2.

opening the compressor starter contacts and stopping the compressor.

The oil pump will continue to run for an additional

3.

30 seconds after the cycling thermostat contacts

open. Keeping the oil pump running after the compressor has stopped will accomplish the following:

a. Bearing lubrication is assured during the spin-

down period.

b. If the compressor cycled off before the vanes

were at minimum load position, the unloading

piston will be driven toward the minimum load

position. (The vanes must be at the minimum

load position before the compressor can start

on the next call for cooling.

4.

The compressor and oil sump heaters are energized

and stay on until the compressor starts again.

5.

A timing relay is incorporated into the control circuit to limit compressor starts to not more than one

every 40 minutes (timed from start). If the com-

pressor operating period prior to shutdown was

less than the time setting, it will be necessary for

the time remaining on the timer to elapse before

the compressor will be permitted to restart. If the

running time prior to shutdown was equal to or

greater than the time setting, the compressor will

be permitted to restart any time the cycling thermostat calls for cooling. A second type of relay was

used on later units where a 20 minute interval from

stop to start was utilized.

In

the event of a power failure during compressor

operation, the compressor bearings will be protected

by oil stored in the emergency cylinder. The spring

loaded piston in this cylinder will force oil into the

various lubrication passages and assure that all bear-

ings are lubricated during the

The exception to the above paragraph is the

through 135W units. These units utilized a solenoid

valve “SD” and condensing pressure to force oil

from the supply line,oil filter and oil cooler into

the compressor bearings.

GUARDISTOR

The compressor motor is protected by the Guardistor

MOTOR PROTECTION

)

spindown

period.

(3’F

PE095W

motor protection circuit. This circuit utilizes thermistors buried in the motor winding to sense temperature changes. At a preset temperature the resistance of the thermistor increases rapidly, this increase

in resistance and the resulting voltage drop causes the

guardistor relay to open and in turn to de-energize

relay

“Rl”

which opens the operating circuit and

energizes motor control relay (MCR).

The Guardistor circuit, once opened, requires manual

resetting before the compressor can be restarted. If

power to the control panel is interrupted for any

reason, the circuit will open and will have to be

manually reset once power is restored to the control

panel.

CAPACITY CONTROL MODULE

The capacity control module, regardless of the type

incorporated in the control panel, will perform the

functions described below. Where a given control

performs in a different manner, the differences will

be covered with details for that particular module

starting on page 7.

The control module is powered from a 5 volt supply

(through a current transformer and resistor located in

the compressor starter).

The control in response to signals relayed from a sen-

sor located in the leaving chilled water will regulate

compressor capacity by opening and/or closing two

solenoid valves “SA” (unload) and “SB” (load).

Opening and/or closing these valves permits oil pres-

sure to build up or drain from opposite ends of a

cylinder containing a floating piston. The compressor

suction inlet guide vanes are linked to the piston and

are positioned by moving it in one direction or the

other until the vane opening is adequate to satisfy

the load requirements.

The temperature control module on a call for increased

cooling capacity can continue to open the suction inlet

vanes until current drawn by the motor reaches the

setting of the current limit control. Once this current

value is reached, the current limit section of the control

will not permit additional loading of the compressor.

The current limit is adjustable from 40 to 100 percent

of rated load current.

The temperature controller can increase or decrease

compressor capacity through solenoid valves

and “SB”.

follows.

Loading

Unloading

Holding

Some older units included solenoid valve “SC”, this

valve was actuated by a low pressure switch and was

utilized to override the normal control and unload the

compressor on a sudden drop in suction pressure,

such as might be caused by a slow opening or sticking

expansion valve. On later units the “SC” valve was

eliminated and the low pressure override switch

actuated valve “SA” directly.

Most of the later panels included a service switch to

permit override of the capacity control and allow

manual control of compressor load level. This switch

has been included as a tool for the service mechanic

and should not be utilized for any other purpose.

3

The valve action to load or unload is as

-

SB energized, SA de-energized

-

SA energized, SB de-energized

-

SA and SB de-energized

de-

“SA”

Page 4

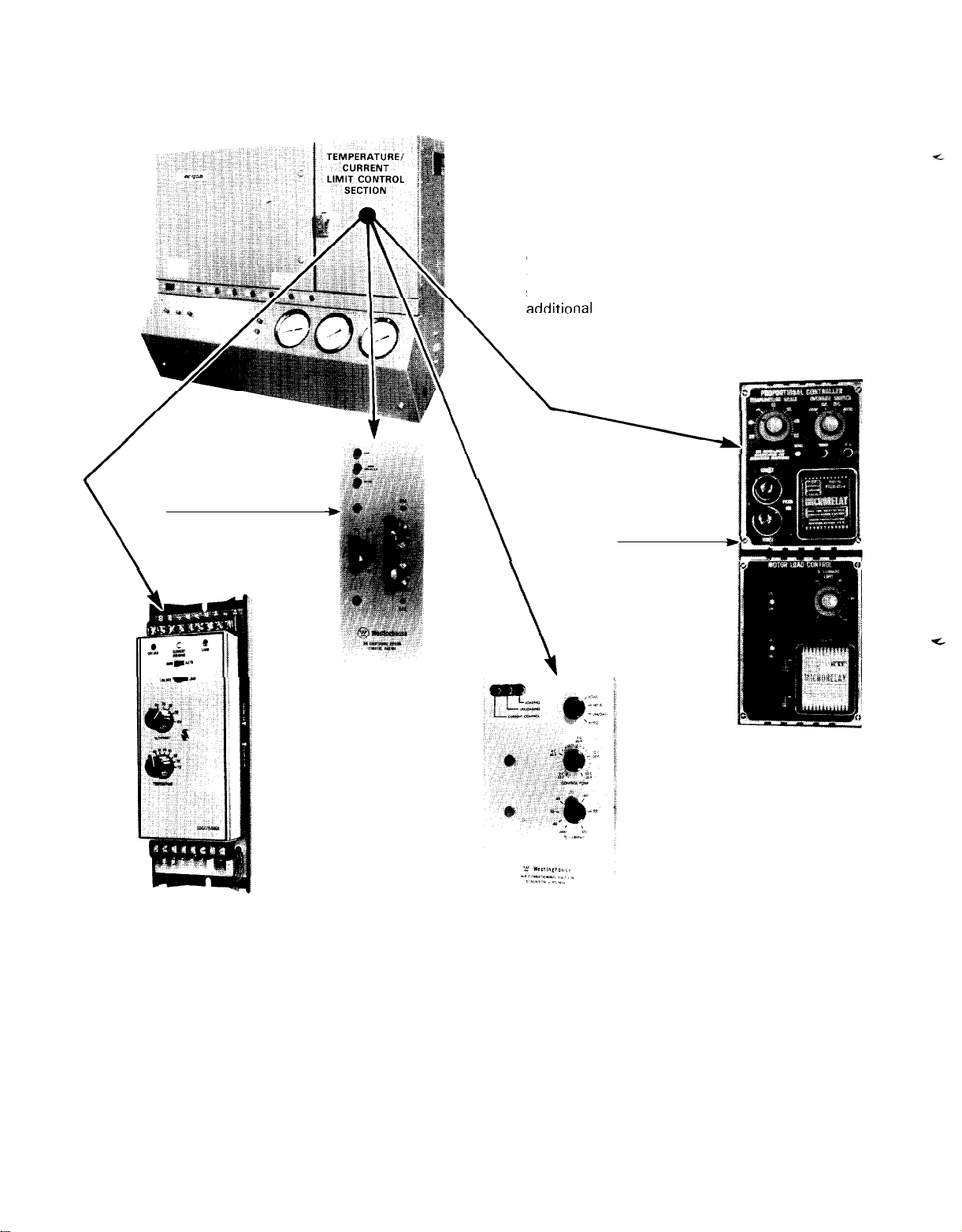

Control Panels Used on Models

Through December

SOLID STATE

TEMPERATURE/CURRENT

LIMIT CONTROLLER

SEE PAGE 8

_,

PE063,079,100

31,1982

During the production life of this control

panel improvements were made. Among

these improvements were a number of

different temperature/current limit control

modules. The different modules used are

shown below with page references for

\

AND 126

ial

information.

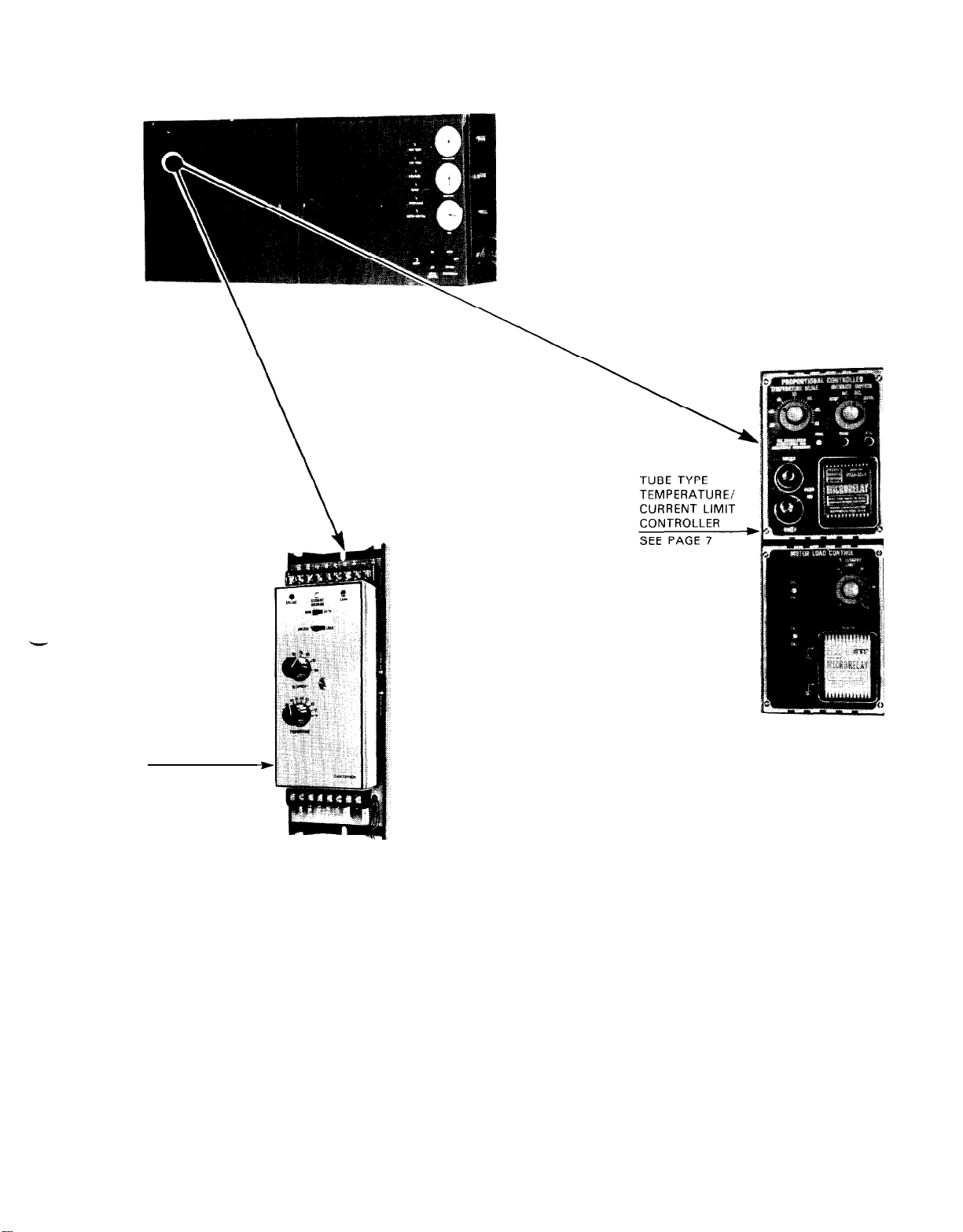

TUBE TYPE

TEMPERATURE/

CURRENT LIMIT

CONTROLLER

SEE PAGE 7

NOTE

*%mii

I

SOLID STATE

TEMPERATURE/CURRENT

LIMIT CONTROLLER

SEE PAGE 11

1.

Panel power supply - l-60-1 15V

2. Disconnect switch in power supply to the control

panel must be on at all times. The oil heaters

receive power through this panel.

3. If panel power is supplied through a transformer,

it must have a minimum rating of 2 KVA with an

inrush of 12 KVA.

4. All panels incorporate a timer to limit starts to a

maximum of three (3) in a two hour period. (40

minutes between starts). Later panels 20 minutes

between stop and start.

5. Earlier versions of this panel included a high

discharge temperature cutout (“HDT”).

SOLID STATE

TEMPERATURE/CURRENT

LIMIT CONTROLLER

SEE PAGE 9

6. Later versions included a low oil temperature cutout

(“LOT”).

7. Later versions included a system monitor relay and

indicating light. The system monitor was utilized to

indicate a problem in the system external to the unit

control box. For example, the compressor starter

open because its overload relays have tripped.

8. Protection against damage caused by compressor

surging was added and a lockout relay and indicating light was incorporated on later versions of the

panel. This was labeled “Surg Gard”.

4

Page 5

This Control Panel was used on all models PE075W through 135W units produced.

SOLID STATE

TEMPERATURE/

CURRENT LIMIT

CONTROLLER

SEE PAGE 11

THIS CONTROL

MODULE IS USED

AS A RETROFIT

DEVICE TO

REPLACE THE

ORIGINAL TUBE TYPE WHICH IS

NO LONGER AVAILABLE.

1. Panel power supply - 1-60-l

15V

2. The disconnect switch in the power supply to the

control panel must be on at all times. The oil

heaters receive power through this panel.

3. If panel power is supplied through a transformer,

it must have a minimum rating of 2 KVA with an

inrush of 12 KVA.

4. The control panel includes a time delay relay

limit compressor motor starts to a maximum of

three (3) in a two hour period. (40 minutes between

starts.

)

to

5. Panel includes a compressor start time delay relay

(CTD) which is set for 5 seconds. This permits oil

pressure to build up and bearings to be lubricated

prior to having the compressor start.

6. The compressor is protected during

spindown

after a power Failure by solenoid valve “SD”.

This is a normally open valve when its coil is

de-energized with this valve open condenser gas

pressure forces oil from the oil supply line and

compressor oil passages to assure bearing lubrication.

5

Page 6

Control Panel used on all Model PF and all model

Single and Dual Units Produced through December

PEO46W

through

31,1982.

PE06OW

THIS CONTROL MODULE

HAS BEEN USED WITH

THIS CONTROL PANEL

AS A RETROFIT DEVICE.

SEE PAGE 11

1.

Panel power supply - 1-60-l 15V

CONTROL MODULE IS MOUNTED

AT REAR OF CONTROL PANEL

BUT IT CAN BE ADJUSTED

FROM THE FRONT.

SEE PAGE 10

2. The disconnect switch in the power supply to the

control panel must be on at all times. The oil

heaters receive power through this panel.

3. If panel power is supplied through a transformer, it

must have a minimum rating of 2 KVA with an

inrush of 12 KVA.

4. All panels include a timer to limit starts to a

maximum of three

(3)

in a two hour period

(40

minutes between starts).

THIS CONTROL MODULE IS

MOUNTED AT THE REAR

OF THE CONTROL PANEL

ACCESS FOR ADJUSTMENTS

REQUIRES THAT THE REAR

PANEL BE REMOVED.

SEE PAGE 9

5. The cooling tower pump motor must cycle with

the compressor (lead compressor on dual com-

pressor units.) The control panel control circuit has

capacity to accomodate a pump motor starter

holding coil or relay with a maximum rating of

10 volt amperes.

6. All interlock contacts must have a minimum rating

of 5 amperes.

7. The alarm circuit will accomodate a load not

ceeding 10 volt amperes.

6

ex-

Page 7

TUBE TYPE (0.45 TO 0.5 VOLTS)

CURRENT LIMIT CALIBRATION

1.

Turn the current limit adjustment clockwise past the 100

percent setting until it hits

the stop.

2.

With the unit running check

the leads on the line side of

the starter to locate the phase

carrying the greatest current.

Attach the ammeter to this

phase. (Remember if the

compressor starter is a star/

delta type, the load side leads

will carry phase current. In

addition, depending on the

method used to wire the line

side it may also be possible

to read phase current on both

sides of the contactor. Phase

current.) Before attempting to calibrate this controller, be sure you know which current you are

reading.

When the compressor motor is drawing rated load

3.

amperes,

the current

resistor combination located in the compressor

motor starter should provide a voltage between

0.45 and 0.5 volts to the control module. If you

are reading phase amperes, line amperes can be

calculated. Line amperes = Phase amperes x

1.732.

4.

The selector switch located to the right of the

temperature adjustment can be used to increase or

decrease compressor load. Using the switch gradually increase the motor load to 105% of rated

load amperes.

the 100% point turn, the “CR1 and

screws all the way clockwise. With these adjust-

ment screws all the way clockwise the current

limit controller is prevented from functioning.

It may not always be possible to load the

compressor to rated load amperes because

of system loading conditions. When this

condition exists, see Section 9 below.

5.

With the compressor drawing 105% of rated load

amperes, slowly turn the

counter clockwise

the cover of the micro-relay is removed the action

of the “CR1 and

6.

Readjust the load on the compressor to reduce the

current drawn to 100% of rated load amperes. At

this point slowly turn the

counterclockwise

7.

Allow the unit to continue operating for a period of

time and recheck the settings of “CR1 and CR2”.

When checking the

necessary to temporarily place a jumper across

terminals “D and E”. (If this jumper is not used,

the compressor will not load beyond 100%

After relay “CR1 and CR2” adjustments are verified

8.

current equals 58% of line

transformer/adjustable

(If

the module will not load beyond

CR2”

adjusting

NOTE

“CRI”

adjusting screw

until the relay energizes. (If

CR2”

relays can be observed.)

“CR2”

adjusting screw

until the relay energizes.

“CR2”

adjustment it will be

1.

remove the jumper between terminals “D and E”

and turn the current limit adjustment knob clockwise against the stop. Loosen the set screw in the

knob and adjust the knob to indicate 100% and

retighten the set screw.

At times the system load may not be adequate to

9.

allow compressor loading to rated load amperes.

When this condition is encountered, reduce the

current limit controller to an obtainable current

value. Using this reduced current, the calibration

currents can be calculated as shown below.

Example -- Assume a unit with a nameplate rated

load ampere value of 400 and an operating load

condition that will not allow loading the compressor

beyond 320 line amperes.

Calculate the percent of full load setting amperes

at the operating condition.

Load

Settrng %

,Load

Amps.

Avail.-(.OSxRated

Rated Load Amperes

z

320 - (.05x400) xl 00

zz

320 - 20 =

400

759’0

400

Load

Amps)xlOO

Calculate the calibration amperes

“CR2”

calibration amperes =

“CR 1” calibration amperes=CR2+(.05xRated

0.75xRated

=

0.75x400 = 300 amps.

=

300+(.05x400) = 320 amps

Load Amperes

Load Amperes)

If phase amperage is being read, it will be

necessary to adjust the calibration amperes. Proceed as shown below.

1.

Rated Load Phase Amperes

=

0.58 x Nameplate Rated Load Amperes

= 0.58 x 400 = 232

2.

Phase Amperes at Load Condition should equal

%

of rated load amperes =

3.

4.

“CR2”

phase current calibration amperes = Rated

320 x 0.58 = 185.6

Phase

Rated Load Phase Amperes

= 185.6 x 100 = 80%

232

Amperes x 100

load phase amperes x % of rated load amperes =

232 x

.80

= 185.6

5.

“CRl”

phase calibration amperes = rated load

phase amperes xl

.05 =

185.6 x 1.05 = 194.9.

TEMPERATURE CALIBRATION

1.

Set the temperature control knob to indicate the

required design leaving water temperature.

2.

With the unit operating adjust the unit capacity

until the required design leaving water is indicated on the thermometer located in the chilled

water leaving the chiller. Allow the unit to run

until the temperature has stabilized at the proper

temperature. Check the temperature adjustment

knob, if it is not reading the same as the leaving

Page 8

water, loosen the set screw and set the knob to

read the correct temperature.

3.

This temperature control module requires the use

of a leaving water temperature sensor part number

350A160HOl

950 ohms at a temperature of 45°F. See Figure

10B. Page 12 for additional temperature vs. re-

sistance relationships for the sensor.

4.

If the panel surrounding the control module does

not have two plug buttons or holes located at about

the center line of the temperature controller, it

will be necessary to remove the grey panel sur-

rounding the control module. The plug buttons or

holes will allow access to terminals “X and T” as

will removal of the panel.

5.

Connect a voltmeter to terminals “X and T”.

(These terminals are located to the left of the temperature controller.)

With the leaving chilled water at the required tem-

6.

perature, turn the calibration adjustment (located

below the selector switch) until the lowest possible

voltage reading is obtained on the voltmeter. (This

is called the null voltage). Once this voltage

.The sensor has a resistance rating of

SOLID STATE CONTROL MODULE

sett-

ing has been determined any change in capacity

(increase or decrease) will cause the voltage to in-

crease above the null value.

Recheck the calibration by rotating the temperature

7.

set point adjustment knob slowly back and forth.

The lowest voltage reading should be obtained

when the dial reading agrees with the thermometer

at the leaving water sensor.

8.

With the voltmeter still connected to terminals

“X and T” the sensitivity can be adjusted.

Set the temperature control to the design

a.

conditions.

Turn the manual selector switch to the stop

b.

position.

Adjust the control point knob to obtain the

C.

lowest voltage reading possible.

Adjust the sensitivity screw to obtain the lowest

d.

possible voltage reading.

Remove the voltmeter and return the selector

e.

switch to the auto position and adjust the

temperature control to the design point.

CURRENT LIMIT CALIBRATION

Turn the current limit adjust-

ment

until it hits the stop just past

100% current limit.

With the unit running, check

the leads on the line side of

the starter to locate the phase

carrying the greatest current.

Attach the ammeter to this

phase. (Remember if the

compressor starter is a star/

delta type, the load side leads

will carry phase current.) In

addition, depending on the

method used to wire the line

side, it may also be possible

to read phase current on both

sides of the contactor. Phase

current

rent.) Before attempting to calibrate this controller, be sure you know which current you

are reading.

With the compressor motor drawing rated load

amperes, the current transformer/adjustable resister combination located in the starter should be

delivering a 5 volt signal to the control module. If

you are reading phase amperes, line amperes can

be calculated. Line Amperes = Phase Amperes,

x 1.7322.

Proper calibration of the current limit section of

the control module requires that the calibration

take place in steps. Begin to load the compressor

until the ammeter reads 40 percent of rated load

amperes, adjust the current limit calibration screw

until both the load and unload lights are out and the

amber light is on. Progressively load the machine

to 60, 80, and 105 percent and follow the same

calibration procedure at each load level. Continue

to watch the ammeter reading with the compressor

knob

clockwise

=

58% of line cur-

motor drawing 105 percent of rated current and

allow the compressor to continue running. Make

any fine adjustments required during this operating

period.

Leave the current limit control against the stop.

5.

Loosen the screw securing the knob to the shaft

and reinstall the knob so the 100 percent current

limit indication is against the stop and retighten the

locking screw. The current limit control is now

calibrated.

TEMPERATURE CALIBRATION

1.

Turn the unit control point to indicate the required

design leaving water temperature.

This temperature control module requires the use of

2.

a leaving water temperature sensor part number

350A160H04.

55F. The sensor has a resistance rating of 40,700

ohms at a temperature of 45°F. See Figure

Page 12 for additional temperature vs. resistance

relationships for the sensor. If temperature is in the

range of 20°F to

This sensor has a resistance of 1380 ohms at 45°F.

See Page 13, Fig. 1 1 B for additional relationships.

With the unit operating, adjust the unit capacity

3.

until the required design leaving water temperature

is indicated on the thermometer located in the

chilled water leaving the chiller. Allow the unit

to run until the temperature has stabilized at the

proper temperature.

4.

Once the design leaving water temperature is

obtained, adjust the temperature calibration screw

until both the load and unload lights remain out.

Allow the machine to continue to run at the

5.

stabilized leaving water temperatures, if an addi-

tional adjustment in calibration is required. Make

it as described in Step 4.

Remove the control point knob and reinstall it to

6.

indicate the correct leaving water temperature.

for temperatures between 35 and

4o”F,

use sensor number

35OA160H08.

10A,

8

Page 9

SOLID STATE CONTROL MODULE

CURRENT LIMIT

side, it may also be possible to read phase cur-

rent on both sides of the contactor. Phase

current = 58% of line current.) Before attempting to calibrate this controller, be sure you know

which current you are reading.

With the compressor motor drawing rated load

amperes, the current transformer/adjustable resister combination located in the starter should be

delivering a 5 volt signal to the control module.

If you are reading phase amperes, line amperes

can be calculated. Line Amperes = Phase Amperes

x 1.7322.

Proper calibration of the current limit section of the

control module requires that the calibration take

place in steps. Begin to load the compressor until

the ammeter reads 40 percent of rated load

amperes, adjust the current limit calibration screw

until both the load and unload lights are out and

the amber light is on. Progressively load the

machine to 60, 80, and 105 percent and follow

the same calibration procedures at each load level.

Continue to watch the ammeter reading with the

CALIBRATION

Turn the current limit

adjustment knob clockwise until it hits the stop

just past 100% current

limit.

With the unit running,

check the leads on the

line side of the starter

to locate the phase carrying the greatest current. Attach the ammeter to this phase.

member if the compressor starter is a star/

delta type, the load side

leads will carry phase

current.) In addition, depending on the method

used to wire the line

(Re-

compressor motor drawing 105 percent of rated

current and allow the compressor to continue running. Make any fine adjustments required during

this operating period.

5.

Leave the current limit control against the stop.

Loosen the screw securing the knob to the shaft

and reinstall the knob so the 100 percent current

limit indication is against the stop and retighten

the locking screw. The current limit control is now

calibrated.

TEMPERATURE CALIBRATION

1.

Turn the unit control point to indicate the required

design leaving water temperature.

2.

This temperature control module requires the use

of a leaving water temperature sensor part number

350A160H07

The sensor has a resistance rating of 2215 ohms at

a temperature of 45°F. See Figure 1 1 A, Page 13 for

additional temperature vs. resistance relationships

for the sensor. If the sensor operating temperature

is between 20 and 40°F a sensor part number

350A160H08

resistance of 1380 ohms at 45°F. See Figure 1 1 B,

Page 13 for additional information.

3.

With the unit operating, adjust the unit capacity

until the required design leaving water temperature

is indicated on the thermometer located in the

chilled water leaving the chiller. Allow the unit

to run until the temperature has stabilized at the

proper temperature.

4.

Once the design leaving water temperature is obtained, adjust the temperature calibration screw

until both the load and unload lights remain out.

5.

Allow the machine to continue to run at the

stabilized leaving water temperatures, if an addi-

tional adjustment in calibration is required. Make

it as described in Step 4.

6.

Remove the control point knob and reinstall it to

indicate the correct leaving water temperature.

for temperatures between 35 and 55F.

will be required. This sensor has a

OLD

PF SOLID STATE CONTROL MODULE

GENERAL

1.

All adjustments to the

control module will require removal of the

rear panel from the con-

trol box.

2.

Calibration of both current limiting and temperature are made at

the rear of the control

box.

3

With the

motor drawing rated

load amperes the current transformer/adjust-

able resistor located in

the motor starter should

be delivering a 5 volt

signal to the control module. If you are read-

compressor

phase amperes line amperes = Phase amperes x

1.732.

4.

Adequate adjustment of the current limit and

temperature sections of the control module will

require that load and unload indicating lights be

added to the unit. These lights should be tied in

parallel with the load and unload solenoid valves.

A green light (load) should be tied in parallel with

solenoid “SB” and a red light (unload) in parallel

with a solenoid “SA”. Older model units will have

two separate solenoids. Later units will have a com-

4-way

bination

newer units the valves will be located in a box

on the rear of the compressor.

valve with two solenoid coils. On

CURRENT LIMIT CALIBRATION

1. The current limit section of the control module

should be set to limit the current drawn by the

9

Page 10

compressor to 105 percent of rated load amperes.

This adjustment should be made in steps to ensure

proper setting at the recommended 105 percent

level.

The model PF unit is generally supplied with Star/

2.

Delta starters mounted and wired. With the compressor running, check the leads on the line side of

the starter. Up through 164 amperes you may find

three power leads supplying the line of contactor

#l

Number 1 with jumpers from Contactor

tactor #2.

three leads from the disconnect to Contactor 1

should read line amperes. Above 164 amperes, the

starter will have 6 leads from the disconnect to

the starter, 3 leads will be connected to Contactor #I

connected to these leads will read phase amperes.

To check whether you are reading line or phase

amperes on a star/delta starter, check the amperage on any of the six leads on the motor side of the

starter, the ammeter will read 58 percent of line

current. If the line and load side of a star/delta

starter have the same ampere reading, you are

reading phase amperes.

Adequate calibration of both the current limit and

3

temperature section of the control module will

require that indicating lights be added to each con-

trol panel. When adding these lights they should be

tied in parallel with the load (SB) solenoid and un-

load

indicate that the machine is loading, a red light

to indicate it is unloading.

4.

Attach an ammeter to the phase on the line side of

the starter carrying the greatest current.

After the indicating lights have been added, reduce

5.

the setting on the current limit controller close to

its minimum point and gradually load the com-

pressor until both indicating lights are out. Read

the ammeter at this point and establish the percent

of rated load current being drawn. (For this

An ammeter connected to any of the

and 3 to Contactor

(SA)

solenoid. A green light is suggested to

#2.

An ammeter

to Con-

illustration assume it is about 70 percent.) Increase

the setting on the load limit control and gradually

load the machine by increasing the compressor load

and the setting of the current limit controller

until the ammeter reads approximately 90 percent

of rated load current and both of the indicating

lights are out. Repeat this procedure once more

until the compressor is drawing 105 percent of

rated load amperes.

Allow the compressor to continue running and

make any adjustment in the load limit that may be

required to keep the indicating lights out when the

compressor is drawing 105 percent of rated load

amperes.

Reduce the load on the compressor and attempt

to reload beyond ammeter reading equivalent

to 105 percent of rated load amperes. When the

current limit control is correctly adjusted, the

load indicating light will go out with the ammeter

indicating a current draw equivalent to 105 percent

of rated load amperes.

TEMPERATURE CALIBRATION

1.

This temperature control module requires the use

of a leaving watertemperature sensor, Part Number

350A160H04.

of 40,700 ohms at a temperature of 45°F. See

Figure

versus temperature relationships for the sensor.

2.

Calibration of the temperature sensor is also made

through the rear of the control box. Check the

thermometer located in the leaving chilled water

and adjust the temperature until the required design

water temperature is obtained. At this point both

the load and unload lights should be out; if they

are not, move the temperature adjustment screw

until both lights remain out.

3.

Allow the unit to continue to operate and make any

fine adjustments required during this period.

The sensor has a resistance rating

IOA,

Page 12 for additional resistance

PF

SOLID STATE CONTROL MODULE (DISCONTINUED JANUARY, 1982)

GENERAL

With the compressor motor

drawing rated load amperes

the current transformer/adjustable resistor located in the

motor starter should be delivering a 5 volt signal to the con-

trol module. If you are reading

phase amperes, line amperes

= phaseamperes x 1.732.

Adequate adjustment of the

current limit and temperature

sections of the control module

will require that load and unload indicating lights be added

to the control panel. These

lights should be tied in parallel

with the load and unload sole-

noid valves. A green light

(load) should be tied in parallel

with solenoid “SB” and a red

light in parallel with solenoid

“SA”. Older units will have two separate sole-

noid valves, later units will have a single four (4)

way valve with two operating solenoid coils. On

10

newer units the valves will be located in a box

attached to the rear of the compressor.

CURRENT LIMIT CALIBRATION

1.

The current limit section of the control module

should be set to limit the current drawn by the

compressor to 105 percent of rated load amperes.

This adjustment should be made in steps to

ensure proper setting at the recommended 105

percent level. The model PF unit is generally

supplied with star/delta starters mounted and

wired, be aware of what current value you are

reading on your ammeter.

2. With the compressor running, check the leads on

the line side of the starter. Up through 164

amperes you may find three leads supplying the

line side of Contactor

tactor #I

to the three leads from the disconnect to Con-

tactor #I

amperes, the starter will have 6 leads from the

disconnect to the starter, 3 leads

to Contactor

connected to these leads will read phase amperes.

To check whether you are reading line or phase

to Contactor

should read line amperes. Above 164

#I

and 3 to Contactor

#I

with jumpers from Con-

#2.

An ammeter connected

will

be connected

#2.

An ammeter

Page 11

amperes on a star/delta starter, check the amperage on any of the six leads on the motor side of

the starter, the ammeter will read 58 percent of

line current. If the line and load side of a star/

delta starter have the same ampere reading, you

are reading phase amperes.

3.

As previously stated, adequate calibration of both

the current limit and temperature section of the

control module will require that indicating lights

be added to each control panel. When adding these

lights they should be tied in parallel with the load

(SB) solenoid and unload (SA) solenoid. A green

light is suggested to indicate the machine is

loading, a red light to indicate it is unloading.

Attach an ammeter to the phase on the line side of

4.

the starter carrying the greatest current.

After the indicating lights have been added, reduce

5.

the setting on the current limit controller close

to its minimum point and gradually load the com-

pressor until both indicating lights are out. Read the

ammeter at this point and establish the percent of

rated load current being drawn. (For this illustration

assume it is about 70 percent.) Increase the

setting on the load limit control and gradually load

the machine by increasing the compressor load

and the setting of the current limit controller

until the ammeter reads approximately 90 percent

of rated load current and both of the indicating

lights are out.

Repeat this procedure once more until the

pressor

amperes.

6.

Allow the compressor to continue running and

make any adjustment in the load limit that may be

is drawing 105 percent of rated load

com-

required to keep the indicating lights out while the

compressor is drawing 105 percent of rated load

amperes.

7.

Reduce the load on the compressor and attempt

to reload beyond an ammeter reading equivalent

to 105 percent of rated load amperes. When the

current limit control is correctly adjusted, the

indicating lights will go out when the compressor

is drawing a current equivalent to 105 percent of

rated load amperes.

TEMPERATURE CALIBRATION

Adjust the temperature control knob to indicate

the required design leaving water temperature.

This temperature control module requires the use of

a leaving water temperature sensor part number

350A160H04.

40,700 ohms at a temperature of 45°F. See Figure

IOA,

Page 12 for additional resistance versus

temperature relationships for the sensor.

With the unit operating, continue to adjust the

control until the design leaving water temperature is

indicated on the thermometer located in the water

line leaving the chiller. Allow the unit to run

until the leaving water has stabilized at the required

temperature.

Once the design water temperature is obtained,

adjust the temperature calibration screw until both

the load and unload lights are out.

Allow the machine to continue to run at the stabilized temperature, if additional fine tuning of the

calibration is required it can be done at this time.

Remove the temperature control knob and reinstall

it to indicate the correct leaving water temperature.

The sensor has a resistance rating of

SOLID STATE CONTROL MODULE (USED FOR

CURRENT CALIBRATION

1.

Start the unit and place the

control module selector switch

in the manual position.

2.

Open the starter door and place

the

amprobe

drawing the highest current on

the load side of the starter.

3.

Remove the control module

cover.

Set current demand limit selec-

4.

tor switch clockwise

the stop (100%).

Set the blue current limit cali-

5.

bration screw (located just to

the left of the temperature control stem) to the full counterclockwise position.

6. Check the compressor motor nameplate rated

load amperes

on the amprobe. Manually adjust the load until

the amperes drawn by the motor match the motor

rated load amperes. If a star/delta starter is

being used be sure you are reading line amperage.

7. When the nameplate and

are equal, turn the current limit calibration screw

clockwise until the amber light just comes on and

stop. This places the unit in current hold. The

internal circuitry of the module will now insure

that, should the current increase to 105 percent of

rated load amperes, the controller will unload the

compressor.

To verify that the calibration is correct, manually

(RlA)

against the amperage reading

on the power lead

amprobe

ampere values

against

11

REl-ROFlT

unload and then reload the compressor to the rated

load ampere value and verify that the current override light glows. The current limit control portion of

the module is now in calibration.

8.

Check the knob setting, if it needs correcting snap

the top off the control knob, loosen the screw and

rotate the knob to indicate 100% of current.

Tighten screw and replace top.

TEMPERATURE CONTROL CALIBRATION

1.

Remove control module cover.

2.

Allow unit to operate until leaving water temperature stabilizes. With the thermometer located

in leaving chilled water, read the water temperature.

3.

On the control module turn the temperature control

knob to a point where both the unload (red) and

load (green) lights remain off. Move the knob to the

midpoint between these points.

4.

Check voltage between control module terminals

“IOM” and “COM” using a DC voltmeter. The

voltage reading should be close to

5.

Read the leaving water temperature once more.

Check this temperature against the temperature

indicated by the pointer at the base of the temperature control stem. If they do not agree, hold

the stem and rotate the pointer until it indicates

a temperature on the scale corresponding to the

thermometer reading.

6.

Replace the control module cover. Check the

temperature indicated by the knob against the

cover temperature scale. If the reading is not

correct, snap the top off the knob, loosen the

screw and rotate the knob until it indicates the

correct temperature. Tighten the screw and replace

the top of the knob.

ON MANY OLDER

7.5V

UNlTS)

(

f

0.5V).

Page 12

Page 13

Page 14

Page 15

Page 16

Loading...

Loading...