Page 1

Product Manual

Air-Cooled Reciprocating Chiller

AGR 070AS - 100AS, Packaged Chiller

AGR 070AM – 100AM, Remote Evaporator

70 to 100 Tons, 245 to 350 kW

R-22, R-134a

60 Hertz

PM AGR-3

Page 2

Table of Contents

Introduction ............................................................................................3

Design Advantages.................................................................................4

Selection Procedure................................................................................9

Application Adjustment Factors...........................................................13

Performance Data .................................................................................16

Part Load Data......................................................................................18

Sound Data ...........................................................................................19

Pressure Drop Curves...........................................................................22

Electrical Data ......................................................................................23

Physical Data ........................................................................................29

Dimensional Data .................................................................................33

Application Data...................................................................................38

Optional Features..................................................................................46

Product Specification, AGR-AS ..........................................................48

Product Specification, AGR-AM.........................................................53

: The Model AGR 070AM through AGR

NOTE

100AM chillers with remote evaporators are

not included in the ARI Certification Program.

: R-134a ratings are not ARI certified.

NOTE

Our Facility is

Document Number: PM AGR-3

Revision: March 2001

Replaces: PM AGR-2

"McQuay" is a registered trademark of McQuay International

"Illustrations and data cover the McQuay International products at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice"

2001 McQuay International

ISO Certified

2

AGR 070A through 100A Product Manual AGR-3

Page 3

Introduction

N

McQuay offers air-cooled chillers from 10 through 425 tons (35 - 1500 kW). This

manual covers two varieties of the reciprocating compressor, air-cooled Global

Chiller Line:

AGR 070 AS - AGR 100AS, Packaged Air-Cooled Chillers, R-22 and R-134a

AGR 070AM - AGR 100AM, Air-Cooled with Remote Evaporator, R-22 only

Nomenclature

A G R - XXX A S

Air-Cooled

Global

Reciprocating Compressor

AGR-AS Model ARI Standard 550/590-98 Certified

Efficiency

Reliability

Features and Benefits

Cross-circuit compresso r staging

•

Copeland Disc us compressors

•

Exceeds ASHRAE Standard 90.1 for

•

efficiency

Rugged, proven c ompressor design

•

Factory installed operating and equipment

•

protection controls

Code and agency approval

•

Application

S= Standard Cooling

=

Design Vintage

ominal To ns

Complete factory assembly and testing

Flexibility

Serviceability

Product Manual AGR-3 AGR 070A through 100A

Sizes available in convenient 5 ton

increments

Multiple control options

Remote evaporator available (R-22 only)

•

Available with HCFC-22 or HFC 134a

•

Dual refrigerant circuits

•

Easy servicing -- All electrical and

•

refrigerant components are readily accessible

Small footprint

•

3

Page 4

Design Advantages

Construction

Factory assembled and mounted on heavy-gauge powder coat painted, galvanized steel channel base.

This base distributes the unit weight for roof loading. Flexible installation is possible by virtue of the

unit’s small footprint and low sound level.

Compressors

The AGR product line uses Copeland DISCUS valve semi-hermetic compressors. These rugged

compressors are designed for R-22 and the high loading associated with air-cooled applications. They

operate under lighter loading with R-134a.

Semi-hermetic, 1750 rpm induction type motors are used. The motors are refrigerant-gas cooled.

Solid-state modules in the motor terminal box respond to temperature sensors imbedded in all three

motor windings, providing inherent thermal overload protection for all run and start conditions.

The compresso r ho using is c o nstr ucte d fro m clo se d gr ai ned , high nic kel co nte nt, a ll oy c ast -ir on with no

bolted joint between the motor and compressor. The housing includes a cast-iron cylinder head and

stator cover, and a crankcase oil sightglass. A suction strainer built into the compressor in the gas

stream between the suction service valve and the motor, filters out foreign and abrasive particles. An

internal relief valve relieves discharge pressure to the suction side for protection at high compression

ratios as required by ANSI/ASHRAE 15 Safety Code.

Main bearings are solid cast bronze insert type with oversized bearing areas that result in ultra-low

bearing loa ding.

The crankshaft is die-forged, high strength iron alloy with integral counterweights, statically and

dynamically balanced for smooth operation.

Connecting rods are lightweight aluminum with integral bearing surfaces on the crankshaft and piston

ends. Pistons are close grain cast iron with oil and compression rings. Piston pins are full floating type

for long life.

Compressors have a force-feed lubrication system with positive oil displacement, a reversible oil pump,

and an operating oil c harge. The pump feeds oil through r ifle drilled passages in the crankshaft to a ll

bearing surfaces. Magnetic plugs trap metal particles that enter the crankcase. The oil supply is filtered

through a large ar ea oil strainer. A crankcase heater minimize s oil d ilution b y refriger ant at co mpressor

startup.

Condenser Coils

Condenser coils have internally enhanced seamless copper tubes arranged in a staggered row pattern.

The coils are mechanically expanded into McQuay lanced and rippled aluminum fins with full fin

collars. An integral subcooler circuit provides subcooling to greatly reduce the possibility of liquid line

flashing. The exterior condenser coils are fitted with a vinyl-coated wire mesh protective guard.

Condenser Fans and Motors

Multiple direct drive dynamically balanced propeller fans operate in formed venturi openings at low tip

speeds for maximum efficiency and minimum noise and vibration. A heavy-gauge vinyl-coated fan

guard protects each fan.

Each condenser fan motor is heavy-duty, 3-phase with permanently lubricated ball bearings and

inherent overload protection. SpeedTrol option includes a single-phase motor with fan speed control on

the lead fan per circuit. Fan motors on the AGR 070-100A are totally-enclosed-air-over (TEAO)

construction providing optimum environmental protection.

Copeland's Compliant Scroll® is a registered trademark of the Copeland Corporation, Sydney, Ohio.

4

AGR 070A through 100A Product Manual AGR-3

Page 5

Evaporator

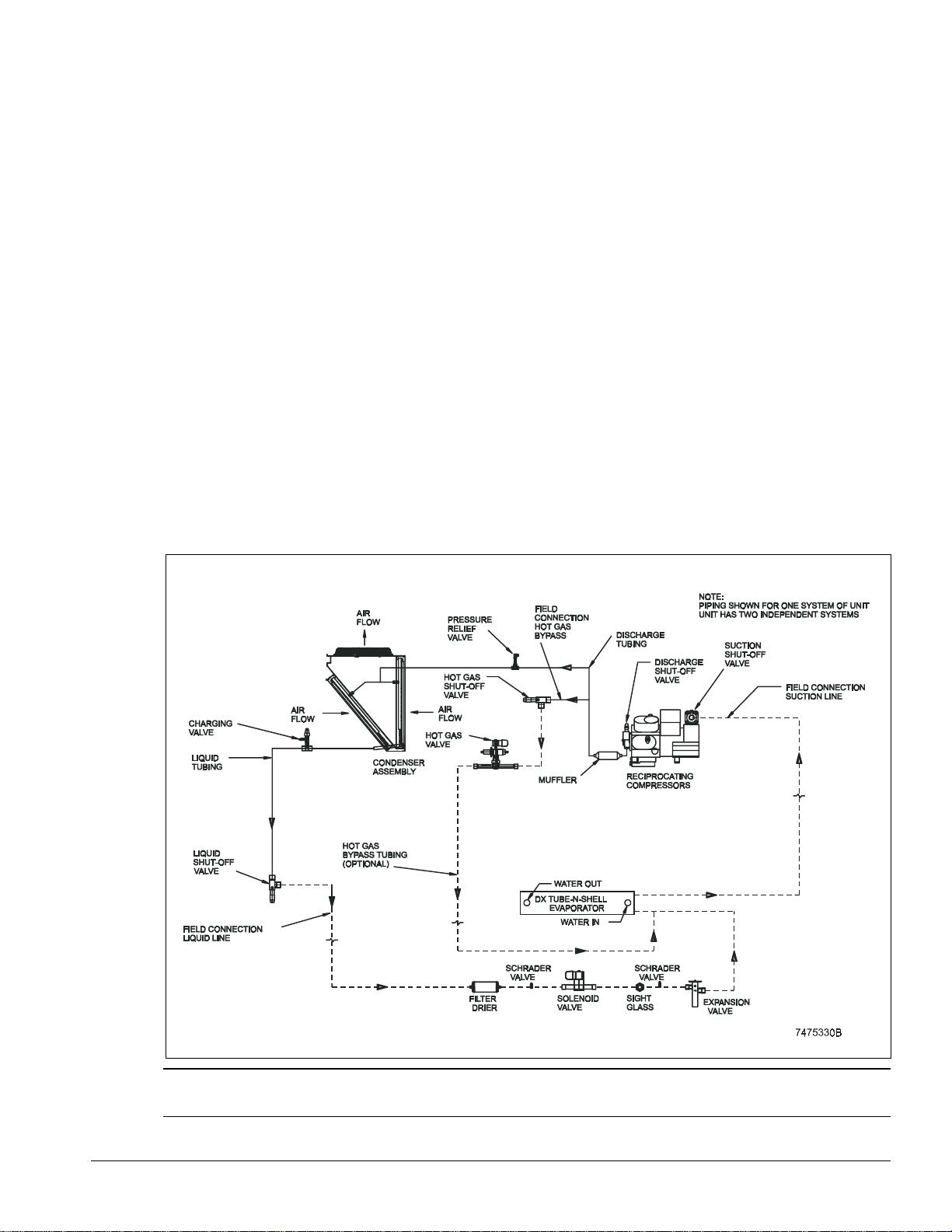

The evaporator is direct expansion, shell-and-tube type with water flowing in the baffled shell side and refrigerant

flowing through the tubes. Two independent refrigerant circuits within the evaporator serve the units dual

refrigerant circuits.

The evaporator has a carbon steel shell and seamless high efficiency copper tubes roller expanded into a carbon

steel tube sheet. Water baffles are polypropylene to resist corrosion.

Refrigerant heads are carbon steel with multi-pass baffles to ensure oil return and are removable to permit access to

the tubes from either end. For water removal, 3/8" (10mm) vent and drain plugs are provided on the top and bottom

of the shell.

The evaporator is wrapped with an electric resistance heater cable and insulated with 3/4" (19mm) thick vinyl nitrate

polymer sheet insulation, protecting against water freeze-up at ambient air temperatures to -20°F (-29°C). An

ambient air thermostat controls the heater cable.

The fitted and glued in place insulation has a K factor of 0.28 at 75°F (23°C).

The refrigerant (tube) side maximum working pressure is 225 psig (1552 kPa). The water side working pressure is

225 psig (1552 kPa). Each evaporator is designed, constructed, inspected, and stamped according to the

requirements of the ASME Boiler and Pressure Vessel Code. Double thickness insulation is an available option.

On Model AGR AM units the evaporator is shipped separate for field mounting and piping to the outdoor unit.

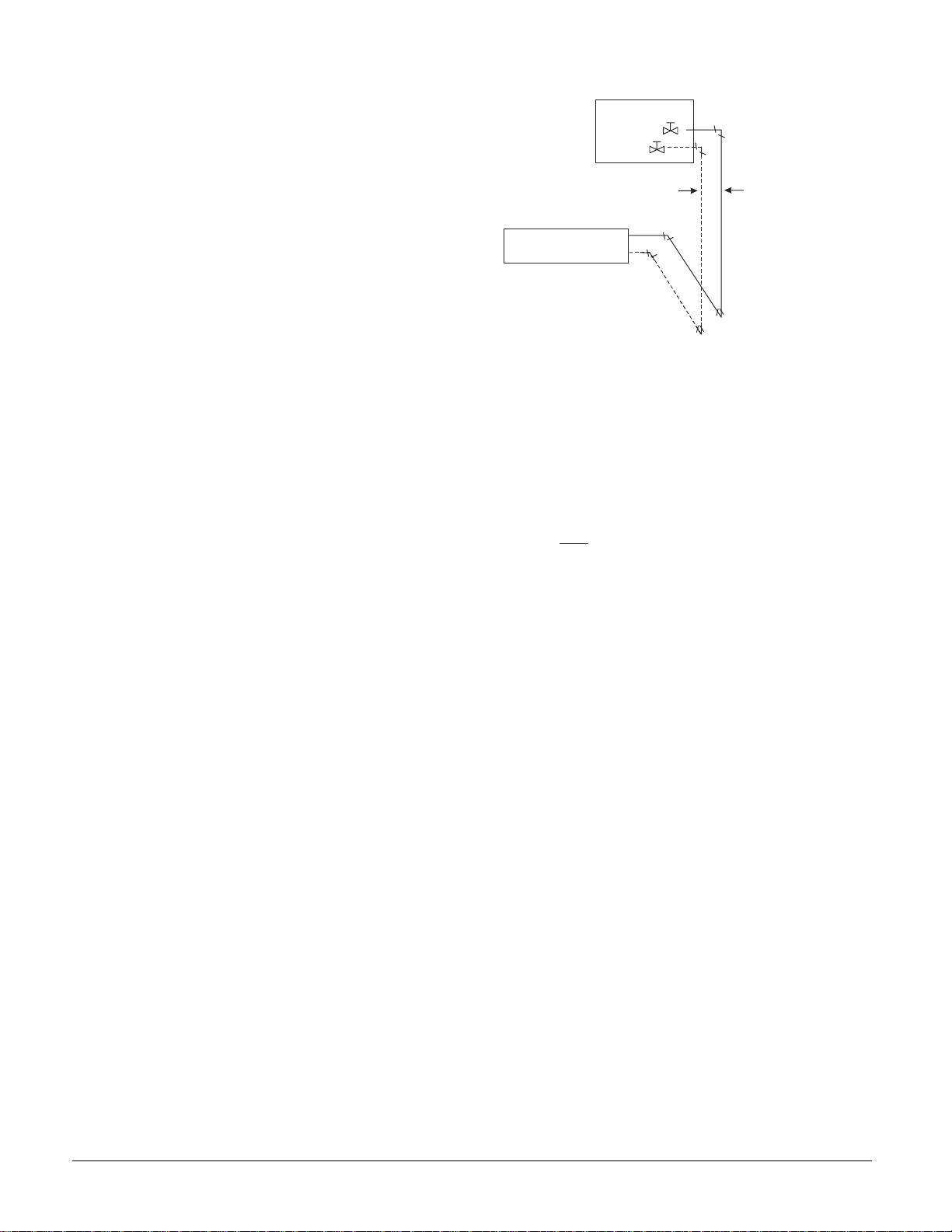

The refrigerant specialties shown in Figure 1 (dotted lines) must be purchased from McQuay with the unit and

installed by the installing contractor.

NOTE:

The remote evaporator option is available on R-22 application only and is outside ARI certification.

Figure 1, AGR ---AM, Remote E vaporator Piping (One of two circuits shown)

NOTE:

protect against evaporator freeze-up under low water flow conditions.

Product Manual AGR-3 AGR 070A through 100A

A water flow switch or both water flow switch and water pump starter interlock, must be field installed to

5

Page 6

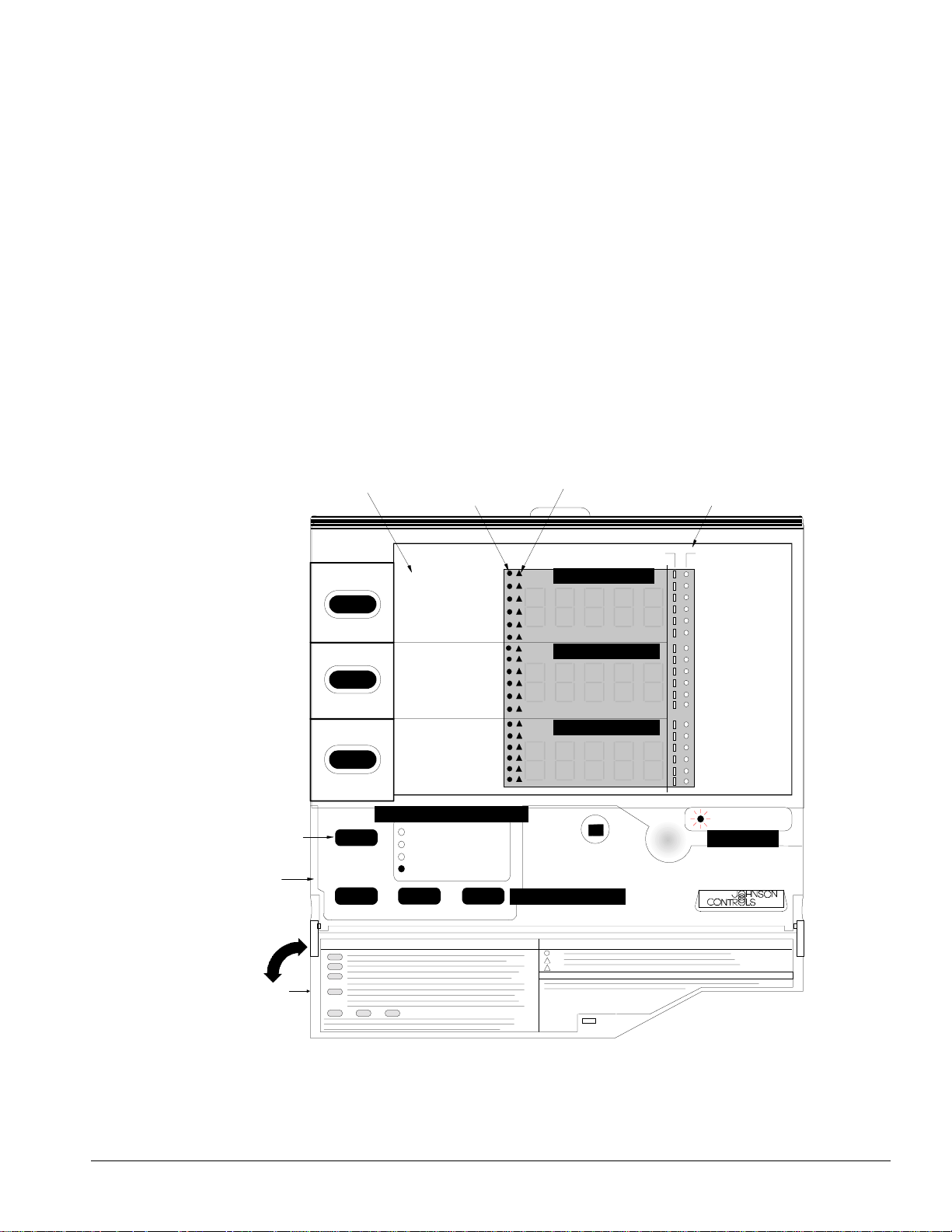

Electrical Control Center

Operating and equipment protection controls and motor starting components are separately housed in a

centrally located, weatherproof control panel with hinged and key locked doors. In addition to one of

the three types of control described in the next sections, the following components are housed in the

panel:

Power terminal block

•

Control, input, and output terminal block

•

120V control circuit transformer

•

Optional disconnect switch with through-the-door operating handle

•

Compressor contactors (circuit breakers are available as an option) (part winding on 208/230V,

•

across-the-line on 380/460/575V) compressor motor inherent thermal and overload protection is

standard.

Optional phase voltage monitor with under/over/phase reversal protection

•

Fan contactors with separate fuse blocks

•

The standard FanTrol system controls fan staging for control of refrigerant discharge pressure.

•

The FanTrol system cycles condenser fans based on discharge pressure and outdoor temperature

and is suited for operation to 40°F (4.4°C).

The optional SpeedTrol control uses both fan cycling and fan speed control on the lead fan per

•

circuit and allows operation to 0°F (-18°C) outdoor temperature.

Mechanical high pressure cutout

•

Global UNT Controller (Standard on R-22)

Microprocessor based control that accomplishes unit capacity control by 6-stage cross-circuit

compressor cycling and unloading based on leaving chilled water temperature. Setpoint and control

band are easily field adjusted. Anti-cycling and stage delay timers are included. Equipment protection

controls include low refrigerant pressure, low evaporator flow (field installed flow switch), low oil

pressure, and sensor failures. Outside air temperature sensor is standard. Reset options are; outside air,

return water, remote reset, demand limit, zone temperature reset. The optional Zone Terminal control is

required to adjust the reset setpoints. The UNT control is used only with R-22.

Thirty feet of sensor cable is included, rolled up in the control panel, on remote evaporator models.

Figure 2, Standard Global UNT Controller

6

AGR 070A through 100A Product Manual AGR-3

Page 7

Global UNT with Zone Terminal (optional)

Can be mounted in the chiller control panel or remotely located providing monitoring and adjusting of

certain functions.

Monitoring

•

Monitor up to three setting or sensed values

•

Monitor 18 different on/off inputs

•

Monitor alarm status via a flashing alarm light and flashing symbol

•

Adjusting allows adjustment of any flashing set points, three at a time, typically set up so that the

•

relationship between values can be viewed simultaneously. For example,

Display 1 = Lvg Water temp

•

Display 2 = Lvg Water SP

•

Display 3 = % Unit Load

•

Figure 3, Zone Terminal Configuration

Display Item List

Display Indicator Dot

Warning Signal

On/Off St at us

Display

Button 1

Mode

Selector

Button

Mode

Selector

Panel

Door

2

3

McQuay AGZ/AGR Global Chiller

Lvg Water Temp

Evap Pres #1

Evap Pres #2

OA/AI3 Input

OA/AI3 HiLimSP

OA/AI3 ResetSP

Lvg Water SP

LvgWtr RBnd SP

Contrl Band SP

Actual Lvg SP

Unoccpd Lvg SP

OA Lockout SP

% Unit Load

Lvg Low Lim SP

SoftSta Capcty

SoftStart Time

Cir #1 Starts

Cir #2 Starts

Operating Mode Indicator

MONITOR

ADJUST

TIME SCHEDULE

PASSWORD

ENTER

INSERT 10

Display Area 11

Display Area 21

Display Area 31

Up/Down Arrow Keys

ON OFF

Occupied

Flow Failure

OA Lockout

Cir#2Lead=On

Pmp/Stp #1=0

Pmp/Stp #2=0

Solenoid #1

Solenoid #2

Frzstat#1Alm

Frzstat#2Alm

MinLowPres#1

MinLowPres#2

Compressor 1

Compressor 2

Stage 3

Stage 4

Stage 5 Opt.

Stage 6 Opt.

ALARM

Alarm Light

AGZ-AGR

Product Manual AGR-3 AGR 070A through 100A

7

Page 8

MicroTech Control (optional on R-22, standard on R-134a)

Exclusive microprocessor control is common throughout McQuay equipment. The interface is a 12 key

keypad and 2-line, 40 character backlit liquid crystal display. The MicroTech continuously performs

self-diagnostic checks on all system temperatures, pressures, and equipment protection controls, and

will automatically shut down a circuit or the entire unit at fault conditions. The cause, time, and date of

the occurrence is recorded and can be displayed. The seven previous incidents are kept in memory for

service reference.

If a fault occurs, the controller takes preventive measures in an effort to keep the unit operating; staging

down capacity, activating a pre-alarm signal, and automatically switching to the alarm menu on the

display. Pre-alarms are self-clearing when the fault condition is no longer present.

Critical shutdown alarms such as high condenser pressure (with mechanical back up), freeze protection,

oil pressure (with mechanical back up), and low evaporator pressure are manual reset and must be

cleared at the keypad to resume operation.

Choose the MicroTech control and Open Protocol options to interface with virtually any building

management system and perform remot e monitor ing and co ntrol b y hard wiring o r mod em. A no minal

site license fee is required for BAS interface.

A single chiller can connect directly to the BAS. Two or more units will require an Open Protocol

Panel (OPM) for connection.

One hundred feet of sensor cable is included, rolled up in the control panel, on remote evaporator

models.

NOTE:

Figure 4, Optional MicroTech Control Panel

The MicroTech control is required on R-134a applications.

8

AGR 070A through 100A Product Manual AGR-3

Page 9

Selection Procedure

Packaged Chiller, Model AS, R-22

Selection with Inch-Pound (I-P) units

Table 9 covers the range of leaving evaporator water temperatures and outside ambient temperatures

included under ARI 550/590. The tables are based on a 10°F temperature drop through the evapor ator.

Adjustment factors for applications having other than a 10°F drop can be found in Table 3. The

minimum leaving chilled water temperature setpoint without glycol is 42°F. For glycol selections, see

Table 1 for ethylene or Table 2 for propylene glycol adjustment factors. Ratings are based on a 0.0001

fouling factor in the evaporator at sea level operation. For other fouling factors, different delta-Ts, or

altitude correction factors, see Table 3. For applications outside the catalog ratings contact your local

McQuay sales representative.

Selection example

Given: 67 tons minimum 95°F ambient temperature

160 gpm, 55°F to 44°F chilled water 0.0001 fouling factor

1. From Performance Table 9, an AGR 070AS at the given conditions will produce 67.5 tons with a

compressor kW input of 77.1 and a unit EER of 9.6.

2. If any elements are unkno wn, use the following equation (water only) to calculate them:

tons−×

=GPM

24

Tdelta

3 Determine the evaporator pressure drop. Using Figure 9, enter at 160 and follow up to the AGR

070AS line intersect. Read horizontally to obtain an evaporator pressure drop of 16.0 feet of water.

Selection example using ethylene glycol

Given:

64 tons minimum

95°F ambient temperature

54°F to 44°F chilled fluid

0.0001 fouling factor

Protect from freezing down to 0°F

1. From Table 1, select an ethylene glycol concentration of 40% to protect against freezing at 0°F.

2. At 40% ethylene glycol, the adjustment factors are: Capacity =0.961, kW = 0.976,

flow = 1.121, pressure drop = 1.263

3. Select the AGR 070AS and correct with 40% ethylene glycol factors.

4. Correct capacity = 0.961 x 67.5 tons = 64.9 tons

5. Correct compressor kW = 0.976 x 77.1 = 75.2 kW

6. Calculate chilled water flow:

249.64

tons°×

= capacity) corrected(at flowWater

10

F

Glycol flow (at 40% solution) = 1.121 X 155.8 = 174.7 GPM

155.8 =

GPM

Determine the evaporator pressure drop. Using Figure 9, enter at 155.7 (flow rate for water) and follow

up to the AGR 070AS line intersect. Read horizontally to obtain an evaporator pressure drop of 15.5

feet. The pressure drop for 40% glycol solution = 1.263 X 15.5 feet = 19.6 feet of water.

Product Manual AGR-3 AGR 070A through 100A

9

Page 10

Selection Procedure 60 Hertz, SI Units

Table 10, covers a range of leaving evaporator water temperatures and outside ambient temperatures.

The tables are b ased on a 5°C temper ature dro p through the evapo rator. The minimum leaving chilled

water temperature setpoint without glycol is 5.6°C. For brine selections, see Table 1 for ethylene or

Table 2 for propylene glycol adjustment factors. Ratings are based on a 0.0176 fouling factor in the

evaporator at sea level operation. For other fouling factors, different Delta-Ts, or altitude correction

factors, see Table 3. For applications outside the catalog ratings contact your local McQuay sales

representative.

Selection Example

Given:

235 kW cooling capacity required

35°C ambient air temperature

11 L/s, 12°C - 7°C chilled water temperature

0.0176 evaporator fouling factor

1. From Table 10, an AGR 070AS at the given conditions will produce 240.0 kW with a compressor

kW input of 77.5 and a COP of 2.84.

2. Determine the evaporator pressure drop. Using Figure 9, enter at 11 L/s and follow to the AGR

070AS line intersect. Read horizontally to obtain an evaporator pressure drop of 55 kPa of water.

Selection example using ethylene glycol

Given:

225 kW cooling capacity required

35°C ambient air temperature

11 L/s, 12°C - 7°C chilled water temperature

0.0176 evaporator fouling factor

Protect against freezing down to -18°C

1. From Table 1, select an ethylene glycol concentration of 40% to protect against freezing

at -18°C

2. At 40% ethylene glycol, the adjustment factors are: Capacity = 0.961, kW = 0.976,

GPM = 1.121, pressure drop = 1.263

3. Select the AGR 070AS and correct with 40% ethylene glycol factors.

4. Correct capacity = 0.961 x 240.0 kW = 230.6 kW

5. Correct compressor kW = 0.976 x 77.5 kW = 75.6 kW

6. Calculate flow:

Glycol flow (at 40% solution) = 1.121 X 11.0 L/s = 12.3 L/s

7. Determine the evaporator pressure drop. Using Figure 9, enter at 11.0 L/s (flow rate for water) and

follow to the AGR 070AS line intersect. Read horizontally to obtain an evaporator pressure drop

of 55 kPa of water.

The pressure drop for 40% solution = 1.263 X 55 kPa = 69.5 kPa

10

AGR 070A through 100A Product Manual AGR-3

Page 11

Packaged Chiller, Model AS, R-134a

NOTE: R-134a performance is not ARI Certified

AGR performance with R-134a refrigerant is calculated from the R-22 ratings as follows:

1) Calculate the unit R-134a capacity;

2) Calculate the unit R-134a power input;

a) Calculate the unit R-22 power (kW shown in tables is compressor only);

22

b) Calculate the unit fan and control power (unaffected by refrigerant);

c) Calculate the R-134a compressor power;

d) Calculate the unit R-134a kW;

3) Calculate R-134a EER:

kWUnitR

−

=

134

multiply the R-22 capacity by 0.68.

12022

xTonsR

EERUnit

2222/

−=

multiply the R-22 compressor kW by 0.615

fan & contro l power from b)+R-134a compressor power c)

EERaR

134

=

134

MBHcapacityaR

kWUnitaR

TablefromkWCompressorRkWUnitRkWControlFan

Remote Evaporator, Model AM

Selection with Inch-Pound (I-P) units

Since the AGR-AM units always include a specific remote shell-and-tube evaporator, the ratings are based on leaving chilled water temperature and ambient air temperature from the Rating Tables corrected for line loss as follows.

Table 9 (Inch-Pound units) and Table 10 (SI units) cover the normal range of leaving evaporator water

temperatures and outside ambient air temperatures. The tables are based on a 10°F (5°C) temperature

drop thro ugh the evapora tor. Adjustment factors for applicati ons having other tha n a 10°F (5°C) drop

can be found in Table 3. The minimum leaving chilled water temperature setpoint without glycol is

42°F (5.6°C). For brine selections, see Table 1 for ethylene Table 2 for propylene glycol adjustment

factors. Ratings are based on a 0.0001 (0.0176) fouling factor in the evaporator at sea level operation.

For other fouling factors, derates for different delta-Ts, or altitude correction factors, see Table 3 . For

applications outside the catalog ratings contact your local McQuay sales representative.

The length and configuration of the interconnecting refrigerant piping will affect the system capacity.

Derates base d on e q uival ent lengt h o f pip e ar e gi ven i n Table 8. Re fer to App li ca tio n Da ta , Re fri ger ant

Piping section for guidelines.

The steps for selecting an AGR-AM are as follows:

1. Add 3% to the required cooling capacity (to approximate correction factors) and make a

preliminary unit selection from performance Table 9 or Table 10.

2. Divide the required capacity by the appropriate capacity correction factors: glycols from Table 1 or

Table 2; altitude, chilled water Delta T, or fouling factor Table 3; and refrigerant piping derate from

Table 8 as explained in step 3 below.

3. Determine the suction line size by summing the equivalent feet (from Table 4) of all the fittings

(use a sketch of the piping layout) and

of tubing. This will then equal the

unit suction connection size from Table 6 as the first try). Knowing the equivalent feet and the unit

size, check the line selection in Table 6 or Table 7 and correct if required.

4. If the unit rated capacity in the tables is less than the corrected required cap acity, redo the selection

with the next larger unit. In most cases the line size will be the unit connection size. If the

selection is satisfactory, correct the power (if applicable) and determine water pressure drop.

Product Manual AGR-3 AGR 070A through 100A

adding the sum of these fitting losses

total equivalent feet

to the actual linear feet

. (To use the equivalent feet, start with the

11

Page 12

Selection example

A

p

Given:

Figure 5, Sample Piping Layout

GR-AM

10 ft.

64 tons required capacity

95°F ambient temperature

Cool 154 gpm from 54°F to 44°F

0.0001 evaporator fouling factor

2,000 foot altitude

Remote Eva

orator

10 ft.

Liquid

Line

20 ft.

Suction

Line

30 ft.

Add 3% to the required capacity for approximate derate: 64 x 1.03 = 66 tons. From Performance Table

9, an AGR-070AM at the given conditions will produce 67.5 tons with a compressor kW input of 77.1

and a unit EER of 9.6.

1. Determine derate factors :

Altitude correction from Table 3: 0.986 Capacity, 1.009 Power

2. Piping cor rection:

Assume 2 1/8" suction line based on connection size in Table 6

(3) 90° Standard ells (Table 4) 3 x 5 ft =15 ft

Plus actual linear feet 70 ft

Total Equivalent Feet 85 ft

Check Table 7 for size and find that 2 1/8” is acceptable size for oil carry. If the selected riser size

is too large, double risers would be required. See Refrigerant Piping section for important

information, including double riser layouts.

The capacity correction factor from Table 8 is 0.984.

3. The corrected capacity of the AGR is: 67.5 tons x 0.986{altitude} x 0.984{piping} = 65.5 tons

This satisfies the 64 ton requirement.

4. Correct the compressor power required: 77.1 kW x 1.009{altitude} = 77.8 kW.

5. Calculate the unit power input from corrected EER:

W = BTU / EER W =65.5 tons x 12,000 / (9.6 EER / 1.009) = 81.1 kW

6. Determine the evaporator pressure drop. Enter the pressure drop curves (Figure 9) at 154 gpm and

read up to AGR 070AM, read over to pressure drop of 15 ft.

Selection example using ethylene glycol

Given: 64 tons required capacity

95°F ambient temperature

54°F to 44°F chilled fluid

0.0001 fouling factor

Protect from freezing down to 0°F

1. From Table 1, select an ethylene glycol concentration of 40% to protect against freezing at 0°F.

2. At 40% ethylene glycol, the adjustment factors are: Capacity =0.961, kW = 0.976,

Flow = 1.121, pressure drop = 1.263

3. Select the AGR 070AM and correct with 40% ethylene glycol factors and piping correction factor.

4. Correct capacity = 0.961 X 67.5 tons = 64.6 tons

5. Correct compressor kW = 0.976 X 77.1 = 75.2 kW

12

AGR 070A through 100A Product Manual AGR-3

Page 13

6. Calculate chilled water flow:

Water flow (at corrected capacity) = = 155.3 GPM

Glycol flow (at 40% solution) = 1.121 X 155.3 GPM = 174.1 GPM

Determine the evaporator pressure drop. Using Figure 9, enter at 155.3 GPM and follow up to the

AGR 070AM line intersect. Read horizontally to obtain an evaporator pressure drop of 15 feet. The

pressure drop for 40% solution = 1.263 X 15 feet = 19 feet.

Selection Procedure 60 Hz Metric Units

The selection procedure for Metric units is exactly the same as English except that Metric tables and

metric units are used.

Application Adjustment Factors

Ethylene and Propylene Glycol Factors

AGR units can operate with a leaving chilled fluid temperature range of 20°F (-6.7°C) to 60°F

(15.6°C). A glycol solution is required when leaving chilled fluid temperature is below 42°F (5.6°C).

The use of glycol will reduce the performance of the unit depending on concentration.

64.7 24

tonsF×

10

°

Altitude Correction Factors

Performance tables are based at sea level. Elevations other than sea level affect the performance of the

unit. The decreased air density will reduce condenser capacity and reduce the unit's performance. For

performance at elevations other than sea level refer to Table 3. Maximum allowable altitude is 6,000

feet (1830 meters).

Evaporator Temperature Drop Factors

Performance tab les are ba sed on a 10 °F (5.5°C) temperature drop through the evapora tor. Adjustment

factors for applications with temperature ranges from 6°F to 16°F (3.3°C to 8.9°C) are in Table 3.

Temperature drops outside this 6 to 16 degrees F (3.3 to 8.9 degrees C) range may affect the control

system's capability to maintain acceptable control and are not recommended.

The maximum water temperatur e that ca n b e c ir cul at ed thr o ugh the eva po r a to r i n a non-o p e ra ti ng mod e

is 100°F (37.8°C). Maximum entering temperature during operation is 90°F (32.2°C).

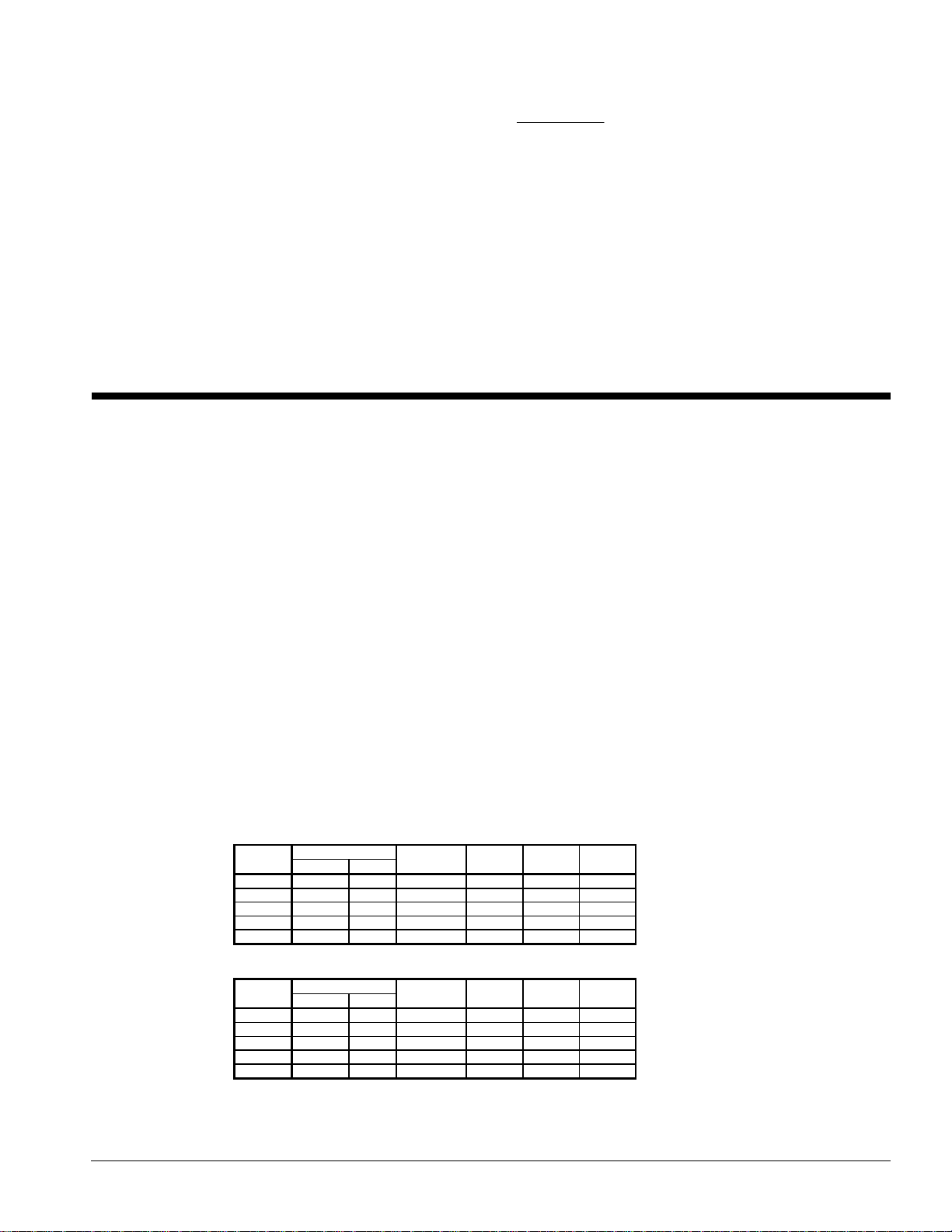

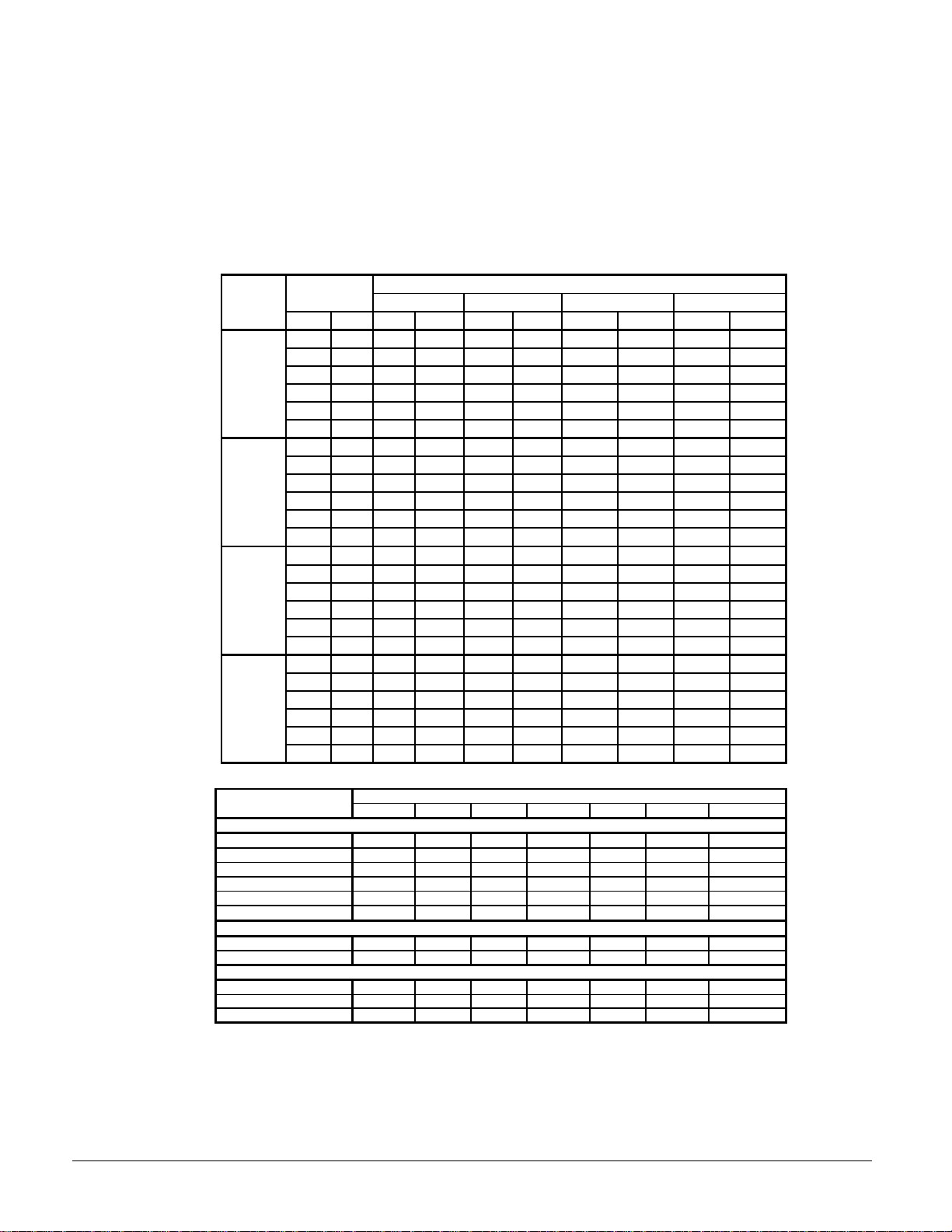

Table 1, Ethylene Glycol

%

E.G.

10 23.0 -5 0.991 0.996 1.013 1.070

20 14.0 -10 0.982 0.992 1.040 1.129

30 1.4 -17 0.972 0.986 1.074 1.181

40 -13.0 -25 0.961 0.976 1.121 1.263

50 -34.6 -37 0.946 0.966 1.178 1.308

Table 2, Propylene glycol

%

P.G.

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

NOTE: Ethylene and propylene glycol ratings are outside the scope of

Freeze Point

°F °C

Freeze Point

°F °C

Standard 550/590-98 certification program

Capacity Power Flow PD

Capacity Power Flow PD

Product Manual AGR-3 AGR 070A through 100A

13

Page 14

Fouling factor

Performance tables are based on water with a fouling factor of

22

per ARI 550/590-98. As fouling increases,

/0176.0,,/0001.0

°×°

kWCmorBTUFxhrxft

performance decreases. For performance at other than 0.0001 (0.0176) fouling factor see Table 3.

Foreign matter in the chilled water system will adversely affect the heat transfer capability of the

evaporator, and could increase the pressure drop and reduce the water flow. To ensure optimum unit

operation, maintain proper water treatment.

Table 3, Capacity and Power Derates

Chilled Water

ALTITUDE

SEA 10 5.6 1.000 1.000 0.993 0.998 0.970 0.991 0.927 0.977

LEVEL 12 6.7 1.005 1.002 0.998 1.000 0.975 0.993 0.932 0.979

2000 feet 10 5.6 0.986 1.009 0.979 1.007 0.956 1.000 0.914 0.986

(610 m) 12 6.7 0.992 1.011 0.985 1.009 0.962 1.002 0.919 0.988

4000 feet 10 5.6 0.973 1.021 0.966 1.019 0.944 1.012 0.902 0.998

(1220 m) 12 6.7 0.978 1.025 0.971 1.023 0.949 1.016 0.906 1.002

6000 feet 10 5.6 0.959 1.031 0.952 1.029 0.930 1.022 0.889 1.008

(1830 m) 12 6.7 0.963 1.034 0.956 1.032 0.934 1.024 0.893 1.011

Delta-T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.992 0.995 0.985 0.993 0.962 0.986 0.919 0.972

8 4.4 0.995 0.997 0.988 0.995 0.965 0.988 0.922 0.974

14 6.8 1.010 1.005 1.003 1.003 0.980 0.996 0.936 0.982

16 8.9 1.014 1.007 1.007 1.005 0.984 0.998 0.940 0.984

6 3.3 0.978 1.005 0.971 1.003 0.949 0.996 0.906 0.982

8 4.4 0.982 1.007 0.975 1.005 0.953 0.998 0.910 0.984

14 6.8 0.997 1.014 0.990 1.012 0.967 1.005 0.924 0.991

16 8.9 1.000 1.016 0.993 1.014 0.970 1.007 0.927 0.993

6 3.3 0.966 1.016 0.959 1.014 0.937 1.007 0.895 0.993

8 4.4 0.969 1.018 0.962 1.016 0.940 1.009 0.898 0.995

14 6.8 0.982 1.027 0.975 1.025 0.953 1.018 0.910 1.004

16 8.9 0.986 1.028 0.979 1.026 0.956 1.019 0.914 1.005

6 3.3 0.953 1.025 0.946 1.023 0.924 1.016 0.883 1.002

8 4.4 0.955 1.028 0.948 1.026 0.926 1.019 0.885 1.005

14 6.8 0.968 1.036 0.961 1.034 0.939 1.026 0.897 1.013

16 8.9 0.972 1.037 0.965 1.035 0.943 1.027 0.901 1.014

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

Table 4, Equivalent Feet for Fittings

Fitting Type

Elbows

90° Standard

90° Long Radius

90° Street

45° Standard

45° Street

180° Bend

Tees

Full Size 1.4 1.7 2.3 2.6 3.3 4.1 5.0

Reducing 2.0 2.6 3.3 4.0 5.0 6.0 7.5

Valves

Globe Valve, Open 22 29 38 43 55 69 84

Gate Valve, Open 0.9 1.0 1.5 1.8 2.3 2.8 3.2

Angle Valve, Open 9.0 12 15 18 24 29 35

7/8 1 1/8 1 3/8 1 5/8 2 1/8 2 5/8 3 1/8

2.0 2.6 3.3 4.0 5.0 6.0 7.5

1.4 1.7 2.3 2.6 3.3 4.1 5.0

3.2 4.1 5.6 6.3 8.2 10 12

0.9 1.3 1.7 2.1 2.6 3.2 4.0

1.5 2.1 3.0 3.4 4.5 5.2 6.4

3.2 4.1 5.6 6.3 8.2 10 12

Fouling Factor

Line Size inch, OD Copper

14

AGR 070A through 100A Product Manual AGR-3

Page 15

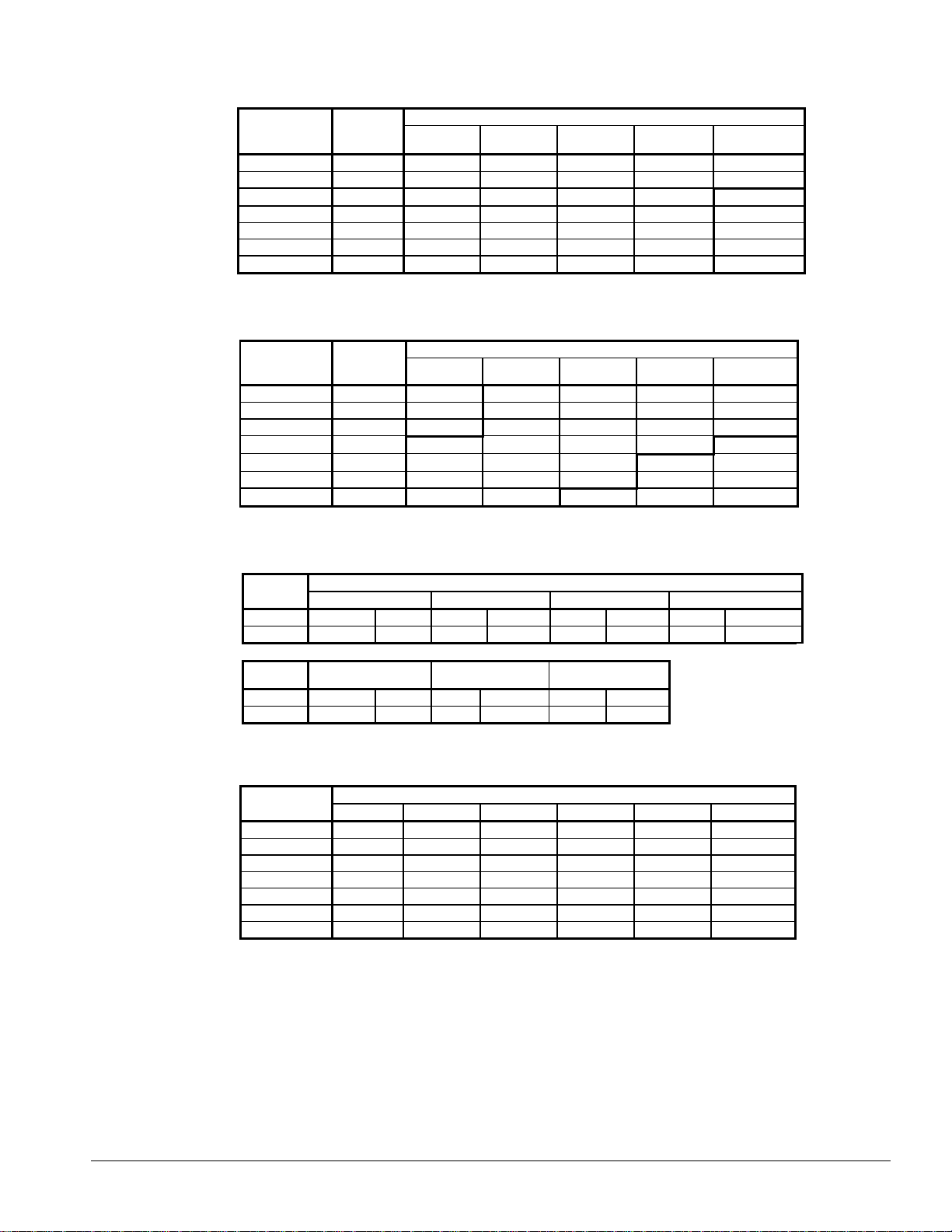

Table 5, Recommended Liquid Line Sizes Per Refrigerant Circuit

AGR-AM

Unit Model

070AM

075AM

080AM

085AM

090AM

095AM

100AM

Liquid

Connection

Size at Unit

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

1 1/8" 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8 "

Up To 50

Equiv. Feet

Recommended Liquid Line Size Per Circuit

Up To 75

Equiv. Feet

Up To 100

Equiv. Feet

Up To 125

Equiv. Feet

Table 6. Recommended Horizontal and Downflow Suction Line Size

AGR-AM

Unit Model

070AM 2 1/8" 2 1/8"

075AM 2 1/8" 2 1/8"

080AM 2 1/8", 2 5/8" 2 1/8", 2 5/8"

085AM 2 5/8"

090AM 2 5/8"

095AM 2 5/8"

100AM 2 5/8"

Suction

Connection

Size at Unit

Up To 50

Equiv. Feet

2 5/8" 2 5/8" 2 5/8" 2 5/8"

2 5/8" 2 5/8" 2 5/8"

2 5/8" 2 5/8" 2 5/8"

2 5/8" 2 5/8"

Recommended Suction Line Size

Up To 75

Equiv. Feet

2 5/8" 2 5/8" 2 5/8" 2 5/8"

2 5/8" 2 5/8" 2 5/8" 2 5/8"

2 5/8" 2 5/8" 2 5/8" 2 5/8"

Up To 100

Equiv. Feet

3 1/8" 3 1/8" 3 1/8"

Up To 125

Equiv. Feet

3 1/8" 3 1/8"

3 1/8" 3 1/8"

Up To 150

Equiv. Feet

1 3/8"

1 3/8"

1 3/8"

1 3/8"

1 3/8"

Up To 150

Equiv. Feet

3 1/8"

Table 7, Minimum Suction Riser Size

AGR

Model

System1 212121 2

Line Size 2 1/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8

AGR

Model

System 1 2 1 2 1 2

Line Size 2 5/8 2 5/8 2 5/8 2 5/8 2 5/8 2 5/8

070AM 075AM 080AM 085AM

090AM 095AM 100AM

Minimum Suction Riser for Oil Carry by Unit System

Table 8, Refrigerant Piping Derates

AGR-AM

Unit Model

070AM 1.0 0.969

075AM 1.0 0.969

080AM 1.0 0.961

085AM 1.0

090AM 1.0

095AM 1.0

100AM 1.0

At Unit 50 Equiv. ft. 75 Equiv. ft. 100 Equiv. ft. 125 Equiv. ft. 150 Equiv. ft.

Capacity Loss Due to Refrigerant Piping

0.984 0.978 0.973 0.967

0.984 0.978 0.973 0.967

0.978 0.971 0.963 0.957

0.982 0.974 0.966 0.957

0.979 0.968 0.957

0.979 0.968 0.957

0.976 0.964

0.980 0.975 0.971

0.978 0.974

0.978 0.974

0.978

Product Manual AGR-3 AGR 070A through 100A

15

Page 16

Performance Data

0

64.8

69

63

9.3

59.3

80.28.3

55.5

86

075.9

66

6

67.5

9.6

63.5

83.0

8.6

59.5

88.97.546.078.6

67.5

8

67.8

078.49.9

65.8

84.3

8.8

61.6

90

6

073.0

65

9

69.3

6

65.5

9

9.3

61.6

80.3

8.3

5

85.6

078.0

67.6

3

9.6

65.9

83.18.6

61.8

88.97.546.0

80.768

676

579.49.8

68.3

84.5

8.8

64.0

90.6

0

8

9

0

80

6

8

83.3

9.3

68.5

89.48.3

6

95.3

0

86

3

8

9

86.19.673.3

92.6

8.5

68.6

99.07.546.0

89

85.184.8

80.5

88.3

9.875.9

9

0

88.379.3

0

83.787.310

90.9

9

5

97.5

8.3

69

3

0

94.3

8

5

89.5

90

93.9

9

9

8.6

646.0

97.5

83

8

92.5

92.5

87.6

96.3

9.9

82.5102.6

8.8

0

90.3

80

85.788.310.8

8

91.9

9.576.298.5

8

0

96.5

83.0

6

9

86.794.9

9.8

81.5102.0

8

0

99.8

84.3

9

9

93.5

5

89.6

9

0

8

8

0

97.9

89.6

9

92.9

98.610.6

87.9102.6

9.3

82.6110.18.3

6

92.8

99.3101.8

0

94.0106.19.6

88

0

8.6

82.8

546.0108.29

9

8

9.8

91.5115.9

8.785.9

99

6

96

9

9.3

90

6

96

5

8.6

90.6135

546.0118.3104.5

8

9.8100

8

94.0137.87.6

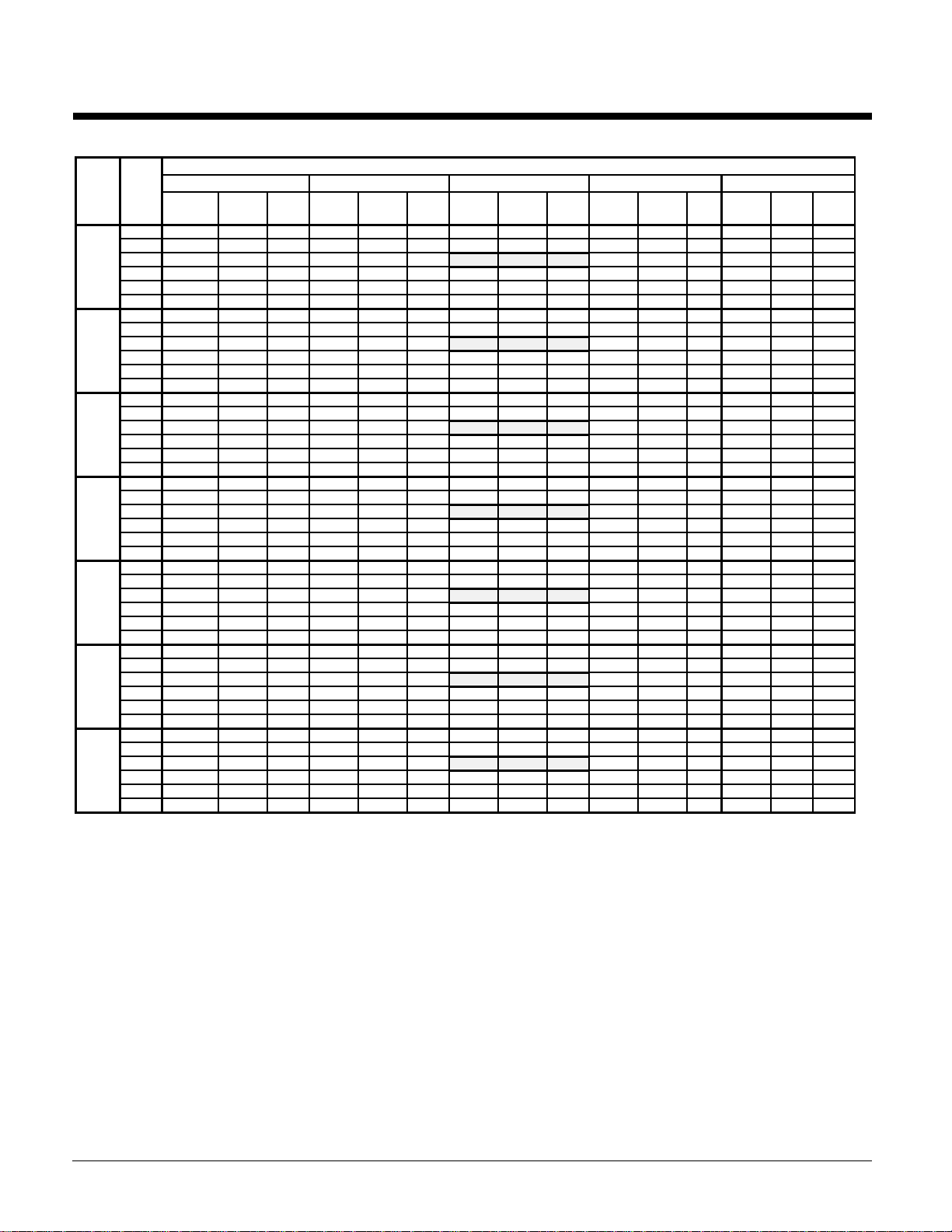

Table 9, AGR 070 – AGR 100, 60 Hz, R-22, I-P Units

See Selection Procedure section for derates for the "AM" remote evaporator units

AGR

LWT

SIZE

(°F)

Capac.

40.

42.0 73.5 65.5 12.4 69.4 70.5 10.9 65.3 75.4 9.5 61.4 81.5 8.5 57.5 87.5 7.4

44.

48.0 81.3 68.6 13.1 76.9 73.5 11.6 72.5 79.7 10.1 68.1 85.7 9.0 63.7 92.1 7.8

50.0 84.0 69.6 13.3 79.4 75.0 11.8 74.9 80.7 10.2 70.4 87.2 9.1 65.8 93.7 7.9

40.

42.0 75.5 66.8 12.1 71.7 73.1 10.8 67.8 76.0 9.5 63.7 81.7 8.4 59.5 87.3 7.4

44.

48.0 83.3 69.6 13.0 79.1 78.0 11.4 74.9 81.8 10.0 70.6 85.9 8.9 66.3 92.2 8.2

50.0 85.9 70.7 13.2 81.6 79.1 11.7 77.3 84.0 10.2 72.9 87.4 9.1 68.6 93.9 8.0

40.

42.0 83.9 74.5 12.2 79.7 81.4 10.8 75.4 84.7 9.5 70.7 91.0 8.4 66.1 97.2 7.3

44.

48.0 92.5 77.4 12.9 87.9 86.9 11.5 83.2 91.1 10.0 78.5 95.7 8.9 73.7 102.7 8.2

50.0 95.5 78.7 13.2 90.7 88.0 11.7 85.8 93.5 10.2 81.1 97.3 9.1 76.3 104.5 8.0

40.

42.0 91.3 81.2 12.3 86.6 88.7 10.9 81.9 92.4 9.5 76.9 99.3 8.5 71.9 106.0 7.4

44.

48.0 100.6 84.5 13.1 95.5 94.7 11.6 90.5 99.3 10.1 85.3 104.3 9.0 80.2 112.0 8.3

50.0 103.8 85.8 13.3 98.6 96.0 11.8 93.3 102.0 10.3 88.1 106.1 9.2 82.9 114.0 8.1

40.

42.0 93.4 82.1 12.4 88.7 89.7 11.0 83.9 93.4 9.6 78.7 100.3 8.6 73.6 107.1 7.5

44.

46.

48.0 103.0 85.4 13.2 97.8 95.8 11.7 92.6 100.4 10.2 87.3 105.4 9.1 82.0 113.2 8.4

50.0 106.3 86.7 13.5 100.9 97.0 11.9 95.5 103.1 10.4 90.2 107.2 9.3 84.9 115.2 8.2

40.

42.0 101.3 91.7 12.1 96.1 100.3 10.8 90.9 104.4 9.5 85.4 112.2 8.4 79.8 119.7 7.4

44.0104.

48.0 111.7 95.4 12.9 106.0 107.0 11.4 100.4 112.3 10.0 94.7 117.9 8.9 89.0 126.5 8.2

50.0 115.2 96.9 13.2 109.4 108.4 11.7 103.6 115.2 10.2 97.8 119.8 9.1 92.0 128.8 8.0

40.0107.1

42.0 110.8 101.8 12.2 105.2 111.2 10.7 99.5 115.8 9.5 93.3 124.4 8.4 87.3 132.9 7.3

44.0114.4 103.012.4 108.7 113.011.0102.8117.79.

48.0 122.1 105.9 12.9 116.0 118.8 11.4 109.8 124.5 10.0 103.5 130.8 8.9 97.2 140.4 8.2

Notes:

1. Boxed ratings certified in accordance with ARI Standard 550/590-98 for "AS" units only. Remote evaporator units (AM) are outside the ARI scope.

2. Ratings based on HCFC-22, evaporator fouling factor of 0.0001, 2.4 gpm/ton, and at sea level.

3. kWi input is for compressors only, EER is for the entire unit, including compressors, fan motors and control power.

4. For 208V units, multiply capacity and EER by 0.98

5. For units with SpeedTrol option, multiply capacity and EER by 0.98

6. Operation below 42°F requires glycol and performance adjustment.

7. Ratings can be interpolated but not extrapolated.

50.0 126.0 107.6 13.2 119.7 120.4 11.7 113.3 127.8 10.2 107.0 133.0 9.1 100.6 142.9 7.9

75°F 85°F 95°F 105°F 115°F

PWR

Tons

71.1

1.2 72.811.

kWi

.2 12.

.4 11.

.7 12.7 76.

.7 75.312.482.

.7 76.512.7

2.2 12.

.4 12.

.2 12.2

4.2 12.6102.7 104.511.2

.4 11.9101.7 109.510.

Capac.

EER

Tons

12.167.1

12.

12.4 74.1 74.2 11.070.1 77.

12.

12.791.

12.

11.

12.4

12.7 112.4 115.911.2 106.3120.

PWR

kWi

.4 10.7

71.7 71.511.1

77.

72.4 11.4 70.

71.910.

.1 11.2 72.

.1 10.

2.7 11.077.

.1 11.184.7

1.1 11.2

4.7

AMBIENT AIR TEMPERATURE

EER

11.2

.7 79.2

11.4

11.

11.

Capac.

Tons

PWR

kWi

.1 74.1

77.1

74.

72.

1.1

7.4 10.

7.2 108.

.1 113.

Capac.

EER

Tons

.4 74.

.7 79.7 100.

4.4 103.78.979.2 111.1 7.

.4 114.

.4 122.28.284.6130.37.2

.7 126.

.1 128.78.

PWR

kWi

4.18.7 71.2 100.87.7

Capac.

EER

.4 71.4 105.1 7.4

.7 76.4 109.1 7.7

PWR

Tons

7.7

4.1

.7 103.97.

74.6108.07.

77.4 110.07.7

77.4 117.4 7.2

122.07.

124.37.7

kWi

.1 7.2

.4 7.

.4 7.

EER

7.2

7.7

7.2

16

AGR 070A through 100A Product Manual AGR-3

Page 17

Table 10, AGR 070 – AGR 100, 60 Hz, R-22, SI Units

See Selection Procedure section for derates for the "AM" remote evaporator units

AMBIENT AIR TEMPERATURE

LWT

SIZE

070AS 7.0 (44.6°F) 265.4 67.6 3.62 247.2 72.4 3.24 240.0 77.5 2.84 227.2 82.8 2.56 214.3 88.1 2.28

070AM 8.0 (46.4°F) 271.6 68.7 3.68 245.1 73.2 3.30 247.9 78.7 2.92 234.5 84.0 2.62 221.1 89.5 2.32

075AS 7.0 (44.6°F) 274.4 69.3 3.57 261.8 75.1 3.21 249.1 77.9 2.83 235.8 83.0 2.56 222.6 88.2 2.27

075AM 8.0 (46.4°F) 282.7 70.4 3.64 269.7 76.9 3.26 256.7 79.9 2.88 243.3 84.3 2.61 229.7 89.7 2.34

080AS 7.0 (44.6°F) 304.9 77.2 3.58 290.8 83.7 3.20 276.7 86.8 2.83 262.1 92.4 2.54 247.3 98.2 2.27

080AM 8.0 (46.4°F) 314.2 78.4 3.65 299.6 85.6 3.26 285.0 88.9 2.88 270.4 93.9 2.59 255.5 99.8 2.34

085AS 7.0 (44.6°F) 331.6 84.2 3.61 316.2 91.2 3.24 300.9 94.6 2.86 285.0 100.7 2.57 268.9 107.2 2.30

085AM 8.0 (46.4°F) 341.5 85.5 3.69 325.7 93.3 3.31 310.1 96.9 2.91 293.9 102.3 2.62 277.8 108.9 2.35

090AS 7.0 (44.6°F) 339.4 85.1 3.65 323.7 92.2 3.27 308.0 95.7 2.89 291.5 101.8 2.60 275.2 108.3 2.33

090AM 8.0 (46.4°F) 349.6 86.4 3.71 333.4 94.4 3.34 317.2 98.0 2.94 300.7 103.4 2.65 284.2 110.0 2.38

095AS 7.0 (44.6°F) 367.9 95.1 3.58 350.9 103.1 3.20 334.0 106.9 2.83 316.1 113.8 2.56 298.4 121.1 2.27

095AM 8.0 (46.4°F) 379.1 96.5 3.63 361.6 105.5 3.26 344.1 109.5 2.88 326.0 115.6 2.59 308.2 123.0 2.33

100AS 7.0 (44.6°F) 402.4 105.5 3.57 384.0 114.3 3.21 365.2 118.6 2.83 345.9 126.3 2.56 326.4 134.3 2.28

100AM 8.0 (46.4°F) 414.6 107.1 3.64 395.5 117.0 3.26 376.3 121.5 2.88 356.7 128.3 2.61 337.1 136.4 2.33

NOTES:

1. Ratings based on HCFC-22, evaporator fouling of 0.00176, 0.048 l/s per kW, and sea level altitude. Remote evaporator units (AM) are outside ARI scope.

2. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings.

3. kWi input is for compressors only. EER is for the entire unit, including compressors, fan motors and control power.

4. For LWT below 4.4°C and below please refer to Application Data.

5. For 208V units, multiply capacity and EER by 0.98

6. For units with SpeedTrol option, multiply capacity and EER by 0.98

7. Operation below 5.6°C requires glycol and performance adjustment.

(°C)

5.0 (41.0°F) 251.4 66.1 3.50 238.6 70.4 3.13 225.8 74.7 2.75 213.6 80.3 2.48 201.4 85.6 2.21

6.0 (42.8°F) 258.9 66.8 3.57 245.8 71.4 3.19 232.7 76.1 2.79 220.3 81.5 2.52 207.8 86.9 2.25

9.0 (48.2°F) 283.8 69.7 3.76 269.8 74.2 3.35 255.8 79.8 2.97 241.9 85.2 2.67 227.9 90.9 2.37

10.0 (50.0°F) 292.2 70.7 3.81 277.7 75.6 3.40 263.4 80.7 2.99 249.2 86.6 2.69 234.6 92.4 2.40

5.0 (41.0°F) 258.5 67.4 3.45 246.6 72.8 3.10 234.4 75.5 2.75 221.7 80.4 2.47 208.9 85.3 2.20

6.0 (42.8°F) 266.3 68.4 3.51 254.1 73.8 3.16 241.7 76.6 2.79 228.6 81.7 2.51 215.4 86.8 2.23

9.0 (48.2°F) 290.9 71.4 3.72 277.6 78.5 3.32 264.3 82.0 2.94 250.6 85.7 2.64 237.0 91.1 2.43

10.0 (50.0°F) 299.1 72.3 3.78 285.5 79.6 3.40 271.8 84.0 2.99 257.9 87.1 2.70 244.3 92.6 2.40

5.0 (41.0°F) 287.4 75.1 3.45 274.0 81.1 3.10 260.6 84.0 2.75 246.4 89.6 2.48 232.1 95.0 2.19

6.0 (42.8°F) 296.0 76.2 3.52 282.4 82.3 3.15 268.7 85.3 2.80 253.9 91.0 2.51 239.2 96.7 2.22

9.0 (48.2°F) 323.1 79.4 3.71 308.5 87.4 3.33 293.5 91.3 2.94 278.6 95.4 2.65 263.5 101.5 2.44

10.0 (50.0°F) 332.5 80.6 3.78 317.3 88.6 3.38 301.7 93.5 2.99 286.9 96.9 2.70 271.7 103.1 2.41

5.0 (41.0°F) 312.5 81.8 3.48 297.8 88.4 3.13 283.3 91.7 2.77 267.9 97.7 2.49 252.4 103.6 2.22

6.0 (42.8°F) 322.0 83.1 3.55 307.0 89.6 3.18 292.0 93.0 2.81 276.1 99.2 2.53 260.2 105.4 2.25

9.0 (48.2°F) 351.3 86.7 3.76 335.2 95.3 3.36 319.3 99.6 2.97 302.8 104.0 2.68 286.6 110.7 2.47

10.0 (50.0°F) 361.4 87.8 3.81 344.9 96.6 3.41 328.1 102.0 3.02 311.7 105.7 2.73 295.2 112.4 2.44

5.0 (41.0°F) 319.7 82.7 3.52 305.0 89.4 3.15 290.1 92.7 2.80 274.2 98.7 2.52 258.4 104.8 2.24

6.0 (42.8°F) 329.5 84.0 3.58 314.3 90.6 3.21 299.0 94.0 2.84 282.5 100.3 2.56 266.4 106.5 2.28

9.0 (48.2°F) 359.7 87.6 3.79 343.2 96.4 3.39 326.7 100.7 3.00 309.9 105.1 2.71 293.1 111.8 2.50

10.0 (50.0°F) 370.0 88.8 3.86 352.9 97.6 3.44 335.9 103.1 3.05 319.1 106.8 2.76 302.3 113.6 2.47

5.0 (41.0°F) 346.7 92.4 3.45 330.5 99.8 3.10 314.4 103.5 2.75 297.3 110.4 2.47 280.2 117.1 2.19

6.0 (42.8°F) 357.2 93.9 3.51 340.6 101.3 3.15 324.0 105.1 2.79 306.5 112.1 2.51 288.8 119.1 2.23

9.0 (48.2°F) 390.0 97.9 3.71 372.0 107.7 3.31 354.2 112.6 2.94 336.1 117.5 2.64 318.1 125.0 2.44

10.0 (50.0°F) 401.1 99.2 3.79 382.7 109.1 3.39 364.3 115.2 2.99 346.0 119.4 2.70 327.6 127.0 2.40

5.0 (41.0°F) 379.3 102.5 3.44 361.7 110.8 3.09 344.0 114.8 2.75 325.1 122.4 2.46 306.4 129.9 2.19

6.0 (42.8°F) 390.8 104.2 3.51 372.7 112.4 3.14 354.6 116.6 2.79 335.2 124.3 2.50 315.9 132.1 2.23

9.0 (48.2°F) 426.5 108.6 3.70 406.9 119.5 3.32 387.3 124.8 2.94 367.5 130.4 2.64 347.6 138.7 2.45

10.0 (50.0°F) 438.7 110.1 3.78 418.6 121.1 3.37 398.4 127.8 2.99 378.6 132.4 2.69 358.4 140.9 2.39

25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F) 45°C (113°F)AGR

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Product Manual AGR-3 AGR 070A through 100A

17

Page 18

Part Load Data

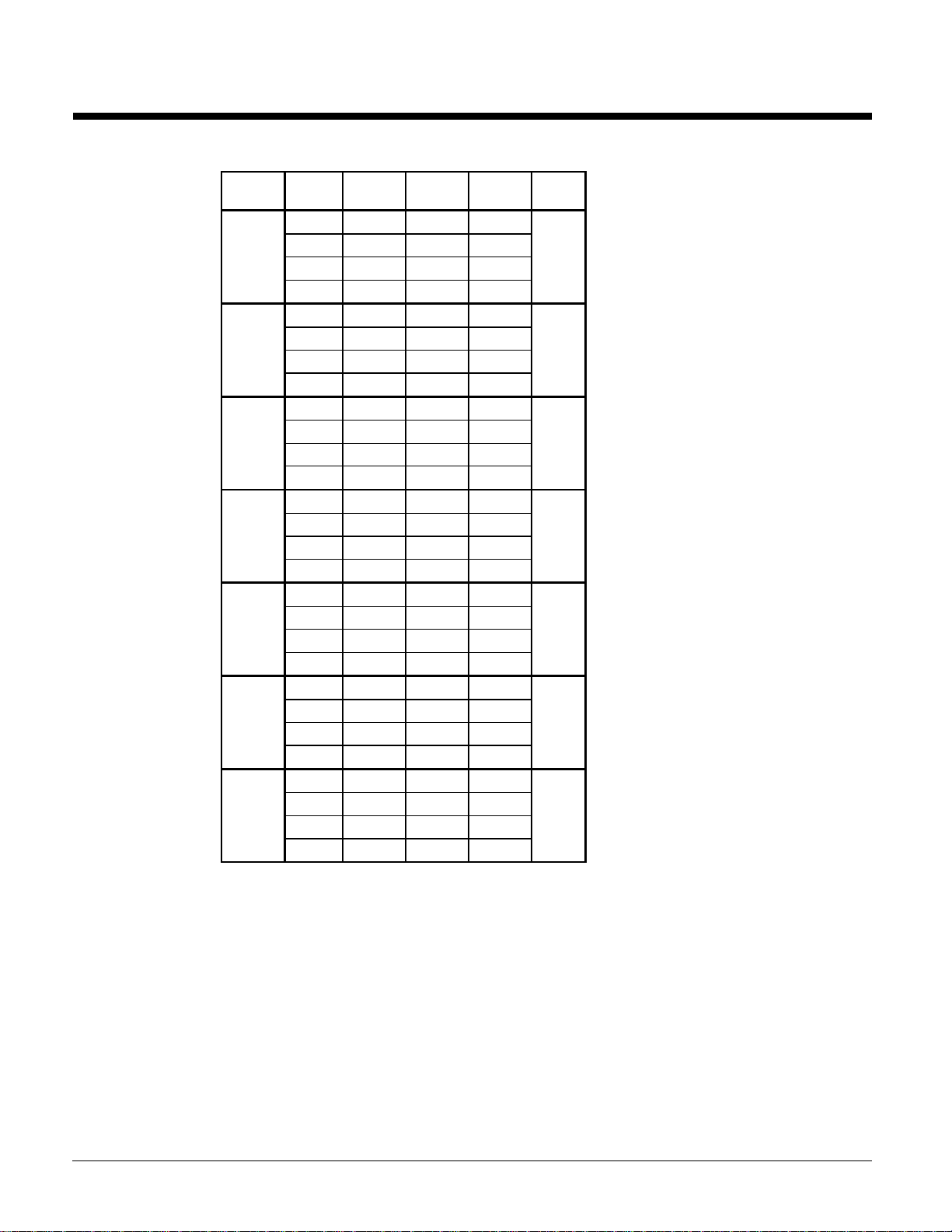

Table 11, 60 Hz, R-22

Unit Size % Load

070AS

075AS

080AS

085AS

090AS

095AS

100AS

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

100.00

75.00

50.00

25.00

Capacity

Tons

67.5 84.4 9.6

50.5 48.9 12.4

33.7 26.7 15.2

16.8 11.8 17.0

70.1 87.6 9.6

52.6 53.8 11.7

35 34.0 12.4

17.5 14.6 14.4

77.9 97.2 9.6

58.4 59.1 11.9

38.9 34 13.7

19.4 16.1 14.5

84.7 104.9 9.7

63.5 63.5 12

42.3 35.2 14.4

21.1 15.4 16.4

86.7 106 9.8

65 64.1 12.2

43.3 35.5 14.6

21.6 15.6 16.6

94 117.6 9.6

70.4 71.5 11.8

46.9 39.2 14.3

23.4 16.5 17.0

102.8 128.5 9.6

77.1 79.3 11.7

51.4 43.9 14.0

25.7 19.3 16.0

Power

Unit kW

EER IPLV

14.2

12.3

13.0

13.6

13.8

13.5

13.2

18

Notes: Certified in accordance with ARI Standard 550/590-98.

AGR 070A through 100A Product Manual AGR-3

Page 19

Sound Data

Table 12, AGR 070AS/AM - 100AS/AM Sound Pressure

Unit

Model

AGR070A

AGR075A

AGR080A

AGR085A

AGR090A

AGR095A

AGR100A

Note: Data at 30 ft. (9m) from side of unit.

63 125 250 500 1000 2000 4000 8000

65 65 64 64 62 56 54 54 66

66 67 65 65 62 56 55 55 67

66 68 65 65 62 56 56 55 67

67 69 66 65 62 56 56 55 67

67 69 66 65 62 56 56 55 67

68 69 67 66 63 58 58 56 68

69 70 68 66 63 58 58 56 68

Sound Pressure At 30 ft. From Sides Of Unit (dB)

Octave Band

Table 13, AGR 070AS/AM – 100AS/AM Sound Power

Unit

Model

AGR070A

AGR075A

AGR080A

AGR085A

AGR090A

AGR095A

AGR100A

Note: Per ARI Standard 370

63 125 250 500 1000 2000 4000 8000

92 92 91 91 89 83 81 81 93

93 94 92 92 89 83 82 82 94

93 95 92 92 89 83 83 82 94

94 96 93 92 89 83 83 82 94

94 96 93 92 89 83 83 82 94

95 96 94 93 90 85 86 83 95

96 97 95 93 90 85 86 83 95

Sound Power

Octave Band

Sound Pressure

Overall

A-Weighted

Sound Power

Overall

A-Weighted

Sound levels are as important as unit cost and efficiency, and must be addressed before to the start of

any development program. Efforts by McQuay design engineers to design chillers that are sensitive to

the sound requirements of the market have paid off.

Background Information

Sound is a vibration in an elastic medium and is essentially a pressure and particle displacement

phenomena. A vibrating body produces compression waves and as the waves are emitted from the

vibrating body, molecules are ultimately compressed. These values are transmitted through gas, liquid,

solidanything which is elastic or viscous.

The sound data provided in this section is presented with both sound pressure and sound power levels.

Sound power is the total sound energy radiated by a source per unit of time integrated over the surface

through which the sound is radiated. Sound power is a calculated quantity and cannot be measure d

directly like sound pressur e. Sound p ower i s not de p end ent on t he sur ro und ing envi ro nment o r d ist anc e

from the source, as is sound pressure.

Sound pressure varies with the distance from the source and is dependent on its surroundings. For

example, a brick wall located 10 feet from a unit will affect the sound pressure measurements

differently than a brick wall at 20 feet. Sound pressure is measured in decibels (dB), which is a

dimensionless ratio (on a logarithmic scale) between measured sound pressure and a reference sound

pressure level.

Sound Pressure Levels - Full Load

All sound pressure tables give the overall "A" weighted sound pressure levels which are considered

typical of what may be measured in a free field with a hand held sound meter, in the absence of any

nearby reflective surfaces. The sound pressure levels are measured at 30 feet (10 meters) from the side

of the unit at 100% unit load and ARI conditions. 95°F (35°C) ambient air temperature and 54/44°F

(12/7°C) evaporator water temperatures for air-cooled units.

Product Manual AGR-3 AGR 070A through 100A

19

Page 20

Sound Power Levels

Acoustical consultants may require sound power octave band data to perform a detailed acoustical

analysis. The tables that follow present sound power levels per ARI Standard 370, “Sound Rating

of Large Outdoor Refrigerating and Air Conditioning Equipment”. These standards were developed

to establish uniform methods of determining the sound power radiated by large outdoor and indoor

equipment. The aforementioned methods are based on providing sound power levels by octave

band and the overall ‘A’ weighted value. Measurements are taken over a prescribed area around the

unit and the data is mathematically calculated to give the sound power, dB.

Sound Reduction due to Distance from the Unit

The distance between a source of sound and the location of the sound measurement plays an

important role in minimizing sound problems. The equation below can be used to calculate the

sound pressure level

at any distance if the

sound power

tabulated in Table 14. Another way of determining the effect of distance is to work from sound

pressure only. “Q”, the directionality factor, is a dimensionless number that compensates for the

type of sound reflection from the source. For example, a unit sitting on a flat roof or ground with

no other reflective surfaces or attenuation due to grass, snow, etc., between source and receiver:

Q=2.

Figure 6, "Q" Definition, Plan View, Unit Located in Center

is known. Results for typical distances are

Uniform Spherical Radiation

Q=1 no reflecting surface

Uniform Hemispherical Radiation

Q=2 single reflecting surface

Uniform Radiation over ¼ of sphere

Q=4 two reflecting surfaces

Sound pressure can be calculated at any distance from the unit if the sound power is known.

Lp=Lw-(20 log r) + (10 log Q) - .5

Lp = sound pressure r = distance from unit in feet

Lw = sound power Q = directionality factor

With Q=1, Unit suspended in space (theoretical condition), the equation simplifies to:

Lp = Lw – (20)(log r) –0.5

With Q=2, for a unit sitting on a flat roof or ground with no adjacent vertical wall as a reflective

surface, the equation simplifies to:

Lp = Lw – (20)(log r) + 2.5

With Q=4 for a unit sitting on a flat roof or ground with one adjacent vertical wall as a reflective

surface, the equation simplifies to:

Lp = Lw – (20)(log r) + 5.5

The equations are reduced to table form in Table 14 for various distances and the two most usual

cases of “Q” type of location.

Table 14, dB Conversion of Sound Power to Pressure for Distance

Distance from Sound Source

ft. (m)

30 (9) 27.1 24.0

50 (15) 31.6 28.5

75 (23) 35.1 32.0

100 (30) 37.6 34.5

150 (46) 41.1 38.0

200 (61) 43.6 40.5

DB Reduction from Sound Power at the Source to Sound

Pressure at Referenced Distance

Q=2 Q=4

20

AGR 070A through 100A Product Manual AGR-3

Page 21

300 (91) 47.6 44.0

Figure 7, Sound Pressure Attenuation Due to Distance from Unit

Unit Orientation to Minimize Sound

The AGR reciprocating chiller’s sound is directional in nature allowing the contractor/engineer to

position the unit to minimize potential noise problems. Because the sound pressure levels are lower at

both ends of the unit than at the sides, the chiller should be oriented such that the control box end or end

opposite the control box faces the direction where the lowest sound level is required.

The control box end provides an excellent acoustic barrier to the compressor sound as it covers one full

end of the unit. The sound pressure levels at the control box end will be 4 dBA less than on the sides.

Figure 8, Sound Directionality

Sound Pressure Levels - Low Ambient Operation

Unit operation at a lower ambient temperature than 95°F will also result in lower sound pressure levels.

The sound pressure level will decrease 1 dBA for ambient temperatures between 85°F to 94°F (29.4°C

to 34.4°C), 2 dBA for ambient temperatures between 75°F to 84°F (23.9°C to 28.9°C), and 3 dBA for

ambient temperatures between 65°F to 74°F (18.3°C to 23.3°C).

Product Manual AGR-3 AGR 070A through 100A

21

Page 22

Pressure Drop Curves

Figure 9, Evaporator Pressure Drops

22

Unit

Size

070AS/AM 16.0 162 10.22 40.5 270 17.04 6.8 101 6.39

075AS/AM 9.6 168 10.60 24.0 280 17.67 4.3 105 6.62

080AS/AM 11.7 187 11.80 29.6 312 19.66 5.1 117 7.37

085AS/AM 13.5 203 12.81 33.3 338 21.35 5.9 127 8.00

090AS/AM 10.5 208 13.12 26.3 347 21.87 4.5 130 8.20

095AS/AM 12.0 226 14.26 30.0 377 23.76 5.2 141 8.91

100AS/AM 13.4 240 15.14 33.6 400 25.24 5.7 150 9.46

: Minimum and maximum flows are established to ensure the Delta-T for each unit size falls within the 6 - 16°F range for

Note

proper unit control. Contact factory for unit operation outside of minimum and maximum flows shown.

(ft) of Water

NOMINAL MAXIMUM MINIMUM

PD

Flow Flow Flow

(gpm) (lps)

PD

(ft) of Water

(gpm) (lps)

(ft) of Water

PD

(gpm) (lps)

AGR 070A through 100A Product Manual AGR-3

Page 23

Electrical Data

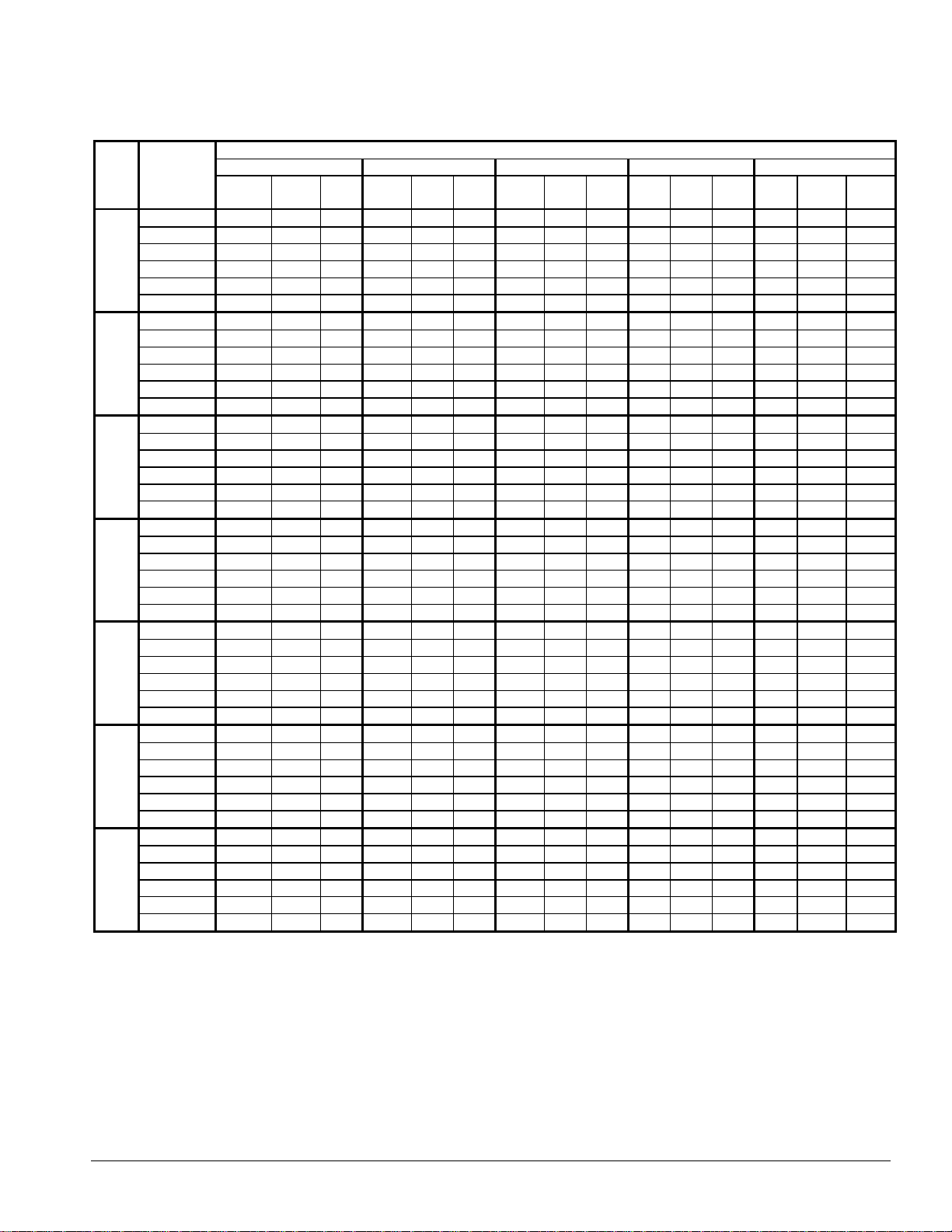

Table 15, 60 Hz, Single Point Power Electrical Data

AGR

Unit

Size

070AS

070AM

075AS

075AM

080AS

080AM

085AS

085AM

090AS

090AM

095AS

095AM

100AS

100AM

All Electrical Data notes are on page 26.

Minimum

Volts

208 322 3 400 1 2.50 450

230 300 3 350 1 2.50 400

380 190 3 3/0 1 2.00 250

460 153 3 2/0 1 1.50 200

575 114 3 #2 1 1.25 150

208 351 3 500 1 3.00 450

230 329 3 400 1 2.50 450

380 220 3 4/0 1 2.00 300

460 163 3 2/0 1 1.50 225

575 126 3 #1 1 1.50 150

208 384 6 3/0 2 2.00 500

230 373 3 500 1 3.00 500

380 240 3 250 1 2.50 300

460 187 3 3/0 1 2.00 250

575 151 3 2/0 1 1.50 200

208 411 6 4/0 2 2.00 500

230 408 6 4/0 2 2.00 500

380 256 3 300 1 2.50 350

460 206 3 4/0 1 2.00 250

575 171 3 3/0 1 2.00 225

208 411 6 4/0 2 2.00 500

230 408 6 4/0 2 2.00 500

380 256 3 300 1 2.50 350

460 206 3 4/0 1 2.00 250

575 171 3 3/0 1 2.00 225

208 461 6 250 2 2.00 600

230 458 6 4/0 2 2.00 600

380 269 3 300 1 2.50 350

460 220 3 4/0 1 2.00 300

575 176 3 3/0 1 2.00 225

208 501 6 250 2 2.00 700

230 498 6 250 2 2.00 700

380 279 3 300 1 2.50 350

460 231 3 250 1 2.00 300

575 180 3 3/0 1 2.00 250

Circuit

Ampacity

(MCA)

Field Wire Conduit Hub

Quantity

POWER SUPPLY

Wire

Gauge

Quantity

Nominal

Size

Max. Fuse

HACR Breaker

Size

or

Product Manual AGR-3 AGR 070A through 100A

23

Page 24

Table 16, 60 Hz, Compressor And Condenser Fan Motor Amp Draw

AGR

Unit

Size

070AS

070AM

075AS

075AM

080AS

080AM

085AS

085AM

090AS

090AM

095AS

095AM

100AS

100AM

Notes:

1. Part winding start is a special option on 380 – 575 volt units.

2. All Electrical Data notes are on page 26.

Volts

Rated Load Amps Locked Rotor Amps

Compressors Compressors

No.

1

208 122 135 7.8 4 30.5 N.A. N.A. 400 463

230 112 127 7.2 4 27.6 N.A. N.A. 340 340

380 65 87 4.1 4 20.0 365 365 N/A N/A

460 60 63 3.6 4 13.8 315 315 195 195

575 42 48 3.0 4 11.0 245 245 152 152

208 135 135 7.8 6 30.5 N.A. N.A. 463 463

230 127 127 7.2 6 27.6 N.A. N.A. 340 340

380 87 87 4.1 6 20.0 365 365 N/A N/A

460 63 63 3.6 6 13.8 315 315 195 195

575 48 48 3.0 6 11.0 245 245 152 152

208 135 162 7.8 6 30.5 N.A. N.A. 463 654

230 127 162 7.2 6 27.6 N.A. N.A. 340 654

380 87 103 4.1 6 20.0 365 740 N/A N/A

460 63 82 3.6 6 13.8 315 510 195 330

575 48 68 3.0 6 11.0 245 405 152 262

208 162 162 7.8 6 30.5 N.A. N.A. 654 654

230 162 162 7.2 6 27.6 N.A. N.A. 654 654

380 103 103 4.1 6 20.0 740 740 N/A N/A

460 82 82 3.6 6 13.8 510 510 330 330

575 68 68 3.0 6 11.0 405 405 262 262

208 162 162 7.8 6 30.5 N.A. N.A. 654 654

230 162 162 7.2 6 27.6 N.A. N.A. 654 654

380 103 103 4.1 6 20.0 740 740 N/A N/A

460 82 82 3.6 6 13.8 510 510 330 330

575 68 68 3.0 6 11.0 405 405 262 262

208 162 202 7.8 6 30.5 N.A. N.A. 654 654

230 162 202 7.2 6 27.6 N.A. N.A. 654 654

380 103 113 4.1 6 20.0 740 740 N/A N/A

460 82 93 3.6 6 13.8 510 510 330 330

575 68 72 3.0 6 11.0 405 405 262 262

208 202 202 7.8 6 30.5 N.A. N.A. 654 654

230 202 202 7.2 6 27.6 N.A. N.A. 654 654

380 113 113 4.1 6 20.0 740 740 N/A N/A

460 93 93 3.6 6 13.8 510 510 330 330

575 72 72 3.0 6 11.0 405 405 262 262

No.

2

Fan

Motors

(Each)

No. Of

Fan

Motors

Fan

Motors

(Each)

Across-The-Line Part Winding (1)

No. 1No. 2No. 1No. 2

24

AGR 070A through 100A Product Manual AGR-3

Page 25

Table 17, 60 Hz Single Point Power, Field Wiring Data

AGR

Unit

Size

070AS

070AM

075AS

075AM

080AS

080AM

085AS

085AM

090AS

090AM

095AS

095AM

100AS

100AM

All Electrical Data notes are on page 26.

Volts

208 335 # 4 - 400 MCM 400 250 - 500 MCM

230 335 # 4 - 400 MCM 400 250 - 500 MCM

380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 150 #2 - 3/0

208 840 (2 qty.) 1/0 - 600 MCM 400 250 - 500 MCM

230 335 # 4 - 400 MCM 400 250 - 500 MCM

380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 150 #2 - 3/0

208 840 (2 qty.) 1/0 - 600 MCM 400 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 400 250 - 500 MCM

380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 250 #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

380 335 # 4 - 400 MCM 400 250 - 500 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 250 #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

380 335 # 4 - 400 MCM 400 250 - 500 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 250 #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

380 335 # 4 - 400 MCM 400 250 - 500 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 250 #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

380 335 # 4 - 400 MCM 400 250 - 500 MCM

460 335 # 4 - 400 MCM 250 #4 - 350 MCM

575 335 # 4 - 400 MCM 250 #4 - 350 MCM

Terminal

Amps

Wiring to Standard Wiring to Optional

Power Block Non-Fused Disconnect Switch

Connector Wire Range

(Copper Wire Only)

Terminal

Amps

Connector Wire Range

(Copper Wire Only)

Product Manual AGR-3 AGR 070A through 100A

25

Page 26

Notes for “Electrical Data Single Point” Power:

1. Unit wire size ampacity (MCA) is equal to 125% of the largest compressor-motor RLA plus 100%

of RLA of all other loads in the circuit including the control transformer.

2. The control transformer is furnished. A separate 115v power supply can be used if desired.

3. If a separate 115V power supply is used for the control circuit, then the wire sizing amps is 10

amps for all unit sizes.

4. Recommended power lead wire sizes for 3 conductors per conduit are based on 100% conductor

ampacity in accordance with NEC. Nominal voltage drop has been included. It is recommended

that power leads be kept short. All terminal block connections must be made with copper (type

THW) wire.

5. “Recommended Fuse Sizes or HACR breaker size” is selected at approximately 150% to 175% of

the largest compressor RLA, plus 100% of all other loads in the circuit.

6. “Maximum Fuse or HACR breaker size” is selected based on 225% of the largest compressor RLA,

plus 100% of all other loads in the circuit.

7. The recommended power lead wire sizes are based on an ambient temperature of 86°F (30°C).

Ampacity correction factors must be applied for other ambient temperatures. Refer to the National

Electrical Code Handbook.

8. Must be electrically grounded according to national and local electrical codes.

9. MCA may vary slightly due to fan motor options such as SpeedTrol.

Voltage Limitations:

Within ± 10 percent of unit nameplate rating.

Notes for “Compressor and Condenser Fan Amp Draw”:

1. Compressor RLA values are for wiring sizing purposes only and may be higher than nominal

operating current draw at rated capacity.

2. If unit is equipped with SpeedTrol condenser fan motors, the first motor on each refrigerant circuit

is a single phase, 1hp motor, with a FLA of 2.8 amps at 460 volts and 5.6 amps at 208, 230 volts

and LRA of 7.3 amps at 460 volts and 14.5 amps at 208, 230 volts.

3. Compressor LRA for reduced inrush start are for the first winding of part-winding start only.

Notes for “Field Wiring Data”:

1. The standard unit requires a single disconnect to supply electrical power to the unit. Power supply

must either be fused or use a HACR type circuit breaker.

2. Multiple point power connection for field wiring is available as an option. Two power terminal

blocks are supplied in the unit, one for each system in the unit. Each power terminal block supplies

both compressor and fan motor power for each system. The control transformer is furnished and

connected to the system #1 power terminal block.

3. All field wiring to unit power block or optional non-fused disconnect switch must be copper.

4. All field wire size values given in table apply to 75°C rated wire per NEC.

26

AGR 070A through 100A Product Manual AGR-3

Page 27

Figure 10, Typica l Field Wiring with MicroTech Controller

See Note 3 for “Electrical Data Single Point Power” on page 26

Product Manual AGR-3 AGR 070A through 100A

27

Page 28

Figure 11, Typical Field Wiring Diagram with UNT Controller

28

See note 3 for “Electrical Data Single Point Power” on page 26

AGR 070A through 100A Product Manual AGR-3

Page 29

Physical Data

AGR-AS, Packaged Chiller

Table 18, AGR 070AS – AGR 085AS

PHYSICAL DATA

STANDARD EFFICIENCY

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 67.5 (237.6) 70.1 (246.7) 77.9 (273.9) 84.7 (298.1)

Number Of Refrigerant Circuits 2222

Unit Operating Charge, R-22, lbs. (kg) 60 (27.2) 84 (38.1) 84 (38.1) 86 (39.9) 86 (39.9) 86 (39.9) 86 (39.9) 86 (39.9)

Unit Operating Charge, R-134a, , lbs. (kg) 63 (28.6) 88 (40.0) 88 (40.0) 90 (41.9) 90 (41.9) 90 (41.9) 90 (41.9) 90 (41.9)

Cabinet Dimensions, LxWxH, In. 94.0 x 88.2 x 96.2 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2

Cabinet Dimensions, LxWxH, (mm) 2388 x 2241 x 2444 3463 x 2241 x 2444 3463 x 2241 x 2444 3463 x 2241 x 2444

Unit Operating Weight, Lbs. (kg) 4755 (2154) 5506 (2497) 5740 (2604) 5921 (2686)

Unit Shipping Weight, Lbs. (kg) 4650 (2106) 5359 (2431) 5593 (2537) 5774 (2619)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 830 (375) 1245 (565) 1245 (565) 1245 (565)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 35 40 40 40 40 50 50 50

Number Of Cylinders Per Compressor 66666888

Oil Charge Per Compressor, oz. 140 255 255 255 255 255 255 255

Oil Charge Per Compressor, (g) (3969) (7229) (7229) (7229) (7229) (7229) (7229) (7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead 0-16-33-49-67 0-17-33-50-67 0-15-42-58-73 0-25-50-63-75

Standard Staging - Circuit #2 in Lead 0-17-33-51-67 0-17-33-50-67 0-27-42-56-71 0-25-50-63-75

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, sq. ft. 58 58 87 87 87 87 87 87

Coil Face Area, (m2) (5.4) (5.4) (8.1) (8.1) (8.1) (8.1) (8.1) (8.1)

Finned Height x Finned Length, In. 100x 83.5 100x 83.5 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3

Finned Height x Finned Length, (mm)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Pumpdown capacity @ 90% lbs. (kg) 108 (49) 108 (49) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73)

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS – DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 4 - 28 (712) 6 - 28 (712) 6 - 28 (712) 6 - 28 (712)

Number Of Motors - HP (kW) 4 - 2.0 (1.5) 6 - 2.0 (1.5) 6 - 2.0 (1.5) 6 - 2.0 (1.5)

Fan And Motor RPM, 60Hz 1140 1140 1140 1140

60 Hz Fan Tip Speed, fpm (m/Sec) 8357 (35.4) 8357 (35.4) 8357 (35.4) 8357 (35.4)

60 Hz Total Unit Airflow, cfm (m3/sec) 40800 (19.3) 61200 (28.9) 61200 (28.9) 61200 (28.9)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, ft. 12.75- 4 12.75 - 5.5 12.75 - 5.5 12.75 - 5.5

Diameter, (mm) – Length, (mm) 324 - 1220 324 - 1676 324 - 1676 324 - 1676

Water Volume, gallons, (l) 12.8 (48.5) 17.6 (66.6) 17.6 (66.6) 17.6 (66.6)

Water Side Design Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Refrigerant Design Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 5 (141.3) 5 (141.3) 5 (141.3) 5 (141.3)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range, R-22.

070AS 075AS 080AS 085AS

-83-100 -83-100 -86-100 -88-100

-84-100 -83-100 -85-100 -88-100

2032 x

2121

2032 x

2121

AGR MODEL NUMBER

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

Product Manual AGR-3 AGR 070A through 100A

29

Page 30

Table 19, AGR 090AS – AGR 100AS

PHYSICAL DATA AGR MODEL NUMBER

STANDARD EFFICIENCY 090AS 095AS 100AS

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 86.7 (305.2) 94.0 (330.1) 102.8 (359.8)

Number Of Refrigerant Circuits 2 2 2

Unit Operating Charge, R-22, lbs.(kg) 90 (40.8) 90 (40.8) 90 (40.8) 92 (41.7) 92 (41.7) 92 (41.7)

Unit Operating Charge, R-134a, lbs.(kg) 94 (42.8) 94 (42.8) 94 (42.8) 96 (43.7) 96 (43.7) 96 (43.7)

Cabinet Dimensions, LxWxH, In. 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2

Cabinet Dimensions, LxWxH, (mm) 3463 x 2241 x 2444 3463 x 2241 x 2444 3463 x 2241 x 2444

Unit Operating Weight, Lbs. (kg) 6184 (2805) 6194 (2810) 6194 (2810)

Unit Shipping Weight, Lbs. (kg) 6008 (2725) 6018 (2730) 6018 (2730)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 1245 (565) 1245 (565) 1245 (565)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 50 50 50 60 60 60

Number Of Cylinders Per Compressor 888888

Oil Charge Per Compressor, oz. 255 255 255 255 255 255

Oil Charge Per Compressor, (g) (7229) (7229) (7229) (7229) (7229) (7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead 0-25-50-63-75 0-23-50-61-75 0-25-50-63-75

Standard Staging - Circuit #2 in Lead 0-25-50-63-75 0-27-50-64-75 0-25-50-63-75

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area, sq. ft. 87 87 87 87 87 87

Coil Face Area, (m2) (8.1) (8.1) (8.1) (8.1) (8.1) (8.1)

Finned Height x Finned Length, In. 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3

Finned Height x Finned Length, (mm)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Pumpdown capacity @ 90% lbs. (kg) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73)

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS – DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, in. (mm) 6 - 28 (712) 6 - 28 (712) 6 - 28 (712)

Number Of Motors - HP (kW) 6 - 2.0 (1.5) 6 - 2.0 (1.5) 6 - 2.0 (1.5)

Fan And Motor RPM, 60Hz 1140 1140 1140

60 Hz Fan Tip Speed, fpm (m/sec) 8357 (35.4) 8357 (35.4) 8357 (35.4)

60 Hz Total Unit Airflow, cfm (m3/sec) 61200 (28.9) 61200 (28.9) 61200 (28.9)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, ft. 14 - 5.5 14 - 5.5 14 - 5.5

Diameter, (mm) – Length, (mm) 356 - 1676 356 - 1676 356 - 1676

Water Volume, gallons, (l) 21.2 (80.3) 21.2 (80.3) 21.2 (80.3)

Water Side Design Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552)

Refrigerant Design Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 5 (141.3) 5 (141.3) 5 (141.3)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

NOTE: Nominal capacity based on 95°F ambient air and 54°F/44°F water range.

-88-100 -86-100 -88-100

-88-100 -89-100 -88-100

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

2540 x

3183

30

AGR 070A through 100A Product Manual AGR-3

Page 31

AGR-AM, Remote Evaporator

Table 20, AGR 070AM - 085AM

PHYSICAL DATA AGR MODEL NUMBER

STANDARD EFFICIENCY 070A M 075AM 080AM 085AM

OUTDOOR UNIT BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Number Of Refrigerant Circuits 2222

Unit Operating Charge, R-22, lbs. (kg) 60 (27.2) 84 (38.1) 84 (38.1) 86 (39.9) 86 (39.9) 86 (39.9) 86 (39.9) 86 (39.9)

Unit Operating Charge, R-134a, , lbs. (kg) 63 (28.6) 88 (40.0) 88 (40.0) 90 (41.9) 90 (41.9) 90 (41.9) 90 (41.9) 90 (41.9)

Cabinet Dimensions, LxWxH, In. 94.0 x 88.2 x 96.2 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2 136.4 x 88.2 x 96.2

Cabinet Dimensions, LxWxH, (mm) 2388 x 2241 x 2444 3463 x 2241 x 2444 3463 x 2241 x 2444 3463 x 2241 x 2444

Unit Operating Weight, Lbs. (kg) 3978 (1802) 4509 (2043) 4743 (2149) 4924 (2331)

Unit Shipping Weight, Lbs. (kg) 3855 (1746) 4384 (1986) 4618 (2092) 4799 (2174)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 830 (375) 1245 (565) 1245 (565) 1245 (565)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 35 40 40 40 40 50 50 50

Number Of Cylinders Per Compressor 66666888

Oil Charge Per Compressor, oz. 140 255 255 255 255 255 255 255

Oil Charge Per Compressor, (g) (3969) (7229) (7229) (7229) (7229) (7229) (7229) (7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead 0-16-33-49-67 0-17-33-50-67 0-15-42-58-73 0-25-50-63-75

Standard Staging - Circuit #2 in Lead 0-17-33-51-67 0-17-33-50-67 0-27-42-56-71 0-25-50-63-75

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 5858878787878787

Coil Face Area, (m2) (5.4) (5.4) (8.1) (8.1) (8.1) (8.1) (8.1) (8.1)

Finned Height x Finned Length, In. 100x 83.5 100x 83.5 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3 100x125.3

Finned Height x Finned Length, (mm)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Pumpdown capacity @ 90% Lbs. (kg) 108 (49) 108 (49) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73) 162 (73)

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 4 - 28 (712) 6 - 28 (712) 6 - 28 (712) 6 - 28 (712)

Number Of Motors - HP (kW) 4 - 2.0 (1.5) 6 - 2.0 (1.5) 6 - 2.0 (1.5) 6 - 2.0 (1.5)

Fan And Motor RPM, 60Hz 1140 1140 1140 1140

60 Hz Fan Tip Speed, FPM (M/Sec) 8357 (35.4) 8357 (35.4) 8357 (35.4) 8357 (35.4)