®

BRAVOS TMFABRIC CARE SYSTEM ELECTRIC DRYER

USE & CARE GUIDE

SECADORA ELECTRICA BRAVOS TMCON

SECHEUSE ELECTRIQUE BRAVOS T_AVEC SYSTEME DE

Z

FOR QUESTIONS ABOUT FEATURES, OPERATION/PERFORMANCE,

PARTS, ACCESSORIES OR SERVICE CALL: 1.800.688.9900

IN CANADA, CALL: 1,800,807,6777

VISIT OUR WEBSITE AT WWW.MAYTAG,COM

IN CANADA, WWW, MAYTAG.CA

CUIDADO DE LA TELAS

MANUAL DE USO Y CUIDADO

SOIN DES TISSUS

GUIDE D'UTILISATION ET D'ENTRETIEN

SI TIENE PREGUNTAS RESPECT() A LAS CARACTERiSTICA8,

FUNCIONAMIENTO, RENDIMIENTO, PARTES, ACCESORIOS O

SERVICIO TI_CNICO, LLAME AL: 1,800,688,9900

O VISITE NUESTRO SITIO WEB EN

WWW.MAYTAG,COM

AU CANADA, POUR ASSISTANCE, INSTALLATION OU SERVICE,

SISTEMA DE

COMPOSER LE : 1,800,807,6777

OU VISITEZ NOTRE SITE {NTERNET _,

WWW.MAYTAG.CA

W10088777A

@ TABLE OF CONTENTS @

P

@ INDICE @

@ TABLE DES MATIERES @

DRYER SAFETY ..................................................................... 3

INSTALLATION INSTRUCTIONS ........................................ 4

TOOI.S AND PARTS .......................................................... 4

EOCATION REQUIREMENTS ........................................... 4

El ECTRICAL REQUIREMENTS - U.S.A. ONI.Y ................... 5

El ECTRICAI. REQ)UIREMENTS - CANADA ONI.Y ............. 7

EEECTRICAL CONNECTION - U.S.A. ONI.Y ..................... 8

VENTING REQ)UIREMENTS ............................................. 14

PI.AN VENT SYSTEM ....................................................... 16

INSFAH. VENT SYSTEM ................................................... 17

INSFAH. EEVEHNG EEGS ................................................ 17

CON NECF VENT ............................................................. 18

EEVEI. [DRYER................................................................... 18

REVERSE DOOR SWING ................................................. 18

COMPI.ETE INSTAL I ATION ............................................ 20

DRYER USE ......................................................................... 21

STAR[ING YOUR [DRYER................................................ 21

STOPPING, PAUSING OR RESTARTING ........................ 22

DRYING AND CYCI.E TIPS .............................................. 22

STATUS HGHTS .............................................................. 23

CYCI.ES ............................................................................ 23

MODIFIERS ...................................................................... 24

OPTIONS ......................................................................... 25

END OF CYCI.E SIGNAl ................................................... 25

CHANGING CYCI.ES, MODIFIERS AND OPTIONS ........ 25

DRYING RACK OPTION ................................................. 26

DRYER CARE ...................................................................... 27

(_I.EANING THE [DRYER I.OCATION ............................... 27

CLEANING THE LINT SCREEN ........................................ 27

CI.EANING THE [DRYER INTERIOR ................................. 28

REMOVING ACCUMUI.ATE[D I.INT ................................ 28

VACATION AND MOVING CARE .................................. 28

CHANGING THE DRUM I.IGHT ..................................... 28

TROUBLESHOOTING ........................................................ 29

ASSISTANCE OR SERVICE .................................................. 31

WARRANTY ....................................................................... 32

SEGURIDAD DE LA SECADORA ....................................... 33

INSTRUCCIONES DE INSTALACION ............................... 34

HERRAMIENTAS Y PIEZAS .............................................. 34

REQUISITOS [DE UBICACION ....................................... 35

REQ)UISITOS EI.ECTRICOS - S(_)[O EN EE. UU ............... 36

CONEXION EI.ECTRICA - S(_)I.O EN EE. UU ................... 38

REQ)UISITOS [DE VENTI[ ACION ..................................... 44

PEANIFICACI(£_N DE[ SISFEMA DE VENTIEACI('£_N ....... 46

INSTAI_ACION [)El. SISTEMA DE VENTH.ACIt'gN ........... 47

INSTAI.ACION DE I.AS PATAS NIVEI.ADORAS .............. 48

CONEXION DEE DUCFO [DE ESCAPE ............................ 48

NIVEEACI('£_N DE EA SECADORA ................................... 48

COMO INVERTIR El.CIERRE DE I.A PUERTA ................. 49

COMPLETE [A INSTALACION ........................................ 51

USO DE LA SECADORA .................................................... 51

PUESTA EN MARCHA [DE EA SECADORA ..................... ._2

C(_)MO DETENER, PAUSAR Y VOEVER A PONER

EN MARCHA ................................................................... 53

SUGERENCIAS [DE CICLOS Y SECADO .......................... 53

EUCES DE ESTADO ......................................................... 54

CICI.OS ........................................................................... 54

MODIFICADORES .......................................................... 55

OPCIONES ...................................................................... 56

SENAL [DE FIN DE CICLO ............................................... 57

CAMBIO DE CICI.OS, MODIFICADORES Y

OPCIONES ...................................................................... 57

OPCION [DE ESTANTE [DESECADO ............................... 58

CUIDADO DE LA SECADORA .......................................... 59

I IMPIEZA DEI. I.UGAR DONDE ESFz_I.A SECADORA...._9

EIMPIEZA DEI. FILFRO DE PEI.USA ................................ 59

EIMPIEZA DEE INTERIOR DE EA SECADORA ................ 59

EHMINACI(_)N DE PEEUSA ACUMUI.ADA .................... 60

CUIDADO DURANTE EAS VACACIONES

Y MUDANZAS ................................................................ 60

CAMBIO DE EA EUZ DEE TAMBOR ............................... 60

SOLUClON DE PROBLEMAS ............................................ 61

AYUDA O SERVICIO Tf_CNICO ........................................ 63

GARANTiA ........................................................................ 64

SECURITIE DE LA SECHEUSE .............................................. 65

INSTRUCTIONS D'I NSTALLATION .................................. 66

OUIII I.AGE ET PIECES .................................................... 66

EXIGENCES D'EMPI.ACEMENT. ...................................... 67

SPECIFICATIONS EEECTRIQUES - POUR LE CANADA

SEUI.EMENT. ................................................................... 68

EXIGENCES CONCERNANT I.'EVACUAT[ON ................ 69

PI.ANIFICAFION DU SYSI-EME D'EVACUATION ........... 70

INSI-AL[AFION DU SYSTEME D'EVACUAFION ............ 72

INSI-AI.I.ATION [DESPIEDS [DE NIVEH.EMENT ............... 72

RACCORDEMENT DU CONDUIT D'[_VACUAFION ...... 72

REG[ AGE [DE UAPEOMB [DE I.A SI_CHEUSE ................... 72

INVERSION DU SENS D'OUVERTURE DE LA PORTE.... 73

ACHEVER I.'INSI-AI.I.ATION ........................................... 75

UTILISATION DE LA Sf_CHEUSE ....................................... 75

MISE EN MARCHE DE [A SECHEUSE ............................. 76

ARRET, PAUSE OU REMISE EN MARCHE ....................... 77

CONSEII_S POUR I.E SECHAGE ET LES

PROGRAMMES ............................................................... 77

TEMOINS LUMINEUX ..................................................... 78

PROGRAMMES ............................................................... 78

MODIFICATEURS ............................................................ 79

OPTIONS ......................................................................... 80

SIGNAl_ DE FIN DE PROGRAMME ................................. 80

CHANGEMENT E)ESPROGRAMMES, MODIFICATEURS

ET OPTIONS .................................................................... 81

OPTION DE GRII.I E [DE SECHAGE ................................. 81

ENTRETIEN DE LA SI_CHEUSE ........................................... 82

NETTOYAGE [DE I.'EMPI.ACEMENT DE EA SECHEUSE... 82

NETTOYAGE DU FII.TRE _, CHARPIE ............................. 82

NETTOYAGE DE L'IN-I [_RIEUR DE I.A SECHEUSE ........... 83

RETRAIT DE [A CHARPIE ACCUMUI.EE ......................... 83

PRECAUTIONS A PREN[)RE POUR LES VACANCES

EF AVANT UN DEMENAGEMENT. ................................. 83

CHANGEMENT [DE I 'AMPOUI E D'ECI AIRAGE

DU TAMBOUR ................................................................ 83

DEPANNAGE ..................................................................... 84

ASSISTANCE OU SERVICE ................................................. 86

GARANTIE ......................................................................... 87

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

SAVETHESEINSTRUCTIONS

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Clean lint screen before or after each load.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See installation instructions for grounding requirements.

I

INSTALLATION INSTRUCTIONS

TOOLS AND PARTS

Gather the required tools and parts before starting installation. Read and follow the

instructions provided with any tools listed here.

Flat-blade screwdriver

#2 Phillips screwdriver

Adjustable wrench that

opens to 1" (2.5 cm) or

hex-head socket wrench

(for adjusting dryer feet)

Wire stripper (direct wire

installations/

Parts supplied:

Remove parts package from dryer drum. Check that all parts were included.

Parts needed:

Check local codes. Check existing electrical supply and venting and see "Electrical

Requirements" and "Venting Requirements" before purchasing parts.

Mobile home installations require metal exhaust system hardware available for purchase from

the dealer from whom you purchased your dryer. For information on ordering, please refer to

the "Assistance or Service" section of this manual. You may also contact the dealer from

whom you purchased your dryer.

• Tin snips/new vent

installations/

Eevel

Vent clamps

Caulking gun and

compound (for installing

new exhaust vent)

[_tpe measure

4 leveling legs

LOCATION REQUIREMENTS

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

• A location that allows for proper exhaust installation. See "Venting Requirements."

• A separate 30-amp circuit.

• If you are using a power supply cord, a grounded electrical outlet located within 2 ft

(61 cm) of either side of the dryer. See "Electrical Requirements."

• A sturdy floor to support the total weight (dryer and load) of 200 Ibs (90.7 kg). The

combined weight of a companion appliance should also be considered.

• A level floor with a maximum slope of 1" (2.5 cm) under entire dryer.

Do not operate your dryer at temperatures below 45°F (7°C). At lower temperatures, the dryer

might not shut off at the end of an automatic cycle. Drying times can be extended.

[he dryer must not be installed or stored in an area where it will be exposed to water and/or

weather.

Check code requirements. Some codes limit, or do not permit, installation of the dryer in

garages,closets,mobile homes or sleeping quarters. Contact your local building inspector.

4

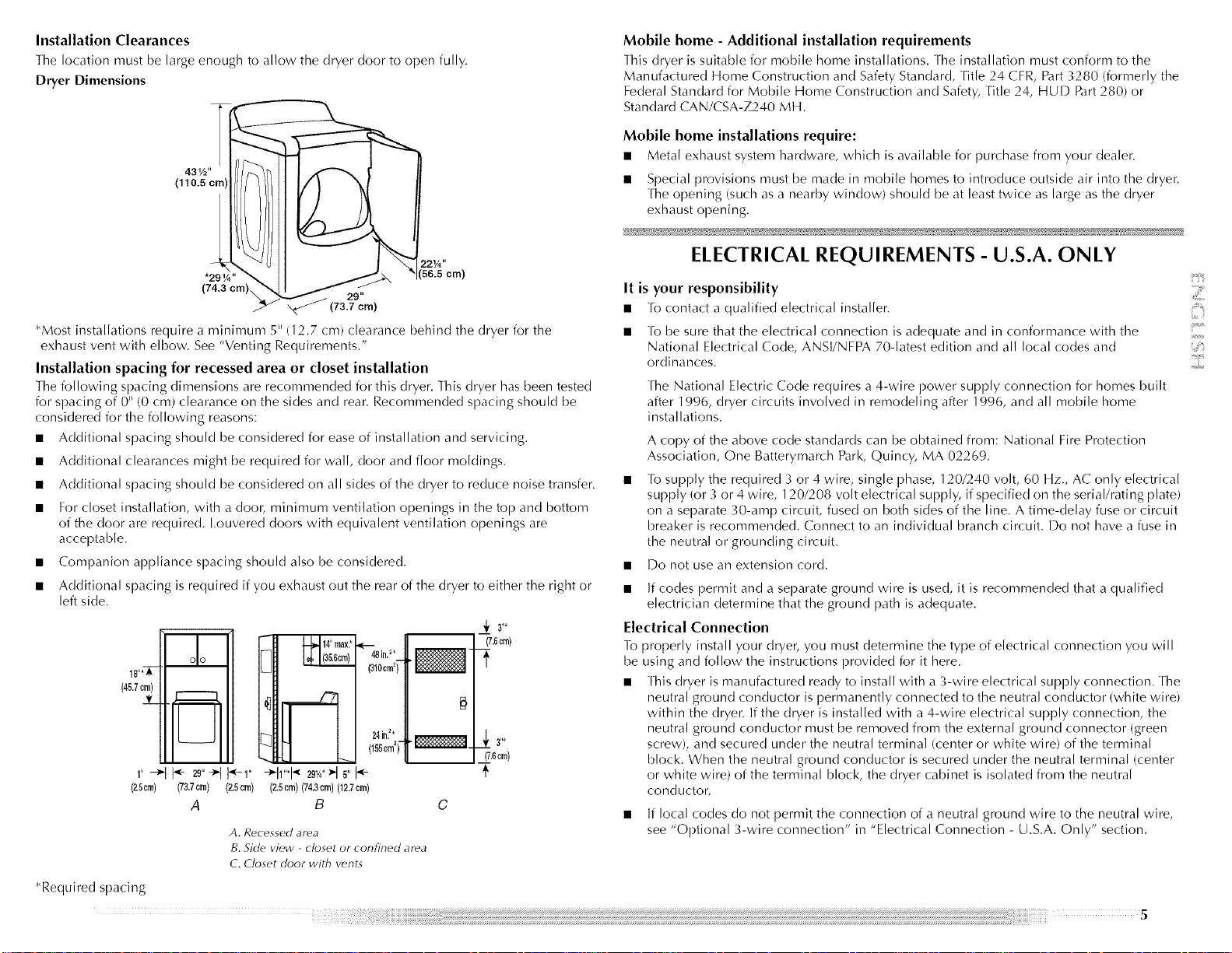

Installation Clearances

The location must be large enough to allow the dryer door to open fully.

Dryer Dimensions

*Most installations require a minimum 5" (12.7 cm) clearance behind the dryer for the

exhaust vent with elbow. See "Venting Requirements."

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this dryer. This dryer has been tested

for spacing of 0" (0 cm) clearance on the sides and rear. Recommended spacing should be

considered for the following reasons:

• Additional spacing should be considered for ease of installation and servicing.

• Additional clearances might be required for wall, door and floor moldings.

• Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

• For closet installation, with a door, minimum ventilation openings in the top and bottom

of the door are required. [ ouvered doors with equivalent ventilation openings are

acceptable.

• Companion appliance spacing should also be considered.

• Additional spacing is required if you exhaust out the rear of the dryer to either the right or

left side.

31,,

_6cm)

__ 3"*

(7.6crn)

7

*Required spacing

i' rtx;

r' _ _- 29"_ I_-1" -_lv'*l_ 99,l_"_4_"

(9.5cm) (2.5cm)

(73.7cm) (2.5cm)(74.3cm)(12.7crn)

A B C

A. Recessed area

B. Side view - closet or confined area

C. Closet door with w_nts

m

48in. 2.

(319cm2i- "[_"

24in.2.

Mobile home - Additional installation requirements

This dryer is suitable for mobile home installations. The installation must conform to the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 (formerly the

Federal Standard for Mobile Home Construction and Safety, Title 24, HUD Part 280) or

Standard CAN/CSA-Z240 MH.

Mobile home installations require:

• Metal exhaust system hardware, which is available for purchase from your dealer.

• Special provisions must be made in mobile homes to introduce outside air into the dryer.

The opening (such as a nearby window) should be at least twice as large as the dryer

exhaust opening.

ELECTRICAL REQUIREMENTS - U.S.A. ONLY

I

It is your responsibility

• [b contact a qualified electrical installer.

• [b be sure that the electrical connection is adequate and in conformance with the

National Electrical Code, ANSI/NFPA 70-latest edition and all local codes and

ordinances.

The National Electric Code requires a 4-wire power supply connection for homes built

after 1996, dryer circuits involved in remodeling after 1996, and all mobile home

installations.

A copy of the above code standards can be obtained from: National Fire Protection

Association, One Batterymarch Park, Quincy, MA 02269.

• lb supply the required _ or 4 wire, single phase, 120/240 volt, 60 Hz., AC only electrical

supply (or ¢ or 4 wire, 120/208 volt electrical supply, if specified on the serial/rating plate)

on a separate 30-amp circuit, fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an individual branch circuit. Do not have a fuse in

the neutral or grounding circuit.

• Do not use an extension cord.

• If codes permit and a separate ground wire is used, it is recommended that a qualified

electrician determine that the ground path is adequate.

Electrical Connection

[b properly install your dryer, you must determine the type of electrical connection you will

be using and follow the instructions provided for it here.

• [his dryer is manufactured ready to install with a 3-wire electrical supply connection. The

neutral ground conductor is permanently connected to the neutral conductor (white wire/

within the dryer. If the dryer is installed with a 4-wire electrical supply connection, the

neutral ground conductor must be removed from the external ground connector/green

screw/, and secured under the neutral terminal (center or white wire) of the terminal

block. When the neutral ground conductor is secured under the neutral terminal icenter

or white wire) of the terminal block, the dryer cabinet is isolated from the neutral

conductor.

• If local codes do not permit the connection of a neutral ground wire to the neutral wire,

see "Optional 3-wire connection" in "Electrical Connection - U.S.A. Only" section.

5

A4-wirepowersupplyconnectionmustbeusedwhentheapplianceisinstalledina

locationwheregroundingthroughtheneutralconductorisprohibited.Grounding

throughtheneutralisprohibitedfor(1)newbranch-circuitinstallations,(2)mobile

homes,(3)recreationalvehicles,and(4)areaswherelocalcodesprohibitgrounding

throughtheneutralconductors.

Ifusing a power supply cord:

Use a UL listed power supply cord kit marked for use with clothes dryers. The kit should

contain:

[] A Ui listed 30-amp power supply cord, rated 120/240 volt minimum. ]he cord should be

type SRD or SRDT and be at least 4 ft (1.22 m) long. ]he wires that connect to the dryer

must end in ring terminals or spade terminals with upturned ends.

[] A UI listed strain relief.

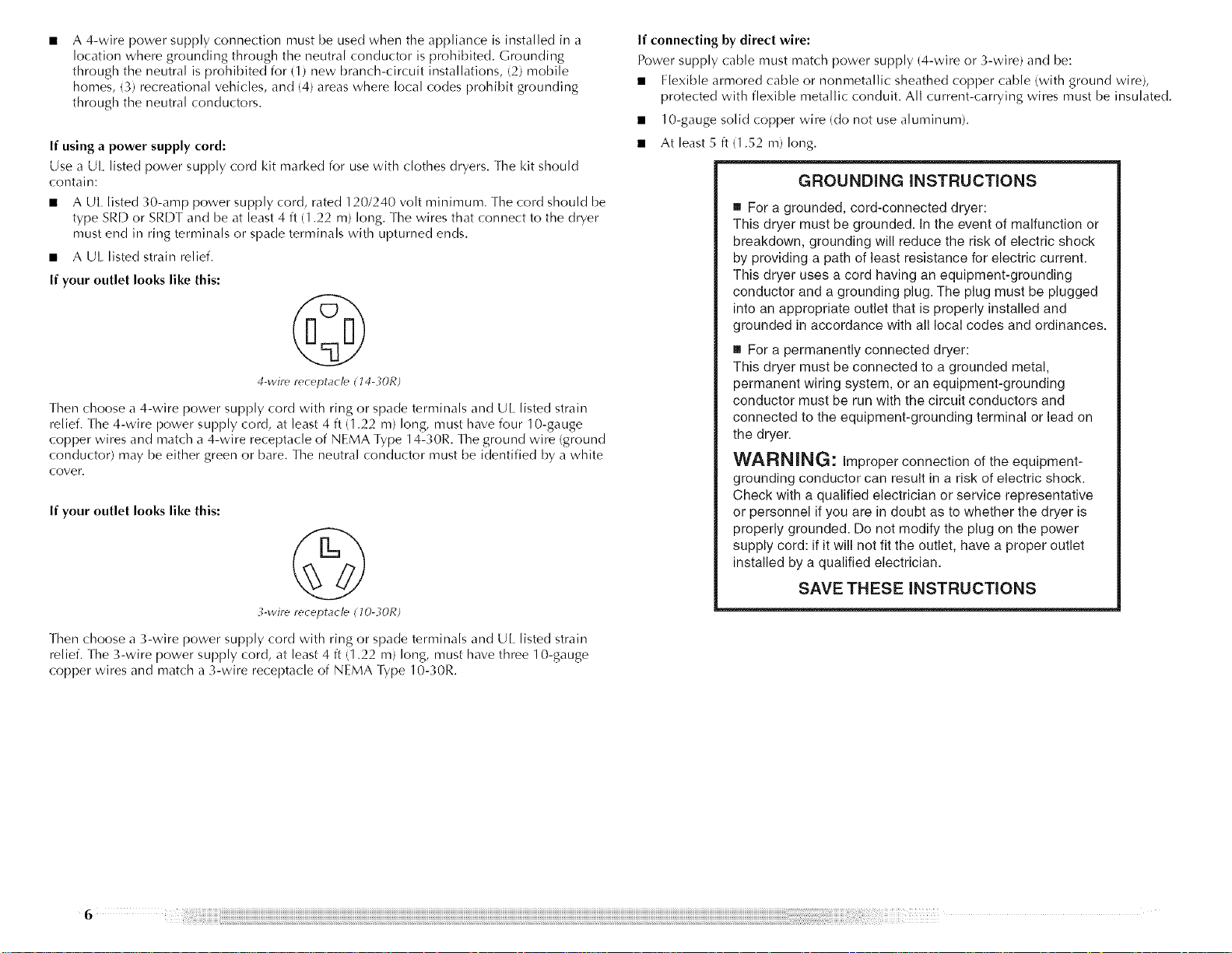

If your outlet looks like this:

4-wirt" rt'cept_cl_' (14-30R)

Then choose a 4-wire power supply cord with ring or spade terminals and U[. listed strain

relief. [he 4-wire power supply cord, at least 4 ft (1.22 m) long, must have four 10-gauge

copper wires and match a 4-wire receptacle of NEMA Type 14-30R. The ground wire (ground

conductor) may be either green or bare. The neutral conductor must be identified by a white

cover.

If your outlet looks like this:

3-wire" re'cept_cle' (lO-30R)

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire) and be:

[] Flexible armored cable or nonmetallic sheathed copper cable (with ground wire),

protected with flexible metallic conduit. All current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

[] At least 5 ft (1.52 m) long.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Then choose a 3-wire power supply cord with ring or spade terminals and U[ listed strain

relief. [he 3-wire power supply cord, at least 4 ff (1.22 m) long, must have three 10-gauge

copper wires and match a 3-wire receptacle of NEMA Type 10-30R.

6

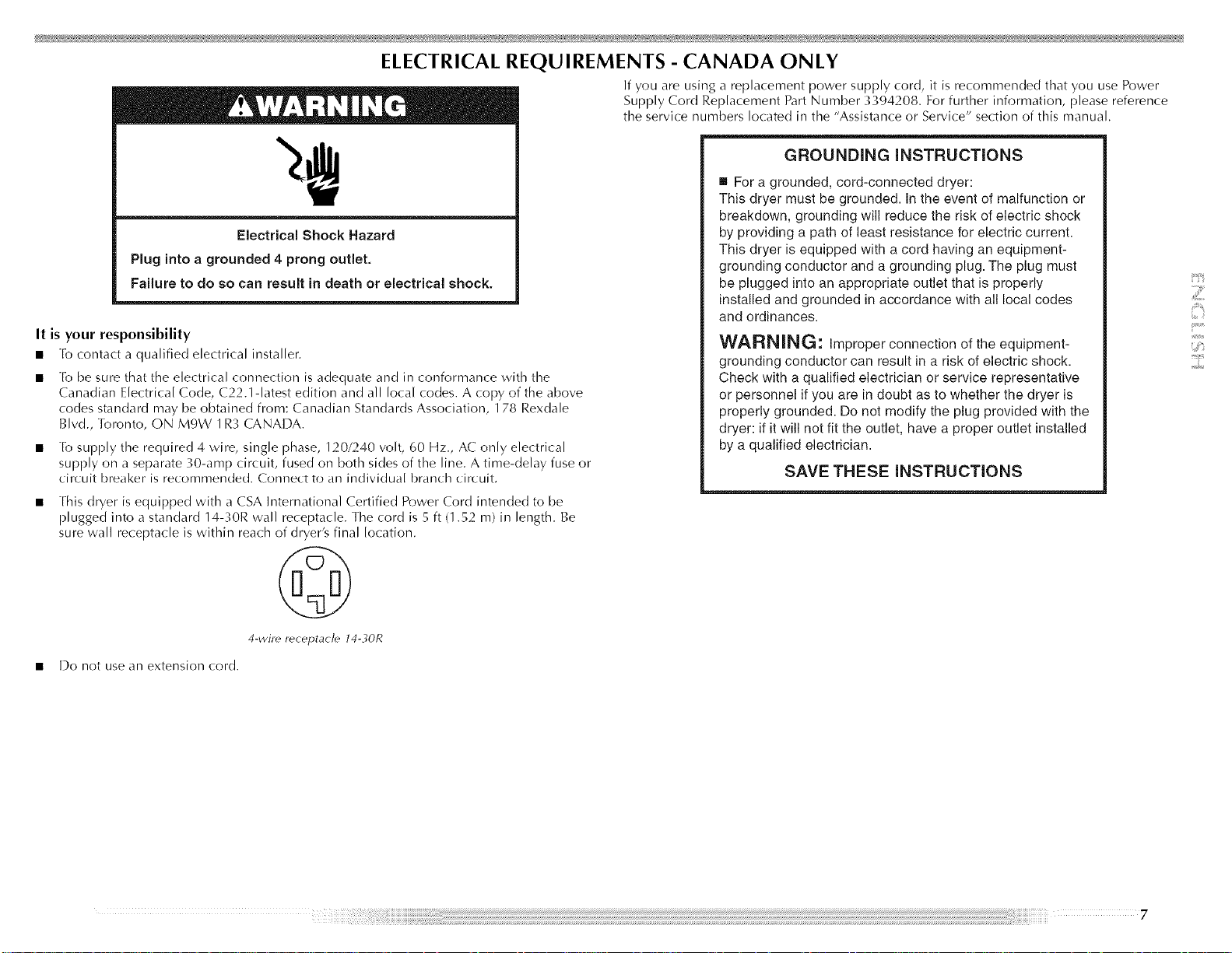

ELECTRICAL REQUIREMENTS - CANADA ONLY

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

It is your responsibility

• [b contact a qualified electrical installer.

• [b be sure that the electrical connection is adequate and in conformance with the

Canadian Electrical Code, C22.1 -latest edition and all local codes. A copy of the above

codes standard may be obtained from: Canadian Standards Association, 178 Rexdale

Blvd., toronto, ON M9W 1R3 CANADA.

[b supply the required 4 wire, single phase, 120/240 volt, 60 Hz., AC only electrical

supply on a separate 30-amp circuit, fused oil both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual branch circuit.

This dryer is equipped with a CSA International Certified Power Cord intended to be

plugged into a standard 14-¢0R wall receptacle. The cord is 5 ft/1.52 m) in length. Be

sure wall receptacle is within reach of dryer's final location.

If you are using a replacement power supply cord, it is recommended that you use Power

Supply Cord Replacement Part Number 3394208. For further information, please reference

the service numbers located in the "Assistance or Service" section of this manual.

GROUNDING INSTRUCTIONS

• For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

I

• Do not use an extension cord.

4wvire receptacle 14-30R

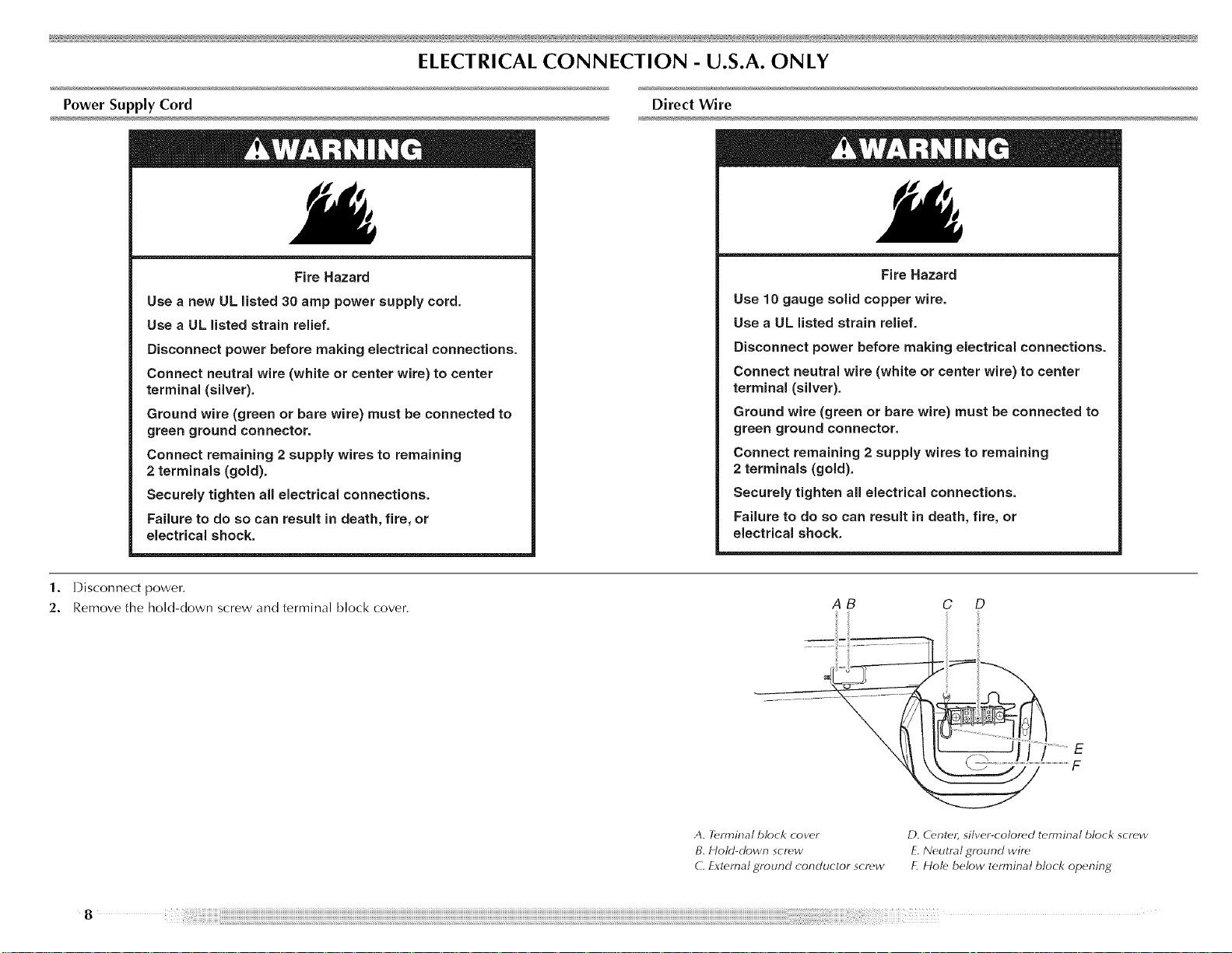

ELECTRICAL CONNECTION - U.S.A. ONLY

Power Supply Cord

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

Fire Hazard

Direct Wire

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

AB

E

F

A. 7_rminal block co_,er D. Center, silw_r-colored terminal block screw

B. Hold-down screw E. Neutral ground wile

C. External ground conductor screw [. Hole below terminal block opening

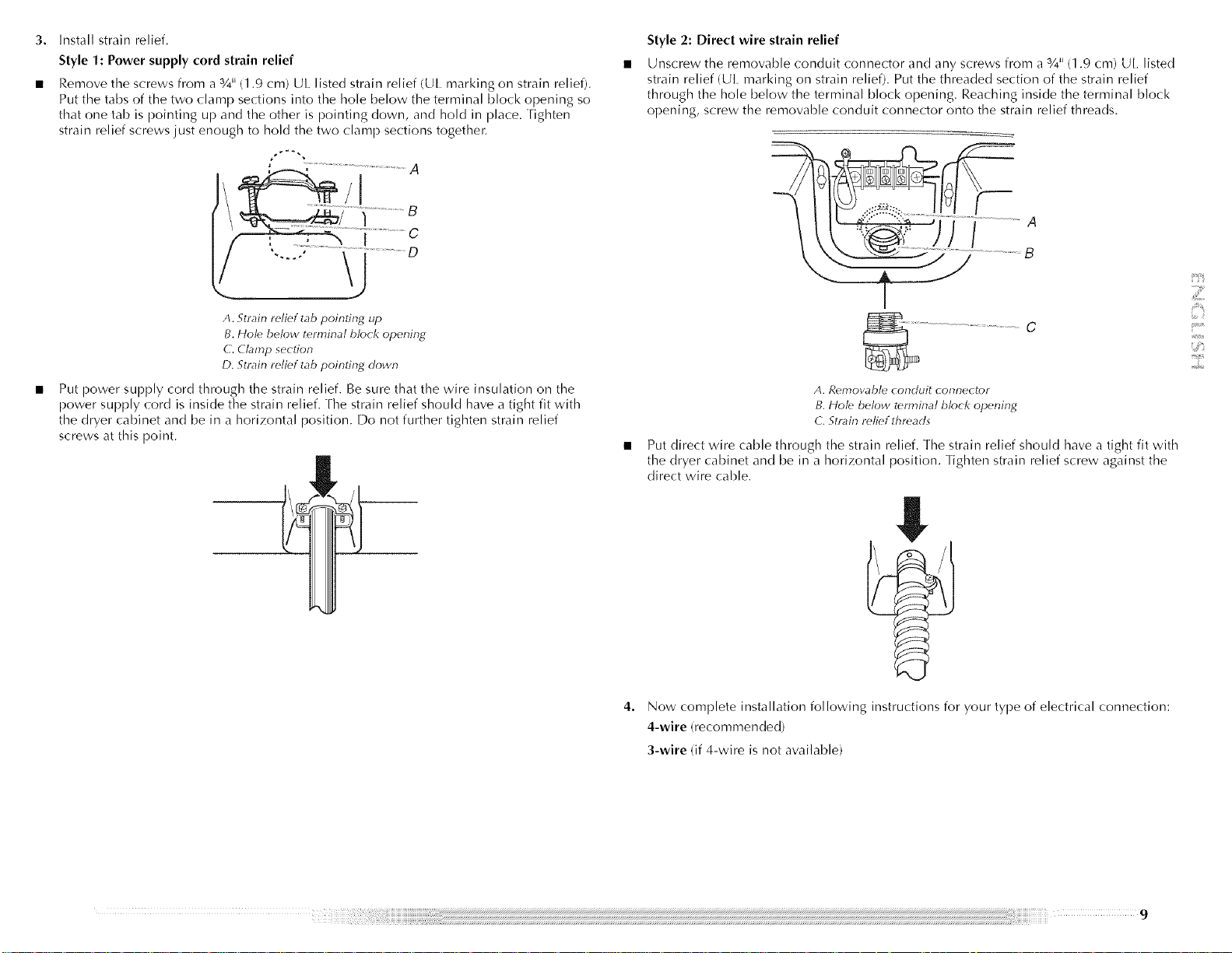

3. Install strain relief.

Style 1: Power supply cord strain relief

• Remove the screws from a %" (1.9 cm) UI. listed strain relief (UI marking on strain relief).

Put the tabs of the two clamp sections into the hole below the terminal block opening so

that one tab is pointing up and the other is pointing down, and hold in place. Tighten

strain relief screws just enough to hold the two clam[) sections togethen

A. Strain relief tab pointing up

B. Hole' below terminal block opening

C. Clamp section

D. Strain relief tab pointing down

Put power supply cord through the strain relief. Be sure that the wire insulation on the

power supply cord is inside the strain relief. The strain relief should have a tight fit with

the dryer cabinet and be in a horizontal position. Do not further tighten strain relief

screws at this point.

Style 2: Direct wire strain relief

Unscrew the removable conduit connector and any screws from a 3/4"(1.9 cm) U[. listed

strain relief (UI. marking on strain relief). Put the threaded section of the strain relief

through the hole below the terminal block opening. Reaching inside the terminal block

opening, screw the removable conduit connector onto the strain relief threads.

A. Removable conduit connector

B. Hole' below t_'rmina] block opening

C. Strain relief threads

Put direct wire cable through the strain relief. ]he strain relief should have a tight fit with

the dryer cabinet and be in a horizontal position. Tighten strain relief screw against the

direct wire cable.

Now complete installation following instructions for your type of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

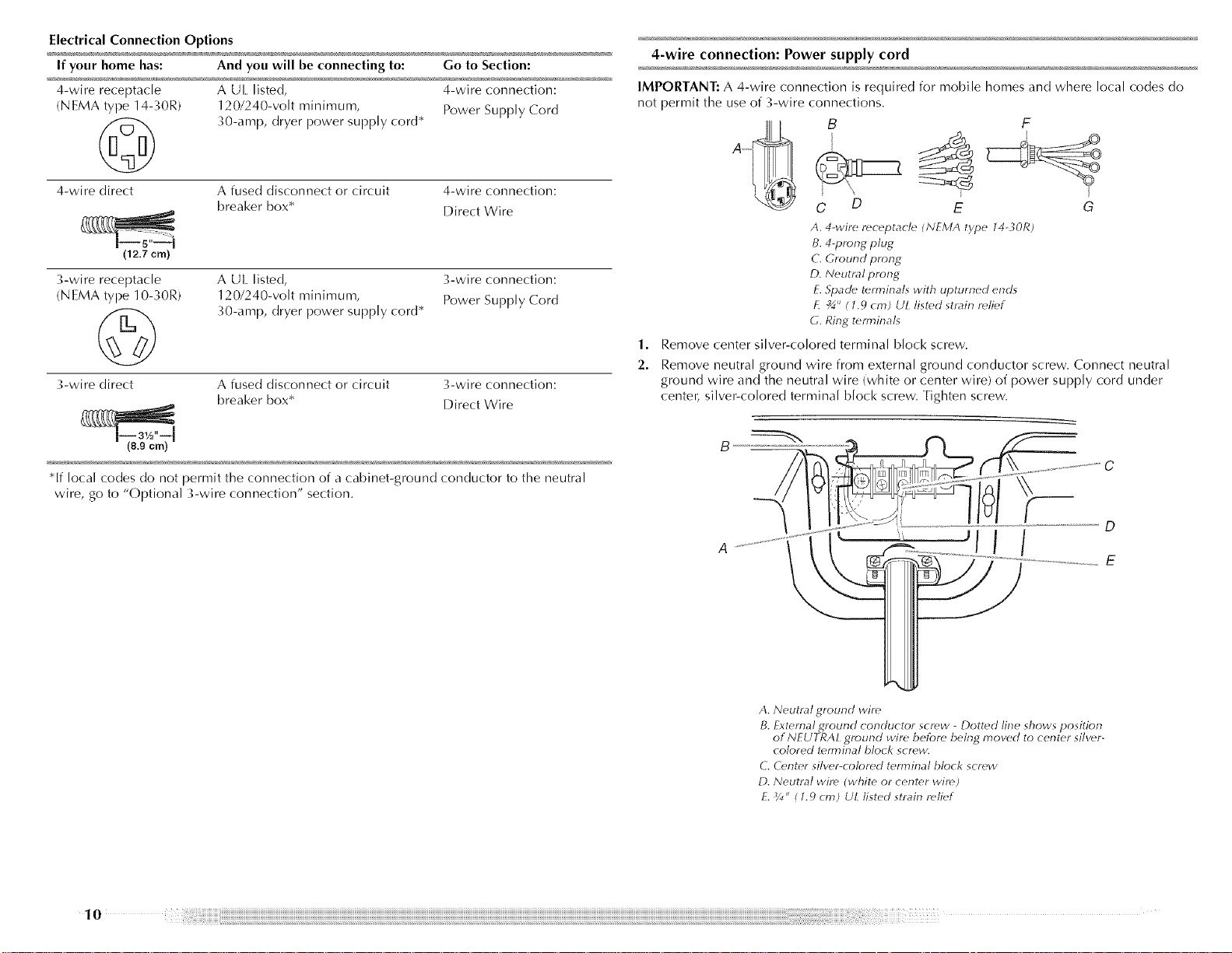

ElectricalConnection Options

If your home has: And you will be connecting to: Go to Section:

4-wire receptacle A UI. listed, 4-wire connection:

iNEMA type 14-30R) 120/240-volt minimum, Power Supply Cord

(_ 30-amp, dryer power supply cord*

4-wire direct A fused disconnect or circuit 4-wire connection:

breaker box* Direct Wire

(12.7 cm)

3-wire receptacle

(NEMA type 10-30R)

A UI. listed,

120/240-volt minimum,

30-amp, dryer power supply cord*

3-wire connection:

Power Supply Cord

©

3-wire direct A fused disconnect or circuit 3-wire connection:

breaker box* Direct Wire

*If local codes do not _ermit the connection of a cabinet-ground conductor to tile neutral

wire, go to "Optional 3-wire connection" section.

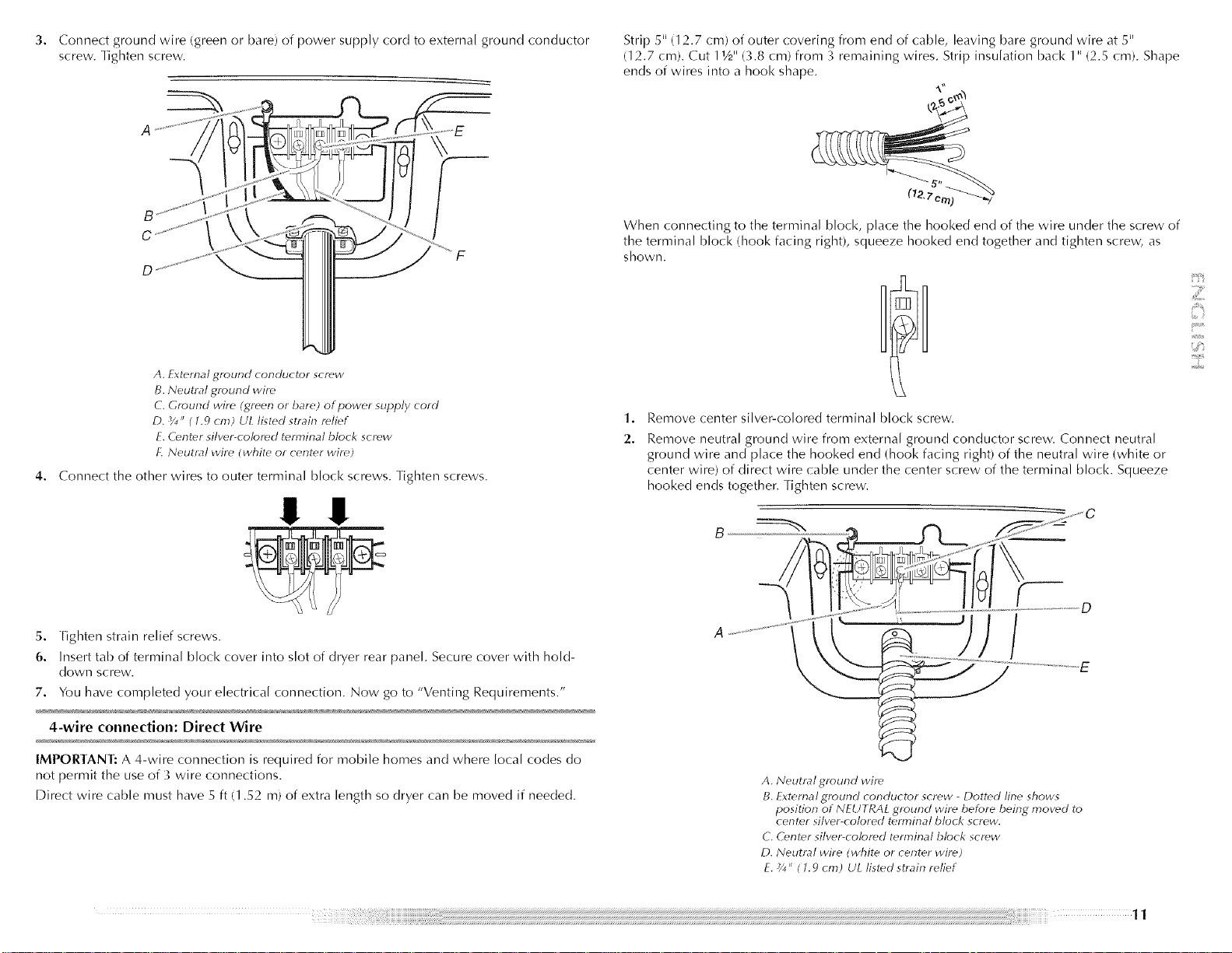

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do

not permit the use of 3-wire connections.

B

C D E G

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned end_

f. ?g" t 1.9 cm) U[ listed strain relief

G. Ring tenTfinals

1.

Remove center silver-colored terminal block screw.

2.

Remove neutral ground wire from external ground conductor screw. Connect neutral

ground wire and the neutral wire (white or center wire) of power supply cord under

center, silver-colored terminal block screw. Tighten screw.

F

D

A. Neutral ground wire

B. Fxternal ground conductor screw - Dotted line shows position

of NEUTRA I, ground wire before being moved to center silver-

colored terminal block screw.

C. Center silver-colored tenTlinal block screw

D. Neutral wire' (white or center wire)

E. _/4" ( 1.9 cm) U[ listed strain re'lief

10

3,

Connect ground wire (green or bare) of power supply cord to external ground conductor

screw. Tighten screw.

A. External ground conductor screw

B. Neutral ground wire

C. Ground wire (green or bare) of power supply cord

D. _/4" ( 1.9 cm) U[ listed strain relief

E. Center silver-colored terminal block screw

[. Neutral wire twhite or center wire)

4,

Connect the other wires to outer terminal block screws. Tighten screws.

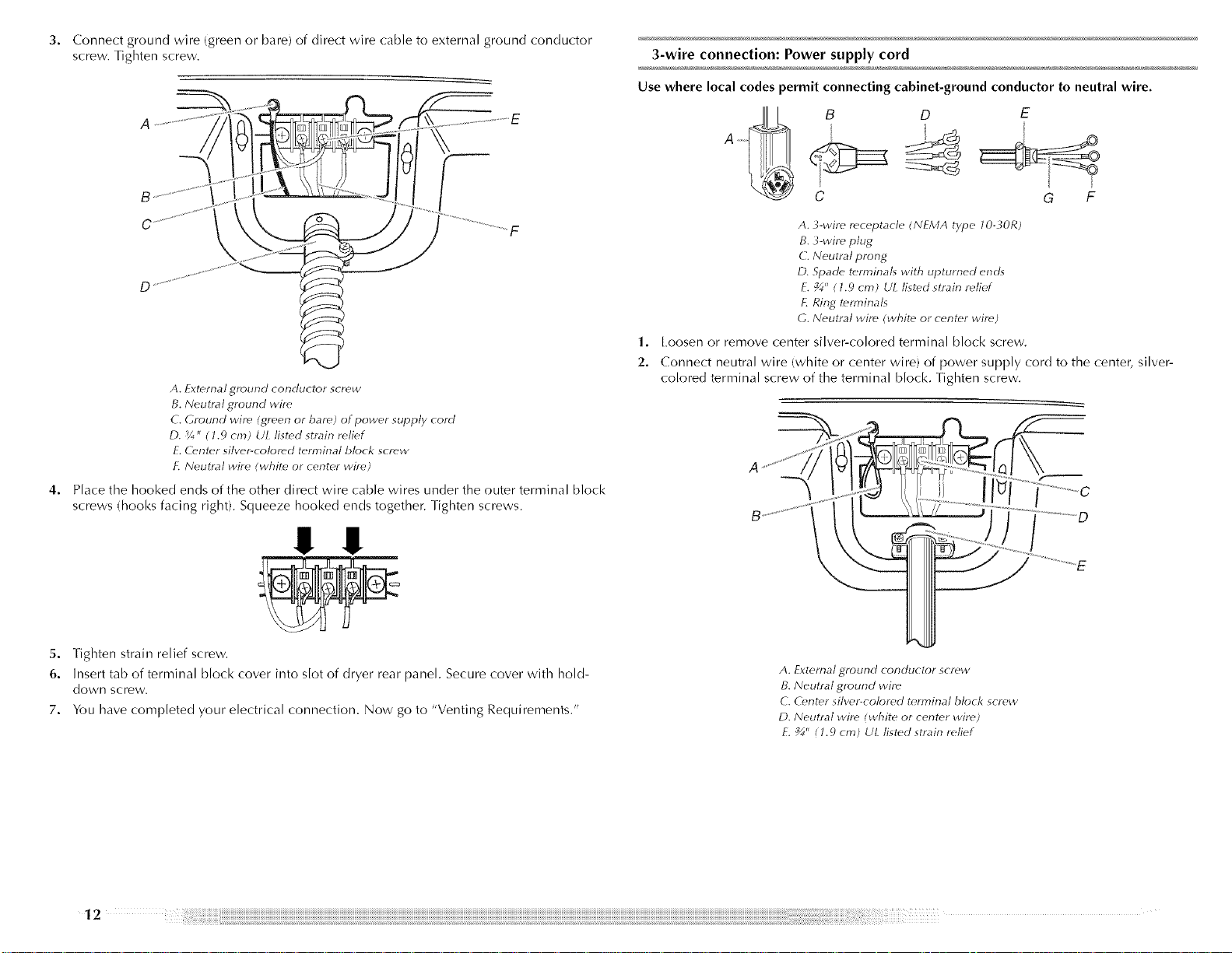

Strip 5" (12.7 cm) of outer covering from end of cable, leaving bare ground wire at 5"

(12.7 cm). Cut 1Vd' (3.8 cm) from 3 remaining wires. Strip insulation back 1" (2.5 cm). Shape

ends of wires into a hook shape.

(12,Z

When connecting to the terminal block, place the hooked end of the wire under the screw of

the terminal block Ihook facing right), squeeze hooked end together and tighten screw, as

shown.

1.

Remove center silver-colored terminal block screw.

2.

Remove neutral ground wire from external ground conductor screw. Connect neutral

ground wire and place the hooked end (hook facing right) of the neutral wire (white or

center wire) of direct wire cable under the center screw of the terminal block. Squeeze

hooked ends together. Tighten screw.

!! !!

5,

Tighten strain relief screws.

6.

Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-

down screw.

7. You have completed your electrical connection. Now go to "Venting Requirements."

4-wire connection: Direct Wire

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do

not permit the use of 3 wire connections.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer can be moved if needed.

t _",

A. Neutral ground wire

B. £xternal glound conductor screw - Dotted line shows

position of NEUTRAL ground wire before being rnoved to

center silver-colored terminal block screw.

C. Center silver-co/ore'd terminal block scre'w

D. Neutral wire (white or center wire)

E. _4" ( 1.9 cm) UL listed strain relic4

,,...................................:_...........................................................D

3,

Connect ground wire (green or bare) of direct wire cable to external ground conductor

screw. Tighten screw.

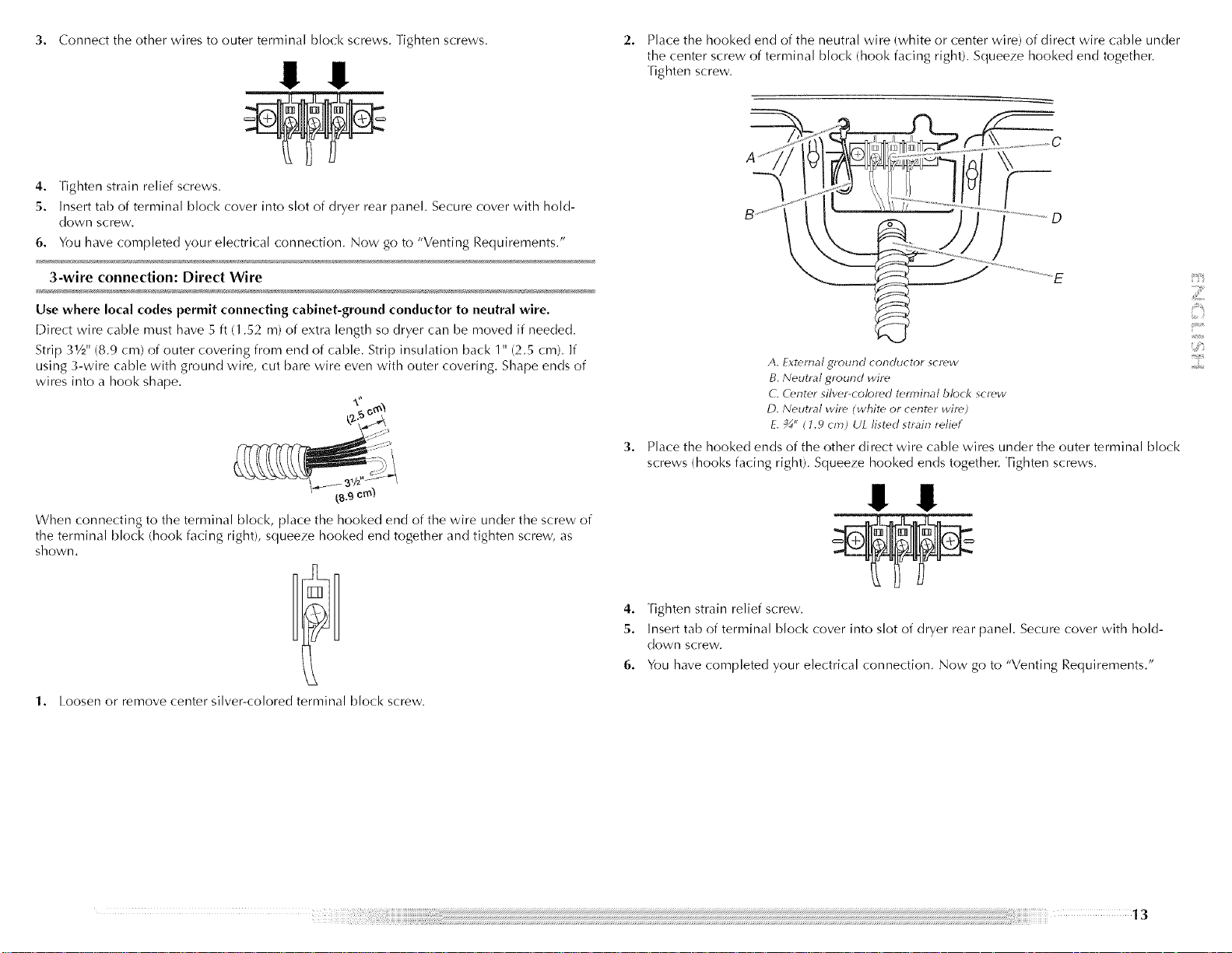

3-wire connection: Power supply cord

Use where local codes permit connecting cabinet-ground conductor to neutral wire.

A ...... /

B

C

A. External ground conductor screw

B. Neutral ground wire

C. Ground wir_' Igreen or bare) of power supply cord

D. _4" ( 1.9 cm) U[ listed strain reli_'f

E. (_ulter silver-color_'d terminal block scr_'w

L Neutral wire (white or center wir_')

4,

Place the hooked ends of the other direct wire cable wires under the outer terminal block

screws (hooks facing right). Squeeze hooked ends together. Tighten screws.

I I

C G F

A. 3-wire re'ceptacle (NFMA type lO-30R)

B. 3-wire plug

C. Neutral prong

D. Spade' te'rminah with upturned ends

E. _" (t.9 cm) U[ list_,d strain r_'lief

£ Ring t_,rminals

G. Neutral wire (white" or center wir_')

1.

Loosen or remove center silver-colored terminal block screw.

2.

Connect neutral wire (white or center wire) of power supply cord to the center, silver-

colored terminal screw of the terminal block. Tighten screw.

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-

down screw.

7. You have completed your electrical connection. Now go to "Venting Requirements."

A. [xternal ground conductor scr_'w

B. Neutral ground wir_"

C. C_'nte'r silver-colored terminal block screw

D. Neutral wir_' (white of center wire)

E. _" ( 1.9 cm) U[ listed strain relief

3. Connect the other wires to outer terminal block screws. Tighten screws.

!! !!

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-

down screw.

6. You have completed your electrical connection. Now go to "Venting Requirements."

Place the hooked end of the neutral wire (white or center wire) of direct wire cable under

the center screw of terminal block (hook facing right). Squeeze hooked end together.

Tighten screw.

3-wire connection: Direct Wire

Use where local codes permit connecting cabinet-ground conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 rn) of extra length so dryer call be moved if needed.

Strip 31/2'' (8.9 cm) of outer covering from end of cable. Strip insulation back 1" (2.5 cm). If

using 3-wire cable with ground wire, cut bare wire even with outer covering. Shape ends of

wires into a hook shape.

_B.9c_

When connecting to the terminalblock, place the hooked end of the wire under the screw of

the terminal block (hook facing right),squeeze hooked end togetherand tightenscrew, as

shown.

1. Loosen or remove center silver-colored terminal block screw.

I

A. f xtemal ground conductor scre'w

B. Neutral ground wire

C. Ce'nter silver-colore'd tenTlinal block scre'w

O. Neutral wire' (white or cente'r wire)

E. _" (1.9 cm) U[ li_te'd strain relief

Place the hooked ends of the other direct wire cable wires under the outer terminal block

screws (hooks facing right). Squeeze hooked ends togethen Tighten screws.

!! !!

4. Tighten strain relief screw.

5. Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-

down screw.

6. You have completed your electrical connection. Now go to "Venting Requirements."

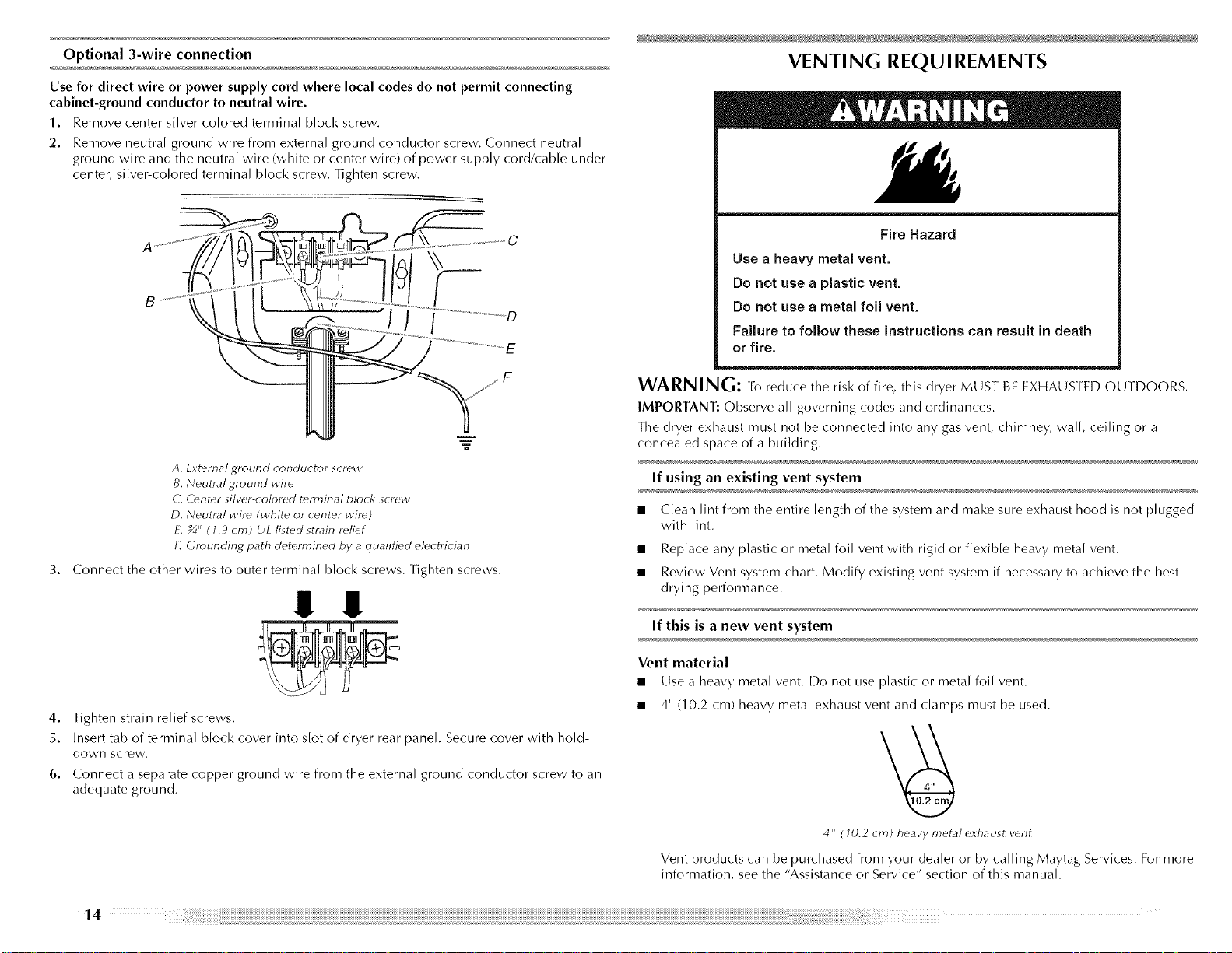

Optional 3-wire connection

Use for direct wire or power supply cord where local codes do not permit connecting

cabinet-ground conductor to neutral wire.

1. Remove center silver-colored terminal block screw.

2. Remove neutral ground wire from external ground conductor screw. Connect neutral

ground wire and the neutral wire (white or center wire) of power supply cord/cable under

center, silver-colored terminal block screw. Tighten screw.

E

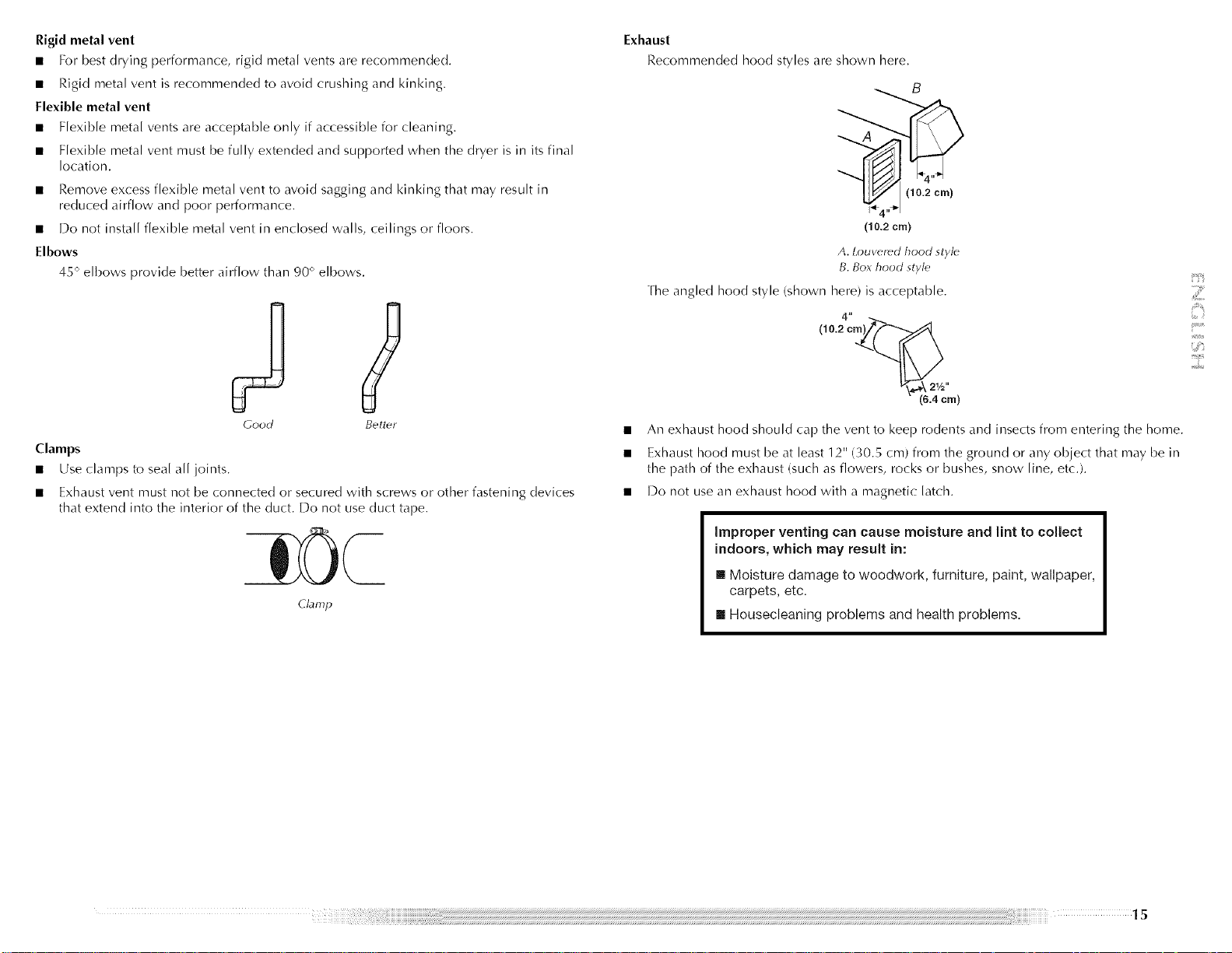

VENTI NG REQUI REMENTS

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

F

A. Fxt_'rnal ground colTductol screw

B. Neutral ground wir_"

C. C_'nter silver-colored t_'rminal block screw

D. Neutral wire (white or center wir_')

E. _" (1.9 cm) UL listed strain r_'li_'f

F. Grounding path determined by a qualifi_'d electrician

3.

Connect the other wires to outer terminal block screws. Tighten screws.

!! !!

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear paneh Secure cover with hold-

down screw.

6.

Connect a separate copper ground wire from the external ground conductor screw to an

adequate ground.

WARNING: lo reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent, chimney, wall, ceiling or a

concealed space of a building.

If using an existing vent system

• Clean lint from the entire length of the system and make sure exhaust hood is not plugged

with lint.

• Replace any plastic or metal foil vent with rigid or flexible heavy metal vent.

• Review Vent system chart. Modify existing vent system if necessary to achieve the best

drying performance.

If this is a new vent system

Vent material

• Use a heavy metal vent. [90 not use plastic or metal foil vent.

• 4" (10.2 cm) heavy metal exhaust vent and clamps must be used.

4" ( 10.2 cm) heavy metal exhaust v_'nt

Vent products can be purchased from your dealer or by calling Maytag Services. For more

information, see the "Assistance or Service" section of this manual.

14

Rigid metal vent

• For best drying performance, rigid metal vents are recommended.

• Rigid metal vent is recommended to avoid crushing and kinking.

Flexible metal vent

• Flexible metal vents are acceptable only if accessible for cleaning.

• Flexible metal vent must be fully extended and supported when the dryer is in its final

location.

• Remove excess flexible metal vent to avoid sagging and kinking that may result in

reduced airflow and poor performance.

• Do not install flexible metal vent in enclosed walls, ceilings or floors.

Elbows

45 ° elbows provide better airflow than 90 ° elbows,

Good Better

Clamps

Use clamps to seal all joints.

Exhaust vent must not be connected or secured with screws or other fastening devices

that extend into the interior of the duct. Do not use duct tape.

Clamp

Exhaust

Recommended hood styles are shown here.

B

I_ 4. _,

(10.2 cm)

A. Louw'red hood style

B. Box hood style

The angled hood style (shown here) is acceptable.

4"

(,02cTii--

"_'k"_ 2_/,'

(6.4 cm)

• An exhaust hood should cap the vent to keep rodents and insects from entering the home.

• Exhaust hood must be at least 12" (30.5 cm) from the ground or any object that may be in

the path of the exhaust (such as flowers, rocks or bushes, snow line, etc./.

• Do not use an exhaust hood with a magnetic latch.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

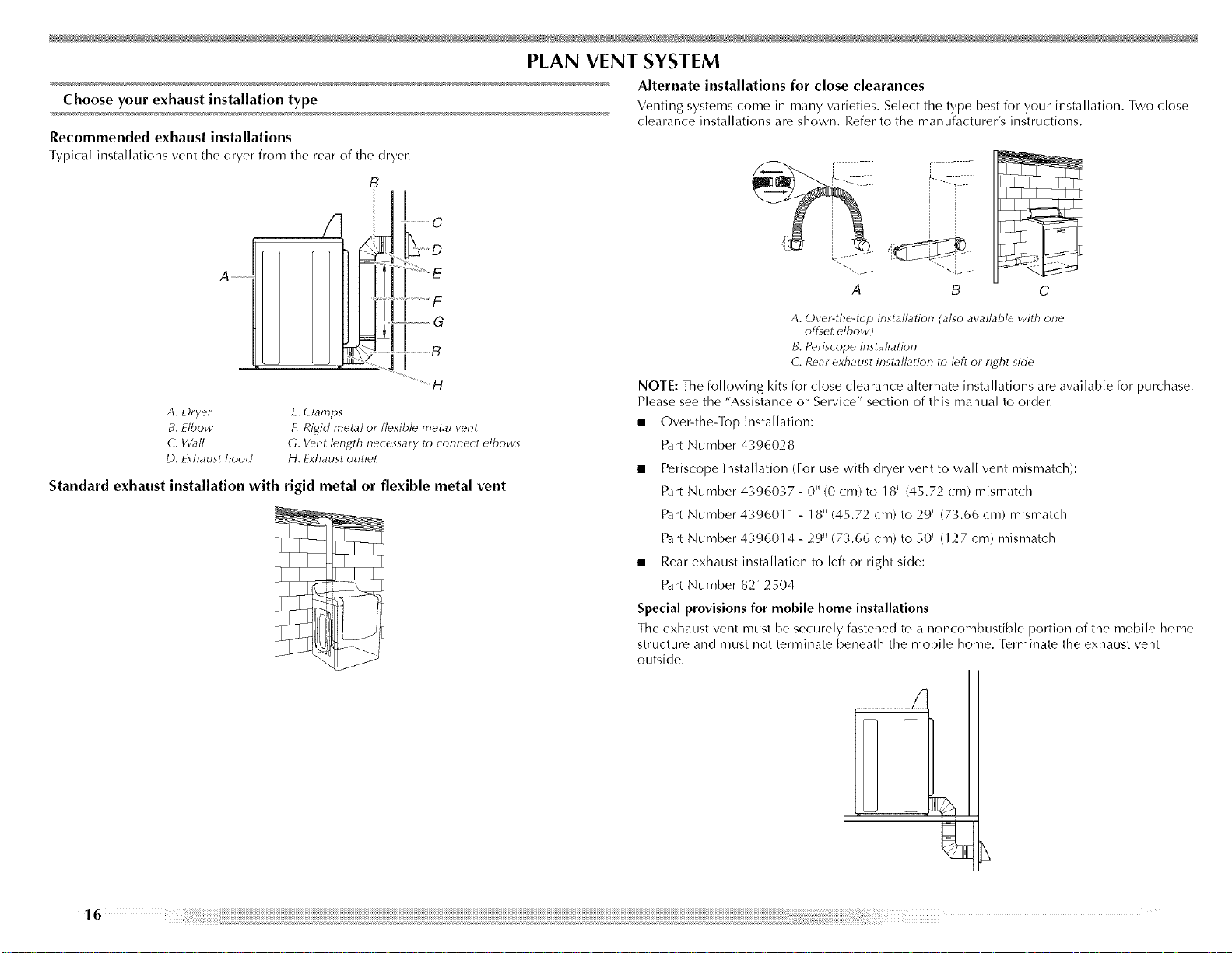

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

B

A ¸

.........i..............................F

A. Dryer

B. Elbow

C. Wall

D. Fxhaust hood

E. Clamps

£ Rigid metal or flexible metal vent

G. Vmlt I_'ngth necessary to connect elbovw

H. Fxhaust outlet

Standard exhaust installation with rigid metal or flexible metal vent

PLAN VENT SYSTEM

Alternate installations for close clearances

Venting systems come in many w_rieties. Select the type best for your installation. |wo close-

clearance installations are shown. Refer to the manufacturer's instructions.

NOTE: The following kits for close clearance alternate installations are available for purchase.

Please see the "Assistance or Service" section of this manual to order.

• Over-the-]bp Installation:

Part Number 4396028

• Periscope Installation (For use with dryer vent to wall vent mismatch):

Part Number 4396037 - 0" (0 cm) to 18" (45.72 cm) mismatch

Part Number 4396011 - 18" (45.72 cm) to 29" (73.66 cm) mismatch

Part Number 4396014- 29" (73.66 cm) to 50" (127 cm) mismatch

• Rear exhaust installation to left or right side:

Part Number 8212504

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible portion of the mobile home

structure and must not terminate beneath the mobile home. Terminate the exhaust vent

outside.

A B C

A. Over-the-top installation (also available with one

offset elbow)

B.P_'riscope inst_llation

C. Rear exhaust installadon to left or right sidle

f

Determine vent path

• Select the route that will provide the straightest and most direct path outdoors.

• Plan the installation to use the fewest number of elbows and turns.

• When using elbows or making turns, allow as much room as possible.

• Bend vent gradually to avoid kinking.

• Use the fewest 90 ° turns possible.

INSTALL VENT SYSTEM

1. install exhaust hood. Use caulking compound to seal exterior wall opening around

exhaust hood.

2. Connect vent to exhaust hood. Vent must fit inside exhaust hood. Secure vent to exhaust

hood with 4" (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible. See "Determine vent path" in

"Plan Vent System." Avoid 90° turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior of the vent to secure vent.

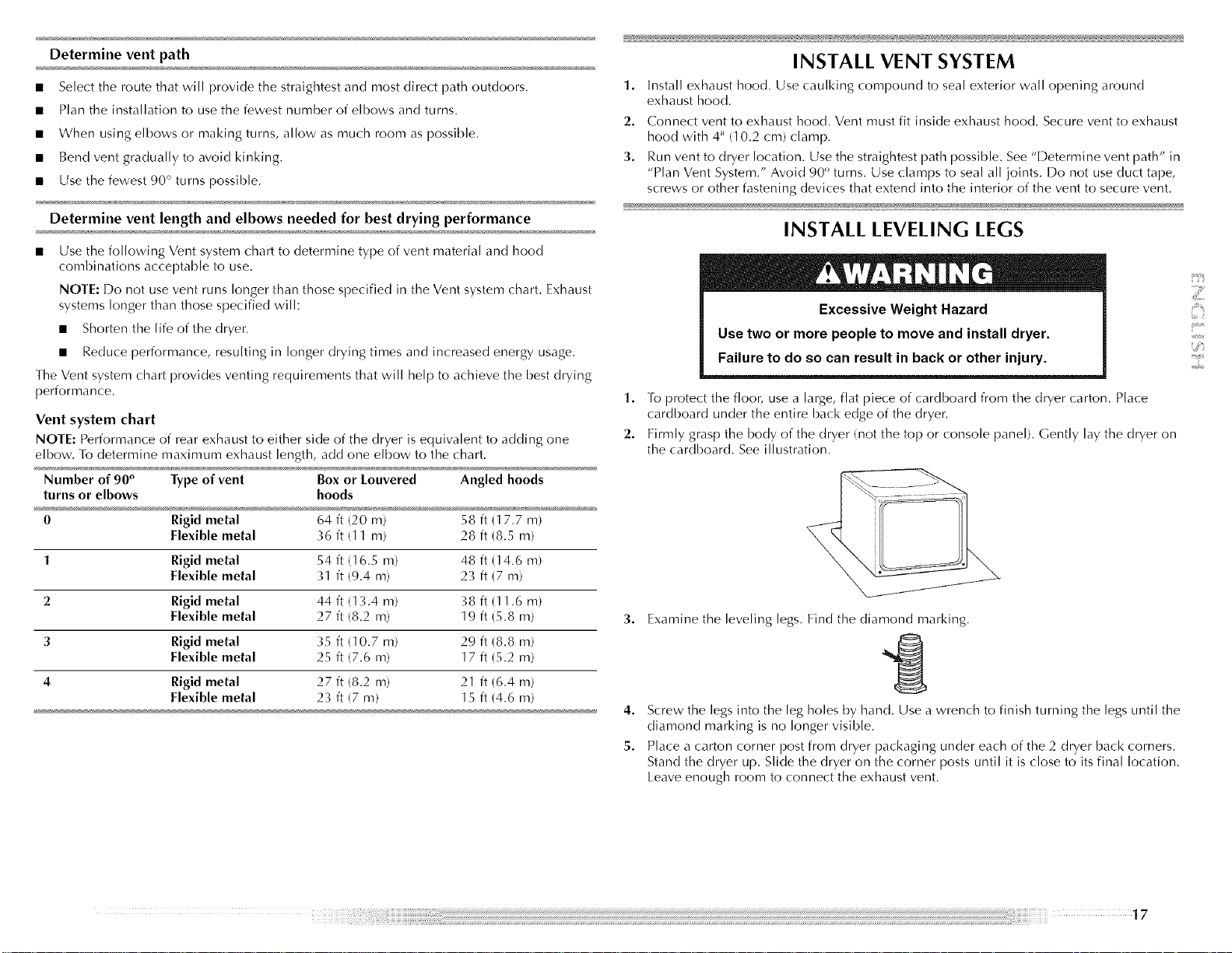

Determine vent length and elbows needed for best drying performance

• Use the following Vent system chart to determine type of vent material and hood

combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in the Vent system chart. Exhaust

systems longer than those specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and increased energy usage.

The Vent system chart provides venting requirements that will help to achieve the best drying

performance.

Vent system chart

NOTE: Performance of rear exhaust to either side of the dryer is equiw_lent to adding one

elbow. To determine maximum exhaust length, add one elbow to the chart.

Number of 90 ° Type of vent Box or Louvered Angled hoods

turns or elbows hoods

0 Rigid metal 64 ft (20 m) 58 ft (17.7 m)

1 Rigid metal 54 ft (16.5 m) 48 ft (14.6 m)

2 Rigid metal 44 ff (13.4 m) 38 ft (11.6 m)

3 Rigid metal 35 ff (10.7 m) 29 ft (8.8 m)

4

Flexible metal 36 ft (11 m) 28 ft (8.5 m/

Flexible metal 31 ft (9.4 m) 23 ft (7 m)

Flexible metal 27 ff (8.2 m) 19 ft (5.8 m/

Flexible metal 25 ff (7.6 m) 17 ft (5.2 m/

Rigid metal 27 ft (8.2 m) 21 ft (6.4 m)

Flexible metal 23 ft 17 m) 15 ft (4.6 m)

INSTALL LEVELING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. lb protect the floor, use a large, flat piece of cardboard from the dryer carton. Place

cardboard under the entire back edge of the dryer.

2. Firmly grasp the body of the dryer (not the top or console panel). Gently lay the dryer on

the cardboard. See illustration.

Examine the leveling legs. Find the diamond marking.

4. Screw the legs into the leg holes by hand. Use a wrench to finish turning the legs until the

diamond marking is no longer visible.

5. Place a carton corner post from dryer packaging under each of the 2 dryer back corners.

Stand the dryer up. Slide the dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent.

CONNECT VENT

1. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in dryer. If connecting to

existing vent, make sure the vent is clean. The dryer vent must fit over the dryer exhaust

outlet and inside the exhaust hood. Check that the vent is secured to exhaust hood with a

4" (102 cm) clamp.

2. Move dryer into its final location. Do not crush or kink vent.

3. (On gas models) Check that there are no kinks in the flexible gas line.

4. Once the exhaust vent connection is made, remove the corner posts and cardboard.

LEVEL DRYER

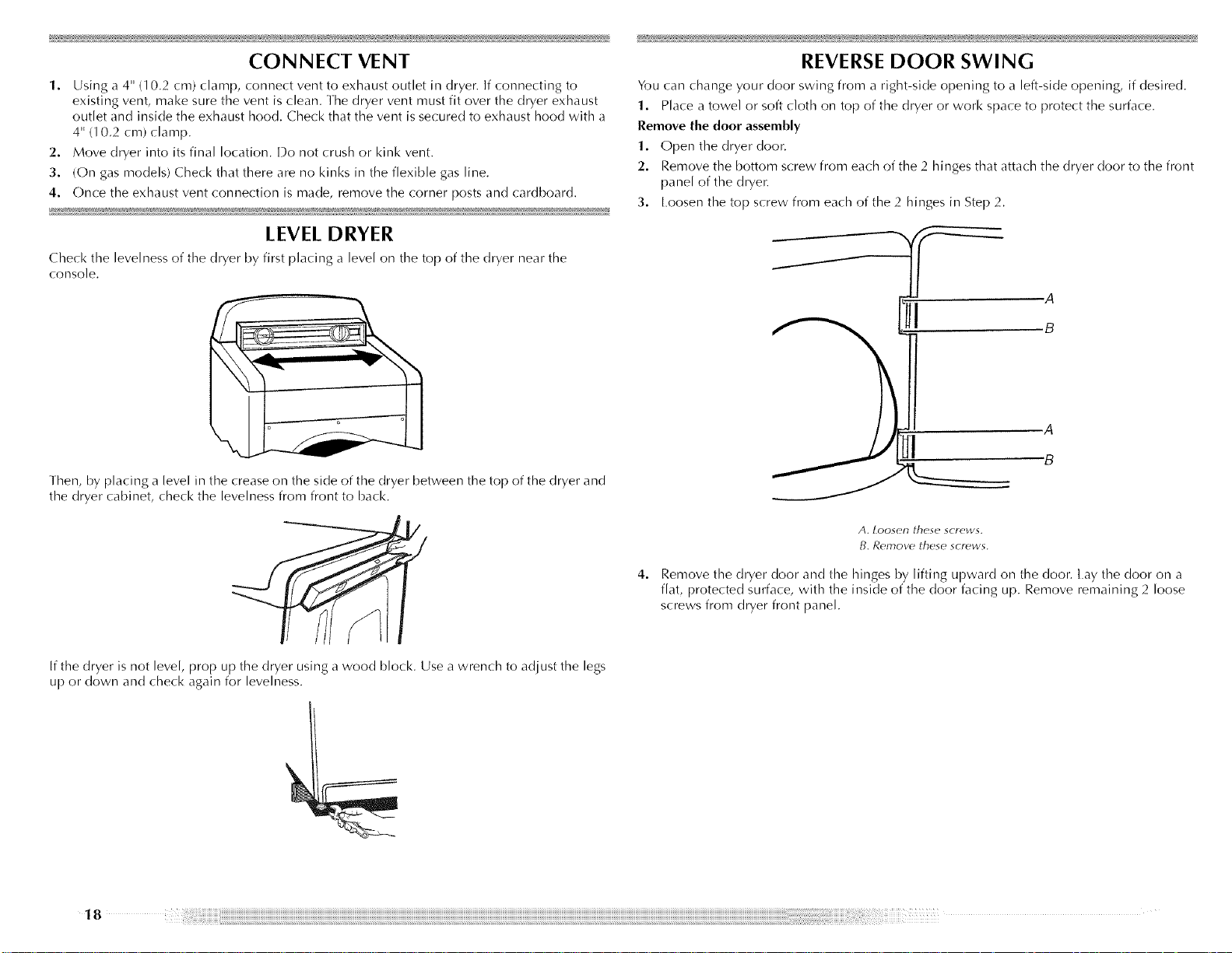

Check tile levelness of the dryer by first placing a level on the top of the dryer near the

console,

Then, by placing a level ill the crease on the side of the dryer between the top of the dryer and

the dryer cabinet, check the levelness from front to back.

REVERSE DOOR SWING

You can change your door swing from a right-side opening to a left-side opening, if desired.

1. Place a towel or soft cloth on top of the dryer or work space to protect the surface.

Remove the door assembly

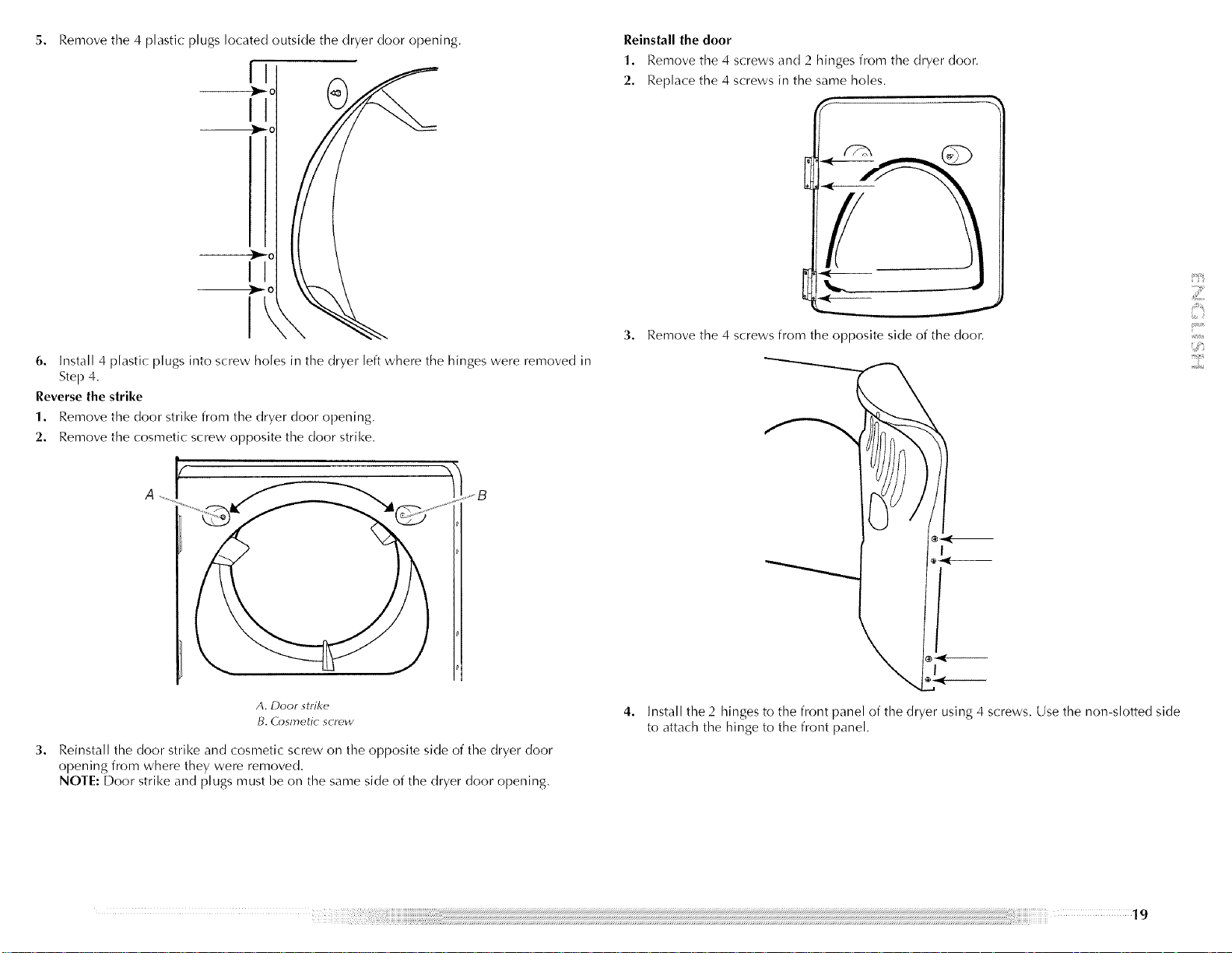

1. Open the dryer door.

2. Remove the bottom screw from each of the 2 hinges that attach the dryer door to the front

panel of the dryer.

3. [oosen the top screw from each of the 2 hinges in Step 2.

A

B

A

B

If the dryer is not level, prop up the dryer using a wood block. Use a wrench to adjust the legs

up or down and check again for levelness.

18

A. _oosd!l} thd!s(! scF(!ws.

B. Rd!movd! t]l(!sd! 8c1(!w8.

4,

Remove the dryer door and the hinges by lifting upward on the door. I.ay the door on a

flat, protected surface, with the inside of the door facing up. Remove remaining 2 loose

screws from dryer front paneh

5. Removethe4plasticplugslocatedoutsidethedryerdooropening.

II

II

6. Install 4 plastic plugs into screw holes in the dryer left where the hinges were removed in

Step 4.

Reverse the strike

1. Remove the door strike from the dryer door opening.

2. Remove the cosmetic screw opposite the door strike.

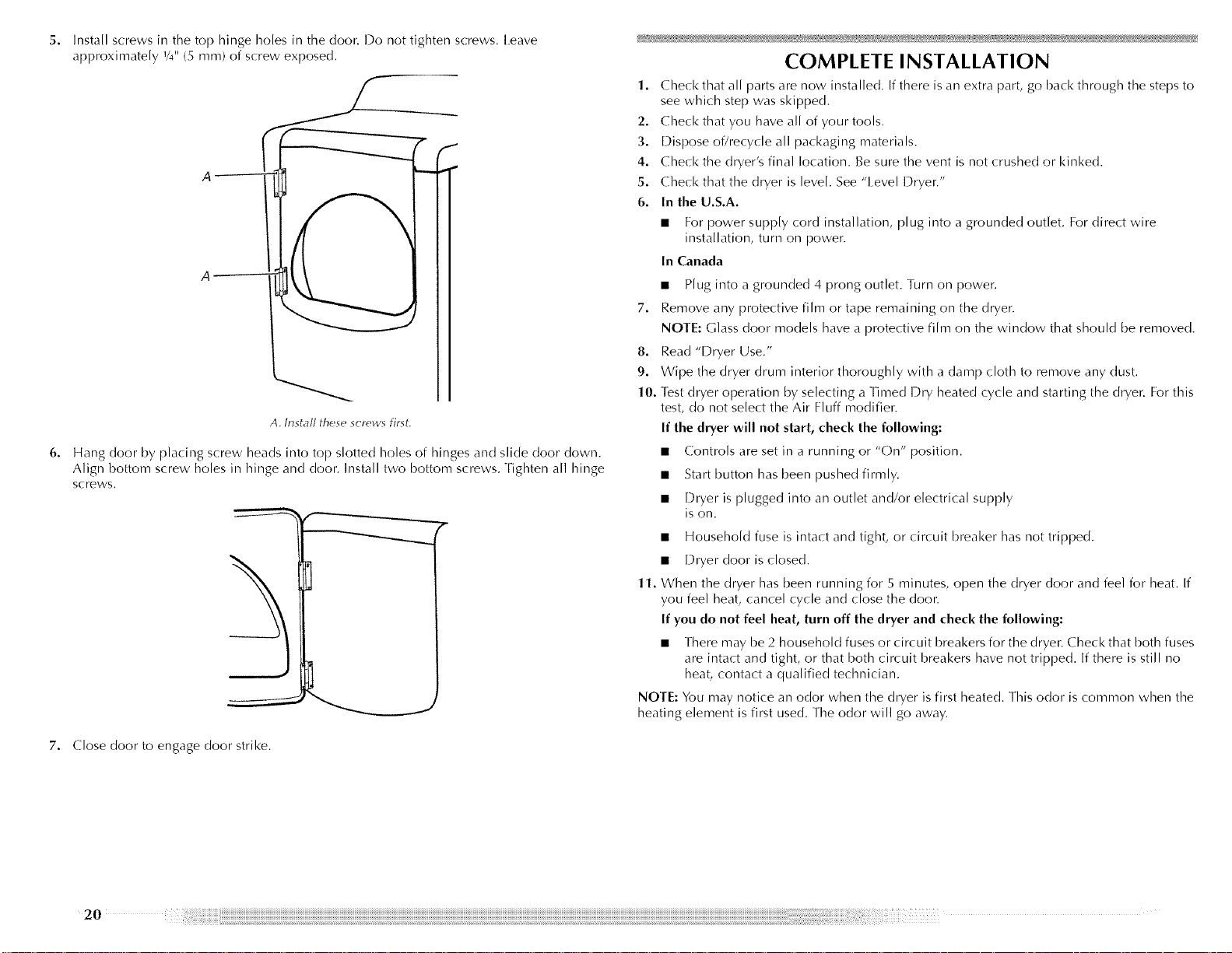

Reinstall the door

1. Remove the 4 screws and 2 hinges from the dryer door.

2. Replace the 4 screws in the same holes.

I

3. Remove the 4 screws from the opposite side of the door.

A. Door strike

m. _OSITI(!tic scr_!\,v

Reinstall the door strike and cosmetic screw on the opposite side of the dryer door

opening from where they were removed.

NOTE: Door strike and plugs must be on the same side of the dryer door opening.

Install the 2 hinges to the front panel of the dryer using 4 screws. Use the non-slotted side

to attach the hinge to the front panel.

5,

Install screws in the top hinge holes ill the door. Do not tighten screws. I.eave

approximately Y2'/5 mm) of screw exposed.

A. hlstall these screws first.

6,

Hang door by placing screw heads into top slotted holes of hinges and slide door down.

Align bottom screw holes ill hinge and door. Install two bottom screws. Tighten all hinge

screws,

COMPLETE INSTALLATION

1. Check that all parts are now installed. If there is an extra part, go back through the steps to

see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check the dryer's final location. Be sure the vent is not crushed or kinked.

5. Check that the dryer is level. See "l.evel Dryer."

6. In the U.S.A.

• For power supply cord installation, plug into a grounded outlet. For direct wire

installation, turn on power.

In Canada

• Plug into a grounded 4 prong outlet, lurn on power.

7. Remove any protective film or tape remaining on the dryer.

NOTE: Class door models have a protective film on the window that should be removed.

8. Read "Dryer Use."

9. Wipe the dryer drum interior thoroughly with a damp cloth to remove any dust.

10. ]i_st dryer operation by selecting a Timed Dry heated cycle and starting the dryer. For this

test, do not select the Air Fluff modifier.

If the dryer will not start, check the following:

• Controls are set in a running or "On" position.

• Start button has been pushed firmly.

• Dryer is plugged into an outlet and/or electrical supply

is on.

• Household fuse is intact and tight, or circuit breaker has not tripped.

• Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the dryer door and feel for heat. [f

you feel heat, cancel cycle and close the door.

If you do not feel heat, turn off the dryer and check the following:

• [here may be 2 household fuses or circuit breakers for the dryer. Check that both fuses

are intact and tight, or that both circuit breakers have not tripped. [f there is still no

heat, contact a qualified technician.

NOTE: You may notice an odor when the dryer is first heated. This odor is common when the

heating element is first used. lhe odor will go away.

7. Close door to engage door strike.

20

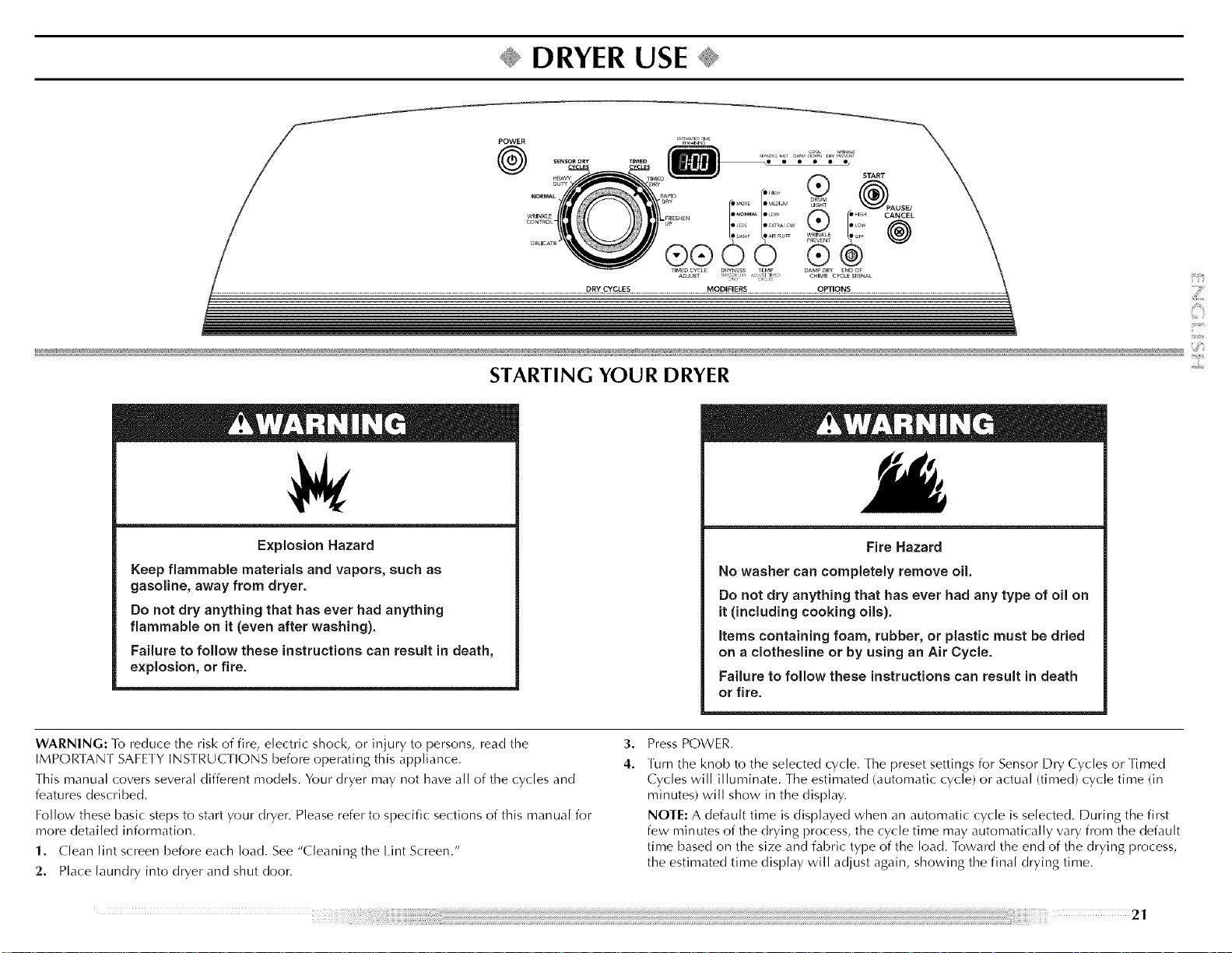

DRYER USE

STARTING Your DRYER

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING: [b reduce the risk of fire, electric shock, or injury to persons, read the

IMPORTANT SAFETY INSTRUCTIONS before operating this appliance.

This manual covers several different models. Your dryer may not have all of the cycles and

features described.

Follow these basic steps to start your dryer. Please refer to specific sections of this manual for

more detailed information.

1. Clean lint screen before each load. See "Cleaning the Lint Screen."

2. Place laundry into dryer and shut door.

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

items containing foam, rubber, or plastic must he dried

on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in death

or fire.

3,

Press POWER.

4.

[urn the knob to the selected cycle. [-he preset settings for Sensor Dry Cycles or Timed

Cycles will illuminate. The estimated (automatic cycle) or actual (timed) cycle time (in

minutes) will show in the display.

NOTE: A default time is displayed when an automatic cycle is selected. During the first

few minutes of the drying process, the cycle time may automatically vary from the default

time based on the size and fabric type of the load. ]oward the end of the drying process,

the estimated time display will adjust again, showing the final drying time.

To use a Sensor Dry Cycle

• Press POWER.

• Turn the knob to desired Sensor Dry Cycle.

• Select DRYNESS to adjust how dry you want the load. As the cycle runs, the control

senses the dryness of the load and adjusts the time automatically for the selected

dryness level.

The default dryness setting is Normal when a Sensor Dry Cycle is selected. You can

select a different dryness level, depending on your load, by pressing [Dryness and

choosing More, less or [)amp. Selecting More, Less or Damp automatically adjusts

the sensed time needed. Once a dryness level is set, it cannot be changed without

stopping the cycle.

• Select the desired Options.

To make changes during a Sensor Dry Cycle:

• Press PAUSE/CANCEl.

• Adjust Dryness.

• MORE

• _OR_Ag

• LESS

DRYNESS

c N_s¸

NOTE: [Dryness selections can be made only while using Sensor Dry Cycles.

How the Sensi-Care TM Drying System Works

Moisture-sensing strips and temperature sensors inside the dryer drum monitor how fast

the load is drying, how hot the air should be and when clothes are dry. The system

automatically stops the cycle to help save time and avoid overdrying.

To use a Timed Cycle

• Turn knob to desired limed Cycle.

• Press the TIMED CYCI.E ADJUST up or down arrows until the desired drying time is

displayed. Press the up or down arrows and the time will change by 1-minute

intervals. Press and hold the up or down arrows and the time will change by 5-minute

intervals.

NOTE: The Timed Cycle Adjust features can be used only with Timed Cycles.

TIMED CYCLE

ADJUST

Press TEMP until the desired temperature illuminates.

• NIGN

• MEDIUM

• ow

• EX RA OW

FI UFF

TEMP

ADIS[ NMD

CYC[ES

NOTE: The ]emp feature can be used only with Timed Cycles.

NOTE: During a Timed Cycle, you can change the settings for Time, Temp, the Wrinkle

Prevent setting and the End of Cycle Signal.

5. (OPTIONAl. STEP) If desired, select OPTIONS. For more details, see "Options."

6. (OPTIONAl. STEP) If desired, press ENID OF CYCI.E SIGNAl.. A signal will sound to alert

you when a cycle ends. For more details, see "End of Cycle Signal."

7. Press STARE Be sure the door is closed.

• If you do not press Start within 5 minutes of selecting the cycle, the dryer

automatically shuts off.

• If you wish to end your drying cycle after pressing Start, press PAUSE/CANCEl. twice.

STOPPING, PAUSING OR RESTARTING

To stop or pause your dryer at any time

Open the door or press PAUSE/CANCEr once. Press PAUSE/CANCEE twice to cancel a cycle.

To restart the dryer

Close the door. Press START until dryer starts.

NOTE: Drying will continue from where the cycle was interrupted if you close the door and

press Start within 5 minutes. If the cycle is interrupted for more than 5 minutes, the dryer will

shut off. Select new cycle settings before restarting the dryer.

DRYING AND CYCLE TIPS

Select the correct cycle and dryness level or temperature for your load. If a Sensor [Dry Cycle

is running, the display shows the estimated cycle time when your dryer is automatically

sensing the dryness level of your load. If a Timed Cycle is running, the display shows the exact

number of minutes remaining in the cycle.

Cool Down tumbles the load without heat during the last few minutes of all cycles. Cool

[:)own makes the loads easier to handle and reduces wrinkling. The length of the Cool Down

depends on the load size and dryness level.

Drying tips

• Follow care label directions when they are available.

• If desired, add a fabric softener sheet. Follow package instructions.

• lb reduce wrinkling, remove the load from the dryer as soon as tumbling stops. ]his is

especially important for permanent press, knits and synthetic fabrics.

• Avoid drying heavy work clothes together with lighter fabrics. This could cause

overdrying of lighter fabrics and lead to increased shrinkage or wrinkling.

22

Cycle tips

• Dry most loads using the preset cycle settings.

• Refer to the Sensor Dry or Timed Preset Cycle Settings chart (in the "Cycles" section) for a

guide to drying various loads.

• Drying temperature and dryness level are preset when you choose a Sensor Dry

Cycle. You call select a different dryness level, depending on your load, by pressing

Dryness and choosing More, Normal, less or Damp.

NOTE: You cannot use the limed Cycle Adjust and you cannot choose a lemperature

with the Sensor Dry Cycles.

• [f you wish to adjust the cycle length of a Timed Cycle, press the Timed Cycle Adjust

up or down arrows. Adjust the temperature of a Timed Cycle by pressing letup until

the desired temperature is selected.

NOTE: You cannot choose a dryness level with Timed Cycles.

Wrinkle Prevent Setting

The Wrinkle Prevent setting light illuminates when this option is selectee]. This indicator stays

on during the Wrinkle Prevent setting.

Indicator lights

()timer indicator lights show Cycle, Modifiers, Options and Cycle Signal settings selectee], lhe

display shows the estimated or actual time remaining.

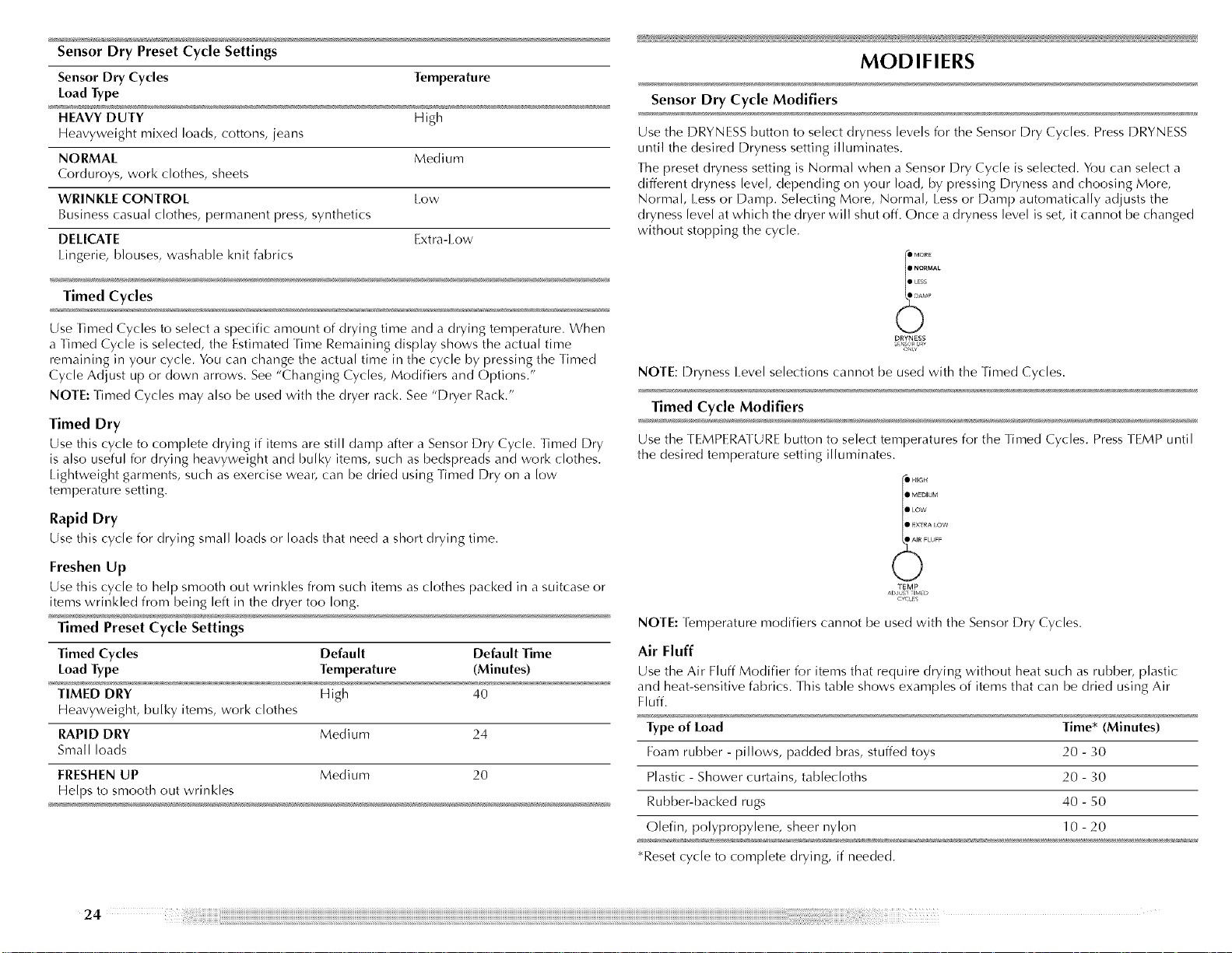

CYCLES

Select the drying cycle that matches the type of load you are drying. See Sensor Dry or limed

Preset Cycle Settings charts.

SENSOR DRY TIMED

I

STATUS LIGHTS

Follow the progress of your dryer with the drying Status indicator lights.

SENSING WET DAMP DOWN DRY PREVENT

\0 • • • • 0_

Sensing

• In a Sensor Dry Cycle, the Sensing light illuminates until a wet item is detected.

• In a Timed Cycle, the Sensing light illuminates at the beginning of a cycle and turns off

5 minutes into the cycle.

Wet

The Wet light illuminates at the beginning of a Sensor Dry Cycle if a wet item is detected.

• in a Sensor Dry Cycle, if a wet item is not detected after approximately 5 minutes, the

dryer goes directly into Cool Down. The Cool Down and the Wrinkle Prevent setting

indicators will illuminate, if selected.

• In a Timed Cycle, wet items are not detected. [he dryer will continue to run for the length

of time selected, and the Wet light will illuminate. The damp light will not illuminate.

Damp

The Damp light illuminates in a Sensor Dry Cycle when the laundry is approximately 80%

dry. Damp Dry Chime beeps, if selected. See "Options."

Cool Down

The Cool [)own light illurninates during the cool down part of the cycle. [aundry cools for

ease in handling.

COOL WRINKLE

WRINKLE

CONTROL_

DRY CYCLES

Sensor Dry Cycles

Sensor Dry Cycles allow you to match the cycle to the load you are drying. See the following

Sensor Dry Preset Cycle Settings chart. Each cycle dries certain fabrics at the recommended

temperature. A sensor detects the moisture in the load and automatically adjusts the drying

time for optimal drying.

Heavy Duty

Use this cycle to get high heat for heavyweight mixed loads, cottons and jeans.

Normal

Use this cycle to get medium heat for drying sturdy fabrics such as work clothes and sheets.

Wrinkle Control

Use this cycle to get low heat for drying no-iron fabrics, such as sport shirts, casual business

clothes and permanent press blends.

Delicate

Use this cycle to get extra-low heat to gently dry items such as lingerie, blouses or washable

knit fabrics.

Dry

The Dry light illuminates whelm the drying cycle is finished. This indicator stays on during tile

Wrinkle Prevent setting.

Sensor Dry Preset Cycle Settings

Sensor Dry Cycles Temperature

Load Type

HEAVY DUTY High

Heavyweight mixed loads, cottons, jeans

NORMAL Medium

Corduroys, work clothes, sheets

WRINKLE CONTROL low

Business casual clothes, permanent press, synthetics

DELICATE Extra-Low

lingerie, blouses, washable knit fabrics

Timed Cycles

MODIFIERS

Sensor Dry Cycle Modifiers

Use the DRYNESS button to select dryness levels for the Sensor [Dry Cycles. Press DRYNESS

until the desired Dryness setting illuminates.

[he preset dryness setting is Normal when a Sensor Dry Cycle is selected. You can select a

different dryness level, depending on your load, by pressing Dryness and choosing More,

Normal, [.ess or Damp. Selecting More, Normal, less or Damp automatically adjusts the

dryness level at which the dryer will shut off. Once a dryness level is set, it cannot be changed

without stopping the cycle.

•MORE

• NO_AL

• _ESS

Use Timed Cycles to select a specific amount of drying time and a drying temperature. When

a Timed Cycle is selected, the Estimated Time Remaining display shows the actual time

remaining in your cycle. You can change the actual time in the cycle by pressing the Timed

Cycle Adjust up or down arrows. See "Changing Cycles, Modifiers and Options."

NOTE: Timed Cycles may also be used with the dryer rack. See "Dryer Rack."

Timed Dry

Use this cycle to complete drying if items are still damp after a Sensor Dry Cycle. Timed Dry

is also useful for drying heavyweight and bulky items, such as bedspreads and work clothes.

[ightweight garments, such as exercise wear, can be dried using Timed Dry on a low

temperature setting.

Rapid Dry

Use this cycle for drying small loads or loads that need a short drying time.

Freshen Up

Use this cycle to help smooth out wrinkles from such items as clothes packed in a suitcase or

items wrinkled from being left in the dryer too long.

Timed Preset Cycle Settings

Timed Cycles Default Default Time

Load Type Temperature (Minutes)

TIMED DrY High 40

Heavyweight, bulky items, work clothes

RAPID DRY Medium 24

Small loads

FRESHEN UP Medium 20

Helps to smooth out wrinkles

DRYNESS

NOTE: [Dryness I.evel selections cannot be used with the Timed Cycles.

Timed Cycle Modifiers

Use fine TEMPERATURE button to select temperatures for the limed Cycles. Press TEMP until

the desired temperature setting illuminates.

• M_DIUM

• ow

• EXTRA_ow

FLUFF

TEMP

ADUS ]M_D

CYCEg

NOTE: lemperature modifiers cannot be used with the Sensor Dry Cycles.

Air Fluff

Use the Air Fluff Modifier for items that require drying without heat such as rubber, plastic

and heat-sensitive fabrics. ]his table shows examples of items that can be dried using Air

Fluff.

Type of Load Time* (Minutes)

Foam rubber - pillows, padded bras, stuffed toys

Plastic- Shower curtains, tablecloths

Rubber-backed rugs

Olefin, polypropylene, sheer nylon

20 - 30

20 - 30

40 - 50

10 -20

*Reset cycle to complete drying, if needed.

24

When using Air Fluff

• Check that coverings are securely stitched.

• Shake and fluff pillows by hand periodically during the cycle.

• Dry item completely. Foam rubber pillows are slow to dry.

NOTE: Air Fluff is not available with Sensor Dry Cycles.

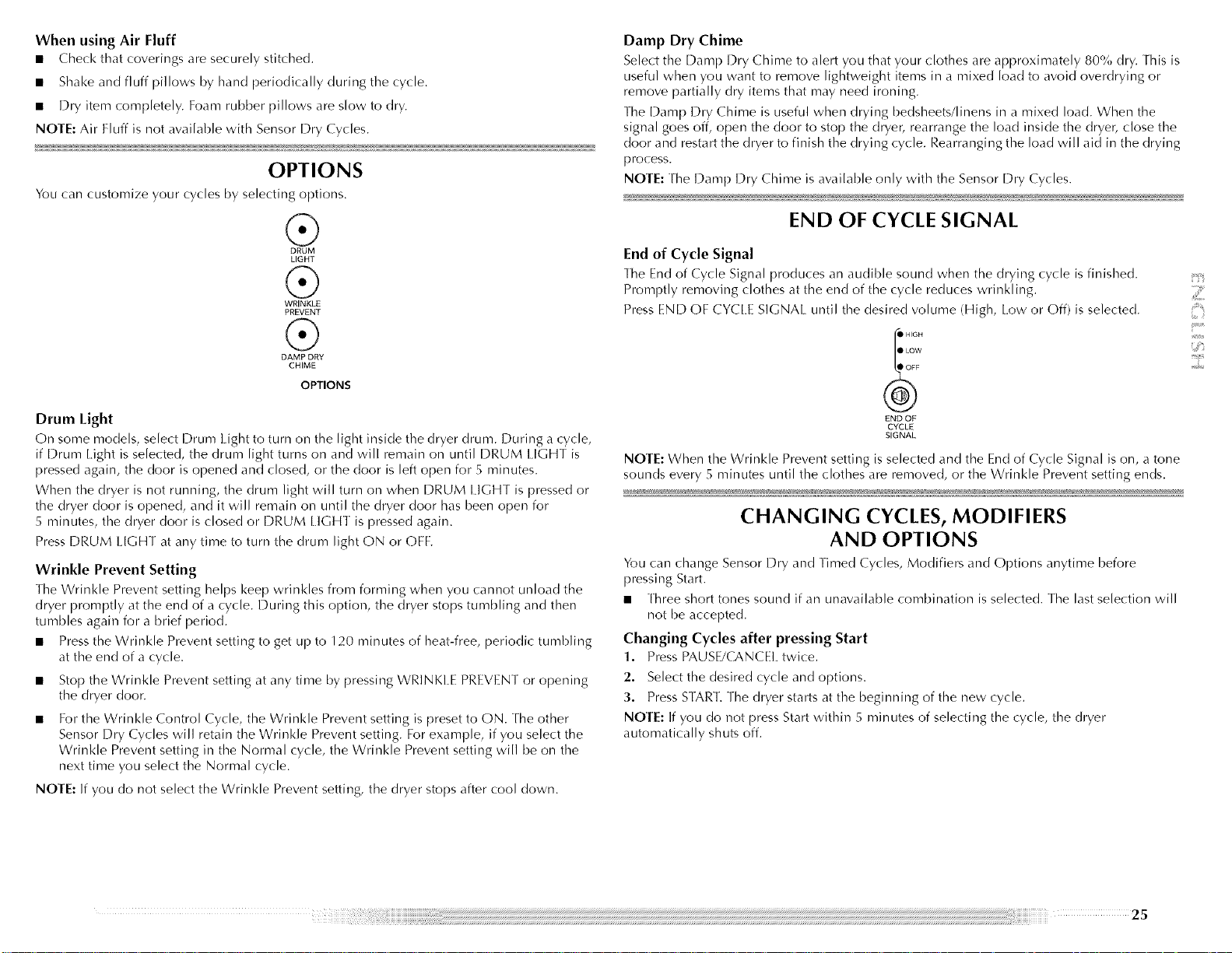

OPTIONS

You can customize your cycles by selecting options.

®

DRUM

LIGHT

®

WRINKLE

PREVENT

®

DAMP DRY

CHIME

OPTIONS

Damp Dry Chime

Select tile Damp Dry Chime to alert you that your clothes are approximately 80% dry. This is

useful when you want to remove lightweight items in a mixed load to avoid overdrying or

remove partially dry items that may need ironing.

[he [)amp Dry Chime is useful when drying bedsheets/linens in a mixed load. When the

signal goes off, open the door to stop the dryer, rearrange the load inside the dryer, close the

door and restart the dryer to finish the drying cycle. Rearranging the load will aid in the drying

process.

NOTE: The Damp Dry Chime is available only with the Sensor Dry Cycles.

END OF CYCLE SIGNAL

End of Cycle Signal

The End of Cycle Signal produces an audible sound when the drying cycle is finished.

Promptly removing clothes at the end of the cycle reduces wrinkling.

Press END OF CYCLE SIGNAl until the desired volume (High, low or Off) is selected.

• HIGH

• LOW

I

Drum Light

On some models, select [)rum light to turn on the light inside the dryer drum. During a cycle,

if [)rum I.ight is selected, the drum light turns on and will remain on until DRUM IEGHT is

pressed again, the door is opened and closed, or the door is left open for 5 minutes.

When the dryer is not running, the drum light will turn on when [)RUM I.IGHT is pressed or

the dryer door is opened, and it will remain on until the dryer door has been open for

5 minutes, the dryer door is closed or [)RUM I.IGHT is pressed again.

Press DRUM IEGHT at any time to turn the drum light ON or OFF.

Wrinkle Prevent Setting

The Wrinkle Prevent setting helps keep wrinkles from forming when you cannot unload the

dryer promptly at the end of a cycle. During this option, the dryer stops tumbling and then

tumbles again for a brief period.

• Press the Wrinkle Prevent setting to get up to 120 minutes of heat-free, periodic tumbling

at the end of a cycle.

• Stop the Wrinkle Prevent setting at any time by pressing WRINKLE PREVENT or opening

the dryer door.

• For the Wrinkle Control Cycle, the Wrinkle Prevent setting is preset to ON. The other

Sensor Dry Cycles will retain the Wrinkle Prevent setting. For example, if you select the

Wrinkle Prevent setting in the Normal cycle, the Wrinkle Prevent setting will be on the

next time you select the Normal cycle.

NOTE: If you do not select the Wrinkle Prevent setting, the dryer stops after cool down.

END OF

CYCLE

SIGNAL

NOTE: When the Wrinkle Prevent setting is selected and the End of Cycle Signal is on, a tone

sounds every 5 minutes until the clothes are removed, or the Wrinkle Prevent setting ends.

CHANGING CYCLES, MODIFIERS

AND OPTIONS

You can change Sensor Dry and Timed Cycles, Modifiers and C)ptions anytime before

pressing Start.

• Three short tones sound if an unavailable combination is selected. The last selection will

not be accepted.

Changing Cycles after pressing Start

1. Press PAUSE/CANCEl twice.

2. Select the desired cycle and options.

3. Press START. The dryer starts at the beginning of the new cycle.

NOTE: If you do not press Start within 5 minutes of selecting the cycle, the dryer

automatically shuts off.

Changing Modifiers and Options after pressing Start

You can change an Option or Modifier anytime before the selected Option or Modifier

begins.

1. Press PAUSE/CANCEl once.

2. Select the new Option and/or Modifiers.

3. Press START to continue the cycle.

NOTE: If you happen to press PAUSFYCANCE[ twice, the program clears and your dryer shuts

down. Restart the selection process.

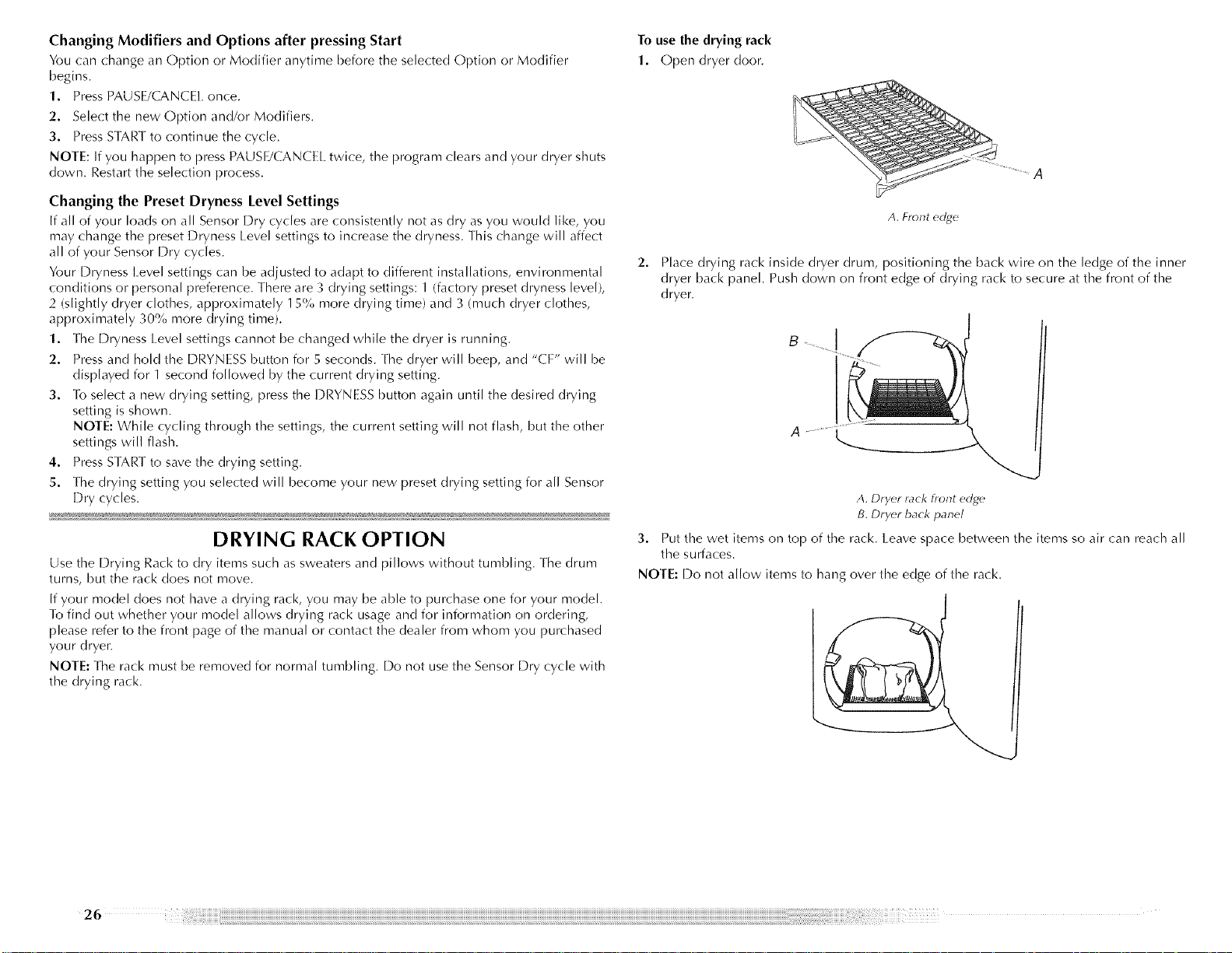

To use the drying rack

1. Open dryer door.

Changing the Preset Dryness Level Settings

[f all of your loads on all Sensor Dry cycles are consistently not as dry as you would like, you

may change the preset Dryness level settings to increase the dryness. This change will affect

all of your Sensor Dry cycles.

Your Dryness level settings can be adjusted to adapt to different installations, environmental

conditions or personal [)reference. There are _¢drying settings: 1 (factory preset dryness level),

2 (slightly dryer clothes, approximately 15% more drying time) and 3 (much dryer clothes,

approximately 30% more drying time).

1. The Dryness ].evel settings cannot be changed while the dryer is running.

2. Press and hold the DRYNESS button for 5 seconds. The dryer will beep, and "CF" will be

displayed for 1 second followed by the current drying setting.

3. lb select a new drying setting, press the DRYNESS button again until the desired drying

setting is shown.

NOTE: While cycling through the settings, the current setting will not flash, but the other

settings will flash.

4. Press START to save the drying setting.

5. The drying setting you selected will become your new preset drying setting for all Sensor

Dry cycles.

DRYING RACK OPTION

Use the Drying Rack to dry items such as sweaters and pillows without tumbling. The drum

turns, but the rack does not move.

If your model does not have a drying rack, you may be able to purchase one for your model.

lb find out whether your model allows drying rack usage and for information on ordering,

please refer to the front page of the manual or contact the dealer from whom you purchased

your dryer.

NOTE: The rack must be removed for normal tumbling. Do not use the Sensor Dry cycle with

the drying rack.

A. bront edge

2. Place drying rack inside dryer drum, positioning the back wire on the ledge of the inner

dryer back panel. Push down on front edge of drying rack to secure at the front of the

dryer.

A. Dryer rack front edge'

B.Dryer back panel

3. Put the wet items on top of the rack. leave space between the items so air can reach all

the surfaces.

NOTE: Do not allow items to hang over the edge of the rack.

26

4. Close the door.

5. Press the POWER button.

6. Select a timed drying cycle and temperature (see following chart). Items containing foam,

rubber or plastic must be dried on a clothesline or by using the Air Fluff temperature

setting.

7. You must select a time by pressing T]MED CYCI.E ADJUST Up or Down. Reset time as

needed to complete drying. Refer to the following table.

8. Press (and hold) START button (about 1 second).

DRYER CARE

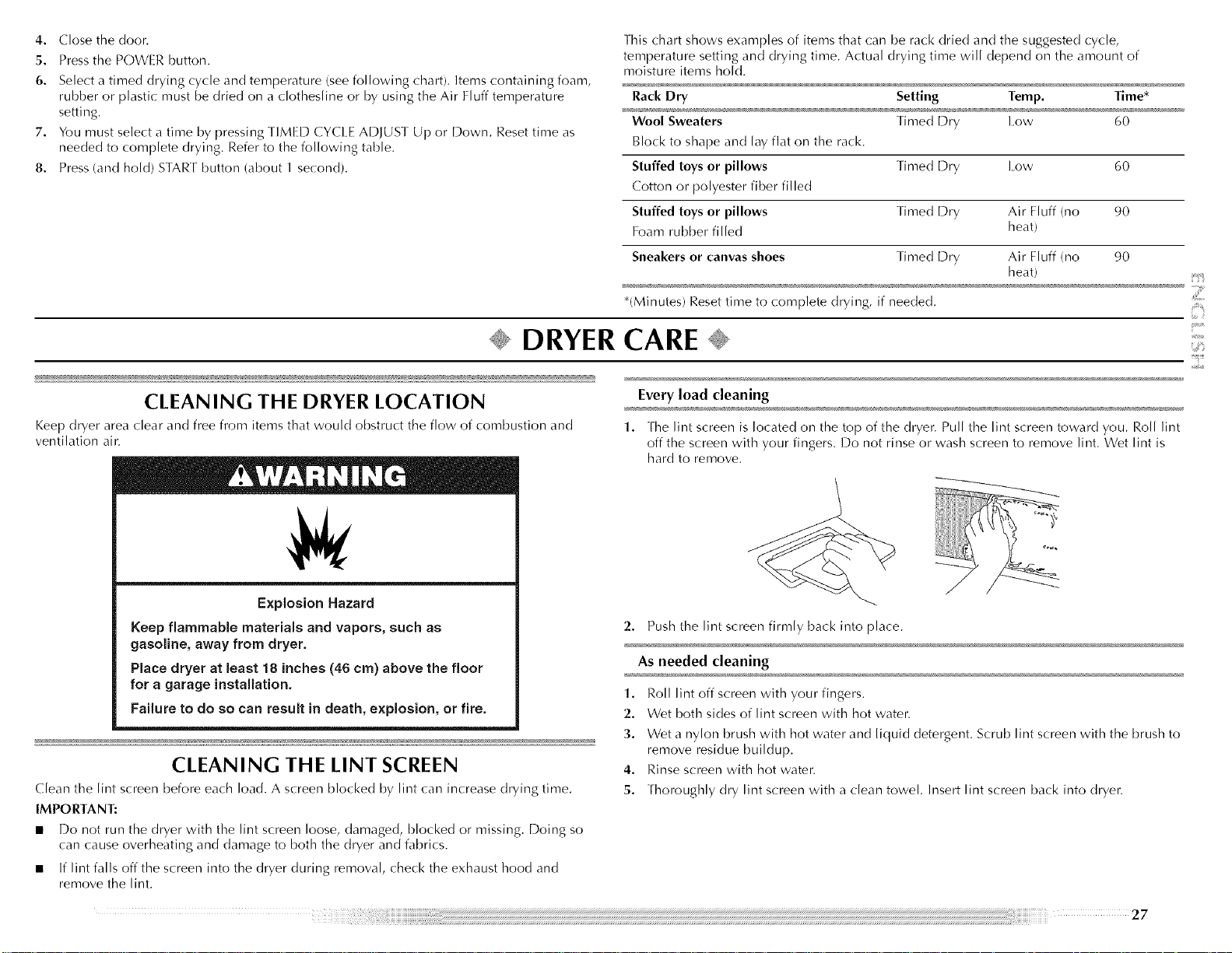

[his chart shows examples of items that can be rack dried and the suggested cycle,

temperature setting and drying time. Actual drying time will depend on the amount of

moisture items hold.

Rack Dry Setting Temp. Time*

Wool Sweaters Timed Dry Low 60

Block to shape and lay flat on the rack.

Stuffed toys or pillows Timed Dry low 60

Cotton or polyester fiber filled

Stuffed toys or pillows Timed Dry Air Fluff (no 90

Foam rubber filled heat)

Sneakers or canvas shoes Timed Dry Air Fluff (no 90

heat )

*(Minutes) Reset time to complete drying, if needed.

CLEANING THE DRYER LOCATION

Keep dryer area clear and free from items that would obstruct the flow of combustion and

ventilation air.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation,

Failure to do so can result in death, explosion, or fire.

CLEANING THE LINT SCREEN

Clean the lint screen before each load. A screen blocked by lint can increase drying time.

IMPORTANT:

• Do not run the dryer with the lint screen loose, damaged, blocked or missing. E)oing so

can cause overheating and damage to both the dryer and fabrics.

• ]f lint falls off the screen into the dryer during removal, check the exhaust hood and

remove the lint.

Every load cleaning

1. The lint screen is located on the top of the dryer. Pull the lint screen toward you. Roll lint

off the screen with your fingers. Do not rinse or wash screen to remove lint. Wet lint is

hard to remove.

2. Push the lint screen firmly back into place.

As needed cleaning

1. Roll lint off screen with your fingers.

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent. Scrub lint screen with the brush to

remove residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Insert lint screen back into dryer.

Loading...

Loading...