Page 1

TrimMac 281

INSTRUCTION MANUAL

IMPORTANT INFORMATION

GB

sure you understand them before using this unit. Retain these instructions for future

reference.

MANUEL D’INSTRUCTIONS

RENSEIGNEMENTS IMPORTANTS:

FR

atentivement les instructions et assurez--vous de les avoir comprises. Conservez

les instructions pour référence ultérieure.

BETRIEBSANWEISUNG

WICHTIGE INFORMA TI ON:

DE

Geräts aufmerksam durch. Verwenden Sie es erst, wenn Sie sicher sind, daß Sie

alle Anweisungen verstanden haben und gut aufbewahren.

: Please read these instructions carefully and make

Avant d’utiliser cet appareil, veuillez lire

Lesen Sie diese Hinweise zur Handhabung des

MANUAL DE INST RU CCIONES

INFORMACIÓN IMPORTANTE:

ES

asegúrese de entenderlas antes de utilizar esta aparato. Conserve las instrucciones para la referencia en el futuro.

Lea atentamente las instrucciones y

530165941 1/1/05

Page 2

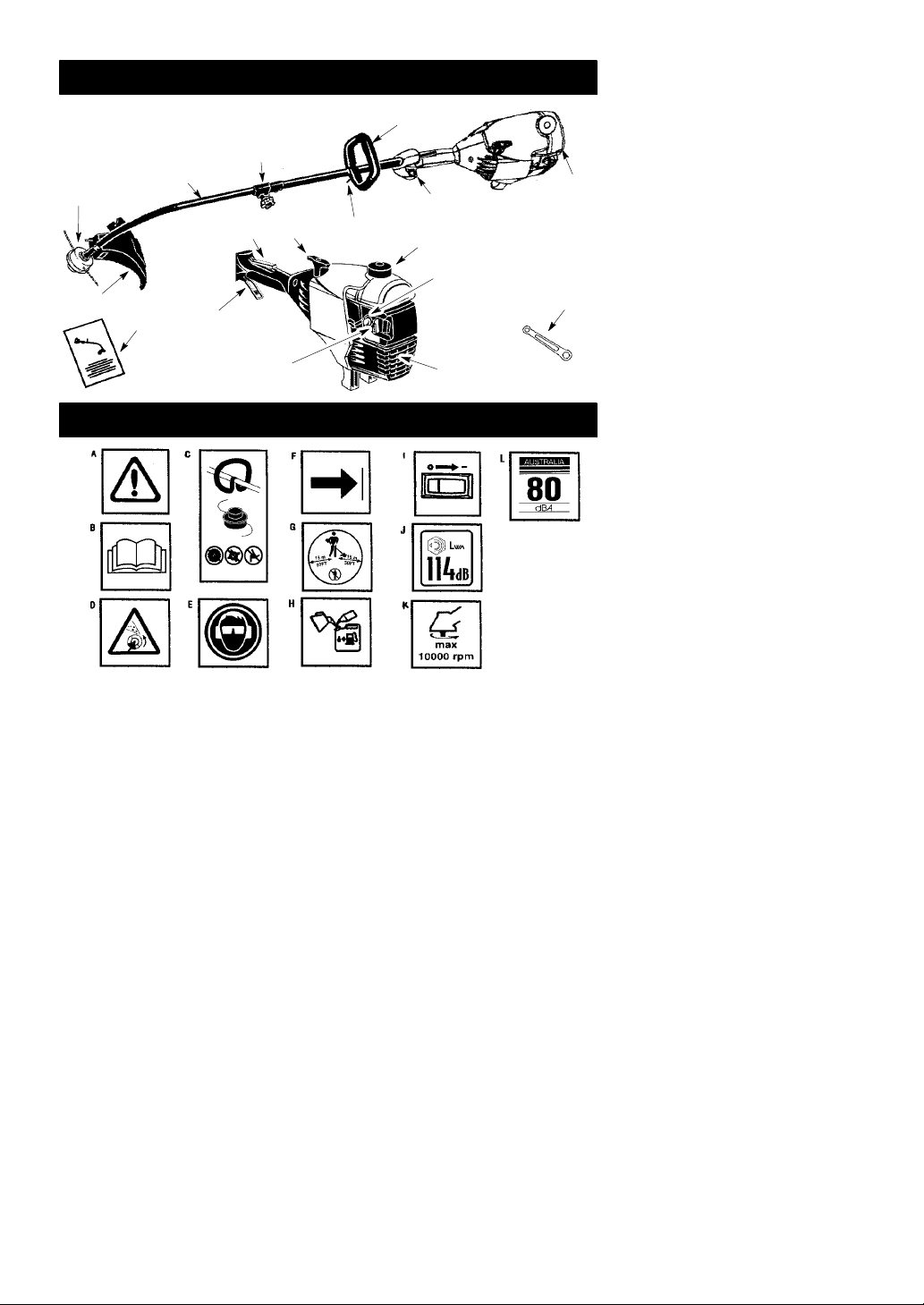

Trimmer

Head

Shield

IDENTIFICATION (WHAT IS WHAT?)

Assist Handle

Coupler

Shaft

ON/OFF Switch

Throttle Lock--out

Manual

Throttle Trigger

Starter

Handle

Assist handle

adjustment

Fuel tank

Fuel Cap

Primer Bulb

Wrench

Choke

Lever

Muffler

IDENTIFICATION OF SYMBOLS

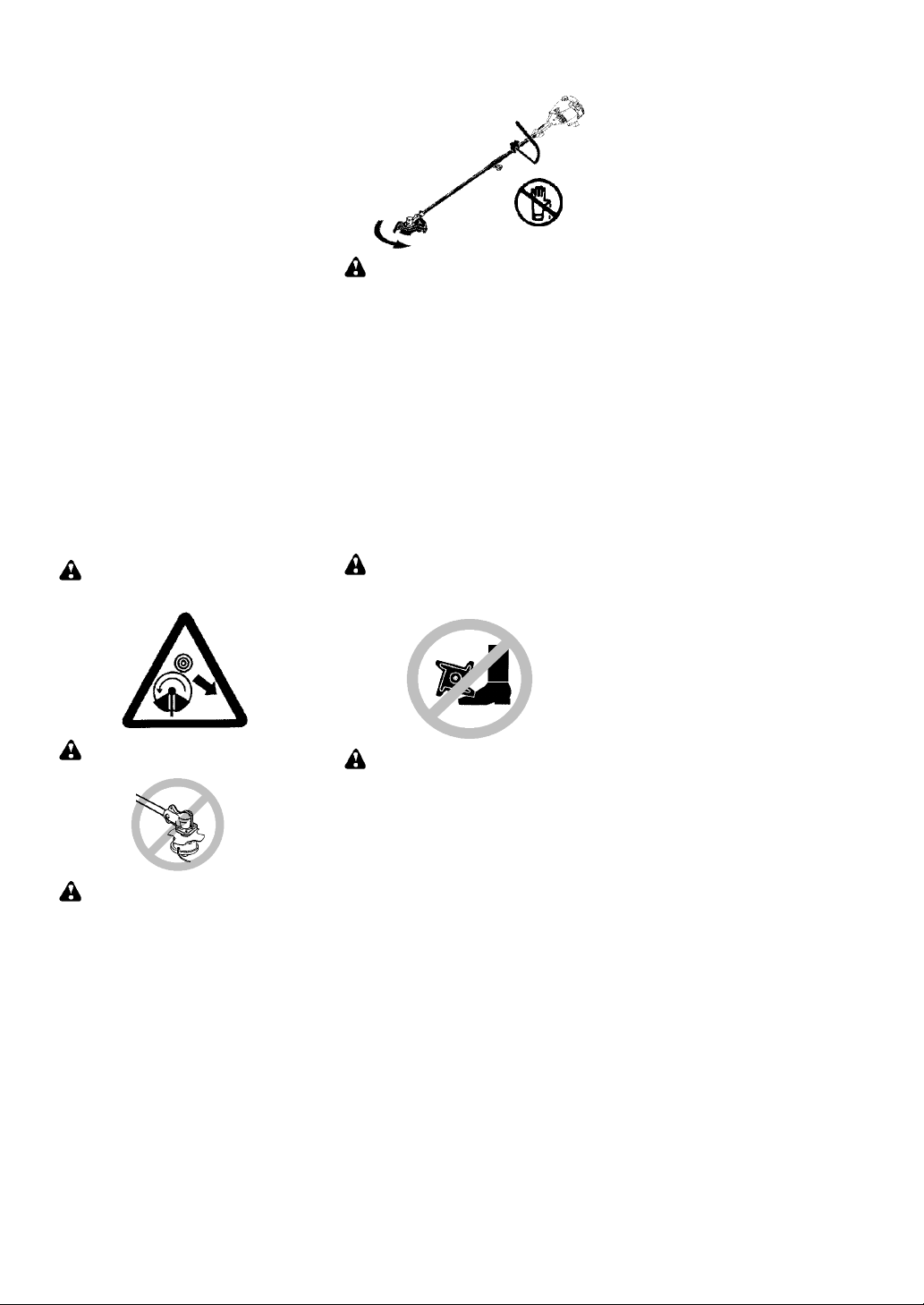

A. WARNING! This trimmercan be dangerous! Careless or improper use cancause

serious or even fatal injury.

B. Read and understand the instruction manual before using the trimmer.

C. With this handle,only use trimmer head. Never use bladesor flailing devices with this

tool.

WARNING! The trimmer line can throw objects violently. You can be blinded or

D.

injured. Always wear eye protection.

E. Always use:

Ear protection

Protective glasses or visor

F. Assist handle to be positioned only below the arrow.

G. The operator of the machine must insure that no one comes within a 15 meterradius

while working. When several operators are working within the same area a safety dis-

tance of at least 15 meters must be observed.

H. Use unleaded or quality leaded petrol and two--stroke oil mixed at a ratio of 2.5%.

I. Engine ON/OFF Switch.

J. Guaranteed sound power level according to Directive 2000/14/EC

K. Maximum rotational frequency of the spindle, rpm

L. Sound pressure level at 7,5 meters

2

Page 3

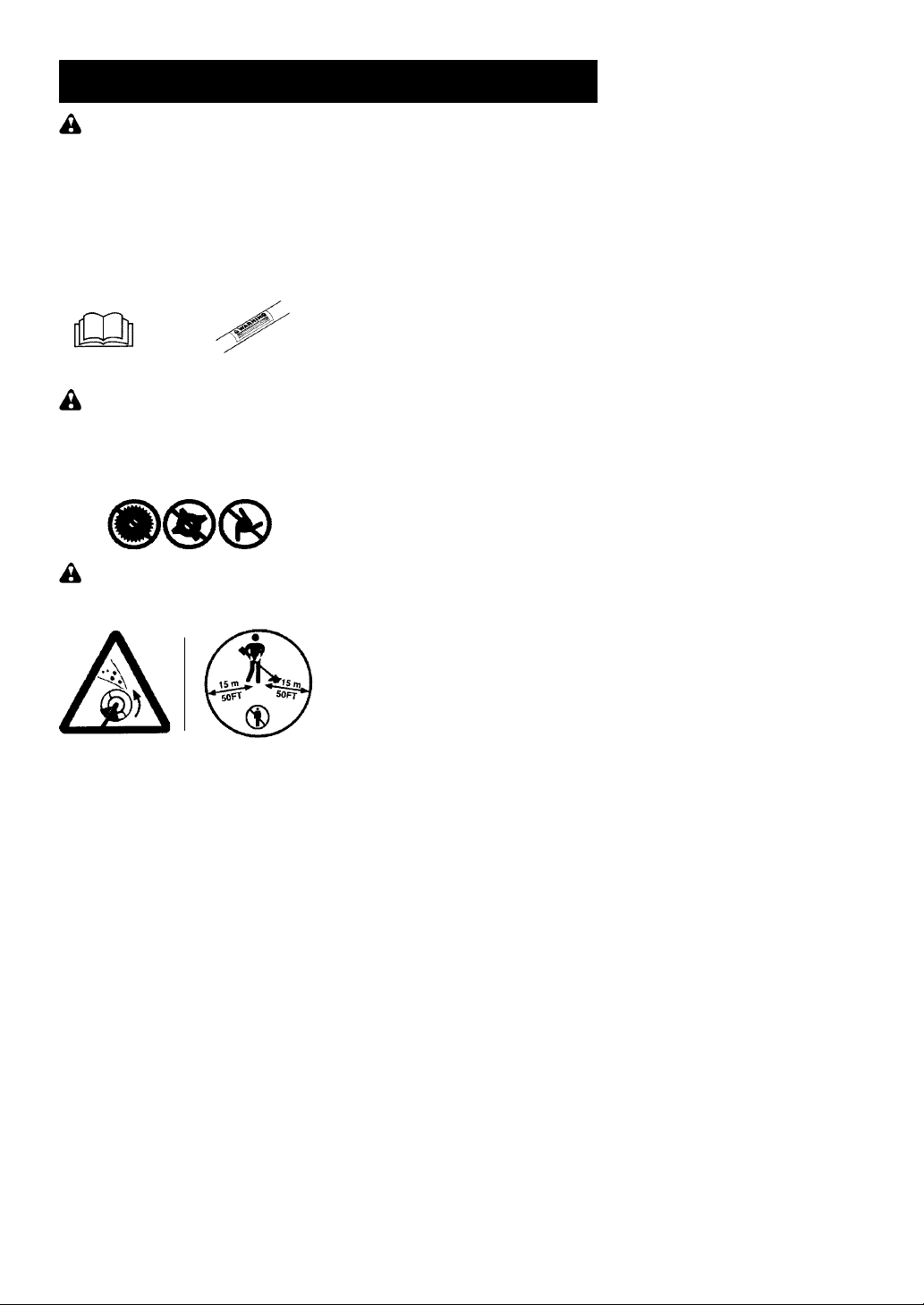

SAFETY RULES

WARNING: When using gardening

appliances, basic safety precautions should always be followed to reduce the risk of fire and

serious injury. Read and follow all instructions.

This power unit can be dangerous! Operator is

responsible for following instructions and warnings on unit and in manual. Read entire instruction manual before using unit! Be thoroughly familiar with the controls and the proper use of the

unit. Restrict the use of this unit to persons who

read, understand, and follow instructions and

warnings on unit and in manual. Never allow

children to operate this unit.

INSTRUCTION

MANUAL

DANGER: Never use blades with line

trimmer attachment. Never use flailing devices with any attachment. This unit (when

used with supplied line trimmer attachment) is

designed forline trimmeruse only.Use of any

other accessories with line trimmer attachment will increase the risk of injury.

WARNING: Trimmer line throws ob-

jects violently. You and others can be blinded/

injured. Wear safety glasses and leg protection. Keep body parts clear of rotating line.

Keep children, bystanders, and animals 15 meters away. If approached stop unit immediately.

If situations occur which are not covered in

this manual, use care and good judgement. If

you need assistance, contact yourauthorized

service dealer.

OPERATOR SAFETY

S Dress properly. Always wear safety

glasses or similar eye protection when operating, or performing maintenance, on

your unit (safety glasses are available).

Eye protection should be marked Z87.

S Always wear face or dust mask if operation

is dusty.

SAFETY INFORMATION

ON THE UNIT

S Always wear heavy, long pants, long

sleeves, boots,and gloves. Wearing safety

leg guards is recommended.

S Always wear foot protection. Do not go

barefoot or wear sandals. Stay clear of

spinning line.

S Secure hair above shoulderlength. Secure

or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc.

They can be caught in moving parts.

S Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

S Stay Alert. Do not operate this unit when you

are tired, ill, upset or under the influence of alcohol, drugs, or medication. Watch what you

are doing; use common sense.

S Wear hearing protection. Long or continu--

ous exposure to high noise levels may

cause permanent hearing impairment.

S Never start or run inside a closed room or

building. Breathing exhaust fumes can kill.

S Keep handles free of oil and fuel.

S Always keep engine on the right hand side

of your body.

S Hold the unit firmly with both hands.

S Keep trimmer head (or other optional at-

tachment) below waist leveland away from

all parts of your body. Do not raise engine

above your waist.

S Keep all parts of your body away from muf-

fler and spinning line (or other optional attachment). Keep enginebelow waist level.

A hot muffler can cause serious burns.

S Keep firm footing and balance. Do not over-

reach or use from unstable surfaces such as

ladders, trees, steep slopes, rooftops, etc.

S Use only in daylight or good artificial light.

S Use only for jobs explained in this manual

(or manuals for optional attachments).

UNIT / MAINTENANCE SAFETY

S Disconnect the spark plug before performing

maintenance except carburetor adjustments.

S Look for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep ingood working

condition.

S Replace trimmer head parts that are

chipped, cracked, broken, or damaged in

any other way before using the unit.

S Maintain unit according to recommended

procedures. Keep cutting line at proper

length.

S Use only 2 mm diameter McCulloch® brand

line. Never use wire, rope, string, etc.

S Install required shield properly before using

the unit. Use only specified trimmer head;

make sure it is properly installed and securely fastened.

S Make sure unit is assembled correctly as

shown in this manual.

3

Page 4

S Make carburetor adjustments with lower

end supported toprevent line fromcontacting any object.

S Keepothers away when making carburetor

adjustments.

S Use only recommended McCulloch® ac-

cessories and replacement parts.

S Have all maintenance and service not ex-

plained in this manual performed by an authorized service dealer.

FUEL SAFETY

S Mix and pour fuel outdoors.

S Keep away from sparks or flames.

S Use a container approved for fuel.

S Do not smoke or allowsmoking nearfuel or

the unit.

S Avoid spilling fuel oroil. Wipe up all fuel spills.

S Move at least 3 meters away from fueling

site before starting engine.

S Stop engine and allow to cool before re-

moving fuel cap.

S Always store gasoline in a container ap-

proved for flammable liquids.

TRANSPORTING AND STORAGE

S Allow the engine to cool; secure unit before

storing or transporting in vehicle.

S Empty fuel tank before storing or transport-

ing the unit. Use upfuel left in thecarburetor

by starting engine and letting it run until it

stops.

S Store unit and fuelin an area where fuelva-

pors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

S Storeunit so linelimiter cannot accidentally

cause injury. Unit can behung by the shaft.

S Store the unit out of the reach of children.

SPECIAL NOTICE: Exposure to vibra-

tions through prolongeduse of gasoline powered hand tools could cause blood vessel or

nerve damage in the fingers, hands, and

joints of people prone to circulation disorders

or abnormal swellings. Prolonged use in cold

weather has been linked toblood vessel damage in otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tooland seekmedical attention. An anti-vibration system does

not guarantee the avoidance of these problems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical condition andthe condition of this tool.

LINE TRIMMER SAFETY

WARNING: Inspect the area to be

trimmed before each use. Remove objects

(rocks, broken glass, nails, wire, etc.) which

can bethrown byor becomeentangled inline.

Hard objects can damage the trimmer head

and be thrown causing serious injury.

S Use only for trimming, scalping, mowing and

sweeping. Do not use for edging, pruning or

hedge trimming.

S Cut from your right to your left. Cutting on

left side of the shield will throw debris away

from the operator.

ADDITIONAL SAFETY RULES

FOR OPTIONAL ATTACHMENTS

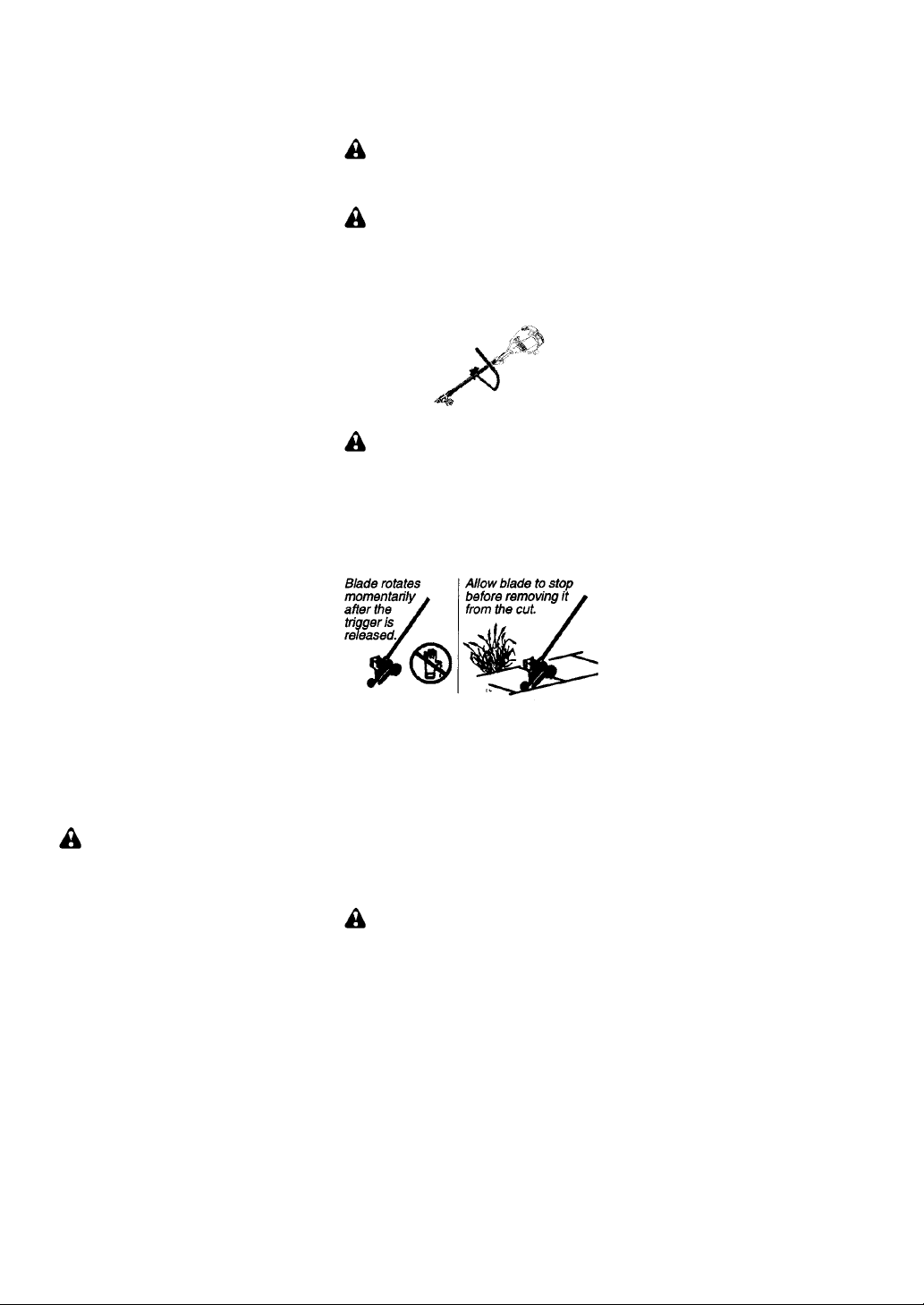

WARNING: For each optionalattach-

ment used,read entire instruction manual before use and follow all warnings and instructions in manual and on attachment.

WARNING: Ensure handlebar is

installed when using edger or brushcutter attachments. Attach handlebar above arrow on

safety label on the upper shaft (engine endof

unit). If your edger or brushcutter attachment

does notinclude ahandlebar, ahandlebar accessory kit (#530071451) is available from

your authorized service dealer.

Handlebar

EDGER SAFETY

WARNING: Inspect the area to be

edged before each use. Remove objects

(rocks, broken glass, nails, wire, etc.) which

can be thrown by the blade or can wrap

around the shaft.

S Blade rotates momentarily after the trigger

is released. The blade can seriously cut

you or others.

S Allow blade to stop before removing it from

the cut.

S Throw away blades that are bent, warped,

cracked, broken or damaged in any other

way. Replace parts that are cracked,

chipped, or damaged before using the unit.

S Do not attempt to remove cut material nor

hold material to be cut when the engine is

running or when cutting blade is moving.

S Always keepthe wheel and depth adjusting

skid in contact with the ground.

S Always push the unit slowly over the

ground. Stay alert for uneven sidewalks,

holes in the terrain, large roots, etc.

S Always use thehandlebar when using edg-

er attachment.

BLOWER/VACUUM SAFETY

WARNING: Inspect areabefore start-

ing unit. Remove all debris and hard objects

such as rocks, glass, wire, etc. that can rico-

4

Page 5

chet, be thrown, or otherwise cause injury or

damage during operation.

S Do not set unit on any surface except a

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc., could be picked up by the air intake

and thrown out through discharge opening,

damaging unit, property, or causing serious

injury to bystanders or operator.

S Never place objects inside the blower

tubes, vacuum tubes or blower outlet. Always direct the blowing debris away from

people, animals, glass, and solid objects

such as trees, automobiles, walls, etc. The

forceof air c an cause rocks, dirt,or sticks to

be thrown or to ricochet which can hurt

people or animals, break glass, or cause

other damage.

S Never run unit without the proper equip-

ment attached. When using your unit as a

blower, always install blower tubes.

S Check air intake opening, blower tubes or

vacuum tubes frequently, always with engine stopped and spark plug disconnected.

Keep vents anddischarge tubes free ofdebris which can accumulate and restrict

proper air flow.

S Never place anyobject inair intake opening

as this could restrict proper air flow and

cause damage to the unit.

S Never use for spreading chemicals, fertiliz-

ers, orother substances which maycontain

toxic materials.

S Toavoid spreading fire,do notuse near leaf

or brush fires, fireplaces, barbecue pits,

ashtrays, etc.

BRUSHCUTTER SAFETY

DANGER: Blade can thrust violently

away from material it does not cut. Blade

thrust can cause amputation of arms or legs.

right hand side of the coasting blade with material already cut.

Stop coasting

blade by contact

with cut material.

WARNING: Inspect the areato becut

before each use. Remove objects (rocks,

broken glass, nails, wire, etc.) which can be

thrown or become entangled in the blade or

trimmer line.

S Throw away and replace blades that are

bent, warped,cracked, broken ordamaged

in any other way.

S Install required shield properly before using

the unit. Use the metal shield for all metal

blade use.

S Useonly specified blade andmake sure it is

properly installed and securely fastened.

S Cut from your left to your right. Cutting on

the right side of the shield will throw debris

away from the operator.

S Always use the handlebar and a properly

adjusted shoulder strap withblade (see ASSEMBLY instructions inbrushcutter attachment instruction manual).

CULTIVATOR SAFETY

WARNING: Rotating tines can cause

serious injury. Keep away from rotating tines.

Stop the engine and disconnect the spark plug

before unclogging tines or making repairs.

WARNING: Do not use trimmer head

as a fastening device for the blade.

WARNING: The blade continues to

spin after the throttle is released or engine is

turned off. The coasting blade can throw objects or seriously cut you if accidentally

touched. Stop the blade by contacting the

WARNING: Inspect the area to be

cultivated before starting theunit. Remove all

debris and hard and sharp objects such as

rocks, vines, branches, rope, string, etc.

S Avoid heavy contact with solid objects that

might stop the tines. If heavy contact occurs, stop the engine and inspect the unit

for damage.

S Never operate the cultivator withoutthe tine

cover in place and properly secured.

S Keep the tines and guard clear of debris.

S After striking a foreign object, stop the en-

gine, disconnect the spark plugand inspect

the cultivator for damage. Repair before restarting.

5

Page 6

S Disconnect attachment from the drive en-

l

lowbl

gine before cleaning the tines with a hose

and water to remove any build--up. Oil the

tines to prevent rust.

S Always wear gloves when servicing or

cleaning the tines. The tines become very

sharp from use.

S Do not run unit at high speed unless culti-

vating.

HEDGE TRIMMER SAFETY

DANGER: RISK OF CUT; KEEP

HANDS AWAY FROM BLADE

moves momentarily after the trigger is released. Do not attempt to clear away cut material when the blade is in motion. Make sure

the switch is in the OFF position, the spark

plug wire is disconnected, and the blade has

stopped moving before removing jammed

material from thecutting blade. Do notgrab or

hold the unit by the cutting blade.

Bladesmove

momentarily

after the

trigger is

released.

A

before removing

them from the cut.

-- B l a d e

adestostop

WARNING: Inspect the area before

starting the unit. Remove all debris and hard

objects such as rocks, glass, wire, etc. that

can ricochet, be thrown, or otherwise cause

injury or damage during operation.

S Do not use a cutting blade that is bent,

warped, cracked, broken or damaged in

any other way. Have worn or damaged

parts replaced by your authorized service

dealer.

S Always keep unit in front of your body.

Keep all parts of your body away from the

cutting blade.

S Keepthe cutting blade andair vents clear of

debris.

POLE PRUNER SAFETY

WARNING: The reciprocating blade/

rotating chain can cause severe injury. Inspect the unitbefore use. Do not operate unit

with abent, cracked or dull bladeor dullchain.

Keep away fromthe blade/chain.The reciprocating blade/rotating chain is sharp. Do not

touch. To prevent serious injury, always stop

engine and ensure blade/chain has stopped

moving, disconnect spark plug, and wear

gloves when changing or handling the blade

or chain.

WARNING: A coasting blade/rotating

chain can cause injury while it continues to

move after the engine is stopped. Maintain

proper control of the unit until the blade/chain

has completely stopped moving. Keep

hands, face and feet at a distance from all

moving parts. Do notattempt to touch orstop

the blade or chain when it is moving.

WARNING: Falling objects can

cause severe headinjury. Wear head protection when operating this unit with a pole pruner attachment.

WARNING: Toprevent serious injury,

do not use more than one boom extension

with a pole pruner attachment.

WARNING: Keep the pruner away

from power lines or electrical wires.

S Only use for pruning limbs or branches up

to 4 inches in diameter.

S Do not operate the unit faster than the

speed needed to prune. Do not run the unit

at high speed when not pruning.

S Always stop the unit when work is delayed

or when walking from onecutting locationto

another.

S Ifyou strike orbecome entangledwith afor-

eign object, stop the engine immediately

and check for damage. Have any damage

repaired by an authorized service dealer

before attempting further operations. Discard blades that are bent, warped, cracked

or broken.

S Stop the unit immediately if you feelexces-

sive vibration. Vibration is asign of trouble.

Inspect thoroughly for loose nuts, bolts or

damage before continuing. Contact an authorized service dealer for repair or replacement of affected parts as necessary.

SNOW THROWER SAFETY

WARNING: Keep hands and feet

away from the rotor when starting or running

the engine. Never attempt to clear the rotor

with the engine/motor running. Stop engine

and disconnect spark plug before unclogging

snow or debris from discharge chute orwhen

adjusting vanes.

6

Page 7

WARNING: Never lean over dis-

charge chute. Rocks or debris could be

thrown intothe eyes andface and cause serious injury or blindness.

WARNING: Inspect the area where

the unit is to be used. Remove objects that

could be thrown or damage the unit. Some

objects may be hidden by fallen snow -- be

alert for the possibility.

S Direct material discharge away from glass

enclosures, automobiles, etc.

S Do not run engine at high speed while not

removing snow.

S Be attentive when using the snowthrower,

and stay alert for holes in the terrain and

other hidden hazards.

ASSEMBLY

WARNING: If received assembled,

repeat allsteps to ensure your unit is properly

assembled and all fasteners are secure.

Examine parts for damage. Do not use damaged parts.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fuel or oil residue onmuffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

INSTALLING TRIMMER ATTACHMENT

CAUTION:

ment, place the unit on a flat surface for stability.

1. Loosen the coupler by turning the knob

counterclockwise.

Shipping

protector

When installing trimmer attach-

Coupler

TIGHTEN

LOOSEN

Knob

S Make sure the rotor will spin freely before at-

taching the snowthrower to the powerhead.

S Ifthe rotor will not rotate freely dueto frozen

ice, thaw the unit before thoroughly before

attempting to operate under power.

S Keep the rotor clear of debris.

S Do not throw snow near other people. The

snow thrower could propel small objects at

high speed causing injury.

S After striking a foreign object, stop the en-

gine, disconnect spark plugand inspect the

snowthrower for damage and repair if necessary before restarting unit.

S Never operate the snowthrower near glass

enclosures, automobiles and trucks.Never

attempt to use the snowthrower on a roof.

S Never operate the snowthrower near win-

dow wells, dropoffs, etc.

S Never discharge snow onto public roads or

near moving traffic.

S Clear snow from slopes by going up and

down; never across. Use caution when

changing directions. Neverclear snow from

steep slopes.

S Let snowthrower run for a few minutes after

clearing snow so moving parts do not freeze.

S Look behind and use care when backing

up. Exercise cautionto avoidslipping orfalling, especially when operating in reverse.

S Know how to stop quickly.

2. Remove shipping protector from coupler.

3. Remove the shaft cap from the trimmer

attachment (if present).

4. Position locking/release button of attachment into guide recess of coupler.

5. Push the attachment into the coupler until

the locking/release button snaps into the

primary hole.

6. Before using the unit, tightenthe knob securely by turning clockwise.

Coupler Primary Hole

Upper

Shaft

Locking/

Release

Button

Guide Recess

Lower

Attachment

WARNING: Make sure the locking/

release button is locked in the primary hole

and the knob is securely tightened before operating theunit. All attachments aredesigned

to be used in the primary hole.

For optional attachments, see the ASSEMBLY section of the applicable attachment instruction manual.

7

Page 8

ATTACHING THE SHIELD

WARNING: The shield must be prop-

erly installed. The shield provides partial

protection from the risk of thrown objects to

the operator and others and is equipped with

a line limiter which cuts excess line. The line

limiter (on underside of shield) is sharp and

can cut you.

1. Remove nut from shield.

2. Insert bracket into slot on shield.

3. Pivot shield until bolt passes throughhole

in bracket.

4. Reinstall nut and tighten securely with

wrench (provided).

Shield

Line Limiter Blade

Slot

Bracket

Nut

OPERATION

WARNING: Be sure to read the fuel

information in the safety rules before you begin. If you do not understand the safety rules,

do not attempt to fuel your unit. Contact an

authorized service dealer.

FUELING ENGINE

WARNING: Remove fuel cap slowly

when refueling.

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a good quality 2-cycle air-cooled engine oil. We recommend McCulloch® brand oil

mixed at a ratio of 40:1 (2.5%). A 40:1 ratio is

obtained by mixing 5 liters of unleaded gasoline

with 0,125 liter of oil. DO NOT USE automotive

oil or boat oil. These oils will cause engine damage. When mixing fuel, follow instructions

printed on oil container. Once oil is added to

gasoline, shake container momentarily to assure that the fuel is thoroughly mixed. Always

read and follow the safety rules relating to fuel

before fueling your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) canattract moisture which leads to

separation andformation ofacids during storage. Acidic gas can damage the fuel system

of anengine while in storage. To avoidengine

ADJUSTING THE HANDLE

WARNING: When adjusting the han-

dle, be sure it remains between the trigger

and the safety label. Assist handle must be

positioned only below the arrow.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an upright position; retighten wing nut.

problems, empty the fuel system before storage for 30days or longer. Drain the gas tank,

start the engine andlet it run untilthe fuellines

and carburetor areempty. Use fresh fuelnext

season. Never use engine or carburetor

cleaner productsin thefuel tank or permanent

damage may occur.

HOW TO STOP YOUR UNIT

S To stop the engine, move the ON/OFF

switch to the OFF position.

ON/OFF Switch

HOW TO START YOUR UNIT

WARNING: Avoid any contact with

the muffler. A hot muffler can cause serious

burns.

ST ARTI NG A COLD ENGINE (or a

warm engine after running out of fuel)

Starting Position

8

Page 9

Throttle

Lock--out

Throttle

Trigger

Primer Bulb

NOTE: The throttle lock- -out must be engaged

to allow operation of the throttle trigger. The

lock--out is engaged with the palm of your hand

as you grip the throttle handle.

1. Set unit on a flat surface.

2. Move ON/OFF switch to the ON position.

3. Slowly press the primer bulb 6 times.

4. Move choke lever to FULL CHOKE position

by aligning lever with position shown on decal (see illustration below).

Choke

position

decal

5. Squeeze and hold trigger through all re-

maining steps.

6. Pull starter rope handle sharply until engine sounds as if it is trying to start, but do

not pull rope more than 6 times.

7. As soon as engine sounds as if it is trying

to start, move choke lever to HALF

CHOKE by aligning lever with position

shown on decal (see illustration below).

Choke

position

decal

8. Pull starter rope sharply until engine runs,

but no more than 6 pulls. If the engine

doesn’t start after 6 pulls (at the HALF

CHOKE position), move the choke lever

to the FULL CHOKE position and press

the primer bulb6 times.Squeeze andhold

the throttletrigger andpull thestarter rope

2 more times. Movethe choke lever to the

HALF CHOKE position and pull the starter rope until theengine runs, but no more

than 6 pulls.

Starter Handle

Muffler

Choke

Lever

NOTE: If engine still doesn’t start, it is

probably flooded. Proceed to STARTING

A FLOODED ENGINE.

9. Once the engine starts, allow it to run 10

seconds, then move the choke lever to

OFF CHOKE by aligning lever with position shown on decal (see following illustration). Allow the unit to run for 30

more seconds at OFF CHOKE before releasing the throttle trigger.

NOTE: If engine dies with the choke le-

ver inthe OFF CHOKE position, move the

choke lever to the HALF CHOKE position

and pull the rope until engine runs, but no

more than 6 pulls.

Choke

position

decal

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

4. Pull starter rope sharply until engine runs,

but no more than 5 pulls.

5. Allow engine to run 15 seconds, then

move thechoke lever tothe OFF CHOKE

position.

NOTE: If engine has not started, pull starter

rope 5more pulls. If engine still does not run, it

is probably flooded.

STARTING A FL OODED ENGINE

Flooded engines can be started by placing

the choke lever in the OFF CHOKE position;

then, pull the rope to clear the engine of excess fuel.This couldrequire pullingthe starter

handle many times depending on how badly

the unit is flooded.

If the unit still doesn’t start, refer to TROUBLESHOOTING TABLE.

OPERATING THE COUPLER

This model is equipped with a coupler which

enables optional attachments to be installed.

WARNING: Always stop unitand dis-

connect spark plug before removing or installing attachments.

REMOVING TRIMMER ATTACHMENT (OR OTHER OPTIONAL ATTACHMENTS)

CAUTION:

tachments, place the unit on a flat surface for

stability.

1. Loosen the coupler by turning the knob

counterclockwise.

9

When removing or installing at-

Page 10

Upper Shaft

L

A

LWA

Y

Coupler

Lower

Attachment

TIGHTEN

2. Press and hold the locking/release button.

ocking/Release

Button

Lower Attachment

3. While securely holdingthe engineand up-

Coupler

per shaft, pull the attachment straight out

of the coupler.

LOOSEN

Knob

Upper Shaft

INSTALLING OPTIONAL ATTACHMENTS

1. Remove the shaft cap from the attach-

ment (if present).

2. Position locking/release button of attach-

ment into guide recess of coupler.

3. Push the attachment into the coupler until

the locking/release button snaps into the

primary hole.

4. Before using the unit, tightenthe knob se-

curely by turning clockwise.

Coupler

Upper

Shaft

Primary Hole

Locking/

Release

Button

Guide Recess

Attachment

WARNING: Make sure the locking/

release button is locked in the primary hole

and the knob is securely tightened before operating the unit.

OPERATING POSITION

SWEAR:

Hearing

Protection

Long Pants

Heavy Shoes

Cut from your right to your left.

Eye Protection

WARNING: Always wear eye protec-

tion and hearing protection. Never lean over

the trimmer head. Rocks or debris can ricochet or be thrown into eyes and face and

cause blindness or other serious injury.

Do not run the engine at a higher speed than

necessary. The cutting line will cut efficiently

when the engine is run at less than full throttle.

At lower speeds, there is less engine noise and

vibration. The cutting line will last longer and will

be less likely to “weld” onto the spool.

Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

To stop engine:

S Release the throttle trigger.

S Move the ON/OFF switch to the OFF posi-

tion.

TRIMMER LINE ADVANCE

The trimmer linewill advance approximately 2

in. (5 cm) each timethe bottom ofthe trimmer

head is tapped on the ground with the engine

running at full throttle.

The most efficient line length is the maximum

length allowed by the line limiter.

Always keep the shield in place when the tool

is being operated.

To advance line:

S Operate the engine at full throttle.

S Holdthe trimmer head parallelto andabove

the grassy area.

S Tap the bottom of the trimmer head lightly on

the ground one time. Approximately 5 cm of

line will be advanced with each tap.

Always tap the trimmer head on a grassy

area. Tapping on surfaces such as concrete

or asphalt can cause excessive wear to the

trimmer head.

If the line is worn down to 5 cm or less, more

than one tap will be required to obtain the

most efficient line length.

WARNING: Use only 2 mm diameter

line. Other sizes andshapes ofline will not advance properly andwill result in improper cutting headfunction orcan cause serious injury.

Do not use other materials such as wire,

string, rope, etc. Wire can break off during

cutting and become a dangerous missile that

can cause serious injury.

CUTTING METHODS

WARNING: Use minimumspeed and

do not crowd the line when cutting around

hard objects (rock, gravel, fence posts, etc.),

which candamage the trimmer head, become

entangled in the line, or be thrown causing a

serious hazard.

S The tip of the line does the cutting. You will

achieve the best performance and mini-

mum linewear by not crowding the line into

the cutting area. The right and wrong ways

are shown below.

10

Page 11

Tip of the Line

Does The Cutting

Right Wrong

S The line will easily remove grass and

weeds fromaround walls, fences, trees and

flower beds, but it also can cut the tender

bark of trees or shrubs and scar fences.

S For trimming or scalping, use less than full

throttle to increase line life and decrease

head wear, especially:

S During light duty cutting.

S Near objects around which the line can-

wrap such as small posts, trees or fence

wire.

S Formowing orsweeping, usefull throttle for

a good clean job.

TRIMMING -- Hold the bottom of the trimmer

head about 80 mm above the ground and at an

angle. Allow only the tip of the lineto make contact. Do not force trimmer line into work area.

Trimming

80 mm above

ground

SCALPING -- The scalping technique removes unwanted vegetation. Holdthe bottom

of the trimmer head about 80 mm above the

Line Crowded Into

Work Area

ground and atan angle. Allow the tipof theline

to strike the ground around trees, posts,

monuments, etc. This technique increases

line wear.

Scalping

MOWING -- Your trimmer is ideal for mowing

in places conventional lawn mowers cannot

reach. In the mowing position, keep the line

parallel to the ground. Avoid pressing the

head into the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING -- The fanning action of the rotating line can be used for a quick and easy

clean up. Keep the line parallel to and above

the surfaces being swept and move the tool

from side to side.

Sweeping

MAINTENANCE

WARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

CHECK FOR LOOSE

FASTENERS AND PARTS

S Spark Plug Boot

S Air Filter

S Housing Screws

S Assist Handle Screw

S Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

S ON/OFF Switch -- Ensure ON/OFF switch

functions properly by moving the switch to

the OFF position. Make sure engine stops;

then restart engine and continue.

S Fuel Tank -- Discontinue use of unit if fuel

tank shows signs of damage or leaks.

S Debris Shield -- Discontinue use of unit if

debris shield is damaged.

INSPECT AND CLEAN UNIT AND

LABELS

S After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

labels using a damp cloth with a mild detergent.

S Wipe of f unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2. Remove parts as illustrated.

NOTE: Do not clean filter ingasoline orother

flammable solvent to avoid creating a fire hazard or producing harmful evaporative emissions.

11

Page 12

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

Button

Air Filter

Air Filter

Cover

SERVICE AND ADJUSTMENTS

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0,6 mm. Ignition timing is

fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 19 mm

socket wrench.

4. Reinstall the spark plug boot.

REPLACING THE LINE

1. Move the ON/OFF switch to the OFF

position.

2. Disconnect the spark plug lead wire.

3. Remove spoolby firmly pullingon tapbutton. Clean entire surface of hub and

spool. Replace witha pre-wound spool, or

cut two lengthsof 4 meters of 2 mm diameter McCullochr brand line.

WARNING: Never use wire, rope,

string, etc., which canbreak offand becomea

dangerous missile.

4. Insert ends of the line about 1 cm into the

small hole on the inside of spool.

Spool

Line exit holes

Hub

5. Wind the line evenly and tightly onto the

spool. Wind in the direction of the arrows

found on the spool.

6. Push the line into the notches, leaving 7-12 cm unwound.

7. Insert the line into the the exit holes in the

hub as shown in the illustration.

8. Align the notches with the line exit holes.

9. Push spool into hub until it snaps into

place.

10. Pull the lines extending outside ofthe hub

to release them from the notches.

Small

Holes

Line in Notch

Line in Notch

CARBURETOR ADJUSTMENT

WARNING: Keep others away when

making idle speed adjustments. The trimmer

head will be spinning during most of this procedure. Wear your protective equipment and

observe all safety precautions. After making

adjustments, the trimmer head must not

move/spin at idle speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if you

notice any of the following conditions:

S Engine will not idle when the throttle is re-

leased.

S The trimmer head moves/spins at idle speed.

Make adjustments with the unit supported so

the cutting attachment is off the ground and

will not make contact with any object. Hold

the unitby handwhile runningand makingadjustments. Keep all parts of your body away

from the cutting attachment and muffler.

Idle Speed Adjustment

Allow engineto idle.Adjust speed untilengine

runs without trimmer headmoving orspinning

(idle speed too fast) or engine stalling (idle

speed too slow).

S Turn idle speed screw clockwise to in-

crease enginespeed if enginestalls or dies.

S Turn idle speed screw counterclockwise to

decrease engine speed if trimmer head

moves or spins at idle speed.

WARNING: Recheck the idle speed

after each adjustment. The trimmer head

must not move or spin at idle speed to avoid

serious injury to the operator or others.

Air Filter

Cover

Idle Speed

Screw

If yourequire further assistance or areunsure

about performing this procedure, contact an

authorized service dealer.

12

Page 13

STORAGE

WARNING: Perform the following

steps after each use:

S Allowengine tocool before storing or trans-

porting.

S Store unit and fuel in a well ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

S Empty fuel tank before storing or transport-

ing the unit.

S Store unit and fuel well out of the reach of

children.

S Store unit with all guards in place. Position

unit so that any sharp object cannot accidentally cause injury.

SEASONAL STORAGE

Prepare unit forstorage at end of season or if

it will not be used for 30 days or more.

If your unit is tobe stored for a period of time:

S Clean the entire unit before lengthy stor-

age.

S Store in a clean dry area.

S Lightly oil external metal surfaces.

ENGINE

S Remove spark plug and pour1 teaspoon of

40:1, 2-cycle engineoil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

S Replace spark plug with new one of recom-

mended type and heat range.

S Clean air filter.

S Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts.

S At the beginning of the next season, use

only fresh fuel having theproper gasoline to

oil ratio.

OTHER

S Do not store gasoline from one season to

another.

S Replace your gasoline can if itstarts to rust.

13

Page 14

TROUBLESHOOTING TABLE

WARNING: Always stopunit anddisconnect spark plugbefore performingall ofthe

recommended remedies below except remedies that require operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start.

Engine will

not idle

properly.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

1. ON/OFF switch in OFF

position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Carburetor requires

adjustment.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

1. Move ON/OFF switch to ON position.

2. See “Starting a Flooded Engine” in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact an authorized service dealer.

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1. Empty fuel tank and refill with

correct fuel mixture.

2. Replace with correct spark plug.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

DECLARATION OF CONFORMITY

relating to 2000/14/EC

EC Declaration of Conformity relating to 2000/14/EC

We, Electrolux Home Products, Inc., Texarkana, TX, 75501, USA, Tél. : +1 903 223

4100, declare under sole responsibility that the McCulloch model TrimMac 281 grass

trimmer was assessed in accordance with Annex V of the DIRECTIVE and from serial

numbers 2004--247N00001 and onwards, conforms to the provisions of the DIRECTIVE.

The cutting width is 431 mm. The measured sound power is 108 dB and the guaranteed

sound power is 114 dB.

Texarkana 04--09--03

Michael S. Bounds, Director

Product Safety and Standards

14

Page 15

DECLARATION OF CONFORMITY

relating to 98/37/EC

EC Declaration of Conformity (Directive98/37/EC,Annex II,A) (Only applies to

Europe)

We, Electrolux Home Products, Inc., T exarkana, TX, 75501, USA, Tél. : +1 903 223

4100, Declare under sole responsibility that the McCulloch model TrimMac 281 grass

trimmer from serial numbers 2004--247N00001 and onwards, follows the provisions of the

DIRECTIVES : 98/37/EC (machinery) and 89/336/EEC (electromagnetic compatibility),

including amendments and is in conformity with the following standards: EN 292-- 2, EN

ISO 11806 and CISPR 12.

SMP, The Swedish Machinery Testing Institute, Fyrisborgsgatan 3 S--754 50Uppsala,

Sweden, has carried out voluntary type approval. The certificate(s) are numbered:

SEC/04/1009.

Texarkana 04-- 09--03

Michael S. Bounds, Director

Product Safety and Standards

TECHNICAL DATA SHEET

MODEL: TrimMac 281

ENGINE

Displacement, cm

Maximum engine power, measured in

accordance with ISO 8893, kW 0,64

ENGINE ROTATIONAL SPEEDS

At maximum engine power, rpm 7000

Maximum rotational frequency of the spindle 10000

Engine speed at recommended maximum

spindle rotational frequency 10000

Recommended speed idling, rpm 3000

FUEL AND LUBRICATION SYSTEM

Fuel tank volume capacity, cm

Fuel consumption at maximum engine power,

measured in accordance with ISO 8893, g/h 399

Specified fuel consumption at max. engine power,

measured in accordance with ISO 8893, g/kWh 435

WEIGHT

Without cutting attachment or shield, empty tank, kg 5

CUTTING ATTACHMENT

Cutting head assembly, part number #530095846

NOISE LEVELS (Octave Band Analysis 100--10000hz 1/3 Octave)

SOUND PRESSURE LEVELS in accordance with ISO/EN 11806

measured in accordance with EN 27917, dB(A) 95,6

SOUND POWER LEVELS in accordance with ISO/EN 11806

measured in accordance with ISO/EN 10884, dB(A) 105,7

VIBRATION LEVELS measured in accordance with ISO 7916

FRONT HANDLE

Idling, m/s

Racing, m/s

REAR HANDLE

Idling, m/s

Racing, m/s

3

3

2

2

2

2

28

325

9,18

7,33

20,1

10,1

YEAR OF CONSTRUCTION: 2005

MANUFACTURER’S ADDRESS: Electrolux Outdoor Products Italy

ViaComo72

Valmadrera, Lecco

ITAL Y I--23868

15

Loading...

Loading...