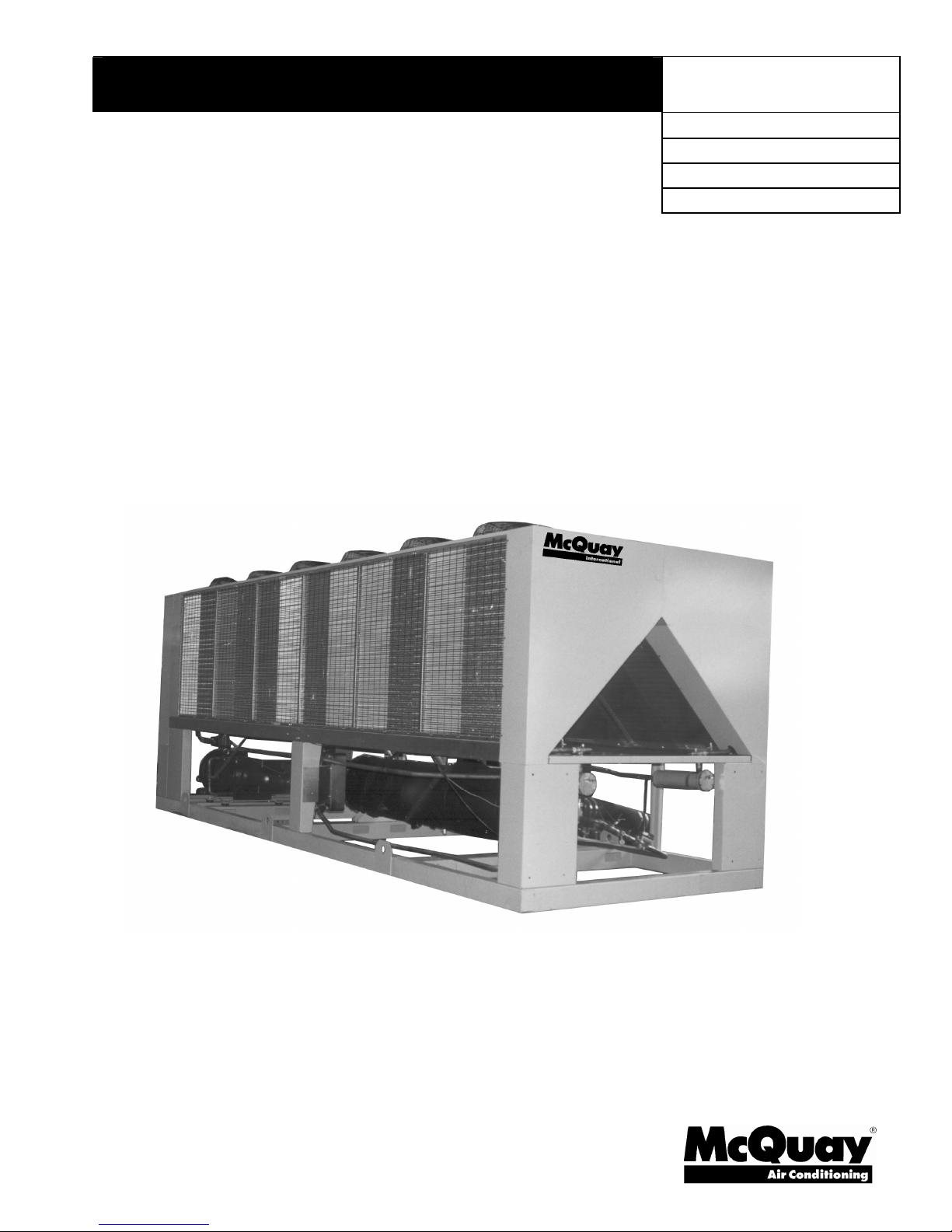

McQuay AGS120CS, AGS 210CS/H, AGS120CH, AGS210CS, AGS210CH Installation And Maintenance Manual

...Page 1

Installation and Maintenance Manual

IMM AGS-2

Air-Cooled Screw Compressor Chiller

AGS 120CS/H - AGS 210CS/H, Packaged

AGS 120CM/B – AHS 210CM/B, Remote Evaporator

60 Hertz, R-134a

Group: Chiller

Part Number: 331373301

Date: July 2008

Supersedes: March 2008

Page 2

Table of Contents

Introduction.............................................................3

General Description............................................3

Nomenclature.....................................................3

Inspection...........................................................3

Installation and Start-up ..........................................4

Handling.............................................................4

Location .............................................................5

Service Access...................................................5

Clearance Requirements....................................6

Restricted Airflow ...............................................7

Vibration Isolators.............................................13

Chilled Water Pump .........................................19

Water Piping ....................................................19

System Water Volume .....................................20

Variable Speed Pumping..................................20

Evaporator Freeze Protection...........................21

Operating Limits: ..............................................22

Flow Switch ......................................................22

Refrigerant Charge...........................................23

Glycol Solutions ...............................................23

Water Flow and Pressure Drop.............................24

Physical Data, Standard Efficiency .......................26

Physical Data, High Efficiency ..............................27

Dimensional Data .................................................29

Electrical Data ......................................................32

Field Wiring ......................................................32

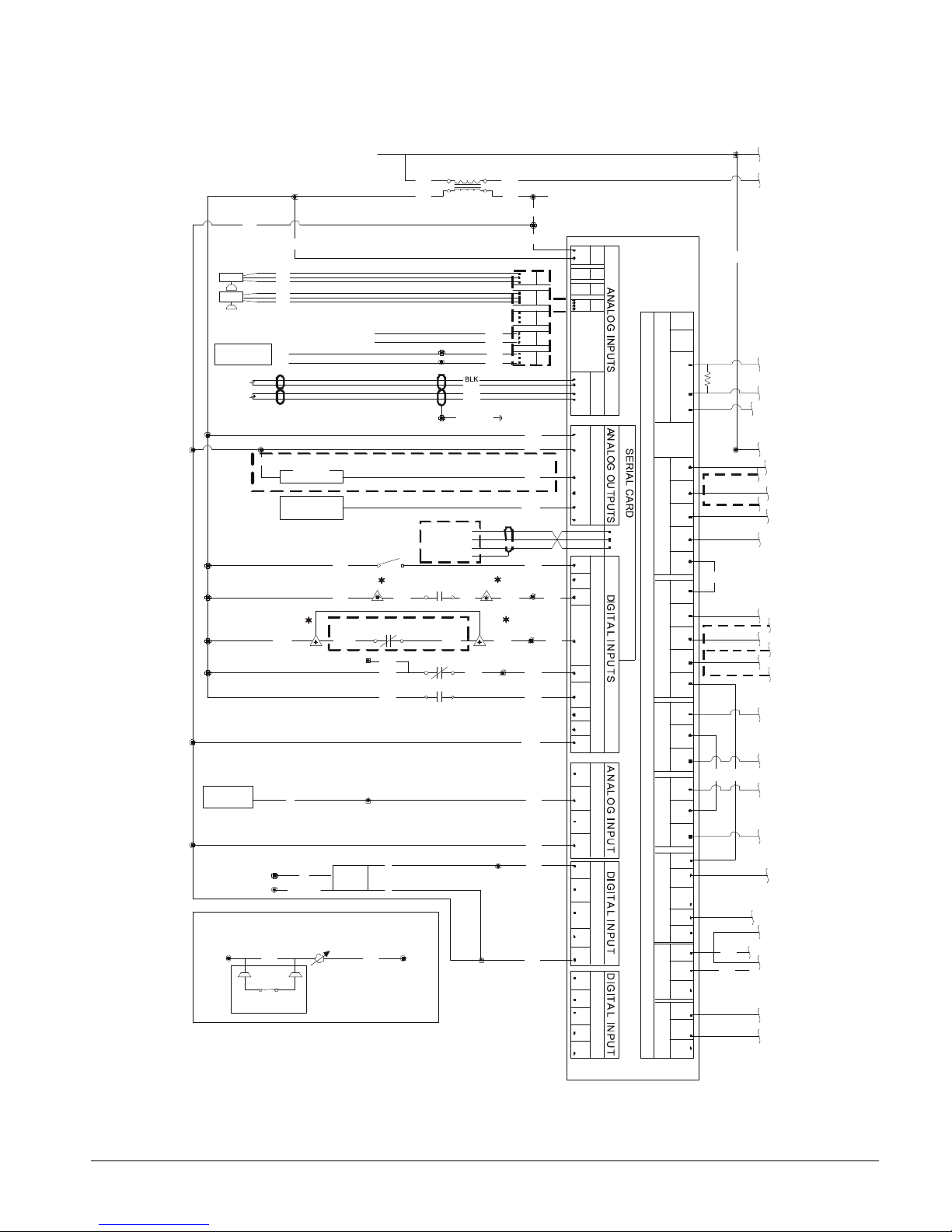

Field Wiring Diagram ............................................42

BAS Interface ...................................................47

Remote Operator Interface Panel .....................47

Remote Evaporator...............................................48

Manufactured in an ISO Certified Facility

"McQuay" is a registered trademark of McQuay International

Information covers the McQuay International products at the time of publication and we reserve the right

The following are trademarks or registered trademarks of their respective companies: BACnet from ASHRAE; LONM

LONW

to make changes in design and construction at anytime without notice.

ORKS

from Echelon Corporation; GeneSys, McQuay and MicroTech II from McQuay International.

Solid State Starters .............................................. 63

Component Location ............................................ 70

System Maintenance ............................................ 74

Warranty Statement ............................................. 77

Service ................................................................. 77

2004 McQuay International

Piping Layout ................................................... 48

Field Wiring (Remote Evaporator) .................... 49

Kit Components ...............................................49

Refrigerant Line Sizing..................................... 49

Dimensions, Unit with Remote Evaporator ....... 51

Vibration Isolators, Remote Evaporator............58

Physical Data, Standard Efficiency...................60

Physical Data, High Efficiency.......................... 61

Major Component Location .............................. 70

Power Panel..................................................... 72

Control Panel ................................................... 73

General ............................................................ 74

Compressor Maintenance ................................ 74

Lubrication .......................................................74

Electrical Terminals.......................................... 75

Condensers...................................................... 75

Liquid Line Sight Glass .................................... 75

Lead-Lag.......................................................... 76

Preventative Maintenance Schedule ................76

Liquid Line Filter-Driers .................................... 77

Compressor Slide Valves ................................. 78

Electronic Expansion Valve (EXV).................... 78

Evaporator .......................................................79

Charging Refrigerant........................................ 79

Standard Controls ............................................80

Controls, Settings and Functions ..................... 82

Troubleshooting Chart......................................83

Periodic Maintenance Log................................84

Unit controllers are LONM

with an optional LONW

communications module

ARK

ARK and

certified

ORKS

2 IMM AGS-2

Page 3

Introduction

General Description

McQuay

refrigerating units that include the latest in engineered components arranged to provide a

compact and efficient unit. Each unit is completely assembled, factory wired, evacuated,

charged, tested and comes complete and ready for installation. Each unit consists of two

air-cooled condenser sections with integral subcooler sections, two semi-hermetic, singlescrew compressors with solid-state starters, a two-circuit shell-and-tube direct expansion

evaporator, and complete refrigerant piping. Each compressor has an independent

refrigeration circuit. Liquid line components included are manual liquid line shutoff valves,

charging ports, filter-driers, sight-glass/moisture indicators, solenoid valves and electronic

expansion valves. A discharge shutoff valve is included and a compressor suction shutoff

valve is optional. Other features include compressor heaters, evaporator heaters for freeze

protection, automatic one-time pumpdown of each refrigerant circuit upon circuit

shutdown, and an advanced fully integrated microprocessor control system.

AGS units are divided between standard efficiency (model numbers ending in “0”) and high

efficiency units (ending in “5”). The high efficiency units have certain larger components.

The units are optionally available with the evaporator shipped separately for remote

mounting indoors.

A high ambient option is required for operation in ambient temperatures above 115°F

(46°C), or 105°F (41°C) on units equipped with optional fan VFDs.

Information on the operation of the unit MicroTech II controller is in the OM AGS manual.

GeneSys

air-cooled water chillers are complete, self-contained automatic

Nomenclature

Rotary Screw Compressor

“0” Last Digit=Std. Efficiency

“5” Last Digit=High Efficiency

Air-Cooled

Global

Nominal Tons

A G S - XXX C S

S=Standard Ambient, Packaged Unit

M=Standard Ambient, Remote Evaporator

H=Packaged with High Ambient Option

B=Remote with High Ambient Option.

Design Vintage

Inspection

When the equipment is received, carefully check all items against the bill of lading to check

for a complete shipment. Check all units for damage upon arrival. All shipping damage

must be reported to the carrier and a claim must be filed with the carrier. Check the unit’s

serial plate before unloading the unit to be sure that it agrees with the power supply

available. Physical damage to unit after acceptance is not the responsibility of McQuay

International.

Note: Unit shipping and operating weights are shown in the Physical Data Tables on page

26 for packaged units and page 60 for remote evaporator models.

IMM AGS-2 3

Page 4

Installation and Start-up

Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Note: Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment.

Start-up by McQuayService is included on all units sold for installation within the USA and

Canada and must be performed by them to initiate the standard limited product warranty.

Two-week prior notification of start-up is required. The contractor should obtain a copy of

the Start-up Scheduled Request Form from the sales representative or from the nearest

office of McQuayService.

Escaping refrigerant can displace air and cause suffocation. Immediately evacuate

and ventilate the equipment area. If the unit is damaged, follow Environmental

Protection Agency (EPA) requirements. Do not expose sparks, arcing equipment, open

flame or other ignition source to the refrigerant.

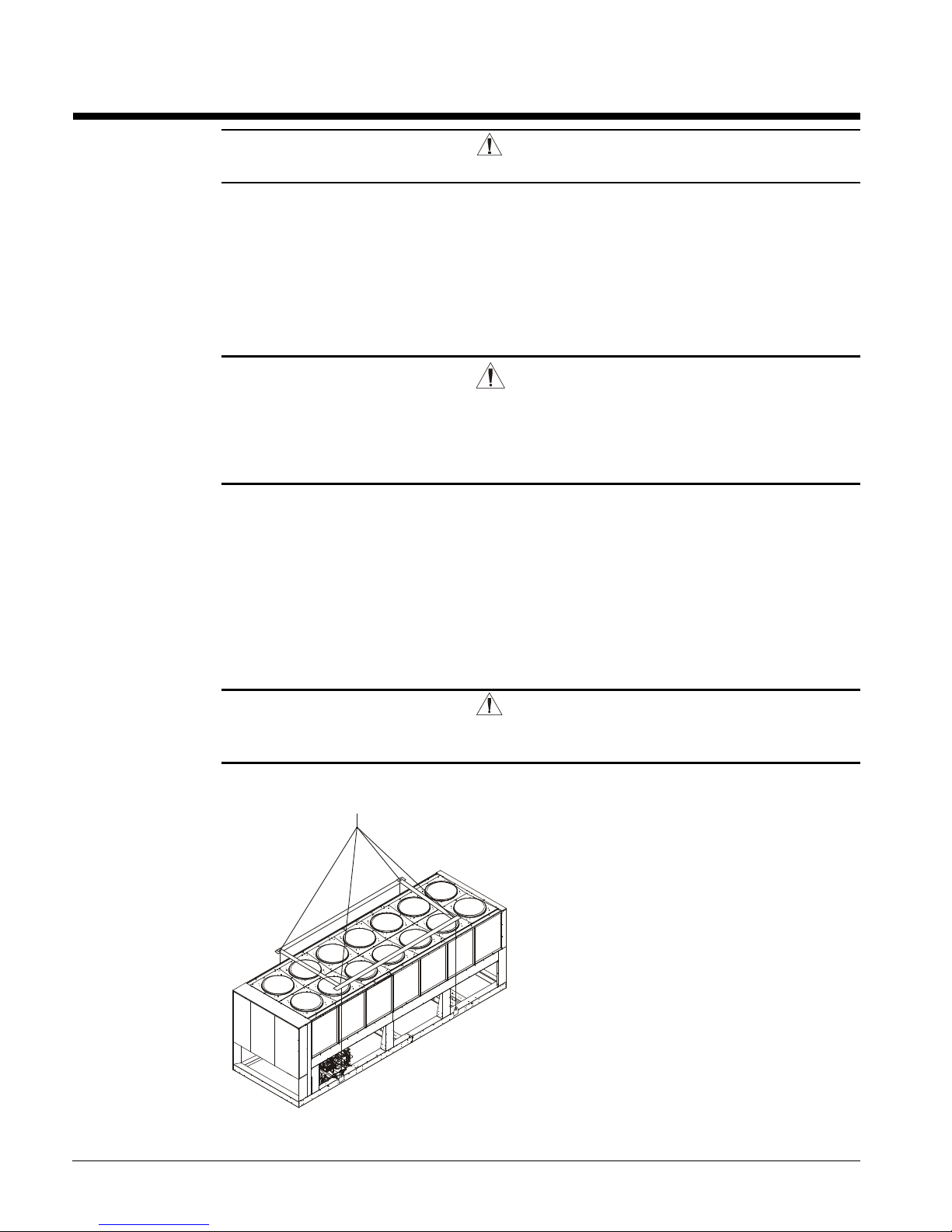

Handling

Avoid rough handling shock due to impact or dropping the unit. Do not push or pull the

unit.

WARNING

WARNING

Never allow any part of the unit to fall during unloading or moving, as this can result in

serious damage.

To lift the unit, lifting tabs with 2½" (64 mm) diameter holes are provided on the base of the

unit. All lifting holes must be used when lifting the unit. Spreader bars and cables should

be arranged to prevent damage to the condenser coils or unit cabinet (see Figure 1).

DANGER

Improper lifting or moving unit can result in property damage, severe

personal injury or death. Follow rigging and moving instructions carefully.

Figure 1, Required Lifting Method

NOTES:

1. All rigging points on a unit must be

used. See location and weights at

lifting points beginning on page 13 for a

specific size unit.

2. Crosswise and lengthwise spreader

bars must be used to avoid damage to

unit. Lifting cables from the unit

mounting holes up must be vertical.

3. The number of condenser sections, and

fans can vary from this diagram.

4 IMM AGS-2

Page 5

Location

Locate the unit carefully to provide proper airflow to the condenser. (See Figure 2 on page

6 for required clearances).

Due to the shape of the condenser coils on the AGS chillers, it is recommended that the unit

be oriented so that prevailing winds blow parallel to the unit length, thus minimizing the

wind effect on condensing pressure and performance. If low ambient temperature operation

is expected, optional louvers should be installed if the unit has no protection against

prevailing winds.

Using less clearance than shown in Figure 2 can cause discharge air recirculation to the

condenser and could have a significant detrimental effect on unit performance.

See Restricted Airflow beginning on page 7 for further information.

For pad-mounted units, it is recommended that the unit be raised a few inches with suitable

supports, located at least under the mounting locations, to allow water to drain from under

the unit and to facilitate cleaning under it

Service Access

Compressors, filter-driers, and manual liquid line shutoff valves are accessible on each side

or end of the unit. The evaporator heater is located on the barrel.

The control panels are located on the end of the chiller. The left-hand control box contains

the unit and circuit microprocessors as well as transformers, fuses and terminal. The righthand panel contains a circuit breaker and solid state starter for each compressor plus fuses,

fan VFD (optional) and fan contactors. A minimum of four feet of clearance is required in

front of the panels.

The side clearance required for airflow provides sufficient service clearance.

On all AGS units, the condenser fans and motors can be removed from the top of the unit.

The complete fan/motor assembly can be removed for service. The fan blade must be

removed for access to wiring terminals at the top of the motor.

WARNING

Disconnect, lockout and tag all power to the unit before servicing condenser fan

motors or compressors.

Failure to do so can cause bodily injury or death.

Do not block access to the sides or ends of the unit with piping or conduit. These areas

must be open for service access. Do not block any access to the control panels with a fieldmounted disconnect switches.

IMM AGS-2 5

Page 6

Clearance Requirements

5ft (1.5m)

5ft (1.5m)

3ft (1m) for service

Air Flo

w

No obstructions allowed

above unit at any heigh

t

See notes 2 & 4

concerning wall

height at unit sides.

6ft (1.8m)

6ft (1.8m)

Figure 2, Clearance Requirements, AGS 120C – AGS 210C

if open fence or 50% open wall

if solid wall (see note 3 for pit)

4ft (1.2m)

For electric

panel access

if open fence or 50% open wall

if solid wall (see note 3 for pit)

No obstructions.

Recommended area

required for unit

operation, air flow

and maintenance

access.

See Note 5

Wall or

Fence

Notes:

1. Minimum side clearance between two units is 12 feet (3.7 meters).

2. Unit must not be installed in a pit or enclosure that is deeper or taller than the height of the unit

unless extra clearance is provided per note 4.

3. Minimum clearance on each side is 8 feet (2.4 meters) when installed in a pit no deeper than the

unit height.

4. Minimum side clearance to a side wall or building taller than the unit height is 6 feet (1.8 meters),

provided no solid wall above 6 feet (1.8 meters) is closer than 12 feet (3.7 meters) to the opposite

side of the unit.

5. Do not mount electrical conduits where they can block service access to compressor controls,

refrigerant driers or valves.

6. There must be no obstruction of the fan discharge.

7. Field installed switches must not interfere with service access or airflow.

8. The evaporator can be removed from the side of the unit and may require the temporary removal

of a coil section support post. See dimension drawings beginning on page 29 for details.

9. If the airflow clearances cannot be met, see the following pages on Restricted Airflow.

6 IMM AGS-2

Page 7

Restricted Airflow

General

The clearances required for design operation of AGS air-cooled condensers are described in

the previous section. Occasionally, these clearances cannot be maintained due to site

restrictions such as units being too close together or a fence or wall restricting airflow, or

both.

The McQuay AGS chillers have several features that can mitigate the problems attributable

to restricted airflow.

• The shape of the condenser section allows inlet air for these coils to come in from both

sides and the bottom. All the coils on one side serve one compressor. Every

compressor always has its own independent refrigerant circuit.

• The MicroTech II control is proactive in response to off-design conditions. In the

case of single or compounded influences restricting airflow to the unit, the

microprocessor will act to keep the compressor(s) running (at reduced capacity) as long

as possible, rather than allowing a shut-off on high discharge pressure.

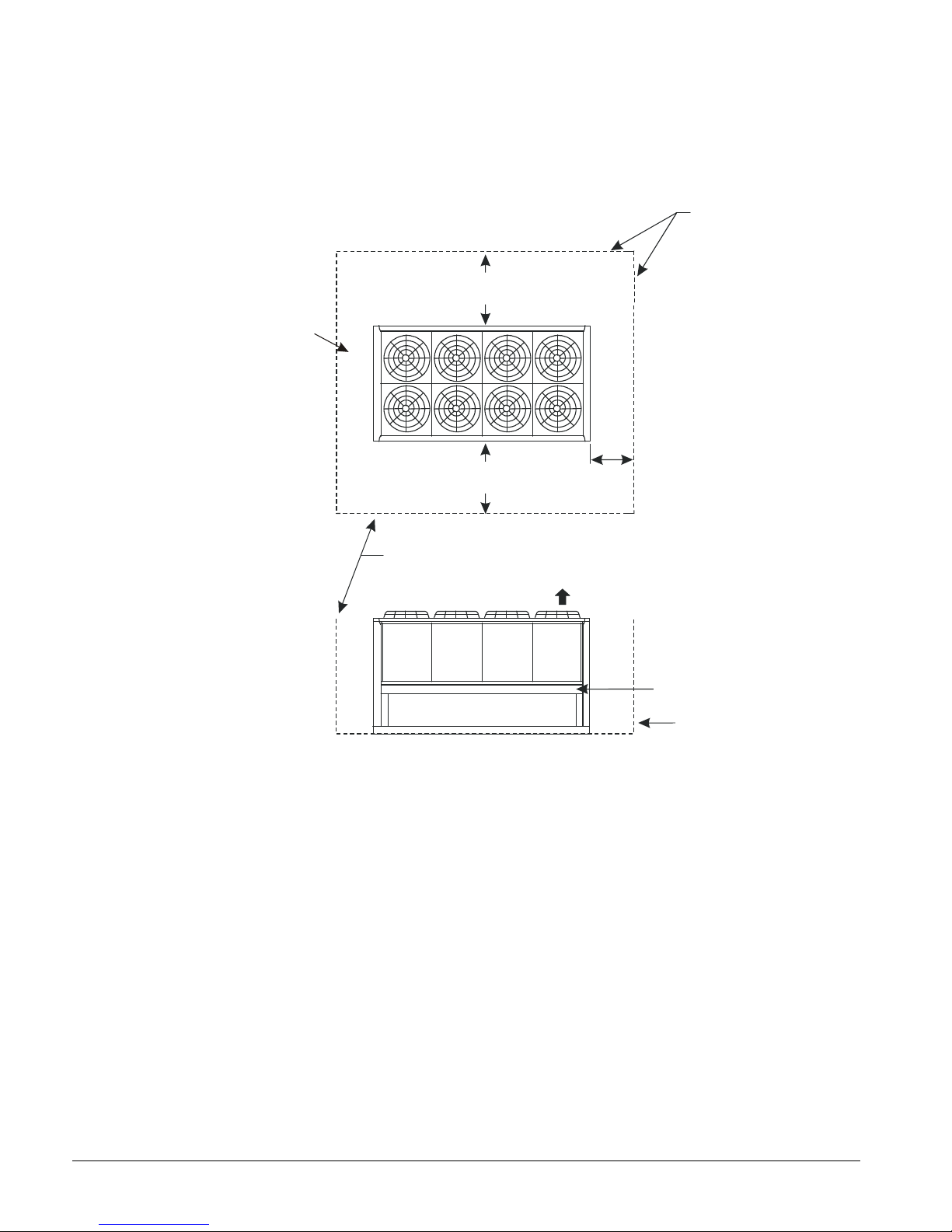

Figure 3, Coil and Fan Arrangement

The following sections discuss the most common situations of condenser air restriction and

give capacity and power adjustment factors for each. Note that in unusually severe

conditions, the MicroTech II controller will adjust the unit operation to remain online until

a less severe condition is reached.

IMM AGS-2 7

Page 8

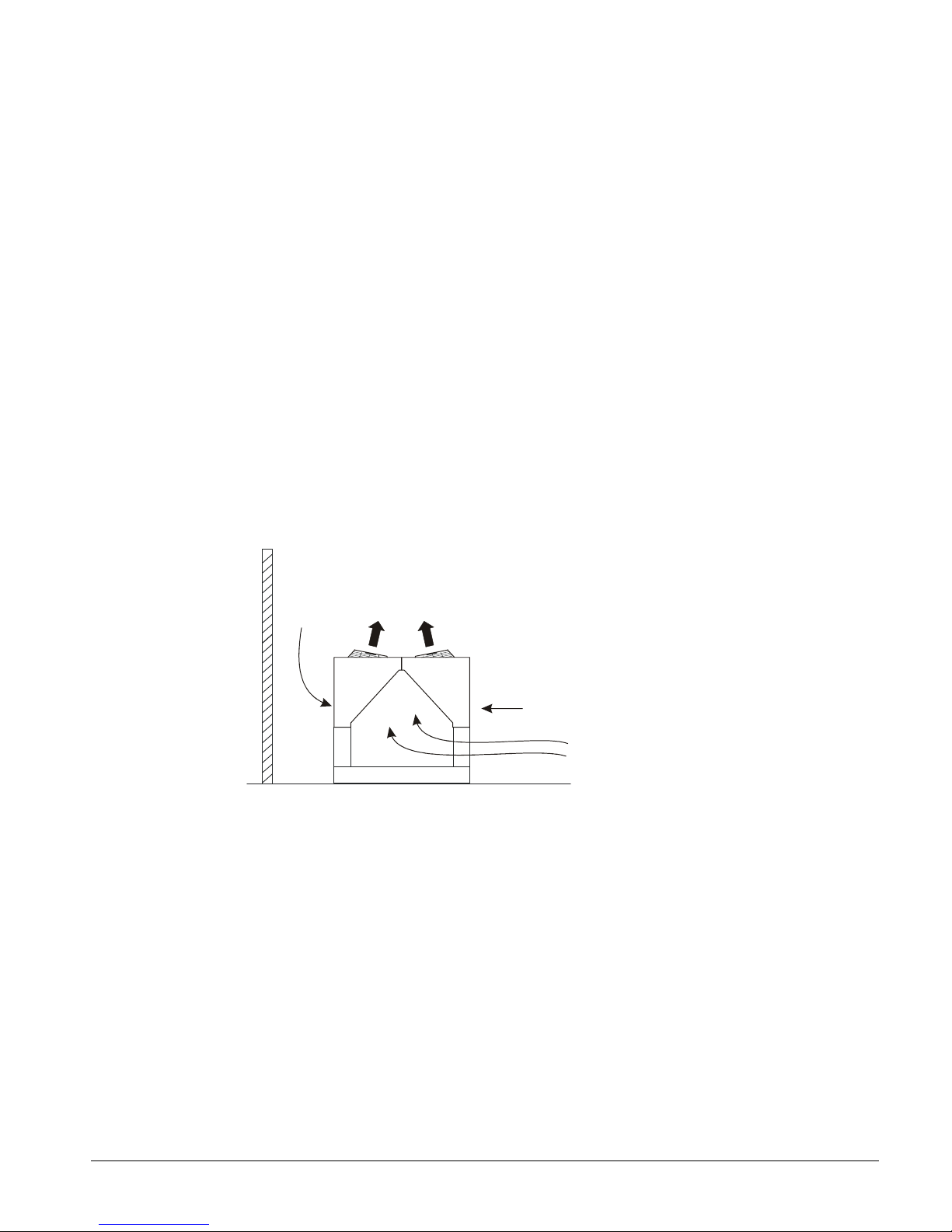

Case 1, Building or Wall on One Side of One Unit

5 ft.

(1.5m)

(1.8m)

The existence of a screening wall, or the wall of a building, in close proximity to an aircooled chiller is common in both rooftop and ground level applications. Hot air

recirculation on the coils adjoining the wall will increase compressor discharge pressure,

decreasing capacity and increasing power consumption.

When close to a wall, it is desirable to place chillers on the north or east side of them. It is

also desirable to have prevailing winds blowing parallel to the unit’s long axis. The worst

case is to have wind blowing hot discharge air into the wall.

Figure 4, Unit Adjacent to Wall

D

H

Figure 5, Adjustment Factors

(1.5m)

6 ft.

(1.8m)

5 ft.

6 ft.

8 IMM AGS-2

Page 9

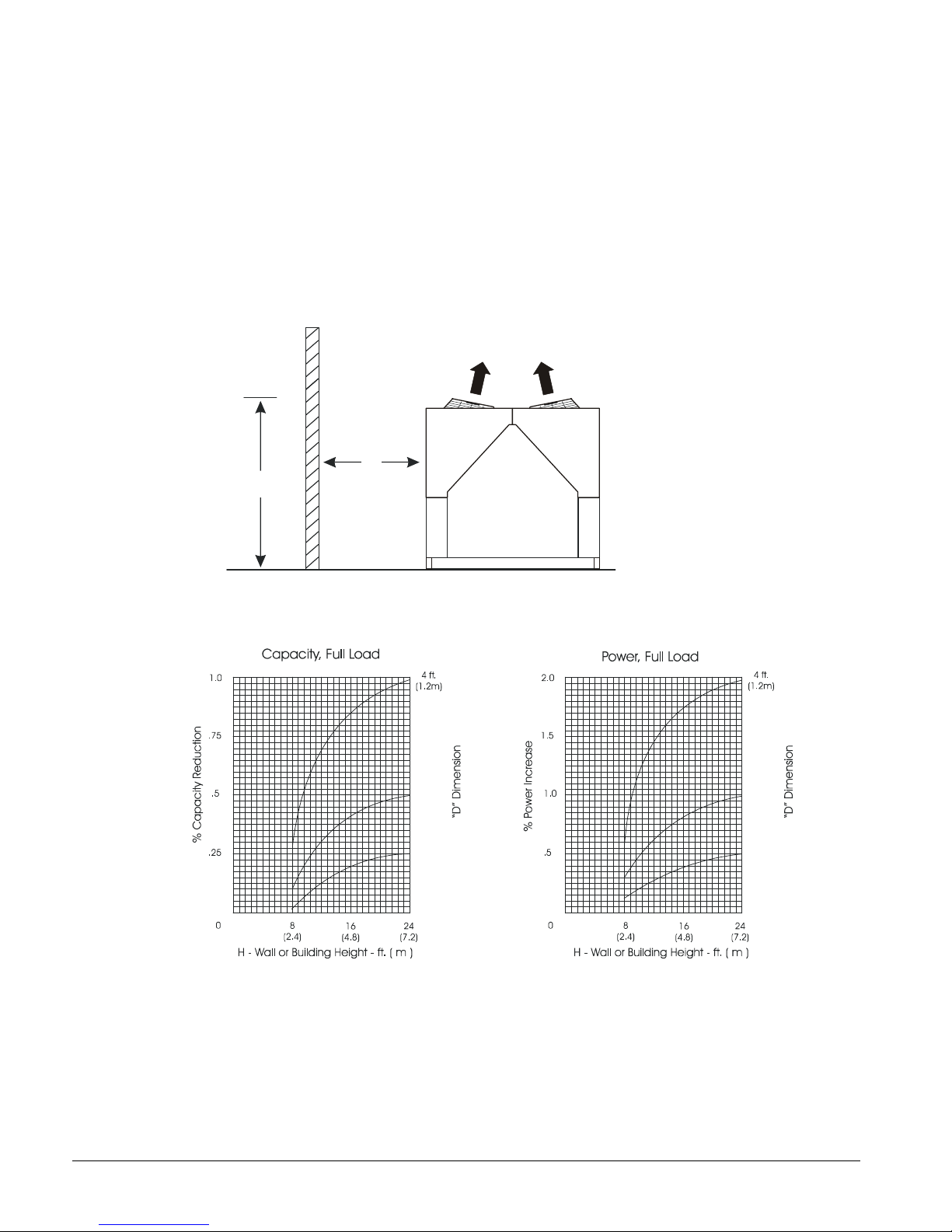

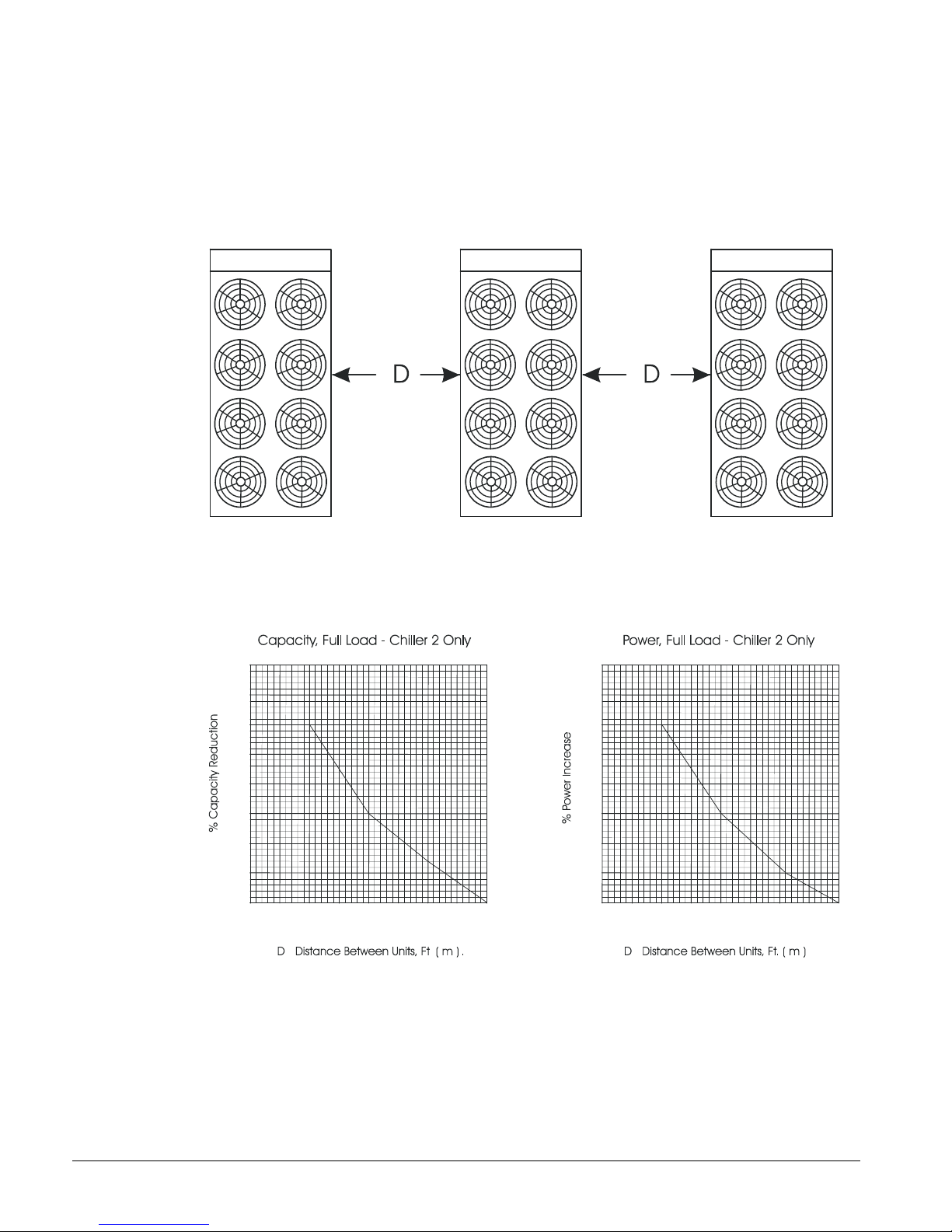

Case 2, Two Units Side By Side

Two or more units sited side by side are common. If spaced closer than 12 feet (3.7 meters), or 8

feet (2.5 meters), depending on size, it is necessary to adjust the performance of each unit.

Circuits adjoining each other are affected. NOTE: This case applies only to two units side by side.

See Case 3 for three or more parallel units. If one of the two units also has a wall adjoining it, see

Case 1. Add the two adjustment factors together and apply to the unit located between the wall

and the other unit.

Mounting units end to end will not necessitate adjusting performance. Depending on the actual

arrangement, sufficient space must be left between the units for access to the control panel door

opening and/or evaporator tube removal. See “Clearance” section of this guide for requirements

for specific units.

Figure 6, Two Units Side by Side

Figure 7, Adjustment Factor

3.0

2.0

1.0

0

9

(2.7)

10

(3.0)

11

(3.3)

12

(3.6)

6.0

4.0

2.0

0

9

(2.7)

10

(3.0)

11

(3.3)

12

(3.6)

IMM AGS-2 9

Page 10

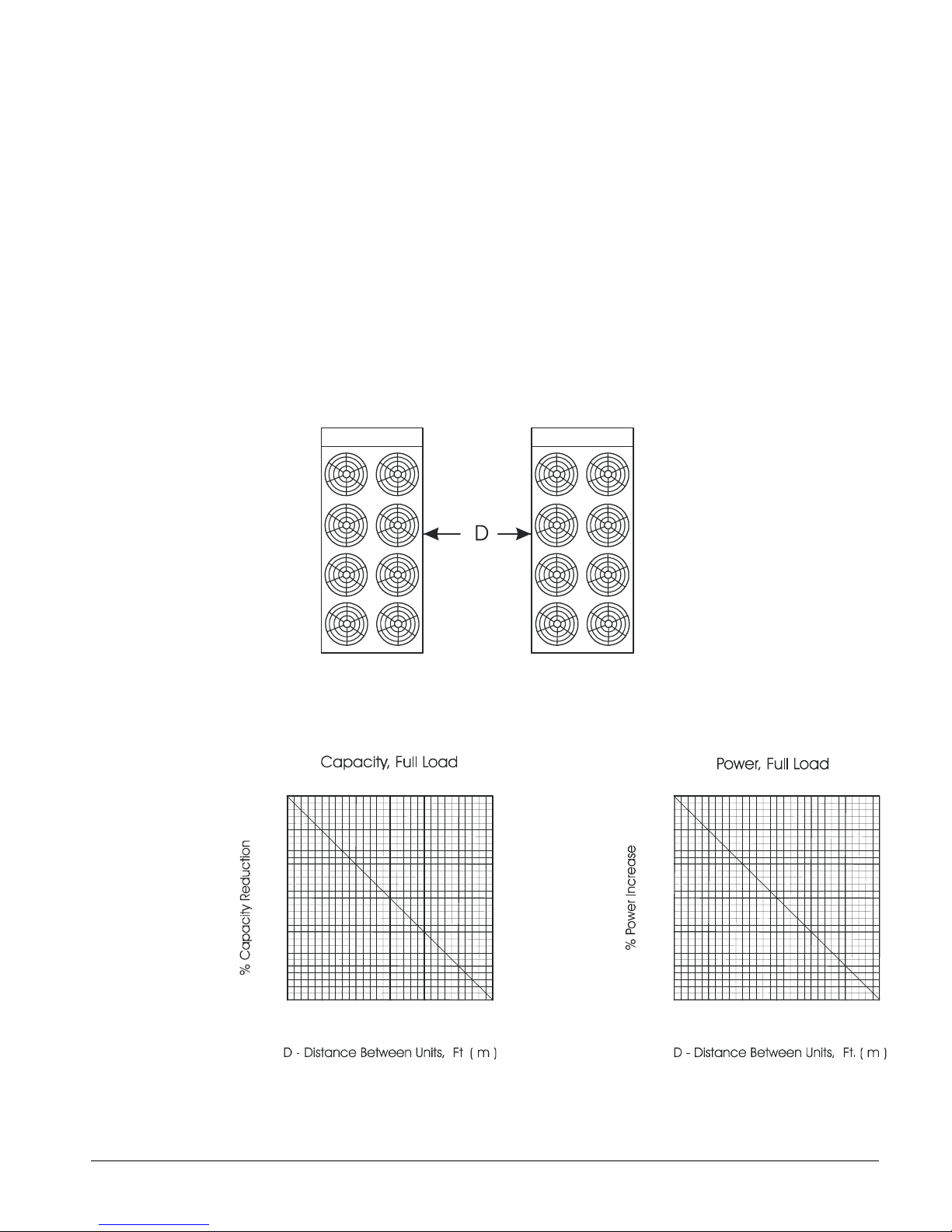

Case 3, Three or More Units Side By Side

When three or more units are side by side, the outside units (chillers 1 and 3 in this case) are

influenced by the middle unit only on their inside circuits. Their adjustment factors will be the

same as Case 2. All inside units (only chiller 2 in this case) are influenced on both sides and must

be adjusted by the factors shown below.

Figure 8, Three or More Units

Chiller 1 Chiller 2 Chiller 3

Figure 9, Adjustment Factor

4.0

3.0

2.0

1.0

0

15

(4.6)

16

(4.9)

17

(5.2)

18

(5.5)

8.0

6.0

4.0

2.0

0

15

(4.6)

16

(4.9)

17

(5.2)

18

(5.5)

10 IMM AGS-2

Page 11

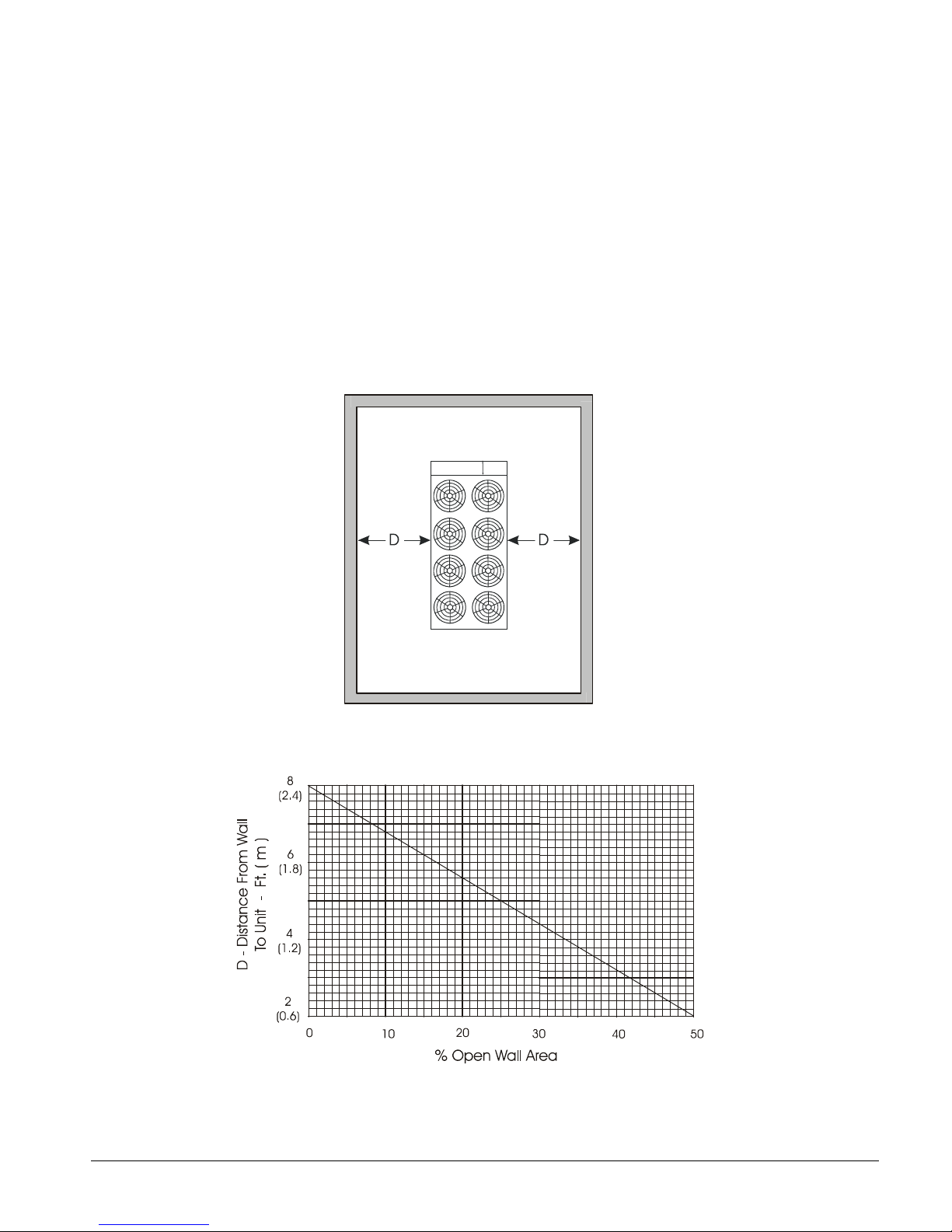

Case 4, Open Screening Walls

Decorative screening walls are often used to help conceal a unit either on grade or on a rooftop.

These walls should be designed such that the combination of their open area and distance from the

unit do not require performance adjustment. It is assumed that the wall height is equal to or less

than the unit height when mounted on its base support. This is usually satisfactory for concealment.

If the wall height is greater than the unit height, see Case 5, Pit Installation.

The distance from the ends of the unit to the end walls must be sufficient for service, opening

control panel doors, and pulling evaporator tubes, as applicable.

If each side wall is a different distance from the unit, the distances can be averaged, providing either

wall is not less than 8 feet (2.4 meters) from the unit. For example, do not average 4 feet and 20

feet to equal 12 feet.

Figure 10, Open Screening Walls

Figure 11, Wall Free Area vs. Distance

IMM AGS-2 11

Page 12

Case 5, Pit/Solid Wall Installation

Pit installations can cause operating problems and great care must be exercised if they are

to be used on an installation. Recirculation and restriction can both occur. A solid wall

surrounding a unit is substantially the same as a pit and the data presented in this case

should be used.

Steel grating is sometimes used to cover a pit to prevent accidental falls or trips into the pit.

The grating material and installation design must be strong enough to prevent such

accidents, yet provide abundant open area or serious recirculation problems will occur.

Have any pit installation reviewed by the McQuay sales office prior to installation to

discuss whether it has sufficient airflow characteristics. The installation design engineer

must approve the work and is responsible for design criteria.

Figure 12, Pit Installation

Figure 13, Adjustment Factor

12 IMM AGS-2

Page 13

Vibration Isolators

“G”

“E”

“F”

“D”

“C”

“A”

“B”

COG

44.00

“CC”

MM

Vibration isolators are recommended for all roof-mounted installations or wherever vibration

transmission is a consideration. Initially installed the unit on shims or blocks at the illustrated "free

height" of the isolator that is six inches for the McQuay isolators shown. When all piping, wiring,

flushing, charging, etc. is complete, adjust the springs upward to load them and to provide clearance

to free the blocks, which are then removed.

Installation of spring isolators requires flexible pipe connections and at least three feet of conduit

flex tie-ins. Support piping and conduit independently from the unit to not stress connections.

There are separate weight and isolator tables for copper fin coils. All other coil types, such as

ElectroFin and Blackfin, use the aluminum fin data.

Isolator bolting: the unit base is an enclosed box design and may have six or ten mounting

locations, depending on the date of manufacture. Mounting locations M1 and M2 at dimension “C”

and locations M5 and M6 at dimension “E” are not used. Locations MM1, MM2, M3, M4, MM5

and MM6 have access holes on top of the base, above the lower mounting holes and should be used

for all isolator types. One simple method of bolting the base to the isolators (if required) is to

remove the short threaded studs, usually provided with isolators, and replace them with eight-inch

threaded rod. The rod will extend above the top of the base and a washer and nut can then be easily

attached.

Figure 14, Mounting and Lifting Dimensions

M6

M5

MM5

L3

L4

“EE”

M4

M3

MM2MM6

L2

L1

M2

1

M1

X

O

B

L

O

R

T

N

O

C

330712801D0400_R0A

NOTE: Dimensions are on the following page.

IMM AGS-2 13

Page 14

Table 1, Dimensions

MODEL A B C CC D E EE F G

120 36.00 136.60 12.00 21.00 57.30 174.60 165.60 71.49 186.60

125 36.00 168.85 12.00 21.00 69.25 212.80 203.80 86.54 224.80

130 36.00 136.60 12.00 21.00 57.30 174.60 165.60 71.49 186.60

135 36.00 168.85 12.00 21.00 69.25 212.80 203.80 86.54 224.80

140 36.00 136.60 12.00 21.00 57.30 174.60 165.80 71.49 186.60

145 36.00 168.85 12.00 21.00 69.25 212.80 203.80 86.66 224.80

160 36.00 136.60 12.00 21.00 57.30 174.60 165.60 74.37 186.60

165 36.00 189.00 12.00 21.00 84.00 251.00 242.00 105.17 263.00

170 36.00 168.85 12.00 21.00 69.25 212.80 203.80 89.65 224.80

175 36.00 189.00 12.00 21.00 84.00 251.00 242.00 105.17 263.00

180 36.00 168.85 12.00 21.00 69.25 212.80 203.80 89.65 224.80

190 36.00 168.85 12.00 21.00 69.25 212.80 203.80 89.65 224.80

195 36.00 189.00 12.00 21.00 84.00 251.00 242.00 105.17 263.00

210 36.00 189.00 12.00 21.00 84.00 251.00 242.00 105.17 263.00

NOTES:

1. Use location “C”, not “CC”, for mounting.

2. Center of gravity (F) is calculated from shipping weight

3. Dimensions are in inches.

4. Mounting holes are 0.75 inch diameter and have center located 2.0 inches from the outside edge.

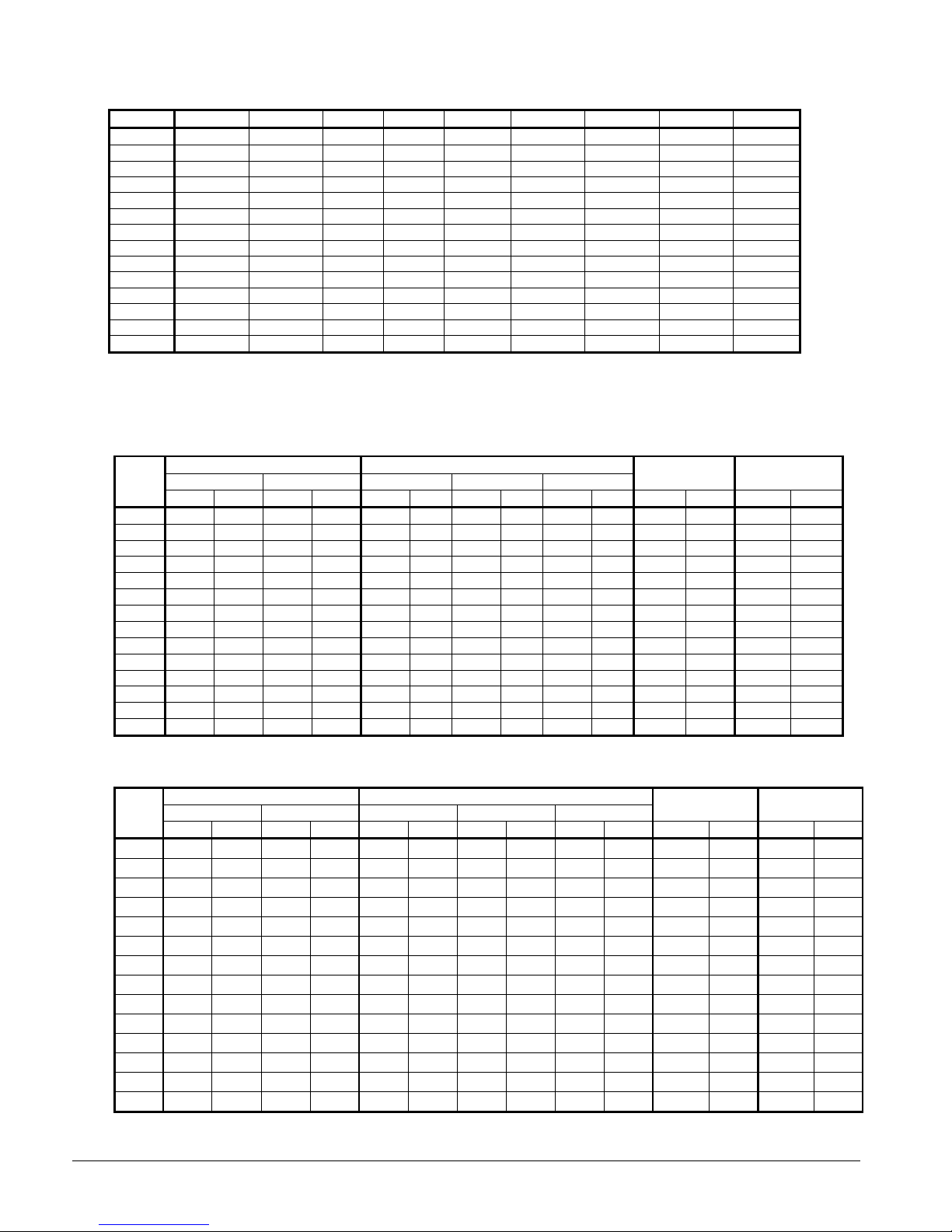

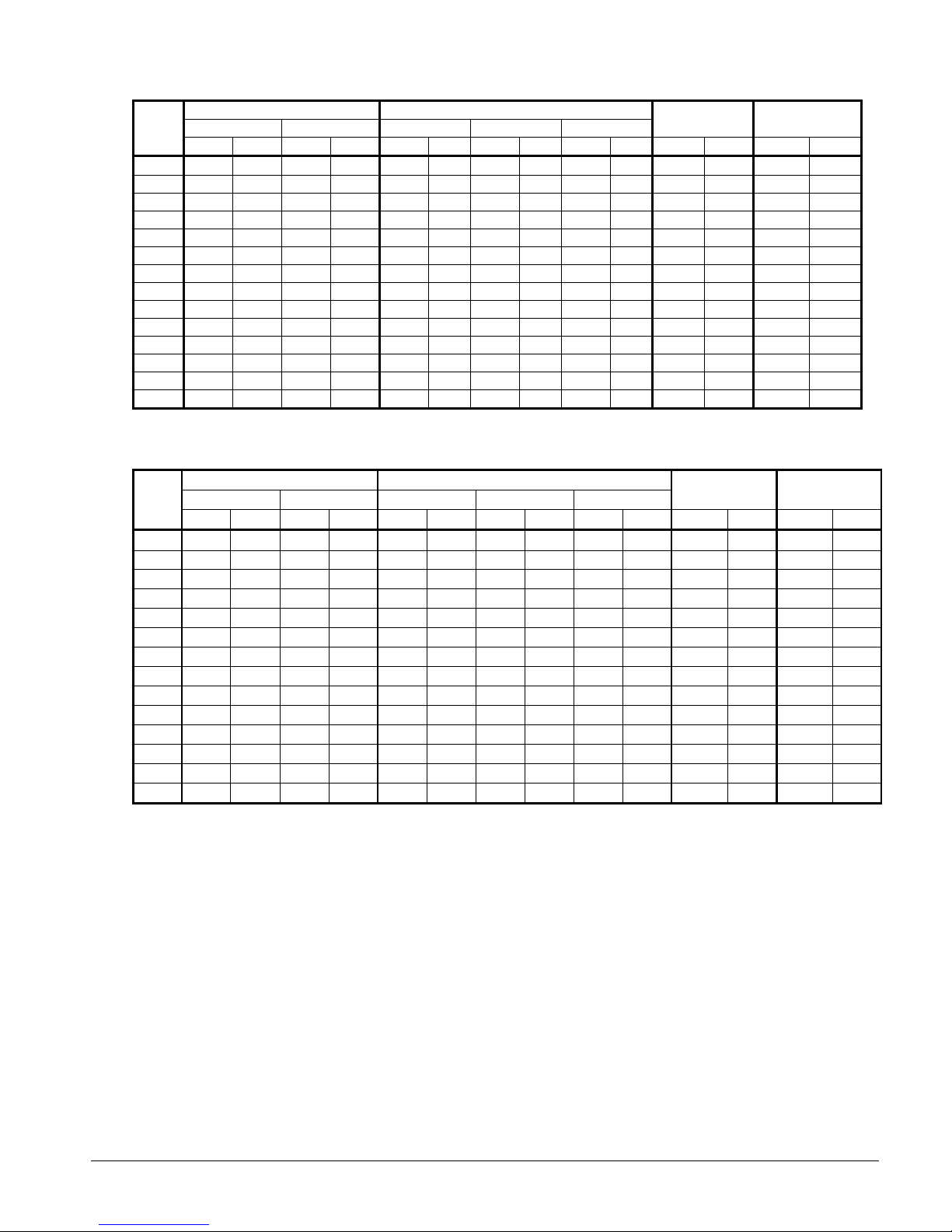

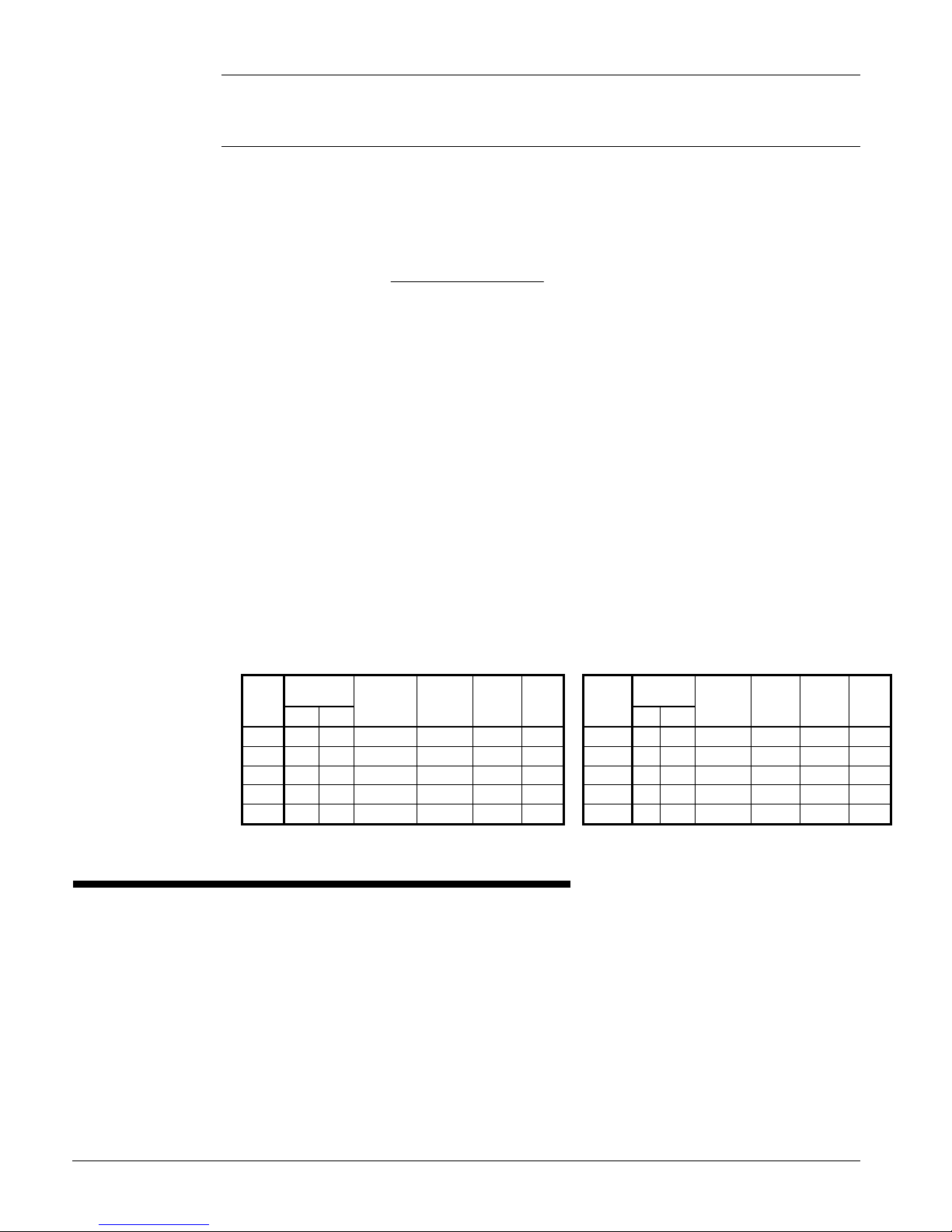

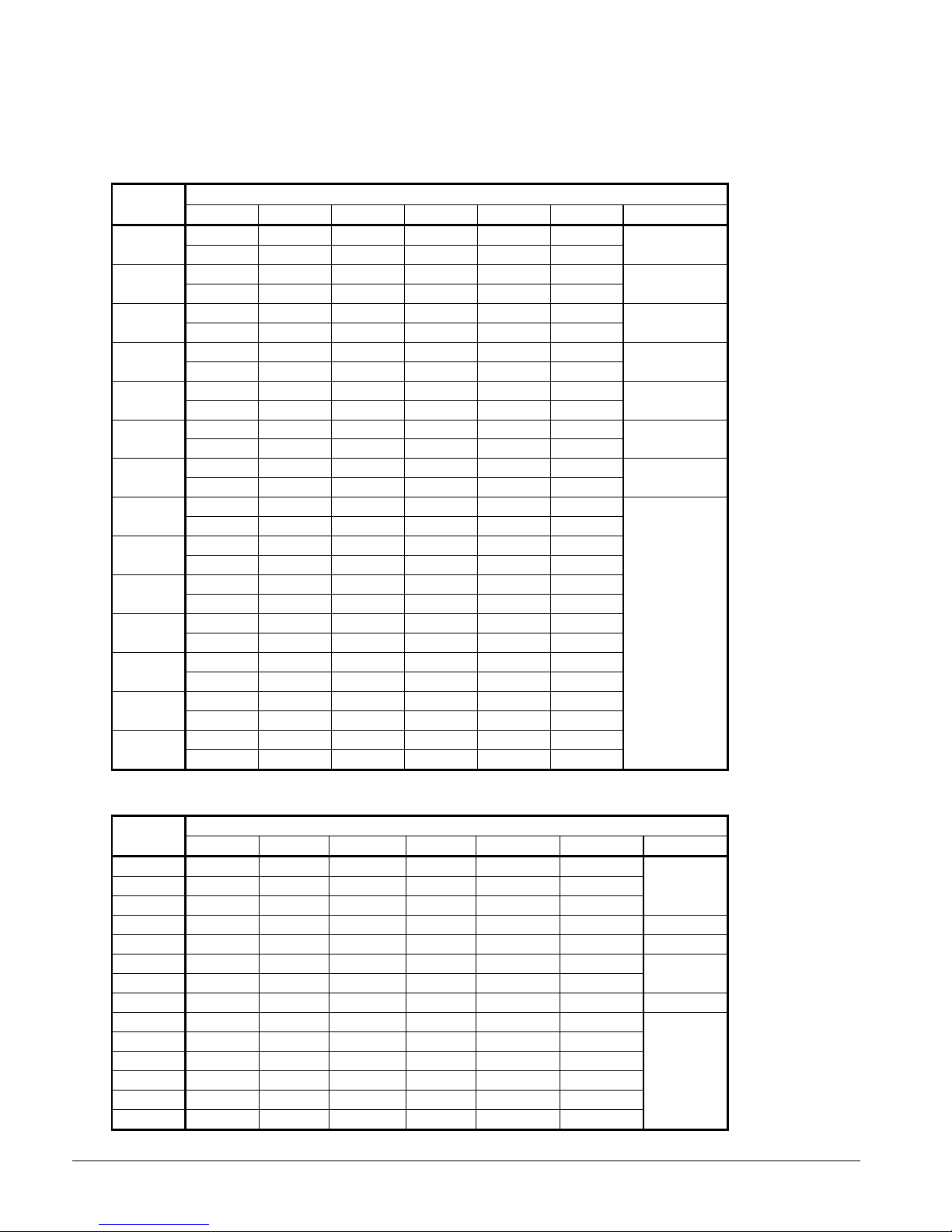

Table 2, Lifting and Mounting Weights, Packaged, Aluminum Fins, AGS-CS/H

AGS

120 2919 1324 1591 722 1749 793 1645 746 1333 605 9452 4287 9020 4091

125 3161 1434 1941 880 1996 905 1887 856 1583 718 10930 4958 10205 4629

130 2919 1324 1591 722 1749 793 1645 746 1333 605 9452 4287 9020 4091

135 3161 1434 1941 880 1996 905 1887 856 1583 718 10930 4958 10205 4629

140 2919 1324 1591 722 1749 793 1645 746 1333 605 9452 4287 9020 4091

145 3075 1395 1896 860 1916 869 1810 821 1517 688 10485 4756 9942 4510

160 2933 1330 1809 821 1802 817 1742 790 1561 708 10209 4631 9484 4302

165 3017 1369 2489 1129 2137 969 2038 924 1789 811 11928 5411 11011 4995

170 3269 1483 2007 910 1945 882 1904 864 1790 812 11277 5115 10552 4786

175 3017 1369 2489 1129 2137 969 2038 924 1789 811 11928 5411 11011 4995

180 3269 1483 2007 910 1945 882 1904 864 1790 812 11277 5115 10552 4786

190 3269 1483 2007 910 1945 882 1904 864 1790 812 11277 5115 10552 4786

195 3017 1369 2489 1129 2137 969 2038 924 1789 811 11928 5411 11011 4995

210 3017 1369 2489 1129 2137 969 2038 924 1789 811 11928 5411 11011 4995

Lifting Weights Mounting Weights

L1, L2 L3, L4 MM1, MM2 M3, M4 MM5, MM6

lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg

Operating

Weight

Shipping

Weight

Table 3, Lifting and Mounting Weights, Packaged Copper Fins, AGS-CS/H

AGS

120

125

130

135

140

145

160

165

170

175

180

190

195

210

Lifting Weights Mounting Weights

L1, L2 L3, L4 MM1, MM2 M3, M4 MM5, MM6

lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg

3557 1613 2229 1011 2174 986 2070 939 1758 798 10728 4866 10296 4670

3959 1796 2739 1242 2528 1147 2419 1097 2115 959 12526 5682 11801 5353

3557 1613 2229 1011 2174 986 2070 939 1758 798 10728 4866 10296 4670

3959 1796 2739 1242 2528 1147 2419 1097 2115 959 12526 5682 11801 5353

3557 1613 2229 1011 2174 986 2070 939 1758 798 10728 4866 10296 4670

3873 1757 2694 1222 2448 1110 2342 1062 2049 929 12081 5480 11538 5234

3571 1620 2447 1110 2227 1010 2167 983 1986 901 11485 5210 10760 4881

3975 1803 3447 1564 2776 1259 2677 1214 2428 1101 13844 6280 12927 5864

4067 1845 2805 1272 2477 1124 2436 1105 2322 1053 12873 5839 12148 5510

3975 1803 3447 1564 2776 1259 2677 1214 2428 1101 13844 6280 12927 5864

4067 1845 2805 1272 2477 1124 2436 1105 2322 1053 12873 5839 12148 5510

4067 1845 2805 1272 2477 1124 2436 1105 2322 1053 12873 5839 12148 5510

3975 1803 3447 1564 2776 1259 2677 1214 2428 1101 13844 6280 12927 5864

3975 1803 3447 1564 2776 1259 2677 1214 2428 1101 13844 6280 12927 5864

Operating

Weight

Shipping

Weight

14 IMM AGS-2

Page 15

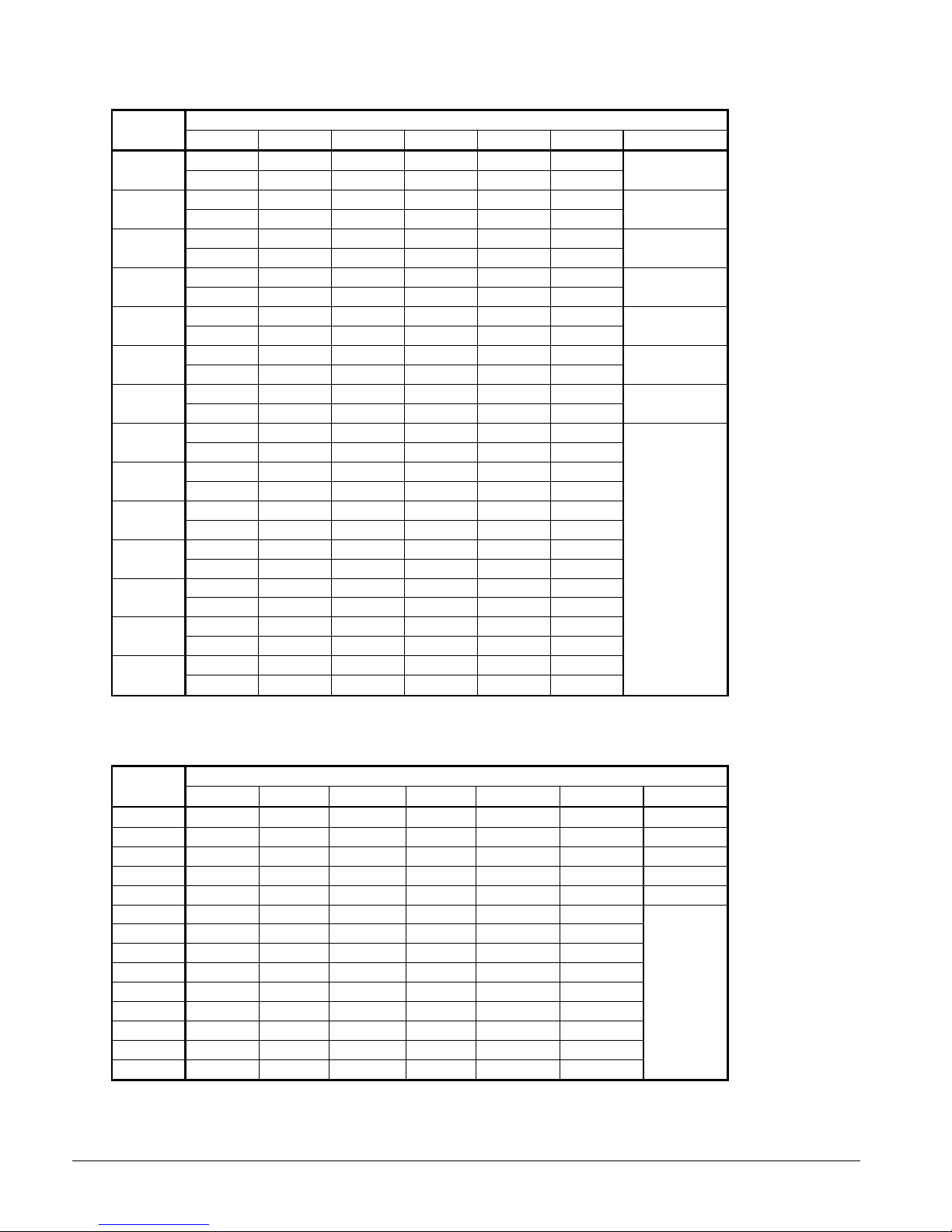

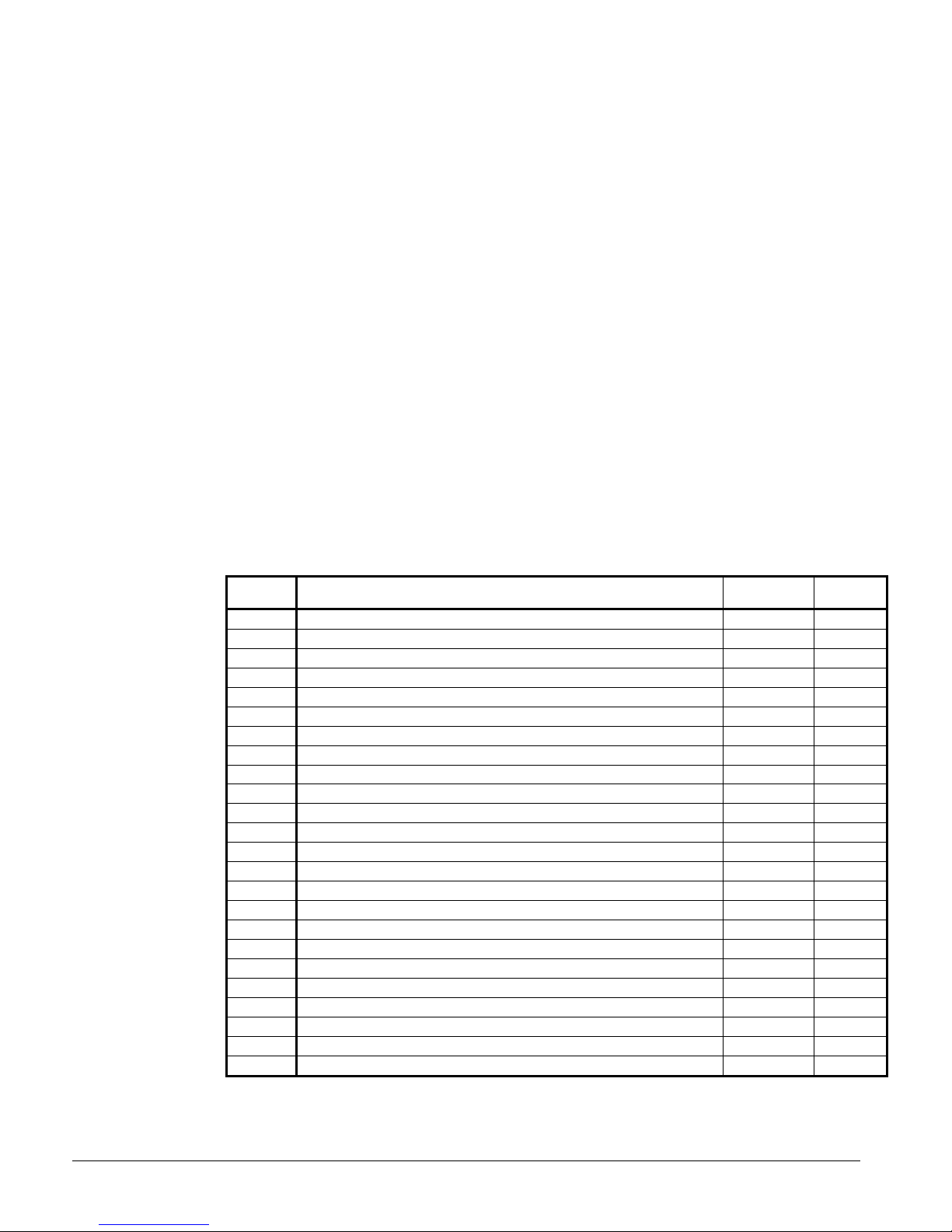

Table 4, Lifting & Mounting Weights, Remote Evaporator, Aluminum Fins, AGS-CM/B

AGS

120

125

130

135

140

145

160

165

170

175

180

190

195

210

Lifting Weights Mounting Weights

L1, L2 L3, L4 MM1, MM2 M3, M4 MM5, MM6

lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg

3029 1374 1021 463 1780 807 1521 690 749 340 8100 3674 8100 3674

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3029 1374 1021 463 1780 807 1521 690 749 340 8100 3674 8100 3674

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3029 1374 1021 463 1780 807 1521 690 749 340 8100 3674 8100 3674

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3029 1374 1021 463 1780 807 1521 690 749 340 8100 3674 8100 3674

3196 1450 1590 721 2099 952 1764 800 923 419 9571 4341 9571 4341

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3196 1450 1590 721 2099 952 1764 800 923 419 9571 4341 9571 4341

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3169 1437 1307 593 1938 879 1659 753 879 399 8952 4061 8952 4061

3196 1450 1590 721 2099 952 1764 800 923 419 9571 4341 9571 4341

3196 1450 1590 721 2099 952 1764 800 923 419 9571 4341 9571 4341

Operating

Weight

Shipping

Weight

Table 5, Lifting & Mounting Weights, Remote Evaporator, Copper Fins, AGS-CM/B

AGS

120

125

130

135

140

145

160

165

170

175

180

190

195

210

Lifting Weights Mounting Weights

L1, L2 L3, L4 MM1, MM2 M3, M4 MM5, MM6

lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg lbs kg

3667 1663 1659 753 2205 1000 1946 883 1174 533 9376 4253 9376 4253

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

3667 1663 1659 753 2205 1000 1946 883 1174 533 9376 4253 9376 4253

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

3667 1663 1659 753 2205 1000 1946 883 1174 533 9376 4253 9376 4253

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

3667 1663 1659 753 2205 1000 1946 883 1174 533 9376 4253 9376 4253

4154 1884 2548 1156 2738 1242 2403 1090 1562 708 11487 5211 11487 5211

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

4154 1884 2548 1156 2738 1242 2403 1090 1562 708 11487 5211 11487 5211

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

3967 1799 2105 955 2470 1120 2191 994 1411 640 10548 4785 10548 4785

4154 1884 2548 1156 2738 1242 2403 1090 1562 708 11487 5211 11487 5211

4154 1884 2548 1156 2738 1242 2403 1090 1562 708 11487 5211 11487 5211

Operating

Weight

Shipping

Weight

IMM AGS-2 15

Page 16

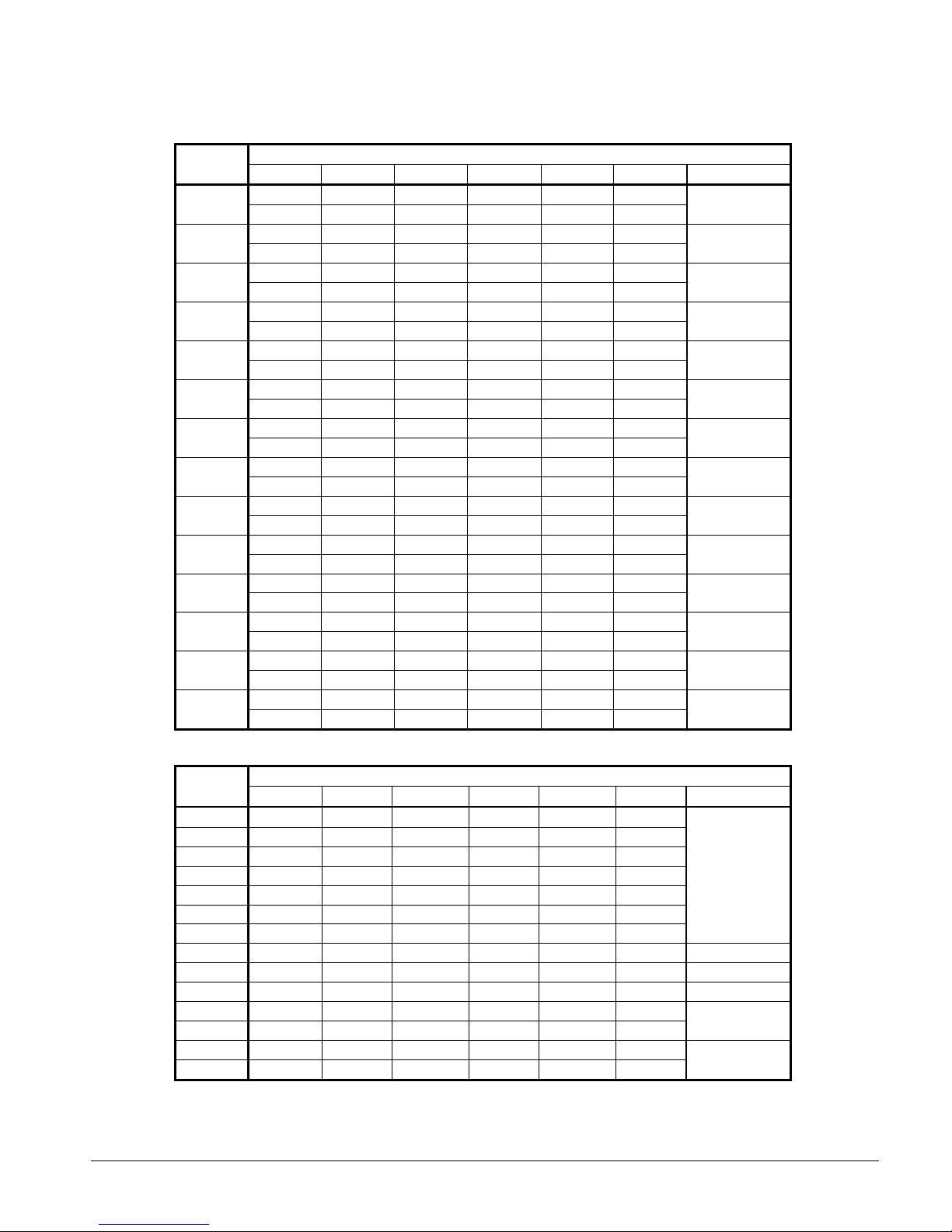

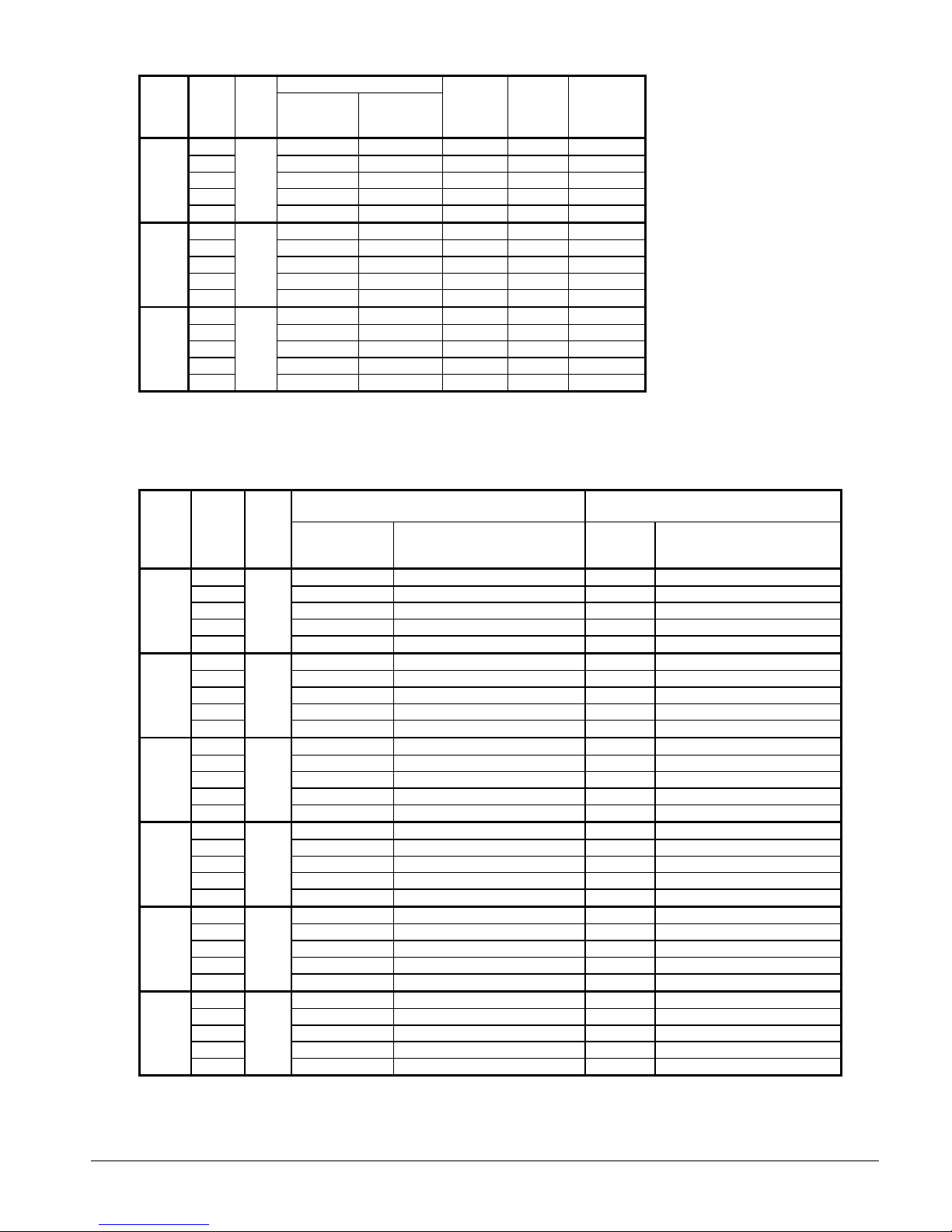

Table 6, Spring Vibration Isolators, Aluminum Fin, AGS-CS/H

AGS

Model

120

125

130

135

140

145

160

165

170

175

180

190

195

210

M1 M2 M3 M4 M5 M6 Kit Number

CP2-28 CP2-28 CP2-28 CP2-28 CP2-27 CP2-27

GREEN GREEN GREEN GREEN ORANGE ORANGE

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-28 CP2-28 CP2-28 CP2-28 CP2-27 CP2-27

GREEN GREEN GREEN GREEN ORANGE ORANGE

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-28 CP2-28 CP2-28 CP2-28 CP2-27 CP2-27

GREEN GREEN GREEN GREEN ORANGE ORANGE

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-28 CP2-28 CP2-28 CP2-28 CP2-28 CP2-28

GREEN GREEN GREEN GREEN GREEN GREEN

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

Mounting Location

330904101

330904102

330904101

330904102

330904101

330904102

330904103

330904104

Table 7, Neoprene-in-Shear Isolators, Aluminum Fin, AGS-CS/H

AGS

Model

120

125

130

135

140

145

160

165

170

175

180

190

195

210

M1 M2 M3 M4 M5 M6 Kit Number

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, BLACK RP-4, BLACK 330904111

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED 330904112

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, BLACK RP-4, BLACK 330904111

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED 330904112

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, BLACK RP-4, BLACK 330904111

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

Mounti ng Location ( See Footprint D ra wings, page 13)

330904112

16 IMM AGS-2

Page 17

Table 8, Spring Vibration Isolators, Copper Fin, AGS-CS/H

AGS

Model

120

125

130

135

140

145

160

165

170

175

180

190

195

210

M1 M2 M3 M4 M5 M6 Kit Number

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-32 CP2-32 CP2-31 CP2-31 CP2-31 CP2-31

WHITE WHITE GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-32 CP2-32 CP2-31 CP2-31 CP2-31 CP2-31

WHITE WHITE GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-28 CP2-28

GRAY GRAY GRAY GRAY GREEN GREEN

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-31 CP2-31 CP2-31 CP2-31 CP2-31 CP2-31

GRAY GRAY GRAY GRAY GRAY GRAY

CP2-32 CP2-32 CP2-32 CP2-32 CP2-31 CP2-31

WHITE WHITE WHITE WHITE GRAY GRAY

CP2-32 CP2-32 CP2-31 CP2-31 CP2-31 CP2-31

WHITE WHITE GRAY GRAY GRAY GRAY

CP2-32 CP2-32 CP2-32 CP2-32 CP2-31 CP2-31

WHITE WHITE WHITE WHITE GRAY GRAY

CP2-32 CP2-32 CP2-31 CP2-31 CP2-31 CP2-31

WHITE WHITE GRAY GRAY GRAY GRAY

CP2-32 CP2-32 CP2-31 CP2-31 CP2-31 CP2-31

WHITE WHITE GRAY GRAY GRAY GRAY

CP2-32 CP2-32 CP2-32 CP2-32 CP2-31 CP2-31

WHITE WHITE WHITE WHITE GRAY GRAY

CP2-32 CP2-32 CP2-32 CP2-32 CP2-31 CP2-31

WHITE WHITE WHITE WHITE GRAY GRAY

Mounting Location

330904102

330904105

330904102

330904105

330904102

330904104

330904104

330904106

330904105

330904106

330904105

330904105

330904106

330904106

Table 9, Neoprene-in-Shear Isolators, Copper Fin, AGS-CS/H

AGS

Model

120

125

130

135

140

145

160

165

170

175

180

190

195

210

M1 M2 M3 M4 M5 M6 Kit Number

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, GRN RP-4, GRN RP-4, GRN RP-4, GRN RP-4, RED RP-4, RED 330904113

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED 330904112

RP-4, GRN RP-4, GRN RP-4, GRN RP-4, GRN RP-4, RED RP-4, RED 330904113

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED RP-4, RED

RP-4, GRN RP-4, GRN RP-4, GRN RP-4, GRN RP-4, RED RP-4, RED

RP-4, GRN RP-4, GRN RP-4, GRN RP-4, GRN RP-4, RED RP-4, RED

IMM AGS-2 17

Mounti ng Location ( See Footprint D ra wing, pg. 13)

330904112

330904112

330904113

Page 18

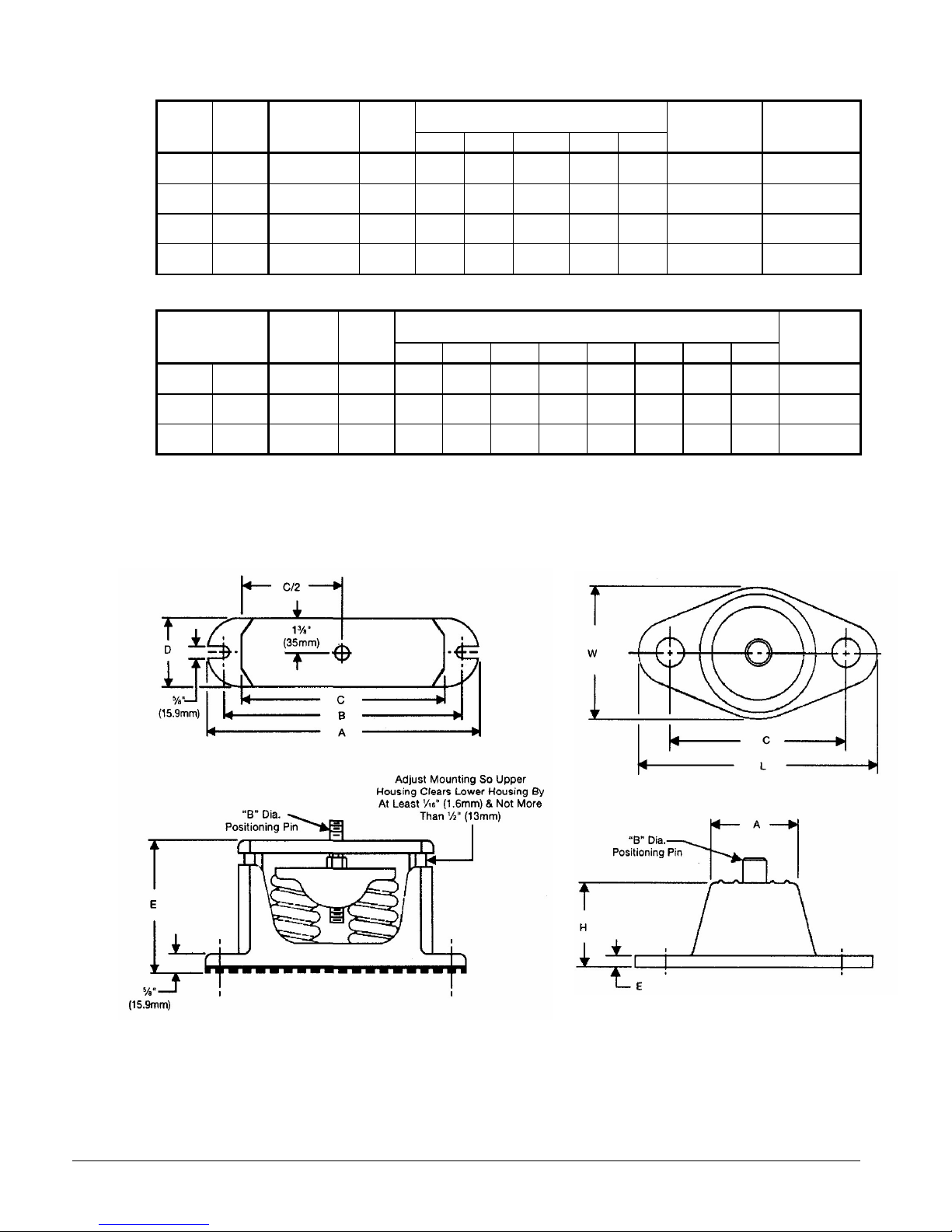

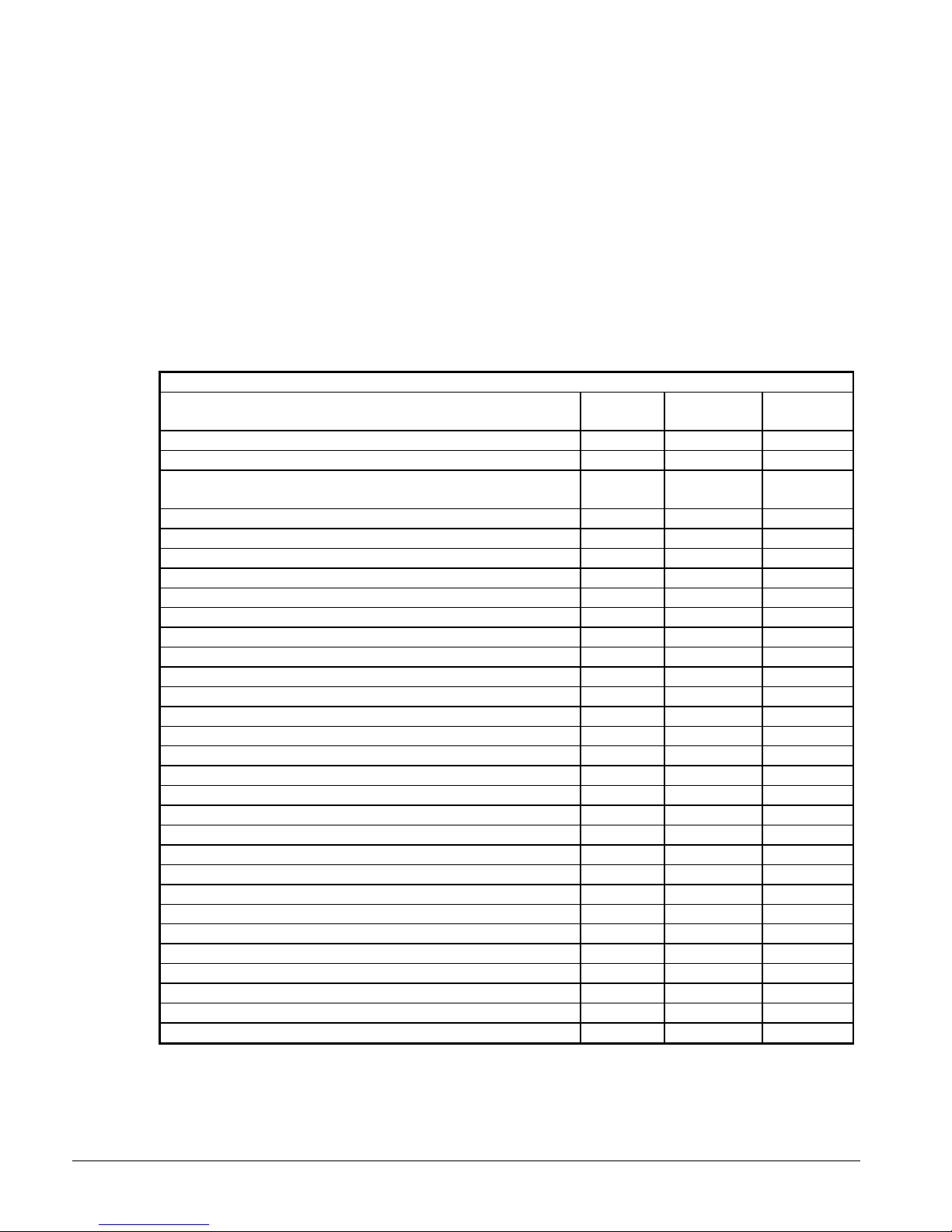

Table 10, Spring Flex Isolators

9.0

(228.6)

9.0

(228.6)

9.0

(228.6)

9.0

(228.6)

Dimensions

In. (mm)

7.7

(195.6)

7.7

(195.6)

7.7

(195.6)

7.7

(195.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

5.75

(146.0)

5.75

(146.0)

5.75

(146.0)

5.75

(146.0)

Housing

Part Number

226103B-00 (2) 226117A-00

226103B-00 (2) 226118A-00

226103B-00 (2) 226119A-00

226103B-00 (2) 226120A-00

Spring

Part Number

Housing

CP-2-27 Orange

CP-2-28 Green

CP-2-31 Gray

CP-2-32 White

Spring

Color

Max. Load

Each

Lbs. (kg)

1500

(681)

1800

(815)

2200

(998)

2600

(1180)

Defl.

In. (mm)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

A B C D E

10.2

(259.1)

10.2

(259.1)

10.2

(259.1)

10.2

(259.1)

Table 11, Neoprene-in-Shear Isolators

5.0

5.0

5.0

Dimensions

In. (mm)

0.56

(14.2)

0.56

(14.2)

0.56

(14.2)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

1.6

(41.1)

1.6

(41.1)

1.6

(41.1)

6.5

(165.1)

6.5

(165.1)

6.5

(165.1)

4.6

(116.8)

4.6

(116.8)

4.6

(116.8)

McQuay

Part Number

216398A-04

216398A-01

216398A-03

Type

RP-4 Black

RP-4 Red

RP-4 Green

Note (1) "D" is the m ou nt ing hole diam eter.

Max. Load

Each

Lbs. (kg)

1500

(681)

2250

(1019)

3300

(1497)

Defl.

In. (mm)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

3.75

(95.3)

3.75

(95.3)

3.75

(95.3)

A B C D (1) E H L W

0.5

(12.7)

(127.0)

0.5

(12.7)

(127.0)

0.5

(12.7)

(127.0)

Figure 15, Spring Flex Mountings Figure 16, Single Neoprene-in-

Shear Mounting

18 IMM AGS-2

Page 19

Chilled Water Pump

It is recommended that the chilled water pumps' starters be wired to, and controlled by, the

chiller's microprocessor. The controller will energize the pump whenever at least one

circuit on the chiller is enabled to run, whether there is a call for cooling or not. Wiring

connection points are shown in Figure 23 on page 42.

Water Piping

Due to the variety of piping practices, follow the recommendations of local authorities.

They can supply the installer with the proper building and safety codes required for a

proper installation.

Design the piping with a minimum number of bends and changes in elevation to keep

system cost down and performance up. It should contain:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

3. Manual or automatic air vent valves at the high points of the system and drains at the

low parts in the system. The evaporator should not be the highest point in the piping

system.

4. Some means of maintaining adequate system water pressure (i.e., expansion tank or

regulating valve).

5. Water temperature and pressure indicators located at the evaporator inlet and outlet to

aid in unit servicing. Any connections should be made prior to filling the system with

water.

6. A strainer to remove foreign matter from the water before it enters the pump. Place the

strainer far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will prolong pump life and

help maintain high system performance levels.

NOTE

the inlet of the evaporator. This will aid in preventing foreign material from entering

the evaporator and causing damage or decreasing its performance. Care must also be

exercised if welding pipe or flanges to the evaporator connections to prevent any weld

slag from entering the vessel.

7. Any water piping to the unit must be protected to prevent freeze-up if below freezing

temperatures are expected.

:

A 40 mesh strainer must also be placed in the supply water line just prior to

CAUTION

If a separate disconnect is used for the 115V supply to the unit, it should power the

entire control circuit, not just the evaporator heaters. It should be clearly marked

so that it is not accidentally shut off during cold seasons. Freeze damage to the

evaporator could result. If the evaporator is drained for winter freeze protection,

the heaters must be de-energized to prevent burnout.

8. If the unit is used as a replacement chiller on a previously existing piping system, flush

the system thoroughly prior to unit installation. Perform regular chilled water analysis

and chemical water treatment immediately at equipment start-up.

IMM AGS-2 19

Page 20

9. In the event glycol is added to the water system as a late addition for freeze protection,

recognize that the refrigerant suction pressure will be lower, cooling performance less,

and water side pressure drop greater. If the percentage of glycol is large, or if

propylene is employed in lieu of ethylene glycol, the added pressure drop and loss of

performance could be substantial.

10. For ice making or low temperature glycol operation, a different freezestat pressure

value is usually required. The freezestat setting can be manually changed through the

MicroTech II controller.

Make a preliminary leak check prior to insulating the water piping and filling the system.

Include a vapor barrier with the piping insulation to prevent moisture condensation and

possible damage to the building structure. It is important to have the vapor barrier on the

outside of the insulation to prevent condensation within the insulation on the cold surface

of the pipe.

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for

the chiller to sense a load change, adjust to the change and stabilize. As the expected load

change becomes more rapid, a greater water volume is needed. The system water volume is

the total amount of water in the evaporator, air handling products and chilled water piping.

If the water volume is too low, operational problems can occur including rapid compressor

cycling, rapid loading and unloading of compressors, erratic refrigerant flow in the chiller,

improper motor cooling, shortened equipment life and other undesirable consequences.

For normal comfort cooling applications where the cooling load changes relatively slowly, a

minimum system volume of three minutes times the flow rate (gpm) is recommend. For

example, if the design chiller flow rate is 400 gpm, we recommend a minimum total system

volume of 1200 gallons (400 gpm x 3 minutes).

For process applications, such as a quenching tank, where the cooling load can change

rapidly, additional system water volume is needed. The load would be very stable until the

hot material is immersed in the water tank. Then, the load would increase drastically. For

this type of application, system volume can need to be increased.

Since there are many other factors that can influence performance, systems can successfully

operate below these suggestions. However, as the water volume decreases below these

suggestions, the possibility of problems increases.

Variable Speed Pumping

Variable water flow involves reducing the water flow through the evaporator as the load

decreases. McQuay chillers are designed for this duty, provided that the rate of change in

water flow is slow, and the minimum and maximum flow rates for the vessel are not

exceeded.

The recommended maximum change in water flow is 10 percent of the change per minute.

The water flow through the vessel must remain between the minimum and maximum values

listed on page 25. If flow drops below the minimum allowable, large reductions in heat

transfer can occur. If the flow exceeds the maximum rate, excessive pressure drop and tube

erosion can occur.

20 IMM AGS-2

Page 21

Evaporator Freeze Protection

AGS chillers are equipped with thermostatically controlled evaporator heaters that help

protect against freeze-up down to -20°F (-28°C).

NOTE: The heaters come from the factory connected to the control power circuit. The

control power can be rewired in the field to a separate 115V supply (do not wire directly to

the heater). See the field wiring diagram on page 42. If this is done, mark the disconnect

switch clearly to avoid accidental deactivation of the heater during freezing temperatures.

Exposed chilled water piping also requires protection.

For additional protection, at least one of the following procedures should be used during

periods of sub-freezing temperatures:

1. Adding of a concentration of a glycol anti-freeze with a freeze point 10 degrees F below

the lowest expected temperature. This will result in decreased capacity and increased

pressure drop.

Note: Do not use automotive grade antifreezes as they contain inhibitors harmful to

chilled water systems. Use only glycols specifically designated for use in building

cooling systems.

2. Draining the water from outdoor equipment and piping and blowing the chiller tubes

dry from the chiller. Do not energize the chiller heater when water is drained from the

vessel.

CAUTION

If fluid is absent from the evaporator, the evaporator heater must be de-energized

to avoid burning out the heater and causing damage from the high temperatures.

1. Providing operation of the chilled water pump, circulating water through the chilled

water system and through the evaporator.

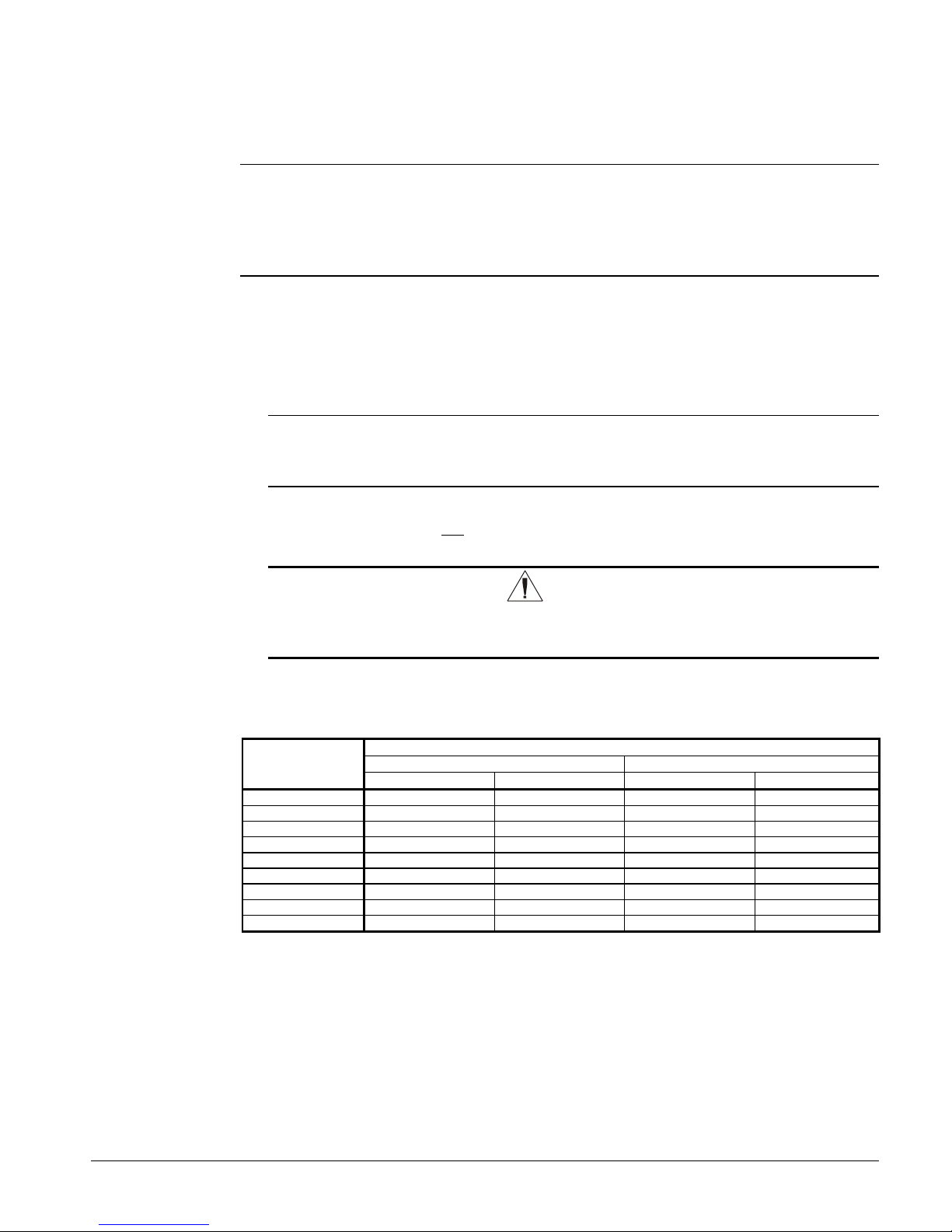

Table 12, Freeze Protection

Temperature

°°°°F (°°°°C)

20 (6.7) 16 18 11 12

10 (-12.2) 25 29 17 20

0 (-17.8) 33 36 22 24

-10 (-23.3) 39 42 26 28

-20 (-28.9) 44 46 30 30

-30 (-34.4) 48 50 30 33

-40 (-40.0) 52 54 30 35

-50 (-45.6) 56 57 30 35

-60 (-51.1) 60 60 30 35

Notes:

1. These figures are examples only and cannot be appropriate to every situation. Generally, for an extended margin of

protection, select a temperature at least 15°F lower than the expected lowest ambient temperature. Inhibitor levels

should be adjusted for solutions less than 25% glycol.

2. Glycol of less than 25% concentration is not recommended because of the potential for bacterial growth and loss of

heat transfer efficiency.

For Freeze Protection For Burst Protection

Ethylene Glycol Propylene Glycol Ethylene Glycol Propylene Glycol

Percent Volume Glycol Concentration Required

IMM AGS-2 21

Page 22

Operating Limits:

Maximum standby ambient temperature, 130°F (55°C)

Maximum operating ambient temperature, see below

Minimum operating ambient temperature (standard), 35°F (2°C)

Minimum operating ambient temperature (optional low-ambient control), 0°F (-18°C)

Leaving chilled water temperature, 40°F to 60°F (4°C to 16°C)

Leaving chilled fluid range (with anti-freeze), 20°F to 60°F (-7°C to 16°C). Unloading is

not permitted with fluid leaving temperatures below 30°F (-1°C).

Operating Delta-T range, 6 degrees F to 16 degrees F (10.8 C to 28.8 C)

Maximum operating inlet fluid temperature, 76°F (24°C)

Maximum startup inlet fluid temperature, 90°F (32°C)

Maximum non-operating inlet fluid temperature, 100°F (38°C)

NOTE: Contact the local McQuay sales office for operation outside any of these limits.

Maximum Operating Ambient Temperatures

Standard Efficiency, designated by a "0" as the last digit in the model number (such as

AGS 170C) are designed for operation up to 125 degrees. Significant unloading above 115

degrees can occur depending on a variety of factors. Contact your sales representative for

performance above 115 degrees. Additional unloading can result with leaving water

temperatures above 45 degrees.

High Efficiency, designated by a "5" as the last digit in the model number (such as AGS

175C) are designed for operation up to 125 degrees without unloading for leaving water

temperatures between 40 and 45 degrees Fahrenheit. Contact your sales representative for

evaporator duty outside of this range. The High Efficiency models have larger components,

and/or more fans than the comparable Standard Efficiency models. This results in

improved efficiency and the ability to operate at higher ambient air temperatures.

High Ambient Option, A factory-installed option that provides components allowing

operation in high ambient temperature locations. It can be applied to any unit and is

mandatory on:

1. All units with the optional VFD low ambient control.

2. All units that can have operating ambient temperatures above 115°F (46°C).

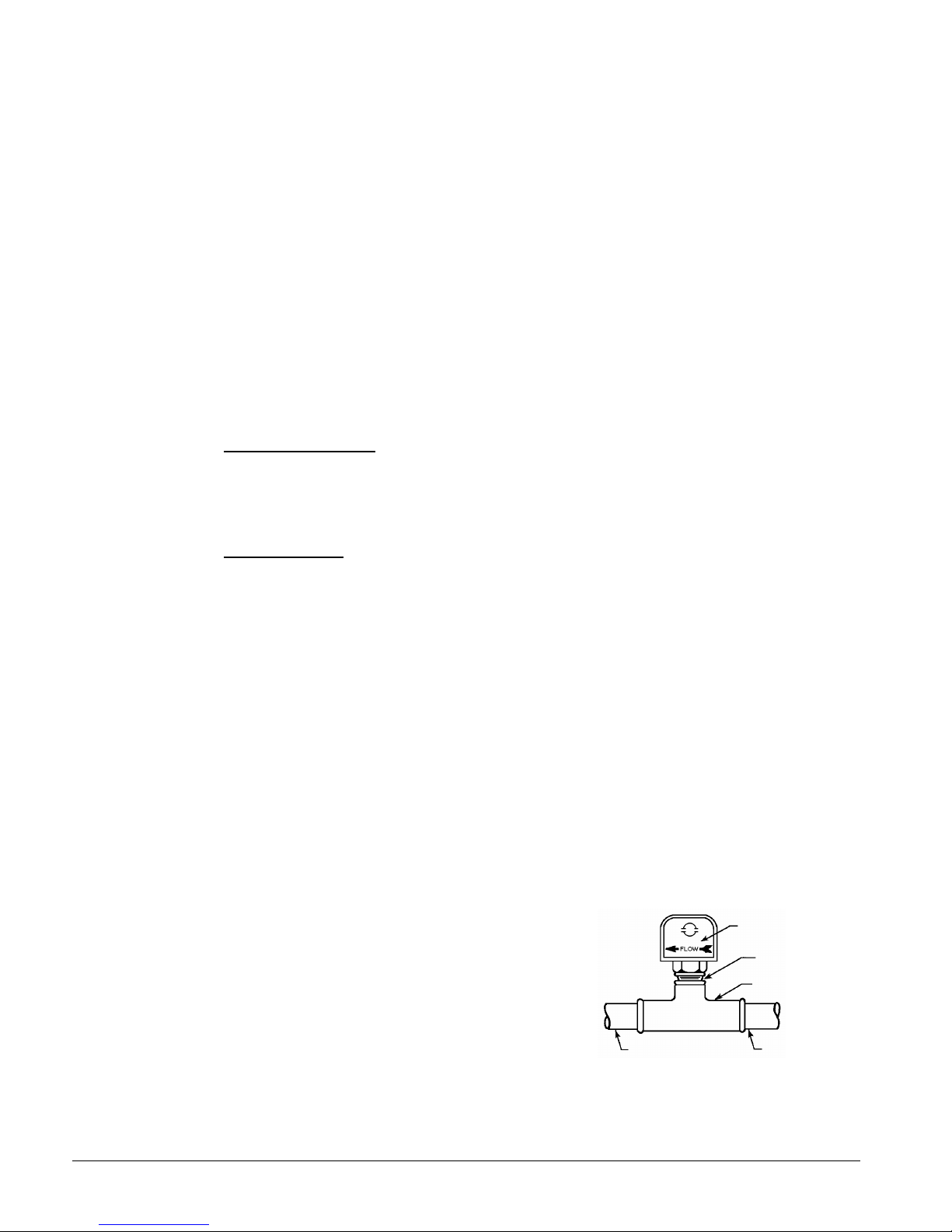

Flow Switch

A flow switch must be included in the

chilled water system to prove that there is

adequate water flow to the evaporator

before the unit can start. It also serves to

shut down the unit in the event that water

flow is interrupted in order to guard

against evaporator freeze-up.

A solid state flow switch that is factorymounted and wired in the chiller leaving

water nozzle is available as an option.

A flow switch for field mounting and

wiring in the leaving chilled water is also

available as an option from McQuay under

22 IMM AGS-2

Figure 17, Flow Switch

1 1/4" (32mm) pipe

dia. min. after switch

Flow direction marked

on switch

1" (25mm) NPT flow

switch connection

Tee

1 1/4" (32mm) pipe

dia. min. before switch

Page 23

ordering number 017503300. It is a paddle-type switch and adaptable to any pipe size from

Vent

Valve

Vibration

Valved

Against Freezing

Vibration

Valve

Valve

1" (25mm) to 8" (203mm) nominal.

Certain minimum flow rates are required to close the switch and are listed in Table 13.

Installation should be as shown in Figure 18.

Electrical connections in the unit control center should be made at terminals 60 and 67 from

switch terminals Y and R. The normally open contacts of the flow switch should be wired

between these two terminals. Flow switch contact quality must be suitable for 24 VAC, low

current (16ma). Flow switch wire must be in separate conduit from any high voltage

conductors (115 VAC and higher) and have an insulation rating of 600 volts.

Table 13, Flow Switch Flow Rates

(NOTE !)

Min.

Adjst.

Max.

Adjst.

Flow

Flow Lpm 0.8 1.1 2.2 2.8 4.3 11.4 22.9 35.9 38.6

Flow

Flow Lpm 2.8 4.1 6.1 7.3 11.4 27.7 53.4 81.8 90.8

NOTES:

1. A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2. Flow rates for a 2-inch paddle trimmed to fit the pipe.

3. Flow rates for a 3-inch paddle trimmed to fit the pipe.

4. Flow rates for a 3-inch paddle.

5. Flow rates for a 6-inch paddle.

inch 1 1/4 1 1/2 2 2 1/2 3 4 5 6 8 Pipe Size

mm 32 (2) 38 (2) 51 63 (3) 76 102 (4) 127 (4) 153 (4) 204 (5)

gpm 5.8 7.5 13.7 18.0 27.5 65.0 125.0 190.0 205.0

Lpm 1.3 1.7 3.1 4.1 6.2 14.8 28.4 43.2 46.6

gpm 3.7 5.0 9.5 12.5 19.0 50.0 101.0 158.0 170.0

No

gpm 13.3 19.2 29.0 34.5 53.0 128.0 245.0 375.0 415.0

Lpm 3.0 4.4 6.6 7.8 12.0 29.1 55.6 85.2 94.3

gpm 12.5 18.0 27.0 32.0 50.0 122.0 235.0 360.0 400.0

No

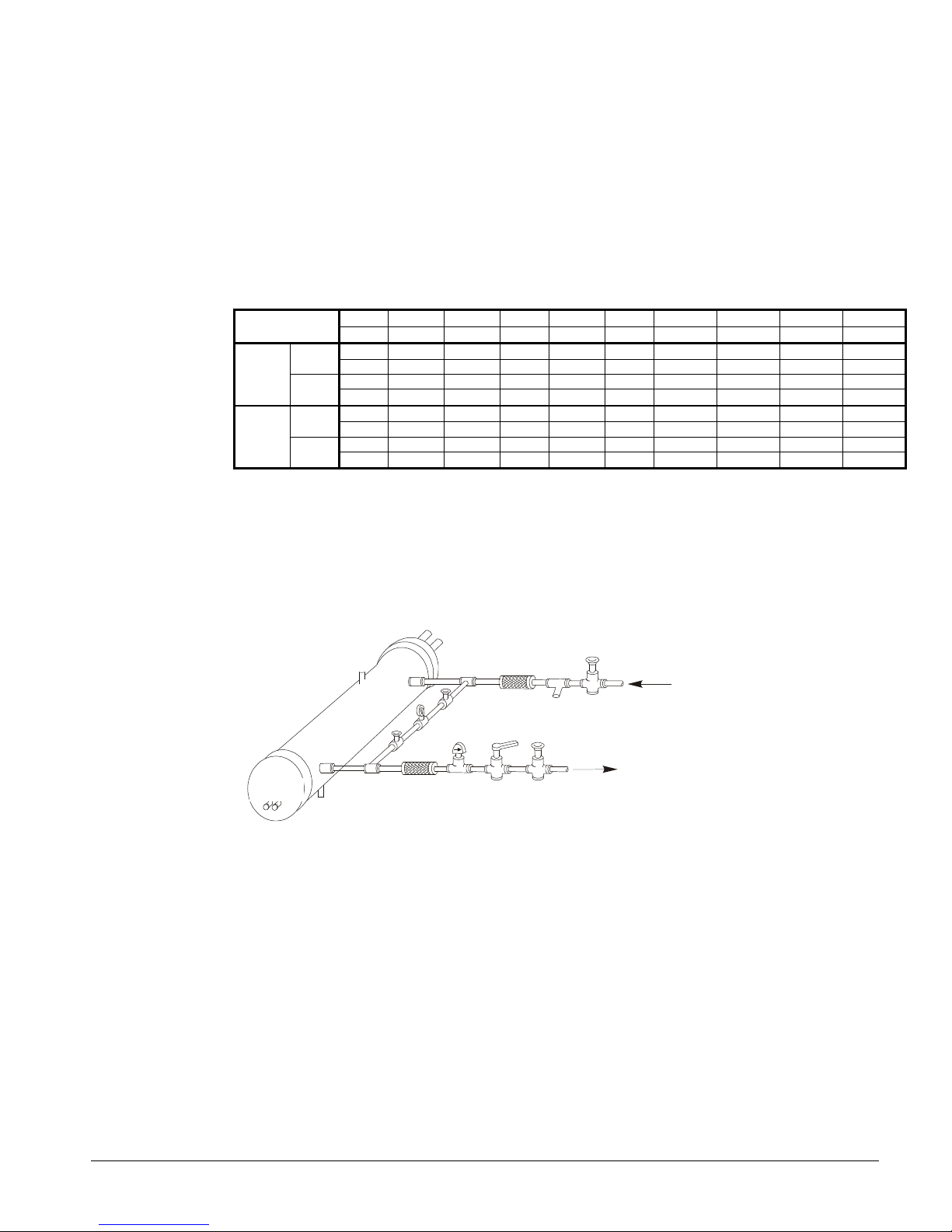

Figure 18, Typical Field Water Piping

Suction

In

Gauge

Flow

Eliminator

Balancing

Pressure

Out

Liquid

Drain

Notes:

1. Connections for vent and drain fittings are located on the top and bottom of the evaporator.

2. Piping must be supported to avoid putting strain on the evaporator nozzles.

Eliminator

Switch

Water

Strainer

Gate

Flow

Gate

Protect All Field Piping

Flow

Refrigerant Charge

All packaged units are designed for use with R-134a and are shipped with a full operating

charge. The operating charge for each unit is shown in the Physical Data Tables beginning

on page 26 for packaged units, and page 60 for remote evaporator models. Model AGSCM/CB with remote evaporators are shipped with a full unit charge. Refrigerant must be

added in the field for the evaporator and for the refrigerant lines.

Glycol Solutions

When using glycol anti-freeze solutions the chiller's capacity, glycol solution flow rate, and

pressure drop through the evaporator can be calculated using the following formulas and

tables.

IMM AGS-2 23

Page 24

Note: The procedure below does not specify the type of glycol. Use the derate factors

()()(

)

found in Table 14 for corrections when using propylene glycol and those in Table 15 for

ethylene glycol.

1. Capacity - Cooling capacity is reduced from that with plain water. To find the

reduced value, multiply the chiller’s water system tonnage by the capacity correction

factor to find the chiller’s capacity when using glycol.

2. Flow - To determine flow (or Delta-T) knowing Delta-T (or flow) and capacity:

GPM−=

24

factorflowtons

TDelta

3. Pressure drop - To determine pressure drop through the evaporator when using

glycol, enter the water pressure drop curve at the water flow rate. Multiply the water

pressure drop found there by the "PD" factor to obtain corrected glycol pressure drop.

4. Power - To determine glycol system kW, multiply the water system kW by the factor

designated "Power".

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in

service stations) to determine the freezing point. Obtain percent glycol from the freezing

point table below. On glycol applications, the supplier normally recommends that a

minimum of 25% solution by weight be used for protection against corrosion or that

additional inhibitors should be employed.

NOTE: Do not use automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors that will cause plating on the copper tubes within

the chiller evaporator. The type and handling of glycol used must be consistent with local

codes.

Table 14, Ethylene Glycol Factors

Freeze

%

E.G.

Point

oF o

26 -3.3 0.996 0.998 1.036 1.097

10

18 -7.8 0.988 0.994 1.061 1.219

20

7 -13.9 0.979 0.991 1.092 1.352

30

-7 -21.7 0.969 0.986 1.132 1.532

40

-28 -33.3 0.958 0.981 1.182 1.748

50

Capacity Power Flow PD

C

Table 15, Propylene Glycol Factors

Freeze

% P.G.

10

20

30

40

50

Point

oF o

26 -3.3 0.991 0.996 1.016 1.092

19 -7.2 0.981 0.991 1.032 1.195

9 -12.8 0.966 0.985 1.056 1.345

-5 -20.6 0.947 0.977 1.092 1.544

-27 -32.8 0.932 0.969 1.140 1.906

Capacity Power Flow PD

C

Water Flow and Pressure Drop

Adjust the chilled water flow through the evaporator to meet specified conditions. The

flow rates must fall between the minimum and maximum values shown in the table on the

following page. Flow rates below the minimum values shown will result in laminar flow

that will reduce efficiency, cause erratic operation of the electronic expansion valve and

could cause low temperature cutouts. On the other hand, flow rates exceeding the

maximum values shown can cause erosion on the evaporator water connections and tubes.

Measure the chilled water pressure drop through the evaporator at field-installed pressure

taps. It is important not to include valve or strainer pressure drops in these readings.

24 IMM AGS-2

Page 25

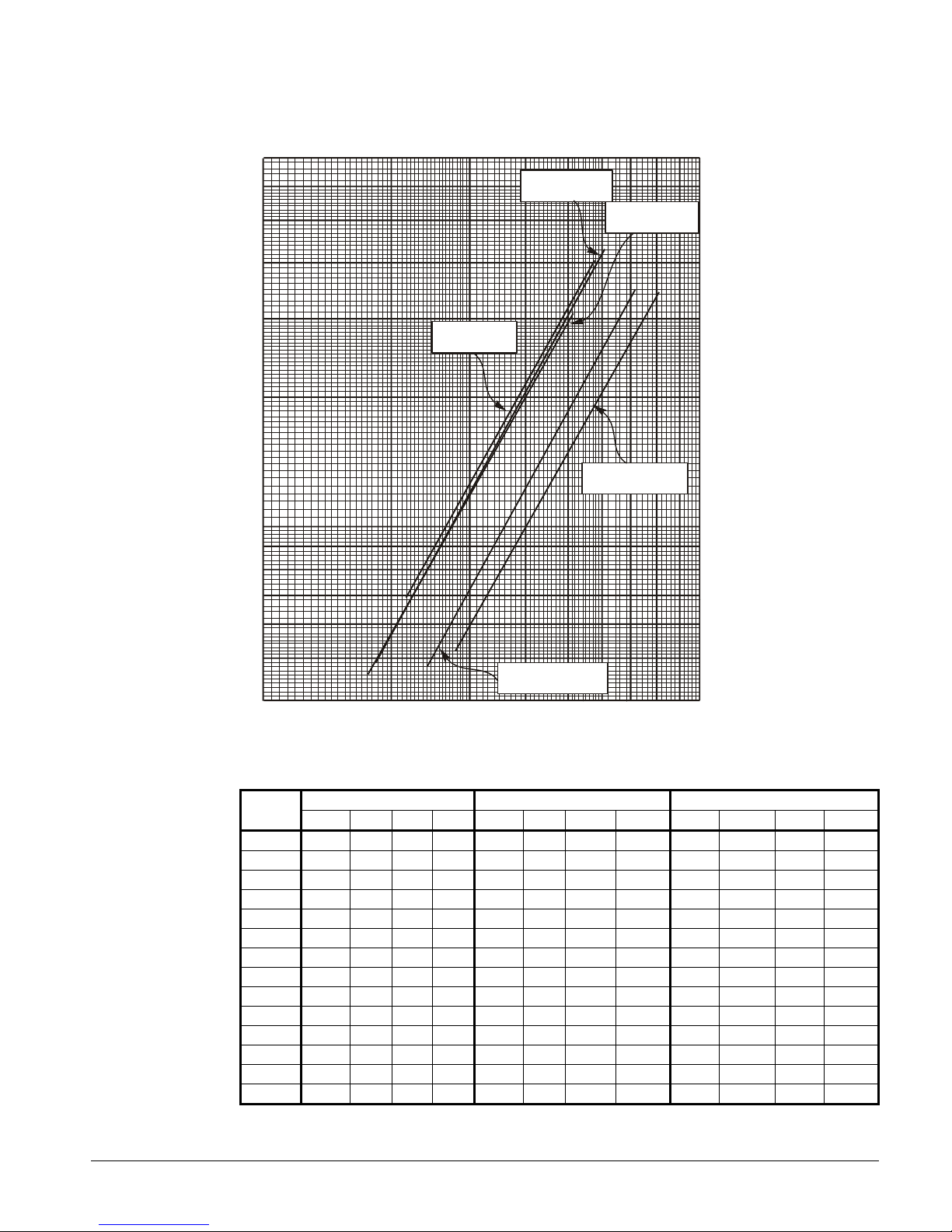

Figure 19, Evaporator Pressure Drops

200

300

400

500

600

700

800

900

1000

Flow Rate (GPM)

P

r

e

s

s

u

r

e

D

r

o

p

(

f

t

o

f

w

a

t

e

r

)

Flow Rate (L/s)

P

r

e

s

s

u

r

e

D

r

o

p

(

k

P

a

)

AGS Models

AGS Models

120, 130, 140

125, 135, 160

AGS Models

6 13 19 25 32 38 44 50 57 63

70

60

50

40

30

20

10

AGS Models

145

9

8

7

AGS Models

190, 195, 210

210

180

150

120

90

60

30

27

24

21

6

5

165, 170, 175, 180

4

100

Minimum/Nominal/Maximum Flow Rates

AGS

MODEL

120

125

130

135

140

145

160

165

170

175

180

190

195

210

MINIMUM FLOW NOMINAL FLOW MAXIMUM FLOW

gpm l/s ft kpa gpm l/s ft kpa gpm l/s ft kpa

175 11.1 4.6 13.7 280 17.7 10.6 31.6 467 29.5 26.5 79.1

182 11.5 4.9 14.6 292 18.5 11.8 35.2 486 30.8 29.2 87.2

188 11.9 5.3 15.8 300 19.0 12.9 38.5 501 31.7 30.4 90.7

196 12.4 5.6 16.7 314 19.9 13.5 40.3 524 33.1 33.5 100.0

201 12.7 5.9 17.6 321 20.3 13.6 40.6 535 33.8 30.4 90.7

215 13.6 6.9 20.6 343 21.7 16.1 48.0 572 36.2 40.2 119.9

227 14.4 7.2 21.5 363 23.0 17.1 51.0 606 38.3 43.0 128.4

241 15.2 4.8 14.4 385 24.4 11.3 33.8 642 40.6 28.6 85.3

252 16.0 5.2 15.7 403 25.5 12.3 36.7 672 42.6 31.1 92.7

259 16.4 5.7 17.0 414 26.2 12.9 38.5 690 43.7 32.6 97.2

269 17.1 5.9 17.7 431 27.3 13.9 41.4 718 45.5 35.0 104.5

278 17.6 5.2 15.5 445 28.2 12.3 36.7 742 47.0 30.7 91.6

285 18.1 5.4 16.1 457 28.9 12.8 38.2 761 48.2 32.6 97.3

302 19.1 5.9 17.6 483 30.6 14.3 42.7 805 50.9 34.5 103.0

18

15

12

IMM AGS-2 25

Page 26

Physical Data, Standard Efficiency

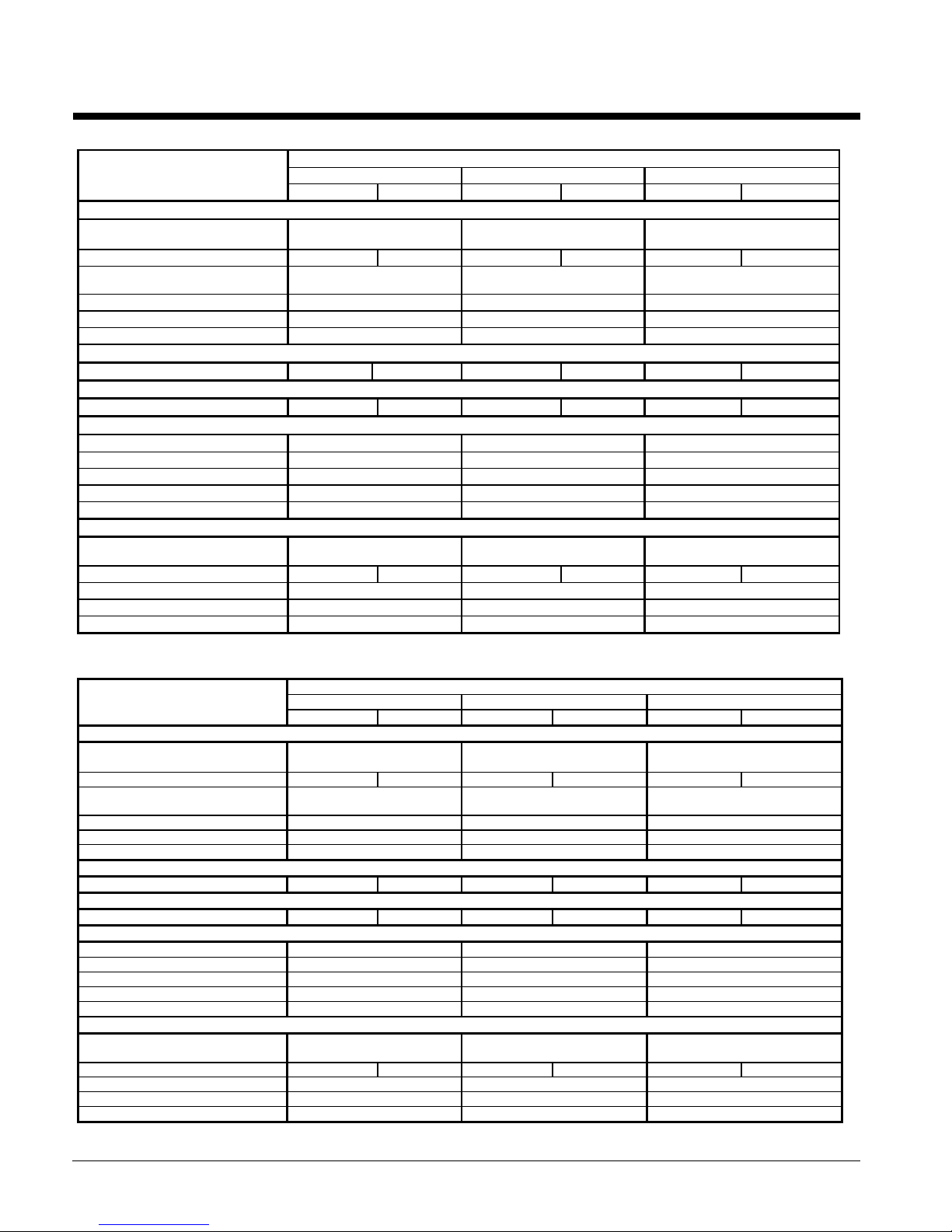

Table 16, Physical Data, AGS 120C – AGS 140C

DATA

BASIC DATA

Unit Cap. @ 44°F LWT, 95°F Ambient

Temperature kW, (tons)

Unit Operating Charge lbs (kg) 131 (59) 131 (59) 131 (59) 131 (59) 131 (59) 131 (59)

Cabinet Dimensions

L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg) 9452 (4291) 9452 (4291) 9452 (4291)

Unit Shipping Weight, lbs (kg) 9020 (4095) 9020 (4095) 9020 (4095)

Economizer No No No

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 60 (211) 60 (211) 60 (211) 70 (246) 70 (246) 70 (246)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER

Pumpdown Capacity, lbs (kg) 358 (163) 358 (163) 358 (163) 358 (163) 358 (163) 358 (163)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans – 30 in. Fan Dia. 8 8 8

No. of Motors -- hp (kW) 8 2 (1.5) 8 2 (1.5) 8 2 (1.5)

Fan & Motor RPM, 60Hz 1140 1140 1140

60 Hz Fan Tip Speed, fpm (m/s) 8950 (4224) 8950 (4224) 8950 (4224)

60 Hz Total Unit Airflow, cfm (l/s) 86900 (41020) 86900 (41020) 86900 (41020)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length

in.(mm) - in. (mm)

Evaporator R-134a Charge lbs (kg) 1.95 (0.9) 1.95 (0.9) 1.95 (0.9) 1.95 (0.9) 1.95 (0.9) 1.95 (0.9)

Water Volume, gallons (liters) 49 (185) 49 (185) 49 (185)

Max. Water Pressure, psi (kPa) 152 (1048) 152 (1048) 152 (1048)

Max. Refrigerant Press., psi (kPa) 352 (2427) 352 (2427) 352 (2427)

120C 130C 140C

Ckt 1 Ckt 2 Ckt 1 Ckt 2 Ckt 1 Ckt 2

116.7 (410) 125.2 (440) 133.7 (470)

187 x 89 x 101

4750 x 2261 x 2565

15.5 x 82.4

(394 x 2093)

AGS MODEL NUMBER

187 x 89 x 101

4750 x 2261 x 2565

15.5 x 82.4

(394 x 2093)

187 x 89 x 101

4750 x 2261 x 2565

15.5 x 82.4

(394 x 2093)

Table 17, Physical Data, AGS 160C – AGS 180C

AGS MODEL NUMBER

DATA 160C 170C 180C

Ckt. 1 Ckt. 2 Ckt. 1 Ckt. 2 Ckt. 1 Ckt. 2

BASIC DATA

Unit Cap. @ 44°F LWT, 95°F Ambient

Temperature kW, (tons)

Unit Operating Charge, lbs (kg) 131 (59) 131 (59) 159 (72) 159 (72) 171 (78) 171 (78)

Cabinet Dim., L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg) 10209 (4635) 11277 (5120) 11277 (5120)

Unit Shipping Weight, lbs (kg) 9484 (4306) 10552 (4791) 10552 (4791)

Economizer No No Yes

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 70 (246) 85 (299) 85 (299) 85 (299) 95 (334) 95 (334)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER

Pumpdown Capacity, lbs (kg) 358 (163) 358 (163) 399 (181) 399 (181) 399 (181) 399 (181)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans; 30 in. Fan Dia., 8 10 10

No. of Motors – hp (kW) 8 2 (1.5) 10 2 (1.5) 10 2 (1.5)

Fan & Motor RPM, 60Hz 1140 1140 1140

60 Hz Fan Tip Speed, fpm 8950 (4224) 8950 (4224) 8950 (4224)

60 Hz Total Unit Airflow, cfm (l/s) 86900 (41020) 108630 (51280) 108630 (51280)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.,Tube Length in.(mm)

Evaporator R-134a Charge lbs (kg) 2.53 (1.1) 2.53 (1.1) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4)

Water Volume, gallons (liters) 83 (314) 106 (401) 106 (401)

Max. Water Pressure, psi (kPa) 152 (1048) 152 (1048) 152 (1048)

Max. Refrigerant Press., psi (kPa) 352 (2427) 352 (2427) 352 (2427)

151.4 (532) 168.1 (591) 179.6 (631)

187 x 89 x 101

4750 x 2261 x 2565

19.4 x 82.4

(493 x 2093)

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

26 IMM AGS-2

Page 27

Table 18, Physical Data, AGS 190C – AGS 210C

DATA

BASIC DATA

Unit Cap. @ 44°F LWT, 95°F Ambient

Temperature kW, (tons)

Unit Operating Charge lbs (kg) 172 (78) 172 (78) 201 (91) 201 (91)

Cabinet Dimensions

L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg) 11277 (5120) 11928 (5415)

Unit Shipping Weight, lbs (kg) 10552 (4791) 11011 (4999)

Economizer Yes Yes

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 95 (334) 95 (334) 95 (334) 95 (334)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER

Pumpdown Capacity, lbs (kg) 399 (181) 399 (181) 438 (199) 438 (199)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans -- 30 in. Fan Dia., 10 12

No. of Motors -- hp (kW) 10 2 (1.5) 12 2.5 (1.9)

Fan & Motor RPM, 60Hz 1140 1140

60 Hz Fan Tip Speed, fpm (m/s) 8950 (4224) 8950 (4224)

60 Hz Total Unit Airflow, cfm (l/s) 108630 (51280) 130360 (61530)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length

in.(mm) - in. (mm)

Evaporator R-134a Charge lbs (kg) 3.63 (1.6) 3.63 (1.6) 3.63 (1.6) 3.63 (1.6)

Water Volume, gallons (liters) 106 (401) 104 (392)

Max. Water Pressure, psi (kPa) 152 (1048) 152 (1048)

Max. Refrigerant Press., psi (kPa) 352 (2427) 352 (2427)

AGS 190C AGS 210C

Ckt 1 Ckt 2 Ckt 1 Ckt 2

185.6 (653) 201.2 (707)

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

263 x 89 x 101

6680 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

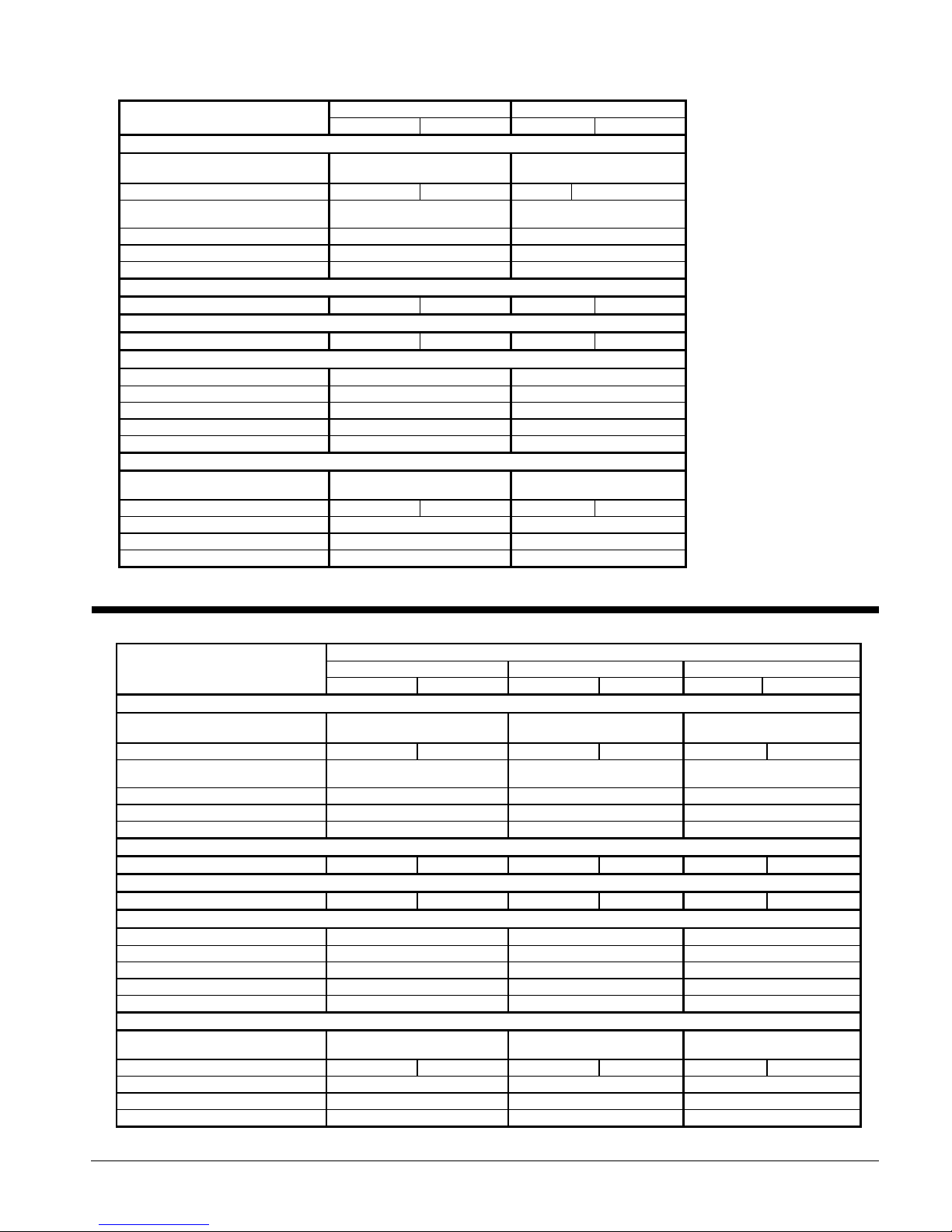

Physical Data, High Efficiency

Table 19, Physical Data, AGS 125C – AGS 145C

DATA

BASIC DATA

Unit Cap. @ 44°F LWT, 95°F Ambient

Temperature kW, (tons)

Unit Operating Charge lbs (kg) 159 (72) 159 (72) 159 (72) 159 (72) 159 (72) 159 (72)

Cabinet Dimensions

L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg) 10930 (4962) 10930 (4962) 10485 (4760)

Unit Shipping Weight, lbs (kg) 10205 (4633) 10205 (4633) 9942 (4514)

Economizer No No No

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 60 (211) 60 (211) 60 (211) 70 (246) 70 (246) 70 (246)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER

Pumpdown Capacity, lbs (kg) 399 (181) 399 (181) 399 (181) 399 (181) 399 (181) 399 (181)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans – 30 in. Fan Dia., 10, 30 (762) 10, 30 (762) 10, 30 (762)

No. of Motors -- hp (kW) 10 2 (1.5) 10 2 (1.5) 10 2 (1.5)

Fan & Motor RPM, 60Hz 1140 1140 1140

60 Hz Fan Tip Speed, fpm (m/s) 8950 (4224) 8950 (4224) 8950 (4224)

60 Hz Total Unit Airflow, cfm (l/s) 108630 (51280) 108630 (51280) 108630 (51280)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length

in.(mm) - in. (mm)

Evaporator R-134a Charge lbs (kg) 2.53 (1.1) 2.53 (1.1) 2.53 (1.1) 2.53 (1.1) 2.44 (1.1) 2.44 (1.1)

Water Volume, gallons (liters) 83 (314) 83 (314) 62 (236)

Max. Water Pressure, psi (kPa) 152 (1048) 152 (1048) 152 (1048)

Max. Refrigerant Press., psi (kPa) 352 (2427) 352 (2427) 352 (2427)

125C 135C 145C

Ckt 1 Ckt 2 Ckt 1 Ckt 2 Ckt 1 Ckt 2

121.6 (428) 130.9 (460) 143.0 (503)

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 82.4

(493 x 2093)

AGS MODEL NUMBER

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 82.4

(493 x 2093)

225 x 89 x 101

5715 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

IMM AGS-2 27

Page 28

Table 20, Physical Data, AGS 165C – AGS 195C

DATA

BASIC DATA

Unit Cap. @ 44°F LWT, 95°F Ambient

Temperature kW, (tons)

Unit Operating Charge lbs (kg) 186 (84) 186 (84) 186 (84) 186 (84) 201 (91) 201 (91)

Cabinet Dimensions

L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg) 11928 (5415) 11277 (5120) 11277 (5120)

Unit Shipping Weight, lbs (kg) 11011 (4999) 11011 (4999) 11011 (4999)

Economizer N0 N0 Yes

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons (kW) 70 (246) 85 (299) 85 (299) 85 (299) 95 (334) 95 (334)

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER

Pumpdown Capacity, lbs (kg) 438 (199) 438 (199) 438 (199) 438 (199) 438 (199) 438 (199)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans – 30 in. Fan Dia. 12 12 12

No. of Motors -- hp (kW) 12 2 (1.5) 12 2 (1.5) 12 2 (1.5)

Fan & Motor RPM, 60Hz 1140 1140 1140

60 Hz Fan Tip Speed, fpm (m/s) 8950 (4224) 8950 (4224) 8950 (4224)

60 Hz Total Unit Airflow, cfm (l/s) 130360 (61530) 130360 (61530) 130360 (61530)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

Shell Dia.-Tube Length

in.(mm) - in. (mm)

Evaporator R-134a Charge lbs (kg) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4) 3.16 (1.4)

Water Volume, gallons (liters) 106 (401) 106 (401) 106 (401)

Max. Water Pressure, psi (kPa) 152 (1048) 152 (1048) 152 (1048)

Max. Refrigerant Press., psi (kPa) 352 (2427) 352 (2427) 352 (2427)

165C 175C 195C

Ckt 1 Ckt 2 Ckt 1 Ckt 2 Ckt 1 Ckt 2

160.5 (564) 172.5 (607) 190.3 (669)

263 x 89 x 101

6680 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

AGS MODEL NUMBER

263 x 89 x 101

6680 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

263 x 89 x 101

6680 x 2261 x 2565

19.4 x 105.1

(493 x 2670)

28 IMM AGS-2

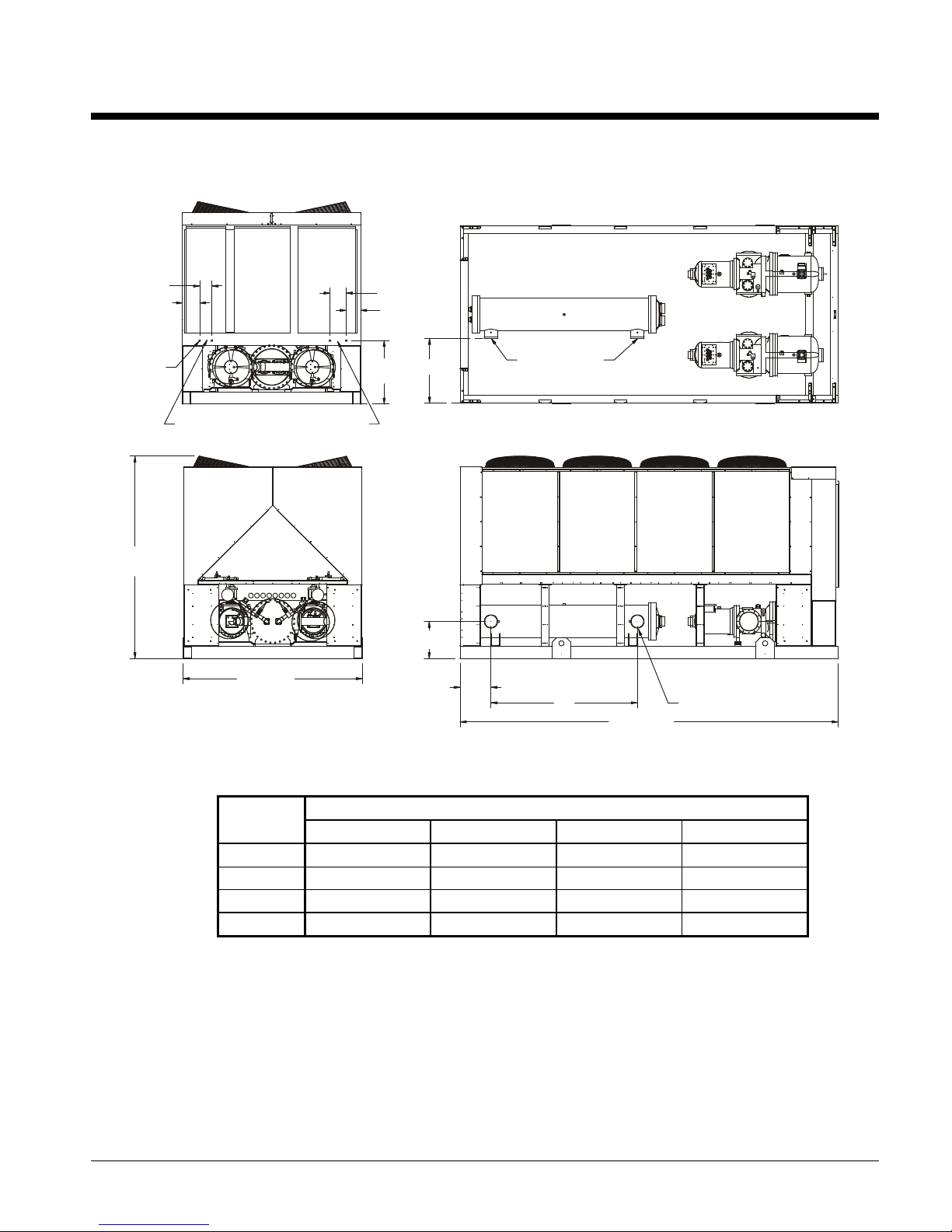

Page 29

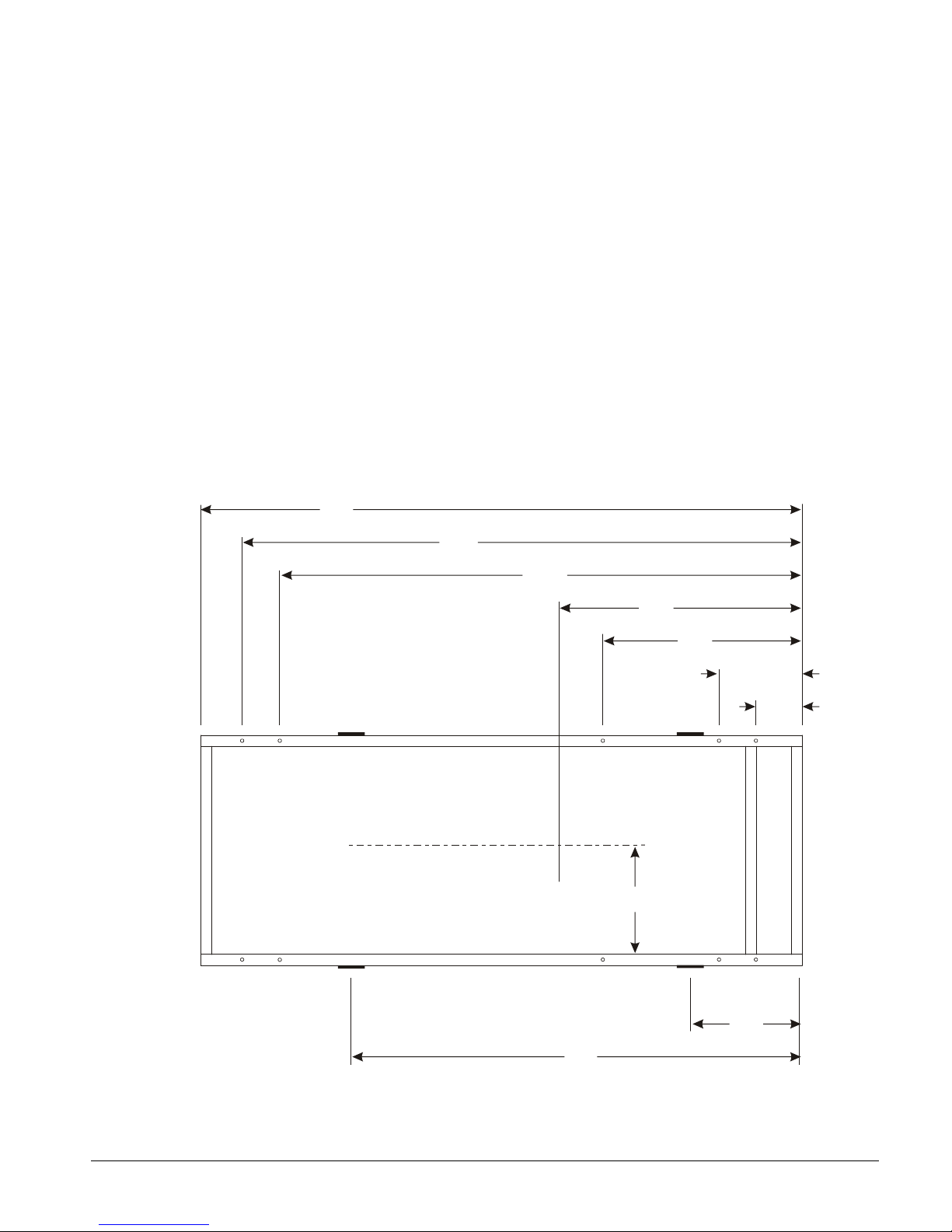

Dimensional Data

" A "

" B "

18.4

(467.4)

" C " VICTAULIC CONNECTION

" D "

INLET

Figure 20, Dimensions, AGS 120CS/H – AGS 160CS/H

Note: See p age 13 for lift ing locations , mount ing locations , weig ht s and m ounting loads.

6.0 (152.4)

8.5 (215.9)

0.875 (22.2)

KNOCK-OUT

( QTY 4 TOTAL)

100.4

(2550.2)

CONTROL

PANEL

FIELD CONTROL

CONNECTION

POWER

PANEL

88.5 (2247.9)

POWER

PANEL

POWER ENTRY

8.0 (203.2)

7.2 (182.9)

31.5

(800.1)

OUTLET

3307127-00-01

186.6 (4739.6)

UNIT

SIZE

AGS120C

AGS130C

AGS140C

AGS160C

" A " " B " " C " " D "

15.2 (386.1) 72.3 (1836.4) 6 (152.4) 32.1 (815.3)

15.2 (386.1) 72.3 (1836.4) 6 (152.4) 32.1 (815.3)

15.2 (386.1) 72.3 (1836.4) 6 (152.4) 32.1 (815.3)

16.2 (411.5) 70.3 (1785.6) 8 (203.2) 30.1 (764.5)

Dimensions In (mm)

IMM AGS-2 29

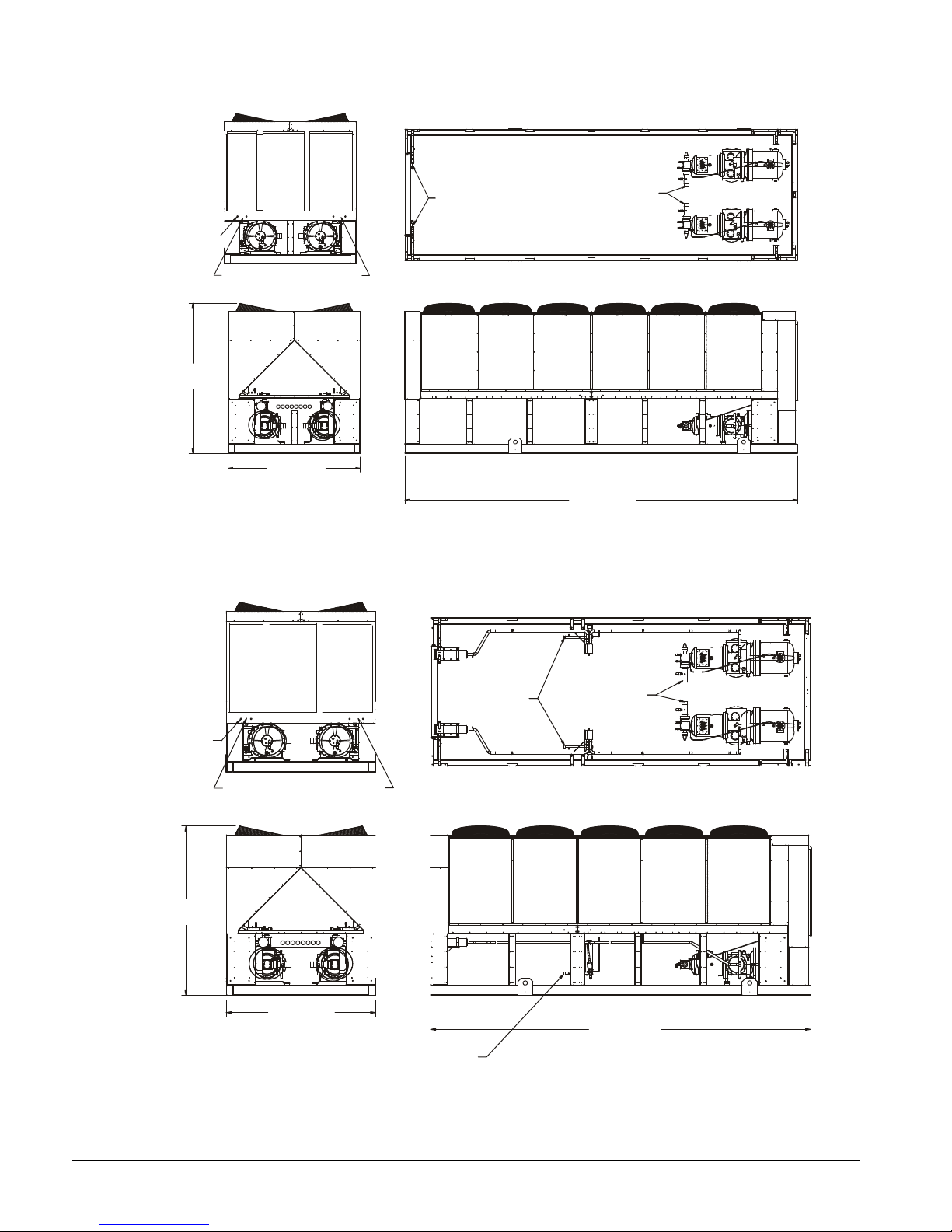

Page 30

Figure 21, Dimensions, AGS 125CS/H –190CS/H

" A "

" B "

(467.4)

"C " VICTAULIC CONNECTION

" D "

INLET

Note: See page13 f or lifting lo cations, mounting lo cations, weights and mountin g loads.

6.0 (152.4)

8.5 (215.9)

0.875 (22.2)

KNOCK OUT

( QTY 4 TOTAL)

100.4

(2550.2)

CONTROL

PANEL

CONNECTION

330712701-00-02

POWER

PANEL

88.5 (2248.9)

POWER

POWER ENTRYFIELD CONTROL

PANEL

8.0 (203.2)

7.2 (182.9)

31.5

(800.1)

18.4

OUTLET

224.8 (5709.9)

UNIT

SIZE

AGS125C

AGS135C

AGS145C

AGS170C

AGS180C

AGS190C

Dimensions In (mm)

" A " " B " " C " " D "

39.3 (998.2) 70.3 (1785.6) 8 (203.2) 30.1 (764.5)

39.3 (998.2) 70.3 (1785.6) 8 (203.2) 30.1 (764.5)

15.6 (396.2) 94.9 (2410.5) 6 (152.4) 32.1 (815.3)

16.7 (424.2) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

16.7 (424.2) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

16.7 (424.2) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

30 IMM AGS-2

Page 31

Figure 22 , Dimensions, AGS 165CS/H –210CS/H

" A "

" B "

" C " VICTAULIC CONNECTION

" D "

INLET

Note: See page 13 for lifti ng locations, mounting l ocations, weights and mo unting loads.

6.0 (152.4)

8.5 (215.9)

0.875 (22.2)

KNOCK OUT

( QTY 4 TOTAL)

100.4

(2550.2)

FIELD CONTROL

CONNECTION

3307127-00-03

POWER

PANEL

88.5 (2247.9)

POWER

PANEL

POWER ENTRY

8.0 (203.2)

7.2 (182.9)

31.5

(800.1)

18.4 (467.4)

OUTLET

263.0 (6680.2)

UNIT

SIZE

AGS165C

AGS175C

AGS195C

AGS210C

Dimensions In (mm)

" A " " B " " C " " D "

54.9 (1394.5) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

54.9 (1394.5) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

54.9 (1394.5) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

54.9 (1394.5) 92.9 (2359.7) 8 (203.2) 30.1 (764.5)

IMM AGS-2 31

Page 32

Electrical Data

Field Wiring

General

Wiring must comply with all applicable codes and ordinances. Warranty does not cover

damage to the equipment caused by wiring not complying with specifications.

An open fuse indicates a short, ground, or overload. Before replacing a fuse or restarting a

compressor or fan motor, the trouble must be found and corrected.

Copper wire is required for all power lead terminations at the unit, and copper must be used for

all other wiring to the unit.

AGS units can be ordered with main power wiring for either multiple-point power (standard)

or single-point connection (optional).

If the standard multiple-point power wiring is ordered, two separate power connections are

made to power blocks (or optional circuit breaker disconnects) in power panel. See the

dimension drawings beginning on page 29 for entry locations. Separate disconnects are

required for each electrical circuit if the McQuay optional factory-mounted disconnects are not

ordered.

If the optional single-point power connection is ordered, a single power connection is made to

a power block (or optional circuit breaker disconnect) in the unit power panel. A separate

disconnect is required if the McQuay optional factory-mounted disconnect is not ordered.

Isolation circuit breakers for each circuit are included.

It can be desirable to have the unit evaporator heaters on a separate disconnect switch from the

main unit power supply so that the unit power can be shut down without defeating the freeze

protection provided by the evaporator heaters. See the field wiring diagram on page 42 for

connection details.

The 115-volt control transformer is factory mounted and wired.

CAUTION

If a separate disconnect is used for the 115V supply to the unit, it must power the entire

control circuit, not just the evaporator heaters. It must be clearly marked so that it is not

accidentally shut off during cold seasons. Freeze damage to the evaporator could result.

If the evaporator is drained for winter freeze protection, the heaters must be de-energized

to prevent heater burnout.

CAUTION

AGS unit compressors are single-direction rotation compressors and can be damaged if

rotated in the wrong direction. For this reason, proper phasing of electrical power is

important. Electrical phasing must be A, B, C for electrical phases 1, 2 and 3 (A=L1,

B=L2, C=L3) for single or multiple point wiring arrangements. The solid-state starters

contain phase reversal protection. DO NOT ALTER THE WIRING TO THE

STARTERS.

32 IMM AGS-2

Page 33

Table 21, AGS 120C – AGS 210C, Electrical Data, Single-Point

AGS

UNIT

SIZE

120C 380 60 320 400 MCM 400 400

125C 380 60 328 400 MCM 400 450

130C 380 60 342 400 MCM 400 450

135C 380 60 350 400 MCM 400 450

140C 380 60 359 2-250 MCM 400 500

145C 380 60 367 2-250 MCM 450 500

160C 380 60 400 2-250 MCM 450 500

165C 380 60 416 2-300 MCM 500 500

170C 380 60 441 2-300 MCM 500 600

175C 380 60 449 2-300 MCM 500 600

VOLTS HZ

208 581 (2) 350 MCM 700 800

230 526 (2) 300 MCM 600 700

460 279 300 MCM 350 350

575 211 4/0 AWG 250 250

208 595 (2) 350 MCM 700 800

230 539 (2) 300 MCM 600 700

460 285 300 MCM 350 350

575 216 4/0 AWG 250 300

208 625 (2) 300 MCM 700 800

230 563 (2) 300 MCM 700 800

460 291 350 MCM 350 400

575 222 4/0 AWG 250 300

208 639 (2) 400 MCM 800 800

230 576 (2) 350 MCM 700 800

460 298 350 MCM 350 400

575 227 4/0 AWG 250 300

208 660 (2) 400 MCM 800 800

230 593 (2) 350 MCM 700 800

460 301 350 MCM 350 400

575 231 250 MCM 300 300

208* 674 (2) 400 MCM 800 800

230 606 (2) 350 MCM 700 800

460 308 350 MCM 350 400

575 236 250 MCM 300 300

208* 716 (2) 2-250 MCM 800 1000

230 646 (2) 400 MCM 800 800

460 325 400 MCM 400 450

575 255 250 MCM 300 350

208* 745 (2) 2-250 MCM 1000 1000

230 672 (2) 400 MCM 800 800

460 338 400 MCM 400 450

575 265 300 MCM 300 350

208* 775 (2) 2-250 MCM 1000 1000

230 701 (2) 400 MCM 800 800

460 351 400 MCM 400 450

575 279 300 MCM 350 350

208* 790 (2) 2-250 MCM 1000 1000

230 714 (2) 2-250 MCM 800 800

460 357 2-250 MCM 400 450

575 284 300 MCM 350 350

MINIMUM

CIRCUIT

AMPACITY

(MCA)

POWER

SUPPLY

(NOTE 1)

FIELD WIRE

Continued on next page.

FIELD FUSE SIZE or

HACR BREAKER SIZE

RECOM-

MENDED

MAXIMUM

IMM AGS-2 33

Page 34

AGS

UNIT

SIZE

180C 380 60 469 (2)-250 MCM 600 600

190C 380 60 469 (2)-250 MCM 600 600

195C 380 60 479 (2)-250 MCM 600 600

210C 380 60 493 (2)-250 MCM 600 600

Notes

1. See Note 1 on page 47 for explanation of wiring nomenclature.

2. Table based on 75°C field wire.

3. A “HACR” breaker is a circuit breaker designed for use on equipment with multiple motors.

4. Complete notes are on page 47.

VOLTS HZ

208* 853 (2) 2-300 MCM 1000 1000

230 772 (2) 2-250 MCM 1000 1000

460 380 2-250 MCM 450 500

575 301 350 MCM 350 400

208* 853 (2) 2-300 MCM 1000 1000

230 772 (2) 2-250 MCM 1000 1000

460 380 2-250 MCM 450 500

575 301 350 MCM 350 400

208* 871 (2) 2-300 MCM 1000 1000

230 788 (2) 2-250 MCM 1000 1000

460 387 2-250 MCM 450 500

575 306 350 MCM 350 400

208* 897 (2) 2-300 MCM 1000 1200

230 812 (2) 2-250 MCM 1000 1000

460 396 2-250 MCM 450 500

575 313 400 MCM 350 400

It stands for Heating, Air Conditioning, Refrigeration.

MINIMUM

CIRCUIT

AMPACITY

(MCA)

POWER

SUPPLY

(NOTE 1)

FIELD WIRE

FIELD FUSE SIZE or

HACR BREAKER SIZE

RECOM-

MENDED

MAXIMUM