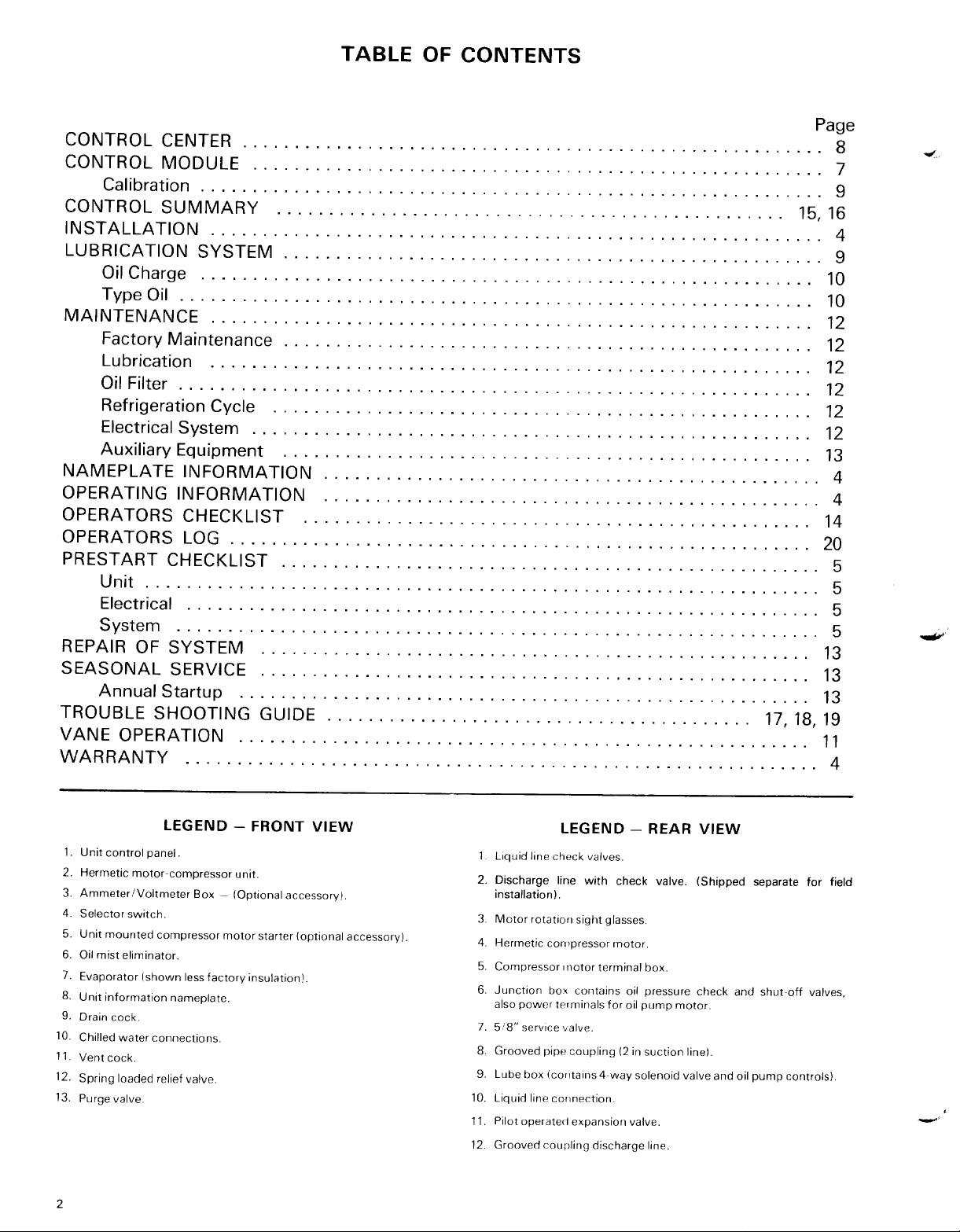

Page 1

Page 2

Page 3

Page 4

GENERAL

UNIT NAMEPLATE

The Model PE less condenser centrifugal water chiller

has been factory assembled, checked and shipped with

a holding charge of R-12 refrigerant. The purchase

price of this equipment includes checkout of the unit

and initial startup by a McQuay service technician. An

integral part of the startup procedure includes instruction of responsible personnel in the operation and

maintenance of this water chilling unit.

It is most important that this equipment be properly

operated and maintained if it is to perform the

operating service it was designed and built to provide.

McQuay offers equipment maintenance and/or inspection programs that can be tailored to fit individual job

requirements. Information on the various service programs is available through the McQuay Service Department or your local McQuay sales representative.

WARRANTY

The McQuay Model PE water chiller unit is covered by

a standard published warranty which covers parts only.

A complete published description of that warranty and

its limitations is provided in a warranty certificate

included with each unit.

First year warranty labor can be purchased separately,

check your local McQuay sales representative to

establish what additional coverage (if any) was purchased for your unit.

Whenever requesting information or assistance on the

Model PE chiller, the unit model number, shop order

number, and serial number should be copied from the

unit nameplate. A reproduction of this nameplate is

shown in Figure 3.

HOLDING

CHARGE

ONLY

STYLE

SERIAL

S.O. NO. PE-5210

\

-~

lPE5210-GO1

5NAl234~0

FACTORY CHARGED

~

LBS. REFRIGERANT

LEAK TEST PRESSURE 100

MOTOR - COMPRESSOR CONTROLLER

AND OVERLOAD PROTECTION FIELD

SUPPLIED. SEE SPEC.

R12

PSIG

PE-D4

mccbuw k.

198PlMHOl A

MADE IN U S A

Note Typical Serial Number

l Prior to January 1, 1983 =

1,

l

After

January

1983

LZ1320

=5NA1234500

INSTALLATION

Information pertaining to the installation of Model PE

water chilling units is available in Installation Bulletin

number PE-L-Gl. A copy of this manual was included

in the envelope shipped with the unit.

MODEL CODE

PE

063J

AN 30 R G A 2 L

UNlT FA::::E-I 1

SPEED CODE

MOTOR CODE

COMPRESSOR MOTOR VOLTAGE

~k;;~~;~;::~R

TYPE OF CHILLER

TUBING

CHILLER CODE

FIGURE 3. UNIT NAMEPLATE

OPERATING INFORMATION

OPERATOR’S RESPONSIBILITY

1.

Before operating the Model PE unit, become familiar with the machine and accessory equipment.

2.

If possible, arrange to attend a McQuay centrifugal

operators school.

After the unit has been checked out and approved

3.

for operation by a McQuay centrifugal service

technician, work with him to learn how to prepare

the system for startup. Start and stop the machine

a number of times while observing the operation of

the interlock function(s). The interlock circuit must

be satisfied before the compressor will run. After

operating the unit, place it in the shutdown mode.

Monitor operation and periodically inspect the

4.

equipment, making routine adjustments where

essa ry

nec-

Maintain a log of operating conditions on a daily

5.

basis. (Log sheets are available in pad form from

McQuay.

Page 5

PRE-START SYSTEM CHECKLIST

p&q

All of the following will have been checked

out by the

during the initial startup procedure. *Items

should always be verified by the unit operator on a routine basis during the operating

season.

A. UNIT

"1.

All service valves are in the operating position.

The control circuit is energized.

“2.

The oil heaters have been operating for a

“3.

minimum of 24 hours. Oil should be hot

(approximately 130 to 140

“4.

The oil charge is visible in the sight glass.

(Mark level on sight glass while machine is

shut down, check level weekly).

Check control circuit, verify that all safety

“5.

switches interrupt compressor starter holding

coil.

“6.

The water flow through the condenser is

correct. (This can be checked from condenser

water pressure drop curves available from

McQuay).

reduced by a plugged strainer which can

cause operating problems and nuisance

outs. New systems are generally susceptible

to blocked water strainers from foreign mate-

rial washing out of the piping.

B. ELECTRICAL

McQuay

On any system, water flow can be

startup technician

F).

trip-

All load equipment is operative (main system

“3.

fans, pumps, etc.).

Condenser fan(s) and controls are operative.

“4.

Condenser water bleed and water treatment

“5.

are adequate (if required).

STARTING

When the 115 volt AC control power supply is applied

to the control panel for the first time or after a power

failure has occurred, the following will take place.

1.

The oil sump heater(s) will be energized.

The external failure light will glow and the external

2.

“R9”)

alarm circuit (energized through Relay

activated.

Push the RESET Button on the control panel. The

3.

external failure light will go out and the external

alarm circuit will be reset (de-energized).

Set the compressor “ON-OFF” switch to “ON”, the

4.

light in this switch will glow. The unit control circuit

has been re-established.

The unit safety circuits have now been reactivated

5.

and the operating portion of the control circuit is

ready to function. (Before the operating portion of

the control circuit can function, the chilled water

pump will have to be running).

The “LRT” (unit cycling thermostat) will, on a call

6.

for chiller operation;

Start the oil pump. (Providing 20 minutes have

elapsed since the unit last stopped and the anti

recycle time delay has timed out and closed its

contacts).

will be

1.

The wire size is correct.

2.

The phase sequence is correct.

“3.

Voltage within plus or minus 10 percent of

rated compressor nameplate voltage.

“4.

Phase voltage unbalance 3 percent or less.

5.

All wiring connections correct per the unit

wiring diagram.

6.

All electrical connections are tight and made

with copper conductors and lugs.

“7.

All starter parts move freely and contacts meet

evenly.

8.

Motor overloads correct size (filled with dash-

C.

SYSTEM

“1. The condenser pump is rotating in the right

direction.

“2. The condenser pump and motor are lubricat-

ed.

When the oil pump develops oil pressure adequate to close the oil differential pressure switch

“OD”

(50

psig above suction pressure), the

switch will close.

A time delay relay “PLT” injects a 10 to 60

second time delay into the compressor starting

control circuit and prevents this portion of the

circuit from being energized while oil pressure is

being developed. At the end of this delay, if the

vane closed switch

gized the condenser pump relay “CWR” the

pump starter interlock contacts will close and

energize relay “MCR” located in the unit starter.

The compressor starter will now be energized

and the compressor will start.

“VC”

has closed and ener-

OPERATING

1. With the compressor running, capacity is controlled

by positioning variable inlet vane(s) located in the

suction gas inlet to the compressor. Opening the

vane(s) allows the compressor to pump more gas

and, as a result, increases capacity. Closing the

vane(s) reduces gas flow and reduces capacity. The

5

Page 6

capacity control system is capable of modulating

the vane position to any capacity from 10 percent

to 100 percent.

The inlet vane(s) are controlled by means of 3

different devices. The capacity will always be

controlled by temperature unless the temperature

control is overridden by Items “b” or “c” below.

a. A temperature sensor located in the leaving

chilled water translates temperature changes

into an electrical signal and through the control

module loads or unloads the compressor (opens

or closes the vane(s).

b. The solid state control module in conjunction

with a current transformer and resistor located in

the compressor motor starter, senses and will

limit current drawn by the compressor motor

depending on the setting of the current limit

control. This controller will override the temperature control and will, whenever motor current

exceeds its setting, open or close the compressor vane(s) in response to changes in current.

Whenever the motor current is less than the

setting on the current limit controller, unit

capacity control is returned to the temperature

sensor. The current limit control can be set to

limit current from 30 to 100 percent of nameplate full load current. The control is easily

adjusted by a knob on the face of the control

module.

c. The low pressure override switch “LPO” built

into the unit control panel senses suction pressure and is set to open at 2 to 5 psig above the

low pressure safety switch. Whenever the setting is reached, the override switch opens and in

turn de-energizes relay

gizes

“SA” and de-energizes “SB” solenoids in

the four way valve. Full oil pressure is applied to

the unloader piston driving the vanes closed.

This action will in most cases catch a momentary “sudden” drop in suction pressure such as

may be caused by a slow acting expansion

valve, a drop that without this unloading feature

would open the low pressure switch and stop

the compressor. The “LPO” pressure switch is

automatically reset, it will close when the pressure rises to a safe limit and return control of

capacity to the temperature sensor.

During normal operation, the compressor will continue to operate and unload to a minimum of 10

percent until the cycling thermostat is satisfied.

When this occurs, the condenser relay

the motor control relay “MCR” are de-energized

and the compressor motor is stopped.

The unit oil pump will continue to run for a

minimum of one minute after the compressor

starter has been de-energized. This will assure

“R4”,

this in turn ener-

“CWR”

and

adequate lubrication for the compressor during the

spin down period.

In addition, on the next call for cooling, the

compressor capacity control vanes must be in a

closed position before the compressor is allowed to

restart. Contacts “VD” (auxiliary contacts located

in the compressor starter) through relay

energize the unload portion of the unit capacity

control circuit. If the vanes were not fully closed

when the compressor was stopped, oil pressure

will continue to be applied to the unloading piston

through the “SA” portion of the four-way solenoid

valve. This pressure continues to drive the vanes to

the closed position while the oil pump is still

running. This will permit the compressor with a

minimum delay to start on the next call for cooling.

(The compressor will not start until the vanes are in

the closed position).

Rapid cycling of centrifugal compressor motors is

not desirable. A time delay through relay “TDR” is

built into the unit control circuit to prevent rapid

cycling. Relay “TDR” will prevent the compressor

from restarting for a period of 20 minutes after the

compressor is stopped unless the “automatic restart after power failure with reduced timed off

cycle” accessory option is used.

In the event of a power interruption during unit

operation,

damage by an emergency oil reservoir and spring

loaded piston. During normal operation enough oil

is stored in the emergency cylinder to lubricate the

bearings during spindown. The oil is forced into the

various passages by a spring loaded piston contained and compressed in the emergency oil cylinder. ‘The spring is compressed by normal machine

oil pressure while the compressor is running and on

a loss of power is available along with the piston to

act as an emergency oil pumping device.

CONTROL CENTER

The control center contains all of the unit protective

controls and most of the operating devices. Table 1

“Control Summary” (on page

control information including electrical diagram sym-

bol, control description, setting, reset information,

location, signal light, and information on the control

function.

Eleven indicating lights are utilized on the unit control

panel. Nine of these lights are normally out and only

glow when a safety circuit has tripped.

Repeated tripping of a given control should be investigated by a competent air conditioning serviceman or

by a

McQuay

damage. Details of the control center are shown in

Figure 5.

the compressor is protected against

15)

contains general

service technician to avoid costly

“R8”

Page 7

Page 8

Two important safety circuits incorporated in the

control system are:

1.

GUARDISTOR

positive motor protection against damage from

motor overheating. Thermistors buried in the motor

winding are super sensitive to changes in motor

winding temperature. These thermistors have been

calibrated to de-energize the “GDR” (guardistor

relay) whenever the motor winding exceeds the

maximum allowable temperature.

The motor protection system, because it is sensing

internal motor winding temperature, provides posi-

tive protection against motor damage from such

heat causing problems as loss of motor cooling, low

voltage, etc. and, is in our opinion, the finest motor

protection system available.

The guardistor control circuit is a manual reset

system which when actuated will require manual

resetting by pushing the reset button on the unit

control panel.

MOTOR PROTECTION - Provides

[-X-l

The control module, through the capacity control

system, is capable of extremely close control of design

set point temperature. Dials provide for manual adjustment of the unit control set point and/or for limiting

the current drawn by the compressor motor at any

level between 30 and 100 percent of rated full load

current.

The pulsing action built into the electronic control

module, coupled with needle valve adjustment of the

hydraulic portion of vane control provides a very stable

temperature control arrangement. During normal operation, it will take approximately 3 to 5 minutes to move

from minimum to maximum capacity and one

minute to move from maximum to minimum capacity.

The water chilling unit can be applied to many different

cooling applications and is adaptable to many different

types of control systems. The particular control ar-

rangement used will be incorporated as a part of the

total job control system. Details on the total system

control should be available in the job file. The vane

control system is explained starting on page 11.

(1)

In the event of a power failure to the unit or

control panel, the guardistor relay will trip

and require manual resetting when power is

restored.

2.

SURGEGARDTM- A surge or rotating stall is not a

normal operating condition for a centrifugal compressor. Under some abnormal unit operating con-

ditions, a compressor surge condition can develop

and, if allowed to continue, can cause compressor

damage. A surge is caused by many things, such as

dirty condenser tubes, reduction in condenser

water flow, increases in condenser water temperature above design, or any other factor which can

act to increase the pressure difference between

suction and discharge pressure (head).

The

McQuay

against damage from surging by a unique protection system which senses a surge condition, should

it occur,and shuts the

Whenever the machine has been stopped as a

result of a surge condition, the

cating

light on the control panel will glow.

SOLID STATE CAPACITY CONTROL

The solid state control module combines temperature

and current limit control in a single solid state package.

In addition, indicating lights on the module indicate

whether the control is calling for the compressor to

load or unload or whether the current override feature

is in control. By setting a switch, it is possible to place

the unit under manual or automatic control of un-

loading.

centrifugal compressor is protected

machine down

SurgeGardTMindi-

before

CONTROL MODULE CALIBRATION

The control module supplied as a standard part of the

unit control center is a solid state electronic device

which operates from a 24V A.C. power source. Except

for its external sensor(s) and a 5 volt (full load) signal

from a current transformer, and resistor located in the

compressor motor starter,

contained. The module can provide many features and

functions, some of which are:

1.

Proportional temperature control (within k 0.5F of

set point).

2.

Current limit control (manually adjustable).

3.

A pulse rate adjustment which permits the module

response speed for loading or unloading to be

varied to meet application requirements encountered on different systems and/or applications.

4.

A “ramp-up” adjustment which can be utilized at

compressor startup to control the time to load and

the point at which the controlled loading begins.

For example, this adjustment can be used to reduce

the power that would be consumed by the unit if it

were allowed to load the machine without a time

restriction.

Indicating lights which glow when the controller is

5.

calling for loading (green), unloading (red) or

current override (amber).

A selector switch to permit manual or automatic

6.

control of unit capacity.

A selector switch to permit manual control of

7.

loading or unloading.

Can be adapted to accept a signal to reset the

8.

control point in response to a change occurring at

it is completely

self-

8

Page 9

another location, such as outside air, return chilled

water or an energy management device.

Can be adapted to unload in response to a signal

9.

from an energy management device used to shed

electrical power loads. The compressor capacity

can be reduced as a function of building entrance

power.

CALIBRATION

The control module is factory calibrated and should

not normally require field calibration. In the event

calibration must be checked, a procedure covering the

steps required for both current and temperature

calibration is outlined in the following paragraphs.

CURRENT CALIBRATION

Equipment needed - an accurate

1.

ammeter.

Start the unit and place the control module

2.

selector switch in the manual position.

Open the starter door and place the

3.

the power lead drawing the highest current on the

load side of the starter.

4.

Remove the control module cover.

Set current demand limit selector switch clock-

5.

wise

(4)

against the stop (100%).

6.

Set the blue current limit calibration screw (located

just to the left of the temperature control stem) to

the full counterclockwise

7.

Check the compressor motor nameplate rated load

amperes (RLA against the amperage reading on

the

amprobe.

amperes drawn by the motor match the motor

rated load amperes.

When the nameplate and

8.

are equal, turn the current limit calibration screw

clockwise until the amber light just comes on and

stop. This places the unit in current hold. The

internal circuitry of the module will now insure

that, should the current increase to 105 percent of

rated load amperes, the controller will unload the

compressor.

To verify that the calibration is correct, manually

unload and then reload the compressor to the

rated load ampere value and verify that the current

override light glows. The current limit control

portion of the module is now in calibration.

Check the knob setting, if it needs correcting snap

9.

the top off the control knob, loosen the screw and

rotate the knob to indicate 100% of current.

Tighten screw and replace top.

Replace module cover, remove

IO.

starter door.

Manually adjust the load until the

(-1

position.

amprobe

amprobe

amprobe

amprobe

ampere values

and close

or

on

TEMPERATURE CONTROL CALIBRATION

Equipment required - accurate thermometer and

1.

DC voltmeter.

Remove control module cover.

2.

Allow unit to operate until leaving water tempera-

3.

ture stabilizes. With the thermometer located in

leaving chilled water, read the water temperature.

On the control module turn the temperature control

4.

knob to a point where both the unload (red) and

load (green) lights remain off. Move the knob to the

midpoint between these points.

Check voltage between control module terminals

5.

“IOM” and “COM” using the DC voltmeter. The

voltage reading should be close to 7.5V

Read the leaving water temperature once more.

6.

Check this temperature against the temperature

indicated by the pointer at the base of the tempera-

ture control stem. If they do not agree, hold the

stem and rotate the pointer until it indicates a

temperature on the scale corresponding to the

thermometer reading.

Replace the control module cover. Check the

7.

temperature indicated by the knob against the

cover temperature scale. If the reading is not

correct, snap the top off the knob, loosen the

screw and rotate the knob until it indicates the

correct temperature. Tighten the screw and replace

the top of the knob.

Remove the voltmeter and thermometer (if neces-

8.

sary). The temperature calibration is complete.

LUBRICATION SYSTEM

A separate motor driven oil pump assembly supplies oil

at controlled temperature and pressure to all bearing

surfaces and in addition is the source of hydraulic

pressure for the capacity control and emergency oil

supply.

The unit control system on a call for cooling will not

permit the compressor to start until oil pressure has

been established for at least one minute. When the

system controller is satisfied and stops the compressor, the oil pump runs for another minute to assure

adequate lubrication during spindown. In addition,

during this period the compressor is unloaded through

the action of the vane closed switch “VC”. The

compressor will then be ready to start unloaded on the

next call for cooling.

The oil pump is completely self-contained and located

in the oil sump. On Model SE046, 048 and 050 units, it

is located inside the compressor housing, for model

SE063 units the oil pump is located in the oil pump

assembly which is mounted at the rear of the unit

adjacent to the condenser.

(

+

0.5V).

9

Page 10

FIGURE 5

In either case, it includes the pump, pump motor, oil

heater and oil separator. The Model SE063 includes

shut off valves for discharge, oil return and suction.

Oil is pumped through an externally adjustable oil relief

valve which is factory adjusted to limit the discharge oil

pressure from 100 to 110 psig above the operating

suction pressure. After leaving the relief valve, oil

flows through a refrigerant cooled oil cooler where the

temperature is reduced to approximately 90 to 100 F.

From the cooler it passes through a replaceable five

(5)

micron oil filter located in the compressor casting. On

Model SE046, 048 and 050 units the oil first passes

through the oil filter and thrust pump before entering

the oil cooler. Filtered oil is then distributed through

internal passages in the compressor casting to the

control system and before entering the bearings on

Model SE063 units it passes into the thrust pump

where the oil pressure to the bearings is boosted.

Oil leaving the compressor and motor bearings is released under pressure into the low pressure gear housing where some of this oil vaporizes. This oil vapor is

used to lubricate the gearing. The remaining oil leaving

the bearings drops to the bottom of the gear housing

where it is drained to the oil sump. On Model SE063

units oil from the gear housing and capacity control is

dumped into the scavenger line and returned to the oil

sump. Oil as it circulates in the oil system (because of

the ability of oil and refrigerant to mix in all proportions) will always have some refrigerant mixed in it.

Most of this refrigerant flashes from the oil as it enters

the oil sump or is driven from the oil by the oil heater.

This refrigerant gas as it is removed from the oil sump

passes through a centrifugal oil separator located on

top of the oil pump rotor.

10

The oil sump is vented to the suction side of the

system just ahead of the compressor wheel eye. Gas

flowing from the oil sump has to pass through the

spinning oil separator where entrapped oil is removed

by centrifugal force and is thrown back to the oil

sump. The refrigerant gas flows on through to the

compressor suction.

The main oil sump on all units is provided with an

electric heater and, in addition, the Model SE063 units

also include a heater in the gear housing.

THESE OIL HEATERS MUST REMAIN

ON AT ALL TIMES THE COMPRESSOR

IS NOT RUNNING. SHOULD AN EX-

TENDED POWER LOSS OCCUR

(DEENERGIZING THE HEATERS) AND ALLOWING THE OIL TO COOL, IT WILL BE

NECESSARY WHEN POWER IS RE-

STORED TO KEEP THESE HEATERS

ENERGIZED FOR A MINIMUM OF 24

HOURS BEFORE ATTEMPTING TO RE-

START THE COMPRESSOR.

If conditions require the compressor to be restarted

immediately, it will be necessary to drain the system oil

and recharge the unit with new oil which is free of

refrigerant.

The low oil temperature thermostat “LOT” (set for 120

F)

supplied as part of the unit safety controls will, if

adjusted properly, prevent the compressor from start-

ing with cold oil. This thermostat is a manual reset

type and when tripped will cause the oil temperature

light to glow.

Quantities of oil required for Model SE units as well as

the recommended oil specifications are:

OIL CHARGE REQUIRED

MODELS PE046,048, and 050 1.75 gallons

MODEL PE063 . . . . . 8 gallons

RECOMMENDED OIL

SUNISO 4G/4GS

or TEXACO CAPELLA 68WF

EMERGENCY OIL SYSTEM

An oil cylinder with a spring loaded piston is incorpo-

rated in the compressor casting to supply emergency

lubrication for bearings in the event of a power loss.

During normal operation, pressure from the oil pump

fills the emergency oil cylinder and compresses the

piston/spring assembly contained in the cylinder. On a

loss of power (and as a result, a loss of oil pressure) oil

is forced into the bearing lubrication passages as the

spring behind the piston expands and forces oil from

the emergency cylinder. The emergency oil system

contains an adequate oil supply under pressure to

assure adequate bearing lubrication during the spin

down period.

Page 11

CAPACITY CONTROL

Capacity variation for the unit is accomplished by

opening or closing vane(s) located in the suction inlet

to the compressor. Vane movement is controlled by

positioning a floating piston to which the inlet vane(s)

are linked. The piston (and as a result the vane(s) are

positioned by building up oil pressure on one side of

the piston and draining or not draining the other side,

depending on how far the piston must move to satisfy

the capacity requirements of the system.

Figures 6, 7 and 8 schematically illustrate the control of

the floating piston.

CONTROL SATISFIED

When the system capacity control is satisfied, an

electrical signal is sent to the control module calling for

no change in capacity. Such a condition is illustrated in

Figure 6. The control module has de-energized both

sections

valve. With both sections de-energized, ports Cl and

C2 are open and outlet port

full pressure to both sides of the piston holding it in a

stationary or satisfied position.

“SA” and “SB” of the four way solenoid

#3

is closed. This directs

riziq

COMPRESSOR

UNLOADER

CYLINDER

r

NOTE ADJUSTABLE

NEEDLE VALVES

INTEGRAL

WITH FOUR WAY

SOLENOID VALVE

ARE NOT SHOWN

IOPENlNG]

- OIL UNDER PRESSURE

-

FLOATING PISTON

LINKED TO INLET VANES

-

OPENS VANES

-

CLOSES VANES

FIGURE 6

-LEGEND-

OIL SUMP PRESSURE

SECTION “SA”

DE ENERGIZED

-

FROM OIL

PUMP

DISCHARGE

VALVE

INCREASE CAPACITY

When the unit capacity is not high enough to satisfy

the load (such a condition is illustrated in Figure

7),

a

signal from the control module will energize section

“SB” and de-energize section “SA”. This will drain oil

DRAIN FROM PISTON

--)

from the right hand side of the piston and allow it to

-

c

#3

OUTLET

0 c2

SECTION “SE”

ENERGIZED

SECTION “SA’

DE~ENERGIZED

move to the right and open the vanes. Oil in the right

hand side of the piston will continue to drain through

the open port C2 and outlet

#3.

The piston will

continue to move to the right until the control module

de-energizes section

that position.

“SB”

thus holding the piston at

FIGURE 7

TO OIL

I-

PUMP

SUMP

FROM OIL

*PUMP

DISCHARGE

DECREASE CAPACITY

When the unit has been running at a higher level of

capacity and the load falls off, the system is required

to reduce compressor capacity. Such a condition is

illustrated in Figure 8. The control module energizes

section

“SA” and de-energizes section

“SB”.

This

permits oil to drain from the left side of the piston

through open port Cl to the outlet

#3.

With section

“SB” de-energized, full oil pressure is applied to the

right end of the compressor piston, moving it to the

left. The piston can be stopped at any point in its

leftward movement when the capacity is satisfied and

the control module signals to de-energize “SA”.

The above descriptions are simplified versions of what

actually happens, neglecting the complicated control

function provided by the control module as it pulses to

control the action of solenoids

“SA” and ”SB”.

[CLOSlNGj

FIGURE 8

DISCHARGE

VALVE

11

Page 12

METERING VALVES

The hydraulic control system utilizes needle type

adjusting valves built into the four way solenoid valve.

These valves are used to adjust the response time for

the floating piston to move through its full length of

travel. The valves are factory set and under normal

operating conditions should not need to be reset.

Attempts to reset the valves by unqualified personnel

will result in very poor operation of the capacity control

system.

MAINTENANCE

It is important that this unit and the air conditioning

system it is part of receive adequate maintenance if full

equipment life and all system benefits are to be

realized.

On a new system,

follow-up inspection of the system after 3 to 4 weeks

of normal operation. Such an inspection is not part of

the unit selling price. It can be provided by McQuay

service at additional cost.

FACTORY MAINTENANCE SERVICE

McQuay offers a variety of maintenance services

through its Nationwide Service Organization. These

contract services include regular inspections and emergency service by factory trained technicians. Services

are available around the clock to keep your equipment

running in top condition.

With a McQuay Assured Maintenance contract, all

parts, labor and materials are furnished

additional cost to the customer.

maintenance

should begin with a

. . .

with no

Model PE046, 046 and 050 units have an internal oil

pump and require that the system refrigerant

charge be pumped into the condenser before

attempting to change the filter. After the unit is

pumped down, break the seal on the oil filter access

cover and permit the pressure to bleed off before

removing the cover. After replacing the filter, crack

open the condenser liquid valve and permit the

pressure to build up and purge the oil filter housing.

Replace the cover and check for leaks.

Model PE063 units have an external oil pump

assembly. Close the oil pump discharge valve.

Loosen the flair fitting feeding oil to the filter and

bleed off the pressure by purging slowly. When the

pressure has been relieved, remove the cover and

replace the filter. When reassembling, vent as

much air as possible from the oil lines before

placing the compressor back into operation.

REFRIGERATION CYCLE

Since the Model PE unit has a semi-hermetic compres-

sor and utilizes R-12 or R-500 refrigerant, normal

system pressures, whether the system is operating or

shut down, will always be above atmospheric.

Unit maintenance generally will consist of proper

inspection and maintenance of an operating log. Visual

inspection of oil level as shown in the sight glass and

noting operating suction, discharge and oil pressures

will generally indicate if the unit operating characteristics are changing.

ELECTRICAL SYSTEM

It is widely recognized that a good maintenance

program is the essential first step in controlling energy

costs. And through McQuay’s Assured Maintenance

and Energy Management Programs, the owner is

assisted in establishing a comprehensive Energy Management plan to meet his needs. For further information concerning the many services available, contact

your local McQuay service representative.

LUBRICATION

Once the unit has been checked out and is placed in

service, no additional oil should be required. the oil

level in the oil sight glass should be marked when the

system is shut down and the level checked periodical-

ly.

OIL FILTER

The oil filter must be changed annually. We do not

recommend that untrained personnel attempt to replace the filter. The filter is contained in a system

under refrigerant as well as oil pressure. If proper care

is not taken when changing the filter personal injury

could occur. In addition air and/or moisture could

enter the system and cause equipment problems.

Generally, maintenance of the electrical system only

involves keeping operating controls clean and electrical

connections tight. In addition, the following items

should be inspected;

1.

The compressor amperage (current) drawn should

be compared to the nameplate rating. Normally, the

current read will be less than nameplate since the

nameplate value represents design full load current.

2.

Check that oil heaters are operative. Heaters are

cartridge type and can be checked by an amperage

reading. They should be energized whenever the

compressor is not operating. When the compressor

runs,

energized.

Once a year all safety controls except compressor

3.

overloads should be made to operate and the

control operating point checked. Any control as it

ages can shift its operating point and this should be

detected.

Pump interlocks and flow switches should interrupt

the control circuit cleanly

switch can be a source of trouble as well as

irritation.

the heater should be automatically

-

a chattering flow

de-

12

Page 13

4. Motor starter contacts should be inspected and

cleaned annually. All terminal connections should

be tightened.

AUXILIARY EQUIPMENT

It

is important that auxiliary equipment used in

conjunction with the Model PE unit be adequately

maintained. Malfunctions in this equipment often

affect the operation of the condensing unit. For

example; improperly maintained air filters in the system

can restrict air flow to the cooling coils and as a result

cause suction pressure to fall to a point where a

nuisance trip out on the low suction pressure cutout

could occur. Items such as the following should be

checked and maintained.

1.

All filters must be cleaned or replaced. The frequency of this service will vary with different

installations.

2.

If evaporative type condenser is used, keep condenser pump water strainer clean. Inspect and

service on a regular basis.

3.

Maintain condenser water treatment to limit buildup

of scale in condenser tubes (if required).

4.

Inspect condenser, clean when required. If unit has

a belt drive, change belts at least annually.

All fans and belts checked and adjusted.

5.

All condensate drains clean.

6.

7.

All motors lubricated.

8.

All electrical connections tight.

9.

All starter contacts are clean and mechanism moves

freely.

SEASONAL SERVICING

At the end of the cooling season and before the unit is

started in the spring, the following service procedures

should be completed.

A.

Annual Shutdown

When the unit may be exposed to freezing tempera-

1.

tures, water piping should be disconnected from

the supply and drained of all water. The chiller is

not self-draining; If all water must be drained from

the unit, remove the water heads and blow dry air

through each tube.

When it is possible to have the unit and/or piping

exposed to freezing temperatures, the only sure

method of protection is forced circulation of an

antifreeze solution through the water circuit.

When an evaporative condenser is used and the

2.

water pump will be exposed to freezing, be sure to

remove the pump drain plug and leave it out so that

any accumulation of water will drain away.

3.

Take measures to prevent the water supply line

shutoff valve from accidentally being turned on.

4.

Open the compressor disconnect switch and remove the fusetrons. If a control circuit transformer

is used for unit control power, the disconnect must

remain on to supply power to the oil sump and gear

housing oil heaters. Set the compressor “on-off”

switch to “off”. To guard against the possibility of

an accidental compressor start, remove relay “R7”

from the control panel. (See Figure 4).

ANNUAL START UP

B.

Before commencing with the seasonal start up

1.

procedures, we recommend that the compressor

and oil pump motor resistance be checked. Annual

checking and recording of this resistance will

provide a record of deterioration in the motor

winding insulation should it occur. All new units

have a compressor

megohms between any motor terminal and ground.

Whenever a marked change in resistance shows or

uniform readings of less than 5 megohms are

obtained, THE UNIT SHOULD NOT BE STARTED

SINCE MOTOR FAILURE WOULD BE PRACTICALLY CERTAIN. In all probability, the motor will

have to be repaired or replaced. Your McQuay

service representative should be called for recommendations and/or repair.

The unit control circuit should have been energized

2.

at all times. If the control circuit has been shut off

and the oil is cool, the machine should not be

started until the heaters in the oil sump (and gear

casing PE063 only) have been energized for a

minimum of 24 hours. If it is necessary to start the

machine without waiting 24 hours, then the oil in

stator

resistance well over 100

the unit should be drained and replaced with fresh

oil.

Check and tighten all electrical connections.

3.

Install fusetrons in the main disconnect switch

4.

they have been removed).

Replace relay “R7” (if it was removed).

5.

Replace drain plug in water pump if it had been

6.

removed.

Reconnect water lines, turn on supply water and

7.

check for leaks.

If evaporative type condenser is used, clean and

8.

flush the sump.

a. Make sure condenser bleed is adequate.

b. Be sure water treatment is adequate to prevent a

buildup of solids in the condenser. Air circulated

through the condenser contains many contami-

nants which are flushed out by the water sprays.

The use of untreated water in most installations

(if

13

Page 14

can result in a reduction of heat transfer in the

condenser tubes or damage to the tubes as a

result of corrosion, erosion, sliming, scaling, or

algae formation. (This section applies to systems

with evaporative type condensers.)

RECOMMENDATION

The service of a competent water treatment organi-

zation be obtained to determine what, if any, water

treatment is required and their recommendations

implemented.

Mcquay assumes no responsibility for operating

problems or damage occurring as a result of

untreated condenser water.

Clean all surfaces and remove all litter. A clean well

9.

maintained unit is the sign of a good operator.

REPAIR OF THE SYSTEM

Information on pumping unit down, pressure testing,

leak testing, evacuation and charging is contained in

installation manual SE-Gl.

OPERATOR’S CHECKLIST

UNIT CHECKS

1. Suction, discharge and oil pressure normal.

2.

Oil level correct.

Voltage within tolerance (plus or minus 10 percent

3.

of compressor nameplate ratings). Phase unbalance

does not exceed 3 percent.

4.

Motor amperage proper for load conditions.

Vanes open and close under manual and automatic

5.

control.

Motor current limiting control operational.

6.

Safety interlocks interrupt compressor operation.

7.

Unit cycling thermostat set 3 to 5 degrees below

8.

unit control set point.

SYSTEM CHECKS

1.

All motors checked for voltage and running

amperes.

All pumps and motors lubricated.

2.

Water strainer(s) clean.

3.

All fans checked, belts tight, bearings lubricated.

4.

Air filters clean.

5.

All electrical connections tight, starter contacts

6.

clean, starter movement proper.

14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Loading...

Loading...