McCulloch Pro-Mac 5000, Pro Mac 5000i Owner's Manual

MMECULLOCH”

cHIPPER/sHREDDER

Pro-Mac 5000

Pro Mac 5000i

.,

(=) OWNER’S MANUAL

,

READ CAREFULLY-

419

●

●

●

WARNING: TO REDUCE THE ?QTENT’fAt- FOR ANY INJURY, COMPLY WITH THE FOLLOWING SAFETY

I&

~screws, nuts, bolts and all other fasteners are properly

~NING: This unit is equipped with an Inlomal ccrmbustion engine and should not be used on or near any unimproved lo~osl-covered.bnrsh-

red or ~rnss+nmrod fond unfess the ongkwr’sexhaust sys!om Is equippd wih a

tpark amoster IS used, II should bo maintained

e

ml laws apply O(I Irxk,ral lands A spmk wrcskr for the mulllcr is

lNSTRUCTfONS. FAILURE TO COMpf-Y WITH THE lNSTRUCllONS MAY RESULT IN PERSONAL INJURY.

TRAINING

Read this owrmr”s manual carefully in fis entirey before

attempting to assemble or operate this machine. Be

completely familiar with the controls and the proper use of

thl.s machine before operai~ it. Keep this manual in a

safe pface for future and rqular reference or for ordering

replacement parts.

Children must never be allowed to operate this

equipment.

No one shoufd operate this unit while intoxicated or while

tafdng medication that imps.ks the senses or reactions.

This equipment shoukf never.be operated in the vicinity of

children, pets or other persons.

Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide,

ydich Is an pcfdess, tasteless and deadly poisonous gas.

Never place your hands or any part of your bocfy or

cbthing inside the”feeding chamber, discharge chute, or

near any moving part while the machine or engine is

running.

If it’ Is necessary for any reason to irrsp&t or repair the

feeding chambers of any part of the macf&e where a

moving part can cqme in co”ntact with your body or

cbthirrg, stop the machine, aflow it to COOI,disconnect the

spark plug wire from the spark plug and move it away from

the spark plug before attempting such inspection or

repair.

PREPARATION

Wear safety gogglos, work gfoves and shoes while

operating the chipper/shredder. Do not wear loose

cbthing or jowcdry.

Operate chippor/shreddcrr only on a level surface.

Do not operate the chipper/shredder on a paved or gravel

surface.

Before starting the chlpperlshredder, check that all

sekxrrcrd. Replaco all damaged or unreadable warning

and oporaling decals.

Check fuel Iovel bolore starting engine. Gasoline is highly

flammable; handle with care. Use only an approved

cOntalnor.

Do not fill fuel tank indoors, when engine Is running, or

until engine is allowed to cool. Do not smoke.

Reinstall fuel cap on tank and fuel container. Wipe the unit

clqan of any spilled fuel.

OPERATION

Beforo starling IIIC machine, operators shall make certain

that Iho

When Iectiiflg m[iteriai in!o this equipmenl, be extremely

carolul th;II

foroign objoc[z aro

damago to thomxhinc coufd result.

cu[tinq charnbor is empty.

piocor, of metal, rocks, bottles. cans or other

not incluctod. Personal injury or

in offoctiw working order by the opcrakx.

SIaIc 01California tile above Is required by law (Section 4442 of the CafifornicrPUMCResources Code) Orhcr sratcwmay tmvc similar laws.

available throw)h your nearest engine mJhoIIzw_I:I:tvIcu deah:f

2

ff the cutting mechanism strikes any foreign object or n

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away from

the spark plug. Aflow the machine to stop and take the

following steps:

InSped for damage.

Repface or repair Wy damaged parts.

Check for any hose parts and tghten to assure continued

safe operat.mn.

The engine must be kept clean of debris and other

accumulations.

Do not allow an accumulation of processed materiaf to

build up in the discharge area as this will prevent proper

discharge and can resutt in kick-bad from feed opening. -

Never pl~e your hands or any other part of your bbdy or

cfothing inside the feeding chamber,” discharge chute or

near any moving part while the engine is running.

Keep all guards and deflectors in place and in good

worfdng cxmditiirr to assure c%ntinued safe operatiin.

Always stand clear of the discharge area wheri operating

this machine.

Keep your face and body back from the feed opening to

avo”d accidental bunco bad of any material..

Do not over-reach. Keep proper balance and footing at all

times.

The engine governor, settings on your machine must not

be altered, changed, or tarripered with. The governor

controls the maximum safe ‘operating speeds and

protods the engine and all moving parts from damage

caused by over-speed. Authorized service personnel

slpuld perform these adjustments if a problem exist.

Do not trans~rt machine while engine is running.

Do not operate engine it air cleaner or cover directly over

carburetor air intake is removed, except for adjustment.

Removaf of such parts cmufd create a fire hazard. .

If chippkhreddor becomes cfogged the operator must

shut-off .e,ngirre, and discxrnnect spark plug before clearing

debris. . .

MA1tiNANCE AND STORAGE

When this equipment is stopped for servicing, inspectio~

storage or to change an accmssory, make sure the spark

plug wire is discmneded from the spark plug and moved

away from the spark plug. Tho machine should be

allowed to c@ down before making such inspection.

adjustments, service, elc. Maintain your machine with

caro and keep it clean Ior tho best and continuod safe

operat’km. Authorized sorwco shall be soughl if a problem

oxisls.

Do not uso flammablo solutionc 10clwrII the air Iiller.

When not in use, your machmo chould t.m stored out of

tho roach of chikfron. Keep

roach an opon tlamo or spark. For kJIXJpurior.ts of storagoo

Iho ‘Sloraao- section of lhi~ rnanu;d.

rofcr to

spark arrosfor meeting apphmbfo local or LIJIC laws (if any),

whoro ga$olino fumes will nof

. . . .,

421

SAFETYRULES

::

,.

ABLE OF CONTENTS

ASSEMBLY

OPERATION

Maintenance .............................................................9

..............................................................

.................................................

..................................................................

................................................................

4-5

6-8

2

3

STORAGE

SERVtCE& ADJUSTMENTS

TROUBLESHOOTING

REPAIR PARTS .......................................................l5.23

ACCESSORIES

.....................................................................

.....................- .........-..11 -13

.................................................l4

......................................................

24-29

10

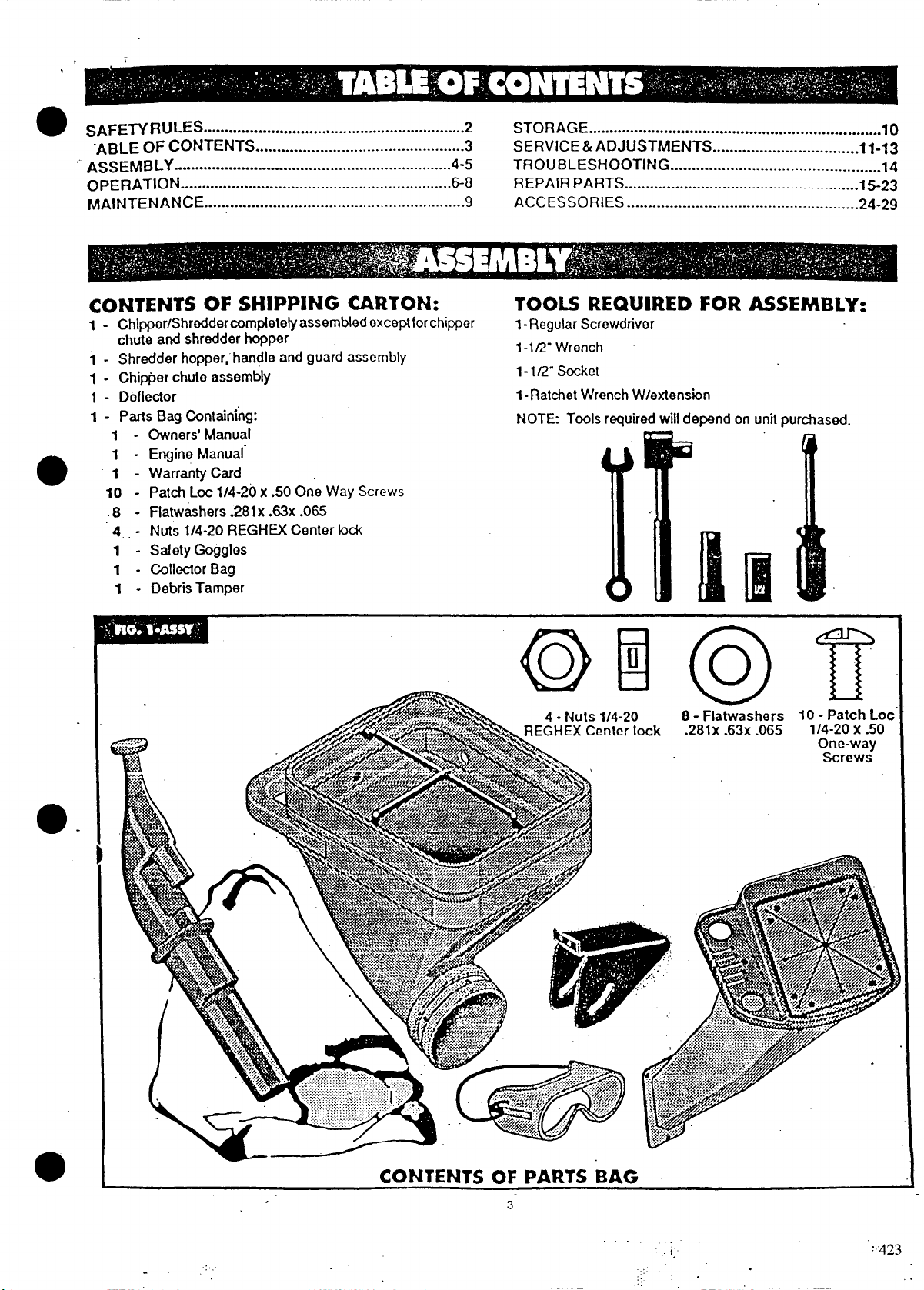

CONTENTS OF SHIPPING CARTON:

Chlppor/Shredder completely assembled oxceptfor chipper

1-

chute and shredder hopper

Shredder hopper,’ handle and guard assembly

i-

Chip@r chute assembly

1-

Deflector

1-

Parts Bag Containing:

1-

- Owners’ Manual

1

- Engine Manual

1

Warranty Card

-

1

- Patch Loc 114-20x .50 One Way Screws

10

- Flatwashers ;281x .63x .065

.8

Nuts 1/4-20 REGHEX Center lock

4,. -

-

Safety Goggles

1

Callector Bag

-

1

-

Debris Tamper

1

TOOLS REQUIRED FOR JWSEMBLY:

I-Regular Screwdriver

1-1Q- Wrench

lR. Socket

11-Ratchet Wrench W/extens.km

NOTE: Tools required will depend on unit purchased.

[

Ii

K!i

CONTENTS OF PARTS BAG

3

. .

.

.:,.

i;

.,. ,

“423

.. . .

●

●

A

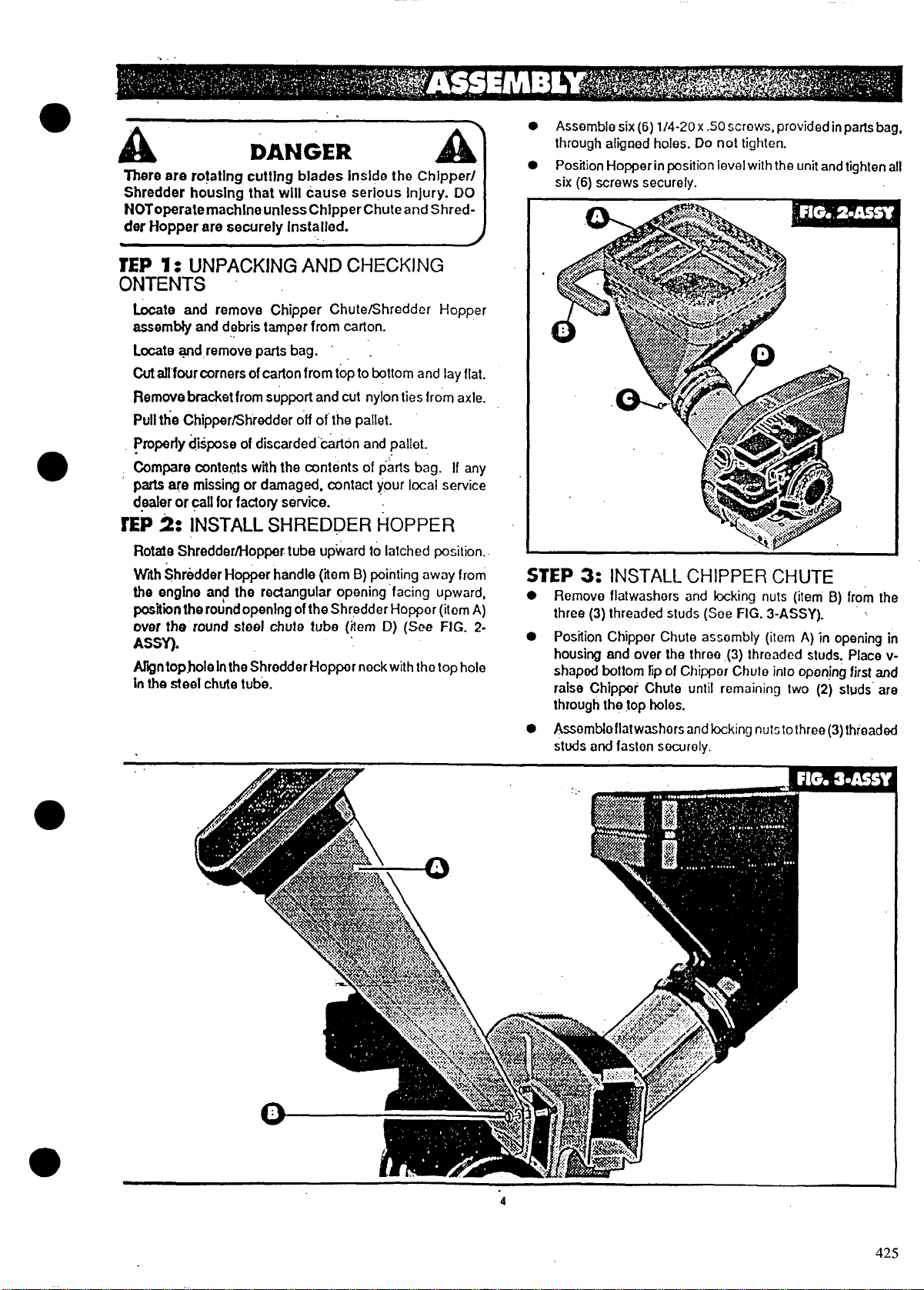

There are rotating cutting blades Inside the Chipper/

Shredder housing that will cause serious Injury. DO

NOToperate machlneunless Chipper Chute and Shred-

der Hopper are securely installed.

DANGER

A

TEP 1: UNPACKING AND CHECKING

ONTENTS

Locate and remove Chipper Chute/Shredder Hopper

assembfy and debris tarnper from carton.

Locate qnd,remove parts bag.

Cutafl”fourcorners of carton from top to bottom and lay flat.

Remove bracket from support and cut nylon ties from axle.

Pull the ChipperX3tiredder off of the pallet.

Pmpafy &+ose of discarded ””&rton and pallet.

Compare cxmter$s with the contents of parts bag. If any

partsare missing or damaged, contact your local service

dealer or @l for factory service.

.

m 2: IIwmu SHREDDER iiOpPER

Rotate Shredder/Hopper tube upward to Ialched Posilion.

Wfih Shredder Hopper handle (iom B) pointing away from

the engine and the rectangular opening “facing upward,

posltiinthe round opening of the Shredder Hoppor (item A)

over the round steel chute tube (item D) (See FIG. 2ASSY).

AfIgntopholelnthe Shredder Hopper rmck with tho top hole

In the steel chute tube.

\

● Assemble six (6) l/4-20x .50 screws, provided inpartsbag,

through aligned holes. Do not tighten.

. Position Hopper in position level with the unit and tighten all

six (6) screws securely.

STEP 3: INSTALLCHIPPER CHUTE

● Remove flatwashors and locking nuts (item B) from the

three (3) threaded studs (See FIG.

● Position Chipper Chule assembly (ilem A) in opening in

housing and over the thr~o (3) threaded studs. Place vshaped bottom fip of Chipper Chuto into oporjng first and

raise Chipper Chute unlil remaining two (2) sluds” are

through the top holes.

● Assombfoflaf washers and locking nuts to three (3) threaded

studs and faston securely. -

3-ASSY). ~~

. .

‘4

425

●

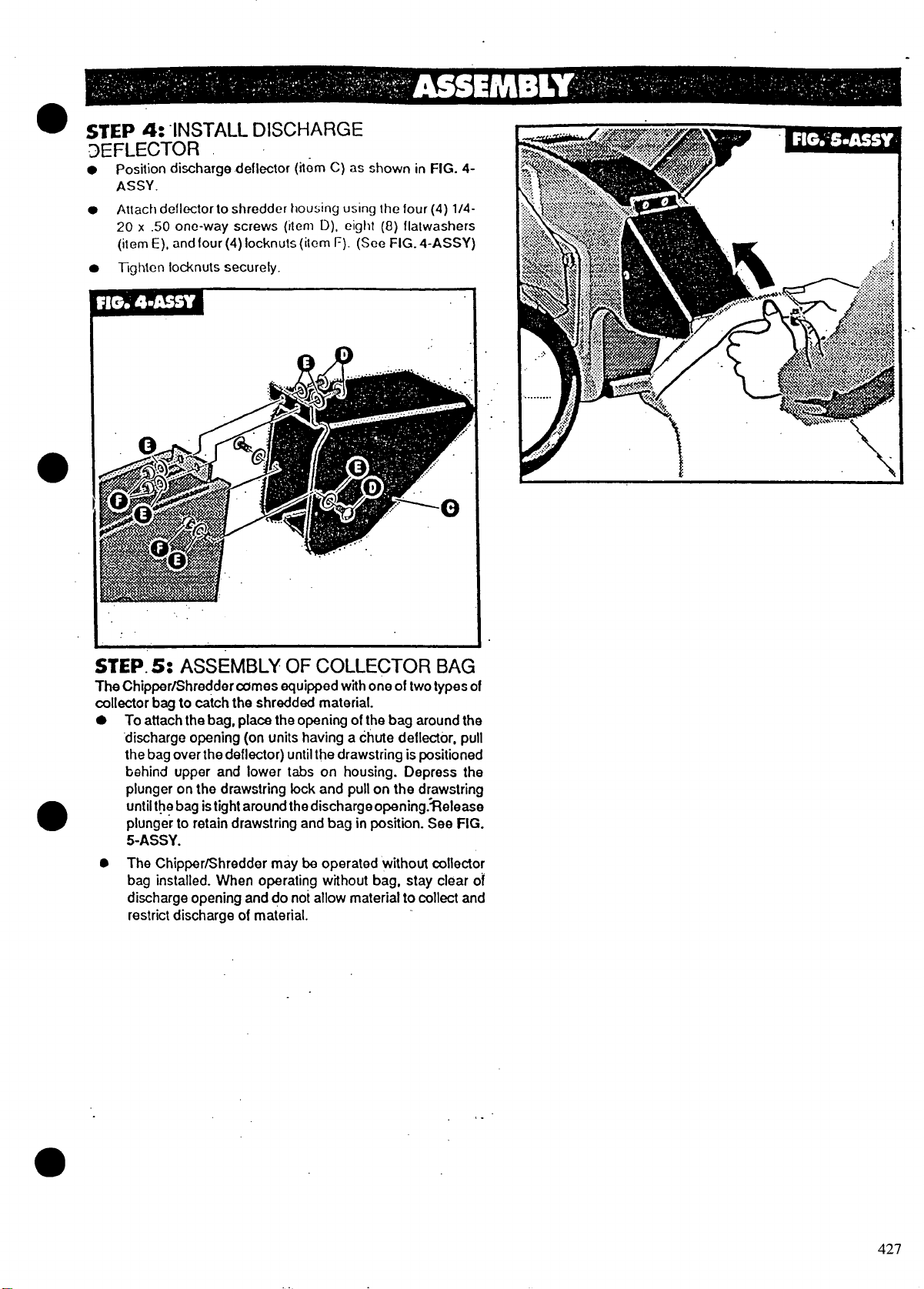

STEP 4: “INSTALLDISCHARGE

3EFLECTOR

● Position discharge deflector (item C) as shown in FIG. 4-

ASSY.

● Attach deflector to shredder housing using

20

x .50 one-way screws (item D), cighf (!3) !Ialwashers

(item E), and four (4) locknuts (ilem F). (See FIG. 4-ASSY)

TQhtcn locknuts securely.

●

the four (4) l/4-

43D’

●

STEP. 5: ASSEMBLY OF COLLECTOR BAG

The Chipper/Shredder comes equipped with one of two types of

collector bag to catch the shredded material.

. To attach the bag, place the opening of the bag around the

‘discharge opening (on units having a chute deflector, pull

the bag over the deflector) until the drawstring is positioned

behind upper and lower tabs on housing. Depress the

plunger on the drawstring fock and pull on the d~awstring

until the bag istight around the discharge opening.Tielease

plunger to retain drawstring and bag in position. See FIG.

5-ASSY.

● The Chipper/Shredder may be operated “without coflector

bag installed. When operating without bag, stay clear of

discharge opening and do not allow materiaf to collect and

restrict discharge of material.

,.’

427

.,

.,

,.

.-

,..:,.,.....

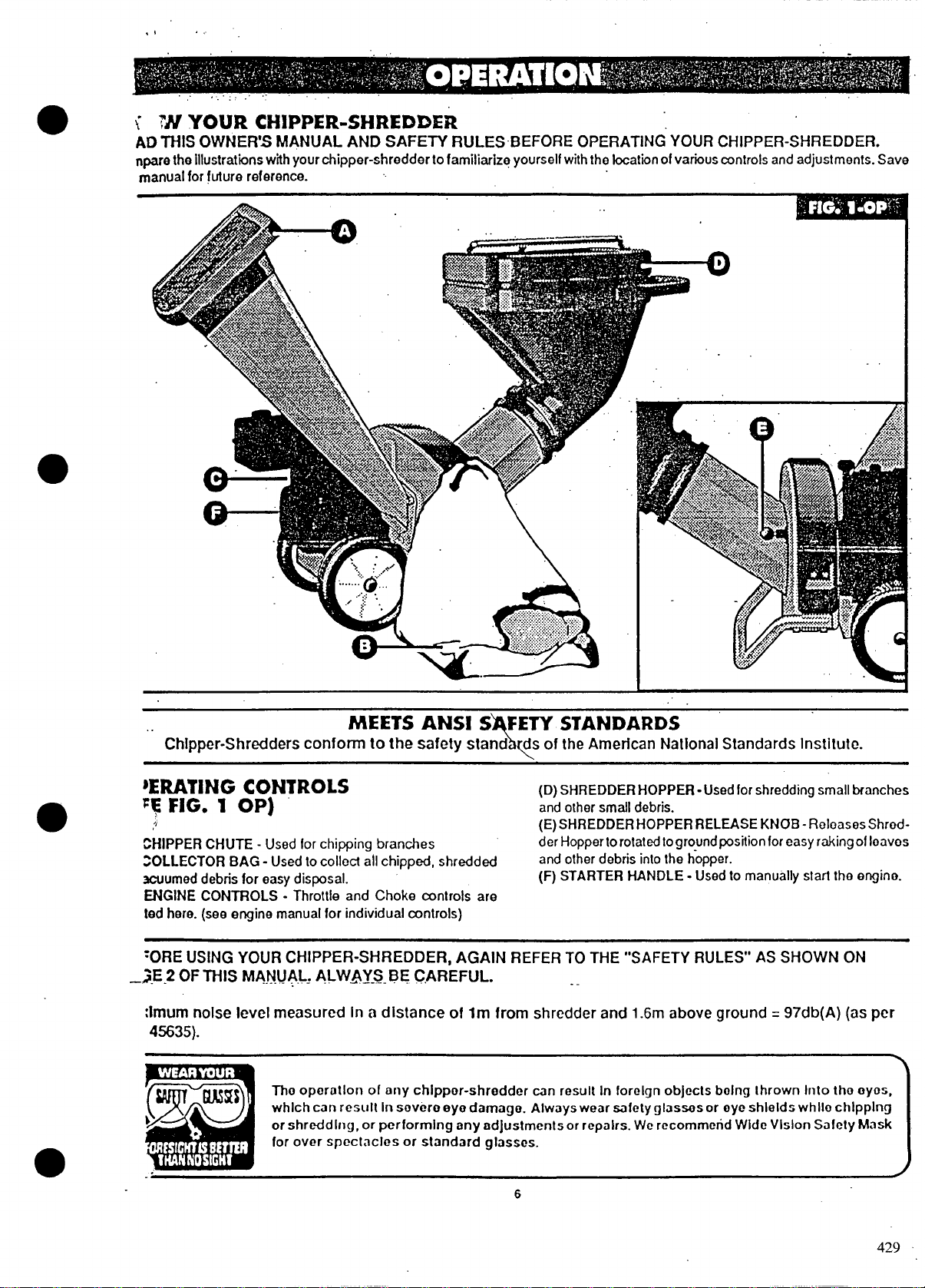

f W YOUR CHIPPER-SHREDDER

AD THISOWNER’S

nparethe lllustrat”~ns with your tiipper-shredder to familiarize yourself with the focation of various controls and adjust ments. Save

manual for future reference.

MANUAL AND SAFETY RULES BEFORE OPERATING” YOUR CHIPPER-SHREDDER.

MEETS ANSI S FETY STANDARDS

Chlpper-Shredders conform to the safety stand Qs of the Amerfcan National Standards fnstitute.

}ERATING coN’fRoLs

F~ EIGO 1 OP)

,/;

CHIPPER CHUTE - Used for chipping branches

COLLECTOR BAG - Used to colloct all chipped, shredded

xwumed debris for easy disposaf.

ENGINE CONTROLS - Throttfe and Choke controls are

ted here. (see engine manual for individual controls)

‘ORE USING YOUR CHIPPER-SHREDDER, AGAIN REFER TO THE “SAFETY RULES” AS SHOWN ON

_;-E2 OF THIS MA.NUA.L, ALW~~.S. BE C,AREFUL.

:Imum noise level measured In a distance of Im from shredder and 1.6m above ground= 97db(A) (as per

45635).

\

(D) SHREDDER HOPPER -Used for shredding small branches

and other smafl debris.

(E) SHREDDER HOPPER RELEASE KNOB -Rofoases Shrodder Hopper to rotat ed10ground position for easy raking of Ioavos

and other debris inlo the hopper.

(F) STARTER HANDLE - Used to manuaffy start the engino.

-.

6

429

● ’

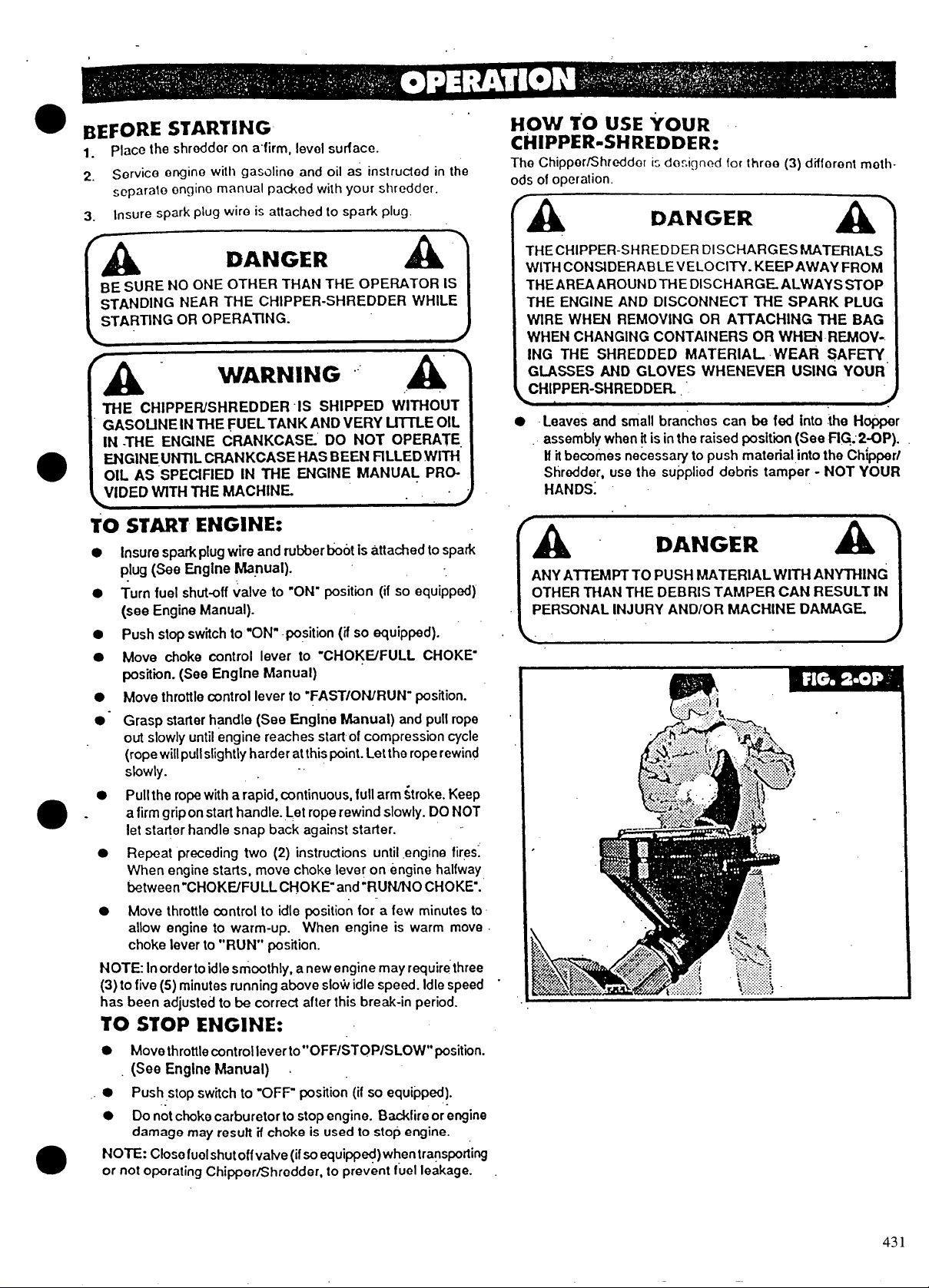

BEFORE STARTING

1- place

!?

-. —

3. Insure

A

BE

sTANDING NEAR THE CHIPPER-SHREDDER WHILE

STARTING OR OPERATING.

[

A

THE CHIPPEIVSHREDDER IS SHIPPED WITHOUT

GASOL!NE IN THE FUEL TANK AND VERY LMLE OIL

IN -THE ENGINE CRANKCASE DO NOT OPERATE

ENGINE UNllL CRANKCASE HAS BEEN FILLED WITH

VIDED WITH THE MACHINE.

the shredder on a“firm, Ievol surface.

Service Ongino with gasolino and oil as instrucfod in the

scparale engino manual packed with your shredder.

spark plug wire is attached to spark plug.

DANGER

SURE NO ONE OTHER THAN THE OPERATOR IS

A

WARNING ~

OIL AS SPEC!FIED IN THE ENGINE MANUAL PRO-

A

.,

,.

HOW To USE YOUR

CHIPPER-SHREDDER:

The ChipporC3hrcddor k do:.qned for three (3) difforont moth

ods of operation

‘A

THECHIPPER-SHREDDER DISCHARGESMATERIALS

WITH CONSIDERABLE VELOCITY. KEEP AWAY FROM

THEAREAAROUNDTHE DISCHARGE ALWAYS STOP

THE ENGINE AND DISCONNECT THE SPARK PLUG

W!RE WHEN REMOVING OR AITACHING THE BAG

WHEN CHANGING CONTAINERS OR WHEN REMOV-

ING THE SHREDDED MATERIAL

GIASSES AND GLOVES WHENEVER USING YOUR

CHIPPER-SHREDDER.

● Leaves and small branches can be fed into the Hewer

assembly when !! is in the raised

Itit

becomes necessary to push material into the Ctipper/

Shredder, use the supplied debris tamper - NOT YOUR

HANDS:

DANGER

A’

WEAR SAFETY

positiin (See FfG:2-6P).

d

TO START ENGINE:

●

Insure spark plug wire and rubber boot is attached to spark

plug (See Engine Manual).

●

Turn fuel shut-off valve to “ON” position (if so equipped)

(see Engine Manual).

Push stop switch to “ON” pq:ition (if so equipped).

Move choke control lever to “CHOKf3FULL CHOKI?

positiin. (See Engine Manual)

Move throttle control lever to ‘FAST/OWRUN” position.

Grasp starter handle (See

out slowly until engine reaches start of compression cycle

(rope will pull slightly harder at this point. Let the rope rewind

slowly.

Pull the rope with a rapid, continuous, full arm ~troke. Keep

a firm grip on start handle. Let rope rewind slowly. DO NOT

let starter handle snap back against starter. ~~

●

Repeat preceding two (2) instructions until engine fires;

When engine starts, move choke lever on engine halfway

between ”CHOKE/FULLCHOKF and”RUN/NO CHOK15.

●

Move throttle control to idle rm.ition for a few minutes to

allow engine to warm-up. When engine is warm move

choke lever to “RUN’* position.

NOTE Inorderto idle srncmthly, a new engine mayrequirethree

(3) to five (5) minutes running above slow idle speed. Idle speed

has been adjusted to be correct after this break-in period.

Engine Manual) and pull rope

.

TO STOP ENGINE:

.

Move throttle ~ntrol lever to”* OFF/STOP/SLOW” position.

(See Engine Manual) .

. Push stop switch to ‘OFF” position (if so equipped).

. Do not choke carburetor to stop engine. Backfire or engine

damage may resuft if choke is used to stop engine.

NOTE: Close fuel shutoff va~e (if so equipp+) when transporting

flOt operating Chipper/Shredder, to prevent fuel leakage.

or

(A

ANY AITEMPTTO PUSH MATERIAL WITH ANYTHING

OTHER THAN THE DEBRIS TAMPER CAN RESULT IN

PERSONAL INJURY AND/OR MACHINE DAMAGE.

DANGER

..,.,.,.,.,,.,:.

m“i

A

.

431

, “A

i

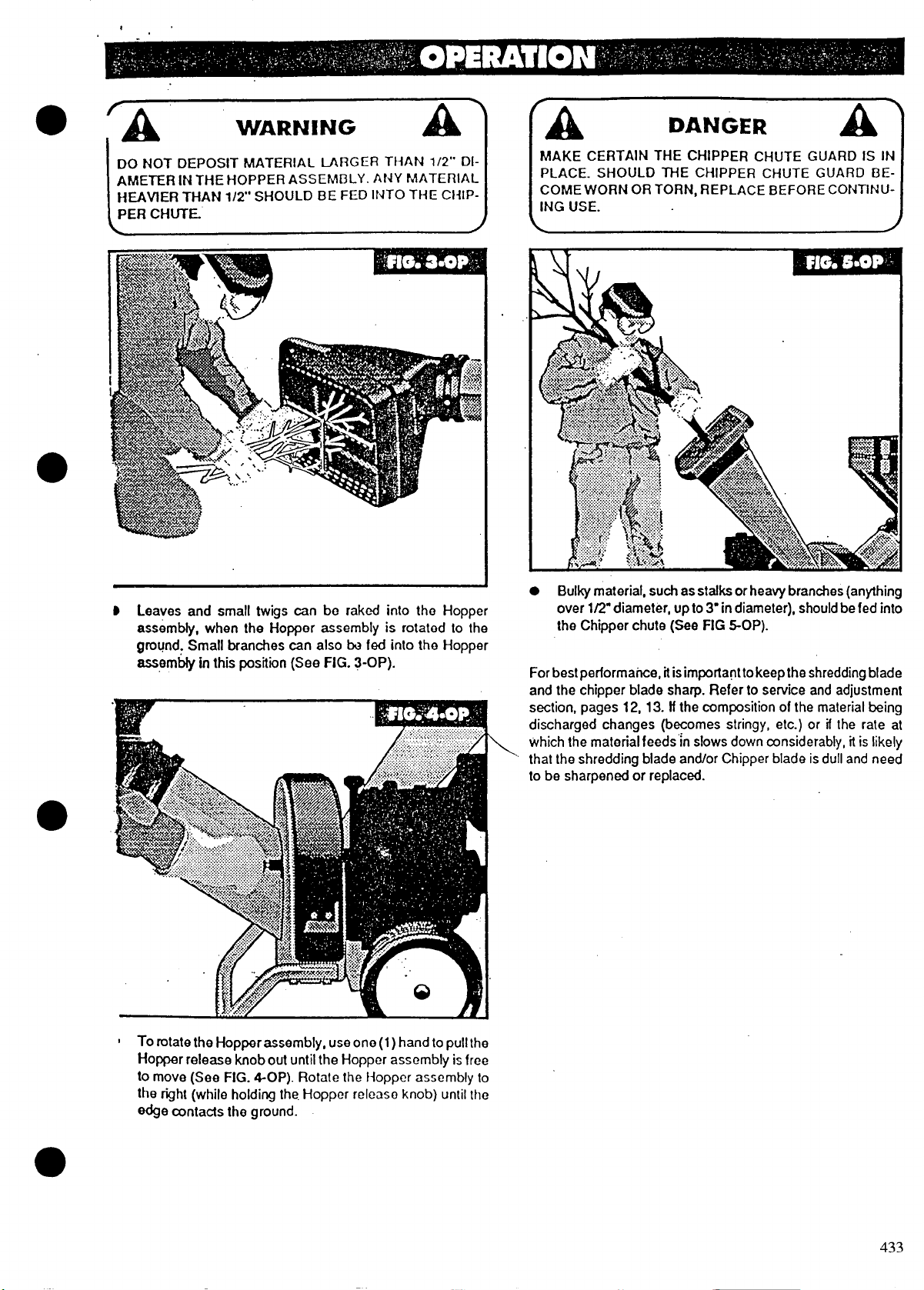

DO NOT DEPOSIT MATERIAL LARGER THAN 1/2’” DlAMETER IN THE HOPPER ASSEMBLY. ANY MATERIAL

HEAVfER THAN 1/2”’ SHOULD BE FED INTO THE Cti[P-

PER CHUTE.

I

WARNING

A“

r

A

MAKE CERTAIN THE CHIPPER CHUTE GUARD IS IN

PLACE. SHOULD THE CHIPPER CHUTE

COME WORN OR TORN, REPLAcE BEFORE CONTINU-

ING USE.

DANGER

A’

GUARD BE-

AI \l /

D Leaves and small twigs can be raked into thG Hoppe

assembly, when the Hopper assembly is rotatod to th,

ground: Small branches can also be fed into the

zu+crmbfy in this position (See FIG. 3-OP).

Hoppe

Bulky material, such as stalks or heavy branches (anything

●

over 1/2” diameter, up to 3“ in diameter), should be fed into

the Chipper chute (See

For best performance, itisimportant tokeepthe shredding blade

and the chipper blade sharp. Refer to service and adjustment

section, pages 12, 13. If the composition of the material being

discharged changes (becomes stringy, etc.) or il the rate at

which the material feeds’~n slows down considerably, it is likely

that the shredding blade and/or Chipper blade is dull and need

to be sharpened or replaced.

FIG 5-OP).

‘ To rotate the Hopper assembly, use one (1 ) hand to pullth

Hopper release knob out until the Hopper assembly is fre

to move (See FIG. 4-OP). Rotate the Hopper assembly t

the right (while holding the Hopper

edge contacts the ground.

releaso knob) until th

433

—

●

LA

ALWAYS STOP ENGINE AND DISCONNECT SPARK

PLUG WIRE BEFORE CLEANING, LUBRICATING OR

PERFORMING

GENERAL RECOMMENDA’fiONS:

.

Periodically check all fasteners and be sure they are tight.

● Follow the Service Recommendation Schedule, in SERVICE

AND ADJUSTMENT

CHIPPER/SHREDDER LUBRICATION:

Lubricate the transport wheel hubs occasionally, with a

good quafii motor oil.

The rotating Hopper assembly requires lubricating 10

maintain optimum performance. Approximately every fiie

(5) hours of operation, before each use, and before storage,

Iubriite the Hopporassembly rotating plate. Using a hand

grease gun, filled with a good quality, all-purpose grease,

lubricate the three (3) zerk fittings found on the Hopper

assembly retainer ring.

Fill each zerk with approximately five

Rotate Hopper assembly to the ground as shown in FIG.!! OP and apply five (5) more shots of grease to each of the

three (3) zerks. Rotate Hopper assembly several times to

spread lubricant around. NOTE: Should Iubr”kati.ng the

Hopper assembly fail to provide adequate rotat”mn, remove

the entire Hopper assembly from unit (See FIG.2-SERV).

Clean debris from all rotating parts, repface or repair any

damaged parts, reassemble Hopper assembly securely to

unit and lubricate according to procedure above.

Caster wheel (optional) approximately every ten (1O)hours

of operation and befo~e storage, lubricate-the ze~ fitting

found above the caster wheel with three (3) shots of a good

quality, all purposo grease.

●

ENGINE LUBR1CATION: ‘“

Refer to the separate engine manual for engine maintenance

instructions. Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow instructions carefully.

AIR CLEANER -

Service aircleanerevery (25) hours or every season, which eve!

comes first. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding usua.fly indi.

cates that the air cleaner should be setviced. To service the ail

cleaner, refer to the separate engine mairual packed with youl

unit.

NOTE Never run your engine without air cleaner completel~

assembled.

- DANGER

ANY REPAIRS OR MAINTENANCE.

section of this manual.

(5) shots of grease.

A)

SPARK PLUG

The. spark plug should be cfoaned and the gap reset once ;

season or every (50) hours of operation (See Engine Manuaf)

Spark plug roplacomonl is recommended at the starl of eat}

season; check engine manuat for correct pkrg type and

specifications.

ga~

CLEAN ENGINE

Clean engino periodically. Remove dirt and debris with a cloth

or brush. Cleaning with a forceful spray of water is not remm.

mended as water could contaminate the fuel system. Yearfy or

every twenty-five (25) hours, which ever occurs first, re’movethe

blower housing and dean the ,@reas shown in your Engine

Manual to avoid over-speeding, over-heating end engine damage. Clean more often if necessary.

,,

MUFFLER

Do not operate the Chipper/Shredder Withoq a muffler or

tamper with the exhaust system. Damaged mufflers or spark

arresters could geate

replace if necessary. If your engine is equipped with a spark

arrester screen assembly, remove every ffiy (50) hours for

cleaning and insp~ion. Replace if damaged.

a fire hazard. Inspect periidk.aily and

CLEANING

. The

● Wash !hebag periodicatlywtih water. Allow to dry thoroughly

Chipper/Shredder may be cleaned by running water

from a hcce through the Shredder Hopper assembly and

Chipper chute with engine running. Allow the Chipper/

Shredder to dry thoroughly.

in the shade. Do Not use heat.

●

FUEL FILTER (IF SO EQUIPPED)

Fuel filter should be rcrplacod once each season. If fuel filte

becomes clogged, obstructing fuel flow to carburetor, replace

ment is required. To service tho air cleaner, refer to the sepa

rate engine manual packed with ‘your unit.

435

.

Loading...

Loading...