Page 1

Operation Manual

Air-Cooled Scroll Compressor Chiller

AGZ 030CH through 190CH, Packaged

AGZ 030CB through 190CB, Remote Evaporator

60 Hertz, R-410A

Software Version AGZDU0102G

OM AGZC-1

Group: Chiller

Part Number: 331376301

Effective: February 2010

Supercedes: April 2009

Page 2

Table of Contents

Introduction........................................3

General Description..................................... 3

Nomenclature .............................................. 3

Ambient Air Temperature Limitations......... 4

Water Flow Limitations ............................... 4

System Water Volume Considerations ......... 5

Glycol Solutions .......................................... 5

Operating/Standby Limits............................ 9

Pressure Drop Curves........................9

oTech II Controller ..................13

Micr

Controller Section Table of Contents ........ 13

Overview ................................................... 14

General Description................................... 14

Setpoints .................................................... 16

Dynamic Defaults...................................... 18

Security...................................................... 19

Control Functions...................................... 19

Unit Enable................................................ 20

Unit Mode Selection.................................. 21

Unit State................................................... 22

Power Up Start Delay................................ 23

Ice Mode Start Delay................................. 23

Low Ambient Lockout............................... 23

Evaporator Water Pump State.................... 23

Leaving Water Temperature (LWT) Reset. 24

Maximum LWT Rate................................. 24

Unit Capacity Overrides ............................ 24

Circuit Capacity Overrides – Limits of Operation

................................................................... 25

Low Ambient Starts ................................... 26

Compressor Sequencing ............................ 26

Manual Compressor Control ..................... 27

Normal Circuit Shutdown.......................... 28

Rapid Circuit Shutdown ............................ 28

Cycle Timers.............................................. 28

Liquid Line Solenoid................................. 28

Hot Gas Bypass Solenoid .......................... 28

EXV Control.............................................. 28

Condenser Fan Control.............................. 29

Alarms and Events.......................... 31

Unit Stop Alarms........................................31

Circuit Stop Alarms....................................31

Circuit Events.............................................33

Clearing Alarms .........................................34

4x20 Display & Keypad.................. 35

Layout ........................................................35

Keys ...........................................................37

Navigation..................................................37

Editing........................................................39

Screen Definitions – MENU......................39

Screen Definitions – VIEW .......................40

Screen Definitions – ALARM/EVENT .....44

Screen Definitions – SET...........................44

Screen Definitions – TEST ........................51

Building Automation System Interface

........................................................... 52

Protocols Supported...................................52

Available Parameters..................................52

Parameter Details....................................... 53

Optional Low Ambient VFD.......... 55

Startup.............................................. 66

Operation......................................... 68

Hot Gas Bypass (Optional) ........................68

VFD Low Ambient Control (Optional)......69

Filter-Driers................................................69

System Adjustment ....................................69

Liquid Line Sight Glass .............................69

Refrigerant Charging .................................69

Thermostatic Expansion Valve...................69

Crankcase Heaters......................................70

Evaporator..................................................70

Phase Voltage Monitor (Optional) .............70

*

©2007 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve the right

to make changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their

respective companies: BACnet from ASHRAE;

L

ONMARK International under a license granted by Echelon Corporation; Compliant Scroll from Copeland Corporation; ElectroFin from AST

ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech II, Open Choices, and SpeedTrol from McQuay International. *Unit

Controllers are L

2 AGZ 030C through 190C OM AGZC-1

ONMARK certified with an optional LONWORKS communication module.

Our facility is ISO Certified

LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed, granted and used by

Page 3

Introduction

General Description

McQuay Air-Cooled Global Water Chillers are

complete, self-contained automatic

refrigerating units. Every unit is completely

assembled, factory wired, charged, and tested

(except remote evaporator option). Each unit

consists of twin air-cooled condensers with

integral subcooler sections, two tandem or

triple scroll compressors, brazed-plate or

replaceable tube, dual circuit shell-and-tube

evaporator, and complete refrigerant piping.

Liquid line components include manual liquid

line shutoff valves, sight-glass/moisture

indicators, solenoid valves, and thermal

expansion valves. Other features include

compressor crankcase heaters, an evaporator

heater for chilled water freeze protection,

BOOT Version 3.0F

limited pumpdown during “on” or “off”

periods, automatic compressor lead-lag to

alternate the compressor starting sequence, and

sequenced starting of compressors.

The electrical control center includes all

equipment protection and operating controls

necessary for dependable automatic operation.

Condenser fan motors are protected in all three

phases and started by their own three-pole

contactors.

This manual covers units with Software

Version AGZDU0102G. Installation,

maintenance and service information is in

IMM AGZC (or current, latest dash number)

manual.

BIOS Version 3.62

Scroll Compressor

Air-Cooled

Global

Nomenclature

A G Z - XXX C H

Application

H= Packaged Chiller

B= Chiller with Remote Evap.

Design Vintage

Model Size

(Nominal Tons)

OM AGZC-1 AGZ 030C through 190C 3

Page 4

Ambient Air Temperature Limitations

Standard/High Ambient Panels

The AGZ-C units for high ambient operation

(105F to 125F maximum) require the

addition of the High Ambient Control Panel

Option, which includes the addition of a small

fan with a filter in the air intake to cool the

control panel.

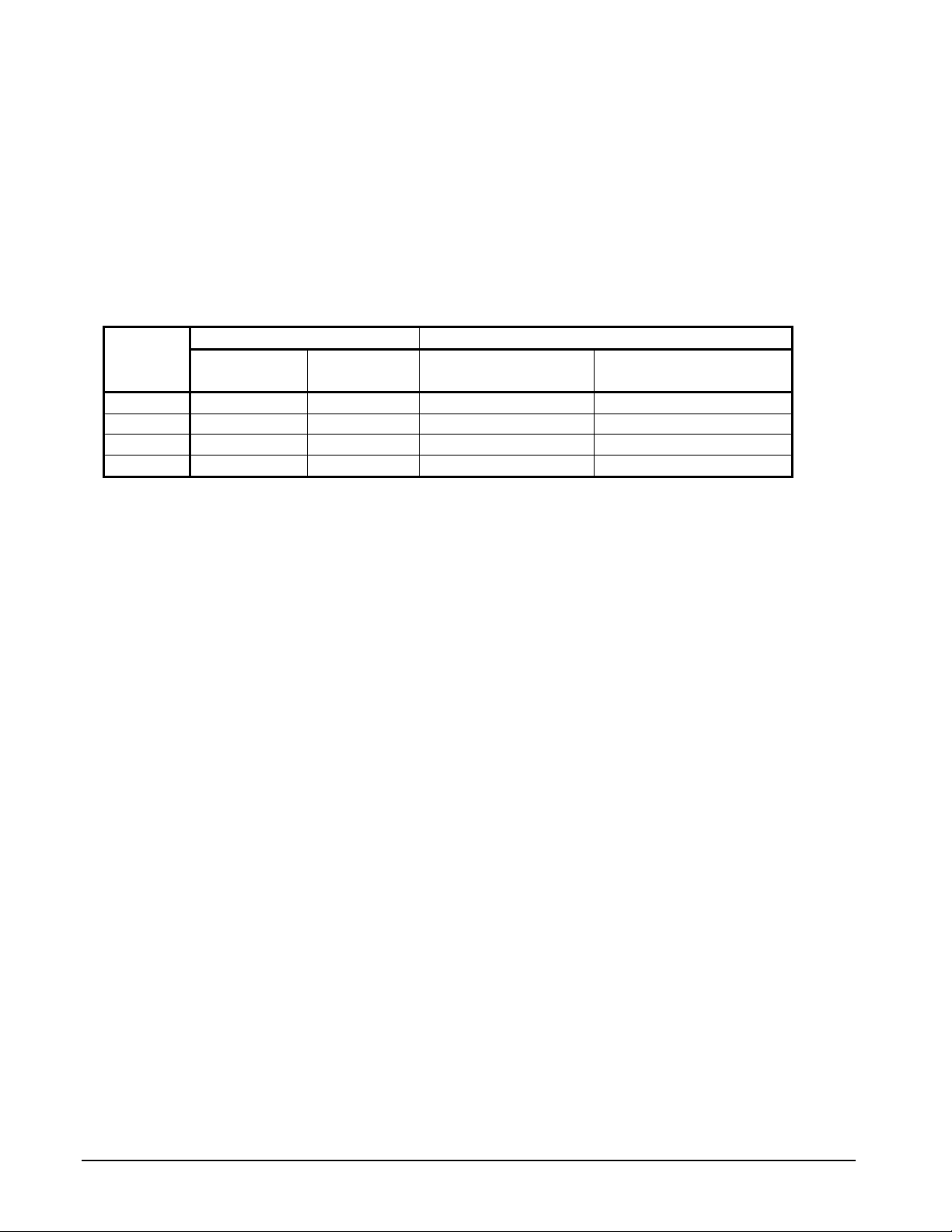

Table 1, Panel Ratings

All units with the optional VFD low ambient

fan control automatically include the High

Ambient Control Panel Option. Operation of

the VFD generates a quantity of panel heat best

removed by use of a control panel fan.

Voltage

208-230

240

380-460

575

Standard

Standard Options

Optional

Panel

35 5 120 120

35 5 100 100

35 5 65 65

5 5 25 25

VFD

Water Flow Limitations

The evaporator flow rates and pressure drops

shown on page 9 (and following) are for full

load design purposes in order to m

proper unit control. The maximum flow rate

and pressure drop are based on a 6 degree

temperature drop. Avoid higher flow rates with

resulting lower temperature drops to prevent

potential control problems resulting from very

small control bands and limited start up/shut

off temperature changes.

Variable Speed Pumping

Variable water flow involves changing the

water flow through the evaporator as the load

changes. McQuay chillers are designed for this

duty provided that the rate of change in water

flow is slow and the minimum and maximum

flow rates for the vessel are not exceeded.

The recommended maximum change in water

flow is 10 percent of the change per minute.

aintain

High Short Circuit

Panel (kA)

The minimum flow and pressure drop is based

on a full load evaporator temperature drop of

16 degrees. Evaporator flow rates below the

minimum values can result in laminar flow

causing freeze-up problems, scaling and poor

control. Flow rates above the maximum values

will result in unacceptable pressure drops and

can cause excessive erosion, potentially

leading to failure.

When units are operated with flow rates less

than nominal (see Table 8), the “Evap Delta T”

setpoint m

match the minimum operating flow rate. The

“Delta T” setting should be increased by the

same percentage as the flow reduction is from

the nominal rating in order to prevent short

cycling. This will require reevaluation of

“Cool LWT”, “Startup Delta T”, and “Stop

Delta T” settings as well.

ust be changed proportionally to

High Interrupt Panel w/

Disconnect Swt. (kA)

4 AGZ 030C through 190C OM AGZC-1

Page 5

System Water Volume

T

Considerations

All chilled water systems need adequate time

to recognize a load change, respond to that

load change and stabilize without undesirable

short cycling of the compressors or loss of

control. In air conditioning systems, the

potential for short cycling usually exists when

the building load falls below the minimum

chiller plant capacity or on close-coupled

systems with very small water volumes.

Some of the things the designer should

consider when looking at water volume are the

minimum cooling load, the minimum chiller

plant capacity during the low load period and

the desired cycle time for the compressors.

Assuming that there are no sudden load

changes and that the chiller plant has

reasonable turndown, a rule of thumb of

“gallons of water volume equal to two to three

times the chilled water gpm flow rate” is often

used.

A properly designed storage tank should be

added if the system components do not provide

sufficient water volume.

Glycol Solutions

The use of a glycol/water mixture in the

evaporator to prevent freezing will reduce

system capacity and efficiency, as well as

increase pressure drop. The system capacity,

required glycol solution flow rate, and pressure

drop with glycol may be calculated using the

following formulas and tables.

1. Capacity – Multiply the capacity based on

water by the Capacity correction factor

from Table 2 through Table 5.

2. Flow – Multiply

by the Flow correction factor from Table 2

through Table 5 to determine the increased

evaporator flow due to gly

If the flow is unknown, it can be calculated

from the following equation:

the water evaporator flow

col.

glycolCapacityTons

)(×24

=(gpm) Flow Glycol

TDelta

×

FactorCorrectionFlow

For Metric Applications

– Use the following equation:

(l/s) Flow Glycol

3. Pressure drop -- Multiply the water

pressure drop from page 10 by Pr

essure

Drop correction factor from Table 2

through Table 5. High concentrations of

lene glycol at low temperatures can

propy

cause unacceptably high pressure drops.

4. Power -- Multiply the water system power

by Power correction factor from Table 2 Table 5.

est coolant with a clean, accurate glycol

T

CapacitykW

Delta

18.4

service stations) to determine the freezing

point. Obtain percent glycol from the freezing

point tables below. It is recommended that a

minimum of 25% solution by weight be used

for protection against corrosion or that

additional compatible inhibitors be added.

Concentrations above 35 % do not provide any

additional burst protection and should be

carefully considered before using.

FactorCorrectionFlow

solution hydrometer (similar to that found in

!

WARNING

Do not use an automotive grade antifreeze. Industrial grade glycols must be used. Automotive antifreeze

contains inhibitors which will cause plating on the copper tubes within the chiller evaporator. The type

and handling of glycol used must be consistent with local codes

OM AGZC-1 AGZ 030C through 190C 5

Page 6

Table 2, Ethylene Glycol Factors for Models AGZ 030C to 130C

% E.G.

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.998 0.998 1.036 1.097

18 -7.8 0.993 0.997 1.060 1.226

7 -13.9 0.987 0.995 1.092 1.369

-7 -21.7 0.980 0.992 1.132 1.557

-28 -33.3 0.973 0.991 1.182 1.791

o

C

Capacity Power Flow PD

Table 3, Propylene Glycol Factors for Models AGZ 030C to 130C

% P.G.

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.995 0.997 1.016 1.100

19 -7.2 0.987 0.995 1.032 1.211

9 -12.8 0.978 0.992 1.057 1.380

-5 -20.6 0.964 0.987 1.092 1.703

-27 -32.8 0.952 0.983 1.140 2.251

o

C

Capacity Power Flow PD

Table 4, Ethylene Glycol Factors for Models AGZ 140C to 180C

% E.G.

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.994 0.998 1.038 1.101

18 -7.8 0.982 0.995 1.063 1.224

7 -13.9 0.970 0.992 1.095 1.358

-7 -21.7 0.955 0.987 1.134 1.536

-28 -33.3 0.939 0.983 1.184 1.755

o

C

Capacity Power Flow PD

Table 5, Propylene Glycol Factors for Models AGZ 140C to 180C

% P.G.

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.988 0.996 1.019 1.097

19 -7.2 0.972 0.992 1.035 1.201

9 -12.8 0.951 0.987 1.059 1.351

-5 -20.6 0.926 0.979 1.095 1.598

-27 -32.8 0.906 0.974 1.142 2.039

o

C

Capacity Power Flow PD

Altitude Correction Factors

Performance tables are based at sea level.

Elevations other than sea level affect the

performance of the unit. The decreased air

density will reduce condenser capacity

consequently reducing the unit's performance.

For performance at elevations other than sea

level, refer to Table 6 and Table 7.

Evaporator Temperature Drop Factors

Performance tables are based on a 10°F (5°C)

temperature drop through the evaporator.

Adjustment factors for applications with

temperature ranges from 6°F to 16°F (3.3°C to

8.9°C) are in Table 6 and Table 7.

emperature drops outside this 6°F to 16°F

T

(3.3°C to 8.9°C) range can affect the control

system's capability to maintain acceptable

control and are not recommended.

The maximum water temperature that can be

circulated through the evaporator in a nonoperating mode is 100°F (37.8°C).

6 AGZ 030C through 190C OM AGZC-1

Page 7

Fouling Factor

Performance tables are based on water with a

fouling factor of:

22

per ARI 550/590-98.

As fouling is increased, performance decreases.

Foreign m

system will adversely affect the heat

transfer capability of the evaporator

kWCmorBTUFhrft

and reduce the water flow. Maintain

and could increase the pressure drop

)/0176.0(/0001.0

proper water treatment to provide

optimum unit operation.

atter in the chilled water

For performance at other than 0.0001 (0.0176)

fouling factor, refer to Table 6 or Table 7.

Table 6, Capacity and Power Derates, Models AGZ 030C to 130C

Fouling Factor

Altitude

Sea

Level

2000 feet

4000 feet

6000 feet

Chilled Water Delta T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.978 0.993 0.975 0.991 0.963 0.987 0.940 0.980

8 4.4 0.989 0.996 0.986 0.994 0.973 0.990 0.950 0.983

10 5.6 1.000 1.000 0.996 0.999 0.984 0.994 0.961 0.987

12 6.7 1.009 1.003 1.005 1.001 0.993 0.997 0.969 0.990

14 7.7 1.018 1.004 1.014 1.003 1.002 0.999 0.978 0.991

16 8.9 1.025 1.007 1.021 1.006 1.009 1.001 0.985 0.994

6 3.3 0.977 1.001 0.973 1.000 0.961 0.996 0.938 0.989

8 4.4 0.987 1.006 0.984 1.004 0.971 1.000 0.948 0.993

10 5.6 0.998 1.009 0.995 1.007 0.982 1.003 0.959 0.996

12 6.7 1.007 1.011 1.004 1.010 0.991 1.006 0.967 0.998

14 7.7 1.014 1.014 1.011 1.013 0.998 1.009 0.974 1.001

16 8.9 1.022 1.016 1.018 1.014 1.005 1.010 0.981 1.003

6 3.3 0.973 1.011 0.970 1.010 0.957 1.006 0.935 0.998

8 4.4 0.984 1.014 0.980 1.013 0.968 1.009 0.945 1.001

10 5.6 0.995 1.019 0.991 1.017 0.979 1.013 0.955 1.005

12 6.7 1.004 1.021 1.000 1.020 0.987 1.016 0.964 1.008

14 7.7 1.011 1.024 1.007 1.023 0.994 1.018 0.971 1.011

16 8.9 1.018 1.027 1.014 1.026 1.002 1.021 0.978 1.014

6 3.3 0.969 1.021 0.966 1.020 0.954 1.016 0.931 1.008

8 4.4 0.980 1.026 0.977 1.024 0.964 1.020 0.942 1.013

10 5.6 0.989 1.029 0.986 1.027 0.973 1.023 0.950 1.015

12 6.7 0.998 1.033 0.995 1.031 0.982 1.027 0.959 1.020

14 7.7 1.007 1.036 1.004 1.034 0.991 1.030 0.967 1.022

16 8.9 1.014 1.037 1.011 1.036 0.998 1.031 0.974 1.024

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

OM AGZC-1 AGZ 030C through 190C 7

Page 8

Table 7, Capacity and Power Derates, Models AGZ 075 to 130

Chilled Water

Altitude

Sea

Level

2000 feet

4000 feet

6000 feet

8000 feet

Delta T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.990 0.997 0.976 0.994 0.937 0.983 0.868 0.964

8 4.4 0.994 0.998 0.981 0.995 0.942 0.984 0.872 0.965

10 5.6 1.000 1.000 0.987 0.996 0.947 0.986 0.877 0.967

12 6.7 1.005 1.001 0.991 0.997 0.951 0.986 0.881 0.968

14 7.7 1.009 1.002 0.995 0.998 0.955 0.987 0.884 0.968

16 8.9 1.013 1.004 1.000 1.000 0.960 0.989 0.889 0.970

6 3.3 0.987 1.005 0.974 1.002 0.934 0.991 0.865 0.972

8 4.4 0.992 1.006 0.979 1.003 0.940 0.992 0.870 0.973

10 5.6 0.997 1.008 0.984 1.004 0.944 0.994 0.875 0.975

12 6.7 1.002 1.009 0.989 1.005 0.949 0.994 0.879 0.975

14 7.7 1.007 1.011 0.993 1.007 0.953 0.996 0.883 0.977

16 8.9 1.011 1.012 0.998 1.008 0.958 0.997 0.887 0.978

6 3.3 0.985 1.014 0.972 1.010 0.933 0.999 0.864 0.980

8 4.4 0.991 1.015 0.977 1.012 0.938 1.001 0.869 0.981

10 5.6 0.995 1.016 0.982 1.013 0.943 1.002 0.873 0.982

12 6.7 1.000 1.018 0.987 1.014 0.947 1.003 0.877 0.984

14 6.8 1.005 1.019 0.991 1.015 0.951 1.004 0.881 0.985

16 8.9 1.009 1.021 0.995 1.017 0.955 1.006 0.884 0.987

6 3.3 0.982 1.023 0.969 1.020 0.930 1.009 0.861 0.989

8 4.4 0.988 1.025 0.975 1.022 0.935 1.010 0.866 0.991

10 5.6 0.992 1.026 0.979 1.022 0.940 1.011 0.870 0.992

12 6.7 0.997 1.028 0.984 1.024 0.944 1.013 0.875 0.994

14 7.7 1.002 1.029 0.989 1.025 0.949 1.014 0.879 0.995

16 8.9 1.006 1.031 0.992 1.027 0.952 1.016 0.882 0.996

6 3.3 0.979 1.034 0.966 1.031 0.927 1.019 0.859 1.000

8 4.4 0.984 1.036 0.971 1.032 0.932 1.021 0.863 1.002

10 5.6 0.990 1.037 0.976 1.033 0.937 1.022 0.868 1.002

12 6.7 0.993 1.039 0.980 1.035 0.941 1.024 0.871 1.004

14 7.7 0.998 1.041 0.985 1.037 0.945 1.026 0.875 1.006

16 8.9 1.003 1.041 0.990 1.038 0.950 1.026 0.879 1.007

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the

application of air-cooled water chillers. To

protect against freeze-up, insulation and an

electric heater cable are furnished with the unit.

This protects the evaporator down to -20°F (29°C) ambient air temperature. Although the

evaporator is equipped with freeze protection,

it does not protect water piping external to the

unit or the evaporator itself if there is a power

failure or heater cable burnout. Consider the

Fouling Factor

vent connections are provided on the

evaporator to ease draining.

2. Add a glycol solution to the chilled water

system to provide freeze protection.

Freeze point should be approximately ten

degrees below minimum design ambient

temperature.

3. The addition of thermostatically controlled

heat and insulation to exposed piping.

4. Continuous circulation of water through

the chilled water piping and evaporator.

following recommendations for additional

protection.

1. If the unit will not be operated during the

winter, drain evaporator and chilled water

piping and flush with glycol. Drain and

The evaporator heater cable is factory wired to

the 115-volt circuit in the control box. This

power should be supplied from a separate

source, but it can be supplied from the control

circuit. Operation of the heater cable is

8 AGZ 030C through 190C OM AGZC-1

Page 9

automatic through the ambient sensing

thermostat that energizes the evaporator heater

cable for protection against freeze-up. Unless

the evaporator is drained in the winter, the

disconnect switch to the evaporator heater must

not be open.

Operating/Standby Limits

Maximum standby ambient air

temperature, 130F (55C)

Maximum operating ambient air

temperature 105 F (40.6 C)

Leaving chilled water temperature, 40F

to 60F (4.4C to 15.6C)

Leaving chilled fluid temperatures (with

anti-freeze), 15F to 60F (-9.4C to

15.6C)

Design chilled water Delta-T range, 6

degrees F to 16 degrees F (3.3 C to

8.9C)

Part load minimum flow for variable

flow systems, varies with unit size, see

Table 8 below.

Minimum operating ambient

temperature (standard), 35F (2C)

Minimum operating ambient

temperature (with optional low-ambient

control), 0F (-18C)

Pressure Drop Curves

Evaporator pressure drop curves on the

following page. They apply to either packaged

or remote evaporator applications. Figure 1,

Evaporator Pressure Drops. See following page

for curve cross-reference on the next page

contains the evaporator reference letter and the

nimum and maximum flows allowed for

mi

each unit.

Maxim

temperature, 76F (24C)

Maximum non-operating inlet fluid

temperature, 100F (38 C).

Occasionally the same evaporator is used on

multiple units resulting in overlapping lines.

The minimum and maximum flows for a given

unit will be at the point where the unit

reference number appears.

um operating inlet fluid

OM AGZC-1 AGZ 030C through 190C 9

Page 10

Figure 1, Evaporator Pressure Drops. See following page for curve cross-reference

See following page for curve cross-reference and min/max flow rates.

Q

A

B

C

F

E

D

J

M

N

K

L

O

P

I

G

H

10 AGZ 030C through 190C OM AGZC-1

Page 11

Table 8, Curve Cross-Reference, Min/Nominal/Max Flows

Curve

AGZ

Unit

Ref.

Model

A 030C ACH130-90DQ 47.3 5.1 3.0 15.4 75.6 12.0 4.8 35.9 126.0 30.1 8.0 90.0 31.5

B 035C ACH130-102DQ 51.2 4.8 3.2 14.2 81.8 11.1 5.2 33.2 136.4 27.9 8.6 83.3 34.1

C 040C ACH130-118DQ 55.7 4.3 3.5 12.8 89.0 10.0 5.6 29.9 148.4 25.1 9.4 75.0 37.1

D 045C ACH130-138DQ 63.2 4.5 4.0 13.5 101.0 10.5 6.4 31.4 168.4 26.3 10.6 78.7 42.1

E 050C ACH130-158DQ 71.4 5.1 4.5 15.1 114.2 11.8 7.2 35.3 190.4 29.6 12.0 88.5 47.6

F 055C ACH130-178DQ 77.1 5.1 4.9 15.3 123.4 11.9 7.8 35.7 205.6 30.0 13.0 89.6 51.4

G 060C ACH250-110DQ 82.7 2.6 5.2 7.8 132.2 6.1 8.3 18.1 220.4 15.2 13.9 45.4 55.1

H 065C ACH250-122DQ 85.7 2.4 5.4 7.2 137.0 5.6 8.6 16.8 228.4 14.1 14.4 42.0 57.1

I 070C ACH250-122DQ 93.4 2.9 5.9 8.6 149.5 6.8 9.4 20.2 249.1 16.8 15.8 50.5 62.3

J 075C ACH350-118DQ 107.4 4.3 6.8 13.0 171.8 10.1 10.8 30.3 286.4 25.4 18.1 75.9 71.6

K 080C ACH350-126DQ 119.3 4.4 7.5 13.2 190.8 10.3 12.0 30.7 318.0 25.7 20.1 76.9 79.5

L 090C ACH350-142DQ 129.4 4.3 8.1 13.0 207.1 10.1 13.0 30.1 345.2 25.2 21.8 75.5 86.3

M 100C ACH350-150DQ 146.7 4.9 9.2 14.7 234.7 11.4 14.8 34.3 391.2 28.7 24.7 85.9 97.8

N 110C ACH350-162DQ 156.3 4.8 9.9 14.3 250.1 11.1 15.8 33.3 416.8 27.9 26.3 83.5 104.2

O 125C ACH350-182DQ 171.5 4.6 10.8 13.8 274.3 10.8 17.3 32.1 457.2 27.0 28.8 80.6 114.3

P 130C ACH350-210DQ 187.1 4.2 11.8 12.5 299.3 9.8 18.9 29.1 498.8 24.5 31.5 73.1 124.7

Q 140C EV34191111/9 200.6 5.0 12.7 15.0 320.9 11.8 20.2 33.1 534.8 29.5 33.7 88.0 133.7

Q 160C EV34191111/9 227.3 6.3 14.3 18.9 363.6 14.7 22.9 41.5 606.0 36.8 38.2 110.2 151.5

Q 180C EV34191111/9 254.0 7.7 16.0 22.9 406.3 18.0 25.6 50.8 677.2 45.1 42.7 134.6 169.3

Q 190C EV34191212/7 270.2 9.4 17.0 28.0 432.2 22.0 27.2 62.1 720.3 55.1 45.4 164.4 180.1

Evap

Model

Minimum Flow Rate Nominal Flow Rate Maximum Flow Rate

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

gpm

DP

ft.

lps

DP

kpa

gpm

DP

ft.

lps

DP

kpa

gpm

DP

ft.

lps

DP

kpa

Nom

Tons

NOTE: Evaporators beginning with ACH are brazed-plate; those beginning with EV are shell-and-tube.

OM AGZC-1 AGZ 030C through 190C 11

Page 12

Figure 2, AGZ030C – AGZ 180C, Typical Field Wiring

3 PHASE

POWER

DISCONNECT

(BY OTHERS)

UNIT MAIN

TERMINAL BLOCK

GND LUG

TO COMPRESSOR(S)

AND FAN MOTORS

NOTE: ALL FIELD WIRING TO BE

INSTALLED AS NEC CLASS 1

WIRING SYSTEM WITH CONDUCTOR

RATED 600 VOLTS

FIELD SUPPLIED

ALARM BELL

REMOTE STOP SWITCH

(BY OTHERS)

ICE MODE SWITCH

(BY OTHERS)

OPTION

CONTROL POWER

OPTION

CHW FLOW SWITCH

---MANDATORY–(BY OTHERS)

N

120VAC

FACTORY SUPPLIED ALARM

FIELD WIRED

ALARM BELL RELAY

TIME

CLOCK

FUSED CONTROL

CIRCUIT TRANSFORMER

DISCONNECT

(BY OTHERS)

10A

FUSE

(BY OTHERS)

CHW PUMP RELAY

120 VAC 1.0 AMP MAX

OFF

AUTO

ON

MANUAL

OFF

AUTO

ON

MANUAL

(BY OTHERS)

120 VAC

CONTROLLER

TB1

TB2

TB1-20

1

2

35

33

34

CONTROL

CIRCUIT

FUSE

120 VAC

N

120 VAC

32

GND

IF REMOTE STOP

585

CONTROL IS USED,

REMOVE LEAD 585

FROM TERM. 52

TO 72.

BELL

12

ALARM BELL OPTION

ALARM BELL

RELAY

COM NO

52

72

43

83

54

74

NOR. OPEN PUM P AUX.

CONTACTS (OPTIONAL)

44

61

4-20MA FOR

EVAP. WATER RESET

(BY OTHERS)

4-20MA FOR

DEMAND LIMIT

(BY OTHERS)

DWG. 330423101 REV.0A

+

-

+

-

LESS EVAPORATOR ONLY

LIQUID LINE #1 SOLENOID

24 VAC 1.5 AMP MAX

LIQUID LINE #2 SOLENOID

24 VAC 1.5 AMP MAX

68

69

70

71

GND

91

93

92

93

24 VAC

N

24 VAC

N

12 AGZ 030C through 190C OM AGZC-1

Page 13

MicroTech II Controller

Software Version AGZDU0102B

Controller Section Table of Contents

Overview........................................................................................................................14

General Description .......................................................................................................14

Setpoints

namic Defaults ..........................................................................................................18

Dy

Security

Control Functions

Unit Enable

Unit Mode Selection

Unit S

Power Up S

Ice Mode S

Low Am

Evaporator

Leaving W

Maxim

Unit Capacity

Circuit Capacity

Low Am

Com

Manual Com

Norm

Rapid Circuit Shutdown

cle Timers..................................................................................................................28

Cy

Liquid Line Solenoid

Hot Gas By

EXV

Condenser Fan Control

........................................................................................................................16

..........................................................................................................................19

..........................................................................................................19

....................................................................................................................20

......................................................................................................21

tate .......................................................................................................................22

tart Delay ....................................................................................................23

tart Delay .....................................................................................................23

bient Lockout ...................................................................................................23

Water Pump State........................................................................................24

ater Temperature (LWT) Reset .....................................................................24

um LWT Rate .....................................................................................................24

Overrides ................................................................................................24

Overrides – Limits of Operation.........................................................25

bient Starts .......................................................................................................26

pressor Sequencing.................................................................................................26

pressor Control..........................................................................................27

al Circuit Shutdown..............................................................................................27

.................................................................................................28

.....................................................................................................28

pass Solenoid ..............................................................................................28

Control..................................................................................................................28

..................................................................................................29

Alarms and Events

top Alarms............................................................................................................31

Unit S

Circuit S

Circuit Events

Clearing

OM AGZC-1 AGZ 030C through 190C 13

top Alarms........................................................................................................31

Alarms.............................................................................................................34

.......................................................................................................31

................................................................................................................33

Page 14

Overview

The MicroTech II® controller’s state-of-the-art

design not only permits the chiller to run more

efficiently, but also can simplify

troubleshooting if a system failure occurs.

Every MicroTech II controller is programmed

and tested prior to shipment to facilitate startup.

Operator-friendly

The MicroTech II controller menu structure is

separated into three distinct categories that

provide the operator or service technician with

a full description of 1) current unit status, 2)

control parameters, and 3) alarms. Security

protection prevents unauthorized changing of

the setpoints and control parameters.

MicroTech II control continuously performs

self-diagnostic checks, monitoring system

temperatures, pressures and protection devices,

and will automatically shut down a compressor

or the entire unit should a fault occur. The

cause of the shutdown will be retained in

memory and can be easily displayed in plain

English for operator review. The MicroTech II

chiller controller will also retain and display

the date/time the fault occurred. In addition to

displaying alarm diagnostics, the MicroTech II

chiller controller also provides the operator

with a warning of limit (pre-alarm) conditions.

General Description

AGZ-C Inputs/Outputs

Table 9, Analog Inputs

# Description Type Signal Source Expected Range

1 Evaporator Refrigerant Pressure #1 C1 0.1 to 0.9 VDC

2 Evaporator Refrigerant Pressure #2 C2 0.1 to 0.9 VDC

3 Condenser Refrigerant Pressure #1 C1 0.1 to 0.9 VDC

4 Leaving Evaporator Water Temperature UT

5 Outside Ambient Temperature UT

6 Condenser Refrigerant Pressure #2 C2 0.1 to 0.9 VDC

7 Reset of Leaving Water Temperature UT 4-20 mA Current 4-20 mA

8 Demand Limit UT 4-20 mA Current 4-20 mA

9 Compressor Suction Temperature #1 C1

10 Compressor Suction Temperature #2 C2

NOTES:

1. C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

NTC Thermister

(10k@

NTC Thermister

(10k@

NTC Thermister

(10k@

NTC Thermister

(10k@

77F)

77F)

77F)

77F)

0 to 132 psi

0 to 132 psi

3.6 to 410 psi

-58 to 212°F

-58 to 212°F

3.6 to 410 psi

-58 to 212°F

-58 to 212°F

Table 10, Analog Outputs

# Description Output Signal Range

1 Fan #1 VFD 0 to 10 VDC 0 to 100% (1000 steps resolution)

2 Fan #2 VFD 0 to 10 VDC 0 to 100% (1000 steps resolution)

3 EXV #1 0 to 10 VDC 0 to 100% (1000 steps resolution)

4 EXV #2 0 to 10 VDC 0 to 100% (1000 steps resolution)

5 Open - 6 Open - -

14 AGZ 030C through 190C OM AGZC-1

Loading...

Loading...