Page 1

Installation and Maintenance Manual IM 672-8

Vision™ Air Handler

Models CAC/CAH 003G – 090G

Group: Applied Air Systems

Part Number: IM 672

Date: November 2011

© 2011 McQuay International

Page 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . .3

Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . . 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . .5

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unit Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembling Sections . . . . . . . . . . . . . . . . . . . . . . . . .7

External Section-to-Section Mounting . . . . . . . . . . . .7

Horizontal Airflow Section Mounting . . . . . . . . . . . . . .7

Vertical Inverted Airflow Section Mounting . . . . . . . . . 8

Extended Coil Section Mounting . . . . . . . . . . . . . . . . 8

Side-by-Side Heatwheel Section Joining . . . . . . . . . .9

Internal Section-to-Section Mounting . . . . . . . . . . . .10

Ceiling Hung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Panels, Frame Channels, and Doors . . . . . . . . . . . . 11

Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Frame Channel Removal . . . . . . . . . . . . . . . . . . . . . 11

Fan Section Doors . . . . . . . . . . . . . . . . . . . . . . . . . .12

Injected-Foam Insulated Panels . . . . . . . . . . . . . . . . 12

Field Mounting Junction Boxes and

Other Components . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Face and Bypass Section Mounting . . . . . . . . . . . . 13

Bypass Into a Vertical Fan Section . . . . . . . . . . . . . 13

External Face and Bypass Duct Assembly

(Sizes 040 to 090) . . . . . . . . . . . . . . . . . . . . . . . . . .14

Multizone Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 15

Multizone Damper Assembly . . . . . . . . . . . . . . . . . .15

Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Multizone Damper Adjustment . . . . . . . . . . . . . . . . . 17

Multizone, Mixing Box and Economizer

Damper Torque Requirements . . . . . . . . . . . . . . . . . 17

Mounting Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Face Bypass Damper Torque Requirements . . . . . . 18

Isolation Dampers for Multiple Fans . . . . . . . . . . . . .18

Piping and Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Water Cooling Coils . . . . . . . . . . . . . . . . . . . . . . . . . 18

Direct Expansion Coils . . . . . . . . . . . . . . . . . . . . . . .18

Steam Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Water Heating Coils . . . . . . . . . . . . . . . . . . . . . . . . .21

Drain Pan Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Internal Isolation Assembly Adjustment . . . . . . . . 21

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . 24

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Startup Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before Starting the Unit . . . . . . . . . . . . . . . . . . . . . . 25

VFD Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fan Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fan Wheel Alignment . . . . . . . . . . . . . . . . . . . . . . . . 26

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Vibration Levels . . . . . . . . . . . . . . . . . . . . . . . . 30

Vibration Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . 31

Ball Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . 31

Motor Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fan Shaft Bearings . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fan Drive Adjustments . . . . . . . . . . . . . . . . . . . . . . 32

VM/VP Variable Pitch Key Type Sheaves . . . . . . . . 32

LVP Variable Speed Sheaves . . . . . . . . . . . . . . . . . 33

MVP Variable Speed Sheaves . . . . . . . . . . . . . . . . 34

Fan Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Front Load Filter Option . . . . . . . . . . . . . . . . . . . . . 36

Filter Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Winterizing Water Coils . . . . . . . . . . . . . . . . . . . . . . 37

Removing and Replacing Components . . . . . . . . . 37

Removing a Side or Top Panel . . . . . . . . . . . . . . . . 37

Removing a Frame Channel . . . . . . . . . . . . . . . . . . 38

Removing the Fan Section . . . . . . . . . . . . . . . . . . . 38

Removing and Replacing the Coil . . . . . . . . . . . . . . 38

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Service and Warranty Procedure . . . . . . . . . . . . . . 41

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Warranty Return Material Procedure . . . . . . . . . . . 41

Check, Test, and Start Procedure Form . . . . . . . . . 42

Quality Assurance Survey Report . . . . . . . . . . . . . 44

2 McQuay IM 672-8

Page 3

Introduction

CAH 003 G D A C

Model

CAH = Custom modular air handler

CAC = Custom modular component

Nominal unit size

(cataloged size—nominal square foot of coil)

003, 004, 006, 008, 010, 012, 014, 017,

021, 025, 030, 035, 040, 050, 065, 080, 085, 090

Vintage of McQua y air ha nd lin g unit

Unit cross section

C = Standard unit cross section

M = Custom size cross section

Motor location

A = Motor along side of fan housing

D = Motor down stream of belt-drive

plenum fan

F = Motor on inline fan

G = Motor downstream of direct-drive

plenum fan

H = Motor downstream of fan array

T = Motor behind twin fan housing

Unit type/coil position

B = Blow-through cooling coil location

D = Draw-through cooling coil location

H = Heating only

V = Vent only

M = Multizone

General Information

Introduction

Receiving and Handling

VisionTM air handlers are not designed to be weather resistant.

Do not install them outdoors.

The system design and installation must follow accepted industry

practice as described in the ASHRAE Handbook, the National

Electric Code, and other applicable standards. This equipment

must be installed in accordance with regulations of authorities

having jurisdiction and all applicable codes.

Installation and maintenance must be performed by qualified

personnel familiar with applicable codes and regulations and

experienced with this type of equipment. Sheet metal parts,

self-tapping screws, clips, and such items inherently have

sharp edges; the installer should exercise caution.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard.

Avoid contact with them.

ATTENTION

Les bords tranchants et les surfaces des bobines sont un

risque de blessure. Ne les touchez pas.

1 Carefully check items against the bills of lading to verify

all crates and cartons have been received. Carefully inspect

all units for shipping damage. Report damage immediately

to the carrier and file a claim.

2 Vision air handler units are constructed of galvanized or

painted steel and are inspected thoroughly before leaving

the factory . Take care during installation to prevent damage

to units.

3 Take special care when handling the blower section. All

fans are dynamically balanced before leaving the factory .

Rough handling can cause misalignment or a damaged

bearings or shaft. Carefully inspect fans and shaft before

unit installation to verify this has not happened.

4 Handle the zone damper of the multi-zone units with

special care. Zone dampers are set and inspected before

leaving the factory, but should be checked on arrival to the

job to verify the bell arm and connecting rod set screws did

not become loose in shipment.

Note: Screws, bolts, etc., for assembling sections are

supplied in a bag attached to each section. All

necessary gasketing is applied in the factory for

section-to-section mounting.

Nomenclature

McQuay IM 672-8 3

Page 4

Introduction

Unit Storage

• Store on a level surface in a clean, dry location where

temperature can be controlled if possible.

• Pack fan and motor bearings (unless motor bearings are

sealed) with compatible grease with the shaft stationary.

After grease has been installed, rotate shaft about 10

rotations.

• Isolate unit from shock and vibration.

• Once a month, rotate shaft a minimum of 10 revolutions.

Insure the stopped position is different than the original

position.

• Coat shafts with lubricant as needed to prevent corrosion.

• A descant bag may be hung in the interior of the unit to

minimize corrosion in humid storage environments.

• Do not clean galvanized steel surfaces with oil dissolving

chemicals. This may remove the protective coating and

accelerate corrosion.

• Do not allow coverings to trap moisture on galvanized

surfaces.

Belt-Driven fans:

• Reduce belt tension by at least 50% or remove the belts.

Remove belts if they will be subjected to temperatures

exceeding 85° F to avoid deterioration.

• Remove belt guard when adjusting belts

• Reduce belt tension prior to removing or installing belts.

Removing or installing tensioned belts may cause personal injury and damage to the sheaves, belts, bearings or

shafts.

• Adjustable sheaves should be opened as wide as possible

and the adjustment threads lubricated so they do not corrode.

Be careful not to put lubricant on the belt running surface

Prior to start up:

• Set screws on bearings, fan wheels, and sheaves need to be

checked for proper torque. Also check bolt torque for any

taper lock hubs either on the wheel or sheaves.

• Check sheaves for corrosion. Significant corrosion can cause

belt or sheave failure.

• Purge old grease from fan bearings while rotating the shaft

to distribute the new grease evenly and prevent bearing seal

failure.

• Correctly align and tension belts. See General Rules of

T ensioning‚ page 35.

4 McQuay IM 672-8

Page 5

Mechanical Installation

4 . 0 0 " b a s e r a i l e x t e n s i o n

W i d t h

3 0 . 0 0 "

4 . 0 0 "

W i d t h o f c o i l s e c t i o n

W i d t h o f

f a n s e c t i o n

3 0 . 0 0 "

H e i g h t

5 4 "

1 2 "

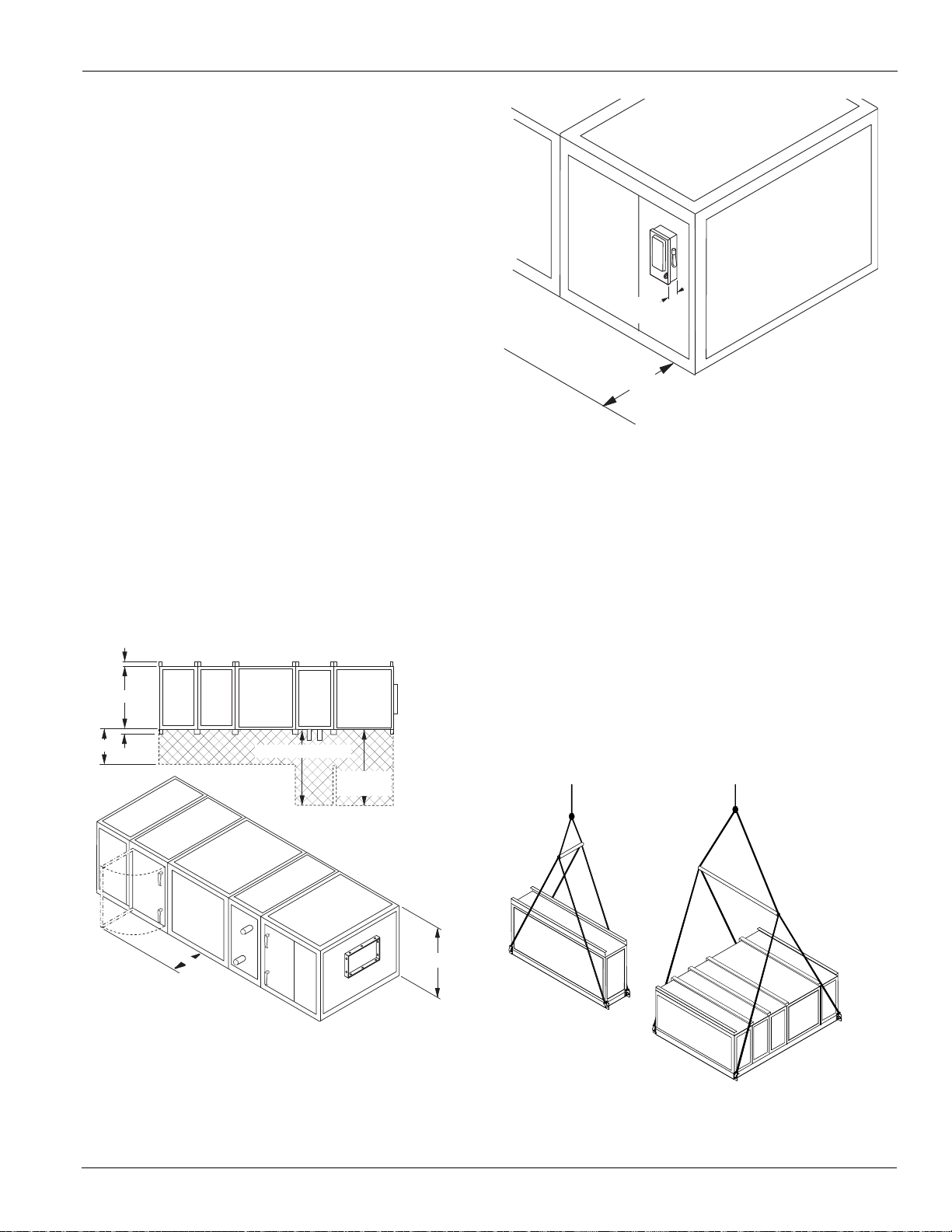

Mechanical Installation

Service Clearances

In addition to providing adequate space around the unit for

piping coils and drains, access to at least one side of the unit is

always required to allow for regular service and routine

maintenance, which includes filter replacement, drain pan

inspection and cleaning, fan bearing lubrication, and belt

adjustment. Provide sufficient space—at least equal to the

length of the coil—on the side of the unit for shaft removal and

coil removal. Space, at least equal to the length of the side coil,

is required for coil removal. Space, at least equal to the fin

height, is required for top coil removal. See Figure 1 for

servicing space requirements.

For routine maintenance purposes, access normally is obtained

through the access doors or by removing panels. Fan and filter

sections are always provided with a service door on one side of

the unit. If requested, doors can be provided on both sides of

the unit. Optional service doors are available for most section

types and are provided based on customer request.

If component replacement is required, the top panel also can

be removed. If necessary, the unit can be disassembled.

Maintain at least 54" of clearance in front of electrical power

devices (starters, VFDs, disconnect switches and combination

devices). Electrical power devices that are mounted on the side

of the unit typically are up to 12" deep (Figure 2). Fan sections

with multiple fans have motor control boxes up to 16" deep

when supplied with VFDs.

Figure 1: Servicing Space Requirements

Figure 2: Service Clearance for Electrical Power Devices

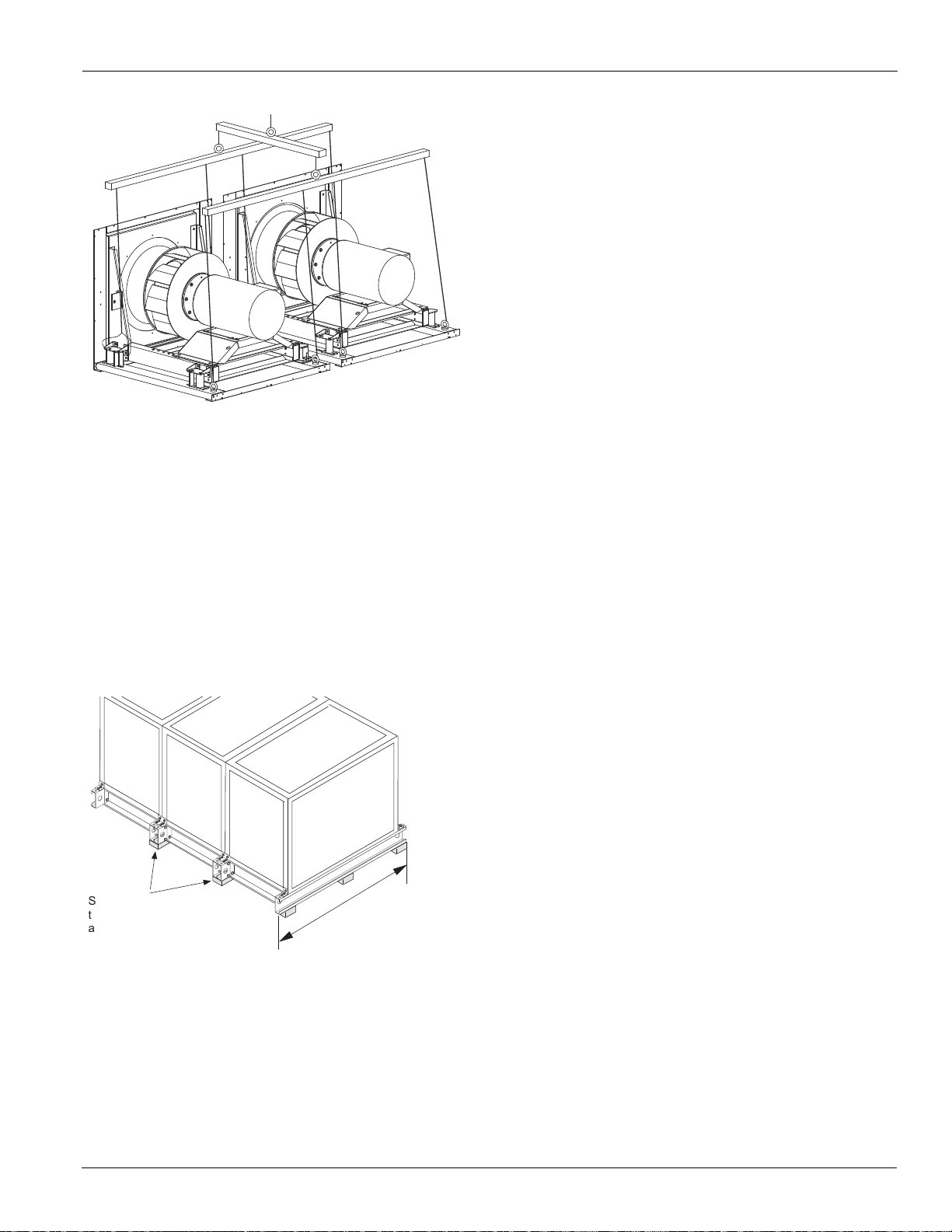

Rigging

Vision air handlers ship as separate sections, completely

assembled, or in modules of assembled sections. The unit

must be rigged as it ships from the factory. Do not rig units

after assembly. When a unit is provided with a

factory-installed base rail, it can be lifted using the 2" diameter

lifting holes located in the corners of each shipping section

(Figure 3). If a unit does not have a base rail, rig it using straps

or a sling. Fasten the strapping under the skid that ships with

the section (Figure 4).

To prevent damage to the unit cabinetry, use spreader bars.

Position spreader bars to prevent cables from rubbing the

frame or panels. Before hoisting into position, test lift for

stability and balance. Avoid twisting or uneven lifting of the

unit.

Figure 3: Units on Base Rails

McQuay IM 672-8 5

Page 6

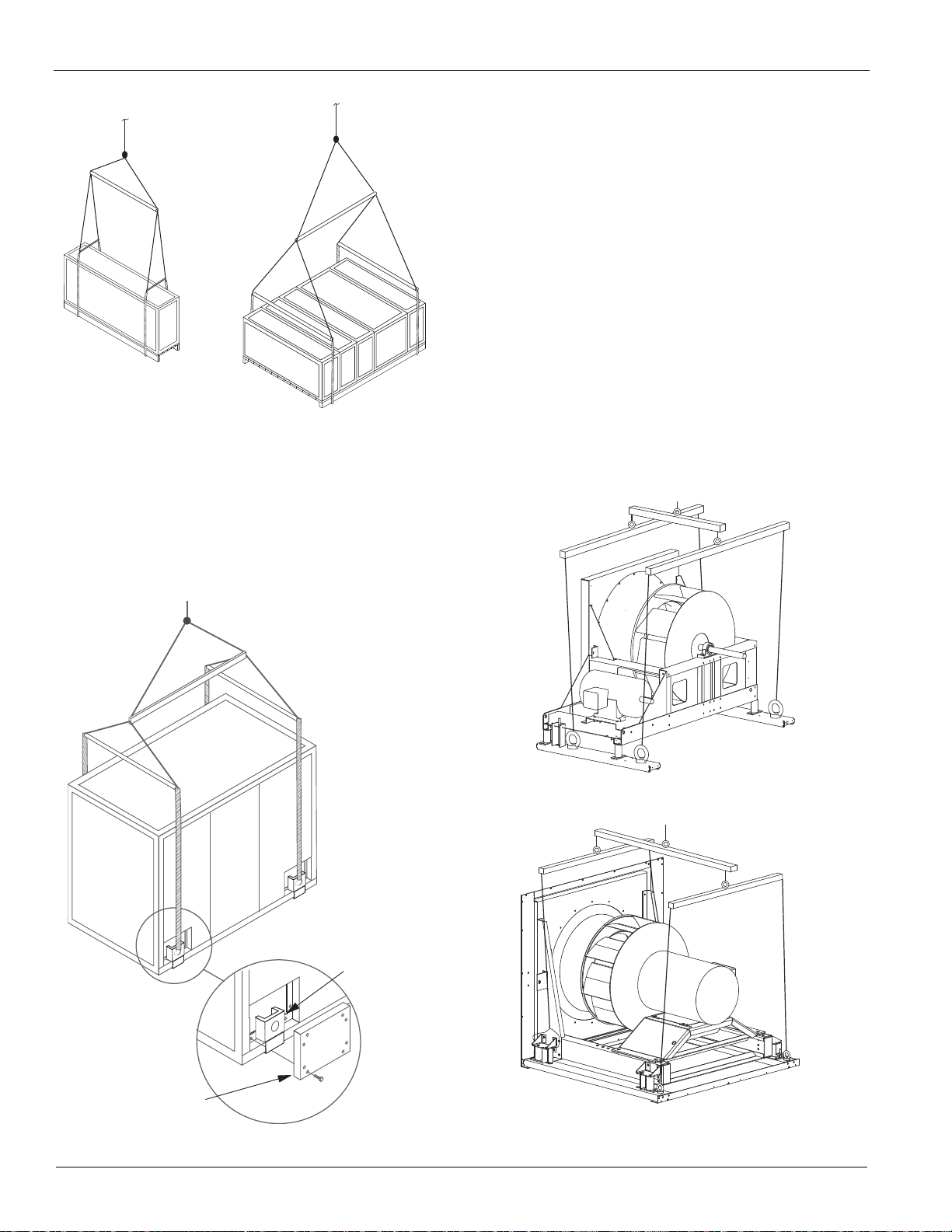

Mechanical Installation

R e m o v e

l i f t i n g

b r a c k e t s ( 4 )

I n s t a l l p a n e l s ( 4 )

Figure 4: Units on Skids

Fan sections greater than 108" wide that are stacked on another

section that are not Class II plenum fans are constructed with

internal fan support frames that have integral lifting brackets

(Figure 5). After the fan section is placed in position, remove

and discard the lifting brackets. Install the small panels

provided to complete the unit cabinet areas where the lifting

brackets were located.

Class II plenum fans that are stacked on another section may

be lifted using the methods shown in the following figures.

The shipping brackets must remain in place and be tight in

order to lift using this method. Figure 6 shows a belt-drive fan

with field supplied eye bolts that are screwed into factory

installed hex AVK fasteners in the main channels supporting

the fan. Figure 7 shows a direct-drive fan with field supplied

eye bolts on the motor end and straps around the spring

bracket on the inlet end. When factory installed hex AVK

fasteners are installed, they should be used for lifting. When

they are not installed, it is acceptable to lift from the shipping

brackets on the fan. Figure 8 shows dual fans being lifted in a

similar manner as the single direct-drive fan. An eight point

lift must be used for dual fans to make sure both fans are

supported properly and the cabinet structure does not become

overloaded along the center.

If the fan section is connected to another section such as a

plenum or access section, then do NOT attempt to lift both

sections using just the fan section. The other section(s) must

be supported separately using straps.

Figure 6: Belt-Drive Class II Plenum Fan Stacked Unit

Figure 5: Large Fan Sections Stacked on Top of a Lower

Section

Figure 7: Direct-Drive Class II Plenum Fan Stacked Unit

6 McQuay IM 672-8

Page 7

Mechanical Installation

S h i m t o p r e v e n t

d i s t o r t i o n i f w i d t h

i s o v e r 1 0 8 "

S h i m s e c t i o n s u n t i l

t h e y a r e s t r a i g h t

a n d l e v e l

Figure 8: Direct-Drive Class II Dual Plenum Fan Stacked

Unit

Unit Leveling

Place the equipment on a flat and level surface. Where the

surface irregularities could cause the equipment to distort, use

a shim so the base of the unit is a straight line. Uneven or

distorted sections cause misfit or binding of the doors and

panels and improper draining of drain pans.

Units that are over 108" wide must rest on a flat surface for the

entire width of the base rails or must be shimmed at one or

more points along the length of the rails to prevent distortion

or sagging of the support rails (Figure 9).

Figure 9: Leveling the Unit

Assembling Sections

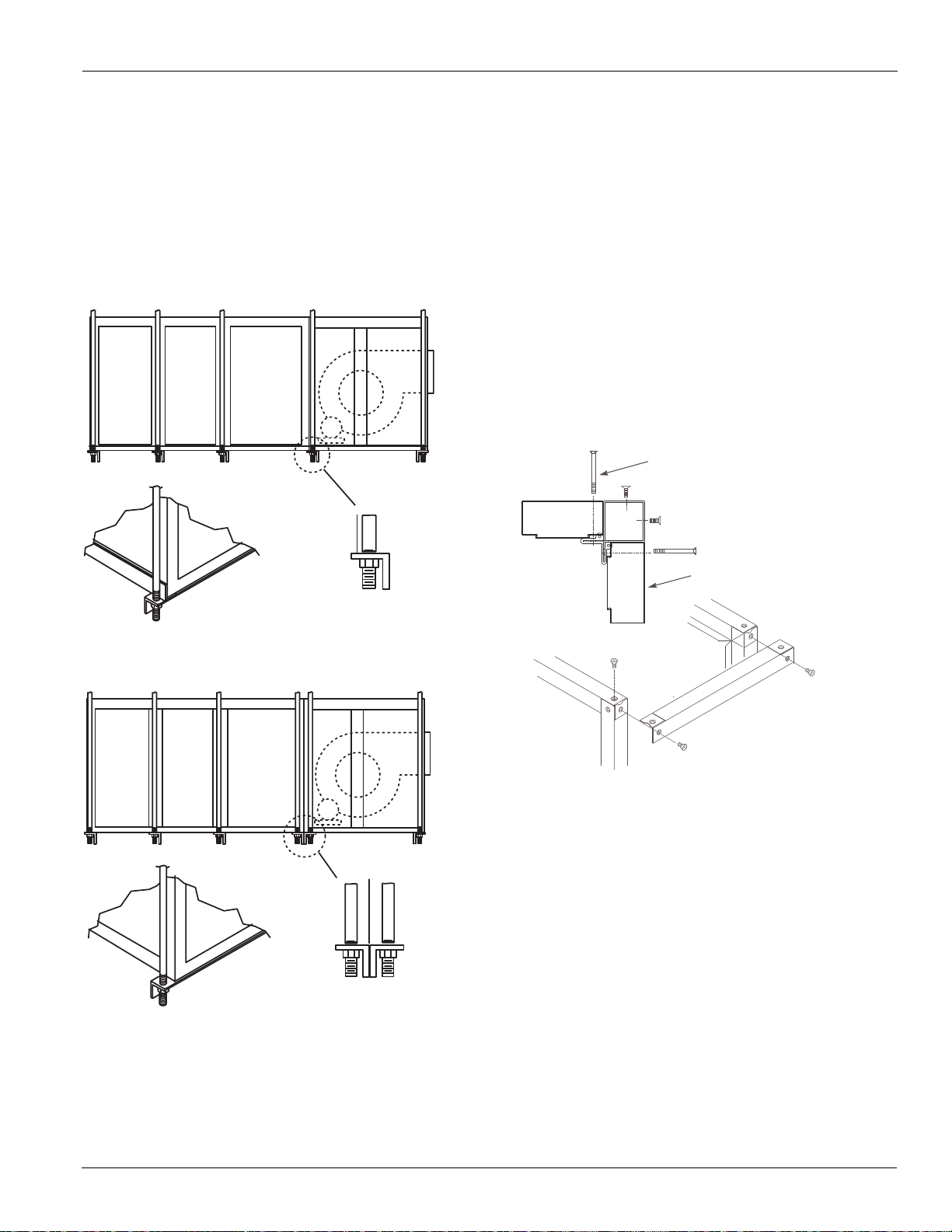

External Section-to-Section Mounting

Vision air handling units can ship fully assembled or as

separate shipping sections. Rig units that require field

assembly of shipping sections into position first. Shipping

sections are provided with a connection splice joint attached

on the leaving air side of the shipping section. The splice joint

is insulated and provides an air-tight seal between two sections

once they are assembled together. If the splice joint was bent

during shipping or rigging, restore it to its original position.

(Figure 19, page 10).

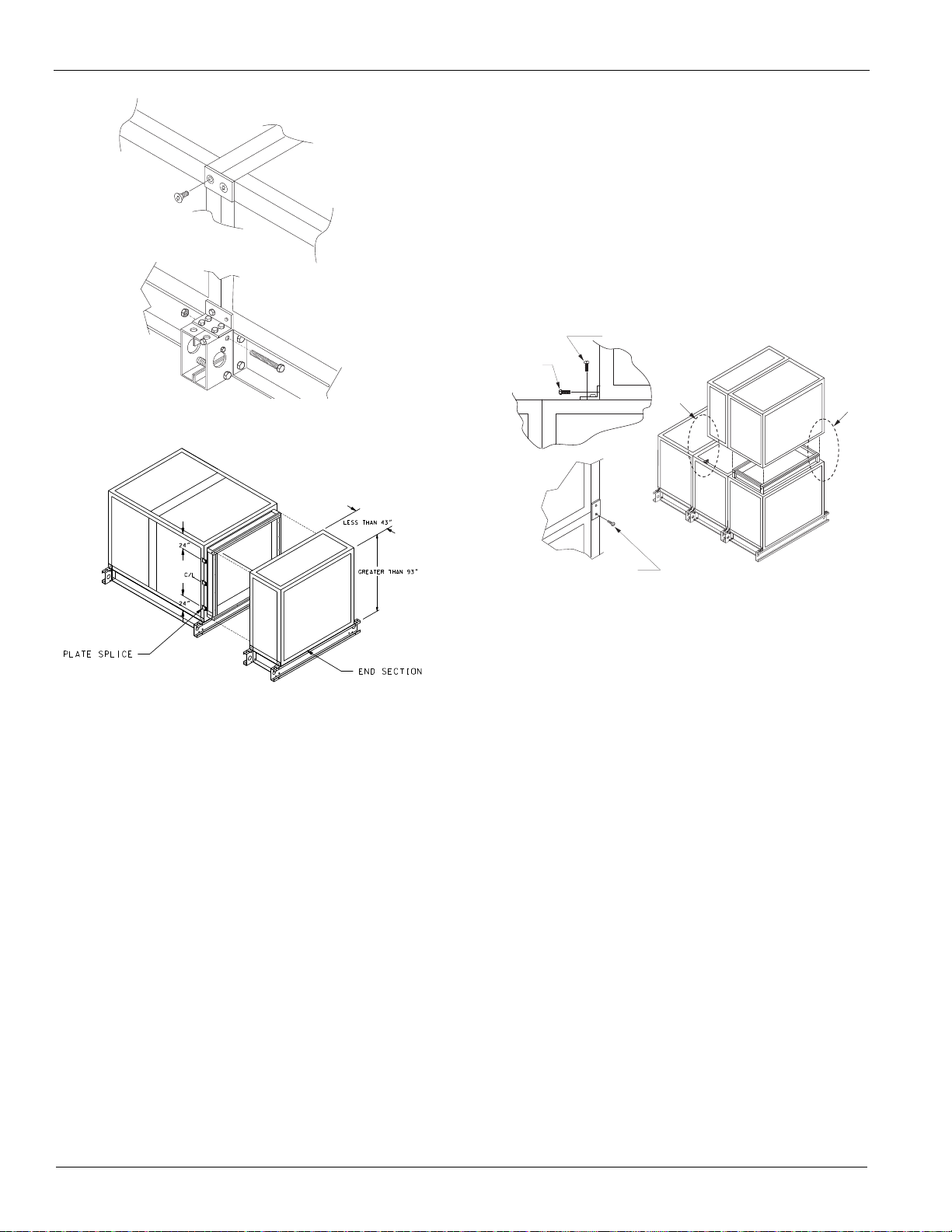

Horizontal Airflow Section Mounting

1 Rig the unit into position and lineup shipping sections in

the direction of air flow. Pull sections together to fasten.

Use a furniture clamp or straps and a ratchet to help pull the

sections together securely (Figure 10).

2 If the unit has a factory-installed base rail, first fasten base

rails together using the 3/8"-16 × 5" bolts located in the

splice kit provided with the unit.

a To fasten two shipping sections together, four bolts are

needed (two on each side of the unit). The bolts are run

from one base rail into the other and fastened with a nut.

Complete each section bottom and top before attaching

additional sections.

3 If no base rail is provided, fasten the unit in the same

manner on the bottom and top frame channels.

4 Once the sections are positioned together, remove the

fastener in each of the channel corners (on the mating edges

in the channel piece).

5 Place a flat section joining plate (found in the splice kit)

over the two coned holes in the channels, so that the plate

spans the two sections.

6 Replace the fasteners in their original position, through the

joining plate.

7 For certain Vision Plus units, use the provided section

joining plates to fasten sections together. Space them as

shown in Figure 11. Using the provided ¼"-14 x 1" self

tapping screws, drill screw the joining plates into the frame

channel on each section, keeping unit sections tight

together. Follow instruction drawing included in the

assembly kit.

McQuay IM 672-8 7

Page 8

Mechanical Installation

T o p

B o t t o m w i t h b a s e r a i l

R e p l a c e m e n t s c r e w

. 3 1 2 - 1 8

x 1 0 0 b o l t

. 2 5 x 1 0 0 d r i l l s c r e w

A

B

B

A

Figure 10: Horizontal Joining Sections

Figure 11: Frame Channel Stiffener Plates (Vision Plus

Units Only)

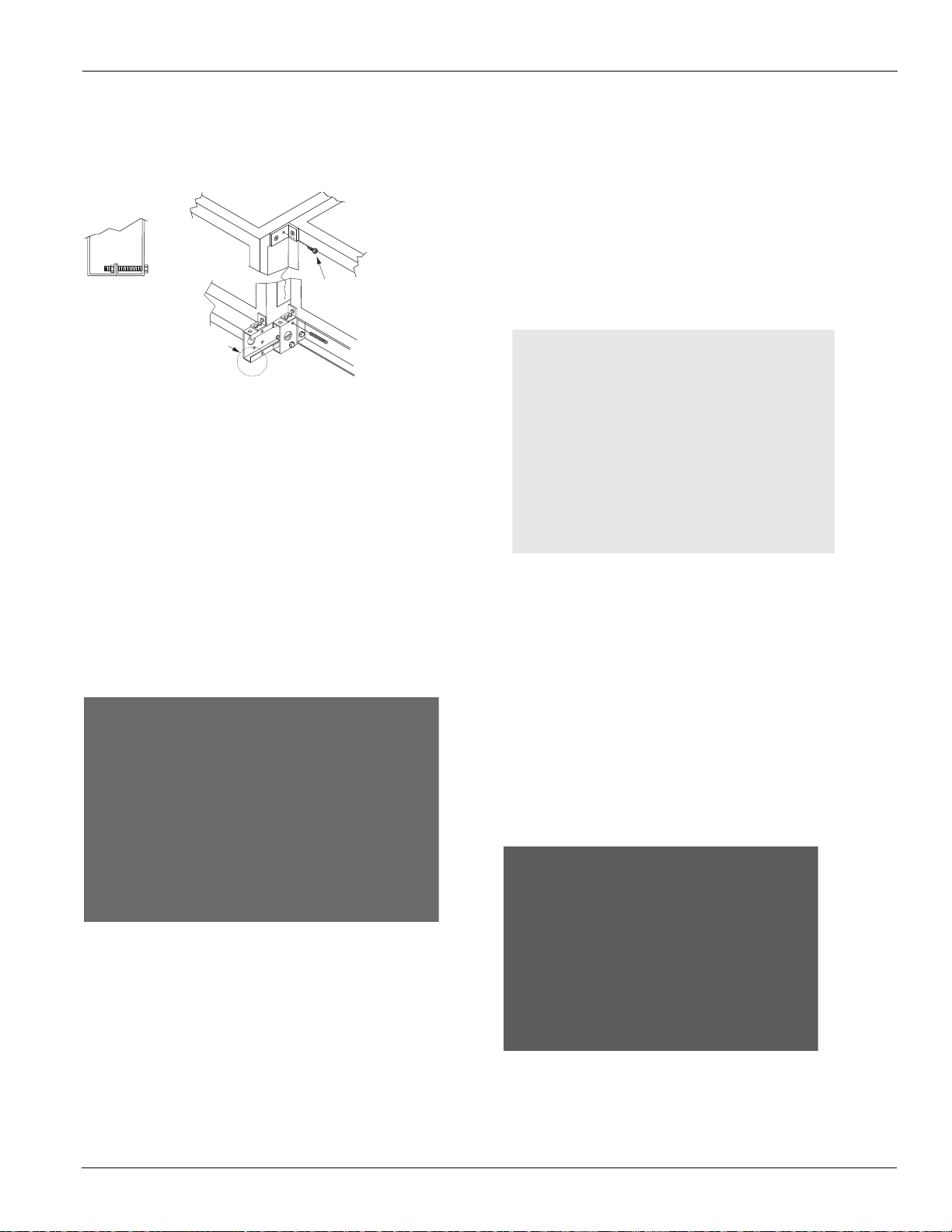

3 Cover the coned holes with a flat joining plate and replace

the flat head fasteners in the holes to secure the joining

plate to both sections (Figure 12).

4 When one section is deeper than the other, secure the two

sections using an L-shaped joining plate. To secure the

L-shaped bracket, remove the flat head fastener from the

corner, position the bracket over the hole, and replace the

flathead fastener with a 5/16"-18 × 1" bolt. Once the bolt is

in place, secure the bracket to the adjoining section with a

1/4 × 1" drill screw. Repeat the same procedure on both

corners of the unit (Figure 12).

Figure 12: Vertical/I nv erte d J oin in g Sections

Vertical Inverted Airflow Section Mounting

For vertical or inverted arrangements, before lifting any top

mounting sections into place, rig into place and fasten together

the bottom tier of sections. Once bottom level sections are in

place and secured, lift stacked components and fasten using

the following procedure:

Note: See Face and Bypass Section Mounting‚ page 13 for the

exception to this procedure.

1 The vertical/inverted section has a splice joint extending

out the top of the bottom joining section. Lower the section

that is to be positioned over the opening over the splice

joint to seal the connection between the two sections.

2 The two sections are fastened together at the four bottom

corners of the mating edge. T o fasten the corners located on

the end of the unit (where bottom section and top section

walls are flush with each other), remove the flat head

fasteners in the corners of both sections.

Extended Coil Section Mounting

The extended coil section is 6" wider than all other sections of

the same unit size. The extension is always located on the coil

connection side of the unit. Because the extended coil section

is wider than other sections, it always ships as a separate

shipping section, and must be joined to other sections in the

field. To join an extended coil section to other components,

first follow the Horizontal Airflow Section Mounting‚ page 7

steps to secure the opposite connection side. To fasten the

connection side, use the following procedure:

1 If the unit has a factory-installed base rail, the extended coil

section base rail is also 6" wider than the adjoining base

rail. Extended coil section base rails on the connection side

are fastened together using the 3/8"-16 by 3" bolts located

in splice kit provided with the unit (Figure 13).

2 If no base rail is provided, the section is fastened in the

same manner on the bottom and top. Once the sections are

positioned together, remove the fastener in the corner of the

channel piece of the section mating to the extended coil

section (Figure 13).

3 Place an L-shaped section joining plate (located in the

splice kit) over the coned hole in the channel.

4 Replace the flat head fastener originally used in the corner

with a 5/16"-18 1" bolt and fasten it through the L-shaped

joining plate.

8 McQuay IM 672-8

Page 9

Mechanical Installation

V i e w A

B o t t o m

w i t h b a s e r a i l

A

T o p

( 2 ) 1 / 4 x 1

D r i l l S c r e w s

5 Position the L-shaped joining plate so it butts up against the

extended coil section frame channel. To secure the plate to

the extended coil section, run two 1/4" × 1" drill screws

through the joining plate and into the frame channel.

Figure 13: Extended Coil Section Joining

Side-by-Side Heatwheel Section Joining

The side-by-side heatwheel will have two individual sections

parallel in the direction of airflow to be attached to either side.

Each section will attach to the heatwheel section and then to

the other parallel section.

1 Rig the unit into position and line shipping sections up in

direction of air flow. Sections must be pulled together to

fasten using a furniture clamp or straps.

a If the heatwheel section width is greater than 143”, then

rig the section into position using the 2 removable

lifting channels. After section is properly placed,

remove cotter pin and bolts from lifting channel and

discard as seen in Figure 14.

Figure 14: Cotter Pin and Bolt Detail

3 If the unit has a factory installed base rail, fasten the base

rails together using the 3/8”-16 x 5” bolts located in the

splice kit provided with the unit.

a To fasten two shipping sections together, two bolts are

required on the one side. The bolts are run from one

base rail into the other and fastened with a nut.

Complete each section bottom and top before attaching

additional sections.

4 Assemble the center base plates as show in Figure 15,

leaving a 5/16” space between each plate to slide onto

section base channels to center point of section width.

Figure 15: Base Plate Detail

5 Once the sections are positioned together, remove the

fastener in each of the channel corners (on the mating edges

in the channel piece).

6 Place a flat section joining plate (found in the splice kit)

over the two coned holes in the channels, so the plate spans

the two sections.

7 7 Replace the fasteners in their original position, through

the joining plate.

8 8 Assemble the next section parallel to the assembled

section by following steps 1 – 7 above.

9 9 Using the 3/8”-16 x 1” bolts provided, fasten the two

parallel sections’ bases together as seen in Figure 16.

Figure 16: Base Section Detail

If included, remove center base plates that are attached to

2

the base channels and save for step 4.

McQuay IM 672-8 9

Page 10

Mechanical Installation

V i e w A

A

S p l i c e C o l l a r

m u s t b e a l i g n e d

t o s e a l t o g a s k e t .

10 Using appropriate safety equipment if necessary, remove

the fastener in each of the channel corners on the top

between the two parallel sections and discard.

11 Use the 2 x 2 holed splice plate with 2 x 5/16”-18 x 1”

screws and 2 x ¼” drill screws. The 2 x 5/16”-18 x 1”

screws will go into the frame channel holes and the 2 x ¼”

drill screws will go into the heatwheel frame channel as

show in Figure 17.

Figure 17: Frame Channel Detail

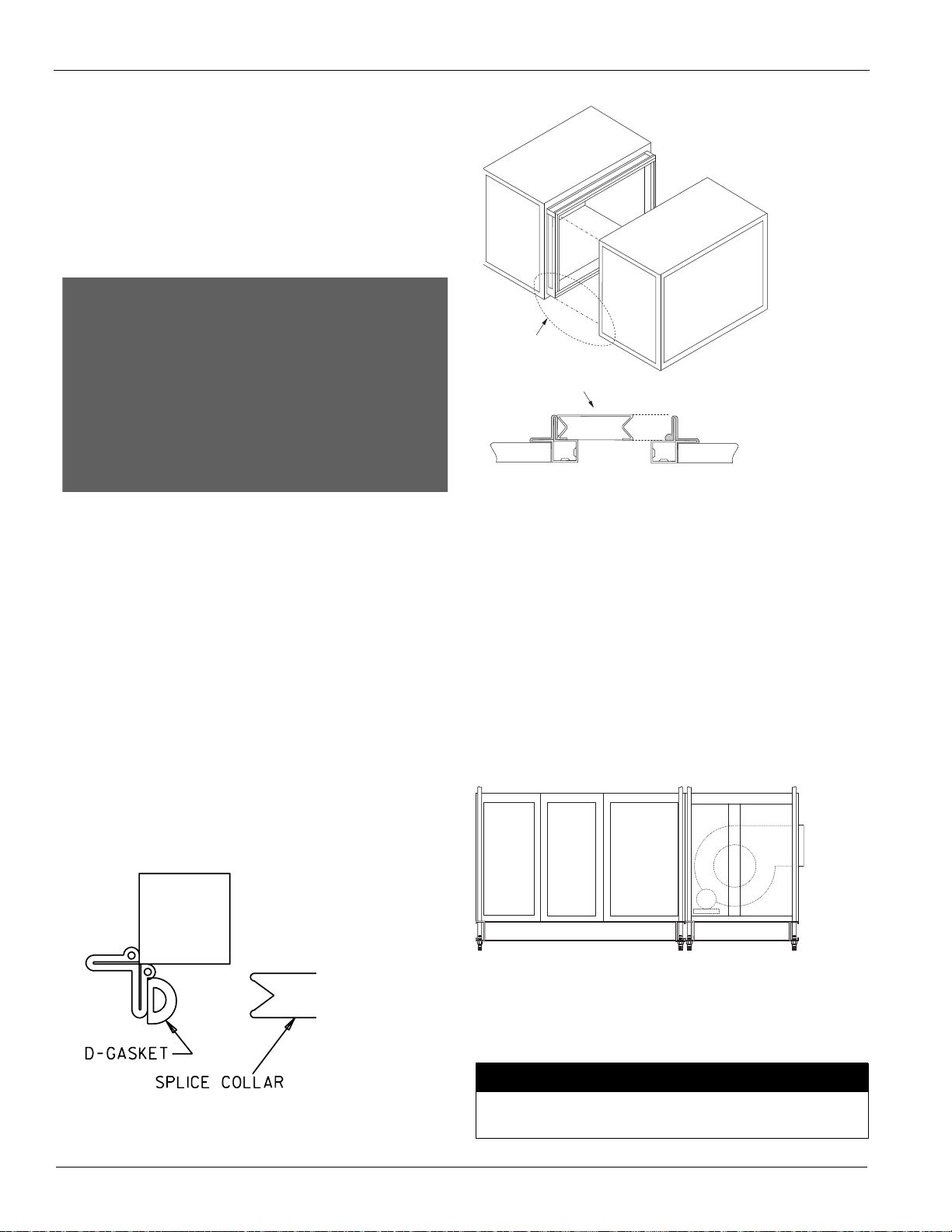

Internal Section-to-Section Mounting

If desired, shipping sections can be fastened together

internally. To fasten internally, run field-provided #10 sheet

metal screws or drill screws (4" long maximum) through the

interior frame channel of one unit into the splice joint of the

neighboring section.

The section-to-section splice joint is always provided on the

leaving air side of a shipping section and seals against the

frame channel on the entering-air side of the adjoining section.

Align the splice joint to seat into the mating gasket to provide

an air seal. If the splice joint was bent during shipping or

rigging, restore it to its original position (Figure 19).

Figure 19: Internal Fastening

Ceiling Hung

When a unit is ceiling hung, support it with a base rail, angle iron,

or channel. The Vision air handler is not designed to be suspended

from the top of the unit. Before hanging, rig and completely

assemble the unit. See Assembling Sections‚ page 7.

Ceiling Hung Using Base Rail

The optional base rail provided by the factory has 5/8" diameter

holes in each corner to run hanger rods through. To properly

support the unit and maintain unit integrity, support each

shipping section with hanger rods in each corner (Figure 20).

For Vision Plus units, ensure that the D-gasket is attached to

Figure 20: Ceiling Suspended with Base Rail

the entering air side frame channel (Figure 18). If it has

dislodged during shipping, restore to original location.

Figure 18: D-Gasket Placement Detail (Vision Plus Units

only)

Ceiling Hung Using Angle Iron Channel

Install field-provided angle iron or channels per SMACNA

guidelines. When a unit is unitized (ships in one piece), channel

support each component under the unit width (Figure 21).

10 McQuay IM 672-8

The supporting angle iron must fully support the 2" frame

channel at each section joint.

NOTE

Page 11

Mechanical Installation

Remove panel

to remove frame

Remove any

panel screws that

engage frame

When a unit is sectionalized (ships in multiple sections), channel

support each component under the unit width and provide support

under the full length of the unit base (Figure 22). Locate hanger

rods so they do not interfere with access into the unit.

Ceiling suspension using the unit base rails is limited to

unit cabinet widths less than 108". Support units with

cabinets 108" wide and greater with structural members

designed to support the unit at the ends and at intermediate

points along the base rails.

Figure 21: Ceiling Suspended w/o Base Rail—Unitized

Construction

Panels, Frame Channels, and Doors

Panel Removal

To remove a side or top panel, remove the flat head Torx 30

fasteners along the sides of the panel. Lift off the panel after

removing all fasteners.

Frame Channel Removal

Frame channels that run the length of the unit along the top can

be removed to allow access to both the side and top of the unit.

To remove the frame channel, first remove the side panel(s).

Once the side panel is off, remove the flat head Torx 30

fasteners in the corner of the frame channels. Then pull the

frame channel out the side. Remove any panel screws that are

within one inch of the of the frame since they are engaged into

the gasketed flange of the frame (Figure 23).

Figure 23: Removing Panel Screws

Figure 22: Ceiling Suspended w/o Base Rail—Modular

Construction

McQuay IM 672-8 11

Page 12

Mechanical Installation

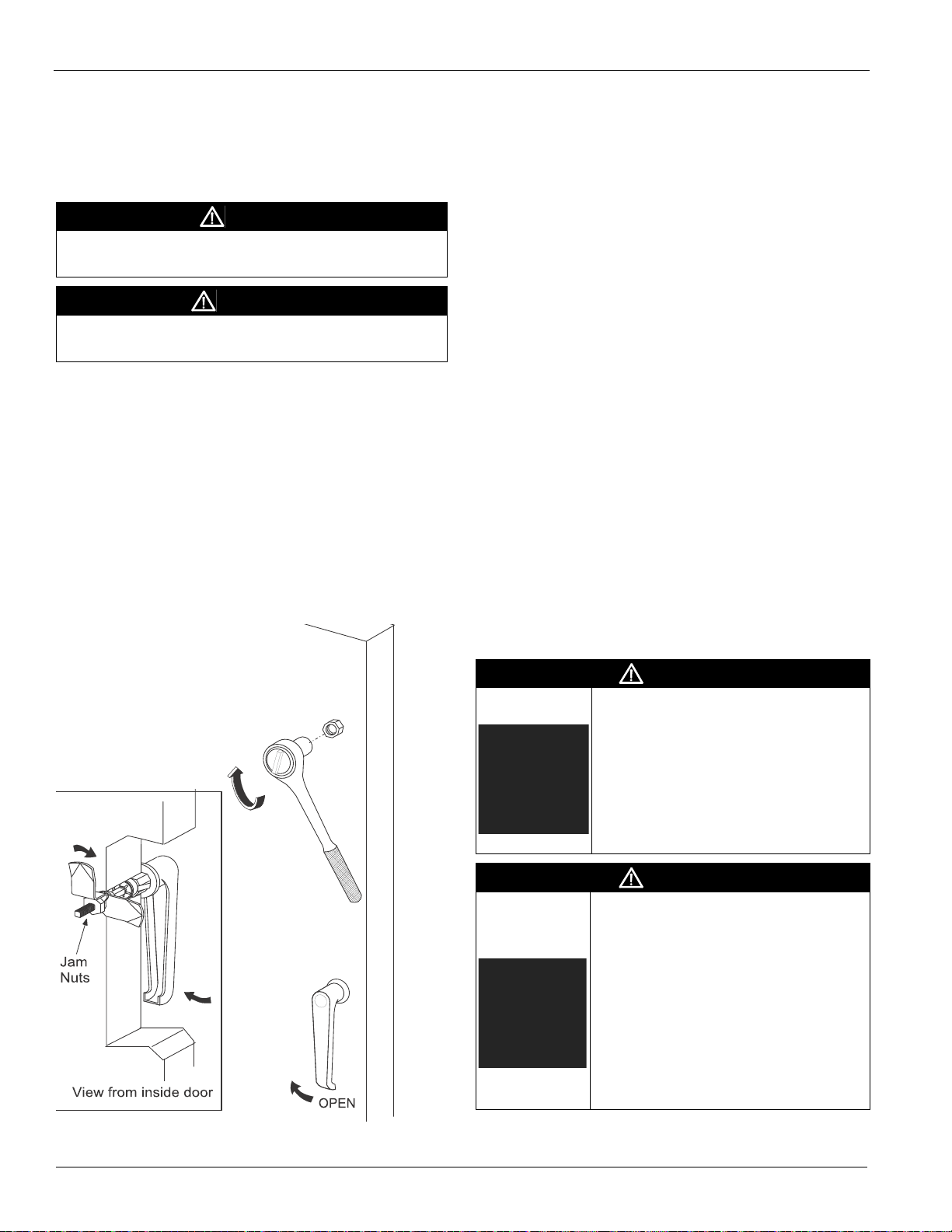

Fan Section Doors

Note: Opening fan section doors requires using a 1/2" socket

wrench (Figure 24), which satisfies ANSI standards and

other codes that require the “use of tools” to access

compartments containing moving parts or electrical

wiring.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard.

Avoid contact with them.

ATTENTION

Les bords tranchants et les surfaces des bobines sont un

risque de blessure. Ne les touchez pas.

1

Insert 1/2" socket and rotate 1/4 turn clockwise as shown in

Figure 24. If the handle is on the left side of the door, rotate

1/4 turn counterclockwise.

2 Rotate the door handle 1/4 turn clockwise and then 1/4 turn

counterclockwise to release any internal pressure or

vacuum and open the door. If the handle is on the left side

of the door, rotate the door handle 1/4 turn

counterclockwise and then 1/4 turn clockwise.

3 T o prevent air leakage, tighten the door panels by adjusting

the jam nuts.

Figure 24: Opening Fan Section Door

Injected-Foam Insulated Panels

Vision air handlers are furnished with double-wall, injectedfoam insulated panels. Foam panels are stronger, more rigid,

and lighter than panels with fiberglass insulation. The

insulation R-value is improved to 13. However, foam

insulation can burn when exposed to flame or other ignition

sources and release toxic fumes. Take care in cutting and

sealing all field-cut openings in these panels.

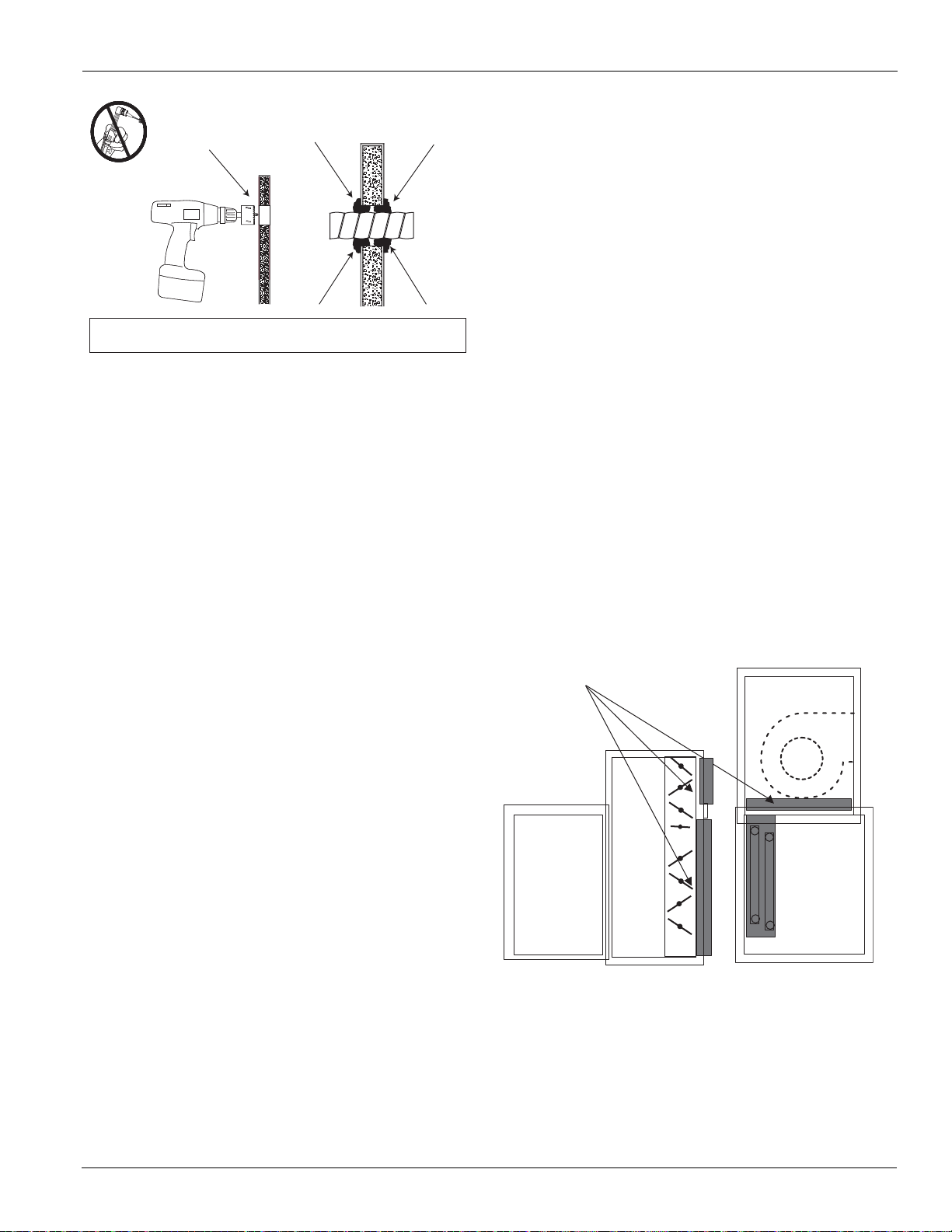

Panel Cutting Procedure

1 Determine the number and location of holes required for

electrical conduit, piping, and control wiring as follows

(also refer to Figure 25):

a Check that adequate space is available inside the unit

for conduit or pipe routing.

b Do not locate holes in a panel that provides access to

key maintenance components such as filters and fan

assemblies.

c Do not locate where the conduit or piping blocks

airflow or obstructs hinged access doors.

2 Once a proper location is determined, drill a small pilot

hole completely through the panel. Then use a sharp hole

saw or a saber saw and cut from each side of the panel.

3 Seal the double-wall panel on each side with an industrial/

commercial grade silicone sealant or duct seal compound.

It is extremely important to seal each panel hole or

penetration securely so that it is airtight, watertight, and

that there is no exposed foam insulation.

WARNING

Flame and smoke can cause eq uipment

damage, severe personal injury, or

death.

Before operating unit, seal all piping and

wiring holes on both inner and outer panels

with an industrial grade silicone sealant or

duct seal compound. Do not use a cutting

torch or expose panel to fire. Panel

damage can occur.

WARNING

La fumée et les flammes peuvent

endommager le matériel et causesr des

blessures graves ou la mort.

Avant d’utiliser le dispositif, obturer tous les

trous de passage de tubulures et de fils

ménagés dans les panneaux intérieurs et

extérieurs au moyen d’une pâte à base de

silicone ou d’un mastic d’étanchéite â

conduits de qualité industrielle.

Ne pas se servir d’un chalumeau coupeur ni

exposer les pannequx à une flamme nue

pour ne pas risquer de les endommager.

12 McQuay IM 672-8

Page 13

Mechanical Installation

Cut hole from both sides of panel

Seal completely with silicone

sealant or duct seal compound

Prop 65—Substances in fuel or from fuel combustion can cause personal injury or death,

and are known to the State of California to cause cancer, birth defects or other reproductive harm.

Figure 25: Cutting/Sealing Injected-Fo a m Insulated panels

Field Mounting Junction Boxes and Other Components

For field mounting 4" × 4" or smaller junction boxes to the

standard panel exterior, use a minimum quantity of four, 3/16"

diameter pop rivets. Do NOT use self-tapping drill screws.

They will not tighten nor secure properly and panel

damage can occur.

If larger, heavier components require mounting on unit panels,

use through-bolts with flat washers through both outer and

inner panels. To maintain panel integrity, seal both ends with

an industrial/commercial grade silicone sealant or duct seal

compound.

The unit frame channel is another excellent location for

securing heavier components; self-tapping screws are not

acceptable. Ensure that the location permits the full operation

of all access doors and panels and does not interfere with other

vital components.

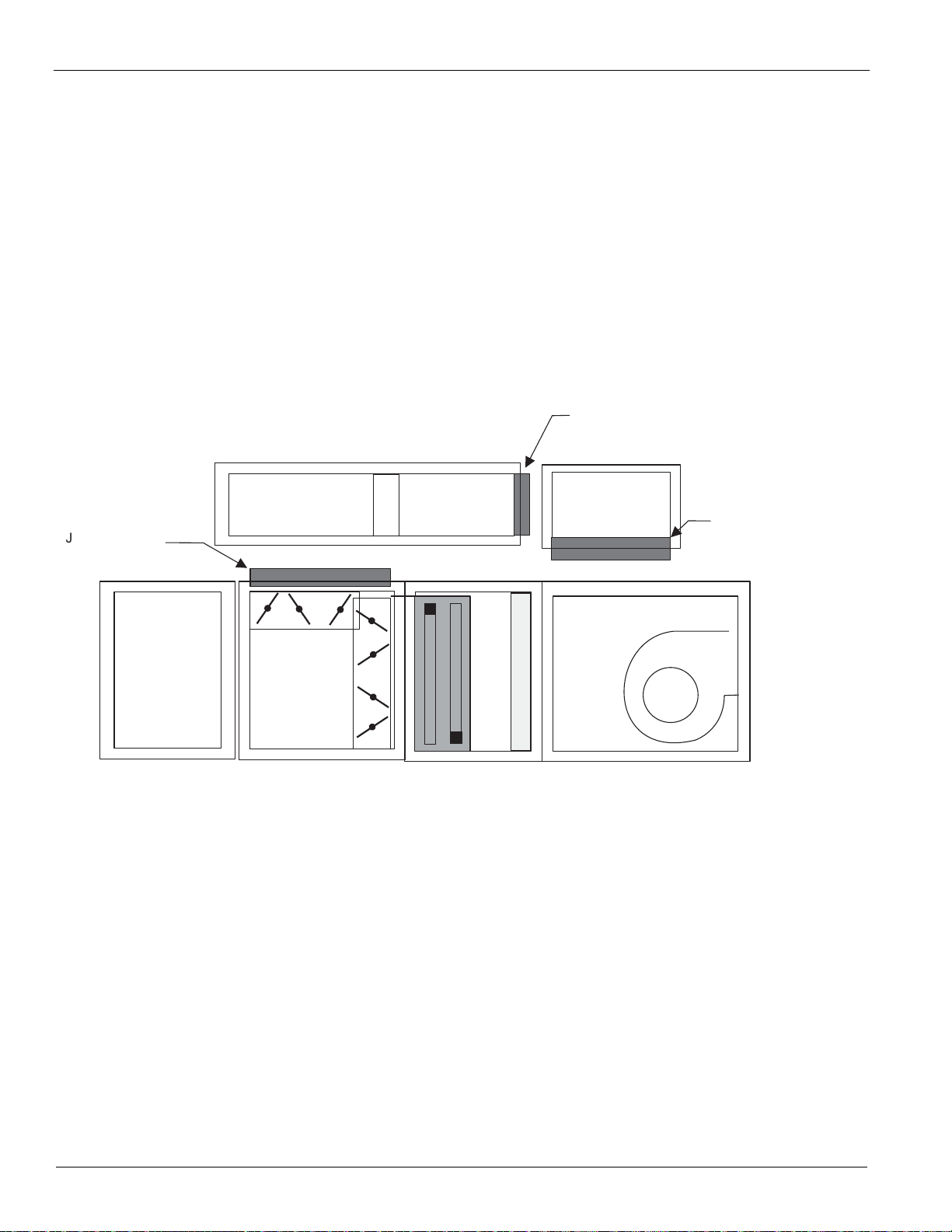

Bypass Into a Vertical Fan Section

Vertical coil sections and the top mounted fan section always

ship separately and must be mounted together at the job site.

The vertical coil section and the bypass duct each has a joining

collar mounted on the leaving air side of the section and duct,

respectively (Figure 26). The mounting collar fits into the side

(bypass) and bottom (vertical coil section) openings in the fan

section. To correctly position the collars in the fan openings,

assemble the fan and coil section first. Use the steps below for

assembly.

1 Place the vertical coil section in position. If an access

section is positioned downstream from the coil section and

not already assembled to the coil section, secure the two

sections together.

2 Lift the fan section on top of the vertical coil section, taking

care to line up the joining collar in the bottom of the fan

section.

3 For sizes 003 to 035, the bypass duct is integral to the unit

construction and does not requ ire attachment to the bypass

section. For sizes 040 to 090, position and assemble the

bypass duct to the bypass section before joining to the fan.

4 Once the fan is positioned on top of the vertical coil section

and the bypass duct and bypass section are assembled,

position the two assemblies and line up the joining collars

with the openings in the fan and vertical coil section.

5 Once the sections are lined up and in position, secure the

unit together by fastening joining plates to the unit.

Figure 26: Assembly of Fan Coil Sections

Joining

collar

Face and Bypass Section Mounting

Internal face and bypass, and external face and bypass for sizes

003 to 035 are mounted together using the instructions for

horizontal components and do not require additional

instruction.

For all size units that bypass directly into a vertical fan section

and for sizes 040 to 090 with external face and bypass, use the

following instructions.

McQuay IM 672-8 13

Page 14

Mechanical Installation

J o i n i n g C o l l a r

J o i n i n g C o l l a r

J o i n i n g C o l l a r

External Face and Bypass Duct Assembly (Sizes 040 to 090)

When unit sizes 040 to 090 are ordered with external face and

bypass, the bypass duct ships separately and must be attached

to the unit in the field. The joining of the bypass duct to the unit

must be done after the unit is assembled. Also, if the bypass

duct is over 90" long, the duct does not ship in one piece and

must be field assembled. The field assembly of the bypass duct

to the unit requires the following steps (also refer to Figure 27).

1 Position the unit shipping sections together and assemble in

the equipment room.

2 After the unit is assembled, lift the duct into position over

the unit. Joining collars are shipped factory assembled to

the unit and duct. There is a joining collar located in the top

Figure 27: Assembly of Bypass Duct to Unit

of the bypass opening and in the leaving air side of the

bypass duct. These joining collars are used to provide air

seals. Line up the duct with the top openings in the unit.

3 If the bypass duct is longer than 90", the duct ships in more

than one piece and must be field assembled. Place the piece

of duct that has the joining collar on the bottom on top of

the unit first. Once it is in place, position the other piece of

duct. Take care to fit the splice collar into the first piece of

duct and then lower the other end into the bypass opening.

4 Once the duct is positioned correctly, fasten the duct pieces

together with the joining plate provided. To do this, remove

the fasteners in the corners of the duct assemblies, place the

plate over the holes in the corners, and then replace the

fasteners (Figure 10, page 8).

14 McQuay IM 672-8

Page 15

Mechanical Installation

Multizone Assembly

The multizone section may ship completely assembled or it

may ship in numerous pieces. Whether the section ships in a

single piece or multiple pieces depends on customer

requirements and the unit size. When a multizone section is

over 90" high or 90" wide, split it into sections for shipping.

The unit may ship in 1, 2, 3, 4, or 5 separate pieces. Typically,

the multizone damper assembly ships separately (see

Multizone Damper Assembly in the next column and

Figure 29) and must be attached at the job site. Attach the

damper after the other components are assembled. Use the

instructions below for assembling the multizone section (also

refer to Figure 28).

1 If the diffuser and the cold deck section ship separately,

join them together first. The joining collar mounted in the

diffuser fits into the entering air side of the coil section.

Line up the two sections and fasten together.

2 Once the diffuser and cold deck sections are joined, lift the

hot deck and bypass sections in place on top of the diffuser/

cold deck section. If possible, assemble the hot deck and

bypass section (if there is one) together before lifting on

top. There always is a joining collar in the diffuser. The

joining collar provides the seal between the sections joints.

It is important to line up and fit the collar in the hot deck

and bypass section. For vertical applications, the cold deck

also has a joining collar in the discharge opening. This

collar fits in the bottom of the vertical bypass section.

3 After the components in the multizone are fitted together,

fasten the joining plates to the corners in the unit exterior.

4 If a damper was ordered, assemble it to the section (see

Multizone Damper Assembly in the next column and

Figure 29).

Note: Verify that the joining collars are aligned to seat into the

gasket. Straighten any collars distorted from shipping or

from rigging.

Multizone Damper Assembly

When a multizone unit is ordered with dampers, depending on

the multizone configuration and size, the damper assembly

may ship separately (all horizontal and units with a total height

over 90").

When the dampers are not factory assembled to the unit, they

ship to the job site on a skid. An assembly kit with screws and

an instruction drawing are included with the damper for field

assembly to the unit.

To assemble:

1 First remove the side plate that encloses insulation from

both sides of the damper assembly.

2 Lift the damper assembly into position (Figure 29).

3 Fasten the assembly to the frame channels within the

multizone openings.

4 Use caulking to seal up the areas around the unit frame

channel to prevent any air leakage.

5 After caulking, put the side plates back in place and secure.

Damper shaft extensions are provided on both ends of the

damper assembly for actuation. The dampers are linked

together by a linkage bar on both ends of the damper. The

linkage bar is cut at the time of installation to divide the

damper into the required number of zones (refer to Multizone

Damper Adjustment‚ page 17).

McQuay IM 672-8 15

Page 16

Mechanical Installation

S e a l w i t h c a u l k

o n b o t h s i d e s .

A i r f l o w

R i g h t h a n d c o i l

R e m o v e a s s e m b l y

i n s u l a t i o n p a n e l

c o v e r f r o m d a m p e r

t o a l l o w c a u l k i n g .

D r i l l s c r e w i n t o

c a b i n e t f r a m e

w i t h # 1 0 A B x . 5 0

d r i l l s c r e w .

1 / 4 A B x . 5 0

O p e n d a m p e r b l a d e s

t o a l l o w f a s t e n i n g .

I f a i r f l o w b a l a n c e p l a t e s

a r e p r e s e n t , t h e n i n s t a l l

d a m p e r s s o t h a t t h e b a l a n c e

p l a t e s a r e o n t h e b o t t o m

o f e a c h z o n e .

D a m p e r b l a d e s

b r o k e n o u t t o

s h o w a i r f l o w

b a l a n c e p l a t e s

b e h i n d t h e m .

Figure 28: Multizone Sections Assembly

Joining

collars

Cooling coilCooling coilDiffuser

Zone

damper

assembly

Upper unit—heating

(and optional bypass)

Figure 29: Multizone Damper Assembly

16 McQuay IM 672-8

Page 17

Mechanical Installation

D u c t w o r k

D u c t c l i p

Z o n e d i v i d e r

4 5 °

4 5 °

C o n n . l i n k

B e l l a r m

Z o n e d a m p e r l i n k a g e

4 5 °

4 5 °

B e l l a r m

I n s t a l l a t i o n m o d i f i c a t i o n f o r m u l t i p l e z o n e s

To divide the damper section into multiple zones, cut and remove sufficient

connecting link to allow adjacent zones to operate independently.

Note: The damper blades on two-deck dampers seal through several degrees

of shaft rotation.The damper blades can rot ate 360° and do not engage a st op.

The hot deck blades are mounted at a 90° to the cold deck blades. Before

installing the zone duct, set up linkages and dampers and adjust. If adjustment

is required and access to the blades is restricted, observe the cold deck blade

position by removing the cabinet panel on the coil section.

Duct Connections

Use flexible connectors on the outlet and inlet duct

connections of all units. Each zone divider has a W-shaped

duct clip. Insert ductwork into this clip (Figure 30).

Figure 30: Duct Connectors

Note: Before connecting to ductwork, refer to Multizone

Damper Adjustment below.

Multizone Damper Adjustment

The installer must clear the damper assemblies of construction

dirt and debris. These materials result in higher torque

requirements and may bend or damage damper components.

Before you begin:

1 Verify that dampers are square and operating smoothly

before ducting.

2 Install duct access panels on the downstream damper for

inspection and maintenance.

Figure 31: Bell Arms at 45° Angle to Vertical Center

If multizone dampers do not close properly, adjust the blades

as follows:

1 Loosen set screws in bell arms for all zones.

2 Close all cold deck dampers tightly.

3 Move bell arms so they are at a 45° angle to the vertical

center when viewing the zone dampers from the cold deck

end of the damper section (Figure 31).

a Two-deck zone dampers—The cold deck closes when

the bell arms are 45° from the vertical center. The hot

deck closes when the bell arms are 45° clockwise from

the vertical center.

b Three-deck zone dampers—The cold deck closes when

the bell arms are 45° clockwise from the vertical center.

The hot deck closes when the bell arms are 45°

counterclockwise from the vertical center.

4 Tighten set screws on bell arms while holding the dampers

closed.

5 All zone damper blades should close properly. If one or a

few zones do not close completely, repeat the procedure for

these zones.

Multizone, Mixing Box and Economizer Damper Torque Requirements

On multizone units, the actuator must drive the connection link

for proper damper actuation. Do not activate multiple dampers

must from the shaft extension opposite the connection link.

Mounting Actuators

The installing contractor is responsible for the mounting of all

field-installed actuators. No provisions are made for the

location of these actuators due to the number of options and

arrangements available and the variety of specific applications.

Typically, actuators are mounted inside the cabinet. Provide

proper support for the actuator to avoid excessive stress in the

cabinet, linkage, or damper shafts.

Fresh air and return air dampers can be linked together and

driven from the same actuator if the dampers are the same size.

If the dampers are different sizes, they must be driven by

separate actuators and controlled appropriately. Exhaust

dampers are always driven by a separate actuator.

McQuay IM 672-8 17

Page 18

Mechanical Installation

A typical rotary electric actuator can handle up to 40 sq. ft. of

damper. For pneumatic actuators, allow 5 in-lb per square foot

of damper area.

CAUTION

Maximum damper rotation is 70°.

Maximum shaft torque is 205 inches/pound.

Greater rotation or torque can cause equipment damage.

ATTENTION

La rotation maximale des volets est de 70°.

Le couple (torque) maximum de l’arbre est de 205 po/lb.

Une plus grande rotation (ou torque) peut endommager

l’équipement.

Face Bypass Damper Torque Requirements

Face and bypass dampers may or may not be linked together.

When dampers are placed before a single bank of coils, they

always are linked together and require a single actuator. When

dampers bypass a stacked or staggered coil, the dampers are

not linked and require multiple actuators. Unit sizes 040 to 090

provided with external face and bypass require three actuators.

Other arrangements with stacked or staggered coils require

two actuators. A damper shaft extension is provided.

Normally, the shaft extension is located on the drive side of the

unit, but it can be moved to the other side.

Face and bypass dampers have a torque requirement of

10 in-lbs per square foot of damper face area.

Isolation Dampers for Multiple Fans

Water Cooling Coils

• Water supply, water return, drain, and vent connections

extend through the end panel of the coil section. All

connections are labeled on the end panel.

• Water supply and water return connections are typically

male NPT iron pipe.

• When installing couplings, do not apply undue stress to the

connection extending through unit panel. Use a backup

pipe wrench to avoid breaking the weld between coil

connection and header.

• Follow recommendations of the control manufacturer

regarding types, sizing, and installation of controls.

Direct Expansion Coils

• The coil distributor and suction connection extend through

the end panel of the coil section.

• Check nozzle in distributor for proper tonnage.

• When a field supplied thermostatic expansion valve is used,

it is located outside the unit and connected directly to the

distributor. Do not apply heat to the body of the expansion

valve.

• The thermostatic expansion valve must be of the external

equalizer tube type. Connect the 1/4-inch diameter external

equalizer tube provided on the coil to connection on

expansion valve.

• Use care when piping the system to see that all joints are

tight and all lines are dry and free of foreign material. For

typical refrigerant piping, see condensing unit product

manual.

Optional isolation dampers can be provided on multiple fans to

prevent backflow through a fan that is turned off for service.

These isolation dampers are not intended to be used to control

flow through the fan. The isolation damper for a fan that is

going to be started must be positioned in the full open position

before the fan is started. Do not start a fan with the damper

located at the inlet with the damper fully or partially closed.

This can cause airflow, vibration, and sound problems that can

lead to failure.

Isolation dampers can be provided with actuators that are

mounted in the airstream. Actuator sizing for the isolation

dampers should be based on 9 in-lb per square foot of damper.

Piping and Coils

When designing and installing piping:

• Follow applicable piping design, sizing, and installation

information in ASHRAE handbooks.

• Observe all local codes and industry standards.

• Do not apply undue stress at the connection to coil headers;

always use a backup pipe wrench.

• Support pipework independently of the coils.

Steam Coils

Piping (see Figure 32)

• All steam coils in units are pitched toward return connection.

• Steam supply and steam return connections typically are

male NPT iron pipe and are labeled on the end panel of coil

section. Connections extend through the coil section end

panel.

• When installing couplings, do not apply undue stress to the

connection extending through unit panel. Use a backup

pipe wrench to avoid breaking the weld between coil

connection and header.

• Support piping independently of coils and provide adequate

piping flexibility. Stresses resulting from expansion of

closely coupled piping can cause serious damage.

• Do not reduce pipe size at the coil return connection. Carry

return connection size through the dirt pocket, making the

reduction at the branch leading to the trap.

18 McQuay IM 672-8

Page 19

Mechanical Installation

Coils

• Install vacuum breakers on all application to prevent

retaining condensate in the coil. Generally, the vacuum

breaker is connected between the coil inlet and the return

main. The vacuum breaker should be open to the

atmosphere, and the trap design should allow venting of

large quantities of air.

• Do not drip supply mains through the coil.

• Do not attempt to lift condensate when using modulating or

on/off control.

Traps

• Size traps in accordance with the manufacturers’

recommendations. Make sure that the required pressure

differential is always available. Do not undersize.

• Use float and thermostatic or bucket traps for low pressure

steam. On high pressure steam, use bucket traps. Use

thermostatic traps only for air venting.

• Use bucket traps for on/off control only.

• Locate traps at least 12 inches below the coil return

connection.

• Multiple coil installation

• Individually trap each coil or group of coils that is controlled individually trapped.

• Coils in series—use separate traps for each coil, or bank

of coils.

• Coils in parallel—a single trap can be used, but an individual trap for each coil is preferred.

• Do not attempt to lift condensate when using modulating

or on/off control.

• With coils arranged for series airflow, use a separate control

on each bank or coil in the direction of airflow.

• As additional protection against freeze-up, install the trap

sufficiently below the coil to provide an adequate hydrostatic head to remove condensate during an interruption in

the steam pressure. Estimate three feet for each 1 psi of

trap differential required.

• On startup, admit steam to coil ten minutes before admitting outdoor air.

• Close fresh air dampers if steam supply pressure falls

below the minimum specified.

Valves

• Do not use modulating steam valves on high pressure

systems.

• Properly size modulating valves. Do not undersize.

• Freezing conditions (entering air temperatures below 35°F).

• McQuay strongly recommends 5JA, 8JA, 5RA and 8RA

coils.

• Supply 5 psi steam to coils at all times.

• Do not use modulating valves. Provide control by face and

bypass dampers.

• Consider using two or three coils in series with two position steam control valves on the coil or coils that handle

35°F or colder air. Use a modulating valve on the downstream coil to provide the desired degree of control.

• Thoroughly mix fresh air and return air before it enters the

coil. Also, to obtain true air mixture temperatures, properly locate temperature control elements.

McQuay IM 672-8 19

Page 20

Mechanical Installation

Chec k Valve Strainer Gate V alve

Control valve

modulating

two position

Float and

thermostatic trap

High Pressure (over 25 psi)

Low Pressure (to 25 psi)

5GA or 8GA coils. Note that the

addition of a vacuum breaker to

permit the coil to drain during

shutdown.

5TA, 8TA, or 5HA coils. Condensate is lifted to overhead return

main

5JA or 8JA coil. Installed in series.

Note that each coil must have a

separate control valve and trap.

5RA, 8RA, or 5SA coils. Banked two

high, individual trapping of each coil as

shown is preferred.

5RA, 8RA, or 5SA coils. Installed

5J, 5G, 8J or 8G coils.

Figure 32: Piping Arrangements

20 McQuay IM 672-8

Page 21

Mechanical Installation

Pressure (P)

at the drain pan

2P

2P

Water Heating Coils

CAUTION

Improper installation, use, or maintenance of water heating

coils can cause equipment damage.

Read and follow instructions carefully.

ATTENTION

Si l’installation, l’utilisation ou l’entretien des

serpentins de chauffage à eau sont inadéquats,

ceci endommagera l’équipement.

Lire et suivre attentivement les instructions.

• Water supply and water return connections extend throu gh

the end panel of the coil section. All connections are labeled

on the end panel.

• Water supply and water return connections are male NPT

iron pipe.

• When installing couplings, do not apply undue stress to the

connection extending through unit panel. Use a backup pipe

wrench to avoid breaking the weld between the coil

connection and header.

• Follow recommendations of the control manufacturer

regarding types, sizes, and installation of controls.

• Do not use hot water coils with entering air below 40°F.

• If fresh air and return air are to be heated by a hot water coil,

carefully design the system to provide thorough mixing

before air enters the coil.

• T o prepare coils for winter operation, see Winterizing Water

Coils‚ page 37.

Drain Pan Traps

Run drain lines and traps full size from the drain pan

connection. Install drain pan trap to allow condensate to drain

freely. On both blow-thro ugh and draw-through units, the trap

depth and the distance between the trap outlet and the drain

pan outlet must be twice the static pressure in the drain pan

section under normal operation so the trap remains sealed

(Figure 33).

Figure 33: Allow Adequate Distance Between Trap Outlet

and Drain Pan Outlet

Internal Isolation Assembly Adjustment

On units with internally isolated fan and motor assemblies, the

assemblies are secured for shipment.

Before Operating the Unit:

Remove the shipping brackets and tie-down bolts (refer to

Figure 35, Figure 36 and Figure 37) and discard. The shipping

brackets located on the opposite drive side of the unit are

difficult to access from the drive side of the unit. Either

remove them before the unit is assembled, or remove the panel

on the opposite drive side to gain access.

The spring isolators under the four corners of the fan and

motor assembly are factory adjusted while the fan was not

running. With the unit operating at normal cfm and static

pressure, all the isolators should be at the same height opening

(Table 1 through Table 5). If adjustments are required, loosen

the 1/2" cap screw on top of the isolator and turn the adjusting

bolt to lower or raise the fan and motor base. Retighten the cap

screw when adjustments are completed.

Table 1: Motor Beside Fan Spring Mount Adjustments

Spring mount adjustment at rest

Isolator

position

1 3.75 3.75 4.25

2 4.25 3.75 4.25

3 4.25 3.75 4.25

4 3.75 3.75 4.25

1 6.00 6.00 6.50

2 6.50 6.00 6.50

3 6.50 6.00 6.50

4 6.00 6.00 6.50

Table 2: Motor Behind Fan Spring Mount Adjustments

Isolator

position

1 6.75 6.75 6.75

2 6.75 6.75 6.75

3 6.75 6.75 6.75

4 6.75 6.75 6.75

1 6.75 6.75 6.75

2 6.75 6.75 6.75

3 6.75 6.75 6.75

4 6.75 6.75 6.75

Top or bottom

horz. H

Unit sizes 003 – 035

Unit sizes 040 – 090

Spring mount adjustment at rest

Top or bottom

horz. H

Unit sizes 003 – 035

Unit sizes 040 – 090

Downblast

H

Downblast

H

Upblast

H

Upblast

H

McQuay IM 672-8 21

Page 22

Mechanical Installation

Adjusting bolt

6"

Unit sizes 006 - 090

For models 040 through 090 with housed fans, the isolators

should be at equal height (6") during fan operation. Center the

fan outlet in the outlet panel opening. If adjustment is required,

loosen the bolt on top of the isolator assembly (Figure 37).

Turn the adjustment nut below the fan frame to lower or raise

the fan motor and frame assembly. Retighten the bolt on top of

the isolator assembly.

Table 3: Class II Belt-Drive Plenum Fan Spring Height

Fan Size Isolator Type Operating Height

Table 4: Class III Plenum Fan Spring Height

Cabinet Width Isolator Type Operating Height

Width < 108" All 4.0"

Width >= 108" All 6.75"

Table 5: Class II Direct-Drive Plenum Fan Spring Height

Fan Size Isolator Type Operating Height

Figure 34: Adjusting Large Spring Mount Assembly

Figure 35: Removing “Motor Behind” Shipping Brackets

13–16 Standard 2" Deflection 4.5"

18–36 Standard 2" Deflection 4.0"

13–36 Seismic 4.0"

40–60 All 6.75"

11–36 All 4.0"

40–44 All 6.75"

22 McQuay IM 672-8

Page 23

Figure 36: Removing “Motor Beside” Shipping Brackets

Unit sizes 006 - 090

Shipping hold-down nut and bolt

Remove and discard - 4 places

Shipping bracket Remove and discard - 4 places

Figure 37: Plenum Fan Typical Shipping Brackets

Mechanical Installation

McQuay IM 672-8 23

Page 24

Electrical Installation

Electrical Installation

Wiring

DANGER

Capacitor Hazardous Voltage! Failure to disconnect power

and discharge capacitors before servicing will result in serious

injury or death.

Disconnect all electric power (including remote disconnects)

before servicing. Perform lockout/tagout procedures to ensure

that power can not be energized. For variable frequency drives,

or other energy storing components that have been furnished

and mounted by either McQuay, or by others, refer to the

specific manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify capacitors have been

discharged using an appropriate voltmeter.

ADVERTISSEMENT

Voltage De Condesateur À Risquee De Danger! À défaut de

débrancher la puissance électrique et de décharger le

condensateur avant de faire le service, il peut en résulter des

blessures sérieuses et même la mort.

Débranchez toute puissance électrique (incluant les

sectionneurs à distance) avant de faire du service. Assurezvous de procéder au cadenassage et à la pose d’avis assurant

que la puissance ne peut être rétablie .

Pour le variateur de fréquence variable ou tout autre

composante pouvant accumuler de l’énergie qui auraient été

fournis et installés par McQuay ou autres, se référer à la

littérature spécifique du manufacturier donnant les périodes

spécifiques d’attente nécessaires pour la décharge du

condensateur. Vérifier que le condensateur est totalement

déchargé avec les voltmètres appropriés.

CAUTION

Use copper conductors only! Failure to use copper

conductors can result in equipment damage.

ATTENTION

Utiliser du fil de cuivre seulement. La non utilisation de fil de

cuivre peut causer des dommages à l’équipement.

• Electrical service to each fan must correspond to the rated

voltage on the motor or electrical panel nameplate and

conform to the National Electric Code and local restrictions.

• Connect each fan section metal frame to the building

electrical ground.

• A door electrical interlock is not provided as standard.

• Thermal motor protection is external to the unit. Unless the

unit is provided with a variable frequency drive (VFD) or a

unit mounted starter, thermal protection and a disconnect

switch provision per electric codes are provided by others.

• When the unit is factory provided with a disconnect switch,

starter or a variable frequency drive (VFD), the components

are mounted on the outside of the unit cabinet. Factory

wiring is provided from the device to the unit internal motor.

• All electrical components must be grounded to the building

central ground. Suitable ground wires and/or (bonding) lugs

are provided for all motors, disconnect switches, starters,

and variable frequency drives. Provide dedicated ground

(bonding) copper conductors in accordance with local and

national codes.

• For units provided with a motor only or with an external

junction box, wire connections are made with suitable wire

nuts or connectors for the gauge wires provided.

• For units provided with a disconnect switch or starter, field

wiring will be terminated to lugs. Wire size and lug torque

requirements are shown on the unit electrical schematic

provided in the component print pocket. All power supply

wire connections must be torqued as shown.

• When the unit is provided with a VFD only, refer to the VFD

manual for wire size and torque requirements. For instances

where multiple motors are being driven by a single VFD, be

sure to set up the VFD and size the wiring according to the

power requirements of all motors that are being driven by

that VFD.

• When not being serviced, close and secure electrical panel

doors to prevent ingress of moisture and airborne

contaminants.

Control Wiring

• Access to the VFD is through the fan cabinet access door for

single fans. Provide shielded cable only as described in the

provided VFD manual. Route wire through the panel so that

it does not interfere with an other components or access

doors. Do not drill through drip pans or drain pans. Refer to

the provided VFD installatio n man ual for detailed control

wiring instructions.

• For multiple fans in parallel, the VFD(s) are mounted inside

of the electrical enclosure, which is mounted on the exterior

of the fan section. When multiple fan sections are provided

with multiple VFDs, they must be set up so that the fans

always start simultaneously and are set to ramp up and down

together. Do not attempt to run fans in parallel at different

speeds as this can result in uneven airflow that can cause

performance, sound, and vibration problems that can lead to

failure. Provided that the fan is capable of running fast

enough and the motor is sized appropriately, VFDs may be

operated up to a maximum recommended frequency of 90

Hertz for 1800 RPM and slower motors. Motors that are

3600 RPM may be operated up to a maximum speed of 4000

RPM or 66.7 Hertz provided the fan is rated that high.

Operation above 4000 RPM can damage motor bearings and

is not recommended.

24 McQuay IM 672-8

Page 25

Operation

Startup Checks

When performing startup and service, always take thorough

safety precautions. Only trained, experienced personnel should

perform these functions.

WARNING

ROTATING FAN

Can cause severe injury or death. Before servicing fans,

lockout and tag out power.

Operation

ATTENTION

Risques de dommages dans le moteur du ventilateur

électrique. Si Ia température de l'air a proximité du

ventilateurest élevée, le moteurdu ventilateur électrique peut

chauffer et brûler. Sur les transmetteurs d'’air à circulation

transversale ou les transmetteurs dont le ventilateur est en

aval de l'’unité de chauffage, régler la température de l'’air

sortant de l'’unité de chauffage à 40°C (104°F).

AVERTISSEMENT

VENTILATEUR EN ROTATION

Peut causer des blessures sévères ou même la mort.

Avant d’effectuer l’entretien des ventilateurs,

bloquer et couper la tension.

WARNING

FIRE/ELECTRIC SHOCK HAZARD.

Can cause property damage, personal injury or death.

Wire fan power supply and ground motor frame in accordance

with local electric codes.

AVERTISSEMENT

Risques d´incendie et d’électrocution pouvant causer des

dommages matériels, des blessures et même la mort.

L’alimentation électrique du moteur du ventilateur de même

que la mise à la terre du chàssis du moteur doivent être faits

conformément aux codes d’nstallations électriques en vigueur.

WARNING

Fan motor requires overload protection.

Failure to provide motor overload protection can result in fire,

property damage, electric shock, personal injury, or death.

Connect motor to an overload protective device rated in

compliance with local electric codes.

Before Starting the Unit

Before entering fan section, make sure that fan electrical

power source is disconnected and locked in the OFF position.

1 Check that the unit is completely and properly installed

with ductwork connected.

2 Check that all construction debris is removed and filters are

clean.

3 Check that all electrical work is complete and properly

terminated.

4 Check that all electrical connections are tight and that the

proper voltage is connected. Phase imbalance must not

exceed 2%.

5 Do not grease ball bearings on the fan shaft and motor

before startup. They are prelubricated.

6 Check tightness of setscrews in bearings and fan wheel(s).

If retightening is needed, position the fan wheel(s) per

Table 6, page 26 through Table 9 and Table 11 through

Table 13, page 28. Torque set screws per Table 10 and

Table 14, page 28.

CAUTION

Equipment damage due to loose fasteners represents

improper start-up and equipment abuse. It is not covered by

the warranty.

AVERTISSEMENT

Risques d’incendie et d’électrocution pouvant causer des

dommages matériels, des blessures et même la mort.

Connecter au moteur du ventilateur électrique un dispositif de

protection contre les surcharges conforme aux codes

d'’installations électriques en vigueur.

Les dommages dus à des attaches installées de façon

inappropriée représentent un démarrage inadéquat et un

abus d’équipement. Ceci n’est pas couvert par la garantie.

7 Check alignment of fan and motor sheaves and belt tension.

Adjust if necessary . Check tightness of sheave setscrews

AVERTISSEMENT

and/or capscrews (refer to Table14, page 28).

CAUTION

DO NOT OVERHEAT FAN MOTOR

High air temperatures in the fan section can cause the fan

motor to burnout. On draw-through air handlers or air handlers

with the fan section down the air stream from the heating

section, the discharge air temperature of the heating section

must not exceed 104°F (40°C).

McQuay IM 672-8 25

8 Leak test the thermal system to verify that connections are

tight.

9 Check that the condensate drain is trapped.

Page 26

Operation

A

A

B

E q u a l s p a c i n g

a l l a r o u n d

I n l e t

F u n n e l

W h e e l

C

C

I n l e t

F u n n e l

10 Rotate the shaft by ha nd to be sure it is free.

11 If multiple fans are suppl ied with a block off plate and it is

installed on one of the fans, make sure to only start the fans

without the block off plate. Do not start any fan that has the

block off plate installed on it.

12 If multiple fans are supplied with isolation dampers, make

sure the isolation dampers are fully open before starting the

fans.

VFD Setup

Fans ordered with VFDs that were factory installed are setup

and tested prior to shipment. Prior to starting the fan(s),

double check the VFD settings according to the

recommendations in the VFD manual.

Once the correct VFD settings are verified, the fans should be

run through a sweep of the full range of operating speeds that

are expected to check for any vibration issues. If any areas of

concern are located, it is recommended to lock out those

frequencies using the VFD (see lock out frequencies or skip

frequencies in the VFD manual). This will ensure that the fans

will never operate continuously at those points, but will rather

pass through them to get to the desired points of operation.

Fan Startup

Start and run fan. See Figure 42 for proper fan rotation.

Observe the rotation. If the fan operates backward, reverse two

legs of the three-phase supply power.

Note: Variable pitch fan drives usually are provided for

operation in the mid-speed adjustment range. However,

the drives usually ship with the adjustment opened up for

minimum fan speed. Adjust the drives for the proper

airflow. See Fan Drive Adjustments‚ page 32.

Fan Wheel Alignment

Figure 38: Wheel-to-Inlet Funnel Relationship—Fan Wheels

(Housed)

Table 6: Wheel-to-Inlet Funnel Relationship—Fan Wheels

(Housed)

1

Airfoil

Unit sizes 003 to 035 Unit sizes 040 to 090

A2

A2

B3

Dia.

(in)

(mm)

13.22 4.56 116 0.21 5.33 20.00 7.19 183 0.31 7.87

14.56 5.06 129 0.21 5.33 22.25 7.69 195 0.33 8.38

16.18 5.62 143 0.21 5.33 24.50 8.56 217 0.31 7.87

17.69 6.90 175 0.22 5.59 27.00 9.47 241 0.63 16.00

21.56 7.59 193 0.24 6.10 30.00 10.47 266 0.39 9.91

24.00 8.45 215 0.23 5.84 33.00 11.75 298 0.38 9.65

Note: 1To obtain rated air performance, dimensional relationship must be held.

2

To obtain dimension A, loosen setscrews in wheel hub(s), shifting

wheel(s) axial as needed, retightening setscrews.

3

To obtain dimension B, loosen screw and washer fasteners around

periphery of funnel(s), shifting funnel radially as required, re-torquing

fasteners.

(in)

B3

(mm)

36.50 12.78 325 0.38 9.65

40.25 14.31 363 0.50 12.70

Figure 39: Wheel-to-Inlet Funnel Relationship—Forward

Curved Fan Wheels

Dia.

A2

(in)

A2

(mm)

B3

(in)

B3

(mm)

After 48 Hours of Operation

WARNING

ROTATING FAN

Can cause severe injury or death. Before servicing fans,

lockout and tag out power.

AVERTISSEMENT

VENTILATEUR EN ROTATION

Peut causer des blessures sévères ou même la mort. Avant

d’effectuer l’entretien des ventilateurs, bloquer et couper la tension.

1 Disconnect and lock electrical power source.

2 Check tightness of all bearing, wheel, and sheave setscrews

(or capscrews). Refer to Table 10.

3 Recheck belt tension and adjust if necessary. Belts

tensioned sufficiently to slip one to two seconds at startup

will perform satisfactorily, extending life and reducing

vibration. If retensioning is necessary, be certain to retain

sheave alignment.

Table 7: Wheel-to-Inlet Funnel Relationship—Forward

Curved Fan Wheels

Forward curved

Unit sizes 003 to 035 Unit sizes 040 to 090

C2

Diameter (in)

9 x 4 0.25 6.35 20 (Class 1 & 2) 0.24 6.10

9 x 7 0.13 3.30 22.38 (Class 1 & 2) 0.41 10.41

9 x 9 0.25 6.35 25 (Class 1 & 2) 0.47 1 1.94

10 0.22 5.59 27.62 (Class 1 & 2) 0.47 11.94

12 0.35 8.89 30 (Class 1 & 2) 0.47 11.94

15 0.44 11.18 33 (Class 1 & 2) 0.50 12.70

18 0.25 6.35 36 (Class 1 & 2) 0.75 19.05

20 (Class 1 & 2) 0.73 8.54

22 1/2 (Class 1 & 2) 0.59 14.99

24 1/2 (Class 1 & 2) 0.56 14.22

Note: 1To obtain rated air performance, dimensional relationship must be

held.

2

Adjust dimension C by loosening wheel hub setscrews, shifting

wheel(s) axial as needed, and retightening setscrews.

(in)

C2

(mm)

1

Diameter (in)

26 McQuay IM 672-8

C

(in)

2

C2

(mm)

Page 27

Operation

Cross Section Reference

C

AROUND DIAMETER

EQUALLY SPACED

B

A

FROM FUNNEL END TO

FANWHEEL OPENING END

Cross Section Reference

B

C

A

FUNNEL END TO FAN

WHEEL OPENING

EQUALLY

SPACED AROUND

DIAMETER

Figure 40: Wheel-to-Inlet Funnel Relationship—13 to 36

Belt-Drive Plenum Fans

Table 8: Wheel-to-Inlet Funnel Relationship—13 to 36 BeltDrive Plenum Fan

Wheel-Funnel Parameters

Size A B C

13 0.25 0.91 3.50

15 0.25 0.91 3.50

16 0.25 0.91 3.50

18 0.38 0.86 3.88

20 0.42 1.11 3.88

22 0.45 1.11 3.88

24 0.51 1.11 3.88

27 0.55 1.36 4.50

30 0.62 1.36 4.50

33 0.55 1.50 5.00

36 0.63 1.50 5.00

Figure 41: Wheel-to-Inlet Funnel Relation s hip —4 0 to 60

Belt-Drive Plenum Fans

Table 9: Wheel-to-Inlet Funnel Relationship—40 to 60 BeltDrive Plenum Fan

Wheel-Funnel Parameters

Size A B C

40 0.82 2.00 4.88

44 0.91 2.25 5.50

49 1.00 2.50 5.50

54 1.10 2.50 5.50

60 1.23 3.00 5.50

Setscrews on MPQ fan wheels must be installed using a

calibrated torque wrench to the value listed below, ±5%.The

fasteners must be periodically checked to satisfy agency

requirements for components on rotating machinery.

Figure 42: Fan Wheel Rotation

McQuay IM 672-8 27

Page 28

Operation

Overlap