Page 1

Installation & Maintenance Data IM 503-1

Group: Unit Ventilator

Part Number: 106101101

Date: June 1999

Model AZS, AZQ HermanNelson® Classroom Unit Ventilator

HermanNelson

©1999 AAF-HermanNelson IM 503-1 (Rev. 6/99)

®

Page 2

Wall Sleeve

Receiving Shipment

Before signing the freight bill, be certain that all items have

been received and that there is no visible damage. Note any

shortages and any damage on all copies of the freight bill.

Each Model AZS, AZQ unit has been carefully inspected and

operated at the factory to verify proper performance. It has

been packed in a sturdy carton, was checked by the carrier

during loading for shipment, and should arrive in perfect

condition. However, if there is damage or any shortages, the

purchaser is responsible for filing the necessary claims with

the carrier. Concealed damage which was not discovered

until after unloading should be reported to the carrier within 15

days after receipt. To help avoid concealed damage, the air

conditioners must be shipped, handled and stored right-side

up. A formal claim for any shortage or damage must be filed

with the carrier within nine (9) months after delivery.

See Table 1 for unit weights and dimensions. Forklift type

vehicles may be used to unload and move the unit. When

using a forklift, it is important that the unit remain banded to

its skid and be lifted only from the end designated on the

carton. See Figure A. Forks on forklift should be a minimum of

36" long. Move only one unit at a time. Do not drop unit.

Storage

If an air conditioner must be stored prior to installation, find a

clean, dry, protected, preferably heated area for storage until

the equipment is needed. Keep within the carton during

storage or handling.

Preliminary Installation

The location and installation of each Model AZS, AZQ unit

should be carefully arranged to ensure convenient service

access for maintenance and, if necessary, removal of the unit.

If the unit has been in storage in an unheated area, care must

be taken that the refrigerant circuit has had time to reach

proper ambient temperature before attempting operation.

The unit consists of two major sections: (1) the unit proper and

(2) the wall sleeve. The wall sleeve contains the unit main

power disconnect switch located in the wall sleeve junction

box. All field connections are made inside the wall sleeve

junction box (see page 8).

The Model AZS, AZQ unit is designed to be installed through

an outside wall. Installation will require that the wall sleeve be

removed from the unit and installed before the unit is installed.

See "Uncrating Unit" section.

On many jobs, the louver and wall sleeve are shipped ahead

of the unit itself. Installation instructions for these components are shipped with the individual components, as well as

being included in this publication.

Table 1. (See note below)

UNIT UNIT

MODEL DEPTH WT., LB. HEIGHT WIDTH

AZS-24, 30

AZQ-24, 30

AZS-36, 42

AZQ-36, 42

AZS-48, 54

AZS-48, 54

IMPORTANT:

1. Move only one unit at a time.

2. Do not drop unit.

3. Store in a clean and dry environment.

4. Lift only from designated end.

5. May be stacked maximum of 2 high.

6. To remove unit from skid, follow instructions

under "Uncrating Unit" on page 3.

NOTE: All dimensions are approximate only and are subject to change

without notice. Refer to approved submittal prints for rough-in details

and construction purposes and for recommended wall opening size.

28 103 31 885 28 84

28 103 31 975 28 96

28 115 31 1075 28 108

AB

SHIP WALL SLEEVE

Page 2 / IM 503-1

Figure A.

39"

A

B

Page 3

Wall Opening Preparation

An opening in the outside wall is required to accommodate the

wall sleeve and louver. The wall opening must be of sufficient

size to allow proper, yet snug, fit of the louver and will depend

on the type of wall. If the louver is to be installed in a masonry

wall, there should also be a lintel to support the wall above the

wall sleeve and louver. The opening should be sleeved to

prevent moisture from seeping into the wall interior. Refer to

approved submittal prints for recommended wall opening

size.

Remodeling Existing Buildings

If the Model AZS, AZQ unit is to be installed in an existing

classroom, an opening must be cut in the outside wall to

accommodate the wall sleeve and louver. This is accomplished as follows:

First, the outside of the wall is cut with a carborundum or other

suitable blade as shown in Figure B. This opening should be

slightly larger than the size of the louver supplied with the unit.

Figure B.

The inside wall is then knocked out in the area cut for the wall

sleeve as shown in Figure D. If the wall consists of concrete

block with brick (or other) veneer, and the louver opening is

smaller than the opening the wall sleeve (which is to be

recessed), be careful not to knock out more veneer than is

necessary.

Figure D.

The completed opening is shown in Figure E. After the opening is finished, a lintel must be installed above the opening in

masonry walls to support the remaining block and brick.

Figure E.

Next, the inside of the wall is cut as shown in Figure C. If any

portion of the wall sleeve is to be recessed into the wall, the

opening must be large enough to accommodate the wall

sleeve (see Table 1, page 2). It is also possible to have a wall

opening smaller than the wall sleeve; in which case, the sleeve

will be nonrecessed and all of the unit will remain in the room.

Other variations are also possible such as dual louvers, etc.

Figure C.

New Buildings

In new construction, if any portion of the wall sleeve is to be

recessed into the wall, the opening must be large enough to

accommodate the wall sleeve (see Table 1, page 2). For

smaller wall openings the wall sleeve will be nonrecessed and

all of the unit will project into the room. In all cases the bottom

of the wall opening must be at the same height as the floor line.

A lintel must be installed above the opening in masonry walls

to support the block and brick.

Uncrating Unit (Figure A)

The unit should be moved to the location at which it is to be

installed before uncrating. Check tagging on unit carton to

confirm that the unit is correct for the location. The carton is

imprinted with the AAF-HermanNelson trademark which is

the "front" or room side of the unit. The end of the carton

marked "Truck from this end" should be on the right-hand side

when facing the front of the carton.

IM 503-1 / Page 3

Page 4

Lower crated unit from dolly (if used), but do not drop.

a

a

a

a

a

Remove external carton by lifting off, and save this carton. To

remove unit from the skid, remove fasteners at each end which

fasten the unit to the skid and slide the front of the unit off of the

skid. Tip unit forward until it is possible to slide skid out from

under the unit. Gently lower the rear of the unit to the floor.

After the unit has been installed, cut out the rear of the carton

and replace it over the unit until all construction has been

completed. This will prevent the unit from being scratched or

damaged by other workers finishing the area.

Remove the protective covering from the interior of the

three front panels to prevent block return air openings. Check

for concealed shipping damage.

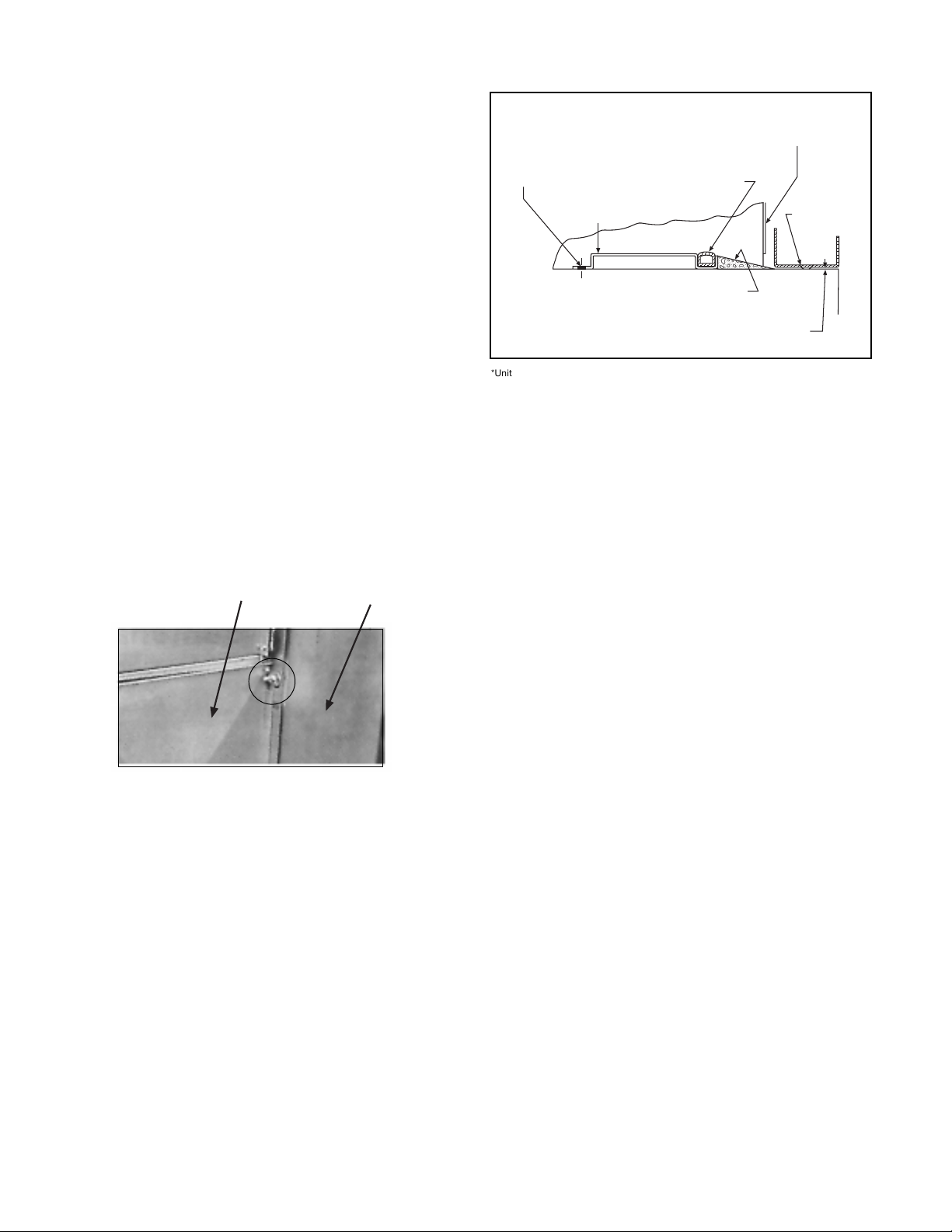

Figure 2. Cross Section Detail of Bottom of

Wall Sleeve & Intake

Fasten cross channel to floor

thru 1⁄4" holes with appropriate

fasteners (by others.)

7 fasteners - AZS/AZQ 24, 30

8 fasteners - AZS/AZQ 36, 42

9 fasteners - AZS/AZQ 44, 48, 54

Bottom of Wall Sleeve

Cross Channel

A "D" shaped seal is

provided at the bottom

rear of the Wall Sleeve

to provide a watertight

seal to the bottom of

the unit when installed.

Seal both ends and top of

Wall Sleeve to building,

watertight at rear flange.

Bottom channel

of Louver

3

⁄16"

Wall Sleeve Installation

General — The wall sleeve must be installed before the unit

can be placed. The wall sleeve measures 85", 96" or 108"

wide by 28" high and may be recessed into the wall up to

3

⁄8" in depth.* Consult the approved AAF submittal draw-

11

ings for the job to determine the proper amount of recess,

if any, and recommended wall opening size.

The wall sleeve is attached to the unit chassis (weld studs)

using 4-nuts and washers, see figure 1.

The AAF wall sleeve and louver design is based on a "wet

sleeve" concept. In brief, this means the design accommodates the penetration of some moisture into the rear section

of the wall sleeve with the provision being made for containment and disposal of this moisture to the outdoors.

It is necessary for that portion of the opening between the

wall sleeve and the louver to be completely enclosed by the

installer to prevent air and water leaks into the building.

*Unit may also be installed with full 28˝ deep cabinet projecting into the room.

Figure 1.

Recessed and Nonrecessed Applications

The installing contractor shall do the following:

1. Make sure there is a masonry lintel supporting the wall

above any masonry opening.

2. Frame and seal air- and watertight all openings not en-

closed by the wall sleeve.

3. Refer to relevant figures for details of required sealing:

Figure 2 for all applications.

Figures 3 and 4 for recessed wall sleeve applications.

Figures 5 and 6 for nonrecessed wall sleeve applications.

4. Seal watertight both ends and top of wall sleeve to building

at rear flange of wall sleeve.

5. Seal watertight bottom of wall sleeve at rear "D" seal to

building and pitch toward louver bottom channel. Also

fasten cross channel to floor through holes with fasteners

(by others). See Figure 2.

Chassis

Wall Sleeve

Seal watertight bottom of Wall Sleeve at rear "D" seal

to building and pitch toward bottom channel of louver

as shown.

*Unit may also be installed with the full 28" deep cabinet projecting into the room.

6. The louver must be installed with the drain notches

located at the bottom and the bird screen located on

the unit side. Openings between notches must be free

of mortar or other foreign material for water removal. Refer

to IM 449 for specific details regarding louver installation.

7. Apply rubber stripping or sealant material (by others)

across full length of wall sleeve splitters.

8. If the louver does not butt up against the wall sleeve:

a. Fabricate a horizontal air splitter from galvanized

steel, redwood or some other suitable weather resistant material. The width of the air splitters is determined

by the width of the wall opening. The depth of the air

splitters is determined by the distance between the

louver horizontal splitter and the wall sleeve splitters.

b. The horizontal air splitters should have a 1" diameter

drain hole approximately 6" from each end.

c. Install the horizontal air splitters by fastening to the

wall sleeve splitters.

d. Apply rubber stripping or sealant material (by

others) across full length of horizontal air splitters

to seal against louver.

9. Permanently seal any remaining air leaks so that, when

finished:

a. There is an airtight separation between the discharge

air and the return air of the condenser fan;

b. There are no air leaks around the perimeter of the wall

sleeve where it adjoins the wall.

Recessed Applications (See Figures 3 and 4)

The installing contractor shall do the following:

1. Place the wall sleeve into the wall opening and recess it

the amount shown on the approved AAF submittal drawings.

2. Level the wall sleeve horizontally and plumb the wall sleeve

vertically.

3. Fasten the wall sleeve securely in place using fasteners

through the two knockouts provided on each end.

4. Caulk or seal any space between the wall sleeve and the

wall on both the room side and the outdoor side.

IMPORTANT: Opening under Louver must be

free of foreign material for water removal.

Page 4 / IM 503-1

Page 5

CAUTION: Sleeves furnished for use with optional heated rear drain will have an electric cord installed along

the length of the wall sleeve splitter. Avoid screw penetration or drilling into this cord when

installing the horizontal air splitter. (Model AZS, AZQ Only)

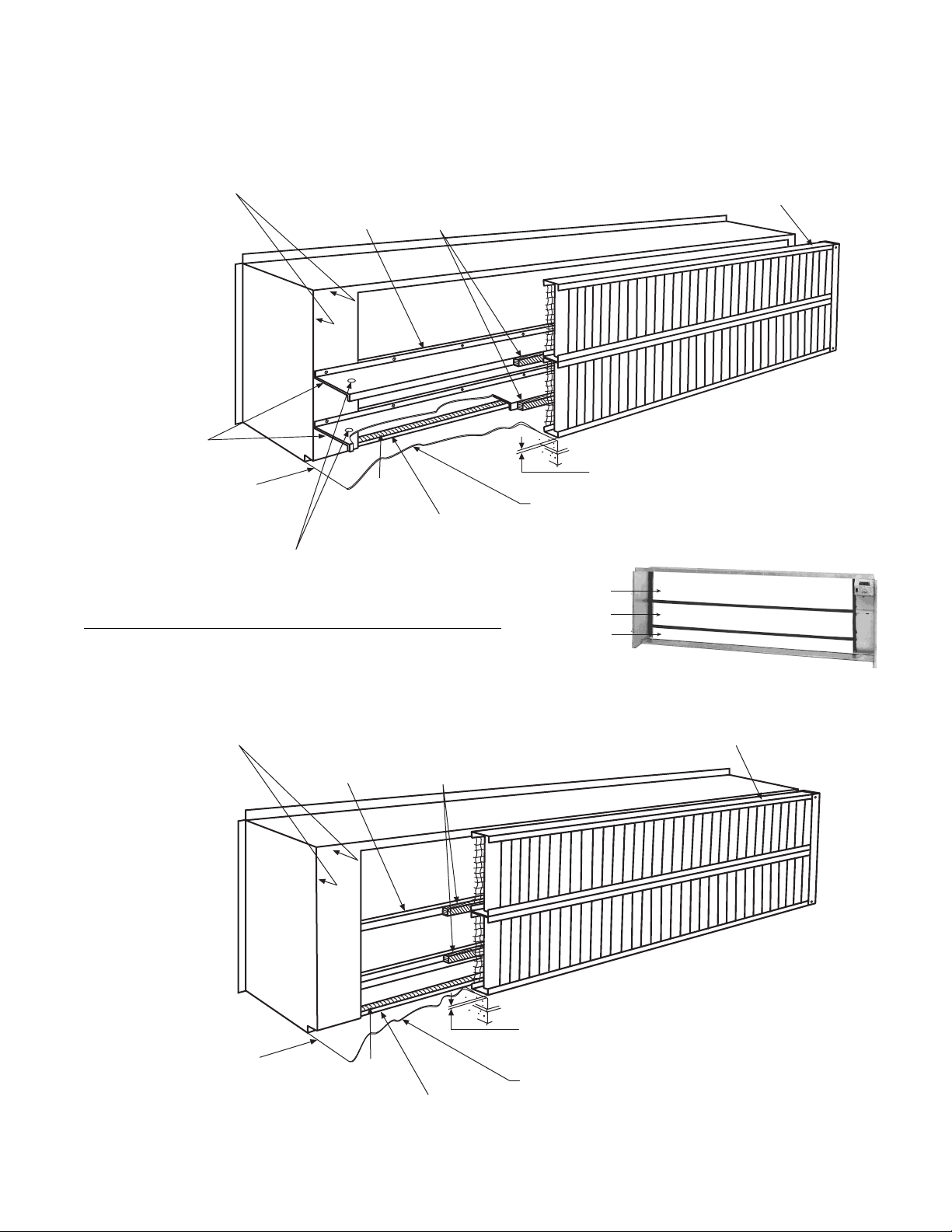

Figure 3. Rear View of Recessed Wall Sleeve With Horizontal Air Splitters

By Others. Wall Sleeve must

be sealed watertight at top and

both ends at location shown.

By Others. Seal Horizontal

Air Splitters to building at

both ends.

By Others. Seal both ends of

opening between Wall Sleeve

and Louver.

IMPORTANT NOTE:

By Others: Attach Horizontal Air Splitters to Wall Sleeve

Splitters as shown. Splitters to have 1" dia. drain hole

approx. 6" from each end.

Wall Sleeve Splitter(s)

(See Caution Above)

"D" Seal

By Others. Wall Sleeve must be sealed

watertight at bottom at location shown.

Refer to cross section detail of bottom

of Wall Sleeve and Louver.

(Figure 2.)

Seal Horizontal Air Splitter(s)

to Louver. (By Others)

3

⁄16" Under Intake must be free for water run-off. INTAKE MUST

STAND ON EMBOSSED FEET LOCATED ON BOTTOM.

By Others. Building must be sealed between Wall

Sleeve and under Louver for water run-off. Pitch

toward Louver.

Condenser discharge

Condenser inlet

Outdoor air inlet

By Others. Louver must be sealed

watertight at top and both ends.

Figure 4. Rear View of Recessed Wall Sleeve Without Horizontal Air Splitters.

By Others. Wall Sleeve must

be sealed watertight at top and

both ends at location shown.

By Others. Seal Horizontal

Air Splitters to building at

both ends.

Wall Sleeve Splitter(s)

(See Caution Above)

"D" Seal

By Others. Wall Sleeve must be sealed

watertight at bottom at location shown.

Refer to cross section detail of bottom

of Wall Sleeve and Louver.

(Figure 2.)

IMPORTANT NOTE: By Others. Seal

Louver to Wall Sleeve at top and bottom Wall Sleeve Splitters, and ends.

3

⁄16" Under Intake must be free for water run-off. INTAKE MUST

STAND ON EMBOSSED FEET LOCATED ON BOTTOM.

By Others. Building must be sealed between Wall

Sleeve and under Louver for water run-off. Pitch

toward Louver.

By Others. Louver must be sealed

watertight at top and both ends.

IM 503-1 / Page 5

Page 6

CAUTION: Sleeves furnished for use with optional heated rear drain will have an electric cord installed along

the length of the wall sleeve splitter. Avoid screw penetration or drilling into this cord when

installing the horizontal air splitter. (Model AZS, AZQ Only)

Figure 5. Rear View of Nonrecessed Wall Sleeve With Horizontal Air Splitters

By Others. Apply sealant (by others) to bottom edge of unit (not

shown) and to top flange and both end flanges of wall sleeve (as

shown.) This must provide a watertight seal to the wall of the

building.

By Others. Seal Horizontal

Air Splitters to building at

both ends.

By Others. Seal both ends of

opening between Wall Sleeve

and Louver.

IMPORTANT NOTE:

By Others: Attach Horizontal Air Splitters to Wall Sleeve

Splitters as shown. Splitters to have 1" dia. drain hole

approx. 6" from each end.

Wall Sleeve Splitter(s)

(See Caution Above)

Seal Horizontal Air Splitter(s)

to Louver.

"D" Seal

By Others. Wall Sleeve must be sealed

watertight at bottom at location shown.

Refer to cross section detail of bottom

of Wall Sleeve and Louver.

(Figure 2.)

3

⁄16" Under Intake must be free for water run-off. INTAKE MUST

STAND ON EMBOSSED FEET LOCATED ON BOTTOM.

By Others. Building must be sealed between Wall

Sleeve and under Louver for water run-off. Pitch

toward Louver.

Condenser discharge

Condenser inlet

Outdoor air inlet

By Others. Louver must be sealed

watertight at top and both ends.

Figure 6. Rear View of Nonrecessed Wall Sleeve Without Horizontal Air Splitters

By Others. Apply sealant (by others) to bottom edge of unit (not

shown) and to top flange and both end flanges of wall sleeve (as

shown.) This must provide a watertight seal to the wall of the

building.

By Others. Seal both ends of opening

between Wall Sleeve and Louver.

Wall Sleeve Splitter(s)

"D" Seal

By Others. Wall Sleeve must be sealed watertight at bottom at location

shown. Refer to cross section detail of bottom of Wall Sleeve and Louver.

(Figure 2.)

IMPORTANT NOTE: By Others. Seal

Louver to Wall Sleeve at top, Wall

Sleeve Splitters and ends.

3

⁄16" Under Intake must be free for water run-off. INTAKE MUST

STAND ON EMBOSSED FEET LOCATED ON BOTTOM.

By Others. Building must be sealed between Wall Sleeve and under

Louver for water run-off. Pitch toward Louver.

By Others. Louver must be sealed

watertight at top and both ends.

Page 6 / IM 503-1

Page 7

Figure 7.

Typical Wall Louver

Louver

Blade

Factory Mounted Bird Screen

Bird Screen

Fasteners

Frame

Optional Flanges

Splitter Lines Up With

Wall Sleeve Splitter

Detail of Notches

(Drain Holes)

Bottom

Flange

Demountable

Louver Section

Drain Notch

At Bottom

Information

Labels

Nonrecessed Applications (See Figures 5 and 6)

The installing contractor shall check the following before

proceeding:

The wall behind the unit should be smooth and plumb.

The seals on the rear of the unit will take up the small

irregularities of normal masonry construction.

Furring strips must be installed on irregular walls or walls

with mullions in order to provide a flush surface for the unit

to seal against.

Any moldings at the floor/wall line should be omitted

behind the unit.

The installing contractor shall do the following:

1. Apply sealant (by others) to bottom edge at rear of unit top

and both end flanges on rear of wall sleeve to provide

watertight seal to interior wall of building.

2. Level the wall sleeve horizontally, and plumb the wall

sleeve vertically.

3. Fasten the wall sleeve securely in place by:

a. Securing it to the floor through the two (2)

3

⁄8" diameter

holes in the turned out bottom flanges of the wall

sleeve at each end, and/or:

b. Securing it to the wall through the two (2)

3

⁄8"

diameter holes in the turned out vertical flanges of the

wall sleeve at each end.

4. a. Panel wall applications should have the wall opening sleeved

to prevent moisture from seeping into the wall interior.

b. If the panel wall is less than 2

1

⁄4" thick, the wall louver

should be installed flush to the interior wall and be

allowed to extend to the outside as required.

5. Seals on rear of unit must be compressed to provide a

watertight seal after installation is complete.

Louver Installation

The standard louver is an aluminum, vertical, divided blade

design complete with bird screen. This louver is also available

with flanges and/or with a heavy-duty exterior lattice grille.

1. Figure 7 shows a detail of a typical louver. Before installation, carefully examine the louver and note the location of

the bird screen and the notches (drain holes). The louver

must be installed with the notches at the bottom and the

bird screen toward the unit.

2. Measure the opening to be sure there is adequate clearance

for the louver around the sides. Observe the opening in

relation to the wall sleeve and unit. For proper unit operation,

the louver must be centered left to right and top to bottom

to the wall sleeve. If the louver is of such a dimension that it

extends above, below, or beyond the wall sleeve, then these

areas must be blocked off airtight (see Figure 8).

3. If the wall sleeve does not extend into the wall far enough

to meet the louver, field fabricated splitter(s) must be

provided. The splitter(s) need to extend far enough to

engage the louver in order to form a proper seal.

4. Check to see if the horizontal divider on the louver is the

Optional Factory Mounted

Exterior Grille

Mechanical Fasteners (Number Required

Varies With Size of Louver)

Figure 8.

Shaded area of louver must

be blocked off & made airand watertight, by installing contractor.

Exaggerated oversize

louver or wall opening.

Unit Wall

Sleeve

same height as the horizontal splitter of the wall sleeve.

The louver consists of a frame, which must be permanently

mounted in the wall, a demountable center louver section

to allow service access to the rear of the unit. To install the

louver in the opening, the demountable center section

must be in place. This will insure that the frame remains

square during installation.

6. Before installing the louver in the opening, place a heavy

bead of caulk along the top and two sides of the frame that

come in contact with the walls of the opening. Use a

flexible, waterproof caulk such as silicone.

7. Once the louver has been placed in the opening, further

mechanical fastening may be desired or required. Fasten

in a manner appropriate to the installation. Care must be

taken if fasteners are to be placed in the frame. If this is

necessary, remove the demountable center section by

removing the screws that hold it in place. Drill holes in the

desired locations and fasten with flat head screws. Be sure

these screws do not interfere with the reinstallation of the

demountable section. Shims must be placed between the

frame and the wall so it won't be distorted. After the frame

has been satisfactorily fastened, reinstall the demountable

center section and secure with fasteners provided.

Once the frame and louver assembly has been installed,

run a bead of caulk around the outside perimeter of the

frame to seal it watertight. Caution: Do not plug the weep

holes in the bottom of the louver.

Louvers With Flanges

1. If the louver is supplied with flanges, follow steps 1 through

6 above. Additionally, place a bead of caulk on the inside

of the top and side flanges that come in contact with the

building facade. Do not caulk the bottom flange.

2. Place the louver in the opening and push it tight against the

building. Fasten it to the exterior of the building using

appropriate fasteners for the installation.

3. Seal the top and two sides with waterproof caulk to make

it weathertight. Do not seal the bottom flange. To do so

may trap water behind the flange.

IM 503-1 / Page 7

Page 8

Electrical Connections

All field wiring should be in accordance with the National

Electric Code and applicable local codes.

Refer to the wiring diagram furnished with the unit to determine electrical connections required.

Refer to Figure 9 for stub-up locations. Refer to pages 12

through 14 for main power connections and field wired controls, if any.

Check nameplate to verify power supply is correct.

Whenever the electric stub-up is brought in through the

Figure 9. Wall Sleeve With Electric Stub-up From Bottom or Side.

floor within the confines of the wall sleeve and any portion of

the wall sleeve is recessed into the wall, the conduit must be

flush with the floor to permit installation of the wall sleeve.

Sufficient space must be left around the conduit to permit the

attachment of continuing conduit after the wall sleeve is

installed. For concrete slabs, it is recommended that this be

accomplished either by sleeving the conduit or by recessing

a junction box into the slab.

2.5/1.75" Dia. Knockout

3.0/2.0" Dia. Knockout

Wall Sleeve

Conduit (by others)

Rear edge of wall sleeve

2.5/1.75" Dia. Knockout

3.0/2.0" Dia. Knockout

Wall Sleeve

.875" Dia. Knockouts (3)

SW1-Main Power Nonfused “On-Off” Switch (AAF-HermanNelson)

Safety Precaution: Reverse this cover when unit is

removed from wall sleeve to cover opening in the

end of switch box.

Wall Sleeve Junction Box

5

/8" x 35/8" opening (for main power wiring from wall

sleeve to chassis). Field connection by others.

Control receptacle with plug-in disconnect (AAFHermanNelson). Leads are provided for wire nut

connection to all remote controls.

Stub-up from

bottom must be

confined in this area.

1

/4"

6

5"

51/2"

.875" Dia. Knockouts (3)

1

/2"

SW1-Main Power Nonfused “On-Off” Switch (AAF-HermanNelson)

Right End

Of Unit

Safety Precaution: Reverse this cover when unit is

removed from wall sleeve to cover opening in the

end of switch box.

Wall Sleeve Junction Box

Whenever the electric stub-up is brought in

through the floor within the confines of the wall

sleeve, and any portion of the wall sleeve is

recessed into the wall, the conduit must be flush

with the floor to permit installation of the wall

sleeve. Sufficient space must be left around the

conduit to permit the attachment of continuing

conduit after the wall sleeve is installed. For

concrete slabs, it is recommended that this be

accomplished either by sleeving the conduit or by

recessing a junction box into the slab.

Conduit (by others)

Rear edge of wall sleeve

Page 8 / IM 503-1

5

/8" x 35/8" opening (for main power wiring from wall

sleeve to chassis). Field connection by others.

16"

1"

9"

5"

Control receptacle with plug-in disconnect (AAFHermanNelson). Leads are provided for wire nut

connection to all remote controls.

Stub-up through side must be confined to this

area: cut in field. Opening must be carefully

prepared and gasketed for air tightness.

Right End

Of Unit

Page 9

Note: These are general instructions. Refer to the AAFHermanNelson submittal drawings for specific dimensions,

unit arrangement, stub-up locations, recommended wall

opening size, etc.

Unit Placement

Before Moving Unit Up To Wall Opening:

1. Confirm unit is correct for the location.

2. Complete the installation of the wall sleeve and air intake

louver in accordance with the instructions on pages 4

through 9.

3. For nonrecessed applications, inspect the field applied

elastic tape to make sure it will seal tightly to prevent air

leaks after unit is installed.

4. Check room air and condenser fan bearings to be sure they

are secure (Figures 10 and 12).

5. Check room air and condenser fan shaft coupling setscrews to be sure they are tightened securely to both

motor shaft and fan shaft.

6. Rotate the room air and condenser fans to be sure they

rotate freely and quietly.

7 Check fan wheel setscrews for tightness.

8. Remove any debris from inside the unit.

Setting the Unit:

Slide the unit up to the wall sleeve aligning the four threaded

studs (Figure 13) on the wall sleeve with the holes on each end

of the unit. Sliding of the unit to the wall can be made easier

with the assistance of Caster Kit P/N - 105629001. A piece of

cardboard placed under the unit will make this job easier and

prevent marring the floor. (Do not leave cardboard under unit

after installation.) The wall sleeve mounting studs should slide

through the holes in the unit. Place the washers over the

threaded studs and tighten the mounting nuts. Do not draw

the nuts up as tight as possible as they may distort the unit and

loosen the caulking and wall sleeve from their position. If an

adapter collar is used, make sure that the unit, adapter collar

and wall sleeve all line up properly.

Figure 10.

ROOM AIR FAN

SHAFT BEARING

OIL CUP

Figure 11.

Oil Here

Caution:

Failure to follow these instructions may rack the

unit which can cause the fan or unit to vibrate

noisily on startup and appear to be in need of fan

balancing. For quiet, smooth unit operation it is

important that the unit be square, level and the

base solidly supported by the floor, using shims

where necessary due to uneven construction in

order to prevent distortion of the cabinet. It is

essential to keep unit level.

Defrost Condenser Drain Piping

It is strongly recommended that the condensate from the

heating defrost cycle be disposed of into a building condensate drain. See Figure 14, page 10 for details. If a building

condensate drain is not used, and the drain line is exposed to

freezing temperatures, adequate freeze protection must be

furnished.

Oiling

Do not attempt to operate the unit fans until the room air fan

shaft bearing has been oiled. Use a high grade SAE 20 or 30

nondetergent oil. A few drops are sufficient. Do not over oil.

Refer to Figure 10 for oil point. The fan motor does not require

oiling until after one year of operation (Figure 11).

Condenser motor and fan shaft bearings are permanently

lubricated.

Figure 12.

Figure 13.

CONDENSER

FAN SHAFT

BEARING

IM 503-1 / Page 9

Page 10

Piping Stub-up Details, 6" End Panel

Piping Stub-up Within Cabinet

Unit End Compartment

A

1

11

⁄

Wall Line

Caution: Space available in left end

compartment for piping stub-up.

Stub-up including unions and shutoff

valves must disconnect below floor

line for unit installation and removal.

2

1

103⁄

4

Left End

of unit

(Less end panel)

Piping Stub-up Within 6" End Panel

Unit End Compartment

1

Wall Line

Space available at left end of unit

for piping stub-up when 6" end

panel is used.

B

Hot Water Coil Piping Arrangements (see Note 12)

4

Left End of unit

(Less end panel)

End Panel 6"

Application and Dimension

6

All dimensions in inches

Piping Within Unit End Compartment Piping Outside Unit End Compartment

F&BP With End-of-Cycle Valve

3-Way Modulating Valve Control

F&BP With End-of-Cycle Valve

3-Way Modulating Valve Control

Page 10 / IM 503-1

Page 11

Coil Piping

Heating valve actuators should be mounted in an upright

position above the centerline of the valve body and should be

piped normally open to the coil. Modulating valve actuators

for hot water applications may be positioned above the valve

body a maximum of 75° from the vertical. For steam applications only, mount the modulating valve actuator above the

valve body at 45° from the vertical. Two-position, end-ofcycle (EOC) valves used with face and bypass damper controlled units may be positioned above the valve body a

maximum of 85° from the vertical. All control valves are

shipped loose to insure that no shipping damage occurs to the

piping or the coil connection stub from the weight of the valve

and to provide the installing contractor with maximum flexibility in making the field piping connections. Refer to AAFHermanNelson factory instruction sheet shipped with the unit

for port orientation and a piping schematic. Control valves

must be installed on the units in which they are shipped.

Indiscriminate mixing of valves among units can result in

valves not properly sized for the desired flow rate. Control

valves should be installed so that there is 2" minimum clearance to remove the actuator from the valve body. As a future

service consideration, provide unions for removal of the unit

coil and/or the control valve.

Notes:

1

Three-way control valve (AAF-HermanNelson)

2

Coil air vent (AAF-HermanNelson)

3

Coil drain (AAF-HermanNelson)

4

Shutoff valve (Others)

5

Balancing shutoff valve(s) (Others)

6

Supply

7

Return

8

Unions (Others)—Must disconect below floor line

9

Two-way, two-posiiton valve (AAF-HermanNelson)

10

Union: Half attached to coil, half attached to valve

11

Modulating control valve (AAF-HermanNelson)

12

All piping, fittings and unions by others (not AAFHermanNelson) except as noted

13

Check valve and pressure equalizing line (AAFHermanNelson)

14

Float and thermostaic steam trap (Others)

15

Supply and return coil connection and stub-up unions by

others

Steam Coil Piping Arrangements (see Note 12)

Piping Within Unit End Compartment Piping Outside Unit End Compartment

F&BP With End-of-Cycle Valve

F&BP With End-of-Cycle Valve

2-Way Modulating Valve Control

IM 503-1 / Page 11

Page 12

Pre-installation Checklist

¨ Lintel installed above wall louver to support masonry

wall

¨ Bird screen on wall louver facing toward room interior

¨ Embossments of wall louver at bottom and free for

drainage.

¨ Wall sleeved to prevent moisture seepage into wall

¨ Free opening under wall louver clear for water run-out

¨ Wall louver anchored and sealed against air and water

leaks

¨ Horizontal air splitter between wall sleeve and louver

(if required)

¨ Wall sleeve anchored and sealed against air or water leaks

¨ Shipping brace on condenser fan shaft removed

¨ Condenser fan shaft coupling and bearing secure

¨ Room air in shaft coupling and bearing secure

¨ All fan wheels rotate freely and quietly

¨ Any debris removed from inside unit

¨ Unit identified and correct for location

¨ Access space provided for maintenance, service and

unit removal

¨ Shipping carton saved for use later to protect unit

¨ Check unit nameplate to verify that power supply is

correct

Post-installation Checklist

¨ Unit securely fastened to wall sleeve

¨ Electrical hook-up complete; power, control, wall

thermostat (if applicable) in accordance with unit wiring

diagrams.

¨ Air filter clean and in place

¨ All access and end panels in place and protective

covering removed

¨ Room air fan shaft bearing oiled

¨ Unit square and level and running smoothly and quietly

¨ No air infiltration

¨ Paint nicks and scratches touched up (as required)

¨ Shipping carton replaced over unit for protection

Page 12 / IM 503-1

Page 13

Field Wiring Controls, Maximum Outdoor Air Unit

Wall Sleeve Junction Box - Right End

YEL

36

37

BRN

Factory Wiring

Furnished

Only As Required

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

904A

910

911

For Further

Information

See Appropriate Field

Wiring Detail

Humidistat

Wiring

Day/Night Changeover Control

(Stand-Alone Units Only)

Control

Receptacle

In Wall Sleeve

Junction Box

YEL

36

37

BRN

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

Day/Night

Changeover

(4VA Inrush)

Energize To

Put Unit In

Night

Mode

Control Receptacle

Field Connection

By Others (Not AAF-HermanNelson)

To The Load Side Of SW-1.

[(2) Wires Per Pole If Unit

Has Electric Heat]

SW-1 - - Main Power “On - Off” Switch

Master/Slave

(Stand-Alone Units Only)

Attach Wires From Unit To Unit In Daisy

Chain Fashion, In Any Order. See Chart 1

For Correct Wire/Line Voltage Combination.

Shields Are To Be Grounded In Each Unit.

YEL

36

37

BRN

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

Control Receptacle

In Wall Sleeve

Junction Box

First Unit

BLU

PNK

GRY

Ground

1

2

3

SW-1

L1

Main Power Supply

(Omit L3 For Single

L2

Phase Applications)

L3

Field Wiring

Network Wiring

(Network Units Only)

Attach Wires From Unit To Unit In Daisy

Chain Fashion. In Any Order, See Chart 2

For Correct Wire/Line Voltage Combination.

Shields Are To Be Grounded In Each Unit.

YEL

36

37

BRN

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

Control Receptacle

In Wall Sleeve

Junction Box

First Unit

BLU

PNK

GRY

Ventilation Lockout Control

(Stand-Alone Units Only)

YEL

36

37

BRN

Control

Receptacle

In Wall Sleeve

Junction Box

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

Exhaust Fan Interlock

YEL

36

37

BRN

Control

Receptacle

In Wall Sleeve

Junction Box

BLK

WHT

RED

GRN

ORG

BLU

PNK

GRY

Vent Lockout

(4VA Inrush)

Energize

To Close The

Outdoor Air Damper

Exhaust Fan

Interlock

(4VA Inrush)

Energize To Open

Outdoor Air

Damper

Chart 1

Belden or

Equivalent

Control Receptacle

In Wall Sleeve

Junction Box

Additional Unit

BLU

PNK

GRY

Control Receptacle In

Wall Sleeve Junction

Box Last Unit

Wire Mfg.

2-Wire 8761 9341

Mfg.’s Wire No.

0-300V 301-600V

Chart 2

Belden or

Equivalent

Control Receptacle

In Wall Sleeve

Junction Box

Additional Unit

BLU

PNK

GRY

Control Receptacle In

Wall Sleeve Junction

Box Last Unit

Wire Mfg.

2-Wire 8761 9341

To Local

Master Panel

Mfg.’s Wire No.

0-300V 301-600V

Pneumatic Day/Night ChangeoverControl

(Stand-Alone Units Only)

YEL

36

Control

Receptacle

In Wall Sleeve

Junction Box

37

BRN

Pneumatic/Electric

BLK

Switch.

WHT

Close Contacts

To Put Unit In

RED

Night Mode. (24VAC,

GRN

Class II, 1 AMP)

ORG

BLU

PNK

GRY

IM 503-1 / Page 13

Page 14

Wall Mounted Room Air Sensors

Control

Receptacle

in wall sleeve

junction box

Control

Receptacle

in wall sleeve

junction box

Sensor

Terminal

Board

Sensor

Terminal

Board

Wall Sensor

3.30

(Ref.)

4.87

3.06

(Ref.)

1.50

Wall Sensor With Tenant Override

3.30

(Ref.)

4.87

3.06

(Ref.)

1.50

Transparent

Lens For

Green LED

Transparent

Lens For

Green LED

Tenant

Override

Switch

Main Power To 0 To 301 To

Unit (Volts) 300V 600V

Shielded Wire Manufacturer

Manufacturer Wire No.

Belden

or Equiv.

Dearborn 4-Wire – 1061804

Do not install sensor wires in same conduit

with power wiring. Ground shield in wall

sleeve junction box.

Main Power To 0 To 301 To

Unit (Volts) 300V 600V

Shielded Wire Manufacturer

Manufacturer Wire No.

Belden

or Equiv.

Dearborn 4-Wire – 1061804

Do not install sensor wires in same conduit

with power wiring. Ground shield in wall

sleeve junction box.

4-Wire 8729 –

4-Wire 8729 –

Control

Receptacle

in wall sleeve

junction box

Control

Receptacle

in wall sleeve

junction box

Wall Sensor With Tenant Override & Setpoint Adjustment

3.30

Sensor

Terminal

Board

1.50

3.06

4.87

(Ref.)

(Ref.)

Setpoint Adjust

Potentiometer

Transparent

Lens For

Green LED

Tenant

Override

Switch

Do not install sensor wires in same conduit

with power wiring. Ground shield in wall

sleeve junction box.

Wall Sensor With Setpoint Adjustment

3.30

(Ref.)

Transparent

Lens For

Green LED

4.87

3.06

(Ref.)

Sensor

Terminal

Board

1.50

Setpoint Adjust

Potentiometer

Do not install sensor wires in same conduit

with power wiring. Ground shield in wall

sleeve junction box.

Main Power To 0 To 301 To

Unit (Volts) 300V 600V

Shielded Wire Manufacturer

Manufacturer Wire No.

Belden

or Equiv.

Dearborn 4-Wire – 1061804

Main Power To 0 To 301 To

Unit (Volts) 300V 600V

Shielded Wire Manufacturer

Manufacturer Wire No.

Belden

or Equiv.

Dearborn 4-Wire – 1061804

4-Wire 8729 –

4-Wire 8729 –

IM 503-1 / Page 14

Page 15

End Panel Assembly

The final step of unit installation is attaching the end panels.

End panels are required unless the unit has adjoining matching cabinets.

1. Refer to Figure 15 for 1 " thick end panel. Attach two (2)

Tinnerman nuts to the top edge of the end panel and two

(2) to the bottom end of the unit. Align the end panel with

the front and top edges of the unit. Attach end panel to the

unit using four (4)

2. Refer to Figure 15 for 6" thick end panel.

a. Position bracket (YC1934) on wall so angle is 5" from

end of unit and near bottom.

Figure 15. 1" End Panel

5

⁄32" hex socket head fasteners provided.

b. Mark and drill required hole for device to fasten bracket

to wall (not included).

c. Attach bracket to wall.

d. Attach two (2) Tinnerman nuts to the top edge of the end

panel and one (1) to the bottom front of the end frame.

e. Align the end panel with the front and top edges of the unit.

5

⁄

Attach end panel to the unit using three (3)

" hex socket

32

head fasteners provided. Bracket should prevent move-

ment of panel toward the unit when pressure is applied to

the end panel.

Figure 15. 6" End Panel

End of Unit

Bracket

YC 1934

IM 503-1 / Page 15

Page 16

Product Warranty

AAF-McQuay Incorporated, hereinafter referred to as the

"Company," warrants that it will provide, at the Company's

option, either free replacement parts or free repair of component parts in the event any product manufactured by the

Company and used in the United States and Canada proves

defective in material or workmanship within twelve (12) months

from initial start-up or eighteen (18) months from the date

shipped by the Company, whichever comes first. For additional consideration, the Company warrants that for four (4)

years following the initial warranty period it will provide, at the

Company's option, free replacement parts for the motorcompressor, or, free replacement for any integral component

of the motor-compressor which proves defective in material

or workmanship. For an additional consideration, the Company warrants that for nine (9) years following the initial

warranty period it will provide free replacement of the heat

exchanger in gas-fired or oil-fired furnaces which proves

defective in material and workmanship. (Extended warranties

for motor-compressors and heat exchangers are not applicable unless separately purchased.)

To obtain assistance under this parts warranty, extended

motor-compressor warranty, or extended heat exchanger

warranty, simply contact the selling agency. To obtain information or to gain factory help for AAF-McQuay, and

HermanNelson brandnames, contact AAF-McQuay Incorporated, Warranty Claims Department, 4900 Technology Park

Boulevard, Auburn, New York 13021-9030, telephone (315)253-2771.

This warranty constitutes the buyer's sole remedy. It is

given In lieu of all other warranties. There is no implied

warranty merchantability or fitness for a particular purpose. In no event and under no circumstances shall the

Company be liable for incidental or consequential damages, whether the theory be breach of this or any other

warranty, negligence or strict tort.

This parts warranty and the optional extended warranties

extend only to the original user. Of course, abuse, misuse, or

alteration of the product in any manner voids the Company's

warranty obligation. Neither the parts or extended warranty

obligates the Company to pay any labor or service costs for

removing or replacing parts, or any shipping charges. Refrigerants, fluids, oils, and expendable items such as filters are

not covered by this warranty.

The extended warranties apply only to integral components of the motor-compressor or heat exchanger, not to

refrigerant controls, electrical controls, or mechanical controls, or to failures caused by failure of those controls.

Attached to this warranty is a requirement for equipment

containing motor-compressors and/or furnaces to report startup information. The registration form accompanying the product must be completed and returned to the Company within

ten (10) days of original equipment start-up. If that is not done,

the date of shipment shall be presumed to be the date of startup and the warranty shall expire twelve (12) months from that

date.

No person (including any agent, salesman, dealer or distributor) has authority to expand the Company's obligation

beyond the terms of this express warranty, or to state that the

performance of the product is other than that published by the

Company.

AAF-HermanNelson

4900 Technology Park Boulevard, Auburn, NY 13021-9030 USA, (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer material.

©1999 AAF-HermanNelson

Page 16 / IM 503-1 (Rev. 6/99)

Loading...

Loading...