Page 1

Operation Manual

OM AGSB-5

GeneSys

™

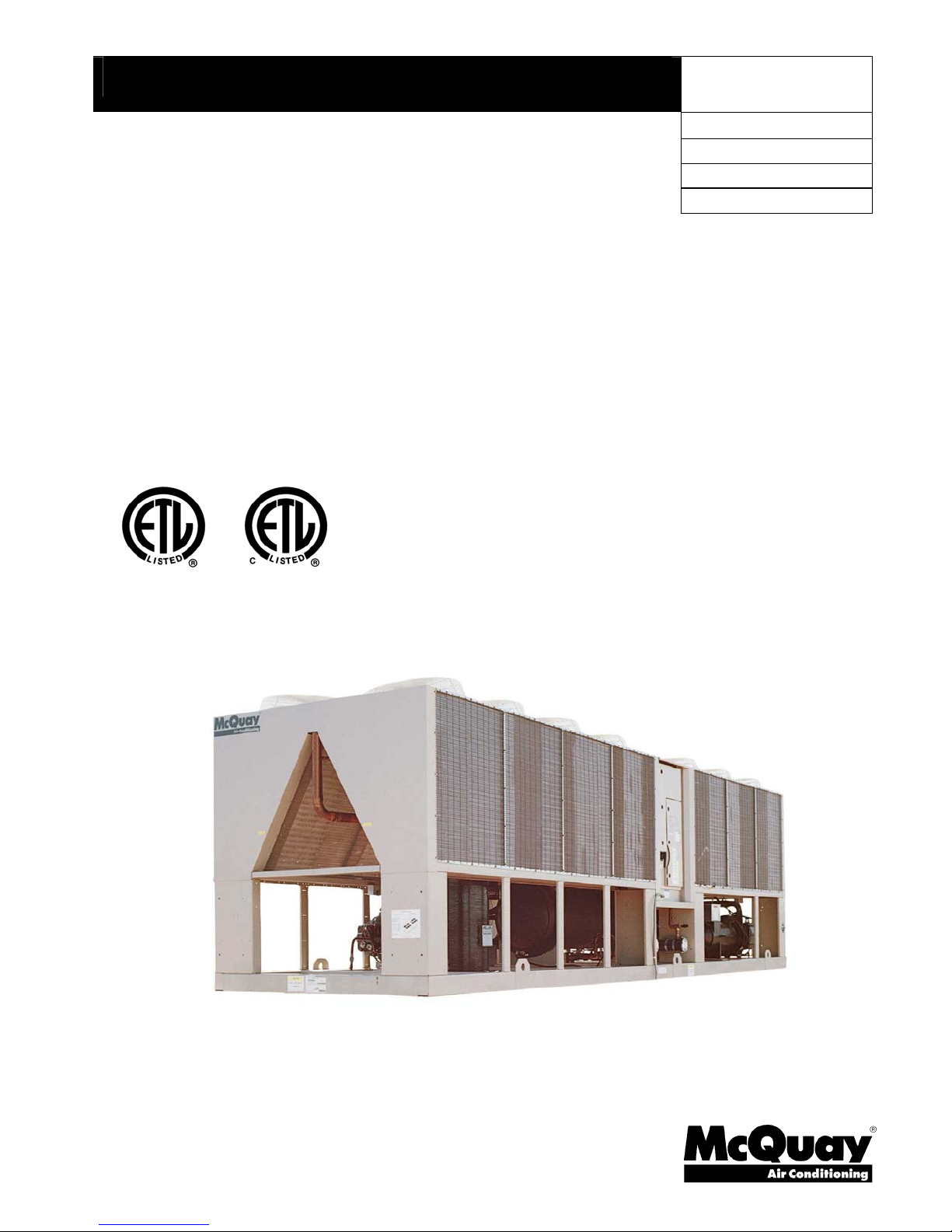

Air-Cooled Screw Compressor Chiller

AGS 230A/B through AGS 475A/B, 60 Hertz

AGS 206A/B through AGS 411A/B, 50 Hertz

Software Version AGSU30101H

Group: Chiller

Part Number: 331373201

Date: June 2005

Supersedes: OM AGSB-4

Page 2

Table Of Contents

MICROTECH II™ FEATURES .......4

GENERAL DESCRIPTION..............5

COMPONENT DESCRIPTION........6

Unit and Circuit Controller Description ..8

CONTROL OPERATION ...............10

CIRCUIT CONTROLLER..............10

Inputs/Outputs.......................................10

Setpoints................................................11

Compressor Control...............................15

Condenser Fan Control..........................19

EXV Control..........................................21

Evaporator Oil Return Line Control......23

Oil Heater Control.................................23

Interstage Injection................................23

UNIT CONTROLLER .....................24

Inputs/Outputs.......................................24

Setpoints................................................24

Unit Enable............................................26

Unit Mode Selection..............................27

Evaporator Pump State Control.............30

Evaporator Heater Control ....................30

Leaving Water Temperature (LWT) Reset

...............................................................30

Manufactured in an ISO Certified facility

ALARMS AND EVENTS ................33

Alarm and Event Logging.....................35

USING THE CONTROLLER.........37

Security..................................................39

Entering Passwords ...............................39

Editing Setpoints ...................................39

Clearing Alarms.....................................39

Unit Controller Menus...........................40

Screen Definitions.................................41

SET Screen Definitions.........................43

Circuit Controller Menus.......................47

Screen Definitions.................................47

SEQUENCE OF OPERATION.......52

START-UP AND SHUTDOWN......54

Expansion Valve Operation...................55

Extended (Seasonal) Shutdown.............57

Evaporator Freeze Protection................58

Operating Limits: ..................................59

REFRIGERANT CHARGING........60

BAS INTERFACE............................63

FIELD WIRING DIAGRAM ..........64

Unit controllers are LONMARK

certified with the optional

communications module.

LONWORKS

"McQuay" is a registered trademark of McQuay International, Information covers the McQuay International products at the time of

publication and we reserve the rig ht to m ak e changes in desi gn an d const ruction at anytime without notice.

®™ The following are trademarks or registered trademarks of their respective companies: BACnet from ASHRAE; L

Corporation; GeneS ys, McQu ay and MicroTech II from McQuay International.

2 OM AGSB-5

ONMARK and LONWORKS from Echelon

Page 3

This manual provides setup, operating, and troubleshooting information for the McQuay

MicroTech ΙΙ™ controller for Model AGS-B vintage, air-cooled rotary screw compressor

chillers. Please refer to the current version of IMM AGSB (available from the local

McQuay sales office or on www.mcquay.com

) for information relating to the solid state

starters and to the unit itself.

NOTE: This manual covers units with Software Version AGSU30101H. The unit’s

software version number can be viewed by pressing the MENU and ENTER keys (the two

right keys) simultaneously. Then, pressing the MENU key will return to the Menu screen.

BOOT version 3.0F

BIOS version 3.56

WARNING

Electric shock hazard. Can cause personal injury or equipment damage. This

equipment must be properly grounded. Connections to and service of the

MicroTech II control panel must be performed only by personnel who are

knowledgeable in the operation of the equipment being controlled.

CAUTION

Static sensitive components. A static discharge while handling electronic circuit

boards can cause damage to the components. Discharge any static electrical charge

by touching the bare metal inside the control panel before performing any service

work. Never unplug any cables, circuit board terminal blocks, or power plugs while

power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with this instruction manual, can cause interference

to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the

interference at the user’s expense. McQuay International Corporation disclaims any

liability resulting from any interference or for the correction thereof.

Temperature and Humidity Limitations

The MicroTech ΙΙ controller is designed to operate within an ambient temperature range of

-20°F to +149°F (-29°C to +65.1°C) with a maximum relative humidity of 95% (noncondensing).

OM AGSB-5 3

Page 4

MicroTech II™ Features

• Control of leaving chilled water within a ±0.2°F (±0.1°C) tolerance.

• Readout of the following temperature and pressure readings:

• Entering and leaving chilled water temperature.

• Saturated evaporator refrigerant temperature and pressure.

• Saturated condenser temperature and pressure.

• Outside air temperature.

• Suction line, liquid line, and discharge line temperatures − calculated superheat for

discharge and suction lines − calcula ted subco oling for liqu id line.

• Automatic control of primary and standby chilled water pumps. The control will start one

of the pumps (based on lowest run-hours) when the unit is enabled to run (not necessarily

running on a call for cooling) and when the ambient temperature reaches a point of freeze

possibility.

• Two levels of security protection against unauthorized changing of setpoints and other

control parameters.

• Warning and fault diagnostics to inform operators of warning and fault conditions in plain

language. All events, alarms, and faults are time- and date-stamped, for identification of

when the fault condition occurred. In addition, the operating conditions that existed just

prior to shutdown can be recalled to aid in isolating the cause of the problem.

• Twenty-five previous alarms and related operating conditions are available.

• Remote input signals for chilled water reset, demand limiting, and unit enable.

• Manual control mode allows the service technician to command the unit to different

operating states. This function can be useful for system checkout.

• Building Automation System (BAS) communication capability via LONWORKS®,

Modbus®, or BACnet® standard protocols for all BAS manufacturers-simplified with

McQuay’s Protocol Selectability™ feature.

• Service Test mode for troubleshooting controller hardware.

• Pressure transducers for direct reading of system pressures. Preemptive control of low

evaporator pressure conditions and high discharge temperature and pressure to take

corrective action prior to a fault trip.

4 OM AGSB-5

Page 5

General Description

General Description

The AGS MicroTech ΙΙ distributed control system consists of multiple microprocessorbased controllers that provide monitoring and control functions required for the controlled,

efficient operation of the chiller. The system consists of the following components:

• Unit Controller

, one per chiller − controls functions and settings that apply to the unit

and communicates with all other controllers. It is located in the control panel for circuit

#1 and is labeled “UNIT CONTROL”.

• Circuit Controller

for each compressor/circuit (two or three depending on model size)

that control compressor functions and settings specific to the circuit. The controllers are

located in their circuit' s contro l pan el th at is mounted between the condenser coil

sections and are labeled “CIRCUIT CONROL”.

In addition to providing all normal operating controls, the MicroTech II control system

monitors equipment protection devices on the unit and will take corrective action if the

chiller is operating outside of its normal design envelope. If an alarm condition develops,

the controller will shut the compressor down and activate an alarm output. Important

operating conditions at the time an alarm condition occurs are retained in the controller’s

memory to aid in troubleshooting and fault analysis.

The system is protected by a password scheme that allows access only by authorized

personnel. The operator must enter the operator password into the controller's keypad

before any setpoints can be altered.

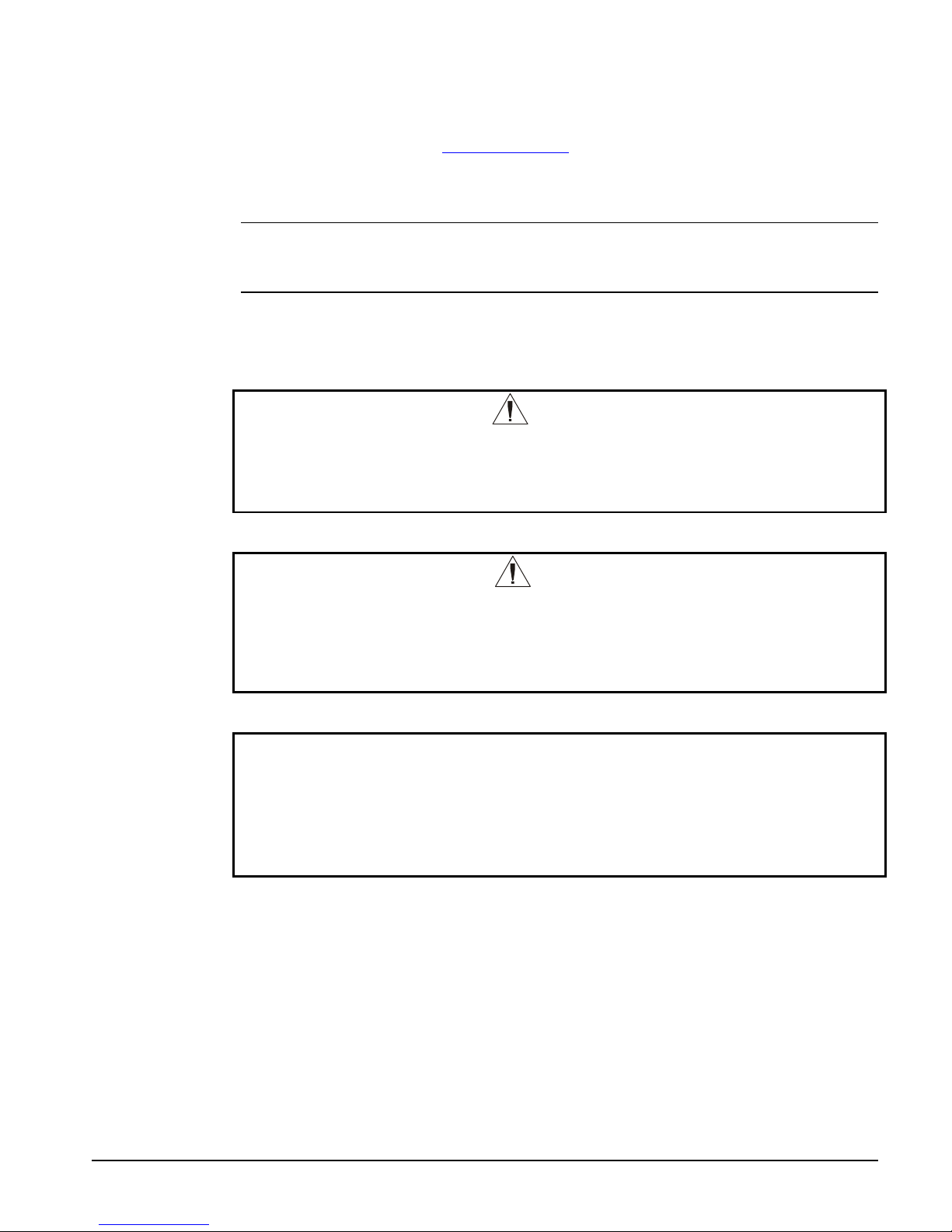

Control Architecture

Figure 1, Major Control Components

BACnet MS/TP

BACnet IP

BACnet Ethernet

LonTalk

Chiller A

RS485/LON/Ethernet

Solid

State

Starter

EXV

OM AGSB-5 5

Unit

Controller

4x20 LCD

RS485

pLAN

(future)

Circuit #1

Controller

4x20 LCD

Other Circuit

Controllers

(future)

Page 6

Component Description

Unit and Circuit Controller Descri ption

Terminology and Definitions

Accumulator

The accumulator is an electronic “bank” that stores information relative to fan operation and

fan capacity required. It is the heart of the controller’s fuzzy logic feature. Various events

such as cooling load changes and ambient air temperature changes, add or subtract points in

the bank. When a certain number of points are accumulated, a fan will be started.

Active Setpoint

The active setpoint is the setting in effect at any given moment. This occurs on setpoints

that can be altered during normal operation. Resetting the chilled water leaving temperature

setpoint by one of several methods, such as return water temperature, is an example.

Condenser Saturated Temperature Target

The saturated condenser temperature target is calculated by first using the following

equation:

Sat condenser temp target raw = 0.833(evaporator sat temp) + 68.34

The “raw” value is the initial calculated value. This value is then limited to a range defined

by the Condenser Saturated Temperature Target min imum an d maxi mum set point s. These

setpoints simply cut off the value to a working range, and this range can be limited to a

single value if the two setpoints are set to the same value.

CPU Error

These are problems caused by a malfunction of the central processing unit.

Dead Band

The dead band is a set of values associated with a setpoint such that a change in the variable

occurring within the dead band causes no action from the controller. For example, if a

temperature setpoint is 44°F and it has a dead band of ± 2 degrees, nothing will happen until

the measured temperature is less than 42°F or more than 46°F.

Delta-T

Delta-T is a range of degrees of temperature. For example, a Start Up Delta-T of 5 degrees

means that the water temperature must be 5 degrees above the LWT setpoint before the start

signal is given.

Discharge Superheat

Discharge superheat shall be calculated for each circuit using the following equation:

Discharge Superheat = Discharge Temperature – Condenser Saturated Temperature

Error

In the context of this manual, “Error” is the difference between the actual value of a variable

and the target setting or setpoint.

Evaporator Approach

The evaporator approach is calculated for each circuit. The equation is as follows:

Evaporator Approach = LWT – Evaporator Saturated Temperature

6 OM AGSB-5

Page 7

EvapRecTimer

The evaporator recirculation timer establishes the length of time the chilled water pump will

run after the controller receives an enable signal and the Wait for Flow timer time out. This

period allows time for the chilled water to circulate sufficiently to determine if there is a

need for cooling.

EXV

Electronic expansion valve, used to control the flow of refrigerant to the evaporator,

controlled by the circuit microprocessor.

High Saturated Condenser – Hold Value

High Cond Hold Value = Max Saturated Condenser Value – 5°F

This function prevents the compressor from loading whenever the pressures approach

within 5 degrees of the maximum discharge pressure. The purpose is to keep the

compressor online during periods of possibly temporary elevated pressures.

Low OAT Start

Allows start attempts at low ambient temperatures.

High Saturated Condenser – Unload Value

High Cond Unload Value = Max Saturated Condenser Value – 3°F.

This function unloads the compressor whenever the pressures approach within 3 degrees of

the maximum discharge pressure. The purpose is to keep the compressor online during

periods of possibly temporary elevated pressures.

Low Pressure Hold Setpoint

The psi evaporator pressure setting at which the controller will not allow further compressor

loading.

Low/High Superheat Error

The difference between actual evaporator superheat and the superheat target.

LWT

Leaving water temperature. The “water” is any fluid used in the chiller circuit.

LWT Error

Error in the controller context is the difference between the value of a variable and the

setpoint. For example, if the LWT setpoint is 44°F and the actual temperature of the water

at a given moment is 46°F, the LWT error is +2 degrees.

LWT Slope

The LWT slope is an indication of the trend of the water temperature. It is calculated by

taking readings of the temperature every few seconds and subtracting them from the

previous value, over a rolling one minute interval.

Maximum Saturated Condenser Temperature

The maximum saturated condenser temperature allowed is calculated based on the

compressor operational envelope .

Mode

There are three possible operating modes for the unit: Some can be combined and then

selected by an external signal or from the keypad.

1. Cool, the compressors are under normal unloading and staging control and the

minimum LWT setpoint is 40°F. Cool with Glycol merely reduces the minimum LWT

to 30°F.

2. ICE, primarily controls the compressor at full load until the LWT setpoint is reached,

then shuts unit off.

3. Test, allows outputs to be actuated manually.

OM AGSB-5 7

Page 8

ms

Milli-second

OAT

Outside ambient air temperature

pLAN

Peco Local Area Network is the proprietary name of the network connecting the control

elements.

Refrigerant Saturated Temperature

Refrigerant saturated temperature is calculated from the pressure sensor readings for each

circuit. The pressure is fitted to an R-134a temperature/pressure curve to determine the

saturated temperature .

Slide

Slide is an abbreviation for the compressor slide valve, which determines the compressor

capacity. It is positioned by the controller such that to unload, it moves toward the main

rotor suction end and discharge gas is bypassed from the rotor discharge back to suction.

Slide Target, Slide Position

See page 14 for explanation of these terms.

SP

Setpoint

SSS

Solid state starter as used on McQuay screw compressors

Suction Superheat

Suction superheat is calculated for each circuit using the following equation:

Suction Superheat = Suction Temperature – Evaporator Saturated Temperature

Stageon/Stageup

Stage On or Stage Up is the act of starting a compressor or fan when another is still

operating. The two phrases are interchangeable and either one can be used depending on

the date of issue of the software. “Start” is the act of starting the first compressor or fan on

a unit.

Stageoff/Stagedown

Stage Off or Stage Down is the act of stopping a compressor or fan when another is still

operating. The two phrases are interchangeable and either one can be used depending on

the date of issue of the software. “Stop” is the act of stopping the last compressor or fan on

a unit.

VDC

Volts, Direct current, sometimes noted as vdc

VFD

Variable Frequency Drive, a device used to vary an electric motor’s speed.

Unit and Circuit Controller Description

Hardware Structure

The controllers are fitted with a 16-bit microprocessor for running the control program.

There are terminals for connection to the controlled devices (for example: solenoid valves,

expansion valves, chilled water pumps). The program and settings are saved permanently in

FLASH memory, preventing data loss in the event of power failure without requiring a

back-up battery. It also has optional remote communication access capability for a BAS

interface.

8 OM AGSB-5

Page 9

Each chiller has one unit controller and a cir cuit controller for each compressor circuit (two

or three depending on unit size). The controllers are connected and communicate via a

pLAN (local area network). The circuit controllers communicate with, and control the

operation of, the compressor's solid state starter and the circuit electronic expansion valve

(EXV).

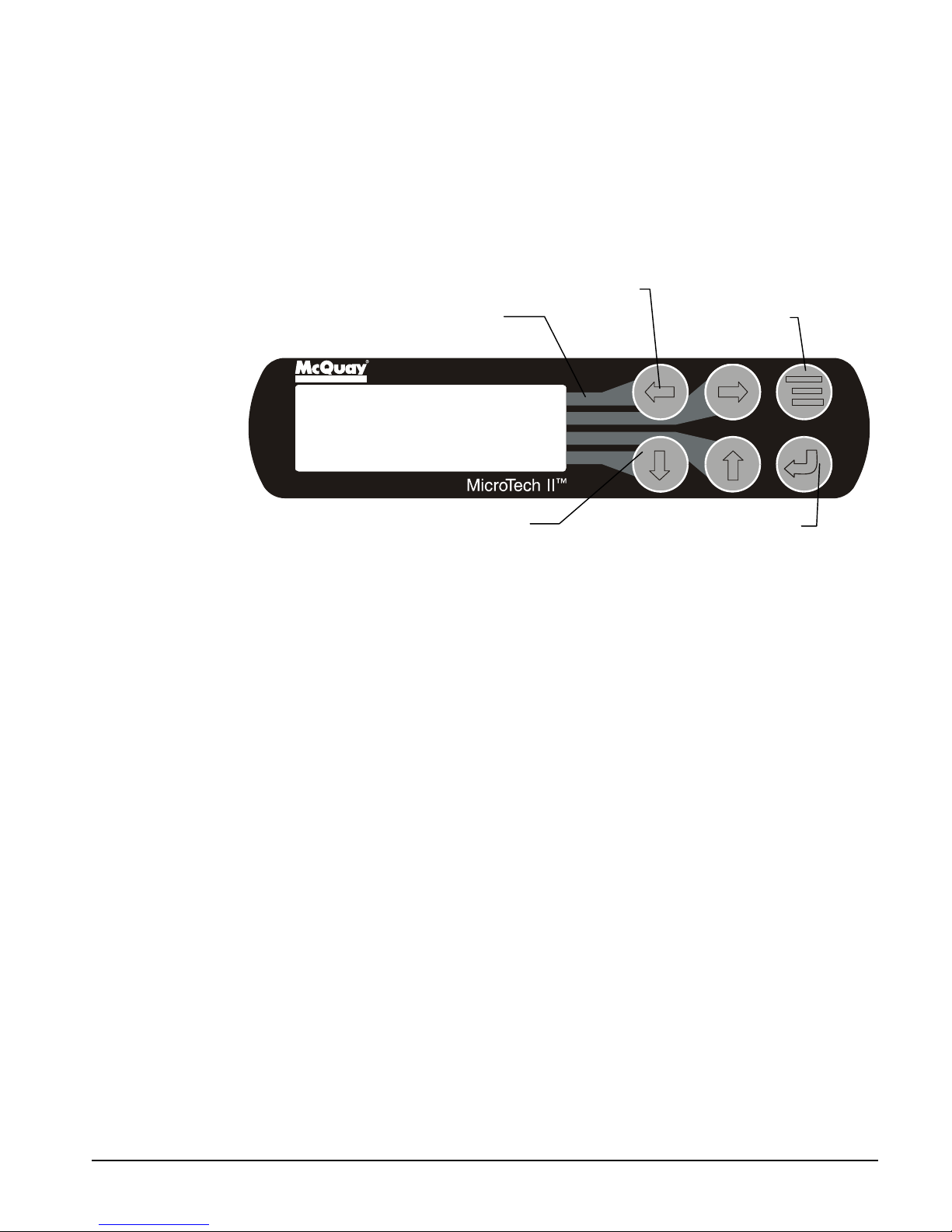

Keypad

A 4-line by 20-character liquid crystal display and 6-button keypad is mounted on the unit

and compressor controllers.

Figure 2, Keypad

Key-to-Screen Pathway

Red Alarm Light

MENU Key

Air Conditioni ng

ALARM

<

VIEW

<

<

ARROW Keys (4)

SET

ENTER Key & Green Ru n Li ght

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use.

1. Scroll between data screens in the direction indicated by the arrows (default mode).

2. Select a specific data screen in the menu matrix using dynamic labels on the right side

of the display such as ALARM, VIEW, etc. (this mode is entered by pressing the

MENU key). For ease of use, a pathway connects the appropriate button to its

respective label on the screen.

3. Change field values in setpoint programming mode as follows:

LEFT key = Default RIGHT key = Cancel

UP key = Increase (+) DOWN key = Decrease (-)

These four programming functions are indicated by one-character abbreviation on the right

side of the display. This programming mode is entered by pressing the ENTER key.

OM AGSB-5 9

Page 10

Control Operation

This section on MicroTech II control is divided into four subsections:

• Circuit Controller, explains the functions of the circuit controller, see page 10.

• Unit Controller, explains the functions of the unit controller, see page 24.

• Using the Controller, explains how to navigate through the menus and how to make

entries, see page 37.

• Screen Content, details the menu screen content and how to use them, see page 41.

Circuit Controller

Inputs/Outputs

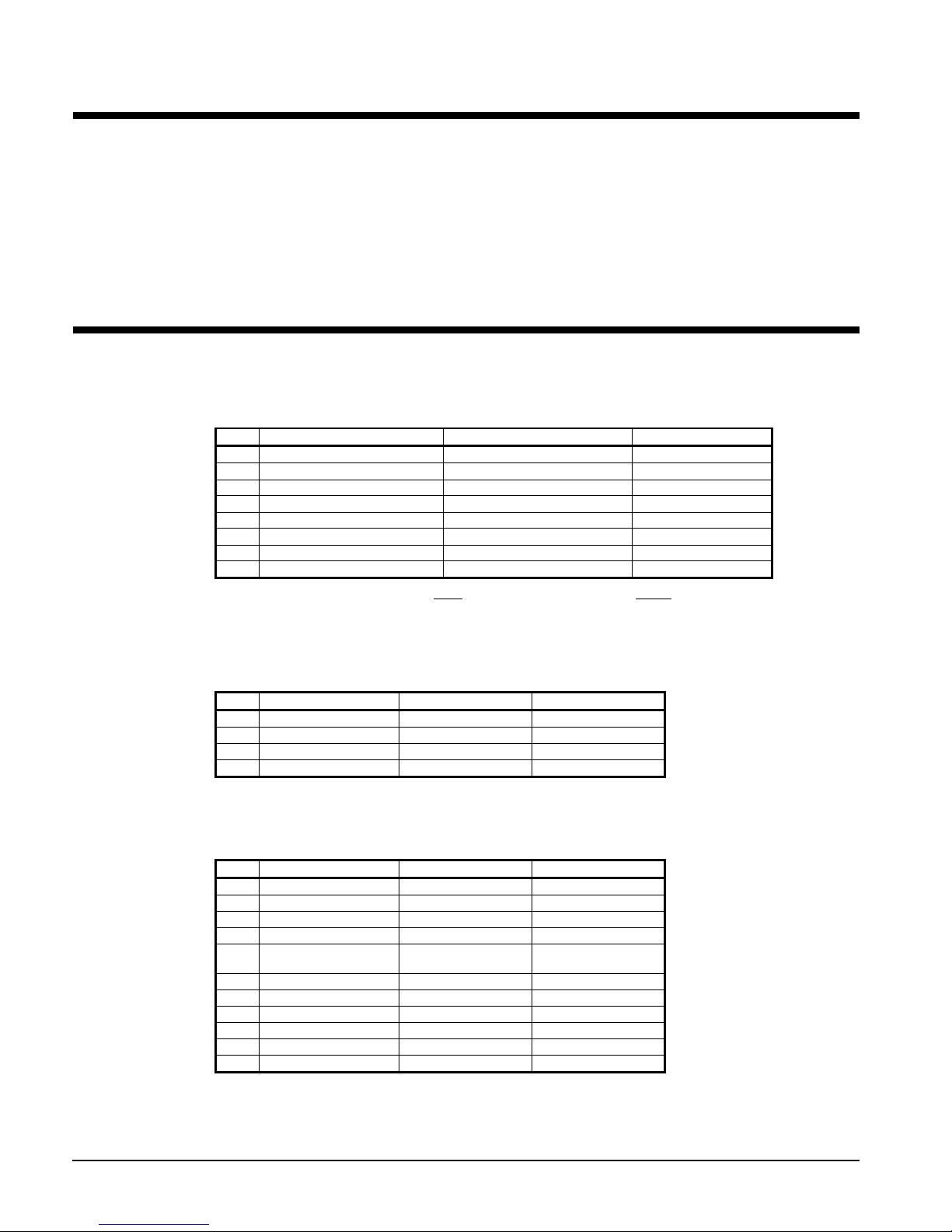

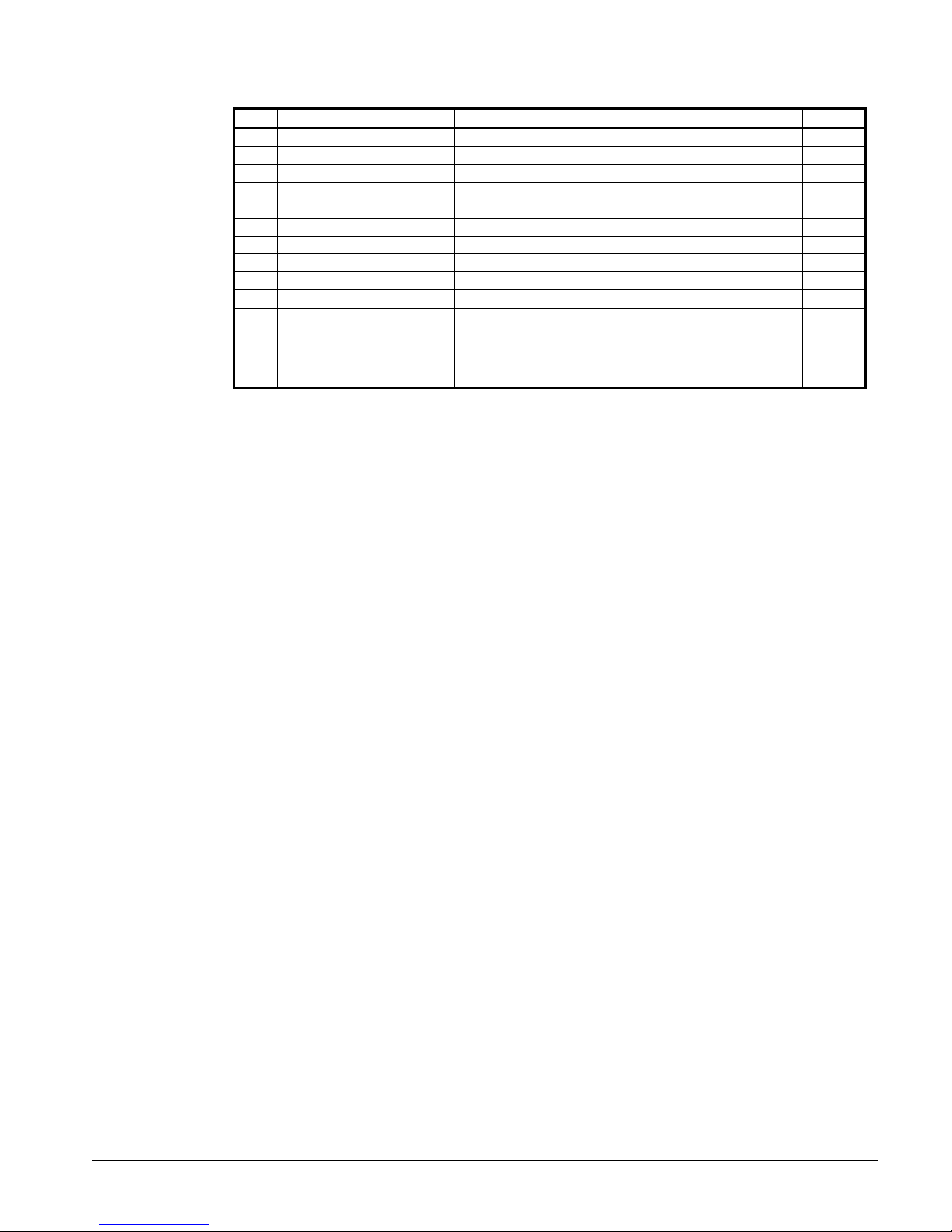

Table 1, Analog Inputs

# Description Signal Source Range

1 Evaporator Pressure 0.5 - 4.5 VDC (NOTE)

2 Condenser Pressure 0.5 - 4.5 VDC (NOTE)

3 Liquid Pressure 0.5 - 4.5 VDC (NOTE)

4 Suction Temperature Thermistor (10k@25°C)

5 Discharge Temperature Thermistor (10k@25°C)

6 Liquid Temperature Thermistor (10k@25°C) -58 to 212°F

7 Slide Load Indicator 4 to 20 mA

8 Open

NOTE: Value at the converter board input. Value at the converter board output is 0.1 VDC – 0.9 VDC.

0 to 132 psi

3.6 to 410 psi

3.6 to 410 psi

-58°F to 212°F

-58° to 212°F

0 to 100%

These parameters are analog inputs to the circuit controller. They are used internally as

needed and are sent to the correct pLAN addresses for use by other controllers or displays.

Table 2, Analog Outputs

# Description Output Signal Range

1 Fan 1&2 VFD 0 to 10 VDC 20 to 60 Hz

2 Open

3 EXV Driver 0 to 10 VDC 0 to 6386 steps

4 Open

These parameters are analog outputs from this controller. The values are sent to the correct

pLAN addresses for use by other controllers or displays.

Table 3, Digital Inputs

# Description Signal Signal

1 Circuit Switch 0 VAC (Off) 24 VAC (Auto)

2 Open

3 Starter Fault 0 VAC (Fault) 24 VAC (No Fault)

4 VFD Fault 0 VAC (Fault) 24 VAC (No Fault)

Oil Differential

5

Pressure Switch

6 Mech High Pressure 0 VAC (Fault) 24 VAC (No Fault)

7 Low Pressure Switch 0 VAC (Fault) 24 VAC (No Fault)

8 Open

9 Oil Level Sensor 0 VAC (Fault) 24 VAC (No Fault)

10 Open

11 Open

0 VAC (Fault) 24 VAC (No Fault)

10 OM AGSB-5

Page 11

Table 4, Digital Outputs

# Description Load Output OFF Output ON Voltage

1 Compressor Starter Contact Relay Compressor off Compressor on 120

2 M1 Contactor (fan 1) Contactor Coil Fans off Fans on 120

3 M2 Contactor (fan 2) Contactor Coil Fans off Fans on 120

4 M3 Contactor (fan 3) Contactor Coil Fans off Fans on 120

5 M4 Contactor (fan 4) Contactor Coil Fans off Fans on 120

6 M5 Contactor (fan 5 & 6) Contactor Coil Fans off Fans on 120

7 Load/Unload Pulse S ol enoi d Hold l oad sl i de Move load slide 24

8 Load/Unload Select Relay Unload Load 24

9 M7 Contactor (fan 7 & 8) Contactor Coil Fans off Fans on 120

10 Oil Return Line Solenoid Closed Open

11 Open

12 Open

13 EXV Close Signal Contact

EXV Follows

0 – 10 VDC

EXV Closed,

Ignores 0 – 10

VDC

10

These parameters are digital outputs from this controller. Their values are sent to the correct

pLAN addresses for use by other controllers or displays.

Setpoints

The following parameters are remembered during power off, are factory set to the

Default value, and can be adjusted to any value in the Range column.

The PW (password) column indicates the password that must be active in order to

change the setpoint. Codes are as follows:

O = Operator, password is 100

M = Manager

Entering a Password

The password is located in the unit controller only and can be found at SET, UNIT SPS on

the last menu conveniently located so that you can scroll up one menu to access the

Password Enter Screen.

OM AGSB-5 11

Page 12

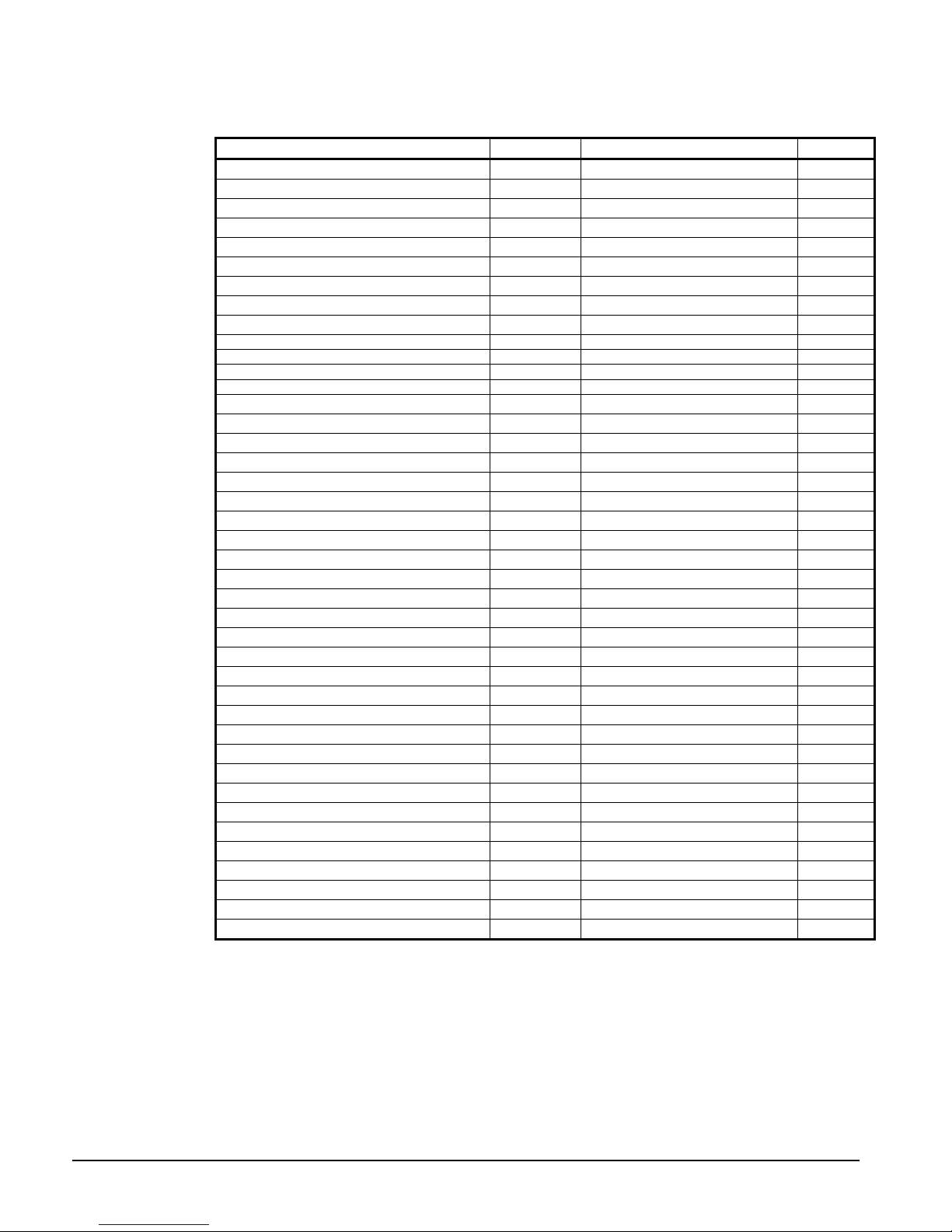

Table 5, Circuit Controller Setpoints

Description Default Range PW

Compressor

Circuit mode Enable Disable, Enable, Test M

Slide control Auto Auto, Manual M

Slide position 0 0-100% M

Compressor Size 205 205,220,235 M

Clear Cycle Timers N o No, Yes M

Maximum Slide Target 100.0 0-100.0% M

EXV

EXV control Auto Auto, Manual M

Manual EXV position 0 0-6386 M

Pre-open timer 60 20-120 sec M

Service Pumpdown No No, Yes M

Fans

Fan VFD enable Yes No, Yes M

Number of fans 6 6,8 M

Saturated Condenser Temp Target 110.0 90. 0 – 130.0 oF M

Stage 1 Up Deadband 5.0 1.0-20.0 oF M

Stage 2 Up Deadband 8.0 1.0-20.0 oF M

Stage 3 Up Deadband 10.0 1.0-20.0 oF M

Stage 4 Up Deadband 12.0 1.0-20.0 oF M

Stage 1 Down Deadband 8.0 1.0-20.0 oF M

Stage 2 Down Deadband 7.0 1.0-20.0 oF M

Stage 3 Down Deadband 6.0 1.0-20.0 oF M

Stage 4 Down Deadband 5.0 1.0-20.0 oF M

VFD Max Speed 100% 90 to 110% M

VFD Min Speed 25% 20 to 60% M

Forced FanTrol™ 1

Forced FanTrol™ 2

Forced FanTrol™ 3

Sensors

Evap pressure offset 0 -10.0 to 10.0 psi M

Cond pressure offset 0 -10.0 to 10.0 psi M

Liquid pressure offset 0 -10.0 to 10.0 psi M

Suction temp offset 0 -5.0 to 5.0 deg M

Discharge temp offset 0 -5.0 to 5.0 deg M

Liquid temp offset 0 -5.0 to 5.0 deg M

Slide Minimum Position 0 -15 to 15% M

Slide Maximum Position 0 -15 to 15% M

1 1-8 M

2 1-8 M

3 1-8 M

12 OM AGSB-5

Page 13

Circuit Operating Mode

The circuits on the chiller can each be individually enable or disabled. Test mode on each

circuit can also be entered independent of the all other circuits. With the circuit switch on,

the circuit mode setpoint offers settings of either Enable or Disable. This simply allows the

circuit to be disabled through a keypad setting.

Cool Mode

When the chiller is in COOL mode, capacity of the compressor is adjusted to maintain

leaving water temperature at the Active LWT setpoint while balancing the load between

running circuits. Load balance offset, LWT error, and LWT slope are used to calculate a

change in slide position.

ICE Mode

Ice mode is designed to have the compressors run at full load until the LWT setpoint is

reached, then shut off until the next ice making cycle starts. ICE settings are made in the

unit controller.

In ICE mode, the compressor capacity is increased at the maximum rate continuously until

reaching the maximum slide position. Load balancing, LWT error, and LWT slope are

ignored. Low and high pressure events are disabled.

An adjustable Start-to-Start Ice Delay Timer will limit the frequency with which the chiller

may start in ICE mode. The timer starts when the first compressor starts while the unit is in

ICE mode. While this timer is active, the chiller cannot restart in ICE mode. The time

delay is user adjustable.

The Ice Delay Timer may be manually cleared to force a restart in ICE mode. A set point

specifically for clearing the ICE mode delay is available. In addition, cycling the power to

the controller will clear the I ce Delay Timer .

Circuit Test Mode

The circuit test mode allows manual testing of all controller outputs. Entering this mode

requires the following conditions.

• Circuit Switch = OFF

• Technician password active

• Circuit Mode setpoint = TEST

A test menu can then be selected to allow activation of the outputs. It is possible to switch

each digital output ON or OFF and set the analog outputs to any value. Upon entering the

test mode, all outputs will always default to the OFF state. Upon leaving the test mode, all

outputs will automatically reset to the OFF state.

Compressors cannot be started in TEST mode.

Slide Position

Each compressor will estimate its slide load percentage from the present value of the slide

load indicator. The percentage is based on the 4-20mA signal from the slide load indicator

and varies somewhat by compressor size. A load percentage value of 0 corresponds to mA

Low signal; a percentage value of 100 corresponds to the mA High signal shown in Table 6.

This information is located on the View Cir Status (1) menu. It shows slide position and

slide target.

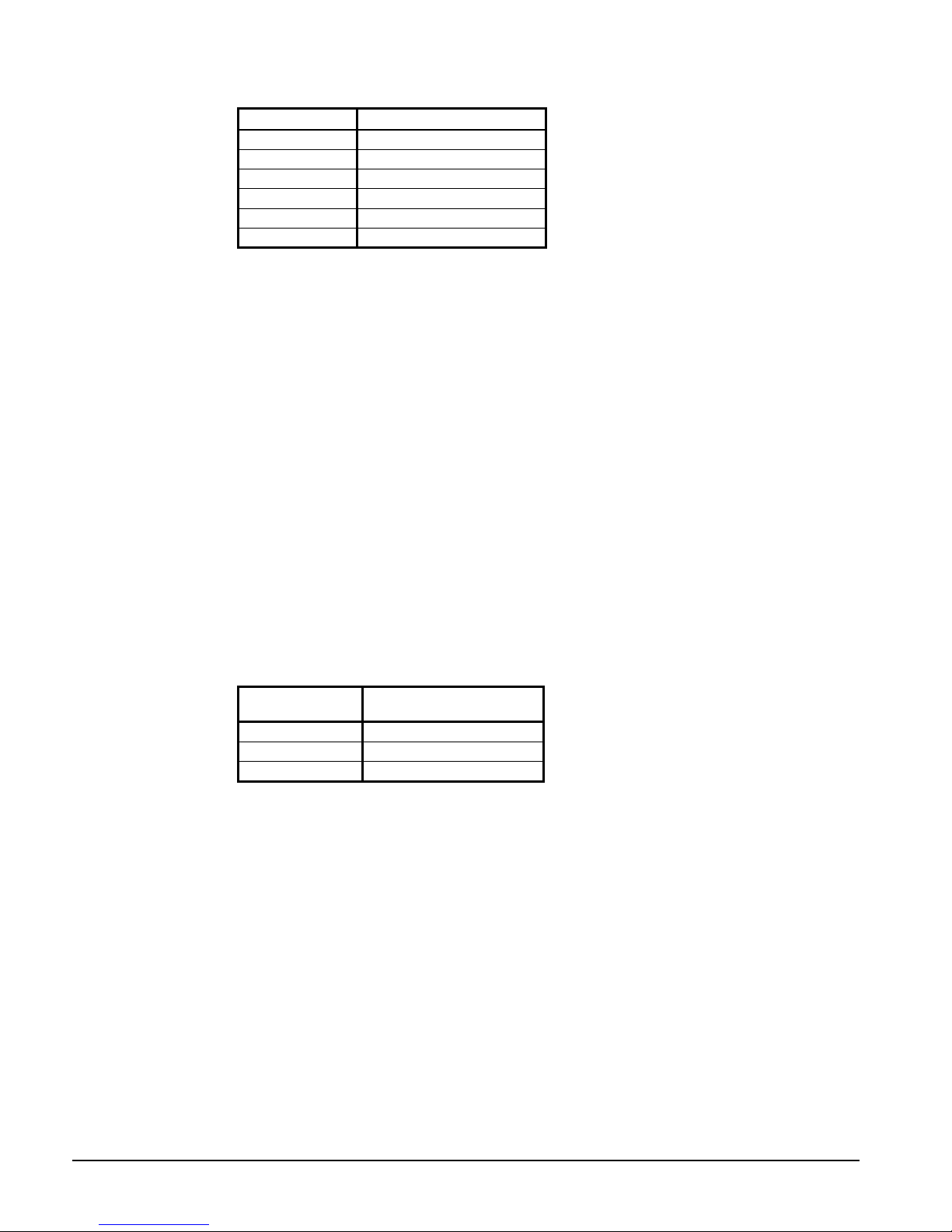

Table 6, Slide Valve Position

Compressor

Size

205

220

235

NOTE: See the Physical Data tables in IMM AGSB-60 for unit compressor sizes.

mA Low mA High

4.94 14.6

4.62 17.0

4.32 19.4

OM AGSB-5 13

Page 14

Slide Calibration Procedure

The slide is calibrated in the factory before shipment but may have to be recalibrated in the

field, especially if relevant slide parts have been replaced.

Slide Position is a relative capacity adjustment from 0.0%(Min load) to 100.0%(Max Load).

There are two MicroTech II controller readings that apply to the indicator, Slide Target and

Slide Position. It is important to understand the difference between these. The Slide Target

is the value in which the controller uses to display the calculated prediction of slide

position. This value represents the destination or goal of pulsing the load and unload

solenoids. The slide target is used for direction of control for all load and unload operations,

including alarm limit events. When putting a circuit in Manual mode, the slide target is the

value that you will be adjusting and the controller will load or unload the chiller to match,

with in about 3%, the target entered with the current slide position value. The second value

is the Slide Position (Pos) this is the slide position value which is the 4-20mA reading

received from the position indicator. These values can be viewed at the circuit controller on

screen “VIEW CIR STATUS (1)”.

A slide target of 0.0% is fully unloaded and the unload solenoid will be constantly

energized. A slide target of 100.0% means that the chiller is at full load and the load

solenoid is continually energized. The chiller will regulate the slide position to infinite steps

between 0% and 100% by pulsing the appropriate solenoid. Facing the front of the

compressor the solenoid on the left is for load (oil vent) and the solenoid on the right is for

unload (oil feed). In Circuit Enable mode (normal operation) the controller makes decisions

to move the Slide target, the calculated value, and pulses the proper solenoid in order to

keep the actual and the target position with in a few percent.

1. It is recommended that the circuit to be calibrated is near normal operating

temperatures, although a preliminary calibration before first starting the compressor is

acceptable, as long as the value is verified soon after compressor shuts down. Note that

it requires sufficient oil pressure to unload the compressor while it is running, and may

load up due to lack of oil pressure. When the compressor is not running there is a large

spring that forces the compressor unloaded, therefore in the off state you have the best

opportunity for verifying an accurate calibration at minimum slide position.

2. On the Circuit controller first verify what your current slide target is at screen “View

Circ Status (1)” and then go to screen “SET COMP SPs (2)” to switch circuit into

manual slide control. Note: Some inhibit limits will be ignored but all alarm limits are

still active.

3. Slowly take the circuit either to 0% or 100% load. When the slide target is at either 0%

or 100%, you may want to verify that the corresponding coil is energized.

4. On the circuit controller scroll all the way to the right, then the calibration and offsets

menu. Scroll down until you see “SET SENSOR OFFSET (3)”. You will see an

adjustment for Min Load and Max Load and on the bottom line you will see the value of

the actual slide position indicator. Add offset until value is within +/-.5%.

5. Repeat until all circuits have both positions calibrated with in +/-.5%.

Note: The Slide Indicator Transducers may vary a considerable amount with temperature

change, and therefore they need to be calibrated at typical running temperatures.

14 OM AGSB-5

Page 15

Compressor Control

Multiple Compressor Staging

This section defines which compressor is the next one to start or stop. The next section

defines when

Functions

1. Can start/stop compressors according to an operator-defined sequence.

2. Can start compressors based on the least number of starts (run hours if starts are equal)

and stop on most run hours.

The above two modes can be combined so that there are two or more groups where all

compressors in the first group are started (based on number of starts/hours) before any in the

second group, etc. Conversely, all compressors in a group are stopped (based on run hours)

before any in the preceding group, etc.

Required Parameters

1. Sequence number setpoint for all compressors. Possible settings = (1-3). Compressors

will start in the specified order. Default operation sequence is 1 for all compressors

(meaning they will start based on number of starts). That is, if all are 1s, the controller

will look at number of starts and run-hours

2. Maximum Number of compressors ON setpoint. Possible settings = (1-3).

3. Number of starts for all compressors.

the start, or stop, is to occur.

4. Number of run hours for all compressors.

5. Status of all compressors (Available/Unavailable, Pumping down, Running, etc.).

Multiple Compressor Start/Stop Timing

This section defines when a compressor is to start, or stop, and the scenario for doing so.

Starting

Staging up, no compressors on the unit are running:

The first compressor can start when the LWT is more than the sum of the active LWT

setpoint and the Startup Delta-T. For example, with default settings, the active setpoint

would be 44°F and the startup delta would be 10 degrees F. In this case, the LWT must be

greater than 54°F. This is a necessary, but may not be a sufficient, condition for starting the

first compressor. The Startup Delta-T is adjustable from 10 degrees down to 0 degrees F.

Staging up, at least one compressor is already running:

Additional compressors can start when the LWT is more than the sum of the active LWT

setpoint and the Stage Delta-T. With the default settings, the active setpoint is 44°F, and the

Stage Delta would be 2 degrees F. So, one necessary condition for staging an additional

compressor on is that the LWT must be higher than 46°F.

If in Cool Mode, an additional requirement is that all running compressors are running at

their maximum capacity, or at least 75% slide position and the Stage Up Delay Timer (5

minute default) has timed out. Also, a compressor is considered to be at its maximum

capacity if it is in an inhibit or unload situation due to low evaporator pressure, high

condenser pressure, or low discharge superheat. If a compressor is set for manual slide

control, or the slide target has reached the maximum allowed by the Max Slide setpoint, it

will also be flagged as being at maximum capacity.

OM AGSB-5 15

Page 16

Stopping

Staging down, at least two compressors running:

For staging off compressors, the LWT must be less than the active LWT setpoint minus the

Stage Delta-T. Based on default settings, the active setpoint would be 44°F, and stage delta

of 2 degrees F. So the LWT must be less than 42°F to stage off a compressor. This is a

sufficient condition to tr ig ger a stage down.

For 3 compressor units, the Stage Down Delay Timer must time out before the second lag

compressor will stage down, unless LWT minus Stage Down Delta-T is exceeded, or the

LWT rises above the setpoint.

Staging down, one compressor running:

With one compressor left running, the stage off requires that the LWT be less than the active

LWT setpoint minus the Stop Delta-T. With default settings, the active setpoint is 44°F, and

the Stop Delta is 3 degrees F, so the LWT must be less than 41°F to stage off the last

compressor. This is a sufficient condition to trigger a stage down.

History Storage

The number of starts and total compressor run hours is maintained in non-volatile memory

and can be viewed on the Unit Controller or corresponding Circuit Controller.

Compressor Capacity Control

Compressor capacity is determined by calculating a slide position target. Adjustment to the

slide target for normal running conditions occurs every 10 seconds. For loading, a

maximum change of 1% is allowed, and for unloading, a maximum change of 2% is

allowed. During alarm conditions, the slide target may be reduced to satisfy alarm limits.

The change to the target is calculated as follows.

Capacity Overrides – Limits of Operation

The following conditions override the automatic slide control when the chiller is in COOL

mode or ICE mode. These overrides keep the circuit from entering a condition in which it

is not designed to run. As previously noted, any compressor that is running with capacity

limits because of these conditions will be considered to be at full load in the compressor

staging logic. An important point to realize is that a particular chiller’s components are

designed for a specific range of capacity and chilled water flow. Varied conditions such as

high water temperature or low condenser pressure can cause higher refrigerant flow than the

chiller is designed to handle, therefore the chiller control may limit unit operation to

maintain system integrity at the highest compressor load possible.

Low Evaporator Pressure

If the compressor is running and the evaporator pressure drops below the Low Evaporator

Pressure-Hold setpoint, the compressor will not be allowed to increase capacity. The slide

position target will be limited to a maximum value equal to the target at the time the hold

condition was triggered. This limit will be active until the evaporator pressure reaches the

hold setpoint plus 2-psi.

If the compressor is running above minimum load capacity and the evaporator pressure

drops below the Low Evaporator Pressure-Unload setpoint, the compressor will begin

reducing capacity. The maximum allowed slide target will be adjusted down 5% every 5

seconds until the evaporator pressure rises above the Low Evaporator Pressure-Unload

setpoint. The slide target will then be limited to the current value until the evaporator

pressure rises to the unload setpoint plus 2-psi. If the pressure drops to the Unload Setpoint,

the EXV will switch to pressure control.

16 OM AGSB-5

Page 17

High Condenser Pressure

If the compressor is running and the condenser pressure rises above the High Lift Pressure

Hold setpoint, the compressor will not be allowed to increase capacity. The slide position

target will be limited to a maximum value equal to the target at the time the hold condition

was triggered. This limit shall be active until the condenser pressure drops 10 psi below the

hold setpoint.

If the compressor is running above minimum load capacity and the condenser pressure rises

above the High Condenser Pressure Unload setpoint, the compressor will begin reducing

capacity. The maximum allowed slide target will be adjusted down 5% every 5 seconds

until the condenser pressure drops below the High Condenser Pressure-Unload setpoint.

The slide target will then be limited to the current value until the condenser pressure drops

to 10 psi below the unload setpoint.

High Leaving Water Temperature

If the LWT is above 50°F, then the Max Slide is limited to 80% to avoid overloading.

Low Discharge Superheat

If the compressor is running, and the discharge superheat is less than 22oF, the compressor

will not be allowed to increase capacity. This limit will be active until the superheat is more

than 22

o

F.

If the compressor is running above minimum load capacity, and the discharge superheat is

less than 20

adjusted down 2% every 5 seconds, as long as the superheat remains below 20

o

F, then the compressor will begin reducing capacity. The slide target will be

o

F.

Maximum LWT Pulldown Rate

The maximum rate at which the leaving water temperature can drop is limited by the

Maximum Rate setpoint. A slope unload factor is used to reduce the slide target if the

pulldown rate exceeds the Maximum Rate setpoint.

Slope Unload Factor: Maximum Rate + LWT slope

If the pulldown rate is too fast, the slide adjustment will be made equal to the slope unload

factor.

Unit Capacity Overrides

Unit capacity limits can be used to limit total unit capacity in COOL and COOL w/

GLYCOL modes only. Multiple limits may be active at any time, and the lowest limit is

always used in the compressor capacity control.

These limits represent a limit on the unit capacity as a whole. Therefore, an estimate of the

current unit capacity is needed. Any circuit that is off is considered to be running at 0% of

its capacity. A running circuit is assumed to be running at a minimum of 20% capacity, and

the assumed capacity will very linearly from 20% to 100% as the slide position varies from

0% to 100%. The unit capacity is calculated using the following formula:

Unit Capacity = (Cir1 Capacity + Cir2 Capacity + Cir3 Capacity) / Number of Circuits

The estimated unit capacity and the active capacity limit are sent to all circuits for use in

compressor capacity contro l.

The active capacity limit values can be viewed at View Unit Status (2) and consist of the

following:

Soft Load

Soft Loading is a configurable function used to ramp up the unit capacity over a given time.

The set points that control this function are:

OM AGSB-5 17

Page 18

• Soft Load – (ON/OFF)

• Begin Capacity Limit – (Unit %)

• Soft Load Ramp – (seconds)

The Soft Load Unit Limit increases linearly from the Begin Capacity Limit set-point to

100%, over the amount of time specified by the Soft Load Ramp set-point. If the option is

turned off, the soft load limit is set to 100%.

Demand Limit

The maximum unit capacity can be limited by a 4 to 20 mA signal on the Demand Limit

analog input. This function is only enabled if the Demand Limit setpoint is set to ON. The

maximum unit capacity changes linearly from 0% (at 20 mA) to the 100% (at 0 mA).

Network Limit

The maximum slide load percentage of the compressor can be limited by a value sent

through a BAS network connection and stored in the Network Limit variable. This function

will be enabled if the control source is set to BAS.

ICE Mode Start Delay

In ICE mode there is a 12 hour delay from the time the unit shuts off until it may start again.

If the chiller is in ICE mode and the delay is active, the unit state will be Off and the unit

status will indicate this condition. The time left will also be displayed. While this delay is

active, the chiller may still start in cool mode.

If needed, the ice delay can be cleared using a setting found in the unit set points menu.

Pumpdown

When a circuit reaches a condition where the compressor needs to shut down normally, a

pumpdown will be performed. The slide target will automatically go to 0 while pumping

down, and the compressor will run until the pumpdown pressure has been reached, or the

pumpdown time has been exceeded. The Pumpdown Setpoint may need to be reduced if the

unit is running in the COOL w/ GLYCOL mode.

Service Pumpdown

If the option for a service pumpdown is enabled, then on the next pumpdown the pressure

setpoint will be 15 psi. The circuit will pumpdown to this pressure and shut off. When the

compressor has completed the service pumpdown, the setpo int is re set to No.

Manual Slide Control Mode

The slide position on each circuit can be controlled manually. A setting on the compressor

setpoints screen in each circuit controller allows the operator to select manual slide control.

On the same screen, a slide target can be selected from 0% to 100%.

Anytime a circuit is in manual slide control, it is considered to be at full load in the staging

logic. It also will not be considered a running compressor for load balancing purposes.

None of the capacity limits outlined above will apply in manual slide control, but all stop

alarms are still applicable.

Slide Positioning

Slide Load Indicator

Each compressor will estimate its slide load percentage from the present value of the slide

load indicator. The percentage is based on the 4-20mA signal from the slide load indicator.

See Table 6 on page 13 for the mA signal corresponding to slide position.

18 OM AGSB-5

Page 19

Load/Unload Select

The load/unload selector determines which solenoid will be pulsed for a change in capacity.

When unloading is required, the load/unload select output should be off. When loading of

the compressor is required, the output should be on.

Slide Pulse

The slide pulse output moves the compressor slide in order to reach the capacity reflected

by the slide position target. The output will pulse for 200 ms every 3 seconds until the slide

position is within a 3% deadband around the target.

Condenser Fan Control

The compressor must be running in order to stage its fans on.

VFD (Standard)

Condenser pressure trim control is accomplished using a variable frequency drive (VFD) on

the first two fans that turn on. This VFD control uses a proportional integral function to

drive the saturated condenser temperature to a target value by changing the fan speed. The

target value is normally the same as the saturated condenser temperature target setpoint.

The VFD will start the fans when the saturated condenser temperature goes above the

temperature target. Once the VFD fans are on, they will not shut off until the saturated

condenser temperature is less than the minimum saturated temperature plus 5 degrees F.

Stage up Compensation

In order to create a smoother transition when another fan is staged on, the VFD compensates

by slowing down initially. This is accomplished by adding the new fan stage up deadband

to the VFD target. The higher target causes the VFD logic to decrease fan speed. Then,

every 10 seconds, 0.5

condenser temperature target setpoint. This will allow the VFD to slowly bring the

saturated condenser temperature back down.

o

F is subtracted from the VFD target until it is equal to the saturated

Condenser Target

This logic is only used with VFD = Yes. Most applications will benefit from using the

default values. In the software versions previous to AGSU30101F, there was only one

setting for condenser target setpoint, with a default of 110°. Beginning with AGSU30101F

software there are two setpoints used to set a minimum (Min) and a maximum (Max) range

for the saturated condenser target. This can be found on the circuit controller at Set Fan

Sps(5). This will allow for a floating condenser target based on saturated evaporator

temperature. The default values of the minimum and maximum are both set to 110°

saturated condensing temperature. This will allow for the most stable unit operation.

Adjusting the Min or Max setpoint at each circuit controller will vary the condenser target

along a line determined by two points which are, 85° saturated condenser at 20° saturated

suction and 110° saturated condenser at 50° saturated suction. Note that the chiller system

is designed for specific refrigerant flow capacities, which may be exceeded by decreasing

the condenser target. The result will be at lower ambient temperatures, the chiller may

attain the maximum unit tonnage capacities while compressor loading will be limited on

low discharge superheat.

Fan Stages with VFD Option

The VFD option must always be enabled. The first two fans are controlled by the fan VFD.

This leaves 6 stages of FanTrol available with 8 fan circuits, and 4 stages available on 6 fan

circuits. Although fans 5/6 and 7/8 are controlled by one contactor each, more stages are

created by using virtual stages. See the table below:

OM AGSB-5 19

Page 20

Table 7, Staging with VFD

Stage Fans On

1 1,2,3

2 1,2,3,4

3 1,2,4,5,6

4 1,2,3,4,5,6

5 1,2,3,5,6,7,8

6 1,2,3,4,5,6,7,8

Staging Up

There are four stage-up deadbands that apply to the FanTrol stages. Stages one through

three use their respective deadbands. Stage four to eight share the fourth stage-up

deadband.

When the saturated condenser temperature is above the Target + the active deadband, a

Stage Up error is accumulated.

The saturated condenser temperature must not be falling for a Stage Up accumulation to

occur.

Stage Up Error Step = Saturated Condenser Refrigerant temperature – (Target + Stage

Up Deadband)

The Stage Up Error Step is added to Stage Up Accumulator once every Stage Up Error

Delay seconds. When Stage Up Error Accumulator is greater than the Stage Up Error

Setpoint, another stage is added.

When a stage up occurs, or the saturated condenser temperature falls back within the Stage

Up deadband, the Stage Up Accumulator is reset to zero.

Forced Fan Stage At Start

Fans may be started simultaneously with the compressor based on outdoor ambient

temperature. When the compressor starts, a FanTrol stage is forced, based on the following

table.

Table 8, Forced Staging

Outside Air

Temperature

> 75oF Forced FanTrol 1 SP

> 90oF Forced FanTrol 2 SP

> 105oF Forced FanTrol 3 SP

Staging Down

FanTrol Stage At Start

There are four Stage Down deadbands. Stages one through three use their respective

deadbands. Stages four to eight share the fourth Stage Down deadband.

When the condenser saturated refrigerant temperature is below the Target – the active

deadband, a Stage Down error is accumulated.

Stage Down Error Step = (Target - Stage Down deadband) - Saturated Condenser

Refrigerant temperature

The Stage Down Error Step is added to Stage Down Accumulator once every Stage Down

Error Delay seconds. When the Stage Down Error Accumulator is greater than the Stage

Down Error Setpoint, another stage of condenser fans turned off.

When a stage down occurs, or the saturated temperature rises back within the Stage Down

deadband, the Stage Down Error Accumulator is reset to zero. The accumulator is also held

at zero after startup until either the outside ambient temperature is less than or equal to 75°F,

or the saturated condenser temperature is greater than the condenser target less the active

stage down deadband.

20 OM AGSB-5

Page 21

EXV Control

Three different expansion valve (EXV) control modes are used. Any time the EXV is not in

one of these control modes, it will be closed. For any of the control modes, the EXV

position is limited to a range based on the slide position target. The minimum setting

provides sufficient flow for motor cooling, the maximum flow limit helps prevent flood

back to the compressor. The table below shows the EXV range for each size compressor, at

mini mum and maximu m capa city. The mini mum and maximu m value s vary l inear ly wit h

slide position, defining a new EXV control range for every change in slide position.

Table 9, EXV Range

EXV Slide %

Min 0 250 250 250

Max 0 3000 3000 3000

Min 100 870 1080 1300

Max 100 3400 4200 5000

205mm 220mm 235mm

Based on the values in the above table, the EXV control range varies as shown in the figure

below. The shaded area is the control range.

Figure 3, EXV Control Range

Max EXV

@ 100%

Compressor Size

EXV Control Range

EXV

Steps

Max EXV

@ 0%

Min EXV

@ 100%

Min EXV

@ 0%

0

Slide Position (%)

100

1. Pre-Open

At the time of a start request, the EXV will perform a pre-open function. This is to provide

sufficient liquid refrigerant in the evaporator to avoid low pressure situations at startup.

During pre-open, the EXV will open to 3000 steps, while the saturated evaporator

temperature is less than the LWT. The EXV will move to 250 steps when the saturated

evaporator temperature is e qual to, or grea ter tha n, the LWT.

The EXV must be in the pre-open state for a time equal to the pre-open timer setpoint

before the compressor will start. This state may be skipped if the start request occurs, and

the evaporator saturated temperature is greater than LWT + 5°F. In this case, the

compressor would start and the EXV would go straight to pressure control.

2. Pressure Control

The EXV will be in pressure control mode after startup, and always when in the ICE mode.

In this mode, the EXV controls discharge superheat with adjustments to the evaporator

pressure target. A proportional integral function is used to keep the evaporator pressure at

the target.

OM AGSB-5 21

Page 22

The base pressure target is calculated using the following formula:

Base target = 2/3LWT – 8

The base target is limited to a range from the low pressure inhibit setpoint, plus 2 psi, up to

52 psi.

The pressure control target may be adjusted if the discharge superheat is not within an

acceptable range. If the superheat is less than 22°F, the base pressure target will be reduced

by a value equal to the low superheat error. If the superheat is more than 40°F, th e ba s e

pressure target will be increased by a value equal to the high superheat error. At any time,

the adjusted target pressure cannot go below the low pressure inhibit setpoint plus 2 psi, or

above 52 psi.

The EXV will transition from pressure control to subcool control when all of the following

are true:

• Discharge Superheat > 22°F for at least 3 minutes while in pressure control

• LWT <= 60°F

• Subcool > current base subcool value

• Unit mode = Cool (includes Available Modes: Cool w/ Glycol. Subcool control is not

used in Ice Mode)

The pressure target will ramp down when transition to pressure control occurs. The

pressure target will decrement 0.2 psi every second until it reaches the normal target. The

starting target is the current pressure at transition to pressure control, but is limited to a

maximum of 52 psi.

The EXV may transition from subcool control back to pressure control. This occurs when

the LWT is greater than 63°F , the unit mode is switched from Cool to Ice, or in F code, a

low evaporator pressure unload occurs. Starting with F code, when suction pressure drops

below the low evaporator pressure unload setpoint, the controller will switch from subcool

control to pressure control, until sufficient subcooling is established.

3. Subcool Control

After completing pressure control, the EXV transitions to the primary mode of operation,

subcool control. In this mode, subcooling is controlled by the EXV, with adjustments to the

subcool target based on discharge superheat. The base subcool target varies linearly from 5

degrees F to 20 degrees F as slide position changes from 0 to 100%.

The base subcool target value is adjusted when the discharge superheat is less than 22

degrees F, or greater than 40 degrees F. For every degree below the minimum, the subcool

target is adjusted up one degree. Similarly, for every degree above the maximum, the

subcool target is adjusted down one degree. The maximum offset to the base subcool value

is 15 degrees F, and the adjusted subcool target is limited to a minimum of 2 degrees F.

When the circuit initially enters subcool control, the subcool target is set to the current

subcool value less 2 degrees. This value may be above the normal 5 to 20 degree range.

The target subcool value is then reduced 0.1 degree every two seconds until it reaches the

calculated target value.

The EXV may transition from subcool control back to pressure control. This occurs when

the LWT is greater than 63°F or if the pressure drops to the LPUnload SP, while in subcool

control.

The EXV will transition from subcool control to pressure control if a low pressure unload

occurs. The normal rules to transition back to subcool control will apply.

22 OM AGSB-5

Page 23

Closed

Any time the EXV is not in pre-open, pressure control, or subcool control, it will be in a

closed state. At this time, the EXV position is 0 steps and the EXV close signal is active.

Manual EXV Control

The EXV position can be set manually. Manual control can only be selected when the

compressor is in the run state. At any other time, the EXV control setpoint is forced to auto.

When EXV control is set to manual, the EXV position is equal to the manual EXV position

setting. If set to manual when the compressor state transitions from run to another state, the

control setting is automatically set back to auto.

To verify EXV operation in an off state, see Unit Test Mode on page 28.

Evaporator Oil Return Line Control

The oil return solenoid shall be on any time the compressor is running and any of the

following occurs:

Slide position target < 60 AND Discharge superheat > 35

Slide position target >= 60 AND Discharge superheat > 50

Oil Level input = open AND Discharge superheat > 35

Oil Heater Control

The oil heater shall be on when the compressor is not running AND the oil level input is

closed.

Interstage Injection

The purpose is to control the discharge temperature at low LWT conditions when the

dischare temperature is high. The interstage injection is activated when the compressor is

running AND the discharge temperature rises above 185°F. The output shall be turned off

when either the compressor is no longer running, OR the discharge temperature drops below

170°F.

OM AGSB-5 23

Page 24

Unit Controller

Inputs/Outputs

The following parameters are analog inputs to this controller. They are used internally as

needed and are sent to the correct pLAN addresses for use by other controllers or displays.

Table 10, Unit Analog Inputs

# Description Signal Source Range

1 Outdoor Ambient Temperature Thermistor (10k@25°C)

2 Demand Limit 4-20 mA Current 25-100 %RLA

3 Chilled Water Reset 4-20 mA Current

4 Leaving Evaporator Water Temperature Thermistor (10k@25°C)

5 Entering Evaporator Water Temperature Thermistor (10k@25°C)

The following parameters are digital inputs to this controller. They are used internally as

needed and are sent to the correct pLAN addresses for use by other controllers or displays.

The status of digital inputs can be viewed on Unit Status screen #4, on the unit controller

only.

Table 11, Unit Digital Inputs

# Description Signal Signal

1 Unit Switch 0 VAC (Stop) 24 VAC (On)

2 Remote Switch 0 VAC (Stop) 24 VAC (Start)

3 Evaporator Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

4 Mode Switch 0 VAC (Cool) 24 VAC (Ice)

5 Open

6 Open

-58°F to 212°F

0 to10 degrees

60°F max inlet

-58°F to 212°F

-58°F to 212°F

The following parameters are digital outputs from this controller. Their values are sent to

the correct pLAN addresses for use by other controllers or displays. The status of digital

outputs can be viewed on Unit Status screen #4, on the unit controller only.

Table 12, Unit Digital Outputs

# Description Load Output OFF Output ON

1 Open

2 Evaporat or Water Pump 1 Pump Contactor Pump OFF Pump ON

3 Evaporat or Water Pump 2 Pump Contactor Pump OFF Pump ON

4 E vap Heat ers Heater relay Heater OFF Heater ON

5 Open

6 Open

7 Open

8 Alarm Remote Alarm No Alarm Stop Alarm

Setpoints

At power-up, the slave node checks if the master node is operational and if so, it sets its

copy of the setpoint equal to the master’s. Otherwise, the setpoint remains unchanged.

During normal operation, any time the master setpoint changes, the slave is updated as well.

The PW (password) column indicates the password that must be active in order to change

the setpoint. Codes are as follows:

O = Operator, M = Manager

24 OM AGSB-5

Page 25

Table 13, Unit Controller Setpoints

Description Default Range PW

Unit

Unit Enable OFF OFF, ON O

Unit Mode COOL

Control source SWITCHES SWITCHES, KEYPAD, NETWORK O

Available Modes COOL

Cool LWT

Ice LWT

Startup Delta-T 10.0 degF 0.0 to 10.0 degF O

Stop Delta-T 3.0 degF 0.0 to 3.0 degF O

Stage Delta-T 2.0 degF 0.0 to 3.0 degF O

Max Pulldown 0.5 degF/min 0.1-5.0 degF/min M

Evap Recirculate 30 sec 0 to 300 sec M

Evap pump control #1 Only #1 Only, #2 Only, Auto M

LWT Reset Type NONE NONE, RETURN, 4-20mA, OAT M

Max Reset 0.0 degF 0.0 to 20.0 degF M

Start Reset Delta-T 10. 0 degF 0.0 to 20.0 degF M

Soft Load On On, Off M

Begin Capacity Limit 40% 20-100% M

Soft Load Ramp 20 min. 1-60 min. M

Demand Limit no No,yes M

Low Ambient Lock

Ice Time Dlay 12 hrs. 1-23 hrs. M

Clear ice Timer No No, Yes M

Display Units

Language English English M

BAS Protocol NONE

Ident number 1 0=200 M

Baud Rate 19200 1200, 2400, 4800, 9600, 19200 M

Compressors

Sequence # Cir 1 1 1-3 M

Sequence # Cir 2 1 1-3 M

Sequence # Cir 3 1 1-3 M

Max Compressors On 3 1-3 M

Start-start timer 20 min 15-60 minutes M

Stop-start timer 5 min 3-20 minutes M

Number of Compressors 2 2-3 M

Pumpdown pressure 25.0 psi 10.0-30.0 psi M

Pumpdown time limit 120 sec 0-180 sec M

Light Load Stage Down Point 255 20-50% Slide M

Light Load Stage Down Delay 3 min. 3-30 min. M

Stage Up Delay 5 min. 0-60 min. M

Alarms

Low Evap Pressure-Unload 28 psi 0 to 45 psi M

Low Evap Pressure-Hold 30 psi 0 to 45 psi M

Low Oil Level Delay 120 s ec 10-180 sec M

High Oil Press Diff Delay 15 sec 0-60 sec M

Min Lift Delay 30 s ec 10-120 sec M

Low Subcooling 5 degF 0 to 10 degF M

High Discharge Temperature

Evaporator Water Freeze

Evap Flow Proof 3 sec 3 to 120 sec M

High Lift Delay 5 sec. 0-30 sec. M

Sensors

OAT sensor offset 0 degF -5.0 to 5.0 degF M

LWT sensor offset 0 degF -5.0 to 5.0 degF M

EWT sensor offset 0 degF -5. 0 t o 5.0 degF M

44. 0°F 25.0(40.0) to 60.0 °F

25.0°F 20.0 to 38.0°F

55°F

°F, psi °F, psi

200° F

36 °F 15(34) to 42 °F

COOL, COOL w/Glycol,

ICE w/Glycol, TEST

COOL, COOL w/Glycol, COOL/ICE

w/Glycol, ICE w/Glycol, TEST

35-70 degF M

NONE, BACnet, LonWorks,

CAREL, MODBUS, N2

150 to 200 F M

O

M

O

O

M

M

M

These parameters are remembered during power off, and are factory set to the Default value.

OM AGSB-5 25

Page 26

Automatic Adjust ed Limits

The following setpoint ranges will be adjusted based on selected options.

Table 14, Evaporator Leaving Water Temperature Range

Mode Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol, Ice, Ice w/ Glycol

Table 15, Evaporator Freeze Temperature Range

Mode Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol, Ice, Ice w/ Glycol

Table 16, Low Evaporator Pressure Inhibit

Mode Range

Unit Mode = Cool 30 to 45 Psig

Unit Mode = Cool w/Glycol, Ice w/ Glycol 15 to 45 Psig

Table 17, Low Evaporator Pressure Unload

Mode Range

Unit Mode = Cool 28 to 45 Psig

Unit Mode = Cool w/Glycol, Ice w/ Glycol 15 to 45 Psig

40 to 60°F

20 to 60°F

34 to 42°F

15 to 42°F

Table 18, Low Ambient Lockout Temperature Range

Fan VFD Range

Fan VFD = N

Fan VFD = Y

35– 60°F

0 – 60°F

Unit Enable

Enabling and disabling the chiller is controlled by the Unit Enable Setpoint with options of

OFF and ON. The Unit OFF input (unit On/Off switch), field installed Remote stop switch,

keypad entry, or BAS request can alter this setpoint providing the correct control source

setpoint is selected. T he Control Source Setpoint determines which sources can change the

Unit Enable Setpoint with options of SWITCHES, KEYPAD, or NETWORK.

Changing the Unit Enable Setpoint can be accomplished according to Table 19 on page 27.

NOTE: An “x” indicates that the value is ignored.

Set Unit Setpoints Screen #1 (shown below) shows three fields “Enable”, “Mode” and

“Source.”

Unit Setpoints

SET UNIT SPs (1)

Enable=On

Mode= COOL

Source = KEYPAD

The Enable field is for use with Source = Keypad only, to enable and disable the chiller

through the key pad, ignoring any other control inputs including unit and pumpdown

switches and BAS controls.

26 OM AGSB-5

Page 27

1. The Mode field is an informational display, showing the active control mode of the

chiller. It is used as an input only when the source is set to keypad, only then can this

field be changed manually.

2. The Source field has three options, “SWITCHES” (default), “KEYPAD”, and “BAS

NETWORK”.

a. Switches source is used when there is no BAS interface

used. This allows the unit switches to function as pumpdown and shut down

switches for the circuit. This option is used with applications using the remote

start/stop input and not using a BAS interface.

b. Keypad source is used to override BAS or remote start/stop

commands. This would be used for servicing only.

c. BAS Network source would be used for those applications

using “MODBUS”, “BACNET”, or “LON” communications through a building

automation system. BAS Protocol is set at Set Unit Setpoints item #11.

Table 19, Unit Enable Settings

Unit On/Off

Switch

OFF x x x x OFF

x SWITCHES OFF x x OFF

ON SWITCHES ON x x ON

ON KEYPAD x OFF x OFF

ON KEYPAD x ON x ON

ON NETWORK x x OFF OFF

ON NETWORK OFF x x OFF

ON NETWORK ON x ON ON

Control Source

Setpoint

Remote

Stop Switch

Key-pad

Entry

BAS

Request

Unit

Enable

All methods of disabling the chiller, except for the unit switch, will cause a normal

shutdown of any running circuits. Any time the unit switch is used to disable the chiller, all

running circuits will shut down immediately, without pumping down.

Shutdown by the unit switch without going through the pumpdown cycle is undesirable and

should only be used for an emergency shutdown or for disabling the unit after both circuits

have gone through a normal shutdown.

Unit Mode Selection

The overall operating mode of the chiller is set by the Unit Mode Setpoint with options of

COOL, COOL w/Glycol, ICE w/Glycol, and TEST. The system switch must be off (unit

not running) to change the mode of operation.

Available Modes setpoint: usually set during initial setup and determines the operational

modes available at any time with options of:

• COOL, cooling only operation, with setpoints available for normal water temperatures.

• COOL w/Glycol, cooling only operation, allows lower setpoints than COOL.

• COOL/ICE w/Glycol, allows cooling and ice mode operation, switchable by a remote

digital signal, by the network or through the keypad.

• ICE w/Glycol, ice mode only, i.e., full load operation until LWT setpoint is reached.

• TEST

OM AGSB-5 27

Page 28

SET UNIT SPs (2)

Available Modes = COOL

Select w/Unit Swt Off

The setpoint can be altered by the keypad, BAS, and Mode input. Changes to the Unit

Mode Setpoint are controlled by two additional setpoints.

• Control Source Setpoint: Determines the source that can change the Unit Mode

Setpoint with options of KEYPAD (pCO

2

), NETWORK, or SWITCHES.

When the Control source is set to KEYPAD, the Unit Mode stays at its previous setting until

changed by the operator. When the Control source is set to BAS, the most recent BAS

mode request goes into effect even if it changed while the Control source was set to

KEYPAD or DIGITAL INPUTS.

Changing the Unit Mode Setpoint can be accomplished according to the following table.

NOTE: An “x” indicates that the value is ignored.

Table 20, Unit Mode Settings

Control Source

Setpoint

x x x x COOL COOL

x x x x COOL w/Glycol COOL w/Glycol

SWITCHES OFF x x COOL/ICE w/Glycol COOL w/Glycol

SWITCHES ON x x COOL/ICE w/Glycol ICE w/Glycol

KEYPAD x COOL w/Glycol x COOL/ICE w/Glycol COOL w/Glycol

KEYPAD x ICE w/Glycol x COOL/ICE w/Glycol ICE w/Glycol

NETWORK x x COOL COOL/ICE w/Glycol COOL w/Glycol

NETWORK x x ICE COOL/ICE w/Glycol ICE w/Glycol

x x x x ICE w/Glycol ICE w/Glycol

x x x x TEST TEST

Remote

ICE Mode

Switch

Keypad Entry

BAS

Request

Available Modes

Setpoint

Resultant Unit

Mode

The Remote ICE Mode Switch (usually a time clock) is a field installed option and is used

to switch from ice mode operation at night to cooling mode operation during the day. This

requires that the Control Source be set to SWITCHES, which in this case refers to the

Remote ICE Mode Switch.

There are really only three operational modes for the unit, although they can be used in

combination:

1. COOL, the unit unloading and compressor staging is controlled by the Active LWT

Setpoint. COOL w/ Glycol is a special case of this mode, providing for lower setpoint

ranges.

2. ICE, the unit runs with all compressors fully loaded until the LWT (set for making ice)

is reached, and the unit shuts off. The Ice Delay Timer can be set to prevent restarting

until the next ice making cycle.

3. TEST, manually energize outputs.

Unit Test Mode

Before beginning you must have the Manager password active. Note: To put each circuit

controller in test mode, you do not have to put the unit controller into test mode, therefore

you may allow one or more circuits to operate while in test mode on another circuit.

28 OM AGSB-5

Page 29

Circuit Controllers:

Be sure the pumpdown switch is in the off position. Press the Menu button (the top far right

button with three horizontal lines on it) on the circuit controller. Press the button that

corresponds to “SET”, then press “COMPRESSOR SPs”. Now press the down arrow

button once. Now that you are on the proper screen (SET COMP SPs (2)) you may push the

enter button to go into Change Values Mode for that screen.

You will now see the cursor blinking on the first line, also there will be a “D”, “C”, “+” and

“-” down the right side of the screen. Press the corresponding “+” or “-” button to scroll

through the menu options. You will see “Enable”, “Disable” and “Test”. To select “Test”,

press the enter button. Press the enter button until the cursor scrolls to the top left corner of

the screen on to the Menu title. Now scroll to the right to the last menu, this menu is the

“Test Circuit” menu. This menu was added when you entered “Test” in the Circuit Mode

field.

“Test Circuit” item #1 is for digital outputs for the fan contactor outputs. The unit is

equipped with fan VFD and fan outputs 1 and 2 will not function. The VFD fans will be

tested later. Press the enter button to go into change values mode. Continue to press enter

until you reach the output you would like to turn on, then press the “+” or “-” turn the

output on or off. Check that each fan is rotating in the proper direction, and does not have

excessive vibration.

“Test Circuit” item #2 is for digital outputs for Slide indicator. You will see a selection to

choose the slide pulse direction, with the options of “Load” (left coil) or “Unload”(right

coil). Then there is a selection to turn the pulse on or off. Choose “on” for the “Pulse” field

and then you can toggle between Load or Unload, checking the corresponding coil to see if

it energizes.

“Test Circuit” item #3 is for digital outputs for the Evaporator oil return line solenoid and

for the EXV close output. Turn the “Oil Return” on and check that the evaporator oil return

line solenoid is energizing. It is located on the base rail behind the suction line connection

to the compressor.

“TEST CIRCUIT” item #4 is for analog outputs for the fan VFD and the EXV. Here you

can ramp up the VFD by adjusting the frequency in the VFD field or manually open and

close the EXV. The EXV operation may be verified by observing operation through the

sight glass on the side of the valve body. Note: Unlike the digital outputs, you must hit

enter for the analog outputs to react to your change.

Unit Controller:

At the main menu select “SET”, then select “UNIT SPs”, scroll down 1 screen to screen #2

on the “SET UNIT SPs” screen. You will see “Available Modes”. Change the mode to

“TEST”. (Note: this will disable all running circuits.) Now scroll all the way to the right on

the unit test screen, there is only one screen. Verify the “Alarm Out” output at J15-NO8.

Verify the evap heaters are on by checking the amps on the appropriate wires. Verify the

evaporator pump outputs and wiring by turning the pump outputs on and off.

Note: When the service test is completed, remember to take both the unit and each of the

circuit controllers out of “Test” Mode and back into “Enable.”

OM AGSB-5 29

Page 30

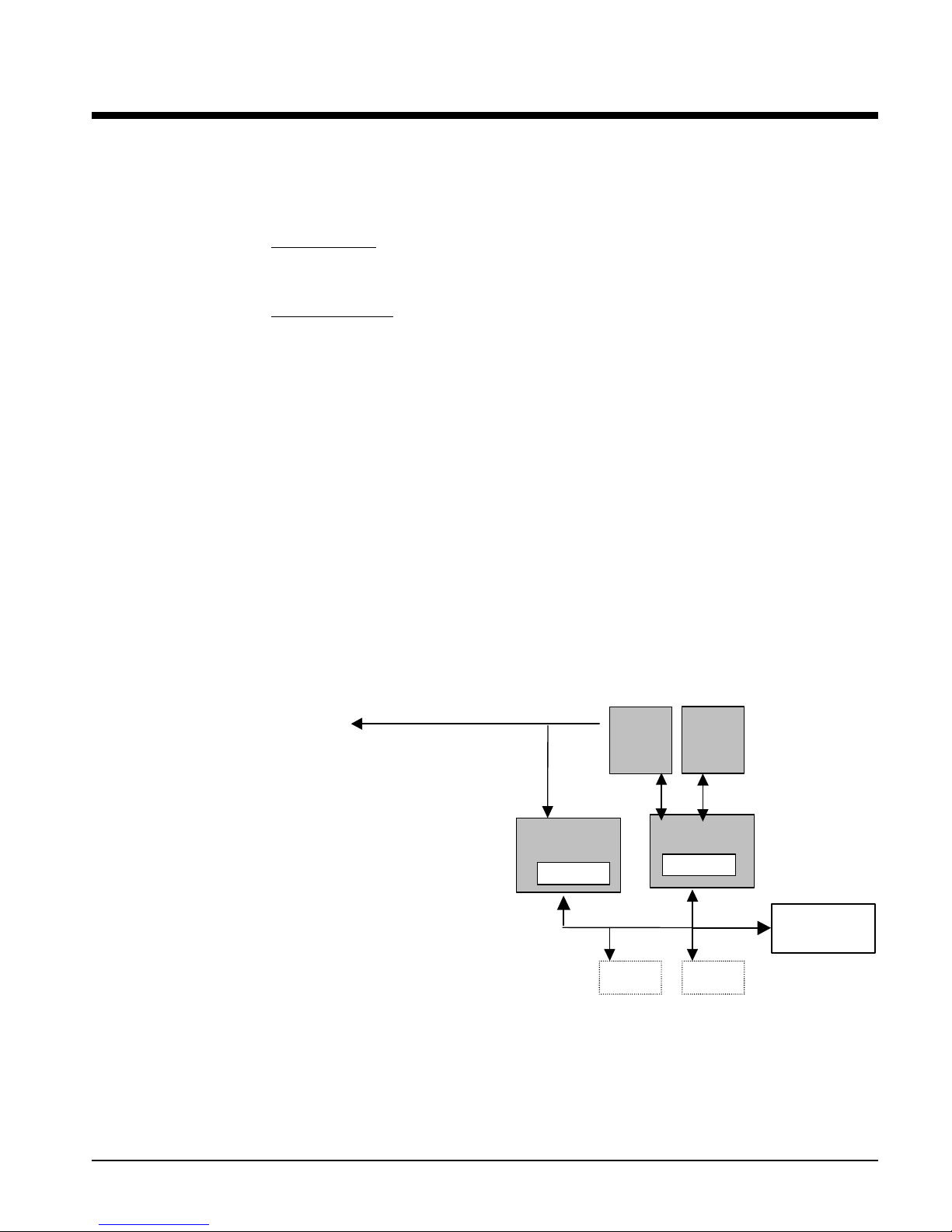

Evaporator Pump State Control

The state-transition diagram shown below controls operation of the evaporator pump.

Figure 4, Evaporator Pump Control

Power ON

[Unit State=OFF

LWT > Freeze sp]

OR

[OAT low

All Comp State=OFF

LWT>70 F]

AND

RUN

AND

AND

OFF

[Unit

LWT > Freeze sp]

OR

[OAT low

All CompState=OFF

LWT>70 F]

Flow OK for

Evap Recirc Time

State=

OFF

AND

AND

[Unit State = AUTO

NOT [OAT low AND LWT > 40 F

OR

LWT < Freeze

AND

AND

sp – 1.0 F

START

One of two pumps can be automatically selected based on run hours. The run-hour counters

are not visible. When in Auto, the pump with the least hours will start. The options are # 1

only, #2 only, Auto.

The pump output used will be determined by the Evap Pump Control setpoint. This setting

allows the operator to select either pump #1 or pump #2. The selected output will be ON if

the Evap State is set to START or RUN. Both outputs will be OFF if the Evap State is set to

OFF.

Evaporator Heater Control

Evaporator heaters are controlled by the unit controller. This output is turned on when the

evaporator LWT is less than the water freeze setpoint + 2

when the LWT is more than the freeze setpoint + 4 degrees F.

degrees F. The output is turned off

Leaving Water Temperature (LWT) Reset

The Active Leaving Water setpoint is set to the current Leaving Water Temperature (LWT)

setpoint, unless the unit is in COOL mode, and any of the reset methods below are selected.

The type of reset in effect is determined by the LWT Reset Type setpoint. The Active

Leaving Water variable is sent to all circuits for capacity control after the applicable reset is

applied.

Reset Type – NONE

The Active Leaving Water setpoint is set equal to the current LWT setpoint.

Reset Type – RETURN

The return water temperature adjusts the Active Leaving Water setpoint. When the chiller

mode = COOL, the Active Leaving Water setpoint is reset using the following parameters:

1. Cool LWT setpoint

2. Max Reset Delta-T setpoint

3. Start Reset Delta-T setpoint

4. Evap Delta-T

30 OM AGSB-5

Page 31

Reset is accomplished by changing the Active Leaving Water setpoint from the Cool LWT

setpoint to the Cool LWT setpoint + Max Reset setpoint as the EWT – LW T (Evap Delta-T)

varies from the Start Reset Delta-T setpoint to 0.

Figure 5, Return Water Reset Conditions

Return Reset

Cool LWT+Max Reset

(54)

Active

LWT

o

F)

(

Max Reset

(10)

Cool LWT Set-Point

(44)

0

Start Reset Delta T

Evap Delta T (oF)

Reset Type – 4-20 mA Input Signal

The Active Leaving Water setpoint is adjusted by the 4 to 20 mA reset analog input.

Parameters used:

1. Cool LWT setpoint

2. Max Reset setpoint

3. LWT Reset signal

Reset is 0 if the reset signal is less than or equal to 4 mA. Reset is equal to the Max Reset

Delta-T setpoint if the reset signal equals or exceeds 20 mA. The amount of reset will vary

linearly between these extremes if the reset signal is between 4 mA and 20 mA.

Figure 6, External Reset Conditions

LWT Reset (Cool mode)

(temperatures are examples only)

(54.0°F)

Max Reset Delta T

(10.0°F)

Cool LWT Set-Point

(44.0°F)

OM AGSB-5 31

0 ma

4 ma

20 ma

Page 32