Page 1

Installation & Maintenance Data

Custom Wall Sleeve (CWS)

Introduction

The wall sleeve is a standard size 16" high, 42" wide

and 13-3/4" deep. Slide channels are factory welded into

the sleeve to facilitate easy installation and removal of

the chassis. Each wall sleeve is predrilled to match the

mounting screws of the chassis. Knockouts are provided

for the optional external drain kit used with the heat

pump models.

Figure 1. Wall Sleeve

Tinnerman Clips

Slide Channels

Note: Wall sleeve shown with optional insulation installed.

IM 880

Group: PTAC

Part No.: 6681093

Date: September 2007

All necessary fasteners are supplied to assemble the

chassis and louver to the wall sleeve.

Wall Opening Requirements

When roughing in the opening for the wall sleeve,

make certain there is sufcient clearance from the

walls and oor. The wall sleeve should be positioned

a minimum of 5/8" from the nished side wall to

accommodate the room cabinet. A minimum distance of

3" above the nished oor is required for return air.

The rough opening should measure 161/4" high x

421/4" wide. When using a louver frame, the opening

must measure 165/8" x 425/8". Louver frames should be

used for panel wall and thin wall applications to assure

positive anchoring to the wall (Figure 13). When a

subbase is used, the opening must start 3" to 4" above

the nished oor (including carpeting) to match the

height of the subbase selected. The subbase is available

in 3" or 4" heights and has adjustable leveling legs that

provide up to an additional 1" height.

A 3" or 4" subbase is required for 265V models and is

optional for 208/230V models.

Figure 2. Unit with Subbase

42" (1067 mm)

43" (1092 mm)

411/2" (1054 mm)

**

133/4"

(349 mm)

161/2"

(419 mm)

*Subbase Side Dimension:

Electric: 43/4" to 133/4" (111mm to 349mm) (See Figure 6)

Hydronic: 0" to 133/4" (0mm to 349mm) (See Figure 7)

**Subbase Height Dimension:

Electric: 3" to 4" (76mm to 102mm) with 0" to 1" (0mm to 25m) leveling screw

Hydronic: 8" (203mm) with 1/4" (6mm) to 11/4" (32mm) leveling bolts

1. Unit pictured with subbase installed. Subbase is optional on 208V and 230V

units. Subbase is standard on all 265V units and units with hydronic heat.

Hydronic subbase is ush with the front of the cabinet. Electric subbase is

ush with wall sleeve.

2. Subbase extends to front edge of unit when furnished with hydronic heat.

3. Opening needs to be 165/8" x 425/8" (422mm x 1083mm) when using a louver

frame.

4. Subbase side channels are adjustable from 43/8" to 133/4" (111mm to 349mm).

16" (406 mm)

22" (559 mm)

81/4"

(210 mm)

*

©2007 McQuay International IM 880 / Page 1 of 8

Page 2

Wall Construction Types

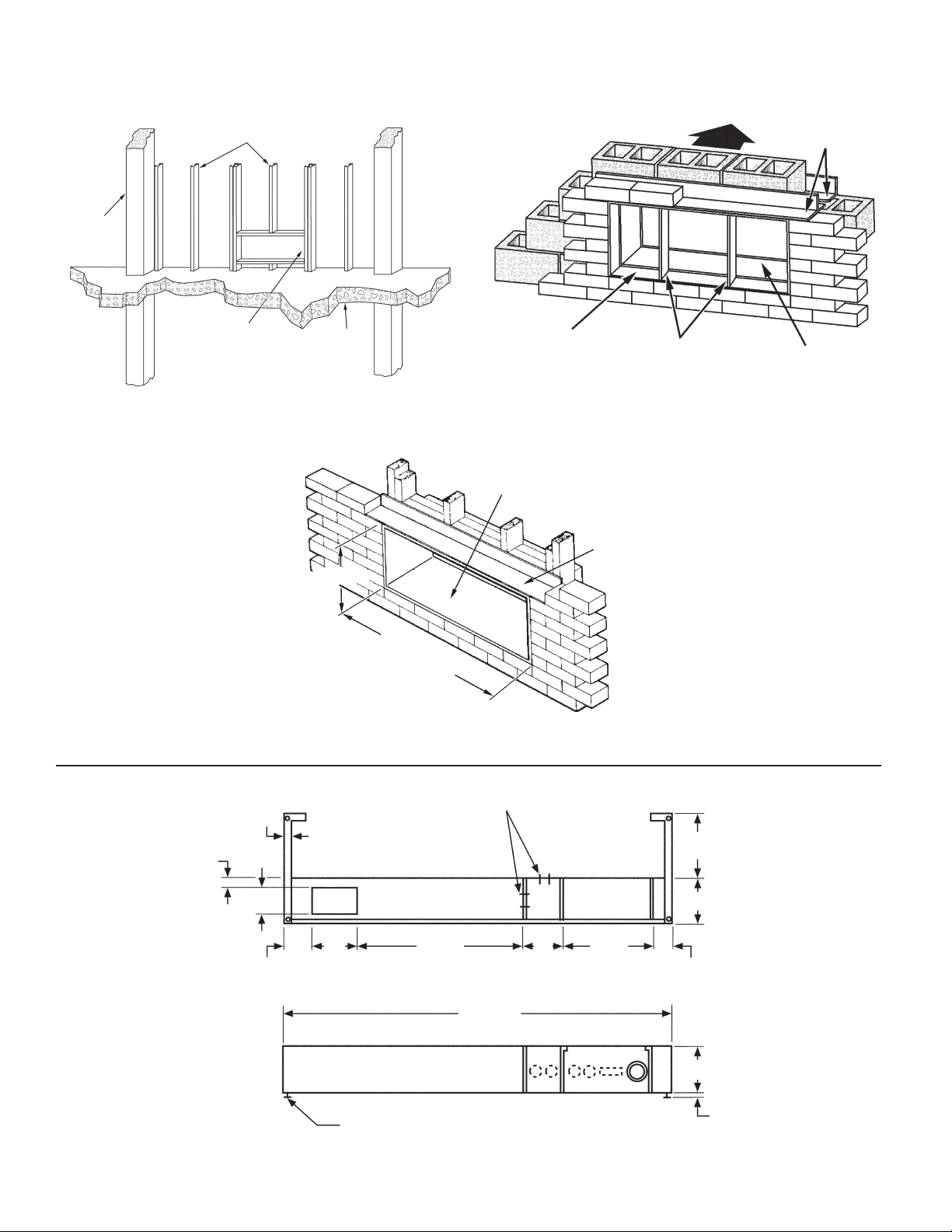

Figure 3. Panel Wall (Thin) Construction

Steel Studs

Concrete

Pillars

161/4" x 421/4"

Wall Sleeve

Rough Opening or

165/8" x 425/8" When using

a Louver Frame

Figure 5. Frame and Brick Construction

Floor

Figure 4. Masonry Wall (Thick) Construction

Room Side

Wall Sleeve Extension

16" x 42"

Wall Sleeve

Lintel

(by others)

Splitters

Lintels (by others)

16" x 42"

Wall Sleeve

Subbases – Dimensions

Figure 6. Electrical Subbase

5

/8"

7

/8"

3"

21/2"

161/4" High

421/4" Wide Wall

Sleeve Rough Opening

5"

Electrical Knockouts

17"

Plan

411/2"

0" to 93/8"

43/8"

12"

11/2"

IM 880 / Page 2 of 8

Leveling Screw (4 Places)

Front Elevation (Three Front Panels in Place)

3"or 4"

0" to 1"

Page 3

Figure 7. Hydronic Subbase

Receptacle (Factory installed when

As Req'd

21/2"

81/4"

3/4"

15"

3" x 5" Opening for Electrical

and/or Piping Rough-in

5

/8" O.D. Copper Sweat

fuse & disconnect are furnished)

21/2"

Top View

3/4"

71/4"

Permanent

Mesh Filter

411/2"

71/2"

63/4"

Front View

Installation Requirements For Recessed

Louver Wall Sleeve

1. The Recessed Louver Wall Sleeve must extend a

minimum of 11/4" past the nished interior wall.

2. The Recessed Louver Wall Sleeve must be installed

so that it is ush with the exterior face of the building

and the drip edge must extend 1/4" beyond the face

(Figure 8).

Installing Recessed Louver Wall Sleeve

1. Clean the opening of all debris that may interfere

with installation.

2. If the unit is to be supplied with a subbase, install

subbase before installing cabinet/wall sleeve (see

IM 879).

3. lf the optional drain kit is to be employed (heat pump

only), see IM 887.

4. Place a thin pad of soft mortar on the bottom of the

opening and slide in the cabinet/wall sleeve. Louver

should be ush to exterior surface when complete.

Note: The wall sleeve is not intended to replace the

lintel.

5. Level the wall sleeve in both directions, left to right

and inside to outside, using the top of the wall

sleeve and plumb wall sleeve for vertical on the

sides.

IMPORTANT!

Do Not level base of wall sleeve. The bottom of the Recessed

Louver Wall Sleeve has a built in pitch to the outside for proper

drainage. (The inside height dimension is 15.88" and the outside

dimension is 16" to provide the necessary drainage pitch).

NOTES:

1. Side channels are adjustable from 0"–93/8" in

length by inverting them. Side channels are

predrilled to allow innite adjustment.

2. Subbase shown with louvered front panel

removed. Front panel is hinged to allow

access to valve, coil, lter & electrical

junction box.

3. Leveling legs are adjustable from 1/4"–11/4".

8"

Leveling Legs

Optional Disconnect

31/4"

11/2"

51/2"

Fuse

Electrical

Knockout

1/4" – 11/4"

End View

NOTICE

Standard Louver can not be used with recessed louver wall

sleeve. Louver is special order. Contact factory for more

information if necessary.

Figure 8. Recessed Louver Wall Sleeve Installation

Level the top of the wall

sleeve, NOT the base

of the wall sleeve (see

IMPORTANT notice)

133/4"

17"

(432mm)

See Note

Finished

Floor

or Carpet

Note: Standard subbase is available in 3" or 4" (76 mm or 102 mm)

81/4"

(209mm)

157/8"(403mm)

Room

Cabinet

Wall Receptacle

(by others)

height. Leveling legs provide adjustment of 1" (25 mm).

(349mm)

Wall Sleeve

Extends 1/4"

beyond the

exterior face of

the building

Steel Lintel

(by others)

5/16" (8mm)

Anchor Hole

16"

(406mm)

Drip Edge

Detail

IM 880 / Page 3 of 8

Page 4

6. Secure by anchoring with appropriate fastener(s).

A 5/16" (8mm) hole is provided on each side, 2"

(51 mm) down from the top and 2" (51mm) in from

the rear of the cabinet/wall sleeve. Additional holes

may be required to rmly secure the cabinet/wall

sleeve (Figure 9).

CAUTION

DO NOT drill holes in the base of the cabinet/wall sleeve.

Figure 9. Anchoring the Wall Sleeve

Rubber Isolation

Washer

Expansion

Anchor Bolt

Molly or

Toggle Bolt

Wood

Screw

2. If the unit is to be supplied with a subbase, install

subbase before installing cabinet/wall sleeve (see

IM 879).

3. lf the optional drain kit is to be employed (heat pump

only), see IM 887.

4. Place a thin pad of soft mortar on the bottom of the

opening and slide in the cabinet/wall sleeve. Be sure

to recess the wall sleeve enough to accommodate

outside louver. This recess is 3/8" (9.5mm) for

stamped louvers and 11/4" (32mm) for architectural

louvers. Louver should be ush to exterior surface

when complete. Note: The wall sleeve is not

intended to replace the lintel.

5. Level cabinet/wall sleeve in both directions and

secure by anchoring with appropriate fasteners.

A 5/16" (8mm) hole is provided on each side, 2" (51

mm) down from the top and 2" (51mm) in from the

rear of the cabinet/wall sleeve. Additional holes may

be required to rmly secure the cabinet/wall sleeve.

CAUTION

Do not drill holes in the base of the cabinet/wall sleeve.

Do Not Drill Holes in Bottom

of Sleeve

(Except for Internal Drain Kit)

Cripple Stud

Main Stud

Attaching Cabinet Wall Sleeve to Subbase

1. Where a subbase is used, secure wall sleeve to

subbase with clips provided.

2. Caulk the cabinet/wall sleeve to the wall opening on

both the inside and outside perimeter. Be careful not

to plug the weep holes. Caulking should be resilient,

nonhardening type such as silicone.

3. Secure the two sections by installing the clip screws

supplied with the hardware bag.

4. Caulk indoor/outdoor perimeter of cabinet/wall

sleeve with resilient caulk such as silicone.

5. Finish any uncompleted electrical and/or plumbing

connections.

Wall Sleeve Installation — Frame and Brick

A heavy-gauge, corrosion resistant cabinet/wall

sleeve is provided for each unit. The cabinet/wall sleeve

is either shipped in a separate carton, shipped in a

multipack of 15 or in a single carton with the heating/

cooling chassis.

The standard cabinet/wall sleeve is designed to be

easily installed in a variety of wall constructions. Note:

The center of gravity is 10" (254mm) from the rear face

of the wall sleeve. The wall sleeve must be inserted

into the wall at least 10" (254mm) or other support

must be employed. Support can be from a factory

supplied subbase or from other eld supplied materials.

Recommended installation procedures are described

below (Figure 10, 11, & 12).

1. Clean the opening of all debris that may interfere

with installation.

IM 880 / Page 4 of 8

6. Where a subbase is used, secure wall sleeve to

subbase with clips provided.

7. Caulk the cabinet/wall sleeve to the wall opening on

both the inside and outside perimeter. Be careful not

to plug the weep holes. Caulking should be resilient,

nonhardening type such as silicone.

Figure 10. Frame and brick with standard electrical

subbase

Steel Lintel

(by others)

Outside

Louver

(349mm)

Mounting

Holes

(by installer)

Wall Sleeve

Caulk Perimeter

both Indoor and

Outdoor Before

Installing Louver

Note: Standard subbase is available in 3" or 4" (76 mm or 102 mm)

height. Leveling legs provide adjustment of 1" (25 mm).

43/8"

(111mm)

133/4"

16"

(406mm)

Subbase

Leveling

Leg

Power Supply Connect

(Alternate Entry)

81/4"

(209mm)

17"

(432mm)

Room

Cabinet

See Note

Finished Floor

or Top

of Carpet

Page 5

Figure 11. Frame and brick with cord connection

Steel Lintel

(by others)

Mounting

Screws

by Installer

Outdoor

Louver

Caulk Perimeter

133/4"

(349mm)

(406mm)

Wall Sleeve

16"

3" Min. (76mm)

Wall

Receptacle

(by others)

81/4"

(209mm)

(432mm)

Room

Cabinet

Finished Floor

or Carpet

17"

Wall Sleeve Installation– Panel Wall Construction

*For panel wall and thin wall construction, it is

recommended that a louver frame be used (Figure 13).

Panel wall and thin wall construction varies only

slightly from frame and brick construction. Note: The

center of gravity is 10" (260mm) from the rear face

of the wall sleeve. The wall sleeve must be inserted

into the wall at least 10" (260mm) or other support

must be employed. Support can be from a factory

supplied subbase or from other eld supplied materials.

Installation for this application is as follows (Figure 14,

15, & 16).

1. Clean the opening of all debris that may interfere

with installation.

2. I

f the unit is to be supplied with a subbase, install

subbase before installing cabinet/wall sleeve (see IM 879).

3. If the optional drain kit is to be employed, see IM 887.

4. Be sure the cabinet/wall sleeve is mechanically

attached to the wall and caulked to assure a proper

seat. It is recommended that the louver frame be

used for this purpose.

5. Recess the wall sleeve so that the louver is ush

with the exterior of the building.

6. Level cabinet/wall sleeve in both directions and

secure by anchoring with appropriate fasteners or

drill additional holes as required to secure rmly.

CAUTION

Figure 12. Frame and brick with hydronic subbase

Steel Lintel

(by others)

Outdoor Louver

133/4"

(349mm)

Mounting

Screws

by Installer

Caulk Perimeter

both Indoors

and

Outdoors

Before Installing

Louver

Subbase Side

Channel

IM 880 / Page 5 of 8

Wall Sleeve

16"

(406mm)

Alternate

Electrical

Connections

81/4"

(209mm)

Room

Cabinet

Hydronic Subbase

17"

(432mm)

Hydronic

Heating

Coil

81/4"

(209mm)

Finished Floor

or Carpet

Leveling Leg

Do not drill holes in the base of the cabinet/wall sleeve.

7. Where a subbase is used, secure wall sleeve to subbase

with clips provided.

8. Caulk the cabinet/wall sleeve to the wall opening on

both the inside and outside perimeter. Be careful not

to plug the weep holes. Caulking should be resilient,

nonhardening type such as silicone.

*Using a Louver Frame

Recess the cabinet/wall sleeve so that the louver is

ush with the outside of the building. Place louver frame

around cabinet/wall sleeve as shown in gure 13. Secure

angles at side and top of walls.

Figure 13. Louver Frame Dimensions

183/16"

(1072mm)

423/16"

(1072mm)

163/16"

(411mm)

33/4"

(92mm)

443/16"

(1122mm)

Note: Wall Sleeve rough opening

when using a Louver Frame

must be 165/8" x 425/8"

Page 6

Figure 14. Panel wall construction with standard electrical

subbase

Louver

Frame

Outside

Louver

Wall Sleeve

17"

(432mm)

See Note

81/4"

(209mm)

(406mm)

Room

Cabinet

16"

Electrical

Subbase

133/4"

(349mm)

Gasket

& Caulk

Perimeter

Figure 16. Panel wall installation with hydronic subbase

Louver

17"

(432mm)

81/4"

(209mm)

81/4"

(209mm)

Room

Cabinet

Hydronic

Heating

Coil

Frame

133/4"

(349mm)

16"

(406mm)

Wall Sleeve

Subbase

Side

Channel

Outside

Louver

Caulk

Perimeter

both Indoors

& Outdoors

Power Supply Connect

(Alternate Entry)

Subbase Side Channel

Note: Standard subbase is available in 3" or 4" (76 mm or 102 mm)

height. Leveling legs provide adjustment of 1" (25 mm).

Figure 15. Panel wall construction with cord connection

(209mm)

17"

(432mm)

Cabinet

3"Min. (76mm)

Floor

Receptacle

(by others)

81/4"

Room

(406mm)

Conduit

Louver

Frame

133/4"

(349mm)

16"

Wall Sleeve

Minimum

2 Supports

(eld supplied)

Outside

Louver

Caulk

Perimeter

both Indoors

& Outdoors

Power Supply Connect

(Alternate Entry)

Leveling Legs with

1" Adjustment

Wall Sleeve Installation – Thick Wall

Construction

Installation of cabinet/wall sleeves for thick walls

requires special consideration. Table 1 should be used

to determine the maximum wall thickness allowed for

the standard cabinet/wall sleeve. For thicker walls,

cabinet/wall sleeve extensions are available from your

representative.

Wall sleeve installation in thick walls is similar to

frame and brick installation. Install as follows (Figure 17,

18 & 19).

1. Clean the opening of all debris that may interfere

with installation.

2. If the unit is to be supplied with a subbase, install

subbase before installing cabinet/wall sleeve (see

IM 879).

3. If the optional drain kit is to be employed (heat pump

only), see IM 887.

4. If wall thickness exceeds dimensions shown in Table

1, a cabinet/wall sleeve extension must be used.

Once the extension is attached to the cabinet/wall

sleeve, place a thin pad of soft mortar on the bottom

of the opening and slide in the wall sleeve/extension

assembly. Be sure to recess the wall sleeve enough

to accommodate outside louver. This recess is 3/8"

(9.5mm) for stamped louvers and 11/4" (32mm) for

architectural louvers. Louver should be ush to

exterior surface when completed. Note: The wall

sleeve is not intended to replace the lintel.

5. Level cabinet/wall sleeve in both directions and

secure by anchoring with appropriate fasteners or

drill additional holes as required to secure rmly.

IM 880 / Page 6 of 8

Page 7

CAUTION

Do not drill holes in the base of the cabinet/wall sleeve.

6. Where a subbase is used, secure wall sleeve to

subbase with clips provided.

7. Caulk the cabinet/wall sleeve to the wall opening on

both the inside and outside perimeter. Be careful not

to plug the weep holes. Caulking should be resilient,

nonhardening type such as silicone.

Table 1. Maximum Wall Thickness

Louver Type

Stamped

Architectural

Subbase

14"(356mm)

147/8"(378mm)

Maximum Wall Thickness

No

91/2"(241mm)

103/8"(264mm)

Standard

Subbase

Hydronic

Subbase

131/8"(333mm)

14"(356mm)

Figure 18. Thick wall construction with cord connection

See

Caulk

Perimeter

Outside

Louver

Mounting

Screws

(by installer)

Table 1

(349mm)

Wall

Sleeve

Wall

Sleeve

Extension

133/4"

16"

(406mm)

1/8" (3mm)

Min.

Steel Lintel

(by others)

81/4"

(209mm)

17"

(432mm)

Room

Cabinet

3"Min. (76mm)

Figure 17. Thick wall construction with standard electrical

subbase

See Table 1

Steel Lintel

(by others)

Caulk

Perimeter

See

Mounting

Screws

(by installer)

Outside

Louver

Note: 1. Standard subbase is available in 3" or 4" (76 mm or 102 mm)

height. Leveling legs provide adjustment of 1" (25 mm).

2. Wall sleeve extension is available in various depths and

supplied as required.

Note

2

Wall

Sleeve

Extension

133/4"

(349mm)

16"

(406mm)

Electrical

Subbase

43/8" Min. (111mm)

81/4"

(209mm)

Room

Cabinet

17"

(432mm)

See Note 1

Floor

Floor

Receptacle

(by others)

Figure 19. Thick wall installation with hydronic subbase

See Table 1

Caulk

Perimeter

Mounting

Screws

(by installer)

Outside

Louver

Wall Sleeve

133/4"

(349mm)

16"

(406mm)

Wall

Sleeve

Extension

Steel Lintel

(by others)

1" (25mm)

Room

Cabinet

81/4"

(209mm)

Hydronic

Heating

Coil

17"

(432mm)

81/4"

(209mm)

Floor

Hydronic

Subbase

IM 880 / Page 7 of 8

Page 8

McQuay Training and Development

Now that you have made an investment in modern, efcient McQuay equipment, its care should be a high priority.

For training information on all McQuay HVAC products, please visit us at www.mcquay.com and click on training, or call

540-248-9646 and ask for the Training Department.

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited

Product Warranty. Consult your local McQuay Representative for warranty details. Refer to Form

933-43285Y. To nd your local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

©2007 McQuay International (800) 432-1342 www.mcquay.com IM 880 / Page 8 of 8

Loading...

Loading...