Page 1

Operation Manual

OM AGSC-11

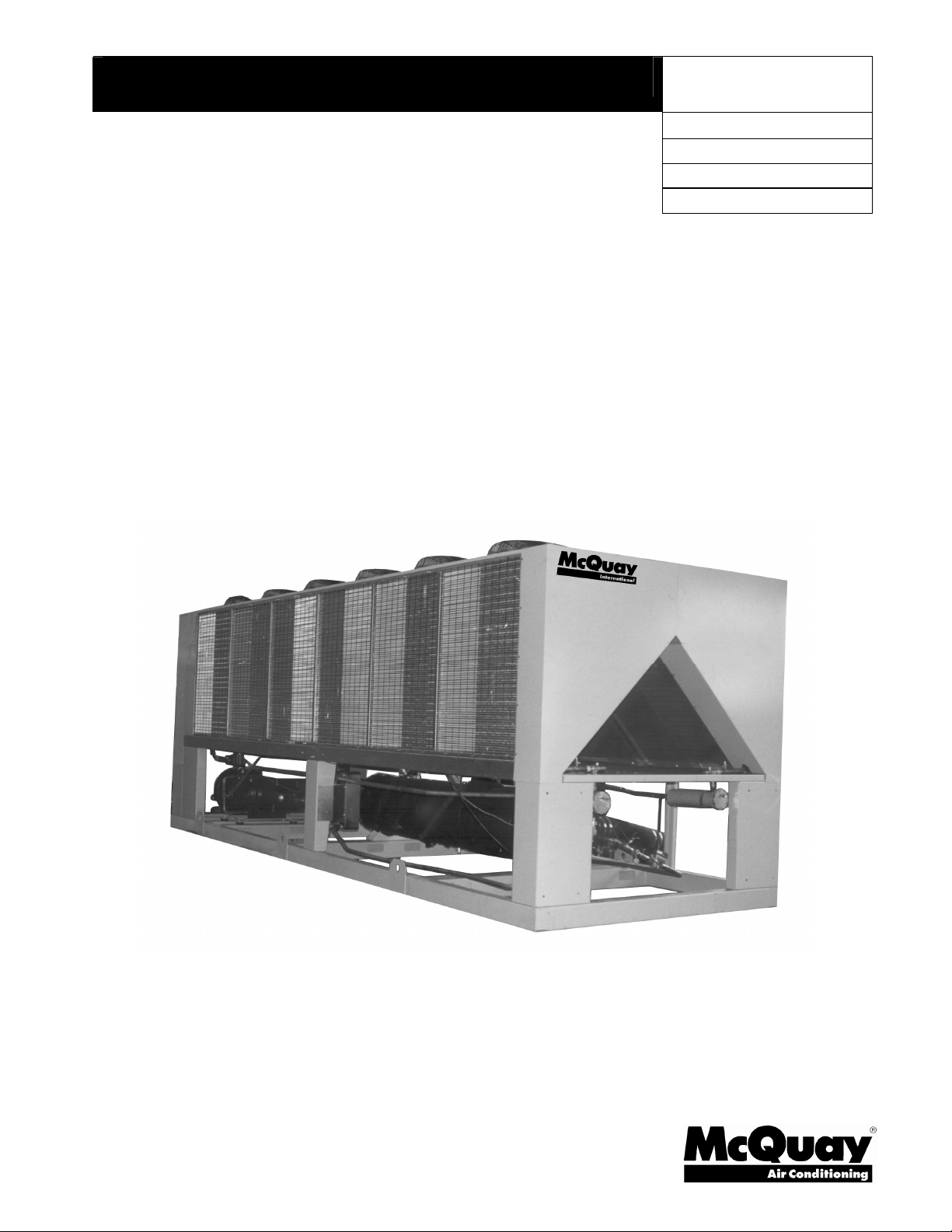

Air-Cooled Screw Compressor Chiller

AGS 120C through AGS 210C

Software Version AGSD30101G/H

60 Hertz, R-134a

Group: Chiller

Part Number: 331373501

Date: May 2008

Supersedes: OM AGSC-10

Page 2

Table of Contents

©2007 McQuay International

ISO Certified facility

CONTROLLER FEATURES......................... 4

GENERAL DESCRIPTION........................... 5

Power Panel Layout...................................... 6

Control Panel Layout.................................... 7

COMPONENT DESCRIPTION .................... 8

Definitions .................................................... 8

Unit and Circuit Controller Description ..... 11

SEQUENCE OF OPERATION.................... 12

CONTROL OPERATION ............................17

UNIT CONTROLLER ..................................17

Inputs/Outputs ............................................17

Setpoints .....................................................18

UNIT CONTROLLER FUNCTIONS..........20

Parameter Definitions .................................20

Unit Enable ................................................. 20

Unit Mode Selection................................... 21

Unit States................................................... 23

Ice Mode Start Delay.................................. 24

Evaporator Pump Control........................... 24

Leaving Water Temperature (LWT) Reset.. 25

Unit Capacity Overrides .............................27

Building Automation System Interface.......28

Quiet Night Operation ................................ 28

CIRCUIT CONTROLLER........................... 29

Inputs/Outputs ............................................29

Setpoints .....................................................30

CIRCUIT CONTROLLER FUNCTIONS ..32

Refrigerant Calculations .............................32

Circuit Operating Mode.............................. 33

Compressor Control.................................... 33

Pumpdown .................................................. 37

Slide Positioning......................................... 37

Unit controllers are LONM

ARK

certified with an optional LONW

ORKS

communications module

Expansion Valve (EXV) Control.................39

Oil Heater Control.......................................41

Economizer Control....................................42

Starter Communications..............................43

Condenser Fan Control ...............................45

ALARMS AND EVENTS..............................48

Unit Stop Alarms.........................................48

Unit Events..................................................49

Circuit Stop Alarms.....................................49

Circuit Events..............................................53

Alarm Logging............................................54

Event Logging.............................................55

USING THE CONTROLLER ......................56

Security .......................................................58

Entering Passwords.....................................58

Editing Setpoints.........................................58

Clearing Alarms ..........................................59

Unit Controller Menus ................................59

Circuit Controller Menus ............................68

SEE "ALARMS AND EVENTS ...................69

Unit Stop Alarms.........................................69

Unit Events..................................................70

Circuit Stop Alarms.....................................70

Circuit Events..............................................74

Alarm Logging............................................75

Event Logging.............................................76

Editing Review............................................82

START-UP AND SHUTDOWN ...................84

Temporary Shutdown..................................84

Extended (Seasonal) Shutdown ..................85

BAS INTERFACE .........................................87

FIELD WIRING DIAGRAM........................91

reserve the right to make changes in design and construction at anytime without notice. ™® The following are trademarks or

registered trademarks of their respective companies: BACnet from ASHRAE; LONM

logo are managed, granted and used by LONM

from Copeland Corporation; ElectroFin from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech II, Open

Choices, and SpeedTrol from McQuay International.

2 OM AGSC-11

. Illustrations and data cover the McQuay International product at the time of publication and we

ARK

ARK

International under a license granted by Echelon Corporation; Compliant Scroll

, LonTalk, LONW

ORKS

, and the LONM

ARK

Page 3

This manual provides setup, operating, and troubleshooting information for the McQuay

MicroTech ΙΙ controller for Model AGS-C vintage, air-cooled, rotary screw compressor

chillers. Please refer to the current version of the installation and maintenance manual IMM

AGSC (available on www.mcquay.com) for information relating to the unit itself.

Among other revisions and upgrades, this software version modifies EXV valve and

economizer operation, modifies start logic and some alarms and events, changes some set

points, and adds to the BAS interface logic.

Software Version: This manual covers units with Software Version AGSD30101G and H.

Version G contains the above changes and Version H only corrects an EXV bug and does

not change this manual. The unit’s software version number can be viewed by pressing the

MENU and ENTER keys (the two right keys) simultaneously. Then, pressing the MENU

key will return to the Menu screen.

BOOT Version: 3.0F

BIOS Version: 3.62

!

DANGER

Electric shock hazard. Can cause personal injury or equipment damage. This equipment

must be properly grounded. Connections to, and service of, the MicroTech II control panel

must be performed only by personnel who are knowledgeable in the operation of the

equipment being controlled.

!

WARNING

Static sensitive components. A static discharge while handling electronic circuit boards can

cause damage to the components. Discharge any static electrical charge by touching the

bare metal inside the control panel before performing any service work. Never unplug any

cables, circuit board terminal blocks, or power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with this instruction manual, can cause interference to radio communications. Operation

of this equipment in a residential area can cause harmful interference, in which case the user will be

required to correct the interference at the user’s own expense.

McQuay International Corporation disclaims any liability resulting from any interference or for the

correction thereof.

Temperature and Humidity Limitations

The MicroTech ΙΙ controller is designed to operate within an ambient temperature range of

-20°F to +149°F (-29°C to +65.1°C) with a maximum relative humidity of 95% (noncondensing).

Language

This version of the software is set up for English language and inch-pounds units of measure

only.

OM AGSC-11 3

Page 4

Controller Features

• Readout of the following temperature and pressure readings:

• Entering and leaving chilled water temperature

• Saturated evaporator refrigerant temperature and pressure

• Saturated condenser temperature and pressure

• Outside air temperature

• Suction line, liquid line, and discharge line temperatures − calculated superheat for

discharge and suction lines

• Automatic control of primary and standby chilled water pumps. The control will start one

of the pumps (based on lowest run-hours) when the unit is enabled to run (not necessarily

running on a call for cooling) and when the water temperature reaches a point of freeze

possibility.

• Three levels of security protection against unauthorized changing of setpoints and other

control parameters.

• Warning and fault diagnostics to inform operators of warning and fault conditions in plain

language. All events and alarms are time- and date-stamped for identification of when the

fault condition occurred. In addition, the operating conditions that existed just prior to an

alarm shutdown can be recalled to aid in isolating the cause of the problem.

• Twenty-five previous alarms and related operating conditions are available.

• Remote input signals for chilled water reset, demand limiting, and unit enable.

• Test mode allows the service technician to manually control the controllers’ outputs and

can be useful for system checkout.

• Building Automation System (BAS) communication capability via LONW

Modbus, or BACnet open standard protocols for all BAS manufacturers-simplified

with McQuay’s Open Choices feature.

• Service Test mode for troubleshooting controller hardware.

• Pressure transducers for direct reading of system pressures. Preemptive control of low

evaporator pressure conditions and high discharge temperature and pressure to take

corrective action prior to a fault trip.

• Distributed control-one unit controller and two independent circuit controllers improves

unit reliability.

• Quiet Night operation limits unit capacity and fan operation to reduce unit sound levels

during low-load, night-time operation.

ORKS

,

4 OM AGSC-11

Page 5

General Description

General Description

The AGS-C MicroTech ΙΙ distributed control system consists of multiple microprocessorbased controllers that provide monitoring and control functions required for the controlled,

efficient operation of the chiller. The system consists of the following components:

• Unit Controller, one per chiller − controls functions and settings that apply to the unit

and communicates with the other controllers. It is located in the control panel and is

labeled “UNIT CONTROL”.

• Circuit Controllers for each compressor/circuit that control compressor functions and

settings specific to the circuit. The controllers are also located in the control panel and

are labeled “CIRCUIT CONROL”.

In addition to providing all normal operating controls, the MicroTech II control system

monitors equipment protection devices on the unit and will take corrective action if the

chiller is operating outside of its normal design envelope. If an alarm condition develops,

the controller will shut down the compressor, or entire unit, and activate an alarm output.

Important operating conditions at the time an alarm condition occurs are retained in the

controller’s memory to aid in troubleshooting and fault analysis.

The system is protected by a password scheme that allows access only by authorized

personnel. The operator must enter the operator password into the controller's keypad before

any setpoints can be altered.

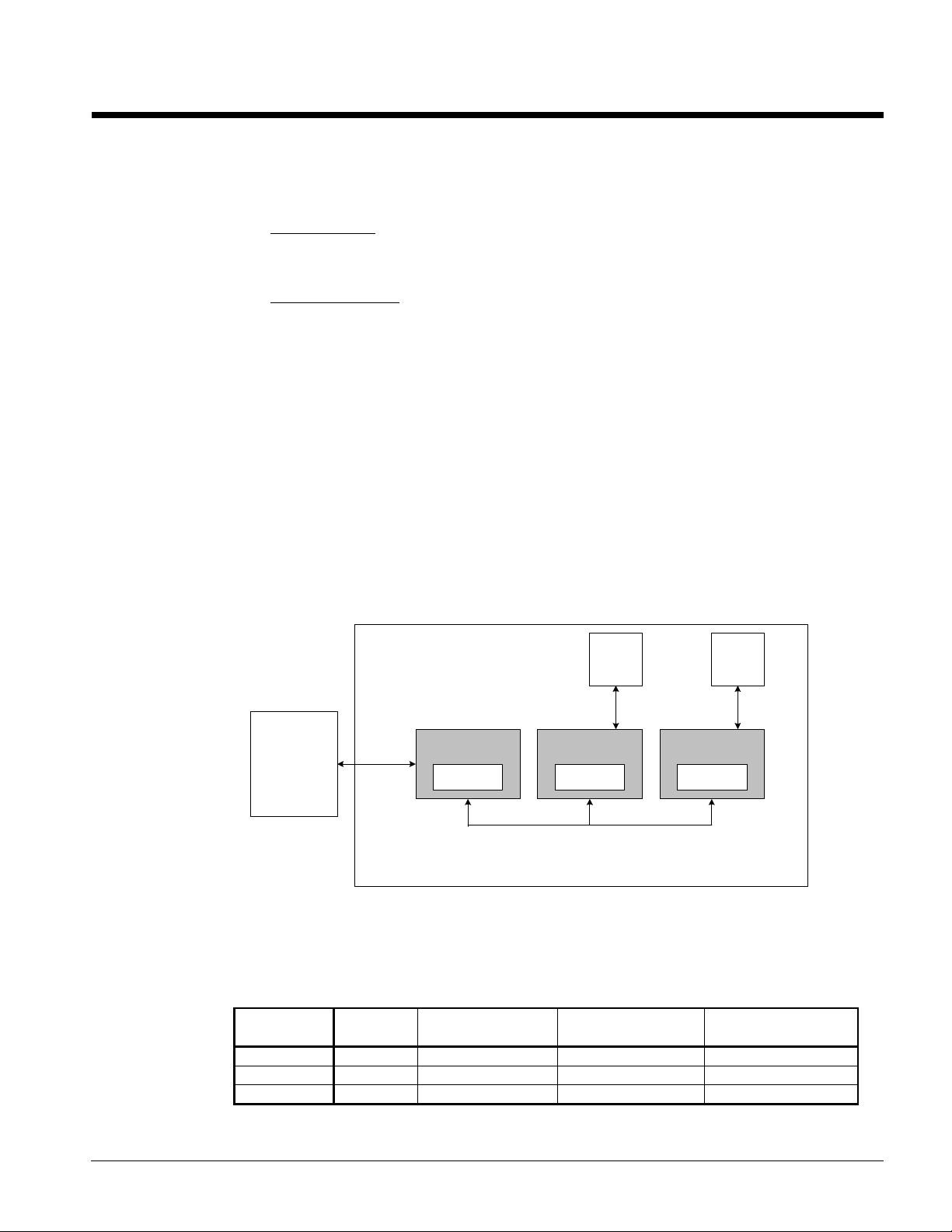

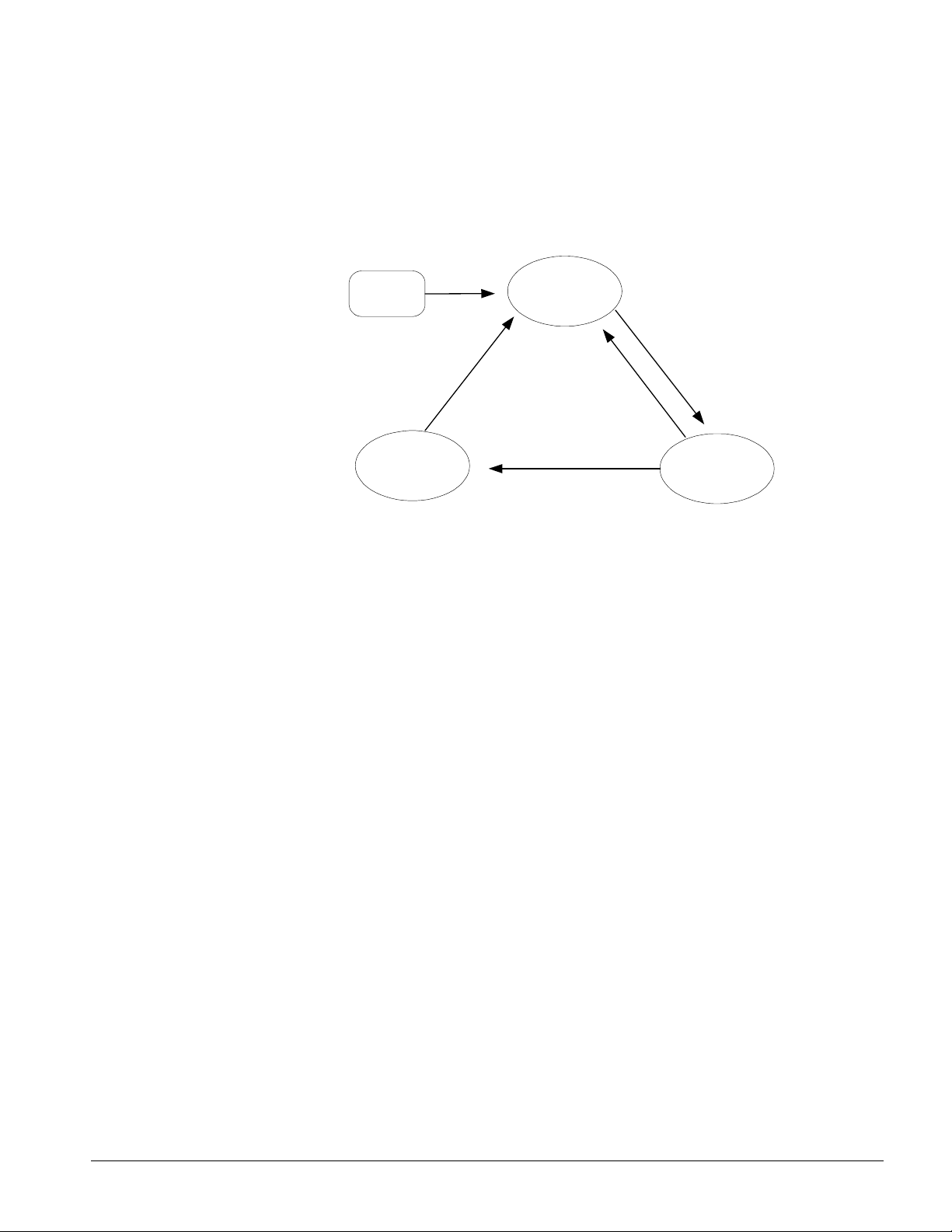

Control Architecture

Figure 1, Major Control Components

BAS Interface-

Modbus,

BACnet,

Lonworks

Chiller

RS485/

LON

Unit Controller

4x20 LCD

Solid

State

Starter

RS485 RS485

Circuit Controller

4x20 LCD

Solid

State

Starter

Circuit Controller

4x20 LCD

Carel pLAN

pLAN Addressing

The pLAN (proprietary local area network) addressing is based on a common scheme used

on all pLAN networked MicroTech II controllers. Only three addresses are needed, and are

designated as shown in the table below.

Controller Address

Dip Sw 1

Position

Unit 5 Up Down Up

Circuit 1 1 Up Down Down

Circuit 2 2 Down Up Down

The Dip switches are located on the upper front of the controller above the screen.

Dip Sw 2

Position

Dip Sw 3 Position

OM AGSC-11 5

Page 6

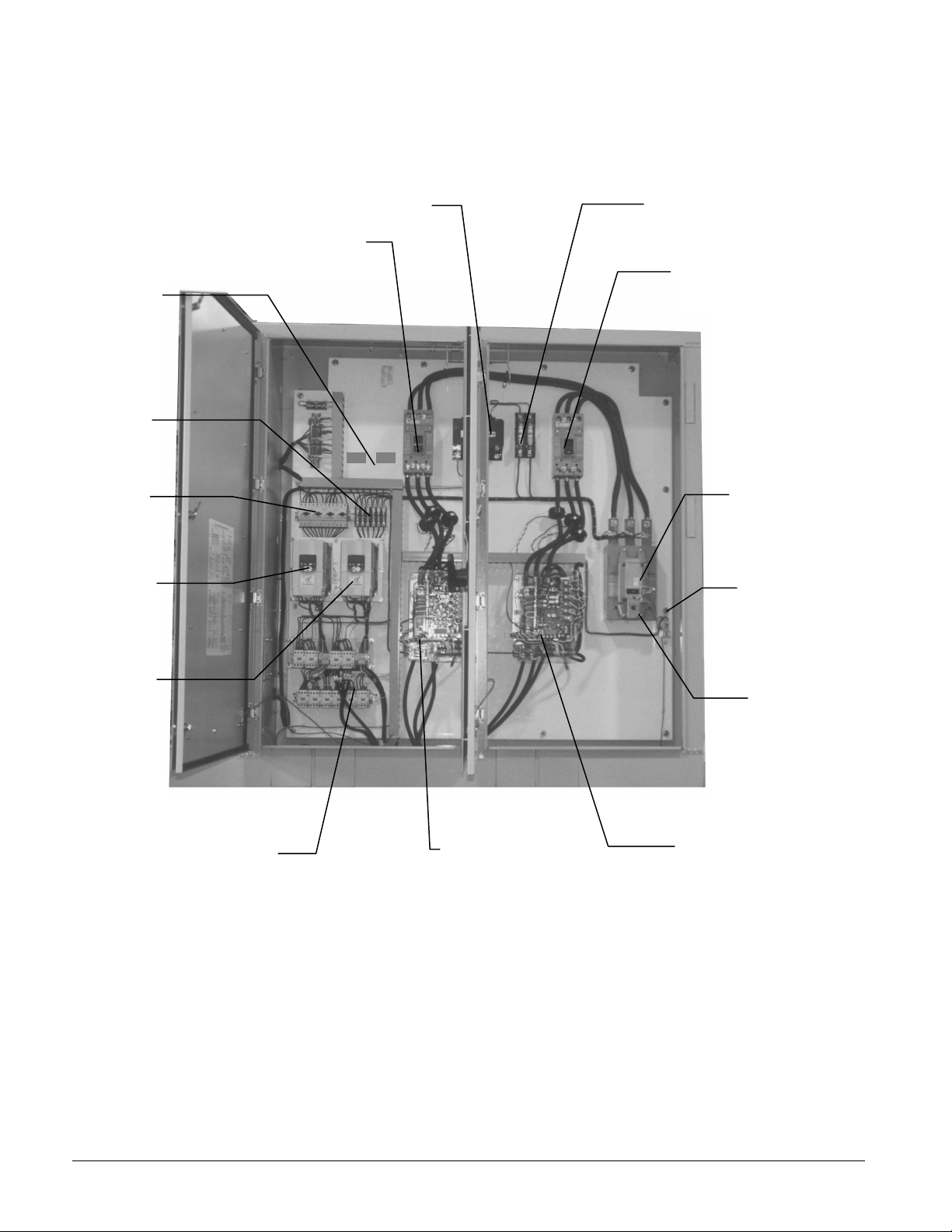

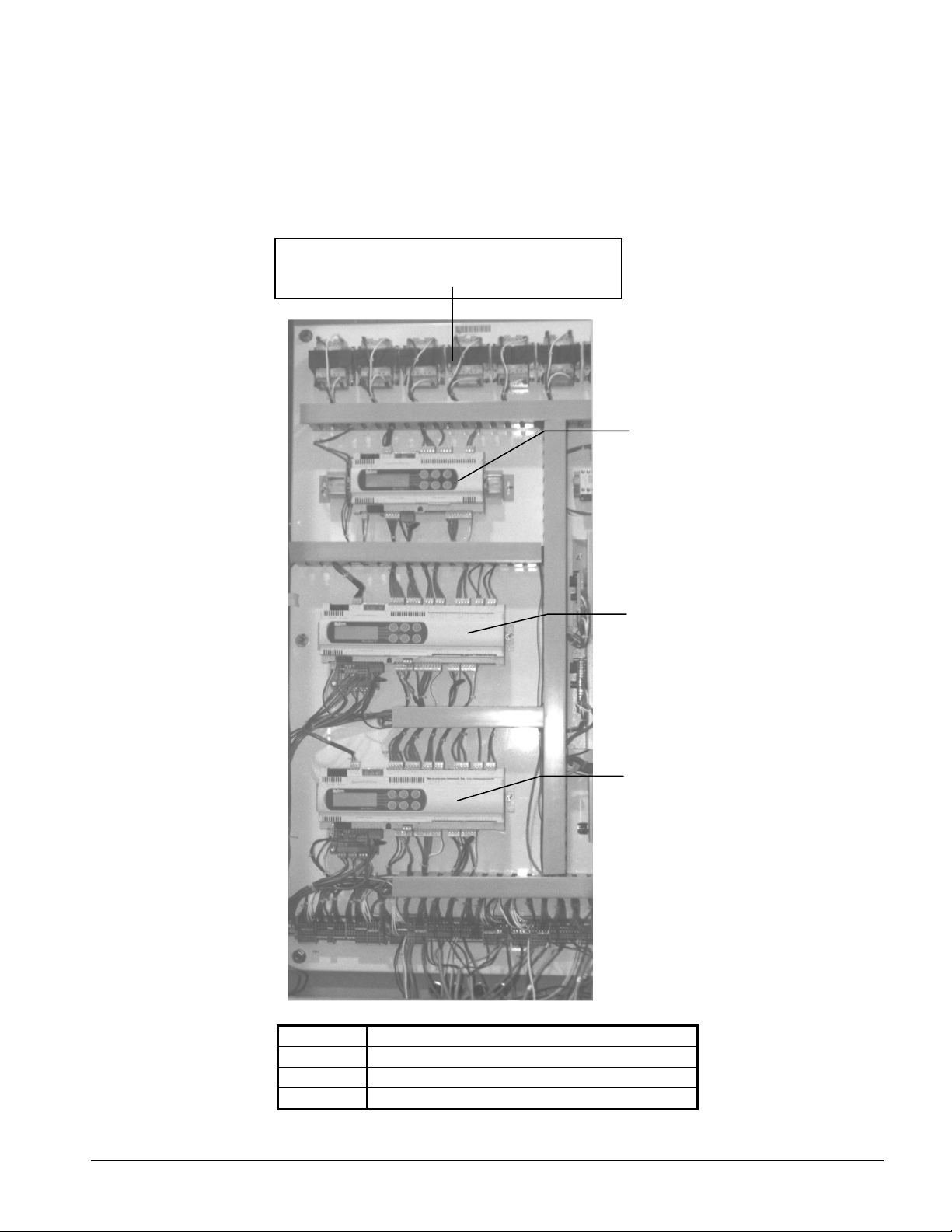

Power Panel Layout

Control Transformer

Fuses

Breakers

The power panel is located on the front of the unit, to the right of the control panel.

Figure 2, Power Panel Components (Single Point Power)

Line

Reactors

for

Optional

VFD

Fan

Circuit

Cir#2 Fan

VFD

(Optional)

Cir#2 Circuit Breaker,

Single Point Power

Primary Control Power

Fuses

Cir#1 Circuit Breaker,

Single Point Power

Unit Circuit

Breaker

(Optional)

Grounding

Lug

Cir#1 Fan

VFD

Fan Contactors

Cir#2 Starter

Incoming

Power

Connection

Cir#1 Starter

6 OM AGSC-11

Page 7

Control Panel Layout

The control panel is located on the front of the unit, to the left of the power panel.

Distributed control architecture enhances unit reliability. Each compressor circuit has its own

microprocessor controller so that if one circuit controller is inoperative, the other circuit controller

will still be able to run its compressor and circuit components.

Figure 3, Control Panel Components

T2 T13 T14 T15 T23 T24 T25

T2 24V Unit Controller Transformer

T13, T23 24V Circuit Controller Transformers

T14, T24 24V Compressor Load/Unload Trns.

T15, T25 24V EXV Driver Transformer

Transformers

Unit Controller

Cir#1 Controller

Cir#2 Controller

OM AGSC-11 7

Page 8

Component Description

Definitions

Active Setpoint

The active setpoint is the setting in effect at any given moment. This variation occurs on

setpoints that can be altered during normal operation. Resetting the chilled water leaving

temperature setpoint by one of several methods, such as return water temperature, is an

example.

Active Capacity Limit

The active setpoint is the setting in effect at any given moment. Any one of several external

inputs can limit a compressor’s capacity below its maximum value.

Condenser Saturated Temperature Target

The saturated condenser temperature target is calculated by first using the following

equation:

Sat condenser temp target raw = 0.833(evaporator sat temp) + 68.34

The “raw” value is the initial calculated value. This value is then limited to a range defined

by the Condenser Saturated Temperature Target minimum and maximum setpoints. These

setpoints simply cut off the value to a working range, and this range can be limited to a

single value if the two setpoints are set to the same value.

CPU Error

These are problems caused by a malfunction of the central processing unit.

Dead Band

The dead band is a range of values surrounding a setpoint such that a change in the variable

occurring within the dead band range causes no action from the controller. For example, if a

temperature setpoint is 44°F and it has a dead band of ± 2 degrees F, nothing will happen

until the measured temperature is less than 42°F or more than 46°F.

DIN

Digital input, usually followed by a number designating the number of the input.

Discharge Superheat

Discharge superheat shall be calculated for each circuit using the following equation:

Discharge Superheat = Discharge Temperature – Condenser Saturated Temperature

Error

In the context of this manual, “Error” is the difference between the actual value of a variable

and the target setting or setpoint.

Evaporator Approach

The evaporator approach is calculated for each circuit. The equation is as follows:

Evaporator Approach = LWT – Evaporator Saturated Temperature

Evap Recirc Timer

A timing function, with a 30-second default, that holds off any reading of chilled water for

the duration of the timing setting. This delay allows the chilled water sensors (especially

water temperatures) to take a more accurate reading of the chilled water system conditions.

8 OM AGSC-11

Page 9

EXV

Electronic expansion valve, used to control the flow of refrigerant to the evaporator,

controlled by the circuit microprocessor.

High Saturated Condenser – Hold Value

High Cond Hold Value = Max Saturated Condenser Value – 5°F

This function prevents the compressor from loading whenever the pressure approaches

within 5 degrees of the maximum discharge pressure. The purpose is to keep the compressor

online during periods of possibly temporary elevated pressures.

High Saturated Condenser – Unload Value

High Cond Unload Value = Max Saturated Condenser Value – 3°F

This function unloads the compressor whenever the pressure approaches within 3 degrees of

the maximum discharge pressure. The purpose is to keep the compressor online during

periods of possibly temporary elevated pressures.

High Superheat Error

The degrees of temperature difference between 40°F and the actual discharge temperature.

Light Load Stg Dn Point

The percent load point at which one of two operating compressors will shut off, transferring

the unit load to the remaining compressor.

Load Limit

An external signal from the keypad, the BAS or a 4-20 ma signal that limits the compressor

loading to a designated percent of full load. Frequently used to limit unit power input.

Load Balance

Load balance is a technique that equally distributes the total unit load among the running

compressors on a unit or group of units.

Low Ambient Lockout

Prevents the unit from operating (or starting) at ambient temperatures below the setpoint.

Lockout cancels when ambient temperature rises 5-degfrees above the setpoint

Low Pressure Hold Setpoint

The psi evaporator pressure setting at which the controller will not allow further compressor

loading.

Low/High Superheat Error

The difference between actual evaporator superheat and the superheat target.

LWT

Leaving water temperature. The “water” is any fluid used in the chiller circuit.

LWT Error

Error in the controller context is the difference between the value of a variable and the

setpoint. For example, if the LWT setpoint is 44°F and the actual temperature of the water at

a given moment is 46°F, the LWT error is +2 degrees.

LWT Slope

The LWT slope is an indication of the trend of the water temperature. It is calculated by

taking readings of the temperature every few seconds and subtracting them from the previous

value, over a rolling one minute interval.

ms

Milli-second

OM AGSC-11 9

Page 10

Maximum Saturated Condenser Temperature

The maximum saturated condenser temperature allowed is calculated based on the

compressor operational envelope.

OAT

Outside ambient air temperature

Offset

Offset is the difference between the actual value of a variable (such as temperature or

pressure) and the reading shown on the microprocessor as a result of the sensor signal. See

page 31.

pLAN

Peco Local Area Network is the proprietary name of the network connecting the control

elements.

Refrigerant Saturated Temperature

Refrigerant saturated temperature is calculated from the pressure sensor readings for each

circuit. The pressure is fitted to an R-134a temperature/pressure curve to determine the

saturated temperature.

Soft Load

Soft Loading is a configurable function used to ramp up the unit capacity over a given time

period, usually used to influence building electrical demand by gradually loading the unit.

SP

Setpoint

SSS

Solid state starter as used on McQuay screw compressors.

Suction Superheat

Suction superheat is calculated for each circuit using the following equation:

Suction Superheat = Suction Temperature – Evaporator Saturated Temperature

Stage Up/Down Accumulator

The accumulator can be thought of as a bank storing occurrences that indicate the need for

an additional fan.

Stageup/Stagedown Delta-T

Staging is the act of starting or stopping a compressor or fan when another is still operating.

Startup and Stop is the act of starting the first compressor or fan and stopping the last

compressor or fan. The Delta-T is the “dead band” on either side of the setpoint in which no

action is taken.

Stage Up Delay

The time delay from the start of the first compressor to the start of the second.

Startup Delta-T

Number of degrees above the LWT setpoint required to start the first compressor.

Stop Delta-T

Number of degrees below the LWT setpoint required for the last compressor to stop.

VDC

Volts, Direct current, sometimes noted as vdc.

VFD

Variable Frequency Drive, a device used to vary an electric motor’s speed.

10 OM AGSC-11

Page 11

Unit and Circuit Controller Description

ALARM

Hardware Structure

The controllers are fitted with a 16-bit microprocessor for running the control program.

There are controller terminals for connection to the controlled devices (for example: solenoid

valves, expansion valves, chilled water pumps). The program and settings are saved

permanently in FLASH memory, preventing data loss in the event of power failure without

requiring a back-up battery. The controllers also have optional remote communication

access capability for a BAS interface using standard protocols.

Each chiller has one unit controller and a circuit controller for each of two compressor

circuits. The controllers are connected and communicate via a pLAN (local area network).

The circuit controllers communicate with, and control the operation of, the compressor's

solid state starter and the circuit’s electronic expansion valve (EXV).

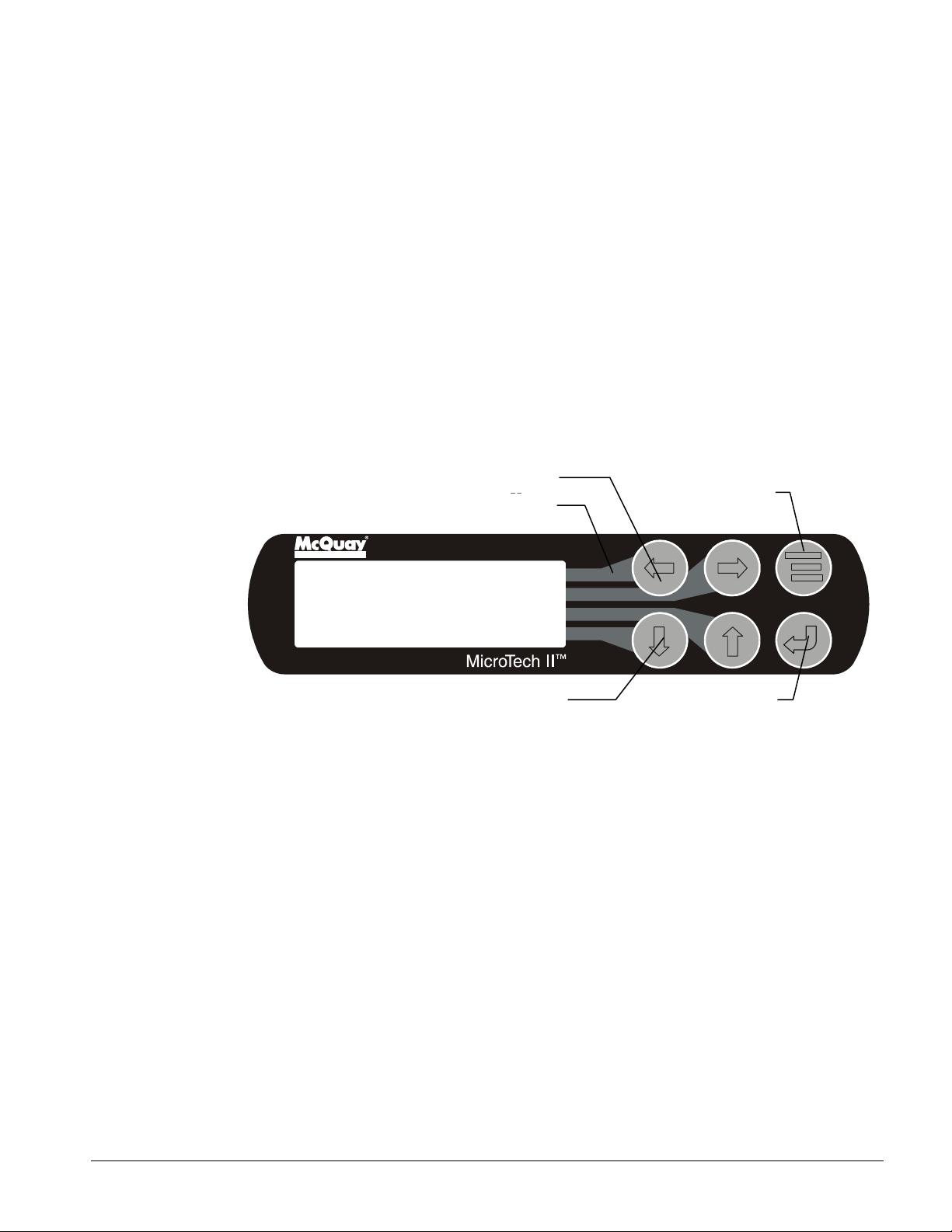

Keypad

A 4-line by 20-character liquid crystal display and 6-button keypad are mounted on the unit

and compressor controllers.

Figure 4, Keypad

Red Alarm Light Behind Arrow

MENU Key

Key-to-Screen Pathway

Air Conditioning

<

VIEW

<

<

SET

ARROW Keys (4)

ENTER Key

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use.

1. Scroll between data screens in the direction indicated by the arrows (default mode).

2. Select a specific data screen in the menu matrix using dynamic labels on the right side of

the display such as ALARM, VIEW, etc. (pressing the MENU key enters this mode).

For ease of use, a visual pathway connects the appropriate button to its respective label

on the screen.

3. Change field values in setpoint programming mode as follows:

LEFT key = Default (D) RIGHT key = Cancel (C)

UP key = Increase (+) DOWN key = Decrease (-)

These four programming functions are indicated by a one-character abbreviation ( ) on the

right side of the display. This programming mode is entered by pressing the ENTER key.

OM AGSC-11 11

Page 12

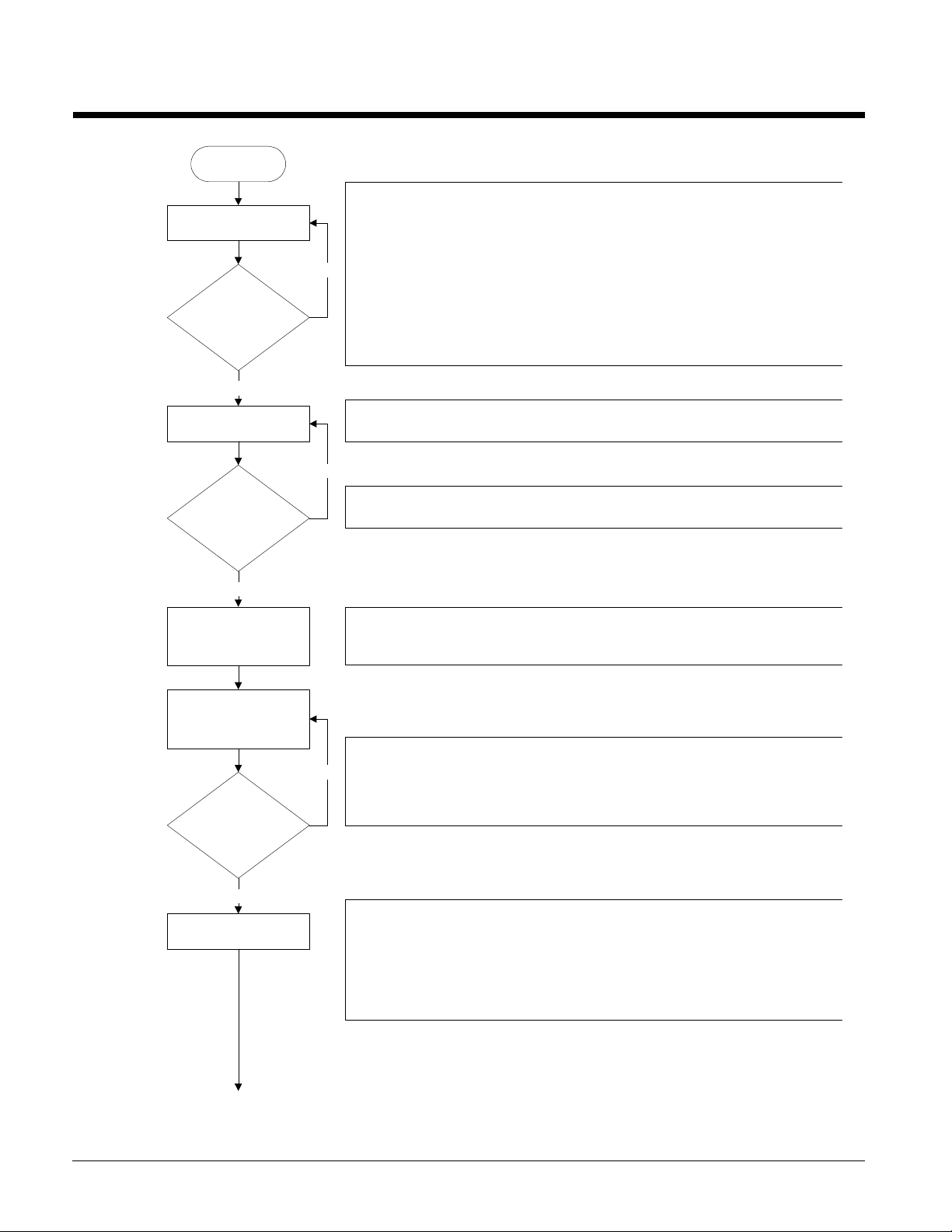

Sequence of Operation

Unit power up

The chiller may be disabled via the unit switch, the remote switch, the keypad

Unit in Off state

Is unit enabled?

Yes

Evaporator pump output on

Is flow present?

enable setting, or the BAS network. In addition, the chiller will be disabled if both

circuits are disabled, either because of an alarm or the circuit pumpdown switch on

each circuit, or if there is a unit alarm. If the chiller is disabled, the unit status

display will reflect this and also show why it is disabled.

No

If the unit switch is off, the unit status will be

disabled due to network command, the unit status will be

the remote switch is open, the unit status will be

alarm is active, the unit status will be

are enabled, the unit status will be

If the chiller is enabled, then the unit will be in the Auto state and the evaporator

water pump output will be activated.

No

The chiller will then wait for the flow switch to close, during which time the unit

status will be

Auto:Wait for flow

Off:Unit Switch

Off:Remote Switch

Off:Unit Alarm

Off:All Cir Disabled

.

. If the chiller is

Off:BAS Disable

. When

. When a unit

. In cases where no circuits

.

Yes

Wait for chilled water loop to

recirculate.

Keep pump output on while

unit is enabled.

Is there enough load to

start chiller?

Yes

Start first circuit.

After establishing flow, the chiller will wait some time to allow the chilled water loop

to recirculate for an accurate reading of the leaving water temperature. The unit

status during this time is

Auto:Evap Recirc

.

The chiller is now ready to start if enough load is present. If the LWT is not high

enough to start, the unit status will be

No

If the LWT is high enough to start, the unit status will be

Auto:Wait for load

.

Auto

. A compressor can

start at this time.

The first circuit to start is generally the one with the least number of starts, or circuit

one if there is a tie. This circuit will go through its start sequence at this point.

A number of fans may be started with the compressor based on the OAT. Fan

stages will be added/removed as needed to control condenser pressure. The EXV

will begin controlling at this point as well. The compressor cannot start loading until

it has at least 22o discharge superheat for more than 30 seconds.

12 OM AGSC-11

Page 13

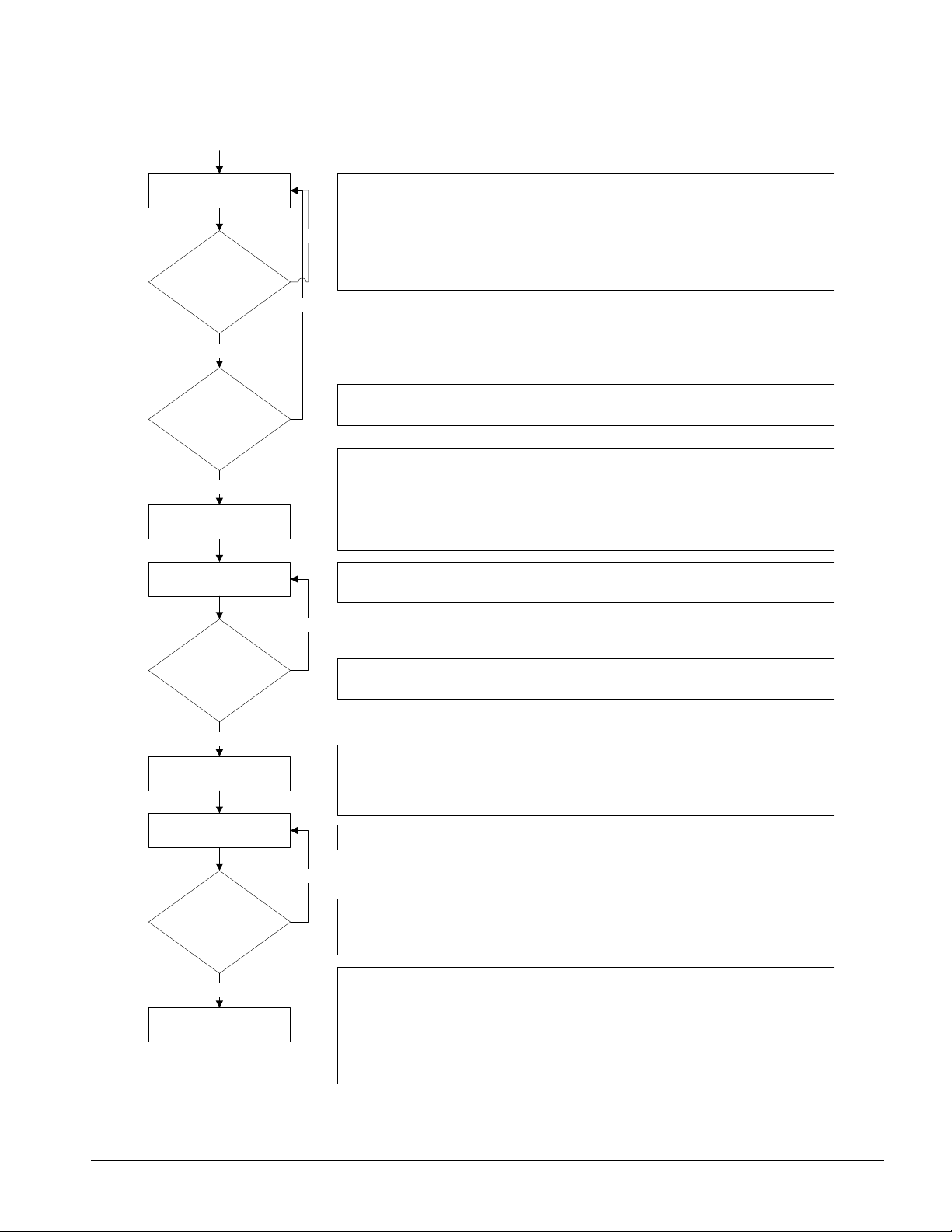

Load/unload as needed to

satisfy load.

Is more capacity

needed to satisfy load?

Yes

Has the stage up time

delay expired?

Yes

Start second circuit.

Load/unload as needed to

satisfy load.

No

The first circuit will load and unload as needed in an attempt to satisfy the load. It

will eventually get to a point where it is considered to be at full load. A circuit is at

full load when it reaches 75% slide target, it reaches the max slide target setting, or

it encounters a problem and is running in an inhibited state.

No

If a single circuit is not enough to satisfy the load, the second circuit will need to be

started.

A minimum time must pass between the start of the first circuit and the second

circuit.

The second circuit will go through its start sequence at this point.

A number of fans may be started with the compressor based on the OAT. Fan

stages will be added/removed as needed to control condenser pressure. The EXV

will begin controlling at this point as well. The compressor cannot start loading until

it has at least 22o discharge superheat for more than 30 seconds.

Both circuits will now load/unload as needed to satisfy the load. In addition, they will

load balance so that both circuits are providing nearly equal capacity.

No

Can one circuit handle

the load?

Yes

Shut down one circuit.

Load/unload as needed to

satisfy load.

Is load satisfied?

Yes

Shut down last circuit.

As the load drops off, the circuits will unload accordingly. If the LWT gets low

enough, or both circuits unload enough, one circuit can shut off.

The first circuit to shut off is generally the one with the most run hours. The circuit

will do a pumpdown by closing the EXV and continuing to run the compressor until it

reaches the pumpdown pressure or exceeds the pumpdown time limit. Then, the

compressor and all fans will be turned off.

The single running circuit will load/unload as needed to satisfy the load.

No

With one circuit running, the load may drop off to the point where even minimum

unit capacity is too much. The load has been satisfied when the LWT drops below

the shutdown point. At this time the only running circuit can shut down.

The last circuit running now shuts down. The circuit will do a pumpdown by closing

the EXV and continuing to run the compressor until it reaches the pumpdown

pressure or exceeds the pumpdown time limit. Then, the compressor and all fans

will be turned off.

The unit should be ready to start again when the LWT gets high enough. The unit

status at this time will be

Auto:Wait for load

.

OM AGSC-11 13

Page 14

The preceding flow diagram illustrates the sequence of operation.

The following sequence of operation expands and clarifies the flow diagram. The sequence

may vary slightly depending on the software revision or various options that may be installed

on the chiller.

Off Conditions

Power is supplied to the power section of the electric panel. The standard power connection

is two separate sources, one to each circuit. Optionally, the power may be supplied to a

single power connection, either a power block or optional disconnect switch.

With power supplied to the unit, 115 VAC power is applied through the control fuse F1 to the

compressor heaters, HTR1 and HTR2, evaporator heater, and the primary of the 24V control

circuit transformer.

!

CAUTION

Compressor heaters must be on for at least 12 hours prior to start-up to avoid compressor

damage..

The 24V transformer provides power to the MicroTech II controller and related components.

With 24V power applied, the controller will check the position of the front panel system

switch. If the switch is in the "stop" position, the chiller will remain off, and the display will

indicate the operating mode to be OFF: Unit Switch. The controller will then check the

pumpdown switches. If any of the switches are in the "stop" position, that circuit’s operating

mode will be displayed as OFF: Pump Down Switch. If the switches for both circuits are

in the "Stop" position, the unit status will display OFF: All Circuits Disabled. If the remote

start/stop switch is open the chiller will be OFF: Remote Switch. The chiller may also be

commanded off via communications from a separate communicating panel such a BAS

protocol interface. The display will show OFF: BAS Disable if this operating mode is in

effect.

If an alarm condition exists which prevents normal operation of both refrigerant circuits, the

chiller will be disabled and the display will indicate OFF: Unit Alarm. If the control mode

on the keypad is set to "Manual Unit Off," the chiller will be disabled and the unit status will

display OFF: Keypad Disable.

Alarm

The red alarm light in back of the left arrow key on the controller will be illuminated when

one or more of the cooling circuits has an active alarm condition which results in the circuit

being locked out or a unit alarm is active and manual reset is required. If only a circuit alarm

is active, the remaining circuits will operate as required. Events (low-level occurrences) will

not cause the key to light.

Start-up

If none of the above "off" conditions are true, the MicroTech II controller will initiate a start

sequence and energize the chilled water pump output relay. The chiller will remain in the

WaitForFlow mode until the field-installed flow switch indicates the presence of chilled

water flow. Once flow is established, the controller will sample the chilled water

temperature and compare it against the Leaving Chilled Water Setpoint, the Control Band,

and the Start-up Delta-Temperature, which have been programmed into the controller’s

memory.

If the leaving chilled water temperature is above the Active Chilled Water Setpoint plus the

adjustable Start-up Delta-T, the controller will select the refrigerant circuit with the lowest

number of starts as the lead circuit and initiate a start request. The circuit controller will

14 OM AGSC-11

Page 15

open the EXV and start the compressor. A green light under the Enter key on the circuit

controller will illuminate to indicate that the compressor is running.

If additional cooling capacity is required, the controller will activate additional cooling. As

the system load increases, the controller will start the lag refrigerant circuit when the lead

circuit reaches 75%, or some other capacity limit is reached, and the interstage timers are

satisfied. The compressors and capacity control solenoids will automatically be controlled as

required to meet the cooling needs of the system. The electronic expansion valves are

operated by the MicroTech II controller to maintain precise refrigerant control to the

evaporator at all conditions.

Standard FanTrol Condenser Fan Control

When the compressor starts, a number of fans may be started, depending on the OAT and the

Forced Fan setpoints. The MicroTech II controller will activate the remaining condenser

fans as needed to maintain proper condenser pressure. The MicroTech II controller

continuously monitors the condenser pressure and will adjust the number of operating

condenser fans as required. The number of condenser fans operating will vary with outdoor

temperature and system load. The condenser fans are matched to the operating compressors

so that when a compressor is off, all fans for that circuit will also be off.

Pumpdown

As the system chilled water load requirements diminish, the compressors will unload. As the

system load continues to drop, the electronic expansion valve will be stepped closed, the

solenoid valve will close, and the refrigerant circuits will go through a pumpdown sequence.

As the evaporator pressure falls below the pumpdown pressure setpoint while pumping

down, the compressor and condenser fans will stop. The unit has a one-time pumpdown

control logic; therefore, if the evaporator pressure rises while the compressor is in the off

state, the controller will not initiate another pumpdown sequence. The circuit controller will

keep the compressor off until the next call for cooling occurs.

The chilled water pump output relay will generally remain energized until the unit is in the

Off State due to the remote stop switch, unit Off switch, BAS command, or keypad setting

calling for the unit to be disabled.

Liquid Line Solenoid Valve (LLSV)

The LLSV cycles with the compressor starter. Its purpose is to provide a positive seal in the

liquid line in the event of a power failure. A power failure may prevent the expansion valve

from closing completely by removing power before the valve steps all the way closed.

OM AGSC-11 15

Page 16

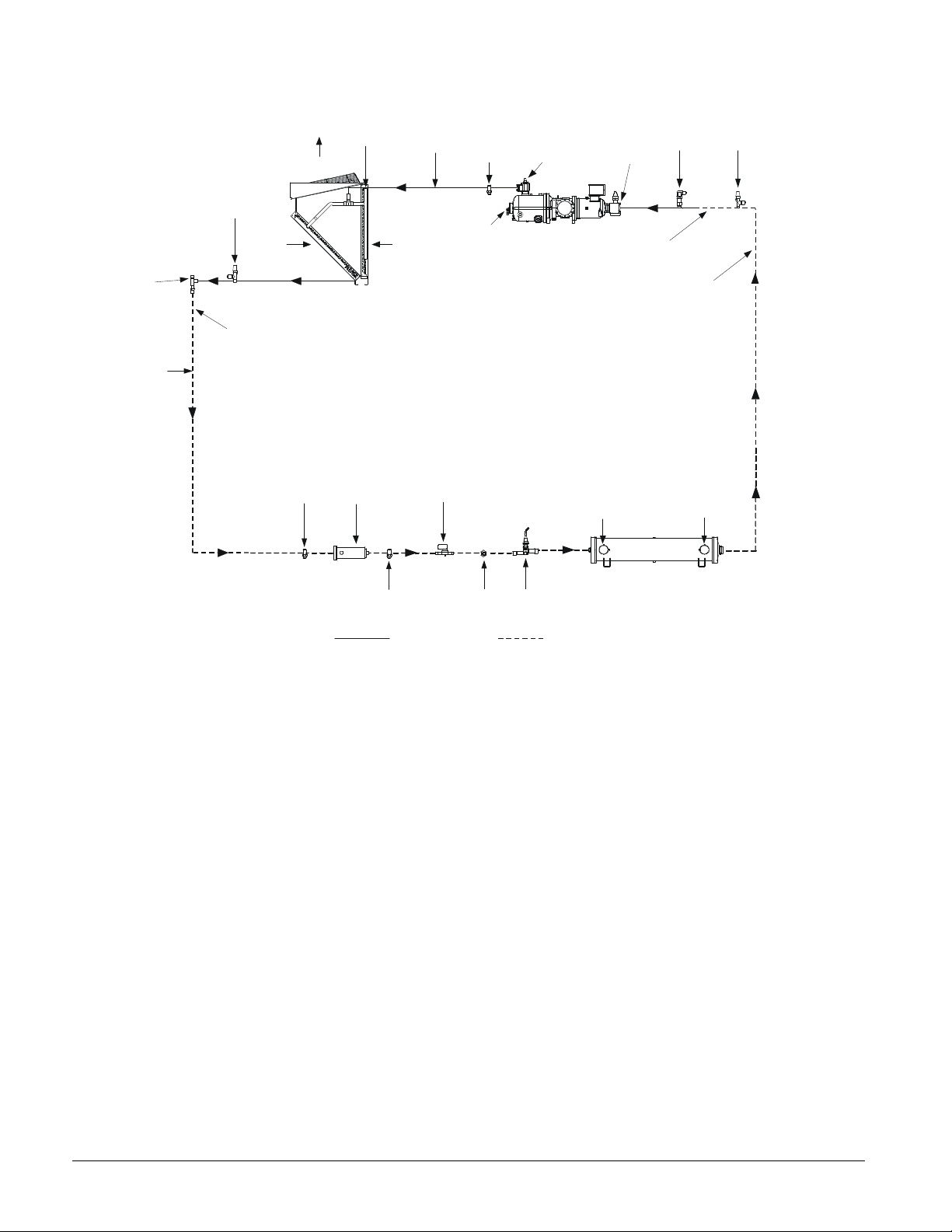

Figure 5, AGS-C Piping Schematic

WATER IN

DX EVAPORATOR

FIELD CONNECTION

SUCTION

SUCTION

CHARGING

330591001-R3

FACTORY PIPING

DISCHARGE

CHECK AND

SCHRADER

(HEADER)

AIR

FLOW

CHARGING

VALV E

AIR

LIQUID

SHUT-OFF

VALVE

LIQUID

TUBING

FLOW

FIELD CONNECTION

LIQUID LINE

VALVE

CONDENSOR

DISCHARGE

AIR

FLOW

ASSEMBLY

TUBING

SCHRADER

VALVE

RELIEF

VALVE

SHUT-OFF

VALVE

FRAME 3200

COMPRESSOR

SHUT-OFF

VALVE

SUCTION LINE

RELIEF

VALVE

VALVE

TUBING

SCHRADER

VALVE

FILTER

DRIER

SCHRADER

VALVE

SOLENOID

VALVE

SIGHT

GLASS

EXPANSION

VALVE

WATER OUT

FIELD PIPING

NOTE: The above figure illustrates the piping for the remote evaporator option. For the standard packaged

version, the field piping shown as dotted would be installed in the factory.

16 OM AGSC-11

Page 17

Control Operation

This section on MicroTech II control is divided into three subsections:

• Unit Controller, explains the functions of the unit controller, see page 17.

• Circuit Controller, explains the functions of the circuit controller, see page 29

• Using the Controller, explains how to navigate through the menus and how to make

entries, see page 48.

Unit Controller

Inputs/Outputs

Analog Inputs

The following parameters are analog inputs to this controller. They are used internally as

needed and are sent via the pLAN to other control devices.

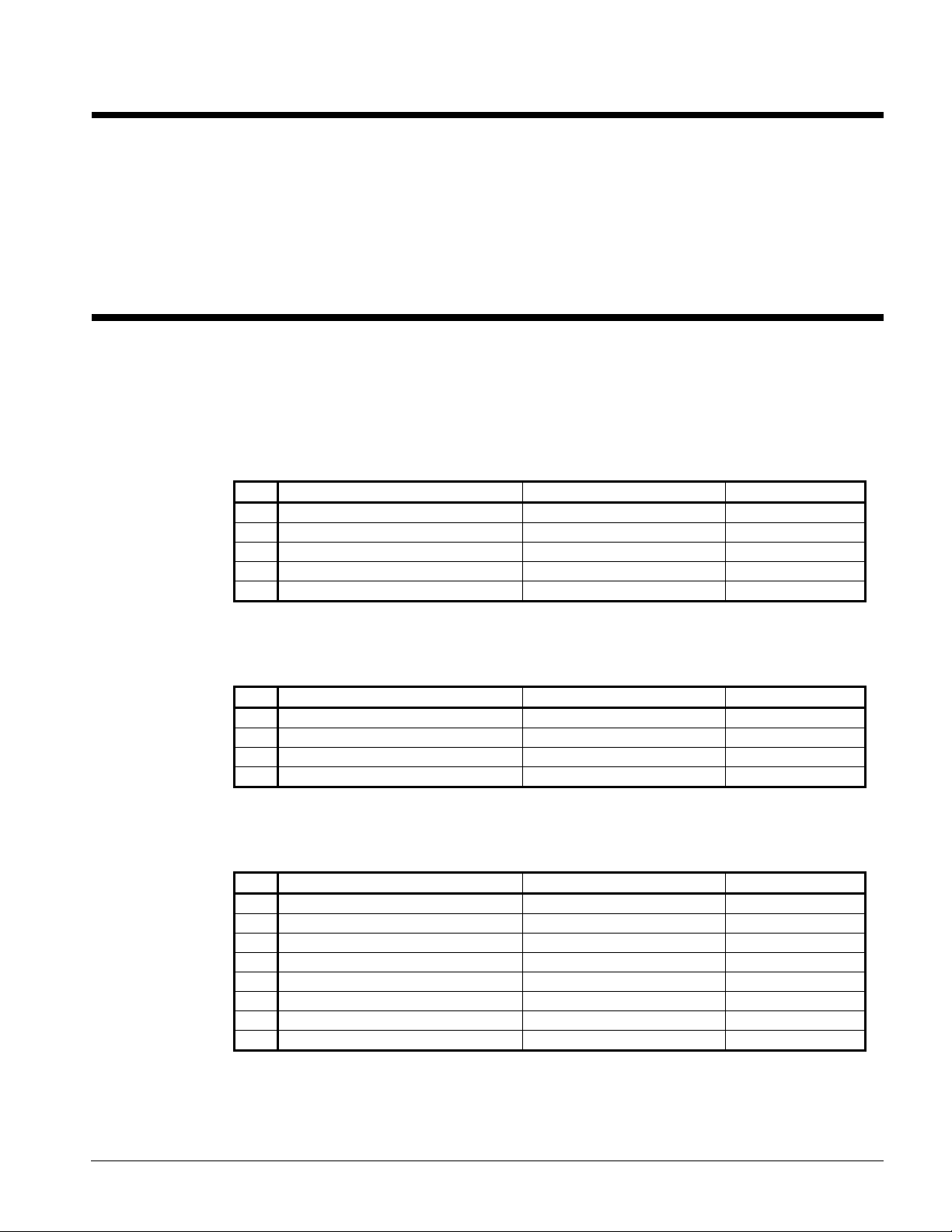

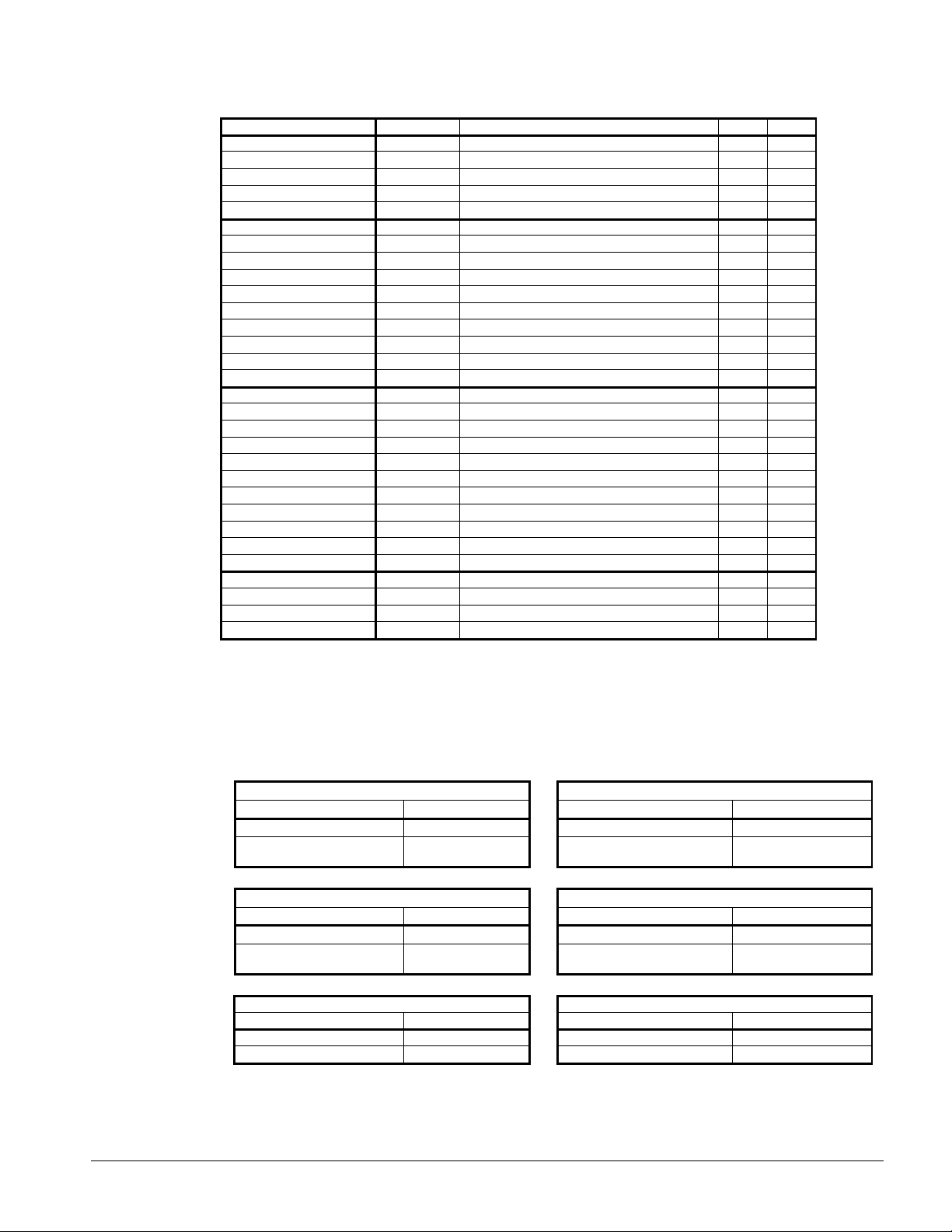

Table 1, Unit Analog Inputs

# Description Signal Source Range

1 Outdoor Ambient Temperature Thermister (10k@25°C) -58 to 212°F

2 Demand Limit 4-20 mA Current, External 0 to 100% limit

3 Chilled Water Reset 4-20 mA Current, External 0 to max reset

4 Leaving Evaporator Water Temperature Thermister (10k@25°C) -58 to 212°F

5 Entering Evaporator Water Temperature Thermister (10k@25°C) -58 to 212°F

Analog Outputs

Table 2, Unit Analog Outputs

# Description Output Signal Range

1 Open -- --

2 Open -- --

3 Open -- --

4 Open -- --

Digital Inputs

Table 3, Unit Digital Inputs

# Description Signal Signal

1 Unit Switch 0 VAC (Stop) 24 VAC (On)

2 Remote Switch 0 VAC (Stop) 24 VAC (Start)

3 Evaporator Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

4 Mode Switch 0 VAC (Cool) 24 VAC (Ice)

5 Open -- --

6 Open -- --

7 Open -- --

8 Open -- --

OM AGSC-11 17

Page 18

Digital Outputs

Table 4, Unit Digital Outputs

# Description Output OFF Output ON

1 Evaporator Water Pump 1 Pump OFF Pump ON

2 Evaporator Water Pump 2 Pump OFF Pump ON

3 Open

4 Open

5 Open

6 Open

7 Open

8 Alarm No alarm Stop alarm

Setpoints

The following parameters are remembered during power off, are factory set to the Default

value, and can be adjusted to any value in the Range column.

The Type column defines whether the setpoint is part of a coordinated set of duplicate

setpoints in different controllers. There are two possibilities as given below:

N = Normal setpoint - Not copied from, or copied to, any other controller

M = Master setpoint - Setpoint is copied to all controllers in the “Sent To” column

The PW (password) column indicates the required password level.

Codes are as follows:

O = Operator, Password is 100 M = Manager

Toggle: Setpoints that have two choices, such as ON and OFF are toggled between the two

settings using the Up or Down keys on the controller.

NOTE: in some software versions the terms “inhibit” and “hold” are used interchangeably.

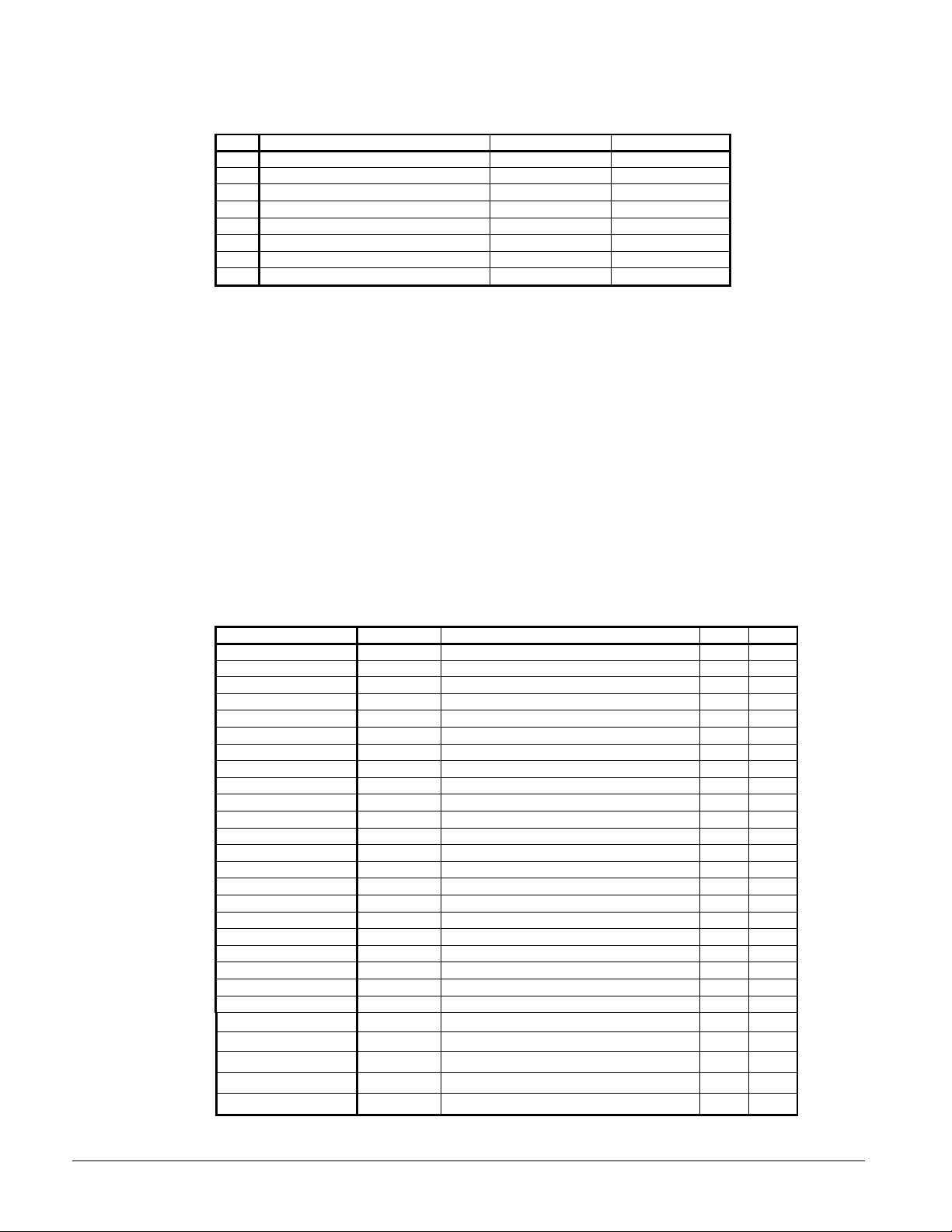

Table 5, Unit Setpoints

Description Default Range Type PW

UNIT

Unit Enable OFF OFF, ON N O

Unit Mode Cool Cool, Ice, Test M O

Control source Switches Switches, Keypad, Network N O

Available Modes Cool

Cool LWT

Ice LWT

Startup Delta T

Stop Delta T

Stage Up Delta T

Stage Down Delta T

Max Pulldown

Evap Recirc Timer 30 0 to 300 seconds N M

Evap Pump Select #1 Only #1 Only, #2 Only, Auto N M

LWT Reset Type NONE NONE, RETURN, 4-20mA, OAT N M

Max Reset

Start Reset Delta T

Soft Load Off Off, On N M

Begin Capacity Limit 40% 20-100% N M

Soft Load Ramp 20 min 1-60 minutes N M

Demand Limit Off Off, On N M

Low Ambient Lockout

Ice Time Delay 12 1-23 hours N M

Clear Ice Timer No No,Yes N M

Remote Evaporator No No, Yes M M

Quiet Night Disabled Disabled, Enabled N M

Quiet Night Start Time 21:00 18:00 - 23:59 N M

Cool, Cool w/Glycol, Cool/Ice w/Glycol, ICE

44°F 25(40) to 60°F

25°F 20 to 38°F

10°F 0 to 10°F

1.5°F 0 to 3°F

2°F 0 to 3°F

1°F 0 to 3°F

5 °F/min 0.5-5.0°F /min

0°F 0 to 20°F

10 °F 0 to 20°F

55°F 0(35) to 70°F

N M

N O

N O

M O

M O

M O

M O

M M

N M

N M

N M

Continued on next page.

18 OM AGSC-11

Page 19

Recirculate Timeout

3 min 1 to 10 min

N M

35 to 70

°F

150 to 200

°F

Unit Setpoints, Continued

Description Default Range Type PW

Quiet Night End Tme 6:00 5:00 – 9:59 N M

Quiet Night Cond Offset

BAS Protocol Modbus BACnet, LONW

Ident number 1 0-200 N M

Baud Rate 19200 1200,2400,4800,9600,19200 N M

COMPRESSORS

Sequence # Cir 1 1 1-2 M M

Sequence # Cir 2 1 1-2 M M

Start-start timer 20 min 15-60 minutes M M

Stop-start timer 5 min 3-20 minutes M M

Pumpdown Pressure 25 psi 10 to 40 psi M M

Pumpdown Time Limit 120 sec 0 to 180 sec M M

Light Load Stg Dn Point 25% 20 to 50% M M

Stage Up Delay 5 min 0 to 60 min M M

Disc Temp Sensor Type PT 1000 NTC, PT 1000 (see note) M M

ALARMS

Low Evap PressureLow Evap PressureLow Oil Level Delay 120 sec 10-180 sec M M

High Oil Press Diff Delay 15 sec 0-90 sec M M

High Discharge

High Lift Pressure Delay 5 sec 0 to 30 sec M M

Evaporator Water

Evaporator Flow Proof 15 sec 5 to 15 sec N M

Startup Timer 60 sec 20 to 180 sec M M

10.0°F 0.0 to 25.0°F

ORKS

, Modbus N M

28 psi 0(26) to 45 psi M M

30 psi 0(28) to 45 psi M M

200°F

36°F 15(36) to 42°F

150 to 200 F M M

N N

N M

SENSORS

Evap LWT sensor offset 0 -5.0 to 5.0 deg N M

Evap EWT sensor offset 0 -5.0 to 5.0 deg N M

OAT sensor offset 0 -5.0 to 5.0 deg N M

NOTE: AGS-C vintage can have either PT1000 or NTC sensors. If an NTC sensor is used with a control setting of

PT1000, the unit will not run because the discharge temperature displayed will be above the allowable operating

temperature and a fault will occur. However, if a PT1000 sensor is used with a control setting of NTC, an unsafe

operating condition exists since the sensor will show the temperature as decreasing, while it is increasing .

Auto-Adjusted Ranges

Some settings have different ranges that are automatically adjusted, based on other settings.

Table 6, Auto Adjusted Ranges

Cool LWT Evaporator Water Freeze

Mode Range Mode Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol

40 to 60°F

25 to 60°F

Low Evaporator Pressure Inhibit Low Evaporator Pressure Unload

Mode Range Mode Range

Unit Mode = Cool 28 to 45 Psig Unit Mode = Cool 26 to 45 Psig

Unit Mode = Cool w/Glycol,

Ice w/ Glycol

0 to 45 Psig

Low Ambient Lockout

Fan VFD Enable Range

= No for All Circuits

= Yes for Any Circuit

-10 to 70°F

It is critical that the chiller system has sufficient anti-freeze to support the settings entered

for freeze-up protection. The glycol freeze or burst temperature must be at least 10

degrees F below the freeze-up setpoint.

Unit Mode = Cool

Unit Mode = Cool w/Glycol,

Ice w/ Glycol

Unit Mode = Cool w/Glycol,

Ice w/ Glycol

High Discharge Temperature

Discharge Temp Type Range

NTC

PT 1000

36 to 42°F

10 to 42°F

0 to 45 Psig

150 to 230°F

OM AGSC-11 19

Page 20

Unit Controller Functions

Parameter Definitions

LWT Slope

LWT slope is calculated so that the slope represents the change in LWT over a time frame of

one minute and is used to help determine the slide valve target.

Every 12 seconds, the current LWT is subtracted from the value 12 seconds back. This value

is added to a buffer containing values calculated at the last five 12-second intervals. The

final result is a slope value that represents the action of the LWT for the past 60 seconds.

Unit Capacity

Unit capacity is estimated based on the slide target of each running circuit. The capacity of a

running circuit is estimated with this equation:

Circuit capacity = 0.8(slide target) + 20

A circuit that is off is assumed to be at 0% capacity. The unit capacity is then calculated by

this equation:

Unit capacity = (Circuit 1 capacity + Circuit 2 capacity)/2

Unit Enable

Enabling and disabling the chiller is controlled by the Unit Enable Setpoint, with options of

OFF and ON. Enabling allows the unit to start if there is a call for cooling and also starts the

evaporator pump.

This setpoint (in other words, enabling the unit to run) can be altered by the Unit OFF input

(unit On/Off switch), a field installed remote stop switch, a keypad entry, or a BAS request.

The Control Source Setpoint determines which sources can change the Unit Enable Setpoint

with options of SWITCHES, KEYPAD or NETWORK.

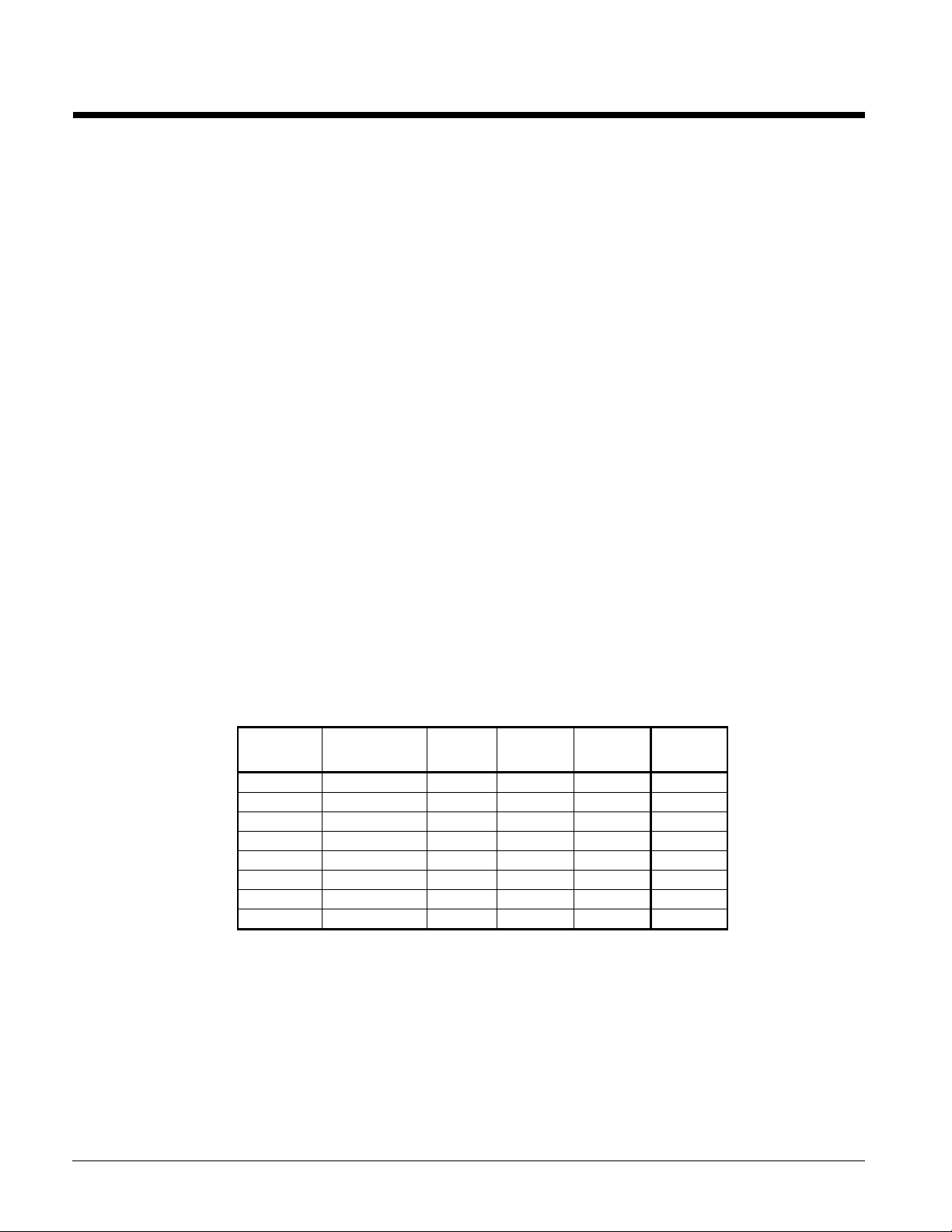

Changing the Unit Enable Setpoint can be accomplished according to the following table.

NOTE: An “x” indicates that the value is ignored.

Table 7, Enable Sources

Unit On/Off

Switch

OFF x x x x OFF

On/OFF SWITCHES OFF x x OFF

ON SWITCHES ON x x ON

ON KEYPAD x OFF x OFF

ON KEYPAD x ON x ON

ON NETWORK x x OFF OFF

ON NETWORK OFF x x OFF

ON NETWORK ON x ON ON

NOTE: An “x” indicates that the value is ignored.

Control

Source

Setpoint

Remote

Stop

Switch

Key-pad

Entry

BAS

Request

Unit

Enable

Example:

1. If the Control Source is set to Switches, the field-installed remote Stop Switch controls

enabling. If the unit-mounted On/Off switch is either On or Off, the unit will be disabled

if the remote switch is Off. If the unit-mounted On/Off switch is On, the unit will be

enabled if the remote switch is On.

2. With the unit-mounted switch On, if the Control Source is Network, and the BAS signal

is Off, the unit is not enabled. If a Remote Switch is Off, the unit is not enabled. If a

Remote Switch is ON and the BAS input is On, the unit will be enabled.

20 OM AGSC-11

Page 21

Chiller Control Source Options:

Set Unit Setpoints Screen #1 (shown below) has three fields: “Enable”, “Mode” and

“Source.”

Unit Setpoints

SET UNIT SPs (1)

Enable=On

Mode= COOL

Source = KEYPAD

1. The Enable field can only be used with Source = Keypad. To enable and disable the

chiller through the keypad, any other control inputs including unit and pumpdown

switches and BAS controls are ignored. The Enable field toggles between On and Off.

2. The Mode field is an informational display, showing the active control mode of the

chiller. It is used as an input only when the source is set to keypad. Only then can this

field be changed manually.

3. The Source field has three options, “SWITCHES”(default), “KEYPAD”, and “BAS

NETWORK”.

a. Switches source is used when there is no BAS interface used. This allows the unit

switches to function as pumpdown and shutdown switches for the circuit. This

option is used with applications using the remote start/stop input and not using a

BAS interface.

b. Keypad source is used to override BAS or remote start/stop commands. This would

be used for servicing only.

c. BAS Network source would be used for those applications using “MODBUS”,

“BACnet”, or “LON” communications through a building automation system. BAS

Protocol is set at Set Unit Setpoints item #14.

All methods of disabling the chiller, except for the unit switch, will cause a normal

pumpdown shutdown of any running circuits. Any time the unit switch is used to disable the

chiller, all running circuits will shut down immediately, without pumping down.

Shutdown by the unit switch without going through the pumpdown cycle is undesirable and

should only be used for an emergency shutdown or for manually and locally disabling the

unit after both circuits have gone through a normal shutdown.

Unit Mode Selection

The overall operating mode of the chiller is set by the Unit Mode setpoint with options of

COOL, ICE and TEST. This setpoint can be altered by the keypad, BAS, and Mode input.

Changes to the Unit Mode Setpoint are controlled by two additional setpoints.

• Available Modes setpoint: usually set during initial setup and determines the operational

modes available at any time with options of:

• COOL, cooling only operation, with setpoints available for normal chilled water

temperatures

• COOL w/Glycol, cooling only operation, allows lower setpoints than COOL

• COOL/ICE w/Glycol, allows both cooling and ice mode operation, switchable by a

field installed remote ICE mode switch, by the network (BAS) or locally through the

keypad.

• ICE w/Glycol, ice mode only, i.e., full load operation until LWT setpoint is reached

• TEST

OM AGSC-11 21

Page 22

• Control Source Setpoint: The setting determines the source that can change the Unit

Mode Setpoint with options of KEYPAD, NETWORK, or SWITCHES.

When the Control source is set to KEYPAD, the Unit Mode stays at its previous setting until

changed by the operator. When the Control source is set to BAS, the most recent BAS mode

request goes into effect, even if it changed while the Control source was set to KEYPAD or

DIGITAL INPUTS.

Changing the Unit Mode Setpoint can be accomplished according to the following table.

NOTE: An “x” indicates that the value is ignored.

Table 8, Unit Mode Setpoint Sources

Control Source

Setpoint

x x x x COOL COOL

x x x x COOL w/Glycol COOL w/Glycol

SWITCHES OFF x x COOL/ICE w/Glycol COOL w/Glycol

SWITCHES ON x x COOL/ICE w/Glycol ICE w/Glycol

KEYPAD x COOL w/Glycol x COOL/ICE w/Glycol COOL w/Glycol

KEYPAD x ICE w/Glycol x COOL/ICE w/Glycol ICE w/Glycol

NETWORK x x COOL COOL/ICE w/Glycol COOL w/Glycol

NETWORK x x ICE COOL/ICE w/Glycol ICE w/Glycol

x x x x ICE w/Glycol ICE w/Glycol

x x x x TEST TEST

Remote

ICE Mode

Switch

Keypad Entry BAS Request

Available Modes

Setpoint

Resultant Unit

Mode

The Remote ICE Mode Switch (usually a time clock) is a field installed option and is used to

switch from ice mode operation at night to cooling mode operation during the day. This

requires that the Control Source be set to SWITCHES, which in this case refers to the

Remote ICE Mode Switch.

There are really only three operational modes for the unit, although they can be used in

combination:

1. COOL, the unit unloading and compressor staging is controlled by the Active LWT

Setpoint. COOL w/ Glycol is a special case of this mode, providing for lower setpoint

ranges.

2. ICE, the unit runs with all compressors fully loaded until the LWT (set for making ice) is

reached, and the unit shuts off. The Ice Delay Timer can be set to prevent restarting until

the next ice making cycle.

3. TEST, manually energize outputs for service testing.

Unit Test Mode

The unit test mode allows manual testing of controller outputs. Entering this mode requires

the following conditions.

• Unit OFF input = OFF (i.e. entire chiller is shut down).

• Technician password active.

• Available Circuit Mode setpoint = TEST

A test menu can then be selected to allow activation of the outputs. It is possible to switch

each digital output ON or OFF and set the analog outputs to any value.

22 OM AGSC-11

Page 23

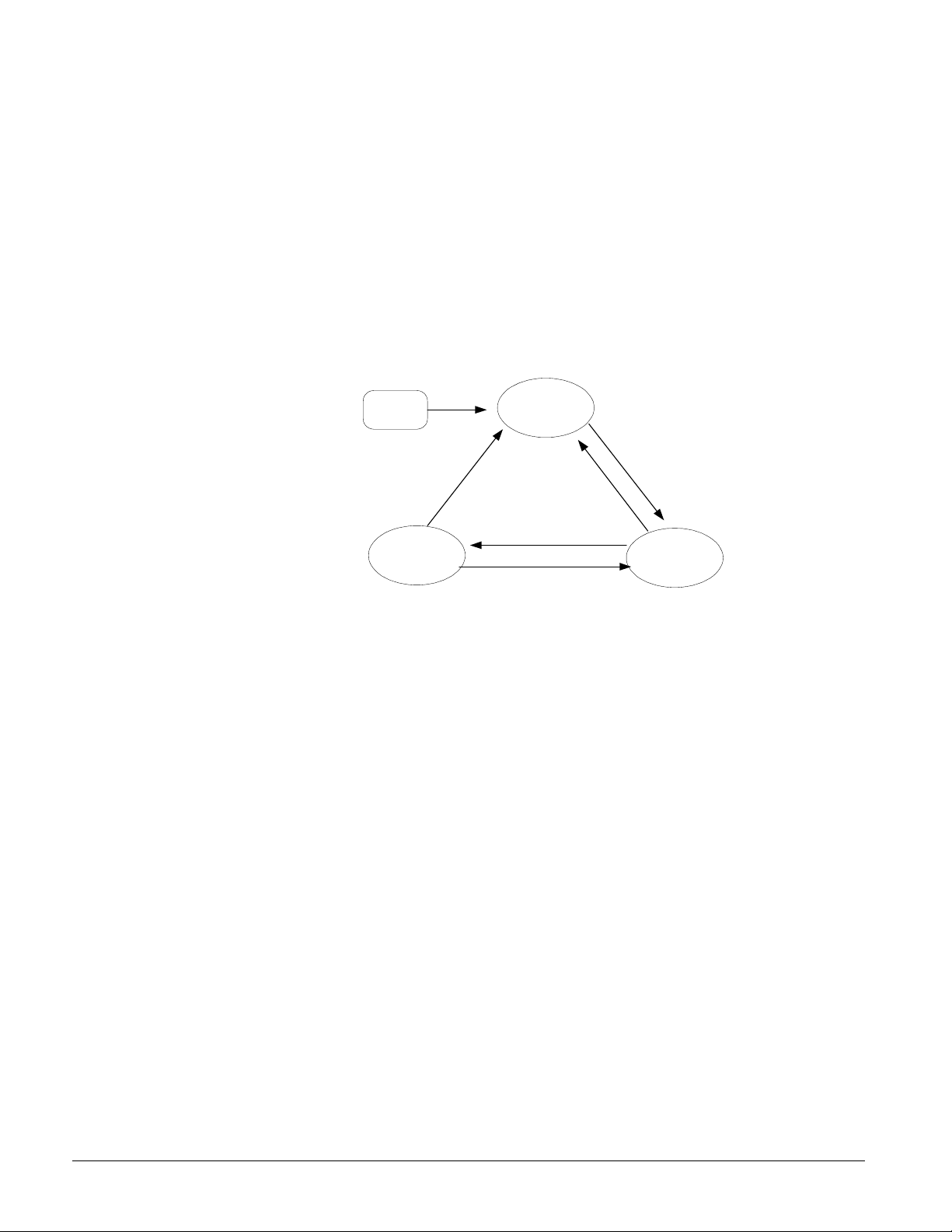

Unit States

The unit will always be in one of three states. Transitions between these states occur as

shown below.

Unit States

Power ON

T3

PUMPDOWN

OFF

T1

T4

T2

AUTO

Transitions:

T1 – Transition from Off to Auto requires all of the following:

• Unit enabled based on settings and switches.

• If unit mode is ice, the ice timer has expired

• No unit alarms exist.

• At least one circuit is enabled and available to start.

T2 – Transition from Auto to Pumpdown requires any of the following:

• Control source is keypad and the unit enable keypad setting is Off.

• Control source is BAS and either the remote switch is Off or the BAS command is Off

• Control source is switches and the remote switch is Off

T3 – Transition from Pumpdown to Off requires any of the following:

• All circuits have finished pumpdown and are Off.

• A unit alarm is active.

• Unit switch is Off.

T4 – Transition from Auto to Off requires any of the following:

• Unit switch is Off.

• A unit alarm is active.

• All circuits are unavailable to start (cannot start even after any cycle timers have

expired).

• The unit mode is ice, all circuits are Off, and the ice mode delay is active.

OM AGSC-11 23

Page 24

Ice Mode Start Delay

An adjustable start-to-start Ice Time Delay limits the frequency with which the chiller may

start in Ice mode. The timer starts when the first compressor starts while the unit is in ICE

mode. While this timer is active, the chiller cannot restart in ICE mode. The time delay is

user adjustable from 1 to 23 hours.

The ice delay timer may be manually cleared to force a restart in ice mode. The Clear Ice

Timer setpoint is specifically for clearing the ICE mode delay. In addition, cycling the

power to the controller will clear the ice delay timer.

Evaporator Pump Control

Operation of the evaporator pump is controlled by the state-transition diagram shown below.

Figure 6, Evaporator Pump States

Evaporator Pump

States

Power ON

T3

RUN

OFF

T1

T4

T2

START

T5

Transitions:

T1 – Transition from Off to Start requires any of the following:

• Unit state = Auto AND If Low OAT Lockout is active then LWT <= 40 °F

• LWT < Freeze setpoint - 1

T2 – Transition from Start to Run:

• Flow OK for time > evaporator recirculate time

T3 – Transition from Run to Off requires any of the following:

• Unit state = Off AND LWT > Freeze setpoint

• Low OAT Lockout is in effect AND No compressors running AND LWT > 70°F

T4 – Transition from Start to Off requires all of the following:

• Unit state = Off AND LWT > Freeze set point

• LWT > Freeze setpoint + 1

T5 – Transition from Run to Start

• Evaporator flow input low AND Evaporator state = Run for time greater than Flow Proof

set point

Pump selection

The pump output used will be determined by the Evap Pump Control set point. This setting

allows the following configurations:

24 OM AGSC-11

Page 25

#1 only – Pump 1 will always be used

#2 only – Pump 2 will always be used

Auto – The primary pump is the one with the least run hours, the other is used as a backup

#1 Primary – Pump 1 is used normally, with pump 2 as a backup

#2 Primary – Pump 2 is used normally, with pump 1 as a backup

Primary/Standby Pump Staging

The pump designated as primary will start first. If the evaporator state is Start for a time

greater than the recirculate timeout set point and there is no flow, then the primary pump will

shut off and the standby pump will start. When the evaporator is in the Run state, if flow is

lost for more than half of the flow proof set point, the primary pump will shut off and the

standby pump will start. Once the standby pump is started, the flow loss alarm logic will

apply if flow cannot be established in the evaporator start state, or if flow is lost in the

evaporator run state.

Auto Control

If auto pump control is selected, the primary/standby logic above is still used. When the

evaporator is not in the run state, the run hours of the pumps will be compared. The pump

with the least hours will be designated as the primary at this time.

Leaving Water Temperature (LWT) Reset

It is often desirable to raise (reset) the LWT setpoint to reduce unit energy consumption.

The Active Leaving Water variable (setpoint value) is normally set to the current Leaving

Water Temperature (LWT) setpoint, unless the unit is in COOL mode and any of the reset

methods shown below are selected and in effect. Reset is not available when in the ICE

mode.

The type of reset in effect is determined by the LWT Reset Type setpoint. The Active

Leaving Water variable is sent from the unit controller to all circuits for capacity control after

the applicable reset is applied.

Reset Type – NONE

The Active Leaving Water variable is set equal to the current LWT setpoint.

Reset Type – RETURN

The Active Leaving Water variable is adjusted by the return water temperature.

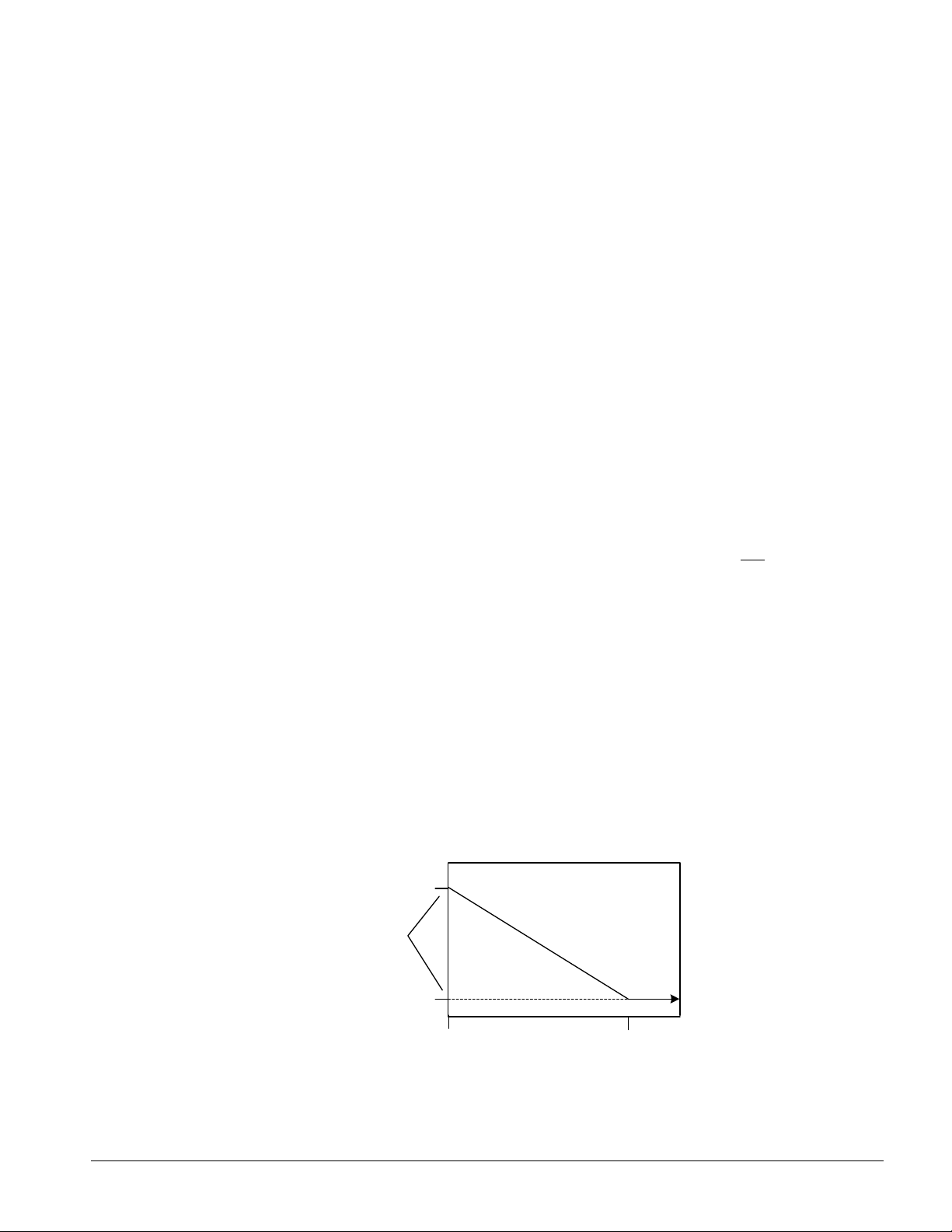

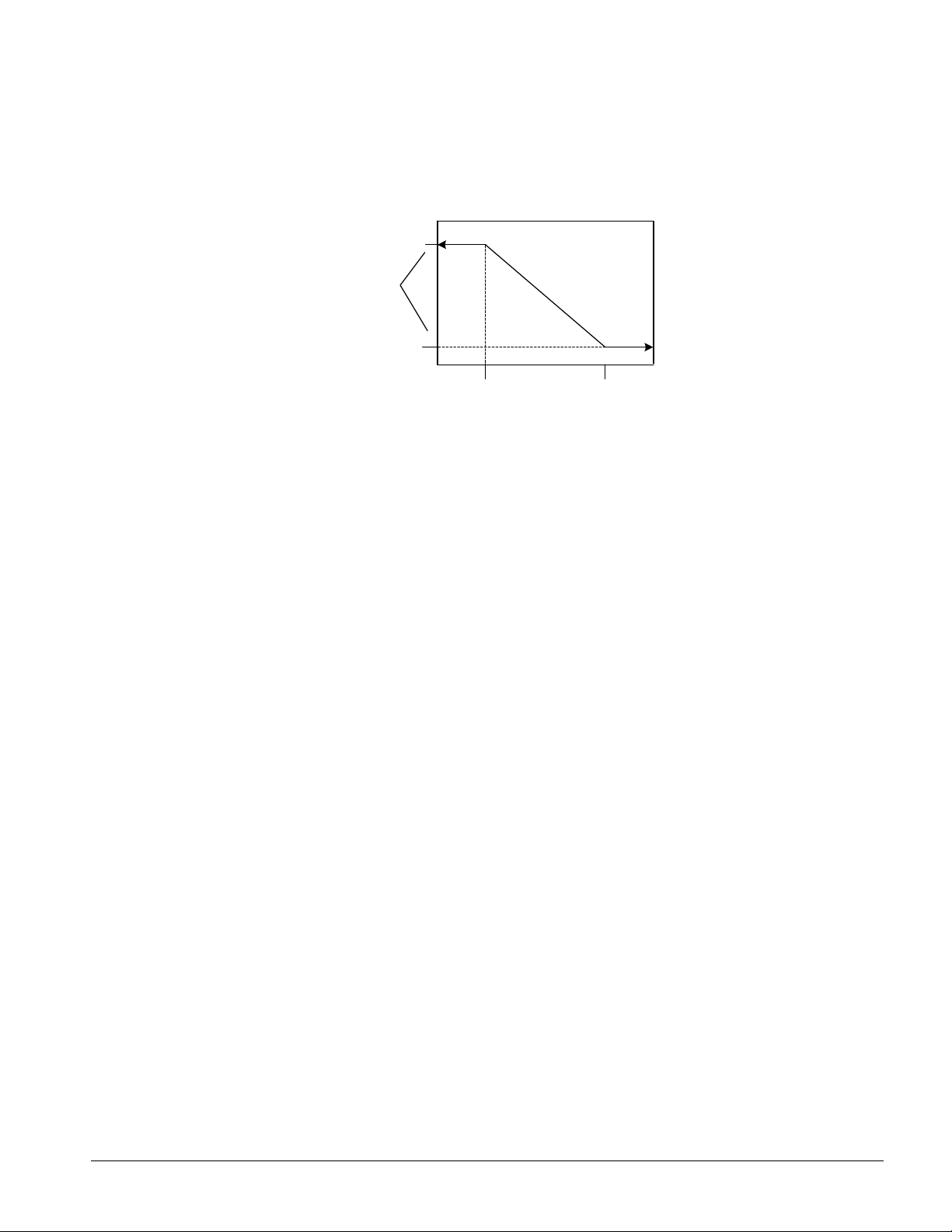

Figure 7, Return Water Reset

Return Reset

LWT set Point+Max Reset

(54)

Active

LWT

(oF)

Max Reset

(10)

LWT Set Point

(44)

0

Start Reset Delta T

Evap Delta T (oF)

OM AGSC-11 25

Page 26

The active setpoint is reset using the following parameters:

1. Cool LWT setpoint

2. Max Reset setpoint

3. Start Reset Delta T setpoint

4. Evap Delta T

Reset is accomplished within the controller by changing the Active Leaving Water variable

from the Cool LWT setpoint to the Cool LWT set-point + Max Reset setpoint as the

Evaporator EWT – LWT (Evap Delta T) varies from the Start Reset Delta T set-point to 0.

Referring to Figure 7 as an example, the LWT is 44°F and a 10-degree maximum reset value

was selected. In other words, the Active LWT setpoint would range from the normal 44°F

setting up to 54°F depending on the Evap Delta-T. The amount of reset would be at the

maximum value (10 degrees) when the Evap Delta-T is zero and at the minimum value when

the Evap Delta-T is at the Start Reset Delta T value and is proportional in between. The Start

Reset Delta T function is available so that the start of reset can be adjusted. For example, on

a system with a 10-degree Delta-T, it may be desirable to not start the resetting until the

evaporator Delta-T goes down to eight degrees (80% load), or some other value.

Reset Type – 4-20 mA

The Active Leaving Water variable is adjusted by the 4 to 20 mA reset analog input.

Parameters used:

1. Cool LWT setpoint

2. Max Reset setpoint

3. LWT Reset signal

Reset is 0 if the reset signal is less than or equal to 4 mA. Reset is equal to the Max Reset

Delta T setpoint if the reset signal equals or exceeds 20 mA. The amount of reset will vary

linearly between these extremes if the reset signal is between 4 mA and 20 mA. An example

of the operation of 4-20 reset in Cool mode is shown below.

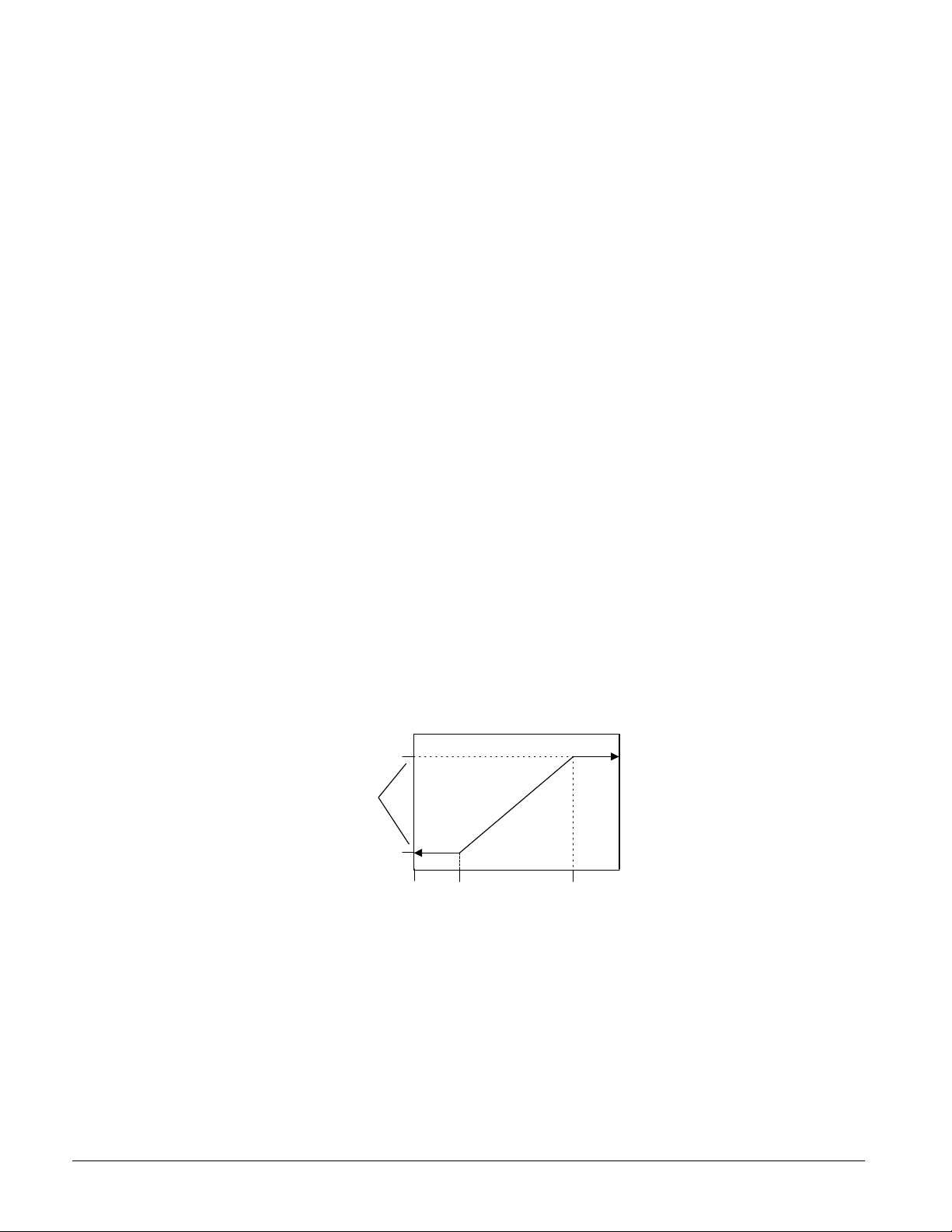

Figure 8, 4-20 mA Remote Reset Signal

4-20 mA Reset - Cool Mode

(54)

Active

LWT

(oF)

Max Reset

(10)

Cool LWT Set

Point (44)

0

4

Reset Signal (mA)

20

Reset Type – OAT

The Active Leaving Water variable is reset based on the outdoor ambient temperature (OAT).

Parameters used:

1. Cool LWT setpoint

2. Max Reset setpoint

3. OAT

26 OM AGSC-11

Page 27

Reset is 0 if the outdoor ambient temperature is greater than 75°F. From 75°F down to 60°F

the reset varies linearly from no reset to the max reset at 60°F. At ambient temperatures less

than 60°F, reset is equal to the Max Reset setpoint.

Figure 9, Outside Air Reset

OAT Reset

Cool LWT+Max Reset

(54)

Active

LWT

(oF)

Max Reset

(10)

Cool LWT Set-Point

(44)

60

OAT (oF)

75

Unit Capacity Overrides

Unit capacity limits can be used to limit total unit capacity in COOL mode only. Multiple

limits may be active at any time, and the lowest limit is always used in the compressor

capacity control.

The estimated unit capacity and the active capacity limit are sent to all circuits for use in

compressor capacity control.

Soft Load

Soft Loading is a configurable function used to ramp up the unit capacity over a given time,

usually to influence building electrical demand by gradually loading the unit. The setpoints

that control this function are:

• Soft Load – (ON/OFF)

• Begin Capacity Limit – (Unit % load at start)

• Soft Load Ramp – (1 to 60 minutes))

The Soft Load Unit Limit increases linearly from the Begin Capacity Limit set-point to

100%, over the amount of time specified by the Soft Load Ramp set-point. If the option is

turned off, the soft load limit is set to 100%.

Demand Limit

The maximum unit capacity can be limited by a 4 to 20 mA signal wired to the Demand

Limit terminals, 70 and 71 on TB1. This function is only enabled if the Demand Limit

setpoint is set to ON.

As the signal varies from 4 mA up to 20 mA, the maximum unit capacity changes linearly

from 100% to 0%. Although the demand limit can call for 0% capacity, this signal will never

cause a running compressor to shut down. Rather, all running compressors will be held at

minimum load, and this may occur at a demand limit value that is actually less than 20mA.

OM AGSC-11 27

Page 28

Network (BAS) Limit

The maximum unit capacity can be limited by a network signal. This function is only

enabled if the unit control source is set to NETWORK. The signal will be received through

the BAS interface on the unit controller.

As the signal varies from 0% up to 100%, the maximum unit capacity changes linearly from

0% to 100%. Although the network limit can call for 0% capacity, this signal will never

cause a running compressor to shut down. Rather, all running compressors will be held at

minimum load, and this may occur at a network limit value that is actually less than more

than 0%.

Building Automation System Interface

Connection to Chiller

Connection to the chiller for all BAS protocols will be at the unit controller. An interface

card (communication module) will have been installed in the unit controller at the factory, if

so ordered, or the module can be field installed after unit installation. The specific module

will depend on the protocol being used. Setting is made in Set Unit Setpoints, menu 14.

Additional information can be found in the following manuals:

LONW

ORKS –

BACnet – ED 15062 Modbus – ED 15063

IM 735 BACnet – IM 736 Modbus – IM 743

Quiet Night Operation

Logic has been added to limit unit capacity and fans running during nighttime hours.

• Settings were added to enable or disable this logic, set the start and end times, and set the

condenser target offset.

• Quiet Night operation is in effect if it is enabled via the set point, the unit is running in

cool mode, and the unit time is between the start and end time settings.

• When Quiet Night is in effect, the maximum LWT reset will be applied. This is to limit

the capacity of the compressors. In addition, the circuits will offset their condenser

targets up. Depending on conditions, this can result in less fans running and/or the VFD

running at a lower speed.

• The unit status will indicate when Quiet Night is in effect (assuming no overriding status

is active).

•

The Quiet Night reset will be overridden by any other reset source (4-20mA, return

water, OAT).

28 OM AGSC-11

Page 29

Circuit Controller

Inputs/Outputs

Table 9, Analog Inputs

# Description Signal Source Range

1 Evaporator Pressure 0.5 – 4.5 V DC (See Note)

2 Condense r Pressure 0.5 – 4. 5 VDC (See Not e)

3 Open

4 Suction Temperature NTC Thermister (10k@25°C ) -58 to 212°F

5 Discharg e Tem perature NTC Thermister (10k@ 25°C) -58 to 212°F

6 Open

7 Slide Lo ad Indicator 4 to 20 mA

8 Open

NOTE: Value at the converter board input. Value at the converter board output is 0.1 VDC – 0.9 VDC.

These parameters are analog inputs to the circuit controller. They are used internally as

needed and are sent to the correct pLAN addresses for use by other controllers or displays.

Table 10, Analog Outputs

# Description Output Signal Range

1 Fan VFD 0 to 10 VDC 0 to 100%

2 Open

3 EXV Driver 0 to 10 VDC 0 to 6386 steps

4 Open

0 to 132 psi

3.6 to 410 psi

0 to 100%

Table 11, Digital Inputs

# Description Signal Signal

1 Circuit Switch 0 VAC (Off) 24 VAC (Auto)

2 Open

3 Open

4 VFD Fault 0 VAC (Fault) 24 VAC (No Fault)

5 Oil Differential Pressure Switch 0 VAC (Fault) 24 VAC (No Fault)

6 Mechanical High Pressure Switch 0 VAC (Fault) 24 VAC (No Fault)

7 Mechanical Low Pressure Switch (1) Fault No Fault

7 Open

8 Open

9 Oil Level Sensor 0 VAC (Fault) 24 VAC (No Fault)

10-14 Open

NOTE (1) With remote evaporator, this alarm will trigger with low pressure after 40 second compressor run time.

The status of digital inputs may be viewed on Circuit Status screen 5, on the circuit

controllers only.

Table 12, Digital Outputs

# Description Output OFF Output ON

1 Fan 1 Contactor Fan off Fan on

2 Fan 2 Contactor Fan off Fan on

3 Fan 3 Contactor Fan off Fan on

4 Fan 4 Contactor Fan off Fan on

5 Fan 5 Contactor Fan off Fan on

6 Fan 6 Contactor Fan off Fan on

7 Load/Unload Pulse Hold load slide Move load slide

8 Load/Unload Select Unload Load

9 Compressor SSS Contact Compressor off Compressor on

Continued next page

OM AGSC-11 29

Page 30

# Description Output OFF Output ON

10 Open

11 Oil Heater Heater off Heater on

12 Economizer Models 180, 190, 210, 195, 161 Economizer off Economizer on

13 EXV Close Signal

EXV follows

0 -10 VDC

EXV closed, ignores 0 –

10 VDC

Setpoints

The following parameters are remembered during power off, are factory set to the Default

value, and can be adjusted to any value in the Range column.

The PW (password) column indicates the password level that must be active in order to

change the setpoint. Codes are as follows:

O = Operator, password is 100, M = Manager,

Entering a Password

The password can be found at SET, UNIT SPS on the last menu, conveniently located so that

you can scroll up one menu to access the Password Enter Screen.

Table 13, Circuit Controller Setpoints

Description Default Range PW

COMPRESSOR

1 Clear Cycle Timers No No, Yes M

2 Compressor Size 167 167, 179, 197 M

3 Maximum Slide Target (Note 3) 100.0 0-100.0% M

4 Circuit mode Enable Disable, Enable, Test M

5 Slide target 0 0-100 M

6 Slide control Auto Auto, Manual M

7 Motor FLA (See Table 14) 1 to 341 amps M

8 Motor RLA (See Table 14) 1 to 341 amps M

9 Ground Fault Enable Disable Enable, Disable M

10 Ground Fault Trip Level 1 0 to 100% M

11 Full Load Amps 10 amps 1 to 9999 amps M

12 Service Factor 125% 100 to 199% M

13 Ground Fault Enable Disable Disable/Enable M

14 Ground Fault Trip Level 1% 1 to 100% M

15 Overload Class 10 0 to 40 M

16 Initial Motor Current 225% 50 - 400% FLA M

17 Maximum Motor Current 300% 100 - 800% FLA M

18 Ramp Time 7 seconds 0 - 300 seconds M

19 Up To Speed Time 10 seconds 1 - 900 seconds M

20 Stop Mode CoS

21 Rated RMS Voltage 460 volts 100 to 1000 volts M

22 Over voltage Trip Level 10% 1 - 40% rated volts M

23 Under voltage Trip Level 10% 1 - 40% rated volts M

24 Ovr/Undr Volt Trip Delay 1.0 seconds 0.1 - 90.0 seconds M

25 Current Imbalance Trip Level 15% 5 - 40% M

26 Auto fault Reset Time 60 seconds 0 - 120 seconds M

27 CT Ratio 864:1 72 – 8000:1 M

EXV

1 Manual EXV position 0 0-6386 M

2 EXV control Auto Auto, Manual M

3 Service Pumpdown No No, Yes M

Continued next page

Coast(CoS)

Voltage Decel (dcL)

M

30 OM AGSC-11

Page 31

Description Default Range PW

FANS

1 Number of fans 4 4 to 6 M

2 Fan VFD On Off, On M

Stage 2 On Dead band (Note 2)

3

(Stage 1 On Dead band)

Stage 3 On Dead band

4

(Stage 2 On Dead band)

Stage 4 On Dead band

5

(Stage 3 On Dead band)

Stage 5 On Dead band

6

(Stage 4 On Dead band)

7 Stage 2 Off Dead band 8.0 (20.0)

8 Stage 3 Off Dead band 7.0 (16.0)

9 Stage 4 Off Dead band 6.0 (11.0)

10 Stage 5 Off Dead band 5.0 (8.0)

11 VFD Min Speed 25% 20 to 60% M

12 VFD Max Speed 100% 90 to 110% M

Saturated Condenser Temp

13

Target Max

Saturated Condenser Temp

14

Target Min

15

Forced FanTrol 1

16

Forced FanTrol 2

17

Forced FanTrol 3

SENSORS (Note 1)

1 Evap pressure offset 0 -10.0 to 10.0 psi M

2 Cond pressure offset 0 -10.0 to 10.0 psi M

3 Suction temp offset 0 -5.0 to 5.0 deg M

4 Discharge temp offset 0 -5.0 to 5.0 deg M

5 Slide Minimum Position Offset 0 -15 to 15% M

6 Slide Maximum Position Offset 0 -15 to 15% M

5.0

(8.0)

8.0

(10.0)

10.0

(11.0)

8.0 (12.0)

110.0

85.0

2 1 to 4 M

3 1 to 4 M

4 1 to 4 M

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

1.0-20.0°F

90.0-120.0°F

80.0-110.0°F

M

M

M

M

M

M

M

M

M

M

Notes:

1. Offsets are used to fine-tune certain readings generated by sensors. For example, if the controller was

showing a 125 psi value and a calibrated pressure gauge at the same location showed 127 psi, an offset of +2

psi would be entered and the controller would then read the corrected value of 127 psi.

2. VFD staging is shown in entries without parenthesis. FanTrol staging is shown in parenthesis.

3. Slide target information is explained on page 37.

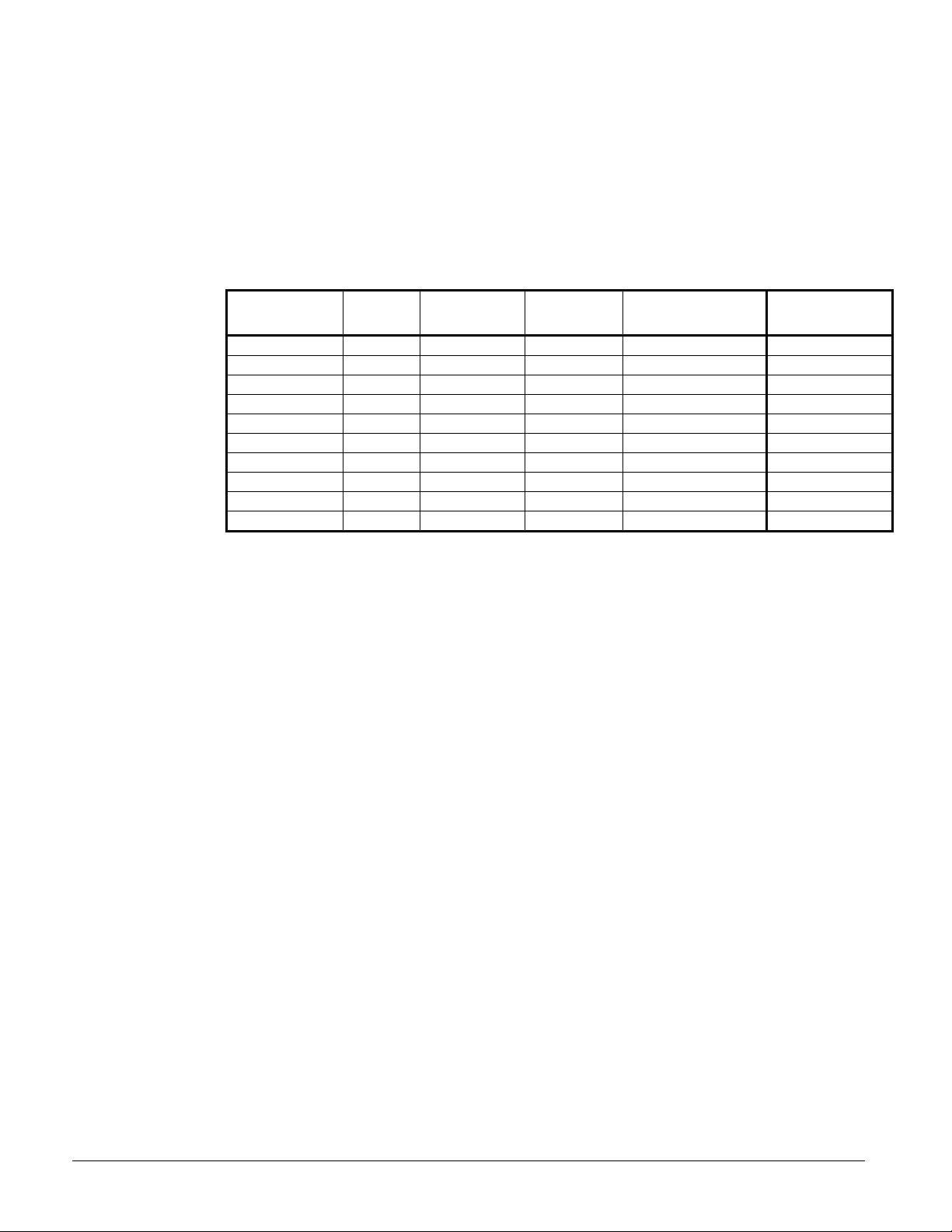

Table 14, FLA/RLA Values

Compressor 575V 460V 380V 230V 208V 400V (50Hz)

RLA Without Economizer (Models 120, 130, 140, 160, 170, 125, 135, 145, 165, 175)

197

179

167

197

All

113 141 178 282 312 141

94 122 145 240 267 122

85 112 128 210 232 112

RLA With Economizer (Models 190, 195, 210)

123 154 187 308 340 154

FLA (All Models)

113 141 178 282 312 141

Dynamic Default Values

The fan staging dead bands have different default values based on the VFD enable setpoint.

When the VFD enable setpoint is changed, a set of default values for the fan staging dead

bands is loaded in accordance with the following table:

OM AGSC-11 31

Page 32

Figure 10, VFD Dynamic Default Values

VFD is Enabled VFD is Disabled

Setpoint Default loaded (oF) Setpoint Default loaded (oF)

Stage 2 On Dead band 5 Stage 1 On Dead band 8

Stage 3 On Dead band 8 Stage 2 On Dead band 10

Stage 4 On Dead band 10 Stage 3 On Dead band 11

Stage 5 On Dead band 8 Stage 4 On Dead band 12

Stage 2 Off Dead band 8 Stage 2 Off Dead band 20

Stage 3 Off Dead band 7 Stage 3 Off Dead band 16

Stage 4 Off Dead band 6 Stage 4 Off Dead band 11

Stage 5 Off Dead band 5 Stage 5 Off Dead band 8

Circuit Controller Functions

Refrigerant Calculations

Refrigerant Saturated Temperature

Refrigerant saturated temperature is calculated from the pressure sensor readings for each

circuit. The pressure will be fitted to a curve made up of 12 straight-line segments. The

points used to define these segments are shown in the following tables.

Table 15, Evaporator Pressure Conversion:

Pressure (PSI) Temperature (oF)

0 -15.0

7.1 0

19.0 20.0

34.7 39.0

50.7 54.0

70.4 69.0

99.6 87.0

129.2 102.0

166.8 118.0

205.4 132.0

246.5 145.0

320.0 165.0

428.5 188.1

Table 16, Condenser Pressure Conversion:

Pressure (PSI) Temperature (oF)

0 0.6

17.5 18.5

31.5 35.9

50.0 53.7

76.0 73.4

115.0 95.6

161.5 116.2

185.0 125.2

260.0 149.2

284.5 155.9

349.5 172.0

365.5 175.5

428.5 188.1

32 OM AGSC-11

Page 33

Circuit Operating Mode

The circuits on the chiller can each be individually enable or disabled with an ON or OFF for

the Unit Enable setting. Test mode on each circuit can also be entered independent of all

other circuits. With the circuit switch on, the circuit mode setpoint offers settings of either

enable, disable, or test. This simply allows the circuit to be disabled through a keypad

setting.

ICE Mode

Ice mode is designed to have the compressors run at full load until the LWT setpoint is

reached, then shut off until the next ice making cycle starts. ICE settings are made in the

unit controller.

In ICE mode, the compressor capacity is increased at the maximum rate continuously until

reaching the maximum slide position. Load balancing, LWT error, and LWT slope are

ignored. Low and high pressure events are disabled.

An adjustable Start-to-Start Ice Delay Timer will limit the frequency with which the chiller

may start in ICE mode. The timer starts when the first compressor starts while the unit is in

ICE mode. While this timer is active, the chiller cannot restart in ICE mode. The time delay

is user adjustable from 1 to 23 hours.

The Ice Delay Timer may be manually cleared to force a restart in ICE mode. A setpoint

specifically for clearing the ICE mode delay (Clear ICE Timer) is available. In addition,

cycling the power to the controller will clear the Ice Delay Timer.

Circuit Test Mode

The circuit test mode allows manual testing of all controller outputs. Entering this mode

requires the following conditions.

• Circuit Switch = OFF

• Technician password active

• Circuit Mode setpoint = TEST

A test menu can then be selected to allow activation of the outputs. It is possible to switch

each digital output ON or OFF and set the analog outputs to any value. Upon entering the

test mode, all outputs will always default to the OFF state. Upon leaving the test mode, all

outputs will automatically reset to the OFF state.

Compressors cannot be started in TEST mode.

Compressor Control

Multiple Compressor Staging

This section defines which compressor is the next one to start or stop. Unless programmed

otherwise, compressors with fewer starts will start first, and compressors with more run

hours will stop first.

Functions

• Can start/stop compressors according to an operator-defined sequence.

• Can start compressors based on # of starts (run hours if starts are equal) and stop on run

hours.

• The above two modes can be combined, so that there are two or more groups, where all

compressors in the first group are started (based on number of starts/hours) before any in

the second group, etc. Conversely, all compressors in a group are stopped (based on run

hours) before any in the preceding group, etc.

These setpoints are a unit function and are programmed in the unit controller.

OM AGSC-11 33

Page 34

Starting

A compressor should be started when all of the following are true:

• Number of compressors running =0

• LWT Error > Startup Delta T SP

The second compressor should be started when all of the following are true:

• Number of compressors running = 1

• Running compressor is running at full load

• LWT Error > Stage Up Delta T SP

• Stage Up Delay is not active

• Max Compressors On set point = 2

Stopping

A compressor should shut off when all of the following are true:

• Number of compressors running > 1

• LWT Error < -(Stage Down Delta T SP)

A compressor should shut off when all of the following are true:

• Number of compressors running > 1

• Running compressors are running with slide position < light load stagedown set point

• LWT Error < Stage Up Delta SP

A compressor should shut off when all of the following are true:

• Number of compressors running = 1

• LWT Error < -(Stop Delta T SP)

Multiple Compressor Start/Stop Timing – Cool Mode

This section defines when a compressor is to start or stop when in Cool mode. The settings

are located in the unit controller.