Page 1

Installation Manual IM 1 167

Group: Chillers

Pathfinder® Air Cooled Chillers

Part Number:

Date: July 23, 2012

Model AWS-B (Rev 0B) • Standard, High, & Premium Efficiencies

Includes models with VFD and models with Remote Evaporator

170 to 550 tons • 600 to 1930 kW • R-134a • 60Hz

IM 1167

REV

00

© 2012 McQuay International

Page 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Modbus

Installation and Startup . . . . . . . . . . . . . . . . . . . . . . 4

Clearance Requirements . . . . . . . . . . . . . . . . . 5

Chilled Water Piping. . . . . . . . . . . . . . . . . . . . 10

Physical Data (non-VFD) . . . . . . . . . . . . . . . . . . . . 15

Physical Data (VFD) . . . . . . . . . . . . . . . . . . . . . . . . 30

Lifting & Mounting Weights (I-P Units). . . . . . . . . 39

Lifting & Mounting Weights (SI Units) . . . . . . . . . 41

Lifting & Mounting Locations - Index of Drawings 43

Dimensions (non-VFD). . . . . . . . . . . . . . . . . . . . . . 44

Dimensions (VFD). . . . . . . . . . . . . . . . . . . . . . . . . . 50

Isolator Locations and Kit Numbers. . . . . . . . . . . 55

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Multipoint Electrical Data (non-VFD) . . . . . . . . . . 67

Multipoint Field Wiring Data (non-VFD) . . . . . . . . 78

Terminal Amps (non-VFD) (single/multi-point) . . 88

Single-point Electrical Data (non-VFD) . . . . . . . . 92

Single-point Field Wiring Data (non-VFD). . . . . . 97

Multipoint Electrical Data (VFD). . . . . . . . . . . . . 101

Multipoint Field Wiring Data (VFD) . . . . . . . . . . 104

Terminal Amps (VFD) (single- and multi-point) 105

Single-point Electrical Data (VFD) . . . . . . . . . . . 106

Single-point Field Wiring Data (VFD). . . . . . . . . 107

Pressure Drop Data. . . . . . . . . . . . . . . . . . . . . . . 108

Remote Evaporators. . . . . . . . . . . . . . . . . . . . . . 115

Remote Evaporator Refrigerant Piping. . . . 116

Remote Evaporator Dimensions . . . . . . . . . . . . 123

Remote Evaporator Unit Dimensions . . . . . . . . 126

Remote Evaporator Lifting & Mounting Weights 152

Remote Evaporator Isolators. . . . . . . . . . . . . . . 154

Remote Evaporator Lifting & Mounting Locations 158

Remote Evaporator Physical Data. . . . . . . . . . . 166

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . 181

Hazard Identification

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not

avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

Document: IM 1167

Issue Date: July 23, 2012

Revision Date: -Replaces: NEW

©2012 McQuay International. Illustrations and data cover the McQuay International product at the time of publicat ion and we reserve the right to make change s in design

and construction at anytime without notice. ™® The following are trademarks or register ed tradema rks of their r espective comp ani es: BACnet from ASHRAE; LONMARK ,

LonTalk, LONWORKS, and the LONMARK logo are managed, granted and used by LONMARK International under a license granted by Echelon Corporation; ElectroFin

from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech III, Open Choices, and SpeedTrol from McQuay International

2 IM 1122-2

Page 3

Introduction

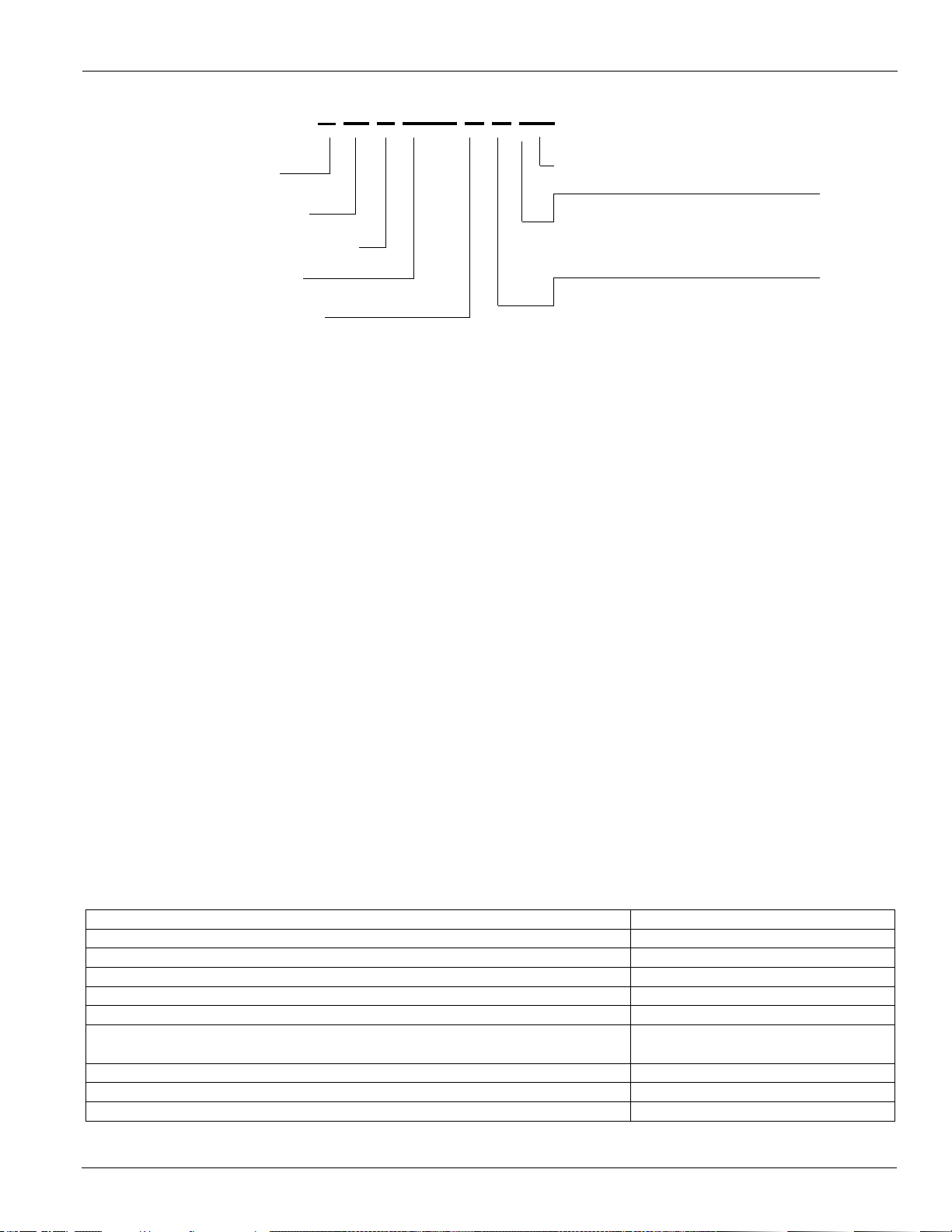

S = Standard Efficiency

H = High Efficiency

A

W S XXX B D SE

Air-Cooled

World Product

Screw Compressor

Nominal Tons

D = Dual Compressor

Design Vintage

T = Triple Compressor

P = Premium Efficiency

E = Standard Packaged

M = Remote Evaporator

Figure 1: Model Nomenclature

General Description

Daikin McQuay Pathfinder™ air-cooled chillers are complete,

self-contained chillers that include the latest in engineered

components arranged to provide a compact and efficient unit.

Each unit is completely assembled, factory wired, evacuated,

charged, tested and comes complete and ready for installation.

Each of two circuits consists of an air-cooled condenser

section with an integral subcooler section, a semi-hermetic,

single-screw compressor with starter, a multi-circuit, shelland-tube, direct expansion evaporator, an economizer and

complete refrigerant piping. Each compressor has an

independent refrigeration circuit. Liquid line components

included are a manual liquid line shutoff valve, charging port,

filter-drier, sight-glass/moisture indicator, and electronic

expansion valve. A combination discharge check and shutoff

valve is included and a compressor suction shutoff valve is

optional. Other features include compressor heaters,

evaporator heaters for freeze protection, automatic, one-time

pumpdown of each refrigerant circuit upon circuit shutdown,

and an advanced fully integrated microprocessor control

system.

Pathfinder units are available as standard efficiency (BDS) or

high efficiency (BDH) or premium efficiency (BDP). A high

ambient option is required for operation in ambient

temperatures above 100F (37.8C) and up to 125F (51.7C)

and when the VFD low ambient option is selected.

Introduction

Information on the operation of the unit MicroTech

controller is in the OM 1123 manual, available on

www.daikinmcquay.com.

Remote Evaporator Models

For enhanced application flexibility, AWS non-VFDand VFD

models are also available as remote evaporator models.

Information on remote evaporator units can be found

beginning on page 117.

Inspection

When the equipment is received, carefully check all items

against the bill of lading to verify for a complete shipment.

Check all units for damage upon arrival. All shipping damage

must be reported to the carrier and a claim must be filed with

the carrier. Check the unit’s serial plate before unloading the

unit to be sure that it agrees with the power supply available.

Physical damage to a unit after shipment is not McQuay

International’s responsibility.

Note: Unit shipping and operating weights are shown in the

Physical Data Tables beginning on page 15.

III

Table 1: Operating Limits

Maximum standby ambient temperature 130°F (55°C)

Maximum operating ambient temperature 100°F (37.8°C)

with optional high ambient package (see detailed information in Cat 600) 125°F (52°C)

Minimum operating ambient temperature (standard control) 35°F (2°C)

Minimum operating ambient temperature (with optional low-ambient control) 0°F (-18°C)

Leaving chilled water temperature 40°F to 60°F (4.4°C to 15.6°C)

Leaving chilled fluid temperatures (with anti-freeze) - Unloading is not permitted with fluid leaving

temperatures below 30°F (-1°C). 20°F to 60°F (-7°C to 16°C)

Operating chilled water delta-T range 6 to 18°F (-14 to -8°C)

Maximum evaporator operating inlet fluid temperature 76°F (24°C)

Maximum evaporator non-operating inlet fluid temperature 100°F (38°C)

IM 1167 3

Page 4

Installation and Startup

Installation and Startup

Installation and maintenance are to be performed only by

qualified personnel who are familiar with local codes and

regulations, and experienced with this type of equipment.

WARNING

Sharp edges and coil surfaces are a potential injury hazard.

Avoid contact with them.

Start-up by McQuay Factory Service is included on all

Pathfinder units sold for installation within the U.S. and

Canada and must be performed by them to initiate the standard

Limited Product Warranty. Start-up by any party other than

McQuay Factory Service or a McQuay Authorized Service

Representative will void the Limited Product Warranty. Twoweek prior notification of start-up is required. The contractor

should obtain a copy of the Start-up Scheduled Request Form

from the sales representative or from the nearest McQuay

Factory Service office.

WARNING

Escaping refrigerant can displace air and cause suffocation.

Immediately evacuate and ventilate the equipment area. If the

unit is damaged, follow Environmental Protection Agency

(EPA) requirements. Do not expose sparks, arcing equipment,

open flame or other ignition source to the refrigerant.

For pad-mounted units, it is recommended that the unit be

raised a few inches with suitable supports such as neoprene

waffle vibration pads, located at least under the mounting

locations. This will allow water to drain from under the unit

and facilitate cleaning under it.

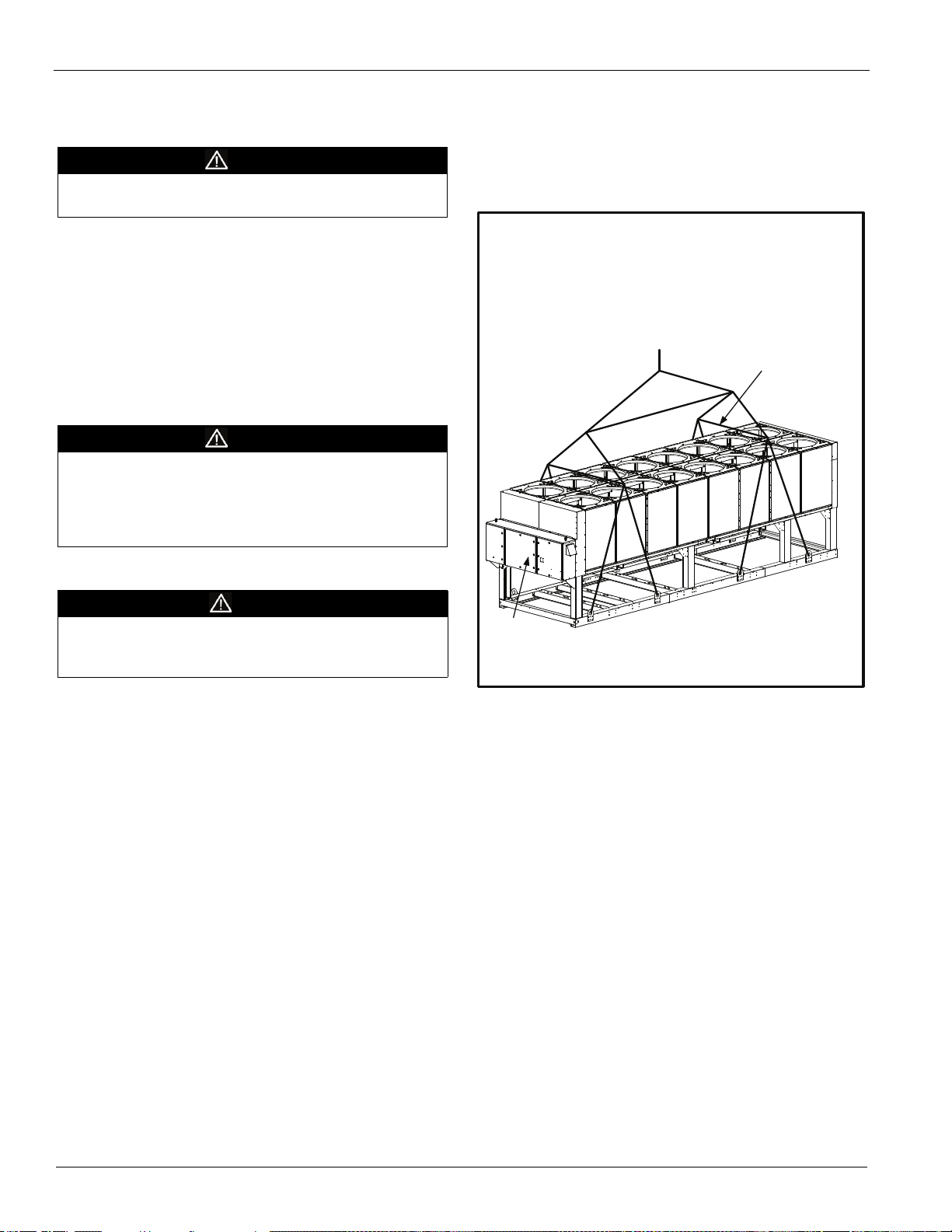

Figure 2: Required Lifting Method

Handling

DANGER

Improper lifting or moving of a unit can result in property

damage, severe personal injury or death. Follow rigging and

moving instructions carefully.

Avoid rough handling shock due to impact or dropping the

unit. Do not push or pull the unit. Never allow any part of the

unit to fall during unloading or moving, as this can result in

serious damage.

To lift the unit, lifting tabs with 3" (76 mm) diameter holes are

provided on the base of the unit. All lifting holes must be used

when lifting the unit. Spreader bars and cables should be

arranged to prevent damage to the condenser coils or unit

cabinet (see Figure 2).

Location

Locate the unit outdoors and carefully to provide proper

airflow to the condenser. (SeeFigure 4, page 5 for required

clearances.)Using less clearance than shown in Figure 4can

cause discharge air recirculation to the condenser and could

have a significant detrimental effect on unit performance.

Due to the shape of the condenser coils on the Pathfinder

chillers, it is recommended that the unit be oriented so that

prevailing winds blow parallel to the unit length, thus

minimizing the wind effect on condensing pressure and

performance. If low ambient temperature operation is

expected, optional louvers should be installed if the unit has no

protection against prevailing winds.

4 IM 1167

NOTES:

1. Unit with 8 lifting points illustrated above; the number of

condenser sections, fans, and lifting points can vary from

this diagram.see lifting/mounting drawings beginning on

page page 44 to identfy the number of lifting points for a

specific unit.

2. All rigging points must be used. See weights at lifting

points beginning on page 39 for each specific size unit.

3. Crosswise and lengthwise spreader bars must be used to

avoid damage to unit.

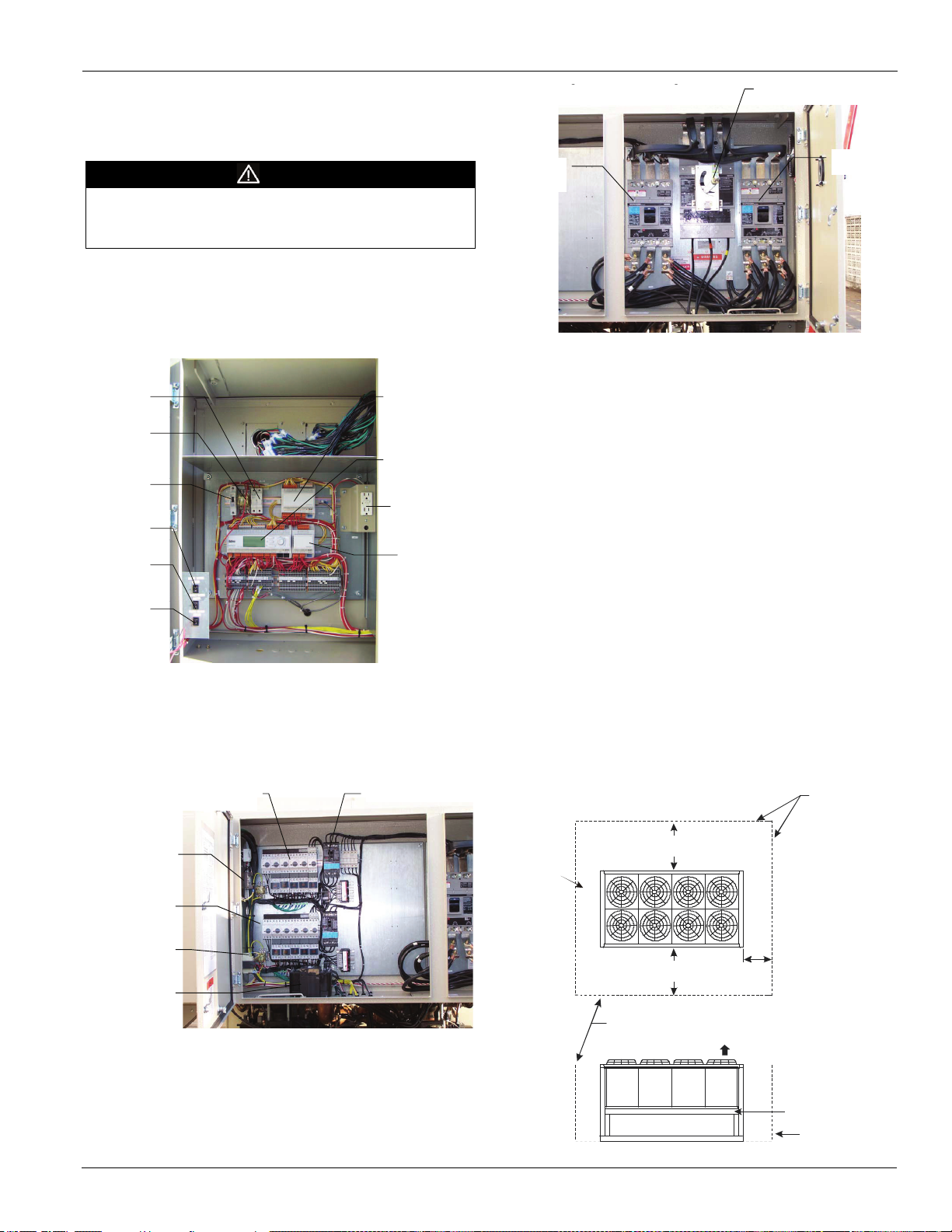

Service Access

Compressors, filter-driers, and manual liquid line shutoff

valves are accessible on each side or end of the unit. The

evaporator heater is located on the barrel.

The control panels are located on the end of the chiller. The

left-hand control box contains the unit and circuit

microprocessors as well as transformers, fuses and terminal.

The right-hand panel contains a circuit breaker. A minimum of

four feet of clearance is required in front of the panels. The

side clearance required for airflow provides sufficient service

clearance.

Page 5

On all Pathfinder units, the condenser fans and motors can be

Fan Contactors, 1 per Fan

Circuit #1

Cir# 1, Fan Circuit Breake

r

Fan Contactors

1

p

er Fan, Circuit #2

Phase/Voltage

Monitor

120/24V

Transforme

r

Line/120V

Transformer

NOTES:

1. The Emergency Switch Relay de-energizes circuit #1 and #2 control power when activated,

causing an immediate compressor and fan shut

down. When ordered, the optional red emergency

button switch is located on the bottom front of the control panel door.

2. The control power transformer is located in the power panel adjacent to the control panel.

3. Additional extension (aka extension) modules are located elsewhere on the chiller.

Alarm & Limit

Extension

Module

MicroTech III

Main

Controller

Optional

115V

Outlet

Cir #1 & #2

Fan Control

Extension

Module

Controller

Fuse

Emergency

Switch

Relay

Control

Circuit

Breaker

Unit On/Off

Switch

Circuit #1

Pumpdown

Switch

Circuit #2

Pumpdown

Switch

g, ,g

Compressor #1

Circuit Breaker

Compressor #2

Circuit Breake

r

5ft (1.5 m)

if open fence or 50% open wall

if solid wall (see note 3 for pit )

5ft (1 .5m)

if open fence or 50% open wall

if solid wall (see note 3 for pit)

No obstructions.

Recommended area

required for unit

operation, air flow

and maintenance

access.

3ft (1m) for service

Se e Note 5

Wall or

Fence

Air Flo

w

No obstructions allowedabove unit at any heightSee notes 2 &

4

concerning wall

height at unit sides.

6ft (1 .8m)

6ft (1.8 m)

4ft (1.2 m)

For electric

panel access

removed from the top of the unit. The complete fan/motor

assembly can be removed for service. The fan blade must be

removed for access to wiring terminals at the top of the motor.

DANGER

Disconnect, lockout and tag all power to the unit before

servicing condenser fan motors or compressors. Failure to do

so can cause bodily injury or death.

Do not block access to the sides or ends of the unit with piping

or conduit. These areas must be open for service access. Do

not block access to the control panels with field-mounted

disconnect switches.

Installation and Startup

Figure 3: Control and Power Panel Component Location

Clearance Requirements

Notes:

1

Minimum side clearance between two units is 12 feet

(3.7 meters).

2 Unit must not be installed in a pit or enclosure that is

deeper or taller than the height of the unit unless extra

clearance is provided per note 4.

3 Minimum clearance on each side is 8 feet (2.4 meters)

when installed in a pit no deeper than the unit height.

4 Minimum side clearance to a side wall or building taller

than the unit height is 6 feet (1.8 meters), provided no

solid wall above 6 feet (1.8 meters) is closer than 12 feet

(3.7 meters) to the opposite side of the unit.

5 Do not mount electrical conduits where they can block

service access to compressor controls, refrigerant driers

or valves.

6 There must be no obstruction of the fan discharge.

7 Field installed switches must not interfere with service

access or airflow.

Figure 4: Clearance Requirements

IM 1167 5

Page 6

Installation and Startup

AWS PACKAGE CHILLER

331994701 REV. 0D

CHARGING

VALV E

LIQUID

TUBING

BALL

VALVE

CHARGING

VALV E

SOLENOID

VALVE

FILTER

DRYER

SOLENOID

VALV E

(OPTIONAL)

SIGHT

GLASS

EXPANSION

VALVE

WATER I N

WATER O UT

DX EVAPORATOR

SUCTION

TUBING

OIL PRESS.

TRANSDUCER

WITH SCHRADER

VALV E

DISCHARGE

TUBING

AIR

FLOW

AIR

FLOW

CONDENSER

ASSEMBLY

F3/F4

COMPRESSOR

RELIEF

VALV E

SUCTION

TEMP. SENSOR

SUCTION

TRANSDUCER

DISCHARGE

TEMP. SENSOR

(WOE)

TEMP. SENSOR

(WIE)

TEMP. SENSOR

OUTSIDE AIR

TEMPERATURE

(WAA)

SCHRADER

VALVE

SCHRADER

VALVE

SHUT-OFF

VALV E

BUTTERFLY

VALVE

(OPTIONAL)

RELIEF

VALV E

DISCHARGE

TRANSDUCER

SCHRADER

VALV E

STRAINER

BALL

VALVE

LIQUID

INJECTION

TUBING

SCHRADER

VALVE

(HEADER)

SCHRADER

VALV E

CHARGING

VALV E

Note: Provide 20-mesh strainer

at evaporator inlet

AWS PACKAGE CHILLER

WITH ECONOMIZER

331994701 REV. 0D

CHARGING

VALV E

LIQUID

TUBING

BALL

VALV E

ECONOMIZER

ECONOMIZER FLASH GAS TO COMPRESSOR INTERSTAGE

LIQUID

INJECTION

TUBING

FILTER

DRYER

SOLENOID

VALV E

(OPTIONAL)

SIGHT

GLASS

EXPANSION

VALV E

WATER I N

WATER OU T

DX EVAPORATOR

SUCTION

TUBING

OIL PRESS.

TRANSDUCER

WITH SCHRADER

VALV E

DISCHARGE

TUBING

AIR

FLOW

AIR

FLOW

CONDENSER

ASSEMBLY

F3/F4

COMPRESSOR

RELIEF

VALV E

SUCTION

TEMP. SENSOR

SUCTION

TRANSDUCER

DISCHARGE

TEMP.SENSOR

(WOE)

TEMP. SENSOR

(WIE)

TEMP. SENSOR

OUTSIDE AIR

TEMPERATURE

(WAA)

SCHRADER

VALV E

SCHRADER

VALV E

SCHRADER

VALV E

CHARGING

VALV E

SOLENOID

VALV E

TGE

EXPANSION

VALV E

SHUT-OFF

VALV E

CHECK

VALV E

CHECK

VALV E

BUTTERFLY

VALV E

(OPTIONAL)

RELIEF

VALV E

DISCHARGE

TRANSDUCER

BALL

VALV E

SCHRADER

VALV E

SOLENOID

VALV E

SCHRADER

VALV E

STRAINER

SCHRADER

VALV E

(HEADER)

VALV E

CHARGING

VALV E

Note: Provide20-mesh strainer

at evaporator inlet

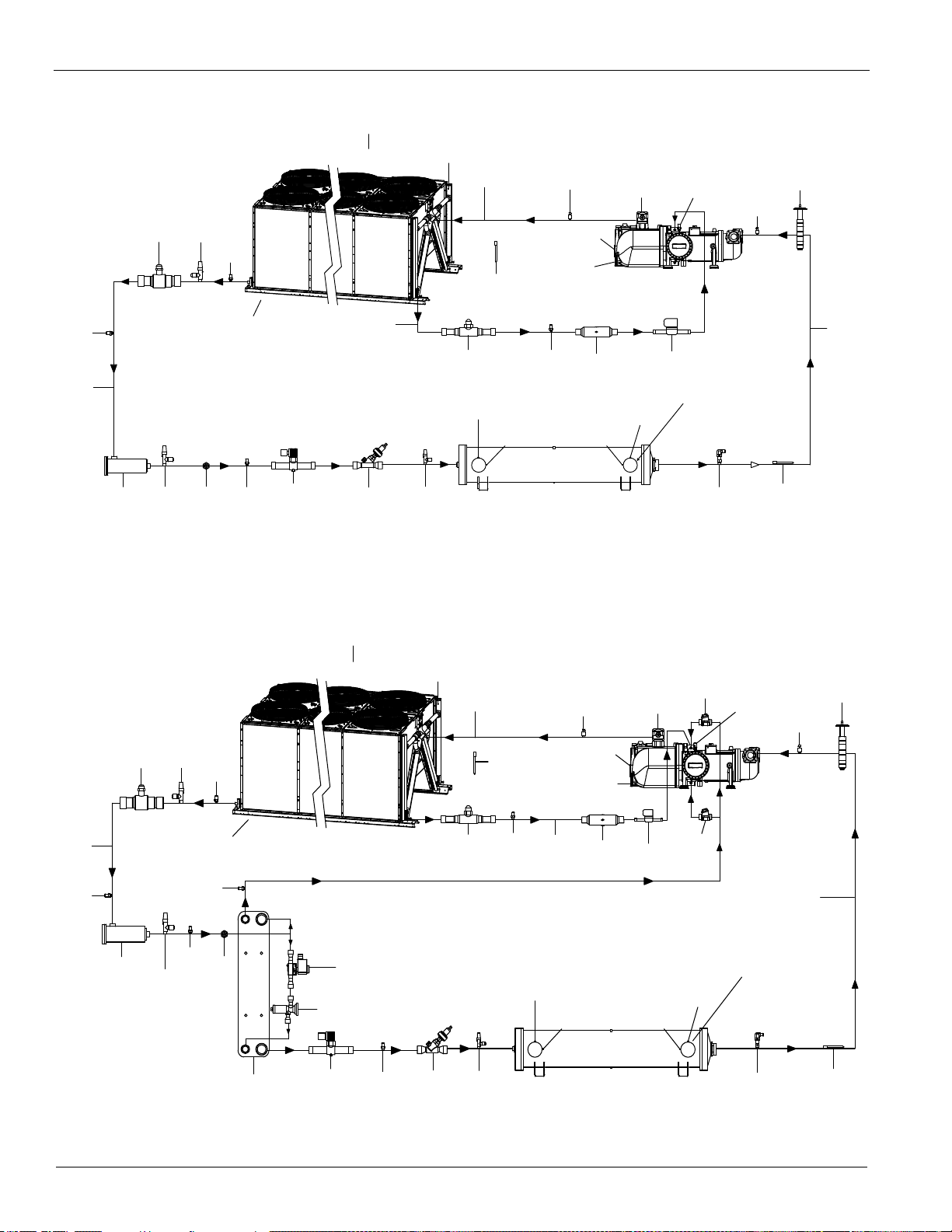

Figure 5: Refrigerant Diagram - All Standard Efficiency Models (one circuit shown of two or three possible circuits)

Figure 6: Refrigerant Diagram-All High and PremiumEfficiency Models (one circuit shown of two - three possible circuits)

6 IM 1167

Page 7

Installation and Startup

Building

Full Load Capacity Adjustment Factor

D=4 ft (1 .2m)

D=5 ft (1 .5m)

D=6 ft (1 .8m)

0.00

0.25

0.50

0.75

1.00

8

(2.4)

16

(4.8)

24

(7.2)

H - Height of W all or Building in ft. (m )

)

Full Load Power Adjustment Factor

D=4 ft (1 .2m)

D=5 ft (1 .5m)

D=6 ft (1 .8m)

0.00

0.50

1.00

1.50

2.00

8

(2.4)

16

(4.8)

24

(7.2)

H - Height of W all or Building in ft . (m)

Power Increase ( %)

H

D

Restricted Air Flow

The clearances required for design operation of Pathfinder aircooled chillers are described in the previous section.

Occasionally, these clearances cannot be maintained due to site

restrictions such as units being too close together or a fence or

wall restricting airflow, or both. Pathfinder chillers have

several features that may help mitigate the penalties

attributable to restricted airflow.

"The condenser section is "W" shaped, as shown below. This

allows inlet air for these coils to come in from both sides and

the bottom. All the coils in one "V" section serve one

compressor. Each compressor has its own independent

refrigerant circuit.

"The MicroTech III control is proactive in response to "offdesign conditions". In the case of single or compounded

influences restricting airflow to the unit, the microprocessor

will act to keep the unit running (at reduced capacity), rather

than allowing a shut-off on high discharge pressure.

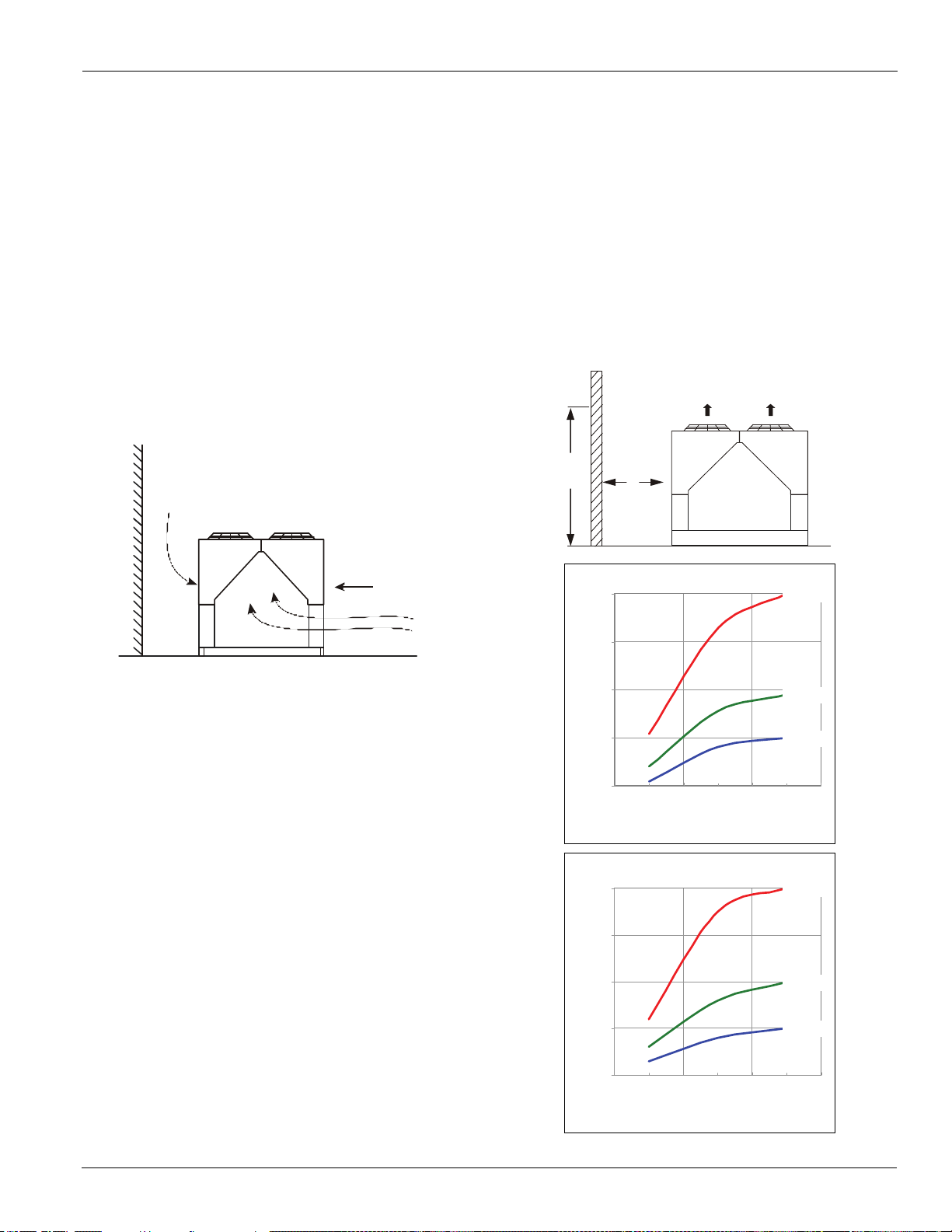

Case 1: Building or Wall on One Side of One Unit

The existence of a screening wall or the wall of a building in

close proximity to an air-cooled chiller is common in both

rooftop and ground level applications. Hot air recirculation on

the coils adjoining the wall will increase compressor discharge

pressure, decreasing capacity and increasing power

consumption.

When close to a wall, it is desirable to place chillers on the

north or east side of them. It is also desirable to have

prevailing winds blowing parallel to the unit's long axis. The

worst case is to have wind blowing hot discharge air into the

wall.

Figure 7: Unit Adjacent to Wall - Adjustment Factors

Capacity Reduction (%

IM 1167 7

Page 8

Installation and Startup

Full Load Capacity Adjustment Factor

0.00

0.50

1.00

1.50

6

(1.8)

8

(2.4)

10

(3.0)

12

(3.6)

Distance Between Units in ft. (m)

)

Full Load Power Adjustment Factor

0.00

0.50

1.00

1.50

2.00

2.50

3.00

6

(1.8)

8

(2.4)

10

(3.0)

12

(3.6)

Distance Between Units in ft. (m)

Power Increase (%)

Full Load Capacity Adjustment Factor

0.00

1.00

2.00

3.00

8

(2.4)

12

(3.6)

16

(4.8)

20

(6.1)

Distance Between Units in ft. (m)

)

Full Load Power Adjustment Factor

0.00

2.00

4.00

6.00

8

(2.4)12(3.6)16(4.8)20(6.1)

Distance Between Units in ft. (m)

Power Increase (%)

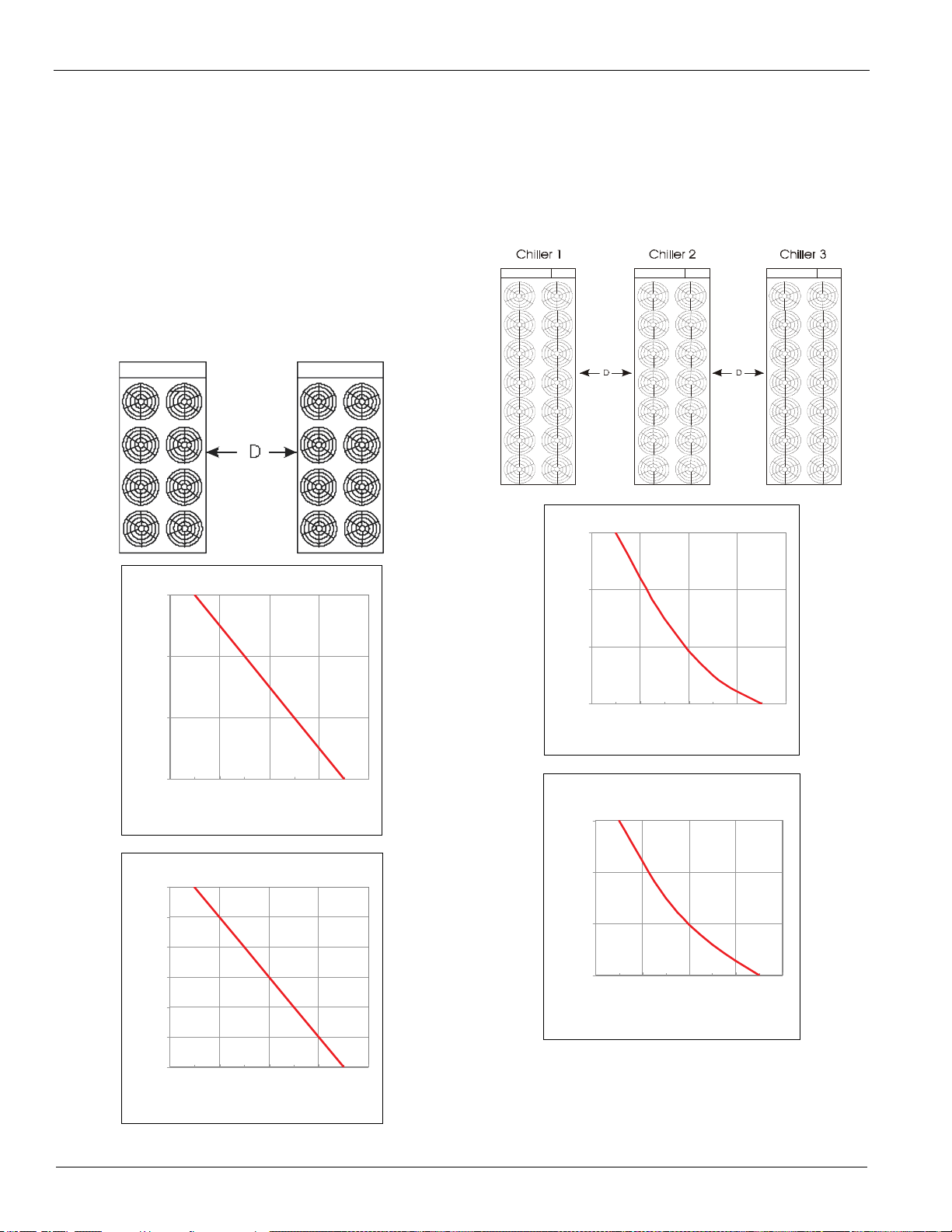

Case 2: Two Units Side By Side

Two or more units sited side by side are common. If spaced

closer than 12 feet (3.7 meters) it is necessary to adjust the

performance of each unit; circuits adjoining each other are

affected. If one of the two units also has a wall adjoining it, see

Case 1. Add the two adjustment factors together and apply to

the unit located between the wall and the other unit.

Mounting units end to end will not necessitate adjusting

performance.

Do not use pit or solid wall surrounds where the ambient air

temperature exceeds 105F (40C).

Figure 8: Two Units Side by Side - Adjustment Factors

Case 3: Three or More Units Side By Side

When three or more units are side by side, the outside chillers

(1 and 3 in this case) are influenced by the middle unit only on

their inside circuits. Their adjustment factors will be the same

as Case 2. All inside units (only number 2 in this case) are

influenced on both sides and must be adjusted by the factors

shown below.

Figure 9: Three or More Units - Adjustment Factor

Capacity Reduction (%

Capacity Reduction (%

8 IM 1167

Page 9

Installation and Startup

Wall Free Area vs Distance

0.00

2.00

4.00

6.00

8.00

0 1020304050

% Open Wall Area

D - Distance from Wall to Unit in Ft. (m)

Full Load Power Adjustment Factor

D= 6 ft ( 1.8 m)

D=8 ft (2.4m )

(3.1 m )

0.00

2.00

4.00

6.00

8.00

8

(2.4)

10

(3.1)

12

(3.7)

14

(4.3)

H - H e ig ht o f W all or B uild in g in ft. ( m)

Power Increas e (%)

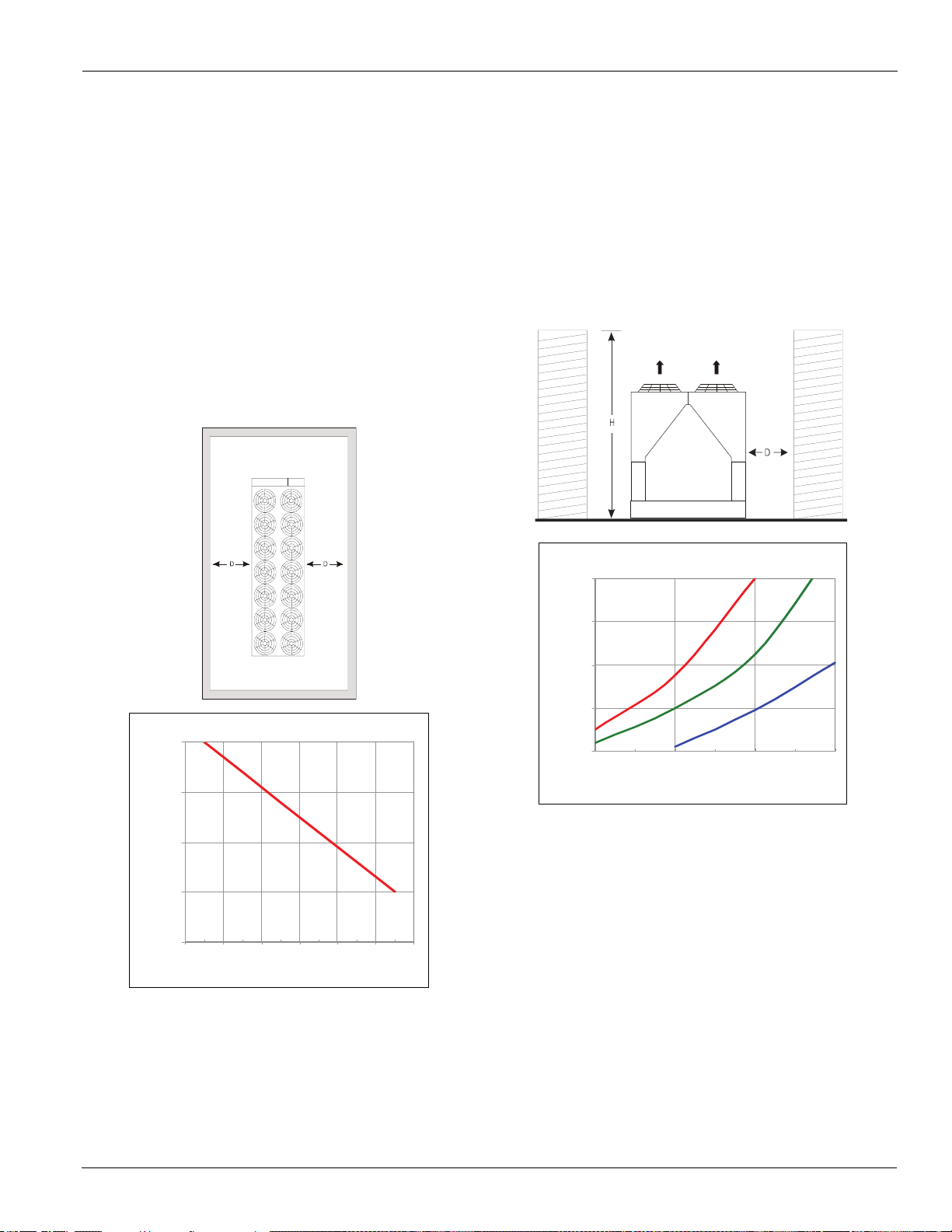

Case 4: Open Screening Walls

Decorative screening walls are often used to help conceal a

unit either on grade or on a rooftop. Design these walls such

that the combination of their open area and distance from the

unit do not require performance adjustment. It is assumed that

the wall height is equal to or less than the unit height when

mounted on its base support. This is usually satisfactory for

concealment. If the wall height is greater than the unit height,

see Case 5, Pit Installation.

The distance from the sides of the unit to the side walls must

be sufficient for service, such as opening control panel doors.

If each side wall is a different distance from the unit, the

distances can be averaged providing either wall is not less than

8 feet (2.4 meters) from the unit. For example, do not average

4 feet and 20 feet to equal 12 feet (1 meter and 5 meters to

equal 3 meters).

Figure 10: Open Screening Walls - Adjustment Factors

Case 5, Pit/Solid Wall Installation

Use care with pit installations as they can cause operating

problems. Recirculation and restriction can both occur. Use

this information for a solid wall around unit A.

If steel grating is used used to cover a pit, the grating material

and installation design must be strong enough to prevent

accidents, yet provide abundant open area to prevent air

recirculation. Have any pit installation reviewed by the Daikin

McQuay sales representative prior to installation to make sure

there is sufficient air-flow clearance. .

Figure 11: Pit Installation - Adjustment Factors

D=1 0 ft

IM 1167 9

Page 10

Installation and Startup

Chilled Water Piping

IMPORTANT: Piping design must be provided by a

qualified Architect or Systems HVAC Design Engineer

familiar with piping design, as well as local codes and

regulations. The manufacturer recommendations provided

here are to be used as a general guide, but do not replace

system design by a qualified professional.

Design the piping with a minimum number of bends and

changes in elevation to keep system cost down and

performance up. It should contain:

1 Vibration eliminators to reduce vibration and noise

transmission to the building.

2 Shutoff valves to isolate the unit from the piping system

during unit servicing.

3 Manual or automatic air-vent valves at the high points of

the system and drains at the low parts in the system. The

evaporator should not be the highest point in the piping

system.

4 Some means of maintaining adequate system water

pressure (i.e., expansion tank or regulating valve).

5 Water temperature and pressure indicators located at the

evaporator inlet and outlet to aid in unit servicing. Any

connections should be made prior to filling the system

with water.

6 A strainer to remove foreign matter from the water

before it enters the pump. Place the strainer far enough

upstream to prevent cavitation at the pump inlet (consult

pump manufacturer for recommendations). The use of a

strainer will prolong pump life and help maintain high

system performance levels. Note: A 20-mesh strainer

must also be placed in the supply water line just prior to

the inlet of the evaporator. This will aid in preventing

foreign material from entering the evaporator and

causing damage or decreasing its performance. Care

must also be exercised if welding pipe or flanges to the

evaporator connections to prevent any weld slag from

entering the evaporator.

7 Any water piping to the unit must be protected to prevent

freeze-up if below freezing temperatures are expected.

8 If the unit is used as a replacement chiller on a

previously existing piping system, flush the system

thoroughly prior to unit installation. Perform regular

chilled water analysis and chemical water treatment

immediately at equipment start-up.

9 In the event glycol is added to the water system as a late

addition for freeze protection, recognize that the

refrigerant suction pressure will be lower, cooling

performance less, and water side pressure drop greater. If

the percentage of glycol is large, or if propylene is

employed in lieu of ethylene glycol, the added pressure

drop and loss of performance could be substantial.

10 Do not use PVC or CPVC piping due to incompatibility

with POE oil in the event of a refrigerant to water leak.

11 For ice making or low temperature glycol operation, a

different freezestat pressure value is usually required.

The freezestat setting can be manually changed through

the MicroTech III controller.

Make a preliminary leak check prior to insulating the water

piping and filling the system.

Include a vapor barrier with the piping insulation to prevent

moisture condensation and possible damage to the building

structure. It is important to have the vapor barrier on the

outside of the insulation to prevent condensation within the

insulation on the cold surface of the pipe.

Chilled Water Pump

It is important that the chilled water pumps be wired to, and

controlled by, the chiller's microprocessor. The chiller

controller has the capability to selectively start pump A or B or

automatically alternate pump selection and also has standby

operation capability. The controller will energize the pump

whenever at least one circuit on the chiller is enabled to run,

whether there is a call for cooling or not. This helps ensure

proper unit start-up sequence. The pump will also be turned on

when the water temperature reaches 1°F below the Freeze

Setpoint to help prevent evaporator freeze-up. Wiring

connection points are shown in Figure 41, page 65.

CAUTION

Adding glycol or draining the system is the recommended

method of freeze protection. If the chiller does not have the

ability to control the pumps and the water system is not drained

in temperatures below freezing, catastrophic evaporator failure

may occur.

Failure to allow pump control by the chiller may cause the

following problems:

1 If any device other than the chiller attempts to start the

chiller without first starting the pump, the chiller will

lock out on the No Flow alarm and require manual reset.

2 If the chiller evaporator water temperature drops below

the “Freeze setpoint” the chiller will attempt to start the

water pumps to avoid evaporator freeze. If the chiller

does not have the ability to start the pumps, the chiller

will alarm due to lack of water flow.

3 If the chiller does not have the ability to control the

pumps and the water system is not to be drained in

temperatures below freezing, the chiller may be subject

to catastrophic evaporator failure due to freezing. The

freeze rating of the evaporator is based on the immersion

heater and pump operation. The immersion heater itself

may not be able to properly protect the evaporator from

freezing without circulation of water.

10 IM 1167

Page 11

Installation and Startup

Optional Inlet Strainer

An inlet water strainer kit is available as a shipped-loose

option, sized per Tab le 2 and with the pressure drop shown in

Figure 12. The kit is field installed and consists of:

• Y-type 40% open area strainer with 304 stainless steel

perforated basket, Victaulic pipe connections and

strainer cap

• Extension pipe with two Schrader fittings that can be

used for a pressure gauge and thermal dispersion flow

switch. The pipe provides sufficient clearance from the

evaporator for strainer basket removal.

• ½-inch blowdown valve

• Two Victaulic clamps

Table 2: Strainer Sizing Data

AWS Model

175ADS-250ADS

210ADH-250ADH

280ADS-350ADS

280ADH-405ADH

375ADS-530ADS

445ADH-530ADH

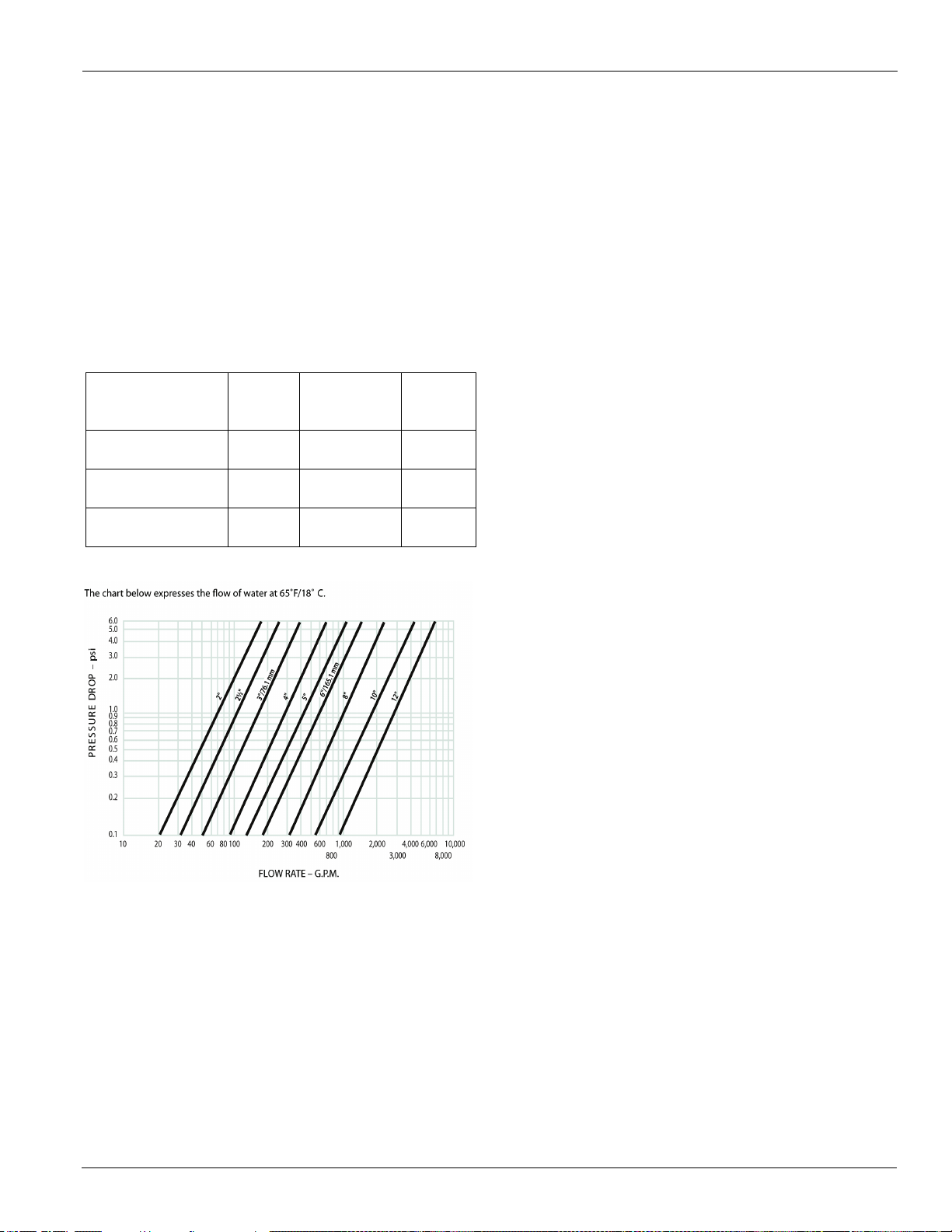

Figure 12: Strainer Pressure Drop

Strainer

Size (in.)

630.572

8 36.0 125

10 43.0 205

Strainer Plus

Pipe Length

(in.)

Strainer

Weight

(lbs)

McQuay thermal dispersion flow switch and a water pressure

gauge. The ball valve can be installed in the strainer basket

cover as a blow-down valve.

System Water Volume

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes.

Some of the things the designer should consider when looking

at water volume are the minimum cooling load, the minimum

chiller plant capacity during the low load period and the

desired cycle time for the compressors.

Assuming that there are no sudden load changes and that the

chiller plant has reasonable turndown, a rule of thumb of

"gallons of water volume equal to two to three times the

chilled water gpm flow rate" is often used.

A properly designed storage tank should be added if the

system components do not provide sufficient water volume.

Variable Speed Pumping

Variable water flow involves reducing the water flow through

the evaporator as the load decreases. Daikin McQuay chillers

are designed for this duty, provided that the rate of change in

water flow is slow, and the minimum and maximum flow rates

for the evaporator are not exceeded.

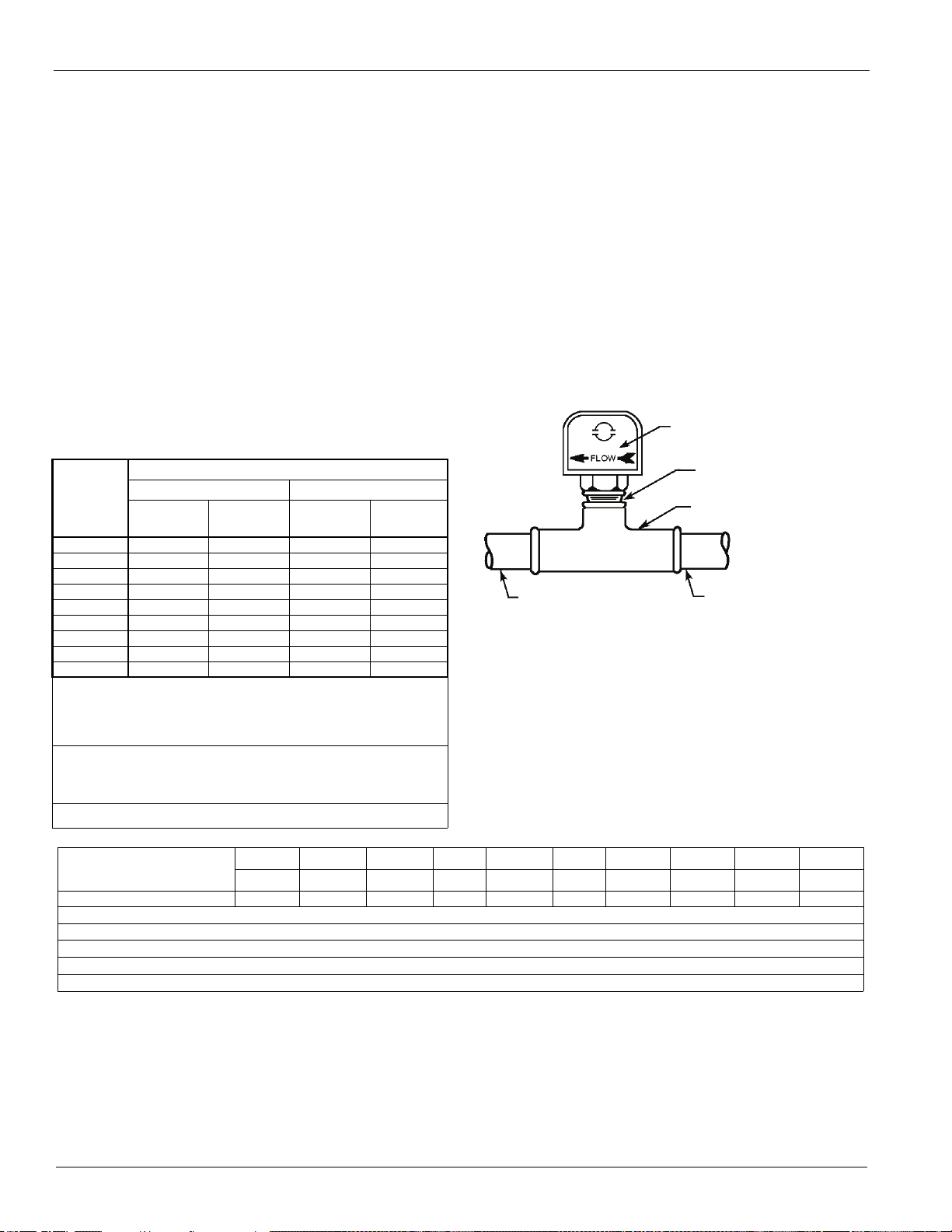

Installing Optional Inlet Strainer

The extension pipe is located adjacent to the evaporator with

the strainer then mounted to it. The strainer must be mounted

per manufacturer's instruction with the arrows in the direction

of flow; inlet and outlet are noted along with the arrows.

Use one Victaulic clamp to mount the extension pipe to the

evaporator and the second to mount the strainer to the pipe.

The clamps to mount the field piping to the strainer are field

supplied. The piping and strainer must be supported to prevent

any stress on the evaporator nozzle.

The extension pipe has two Schrader fittings that can be used

as desired, frequently for mounting the optional Daikin

The recommended maximum change in water flow is 10

percent of the change per minute. For example, if the

maximum (design) flow is 200 gpm and the flow is reduced to

a minimum of 140 gpm, the change in flow is 60 gpm, so the

maximum change per minute would be 10% of 60, or 6 gpm

per minute. It would take ten minutes to change the flow

through the entire range.

The water flow through the evaporator must remain between

the minimum and maximum values listed on page 108. If flow

drops below the minimum allowable, large reductions in heat

transfer can occur. If the flow exceeds the maximum rate,

excessive pressure drop and tube erosion can occur.

Evaporator Freeze Protection

Pathfinder chillers are equipped with thermostatically

controlled evaporator heaters that help protect against freezeup down to -20°F (-28°C). The immersion heater itself may

not be able to properly protect the evaporator from freezing

without circulation of water, and it is important that the chilled

water pumps are wired to, and controlled by, the chiller’s

controller. Additionally, use at least one of the following

procedures during periods of sub-freezing temperatures:

1 Add a concentration of a glycol anti-freeze with a freeze

point 10°F below the lowest expected temperature. This

IM 1167 11

Page 12

Installation and Startup

on s wit ch

1" (25mm) NPT flow

switch connection

Tee

dia. min. before switch

1 1/4" (32mm) pipe

dia. min. after switch

on switch

1" (25mm) NPT flow

switch connection

1 1/4" (32mm) pipe

dia. min. before switch

1 1/4" (32mm) pipe

dia. min. after switch

Tee

will result in decreased capacity and increased pressure

drop. Note: Do not use automotive grade antifreezes as

they contain inhibitors harmful to chilled water systems.

Use only glycols specifically designated for use in

building cooling systems.

2 Drain the water from outdoor equipment and piping and

blow the chiller tubes dry from the chiller. Do not

energize the chiller heater when water is drained from

the vessel.

Note: The heaters come from the factory connected to the

control power circuit. The control power can be rewired

in the field to a separate 115V supply (do not wire directly

to the heater). See the field wiring diagram on page 65. If

this is done, it should power the entire control circuit.

Mark the disconnect switch clearly to avoid accidental

deactivation of the heater during freezing temperatures.

Exposed chilled water piping also requires protection. If

the evaporator is drained for winter freeze protection, the

heaters must be de-energized to prevent heater

burnout..

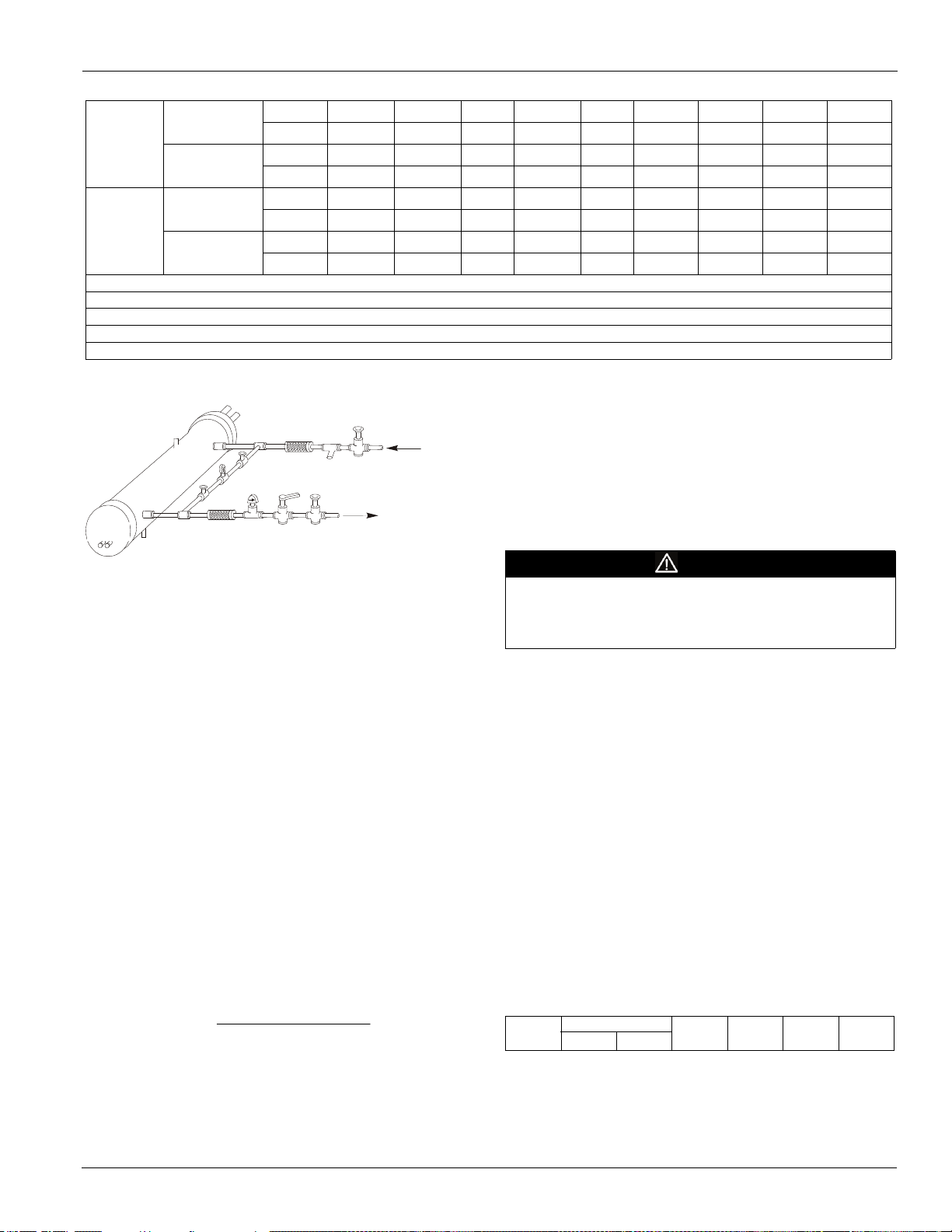

Table 3: Freeze Protection

% Volume Glycol Concentration Required

Temp.

F (C)

20 (6.7) 16 18 11 12

10 (-12.2) 25 29 17 20

0 (-17.8) 33 36 22 24

-10 (-23.3) 39 42 26 28

-20 (-28.9) 44 46 30 30

-30 (-34.4) 48 50 30 33

-40 (-40.0) 52 54 30 35

-50 (-45.6) 56 57 30 35

-60 (-51.1) 60 60 30 35

Note: “Freeze protection” maintains the solution in a pumpable, usable

Note: These figures are examples only and cannot be appropriate to every

Note: Glycol of less than 25% concentration is not recommended because

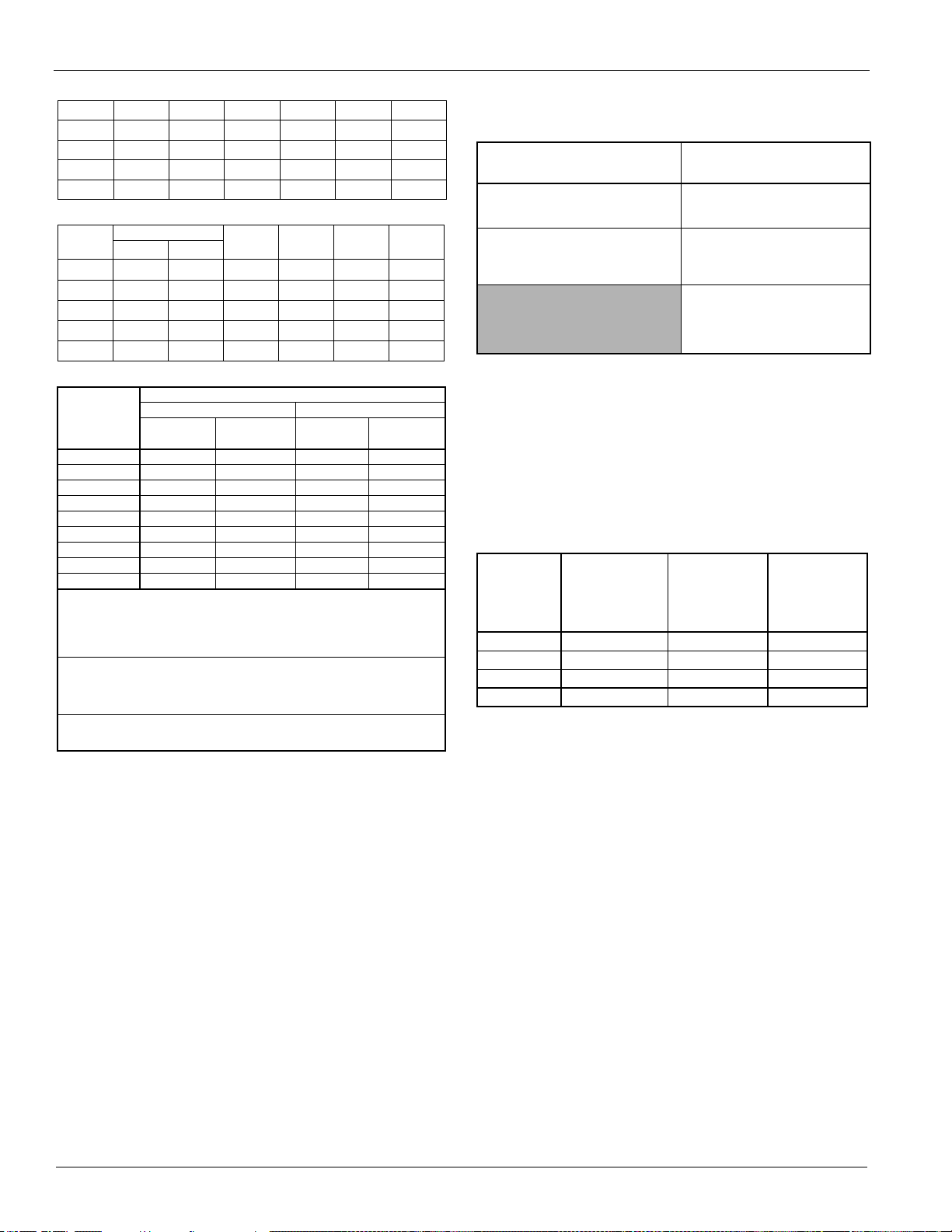

Table 4: Paddle Type Flow Switch Flow Rates

Note:

Note:

Note:

Note:

Note:

For Freeze Protection For Burst Protection

Ethylene

Glycol

liquid state. “Burst protection” prevents pipes from rupturing, but

solution may be in a gel state and not pumpable. In most

applications, “burst” protection is sufficient; concentrations over 30%

Ethylene Glycol or 35% Propylene Glycol will result in efficiency and

capacity losses with negligible protection increases

situation. Generally, for an extended margin of protection, select a

temperature at least 15°F lower than the expected lowest ambient

temperature. Inhibitor levels should be adjusted for solutions less

than 25% glycol.

of the potential for bacterial growth and loss of efficiency.

Pipe Size

(NOTE) - (2) (2) (3) (4) (4) (4) (5)

1

A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2

Flow rates for a 2-inch paddle trimmed to fit the pipe.

3

Flow rates for a 3-inch paddle trimmed to fit the pipe.

4

Flow rates for a 3-inch paddle.

5

Flow rates for a 6-inch paddle.

Propylene

Glycol

inch 1 1/4 1 1/2 2 2 1/2 3 4 5 6 8

mm 32 38 51 63 76 102 127 153 204

Ethylene

Glycol

Propylene

Glycol

Flow Switch

A flow switch must be included in the chilled water system to

prove that there is adequate water flow before the unit can

start. It also serves to shut down the unit in the event that water

flow is interrupted in order to guard against evaporator freezeup.

A factory-mounted, solid state, thermal dispersion flow switch

is available as an option. A field-installed version is also

available as a kit (Accessory part number 332688401).

A paddle-type flow switch for field mounting and wiring is

also available as a kit (Accessory part number 017503300). It

is adaptable to pipe sizes from 1" (25mm) to 8" (203mm).

Certain minimum flow rates are required to close the switch

and are listed in Table 4. Installation should be as shown in

Figure 13.

Fl ow di r e ction marke d

Flow direction marked

1 1/4" (32mm) pipe

Electrical connections in the unit control center should be

made at terminals 60 and 67 from switch terminals Y and R.

The normally open contacts of the flow switch should be wired

between these two terminals. Flow switch contact quality must

be suitable for 24 VAC, low current (16ma). Flow switch wire

must be in separate conduit from any high voltage conductors

(115 VAC and higher) and have an insulation rating of 600

volts.

12 IM 1167

Page 13

Table 4: Paddle Type Flow Switch Flow Rates

Drain

Gate

Water

Strainer

Eliminator

Pressure

Gauge

In

Out

Protect All Field Piping

Against Freezing

Flow

Eliminator

Flow

Switch

Balancing

Gate

Flow

Liquid

Suction

TDelta

factorflowtons

GPM

24

Min.

Flow

Adjst.

No Flow

Flow

Max.

Adjst.

No Flow

Note: 1A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2

Flow rates for a 2-inch paddle trimmed to fit the pipe.

Note:

3

Flow rates for a 3-inch paddle trimmed to fit the pipe.

Note:

4

Flow rates for a 3-inch paddle.

Note:

5

Flow rates for a 6-inch paddle.

Note:

gpm

Lpm

gpm

Lpm

gpm

Lpm

gpm

Lpm

5.8 7.5 13.7 18.0 27.5 65.0 125.0 190.0 205.0

1.3 1.7 3.1 4.1 6.2 14.8 28.4 43.2 46.6

3.7 5.0 9.5 12.5 19.0 50.0 101.0 158.0 170.0

0.8 1.1 2.2 2.8 4.3 11.4 22.9 35.9 38.6

13.3 19.2 29.0 34.5 53.0 128.0 245.0 375.0 415.0

3.0 4.4 6.6 7.8 12.0 29.1 55.6 85.2 94.3

12.5 18.0 27.0 32.0 50.0 122.0 235.0 360.0 400.0

2.8 4.1 6.1 7.3 11.4 27.7 53.4 81.8 90.8

Installation and Startup

Figure 13: Typical Field Water Piping

4 Power - To determine glycol system kW, multiply the

water system kW by the factor designated "Power".

Test coolant with a clean, accurate glycol solution hydrometer

Vent

Valved

Vibration

Valve

(similar to that found in service stations) to determine the

freezing point. Obtain percent glycol from the freezing point

table below. On glycol applications, the supplier normally

recommends that a minimum of 25% solution by weight be

used for protection against corrosion or that additional

Vibration

Valve

Valve

inhibitors should be employed.

CAUTION

Note:

Connections for vent and drain fittings are located on the top

and bottom of the evaporator.

Note: Piping must be supported to avoid putting strain on the

evaporator nozzles.

Do not use automotive grade antifreeze. Industrial grade glycols must

be used. Automotive antifreeze contains inhibitors that will cause

plating on the copper tubes within the chiller evaporator. The type and

handling of glycol used must be consistent with local codes.

Refrigerant Charge

All packaged units are designed for use with R-134a and are

shipped with a full operating charge. The operating charge for

each unit is shown in the Physical Data Tables beginning on

page 15.

Glycol Solutions

When using glycol anti-freeze solutions, the chiller's capacity,

glycol solution flow rate, and pressure drop through the

evaporator can be calculated using the following:

Note: The procedure below does not specify the type of

glycol. Use the derate factors found in Table 5 or Table 6

forcorrections when using glycol.

1 Capacity - Cooling capacity is reduced from that with

plain water. To find the reduced value, multiply the

chiller’s water system tonnage by the capacity correction

factor to find the chiller’s capacity when using glycol.

2 Flow - To determine flow (or Delta-T) knowing Delta-T

(or flow) and capacity:

3 Pressure drop - To determine pressure drop through the

evaporator when using glycol, enter the water pressure

drop curve at the water flow rate. Multiply the water

pressure drop found there by the "PD" factor to obtain

corrected glycol pressure drop.

IM 1167 13

Performance Adjustment Factors

AWS chiller units are designed to operate with leaving chilled

fluid temperatures of 20.0°F to 60.0°F (-6.7°C to 15.6°C).

Consult the local Daikin McQuay sales office for performance

outside these temperatures. Leaving chilled fluid temperatures

below 40°F (4.4°C) result in evaporating temperatures at or

below the freezing point of water and a glycol solution is

required. MicroTech III control inhibits compressor unloading

at leaving fluid temperatures below 30°F (-1°C).

Low fluid temperatures or high equipment room humidity may

require optional double evaporator insulation. The system

designer should determine its necessity. The use of glycol will

reduce the performance of the unit depending on its concentration. Take this into consideration during initial system design.

On glycol applications, the supplier typically recommends that

a minimum of 25% solution by weight be used for protection

against corrosion, or additional inhibitors will be required.

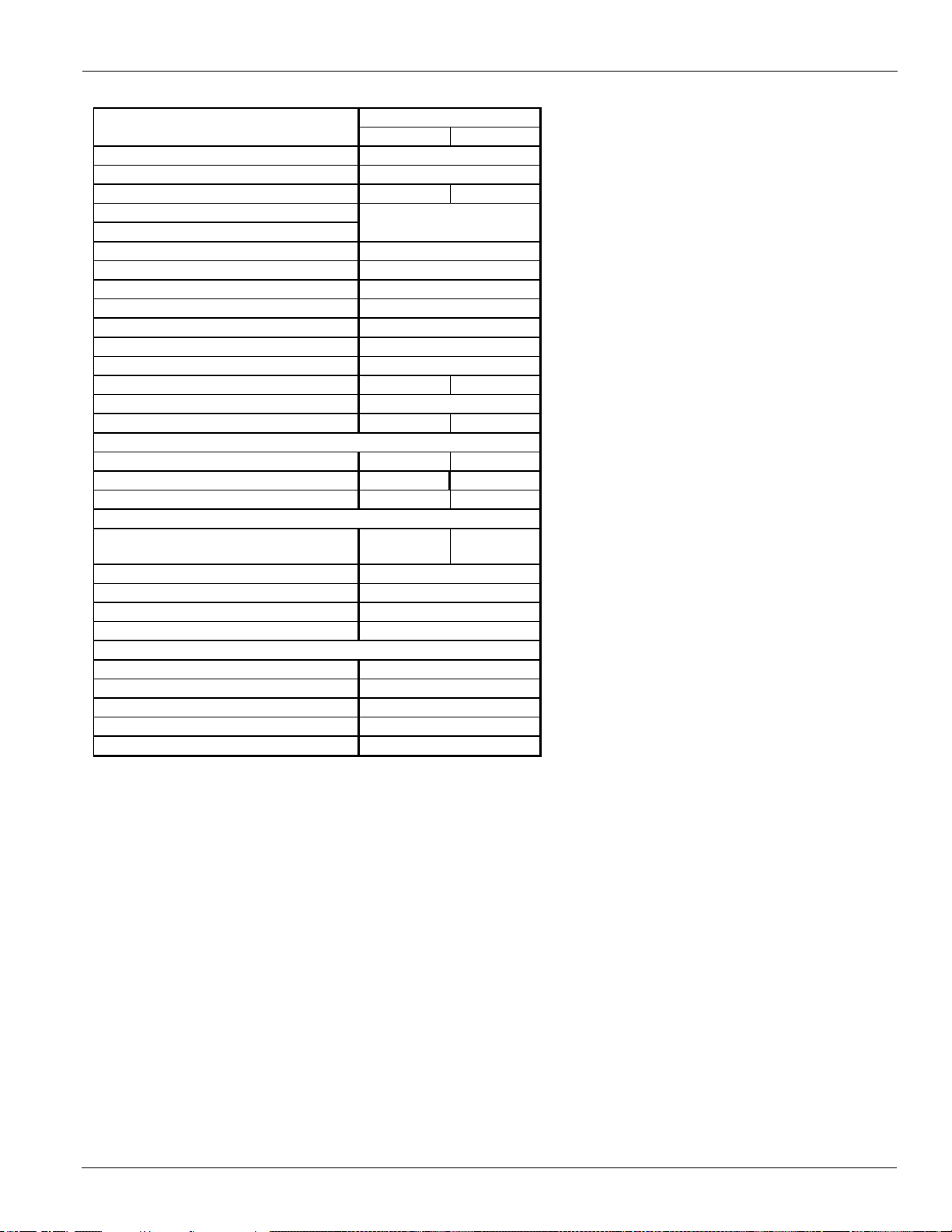

Table 5: Ethylene Glycol Correction Factors

% E.G

Freeze Point

o

F

o

Capacity Power Flow PD

C

Page 14

Installation and Startup

Table 5: Ethylene Glycol Correction Factors

10 26 -3.3 0.996 0.998 1.036 1.097

20 18 -7.8 0.988 0.994 1.061 1.219

30 7 -13.9 0.979 0.991 1.092 1.352

40 -7 -21.7 0.969 0.986 1.132 1.532

50 -28 -33.3 0.958 0.981 1.182 1.748

Table 6: Propylene Glycol Correction Factors

Freeze Point

% P.G

10 26 -3.3 0.991 0.996 1.016 1.092

20 19 -7.2 0.981 0.991 1.032 1.195

30 9 -12.8 0.966 0.985 1.056 1.345

40 -5 -20.6 0.947 0.977 1.092 1.544

50 -27 -32.8 0.932 0.969 1.14 1.906

o

F

o

Capacity Power Flow PD

C

Table 7: Ambient Freeze Protection

Percent Volume Glycol Concentration Required

For Freeze Protection For Burst Protection

Temperature

F (C)

20 (6.7) 16 18 11 12

10 (-12.2) 25 29 17 20

0 (-17.8) 33 36 22 24

-10 (-23.3) 39 42 26 28

-20 (-28.9) 44 46 30 30

-30 (-34.4) 48 50 30 33

-40 (-40.0) 52 54 30 35

-50 (-45.6) 56 57 30 35

-60 (-51.1) 60 60 30 35

Note: “Freeze protection” maintains the solution ina pumpable, usable

liquid state. “Burst protection” prevents pipes from rupturing, but the

solution may be in a gel state and not pumpable. In most

applications, “burst” protection is sufficient; concentrations over

30% Ethylene Glycol or 35% Propylene Glycol will result in

efficiency and capacity losses with negligible protection increases.

Note: These figures are examples only and may not be appropriate to

every situation. Generally, for an extended margin of protection,

select a temperature at least 15°F (-12°C) lower than the expected

lowest ambient temperature. Adjust inhibitor levels for solutions

less than 25% glycol

Note: Glycol of less than 25% concentration is not recommended because

of the potential for bacterial growth and subsequent loss of heat

transfer efficiency. Additional inhibitors may be required.

Ethylene

Glycol

Propylene

Glycol

Ethylene

Glycol

Propylene

Glycol

Electrical Connections

All wiring must be done in accordance with applicable local

and national codes. Pathfinder units can be ordered with either

standard multi-point power or optional single point power

connections and with various disconnect and circuit breaker

options. Wiring within the unit is sized in accordance with the

U.S.A. National Electrical Code. Field-supplied disconnect

switches are required if not factory-supplied with the unit.

Table 8: Electric Power Connection Option

Multi-Point

Power Connection

Disconnect switch per circuit, no

compressor isolation circuit breakers

High short circuit current rated panel

with disconnect switch and no

Note: Disconnect switches are molded case construction with lockable

Note: The individual compressor isolation circuit breakers for each circuit

Note: The high short circuit rated panel means that a short circuit current

Note: The factory-mounted control power transformer is protected by fuses.

Standard:

Optional:

isolation circuit breakers

through-the-door handles. They can be used to remove the unit/

circuit from the power system.

isolate the compressor and do not have through-the-door handles.

They are operable only after the panel doors are opened.

up to the ratings shown in Table 9, Interrupt Ratings (kAmps)will be

contained in the panel. There is a short period of time when the

circuit breaker will short circuit before opening a circuit that can

damage downstream components. In other words, the enclosure is

stronger than a standard enclosure. It has a high interrupt rated

disconnect switch.

Condenser fans are protected and isolated by circuit breakers.

One disconnect switch replacing

panel with disconnect switch and

Single-Point

Power Connection

one power block, compressor

the power block, compressor

High short circuit current rated

compressor isolation circuit

Optional:

isolation circuit breakers

Optional:

isolation circuit breakers

Optional:

breakers

Table 9: Interrupt Ratings (kAmps)

STANDARD

VOLTAGE

208-230 10kA 100kA 208-230

380 10kA 65kA 380

460 10kA 65kA 460

575 5kA 25kA 575

SHORT

CIRCUIT

PANEL

RATING

HIGH SHORT

CIRCUIT

RATED

PANEL

VOLTAGE

Disconnecting means are addressed by Article 440 of the

U.S.A. National Electrical Code (NEC), which requires

“disconnecting means capable of disconnecting air

conditioning and refrigerating equipment including motorcompressors, and controllers from the circuit feeder.” Select

and locate the disconnect switch per the NEC guidelines.

Maximum recommended fuse sizes are given in the electrical

data tables of this catalog for help in sizing the disconnect.

Terminals are provided in a unit control panel for optional field

hookup of the control circuit to a separate fused 115-volt

power supply in lieu of the standard factory installed control

transformer.

RapidRestore Option

This option does not require field installation. Exception: Field

supplied inputs are required in the case of a backup unit being

started after the power interruption rather than restarting the

primary unit.. A field supplied control (normally a BAS) must

turn off the Backup Chiller connection on the primary chiller

and turn on the connection on the backup chiller at the time of

switching. See the unit Field Wiring Diagram for the Backup

Unit connection point (terminals #61 and #62).

14 IM 1167

Page 15

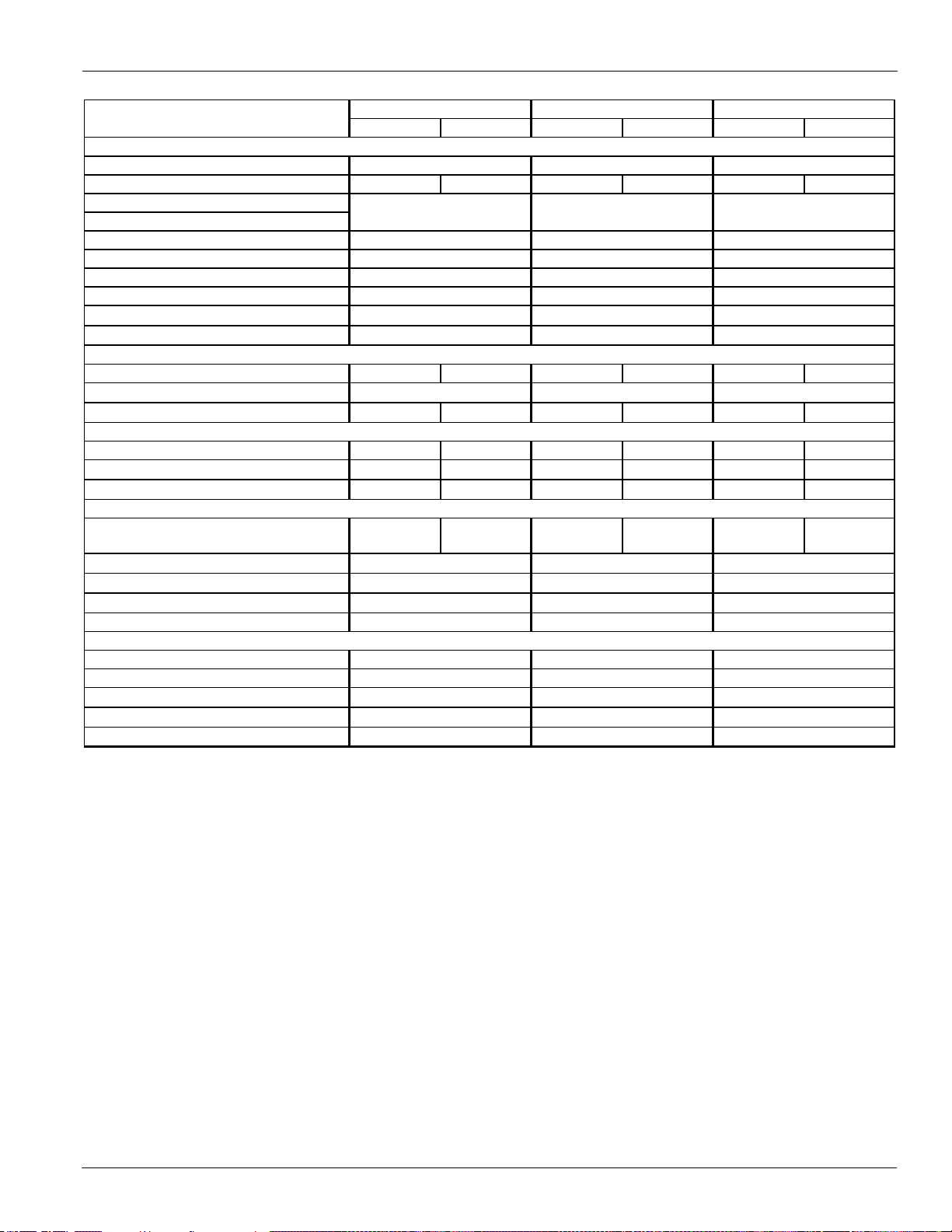

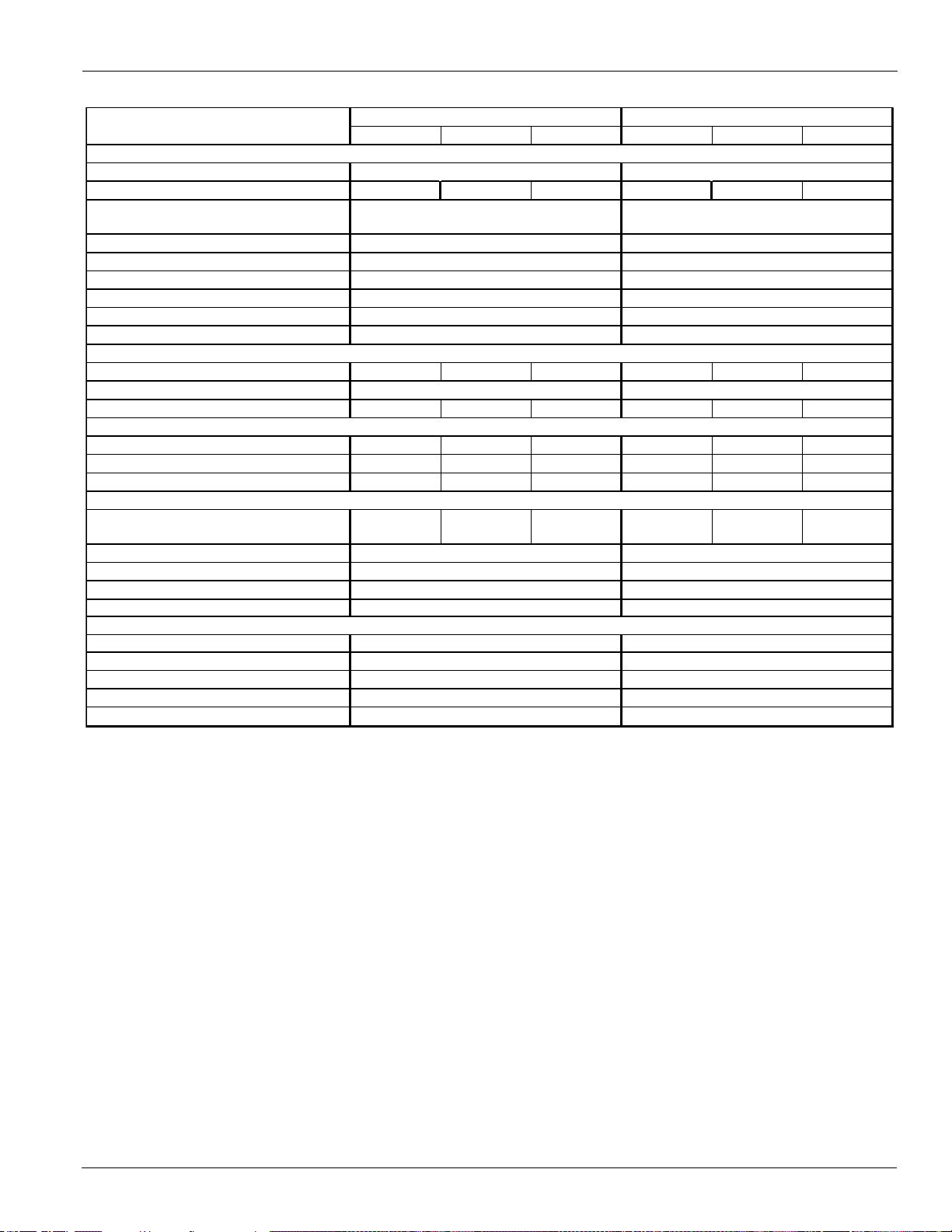

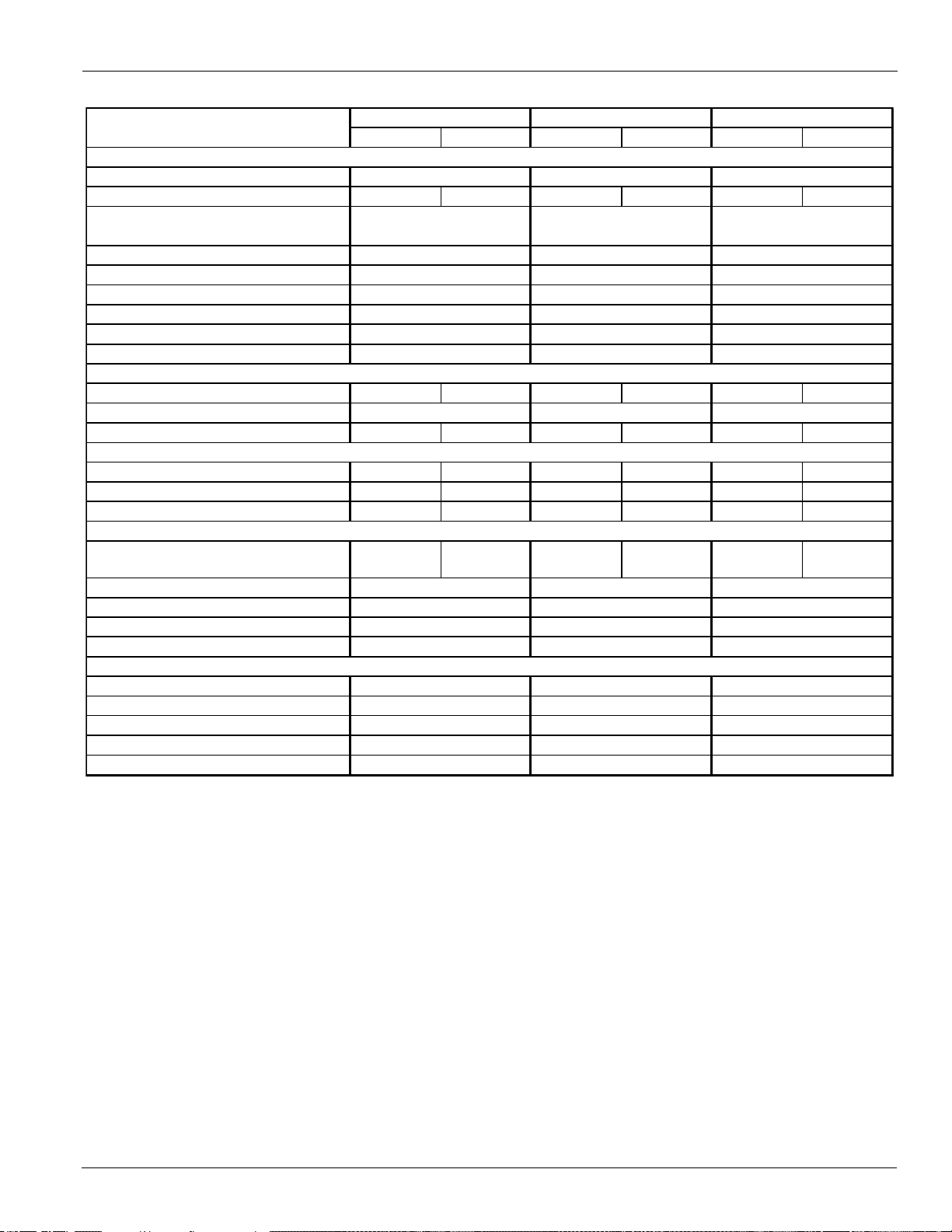

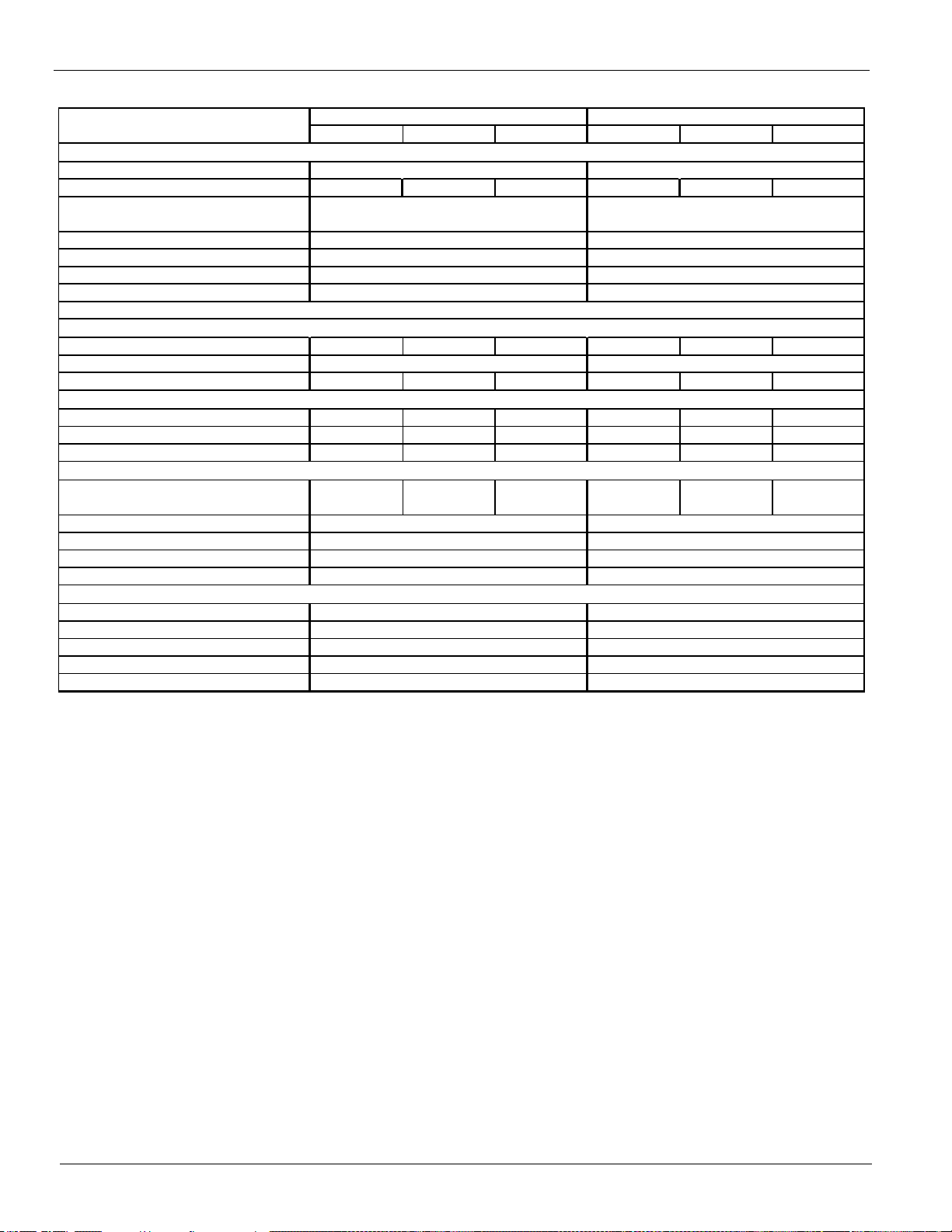

Physical Data (non-VFD)

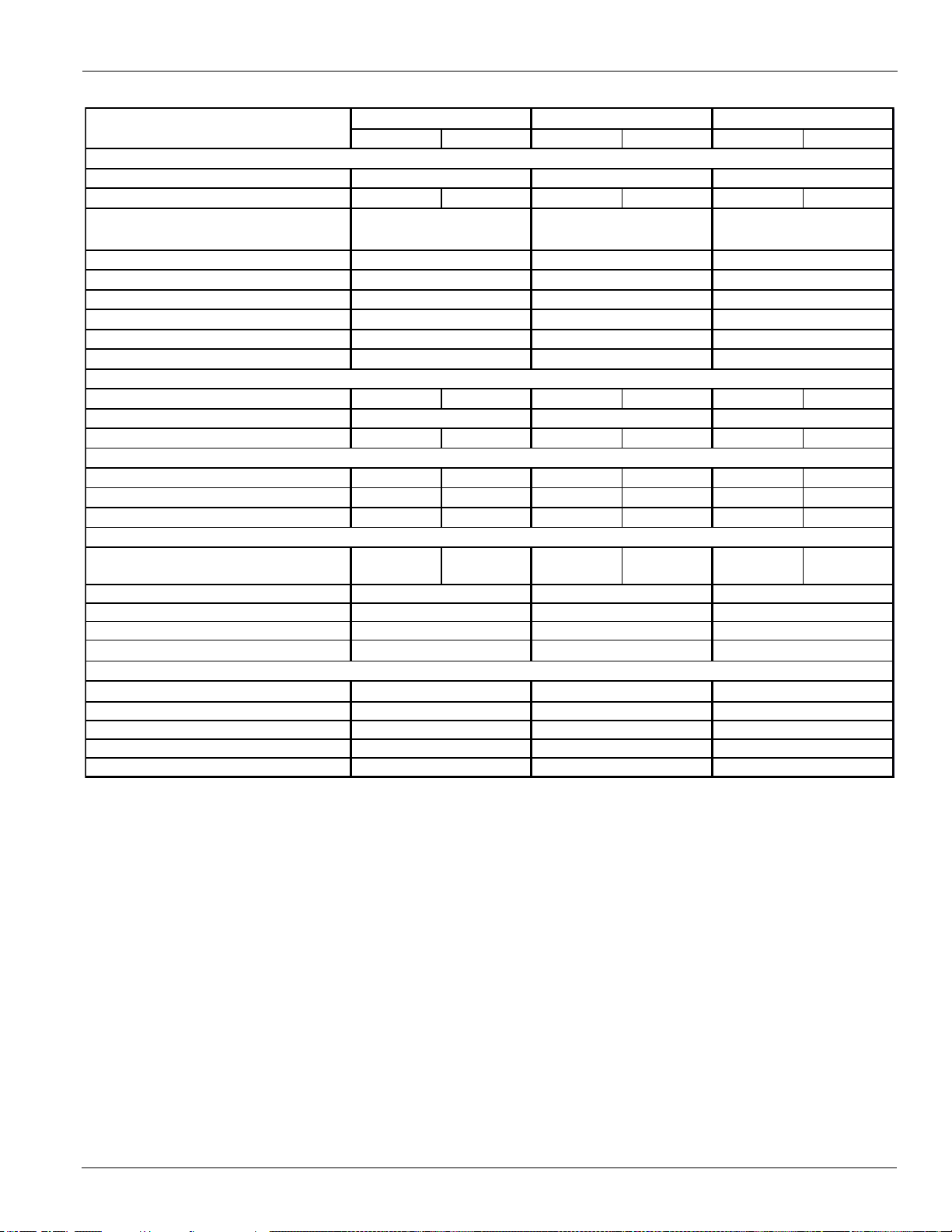

CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2

BASIC DATA

Unit Cap. @ AHRI tons (kW)

Unit O per ating Charge lbs (kg) 145 (66) 145 (66) 165 (75) 165 (75) 165 (75) 165 (75)

Unit Dimensions

L x W x H, in. (mm)

Unit Oper ating W eig ht, lbs. ( k g)

Unit S hipping W eight , lbs (kg)

Weight - Add for Copper Fins, lbs (kg)

g

Weight - Add for PFCC opt ion, lbs (kg)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 95 (334) 95 (334) 95 (334) 115 (404) 115 (404) 115 (404)

Minimum Capacity (% of F ull Load )

Oil char ge per c ir cuit , gallons (liters) 4.5 (17) 4.5 (17) 4.5 (17) 5.5 (21) 5.5 (21) 5.5 (21)

CONDENSERS, HIGH EF FICIENCY F IN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 208 (94) 208 (94) 250 (113) 250 (113) 250 (113) 250 (113)

Coil Inlet Face Area, sq. ft. ( sq. m.) 123.1 (11.4) 123.1 (11.4) 147.7 (13. 7) 147.7 (13.7) 147.7 (13. 7) 147.7 (13.7)

Rows Deep/Fins Per Inch 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp (kW)

Fan & Motor RPM

Fan T ip S peed, f pm (m/s)

A irflow, cfm (l/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length, in.(mm)

Water Volume, gallons (liters)

Victaulic inlet/outlet conn. in. (mm)

M ax. W ater Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

180.1 (633) 201.3 (708) 216.3 (760)

Data

AWS190BDS AWS210BDS AWS225BDS

245 x 88 x 100 245 x 88 x 100

(6220 x 2225 x 2548 ) (6220 x 2225 x 2548 ) (6220 x 2225 x 25 48)

13072 (5930) 13788 (6255)

245 x 88 x 100

12529 (5684) 13245 (6008)

1786 (810)

56

160 (73)

15 15

676 (307) 788 (357)

110850 (52315)

5

1.4 (1.05)

6984 (35)

850 850 850

666

1.4 (1.05)

477 (216) 477 (216) 477 (216)

1786 (810) 1786 (810)

66 (251)

15

6984 (35)

14335 (6503)

13792 (6256)

16 x 108 (40 6 x 2750) 16 x 108 (40 6 x 2750)

6984 (35)

66 (251)

1.4 (1.05)

788 (357)

160 (73)

6 (168) 6 (168) 6 (168)

325 (2241) 325 (2241) 325 (2241)

152 (1048) 152 (1048)

133020 (62778) 133020 (62778)

152 (1048)

16 x 406 (40 6 x 2750)

68 (258)

160 (73)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Table 10: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

Weight - Add for Louvered Panels, lbs (kg)

Weight-Add for S oun d E nc l osures, lbs (k

Physical Data (non-VFD)

Number of Fans per Circuit

Fan Diameter: 31.5 in. ( 800 mm)

IM 1167 15

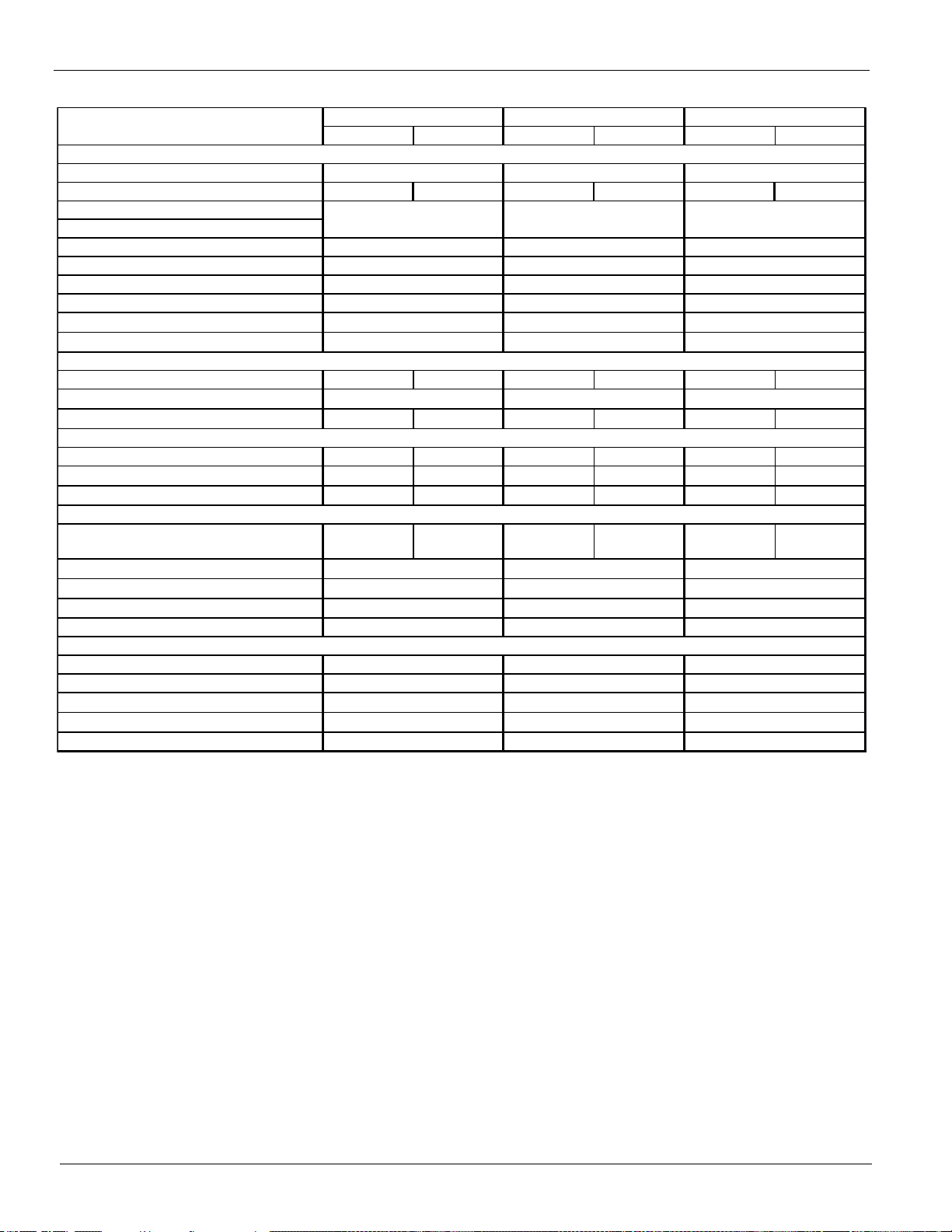

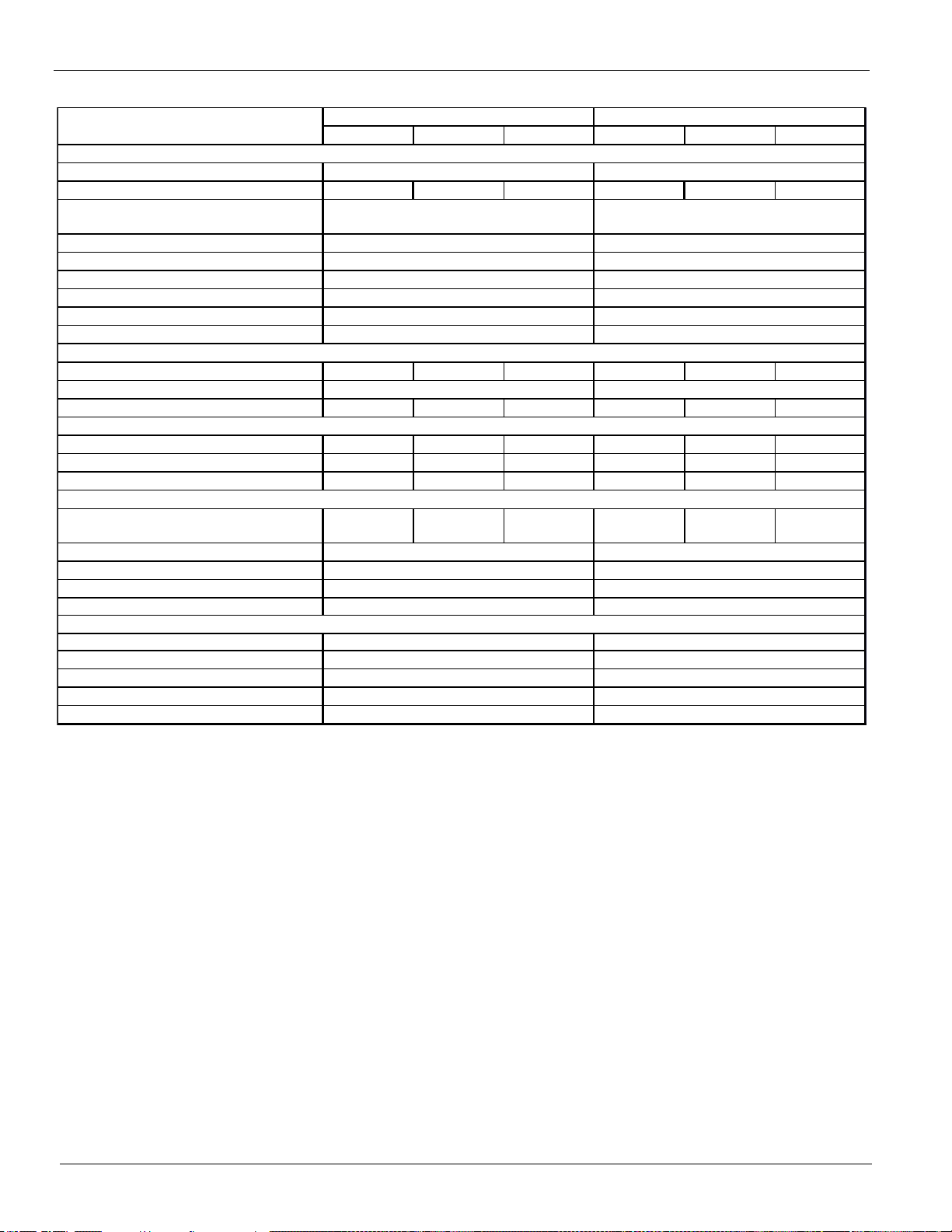

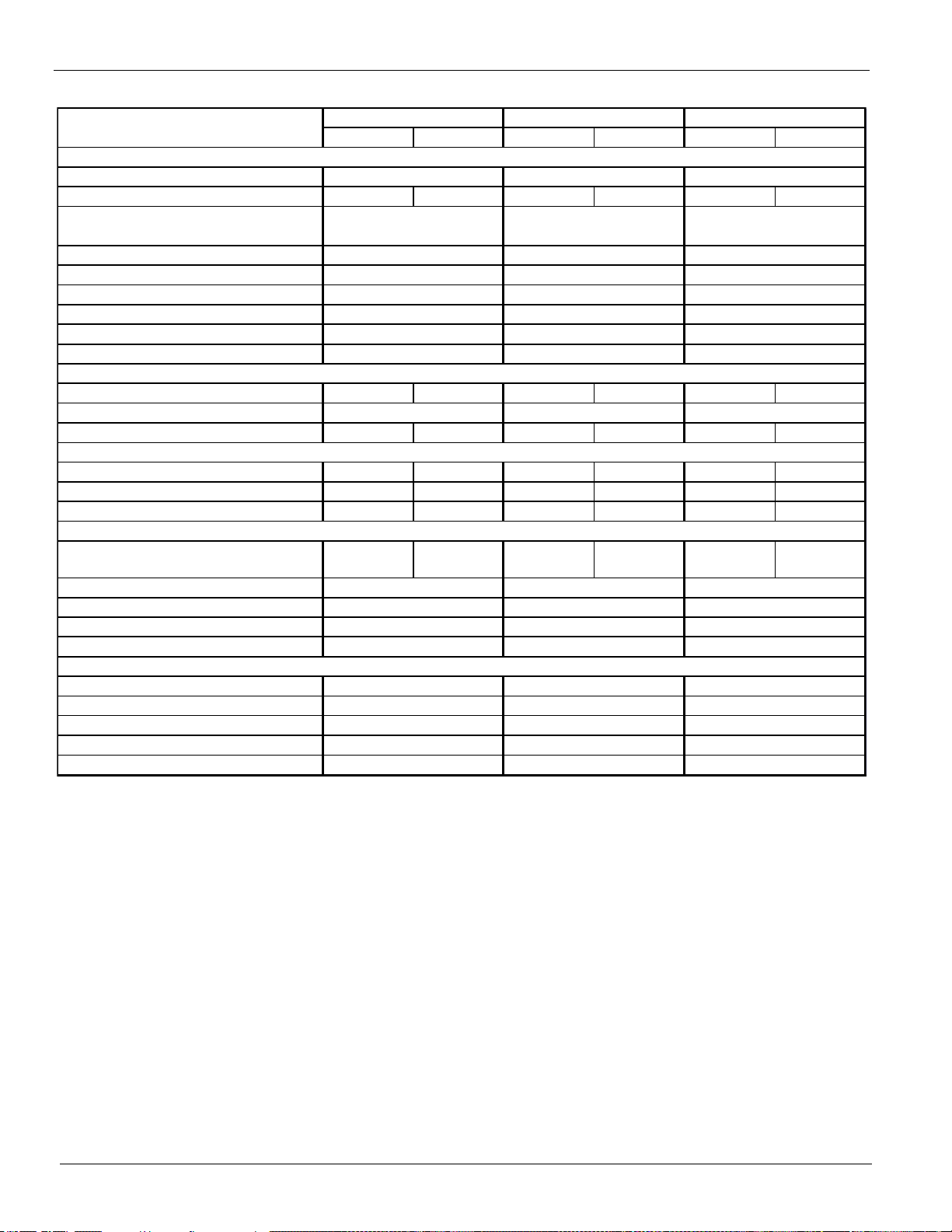

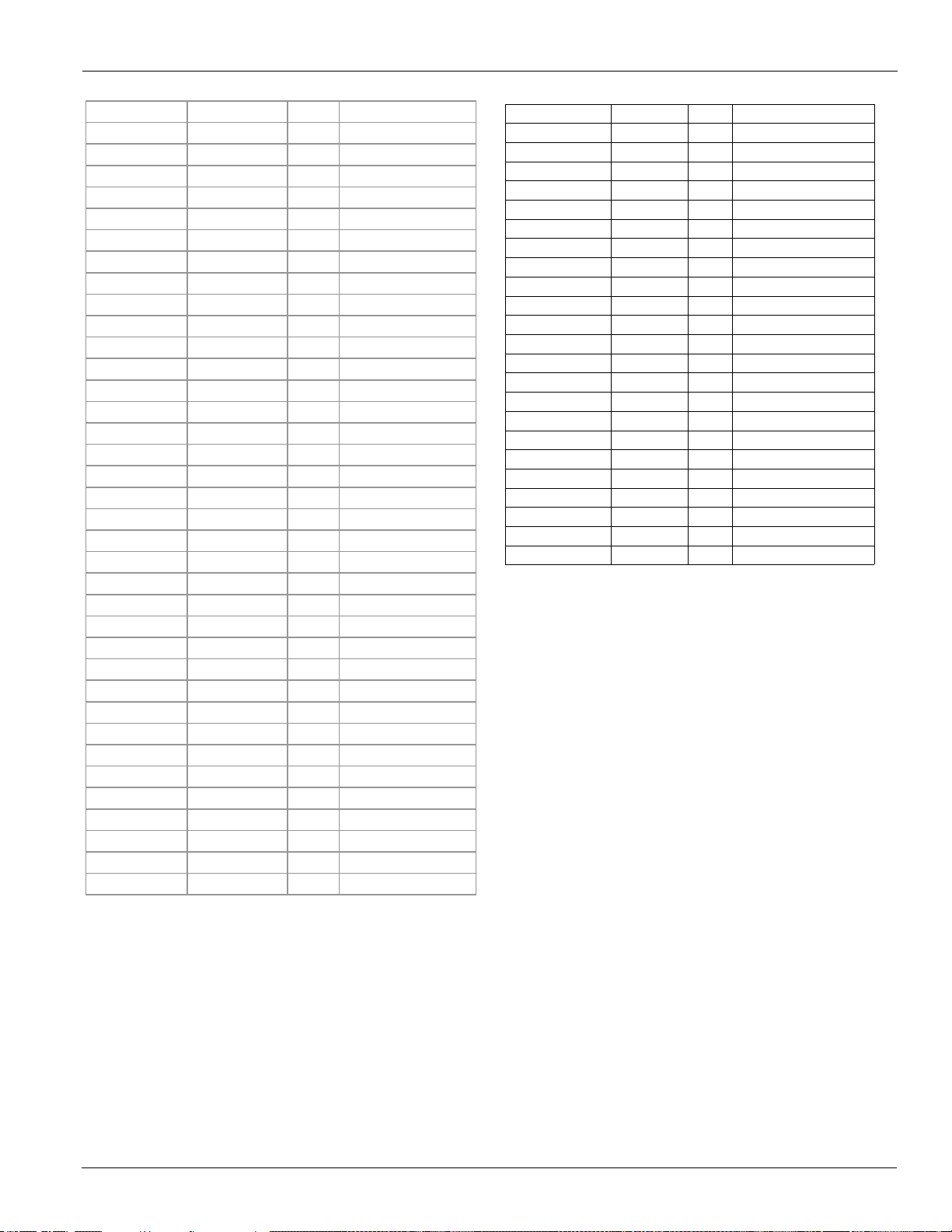

Page 16

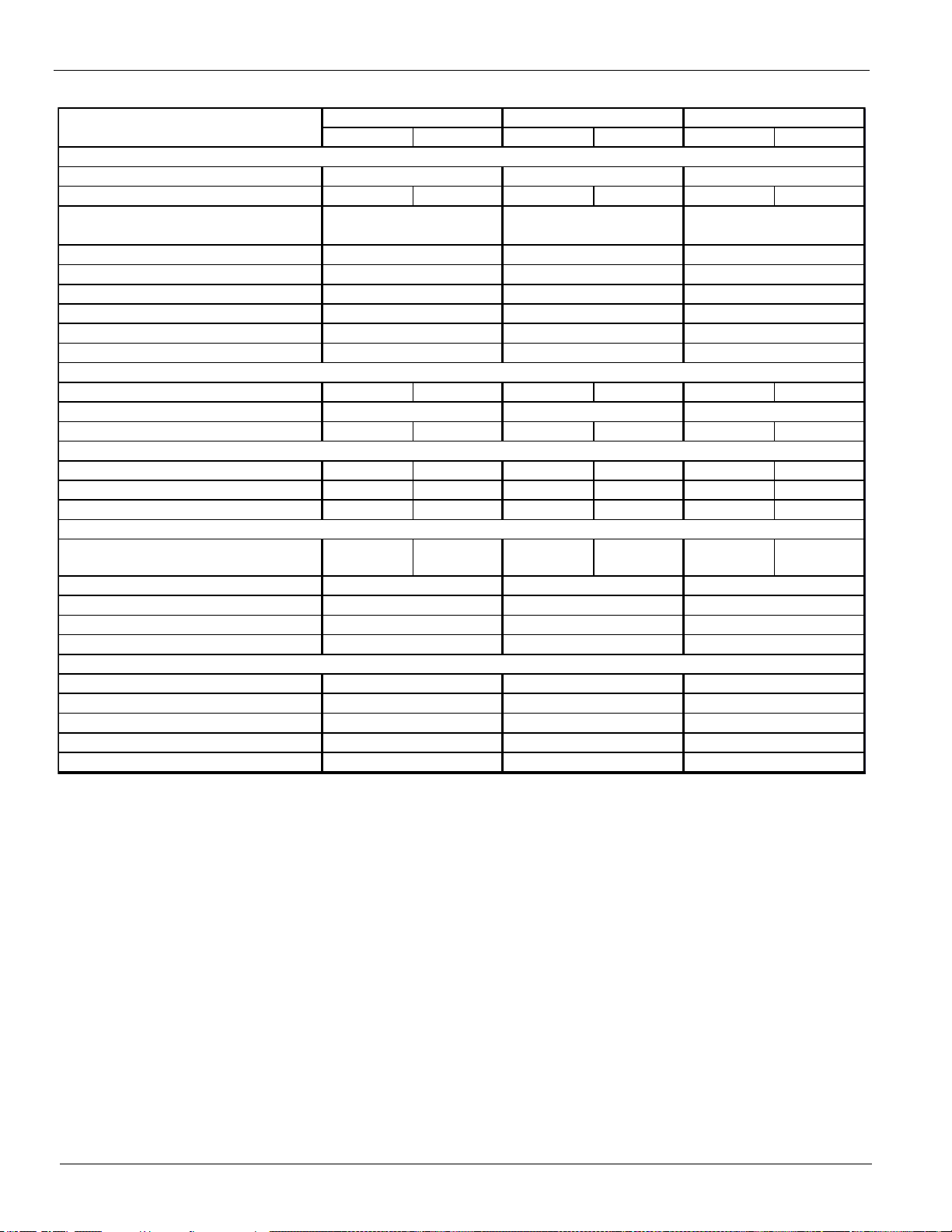

Physical Data (non-VFD)

CIRC U IT 1 CIRCUIT 2 C IRC U IT 1 CIRCUIT 2 CIRCUIT 1 CIR C U IT 2

BASIC DATA

Unit Cap. @ AHRI tons (kW)

Unit O per ating Charge lbs (kg) 185 (84) 185 (84) 185 (84) 185 (84) 210 (95) 210 (95)

Unit Dimensions

L x W x H, in. (mm)

Unit O per ating W eight, lbs. (k g)

Unit Shipping Weight , lbs (kg)

Weight - Add for Copper Fins, lbs (kg)

Weight - Add for Louvered Panels, lbs (kg)

g

Weight - Add for P F CC option, lbs (kg)

COMPRESSORS, SC REW, SEMI -HE RMETI C

Nominal Capacity, tons (kW ) 115 (404) 135 (475) 135 (475) 135 (475) 135 (475) 155 (545)

Minimum Capacity (% of F ull Load)

Oil char ge per c ir c uit , gallons (liter s) 5.5 (21) 5.5 ( 21) 5.5 (21) 5.5 (21) 5.5 (21) 6 (23)

CONDENSERS, HIGH EF FICIENCY FIN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 291 (132) 291 (132) 291 (132) 291 (132) 333 (151) 333 (151)

Coil Inlet Face Area, sq. f t. ( sq. m.) 172.3 (16. 0) 172.3 (16.0) 172.3 (16. 0) 172.3 ( 16.0) 196.9 ( 18. 3) 196.9 (18. 3)

Rows Deep/Fins Per I nc h 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp ( kW)

Fan & Motor RP M

Fan T ip S peed, f pm (m/s)

Airflow, cfm (l/s )

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.- Tube Lengt h, in. ( mm)

Water Volume, gallons (liters)

Vict aulic inlet/ outlet c onn. in. ( mm)

M ax. W ater Pressure, psi (kPa)

Max. Refrigerant P ress., psi (kPa)

AWS290BDS

235.8 (829)

AWS260BDS

280 x 88 x 100

(7121 x 2225 x 2548)

15188 (6890)

Data

2084 (945)

AWS250BDS

14645 (6643)

2084 (945)

6984 (35)

152 (1048)

850

6984 (35)

900 (408)

477 (216)

177360 (83704)

15

325 (2241)

1.4 ( 1.05)

850

1.4 ( 1.05)

77 88

6984 (35)

16624 (7541)

2372 (1076)

1012 (459)

15

77

160 (73) 160 (73)

850

64 (243)

6 (168)

20 x 108 / (508 x 2750)

282.9 (995)

316 x 88 x 100

(8022 x 2225 x 2548)

17491 (7934)

477 (216)

15

325 (2241)

155190 (73241)

325 (2241)

107 (403)

8 (219)

152 (1048)

16 x 108 / (406 x 2750)

64 (243)

6 (168)

152 (1048)

250.5 (881)

280 x 88 x 100

(7121 x 2225 x 2548)

15188 (6890)

155190 (73241)

16 x 108 / (406 x 2750)

1.4 ( 1.05)

14645 (6643)

900 (408)

477 (216)

160 (73)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Table 11: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

Weight - Add for S ound Enc losures, lbs (k

Number of Fans per Circ uit

Fan Diameter : 31. 5 in. (800 mm)

16 IM 1167

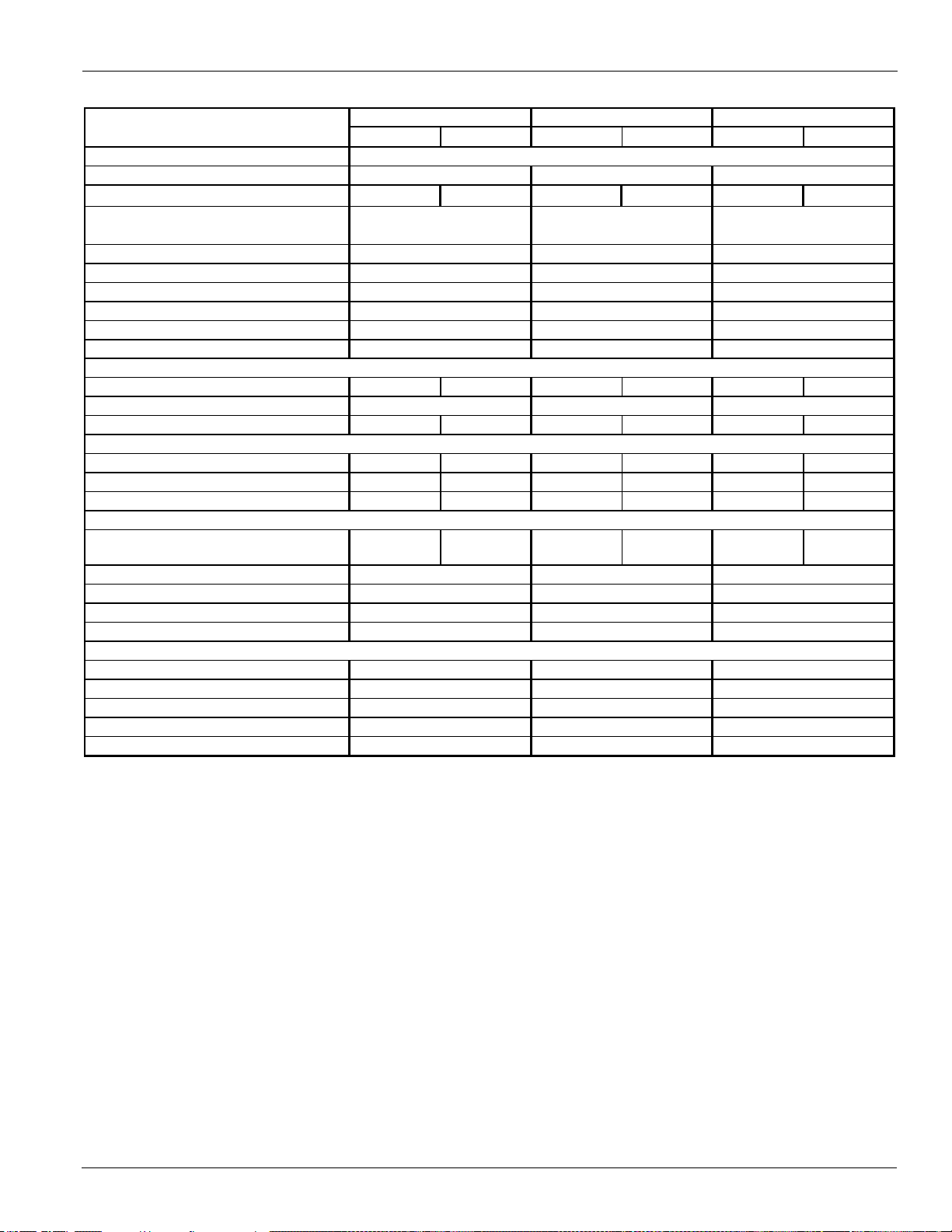

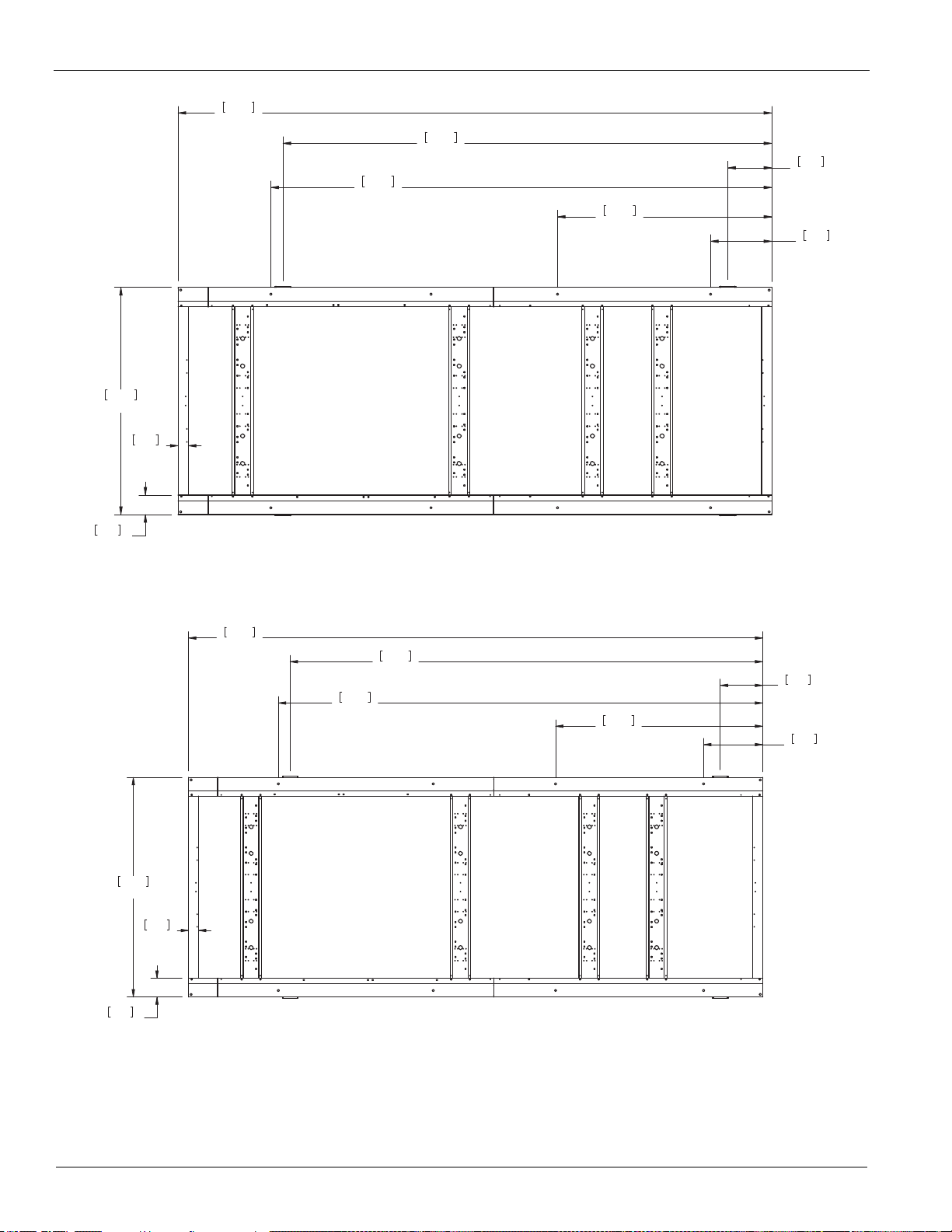

Page 17

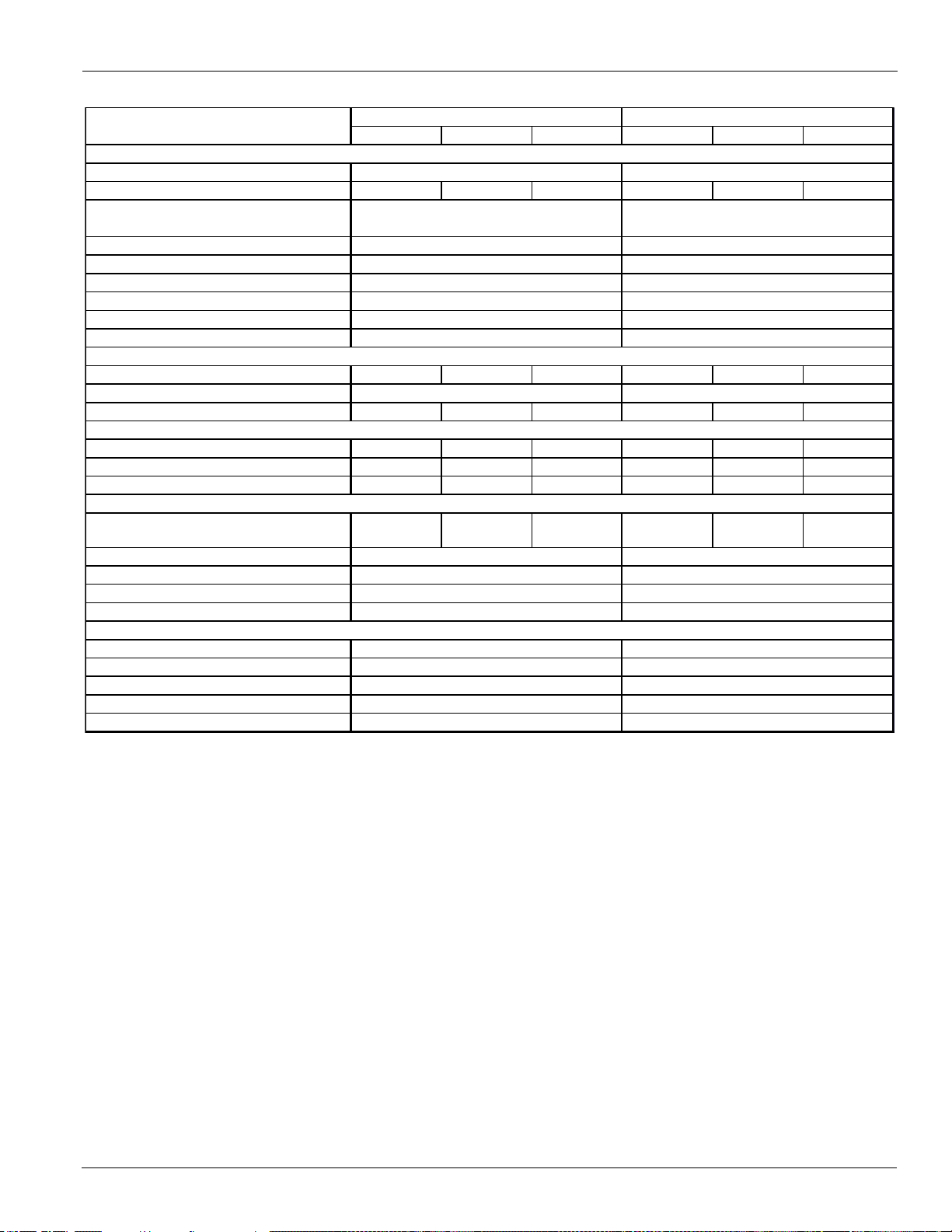

Table 12: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2

BASIC DATA

Unit Cap. @ AHRI tons (kW)

Unit O per at ing Char ge lbs (kg) 215 (98) 215 (98) 265 (120) 265 (120) 265 (120) 265 (120)

Unit Dimensions

L x W x H, in. (mm)

Unit O perating W eight, lbs. (kg)

Unit S hipping Weight , lbs (kg)

Weight -Add for Copper F ins, lbs (kg)

g

Weight - Add for PFCC option, lbs (kg)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW ) 155 ( 545) 155 (545) 155 (545) 185 (650) 185 (650) 185 (650)

Minimum Capacity (% of F ull Load)

Oil char ge per circ uit , gallons (liters) 6 ( 23) 6 (23) 6 (23) 6 (23) 6 (23) 6 (23)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 333 (151) 333 (151) 416 (189) 416 (189) 416 (189) 416 (189)

Coil Inlet F ac e Area, sq. ft . ( sq. m.) 196.9 (18. 3) 196.9 (18.3) 246.1 (22. 8) 246.1 (22. 8) 246.1 (22. 8) 246.1 (22. 8)

Rows Deep/Fins Per Inch 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp (k W)

Fan & Motor RPM

Fan Tip Speed, f pm (m/s)

A irflow, cfm (l/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length, in. ( mm)

Wat er Volume, gallons (liters)

V ic t aulic inlet / out let c onn. in. (mm)

M ax. W ater Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

18161 (8238) 19803 (8983)

(8026 x 2225 x 2548) (9823 x 2225 x 2548)

316 x 88 x 100 387 x 88 x 100

(9823 x 2225 x 2548)

387 x 88 x 100

300.4 (1056) 340.6 (1197) 361.4 (1271)

Data

AWS310BDS AWS350BDS AWS375BDS

17294 (7845) 18936 (8590) 18936 (8590)

2372 (1076) 2968 (1346) 2968 (1346)

1012 (459) 1236 (561) 1236 (561)

477 (216) 477 (216) 477 (216)

15 15 15

160 (73)

8810

20 x 108 / ( 508 x 2750)

1.4 ( 1. 05 ) 1. 4 (1 . 05)

10

20 x 108 / (508 x 2750)

8 (219) 8 (219) 8 (219)

152 (1048) 152 (1048)

325 (2241) 325 (2241) 325 (2241)

20 x 108 / ( 508 x 2750)

107 (403)

10 10

19803 (8983)

160 (73) 160 (73)

102 (386) 102 (386)

6984 (35) 6984 (35) 6984 (35)

177360 (83704) 221700 (104630) 221700 (104630)

152 (1048)

1.4 (1.05)

850 850 850

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Weight - Add for Louvered Panels, lbs (kg)

Weight - Add for Sound Enc losures, lbs (k

Physical Data (non-VFD)

Number of F ans per Cir cu it

Fan Diameter: 31.5 in. ( 800 mm)

IM 1167 17

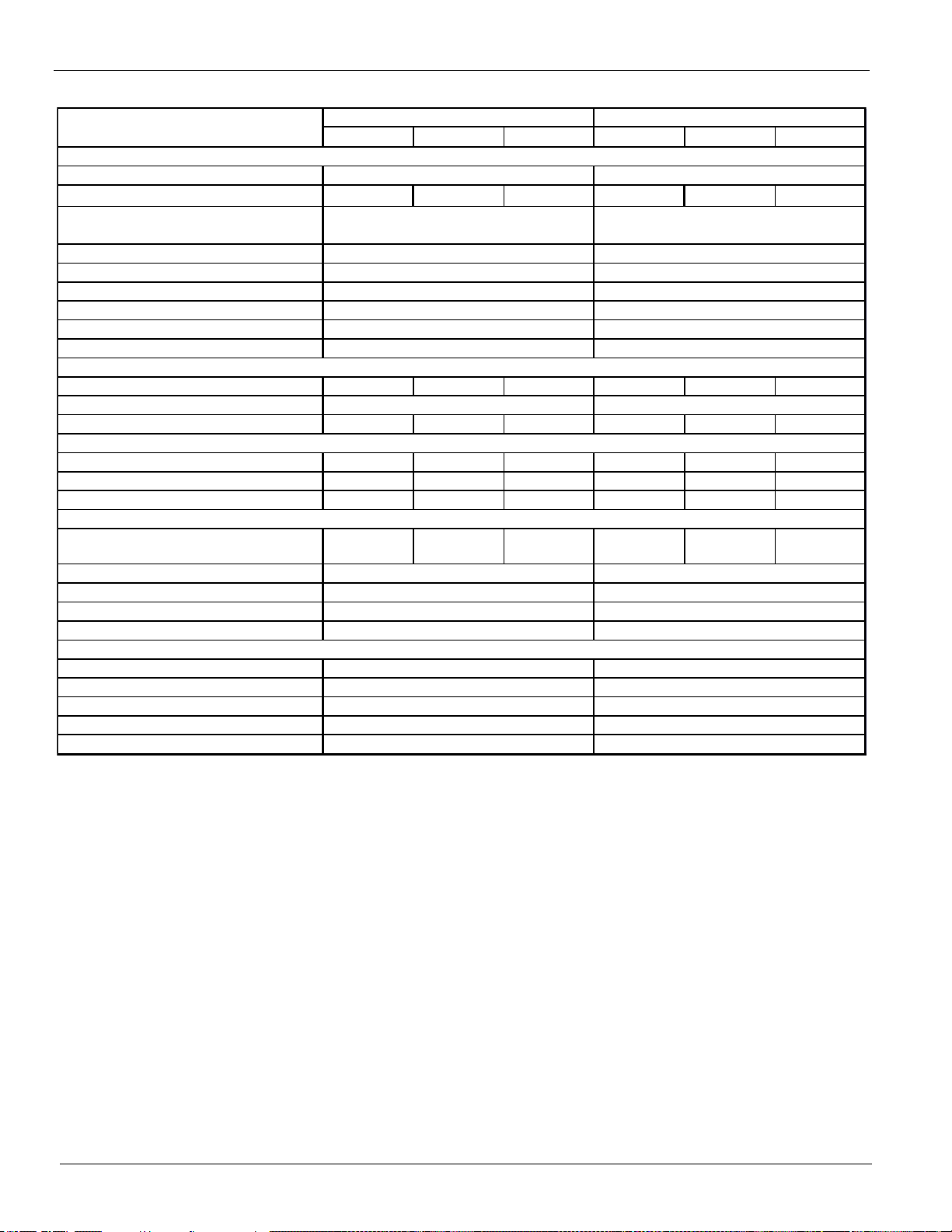

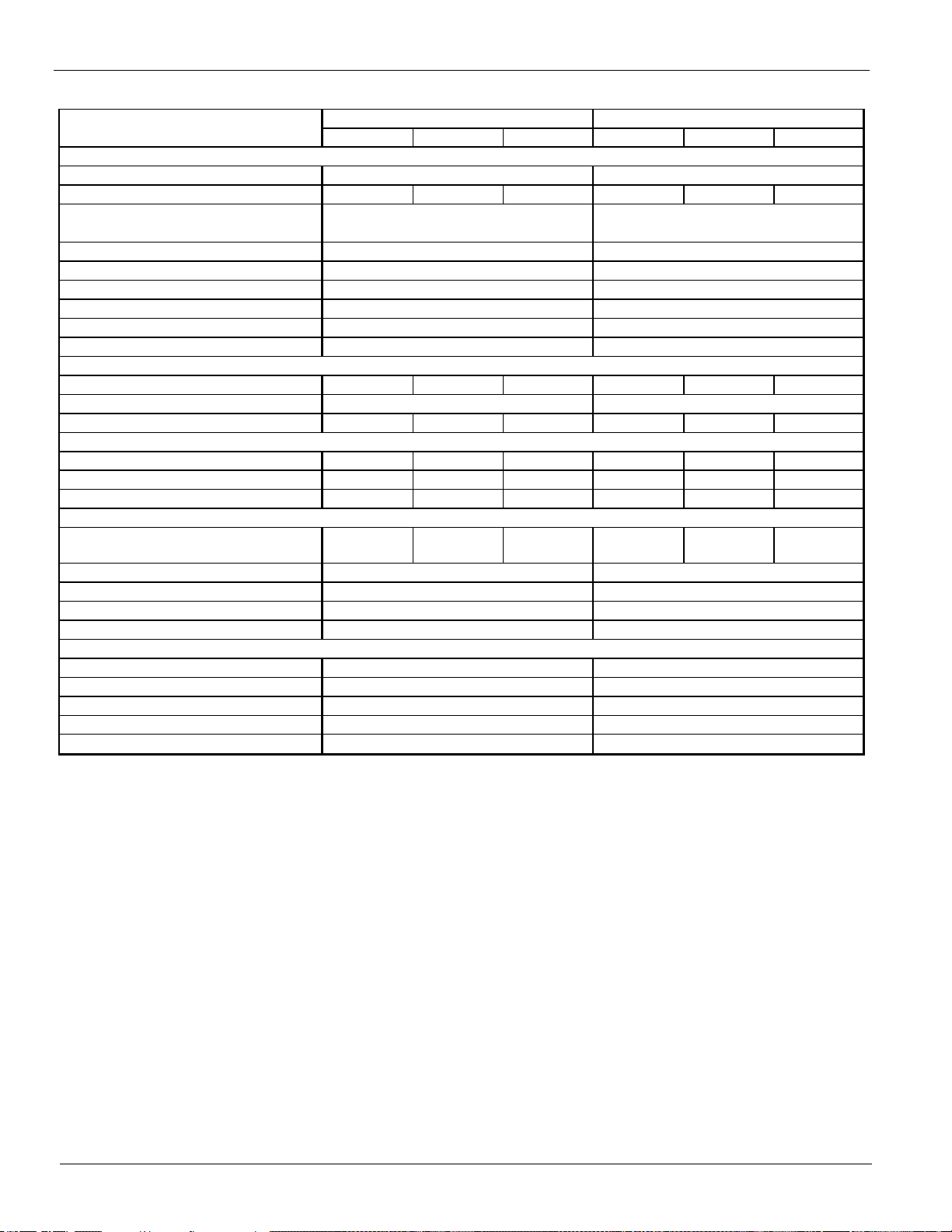

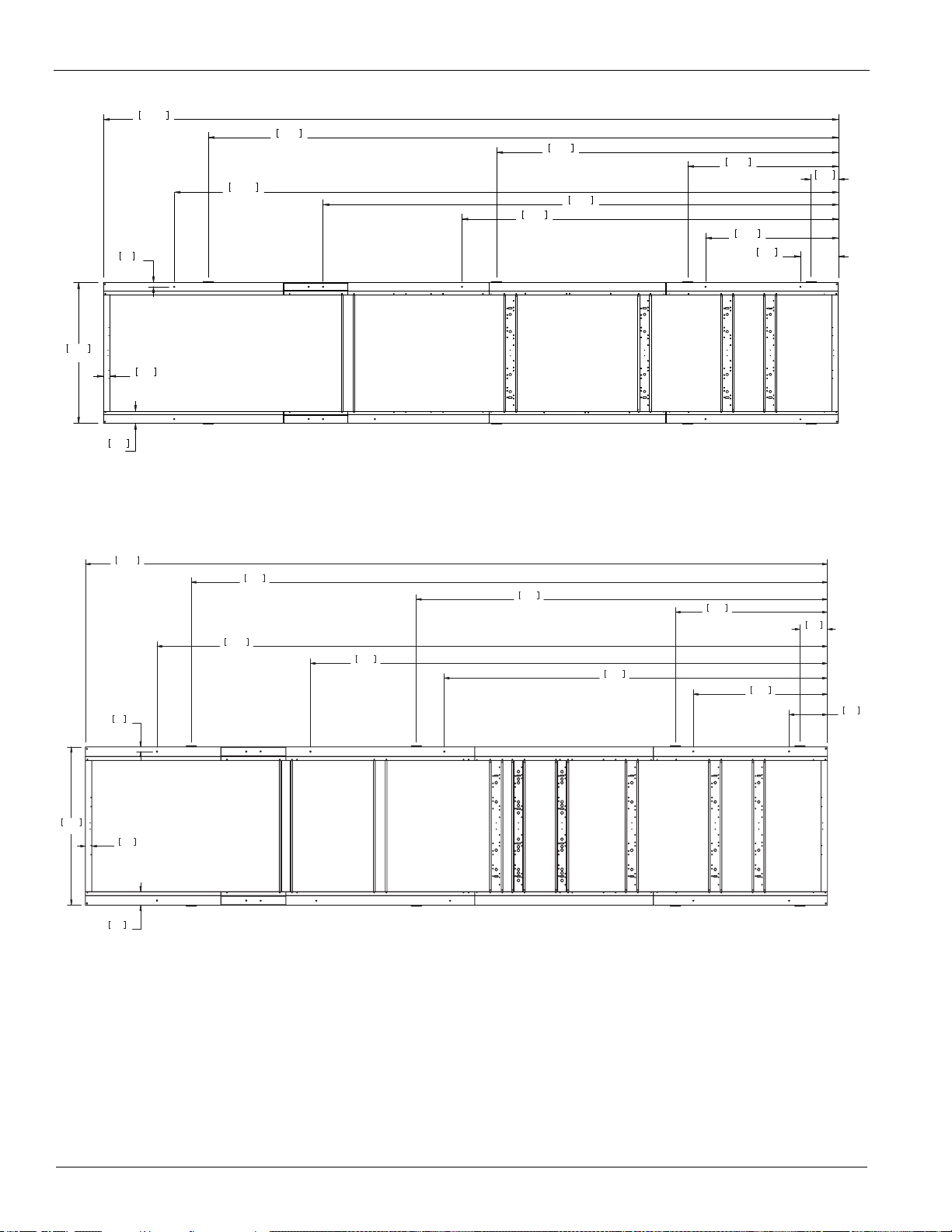

Page 18

Physical Data (non-VFD)

CIRC U IT 1 CIRCU IT 2 C IR C U IT 3 CIRCUIT 1 CIRCU IT 2 CIRCUIT 3

BASIC DATA

Unit Cap. @ AHRI tons (kW )

Unit O per at ing Char ge lbs (kg) 185 (84) 185 (84) 220 (100) 185 (84) 185 (84) 220 (100)

Unit Dimensions

L x W x H, in. (mm)

Unit O per at ing Weight, lbs. (kg)

Unit Shipping Weight, lbs (kg)

Weight - Add for Copper F ins, lbs (kg)

Weight - Add for Louvered P anels, lbs (kg)

g

Weight - Add for PF CC option, lbs (kg)

COMPRESSOR S, SC RE W, SE MI -H ER METI C

Nominal Capacity , t ons (kW ) 135 (475) 135 (475) 135 (475) 135 (475) 135 (475) 155 (545)

Minimum Capacity (% of F ull Load)

Oil char ge per c ir cuit , gallons (liters) 5.5 (21) 5.5 (21) 5.5 (21) 5.5 (21) 5.5 (21) 6 ( 23)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 291 (132) 291 (132) 333 (151) 291 (132) 291 (132) 333 (151)

Coil Inlet Face Area, sq. ft. (sq. m.) 172.3 (16. 0) 172.3 ( 16. 0) 196.9 (18.3) 172.3 ( 16. 0) 172.3 (16.0) 196.9 ( 18. 3)

Rows Deep/Fins Per Inc h 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp ( k W)

Fan & Motor RP M

Fan T ip S peed, fpm (m/s)

Airflow, cfm (l/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Lengt h, in. ( mm)

Water Volume, gallons (liters)

Vict aulic inlet / outlet conn. in. ( mm)

M ax. W at er Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

AWS425BTS

Data

418.7 (1472)

438 x 88 x 100

AWS400BTS

398.3 (1400)

(11123 x 2225 x 2548)

24931 (11309)

23532 (10674)

3256 (1477)

6984 (35)

120 (55) 120 (55)

778

1.4 ( 1. 05)

8

850

1.4 (1.05)

850

266040 (125556) 243870 (115094)

26 x 130 / (660 x 3300)

225 (850)

26 x 130 / (660 x 3300)

225 (850)

10 (273)

152 (1048)

10 (273)

152 (1048)

325 (2241)325 (2241)

24260 (11005)

22861 (10370)

3256 (1477)

77

1348 (611)

776 (352)

8

6984 (35)

438 x 88 x 100

8

(11123 x 2225 x 2548)

1348 (611)

776 (352)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Table 13: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

Weight - Add for Sound E nclosures, lbs (k

Number of Fans per Circuit

Fan Diameter: 31. 5 in. (800 mm)

18 IM 1167

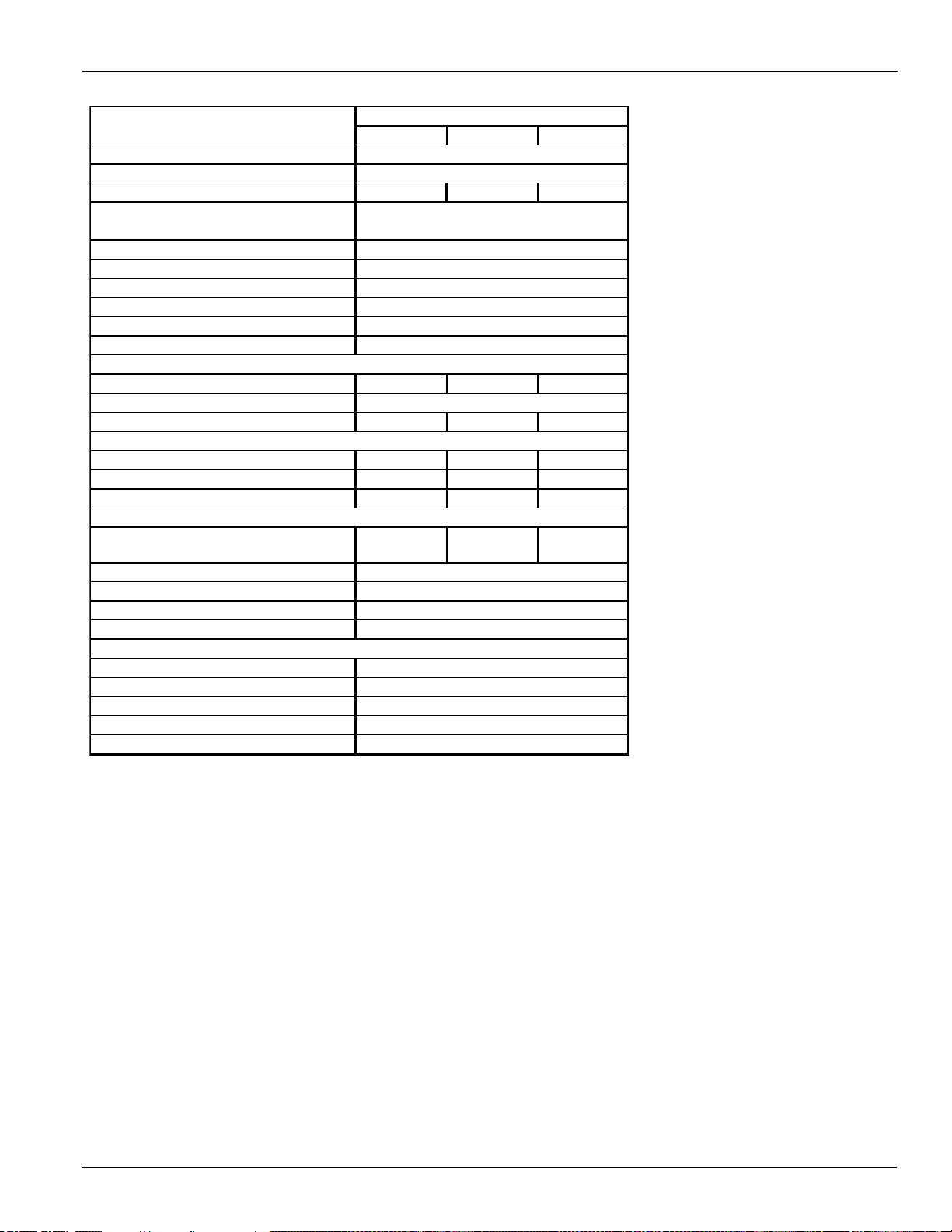

Page 19

Table 14: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

CIRCU IT 1 CIRCUIT 2 CIRC U IT 3 C IRC U IT 1 CIRCUIT 2 CIRC U IT 3

BASIC DATA

Unit Cap. @ AHRI t ons (kW)

Unit Operating Charge lbs (kg) 210 (95) 210 (95) 220 (100) 210 (95) 210 (95) 220 (100)

Unit Operating Weight, lbs. ( k g)

Unit S hipping W eight, lbs (kg)

Weight-Add for Copper Fins, lbs (kg)

g

Weight-Add for PFCC opt ion, lbs (kg)

COMPRESSOR S, SCR EW, SEMI-HER METI C

Nominal Capacity, tons (k W ) 135 (475) 155 (545) 155 (545) 155 (545) 155 (545) 155 (545)

Minimum Capacity (% of F ull Load)

Oil c har ge per c ir c uit , gallons (lit er s) 5.5 (21) 6 (23) 6 (23) 6 (23) 6 (23) 6 (23)

CONDENSERS, HIGH EFF ICIENCY FIN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 333 (151) 333 (151) 333 (151) 333 (151) 333 (151) 333 (151)

Coil Inlet F ac e Area, sq. f t. ( sq. m.) 196.9 (18.3) 196.9 ( 18.3) 196.9 ( 18.3) 196.9 ( 18.3) 196.9 ( 18.3) 196.9 ( 18.3)

Rows Deep/Fins Per Inch 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FAN S, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp ( k W)

Fan & Motor RPM

Fan Tip Speed, f pm (m/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Water Volume, gallons (liters)

Victaulic inlet /outlet c onn. in. ( mm)

Max. Water Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

25019 (11349)

3553 (1612)

25744 (11678)

3553 (1612)

Data

8888

88

776 (352)

225 (850)

26 x 130 / ( 660 x 3300)

220 (831)

6984 (35)

266040 (125556)

6984 (35)

266040 (125556)

26 x 130 / ( 660 x 3300)

325 (2241) 325 (2241)

10 (273)

152 (1048)

10 (273)

152 (1048)

8

1460 (662)

776 (352)

1460 (662)

8

1.4 ( 1.05)

850

1.4 ( 1.05)

850

459.2 ( 1615)

473 x 88 x 100

26418 (11984)

(12024 x 2225 x 2548)

27143 (12312)

(12024 x 2225 x 2548)

441.4 ( 1552)

473 x 88 x 100

AWS450BTS AWS470BTS

120 (55) 120 (55)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Unit Dimensions

L x W x H, in. (mm)

Weight -Add f or Louvered Panels, lbs (kg)

Weight-Add for Sound Enclosures, lbs (k

Physical Data (non-VFD)

Number of F ans per Circ uit

Fan Diameter : 31. 5 in. (800 mm)

Airflow, cfm (l/s)

Shell Dia. - Tube Length, in.(mm)

IM 1167 19

Page 20

Physical Data (non-VFD)

CIRCU IT 1 C IRC U IT 2 C IRC U IT 3 CIRCUIT 1 CIRCU IT 2 CIRCUIT 3

BASIC DATA

Unit Cap. @ AHRI t ons (kW)

Unit Operating Charge lbs (kg) 210 (95) 210 (95) 280 (127) 265 (120) 265 (120) 220 (100)

Unit Operating W eight, lbs. (kg)

Unit S hipping Weight , lbs (kg)

Weight-Add for Copper Fins, lbs (kg)

Weight-Add for Louvered Panels, lbs (kg)

g

Weight-Add for PFCC opt ion, lbs (kg)

COMPRESSORS, SC REW, SE MI -HER MET I C

Nominal Capacity, tons (kW) 155 (545) 155 (545) 185 (650) 185 (650) 185 (650) 155 (545)

Minimum Capacity (% of F ull Load)

Oil c harge per c ircuit , gallons (liters) 6 (23) 6 (23) 6 (23) 6 (23) 6 (23) 6 (23)

CONDENSERS, HIGH EFF ICIENCY F IN AND TUBE TYPE

Pumpdown Capacity, lbs (kg) 333 (151) 333 (151) 416 (189) 416 (189) 416 (189) 333 (151)

Coil Inlet F ac e Area, sq. ft . (sq. m.) 196.9 (18.3) 196.9 ( 18.3) 246.1 ( 22.8) 246.1 ( 22.8) 246.1 (22.8) 196.9 (18. 3)

Rows Deep/Fins Per Inch 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp ( k W)

Fan & Motor RPM

Fan Tip Speed, fpm (m/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Water Volume, gallons (liters)

Victaulic inlet/out let conn. in. ( mm)

M ax. Water Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

Data

509 x 88 x 100

517.7 ( 1820)

544 x 88 x 100

AWS500BTS AWS525BTS

4168 (1891)

1572 (713)

776 (352)

1684 (764)

776 (352)

(12921 x 2225 x 2548)

27902 (12657)

(13823 x 2225 x 2548)

28901 (13110)

6984 (35)

288210 (136019) 310380 (146482)

1.4 ( 1.05)

850

1.4 (1.05)

850

6984 (35)

10 (273)

152 (1048)

10 (273)

152 (1048)

26 x 130 / ( 660 x 3300)

220 (831)

26 x 130 / ( 660 x 3300)

220 (831)

325 (2241) 325 (2241)

88 8 10 10

88

120 (55)

27502 (12475)

120 (55)

26503 (12022)

3870 (1755)

488.3 ( 1717)

10

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Table 15: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

Unit Dimensions

L x W x H, in. (mm)

Weight-Add for Sound E nc losures, lbs (k

Number of F ans per Circ uit

Fan Diameter : 31.5 in. (800 mm)

Airflow, cfm (l/s )

Shell Dia. - Tube Lengt h, in.(mm)

20 IM 1167

Page 21

Table 16: Physical Data (60 Hz, Standard Efficiency, non-VFD models)

CIRCUIT 1 CIRCUIT 2 CIRCUIT 3

BASIC DATA

Unit Cap. @ AHRI tons (kW)

Unit O perat ing Charge lbs (kg) 270 (122) 270 (122) 280 (127)

Unit Dimensions

L x W x H, in. (mm)

Unit Oper at ing Weight , lbs. (k g)

Unit S hipping Weight , lbs (kg)

Weigh t -Add for Copper Fins, lbs (kg)

g

Weigh t - Add for PFCC opt ion, lbs (kg)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, to ns (kW) 185 (650) 185 (650) 185 (650)

Minimum Capacity (% of Full Load)

Oil c har ge pe r cir c uit , gallons (lit er s) 6 (2 3) 6 (23) 6 (23)

CONDENSERS, HIGH EFF ICIENCY F IN AND TUBE TYPE

Pumpdown Capacit y, lbs (kg) 416 (189) 416 (189) 416 (189)

Coil Inlet Fac e Area, sq. ft. (sq. m.) 246.1 (22. 8) 246. 1 (22.8) 246.1 ( 22. 8)

Rows Deep/F ins Per I nc h 3 / 16 3 / 16 3 / 16

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

Fan Motor, hp ( kW)

Fan & Motor RPM

Fan Tip Speed, fpm (m/s)

A irflow, cfm (l/s)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length, in. ( mm)

W ater Volume, gallo ns (lit e r s)

Victaulic inlet/outlet conn. in. (mm)

M ax. W ater Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

Data

AWS550BTS

(14722 x 2225 x 2548)

29643 (13446)

547.3 (1924)

580 x 88 x 100

1796 (815)

776 (352)

28244 (12812)

4466 (2026)

10 10 10

8

6984 (35)

332550 (156945)

1.4 (1. 05)

850

10 (273)

152 (1048)

26 x 130 / (660 x 3300)

220 (831)

325 (2241)

120 (55)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Weigh t - Add for Louvered Panels, lbs (kg)

Weight -Add for Sound Enclosures, lbs (k

Physical Data (non-VFD)

Number of Fans per Circuit

Fan Diameter: 31. 5 in. (800 mm)

IM 1167 21

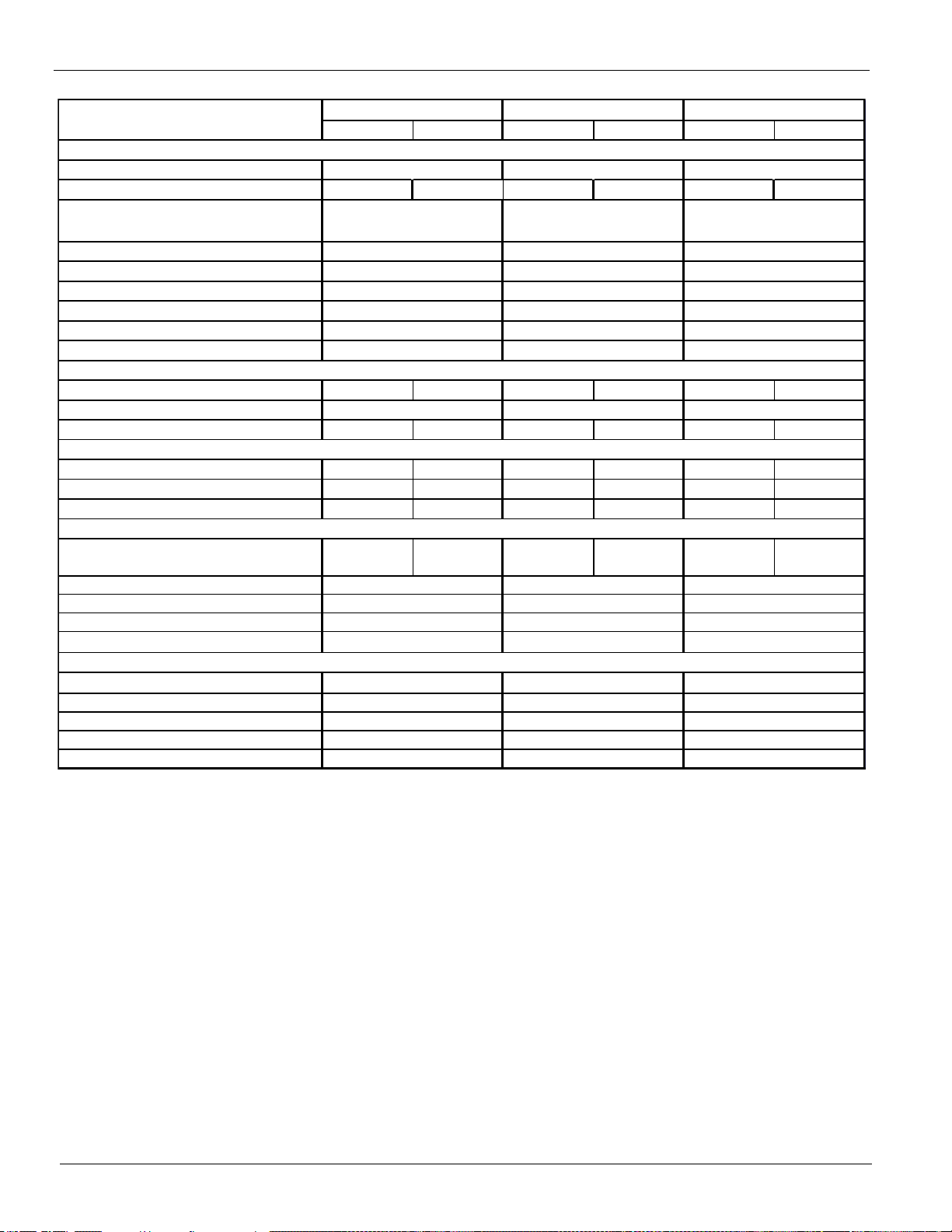

Page 22

Physical Data (non-VFD)

CIR C UIT 1 CIRC UIT 2 CIR C U IT 1 CIRC UIT 2 CIRC UIT 1 CIRCU IT 2

Unit Cap. @ AHRI tons (kW)

U nit Operating Charge lbs (kg)

160 (73) 160 (73) 180 (82) 180 (82) 180 (82) 180 (82)

Unit Dimensions

L x W x H, in. (mm)

Unit O perating Weight, lbs. (kg)

U nit Shipping Weight, lbs (kg)

W eight-Add for Copper F ins, lbs (kg)

g

W eight-Add for PF CC opt ion, lbs (kg)

N ominal Capacity, tons (kW)

105 (369) 105 (369) 105 (369) 125 (439) 125 (439) 125 (439)

Minimum Capacity (% of Full Load)

Oil charge per circuit , gallons (liters)

4.5 (17) 4.5 (17) 4.5 (17) 5.5 (21) 5.5 (21) 5.5 (21)

Pumpdown Capacity, lbs (kg)

250 (113) 250 (113) 291 (132) 291 (132) 291 (132) 291 (132)

Coil Inlet Fa ce Area, sq. ft. (sq. m.)

147.7 (13.7) 147.7 (13.7) 172.3 (16.0) 172.3 (16.0) 172.3 (16.0) 172.3 (16.0)

Row s Deep/Fins Per Inch

3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

N umber of Fans per Circuit

Fan Diameter: 31.5 in. (800 m m)

Fan Motor, hp (kW)

Fan & Motor RPM

Fan Tip Spee d, fpm (m /s)

Airflow, cfm (l/s)

Shell Dia.-Tube Length, in.(m m)

Water Volume, gallons (liters)

Victaulic inl e t/o utl e t conn . i n . (mm)

Max. W ater Pressure , psi (kPa)

Max. Refrigerant P ress., psi (kP a)

BASIC DATA

COMPRESSORS, SCRE W , SE MI-HERMETIC

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE

Data

AWS210BDH AWS230BDH AWS250BDH

15282 (6932)

205.7 (723) 225.2 (792) 240.6 (846)

245 x 88 x 100 280 x 88 x 100 280 x 88 x 100

15

788 (357) 900 (408)

(6220 x 2225 x 2548) (7121 x 2225 x 2548)

14622 (6633)

(7121 x 2225 x 2548)

13653 (6193) 15165 (6879) 15825 (7179)

777

1876 (851) 2084 (945) 2084 (945)

477 (216) 477 (216)

15 15

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

1.4 (1.05) 1.4 (1.05) 1.4 (1.05)

850 850 850

667

6984 (35) 6984 (35) 6984 (35)

133020 (62778) 155190 (73241) 155190 (73241)

16 x 108 / (406 x 2750) 16 x 108 / (406 x 2750) 16 x 108 / (406 x 2750)

66 (251) 64 (243) 64 (243)

6 (168) 6 (168) 6 (168)

152 (1048) 152 (1048) 152 (1048)

325 (2241) 325 (2241) 325 (2241)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

477 (216)

13110 (5947)

160 (73) 160 (73) 160 (73)

900 (408)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

Table 17: Physical Data (60 Hz, High Efficiency, non-VFD models)

W eight-Add for Louv ered P anels, lbs (kg)

W eight-Add for Sound E nc losures, lbs (k

22 IM 1167

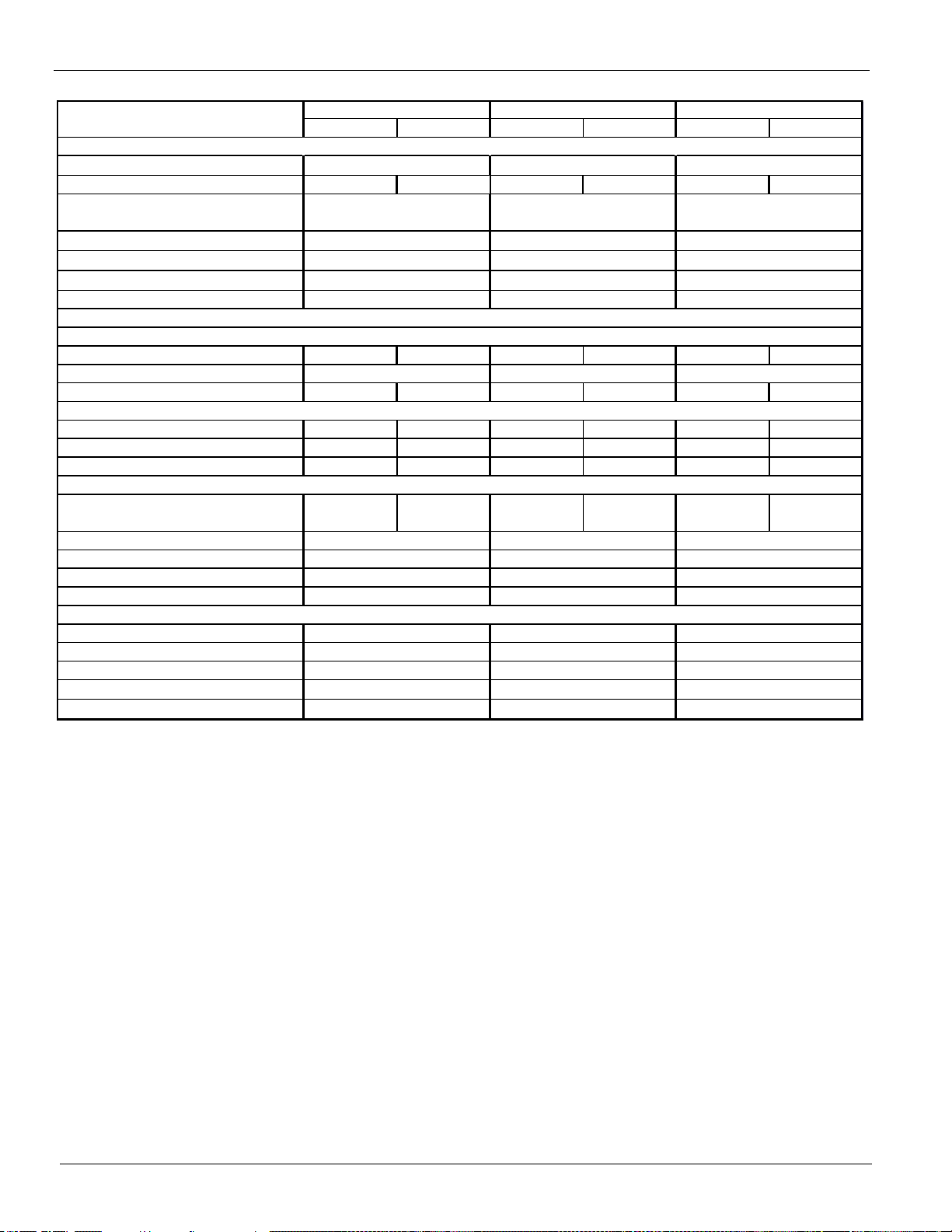

Page 23

Table 18: Physical Data (60 Hz, High Efficiency, non-VFD models)

CIR C UIT 1 CIRC UIT 2 CIRCU IT 1 CIRCU IT 2 CIRCU IT 1 CIR C U IT 2

Unit Cap. @ AHRI tons (kW)

U nit Operating Charge lbs (kg)

230 (104) 250 (113) 250 (113) 250 (113) 260 (118) 285 (129)

Unit Dimensions

L x W x H, in. (mm)

U nit Operating Weight, lbs. (kg)

Unit Shipping W eight, lbs (kg)

W eight-Add for Copper F ins, lbs (kg)

W eight-Add for Louv ered P anels, lbs (kg)

g

W eight-Add for PF CC opt ion, lbs (kg)

N ominal Capacity, tons (kW)

125 (439) 150 (528) 150 (528) 150 (528) 150 (528) 175 (615)

Minimum Capacity (% of Full Load)

Oil charge per circuit , gallons (liters)

5.5 (21) 5.5 (21) 5.5 (21) 5.5 (21) 5.5 (21) 6 (23)

Pumpdown Capacity, lbs (kg)

333 (151) 333 (151) 333 (151) 333 (151) 416 (189) 416 (189)

Coil Inlet Fa ce Area, sq. ft. (sq. m.)

196.9 (18.3) 196.9 (18.3) 196.9 (18.3) 196.9 (18.3) 246.1 (22.8) 246.1 (22.8)

Row s Deep/Fins Per Inch

3 / 16 3 / 16 3 / 16 3 / 16 3 / 16 3 / 16

N umber of Fans per Circuit

Fan Diameter: 31.5 in. (800 m m)

Fan Motor, hp (kW)

Fan & Motor RPM

Fan Tip Speed, fpm (m/s)

Airflow, cfm (l/s)

Shell D i a.-Tube Length, in.(mm)

Water Volume, gallons (liters)

Victaulic inlet/outlet conn. in. (m m)

Max. Water Pressu re, psi (kPa)

Max. Refrigerant P ress., psi (kP a)

BASIC DATA

COMPRESSORS, SCRE W , SE MI-HERMETIC

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Data

AWS280BDH AWS300BDH AWS330BDH

(9823 x 2225 x 2548)

17461 (7921) 17461 (7921) 19764 (8965)

271.9 (956) 288.7 (1015) 327.3 (1151)

316 x 88 x 100 316 x 88 x 100 387 x 88 x 100

1236 (561)

477 (216) 477 (216) 477 (216)

16594 (7527) 16594 (7527) 18897 (8572)

2372 (1076) 2372 (1076) 2968 (1346)

15 15 15

88881010

1.4 (1.05) 1.4 (1.05) 1.4 (1.05)

850 850 850

6984 (35) 6984 (35) 6984 (35)

177360 (83704) 177360 (83704) 221700 (104630)

20 x 108 / (508 x 2750) 20 x 108 / (508 x 2750) 20 x 108 / (508 x 2750)

107 (403) 107 (403) 102 (386)

8 (219) 8 (219) 8 (219)

152 (1048) 152 (1048) 152 (1048)

325 (2241) 325 (2241) 325 (2241)

160 (73) 160 (73) 160 (73)

1012 (459) 1012 (459)

(8022 x 2225 x 2548) (8022 x 2225 x 2548)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.

W eight-Add for Sound Enc losures, lbs (k

Physical Data (non-VFD)

IM 1167 23

Page 24