Page 1

Installation, Operation, and Maintenance Manual

IOM AFSD-1

Direct Drive Fluid Coolers

Type AFS 005 Through AFS 107

Type AFD 046 Through AFD 212

Group: Chiller

Part Number: 331375001

Effective: February 2007

Supersedes: January 2005

Page 2

Table of Contents

Product Offering ........................................................................................................3

Introduction................................................................................................................4

Installation ..................................................................................................................4

Unit Location .....................................................................................................................................5

Holding Charge ..................................................................................................................................5

Sound Vibration .................................................................................................................................6

Walls or Obstructions .........................................................................................................................6

Multiple Units ....................................................................................................................................6

Units in Pits........................................................................................................................................6

Decorative Fences ..............................................................................................................................6

General...............................................................................................................................................7

Piping Installation ..............................................................................................................................7

Glycol Charge ....................................................................................................................................9

Mixing Glycol and Water ...................................................................................................................9

Glycol Sludge Prevention...................................................................................................................9

Fluid Circulating Pump ......................................................................................................................9

Physical Data ............................................................................................................10

Dimensional Data .....................................................................................................12

Electrical Data..........................................................................................................14

Electrical Wiring ..............................................................................................................................14

Wiring Diagrams..............................................................................................................................17

Start Up.....................................................................................................................18

Prestart .............................................................................................................................................18

Filling and Purging the System.........................................................................................................18

Temperature Control ........................................................................................................................18

Maintenance .............................................................................................................29

Cleaning Instructions........................................................................................................................29

Manufactured in an ISO certified facility

Illustrations cover the general appearance of McQuay International products at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice.

2 Direct Drive Fluid Coolers IOM AFSD-1

2004 McQuay International

Page 3

AFS

07042A

C

VOLTAGE

CONTROL

ROUGH

OPTION

056

CIRCUIT

Product Offering

MODEL

SIZE

OPTION

OPTION

DUTY

FEED

OPTION

Model

AFS - 1140 RPM fan motors, single-row of fans

AFD - 1140 RPM fan motors, double row of fans

Size

Models 005 through 021 – 1/3 horsepower motors, 1140 RPM fan motors

Models 023 through 212 – 1 ½ horsepower motors, 1140 RPM fan motors

Voltage Option

42 = 208/230 volts / 60 Hertz / 3-phase

27 = 460 volts / 60 Hertz / 3-phase

37 = 575 volts / 60 Hertz / 3-phase

Special – 208 volts / 60 Hertz/ 1-phase, 208/230/380/460 volts/50 Hertz/3-phase

Control Option

A = Fan Cycling Thermostat with Control Transformer (120V)

E = Control Transformer Only (120V)

Y = None

Rough Duty Options

A = Totally enclosed motors

B = Sealtite Wiring

C = PolyGuard fin coating with totally enclosed motors and Sealtite wiring

D = ElectroFin coating with totally enclosed motors and Sealtite wiring

E = PolyGuard Only

F = ElectroFin Only

G = Copper Fins Only (not available on 5 or 6-fan length models)

H = Copper Fins with totally enclosed motors and Sealtite wiring

Circuit Feed Option

Equals the number of feeds (from the header to the first pass of tubes) from capacity tables.

IOM AFSD-1 Direct Drive Fluid Coolers 3

Page 4

Introduction

Carefully check each shipment against the bill of lading and account for all items. Report any shortage

or damage to the delivering carrier. Damaged material is the delivering carrier’s responsibility. Do not

return to the manufacturer without prior approval.

Be careful when uncrating, to prevent damage. Heavy equipment should be left on units shipping base

until it has been moved to the final location. This equipment must be installed in accordance with

accepted industry standards. Failure to meet the following conditions may void the warranty:

1. System piping must be installed following industry standards for good piping practices.

2. Inert gas must be charged into piping during welding.

3. System must be thoroughly leak checked before initial charging.

4. Power supply to system must meet the following conditions:

Voltage for 208/230 motors not less than 195 volts or more than 253 volts.

All other voltages must be within 10% of nameplate ratings.

Phase imbalance not to exceed 2%.

5. All controls and equipment protection circuits properly connected per wiring diagram.

6. Factory installed wiring must not be changed without written factory approval.

7. Relief valves must meet all code requirements.

Installation

Inspection

When the equipment is received, carefully check all items against the bill of lading to check for

a complete shipment. Check all units for damage upon arrival. All shipping damage must be

reported to the carrier and a claim must be filed with the carrier. Check the unit’s serial plate

before unloading the unit to be sure that it agrees with the power supply available. Physical

damage to unit after acceptance is not the responsibility of McQuay International.

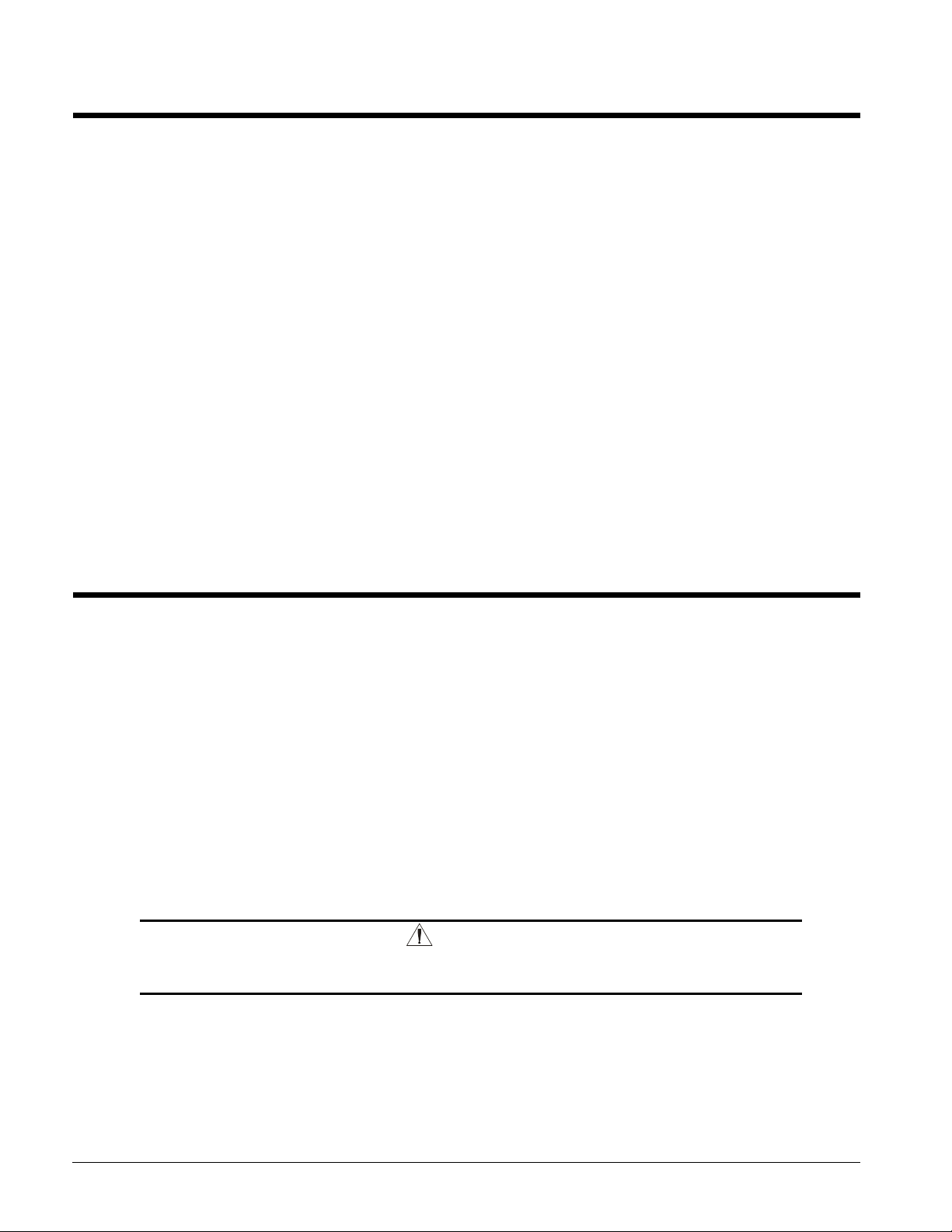

Handling

Note: Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment.

Avoid rough handling shock due to impact or dropping the unit. Do not push or pull the unit.

Never allow any part of the unit to fall during unloading or moving, as this can result in serious

damage.

Improper lifting or moving unit can result in property damage, severe

personal injury or death. Follow rigging and moving instructions carefully.

DANGER

4 Direct Drive Fluid Coolers IOM AFSD-1

Page 5

Figure 1, Unit Rigging

Unit Location

Units are designed for outdoor application and may be mounted on a roof or concrete slab

(ground level installation). Install roof mounted units on steel channels or an I-beam frame to

support the unit above the roof. Use of vibration pads or isolators is recommended. The roof

must be strong enough to support the weight of the unit. For ground level installation, mount

units on a one-piece concrete slab with footings extending below the frost line. Be certain

concrete slabs are installed level and are properly supported to prevent settling. Locate the

unit far enough away from any wall or other obstruction to provide sufficient clearance for air

entrance. Do not attach more than two-feet of ductwork to the fan outlet. Avoid air

recirculation conditions that may be caused by sight screening, walls, etc. and keep unit fan

discharge away from any building air intakes. Do not install unit where exhaust or ventilation

equipment will affect entering air temperature or foul coils.

Holding Charge

The unit is shipped with a holding charge of dry nitrogen under nominal pressure.

IOM AFSD-1 Direct Drive Fluid Coolers 5

Page 6

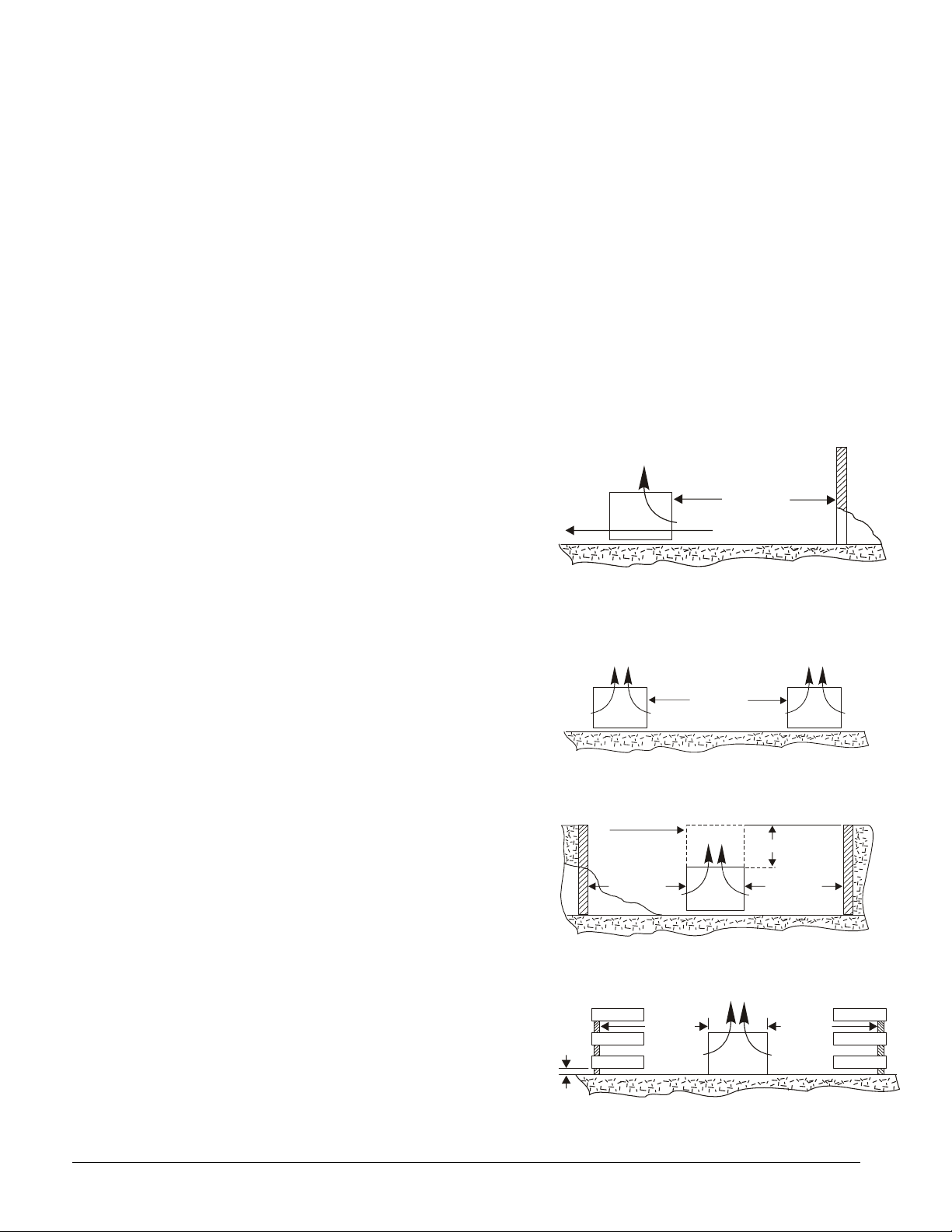

Sound Vibration

AFS = 4 ft.

AFD = 6 ft.

AFS = 4 ft.

AFD = 6 ft.

AFS = 3 ft.

AFD = 4 ft.

Install units away from occupied spaces, utility areas, corridors and auxiliary spaces to

reduce the transmission of sound and vibration to occupied spaces. The fluid piping should

be flexible enough to prevent the transmission of noise and vibration from the unit into the

building. If the fluid lines are to be suspended from the structure of the building, use

isolation hangers to prevent the transmission of vibration. Where piping passes through a

wall, pack fiberglass and sealing compound around the lines to minimize vibration and

retain flexibility. The unit must be secured in its final location. Holes are provided in the

base runner for this purpose

Vertical airflow type units should be located no closer than the width of the unit from a wall

or other obstruction. It two or more units are to be positioned in the same area, a similar

distance should be maintained between adjacent units. Sufficient free area should be left

around and below unit to avoid air restriction to coil.

Walls or Obstructions

Locate the unit to ensure that air can

circulate freely and not be recirculated. For

proper air flow and access, all sides of the

unit must be at least the distance shown away

from any wall or obstruction. Increase this

distance whenever possible. Be sure enough

room is left for maintenance through access

doors and panels. Overhead obstructions are

not permitted. When enclosed by three walls

the unit must be installed as indicated for

units in a pit.

AIR FLOW

Multiple Units

For units placed side by side, the minimum

distance between units is as shown. If units

are placed end to end, the minimum distance

between units is 4 feet.

Units in Pits

The top of the unit should not be more than

two feet below the top of the pit, and side

minimum distance on all four sides as

shown.

Decorative Fences

Fences must have 50% free area, with 1 foot

undercut, at least the width of condenser

minimum clearance, and must not be higher

than the top of unit. If these requirements

are not met, unit must be installed as

indicated for "Units in Pits".

AIR FLOW AIR FLOW

AFS = 6 ft.

AFD = 8 ft.

1 IN.

MIN.

STACK

(BY OTHERS

IF SUPPLIED)

AFS = 4 ft.

AFD = 6 ft.

AFS = 3 ft.

AFD = 4 ft.

AIR

FLOW

AIR FLOW

2 FT. MAX.

6 Direct Drive Fluid Coolers IOM AFSD-1

Page 7

General

1. Structure supporting unit must be designed to support both the unit and the fluid.

Table 1 provides weight of fluid per gallon. Provide suitable flashing of the roof, if this

is a roof installation. For ground level mounting, a concrete pad is recommended.

Mounting holes permit the units to be bolted down to withstand wind pressures.

Provide adequate clearance for unobstructed air flow to coils.

2. Level mounting is necessary to ensure proper fluid distribution through the coil as well

as flooded suction for the pump.

Table 1, Fluid Weight Per Gallon at 130

Percent Glycol

0 (Water) 8.25 8.22

10 8.33 8.29

20 8.50 8.37

30 8.58 8.42

40 8.80 8.49

50 8.82 8.53

Pounds per Gallon

Ethylene Glycol

°°°°

F

Pounds per Gallon

Propylene Glycol

3. Water piping must comply with local codes. Correct pipe sizing will help reduce

pumping power and operating costs.

4. In case of doubt, consult the manufacturer for the dry cooler fluid pressure drop at the

specific conditions on your job.

5. Provide sufficient valves and unions to permit easy access to parts subject to wear and

possible repair or replacement.

6. After fluid piping is completed, all joints should be leak tested.

7. Where city water make-up is required, follow local codes, making certain that

disconnecting provisions are provided.

8. Select wire in accordance with nameplate data and local codes.

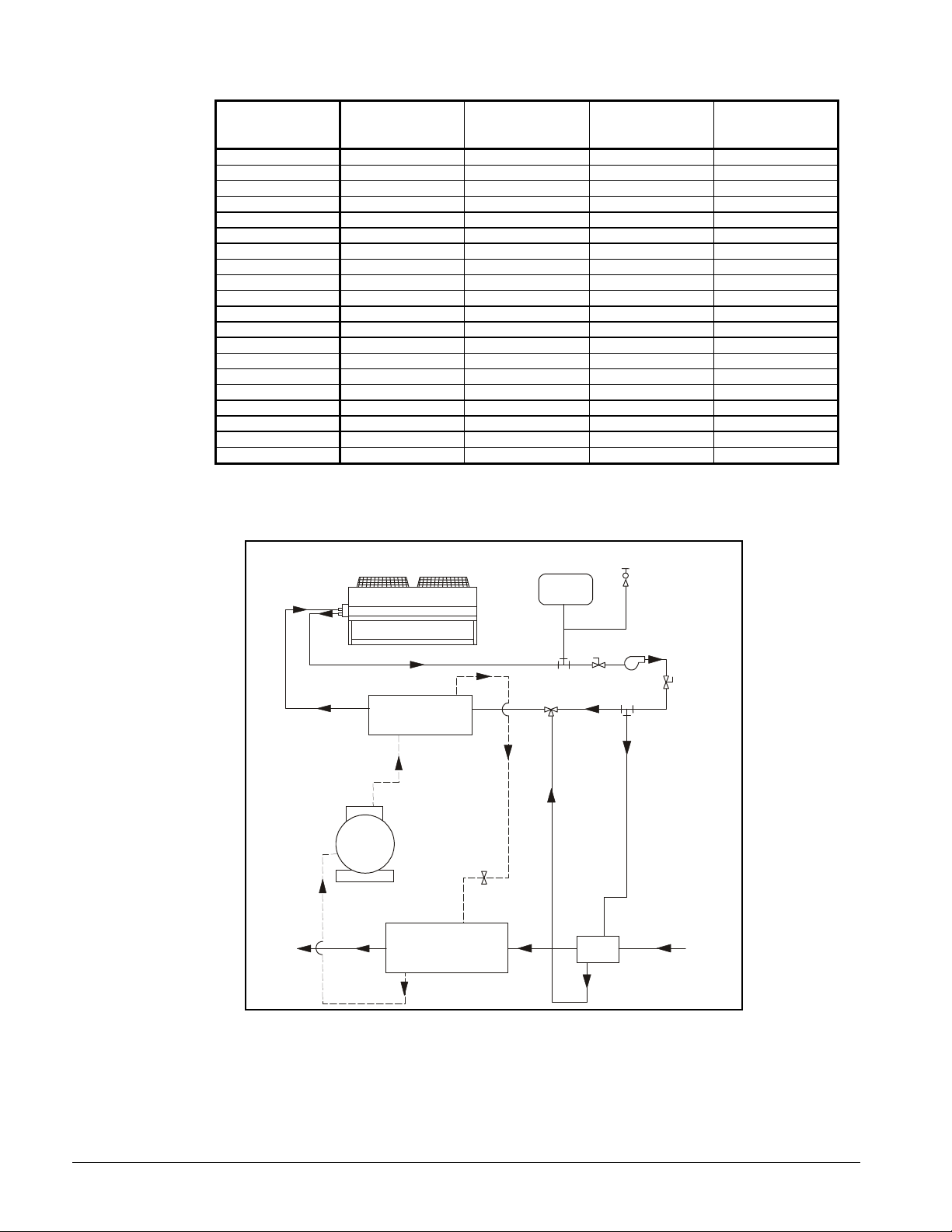

Piping Installation

The piping system should provide maximum leak prevention. Weld or sweat joints should

be used where possible. The fact that glycol solutions or other heat transfer fluids will leak

where water will not, must be taken into account.

The glycol system should not employ an automatic fill with a pressure-reducing valve. This

is because a slight leak would lead to dilution of the mixture and possible freeze potential.

Any refill should be controlled so as to maintain the proper glycol-to-water ratio.

Table 2 shows pressure drops for various pipe sizes at flow rates commonly used with a

typical dry cooler. These pipe sizes are not necessarily always correct for the run from the

condenser to the dry cooler. Proper pipe size will depend on available pump head. This can

be determined by subtracting from the total available pump head at design flow, the

condenser pressure drop and the dry cooler pressure drop. Allow some safety factor for last

minute pipe fittings added to the system and for eventual fouling of the system.

a) Glycol piping requires no insulation except when fluid temperature will be below

ambient dewpoint temperatures.

b) Vents are required at all high points in the piping to bleed air when filling the system.

If fluid coolers are at high points, vent valves should be installed at each fluid cooler.

c) It is recommended that gate valves be installed on both sides of the pump to prevent

loss of fluid in the event the pump should require repair or replacement. Shut-off

valves are also recommended at water cooled condensers in case the condensing unit is

to be moved or requires maintenance involving the coolant system.

IOM AFSD-1 Direct Drive Fluid Coolers 7

Page 8

Table 2, Pressure Loss in Feet of Water

Flow

gpm

15 1 1 1/8 17.6 15.0

20 1 1 1/6 30.2 23.1

25 1 1 1/8 34.6

25 1 1/4 1 3/8 11.5 12.6

30 1 1/4 1 3/8 16.3 17.4

35 1 1/4 1 3/8 21.8 23.0

40 1 3/8 - 26.3

40 1 112 1 5/8 13.0 12.9

45 1 1/2 1 5/8 16.5 15.7

60 - 1 5/8 - 26.3

60 2 2 1/8 7.9 7.0

80 2 2 1/8 13.7 12.0

100 2 1/2 2 5/8 8.5 6.1

150 2 1/2 2 5/8 18.6 12.9

200 3 3 1/8 10.7 9.1

250 3 3 1/8 16.5 13.7

300 3 1/2 3 5/8 11.1 9.2

300 4 4 1/8 5.9 4.9

350 4 4 1/8 7.9 6.5

400 4 1/8 10.2 8.2

Pipe

Size Steel

in.

Type “L”

O.D. Copper

in.

Schedule 40 Steel

Head ft/100 ft

Equiv. Length

Figure 2, Typical Piping

FLUID COOLER

EXPANSION

TANK

VENT AND

FILL VALVE

Copper Tube

Head ft/100 ft.

Equiv. Length

WATER COOLED

CONDENSER

DIVERTING

SHUT-OFF

VALVE

VALVE

CIRCULATING

PUMP

SHUT-OFF

VALVE

REFRIGERATION

COMPRESSOR

EVAPORATOR

WATER CHILLER

TXV

CHILLED WATER

HEAT EXCHANGER

FOR SUPPLEMENTAL

FREE COOLING

NOTE: Isolation valves, vents, drains and other piping specialties are not shown, but are

required for a fully operational system.

8 Direct Drive Fluid Coolers IOM AFSD-1

Page 9

Glycol Charge

The amount of ethylene glycol required depends upon the following:

• The holding volume of the system that includes the holding capacity of the heat source,

the interconnecting piping and the dry cooler.

• Percentage of glycol required by volume to provide protection at the design minimum

operating temperature.

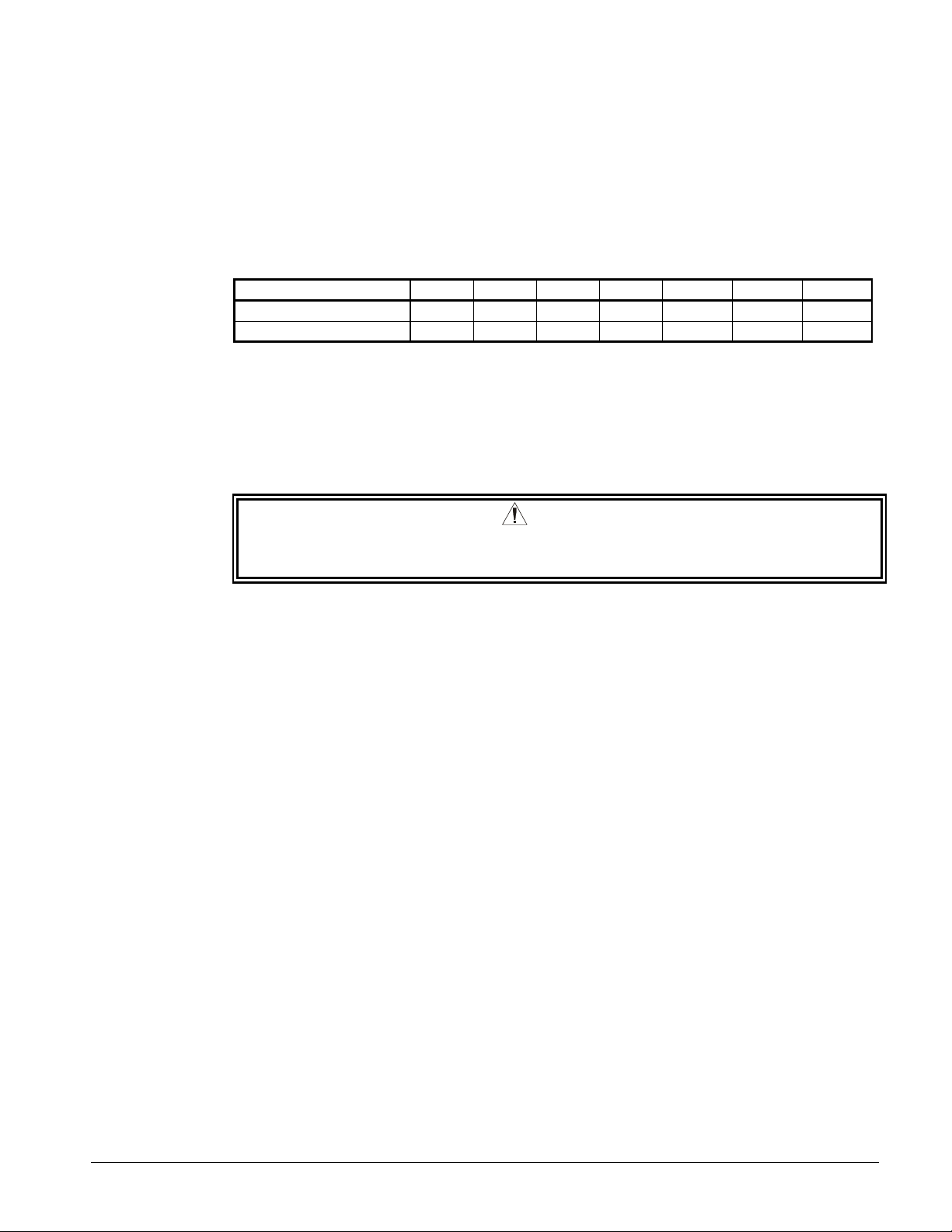

Table 3, Percentage of Glycol to be Added by Percent Volume

Freeze Point °°°°F (°°°°C)

Percent Propylene Glycol

Percent Ethylene Glycol

Use as a guide only. Proper precautions need to be taken to prevent freeze damage during low ambient. Consult

glycol vendor recommendations for specific freeze protection for your location.

30 (-1) 20 (-7) 10 (-12) 0 (-18) -10 (-23) -20 (-29) -30 (-34)

4 16 25 32 38 44 48

5 19 29 36 42 47 51

Mixing Glycol and Water

Regardless of the strength of the mixture, you MUST premix the glycol and water prior to

adding it to the system. The chemical reaction between the two will release oxygen, which

is extremely undesirable in a close-loop system.

CAUTION

For dry coolers operating without a glycol mixture, adequate fluid freeze protection of

some type is necessary during ambient air temperatures below 32°F.

Glycol Sludge Prevention

Glycol systems may be subject to sludge formation in coils, due to one or more of the

following causes:

• Reaction of the corrosion inhibitor with galvanized piping (zinc).

• Reaction of the glycol with chromate type water additives.

• Reaction of the glycol with pipe dope, cutting oils, solder flux, and other system dirt.

Glycol manufacturers offer a specially inhibited glycol (formulated for snow melting

systems) that does not react with zinc. This glycol is also suitable for heat transfer systems.

Glycol manufacturers also provide inhibitor check services on a regular basis.

Consequently, good glycol system design requires the following precautions:

• No galvanized piping is to be used.

• System piping must be thoroughly cleaned and flushed with a heated trisodiurn

phosphate solution before filling with the water/glycol mixture.

• Chromate inhibitor treatment must not be used.

• The glycol manufacturer should provide inhibitor check service and supply additional

inhibitor as required.

Fluid Circulating Pump

Mechanical seal type pumps must be used for glycol systems. Gland type pumps would

cause glycol waste and, if used with a pressure reducing valve, will lead to dilution of the

glycol mixture and eventual freeze-up.

IOM AFSD-1 Direct Drive Fluid Coolers 9

Page 10

Pumps are selected for piping friction loss plus fluid pressure drop through the dry cooler

coil, plus pressure drop through the heat source. No allowance for vertical lift is made

since in a closed system a counterhead acts on the pump suction.

With glycol solutions the pump performance curve will drift to the right from its design

point, due to differences in circuit design, control valve application, pressure drop

calculations, etc. The pump should be selected high on the curve so as to provide for the

"drift'. The pump curve should be "flat" so that the pump will compensate for the inability

to exactly predict the final operating system flow condition and to provide sufficient flow

for satisfactory heat transfer and maximum protection against freezing at the far end of the

circuit. The pump motor should have sufficient power for operating over the entire pump

curve to prevent motor overload at reduced voltages. Paralleled pumps can also be used for

good power economy and continuous and automatic standby operation. Properly applied

parallel pumps will guard against system breakdown caused by a simple pump failure.

Certain older systems have non-operating standby pumps of equal capacity to the operating

unit. We recommend parallel pumps in continuous operation because they provide

practically the same type of standby, in addition to being completely automatic, at lower

initial and operating cost.

Physical Data

The inlet and outlet connection size will be based on the number of feeds in the fluid cooler

circuit. Use the tables below to determine connection sizes.

Table 4, AFS 005 – 021, Connection Sizes

Feeds Inlet / Outlet, in. Feeds Inlet / Outlet, in.

8 1 1/8 24 2 1/8

12 1 3/8 32 2 1/8

16 1 3/8 48 2 5/8

21 1 5/8 64 2 5/8

Table 5, AFS 023 – 107, Connection Sizes (Single-Row of Fans)

Feeds Inlet / Outlet, in.

14 2 1/8

18 2 1/8

21 2 5/8

28 2 5/8

42 3 1/8

56 3 5/8

Table 6, AFD Connection Sizes (Double-Row of Fans, Dual Fluid Connections)

Feeds Inlet / Outlet, in.

18 2 @ 2 1/8

28 2 @ 2 1/8

36 2 @ 2 1/8

42 2 @ 2 5/8

56 2 @ 2 5/8

84 2 @ 3 1/8

112 2 @ 3 5/8

10 Direct Drive Fluid Coolers IOM AFSD-1

Page 11

Table 7, Model 005 through 021, Physical Data

Fan Data

Model

005 1x1 24 180 325 240

008 1x1 26 260 380 330

010 1x2 24 450 600 537

012 1x2 26 470 620 557

014 1x2 26 510 650 615

016 1x2 26 530 680 635

021 1x3 26 550 725 698

Note; Net weight is dry unit only.

Fan

Configuration

Diameter of

Fans

Approx.

Net

Weight, lb.

Approx.

Shipping

Weight, lb.

Approx

Operating

Weight, lb.

Table 8, Model 023 through 212, Physical Data

Model

Configuration

023 1x2 2 23,000 6.7 730 800 788

027 1x2 2 23,200 9.2 790 840 870

031 1x2 2 21,900 9.2 790 860 870

035 1x2 2 20,700 11.8 889 950 992

041 1x3 3 34,800 13.0 1190 1280 1303

045 1x3 3 32,900 13.0 1210 1300 1323

049 1x3 3 31,800 16.7 1240 1330 1385

053 1x4 4 46,400 16.7 1580 1690 1725

061 1x4 4 43,900 16.7 1620 1730 1765

065 1x4 4 42,400 21.7 1650 1760 1839

071 1x4 4 41,500 21.7 1760 1870 1949

075 1x5 5 54,900 20.4 2000 2150 2177

079 1x5 5 54,800 26.6 2020 2150 2251

089 1x5 5 51,800 26.6 2200 2390 2431

097 1x6 6 65,800 31.6 2390 2610 2665

107 1x6 6 62,200 31.6 2630 2850 2905

046 2x2 4 46,000 13.5 1540 1730 1657

054 2x2 4 46,400 18.5 1580 1770 1741

060 2x2 4 43,900 18.5 1620 1820 1781

066 2x2 4 42,400 23.5 1650 1840 1854

070 2x2 4 41,500 23.5 1760 1950 1964

080 2x3 6 69,700 25.9 2360 2570 2585

086 2x3 6 67,000 25.9 2380 2620 2605

090 2x3 6 65,800 25.9 2420 2630 2645

098 2x3 6 63,600 33.4 2480 2690 2771

106 2x4 8 92,900 33.3 3150 3360 3440

120 2x4 8 87,800 33.3 3230 3420 3520

132 2x4 8 84,800 43.3 3300 3470 3677

140 2x4 8 83,000 43.3 3510 3730 3887

152 2x5 10 190,700 40.7 4040 4290 4394

162 2x5 10 109,700 53.1 3990 4270 4452

168 2x5 10 106,000 53.1 4130 4450 4592

178 2x5 10 103,700 53.1 4390 4680 4852

194 2x6 12 131,600 63.1 4790 5150 5339

202 2x6 12 127,200 63.1 4960 5330 5509

212 2x6 12 124,400 63.1 5270 5670 5819

NOTES:

1. All fans are 30 inches in diameter.

2. Net weight is unit only.

3. Operating weight based on 50% ethylene glycol at 130°F.

Fan

Fan Data

Number of

Fans

CFM

AFS Single-Row of Fans

AFD Double Row of Fans

Operating

Charge, gal.

Approx.

Net

Weight, lb.

Approx.

Shipping

Weight, lb.

Approx.

Operating

Weight, lb.

IOM AFSD-1 Direct Drive Fluid Coolers 11

Page 12

Dimensional Data

B

A

B

Figure 3, Dimensions for AFS 005 through AFS 021 with Vertical Flow

21 ½

17

43

34

(3) 7/8 Dia.

8¾

24 ½

Adjustable

16 - 25

Figure 4, Dimensions for AFS 005 through AFS 021 with Horizontal Flow

43

2 ½

37 ½

42 ½

8¾

A

(2) 7/8 Dia.

AFS Model

005 1 39 ¾ 30

008 1 49 ¾ 40

010 2 69 ¾ 60

012 2 69 ¾ 60

014 2 89 ¾ 80

016 2 89 ¾ 80

021 3 129 ¾ 120

Number of

Fans

Dimensions (inches)

A B

NOTES:

1. Inlet is the top connection, outlet the bottom. See

2. The electrical box is on the same end as the fluid connections with knockouts on the bottom and sides.

Table 4

on page 10 for connection sizes.

12 Direct Drive Fluid Coolers IOM AFSD-1

Page 13

NOTES:

1.

Leg extension kits are available to raise unit by 30, 36, or 42 inches.

2.

Inlet is the top connection, outlet the bottom. See

3.

The electrical box is on the same end as the fluid connections with knockouts on the bottom and sides.

4.

Two-fan units, AFD, have two sets of connections and an optional field-installed header.

IOM AFSD-1 Direct Drive Fluid Coolers 13

Table 5

and

Table 6

on page 10 for connection sizes.

Page 14

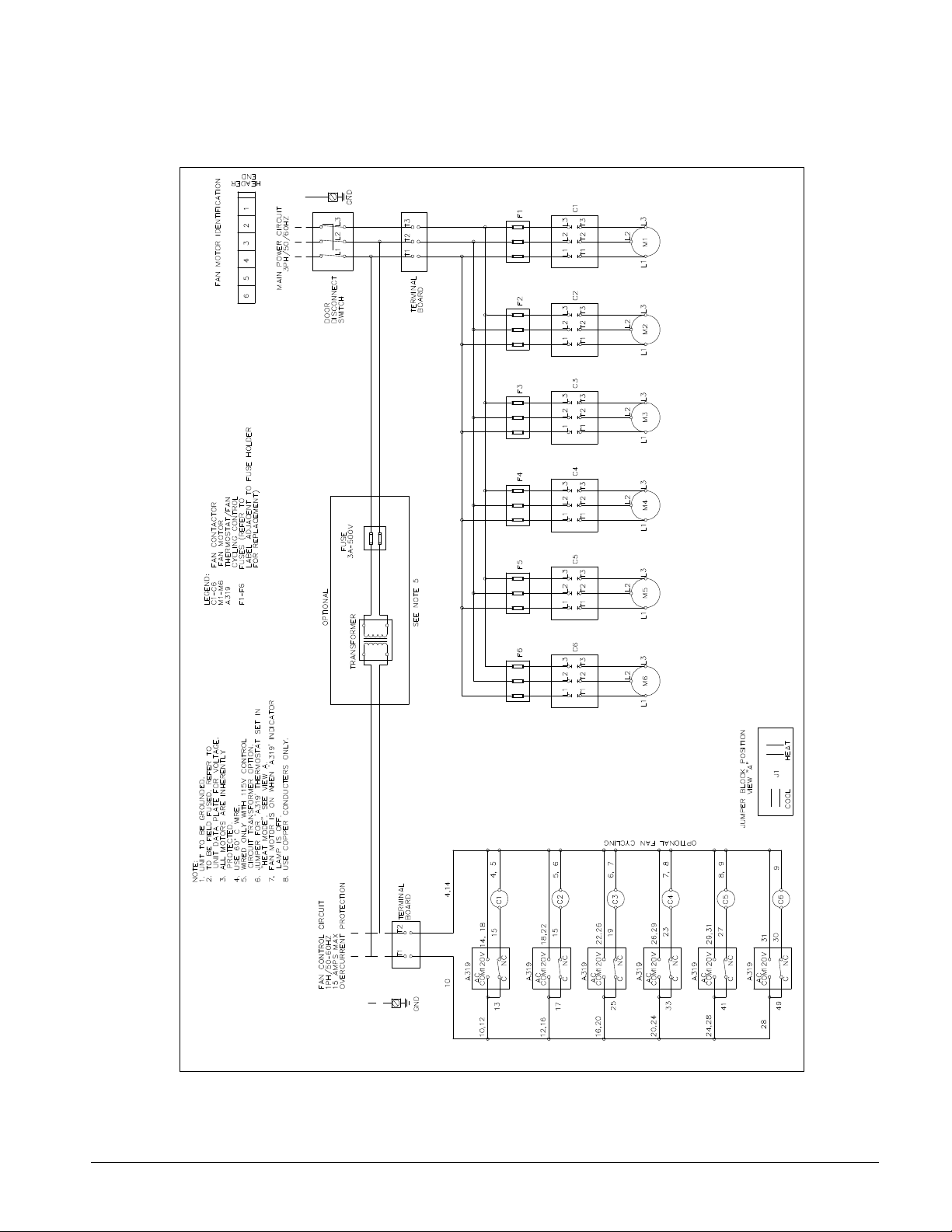

Electrical Data

Electrical Wiring

The electrical installation should be in accordance with National Electrical Code, local

codes and regulations. Wiring diagrams shown are only basic and do not show fuses,

additional disconnect switches, etc., which must be provided in the field.

Units have a disconnect switch, mounted in the electrical box, with a through-the-door

handle.

All standard motors have internal inherent overload protectors. Therefore, contactors can

be used instead of starters requiring thermal protectors, eliminating the problem of

furnishing the proper heating elements.

All fluid coolers are furnished with either single-phase or three-phase fan motors which, are

identified by the unit data plate.

Electrical leads from each motor terminate at the unit junction box. Field connections must

be made from these leads in accordance with local, state and national codes.

Three-phase motors must be connected to three-phase power of voltage to agree with motor

and unit dataplate.

The motors are wired into a common junction box. The motors must be checked for proper

rotation. Be sure to check that motor voltage and control connection agree with electric

services furnished.

14 Direct Drive Fluid Coolers IOM AFSD-1

Page 15

1140 RPM Motor Data

Table 9, Electrical Data, Model 005 through 021, 1140 RPM

AFS

Model

005 5,050 1 24 1/3 2.6 3.3 6 1.3 1.6 3 1/3 3.4 4.2 6

008 6,450 1 26 1/3 2.6 3.3 6 1.3 1.6 3 1/2 3.9 4.2 6

010 10,100 2 24 1/3 5.2 5.9 10 2.6 2.9 6 1/3 6.8 7.6 10

012 12,400 2 26 1/3 5.2 5.9 10 2.6 2.9 6 1/2 7.8 8.8 10

014 13,700 2 26 1/3 5.2 5.9 10 2.6 2.9 6 1/2 7.8 8.8 10

016 12,900 2 26 1/3 5.2 5.9 10 2.6 2.9 6 1/2 7.8 8.8 10

021 20,500 3 26 1/3 7.8 8.5 10 3.9 4.2 6 1/2 11.7 12.7 15

Notes: 1. Standard motor voltage 208-230-460/3/60.

CFM

Table 10, Electrical Data, Models 023 through 212, 1140 RPM

Model

023 1x2 2 23,000 14.0 15.8 20 7.0 7.9 10 5.6 6.4 10

027 1x2 2 23,200 14.0 15.8 20 7.0 7.9 10 5.6 6.4 10

031 1x2 2 21,900 14.0 15.8 20 7.0 7.9 10 5.6 6.4 10

035 1x2 2 20,700 14.0 15.8 20 7.0 7.9 10 5.6 6.4 10

041 1x3 3 34,800 21.0 22.8 25 10.5 11.4 15 8.4 9.2 10

045 1x3 3 32,900 21.0 22.8 25 10.5 11.4 15 8.4 9.2 10

049 1x3 3 31,800 21.0 22.8 25 10.5 11.4 15 8.4 9.2 10

053 1x4 4 46,400 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

061 1x4 4 43,900 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

065 1x4 4 42,400 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

071 1x4 4 41,500 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

075 1x5 5 54,900 35.0 36.8 40 17.5 18.4 20 14.0 14.8 15

079 1x5 5 54,800 35.0 36.8 40 17.5 18.4 20 14.0 14.8 15

089 1x5 5 51,800 35.0 36.8 40 17.5 18.4 20 14.0 14.8 15

097 1x6 6 65,800 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

107 1x6 6 62,200 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

046 2x2 4 46,000 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

054 2x2 4 46,400 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

060 2x2 4 43,900 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

066 2x2 4 42,400 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

070 2x2 4 41,500 28.0 29.8 30 14.0 14.9 15 11.2 12.0 15

080 2x3 6 69,700 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

086 2x3 6 67,000 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

090 2x3 6 65,800 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

098 2x3 6 63,600 42.0 43.8 50 21.0 21.9 25 16.8 17.6 20

106 2x4 8 92,900 56.0 57.8 60 28.0 28.9 30 22.4 23.2 30

120 2x4 8 87,800 56.0 57.8 60 28.0 28.9 30 22.4 23.2 30

132 2x4 8 84,800 56.0 57.8 60 28.0 28.9 30 22.4 23.2 30

140 2x4 8 83,000 56.0 57.8 60 28.0 28.9 30 22.4 23.2 30

152 2x5 10 190,700 70.0 71.8 80 35.0 35.9 40 28.0 28.8 30

162 2x5 10 109,700 70.0 71.8 80 35.0 35.9 40 28.0 28.8 30

168 2x5 10 106,000 70.0 71.8 80 35.0 35.9 40 28.0 28.8 30

178 2x5 10 103,700 70.0 71.8 80 35.0 35.9 40 28.0 28.8 30

194 2x6 12 131,600 84.0 85.8 90 42.0 42.9 45 33.6 34.4 40

202 2x6 12 127,200 84.0 85.8 90 42.0 42.9 45 33.6 34.4 40

212 2x6 12 124,400 84.0 85.8 90 42.0 42.9 45 33.6 34.4 40

1. All fan blades are 30” in diameter.

2. Standard motors are 1 ½ HP, 208-230/460/3/60 or 575 volt.

1. Optional single-phase motors are ¾ hp, 208/230 volt, 4.8 FLA, 1140 rpm.

Fan Data 208-230/3/60 460/3/60 575/3/60

Fan

Config.

Fans 208-230/3/60 460/3/60 208-230/1/60

No.

No. of

Fans

Dia.

in.

HP

cfm

Total

FLA

MCA

Total

FLA

AFS Single-row of Fans

AFD Double Row of Fans

MCA

Max

Fuse

Max.

Fuse

Total

FLA

Total

FLA

MCA

MCA

Max

Fuse

Max.

Fuse

HP

Total

FLA

Total

FLA

MCA

MCA

Max

Fuse

Max.

Fuse

IOM AFSD-1 Direct Drive Fluid Coolers 15

Page 16

830 RPM Motor Data

Table 11, Electrical Data, Models 023 through 212, 830 RPM

Model

023 1x2 2 9.6 10.8 15 4.8 5.4 6 4.0 4.5 10

027 1x2 2 9.6 10.8 15 4.8 5.4 6 4.0 4.5 10

031 1x2 2 9.6 10.8 15 4.8 5.4 6 4.0 4.5 10

035 1x2 2 9.6 10.8 15 4.8 5.4 6 4.0 4.5 10

041 1x3 3 14.4 15.6 20 7.2 7.8 10 6.0 6.5 10

045 1x3 3 14.4 15.6 20 7.2 7.8 10 6.0 6.5 10

049 1x3 3 14.4 15.6 20 7.2 7.8 10 6.0 6.5 10

053 1x4 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

061 1x4 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

065 1x4 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

071 1x4 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

075 1x5 5 24.0 25.2 30 12.0 12.6 15 10.0 10.5 15

079 1x5 5 24.0 25.2 30 12.0 12.6 15 10.0 10.5 15

089 1x5 5 24.0 25.2 30 12.0 12.6 15 10.0 10.5 15

097 1x6 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

107 1x6 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

046 2x2 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

054 2x2 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

060 2x2 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

066 2x2 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

070 2x2 4 19.2 20.4 25 9.6 10.2 15 8.0 8.5 10

080 2x3 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

086 2x3 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

090 2x3 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

098 2x3 6 28.8 30.0 30 14.4 15.0 15 12.0 12.5 15

106 2x4 8 38.4 39.6 40 19.2 19.8 20 16.0 16.5 20

120 2x4 8 38.4 39.6 40 19.2 19.8 20 16.0 16.5 20

132 2x4 8 38.4 39.6 40 19.2 19.8 20 16.0 16.5 20

140 2x4 8 38.4 39.6 40 19.2 19.8 20 16.0 16.5 20

152 2x5 10 48.0 49.2 50 24.0 24.6 25 20.0 20.5 25

162 2x5 10 48.0 49.2 50 24.0 24.6 25 20.0 20.5 25

168 2x5 10 48.0 49.2 50 24.0 24.6 25 20.0 20.5 25

178 2x5 10 48.0 49.2 50 24.0 24.6 25 20.0 20.5 25

194 2x6 12 57.6 58.8 60 28.8 29.4 30 24.0 24.5 30

202 2x6 12 57.6 58.8 60 28.8 29.4 30 24.0 24.5 30

212 2x6 12 57.6 58.8 60 28.8 29.4 30 24.0 24.5 30

Notes:

1. All fan blades are 30” in diameter.

2. All motors are 1 HP, 208-230/460/3/60 or 575 volt.

Fan Data 208-230/3/60 460/3/60 575/3/60

Fan

Config.

No. of

Fans

Total

FLA

MCA

AFD Double Row of Fans

Max.

Fuse

AFS Single-row of Fans

Total

FLA

MCA

Max.

Fuse

Total

FLA

MCA

Max.

Fuse

16 Direct Drive Fluid Coolers IOM AFSD-1

Page 17

Wiring Diagrams

Figure 5, Typical Wiring for AFS Models

NOTE: Unit specific wiring diagrams are shipped with the unit.

IOM AFSD-1 Direct Drive Fluid Coolers 17

Page 18

Start Up

Prestart

Check for correct dry cooler fan rotation. This can be done by quickly jogging the fan

contactor. Be sure that the fans run freely. The same check is recommended for pumps.

Filling and Purging the System

The system should be pressure tested before adding glycol. The system can be tested with

air or water, however if the ambient temperature is at or below freezing the use of air is

recommended. Test pressure should not exceed 60 psig.

Roof Mounted Fluid Cooler

To fill the system, pour the premixed water and glycol into the expansion tank. Fill the

system until the expansion tank is half full, then purge the air from all vents. Operate the

system for a minute, then purge all vents again, and add glycol as required. Repeat the

purging of vents after the first hour of operation and again after several hours of operation.

Ground Mounted Fluid Cooler

The fluid cooler may be lowest point in the system; consequently the premixed water and

glycol will have to be pumped into the system.

Temperature Control

General

Some method of controlling the fluid temperature is required.

The standard temperature control consists of fan contactors arranged for field-connection to

a field-supplied and mounted control system; in other words, no control. Setting and

adjusting these controls will depend on the type furnished.

McQuay can furnish an optional control system using Johnson Controls A419 temperature

controls. Installation and adjustment are explained in the following paragraphs.

Installation

If the fan cycle thermostat option is provided, the solid state sensors are shipped coiled in

the control panel to prevent damages during shipment and installation. Mounted the sensors

securely to the fluid cooler header and insulate. Mount sensors on the entering or leaving

fluid headers depending on site requirements. Route and secure sensor wiring for

protection from vibration and interference.

Setting

The control is a single-stage, electronic temperature control with an SPDT output relay. It

has the following features:

• lockable keypad for programming,

• LCD for temperature and status display,

• LED for output relay status

• heating and cooling modes with adjustable setpoint and differential

18 Direct Drive Fluid Coolers IOM AFSD-1

Page 19

The electronic temperature control must be set for heating or cooling application by

placement of the mode jumper. Temperature setting is selected based on entering or leaving

fluid temperature control. Differential settings are selected to prevent excessive fan cycling

and fluid temperature swing.

Definitions

• Cut-in: The temperature at which the N.O. (Normally Open) SPDT (Single-Pole,

Double-Throw) output relay contact closes.

• Cut-out: The temperature at which the N.O. SPDT output relay contact opens.

Control Functions

The A419 control allows the user to set a variety of functions using the keypad and

jumpers. These functions are described below. For instructions on setting function

parameters, see the Adjustments section.

Keypad Programmable Functions

Setpoint (SP) establishes the temperature at which the equipment is switched on or off,

depending on the user selected mode of operation. Setpoint range is -30 to 212°F (-34 to

100°C). See the Cooling/Heating and Setpoint Modes section on page 21.

If Setpoint mode is set to Cut-in, the setpoint is the temperature at which the control closes

the N.O. contacts. If Setpoint mode is set to Cut-out, the setpoint is the temperature at

which the N.O. contacts open. Refer to Figure 8 and Figure 9.

Differential (dIF) establishes the difference in temperature between Cut-in and Cut-out.

The differential is set relative to Setpoint and may be set from 1 to 30F° or C. Refer to

Figure 8 and Figure 9.

Anti-Short Cycle Delay (ASd) establishes the minimum time that the fan remains off

before restarting again. The anti-short cycle delay is activated when the A419 control has

cycled the fan off. The delay does not allow the fan to be restarted until the programmed

amount of time has elapsed. When the delay is activated, the LCD alternately flashes the

sensor temperature and ASd. The anti-short cycle delay may be programmed for 0 to 12

minutes in 1-minute increments.

For example, if the anti-short cycle delay is programmed for 7 minutes, the control will not

restart the fan until 7 minutes after the equipment was turned off, regardless of the

temperature. During the 7-minute period, if the temperature reaches the cut-in setpoint, the

display alternates between the sensor temperature and ASd to indicate that the on cycle is

being delayed. After the 7-minute delay has elapsed, the fan is turned on, and ASd stops

flashing.

Note: A power interruption to the control will activate the anti-short cycle delay.

Figure 6, Anti-short Cycle Delay

IOM AFSD-1 Direct Drive Fluid Coolers 19

Page 20

Sensor Failure Operation (SF): establishes how the A419 control operates the fan in the

event of a sensor or sensor wiring failure. The user may select either to run the equipment

continuously or to shut it down. When the control detects a sensor circuit failure, the LCD

flashes SF alternately with OP if the sensor circuit is open, or SH if the sensor circuit is

shorted. Before indicating a failure, the control implements a 1-minute delay, which allows

verification of failure condition and avoids nuisance failure indications.

Temperature Offset (OFS): establishes the temperature setpoint shift (F° or C°) applied

when the binary input (BIN) and common (COM) terminals are connected together. The

Temperature Offset may be set from 0 to 50F° or C°. See the Offset Function section on

page 20.

Temperature Units: establishes the units of temperature (Fahrenheit or Celsius) displayed

on the LCD.

Functions Set by Jumper Position

For instructions on positioning jumpers, see Positioning the Jumpers on page 22 in the

Adjustments section. Refer to Figure 11 for jumper locations.

Heating/Cooling: Removing or installing the upper jumper at P4 establishes whether the

control operates in the Heating or Cooling mode.

Setpoint Mode: Removing or installing the lower jumper at P4 establishes whether

Setpoint is the Cut-in temperature or Cut-out temperature.

Keypad Lock: Removing or installing the jumper at P5 establishes whether the keypad is

locked or unlocked. Locking the keypad deters accidental or unauthorized changes to all of

the function parameters.

Temperature Offset Function

The Temperature Offset function shifts Heating setpoint lower and Cooling setpoint higher

by the value

applications.

The Temperature Offset is activated by closing a circuit between BIN and COM. (See

Figures 7, 8, or 9.) The BIN and COM terminals may be connected to a user-supplied

external switching device, such as a time clock, that has a set of SPST contacts.

This option enables the control to alternate between two temperature setpoints based on the

position of the binary input switch. The number of degrees added to, or subtracted from,

Setpoint is established in the Temperature Offset function (OFS) using the keypad, as

described in Setting Other Functions on page 25.

Table 12 shows an example of the effect of the Temperature Offset function when

active.

Table 12, Sample Offset Function Effect

Mode Setpoint

Cooling

Heating

*Setpoint when switch is closed.

in

the Temperature Offset. This function is not normally used on fluid cooler

Temperature

Offset Value

70° 8° 78°

70° 8° 62°

Shifted

Setpoint*

it

is

When the binary input (BIN) is connected to the common (COM), the Offset function is

enabled and BIN is displayed on the LCD above the °F or °C symbol, as shown in Figure 4.

20 Direct Drive Fluid Coolers IOM AFSD-1

Page 21

Display

The front panel of the A419 control has a liquid crystal display (LCD) and an output relay

status LED (Light-Emitting Diode) indicator.

Liquid Crystal Display

During normal operation, the LCD displays the sensor temperature, a symbol indicating

units of temperature (°F or °C), and an icon indicating Heating ( ) or Cooling (∗) mode.

See Figure 7.

The temperature value ranges from -30 to 212°F (-34 to 100°C) in 1° increments. The LCD

also displays BIN if the Temperature Offset function is activated.

Figure 7, Front Panel and Display

During programming, the LCD

displays the control functions and

their programmed values. After

30 seconds of inactivity, the

display returns to the sensor

temperature. See the Adjustments

section for instructions on using

the keypad to change settings.

Output Relay Status Indicator LED

A green LED on the control’s front panel illuminates when the output relay is energized and

the N.O. contacts are closed.

Cooling/Heating and Setpoint Modes

Jumpers are used to place the A419 control in Cooling or Heating mode and set whether

Cut-in or Cut-out occurs at Setpoint. Four operating modes are possible: Cooling/Cut-in,

Cooling/Cut-out, Heating/Cut-in, and Heating/Cut-out.

Cooling Modes

When Cooling/Cut-in mode is selected, the differential is below Setpoint. The output relay

energizes and the LED indicator illuminates when the temperature rises to Setpoint. When

the temperature drops to Setpoint minus the differential value, the output relay and LED

indicator de-energize.

When Cooling/Cut-out mode is selected, the differential is above Setpoint. The output

relay energizes and LED indicator illuminates when the temperature rises to Setpoint plus

the differential value. When the temperature drops to Setpoint, the output relay and LED

indicator de-energize.

IOM AFSD-1 Direct Drive Fluid Coolers 21

Page 22

Figure 8, Cooling Modes

Heating Modes

When the Heating/Cut-in mode is selected, the differential is above Setpoint. The output

relay energizes and LED indicator illuminates when the temperature drops to Setpoint.

When the temperature rises to Setpoint plus the differential value, the output relay and LED

de-energize.

When Heating/Cut-out mode is selected, the differential is below Setpoint. The output

relay energizes and LED indicator illuminates when the temperature drops to Setpoint

minus the differential value. When the temperature rises to Setpoint, the output relay and

LED indicator de-energize.

Figure 9, Heating Modes

Adjustments

This section provides instructions for adjusting the A419 control using the jumpers and

keypad.

IMPORTANT: Verify that the Cooling/Heating jumper is positioned properly before

powering the A419 control, so that the relay operates as intended.

Positioning the Jumpers

The P5 Jumper Pin Block has a single set of jumper pins and is used to lock or unlock the

keypad. The P4 Jumper Pin Block has two sets of jumper pins.

22 Direct Drive Fluid Coolers IOM AFSD-1

Page 23

The top set of pins at P4, labeled JUMPI, is used to set the control for Heating or Cooling

mode. The bottom set of pins, labeled JUMP2, is used to establish Setpoint at cut-in or at

cut-out. See Figure 11.

Figure 10, Positioning the Jumpers

To position a jumper in the

Installed position, place the

jumper on both pins. To position

a jumper in the Removed position,

place the jumper on only one pin.

(Saving the jumper in case it is

required in the future.) See

Figure 10.

Set the jumpers as follows, using Figure 10 and Figure 11 as guides.

1. Verify that all power to the A419 control has been removed.

2. Remove the control’s cover by loosening the four captive cover screws.

3. Position the jumpers to set Cooling/Heating, Setpoint, and Keypad Lock functions.

4. Replace the cover and fasten in place with the four screws.

5. Restore power to the control.

Figure 11, Jumper Positions and Control Settings

IOM AFSD-1 Direct Drive Fluid Coolers 23

Page 24

Table 13, Jumper Designations, Positions, and Control Settings

Function

Operating Mode

Cooling/Heating

Setpoint

Keypad Lock P5-Keypad Unlock

Jumper Pins Designation

on Control

JUMP1

(Top Pair of Pins on Block

P4)

JUMP2

(Bottom Pair of Pins on

Block P4)

Setting

Cooling Removed

Heating Installed

At Cut-in Removed

At Cut-out Installed

Locked Removed

Unlocked Installed

*IMPORTANT: The keypad cannot be unlocked without a jumper. Do not discard any

jumpers in case they are required in the future. To position a jumper in the Removed

position, place the jumper on only one pin. (Saving the jumper in case it is required in the

future.)

Jumper

Position*

Factory Default Setting

(and Jumper Position)

Cooling

(Removed position)

Cut-in

(Removed Position)

Unlocked

(Installed Position)

Changing Temperature Units

The A419 control is set at the factory to display in Fahrenheit temperature units.

To convert to Celsius units, press the Up and Down buttons

simultaneously. Press them again to return to Fahrenheit units.

Note: Make sure the Keypad Lock jumper is in the unlocked (installed) position before

adjusting the control. Verify that the control is displaying the desired temperature units

before setting the setpoint.

Setting the Setpoint

To view and adjust the setpoint, follow these steps:

1. Press and hold the Menu button until the display changes to flashing

SP. This will take about 2 seconds.

Note: If no entries are made for 30 seconds, the control reverts to the temperature display.

2. Press the Menu button again. The current setpoint is displayed.

3. Press the Up or Down button to adjust the setpoint temperature.

4. Press the Menu button to save. The display then returns to the sensor

temperature

.

Note: If the Menu button is not pressed after changing the setpoint, the control reverts to

the setpoint value previously programmed into the A419 control.

24 Direct Drive Fluid Coolers IOM AFSD-1

Page 25

Table 14, Function Ranges and Settings

Function Range

SP: Setpoint

dIF: Differential

ASd: Anti-short Cycle_Delay

OFS: Temperature Offset

SF: Sensor Failure

Operation

-30to212°F

(-34 to 100°C)

I to 30° (F or C) 5

0 to 12 minutes I

0 to 50° (F or C) 0

0 = output de-energized

1 = output energized

Factory

Setting

30

1

NOTES:

Operation at Extremes: If the combination of setpoint, plus or minus the differential, falls

outside the temperature range (-30 to 212°F), the A419 control operates as follows:

Cooling/Cut-in: If the control is operating in Cooling/Cut-in mode and setpoint minus

differential is less than -30°F, the control switches on at setpoint and off when the

temperature drops below -30°F (-34°C).

Heating/Cut-in: If the control is operating in Heating/Cut-in mode and setpoint plus

differential is greater than 212°F (100°C), the control switches on at setpoint and off when

the temperature exceeds 212°F (100°C).

Cooling/Cut-out: If the control is operating in Cooling/Cut-out mode and setpoint plus

differential is greater than 2 12°F (100°C), the control switches on when the temperature

exceeds 212°F (100°C) and off at setpoint.

Heating/Cut-out: If the control is operating in Heating/Cut-out mode and setpoint minus

differential is less than -30°F (-34°C), the control switches on when the temperature drops

below -30°F (-34°C) and off at setpoint.

Setting Other Functions

To set the Differential (dIF), Anti-short Cycle Delay (ASd), Temperature Offset (OFS), or

Sensor Failure (SF) operation, use the following method.

Figure 12, Order of the Functions

Figure 12 illustrates the order of functions shown

using the Up or Down button. The Up button

accesses functions in the clockwise direction; the

Down button accesses functions in the

counterclockwise direction.

IOM AFSD-1 Direct Drive Fluid Coolers 25

Page 26

1.

Press and hold the Menu button until the display changes to

flashing SP. This will take about 2 seconds

.

Note: If no entries are made for 30 seconds while programming is in progress, the control

reverts to the temperature display.

2.

Press the Up or Down button repeatedly until the desired function

is displayed

.

3. Press the Menu button to display the function’s current value.

4. Press the Up or Down button until the desired value is displayed.

5. Press the Menu button to save the new value. The display then

returns to the sensor temperature.

Note: If you do not press the Menu button after setting the new value, the

control reverts to the previously programmed value for that function

.

Checkout

Before applying power, make sure installation and wiring connections are according to job

specifications. After necessary adjustments and electrical connections have been made, put

the system in operation and observe the control for at least three complete operating cycles

before leaving the installation.

Troubleshooting

If the control system does not function properly, verify that the unit is wired, configured,

and set properly. If the problem persists, use the following procedures to determine the

cause of the problem:

1. Check for proper supply voltage to the A419 control.

a) Remove the cover by loosening the four captive cover screws.

WARNING

Risk of Electrical Shock. High voltages may be present at electrical terminals

and other exposed internal metal surfaces. Avoid contact with all metal

surfaces on control when cover is removed.

26 Direct Drive Fluid Coolers IOM AFSD-1

:

Page 27

b) Use a reliable AC voltmeter to check the voltage between the COM and I20V or

240V terminals on line voltage models and the two 24V terminals on low-voltage

models. Refer to the wiring diagrams furnished with the unit.

c)

The voltage must be between 20 and 30 VAC for 24 volt applications, 102 and 132

VAC for 120 volt applications, 177 and 264 VAC for 208/240 volt applications

If the voltage reading is within the required range, proceed to Step 2.

If the voltage reading is not within the required range, check the power source and

input power wires for problems.

2. Check for proper sensor operation.

a. Disconnect all power sources to control.

b. Take a temperature reading at the sensor location, using an accurate thermometer.

c. Disconnect the sensor from the control.

d. Using an ohmmeter, measure the resistance across the two sensor leads while the

sensor is at the temperature taken in step b.

e. Consult

to established temperature and resistance values.

f. If the measured values conform to the values in

g. If the sensor’s measured resistance value is substantially different from the

expected value for that temperature, check the sensor wiring. If sensor wiring is

OK, replace the sensor.

Figure 13, Nominal Temperature vs. Sensor Resistance

Figure 13

to verify that the measured temperature and resistance conform

Figure 13

, proceed to Step 3.

Check the A419 for proper operation.

Note: Perform Troubleshooting Steps 1 and 2 before performing this step.

a. Disconnect the load from the output relay terminals.

b. Check that the Keypad Lock jumper is installed, so that the keypad is unlocked.

c. Reconnect the sensor leads and supply power to the control.

d. Replace the cover.

e. Check the control settings for proper values.

IOM AFSD-1 Direct Drive Fluid Coolers 27

Page 28

f. Press and hold the Menu button until Setpoint appears (occurs in about 2 seconds).

g. Use the Up and Down buttons to change the Setpoint temperature above and below

the current sensor temperature until the output relay energizes and de-energizes as

shown in

Table 15

.

Note: If the anti-short cycle delay has a time greater than 0 minutes, the relay will

not energize until the timed delay has elapsed.

h. If the output relay does not perform as indicated in

Table 15

, replace the A419

control.

i. If proper operation of the A419 control is verified, reconnect the load and consult

the equipment manufacturer’s instructions for troubleshooting the controlled

equipment.

Table 15, A419 Output Relay Operation

Setpoint

Mode

Cut-out

Cut-in

Operating

Mode

Cooling Setpoint plus differential Setpoint

Heating Setpoint minus differential Setpoint

Cooling Setpoint

Heating Setpoint

Output Relay Energized at... Output Relay De-energized at...

Setpoint minus

differential

Setpoint plus

differential

Note: When the relay is energized, the N.O. contacts are closed and the LED is illuminated.

Fault Codes

If the LCD displays an alarm or fault code (SF or EE), consult Table 6 for explanation.

Table 6, Fault Codes Defined

Fault Code Definition System Status Solution

SF flashing

alternately

with Op

SF flashing

alternately

with SH

EE

Open temperature

sensor or sensor

wiring

Shorted

temperature

sensor or sensor

wiring

Program failure Output is off Reset the control by

Output functions

according to the selected

sensor failure mode (SF

setting)

Output functions

according to the selected

sensor failure mode (SF

setting)

See Troubleshooting

section. Cycle power to

reset the control.

See Troubleshooting

section. Cycle power to

reset the control.

pressing the Menu button.

If problems persist,

replace the control.

28 Direct Drive Fluid Coolers IOM AFSD-1

Page 29

Maintenance

Fluid coolers require a minimum of maintenance. Electrical connections should be checked

on an annual basis. Fan contactors should be inspected and replaced when there is evidence

of pitting or burning. Verify controls settings and operation at least on an annual basis.

Condenser fan motors have sealed ball bearings that do not require service. Replace

bearings when necessary.

The cooling fluid should be checked on a regular basis for proper inhibitors and glycol mix.

The unit coil will require periodic cleaning based on operation and atmosphere conditions.

Clean the unit using a brush or commercially available coil cleaners and water. Take care

not to deform the fin material. Straighten any bent fins using a fin tool.

Cleaning Instructions

Clean the finned surface at least every six months; more frequent cleaning may be required

if extreme conditions cause clogging or fouling of air passages through the finned surface.

Use Calgon Corporation's CalClean 41352 (or equal). Apply CalClean liberally to entering

air and leaving air surfaces of the finned area according to label directions and rinse

thoroughly to remove all cleaners.

CAUTION

Never clean this unit with an acid based cleaner.

IOM AFSD-1 Direct Drive Fluid Coolers 29

Page 30

This document contains the most current product information as of this printing. For the most up-todate product information, please go to www.mcquay.com.

Post Office Box 2510 Staunton, Virginia 24402-2510 USA • 540.248.0711 • www.mcquay.com IOM AFSD-1 (2/07)

Loading...

Loading...