Mazda RX-7 1989 Service Highlights

RX-7

CONTENTS

•

TITLE

ENGINE

LUBLICATION

COOLING SYSTEM

FUEL AND EMISSION

CONTROL

-----

---

FUEL AND EMISSION

CONTROL

ENGINE ELECTRICAL SYSTEM

MANUAL

AUTOMATIC TRANSMISSION

(ELECTRONICALLY -CONTROLLED)

FRONT AND REAR AXLES

STEERING SYSTEM

BRAKING SYSTEM

SUSPENSION

BODY 14

BODY ELECTRICAL SYSTEM 15

-

--

--

---

--

--

-

SYSTEM

-

SYSTEMS

--- ---

SYSTEMS (TURBO)

--

TRANSMISSION

--

----

(NON-

----

-

--

-

-----

TURBO)

---

--

SECTION

1

2

3

4

5

7

9

10

11

13

•

c

-

ENGINE

OUTLINE

..................................................

C-

2

OUTLINE OF CONSTRUCTION

.................

C-

2

STRUCTURAL VIEW

................................

C-

2

SPECIFICATIONS

....................................

C-

4

INTERCHANGEABILITY

............................

C-

5

TENSION BOLT

........................................

C-

6

FRONT COVER

.........................................

C-

7

ROTOR

....................................................

C-

8

97UOCX

501

e

e

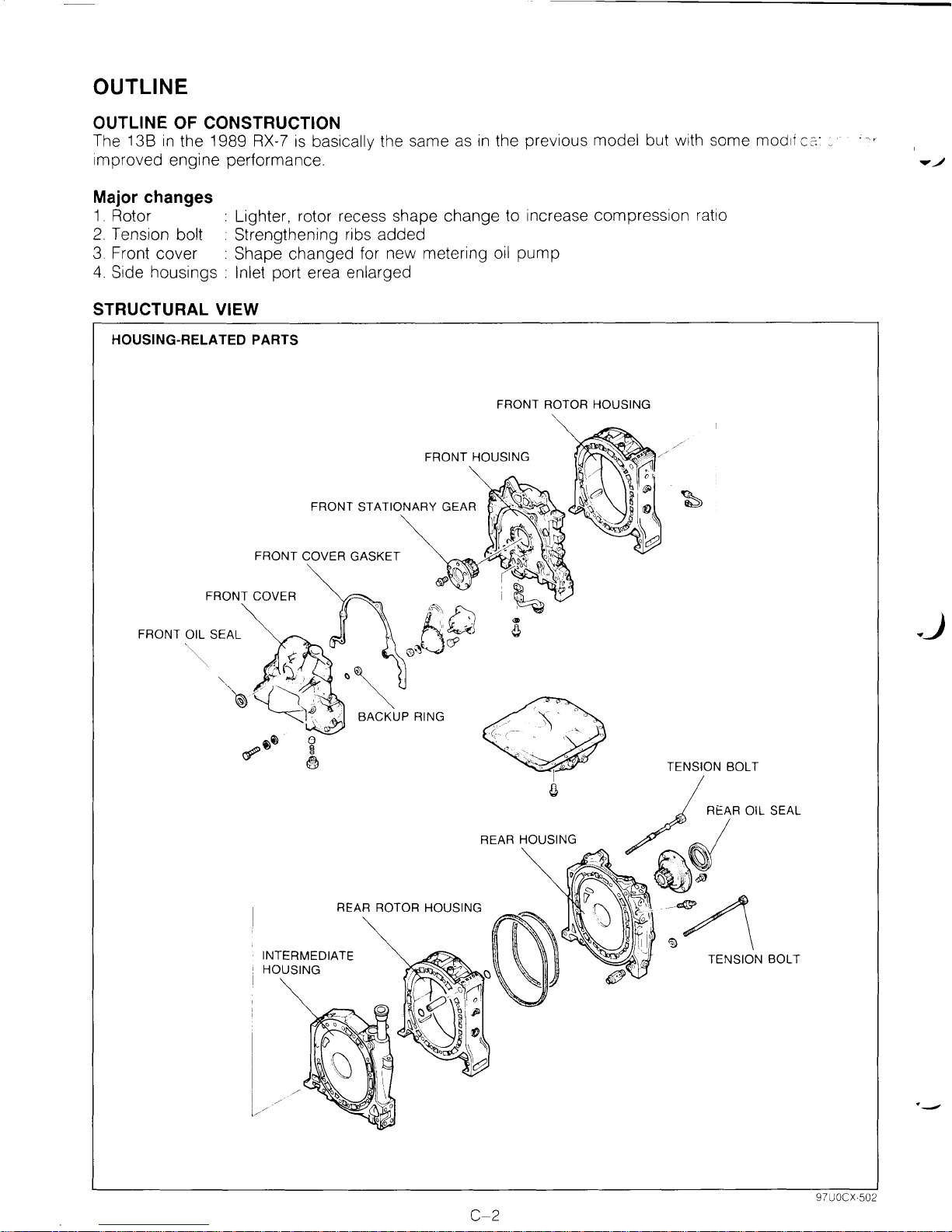

OUTLINE

OUTLINE OF CONSTRUCTION

The 13B

in

the 1989

RX-7

is

basically the same as

in

the previous model but with some modli

c:=:-

_

improved engine performance.

Major changes

1.

Rotor : Lighter, rotor recess shape change to increase compression ratio

2.

Tension bolt : Strengthening ribs added

3.

Front cover : Shape changed for new metering

oil

pump

4.

Side housings : Inlet port erea enlarged

STRUCTURAL VIEW

HOUSING-RELATED PARTS

FRONT ROTOR HOUSING

FRONT HOUSING

FRONT OIL SEAL

REAR HOUSING

REAR ROTOR HOUSING

INTERMEDIATE

HOUSING

C-2

97UOCX·502

._)

·-

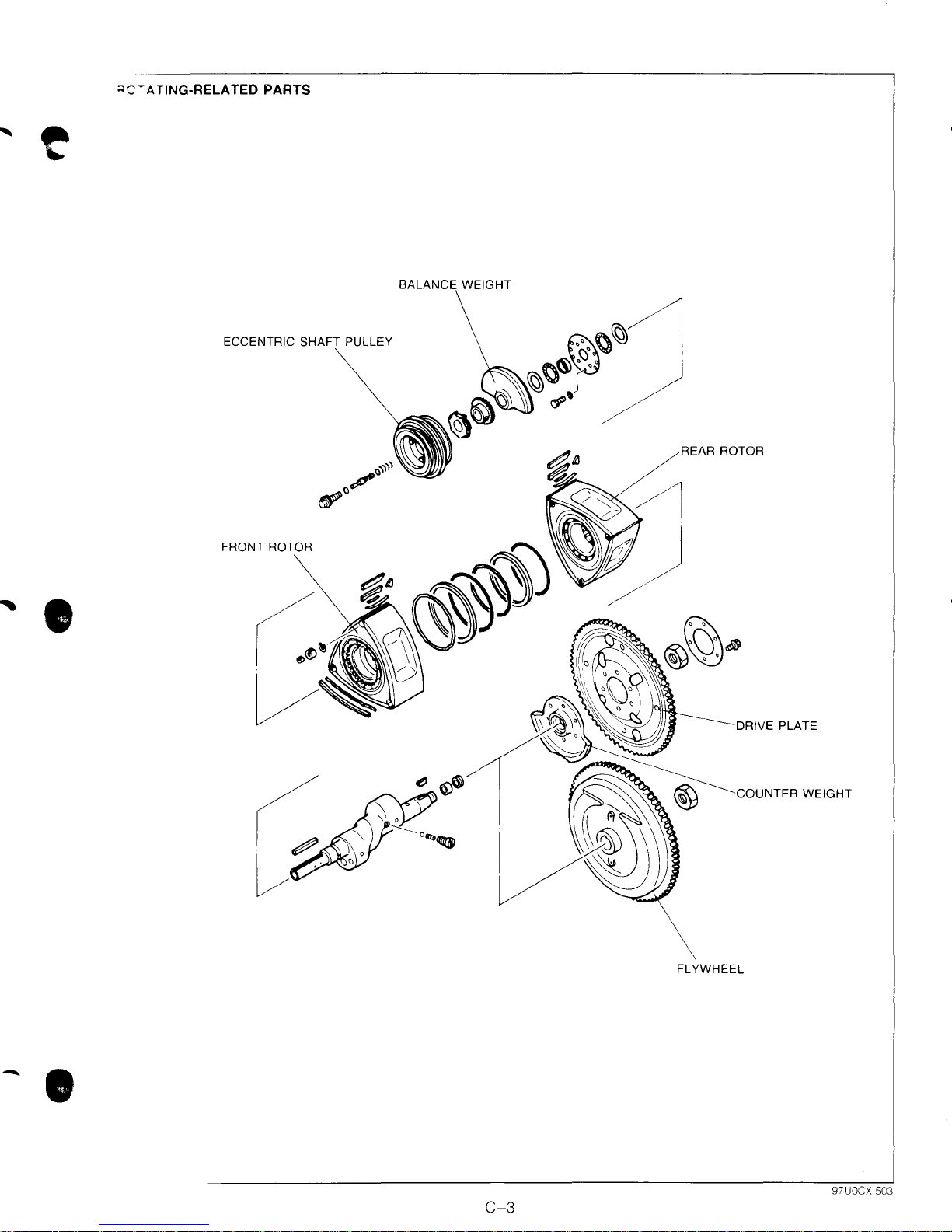

;:;'"'TA

~

TING-RELATED

PARTS

BALANCE WEIGHT

ECCENTRIC PULLEY

REAR ROTOR

' •

FRONT ROTOR

DRIVE PLATE

COUNTER WEIGHT

FLYWHEEL

-.

C-3

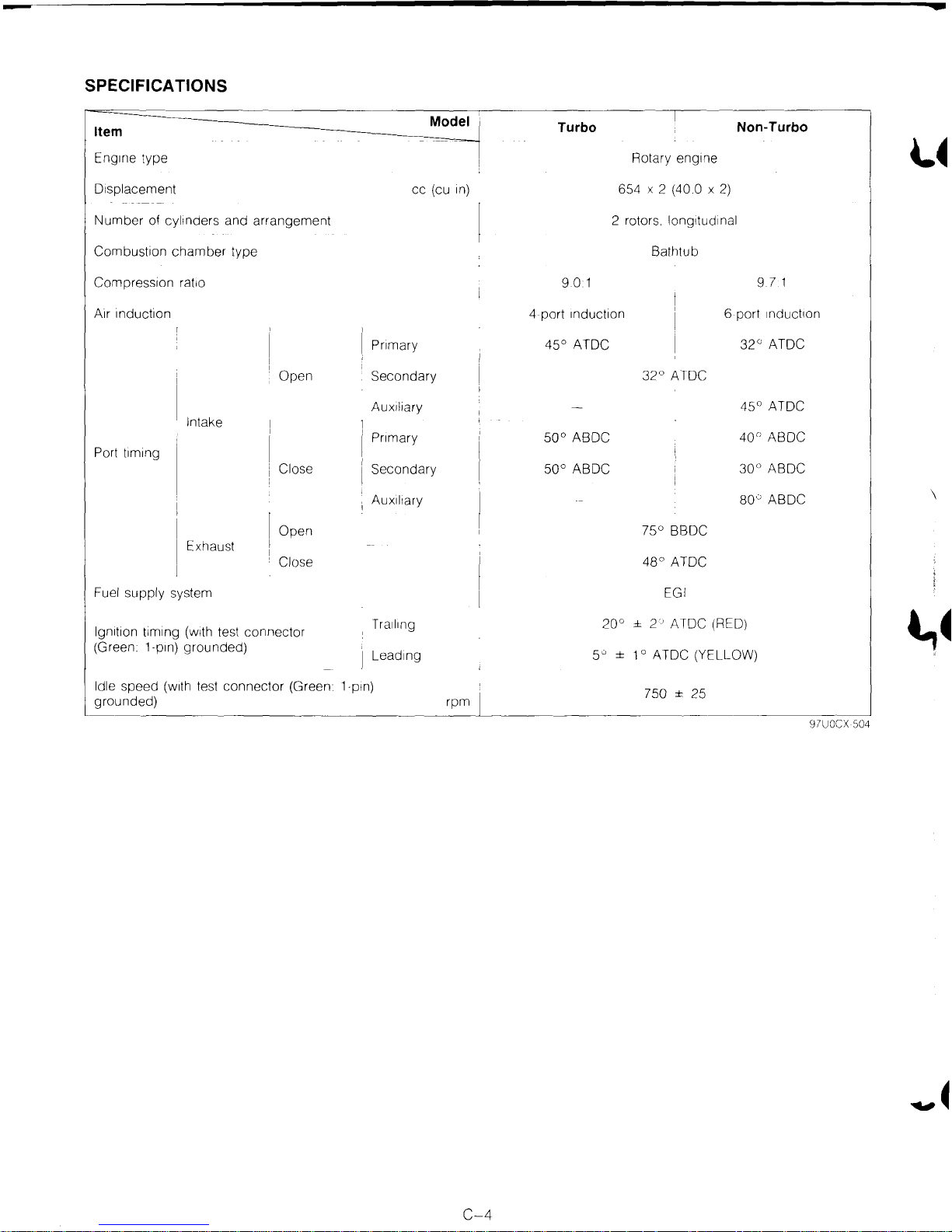

SPECIFICATIONS

cc

Model

(cu

1n)

Item

Eng1ne type Rotary eng1ne

Displacement

Number

Combustion

Compression

A1r

Port

of cyl1nders and

chamber

Induction

t1m1ng

rat10

Intake

Exhaust

arrangement

type

Open

Close

Open

Close

Pnmary 4S0 ATOC

Secondary

Auxiliary

Pnmary

Secondary

Auxil1ary

Turbo Non-Turbo

6S4 X 2 (40.0 X

2 rotors. longitudinal

Bathtub

9.0 1

4 port

1nduct1on

32°

ATOC

S0°

ABOC

soo

ABOC

0

7S

BBDC

48°

ATOC

2)

6 port

32°

4S

40°

30°

80"

9.7 1

1nduct1on

ATOC

0

ATOC

ABOC

ABOC

ABOC

~~

\

Fuel

supply

lgn1t1on

(Green

Idle

grounded)

t1ming

1-p1n)

speed

system EGI

(w1th

grounded)

(w1th

test

test

connector

connector

(Green

Tra1l1ng

Lead1ng

1-pln)

rpm

± 2 ' ATOC (REO)

20°

so

±

1 o ATOC (YELLOW)

750 ± 25

l,~

97UOCX 504

C-4

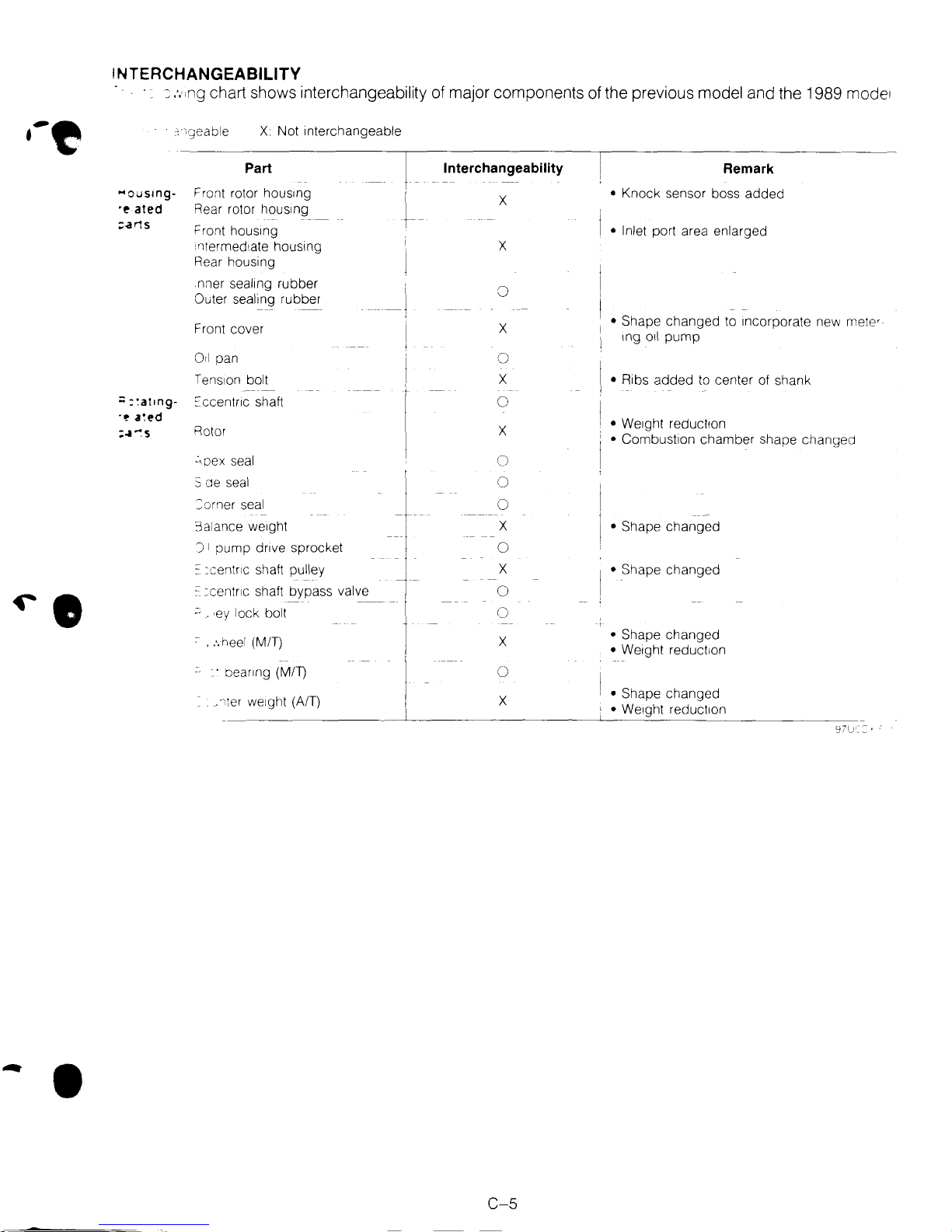

INTERCHANGEABILITY

:::

,.,,ng

chart shows interchangeability of major components of the previous model and the 1989 mode'

X Not interchangeable

...

ousmg-

·~

ated

;:.a

r1S

;;

:~at1ng-

-~

a~ed

=~~s

Part

Front rotor hous1ng

Rear rotor hous1ng

Front

hous1ng

i ntermed1ate housing

Rear housing

seal1ng

nner

Outer sealing rubber

Front cover

Orl

pan

Tens1on

::ccentnc shaft

Rotor

~~pex

S de

seal

:::orner

3a',ance weight I

J I pump dnve sprocket

: :centr1c

'C

=centnc shaft bypass valve - -

~

. ·ey lock bolt

~

.

:.

heel

• · beanng

.1ter

rubber

bolt

seal

seal

shaft pulley t

(MIT)

(MIT)

we1ght

(A/T)

-1

. -

i

---1

I

+

J

-~·

.

l

I,

Interchangeability

X

X

0

X

0

X

0

X

0

0

0

X

0

X

0

0

X

0

X

Remark

• Knock sensor boss added

• Inlet port area enlarged

• Shape changed to Incorporate new

tng

Oil

pump

• Ribs added

•

We1ght

•

Combustion chamber shape changed

• Shape changed

• Shape changed

• Shape changed

•

We1ght

•

Shape changed

•

We1ght

'

to

center of shank

reduct1on

reduct1on

reduct1on

metw

•

C-5

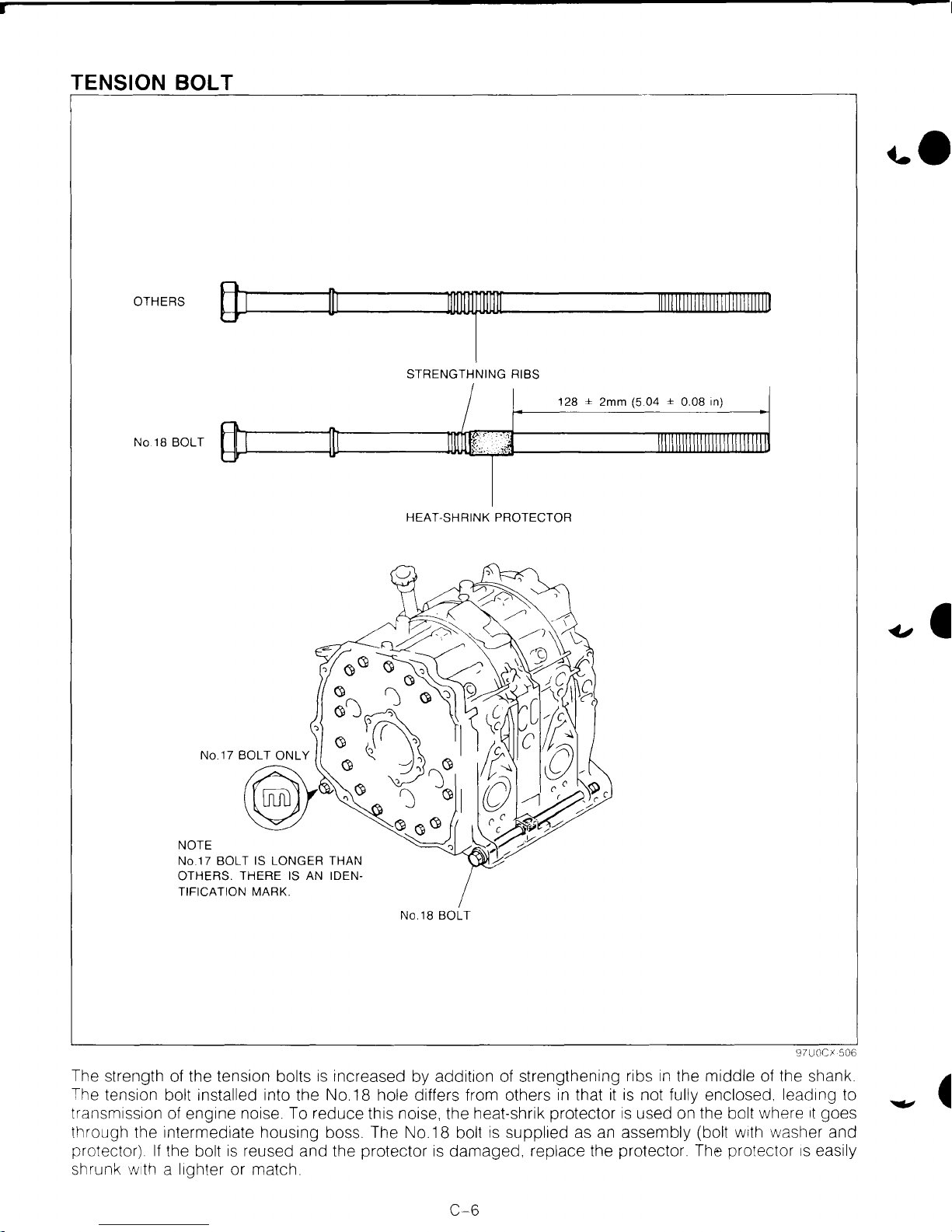

TENSION BOLT

OTHERS

(}1

No.18 BOLT

NOTE

No.1? SOL

T IS LONGER THAN

OTHERS. THERE IS AN IDENTIFICATION

MARK.

T

lllllllllllllllllllllllllllllll

STRENGTHNING RIBS

128 ± 2mm

(5.04 ± 0.08 in)

HEAT-SHRINK PROTECTOR

No.18 BOLT

97UOCI 506

The strength of the tension bolts

1s

increased by addit1on of strengthening ribs

in

the middle of the shank.

The tension

bolt installed into the No. 18 hole differs from others

in

that

it

is

not fully enclosed. lead1ng to

transmiss1on of eng1ne noise. To reduce this noise. the heat-shrik protector

is

used on the bolt where

1t

goes

through the intermediate housing boss. The No. 18

bolt

is

supplied as an assembly (bolt

w1th

washer and

protector).

If

the bolt

is

reused and the protector

is

damaged, replace the protector. The protector

1s

easily

shrunk

w1th

a l1ghter or match.

C-6

...

,

.•

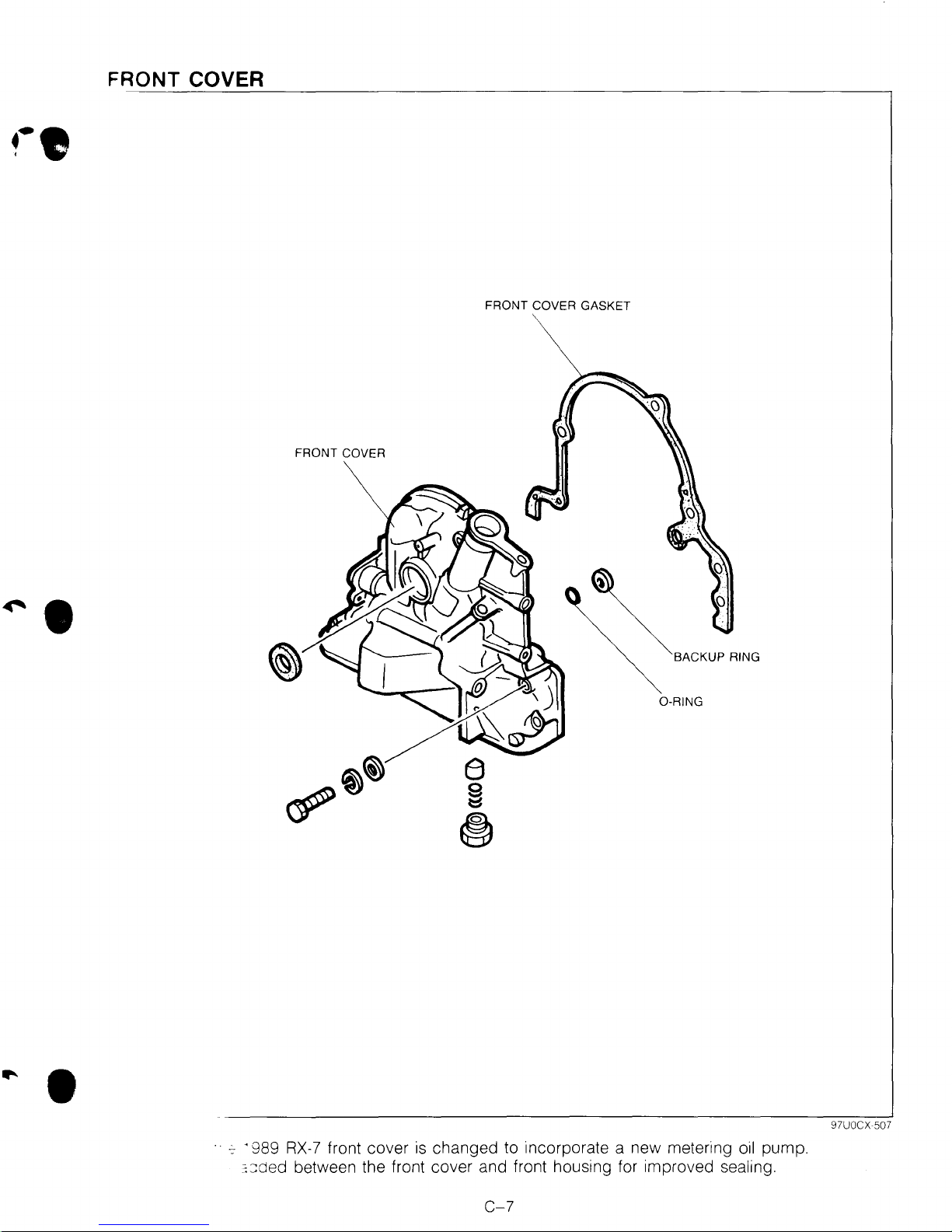

FRONT COVER

FRONT COVER GASKET

FRONT COVER

~.

~BACKUP

0-RING

RING

•

~

· 989

RX-7

:::::ded

between the front cover and front housing for improved sealing.

front cover

is

changed to incorporate a new metering

C-7

oil

97UOCX 507

pump.

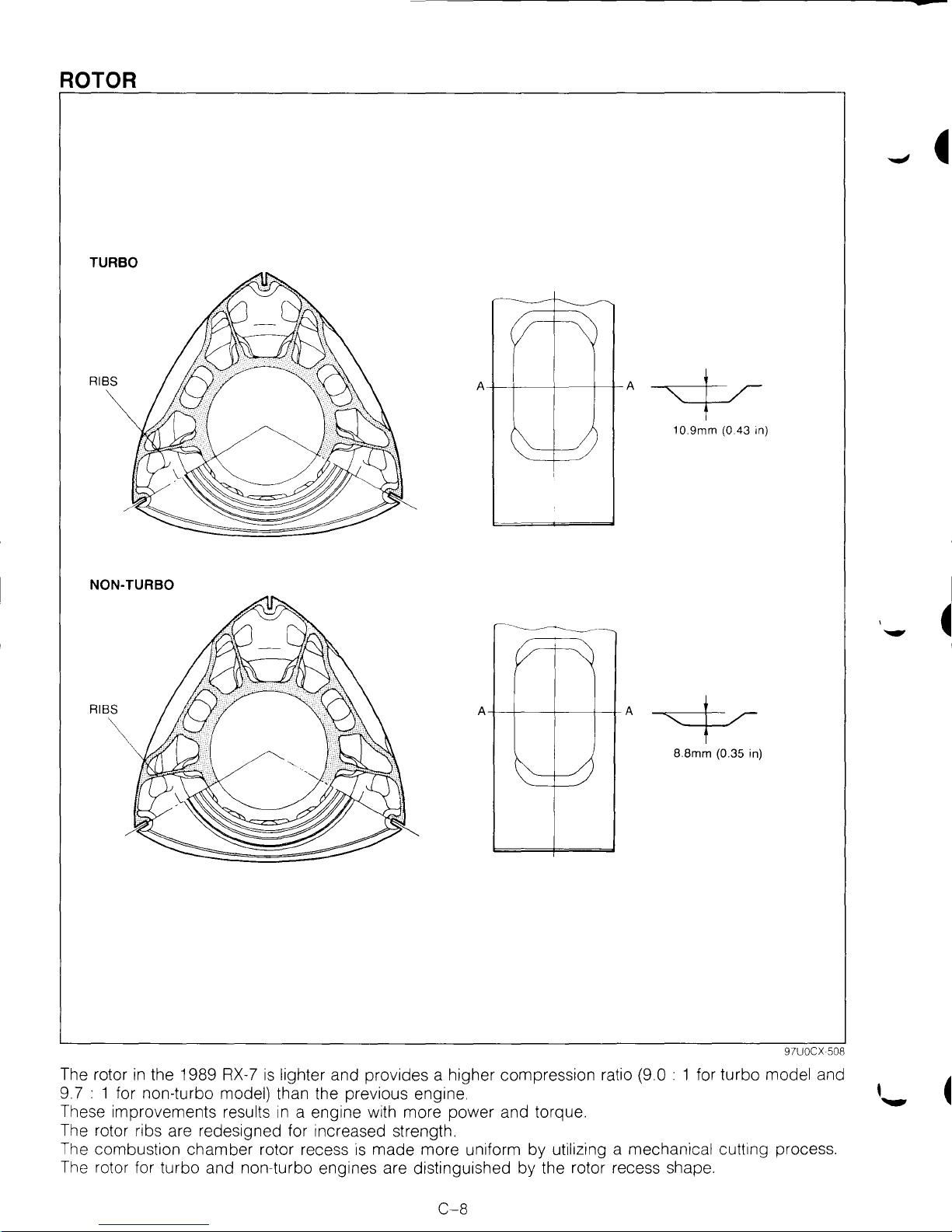

ROTOR

TURBO

RIBS

NON-TURBO

RIBS

~

~

\

A

/J

I

c--~~

v

A A

~

A~

1 0.9mm (0.43 in)

,_

4

8.8mm (0.35 in)

r---/1

~-

The rotor

9.7 :

These improvements

The rotor ribs are redesigned for increased strength.

The combustion chamber rotor recess

The rotor for turbo and non-turbo engines are distinguished by the rotor recess shape.

in

the 1989

1 for non-turbo model) than the previous engine.

RX-7

results

is

lighter and provides a higher compression ratio (9.0 : 1 for turbo model and

in

a engine with more power and torque.

1s

made more uniform by utilizing a mechanical cutting process.

97UOCX 508

C-8

D

...

LUBRICATION SYSTEM

OUTLINE

..................................................

D-

2

OUTLINE OF CONSTRUCTION

.................

D-

2

STRUCTURAL VIEW

................................

D-

2

SPECIFICATIONS

....................................

D-

3

INTERCHANGEABILITY

............................

D-

3

METERING OIL PUMP

...............................

D-

4

OUTLINE

...............................................

D-

4

OPERATION

...........................................

D-

5

FAIL-SAFE FUNCTION

.............................

D-

5

SERVICE POINT

.......................................

D-

6

OIL FILTER

............................................

D-

6

97UODX 501

-

-

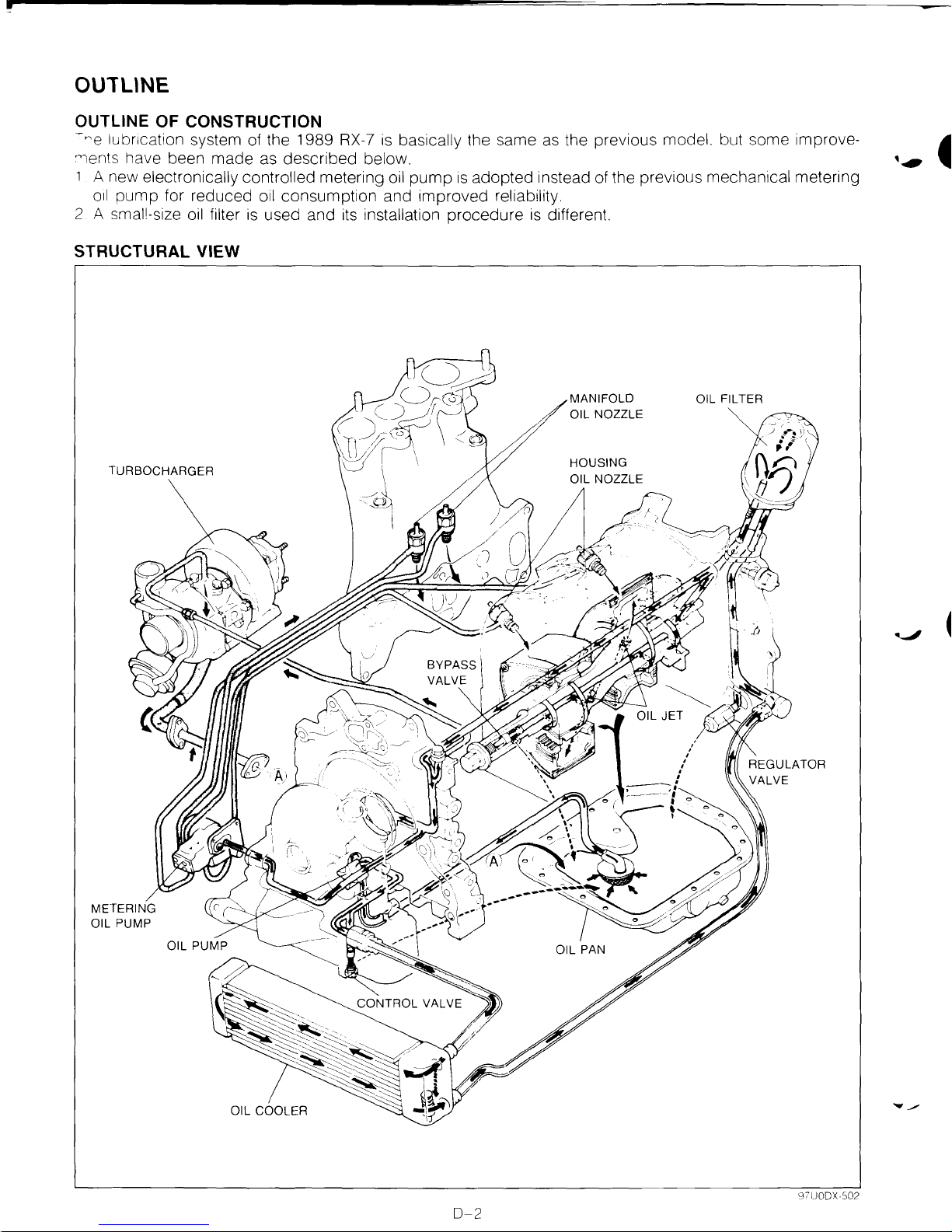

OUTUNE

OUTLINE OF CONSTRUCTION

-~e

lubncation system of the 1989

"lents have been made

1 A new electronically controlled metering

oil

pump for reduced

2 A smal!-size

oil

filter

as

described below.

oil

consumption and improved reliability.

is

used and

STRUCTURAL VIEW

RX-7

its

installation procedure

is

basically the same

oil

pump

is

adopted instead

as

the previous model. but some improve-

of

the previous mechanical metering

is

different.

MANIFOLD

OIL NOZZLE

TURBOCHARGER

HOUSING

0-2

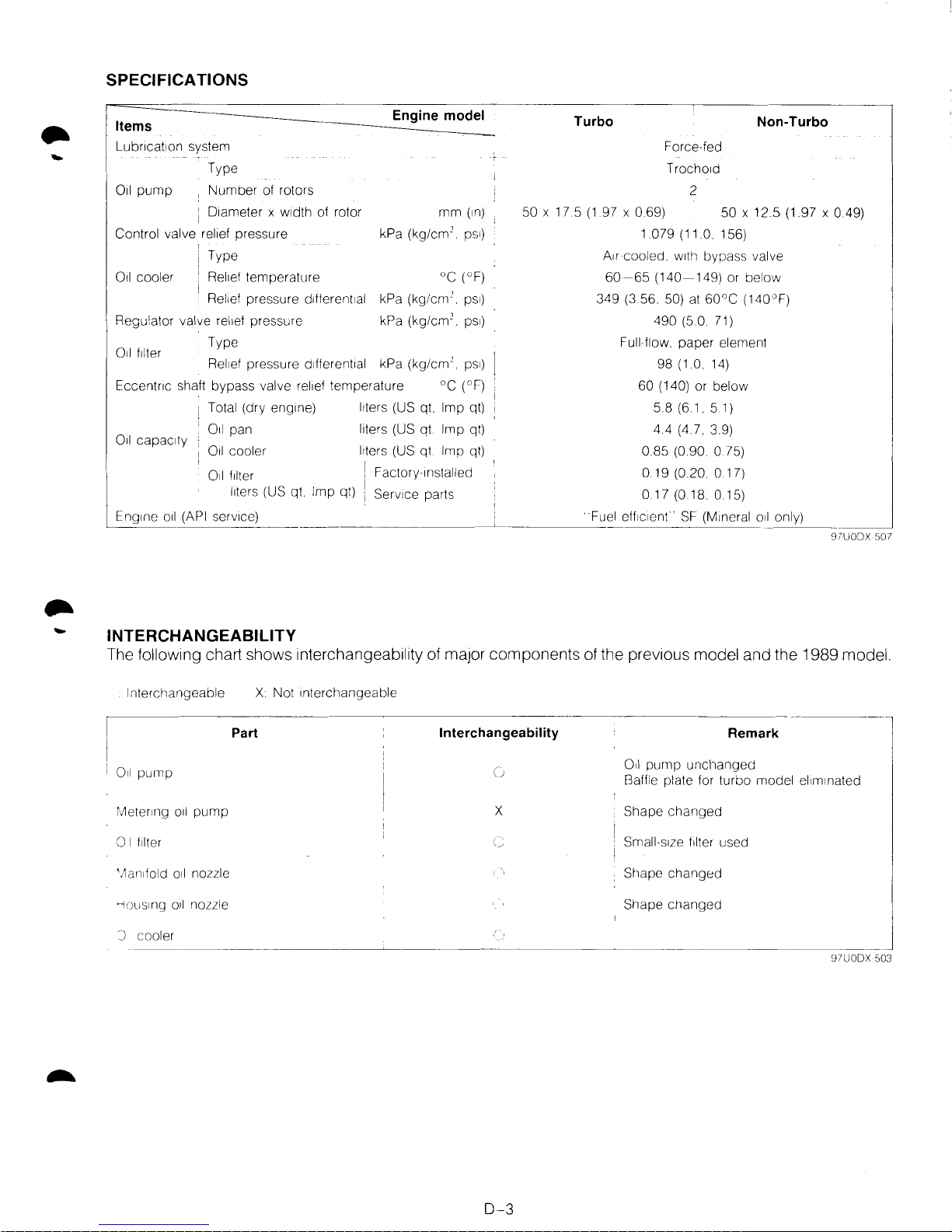

SPECIFICATIONS

Items

Engine model

Lubncat1on system

Type

011

pump

1

Number

of rotors

1 D1ameter x

w1dth

of rotor

Control valve relief pressure

mm

(1n)

kPa (kg/cm

2

.

ps1)

Oil cooler

Type

Rel1ef

temperature

oc

(°F)

Rel1ef

pressure dlfferent1al kPa

(kg/em'.

ps1)

Regulator valve

rel1ef

pressure kPa

(kg/em'.

ps1)

Type

Oil filter

Rel1ef

pressure

d1fferent1al

kPa

(kg/em'.

ps1)

Eccentnc shaft bypass valve

rel1ef

temperature

oc

(°F)

Oil

capaCity

Total (dry

eng1ne)

l1ters

(US qt. Imp qt)

011

pan

Oil cooler

liters

(US qt. Imp qt)

l1ters

(US

qt

Imp

qt)

\ F

011

filter , actory-1nstalled

I

l1ters

(US qt Imp qt) i Serv1ce parts

Turbo

Force-fed

Trocho1d

2

Non-Turbo

50 X 17.5

(1

97 X

069)

50 X 12.5 (1.97 X 0.49)

1.079 (11.0.

156)

A1r

cooled.

w1th

bypass valve

60-65

(140-149)

or below

349

(3

56. 50)

at

60°C

(140"F)

490 (5.0. 71)

Full flow.

paper

element

98

(1.0. 14)

60 (140) or below

5.8 (6 1 5.1)

4.4 (4.7. 3

9)

0.85 (0.90. 0

75)

0.19 (0.20 0 17)

0.17 (0.18. 0 15)

Eng1ne

oil

(API

serv1ce)

Fuel

eff1c1enr·

SF

(M1neral oil only)

_____

_[_________

----

___

_j

97UODX

507

INTERCHANGEABILITY

The following chart shows interchangeability of major components of the previous model and the 1989 model.

Interchangeable X Not Interchangeable

Part

Interchangeability

Remark

011

pump

Oil

pump

unchanged

Baffle plate for turbo model

el1m1nated

rl1eterlllg

oil

pump

X

Shape

changed

0 I

f1lter

Small-s1ze filter used

Shape

changed

--1ous1ng

oil

nozzle Shape cr1anged

J

_c_o_o_le_r

______________

~

______________________________

j

97UODX

503

0-3

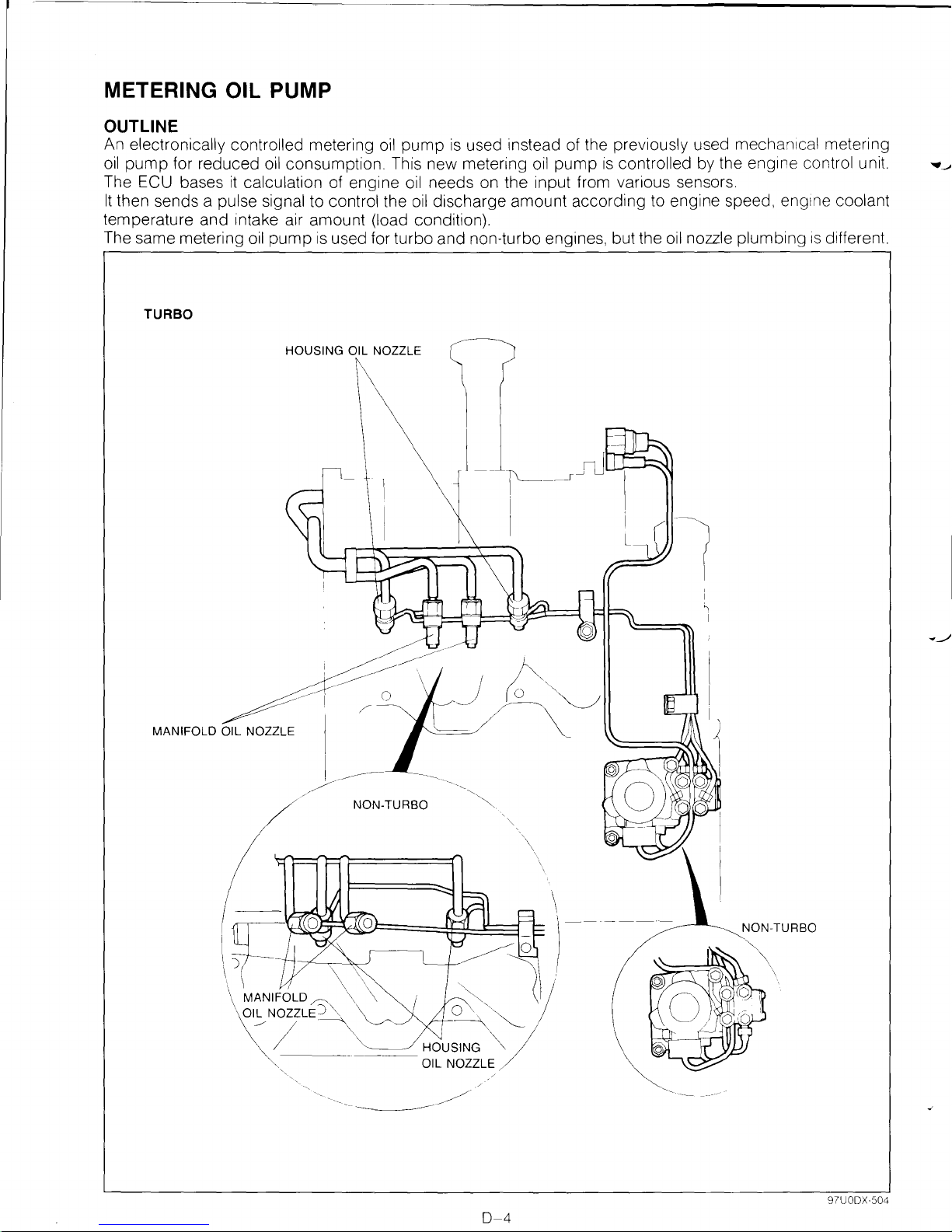

METERING OIL PUMP

OUTLINE

An electronically controlled metering

oil

pump

The ECU bases

It

then sends a pulse signal to control the

for reduced

it

calculation of engine

oil

consumption. This new metering

temperature and intake air amount (load condition).

The same metering

TURBO

oil

pump

is

used for turbo and non-turbo engines, but the

HOUSING OIL NOZZLE

oil

pump

is

used instead of the previously used mechan1cal metering

oil

needs on the input from various sensors.

oil

discharge amount according to engine speed,

oil

pump

is

controlled by the

oil

nozzle plumbing

eng1ne

eng1ne

control unit.

coolant

1s

different

...

~

MANIFOLD OIL NOZZLE

NON-TURBO

~

I

NON-TURBO

97UODX·504

0-4

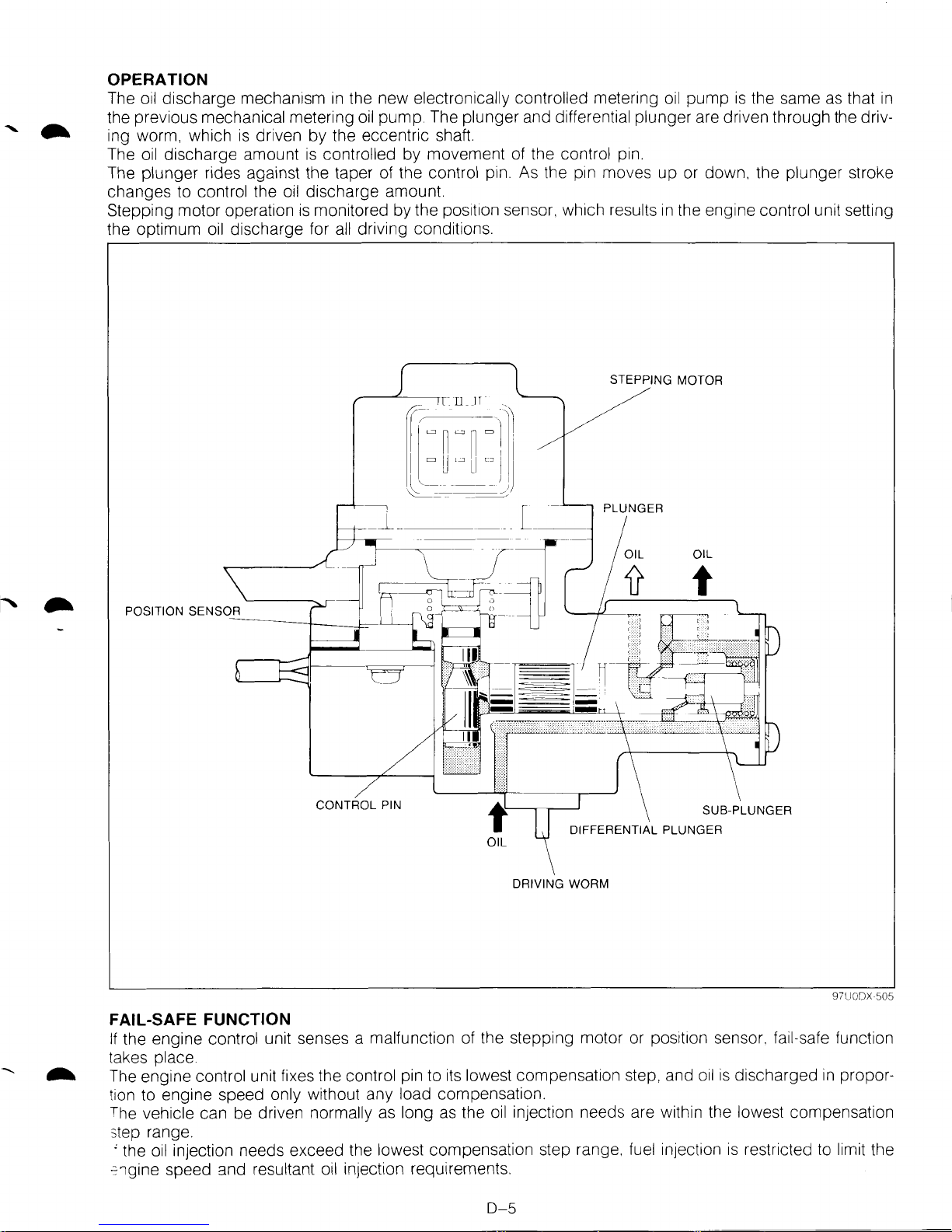

OPERATION

The

oil

discharge mechanism

in

the new electronically controlled metering oil pump

is

the same

as

that

in

the previous mechanical metering

oil

pump. The plunger and differential plunger are driven through the driv-

ing worm, which

is

driven by the eccentric shaft.

The

oil

discharge amount

is

controlled by movement

of

the control

p1n.

The plunger rides against the taper

of

the control pin.

As

the

p1n

moves up or down, the plunger stroke

changes to

control the

oil

discharge amount.

Stepping motor operation

is

monitored by the

pos1t1on

sensor, which results

in

the engine control unit setting

the optimum

oil

discharge for

all

driving conditions.

CONTROL PIN

f

OIL

FAIL-SAFE FUNCTION

STEPPING MOTOR

/

SUB-PLUNGER

DIFFERENTIAL PLUNGER

DRIVING WORM

97UODX 505

If

the engine control unit senses a malfunction of the stepping motor or

posit1on

sensor. fail-safe function

takes

place.

The engine control unit fixes the control pin to

its

lowest compensation step, and

oil

is

discharged

in

propor-

tion to engine speed

only without any load compensation.

The

vehicle can be driven normally

as

long

as

the

oil

injection needs are within the lowest compensation

step range.

' the

oil

injection needs exceed the lowest compensation step range. fuel injection

is

restricted to limit the

~1gine

speed and resultant oil injection requirements.

D-5

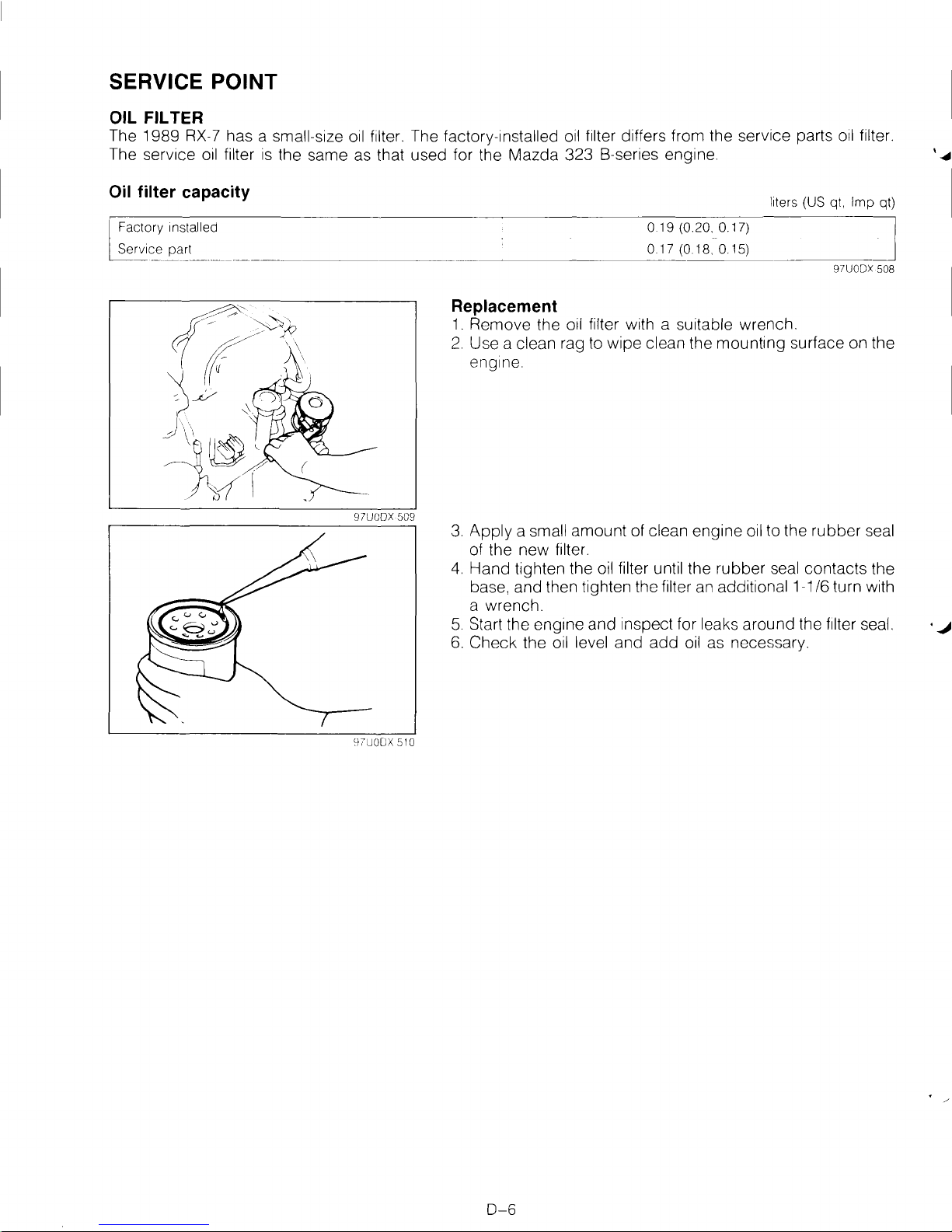

SERVICE POINT

OIL FILTER

The 1989

The service oil filter

RX-7

has a small-size

is

oil

filter. The factory-installed oil filter differs from the service parts oil filter.

the same as that used for the Mazda 323 B-series engine. '

.....

Oil filter capacity

ctory 1nstalled

rvice part

-

--·-----·-----

019

0.17

(0.20, 0.17)

(0

18.

0.15)

liters (US qt,

_,]

Imp

qt)

97UODX 508

Replacement

1.

Remove the oil filter with a suitable wrench.

2.

Use a clean rag to wipe clean the mounting surface on the

engine.

3.

Apply a small amount of clean engine oil to the rubber seal

of the new filter.

4.

Hand tighten the oil filter until the rubber seal contacts the

base, and then tighten the filter an additional 1-1/6 turn with

a wrench.

5.

Start the engtne and inspect for leaks around the filter seal. ·

6.

Check the oil level and

add

oil as necessary.

.J

0-6

COOLING SYSTEM

E

OUTLINE

OUTLINE OF CONSTRUCTION

STRUCTURAL VIEW

SPECIFICATIONS

INTERCHANGEABILITY

COOLING FAN

WATER PUMP

THERMOSTAT

RADIATOR

..................................................

................................

....................................

............................

..........................................

..........................................

..........................................

...............................................

..................

E-

EEE-

E-

EEEE-

97UOEX 501

2

2

2

3

3

4

5

6

7

-

OUTLINE

OUTLINE

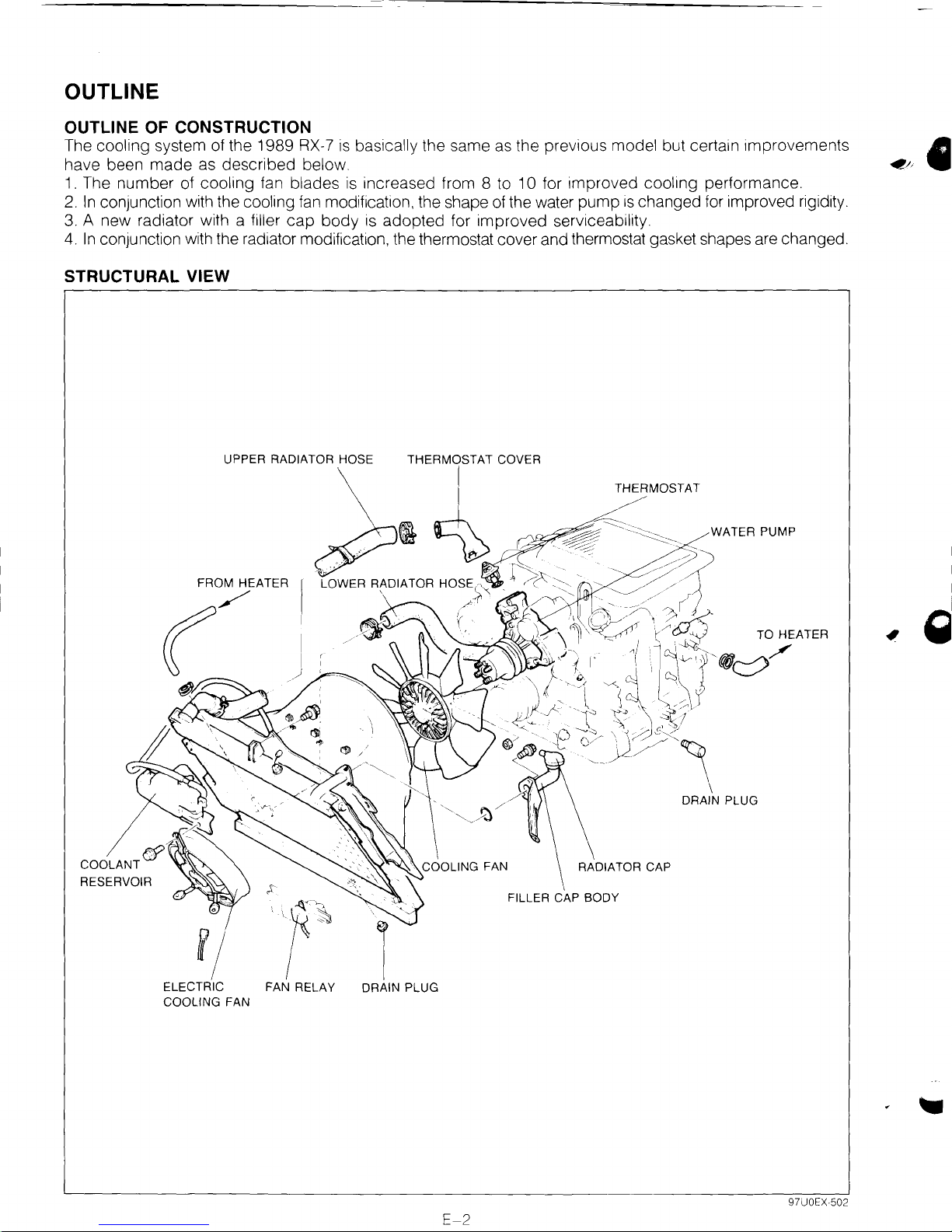

The cooling system of the 1989

have been

1.

The number of cooling fan blades

2.

In

3.

A new radiator with a filler

4.

In

OF

CONSTRUCTION

RX-7

is

basically the same as the previous model but certain improvements

made

conJunction with the cooling

conjunction with the radiator modification, the thermostat cover and thermostat gasket shapes are changed.

as described below.

fan

modification, the shape of the water pump

cap

body

is

increased from 8 to 1 0 for improved cooling performance.

is

changed for improved rigidity.

is adopted for improved serviceability.

STRUCTURAL VIEW

THERMOSTAT

~

WATER PUMP

RESERVOIR

FROM HEATER

(/

fj

ELECTRIC

COOLING

FAN

FAN RELAY

RADIATOR CAP

FILLER CAP BODY

DRAIN PLUG

97UOEX-502

E-2

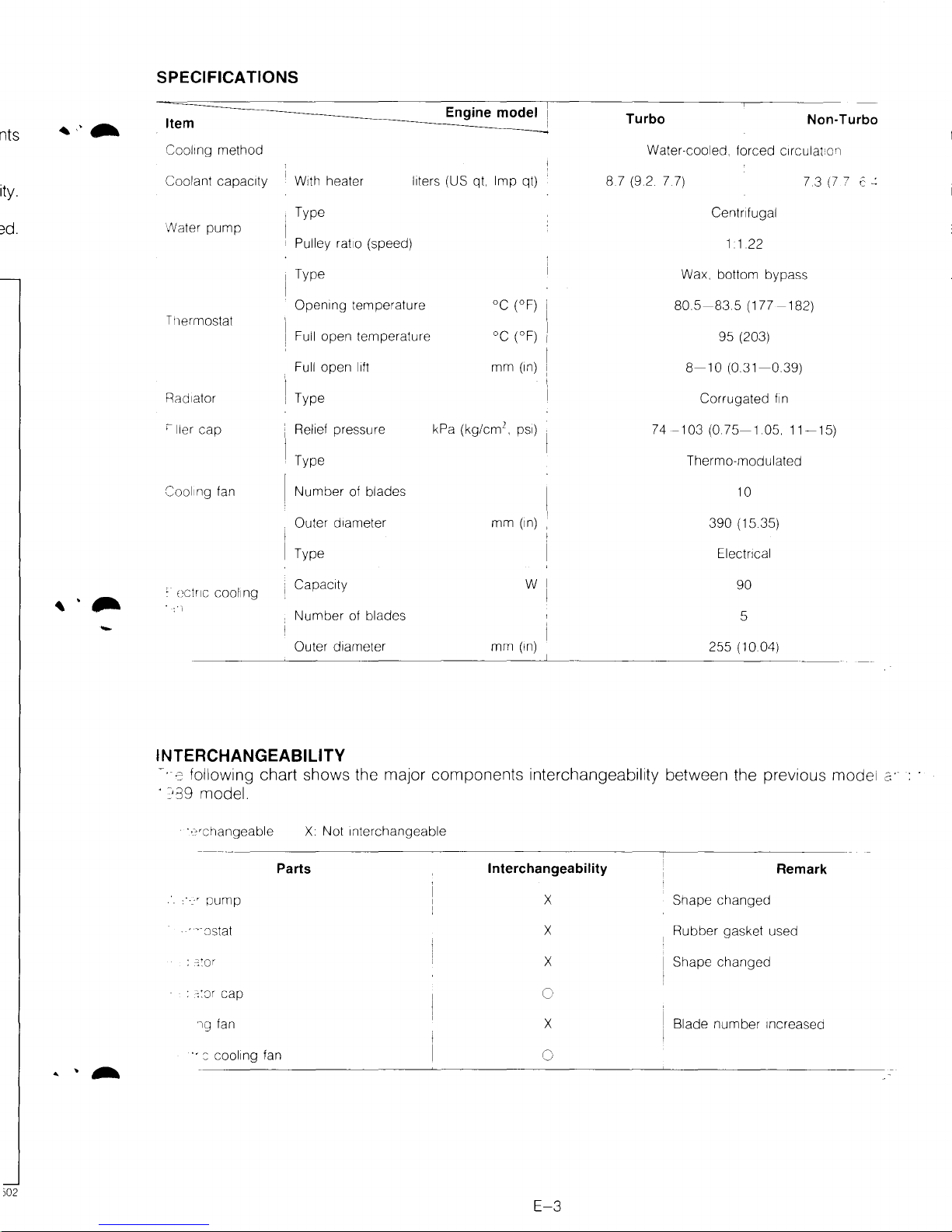

SPECIFICATIONS

nts

Item

Cool1ng

Coolant capac1ty

/Vater

Tl1ermostat

Rad1ator

'ller

Cool1ng fan

method

pump

cap

W1th

heater

Type

Pulley

rat1o

Type

Open1ng

Full

Full

[

Type

Relief pressure

Type

Number

Outer

Type

temperature

ope'l

open

of blades

d1ameter

liters (US qt.

(speed)

temperature

l1ft

Engine

kPa

mode~

Imp

°C

oc

mm

2

(kg/cm

•

mm

qt)

(°F) i

(oF) i

(1n)

ps1)

(1n)

Turbo

Water-cooled,

8.7 (9.2 7.7)

forced

Ce'ltnfugal

Non-Turbo

c1rculat:o'l

7.3

(7

7 c

~

1 1.22

Wax. bottom

I

80.5-83.5

95

I

8-10

Corrugated

74-103

(0.75-1.05.

Thermo-modulated

bypass

(177

-182)

(203)

(0.31-0.39)

f1n

11-15)

10

390

(15 35)

Electncal

-

mm

w

(1n)

255

90

5

(10.04)

:

(;CtriC

COOling

i Capac1ty

Number

Outer d1ameter

of blades

INTERCHANGEABILITY

~.

;co

following chart shows the major components interchangeability between the previous model

· ?39 model.

· ·_?•changeable

· ":Jstat

:

c::or

:

:::Jr

cap

'lQ fan

Parts

X

Not

Interchangeable

Interchangeability

X

X

X

c

X

Shape

Rubber

Shape

Blade

changed

gasket used

changed

number

Increased

Remark

c:·

··::

::ooling fan

)02

0

E-3

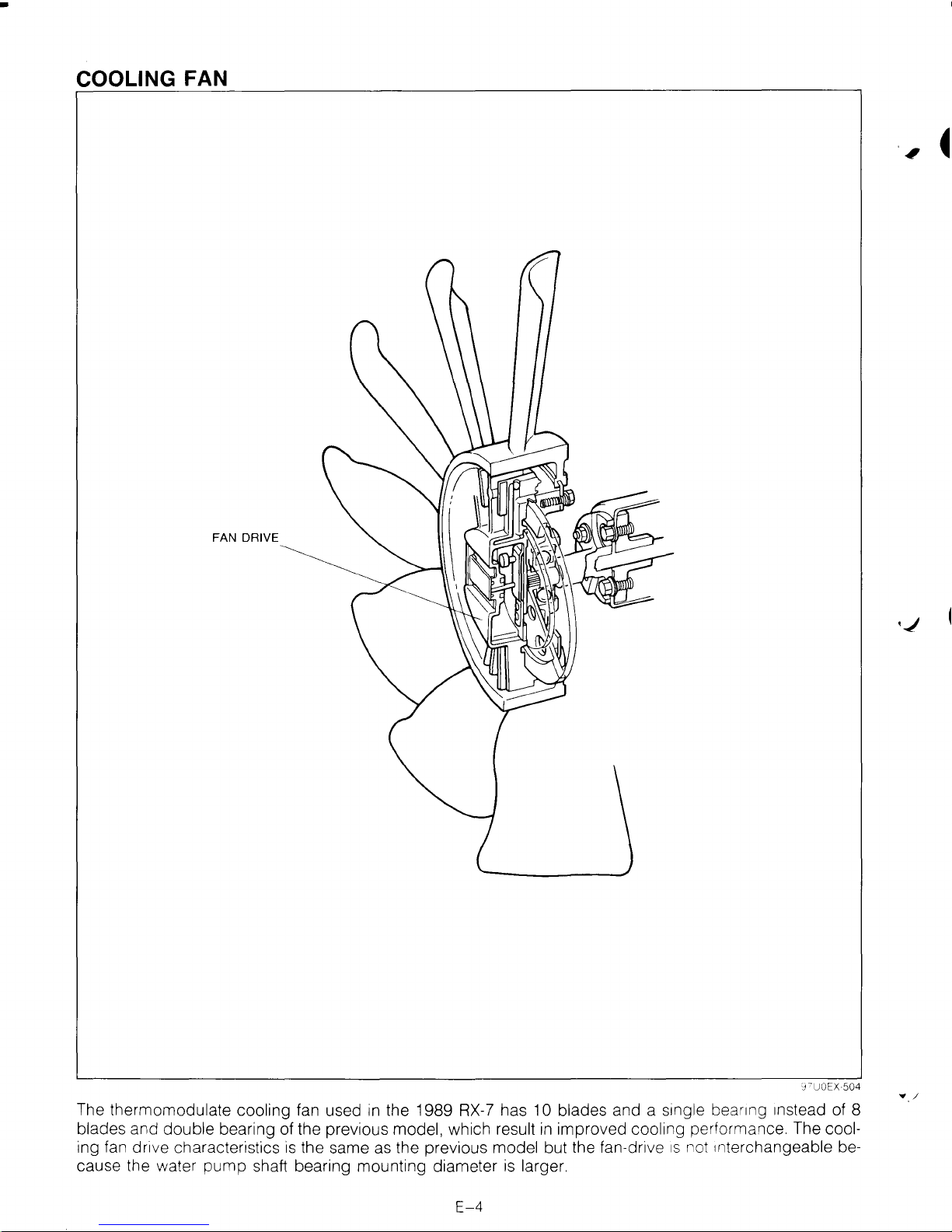

COOLING FAN

FAN DRIVE

The thermomodulate cooling fan used

blades and double bearing of the previous model, which result

ing fan drive characteristics

cause the water

pump

is

the same as the previous model but the fan-dr1ve

shaft bearing mounting diameter

in

the 1989 RX-7 has 10 blades and a

in

improved cooling performance. The cool-

is

larger.

E-4

s1ngle

bear1ng 1nstead of 8

1s

not Interchangeable be-

•_/

"'

\ -

-

WATER PUMP

SHAFT BEARING

PULLEY BOSS

\

@~

I

I

WATER PUMP BODY

EXTRA RIBS

BEARING HOUSING

WATER

PUMP GASKET

97UOEX

505

:.

:=::er

pump shape

is

changed to incorporate the new cooling fan and thermostat.

•.

·-g

housing : Extra ribs are used for improved rigidity.

·-.·

:Jump gasket : The shape

is

changed because of the bearing housing change .

...

:::earing and pulley boss : The shaft bearing shaft outer diameter and pulley boss inner diameter are

increased to incorporate the new

cooling fan.

·.

· :Jump body : The body shape

is

changed to incorporate the new thermostat and cov-

er. The water thermoswitch for automatic transmission and Turbo

models

is

in

the

pump

body.

·-=-·~al

parts are interchangeable with the previous

RX-7.

E-5

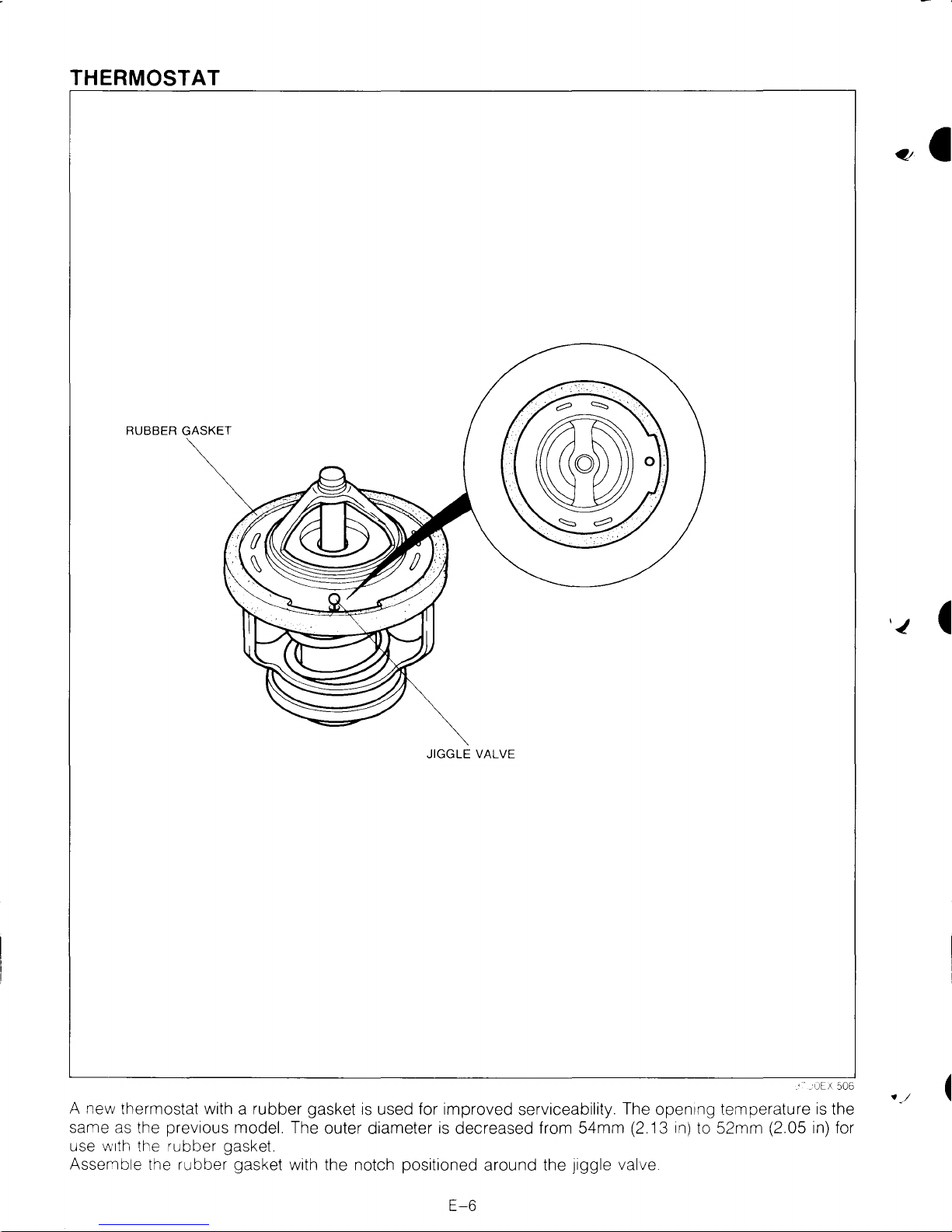

THERMOSTAT

RUBBER GASKET

VALVE

is

decreased from 54mm (2.13

A new thermostat with a rubber gasket

same

as

the prev1ous model. The outer diameter

use

w1th

the rubber gasket.

JIGGLE

is

used for improved serviceability. The open1ng temperature

Assemble the rubber gasket with the notch positioned around the Jiggle valve

1n)

to 52mm (2.05

is

in)

the

for

E-6

'

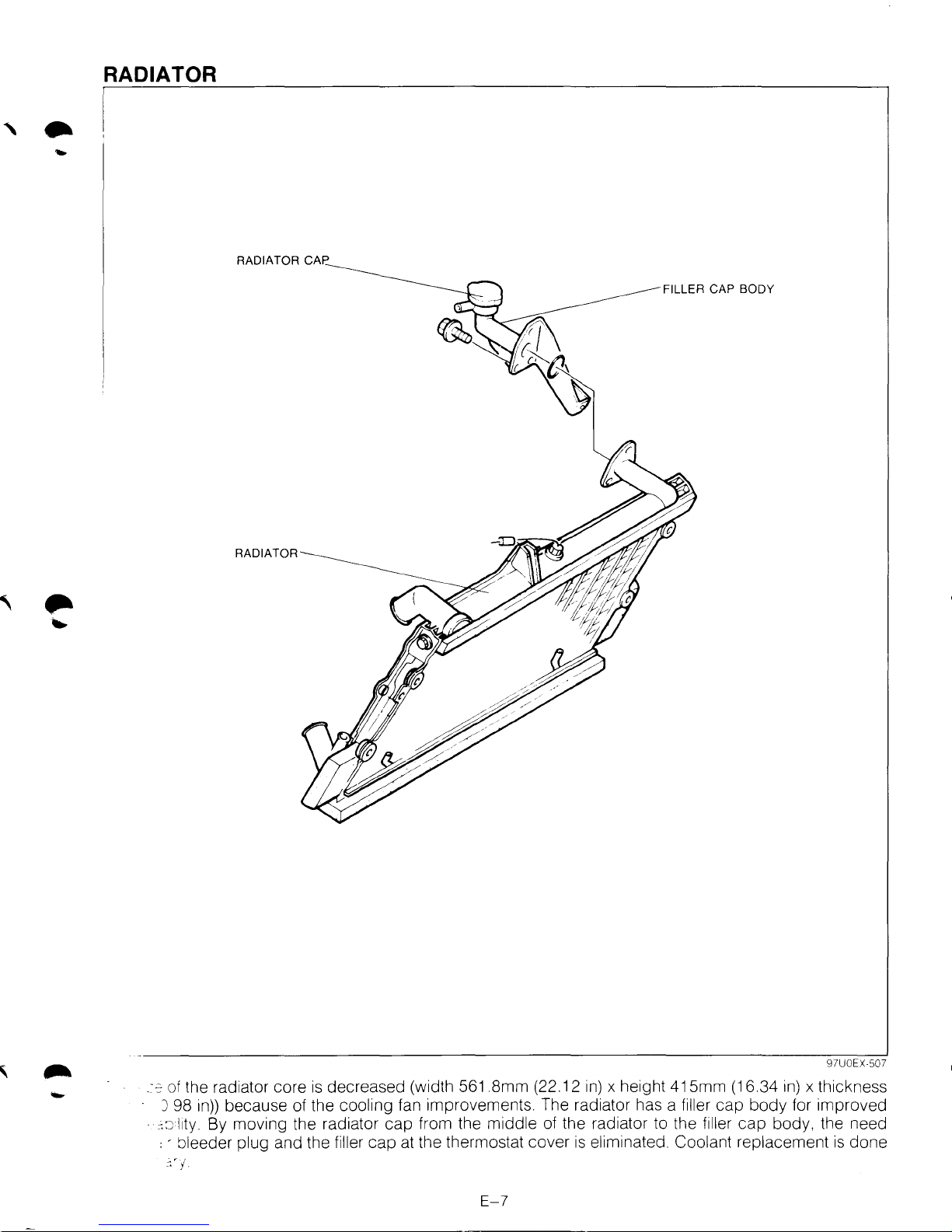

RADIATOR

..

RADIATOR CAP

FILLER CAP BODY

RADIATOR

.:::::of

the radiator core

J 98

in))

-

· :::J

l1ty.

, - bleeder plug and the filler cap at the thermostat cover

':'j

because of the cooling fan improvements. The radiator has a filler cap body for improved

By moving the radiator cap from the middle of the radiator to the filler

is

decreased (width

561

.Smm (22.12

E-7

in)

x height 415mm (16.34

is

eliminated. Coolant replacement

in)

cap

body, the need

97UOEX-507

x thickness

is

done

•

•

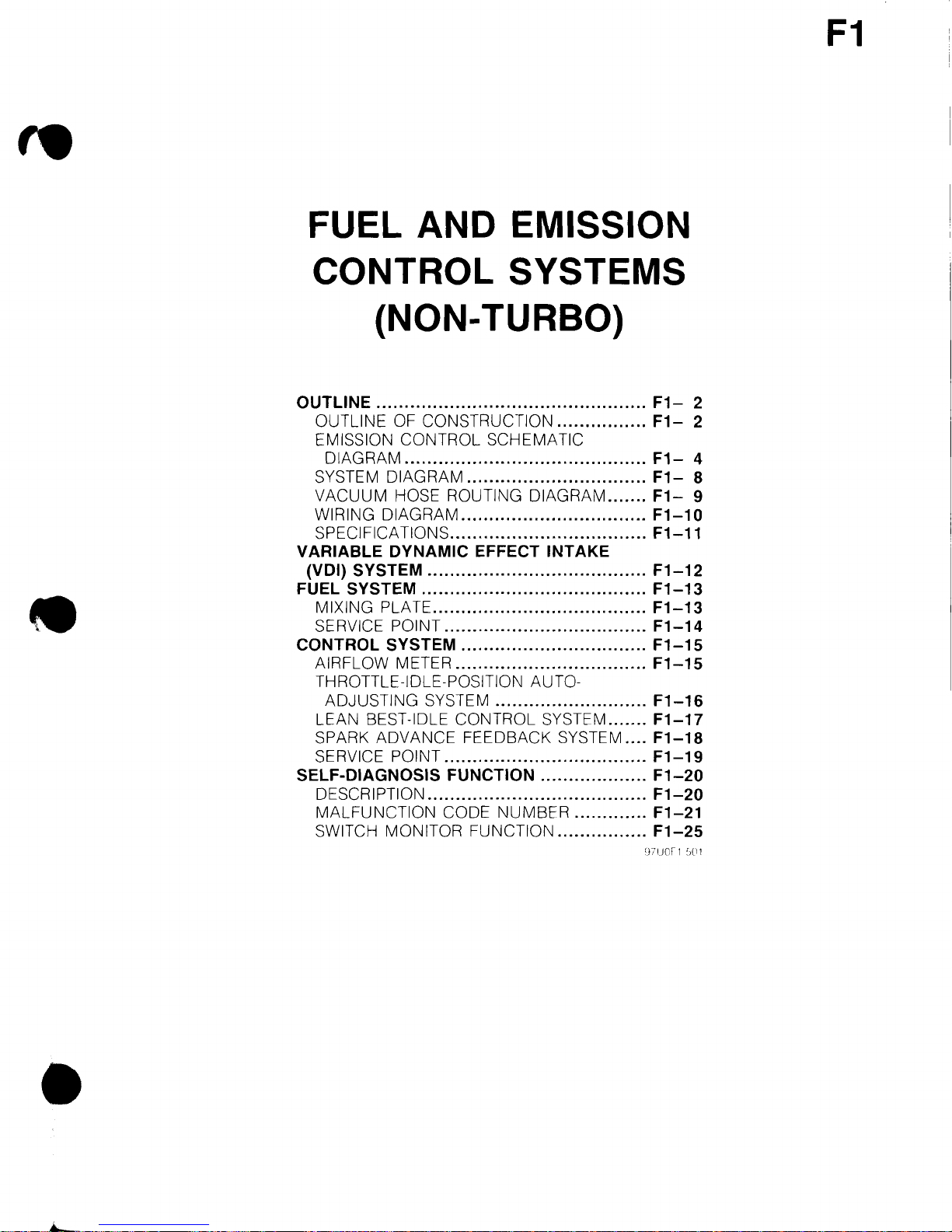

FUEL

AND

EMISSION

CONTROL SYSTEMS

{NON-

TURBO)

OUTLINE

................................................

F1-

2

OUTLINE OF CONSTRUCTION

................

F1-

2

EMISSION CONTROL SCHEMATIC

DIAGRAM

...........................................

F1-

4

SYSTEM DIAGRAM

................................

F1-

8

VACUUM

HOSE ROUTING DIAGRAM

.......

F1-

9

WIRING DIAGRAM

.................................

F1-10

SPECIFICATIONS

...................................

F1-11

VARIABLE DYNAMIC EFFECT INTAKE

(VDI) SYSTEM

.......................................

F1-12

FUEL SYSTEM

........................................

F1-13

MIXING PLATE

......................................

F1-13

SERVICE POINT

....................................

F1-14

CONTROL SYSTEM

.................................

F1-15

AIRFLOW METER

..................................

F1-15

THROTTLE-IDLE-POSITION AUTO-

ADJUSTING SYSTEM

...........................

F1-16

LEAN BEST-IDLE CONTROL SYSTEM

.......

F1-17

SPARK ADVANCE FEEDBACK SYSTEM

....

F1-18

SERVICE POINT

....................................

F1-19

SELF-DIAGNOSIS FUNCTION

...................

F1-20

DESCRIPTION

.......................................

F1-20

MALFUNCTION

CODE

NUMBER

.............

F1-21

SWITCH MONITOR FUNCTION

................

F1-25

'J7UOII

c,[11

F1

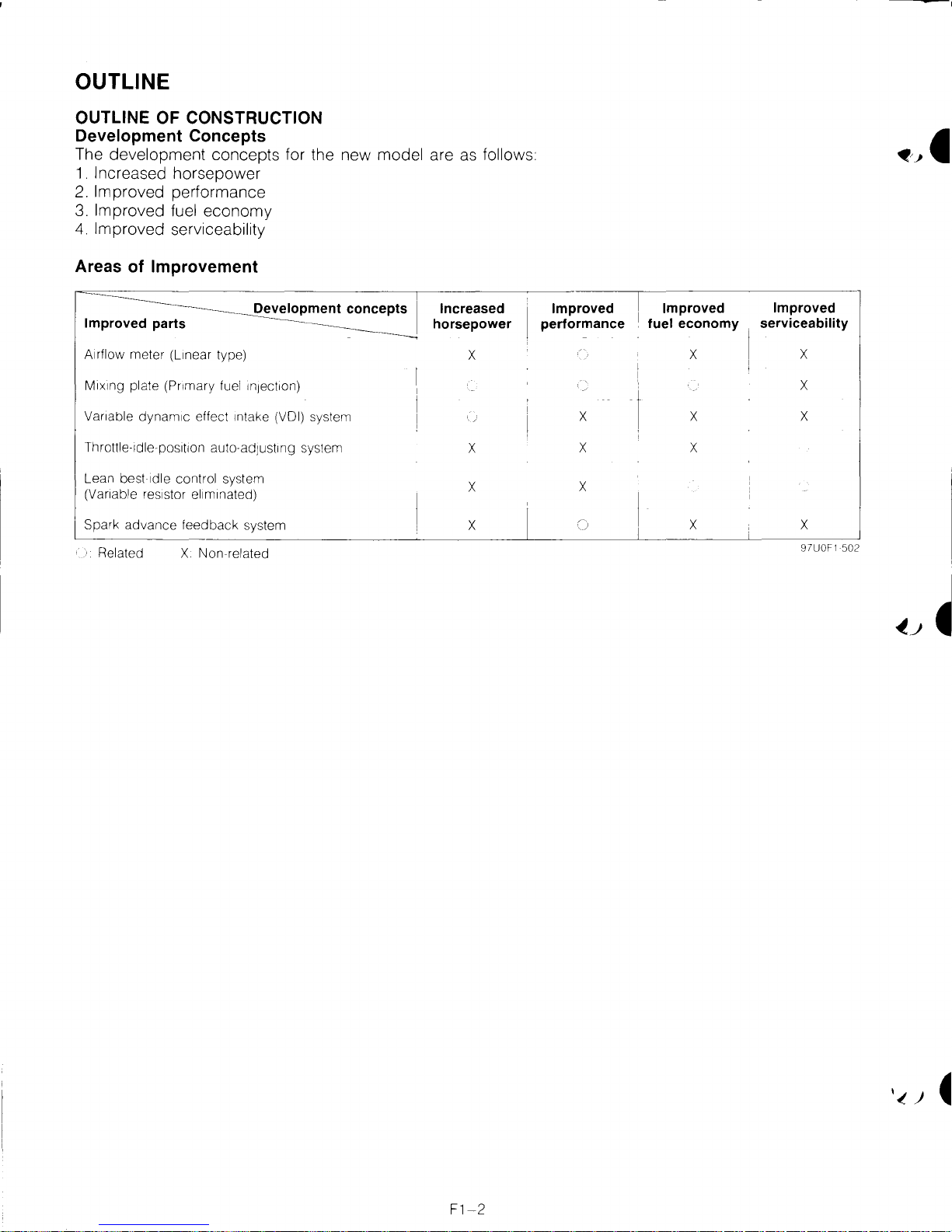

OUTLINE

OUTLINE OF CONSTRUCTION

Development

The

development concepts for the new model are

1.

Increased horsepower

2.

Improved performance

3.

Improved fuel economy

4.

Improved serviceability

Concepts

as

follows

Areas of

Improved parts

Airflow

M1x1ng

Vanable

Throttle-1dle-pos1t1on auto-adJUSting system

Lean best

(Vanable res1stor el1m1nated)

Spark

'.

Related X

Improvement

Development concepts

meter

(L1near type)

plate

(Pnmary

dynam1c effect 1ntake (VOl) system

1dle

advance

fuel

1nJ8ct1on)

control system

feedback

Non

system

related

Increased

horsepower

X

X

X

X

Improved

performance

X

X

X

Improved

fuel

I

I

economy

X

X

X

X

Improved

serviceability

X

X

X

X

97UOF1 502

Loading...

Loading...