Page 1

Installation & Maintenance Data

AAF–McQuay Suite™ With Top Mounted Heat Section

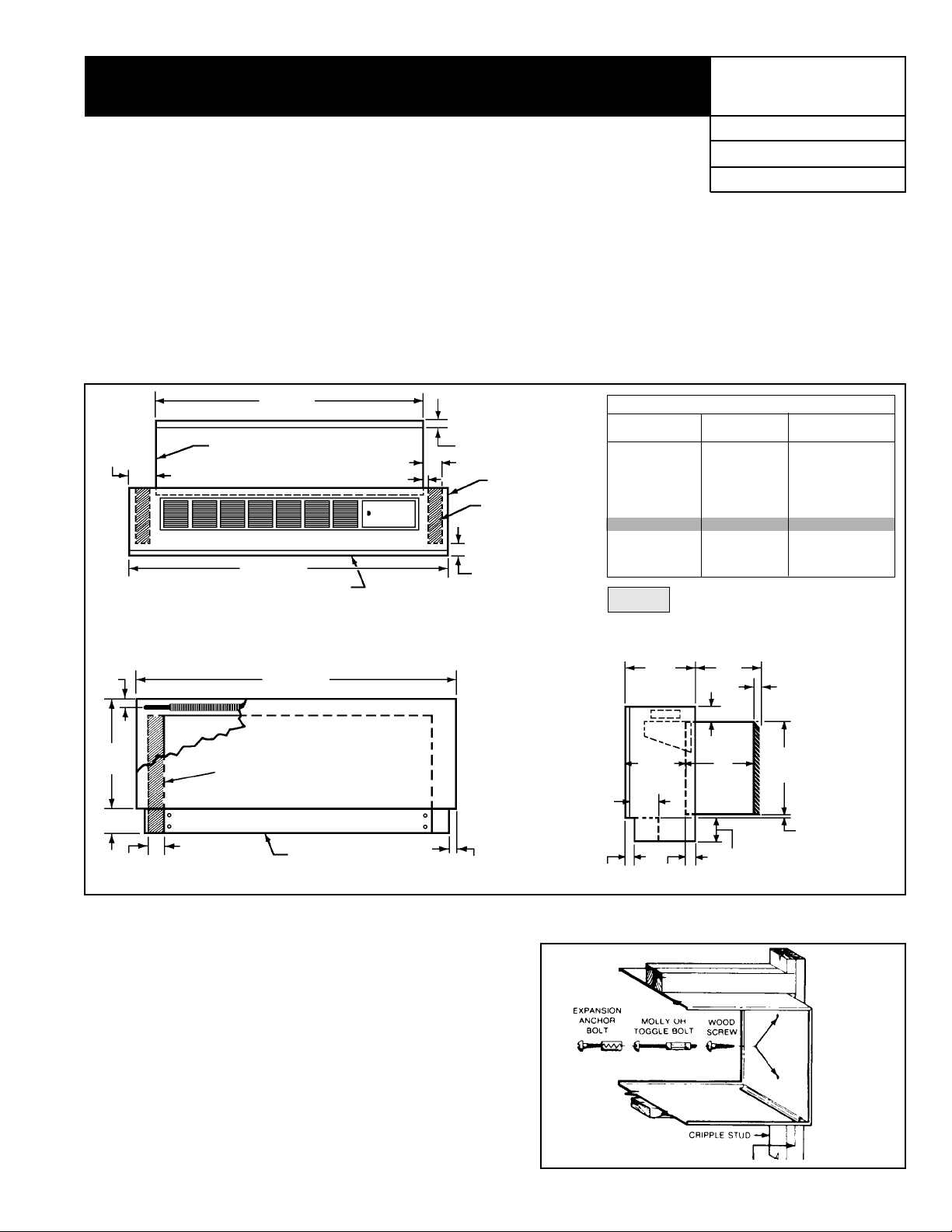

Wall Sleeve Installation

Wall Opening Requirements

Before installing the unit, check the wall opening to be sure the

wall sleeve will slide into the opening unobstructed. For masonry

walls, a lintel must be used to provide support over each opening.

Figure 1.

IM 426-1

Group: PTAC

P art No.: 106018741

Date: May 1999

1

The rough opening should measure 16

opening must be a minimum of 4" above the finished floor (including

carpeting).

/4" high X 421/4" wide. The

42"

(1069mm)

5"

(127mm)

Wall Sleeve

52" (1320mm)

Removable Cabinet

Front Panel

Note: Electrical rough-in should be located behind kickplate

(removable front) and below wall sleeve.

11⁄2"

(38mm)

191⁄2"

(495mm)

3"

(76mm) Min.

3"

(76mm)

52" (1320mm)

Wall Space For Piping Rough-in

(Typ. R.H. & L.H.)

Kickplate (Removable

Front)

31⁄2" (89mm)

1

⁄2" (13mm)

11⁄4" (32mm)

(Architectural)

Cabinet

Floor Space

For Piping

Rough-in (Typ.

R.H. & L.H.)

2" (51mm)

7

⁄8"

(22mm)

51⁄2"

(140mm)

15⁄16"

(33mm)

11/4" RECESS FOR ARCHITECTURAL LOUVER

“A”

ROOM CABINET

173/4"

163/4"

153/4"

143/4"

133/4"

123/4"

113/4"

103/4"

103/4"

103/4"

103/4"

103/4"

“B”

WALL SLEEVE

133/4"

133/4"

133/4"

133/4"

133/4"

133/4"

133/4"

133/4"

143/4"

153/4"

163/4"

173/4"

WALL THICKNESS

53/4" to 63/4"

63/4" to 73/4"

73/4" to 83/4"

83/4" to 93/4"

93/4" to 103/4"

103/4" to 113/4"

113/4" to 123/4"

123/4" to 133/4"

133/4" to 143/4"

143/4" to 153/4"

153/4" to 163/4"

163/4" to 173/4"

Standard Size Wall Sleeve

Wall

Thickness

“A”

91⁄8"

(232mm)

15⁄8"

(41mm)

“C”

27⁄8" (67mm)

“B”

3" (76mm) Min.

Kickplate Height

11⁄4" (32mm)

16"

(406mm)

7

⁄8" (22mm)

“C”

Anchoring

Figures 3 through 5 on the following pages illustrate typical wall

sleeve installations. After the wall sleeve has been set in place

anchor it in the opening as shown in Figure 2. It is recommended

that rubber isolation washers be used with the fasteners to minimize sound transmission from the equipment to the wall, at the

point of contact.

Level w all sleeve in all directions and anchor with appropriate

fasteners (as shown in Figure 2). A

side, 2" down from the top and 2" in from the rear of the wall

sleeve. It may be necessary to drill additional holes in the wall

sleeve to firmly secure it. CAUTION: Do not drill holes in the base

of the wall sleeve . Use shims between the wall and the wall sleev e

to prevent wall sleeve distortion during anchoring.

5

/16" hole is provided on each

©1999 AAF–McQuay Incorporated IM 426-1 / Page 1 (Rev. 5/99)

Figure 2.

Page 2

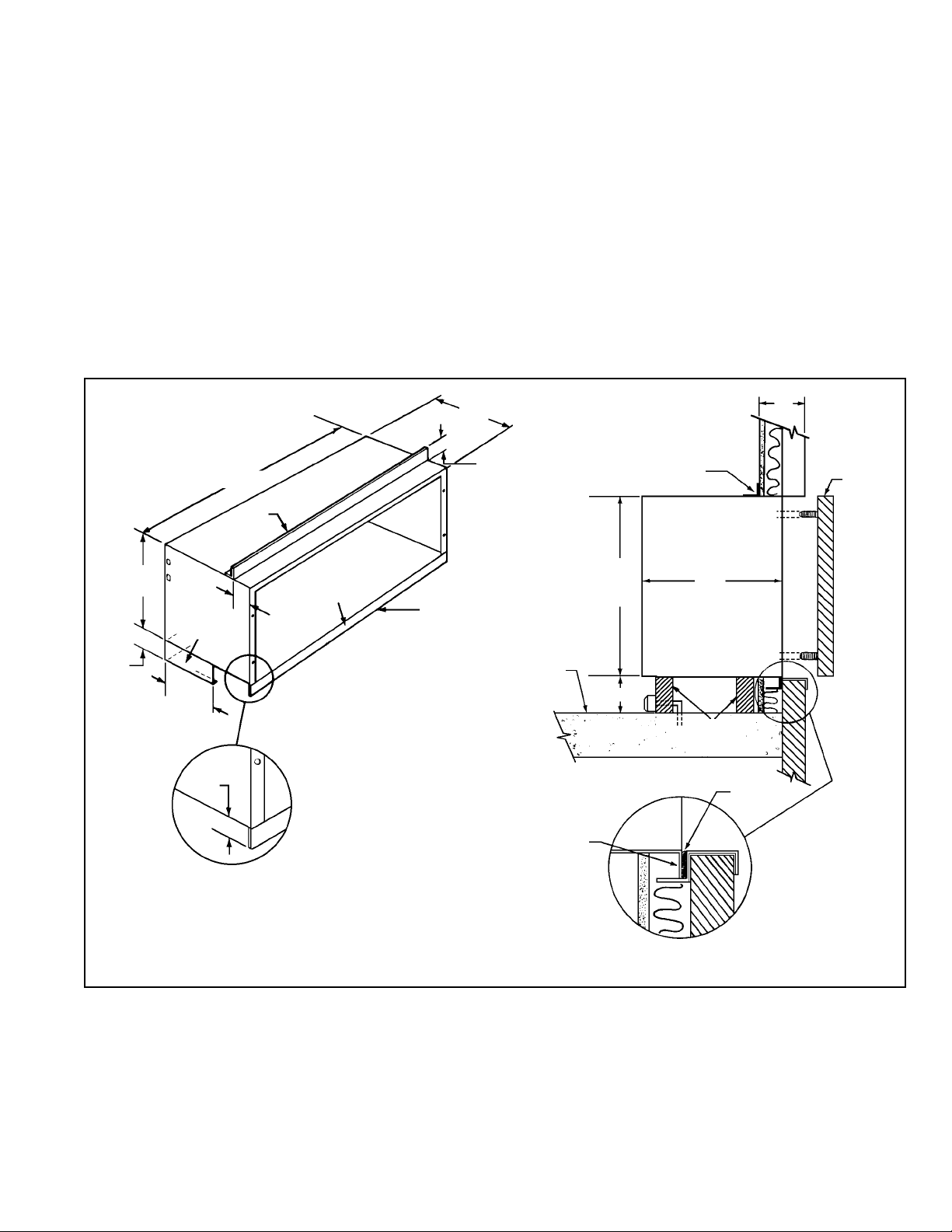

Wall Sleeve Installation – Thin Wall Construction

The standard wall sleeve is designed to be easily installed in a

variety of wall constructions. For panel wall and thin wall construction, it is recommended that the optional top angle be used

wall sleeve. If a subbase is not used, field support must be

provided up to the center of gravity. This support can be metal,

wood or concrete.

and the wall sleeve be supplied with a turned down flange

(see Figure 3).

The recommended procedure for installing units in panel wall

and thin wall construction is as follows:

3. Level wall sleeve in all directions and anchor with appropriate

fasteners. Use holes provided (see Figure 2, page 1) or drill

additional holes as required to secure firmly . Caution: Do not

drill holes in the base of the wall and the wall sleeve to

1. Clean the opening of all debris that may interfere with

prevent wall sleeve distortion during anchoring.

installation.

4. Caulk the wall sleeve to the wall opening on both the inside

2. Recess the wall sleeve so that the louver is flush with the

exterior of the building (refer to Figure 3). The center of grav-

and outside perimeter. This can be done from the inside of

the building. Be careful not to plug the weep holes.

ity is approximately 10 3/4" from the rear face of the standard

Figure 3. Wall Sleeve Installation Using Top Angle & Factory Supplied Louver

131⁄4"

(337mm)

42"

(1069mm)

Optional

Top Angle

Wall

Sleeve

11⁄4" (38mm)

Optional

Top Angel

C**

Outside

Louver

16"

(406mm)

Y*

Optional

Subbase

3"

(76mm)

Min .

Notes:

** See Figure 1, page 1, for dimensions “B” and “C”.

* Dimension “Y” is field determined or specified. Angle is factory welded at

101⁄2"

(267mm)

Max.

1"

(25mm)

given dimension when option is designated.

Turndown

Flange

(See Detail)

Outside

Edge of

Sleeve

Fininish Floor

Including Carpet

Turndown

Flange

16"

(406mm)

37⁄8" (98mm)

Min.

B**

Wall Sleeve

Support

By Others

(2 Req’d).

Caulk

IM 426-1 / Page 2 (Rev. 5/99)

Page 3

Wall Sleeve Installation — Thin Wall Construction

Applications utilizing field supplied louvers require additional

considerations:

Assuming the louver meets the manufacturer’ s criteria, as stated

previously, proceed to install the wall sleeve as follows:

1. Louvers supplied by others must have 70% free area or a

pressure drop not exceeding 0.05 in. w.g. at 300 fpm face

1. Clean the opening of all debris that may interfere with

installation.

velocity , and a blade design that will not cause recirculation of

condenser air.

2. Position the wall sleeve into the w all so that it is flush with the

exterior wall. Important: If the wall sleeve has been installed

2. AAF–McQuay Incorporated does not warrant the rain and

water leakage resistance of its equipment when used with

louvers by others.

into a thick wall, make certain the wall sleeve protr udes into

the room a minimum of 1

This is to accommodate the heat section and room cabinet.

The center of gravity is 103/4" from the rear face of the

3. All louvers by others must be approved by the manufacturer

prior to installation.

standard wall sleeve. If no subbase is being employed,

adequate support for the wall sleeve up to the center of g ra vity must be provided at the jobsite. This support can be wood,

4. Be sure to install foam type gaskets on all sides of the

metal or concrete.

condenser to prevent re-circulation or bypass of condenser air .

3. Level wall sleeve in all directions and anchor with appropriate

Figure 4 illustrates a typical installation using a field supplied,

continuous louver. This method is for illustration purposes only.

Other variations may be employed as long as they meet

manufacturer’ s louver specifications listed above and so long as

adequate wall sleeve support is achiev ed. All structural supports

fasteners using holes provided (see Figure 2, page 1), or drill

additional holes as required to secure firmly . Caution: Do not

drill holes in the base of the wall sleeve. Use shims between

the wall and the wall sleeve to prevent wall sleeve distortion

during anchoring.

and fasteners (except the optional top angle and turned down

flange) are field supplied.

Installation of wall sleeves with continuous louvers is very

similar to that of applications with factory furnished louvers.

4. Caulk the wall sleeve to the wall opening on both the inside

and outside perimeter. This can be done from the inside of

the building. Be careful not to plug the weep holes.

Figure 4. Wall Sleeve Installation Using Top Angles & Field Supplied Continuous Louver

1

/8" beyond the finished wall surf ace.

(406mm)

3"

(76mm)

Min.

16"

Optional

Subbase

101⁄2"

(267mm)

Max.

(25mm)

1"

42"

(1069mm)

Optional

Top Angle

Y*

133⁄4"

(349mm)

11⁄4"

(38mm)

Wall

Sleeve

Turndown

Flange

(See Detail)

Outside Edge

of Sleeve

Finished Floor

Including Carpet

Notes:

1. Caulk entire perimeter of wall sleeve after installation.

2. Seal area between louver and wall sleeve to prevent condenser air recirculation.

3. Dimensions shown in table on page 1 do not apply to this

application.

*Dimension “Y” is field determined or specified. Angle is factory

welded at given dimension when option is designated.

(406mm)

Min. 37⁄8"

(98mm)

16"

Optional

Top Angle

Supports By Others

Insulated

Panel

Wall Sleeve

(2 Req’d.)

Sleeve

Outside Louver

By Others

Turndown

Flange

Insulated

Panel

Wall

Wall

Frame

By Others

Resilient

Caulking

Resilient

Caulking

IM 426-1 / Page 3 (Rev. 5/99)

Page 4

Wall Sleeve Installation — Thick Wall Construction

A heavy-gauge, corrosion resistant wall sleeve is provided for

each unit. The wall sleeve is either shipped in a separate carton

or shipped in a multi-pack of 15.

Typical installation for masonry walls is shown in Figure 5.

The recommended installation procedure for this type of

construction is as follows:

1. Clean the opening of all debris that may interfere with instal-

lation.

2. Be sure the unit’s center of gravity falls within the load

bearing surface of the wall. The center of gr avity f or the unit is

3

approximately 10

/4" from the rear edge of the wall sleeve. If

the center of gravity is not within the load bearing surface,

then additional support such as wood, metal or concrete must

be provided in the field.

3. Place a thin pad of soft mortar on the bottom of the opening.

Important: Make certain the wall sleeve protrudes into the

1

room a minimum of 1

/8" beyond the finished wall surface to

accommodate the heat section and room cabinet. Be sure to

recess the wall sleeve enough to accommodate outside louver . This recess is

3

/8" for stamped louvers and 11/4" for architectural louvers. The louver should be flush to e xterior surface

when completed.

4. If a brickstop is employed (as shown in Figure 5), slide the

wall sleeve into the wall until the br ickstop contacts the exterior bricks, as illustrated below. If a brickstop is not used,

slide the wall sleeve in the wall so that it extends into the

1

room a minimum of 1

/8" beyond the finished interior wall surface. This allows room to attach the heat section and room

cabinet. The wall sleeve should also be recessed enough to

accommodate the outside louver.

5. After the mortar has dried, remove the masonry suport from

the wall sleeve. Note: The wall sleeve is not intended to replace the lintel.

6. Level wall sleeve in all directions and anchor with appropriate

5

fasteners (as shown in Figure 2, page 1). A

/16" hole is provided on each side, 2" down from the top and 2” in from the

rear of the wall sleeve. It may be necessary to drill additional

holes in the wall sleeve to firmly secure it. Caution:

Do not

drill holes in the base of the wall sleeve. Use shims between

the wall and the wall sleeve to prevent wall sleeve distortion

during anchoring.

7. Caulk the wall sleeve to the wall opening on both the inside

and outside perimeter using a resilient, non-hardening caulk

such as silicone. Be careful not to plug the weep holes.

Figure 5. Wall Sleeve Installation Using Brickstops

C

5

1

⁄8" (41mm) Min.

1

[–

Outside

Louver

1

1

⁄4"

(32mm)

Optional

Brickstop

B

Wall Sleeve

⁄2" (13mm)]

16"

(406mm)

37⁄8" (98mm)

Min.

NOTES:

(1) For dimensions B and C, see table on page 1.

(2) Dimension X is “as required” and is usually sent to the factory to be welded during wall sleev e fabrication.

(3) Caulk entire perimeter of wall sleeve after installation.

Finished Floor

Including Carpet

B

X

Outside Edge

of Sleeve

Wall

Sleeve

Optional

Brickstops

42" (1067mm)

1

1

⁄4"

(32mm)

16"

(406mm)

AAF–McQuay Incorporated

4900 Technology Park Boulevard, Auburn, New York 13021-9030 USA (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer recycled material.

IM 426-1 / Page 4 (Rev. 5/99)

Loading...

Loading...